Page 1

Agilent TS-5000

Functional Test System

E6198B Switch/Load Unit

User Manual

Agilent Technologies

Page 2

Notices

CAUTION

WARNING

© Agilent Technologies, Inc. 2007-2012

No part of this manual may be reproduced

in any form or by any means (including

electronic storage and retrieval or translation into a foreign language) without prior

agreement and written consent from Agilent Technologies, Inc. as governed by

United States and international copyright

laws.

This manual covers the following

Agilent equipment:

• E6198B Switch/Load Unit

• E6175A 8-Channel High Current

Load Card

• E6176A 16-Channel High Current

Load Card

• E6177A 24-Channel Medium Current

Load Card

• U1777A 24-Channel Medium

Current Load Card

• U7178A 8-Channel Heavy Duty Load

Card

• U7179A 16-Channel High Current

Load Card

• E6178B 8-Channel Heavy Duty Load

Card

• N9377A 16-Channel Dual-Load Load

Card

• N9378A 24-Channel Low Resistance

Load Card

• N9379A 48-Channel High Density

Load Card

• E8792A Pin Matrix Card

• E8793A Pin Matrix Card

• E8782A 24-Instrument,

40-Measurement Matrix Card

• E8783A 64-Pin Matrix Card

• E8794A Custom Card

Manual Part Number

E6198-90050

Edition

9th Edition, August 2012

Printed in Malaysia

Agilent Technologies Microwave Products

(Malaysia) Sdn. Bhd.

Bayan Lepas Free Industrial Zone

11900 Penang, Malaysia

Warranty

The material contained in this document is provided “as is,” and is subject to being changed, without notice,

in future editions. Further, to the maximum extent permitted by applicable

law, Agilent disclaims all warranties,

either express or implied, with regard

to this manual and any information

contained herein, including but not

limited to the implied warranties of

merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for incidental or

consequential damages in connection

with the furnishing, use, or performance of this document or of any

information contained herein. Should

Agilent and the user have a separate

written agreement with warranty

terms covering the material in this

document that conflict with these

terms, the warranty terms in the separate agreement shall control.

Technology Licenses

The hardware and/or software described

in this document are furnished under a

license and may be used or copied only in

accordance with the terms of such license.

Restricted Rights Legend

defined in FAR 2.101(a) or as “Restricted

computer software” as defined in FAR

52.227-19 (June 1987) or any equivalent

agency regulation or contract clause. Use,

duplication or disclosure of Software is

subject to Agilent Technologies’ standard

commercial license terms, and non-DOD

Departments and Agencies of the U.S.

Government will receive no greater than

Restricted Rights as defined in FAR

52.227-19(c)(1-2) (June 1987). U.S. Government users will receive no greater than

Limited Rights as defined in FAR 52.227-14

(June 1987) or DFAR 252.227-7015 (b)(2)

(November 1995), as applicable in any

technical data.

Safety Notices

A CAUTION notice denotes a hazard. It calls attention to an operating procedure, practice, or the like

that, if not correctly performed or

adhered to, could result in damage

to the product or loss of important

data. Do not proceed beyond a

CAUTION notice until the indicated

conditions are fully understood and

met.

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly performed or adhered to, could result

in personal injury or death. Do not

proceed beyond a WARNING

notice until the indicated conditions are fully understood and

met.

If software is for use in the performance of

a U.S. Government prime contract or subcontract, Software is delivered and

licensed as “Commercial computer software” as defined in DFAR 252.227-7014

(June 1995), or as a “commercial item” as

Page 3

Contents

1 Legal Information

Legal Information 1-2

Warranty 1-2

Technology Licenses 1-2

Restricted Rights Legend 1-2

Service and Support 1-3

Agilent on the Web 1-3

Agilent By Phone 1-3

2 Safety and Regulatory Information

Declaration of Conformity 2-2

Safety Information 2-3

Safety Summary 2-3

Safety Notice 2-3

General Safety Information 2-3

Environmental Conditions 2-4

Before Applying Power 2-4

Ground the System 2-5

Fuses 2-5

Operator Safety Information 2-5

Safety Symbols and Regulatory Markings 2-6

End of Life: Waste Electrical and Electronic Equipment (WEEE) Directive

2002/96/EC 2-8

3 Switch/Load Unit and Plug-In Cards

E6198B Standalone/Integrated Switch/Load Unit Rating 3-2

Electrical 3-2

Mechanical 3-2

E6198B Standalone Switch/Load Unit Description 3-3

USB Interface 3-5

Digital I/O 3-5

Digital Input 3-5

Open Drain Digital Output 3-6

DAC Channels 3-7

+5 Vdc, +12 Vdc, –12 Vdc, Spare Power 3-7

Current Sense 3-7

Power Bus Sense 3-7

Switch/Load Unit Block Diagram 3-7

E6198B Integrated Switch/Load Unit Description 3-9

E6198B/E6218A Switch/Load Unit User Manual iii

Page 4

Backplane And Breakout Board Connectors and LEDs 3-10

Backplane Connector Name 3-12

Backplane J1, J2 and J3 Connectors 3-13

Breakout Board Connector Name (for E6198B Standalone

option) 3-14

Backplane Connectors 3-15

Backplane LEDs 3-16

J102 Pinouts 3-16

J1 Pinout 3-20

J2 Pinout 3-20

J3 Pinout 3-20

T1-T14 SLU Logic Power Supply Connector 3-21

Differentiating E6198B Standalone Option and System Integrated

Option 3-22

Fuse Ratings 3-24

DC Power Bus Connections 3-24

4 Configuring the Switch/Load Unit

Card Location Recommendations 4-2

Load Card Types and IDS 4-4

Connecting an Additional (Spare) Power Supply 4-5

Configuring the Power Busses 4-6

Setting the UUT Power Supply Remote/Local Sense Jumpers 4-8

Configuring the Current-Sense Jumpers 4-10

Connecting E6198B to the Computer via USB Interface or Parallel

Port 4-12

Adding a Second Switch/Load Unit 4-13

Load Box Installation 4-14

5 Using Load Cards and Loads

Load Card Capabilities 5-2

Loads Overview 5-4

Using the Load Cards 5-5

Load Card Type and Configuration ID 5-5

Using the Agilent E6175A 8-Channel Load Card 5-7

Selecting a Power Supply Configuration 5-9

Selecting a Current-Sense Method 5-10

Installing a LEM Current Transducer 5-11

Selecting and Loading Flyback Protection 5-14

Protection Devices 5-16

iv E6198B/E6218A Switch/Load Unit User Manual

Page 5

Selecting a Load Fuse 5-17

Sample Load Configurations 5-17

Setting up a Bridge Configuration 5-19

Connecting Loads 5-20

Load Wiring 5-21

Current Sharing 5-22

UUT Connections 5-23

Using the Agilent E6176A 16-Channel Load Card 5-25

Selecting a Power Supply Configuration 5-27

Selecting a Current-Sense Resistor Value 5-28

Selecting a Load Fuse 5-28

Selecting and Loading Flyback Protection 5-28

Protection Devices 5-30

Connecting Loads 5-32

Load Wiring 5-32

Current Sharing 5-34

External Load Mounting Options 5-35

UUT Connections 5-36

Using the Agilent E6177A 24-Channel Load Card 5-38

Card Layout 5-40

Selecting a Power Supply Configuration 5-41

Using the Power Switches as General Purpose Relays 5-41

Connecting Loads 5-42

Load Wiring 5-44

UUT Connections 5-45

Using the Agilent U7177A 24-Channel Load Card 5-47

Selecting a Power Supply Configuration 5-49

Selecting a Current-Sense Resistor Value 5-50

Using the Power Switches as General Purpose Relays 5-50

Connecting Loads 5-51

Load Wiring 5-52

UUT Connections 5-54

Using the Agilent E6178B 8-Channel Load Card 5-55

Selecting a Power Supply Configuration 5-57

Local / Remote Sensing 5-58

Selecting a Load Fuse 5-58

Current Monitor 5-59

Selecting and Loading Flyback Protection 5-59

Protection Devices 5-60

Load and UUT Connections 5-61

Using the Agilent U7178A 8-Channel Heavy Duty Load Card 5-63

E6198B/E6218A Switch/Load Unit User Manual v

Page 6

Selecting a Power Supply Configuration 5-65

Local/Remote Sensing 5-66

Selecting a Load Fuse 5-66

Current Monitor 5-66

Selecting and loading flyback protection 5-67

Protection Devices 5-68

Load and UUT connections 5-69

Using the Agilent U7179A 16-Channel High Current Load Card 5-71

Selecting a Power Supply Configuration 5-73

Selecting a Current-Sense Resistor Value 5-74

Selecting a Load Fuse 5-74

Selecting and Loading Flyback Protection 5-74

Protection Devices 5-75

Load Wiring 5-77

External Load Mounting Options 5-79

UUT Connections 5-81

Using the Agilent N9377A 16-Channel Dual-Load Load Card 5-83

Selecting a Power Supply Configuration 5-86

Selecting a Current-Sense Resistor Value 5-86

Selecting a Load Fuse 5-86

Selecting and Loading Flyback Protection 5-87

Protection Devices 5-88

Connecting Loads 5-90

Load Wiring 5-90

Recommended Connectors 5-94

Current Sharing 5-95

External Load Mounting Options 5-95

UUT Connections 5-96

Using the Agilent N9378A 24-Channel Low Resistance Load Card 5-97

Selecting a Power Supply Configuration 5-100

Using the Power Switches as General Purpose Relays 5-100

Connecting Loads 5-101

Installing and Removing Mezzanine Cards 5-102

Wiring the Mezzanine Cards 5-103

UUT Connections 5-103

Using the Agilent N9379A 48-Channel High-Density Load Card 5-105

Card Layout 5-107

Load Circuit Details 5-109

Selecting a Power Supply Configuration 5-109

Using the Power Switches as General Purpose Relays 5-110

Connecting Loads 5-110

vi E6198B/E6218A Switch/Load Unit User Manual

Page 7

6 Using the Pin Matrix Cards

Using the 32-Pin Matrix Cards 6-2

Conceptual Overview 6-2

Features 6-2

Detailed Block Diagram Descriptions 6-3

Differences Between the Cards 6-3

Features Common to Both Cards 6-3

Relay Timer 6-7

Column Disconnect Relay Control 6-7

OAR 6-7

Reset 6-7

Protection Bypass 6-8

Reset State 6-8

User Connectors and Pinouts 6-8

J1 Connector Pinouts 6-9

J1 Instrument Connections 6-11

P2 Connector Pinouts 6-14

Installing in the Switch/Load Unit 6-15

Using the 64-Pin Matrix Cards 6-16

Conceptual Overview 6-16

Features 6-16

Detailed Block Diagram Descriptions 6-17

Differences Between the Cards 6-17

Features Common to Both Cards 6-17

OAR 6-21

Reset 6-21

Protection Bypass 6-21

Reset State 6-22

User Connectors and Pinouts 6-22

J1 Connector Pinouts 6-23

P2 Connector Pinouts 6-27

Installing in the Switch/Load Unit 6-29

7 Using the Custom Card

General-Purpose Breadboard 7-2

TS-5430 Series I Emulation 7-2

Digital I/O 7-2

Connector Breakouts 7-4

J2 Connector Breakouts 7-4

J3/J4 Connector Breakouts (DAC) 7-5

J3 or J4 Connector Breakouts (Event Detector) 7-6

J5 and J6 Connector Breakouts (32-Pin Matrix Cards) 7-7

E6198B/E6218A Switch/Load Unit User Manual vii

Page 8

E8794A Components and Schematics 7-8

A Switch/Load Unit And Card Specifications

Agilent E6198B Switch/Load Unit Specifications A-2

Agilent E6175A 8-Channel High-Current Load Card Specifications A-3

Agilent E6176A 16-Channel High-Current Load Card Specifications A-4

Agilent E6177A 24-Channel Medium-Current Load Card

Specifications A-5

Agilent U7177A 24-Channel Medium-Current Load Card

Specifications A-6

Agilent E6178B 8-Channel Heavy Duty Load Card Specifications A-7

Agilent U7178A 8-Channel Heavy Duty Load Card Specifications A-8

Agilent U7179A 16-Channel High Current Load Card Specifications A-9

Agilent N9377A 16-Channel Dual-Load Load Card Specifications A-10

Agilent N9378A 24-Channel Low-Resistance Load Card

Specifications A-11

Agilent N9379A 48-Channel High-Density Load Card Specifications A-12

Agilent E8792A and E8793A Specifications A-13

Instrument Multiplexer (Agilent E8792A Only) A-13

General Specifications (Agilent E8792A and E8793A) A-13

Relay Characteristics (Agilent E8792A and E8793A) A-14

Agilent E8782A and E8783A Specifications A-15

Instrument Multiplexer (Agilent E8782A Only) A-15

General Specifications (Agilent E8782A and E8783A) A-15

Relay Characteristics (Agilent E8782A and E8783A) A-16

Relay Life A-16

End-of-Life Detection A-16

Replacement Strategy A-17

B Register Definitions

Address Space B-2

Base Address B-3

Switch/Load Unit Register Definitions B-4

Card Type (R)Base + 0

Card Configuration (R) Base + 1

Status Register (R) Base + 2

Fixture ID (R) Base + 3

Digital Input (R) Base + 4

DAC1 Output MSB (W) Base + 8

h B-5

h B-5

h B-5

h B-6

h B-6

h B-6

viii E6198B/E6218A Switch/Load Unit User Manual

Page 9

DAC1 Output LSB (W) Base + 9

h B-6

DAC Scaling B-7

Control Register (W) Base + A

Open Collector Output (W) Base + B

Digital Output (W) Base + C

DAC2 Output MSB(W) Base + D

DAC2 Output LSB (W) Base + E

h B-7

h B-8

h B-8

h B-8

h B-9

Load Card Register Definitions B-10

Agilent E6175A 8-Channel High-Current Load Card B-11

Agilent E6176A 16-Channel High-Current Load Card B-15

Agilent E6177A 24-Channel Medium-Current Load Card B-19

Agilent U7177A 24-Channel Medium-Current Load Card With Current

Sense B-23

Agilent U7178A 8-Channel 40 A Load Card B-28

Agilent U7179A 16-Channel 15 A Load Card B-29

Agilent E6178B 8-Channel 30 Amp Load Card Register

Definitions B-32

Agilent N9377A 16-Channel Dual-Load Load Card B-34

Agilent N9378A 24-Channel Low-Resistance Load Card B-40

Agilent N9379A 48-Channel High-Density Load Card B-50

Pin Matrix Card Register Definition B-63

C Repair Information

Support Strategy C-2

Locating Load Card Components C-2

A Glossary Of Terms

Agilent E8792A and E8793A Pin Card Register Definitions B-63

Agilent E8782A 24-Instrument, 40-Measurement Matrix Card B-71

Agilent E8783A 64-Pin Matrix Card B-80

Agilent E8794A Custom Card Register Definitions B-89

Agilent E6175A 8-Channel High-Current Card C-2

Agilent E6176A 16-Channel High-Current Card C-4

Other Load Cards C-5

32-Pin Matrix Modules C-5

64-Pin Matrix Modules C-8

E6198B/E6218A Switch/Load Unit User Manual ix

Page 10

THIS PAGE IS INTENTIONALLY LEFT BLANK.

x E6198B/E6218A Switch/Load Unit User Manual

Page 11

List of Figures

1 Legal Information

2 Safety and Regulatory Information

3 Switch/Load Unit and Plug-In Cards

Figure 3-1. Agilent E6198B Standalone Switch/Load Unit Front View 3-4

Figure 3-2. Agilent E6198B Standalone Switch/Load Unit Back View 3-4

Figure 3-3. Digital Input Example 3-6

Figure 3-4. Digital Output Example 3-6

Figure 3-5. Switch/Load Unit Block Diagram 3-8

Figure 3-6. E6198B Integrated SLU Back View 3-9

Figure 3-7. Switch/Load Unit Backplane Connectors (USB port adaptor board Not

Figure 3-8. Switch/Load Unit Breakout Board Connectors (Standalone only) 3-11

Figure 3-9. Switch/Load Unit J102 Connector Pinouts 3-17

Figure 3-10. Cable Connector Pinouts 3-18

Figure 3-11. Switch/Load Unit Rear View (Standalone Option) 3-22

Figure 3-12. Switch/Load Unit Rear View (System Integrated Option) 3-23

Shown) 3-10

4 Configuring the Switch/Load Unit

Figure 4-1. Example of Load/Matrix/Custom Cards Loading Order 4-3

Figure 4-2. Component Location/Schematic for User-Installed External Power

Supply 4-5

Figure 4-3. Spare Supply (Input) Connector on SLU rear (SLU standalone) 4-5

Figure 4-4. Power Bus Connectors J801 and J802 4-6

Figure 4-5. Example A: Three Separate Supplies on PB1 - PB4 4-7

Figure 4-6. Example B: Isolated Power Supplies 4-7

Figure 4-7. DC Power Bus Connector Of Standalone SLU 4-8

Figure 4-8. Conceptional View of Local/Remote Sensing 4-9

Figure 4-9. PB Sense Remote/Local Interface (Standalone SLU) 4-10

Figure 4-10. PB Sense Remote/Local and Frame Select Interface (Integrated SLU) 4-10

Figure 4-11. ISense Bussed/Split Interface (Standalone SLU) 4-11

Figure 4-12. ISense Bussed/Split Interface (Integrated SLU) 4-11

Figure 4-13. USB Cable Connections 4-12

Figure 4-14. Frame Select Interface (Standalone SLU) 4-13

Figure 4-15. Load Box Installed 4-14

5 Using Load Cards and Loads

Figure 5-1. Loads/Sources Conceptual Overview 5-4

Figure 5-2. Pin Assignments on the Card Configuration Jack 5-5

E6198B/E6218A Switch/Load Unit User Manual xi

Page 12

Figure 5-3. Agilent E6175A 8-Channel High-Current Load Card Block Diagram 5-8

Figure 5-4. Agilent E6175A 8-Channel Load Card Layout 5-9

Figure 5-5. LEM Current Transducer 5-11

Figure 5-6. Component Location for Installing LEM Current Transducer Module 5-12

Figure 5-7. Wiring Options of LEM Model LA25-NP Primary for Various Current

Ranges 5-13

Figure 5-8. 8-Channel Load Card Detail - Flyback Protection Circuit 5-15

Figure 5-9. Agilent E6175A Flyback Protection Polarity 5-15

Figure 5-10. Typical Agilent E6175A Load Card Flyback Protection Circuit 5-16

Figure 5-11. Agilent E6175A Load Examples 5-18

Figure 5-12. Bridge Configuration for Channels 7 and 8 on 8-Channel Load Card 5-19

Figure 5-13. Agilent E6175A Load Mounting Area and CN1/J1 Connectors 5-20

Figure 5-14. Agilent E6175A Load Wiring Schematic and CN1 Pinouts 5-21

Figure 5-15. Agilent E6175A Current Sharing Example 5-22

Figure 5-16. Agilent E6175A 8-Channel High-Current Load Card UUT Connections 5-24

Figure 5-17. Agilent E6176A 16-Channel High-Current Load Card Block Diagram 5-26

Figure 5-18. Agilent E6176A 16-Channel Load Card Layout 5-27

Figure 5-19. 16-Channel Load Card - Flyback Device Polarity Orientation 5-29

Figure 5-20. 16-Channel Load Card - Flyback Circuit Detail 5-30

Figure 5-21. Typical Agilent E6176A Load Card Flyback Protection Circuit 5-31

Figure 5-22. Agilent E6176A Connectors J1/J2 and Mating Connectors CN1/CN2 5-32

Figure 5-23. Agilent E6176A Load Wiring Schematic and CN1/CN2 Pinouts 5-33

Figure 5-24. Agilent E6176A Current Sharing Example 5-34

Figure 5-25. Example: Load Plate with Loads 5-36

Figure 5-26. Agilent E6176A CN2 Connector Pinouts 5-37

Figure 5-27. Agilent E6177A 24-Channel Medium-Current Load Card Block

Diagram 5-39

Figure 5-28. Agilent E6177A 24-Channel Load Card Layout 5-40

Figure 5-29. Using the 24-Channel Load Card Switches as GP Relays 5-42

Figure 5-30. Agilent E6177A Load Mounting Area and CN1/J1 Connectors 5-43

Figure 5-31. Agilent E6177A Load Wiring Schematic and CN1 Pinouts 5-44

Figure 5-32. Agilent E6177A 24-Channel Medium-Current Load Card UUT

Connections 5-46

Figure 5-33. Agilent U7177A 24-Channel Medium-Current Load Card Block

Diagram 5-48

Figure 5-34. The U7177A Layout 5-49

Figure 5-35. Using the 24-Channel Load Card Switches as GP Relays 5-51

Figure 5-36. Agilent U7177A Connector J1 and Mating Connector CN1 5-52

Figure 5-37. Agilent U7177A Load Wiring Schematic and CN1 Pinouts 5-53

Figure 5-38. Agilent U7177A 24-Channel Medium-Current Load Card UUT

Connections 5-54

Figure 5-39. Agilent E6178B 8-Channel Heavy Duty Load Card Block Diagram 5-56

Figure 5-40. Agilent E6178B 8-Channel Heavy Duty Load Card Layout 5-57

Figure 5-41. Typical Agilent E6178B Load Card Flyback Protection Circuit

5-60

xii E6198B/E6218A Switch/Load Unit User Manual

Page 13

Figure 5-42. Agilent E6178B Load Card Wiring 5-62

Figure 5-43. Agilent U7178A 8-Channel Heavy Duty Load Card Block Diagram 5-64

Figure 5-44. Agilent U7178A 8-Channel Heavy Duty Load Card Layout 5-65

Figure 5-45. Typical Agilent U7178A load card flyback protection circuit 5-68

Figure 5-46. Agilent U7178A load card wiring 5-70

Figure 5-47. Agilent U7179A 16-Channel High-Current Load Card Block Diagram 5-72

Figure 5-48. Agilent U7179A 16-Channel Load Card Layout 5-73

Figure 5-49. Typical Agilent U7179A Load Card Flyback Protection Circuit 5-76

Figure 5-50. Agilent U7179A Connectors J1/J2 and Mating Connectors CN1/CN2 5-77

Figure 5-51. Agilent U7179A Load Wiring Schematic and CN1/CN2 Pinouts 5-78

Figure 5-52. Agilent U7179A Current Sharing Example 5-79

Figure 5-53. Example: Load Plate with loads 5-80

Figure 5-54. Agilent U7179A CN2 Connector Pinouts 5-82

Figure 5-55. Agilent N9377A 16-Channel Dual-Load Load Card Block Diagram 5-84

Figure 5-56. N9377A 16-Channel Load Card Layout 5-85

Figure 5-57. N9377A Load Card - Flyback Locator and Polarity Orientation 5-87

Figure 5-58. N9377A Load Card - Flyback Circuit Detail 5-88

Figure 5-59. Typical Agilent N9377A Load Card Flyback Protection Circuit 5-89

Figure 5-60. Agilent N9377A Connectors J1/J2 and Mating Connectors J1/J2 5-90

Figure 5-61. N9377A Load Wiring Schematic 5-92

Figure 5-62. J1 and J2 Connector Layout 5-93

Figure 5-63. Agilent N9377A Pinout Table (160-pin option) 5-94

Figure 5-64. Agilent N9377A Current Sharing Example 5-95

Figure 5-65. Agilent N9378 24-Channel Low-Resistance Load Card Block Diagram 5-98

Figure 5-66. Agilent N9378A 24-Channel Load Card Layout 5-99

Figure 5-67. Load circuit details 5-100

Figure 5-68. Agilent N9378A Load Mounting Area and CN1/J1 Connectors 5-102

Figure 5-69. Mezzanine Card Pinouts for N9378A 24-Channel Load Card 5-103

Figure 5-70. Agilent N9378A UUT Connector 5-104

Figure 5-71. Agilent N9379A 48-Channel High-Density Load Card Block Diagram 5-106

Figure 5-72. Agilent N9379A Layout 5-108

Figure 5-73. Load Circuit Details 5-109

Figure 5-74. Agilent N9379A Mezzanine Card 5-110

6 Using the Pin Matrix Cards

Figure 6-1. Pin Matrix Cards Conceptual Overview 6-2

Figure 6-2. Agilent E8792A Detailed Block Diagram 6-5

Figure 6-3. Agilent E8793A Detailed Block Diagram 6-6

Figure 6-4. Column Disconnect and Protection Bypass Relays 6-8

Figure 6-5. J1 Pinouts--Instrument and Abus Access 6-10

Figure 6-6. J1 Example Instrument Connections 6-11

Figure 6-7. Instrument BNC Cables 6-12

Figure 6-8. J2 Pinouts--Rear Aux Access 6-13

E6198B/E6218A Switch/Load Unit User Manual xiii

Page 14

Figure 6-9. P2 Pinouts--Row, Aux, and UUT Common Main Access 6-14

Figure 6-10. Installed 32-Pin Matrix Cards 6-15

Figure 6-11. Pin Matrix Cards Conceptual Overview 6-16

Figure 6-12. Agilent E8782A Detailed Block Diagram 6-19

Figure 6-13. Agilent E8783A Detailed Block Diagram 6-20

Figure 6-14. Column Disconnect and Bypass Protection Relays 6-22

Figure 6-15. J1 Pinouts--Instrument and Abus Access 6-23

Figure 6-16. J2 Pinouts--Rear Aux Access for E8782A 6-25

Figure 6-17. J2 Pinouts--Rear Aux Access for E8783A 6-26

Figure 6-18. P2 Pinouts--Row, Aux, and UUT Common Main Access for E8782A 6-27

Figure 6-19. P2 Pinouts-Row, Aux, and UUT Common Main Access for E8783A 6-28

Figure 6-20. Installed 32-Pin Matrix Cards 6-29

7 Using the Custom Card

Figure 7-1. Custom Card Features 7-3

Figure 7-2. J2 Configuration Lines Pinouts 7-4

Figure 7-3. J3/J4 Breakouts for Agilent E1418 DAC 7-5

Figure 7-4. J3 or J4 Connector Breakouts for Agilent E6174 Event Detector 7-6

Figure 7-5. J5 and J6 Breakouts (32-Pin Matrix Cards) 7-7

Figure 7-6. E8794A Layout 7-8

Figure 7-7. E8794A Component Locator 7-9

Figure 7-8. E8794A Schematic 7-10

Figure 7-9. Status and Control Interface 7-11

A Switch/Load Unit And Card Specifications

B Register Definitions

Figure B-1. Relay controlled by registers Base+03h-Base+09h B-35

Figure B-2. Mezzanine Card Layout B-42

Figure B-3. Mezzanine Card Layout B-53

C Repair Information

Figure C-1. Agilent E6175A Component Locator (Rear View) C-3

Figure C-2. Agilent E6176A 16-Channel Load Card Component Locator (Rear View) C-4

A Glossary Of Terms

xiv E6198B/E6218A Switch/Load Unit User Manual

Page 15

List of Tables

1 Legal Information

2 Safety and Regulatory Information

3 Switch/Load Unit and Plug-In Cards

4 Configuring the Switch/Load Unit

Table 1-1. Agilent Sales And Support Contact Numbers 1-3

Table 2-1. Environment Requirements 2-4

Table 2-2. Safety Symbols and Regulatory Markings 2-6

Table 3-1. Switch/Load Unit Rating (Electrical) 3-2

Table 3-2. Switch/Load Unit Rating (Mechanical) 3-2

Table 3-3. Backplane Connectors for E6198B 3-12

Table 3-4. Backplane Factory Default Connector Settings 3-13

Table 3-5. Breakout Board Connectors 3-14

Table 3-6. J102 signal definitions 3-19

Table 3-7. Switch/Load Unit J1 Pinout 3-20

Table 3-8. Switch/Load Unit J2 Pinout 3-20

Table 3-9. Switch/Load Unit J3 Pinout 3-20

Table 3-10. Power Supply Input for each Jumpers 3-21

Table 3-11. Fuses Ratings 3-24

5 Using Load Cards and Loads

Table 5-1. Load Card Capabilities 5-2

Table 5-2. Components involved in LEM Module Installation 5-13

Table 5-3. CH1 to CH16 flyback protection 5-75

6 Using the Pin Matrix Cards

7 Using the Custom Card

A Switch/Load Unit And Card Specifications

B Register Definitions

Table B-1. Standard Registers B-2

Table B-2. Standard Registers B-2

Table B-3. Switch/Load Unit Registers B-4

Table B-4. DAC Scaling Examples B-7

Table B-5. OCout

Table B-6. Summary of Load Card Register Definitions B-10

States B-8

x

E6198B/E6218A Switch/Load Unit User Manual xv

Page 16

C Repair Information

Table C-1. Measurement Matrix Relays C-5

Table C-2. Instrument Matrix Relays C-7

Table C-3. Bypass and Disconnect Relays C-7

Table C-4. Miscellaneous Relays C-7

Table C-5. Measurement Matrix Relays for E8782A C-8

Table C-6. Measurement Matrix Relays for E8783A C-10

Table C-7. Bypass and Disconnect Relays for E8782A and E8783A C-12

A Glossary Of Terms

xvi E6198B/E6218A Switch/Load Unit User Manual

Page 17

Agilent TS-5000

E6198B/E6218A Switch/Load Unit User Manual

1

Legal Information

Legal Information 1-2

Warranty 1-2

Technology Licenses 1-2

Restricted Rights Legend 1-2

Service and Support 1-3

Agilent on the Web 1-3

Agilent By Phone 1-3

Agilent Technologies

1-1

Page 18

1 Legal Information

Legal Information

Warranty

The material contained in this document is provided “as is,” and

is subject to being changed, without notice, in future editions.

Further, to the maximum extent permitted by applicable law,

Agilent disclaims all warranties, either express or implied, with

regard to this manual and any information contained herein,

including but not limited to the implied warranties of

merchantability and fitness for a particular purpose. Agilent

shall not be liable for errors or for incidental or consequential

damages in connection with the furnishing, use, or performance

of this document or of any information contained herein.

Should Agilent and the user have a separate written agreement

with warranty terms covering the material in this document

that conflict with these terms, the warranty terms in the

separate agreement shall control.

Technology Licenses

The hardware and/or software described in this document are

furnished under a license and may be used or copied only in

accordance with the terms of such license.

Restricted Rights Legend

If software is for use in the performance of a U.S. Government

prime contract or subcontract, Software is delivered and

licensed as “Commercial computer software” as defined in

DFAR 252.227-7014 (June 1995), or as a “commercial item” as

defined in FAR 2.101(a) or as “Restricted computer software” as

defined in FAR 52.227-19 (June 1987) or any equivalent agency

regulation or contract clause. Use, duplication or disclosure of

Software is subject to Agilent Technologies’ standard

commercial license terms, and non-DOD Departments and

Agencies of the U.S. Government will receive no greater than

Restricted Rights as defined in FAR 52.227-19(c)(1-2)(June

1987). U.S. Government users will receive no greater than

Limited Rights as defined in FAR 52.227-14 (June 1987) or

DFAR 252.227-7015 (b)(2)(November 1995), as applicable in any

technical data.

1-2 E6198B/E6218A Switch/Load Unit User Manual

Page 19

Service and Support

Agilent on the Web

Agilent By Phone

Legal Information 1

Any adjustment, maintenance, or repair of this product must be

performed by qualified personnel. Contact your customer

engineer through your local Agilent Technologies Service

Center.

You can find information about technical and professional

services, product support, and equipment repair and service on

the Web: http://www.agilent.com/

Double-click the link to Test & Measurement. Select your country

from the drop-down menus. The Web page that appears next has

contact information specific for your country.

If you do not have access to the Internet, call one of the

numbers in Table 1-1

Table 1-1 Agilent Sales And Support Contact Numbers

Americas Canada (877) 894-4414

Latin America 305 269 7500

United States (800) 829-4444

Asia Pacific Australia 1 800 629 485

China 800 810 0189

Hong Kong 800 938 693

India 1 800 112 929

Japan 0120 (421) 345

Korea 080 769 0800

Malaysia 1 800 888 848

Singapore 1 800 375 8100

Taiwan 0800 047 866

Thailand 1 800 226 008

E6198B/E6218A Switch/Load Unit User Manual 1-3

Page 20

1 Legal Information

Table 1-1 Agilent Sales And Support Contact Numbers (continued)

Europe & Middle East Austria 01 36027 71571

Belgium 32 (0) 2 404 93 40

Denmark 45 70 13 15 15

Finland 358 (0) 10 855 2100

France 0825 010 700*

*0.125 €/minute

Germany 07031 464 6333**

**0.14 €/minute

Ireland 1890 924 204

Israel 972-3-9288-504/544

Italy 39 02 92 60 8484

Netherlands 31 (0) 20 547 2111

Spain 34 (91) 631 3300

Sweden 0200-88 22 55

Switzerland 0800 80 53 53

United Kingdom 44 (0) 118 9276201

Other European

Countries:

www.agilent.com/find/

contactus

Manufacturing Address

Agilent Technologies Microwave Products (Malaysia) Sdn. Bhd.

Bayan Lepas Free Industrial Zone,

11900 Penang,

Malaysia.

1-4 E6198B/E6218A Switch/Load Unit User Manual

Page 21

Agilent TS-5000

E6198B/E6218A Switch/Load Unit User Manual

2

Safety and Regulatory Information

Declaration of Conformity 2-2

Safety Information 2-3

Safety Summary 2-3

Safety Notice 2-3

General Safety Information 2-3

Environmental Conditions 2-4

Before Applying Power 2-4

Ground the System 2-5

Fuses 2-5

Operator Safety Information 2-5

Safety Symbols and Regulatory Markings 2-6

End of Life: Waste Electrical and Electronic Equipment (WEEE)

Directive 2002/96/EC 2-8

Agilent Technologies

2-1

Page 22

2 Safety and Regulatory Information

NOTE

Declaration of Conformity

The Declaration of Conformity (DoC) for this product is

available on the Agilent Technologies website. You can search

for the DoC by its product model or description at the following

web address:

http://regulations.corporate.agilent.com/DoC/search.htm

If you are unable to locate the DoC, please contact your local Agilent

representative.

2-2 E6198B/E6218A Switch/Load Unit User Manual

Page 23

Safety Information

CAUTION

WARNING

WARNING

Safety Summary

Safety Notice

Safety and Regulatory Information 2

The following general safety precautions must be observed

during all phases of operation of this instrument. Failure to

comply with these precautions or with specific warnings

elsewhere in this manual violates safety standards of design,

manufacture, and intended use of the instrument. Agilent

Technologies, Inc. assumes no liability for the customer's failure

to comply with these requirements.

A CAUTION notice denotes a hazard. It calls attention to an

operating procedure, practice, or the like, that, if not correctly

performed or adhered to, could result in damage to the product or

loss of important data. Do not proceed beyond a CAUTION notice

until the indicated conditions are fully understood and met.

A WARNING notice denotes a hazard. It calls attention to an

operating procedure, practice, or the like that, if not correctly

performed or adhered to, could result in personal injury or death.

Do not proceed beyond a WARNING notice until the indicated

conditions are fully understood and met.

General Safety Information

This product is provided with a protective earth terminal. The

protective features of this product may be impaired if it is used

in a manner not specified in the operation instructions.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE. Do not

operate the product in the presence of flammable gases or

flames.

E6198B/E6218A Switch/Load Unit User Manual 2-3

Page 24

2 Safety and Regulatory Information

WARNING

WARNING

CAUTION

Environmental Conditions

DO NOT REMOVE RACK PANELS OR INSTRUMENT COVERS.

Operating personnel must not remove any rack panels or

instrument covers. Component replacement and internal

adjustments must be made only by qualified service personnel.

Products that appear damaged or defective should be made

inoperative and secured against unintended operation until they

can be repaired by a qualified service personnel.

The protection provided by the Agilent TS-5000 system may be

impaired if the system is used in a manner not specified by

Agilent.

The Automotive Electronics Functional Test System is designed

for indoor use only. Table 2-1 shows general environmental

requirements.

Table 2-1 Environment Requirements

Environment Conditions Requirements

Maximum Altitude 2000 meters

Temperature (Operation) 5 °C to 40 °C

Maximum Relative Humidity The test system is designed to

operate in the range from 5% to 80%

relative humidity (non-condensing).

This product is designed for use in Installation Category II and

Pollution Degree 2, per IEC 61010-1.

Before Applying Power

Verify that the product is set to match the available line voltage

and all safety precautions are taken. Note the external markings

of the instruments described in “Safety Symbols and Regulatory

Markings”.

2-4 E6198B/E6218A Switch/Load Unit User Manual

Page 25

Ground the System

WARNING

WARNING

WARNING

To minimize shock hazard, the instrument chassis and cover

must be connected to an electrical protective earth ground. The

instrument must be connected to the ac power mains through a

grounded power cable, with the ground wire firmly connected

to an electrical ground (safety ground) at the power outlet. Any

interruption of the protective (grounding) conductor or

disconnection of the protective earth terminal will cause a

potential shock hazard that could result in personal injury.

Fuses

Use only fuses with the required rated current, voltage, and

specified type (normal blow, time delay). Do not use repaired

fuses or short-circuited fuse holders. To do so could cause a

shock or fire hazard.

For AC inlet fuse, use only 5A/250 Vac fuse with Time-Lag and

Low Breaking capacity. For other fuse ratings, refer Table 3-11.

Safety and Regulatory Information 2

In order to avoid electrical hazards, all system internal fuses must

be replaced by trained and qualified personnel.

Operator Safety Information

Module connectors and Test Signal cables connected to them

cannot be operator accessible.

M

Cables and connectors are considered inaccessible if a tool (e.g.

screwdriver, wrench, socket, etc.) or a key (equipment in a

locked cabinet) is required to gain access to a conductive

surface connected to any cable conductor (High, Low or Guard).

Assure the equipment under test has adequate insulation

between the cable connections and any operator-accessible parts

(doors, covers, panels shields, cases, cabinets, etc.)

Verify there are multiple and sufficient protective means (rated

for the voltages you are applying) to assure the operator will

NOT come into contact with any energized conductor even if

one of the protective means fails to work as intended. For

E6198B/E6218A Switch/Load Unit User Manual 2-5

Page 26

2 Safety and Regulatory Information

Safety Symbols and Regulatory Markings

example, the inner side of a case, cabinet, door cover or panel

can be covered with an insulating material as well as routing the

test cables to the front panel connectors of the module through

non-conductive, flexible conduit such as that used in electrical

power distribution.

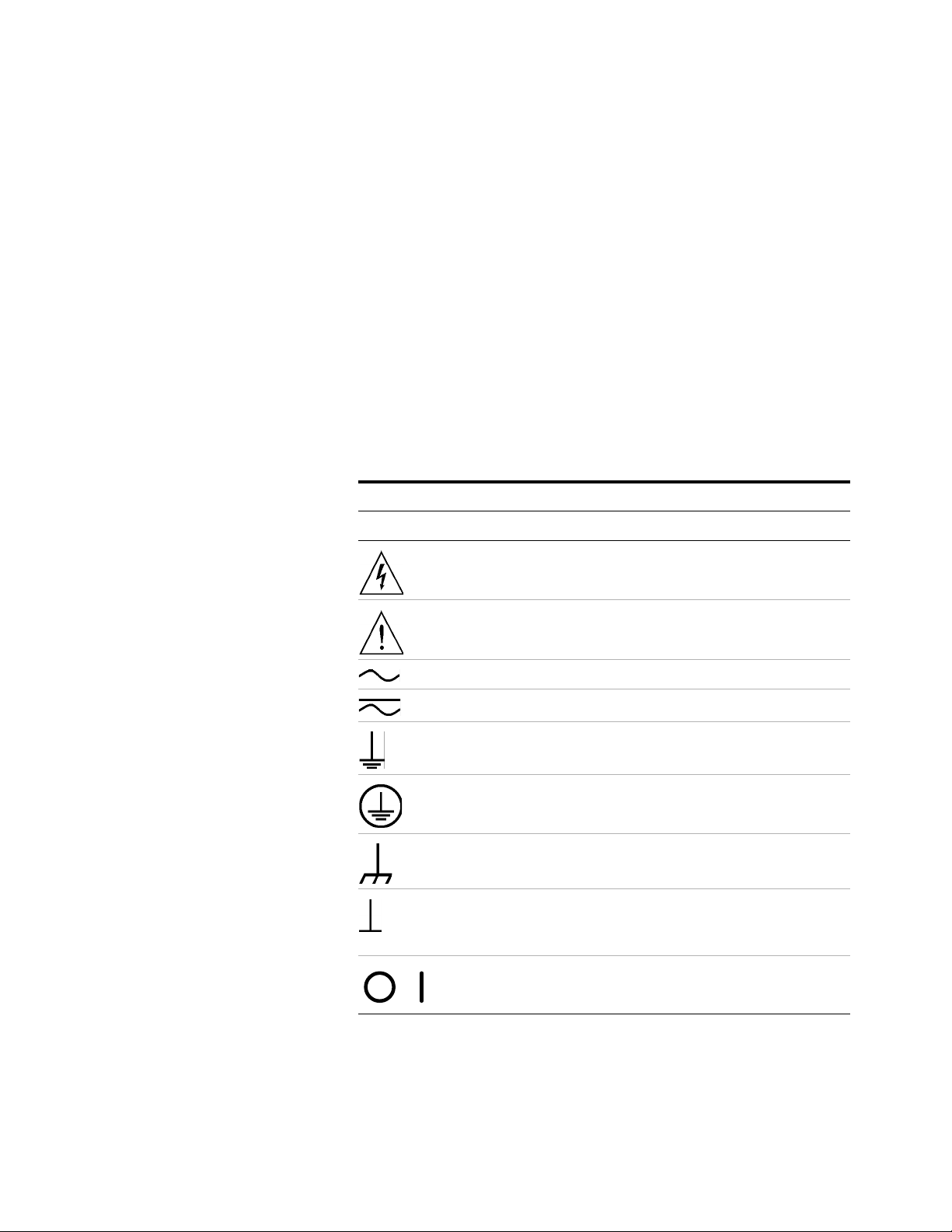

Symbols and markings on the system, in manuals and on

instruments alert you to potential risks, provide information

about conditions, and comply with international regulations.

Table 2-2 defines the symbols and markings you may find in a

manual or on an instrument.

Table 2-2 Safety Symbols and Regulatory Markings

Symbols Description

Safety symbols

Warning: risk of electric shock.

Caution: refer to accompanying documents.

Alternating current.

Both direct and alternating current.

Earth (ground) terminal

Protective earth (ground) terminal

Frame or chassis terminal

Terminal is at earth potential. Used for measurement and

control circuits designed to be operated with one terminal at

earth potential.

Switch setting indicator. O = Off, | = On.

2-6 E6198B/E6218A Switch/Load Unit User Manual

Page 27

Safety and Regulatory Information 2

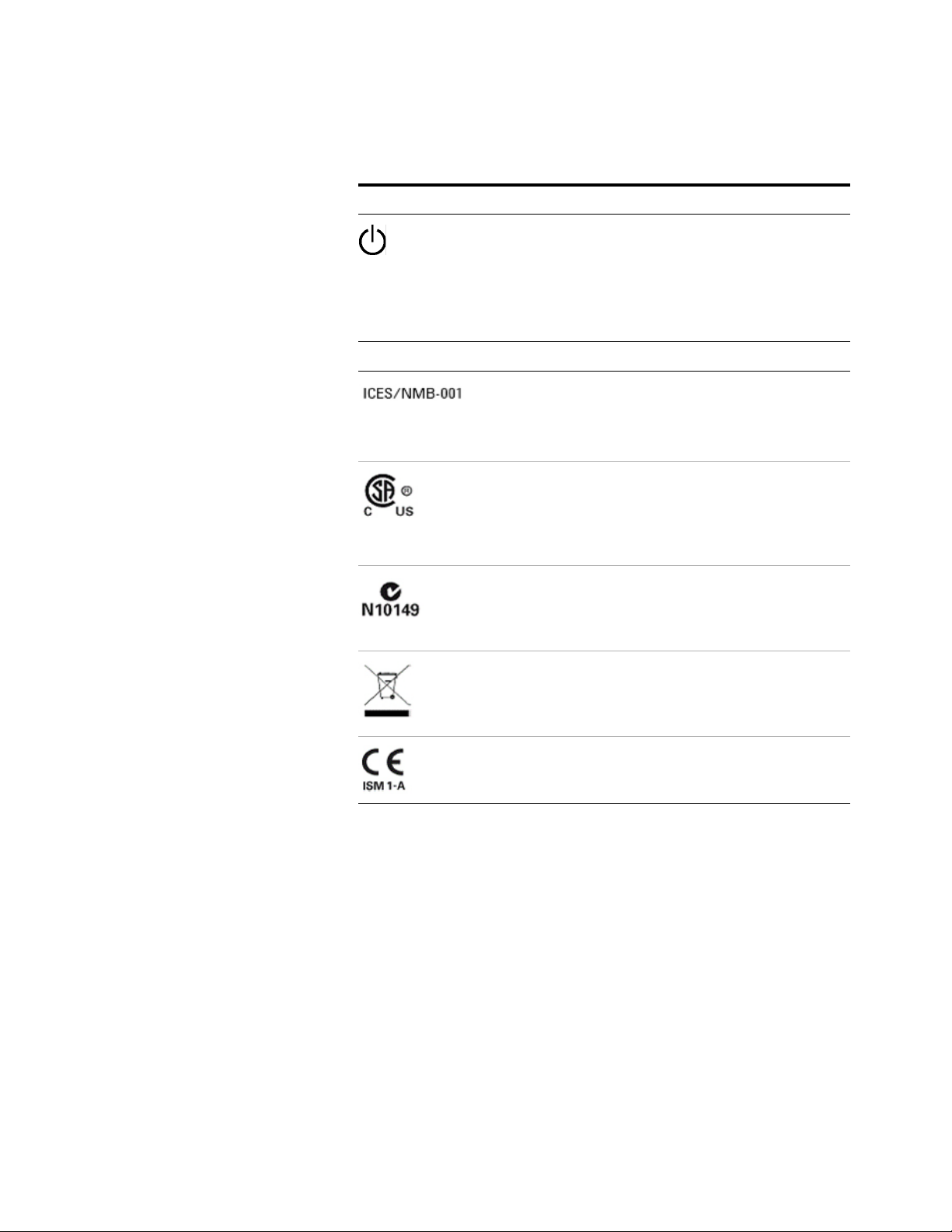

Table 2-2 Safety Symbols and Regulatory Markings (continued)

Symbols Description

Standby (supply); units with this symbol are not completely

disconnected from ac mains when this switch is off. To

completely disconnect the unit from ac mains, either

disconnect the power cord, or have a qualified electrician

install an external switch.

Regulatory markings

This text indicates that the ISM device complies with

Canadian ICES-001.

Cet appareil ISM est conforme à la norme NMB-001 du

Canada.

The CSA mark is a registered trademark of the Canadian

Standards Association. A CSA mark with the indicators “C”

and “US” means that the product is certified for both the

U.S. and Canadian markets, to the applicable American and

Canadian standards.

The C-tick mark is a registered trademark of the Spectrum

Management Agency of Australia. This signifies compliance

with the Australia EMC Framework regulations under the

terms of the Radio Communication Act of 1992.

This instrument complies with the WEEE Directive

(2002/96/EC) marking requirement. This affixed product

label indicates that you must not discard this

electrical/electronic product in domestic household waste.

The CE mark is a registered trademark of the European

Community. This CE mark shows that the product complies

with all the relevant European Legal Directives.

E6198B/E6218A Switch/Load Unit User Manual 2-7

Page 28

2 Safety and Regulatory Information

End of Life: Waste Electrical and Electronic Equipment (WEEE) Directive 2002/96/EC

This product complies with the WEEE Directive (2002/96/EC)

marking requirement. The affixed product label (see below)

indicates that you must not discard this electrical/electronic

product in domestic household waste.

Product Category:

With reference to the equipment types in the WEEE directive

Annex 1, this product is classified as a “Monitoring and Control

Instrumentation” product.

Do not dispose in domestic household waste

To return unwanted products, contact your local Agilent office,

or see:

http://www.agilent.com/environment/product

for more information.

2-8 E6198B/E6218A Switch/Load Unit User Manual

Page 29

Agilent TS-5000

E6198B Switch/Load Unit User Manual

3

Switch/Load Unit and Plug-In Cards

E6198B Standalone/Integrated Switch/Load Unit Rating 3-2

E6198B Standalone Switch/Load Unit Description 3-3

E6198B Integrated Switch/Load Unit Description 3-9

Backplane And Breakout Board Connectors and LEDs 3-10

Differentiating E6198B Standalone Option and System Integrated

Option 3-22

This chapter gives an overview of the Agilent E6198B

(Standalone and Integrated) Switch/Load Unit (SLU), load

cards, and other associated equipment.

Agilent Technologies

3-1

Page 30

3 Switch/Load Unit and Plug-In Cards

E6198B Standalone/Integrated Switch/Load Unit Rating

Electrical

Tab le 3- 1 Switch/Load Unit Rating (Electrical)

Parameter Value

Input Voltage 100–240 VAC nominal

Frequency 50/60 Hz

Power 325 W maximum

Mechanical

Tab le 3- 2 Switch/Load Unit Rating (Mechanical)

Parameter Value

Width 484.64 mm

Height 373.61 mm

Depth 520.52 mm

Weight 15.0 kg

3-2 E6198B/E6218A Switch/Load Unit User Manual

Page 31

Switch/Load Unit and Plug-In Cards 3

E6198B Standalone Switch/Load Unit Description

The Switch/Load Unit (Figure 3-1) consists of a standard VME

type enclosure, a custom high current backplane, and slots for

up to 21 optional Agilent plug-in cards. The following plug-in

cards are available:

• Agilent E6175A 8-channel load card

• Agilent E6176A 16-channel load card

• Agilent E6177A 24-channel load card

• Agilent U7177A 24-channel load card with current sense

• Agilent E6178B 8-channel heavy duty load card

• Agilent N9377A 16-channel dual-load load card

• Agilent N9378A 24-channel low resistance load card

• Agilent N9379A 48-channel high-density load card

• Agilent E8792A 32-pin matrix card with instrumentation

support

• Agilent E8793A 32-pin matrix card

• Agilent E8782A 40-pin matrix card with 24 instrumentation

support

• Agilent E8783A 64-pin matrix card

• Agilent E8794A custom card

• Agilent U7178A 8-channel heavy duty load card

• Agilent U7179A 16-channel high current load card

Load cards are described in detail in Chapter 5 and Appendix A

to Appendix C of this manual. The pin matrix cards are

described in Chapter 6. The E8794A custom card is discussed in

Chapter 7.

E6198B/E6218A Switch/Load Unit User Manual 3-3

Page 32

3 Switch/Load Unit and Plug-In Cards

Figure 3-1 Agilent E6198B Standalone Switch/Load Unit Front View

Figure 3-2 Agilent E6198B Standalone Switch/Load Unit Back View

3-4 E6198B/E6218A Switch/Load Unit User Manual

Page 33

USB Interface

Switch/Load Unit and Plug-In Cards 3

In addition to holding load cards, pin matrix cards, and custom

cards, the Switch/Load Unit also provides the following

capabilities:

• Built-in USB interface

• Digital I/O

• Current Sense

• Power Bus Sense

• Two DAC Channels

• +5, +12V, –12V, and Spare Power

Each of the above features is described in detail in the following

sections.

The Switch/Load Unit switching and data transfer is controlled

by a built-in USB interface. Figure 4-13 shows the location of

the USB interface.

Digital I/O

Digital Input

The Switch/Load Unit provides 8-bits of digital input, 8-bits of

digital output (Open Drain Out), and 8-bits of TTL-level digital

output (Spare Digital Out). There is no handshaking capability

in the digital I/O. Typical usage of the digital I/O includes:

• Automation control

• Digital control of circuitry on the Agilent E8794A Custom

Card

• Digital switches (for example, to indicate door open/closed)

• Actuator control

• Fixture ID

The digital input bits have TTL thresholds (0.55 Vdc for low,

3.0 Vdc for high) and are protected to ±24 Vdc. These includes

the Fixture IDs that also use standard TTL inputs, but are not

protected to ±24 Vdc. Figure 3-3 is a typical example showing

the usage of a digital input bit.

E6198B/E6218A Switch/Load Unit User Manual 3-5

Page 34

3 Switch/Load Unit and Plug-In Cards

Open Drain Digital Output

Figure 3-3 Digital Input Example

The digital output bits use open drain drive circuitry designed

for pull-ups up to +24 Vdc. The output port FET can sink up to

250 mA. Figure 3-4 shows one digital output bit controlling a

relay.

Figure 3-4 Digital Output Example

3-6 E6198B/E6218A Switch/Load Unit User Manual

Page 35

DAC Channels

NOTE

The two 14-bit channels of DAC provide ±16 V at 10 mA each. To

provide this voltage swing, a charge pump is used to step-up the

±12 V supply. The DAC channels are typically used for

controlling differential input, voltage-controlled power supplies.

+5 Vdc, +12 Vdc, –12 Vdc, Spare Power

+5 V, +12 V, and –12V from the Switch/Load Unit Power Supply.

The +5 V supply can deliver 7.5 A to 30 A, +12 V supply can

deliver 2.5 A to 12.5 A, and the –12 V supply can deliver 700 mA

to 1 A. You can also connect an additional (spare) power supply

to the Switch/Load Unit backplane, see “Connecting an

Additional (Spare) Power Supply for details.

Power supplies +5 V, +12 V, and –12 V for E6198B have non-resettable

fuses. (Non-resettable fuses need to be replaced, refer to Table 3-11 for

fuse ratings.)

Switch/Load Unit and Plug-In Cards 3

Spare supply has resettable fuse. If an overload occurs, the fuse(s) open.

To reset the fuse(s), remove power from the Switch/Load Unit for

approximately 20 seconds. The fuse(s) reset when power is re-applied.

Current Sense

The Isense+ and Isense– lines sense current on a selected load

card channel. They connect to the current sense bus on the SLU

backplane. Current sense lines of each channel are multiplexed.

Only one channel can connect to the current sense bus at one

time.

Power Bus Sense

Power Bus Sense lines 1-4 remotely sense power supplies

connected to power buses 1-4. This sensing compensates the

losses in the system wiring to ensure that the set voltage is

applied to the sense point.

Switch/Load Unit Block Diagram

Figure 3-5 shows a block diagram of the SLU. All plug-in cards

are optional so your system will have a different mix of cards

from that shown here. The Test System Interface or Mass

Interconnect are also optional — you can also interface directly

to the Switch/Load Unit. See Chapter 4 for details.

E6198B/E6218A Switch/Load Unit User Manual 3-7

Page 36

3 Switch/Load Unit and Plug-In Cards

Load Card #2

Pin Matrix Card #2

Load Card #1

Pin Matrix Card #1

Custom Card

Agilent E6198B Switch/Load Unit

Load Card #n

Pin Matrix Card #n

Digital In, Power Bus Sense ,

Isense

Switch/Load Unit

Circuitry

Digital Out, DAC, +12 V, -12V

Power Bus

Power

Supply #1

Power

Supply #2

Power

Supply #3

An alog B us

Test System Interface or Mass Interconnect

Note : All plug -in car ds are opti onal - -the m ix and numbers of car ds in your system w i l l be di ffer ent than shown here .

To/From

UUT

Figure 3-5 Switch/Load Unit Block Diagram

3-8 E6198B/E6218A Switch/Load Unit User Manual

Page 37

E6198B Integrated Switch/Load Unit Description

Sense Bussed/Split PB Sense Remote/Local Frame SelectSense Bussed/Split

The Agilent E6198B now comes as a system integrated unit or

as a standalone unit. The features and functionality remains the

same as the previous E6198A. Differences between the two are

in the cabling and function selection panel.

Figure 3-6 E6198B Integrated SLU Back View

Switch/Load Unit and Plug-In Cards 3

E6198B/E6218A Switch/Load Unit User Manual 3-9

Page 38

3 Switch/Load Unit and Plug-In Cards

BACKPLANE SLU

T4 T8 T9 T1 T5 T10 T11 T2 T6 T12 T13 T3 T7 T14

J102

J101

J1

J3

J2

J803

J801

J802

1

2

14

13

1

214

13

1

2

14

13

1

3

94

96

1

3

94

96

J201

J202J203

J204

J205

J206J207

J208J209

J210J211

J212

J213

J214J215

J216

J217

J218J219

J220

J221

J104

J111 J110

J109

J106 J107

J105 J108

Backplane And Breakout Board Connectors and LEDs

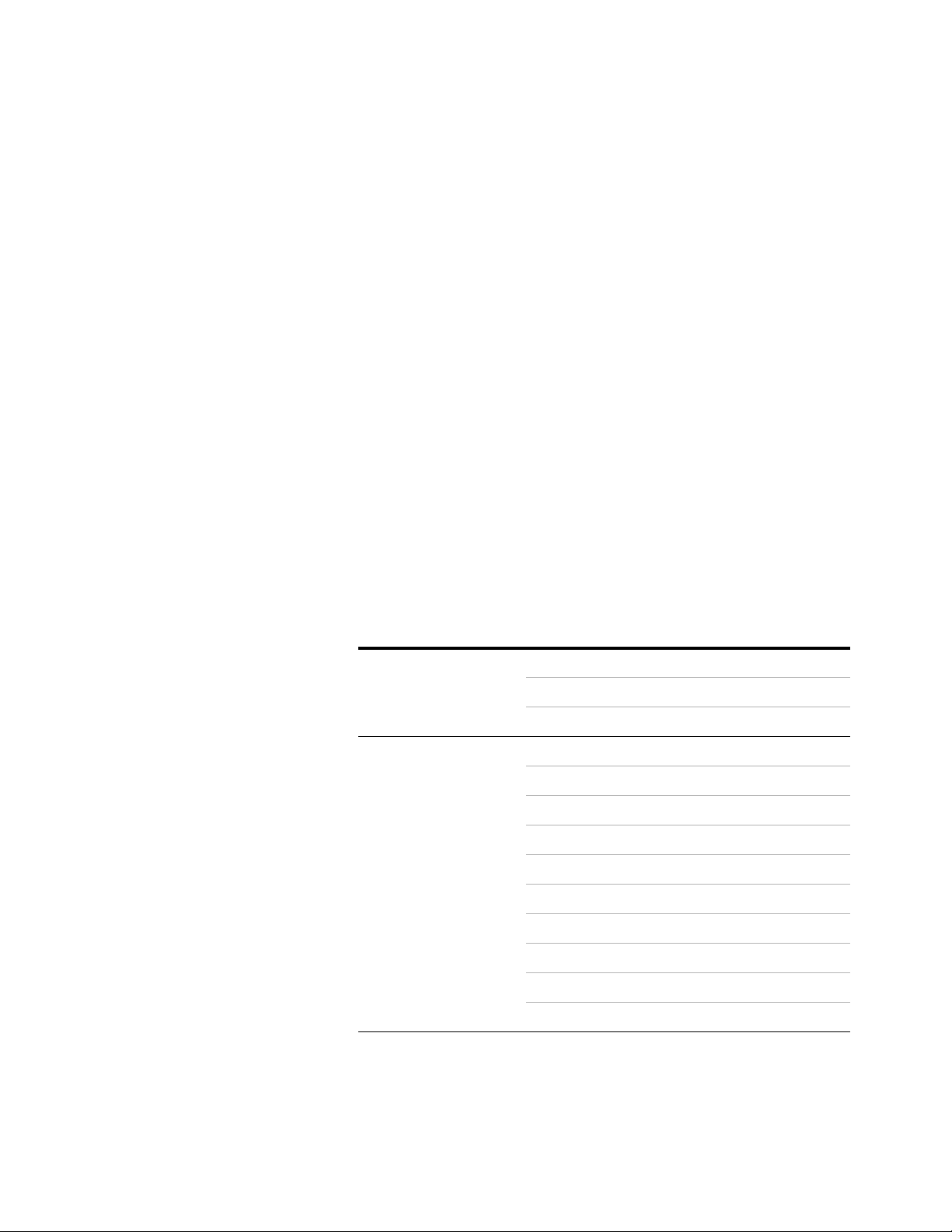

Figure 3-7 Switch/Load Unit Backplane Connectors (USB port adaptor board Not Shown)

3-10 E6198B/E6218A Switch/Load Unit User Manual

Page 39

Switch/Load Unit and Plug-In Cards 3

BREAKOUT BOARD (External Board)

BACK

J_5

J_6

J_7

J_3

FRONT

J_1

J_8

S3A-S3F

S1A-S1D

S2A-S2H

Figure 3-7 shows the locations of the various backplane

connectors and LEDs. These components are described on the

following pages. See Table 3-3 for more detail.

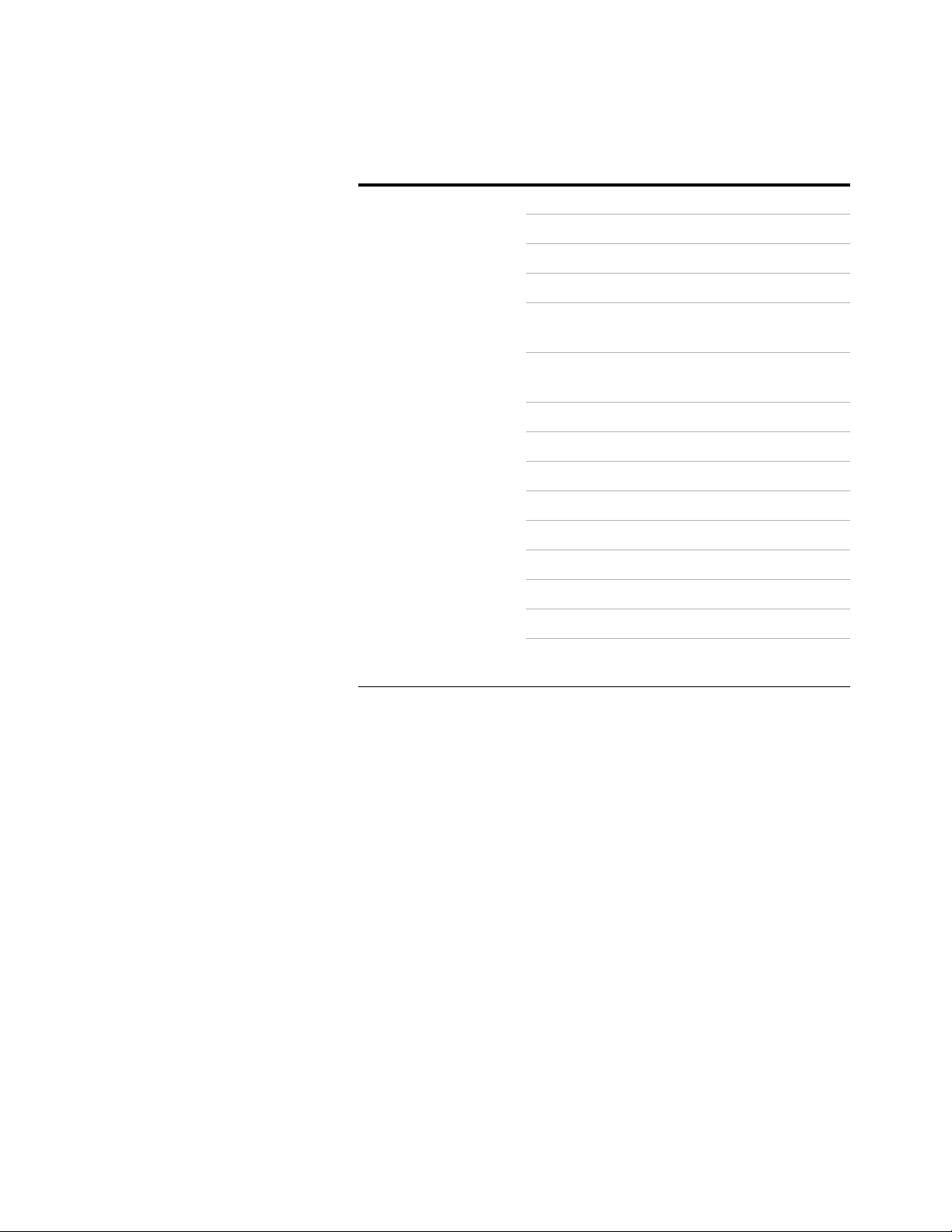

Figure 3-8 Switch/Load Unit Breakout Board Connectors (Standalone

only)

Figure 3-8 shows connector locations on the breakout board

(external board). Refer Table 3-5 for the detailed descriptions.

The breakout panel is available with the E6198B Standalone

option and is easily accessible from the SLU rear.

E6198B/E6218A Switch/Load Unit User Manual 3-11

Page 40

3 Switch/Load Unit and Plug-In Cards

Backplane Connector Name

Table 3-3 lists the connectors on a E6198B backplane.

Tab le 3- 3 Backplane Connectors for E6198B

E6198B Reference

Designator

J2 SLU Current Sense: Bussed/Split

J3 SLU Power Bus Sense Select: Local/Remote

J1 Frame Select

T1-T14 SLU Logic Power Supply Connector

J101 To USB Controller Connector

J102 Utility Connector

J104 External Reset (reserved)

J105 +5 V Indicator (+5 V Status)

J106 +12 V Indicator (+12 V Status)

J107 –12 V Indicator (–12 V Status)

J108 READY Indicator (Control Status)

J109 +12 V Output For Fan

J110 +12 V Output For Fan

J111 +12 V Output For Fan

J201-J221 Load Card Slots Connector

Description

J801 & J802 Power Busses PB1-PB4

J803 Sense For PB1-PB4

3-12 E6198B/E6218A Switch/Load Unit User Manual

Page 41

Backplane J1, J2 and J3 Connectors

Table 3-4 shows the factory default configuration for the

backplane connectors.

Tab le 3- 4 Backplane Factory Default Connector Settings

Switch/Load Unit and Plug-In Cards 3

Connector

J1 0 (Zero)

J2 Bussed Switch/Load Unit Current-Sense Bus

J3 Local

Default

Setting

Description

Frame Select address 0-7. When using multiple

Switch/Load Units in your test system, Connector

J1 provides a unique address for each

Switch/Load Unit. Factory default (one

Switch/Load Unit) is 0.

Switch/Load Unit Power Bus Sense select:

Local/Remote

E6198B/E6218A Switch/Load Unit User Manual 3-13

Page 42

3 Switch/Load Unit and Plug-In Cards

NOTE

Breakout Board Connector Name (for E6198B Standalone option)

Breakout board extends the connection from backplane to SLU

rear. Table 3-5 lists the description of each connector.

Tab le 3- 5 Breakout Board Connectors

Connector Description

J_1 Utility Connector (J102 extension connector)

J_3 Utility Connector (J102 internal connector)

J_5

J_6

J_7

J_8 Spare Supply Connector

S1A-S1D Toggle switches for Local/Remote

S2A-S2H Toggle switches for Frame Select

S3A-S3F Toggle switches for Isense Bussed/Split

The breakout board is not available with E6198B System Integrated

Frame Select & Spare Supply (Connect to J1 of

backplane internal connector)

Power Bus Sense Local/Remote (Connect to J3 of

backplane internal connector)

Isense Bussed/Split (Connect to J2 of backplane

internal connector)

option. See Figure 3-6.

3-14 E6198B/E6218A Switch/Load Unit User Manual

Page 43

Backplane Connectors

The following connector descriptions are referenced to

Figure 3-9.

T1-T14 are the Switch/Load Unit power supply connectors.

The supply provides the required +5 V and ±12 V for

powering the backplane and Load Cards. These power supply

lines are protected by fuses.

J102 connects the signals that are cabled between the

Switch/Load Unit and the mass interconnect. These signals

include:

Eight-bit fixture ID pins allow the user to configure a

unique ID for each mass interconnect fixture and read it

back. Address 0 of the backplane is used for the fixture ID

and to read back the status of reset and busy state of the

backplane.

Switch/Load Unit and Plug-In Cards 3

Digital In/Digital Out eight bits each (TTL level).

Open Drain Outputs eight bits each.

Four pairs of current sense busses correspond to the

current sense pairs from slots 1-5, 6-10, 11-15, and 16-21.

These busses may be connected together to form a single bus,

or split into independent current sense busses using jumpers

on SLU backplane J2 connector (Integrated) or switches

S3A-S3F on breakout board (Standalone). Factory default

connects all sense busses to a single bus. Find more

information on when should you split the busses and how in

Chapter 3.

Four remote power bus sense pins remotely sense the

power busses at the UUT. Remote or local sensing for power

bus PB1-PB4 can be set using jumpers on SLU backplane J3

connector or S1A-S1D on breakout board (Standalone).

Factory default is remote sense.

DAC 1 and DAC 2 outputs.

J201-J221 are the slot connectors for Pin Matrix Card or

Load Card, slots 1-21 respectively. The top half of each slot

connector is used to provide slot power, address, data, and

control lines. The bottom half of each connector is used to

connect the power busses to the Load Cards.

E6198B/E6218A Switch/Load Unit User Manual 3-15

Page 44

3 Switch/Load Unit and Plug-In Cards

Backplane LEDs

J801 and J802 provide the high power connections to power

busses PB1-PB4. Three supplies with a common connection

to PB1 or two independent supplies can be configured on the

four power busses. Bulk bypassing between power busses

may be desirable in certain applications.

J803 provides the sense connections for the four power

busses.

Two sets of LEDs are provided on the backplane for a visual

indication that the Switch/Load Unit is functioning:

Power LEDs. The +5V, +12V and –12V LEDs indicate the status

of the corresponding voltage lines from the Switch/Load Unit

power supply and READY LED indicate the status of SLU ready

to operate. If one or more LEDs is NOT illuminated, the most

likely problem was an overcurrent situation that opened the

non-resettable fuse(s). To change fuse(s), remove power from

the Switch/Load Unit for approximately 20 seconds. The fuse(s)

will reset when power is re-applied. (Non-resettable fuses need

to be replaced rather than power off to reset, refer to Table 3-11

for fuse ratings.)

Frame LEDs. The Frame Access LED flashes to indicate a data

access has occurred to that Switch/Load Unit. The five Slot

Address LEDs indicate the slot currently being addressed.

J102 Pinouts

Switch/Load Unit backplane connector J102 carries signals

such as the Digital I/O, DAC 1 and 2, and ISense (current sense)

lines. When configured as part of a standard Agilent system,

J102 of the Switch/Load Unit is connected via cable to a mass

interconnect panel. User connections to the UUT are then made

from the mass interconnect panel. Refer to the appropriate

mass interconnect wiring guide for connection details.

You can also make connections directly to J102 or to the

exposed end of an Agilent E3750-61607, Agilent E6170-61610,

or Agilent E6198-61625 cable connected to J102. Figure 3-9 is a

J102 connector pinout and Figure 3-10 shows the pinouts for

the exposed cable connector end. Table 3-6 defines the signals

available on J102.

3-16 E6198B/E6218A Switch/Load Unit User Manual

Page 45

Figure 3-9 Switch/Load Unit J102 Connector Pinouts

Open Drain Out (7)

Open Drain Out (5)

Open Drain Out (1)

Open Drain Out (3)

Open Drain Out (6)

Open Drain Out (2)

Open Drain Out (0)

Open Drain Out (4)

DAC2

DAC1

No Connection

System Gnd

System Gnd

Spare Supply

+12 Vdc Supply

+12 Vdc Supply

Power Bus Sense 4

Power Bus Sense 2

ISense+ (4)

ISense+ (3)

ISense+ (2)

ISense+ (1)

Spare_DigOut (7)

Spare_DigOut (5)

Spare_DigOut (3)

Spare_DigOut (1)

Digital In (7)

Digital In (5)

Digital In (3)

Digital In (1)

System Gnd

Fixture ID (7)

Fixture ID (5)

Fixture ID (3)

Fixture ID (1)

System Gnd System Gnd

Fixture ID (0)

Fixture ID (2)

Fixture ID (4)

Fixture ID (6)

System Gnd

Digital In (0)

Digital In (2)

Digital In (4)

Digital In (6)

Spare_DigOut (0)

Spare_DigOut (6)

Spare_DigOut (4)

Spare_DigOut (2)

ISense- (1)

ISense- (4)

ISense- (3)

ISense- (2)

Power Bus Sense 1

Power Bus Sense 3

System Gnd

System Gnd

System Gnd

System Gnd

No Connection

-12 Vdc Supply

+12 Vdc Supply

+12 Vdc Supply

96

94

93 90

91 888785

84 81

82 79

78

76

75 72

73 706967

66 63

64 61

60

58

57 54

55 525149

48 45

46 43

42

40

39 36

37 343331

30 27

28 25

24 21

22 19

18

16

15 12

13 1097

63

41

NC NC NC NC NC NC NC NC NC NC NC NC NC NC NC NC NC NC NC NC NC NC NC NC NC NC NC NC NC NC NC NC

A

B

C

Row 1

Row 2

Row 3

Row 4

Row 5

Row 6

Row 7

Row 8

Row 9

Row 10

Row 11

Row 12

Row 13

Row 14

Row 15

Row 16

Row 17

Row 18

Row 19

Row 20

Row 21

Row 22

Row 23

Row 24

Row 25

Row 26

Row 27

Row 28

Row 29

Row 30

Row 31

Row 32

NOTE

Switch/Load Unit and Plug-In Cards 3

For E6198B Standalone option, connector J102 is extended from the

backplane to the breakout board. See Figure 3-8.

E6198B/E6218A Switch/Load Unit User Manual 3-17

Page 46

6 4

9 7

12 10

15 13

18 16

21 19

27 25

30 28

33 31

36 34

39 37

42 40

45 43

51 49

53 52

57 55

60 58

63 61

66 64

69 67

1

Open Drain Out (6)

Open Drain Out (2)

Open Drain Out (0)

Open Drain Out (4)

System Gnd

Fixture ID (0)

Fixture ID (2)

Fixture ID (4)

Fixture ID (6)

System Gnd

Digital In (0)

Digital In (2)

Digital In (4)

Digital In (6)

Spare_DigOut (0)

Spare_DigOut (6)

Spare_DigOut (4)

Spare_DigOut (2)

ISense- (1)

ISense- (4)

ISense- (3)

ISense- (2)

Power Bus Sense 1

Power Bus Sense 3

System Gnd

System Gnd

System Gnd

System Gnd

No Connection

-12 Vdc Supply

+12 Vdc Supply

+12 Vdc Supply

3

Open Drain Out (7)

Open Drain Out (5)

Open Drain Out (1)

Open Drain Out (3)

DAC2

DAC1

No Connection

System Gnd

System Gnd

Spare Supply

+12 Vdc Supply

+12 Vdc Supply

Power Bus Sense 4

Power Bus Sense 2

ISense+ (4)

ISense+ (3)

ISense+ (2)

ISense+ (1)

Spare_DigOut (7)

Spare_DigOut (5)

Spare_DigOut (3)

Spare_DigOut (1)

Digital In (7)

Digital In (5)

Digital In (3)

Digital In (1)

System Gnd

Fixture ID (7)

Fixture ID (5)

Fixture ID (3)

Fixture ID (1)

System Gnd

75 73

78 76

81 79

84 82

87 85

90 88

93 91

24 22

48 46

72 70

96 94

ABC

Cable Connector Endand Front View

(Center Column Not Used)

Row 24

Row 23

Row 21

Row 22

Row 32

Row 31

Row 30

Row 29

Row 28

Row 27

Row 26

Row 25

Row 20

Row 19

Row 18

Row 17

Row 16

Row 15

Row 14

Row 13

Row 12

Row 11

Row 10

Row 9

Row 8

Row 7

Row 6

Row 5

Row 4

Row 3

Row 2

Row 1

3 Switch/Load Unit and Plug-In Cards

Figure 3-10 Cable Connector Pinouts

3-18 E6198B/E6218A Switch/Load Unit User Manual

Page 47

Tab le 3- 6 J102 signal definitions

Switch/Load Unit and Plug-In Cards 3

+12Vdc, –12Vdc

Supply

Spare Supply Connection for a user installed power supply not included in the standard system. Refer

DAC1

DAC2

Digital In 0 - 7

Open Drain Out 0 - 7

Spare_DigOut

Fixture ID (0 - 7) The Fixture ID lets you configure a unique ID for each mass interconnect fixture and

Isense+ (1 - 4)

Isense– (1 - 4)

+12V and –12V from the Switch/Load Unit Power Supply. The +12V supply can deliver

12.5A, the –12V supply can deliver 2.1A.

to “Connecting an Additional (Spare) Power Supply" for details.

The Switch/Load Unit provides two 14-bit channels of DAC which supply ±16 V at 10 mA

each.

The Switch/Load Unit provides 8-bits of digital input, 8-bits of open drain digital output,

and 8-bits of TTL-level digital output (Spare_DigOut). There is no handshaking

capability.

read it back. ID sent as TTL level bits.

These lines connect to the current sense bus on the Switch/Load Unit backplane. These

lines are used for sensing current on a selected load card channel. The 8-channel and

16-channel load cards are designed to connect to the current sense bus. Each load card

channel’s current sense lines are multiplexed so that on each card only one channel at a

time can be connected to the current sense bus. The current sense lines and the slots

they connect to are:

Isense lines (1) connect to Switch/Load Unit slots 1 - 5.

Isense lines (2) connect to Switch/Load Unit slots 6 - 10.

Isense lines (3) connect to Switch/Load Unit slots 11 - 15.

Isense lines (4) connect to Switch/Load Unit slots 16 - 21.

Two or more sets of the above lines can be bussed together select from toggle switches.

Refer to page 12 for details.

Power Bus Sense 1 - 4 The remote sense lines for the power supplies connected to power buses 1 - 4.

Gnd Chassis ground of the Switch/Load Unit.

E6198B/E6218A Switch/Load Unit User Manual 3-19

Page 48

3 Switch/Load Unit and Plug-In Cards

J1 Pinout

Tab le 3- 7 Switch/Load Unit J1 Pinout

FS1 FS3 FS5 FS7 NC GND SS

FS0 FS2 FS4 FS6 FRAME GND SS

J2 Pinout

Table 3-7 shows pinout of J1 Frame Select & Spare Supply (SS).

Frame 0 is selected if FS0 and FRAME are both are connected;

Frame 1 is selected if FS1 and FRAME are both are connected,

and so on. Default setting is frame 0 (zero). More detail about SS

(Spare Supply), please refer “Connecting an Additional (Spare)

Power Supply" .

Table 3-8 show pinouts of J2 ISENSE Bussed/Split. Default

setting for J2 is ISENSE Bussed.

Tab le 3- 8 Switch/Load Unit J2 Pinout

J3 Pinout

Tab le 3- 9 Switch/Load Unit J3 Pinout

IS(-2) IS(+2) IS(-3) IS(+3) IS(-4) IS(+4) NC

IS(-1) IS(+1) IS(-2) IS(+2) IS(-3) IS(+3) NC

Table 3-9 shows pinouts of Power Bus Sense Local/Remote.

Local 1 is selected if LOC_S1 is connected with PB1; Remote 1 is

selected if REM_S1 is connected with PB1, and so on. Default

setting for J3 is Local.

LOC_S1 PB2 REM_S2 LOC_S3 PB4 REM_S4 LOC_S1

PB1 REM_S1 LOC_S2 PB3 REM_S3 LOC_S4 PB1

3-20 E6198B/E6218A Switch/Load Unit User Manual

Page 49

T1-T14 SLU Logic Power Supply Connector

T1-T14 provides the required +5 V and ±12 V for powering the

backplane and Load Cards. Table 3-10 lists each jumper and its

corresponding input voltage.

Table 3-10 Power Supply Input for each Jumpers

Jumper Input Voltage

T1 +5 V

T2 +5 V

T3 +5 V

T4 –12 V

T5 +12 V

T6 +12 V

T7 +12 V

Switch/Load Unit and Plug-In Cards 3

T8 GND

T9 GND

T10 GND

T11 GND

T12 GND

T13 GND

T14 GND

E6198B/E6218A Switch/Load Unit User Manual 3-21

Page 50

3 Switch/Load Unit and Plug-In Cards

Differentiating E6198B Standalone Option and System Integrated Option

The key differences between the standalone and system

integrated option can be found at the SLU rear cover.

On a standalone unit, the backplane connectors are extended to

the breakout board attached to the SLU rear cover. At the SLU

rear, you will find toggle switches for SLU configuration, and

power and sense buses connectors protected by a cable

enclosure. (See Figure 3-11.)

On a system integrated unit, you will find cut-outs on the SLU

rear cover to allow cable routing from the SLU backplane.

Jumpers are used for SLU configuration.

Figure 3-11 Switch/Load Unit Rear View (Standalone Option)

3-22 E6198B/E6218A Switch/Load Unit User Manual

Page 51

Figure 3-12 Switch/Load Unit Rear View (System Integrated Option)

Switch/Load Unit and Plug-In Cards 3

E6198B/E6218A Switch/Load Unit User Manual 3-23

Page 52

3 Switch/Load Unit and Plug-In Cards

Fuse Ratings

Fuses are incorporated inside E6198B Switch/Load Unit. There

are 10 fuses and 7 fuses for Standalone SLU and Integrated SLU

respectively. Please refer Table 3-11 for more detail.

Table 3-11 Fuses Ratings

Standalone Integrated Description

Fuse1 Fuse1 1 A, –12 V

Fuse2 Fuse2 6 A, +12 V_1

Fuse3 Fuse3 6 A, +12 V_2

Fuse4 Fuse4 Not Used

Fuse5 Fuse5 15 A, +5 V_1

Fuse6 Fuse6 15 A, +5 V_2

Fuse7 Fuse7 Not Used

Fuse8 - 30 A, PB2

Fuse9 - 30 A, PB3

Fuse10 - 30 A, PB4

DC Power Bus Connections

PB1 to PB4 are the DC power bus connections as seen in

Figure 3-11 for the standalone unit. Notice the protective cable

enclosure covering both the power bus cabling and power sense

cabling for better protection.

For the integrated unit, there is no protective cable enclosure,

and you will need to configure the cabling directly onto the

backplane, behind the SLU backcover.

3-24 E6198B/E6218A Switch/Load Unit User Manual

Page 53

Agilent TS-5000

WARNING

CAUTION

E6198B Switch/Load Unit User Manual

4

Configuring the Switch/Load Unit

Card Location Recommendations 4-2

Connecting an Additional (Spare) Power Supply 4-5

Configuring the Power Busses 4-6

Connecting E6198B to the Computer via USB Interface or Parallel

Port 4-12

Adding a Second Switch/Load Unit 4-13

Load Box Installation 4-14

This chapter shows you how to configure the Switch/Load Unit.

SHOCK HAZARD. Only service-trained personnel who are aware

of the hazards involved should install, remove, or configure the

Switch/Load Unit or plug-in cards. Before you remove any

installed card, disconnect AC power from the mainframe and from

other cards that may be connected to the cards.

STATIC ELECTRICITY

Static electricity is a major cause of component failure. To prevent

damage to electrical components, observe anti-static techniques

whenever installing or removing a card in the Switch/Load Unit or

whenever working on a card.

Agilent Technologies

4-1

Page 54

4 Configuring the Switch/Load Unit

Card Location Recommendations

Slot 1 to 21 of a Switch/Load Unit are identical and able to take

any supported Pin Matrix or Load Cards. This sections provides

an example on card installation guideline to maintain

consistency between test systems. Your test system may use a

different guideline that fits your application.

For a single Agilent E6198B Switch/Load Unit installed in the system

Install matrix cards first. Slots 15 through 21 are reserved for

the matrix and custom modules. Starting from slot 21 and

working down, install matrix modules and custom modules in

the following order:

• Agilent Pin Matrix and Instrument Multiplexer Card

(E8792A or E8782A)

• Agilent Pin Matrix Card(s) (E8793A and/or E8783A)

• Agilent E8794A Custom Card(s)

Install the load cards using the following rules:

• Agilent N9379A 48-Channel Load Cards

Install any N9379A cards first, starting at slot #1.

• Agilent E6177A 24-Channel Load Cards

Install any E6177A cards next.

• Agilent U7177A 24-Channel Load Cards with Current

Sense

Install any U7177A cards next.

• Agilent N9378A 24-Channel Load Cards

Install any N9378A cards next. To allow for future expansion,

leave an open slot after the last N9378A card.

• Agilent E6176A 16-Channel Load Cards

Install any Agilent E6176A cards next.

• Agilent N9377A 16-Channel Load Cards

Install any Agilent N9377A cards next. To allow for future

expansion, leave an open slot after the last N9377A card.

• Agilent E6178B 8-Channel Heavy Duty Load Cards

Agilent E6178B 8 channel Heavy Duty cards require two slots

each. These cards are installed in even slot locations only.

Install E6178B cards starting with the first available even

slot following the 16 channel cards.

4-2 E6198B/E6218A Switch/Load Unit User Manual

Page 55

Configuring the Switch/Load Unit 4

CAUTION

Slot:

E8792A 32-Pin

Matrix and

Instrument

Multiplexer

Card

E6175A

8-Channel

Agilent E6176A

16-Channel

Load Cards

N9379A

48-Channel

Switch/Load Unit Slot Front View

Agilent E8794A

Custom Card

Empty

E6177A

24-Channel

Empty

N9378A

24-Channel

Empty

Empty

Empty

N9378A

24-Channel

Empty

1 2 3

4 5 6

7 8 9

10

11 12

13

14 15

16

17 18 19

20 21

• Agilent E6175A 8-Channel Load Cards

Agilent E6175A 8 channel cards require two slots each.

These cards are installed in even slot locations only. Install

E6175A cards in first available even slot following the

E6178B 8-Channel Heavy Duty cards.

Please close the gap for rear side of the connector if using own

fabricated cable with connector.

For example, Figure 4-1 shows the standard locations for matrix

and load cards for a system which contains three matrix cards,

a custom card, two 24 channel, four 16 channel, one 8 channel,

and one 8 channel heavy duty load card. If using this

configuration, be sure to leave the slots open between the cards,

as shown in the figure.

Figure 4-1 Example of Load/Matrix/Custom Cards Loading Order

E6198B/E6218A Switch/Load Unit User Manual 4-3

Page 56

4 Configuring the Switch/Load Unit

Load Card Types and IDS

Each card is assigned a different type and has a 10-pin

connector that lets you assign a unique binary code ID number

to each card. See“Load Card Type and Configuration ID" for

more information.

4-4 E6198B/E6218A Switch/Load Unit User Manual

Page 57

Configuring the Switch/Load Unit 4

C507

100uF

50V

HP 0180-3334

RT505

700m

HP 0837-0440

J1

+

Raytheon P/N

SMD100 or

equivalent

V+24V

To J102

J1

1

2

14

13

SS ( +ve Polarity)

Connecting an Additional (Spare) Power Supply

The Spare Supply pinout located at SLU backplane connector J1

(Integrated) allows you to add an additional power supply such

as a +24 V power supply for powering higher voltage relays. It is

necessary to remove the SLU rear cover to access this

connector. Figure 4-2 shows the placement and orientation on

the backplane for the power supply components. Both

Connector J1 and Capacitor C507 are loaded at the factory.

Capacitor C507 is to minimize high-frequency noise on the

supply line. The auxiliary supply output (Spare Supply) appears

on Switch/Load Unit connector J102 pin 79.

Figure 4-2 Component Location/Schematic for User-Installed External Power Supply

For SLU Standalone option, you can connect to the Spare

Supply Input directly from SLU rear. See Figure 4-3.

Figure 4-3 Spare Supply (Input) Connector on SLU rear (SLU standalone)

E6198B/E6218A Switch/Load Unit User Manual 4-5

Page 58

4 Configuring the Switch/Load Unit

J801 J802

PB1 PB2 PB3 PB4

PC Board Traces

Configuring the Power Busses

The UUT power supplies are connected to the power busses

PB1-PB4. Figure 4-4 shows the power bus connectors J801 and

J802 located on the Switch/Load Unit backplane for integrated

option. These connectors use screw terminations for high

current. The J801 connectors are shorted on board, providing a

common connection for up to three supplies. Example A and B

below show the two most common ways of configuring the

power busses.

Figure 4-4 Power Bus Connectors J801 and J802

The following examples A and B show the two most common

ways of configuring the power busses.

Example A shows three separate supplies attached to the

busses, with all three sharing a common ground on Power Bus 1

(PB1). This is the factory default configuration. The grounds for

all three supplies are connected together on connector J801.

4-6 E6198B/E6218A Switch/Load Unit User Manual

Page 59

Configuring the Switch/Load Unit 4

+5V-12V+12V

PB1

PB2

PB3

PB4

V

BATT

PB1

PB2

PB3

PB4

V

UUT

Figure 4-5 Example A: Three Separate Supplies on PB1 - PB4