Page 1

Errata

4935A Operating & Service

Manual

04935-90029

November 1966

Title & Document Type:

Manual Part Number:

Revision Date:

HP References in this Manual

This manual may contain references to HP or Hewlett-Packard. Please note that HewlettPackard's former test and measurement, semiconductor products and chemical analysis

businesses are now part of Agilent Technologies. We have made no changes to this

manual copy. The HP XXXX referred to in this document is now the Agilent XXXX.

For example, model number HP8648A is now model number Agilent 8648A.

About this Manual

We’ve added this manual to the Agilent website in an effort to help you support your

product. This manual provides the best information we could find. It may be incomplete

or contain dated information, and the scan quality may not be idea l. If we find a better

copy in the future, we will add it to the Agilent website.

Support for Your Product

Agilent no longer sells or supports this product. You will find any other available

product information on the Agilent Test & Measurement website:

www.tm.agilent.com

Search for the model number of this product, and the resulting product page will guide

you to any available information. Our service centers may be able to perform calibration

if no repair parts are needed, but no other support from Agilent is available.

Page 2

Operating and Service Manual

HP 4935A

Transmission Impairment

Measuring Set

Serial Numbers

This manual applies to instruments with serial numbers prefixed:

:2846A

Copyright Hewlett-Packard

5070

Centennial Blvd., P.O. Box

Manual Part No: 04935-90029

Microfiche Part No: 0493598804

Co./Colorado

ALL RIGHTS RESERVED

7050,

Telecommunications Division 1987

Colorado Springs, Colorado 80933

Printed Nov.

Printed in U.S.A.

1966

Page 3

Warnirlgs/(:autions

[

WARNING

1

SAFETY GROUNDING

Model

4YXA

If this instrument is to be energized via an autotransformer

for voltage reduction, make sure the common terminal is

connected to the earthed pole of the power source.

BEFORE SWITCHING ON THIS INSTRUMENT, the

protective earth terrninals of this instrument must be

connected to the protective conductor of the (mains)

power cord. The rnains plug shall only be inserted in a

socket outlet provided with a protective earth contact. The

protective

extension cord (power cable) without a protective conductor (grounding).

Make sure that only fuses with the required rated current

and of the specified type (normal blow, time delay, etc.)

are used for replacement. The use of repaired fuses and the

short-circuiting of fuse holders must be avoided.

Whenever It is likely that the protection offered by fuses

has been impaired, the instrument must be made

inoperative and be secured against any unintended

operation.

actlon

must not be negated by use of an

Any interruption of the protective (grounding) conductor

(inside or outside the instrument) or disconnecting the

protective earth terminal can

dangerous. Intentional interruption is prohibited.

make this instrument

HIGH VOLTAGE

Any adjustment, maintenance, and repair of the opened

instrument under voltage should be avoided as much as

possible and, when inevitable, should be carried out only by

a skilled person who is aware of the hazard involved.

Capacitors inside the instrument may still be charged even

if the instrument has been disconnected from its source of

SUPPlY.

Adjustments and service described herein are performed

with power supplied to the instrument while protective

covers are removed. Energy available at many points, if

contacted, result in personal injury.

LINE VOLTAGE

BEFORE SWITCHING ON THIS INSTRUMENT, make

sure instrument requirements match the voltage of the

power source.

GROUNDING

BEFORE SWITCHING ON THIS INSTRUMENT, ensure

that all devices connected to this instrument are connected

to the protective (earth) ground.

ii

BEFORE SWITCHING ON THIS INSTRUMENT, ensure

that the line power (mains) plug is connected to a

three-conductor line power outlet that has a protective

(earth) ground. (Grounding one conductor of a

conductor outlet is not sufficient.)

two-

Page 4

Model

&%A

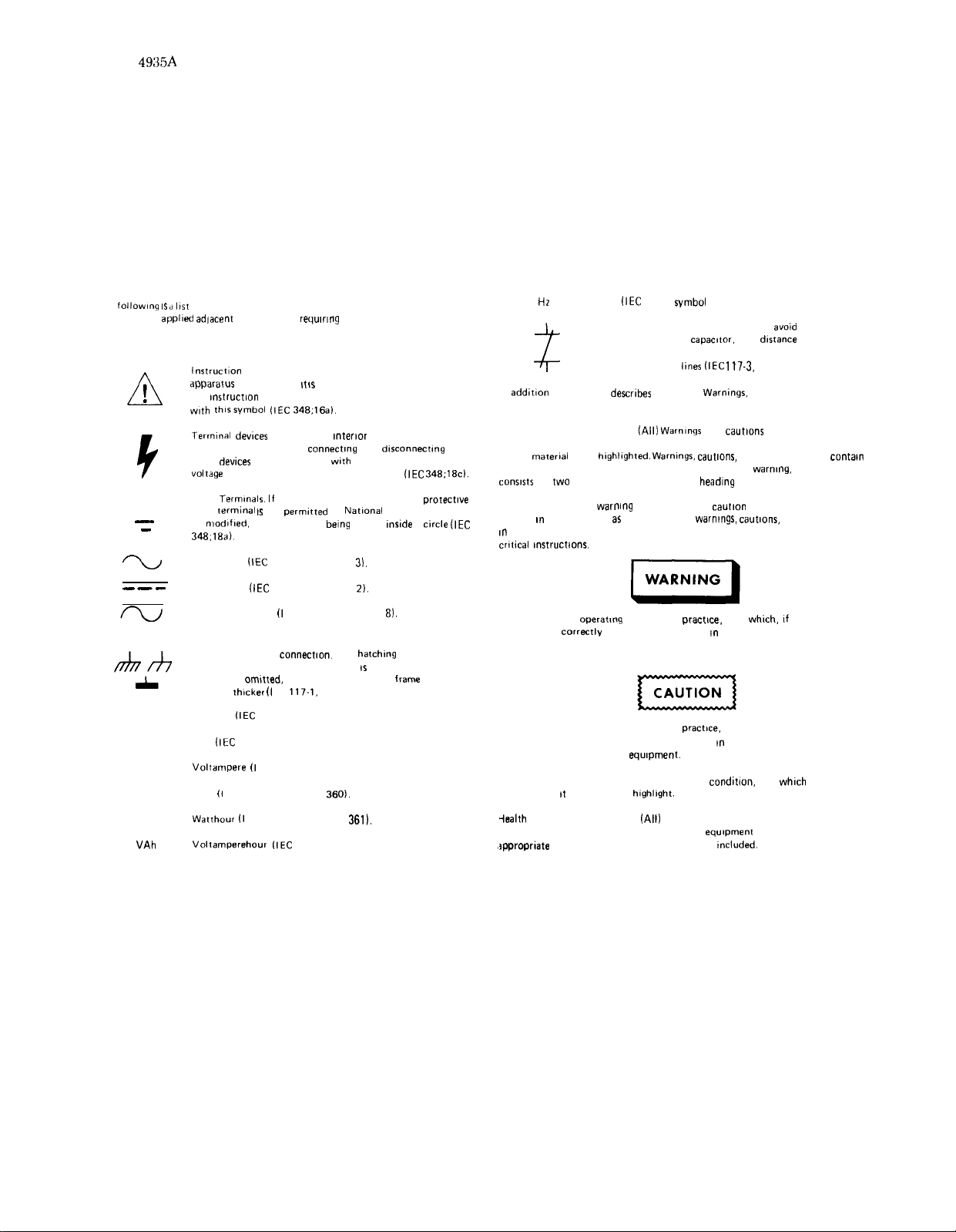

IEC Symbols

IEC SYMBOLS

The

follownq IS rl 1151

are normally

be placed on removable parts likely to be detached or lost.

A

1

-

-

---

VA

w

applwd adlacent

!

A

V

of key I EC symbols used by Hewlett-Packard. All symbols

to the device

lnstrucf~on

apparatus

the

wth thlssymbol (IEC 348;16a).

Termnal dewces

may be dangerous when

those

volrdge

Earth

earth

be

348.18a).

AC current

DC current

AC or DC current (I EC 1 17-l. symbol No.

pletely or partly omitted if there II no ambiguity. If the

hatching is

shall be

Ampere

Volt

Voltampere (I

Watt (I EC 1174, symbol No.

Manual symbol: If necessary. to preserve the

from damage !t IS necessary for the user to refer to

mstruct~on

dewces

shall be marked

exceeds 1 KV: The flash shall be red

Termunals. If

termmal 1s

modlfled.

for example, by

(IEC

fIEC

Frame or chaws

omated,

thrcker (I

(IEC

lltC

1174. symbol No. 357).

requur~ng

the symbol. They shall not

manual, then shall the apparatus be marked

fad from the

the use of this symbol for the

not

permttted

117-l. symbol No.

117-l. symbol No.

connection.

the line representing the

EC

1174, symbol No. 356).

EC 1174, symbol No. 358).

connecting

117.1,

symbol No. 87).

~ntertor

wth

by

bang

The

3601.

National

by live voltages that

to or

dlsconnectlng

the flash shown when the

Standards, it may

placed

irwde

3).

2).

8).

hatchmg

may be com-

frame

from

(IEC 348;lEc).

protectwe

a

circle (IEC

or chassis

HZ

z

In

addltlon

in HP Automatic Test System Manuals.

Warnings, cautions and notes.

to which each apples but notes may precede or follow applicable text depending

on the

material

procedural steps nor shall they be numbered. When a

consists

of

shall not be repeated above each paragraph. If it is ever necessary to precede a

paragraph by both a

appear m the sequence as noted, namely.

I”

the text shall be short and concise and be used to emphasize important and

critical mstructtons.

Hertz

(IEC

1174.

symbol

No. 365).

Contactor, normally closed. In order to

the symbol for a

horizontal (as drawn here) lines should be at least equal to

the length of those

the following

two

An

correctly

loss of life.

An operating procedure,

strictly observed, could result tn damage to, or

destruction of,

NOTE: An operating procedure,

it

describes

(All) Warmngs

to be

highllghted. Warnings, cautions,

or more paragraphs, the

warmng

and a note, or a

operating

procedure,

followed, could result

eqwpment.

is essential to

hIghlIght.

lines (IEC 117-3,

the use of

practtce.

practw,

capacitor.

the

deance

symbol No. 215.21.

Warmngs.

Cautions and Notes used

and

caut!ons

shall precede the text

and notes shall not

heading

warnings. cautions,

warmng,

WARNING, CAUTION, NOTE,

caution

and a note, etc. they shall

etc.

which. If

III

personal injury or

etc. which, if not

condmon,

etc.

avold

confusion with

between the

contan

caution, or note

notes. Such inserts

not

whwzh

Wh

VAh

Watthour (I

Voltamperehour (IEC

EC 1174, symbol No.

361).

1174, symbol No. 362).

-health

hazards precaution data.

factors, in the environment or use of the

,tppropriate

precautionary requirements shall be

(All)

When hazardous chemicals or adverse health

equipment

cannot be eliminated,

mcluded.

iii/(iv blank)

Page 5

Page 6

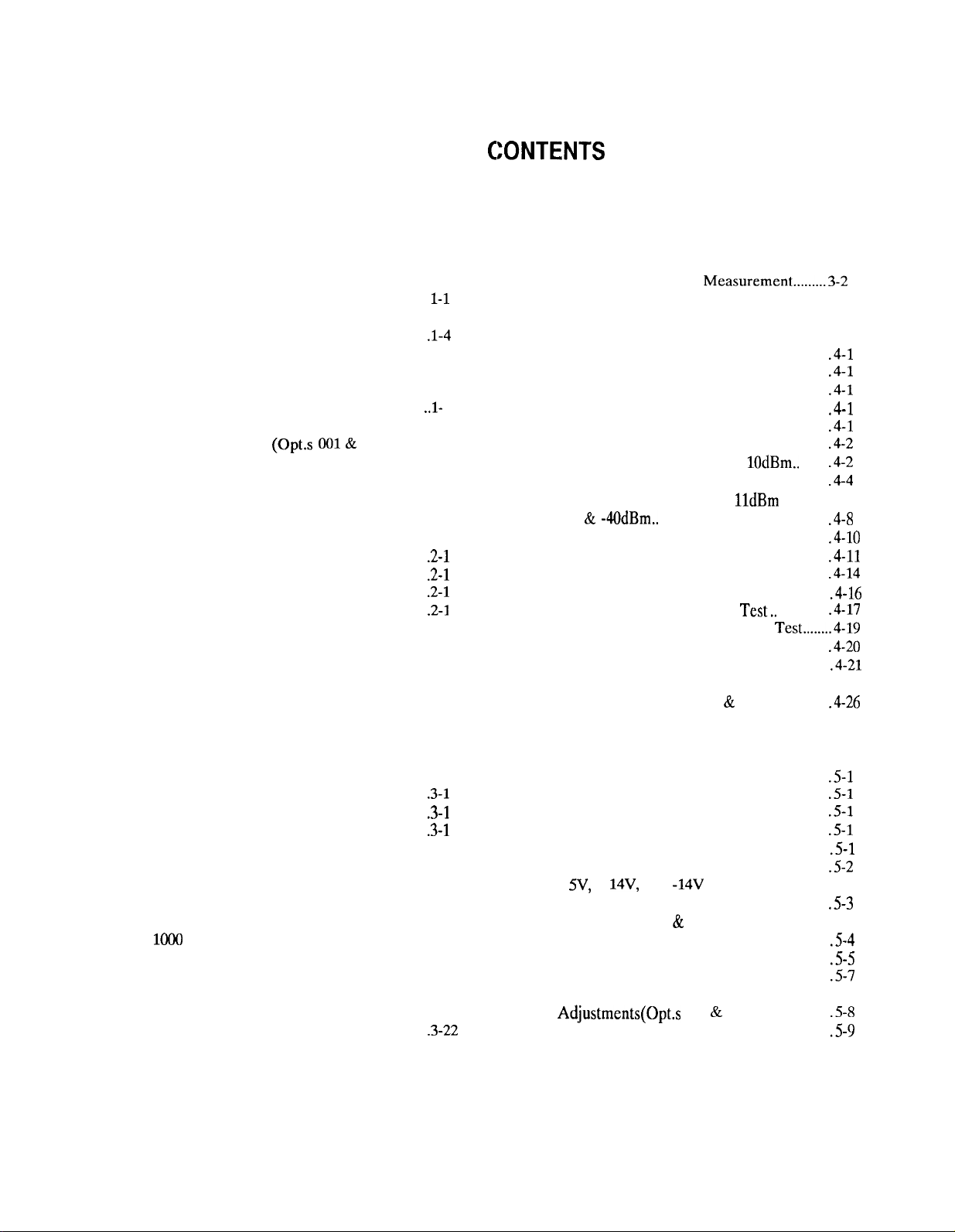

Model 4935A Table of Contents

TABLE OF

Section Title

I. GENERAL INFORMATION

l-l. Introduction.. ................................................... l-l

l-3. General

l-5. Instrument Identification..

l-7. Specifications.. .................................................

l-9.

Safety

Related Manuals............................................. l-4

1-12.

1-14. User Repair.. ...................................................

1-16.

Options

1-19.

Warranty.. ......................................................

1-21.

Recommended Test Equipment.. .................

l-23. Battery Operation

l-26. Charging the Batteries.. ...........................

l-29. Operating Temperature.. .........................

II. INSTALLATION

2-l. Introduction.. ..................................................

2-3. Initial Inspection.. ..........................................

2-6. Preparation for Use.......................................

2-7. Power Requirements.. ...................................

2-9. Line Voltage Selection..

2-11. Power Cable.. .................................................

2-13. Operating Environment.. ..............................

2-16. Storage

2-17.

Instrument Packaging ................................... .2-2

2-19.

III. OPERATION

3-l. Introduction....................................................

3-3. Self Check.......................................................

3-5. Error

3-7. Operating

3-9. Measurements

3-10. Measurement Principles ............................... .3-17

3-12. Input-Output

3-19. Level and Frequency Measurements..

1000

3-21.

3-24. Frequency Shift

3-26. Attenuation Distortion.. ................................

3-30. SF Skip ............................................................

Message Circuit Noise Measurements..

3-32.

3.40. Noise Measurements.....................................

3-42. Noise-with-Tone (Notched Noise)

3-45. Signal-to

Description.. ..................................... l-l

.............................

Considerations..

and Accessories..

..................................

.............................. l-4

(0pt.s 001 &

003) ..........

................................. 2-l

and

Shipment.. .................................

Environment..

Messages..

........................................... .2-2

............................................

Instructions

..................................

................................................

Switching ................................ .3-17

Hz Loss.. ................................................

.............................................. .3-18

...............3-22

Noise Measurement.. .................... .3-22

........

....

C:ONTENTS

Page Section Title

3-48. Signal Frequency Interference .................... .3-24

3-52. Impulse Noise.. .............................................. .3-24

3-55. Noise-to-Ground Measurement..

l-1

l-l

.1-4

l-4

..l-

4

l-4

l-6

l-6

l-6

.2-l

.2-l

.2-l

.2-l

.2-2

.2-2

.2-2

.3-l

.3-l

.3-l

.3-6

.3-7

.3-18

.3-18

.3-18

.3-19

..3-19

.3-22

3-59. Peak-to-Average Ratio

IV. PERFORMANCE TESTS

4-l. Introduction ...................................................

4-3. Equipment Required.. ..................................

4-5. Test

Record

...................................................

4-7. Self Check ......................................................

4-9. Performance Verification.. ...........................

4-12. Performance Tests........................................

4-13. Transmitter Flatness at +

4-14. Transmitter

4-15. Receiver Accuracy at t

& -4OdBm..

4-16. Autorange Test........................................

4-17. Filter Tests..

4-18.

Impulse Noise DAC Test.. .....................

4-19. Count Limit Test.. ...................................

4-20.

Termination Impedance

4-21. Hold Tone Dropout Detector

4-22.

4-23. Distortion

4-24. P/AR

Hold Circuit Test

Test

Test..

4-25. Noise-to-Ground(Std. dc Opt. 001).

V. ADJUSTMENTS/CALIBRATIONS

5-l. Introduction ...................................................

5-3.

Safety

Considerations.. .................................

5-5. Equipment

5-6. Instrument

5-9. Adjustment

Required.. ..................................

Access..

Locations...................................

5-11. Adjustments.. .................................................

5-13. t

5V,

+

Supply

14V,

and

Adjustments

5-14. Output Level & Transmit

Monitor

Loop Adjustments.. .................

5-15. Receiver Adjustments...................................

5-17. Notch Filter Adjustments.............................

5-18. Al3 P/AR Filter and Latch

Adjustments(0pt.s

5-19. Hold Circuit Adjustments.. ....................

Measurement.........3-2

Flatness at

..............................................

.............................................

....................................

........................................

..............................................

.................................

-14V

Power

......................................

001&003). ...................

................ .3-25

10dBm..

-40dBm..

1ldBm

Test..

Test........4-19

........

..........

..............

......

Page

5

.4-l

.4-l

.4-l

.4-l

.4-l

.4-2

.4-2

.4-4

.4-8

.4-10

.4-11

.4-14

.4-16

.4-17

.4-20

.4-21

.4-25

.4-26

.5-l

.5-l

.5-l

.5-l

.5-l

.5-2

.5-3

.5-4

.5-5

.5-7

.5-8

.5-9

V

Page 7

Table of Contents Model

4935A

TABLE OF CONTENTS

Section

VI. REPLACEABLE PARTS

6-l. Introduction..

6-3. Replaceable Parts List.. ...............................

6-5. Ordering Information ...................................

VII. MANUAL CHANGES

7-1. Introduction ....................................................

7-3. Manual Changes.. ..........................................

7-6. Manual Change Instructions.......................... 7-l

VIII. SERVICE

8-l. General Information ....................................

8-8. How Measurements are Made

8-10. Level

8-13. Noise.. ......................................................... 8-4

8-16. Noise-with-Tone ......................................

8-19. Signal-to-Noise.. .......................................

8-22. Impulse Noise ..........................................

8-26. Noise-to-Ground (Std & Opt. 001).

8-29. Peak-to-Average Ratio: P/AR

(0pt.s

8-32. Frequency Measurement.. ............................

8-34. Level

Measurement..

8-38. How to Compute Frequency and Level

Measurement .................................................

8-39. Level Calculation Example.. ...................

8-42. Control Theory of Operation.......................

8-44. MicroprocessortoInstrument.. ................... .8-11

8-45.

System

8-48. InstrumenttoMicroprocessor.. ................... .8-12

8-51. Operator to Microprocessor ........................ .8-12

8-52.

8-54.

Keyboard Interrupt.. ................................ .8-12

Receiver Impedance

8-57. MicroprocessortoOperator.. ......................

8-58. Displays..................................................... .8-13

8-60.

InstrumenttoOperator ................................ .8-13

8-62. Monitor Amp ........................................... .8-13

8-64. Beep Generator ....................................... .8-13

8-66. OperatortoInstrument ................................ .8-13

8-68. Miscellaneous Circuitry................................ .8-13

8-73. Receiver Theory of Operation..................... .8-15

8-76.

I/O

Termination ..............................................

Title Page Section Title

..................................................

....................

and

Frequency.. .............................

......

002&003) ....................................

.....................................

Latches.........................................

Switches..

.............. .8-12

Switching/Hold Circuits/

.6-l

..6- 1

.6-l

.7-l

.7-l

..8- 1

.8-3

.8-4

.8-4

.8-5

.8-5

.8-6

.a-6

.8-6

.8-7

.8-8

.8-8

.8-11

.8-H

.8-13

.a-16

(cord)

Page

8-80. Input Select/Notch Filter/

25dBAmp.. ............................................. .8-17

8-85.

8-97. Level Detectors ....................................... .8-19

8-100.

8-102.

8-104.

811.3.

8-126. Power Supply Theory....................................

8-128. AC Line Supplies ....................................

8-131. Regulators.. ..............................................

8-139. Charger Board Theory of Operation..

8-141. Battery Charging.. ...................................

8-144. Power Source Selection.. ........................

8-146. Relay Drive Circuitry.. ............................

8-148. Inhibit Circuit ........................................... 8-26

8-153. Maintenance ..................................................

8-1.55.

8- 157.

8-159. Component Replacement ......................

8-164. Soldering ..................................................

8-166

8-168. Disassembly .................................................... 8-29

8-169.

8-171.

8-173. Switchboard/Front Panel Removal..

8-175. Transmitter Board Removal.. ...................... .8-30

8-177. Reassembly.. ..................................................

8-179. Power Supply Troubleshooting.. .................

8-181. Minimum Core Troubleshooting................

8-183. Procedure .................................................. 8-35

8-186. Display Troubleshooting.. ......................

8-189. Control Troubleshooting..............................

8-190.

8-192. Control and Counting Section

8-194. Transmitter Troubleshooting ......................

8-196.

8-200.

8-202.

8-204. Filter and Signal Select Circuitry..

8-207.

8-210.

8-212. Receiver Troubleshooting............................

Noise Filter Circuitry.. ............................ .8-17

Impulse Noise Detectors.. ...................... .8-19

Transmitter .................................................... .8-19

Test Signal

Generation Method..

..........

.8-20

Circuit Description.. ................................ .8-21

.8-23

.8-23

.8-24

........

.8-25

.8-26

.8-26

.8-26

.8-28

Periodic Maintenance.. ........................... .8-28

Failure Maintenance.. .............................

.8-28

.8-28

.8-28

.

Cleaning.. ..................................................

Remove Case.. .........................................

.8-28

.8-29

Receiver Board/Shield Plate/

Battery Charger Board Disassembly..

........

..........

.8-29

.8-30

.8-31

.8-33

.8-34

.8-36

.8-36

Troubleshoot

Interrupt Circuitry.. .................................

Keyscan/

.8-36

Troubleshooting.. .......................................... .8-36

.8-37

Transmit Clock Generator.. ...................

.8-37

Transmitter Signature Analysis

Procedure.. ...............................................

Digital-to-Analog Conversion ...............

Output Amplifier.. ...................................

Transmit Monitor.. ..................................

........

.8-37

.8-39

.8-40

.8-42

.8-43

.8-43

vi

Page 8

Model 4935A

Table of Contents

TABLE OF CONTENTS

Section Title Page Section Title Page

8-217.

8-219.

8-222.

8-225.

8-227.

8-229.

8-232.

8-233.

8-235.

8-237.

8-239.

8-242.

8-246. Noise Filters ...................................................

8-248. Autorange ................................................. .8-49

8-250. Detector Troubleshooting.. ....................

8-252. Impulse Noise Circuitry.. ..............................

82.54.

8-255. Procedure .................................................

8-257.

Setup..........................................................

Overall Transmit Monitor

Transmit Monitor Signal ........................

Noise Filter.. .............................................

Simplified Autorange Check.. ................

Detector Select.........................................

Inputs from Front Panel/

Notch Filter/ 25dB Amp/Tone

Dropout Signal Path.. ..............................

Setup..........................................................

Input Transformer.. .................................

Noise-to-Ground Input Path

(Noise-to-Ground Units

Tone Dropout

Notch Filter ..............................................

Charger Board Troubleshooting .................

Charge Circuitry/Charge

Inhibit Circuitry .......................................

Signal

Test

.............

only)

............... .8-48

Path...................... .8-49

.8-44

.8-44

.8-45

.8-45

.8-46

.8-47

.8-47

.8-48

.8-48

.8-49

.8-49

.8-50

.8-50

.8-52

.8-52

.8-52

8-259. Relay Drive Circuitry,

Low Voltage Inhibit Circuitry.. .............

8-261.

8-263. Delay and Relay Drive Circuitry..

8-265. AC and Low Voltage Inhibit

8-267. Service Aids ...................................................

8-268. Service Selection of Input/

8-270.

8-272. Service Selection of Noise Filters

8-274. Procedure .................................................

8-276. Service Selection of Autorange

8-278. Procedure ................................................. .8-58

8-279. Hand Selection of

8-282. Hand Selection of C57 and

8-283.

Inhibit Circuitry AC and

Low Voltage.. ...........................................

Troubleshooting ......................................

Notch

Filter/25dB

Procedure.. ...............................................

by

Hand.. ........................................................

Gain for Service.............................................

(A3C57

for Desired Frequency

FiIters:

and

Response of Each Stage.. ................

Amp.. .............................

AX57

and

A3C160

for P/AR Units)

Response..

A3C160

..............

Cl60..

.........

........

.8-53

.8-54

.8-54

.8-55

.8-57

.8-57

.8-57

.8-58

.8-58

.8-58

.8-59

.8-60

.8-60

vii

Page 9

Table of

Contents

Model 4935A

LIST OF ILLUSTRATIONS

Section

l-l.

Model

4935A Transmission Impairment

Measuring

Title Page Section

................................................

Set

.1-O

l-2. Charge Acceptance at Various

Tempcraturcs..

2-l.

Lint

Voltage Selection.. ................................

3-l. Front and

Connectors/indicators..

3-2.

Measurements

3-3. Input-Output Switching

3-4. Level and Frequency Mcasurcments.. ........

3-5. Message Circuit Noise

3-6. C-Mcssagc Weighting Characteristic.. ........

3-7. 3

kHz

Flat Weighting Characteristic..

................................................ l-6

Rear

Panel Controls/

................................ .3-2

................................................

................................. 3-17

Measurements

......

.........

.2-l

.3-6

.3-18

..3-19

.3-20

.3-20

3-8. Program Weighted liltcr.. ............................. .3-21

3-9.

15

kHz

3-10.

Flat Filter ..........................................

SOkBit Filter.

................................................... .3-22

.3-21

3-11. C-Message Weighting with Notch

Characteristic.. ............................................... .3-23

3-12. Signal-to-Noise Measurement ..................... .3-23

3-13. Impulse Noise Waveform

Rcprcscntation..

3-14. Noise-to-Ground

Circuit Noise

............................................. .3-24

Related

to

Message

..................................................

.3-2.5

3-15. P/AR Transmit Signal Frcqucncy

Spectrum.. ....................................................... .3-26

3-16. P/AR Transmit Signal

Envelope..

...............

.3-26

4-l. Transmitter Flatness Test

at + 10

4-2.

Transmitter

at

-40 dBm

4-3. Reccivcr Test at + 11

and

-40

4-4. Autorangc

4-5. Filter

4-6. Impulse Noise

4-7. Count Limit

4-8.

Termination

4-9. Hold

4-10. Hold

4-11. Distortion

4-12. -40

dBm

4-13. Filter Circuits .................................................

4-14. P/AR Test.. ....................................................

.................................................... .4-2

dBm

Flatness Test

...................................................... .4-4

dBm

dBm

................................................... .4-8

Test

.............................................. .4-10

Tests..

....................................................

DAC

Test

............................. .4-14

Test

...........................................

Impedance Test.. ..................... .4-17

Tone

(Xrcuit

Dropout

‘Test..

Test

Detector Test..

......................................... .4-20

................................................

...........

Distortion Test.. ............................. .4-22

.4-11

.4-16

.4-19

.4-23

.4-25

4-15. Noise-to-Ground Test.. ................................. .4-26

4-21

Title Page

5-1. Output Level and Transmit Monitor

Loop Adjustments..

5-2. Receiver

Adjustments...................................

5-3. Hold Circuit Adjustments..

6-l. Exploded View Case and Covers..

6-2. Exploded

View

6-3. Exploded View Battery Option..

.......................................

..........................

...............6-4

Assemblies and Cables..

.................

7-l. A2 Switch Board Component Locator..

..

....

.5-4

.5-5

.5-9

..6- 5

.6-7

..7-10

7-2. A5 Charger Board Component Locator.....7-14

7-3. Partial A5 Charger Board Schematic..

.......

.7-14

7-4. Al4 Transmitter Board Component

Locator ........................................................... .7-15

7-5. Partial A4 and Al4 Schematic ...................... 7-16

7-6. Al4 P/AR Transmitter Board

Component Locator.. ....................................

7-7. A4 Transmitter Board

Locator

........................................................... .7-17

Component

7-8. Partial Power Supply Schematic.. ................

.7-16

.7-18

7-9. Al3 P/AR Receiver Board Component

Locator ........................................................... .7-19

7-10. A3 Receiver Board Component

Locator ........................................................... .7-20

7-11.

A3 Receiver Board Schematic

1

(Sheet

of 2) ................................................. .7-21

7-12. A3 Receiver Board Schematic

(Sheet 2 of 2) ................................................. .7-23

7-13. Al3 P/AR Receiver Board Component

Locator

........................................................... .7-25

7-14. A3 Receiver Board Component

Locator

........................................................... .7-26

7-15. A3 Receiver Board Schematic

Diagram (Partial). .........................................

.7-27

7-16. A4 Transmitter Board Component

Locator ........................................................... .7-28

7-17. Al4 Transmitter Board Component

Locator

...........................................................

.7-28

7-18. A4 Transmitter Board Schematic

Diagram

......................................................... .7-29

7-19. Al4 Transmitter Board Schematic

Diagram (Partial). ......................................... .7-30

7-20. Al4 Transmitter Board Schematic

Diagram (Partial). ......................................... .7-30

.......

........

.7-32

.7-33

7-21. A2 Switchboard Component Locator..

7-22. A2 Switchboard Schematic Diagram..

7-23. A3 Receiver Board

Component

VW

. . .

Page 10

Model 4935A

Table of Contents

LIST OF ILLUSTRATIONS

Section Title Page Section

Locator.. .......................................................... .7-34

7-24. Al3 Receiver Board Component

Locator.. ..........................................................

7-25. Receiver Board Schematic

Diagram (Sheet1of 2) ................................. .7-36

7-26. Receiver Board Schematic

Diagram (Sheet 2 of 2) ................................. .7-37

7-27. A4 Transmitter Board Component

Locator.. .......................................................... .7-38

.7-35

8-19. P/AR Signal Frequency Spectrum ..............8-41

8-20. P/AR Transmit Signal Envelope................

8-21. 20 Hz Waveform ...........................................

8-22. Transmit Monitor Test Output ...................

8-23. 4935A Signal

8-24. Al Front Panel Schematic Diagram............8-69

8-25. A2 Switchboard Component Locator..

8-26. A2 Switchboard Schematic Diagram..

8-27. A3 Receiver Board Component

7-28. Al4 Transmitter Board Component

Locator

............................................................ .7-39

8-28. Al3 Receiver Board Component

7-29. A4 Transmitter Board Schematic

Diagram (Sheet 1 of 2) ................................. .7-40

8-29. A3 Receiver Board Schematic

7-30. A4 Transmitter Board Schematic

Diagram (Sheet 2 of 2)

7-31. A5 Charger Board Component

7-32. A5 Charger Board Schematic

.................................

Locator......7-4

Diagram.......7-4

8-l. 4935A Main Block Diagram.. .......................

.7-41

2

3

.8-l

8-30. A3 Receiver Board Schematic

8-31. A3 Receiver Board Schematic

8-32. A3 Receiver Board Schematic

8-2. Voltage-to-Frequency Conversion

Characteristics ................................................. 8-7

8-33. A4 Transmitter Board Component

8-3. Voltage-to-Frequency Conversion

output .............................................................

.8-8

8-34. Al4 Transmitter Board Component

8-4. Frequency and Level Measurement

Timing.. ...........................................................

.8-9

8-35. A4 Transmitter Board Schematic

8-5. Control Circuitry Block Diagram................ .8-11

8-6. Receiver Block Diagram.. .............................

8-7. Switchboard Block Diagram ........................

8-8. Input-Output Switching ................................

.8-14

.8-15

.8-16

8-36. A4 Transmitter Board Schematic

8-37. A4 Transmitter Board Schematic

8-9. Filter Block Diagram .................................... .8-17

8-10. Autorange Block Diagram ........................... .8-18

8-38. A4 Transmitter Board Schematic

8-11. Stair-Step Sinewave.. ..................................... .8-20

8-12. Transmitter Block Diagram ......................... .8-21

8-13. Power Supply Block Diagram.. ....................

.8-23

8-14. Charger Board Block Diagram.. .................. .8-25

8-17. Instrument Troubleshooting ........................

8-18. Stair-Step Sinewave.. .....................................

.8-32

.8-39

8-39. A4 Transmitter Board Schematic

8-40.

8-41. A5 Charger Board Schematic Diagram......8-9 1

Title Page

.8-42

.8-43

.8-44

Flow

Block Diagram.. ...........

Locator ...........................................................

Locator ...........................................................

Diagram (Sheet1of 4). ................................

Diagram (Sheet 2 of 4).................................

Diagram (Sheet3of 4).................................

Diagram (Sheet 4 of4). ................................

.......

........

.8-67

.8-70

.8-71

.8-72

.8-72

.8-73

.8-75

.8-77

.8-79

Locator ........................................................... .8-80

Locator ........................................................... .8-80

Diagram (Sheet1of 5)................................. .8-81

Diagram (Sheet2of 5). ................................

Diagram (Sheet3of 5).................................

Diagram (Sheet 4 of 5). ................................

Diagram (Sheet5of 5). ................................

.8-83

.8-85

.8-87

.8-89

A5 Charger Board Component Locator....,890

ix

Page 11

Table of Contents

LIST OF TABLES

Model

4935A

Table

l-l.

l-2.

l-3.

2-l.

4-1.

4-2.

4-3.

4-4.

4-5.

4-6.

4-7.

4-8.

4-9.

4-10.

4-11.

4-12.

4-13.

4-14.

4-15.

4-16.

6-l.

6-2.

6-3.

Title Page Table

Specificalions..

Recommended

................................................. l-2

Test

Equipment.. ................. l-5

List of Parts Used for Performance

Tests

................................................................. l-5

HP Plug

Transmitter Flatness

Transmitter Flatnessat-40 dBm..

Styles..

............................................... 2-3

at +

10

dBm

............... .4-3

...............

.4-5

Abbreviated Transmitter Flatness................4-7

Receiver

Accuracy Test

Table ..................... .4-9

Abbreviated Receiver Accuracy

Test

Table.. ..................................................... .4-9

Autorange

..............................................

Test

.4-10

C-Message Filter Test................................... .4-11

3

kHz

Filter Test............................................ .4-12

15

khz flat Filter Test.. .................................. .4-12

Program Filter Test....................................... .4-12

50

kBit

Filter Test.. ........................................ .4-13

Test..

Notch Filter

Impulse Noise

Filter Circuit

.......................................... .4-13

DAC Test ............................. .4-15

Parts List.. ............................... .4-23

Abbreviated Distortion Test ........................ .4-24

P/AR Filter

Responses

................................ .4-25

Reference Designation and

Abbreviations

Manufacturer

Replaceable

................................................. .6-2

Code List

...............................

Parts.. ........................................

.6-8

.6-9

Title Page

7-l. Manual Changes.. ..........................................

8-l. Measurements

8-2. Noise Amplification..

Summary.. ............................

.....................................

.7-l

.8-3

8-5

8-3. Reference Signatures.. .................................. .8-38

8-4.

Wideband

8-5. 5

kHz

8-6. Output Select MUX.. ....................................

8-7. Transmit Monitor Test.................................

8-8.

A3UlB

8-9. TP3 Voltages

S-10.

Hand Selection of Noise Filters ..................

8-11. Autorange

8-12. Hand Selection of C57 and

8-13. 4935A C-Message

8-14. 4935A 3

8-15. 4935A

Filter Response ...........................

Low Pass Filter Response

.................8-40

Voltages ...........................................

................................................. .8-51

States........................................... .8-59

Cl60..

..............

Filter..

.............................

kHz

Filter.. ...................................... .8-61

kHz

Filter...................................... .8-61

15

S-40

.8-41

.8-43

.8-51

.8-58

.8-60

.8-61

8-16. 4935A Program Filter.. ................................. .8-61

8-17. 4935A 50

8-18. 4935A

kBit

Filter.. .................................... .8-62

Notch

Filter.. ...................................... .8-62

8-19. 4935A P/AR Filter ....................................... .8-62

8-20. 4935A 150

8-21. 4935A 110

8-22. Bell

8-23. Bell 410093kHz

8-24. Bell 4100915kHz

8-25. Bell 41009

8-26. Bell 41009

8-27. Bell 41009

8-28. Bell 41009 Notch

kHz

Low Pass Filter ..................

kHz

Low Pass Filter

C-Message Filter.. ......................

41009

Filter.................................

Filter.. .............................

Program Filter.. .......................... .8-64

50

kBit

Filter.. ............................. .8-65

P/AR Filter ................................

Filter.. ...............................

.8-62

.................. .8-63

.8-63

.8-64

.8-64

.8-65

.8-65

x

/(xi blank)

Page 12

Page 13

(hctral Inii,rmi,ti~,,,

Model 4935A

Figure f-1.

Model

4935A f

ransnhdon

Impairment

Measuring set

Page 14

Model 4935A. t

General Information

SECTION I

GENERAL INFORMATION

l-l.

1-2.

the HI’ Model

49XA

following information:

INTRODUCTION

This Operating and Service manual contains information to install, operate, maintain, and service

49:{5A

Transmission Impairment Measuring Set (TIMS). Figure 1-l shows the HP Model

with cover and power cord. The manual is divided into eight major sections which provide the

SECTION I. GENERAL INFORMATION. Provides identification, specifications, related

manuals, and user-repair information.

SECTION II. INSTALLATION. Contains unpacking and inspection information, power

requirements, packaging, and storage instructions.

SECTION III. OPERATION. Includes an explanation of controls, connectors, indicators, and an

automatic self check procedure. Describes measurement principles and front panel instructions for

making each measurement.

SFCTION

instrument’s performance is in accordance with the specifications.

SECTION V. ADJUSTMENTS. Provides adjustment and calibration procedures.

SECTION VI.

replaceable parts.

SEXTION

instruments with earlier serial numbers.

IV. PERFORMANCE TESTS. C’xtves

REPLACEARLE

VII. MANUAL CHANGES. C

PARTS. Lists and identifies the instrument assemblies and

or

ams

test procedures required to verify that the

information to backdate the manual fort

SECTION VIII. SERVICE. Includes theory of operation, troubleshooting procedures, flowcharts,

component locators, and schematic diagrams.

1-3.

l-4.

data and voice impairments. The frequency range over which measurements are made is 20 Hz to 110 kHz,

in steps of I, 10, 100, 1000, or 10,000 Hz. There are four permanently stored, fixed frequencies -404, 1004,

2804. and

1-5.

l-6. A IO character serial number (OOOOAOOOOO) is inscribed on the rear panel. The first four digits and

the letter are the serial prefix. The serial prefix will change only if changes are made to the instrument; a

Manual Change Sheet will be included with the manuals of any instruments affected.

form the serial suffix which is unique to each instrument.

1-7.

l-8. Instrument specifications are listed in Table I -1.

GENERAL DESCRIPTION

HI’ Model

271:s

49XA

is a Transmission Impairment Measuring Set (TIMS) which measures wideband

Hz. Any other four frequencies may be temporarily assigned and stored by the user.

INSTRUMENT IDENTIFICATION

Thelast

SPECIFICATIONS

five numbers

l-l

Page 15

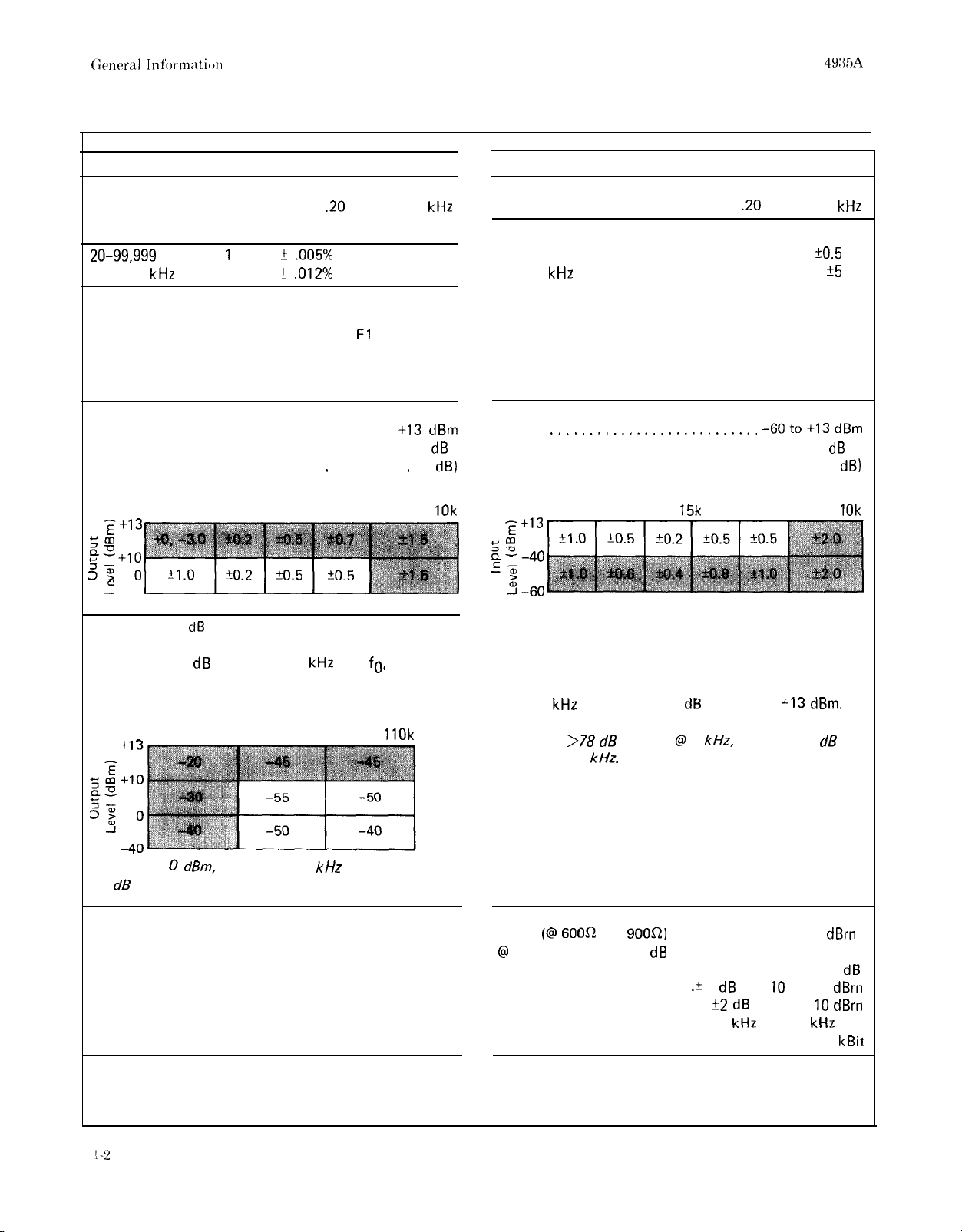

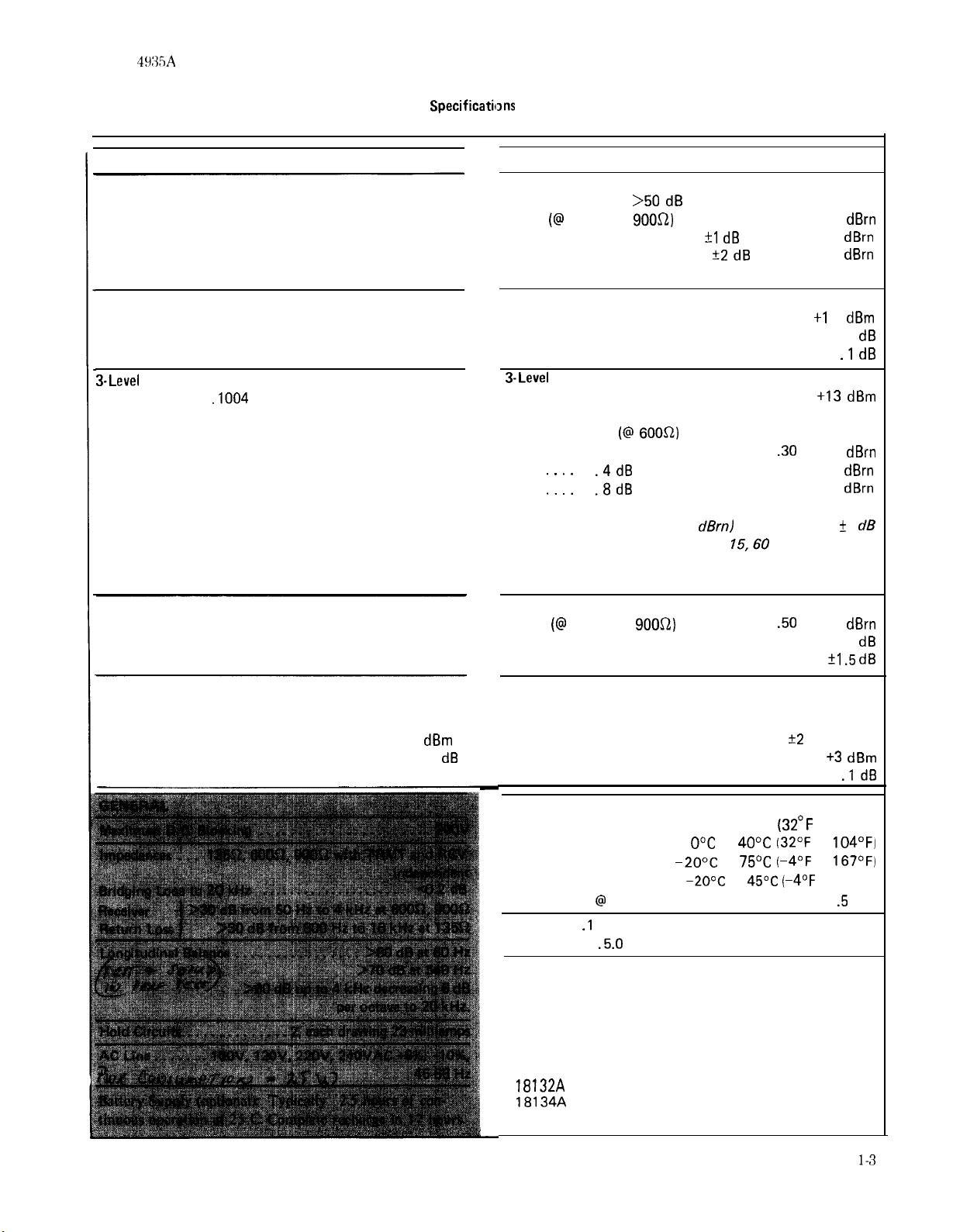

Table l-l. Specifications

Model

49:EA

TRANSMITTER

Frequency

Frequency Range . . . . . . . . .

Resolution Accuracy

1

20-99,999

100-l 10

Store and Recall Functions

SK Skip . . . At power up skips a band from 2450-2750 HZ

Frequencies . . . . . At power up Fl is 404 HZ

Level

Range . . . . . . . . . . . . . . . .-40 to

Resolution . . . . . . . . . . . . . . . . . . . . . 0.1

Flatness . . . . . . . . . . . . . . . . . _ . . . . . . . _ (in

z+13

+im

g;+1;

3

Hz

kHz

20 200

-40

Hz

10 Hz

FREQUENCY, Hz

15k

f .005%

t .012%

60k 85k

.20

Hz to 110

of output frequency 20-9.999 Hz 1 Hz

of output frequency 10-110

F2 is 1004 Hz

F3 is 2804 Hz

F4 is 2713 Hz

kHz

+13 dl3m

dB

dB)

1

IOk

RECEIVER

Frequency

Frequency Range.. . . . . . . . . . . .

Resolution Accuracy

kHz

Level

Range .

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.1

Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (in

5:

Q---40

K.s

.._........................

20 50 200

z-+13

10 Hz

FREQUENCY (Hz)

15k

.20

60k

Hz to 110

kO.5

-6Oto+13dBm

85k

3-60

+5

dB

1

kHz

Hz

Hz

dl3)

IOk

Distortion: (in dB from fundamental)

(Includes harmonics, spurious and background noise within

a filter with a 3 dB bandwidth of 4

is greater.)

FREQUENCY (Hz)

_

30 Hz

At 1004 Hz, 0

65 dB down from the fundamental.

Message Circuit Noise

Transmitter is quiet terminated

100 Hz 4k

dBm,

THD using a 4

kHz

or 4

f0,

kHz

filter is more than

whichever

IlOk

Receiver accuracy not specified below 500 Hz when using

13562 termination.

At 1004

Cross talk:

octave above 4

Message Circuit Noise

Range (@

@

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Accuracy . . . . . . . . . . . . .

Filters . . . . . . . . . . .

kHz

accuracy is fO.l dB from -20 to

>78 dB

6OOa

13516 lower limit is 7 dB higher

isolation @ 4

kHz.

and

9OOn)

. . . . . . . . . . .O to 100

. . .+ 1 dB from IO to 100

.C-Message, 3

+I3 dBm.

kHz,

decreasing 6 dB per

+2 dB

from 0 to IO

kHz

Flat, 15

Program, 50

kHz

dBrn

dBrn

dBrn

Flat,

kBit

dB

Specifications describe the instrument’s warranted performance. Supplemental characteristics shown in shaded areas or in

italics are intended to provide information useful in applying the instrument by giving typical, but non-warranted

performance parameters.

Page 16

Model

4935A

General Information

Table l-l.

TRANSMITTER

Noise with Tone

Frequency . . . . . . . . . . . . . . 1004 Hz fixed tone

(For other specifications, see Level and Frequency)

Signal-to-Noise Ratio

Frequency . . . . . . . . . . . . . . . . 1004 Hz fixed tone

(For other specifications, see Level and Frequency)

3-Level

Impulse Noise

Frequency . . . .

(For other specifications, see Level and Frequency)

Noise-to-Ground

Transmitter is quiet terminated

P/AR (Optional)

Frequency . . Signal spectrum is a complex pulse train of

Level Range . . . . . . . . . . . . . . . . . . . . .-40 to 0

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

.1004

Hz fixed tone or quiet terminated

depending on filter selection

16 frequencies between 140 Hz and 3890 Hz.

SpecificatilJns

dBm

dB

(Continued)

RECEIVER

Noise with Tone

Notch Filter. .....

Range (@ 600R and

Accuracy .................?I dB from 20 to 100

(For other specifications, refer to Message Circuit Noise)

Signal-to-Noise Ratio

Signal Level Range

Ratio Range

Resolution .................................

3-Level

Impulse Noise

Level Range

Notch Filter. ................... .See Noise with Tone

Threshold Ranges (@

Low .............................

Mid

High : : : :....

Loss of Holding Tone Indication

Threshold Accuracy (above 40

Count Timer ............... 5,

Count Range ............... O-9999 for each threshold

Count Rate

Noise-to-Ground

Range (@ 600R and

Resolution

Accuracy

P/AR (Optional)

P/AR Range. .................. .O to 120 P/AR units

Resolution ........................... 1 P/AR unit

Accuracy (from 30 to 110 P/AR units) ...+2 P/AR units

Level Range

Resolution

.................................. 1

................................

>50 dB

900R)

..................

........................... IO to 45

....................... .-40 to

.4 dB

above Low to a maximum of 109

.8 dB

above Low to a maximum of 109

............................. 8per sec.

....................... .-40 to +3

................................

rejection from 995 to 1025 HZ

..............

*2 dB

from 10 to 20

.-40 to +I 3

6OOfi)

............ Minus sign

............

dBrnl

15,60

min. or non-stop

............

9OOfi)

IO-100

.30

to 109

.50

to 130

dBrn

dBrn

dBrn

dBm

.I dB

+I3 dBm

dBrn

dBrn

dBrn

+ 1

dBrn

+I .5 dl3

dBm

.I dB

1

dB

dB

dB

Temperature Range:

Operating . . . . . . . . . . . . . . 0°C to 50°C

with batteries

Storage . . . . . . . . . .

with batteries

Warm up time @ 20°C for stated accuracy . . . . . . . . .5 min.

Dimensions .I 1.2 x 25.9 x 28.6 cm (4.4 x 10.2 x 11.25 in.)

Weight . . . . .

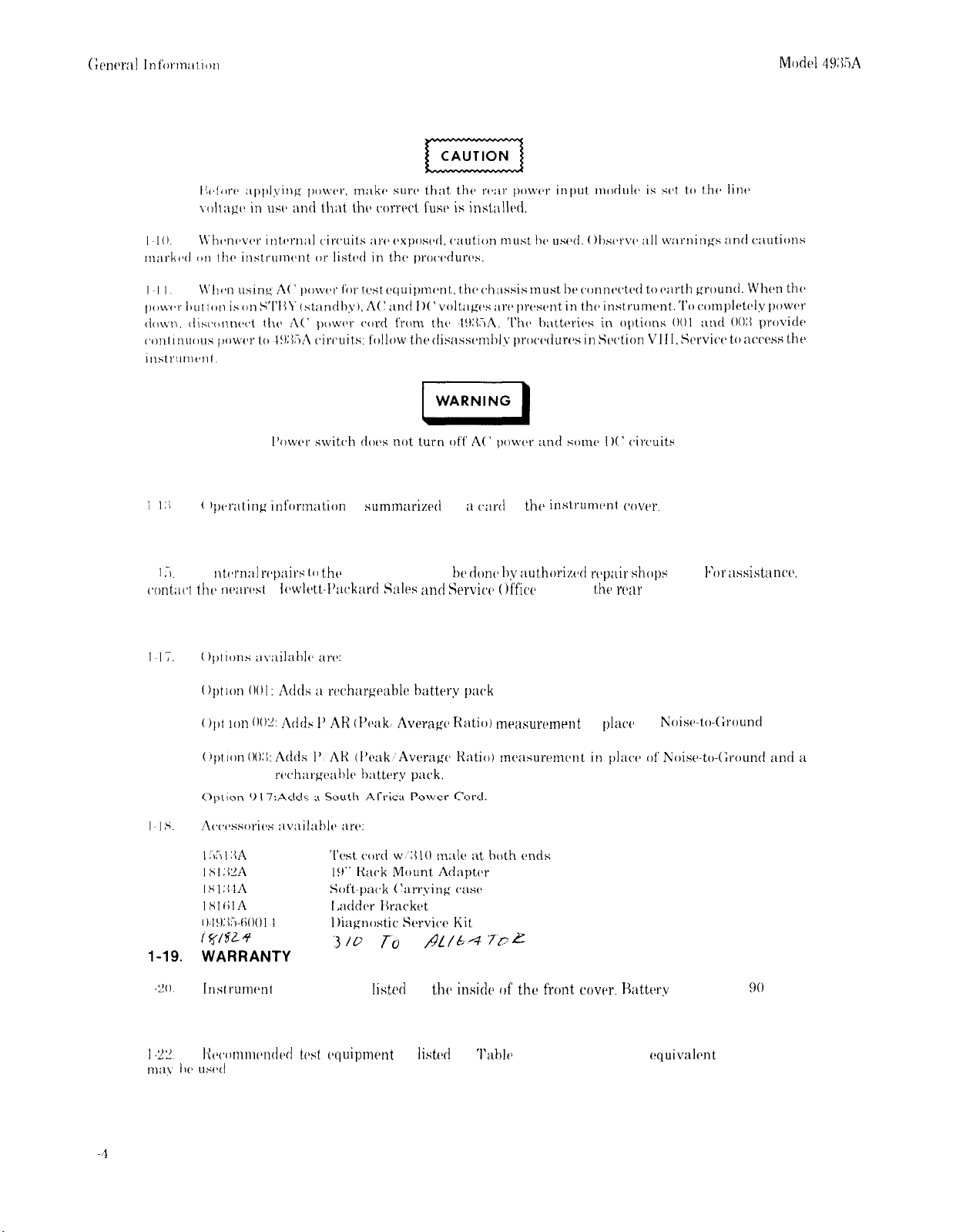

OPTIONS

001

. . . . . . . . . . . . . . . . .

002 Adds P/AR measurement in place of Norse-to-Ground

003 . . . . . . . . . . . . .

ACCESSORIES:

15513A . . . . . . . . . Test cord w/31 0 male at both ends

18132A

18134A

18161 A

.5.0

kg (11 Ibs.), 6.5 kg (14 Ibs.) with battery

. . . . . . . . . . . . . . . . . . . 19” rack mount adapter

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . , . . . . . . .

O°C

to

-20°C

to

-2O’C

to

Adds rechargeable battery pack

Adds both battery pack and P/AR

Deletes Noise-to-Ground

Soft pack carrying case

(32’F

40°C (32OF

75’C (-4OF

45’C (-4’F

Ladder bracket

to 122°F)

to

104OF)

to

167OF)

to 113°F)

I-3

Page 17

(;cnt~r:tl Inf’orm;rtIotl

1-9. SAFETY CONSIDERATIONS

1-12. RELATED MANUALS

1

1:;

( lI)t.ritting int’t~rtnation

is

summariztd

on it

t,arcl

in

the instrumt~nt t‘ovtsr.

l-14. USER REPAIR

I I

.-I.1 ntctrnal rthpairs tcl thta

c,ont;it.t thus tlta;lrtsst

t

It~u,l~~tt-~‘at,kartl Sales antI Servit,ta Of’fit~,

instrument should

1-16. OPTIONS AND ACCESSORIES

()I)( eon 002: Adds 1’ Al< (I’ta;ik! Avrragts Ratio) mr;lsurt~mrnt

t)rl dents by ;tuthoriztd rtbpair shops

listed at

the r(‘ar

in

of’ this manual.

Plato

of’

only.

I~orassistant~t~,

Nois+to-(;round

1 -4

I -%(I.

Itlstrumr~nt

warranty is as

listctl

on

thth insidtx of’ the f’ront c’ovt’r. Hattc~ry

1-21. RECOMMENDED TEST EQUIPMENT

l-22.

m;,y tit) llS~‘(l

tit~t~~~rnmc~ntlt~tl ttsst tquipmt~nt

is

listed

in

‘I’whlt~

l-2. Equipment with

warranty is 90 days

quivnlcnt

characteristics

Page 18

Model

4935A

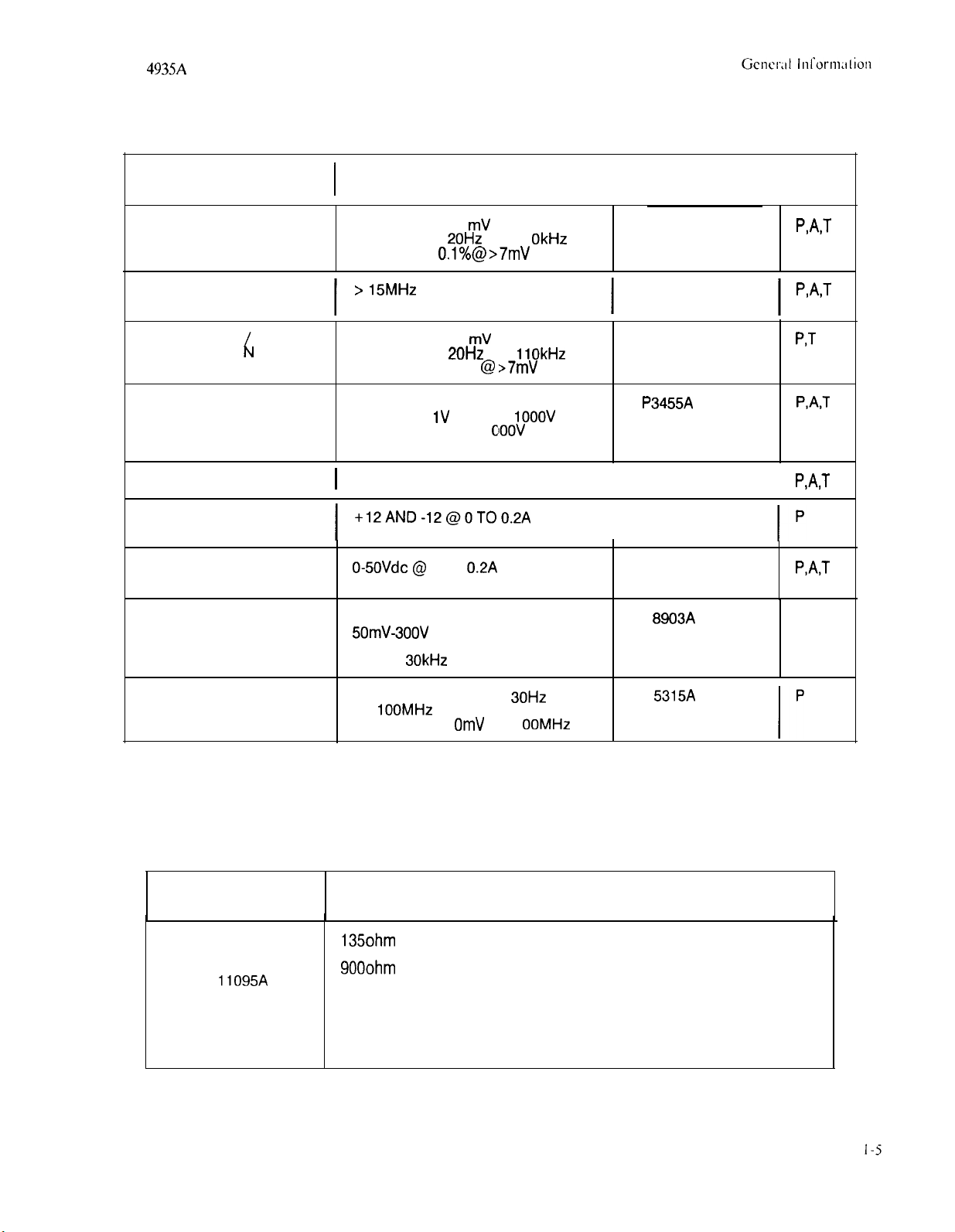

Table

INSTRUMENT

AC CALIBRATOR OUTPUT LEVEL 1 mV TO 1 OV

OSCILLOSCOPE

SYNTHESIZER OUTPUT LEVEL 1 mV TO 1 OV HP 3325A

FUNCTION GEIcERATOR FREQUENCY: 20Hz TO 110kHz

MULTIMETER AC AND DC FUNCTIONS

DIGITAL MULTIMETER

DUAL OUTPUT POWER

SUPPLY

I

1 DC CURRENT: 1 AMF’ MAX

1-2.

CRITICAL SPECIFICATIONS

FREQUENCY: 20Hz TO 11 OkHz

ACCURACY

>

15MHz BANDWIDTH

A VS B CAPABILITY

ACCURACY 0.1% @

AC VOLTS: 1V MIN. TO

DC VOLTS: .l V TO 1

BALANCED INPUT

+12AND-12@OTO0.2A

Recommended Test Equipment

O.l%@>7mV

>7mV

1OOOV

OOOV

MODEL

RECOMMENDEDIUSE*

FLUKE 5200A

OR EQUIVALENT

HP 1740A

H P3455A

HP 3466A

I

HP 6234A

I

PAT

PAT

P,T

PAT

PAT

DUAL RANGE

DC POWER SUPPLY

AUDIO ANALYZER

COUNTER RANGE: AC COUPLED 30Hz

*P = PERFORMANCE TESTS A = ADJUSTMENTS

Table 1-3. List of Parts Used for Performance Tests

PART NUMBER

(IF APPLICABLE)

0698-7364

0698-7408

0698-6344

HP

11095A

1250-0781

1251-3757

0493560014

OdOVdc @

INPUT VOLTAGE RANGE

50mV-300V

BANDWIDTH 500kHz

FILTER 3OkHz

TO

100MHz

SENSITIVITY: 1 OmV TO 1 OOMHz

135ohm 1% RESISTOR

6000hm 1% RESISTOR

900ohm

TERMINATION, 6000hm BNC-TO-BNC

BNC-TEE FEMALE

BNC TO TYPE 310 POMONA NO. 2798 OR EQUIVALENT

BNC TO DUAL BANANA JACK POMONA NO. 1296

DUAL BANANA COMPONENT CARRIER POMONA NO. 1

DIAGNOSTIC SERVICE KIT

0 TO

0.2A HP 6218A

DESCRIPTION

1% RESISTOR

HP 8903A

HP 5315A

T = TROUBLESHOOTING

PAT

P

330-ST

Page 19

General Information Model

497’,A

t

<

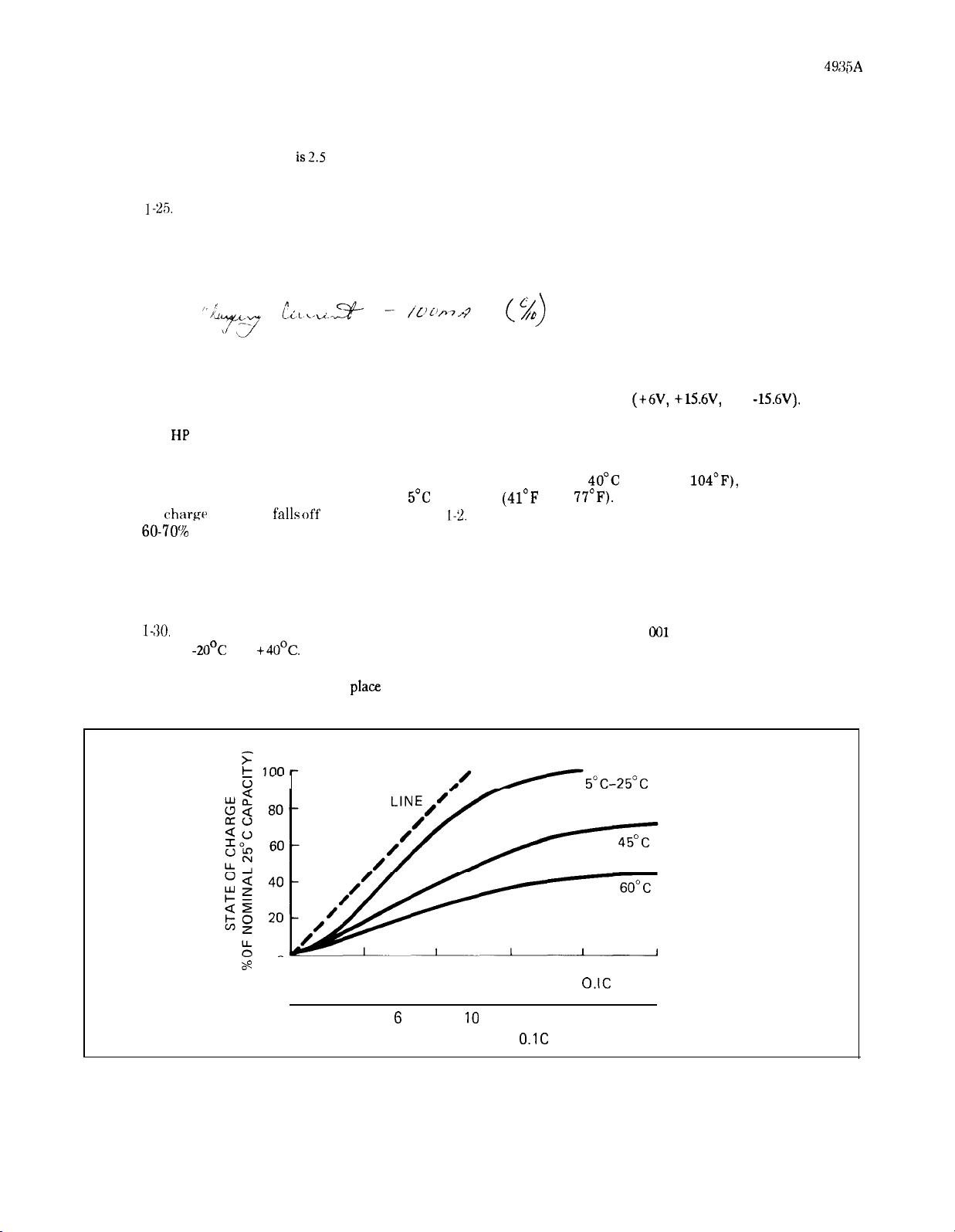

l-23.

l-24. Nickel-Cadmium batteries enable the 4935A to be used in areas removed from AC power.

Typical operating time

BATTERY OPERATION (Options 001 and 003)

is2.5

hrs when fully charged.

The batteries are trickle-charged whenever the

instrument is connected to an AC source and the POWER switch is in STBY.

1 -EL

Regular discharge-charge cycles are recommended to maintain battery capacity. The instrument

should be operated until batteries are discharged (instrument stops working) then recharged, at least every

30 days. Normal recharge time is about 17 hours. Typical battery life under normal operating conditions

should he at least 100 charge-discharge cycles.

l-26.

l-27.

Charging the Batteries

The internal battery pack consists of three rechargeable battery packs

(+6V, +156V,

and

-156V).

These provide typically 2.5 hours of continuous use without recharging. To recharge the battery packs, connect

the HP 4935A to an AC power source and press the power switch to STBY. Normal recharge time is about 17

hours.

I-28.

greater charge capacity if charged between

the

60-70’s

The batteries may be charged at temperatures between 5°C and

5’C

charge

acceptance

falls off’

and 25°C

as shown in Figure

1-2.

(41°F

For example, a cell charged at 45°C accepts about

and

4O’C

(41°F and

77’F).

At temperatures above 25°C

104”F),

but have

of its rated capacity. Temperatures below 5°C cause pressure to build up within the cell as it is

charged, which could result in venting of the cell. This results in a permanent degradation of the battery

capacity due to loss of electrolyte.

l-29. Operating Temperature

I-30.

between

Normal operating temperature of the I-IP 4935A with batteries (options

-2OOC

and

+40°C.

However, there will be a loss of capacity when operating at the extremes. At low

001

and 003) should be

temperatures, the batteries cannot fully discharge even if they were fully charged at room temperature. At high

temperatures this same effect take

place

to a lesser degree, in addition to the problem of charge acceptance

previously mentioned.

100% EFFICIENCY

8

U

CHARGE INPUT (% OF NOMINAL CAPACITY) -

0 2 4

CHARGING TIME IN HOURS

40 80 120 160 200

O.IC

CHARGE RATE

G

8

lo

12 14 16 18

- O.lC

CHARGE RATE

20

l-6

Figure 1-2. Charge

Acceptance at Various Temperatures

Page 20

SECTION II

INSTALLATION

Installation

2-l.

2-2.

antI storagcb

2-3.

2-4.

INTRODUCTION

This section contains information on initial inspection, preparation

and shipment. Table 2-l shows all power cords available.

for

use, power requirements

INITIAL INSPECTION

Inspect the shipping container for damage. I“ the container or cushioning material is damaged,

keep it. Check the contents of the shipment for completeness, then check the unit mechanically and

electrically. Refer to Section IV for electrical checks.

2-5.

officbe

If the unit is mechanically damaged or fails electrical tests, notify the carrier and the nearest HP

(listed at the rear of this manual). Hewlett-Packard will arrange for repair or replacement of the

instrument without waiting for claim settlement.

2-6.

PREPARATION FOR USE

Before connecting this instrument to an AC power source, be sure that the rear panel line

module is set to the

2-7.

2-8.

voltage is

POWER

This instrument requires a power source of 100, 120, 220, or 240

installedk.BiAmp

REOlJlk’lENTS

single phase. Power consumption is no more than 25

szme

voltage as the AC

-

for 120

so_urce

Vac<&Q@Amp

(I A. SC

Vat.

and that the correct fuse for that AC

for 220

Vat).

Vat. +5’%-lo%,

48 to 66 Hz

2-9.

2-10.

120

LINE VOLTAGE SELECTION

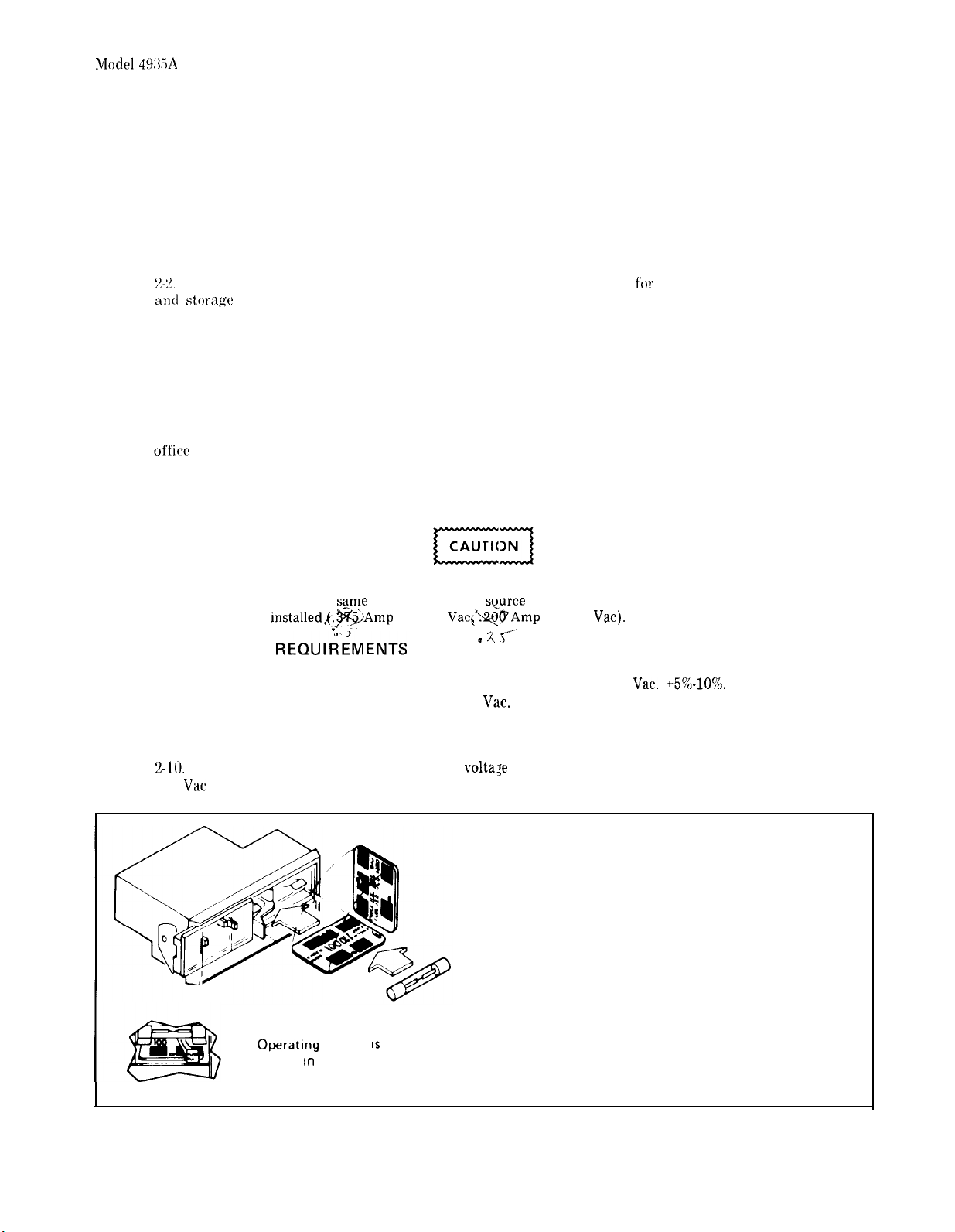

Figure 2-1 provides instructions for line

Vat

operation.

voltasje

selection. Card and fuse are factory installed for

I

PROCEDURE

1. Slide cover door to left (the line power cord

must be disconnected).

2. Rotate FUSE PULL to left. Remove the fuse.

3. Remove the PC board by pulling it out. Select

operating voltage by positioning PC board to

show the desired voltage on top-left side,

4. Reinsert the PC board.

Operatang

shown In module window.

voltage

1s

5. Rotate FUSE-PULL back into normal position

and reinsert fuse. Use caution to select correct

fuse value.

I

Figure 2-1. Line Voltage Selection

2-1

Page 21

Installation

2-11. POWER CABLE

Any interruption of the protective (grounding) conductor (inside or outside the

instrument) or disconnecting the protective earth terminal can make this

instrumenl dangerous. Intentional interruption is prohibited.

Model

49:&A

2-12.

threewIre ac

This instrument is supplied with a three-wire power cable. When connected to an appropriate

power receptacle, the cable grounds the instrument chassis.

2-13. OPERATING ENVIRONMENT

2-14.

+122”F).

2-15.

R.H. @ 40°C. However, the instrument should be protected from temperature extremes which cause

condensat.ion

TEMPERATURE. The instrument may be operated in temperatures from 0” to 50°C (32°F to

Temperature for battery unit operation is 0” to

HUMIDITY. The instrument may be operated in environments with humidity from 5% to 95%

within the instrument.

40°C

(32°F to 103°F).

2-16. STORAGE AND SHIPMENT

2-17. ENVIRONMENT

2-18.

2-19.

2-20.

obtained through Hewlett-Packard sales and service offices listed at the rear of this manual. If the

instrument. is returned to HP for repair, attach a tag listing the type of service or repair needed. Include

return address, model number, option number (if applicable) and complete serial number. Also, mark the

container ”FRAGILE” to ensure careful handling. In any letters, refer to the instrument by model number,

option number (if applicable) and complete serial number.

The 49:15A

Temperature:

Humidity: 90% R.H. @ 65°C

(all options) may be stored and shipped within the following environmental limits:

-20°C to

(-4OF

to

t45”C

+113”F)

Do not store or ship where temperature extremes will

cause condensation within the instrument.

INSTRUMENT PACKAGING

ORIGINAL PACKAGING. Containers and packing material used in factory packaging can be

2-2

Z-2 I.

materials:

a.

b.

c.

d.

2-22.

please complete one of the blue tags located at the back of this manual and attach it to the instrument.

OTHER PACKAGING. Use these general instructions for packaging with commercially available

Wrap the instrument in heavy paper or plastic. If shipping to an HP Sales or Service Office, include

a tag listing type of service needed, return address, model number, option number (if applicable)

and complete serial number.

Use a strong shipping container such as a double-wall carton with 275 Ibs. burst test.

Use a layer of shock absorbing material, 70-100 mm (3-4 in.) thick. This provides a firm cushion

and prevents movement inside the container. Protect the front panel with cardboard or the front

cover.

Seal

the carton securely and mark it “FRAGILE” to ensure careful handling.

‘I’A(;GING

FOR SERVICE. If the instrument is being returned to Hewlett-Packard for service,

Page 22

Installation

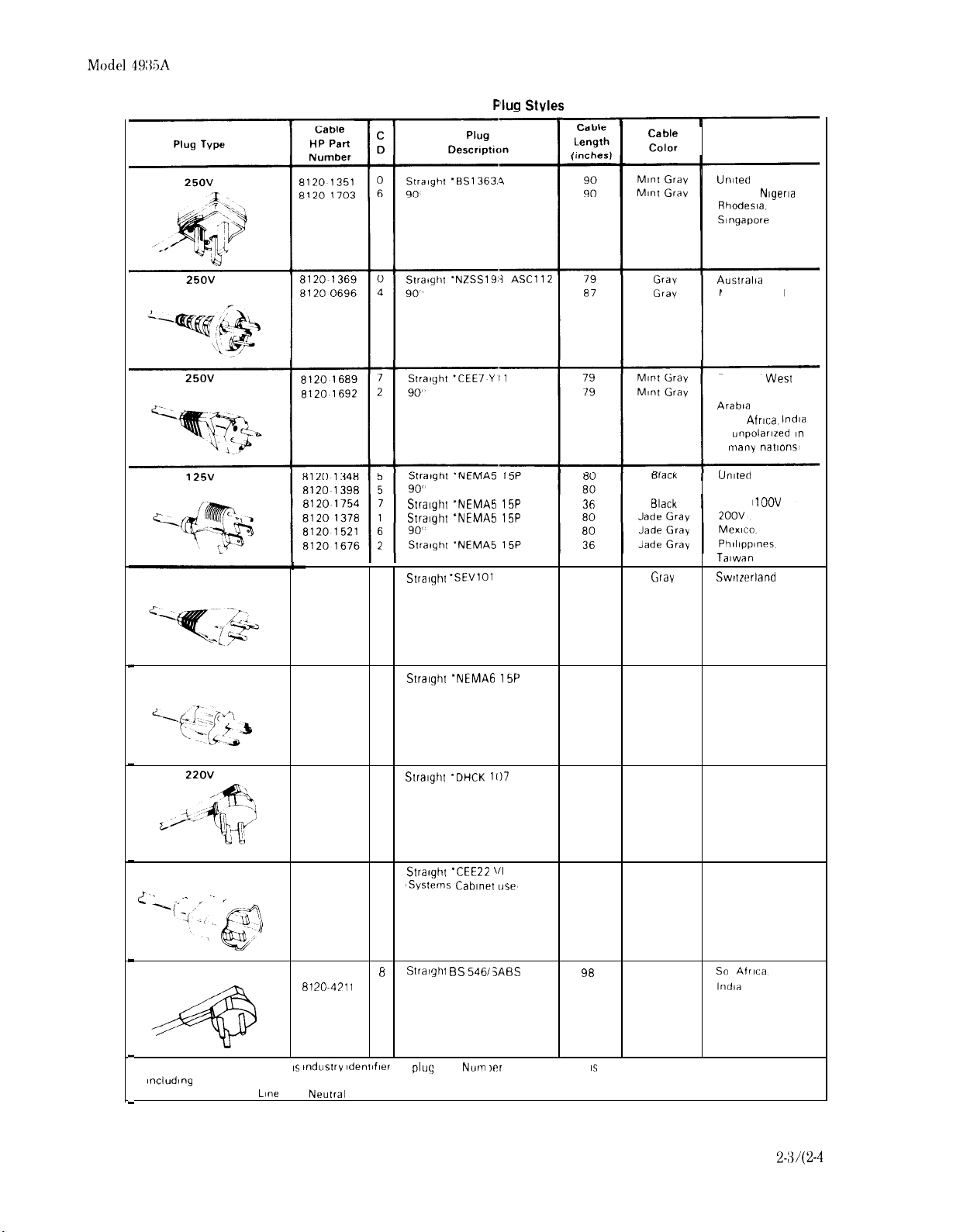

Table 2-1. HP

Stralghr ‘NEMA5 15P

Straight ‘NEMA5 15P

Plus Stvles

Black

For Use

In Country

United

Kingdom.

Cyprus

Nlgerla

Australea

New Zealand

East and

Europe, Saudi

Arabta

So

Umted

Canada.

Japan

Wesl

Egypt.

Africa. lndla

unpolarlred in

many natIons

Stares

llOOV

or

c-

81202104 3

8120.0698 6

8120 1957 2

8120 2956 3 90’

8120 1860 6

,-

250V

250V

250V

-i

250V 8120-4600

8120.4211

Straight ‘SEVlOl

1959 24507

Type 12

Slralght ‘NEMAG 15P

Straight ‘DHCK 1117

Straight ‘CEE22 \/I

6yslerns Cablner use’

8 StralrJhl BS 5461SABS

7 90”

Taiwan

1

164

79

79

79

98

98

Gray

Gray

Gray

Black

Black

Swtrerland

United States

Canada

Denmark

‘Part number shown for plug IS

lncludlng

E Earth Ground. L

plug

Lone

N

Industry ldentlfler

Neutral

for

pluq

only

Num xr

shown for cable IS HP Part Number for complete cable

2-t3/(2-4

blank)

Page 23

Page 24

Operation

SECTION

III

OPERATION

3-1.

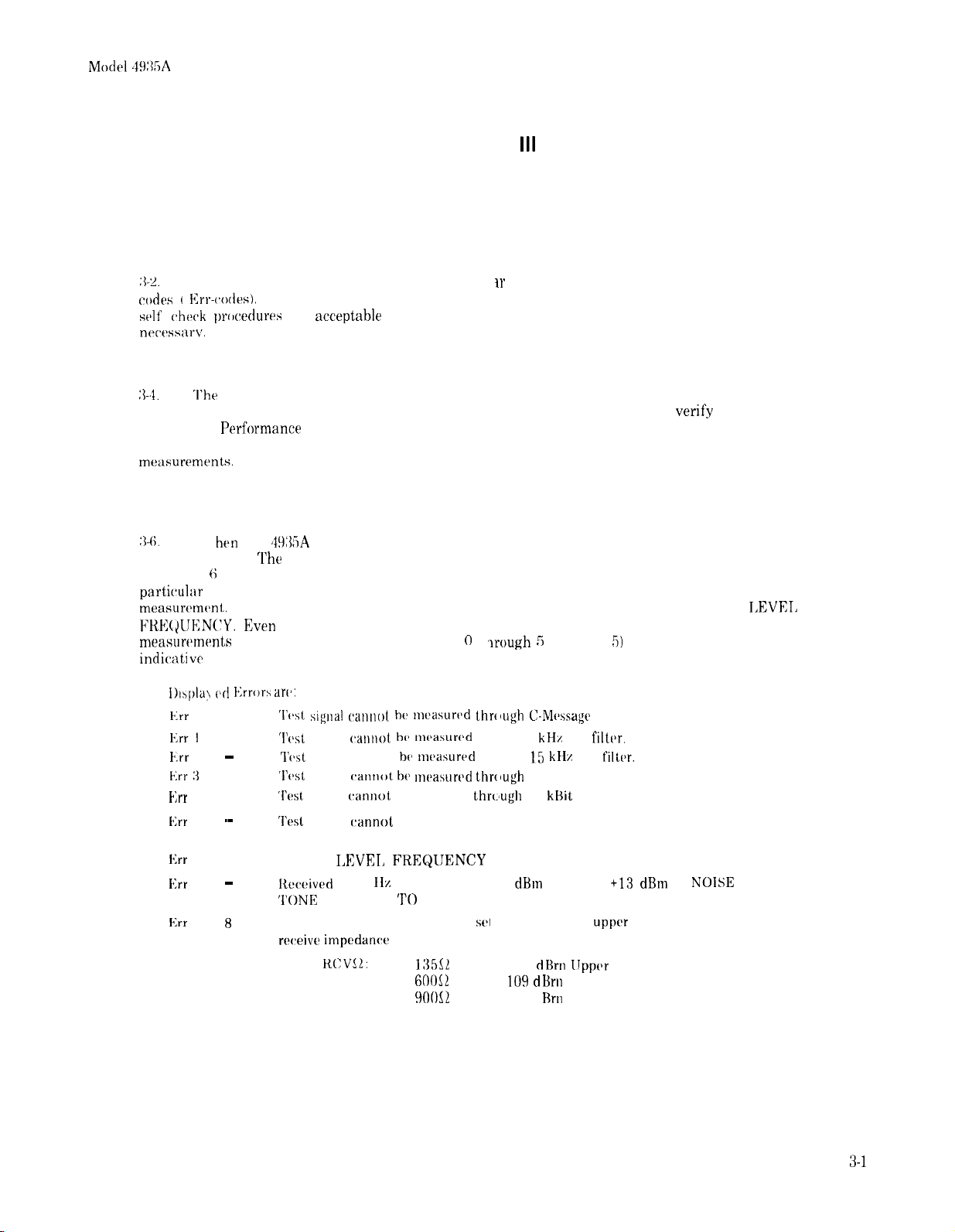

:3-z.

c-odes ( Err-c,otlrs).

self’ check prc,cedurrs

necessarv.

3-3.

:1-4.

major circuits are checked and any problems are identified. Self check does not

specifications.

instrument to pass any self check procedure indicate? a malfunction that can possibly affect other

mr:asurrmc~nt.s.

3-5. ERROR MESSAGES

3-6.

through thr filters.

0 through 6 indicate there are problems during self check. Errors 7 and 8 highlight problems during a

particbular

measurc~mc~nt.

FREI$UF:N(‘Y. &en

measuremrnts

indic,ativc

INTRODUCTION

This section contains information on front and re jr panel features, self check procedures, and error

Also covered are the principles of operation for all measurements. If any of the automatic

fail

acceptable

limits as specified in the checks, then adjustment or repair may be

SELF CHECK

The

self check procedures are performed automatically at power-up by the instrument. Most of the

verif.y

performance

I’rrformance

W

hthn

the

measurement. Other indications of errors during measurement are described by the particular

After startup self-check, the instrument automatically goes into Transmit Mode,

affected hy the displayed errors. Errors 0 t

of a system level failure more than a filter failure.

checks verify that the instrument meets published specifications. Failure of the

4!4:ki,A

is powered up, the instrument automatically transmits a signal into its receiver

The

signal is checked after each filter, to verify that it is within acceptable limits. Errors

if error messages occur, the instrument continues to operate correctly except for those

Trough 5

(Err O-Err 5) followed by Error 6 (Err 6) is

IXVEI,

I)15pla> otl F:rrors arc’:

F1rr

0

I*;rrl ~~

b.rr

2

~

I.:rrS

Krr

4

~~

Err

5

~~

Krr

6 Error in

l+Zrr

7

~

Krr

8

‘I’c~st signal cannot h(x measurt~d thrclugh C-Mt~ssagc~

‘I’c~sl

‘I&t

‘I’tast

Test

‘I’esl

Err 0.

Received

‘I’ONE

IMPULSE NOISE threshold is

rctc&e impedanchtr

signal

c,a~~trot h(a mclasurc,d

signal cannot

signal

signal

signal

cannot hc measurc>d thrclugh

cannot

c-annot

I,EVEI2 FREQIJENCY

1004

11~

or SIGNAL

RCVL2:

filter.

through 3

hc‘ mcxasurrd

he measured

be measured through P/AR filter. If not a P/AR unit refer to

tone is below -16

‘1’0

NOISE.

as follows:

13512

60012

90012 107 d Hrn

through 15

thrc.+$

signal path.

sct1

too high. Thr

kHz

flat

kHz

Program filter.

50

kHit

dBm

or above

116

dHrn lippclr

109 dBrn

filt~~r.

flat

filter.

upper

filtclr.

+13 dBm

Limit

in

NOISE:

limit varies with the

WITH

3-l

Page 25

Model

4935A

0

I

5

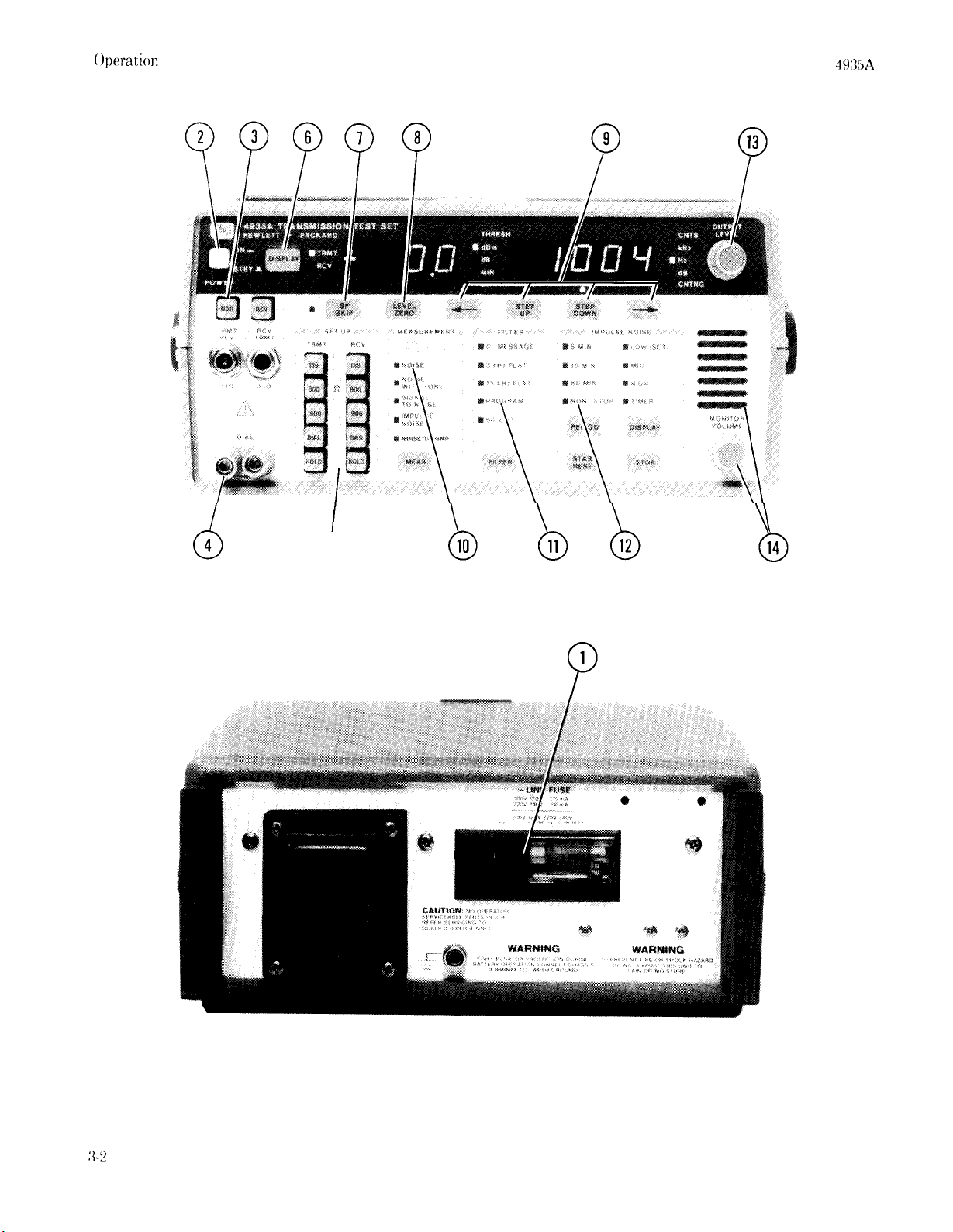

Figure 3-1. Front and Rear Panel Controls/Connectors/Indicators

Page 26

Model

49XiA

Operation

1.

CONTROLS, CONNECTORS AND

INDIC.ATORS

Power Cord Module. Accepts power cord supplied with instrument. Contains line fuse and PC

board for selecting line voltage (see Section II, paragraph 2-9 for procedure to select line voltage).

(WARNINGI

Always connect power cord to a proper y grounded

Do not connect more than 200VDC signal to terminals.

!

A

POWER button. Switches power to front panel

bvhen

in ON position. In STBY position power is

3-wire

power outlet.

still applied to some circuits. If unit has battery option there will still be power available to some

internal circuits even in STBY position.

NOR and REV switches. NOR switch depressed connects the left 310 jack to the transmitter and

the right 310 jack to the receiver. REV switch depressed connects the left 310 jack to the receiver

and the right 310 jack to the transmitter. Both switches out simultaneously or depressed

simultaneously internally loops the transmitter to the receiver.

DIAL Binding Posts. Handset can be connected to binding posts to dial-up a line through the 310

lacks.

SET UP Switches.

TRMT.

13512,

60012, 90012:

Provides terminating impedance to match the lines’ characteristic

impedance.

9.

DIAL: Disconnects TRMT-RCV 310 jack from the transmitter and connects the TRMT-RCV 310

jack to the DIAL binding posts.

HOLD: Connects the hold circuits to the TRMT-RCV 310 jacks to hold dial-up lines.

RCV.

13512, 60011, 90012: Provides terminating impedance to match the lines’ characteristic

impedance.

[(I~(;:

Connects the RCV-TRMT

:310

jack through

high

impedance when the

49:I5A

bridges

the circuit under test instead of terminating the line.

HOLD: Connects the receive-hold-circuits to the RCV-TRMT 310 jack to hold the dial-up lines.

I)ISI’lAY

(:orrcspondinu 131)

SF SKII’

designatrd

c,n

dial-up lines. Operates only in

I,EVEI,

measurements will be made in dB relative to this reference. DR

light.

Key. TKMT-RCV. Selects either the transmitted or the received

will

light.

Key. Prevents the transmitter from transmitting within

+I50

Hz

signal

to be displayed.

(300

Hz band) of a

frequency. This feature eliminates accidental disconnection by SF signaling units

LEVEL FREI$UENCY. I>EI)

ZERO Key. Sets a 0 dH reference in KCV

A

“-”

(minus) dH reading indicates levels higher than the reference level per the telephone

IXVEI, FREQIJENCY

will light when key is pressed.

mode. All subsequent

LED

in center of front panel will

industry convention.

STEEP

UP, STEP DOWN, + and

FREQUENCY: (-

or

~-f

selects the position of digit to be increased or decreased. Lighted cursor

--f

Keys. In TRMT Mode (right display) and LEVEL

indicates one-of-five digit positions. Digit value is incremented by pressing STEP UP and

decremented by pressing STEP DOWN. Holding the STEP UP or STEP DOWN key depressed

causes the actions to

Figure

3-I.

reneat.

Front and Rear Panel Controls/Connectors/Indicators (Continued)

Page 27

Operation

+

1TRCV

Mode (left display) and IMPULSE NOISE;

or + selects the position of the threshold

digit to be increased or decreased. Lighted cursor indicates one-of-two digit positions. Digit value is

inc.remented

d&-n

by pressing STEP UP and decremented by pressing STEP DOWN. THRESH LED,

and LOW(SET) LED will be on.

Model

4935A

10.

11.

12.

MEASUREMENT Section.

MK4S

Key. Selects measurement to be made. Lighted LED indicates selected measurement. For

detailed measurement information of each mode see Figure 3-3. Measurement modes are:

LEVEL

FREQUENCY (Blue)

NOISE

NOISE WITH TONE

SIGNAL TO NOISE

IMPULSE NOISE

N( )ISE TO GKOIINIl

(Standard units and option 001)

P/AR (Options 002, 003)

FILTER Section.

1’1

I

~‘I’KR~‘STOKK

wrighting-filter

on right display to he stored for recall using the

used

to

change

Key. Selects desired weighting filter for Noise Measurements. Selected

I,EI)

will light. In

IXVEI, FKEQIJENC~Y

Fl, E’2, F:J,

the STORE function enables frequencies

or P4 keys. The STORE function is also

the SF SKIP Frequency.

IMPULSE NOISE Section.

Impulse-Noise controls are used in KCV and in conjunction with the MEASUREMENT section

IMPULSE NOISE mode. Four keys control this section:

PERIOD/Fl-404

DlSPLAY/F2-1004

START

STOP/

RESET/F3-2804

F4-2713

PERIOD: Sets the instrument timer for the impulse noise test (5 MIN, 15 MIN, 60 MIN or

NON-STOP). Also provides the

Fl-404

Hz preprogrammed frequency for LEVEL FREQUENCY

Mode.

DISPLAY: Changes the display through each of the threshold values and their impulse noise

counts then displays the TIMER setting selected by the PERIOD key. Also provides the

I-Ix

preprogrammed frequency for LEVEL FREQUENCY Mode.

F2-1004

START/RESET: Starts the impulse noise test and resets the count to zero for every threshold.

Also provides the

F3-2804

Hz preprogrammed frequency for LEVEL FREQUENCY Mode.

STOP: Stops the impulse noise test but retains the displayed count values. Also provides the

F4-2713

Hz preprogrammed frequency for LEVEL FREQUENCY Mode.

Figure 3-1. Front and Rear Panel Controls/Connectors/Indicators (Continued)

Page 28

Model

49:l:iA

Operation

13.

14.

OUTPUT LEVEL Control

Adjusts the transmitter output level

continuou;ly

displayed on left display.

MONITOR VOLUME Control and Speaker.

Permits adjustable volume for listening to the

Figure 3-I. Front and Rear Panel

Controlv/Connectors/Indicators

-40

dBm

to

from

cirl:uit

under test or to the Test Set Transmitter.

+13 dBm.

(Continued)

Output level is

Page 29

Operation

3-7. OPERATING INSTRUCTIONS

Model

4935A

:I-H.

I:inurc :<-2

lists the various measurement modes available. A brief Power On and Set

preccdcs the* dctailcd explanation.

accompanvinfi text.

POWER ON and SET UP

A.C. POWER

1.

(‘onncct power

p;rragraph

2.

Press POWER button ON. The 4935A will automatically do a self check of the transmitter, the

filters, and the

BATTERY POWER (Optional)

1.

Press POWER button ON with no power cord connected. When switching between battery and

A C power cycle the POWER button from STBY to ON again.

cord to the rear line module on which the correct

2-9 of Installation section

Always connect power cord to a properly grounded 3-wire power outlet.

LEDs.

For operator protection during battery operation, connect

terminal on the rear panel to earth ground.

IJp

procedure

Each measurement mode is explained with a drawing and

line

voltage has been selected. See

for

procedure to

select line

voltages.

the

chassis

SET UP

1.

2.

Impedance

1.

2.

NOTE: Proper care in charging and discharging

NiCad

batteries can dramatically improve their

lives. Consult Section I of this manual for recommended procedures.

Connect circuit to 310 jacks. Do not connect more than

BOOVDC

or 10 Vrms at 60 Hz to these

jacks.

I’rcss

in

the

NOR button to connect the left 310 jack to the transmitter and

theright 810

jack to the

recf:iver.

To

reverse the direction of the test press the REV button IN

Press the TRMT impedance button 12 that matches the impedance of the circuit on the TRMT

side.

Press the RCV impedance button $1 that matches the impedance of the circuit on the RCV side. If

the test set is to be used in the bridged mode press the BRG button also. This means that in the

bridged mode two RCV Setup buttons will be pressed in - the correct circuit impedance and the

BRG button. Note: Do not leave the BRG button IN while the instrument is actually terminating

the circuit as it will cause a 6 dB error.

Figure 3-2. Measurements

Page 30

Operation

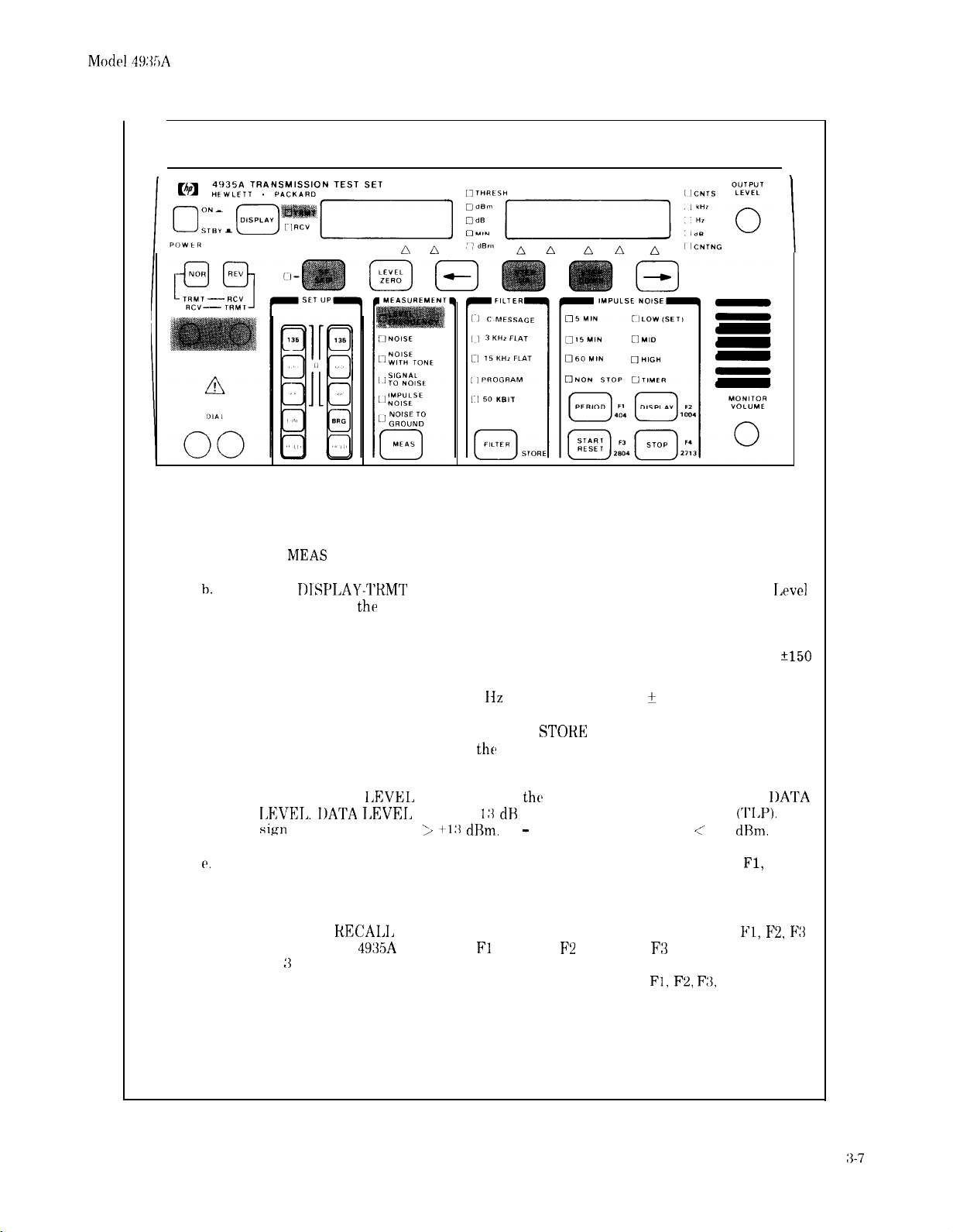

3-9.

MEASUREMENTS

LEVEL AND FREQUENCY-TRANSMITTER

a.

b.

c.

d.

f’.

Use

MEAS

key to select LEVEL FREQUENCY.

Press

I)ISPLAY-TKMT

can be read in

the

key to display the transmitted signal. TRMT light is ON.

left display and frequency in the right.

I,rvel

If SF signalling units are used on the circuit under test, press SF SKIP key to turn on SF

SKIP. When the light is on the transmitter is blanked from 2450 Hz to 2750 Hz or

?150

Hz around a stored SF SKIP frequency.

SF SKIP frequency is preset at 2600

IIz

(Skip will be 2600 Hz -t 150 Hz). The SF SKIP

center frequency can be changed by putting the desired skip frequency into the

transmitted frequency display. Then press the

to disconnect the transmit side of

the

STORE:

key and the SF SKIP key. He sure

line from the test set first to avoid dropping the

circuit during the storage procedure.

Turn OUTPUT

IXVEI,. I)ATA IXVEI,

sign

indicates the level is >

Use the STEP UP and STEP DOWN keys to set the desired frequency or press

1,EVEL

knob to adjust

is usually

I:( dR

tl:{ dHm.

A - sign indicates the level is < -40

the

level of the transmitted signal to