Page 1

BRIDGING THE DIVIDE

How award-winning Japanese architecture rm, Kengo Kuma and Associates

(KKAA), is using modern technology to bridge the divide between traditional

Japanese architecture and digital innovation.

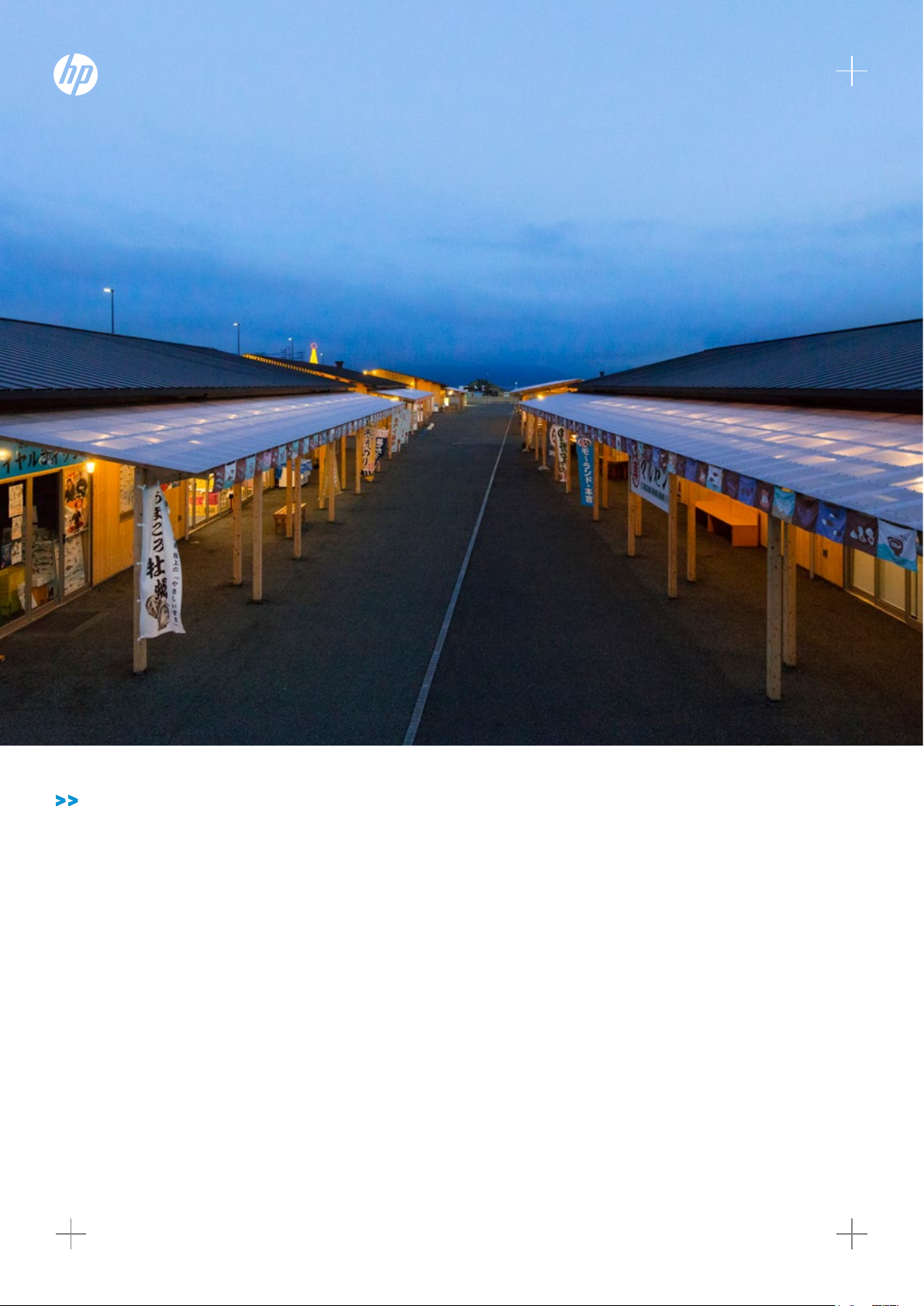

In 2011, the Great East Japan Earthquake and subsequent

tsunami obliterated much of Minamisanriku, decimating the area

and leaving gaping reminders of the tragedy. In 2013, awardwinning architectural practice, Kengo Kuma and Associates (KKAA),

worked with the mayor and residents’ plans to design and build a

brand-new retail village away from risk zones.

It was crucial for KKAA, based nearly 500km away in Tokyo, to

utilize to utilize traditional Japanese craftsmanship, alongside

contemporary architectural techniques to build the Sun Sun

Shopping Village. It was also vital to safely incorporate the

city’s historical relationship with the sea.

“Disaster prevention was paramount and a huge hurdle,” explains

chief of design, Toshiki Meiji. “If you can see the ocean that normally

would mean you would be at risk of tsunami. So, we raised the

ground and when it was stabilized we embarked on the

retail complex.”

DECEMBER 2018, KKAA CASE STUDY

The initial step says Meijo was to develop a master plan of the

shopping complex. This required a model of the entire site –

achieved through a blend of both physical models and 3D

modeling technology.

“The mountains are very close to the site so we had to do tons of

printouts, cut them out and then assemble them together by hand.

After that, we worked out the volume of the buildings and adjusted

the physical model this way and that. At the same time, we

created data with 3D modeling. For eye-level conrmation, 3D

is vastly superior.”

“THE MOUNTAINS ARE VERY CLOSE TO

THE SITE SO WE HAD TO DO TONS OF

PRINTOUTS, CUT THEM OUT AND THEN

ASSEMBLE THEM TOGETHER BY HAND.”

Page 2

BRIDGING THE DIGITAL DIVIDE WITH PAPER

Paper sits at the heart of all processes and one key issue KKAA

faced was communicating vital information between their studio

architects and their onsite contractors.

“In Japan, architects may be using digital technology but the

craftspeople and others that we hire for our projects are not.

This became very challenging for us and bridging this divide had,

up until now, been a diicult dilemma to resolve,” Meijo explains.

“In the area of site supervision, we used a tremendous amount

of paper. So for the team doing nal inspections, for example,

everything was conrmed on paper. The reason is that while we

can make general checks using digital platforms when we need to

check the ne details we must make A1 or A0 printouts. Looking at

them, we can take in everything, every detail with our eyes.

“Paper is great as a base when going back and forth with a client,

because you can make adjustments. But you don’t lose the

changes. It’s a record of changes and sketches. It’s a record of

meetings, too. It’s a huge advantage. With digital, making

changes is eortless but it won’t leave a record.

“PAPER IS A RECORD OF

CHANGES AND SKETCHES. IT’S

A RECORD OF MEETINGS, TOO.

IT’S A HUGE ADVANTAGE.”

DECEMBER 2018, KKAA CASE STUDY

Page 3

MARRYING PHYSICAL AND DIGITAL TOGETHER

This is where the HP DesignJet MFP presented itself as the solution

for KKAA. With its built-in scanner this printer allowed for quick

creative changes and the ability to transfer work from the physical

to the digital world via built in Wi-Fi capabilities.

“Our new printer has a scanner function. So now we can check

the design, amend it, scan it and send it to clients or contractors

onsite. This was not a function of the previous [printer]. To

share an A1 size document, we had to scan it in A3 and send it

on to clients piecemeal. Now we can do this all in one go. This is

incredibly convenient.

“Because we regularly work with A1 size documents on our sites we

get many blueprints in that size. The fact that we can check them

and return them and retain a record is enormously benecial.”

“OUR NEW PRINTER HAS A

SCANNER FUNCTION. SO NOW WE

CAN CHECK THE DESIGN, AMEND IT,

SCAN IT AND SEND IT TO CLIENTS

OR CONTRACTORS ONSITE.”

Alongside the scanner, the HP DesignJet T2530 remains an easy-

perate printer featuring one intuitive control panel for print,

to-o

scan and copy functions and two rolls. Its advanced design also

prints KKAA’s blueprints incredibly quickly —up to 21 seconds

for A1/D-size prints with 2.5 inch-per-second color scanning

capabilities to maximize productivity.

“The speed is a huge benet for us. And because the printer and

scanner are one unit it is also very compact and space eicient.

Our oices are very cramped, so we are very grateful for this.

When HP sent us [this] to test and provide feedback we were

quickly very satised with the functionality and performance

and knew we wanted to buy it.”

All this digital assistance paid o. In the year and a half since

the Minamisanriku Sun Sun Shopping Village opened its doors,

its seen a million visitors and locals report that its revitalized

the community, both spiritually and economically.

As Toshiki Meijo concludes:

“We are proud of the shopping complex’s popularity. The shop

owners are getting more red up and enterprising. To see this,

and the changes, each time we visit…well, it makes me so happy.”

Discover more about HP DesignJet printers.

FIND OUT MORE

DECEMBER 2018, KKAA CASE STUDY

4AA7-4367EEW December 2018

Loading...

Loading...