Errata

Title & Document Type: 4262A LCR Meter Operating and Service Manual

Manual Part Number: 04262-90007

Revision Date: October 1983

HP References in this Manual

This manual may contain references to HP or Hewlett-Packard. Please note that Hewlett-Packard's former test and measurement, semiconductor products and chemical analysis businesses are now part of Agilent Technologies. We have made no changes to this manual copy. The HP XXXX referred to in this document is now the Agilent XXXX. For example, model number HP8648A is now model number Agilent 8648A.

About this Manual

We've added this manual to the Agilent website in an effort to help you support your product. This manual provides the best information we could find. It may be incomplete or contain dated information, and the scan quality may not be ideal. If we find a better copy in the future, we will add it to the Agilent website.

Support for Your Product

Agilent no longer sells or supports this product. You will find any other available product information on the Agilent Test & Measurement website:

www.tm.agilent.com

Search for the model number of this product, and the resulting product page will guide you to any available information. Our service centers may be able to perform calibration if no repair parts are needed, but no other support from Agilent is available.

(__)

| Μ | Α | Ν | U | Α | L | С | Н | Α | Ν | G | Ε | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| - | • | - |

4262A

DIGITAL LCR METER

| — MANUAL II | DENTIFICATION |

|---|---|

| lodel Number: | 4262A |

| ate Printed: | OCT. 1983 |

| art Number: | 04262-90007 |

This supplement contains important information for correcting manual errors and for adapting the manual to instruments containing improvements made after the printing of the manual

To use this supplement:

Make all ERRATA corrections.

Make all appropriate serial number related changes indicated in the tables below.

| MAKE MANUAL CHANGES | MAKE MANUAL CHANGES | |

|---|---|---|

| A11 | 1 | |

| ,,_, | ||

| ······································ | ||

NEW ITEM

.

ERRATA

Page 2-8, Table 2-1: Add the following item to the option 101 (HP-IB) components.

PN 2190-0577 2ea. Spring Washer

Page 3-22, Figure 3-9:

Delete the following sentence from beneath the table in step 3: "*Bias current when +40V is applied to DC BIAS connector."

NOTE

Manual change supplements are revised as often as necessary to keep manuals as current and accurate as possible. Hewlett-Packard recommends that you periodically request the latest edition of this supplement. Free copies are available from all HP offices. When requesting copies quote the manual identification information from your supplement, or the model number and print date from the title page of the manual.

Comparison TTL output pins* LCR 19 20 45 HIGH 0.C. I OW IOW τN LOW LOW 0.0. LOW LOW 0.C. LOW DO 15 16 41 HIGH 0.C. LOW LOW IN LOW LOW 0.C. LOW 0.C. LOW

Page 4-24, Figure 4-9: Correct the TTL outputs table in Figure 4-9 as follows:

* TTL low-level output is indicated as LOW, and open-collector turn-off state is indicated as O.C.

▶ Page 8-47, Figure 8-29:

Change the part number for the power transformer to 9100-0865.

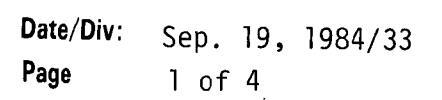

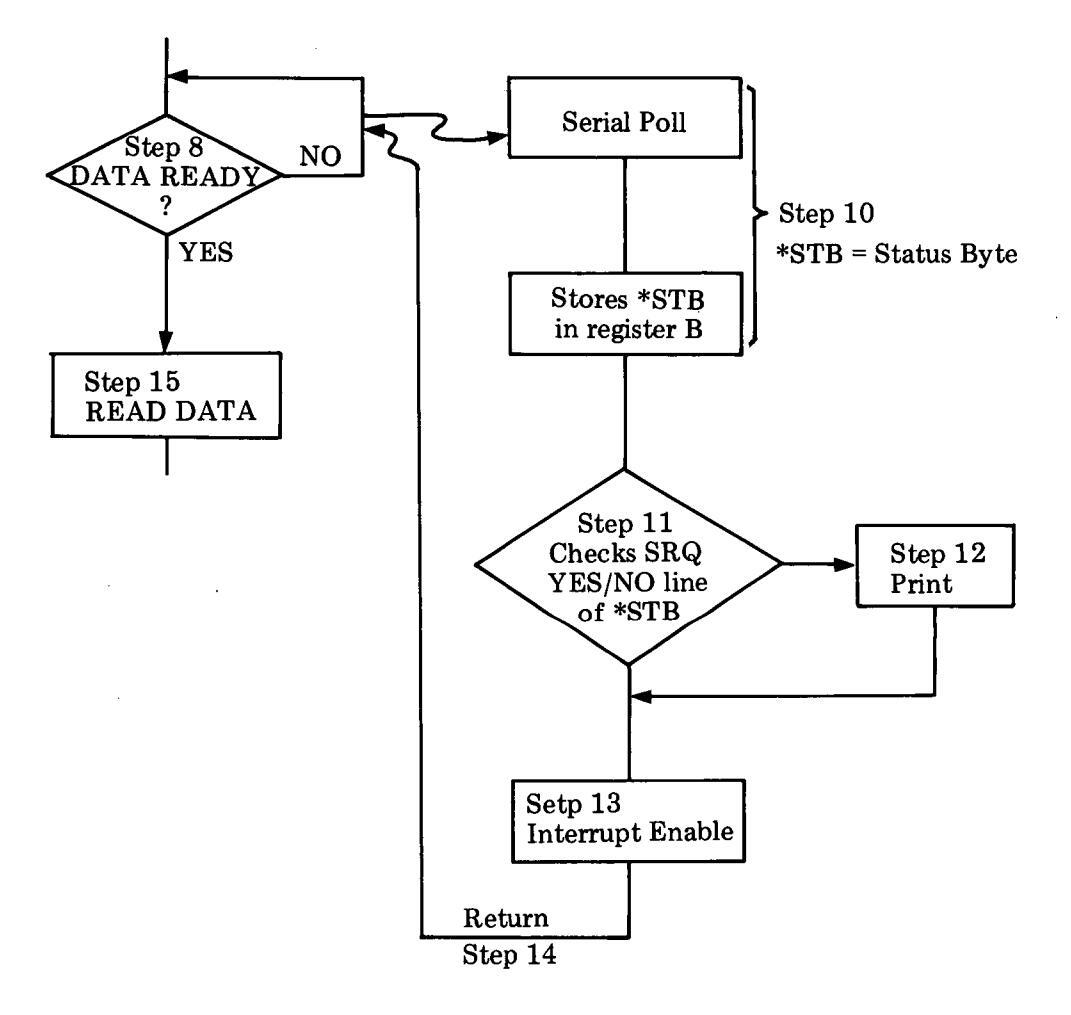

Page 8-53, Figure 8-39, Correct the flow diagram as shown below:

CHANGE 1

▶ Page 1-10, Table 1-4:

Change the recommended oscilloscope to the HP 1740A.

Table 6-3:

Change the table as shown below:

|

Reference

Designation |

HP Part

Number |

Description |

|---|---|---|

| A14 Q4 | 1855-0570 | TRANSISTOR J-FET N-CHAN SI |

| R5 (ZERO ADJ L) | 2100-4086 | RESISTOR-VAR 500 10% |

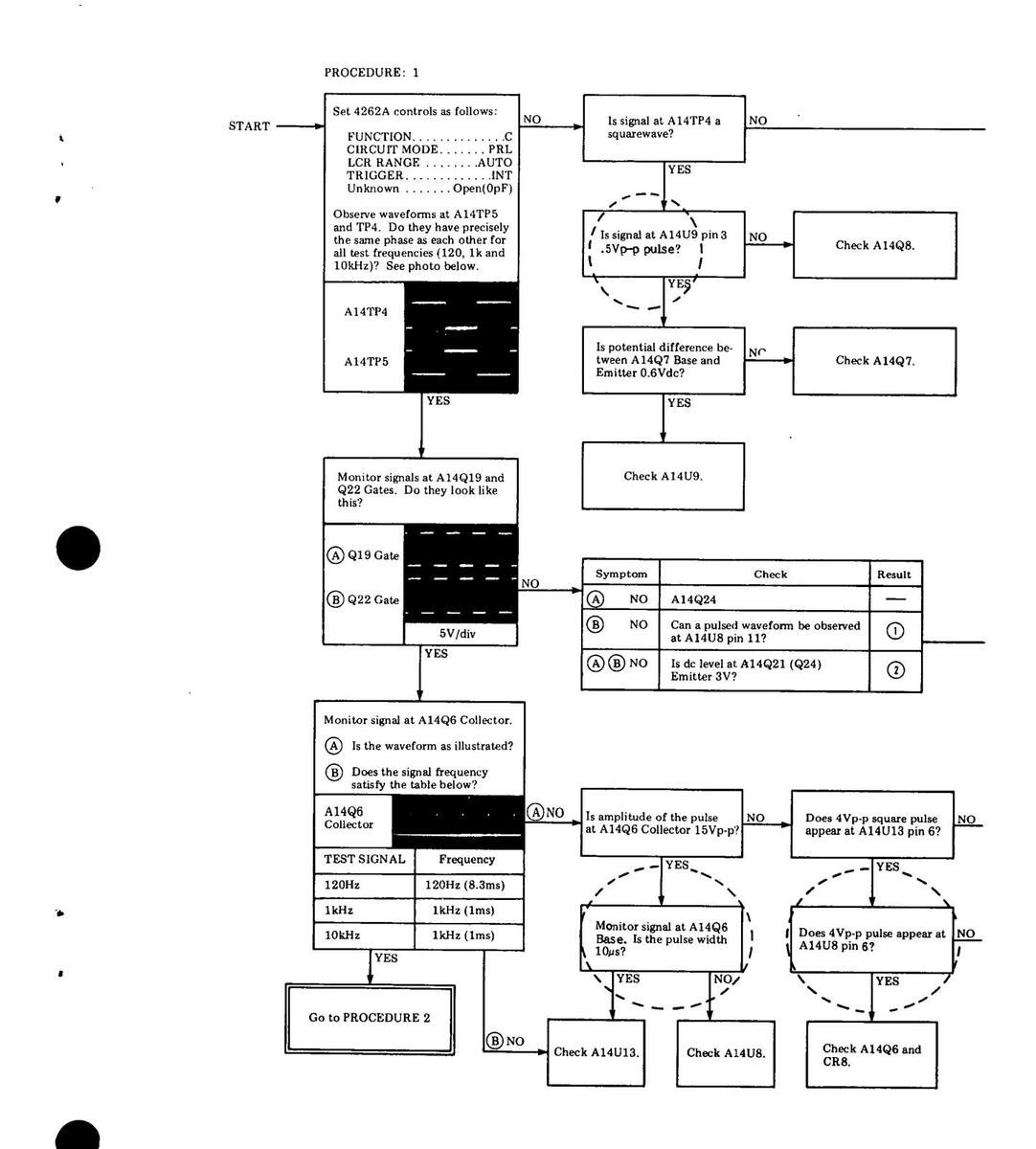

| 66 | 04262-24004 | NUT-HEX-DBL-CHAM 1/4-32-THD |

| 68 | 2190-0016 | WASHER-LK INTL T NO3/8 |

Page 6-25:

Add a washer (reference designation ()) to the illustration, as shown below:

OPERATING AND SERVICE MANUAL

MODEL 4262A LCR METER

(including Options 001,004,010, and 101)

SERIAL NUMBERS

This manual applies directly to instruments with serial numbers prefixed 2022J

With changes described in Section VII, this manual also applies to instruments with serial numbers prefixed 1710J, and 1739J.

For additional important information about serial numbers, see INSTRUMENTS COVERED BY MAN-UAL in Section I.

© COPYRIGHT: YOKOGAWA-HEWLETT-PACKARD, LTD., 1977 9-1, TAKAKURA-CHO, HACHIOJI-SHI, TOKYO, JAPAN

Manual Part No. 04262-90007 Microfiche Part No. 04262-90057

Printed: OCT. 1983

n . .

TABLE OF CONTENTS

Dama

| sec | tion | Title | rage |

|---|---|---|---|

| I |

GENEI

1-1. 1-4. 1-8. 1-10. 1-13. 1-18. 1-20. 1-22. 1-24. 1-26. 1-28. 1-31. 1-33. INSTA 2-1. 2-5. 2-6. 2-8. 2-10. 2-14. 2-16. 2-19. |

RAL INFORMATION.

Introduction |

1-1

1-1 1-7 1-7 1-7 1-7 1-7 1-8 1-8 1-8 1-8 1-8 1-8 1-8 1-8 |

|

2-19.

2-21. 2-23. 2-24. 2-26. 2-29. 2-31. 2-32. 2-33. 2-33. |

Installation Instructions

Installation of Options 907, 908 and 909 Storage and Shipment Environment Packaging Option Installation Option 001 BCD Data Output Installation Option 004 Comparator Installation Coupling Option 004 Comparator with Option 001 BCD Data Output Installation Option 101 HP-IB Remote Contr and Data Output Installation |

2-3

2-3 2-3 2-3 2-3 2-6 2-6 2-6 2-6 2-6 01 2-6 |

|

| ш |

OPER,

3-1, 3-3, 3-5, 3-7, 3-9, 3-11, 3-13, 3-15, 3-17, 3-19, 3-21, 3-23, 3-25, 3-28, |

ATION.

Introduction. Panel Features. Self Test (Basic Operating Check). Test Signals Measurement Range Initial Display Test Initial Control Settings D/Q Measurement LCR Measurement D/Q Blanking Function (Switch selectable function inside cabinet). General Component Measurement Semiconductor Device Measurement External DC Bias External Triggering |

3-1

3-1 3-1 3-6 3-6 3-7 3-7 3-7 3-7 3-7 3-9 3-9 3-9 3-9 3-9 3-9 |

m:+1 -

| Section | Title | Page |

|---|---|---|

|

3-30.

3-32. |

Terminal Configuration

Offset Adjustment |

3-10

3-10 |

|

3-40.

3-42. |

Option Operation

Option 001: BCD Parallel Data |

3-27 |

| 3-44. |

Output Data and Pin

Assignment |

3-27 |

| 3-46. | Alternate Output of LCR and D/Q Data | 3-27 |

| 3-47 | Output Timing | 3-27 |

| 3-49 | Ontion 004-COMPARATOR | 3-30 |

| 3-51. | Front Panel Features | 3_30 |

| 3 59 | I IMIT Sotting Worning | 3-30 |

| 3-34. | 9-01 | |

| 5-55. | Output Connector Decision | 2 21 |

| 2 60 | Output | 2 20 |

| 3-00. | Connection to UD IP Controllor | 2 22 |

| 3 63 | HD. ID. Status Indicator | 3-32 |

| 3-64 | 3-32 | |

| 3-65 | HD-IB Interface Capabilities | 3-32 |

| 3-66 | Source and Accentor | 0-00 |

| 5-00. | Handshaka: SH1 AH1 | 3-32 |

| 3-67 | Talker Canability: T5 | 3-32 |

| 3-68 | Functions Related to | 0 02 |

| 0.00. | 3-33 | |

| 3-69. | Listener Capability: L4. | 3-33 |

| 3-70. | Capability: SR1 | 3-33 |

| 3-71. | Capability: RL1 | 3-36 |

| 3-72. | Device Clear | 2 20 |

| 3-73. | Device Trigger | 3-30 |

| Capability: DT1 | 3-36 | |

| 3-74. | ADDRESS Switch | 3-36 |

| 3-75. | Remote Message Coding | 3-36 |

| IV PERF | ORMANCE TEST | 4-1 |

| 4-1. | Introduction | 4-1 |

| 4-3. | Equipment Required | 4-1 |

| 4-5. | Test Record | 4-1 |

| 4-7. | Calibration Cycle | 4-1 |

| Preliminary Operations | 4-2 | |

| Calibration of DUT's | 4-4 | |

| 4-9. | Measurement Frequency Test | 4-7 |

| 4-10. | Capacitance Accuracy Test | 4-8 |

| 4-11. | Resistance/ESR Accuracy Test | 4-12 |

| 4-12. | Dissipation Factor Confirmation Check . | 4-14 |

| 4-13. | Inductance Accuracy Test | 4-17 |

| 4-14. | Internal DU Blas Source Test | 4-19 |

|

4-10.

1 10 |

Comparator Test (Ontion 004 Only) | 4-40 |

| 4-10. | HD_IB Interface Test | 1-44 |

| (Option 101 Only) | 4-25 |

..

.

٠

TABLE OF CONTENTS

Se

| Sec | tion | Title | Page |

|---|---|---|---|

| v |

ADJU:

5-1. 5-3. 5-7. 5-9. 5-12. 5-14. 5-16. 5-20. 5-21. 5-22. 5-22. 5-23. 5-24. 5-25. |

STMENT |

. 5-1

. 5-1 . 5-1 . 5-1 . 5-1 . 5-1 . 5-4 . 5-5 . 5-6 . 5-7 . 5-8 . 5-9 5-14 5-17 |

| J-20. | (A12) | 5-22 | |

| VI | REPL | ACEABLE PARTS | 6-1 |

| 6-1. | Introduction | 6-1 | |

| 6-3. | Abbreviations | 6-1 | |

| 6-5. | Replaceable Parts List | 6-1 | |

| 6-7. | Ordering Information | 6-2 | |

| 6-12. | Direct Mail Order System | 6-2 | |

| VΠ | MANU | AL CHANGES | 7-1 |

| • | 7-1. | Introduction | 7-1 |

| 7-3. | Manual Changes | 7-1 | |

| vm | SERVI | CE | 8-1 |

| 8-1. | Introduction | 8-1 | |

| 8-3. | Theory of Operation | 8-1 | |

| 8-5. | Troubleshooting | 8-1 | |

| 8-7. | Recommended Test Equipment | 8-1 | |

| 8-9. | Repair | 8-1 |

| ction | Title | Page |

|---|---|---|

| 8-11 | Basic Theory | Q_ 7 |

| Principles of Operation | 9A | |

| 8-21 | Block Diagram Discussion | 8_8 |

| 8-22 | Analog Section Discussion |

. 0-0

8_8 |

| 8-23 | All Oscillator and | . 0-0 |

| 0 10. | Source Resistor | 8-8 |

| 8-25 | A12 Range Resistor |

. 0-0

8_8 |

| 8-26 | A13 Process Amplifier | 8_8 |

| 8-27 | A14 Phase Detector and | . 0-0 |

| • = | Integrator | 8_8 |

| 8-28 | Digital Control Section | 8_10 |

| 8-30. | A23 Processor and ROM | 8_10 |

| 8-31 | A21 Keyboard Control | 8_11 |

| 8-32 | A22 Display Control | 0-11 |

| • •-• | & RAM | 8_11 |

| 8-33. | A2 Display and Keyboard | 8-11 |

| 8-34. | Timing Diagram Discussion | 8-12 |

| 8-37. | Options | 8-14 |

| 8-39. | Option 001 BCD Data | • - 1 |

| Output (A35) | 8-14 | |

| 8-40. | Option 004 Comparator | • |

| (A4, A5 & A24) | 8-15 | |

| 8-41. | Option 101 HP-IB | |

| Compatible (A25) | 8-15 | |

| 8-42. | Troubleshooting | 8-16 |

| 8-46. | Repair | 8-26 |

| 8-47. | Removal of Q2 and Q3 | 8-26 |

| 8-48. | Line Switch (S1) Removal | 8-26 |

| 8-49. | Protective Diode Replacement | |

| (CR4, CR5, CR6 and CR7) | 8-27 | |

| 8-50. | ZERO ADJ Control Potentiometer | |

| (R4 and R5) Replacement | 8-27 | |

| 8-51. | A2 Keyboard and Display | |

| Board Disassembly | 8-27 | |

| 8-52. | Keyboard Switch LED Replacement | 8-28 |

| 8-53. | Product Safety Checks | 8-29 |

LIST OF TABLES

| Number | Title | Page | Number | Title P | age |

|---|---|---|---|---|---|

|

1-1.

1-2. 1-3. 1-4. |

Specifications

General Information Equipment Available Recommended Test Equipment |

1-2

1-6 1-9 1-10 |

5-1.

5-2. 5-3. 5-4. |

Adjustable Components

Factory Selected Components DUT's Recommended for Making Adjustments Adjustment Requirements |

5-2

5-3 5-4 5-5 |

|

2-1.

3-1. 3-2. 3-3. 3-4. 3-60. |

Option Components Test Signal Level Measurement Ranges Annunciation Display Meanings Unusual Operating Indications Remote Program Codes |

2-8

3-6 3-12 3-21 3-32 |

6-1.

6-2. 6-3. 6-4. 7-1. 7-2. |

List of Reference Designators

and Abbreviations Manufacturers Code List Replaceable Parts Option 010 Modification Manual Changes by Serial Number Summary of Changes by Assembly |

6-1

6-2 6-3 3-24 7-1 7-1 |

|

3-61.

4-1. |

Remote Message Coding

Recommended Components for Accuracy Checks |

3-33

4-6 |

8-1.

8-2. 8-3. 8-4. |

Currently Available Options 8

Symptoms Likely to Mislead 8 Front Panel Symptoms of Internal Control Misadjustment 8 Front Panel Isolation Procedure 8 |

-14

-18 -19 -20 |

LIST OF ILLUSTRATIONS

| Number | Title | Page | Number | Title Page |

|---|---|---|---|---|

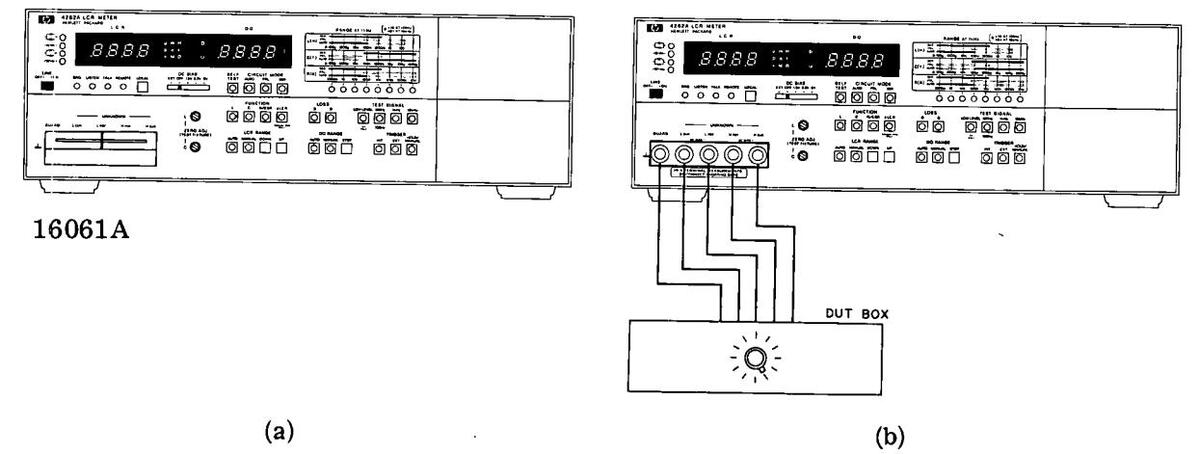

| 1-1. | Model 4262A and Accessories | . 1-1 | 4-4. | Dissipation Factor Confirmation Check |

| 1-2. | Serial Number Plate | . 1-7 | Setups | |

| 4-5. | Inductance Accuracy Test Setup 4-17 | |||

| 2-1. | Voltage and Fuse Selection | . 2-2 | 4-6. | Internal DC Bias Source |

| 2-2. | Power Cable | . 2-4 | Test Setup 4-19 | |

| 2-3. | Rack Mount Kit | . 2-5 | 4-7. | Offset Adjustment Test Setup 4-20 |

| 2-4. | Option Installation Illustrations | . 2-7 | 4-8. | Comparator Test Setups 4-22 |

| 4-9. | Comparator Output (J6) data format 4-24 | |||

| 3-1. | Front Panel Features | . 3-2 | 4-10. | HP-IB Interface Test Setup 4-25 |

| 3-2. | Rear Panel Features | . 3-4 | 4-11. | SRQ Service Routing 4-29 |

| 3-3. | Test Fixture and Leads | . 3-8 | ||

| 3-4. | Measurement Error due to | 5-1. | Power Supply Voltage Adjustment 5-6 | |

| Misadjusted ZERO ADJ controls. | .3-10 | 5-2. | Nanoprocessor Operating Power | |

| 3-5. | Conversion between Parallel and | Voltage Adjustment Location 5-7 | ||

| Series Equivalents | . 3-12 | 5-3. | A12 Board Offset Adjustment 5-8 | |

| 3-6. | Relationship of Dissipation to | - | 5-4. | Waveform at A12Q11 Source 5-9 |

| Series and Parallel Resistance | .3-13 | 5-5. | A13 Board Offset Adjustment | |

| 3-7. | General Component Measurements. | .3-15 | 5-6. | Waveform at A13TP1 |

| 3-8. | Semiconductor Device Measurement | 3-18 | 5-7. | Waveform at A13TP2 5-11 |

| 3-9. | External DC Bias Circuits | .3-20 | 5-8. | Waveform at A13TP3 5-12 |

| 3-40. | Pin Assignments of Output | 5-9. | A14 Phase Detector & Integrator | |

| Connector and Output Format | . 3-28 | Adjustment | ||

| 3-41. | Timing Chart of BCD Data Output. | 3-29 | 5-10. | A22S1 Switch Setting |

| 3-42. | Front Panel Features | 3-30 | 5-11. | Zero Detector & APAO Adjustments 5-15 |

| 3-43. | Option 004: COMPARATOR | 3-30 | 5-12. | 10kHz Measurement Accuracy |

| 3-44. | Pin Location of Comparator | • | Adjustment | |

| Data Output | . 3-31 | 5-13. | Offset Adjustment Setup 5-22 | |

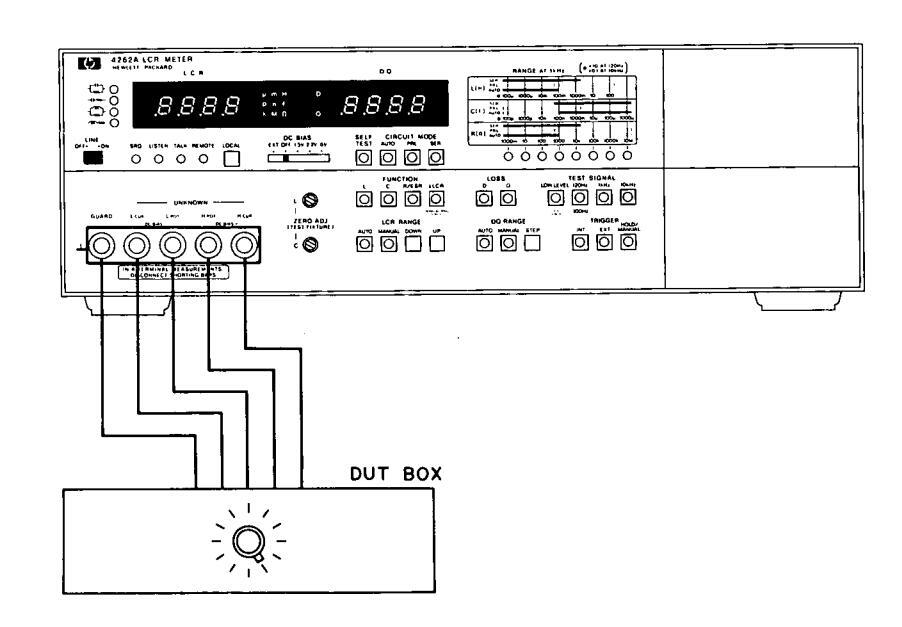

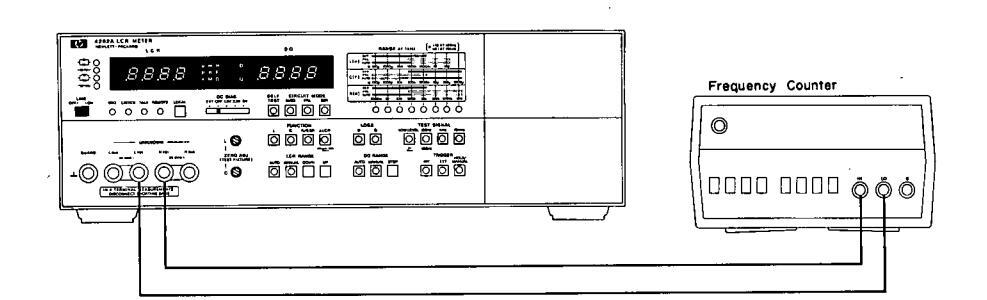

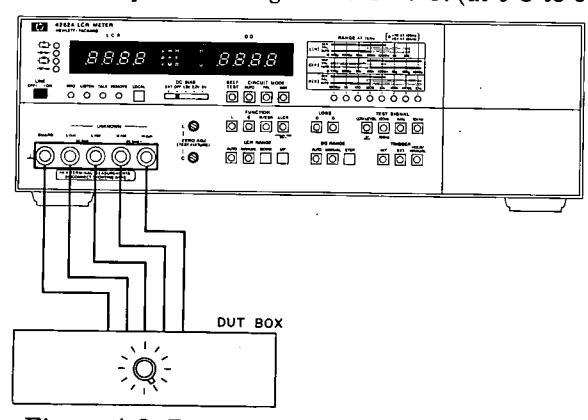

| 4-1. | Measurement Frequency Test Setup | . 4-7 | 6-1. | Major Mechanical Parts |

| 4-2. | Capacitance Accuracy Test Setup | 4-8 | - Exploded View 6-23 | |

| 4-3. | Resistance Accuracy Test Setup | .4-12 | 6-2. | Mechanical Parts |

| - | - Exploded View 6-25 |

٠

...

•

CERTIFICATION

Hewlett-Packard Company certifies that this product met its published specifications at the time of shipment from the factory. Hewlett-Packard further certifies that its calibration measurements are traceable to the United States National Bureau of Standards, to the extent allowed by the Bureau's calibration facility, and to the calibration facilities of other International Standards Organization members.

WARRANTY

This Hewlett-Packard instrument product is warranted against defects in material and workmanship for a period of one year from date of shipment, except that in the case of certain components listed in Section 1 of this manual, the warranty shall be for the specified period. During the warranty period, Hewlett-Packard Company will, at its option, either repair or replace products which prove to be defective.

For warranty service or repair, this product must be returned to a service facility designated by HP. Buyer shall prepay shipping charges to HP and HP shall pay shipping charges to return the product to Buyer. However, Buyer shall pay all shipping charges, duties, and taxes for products returned to HP from another country.

HP warrants that its software and firmware designated by HP for use with an instrument will execute its programming instructions when properly installed on that instrument. HP does not warrant that the operation of the instrument, or software, or firmware will be uninterrupted or error free.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper or inadequate maintenance by Buyer, Buyer-supplied software or interfacing, unauthorized modification or misuse, operation outside of the environment specifications for the product, or improper site preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. HP SPECIFICALLY DIS-CLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILTY AND FITNESS FOR A PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYER'S SOLE AND EXCLUSIVE REMEDIES. HP SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER BASED ON CON-TRACT, TORT, OR ANY OTHER LEGAL THEORY.

ASSISTANCE

Product maintenance agreements and other customer assistance agreements are available for Hewlett-Packard products.

For any assistance, contact your nearest Hewlett-Packard Sales and Service Office. Addresses are provided at the back of this manual.

SAFETY SYMBOLS

General Definitions of Safety Symbols Used On Equipment or In Manuals.

Instruction manual symbol: the product will be marked with this symbol when it is necessary for the user to refer to the instruction manual in order to protect against damage to the instrument.

4

(___`

Indicates dangerous voltage (terminals fed from the interior by voltage exceeding 1000 volts must be so marked).

Protective conductor terminal. For protection against electrical shock in case of a fault. Used with field wiring terminals to indicate the terminal which must be connected to ground before operating equipment.

Low-noise or noiseless, clean ground (earth) terminal. Used for a signal common, as well as providing protection against electrical shock in case of fault. A terminal marked with this symbol must be connected to ground in the manner described in the installation (operating) manual, and before operating the equipment.

Frame or chassis terminal. A connection to the frame (chassis) of the equipment which normally includes all exposed metal structures.

- ✓ Alternating current (power line).

- ____ Direct current (power line).

- Alternating or direct current (power line).

- WARNING A WARNING denotes a hazard. It calls attention to a procedure, practice, condition or the like, which, if not correctly performed or adhered to, could result in injury or death to personnel.

-

CAUTION The CAUTION sign denotes a hazard. It calls attention to an operating procedure, practice, condition or the like, which, if not correctly performed or adhered to, could result in damage to or destruction of part or all of the product.

- Note A Note denotes important information. It calls attention to a procedure, practice, condition or the like, which is essential to highlight.

...

.

LIST OF ILLUSTRATIONS

| Number | Title | Page |

|---|---|---|

|

8-1.

8-2. 8-3. |

Basic Block Diagram

Cp Measurement Measurement Principles |

8-2

8-3 8-7 |

| 8-4. | Offset Control Principle | 8-6 |

| 8-5. | DC Bias Circuit | 8-6 |

| 8-6. | Analog Section Block Diagram | 8-9 |

| 8-7. | Digital Section Block Diagram | 8-11 |

| 8-8. | Timing Diagram | 8-13 |

| 8-9. | Option Section Block Diagram | 8-15 |

| 8-10. | How to Use Troubleshooting Guid | es 8-17 |

| 8-11 | Self Test Function | 8-21 |

| 8-12 | Signature Analysis Guide | 8-23 |

| 8-13. |

Protective Diode and ZERO ADJ

Control Potentiometer |

|

| 8-14. | Replacement | 8-26 |

| Board Disassembly | 8-27 | |

| 8-15. | Inserting Tubing into Switch Plun | ger 8-28 |

| 8-16. | LED Installation in Switch | 8-28 |

| 8-17. |

Analog and Digital Section

Isolation Procedure |

8-31 |

| 8-18. |

Analog Section Troubleshooting

Procedure to Assembly Level |

8-33 |

| 8-19. |

Digital Section Troubleshooting

Procedures |

8-35 |

| 8-20. | Schematic Diagram Notes | 8-43 |

| 8-21. | Assembly Locations | |

| 8-22. | Adjustment Locations | 8-43 |

| 8-23. | Front Panel Component Locations | 58-44 |

| 8-24. | Rear Panel Component Locations | 8-44 |

| 8-25. | A2 Keyboard & Display Board | 8_45 |

| 8-26. |

A2 Keyboard & Display Board

Assembly Schematic Diagram |

8-45 |

| 8-27. |

A9 Power Supply Board

Troubleshooting Tree |

8-46 |

| 8-28. |

A9 Power Supply Board Assembly

Component Locations |

0 17 |

| 8-29. | A9 Power Supply Board Assembly | 7 |

| 8-30. | All OSC & Source Resistor Boar |

8-47

d |

| 8-31. | All OSC & Source Resistor Boar |

8-48

d |

| 8-32. |

Assembly Component Locations

All OSC & Source Resistor Board |

d

8_49 |

| 8-33. |

A12 Range Resistor Board

Troubleshooting Tree |

8-50 |

| 8-34. | A12 Range Resistor Board Assem | ibly |

| 8-35. | A12 Range Resistor Board | 0 51 |

| 8-36. | All Process Amplifier Board | 8-51 |

| roubleshooting Tree | 8-92 |

| Number | Title | Page |

|---|---|---|

| 8-37. |

A13 Process Amplifier Board

Assembly Component Locations |

.8-53 |

| 8-38. |

A13 Process Amplifier Board

Assembly Schematic Diagram |

. 8-53 |

| 8-39. | A14 Phase Detector & Integrator | 0 54 |

| 8-40. | A14 Phase Detector & Integrator | .0-54 |

| 8-41. |

Board Troubleshooting Tree(B)

A14 Phase Detector & Integrator |

.8-55 |

| 0.49 | .8-57 | |

| 8-42. | Board Assembly | 0 5 5 |

| 8-43. | A21 Keyboard Control Board | .8-97 |

| 8-44. |

Assembly Component Locations

A21 Keyboard Control Board |

.8-39 |

| 8-45. |

Assembly Schematic Diagram

A22 Display Control & RAM Board |

0 61 |

| 8-46. |

Assembly Component Locations

A22 Display Control & RAM Board |

.0-01

8-61 |

| 8-47. |

A23 Processor & ROM Board

Assembly Component Locations |

8-63 |

| 8-48. |

A23 Processor & ROM Board

Assembly Schematic Diagram |

8-63 |

| 8-49. |

A4 Thumbwheel Switch Board

Assembly Component Locations |

.8-65 |

| 8-50. |

A5 Comparator Keyboard Board

Assembly Component Locations |

. 8-65 |

| 8-51. |

A4 Thumbwheel Switch Board and

A5 Comparator Keyboard Board |

0 05 |

| 8-52. |

Assembly Schematic Diagram

A24 Comparator Control Board |

.8-05 |

| 8-53. | A24 Comparator Control Board | .8-66 |

| 8-54. |

Assembly Component Locations

A24 Comparator Control Board |

.8-07 |

| 8-55. |

A25 HP-IB Interface Board

Diagnostic Flow Diagram |

8-68 |

| 8-56. |

A25 HP-IB Interface Board

Assembly Component Locations |

8-69 |

| 8-57. |

A25 HP-IB Interface Board

Assembly Schematic Diagram |

.0-05

8-69 |

| 8-58. |

A35 BCD Output Control Board

Diagnostic Flow Diagram |

8-70 |

| 8-59. |

A35 BCD Output Control Board

Assembly Component Locations |

8-71 |

| 8-60. |

A35 BCD Output Control Board

Assembly Schematic Diagram |

.8-71 |

v

SECTION I GENERAL INFORMATION

1-1. INTRODUCTION.

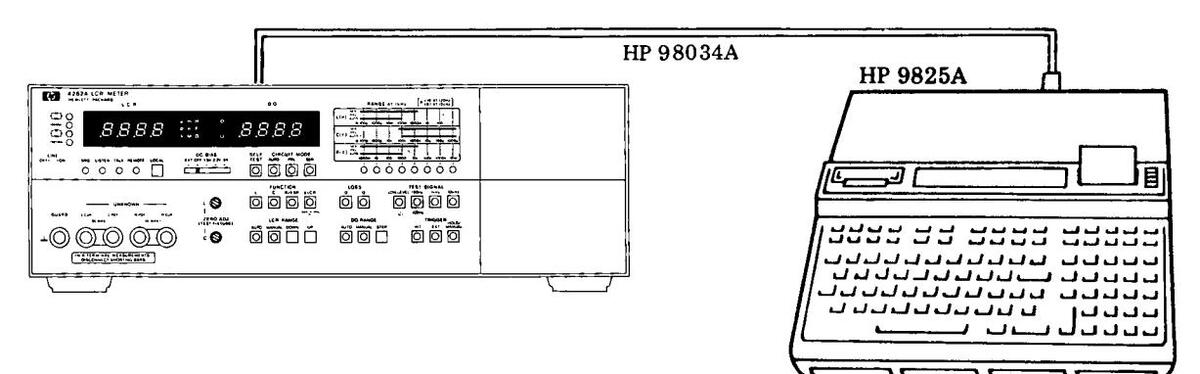

1-2. This operating and service manual contains the information required to install, operate, test, adjust and service the Hewlett-Packard Model 4262A Digital LCR Meter. Figure 1-1 shows the instrument and supplied accessories. This section covers specifications, instrument identification, description, options, accessories, and other basic information.

1-3. Listed on the title page of this manual is a microfiche part number. This number can be used to order 4 x 6 inch microfilm transparencies of the manual. Each microfiche contains up to 60 photoduplicates of the manual pages. The microfiche package also includes the latest manual changes supplement as well as all pertinent service notes. To order an additional manual, use the part number listed on the title page of this manual.

1-4. DESCRIPTION.

1-5. The HP Model 4262A LCR Meter is a general

purpose, fully automatic test instrument designed to measure the parameters of an impedance element with high accuracy and speed. The 4262A measures capacitance, inductance, resistance (equivalent series resistance) and dissipation factor or quality factor over a wide range at test frequencies of 120Hz, 1kHz and 10kHz employing a five-terminal connection configuration between the component and the instrument. The measuring circuit for the device to be measured is capable of both parallel and series equivalent circuit measurements and the measured values are displayed by the two three-full digits LED displays on the front nanel A convenient diagnostic function also featured in the 4262A is actuated by a SELF TEST switch This confirms functional operation of the instrument.

1-6. The measuring range for capacitance is from 0.01pF to 19.99mF, inductance from 0.01µH to 1999H, and resistance from 1mΩ to 19.99MΩ, which are measured with a basic accuracy of 0.2 to 0.3% depending on test signal level, frequency, and measuring equivalent circuit, and at typical measuring speeds of 220 to 260 milliseconds at

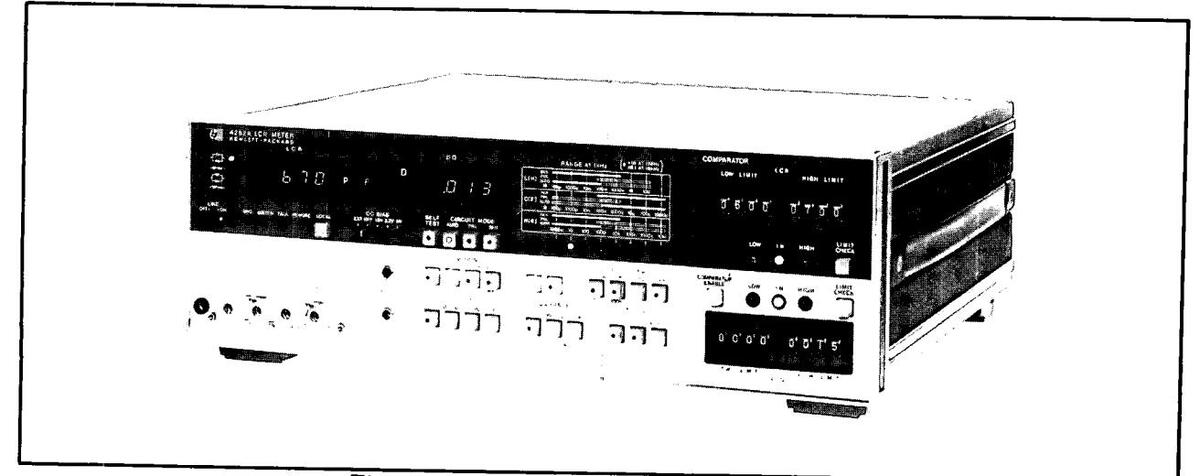

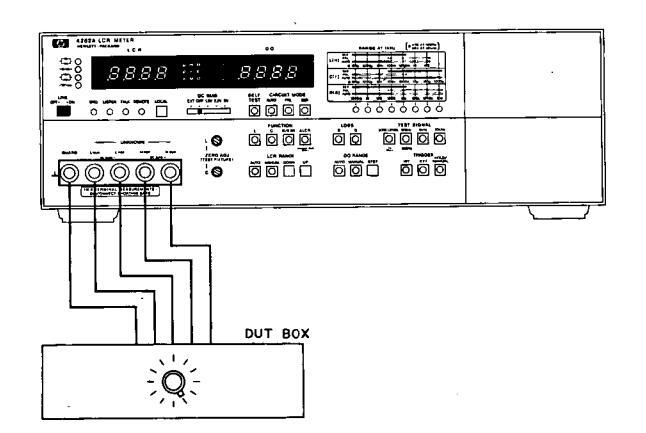

Figure 1-1. Model 4262A and Accessories.

COMMON SPECIFICATIONS

Parameters Measured: C - D or Q (1/D) L - D or Q (1/D) R (ESR) (Loss measurement can be negated by switch on internal board).

- Display: 3-1/2 Digit, Maximum Display 1999 (When D value is more than 10, maxmum display is 199).

- Measurement Circuit Modes: Auto, Parallel, and Series

Measurement Terminals: 5-terminal configuration (high and low terminals for both potential and current leads plus guard).

- Range Modes: LCR Auto and Manual (up-down) DQ - Auto and Manual (step)

- Measurement Frequencies: 120(100)Hz, 1kHz and 10kHz ±3%.

- Test Signal Level: Normal level: 1Vrms. Low level : 50mVrms (parallel capacitance mode only)

Warm-up Time: 15 minutes

- Deviation Measurement: When △LCR key is depressed, the existing measured value is stored as a reference value and displayed value is offset to zero. The range is held and deviation is displayed as the difference between the referenced value and subsequent result. (Deviation spread in counts from -999 to 1999).

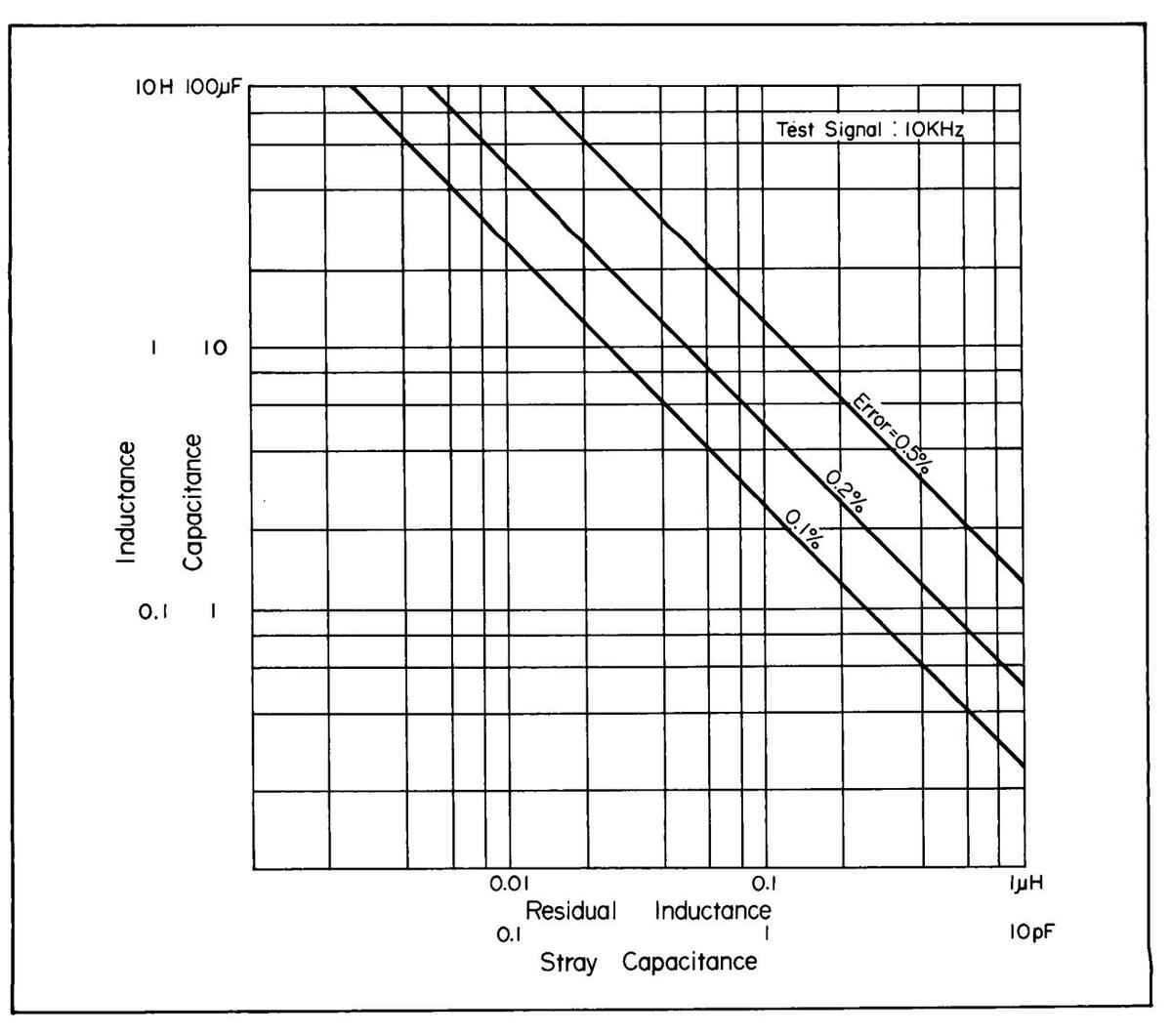

- Offset Adjustment: Stray capacitance and residual inductance of test jig can be compensated for as follows:

C: up to 10pF L: up to 1µH

Self Test: Annunciates either Pass, or Fail for performance in each of the five basic ranges.

DC Bias:

- Internal: 1.5V, 2.2V, 6V (Selectable at front panel). Accuracy ±5%

- External: External DC bias connector on rear panel. Maximum +40V.

Trigger: Internal, External, or Manual

GENERAL

Operating Temperature & Humidity: 0°C to 55°C at 95% RH(to 40°C)

Power Requirements: 100/120/220V ±10%, 240V +5% -10% 48 - 66Hz

Power Consumption: 55VA with any option

Dimensions: 426(W) x 147(H) x 345(D)mm (16-3/4" x 5-3/4" x 13-3/4")

Weight: Approximately 8kg (Std)

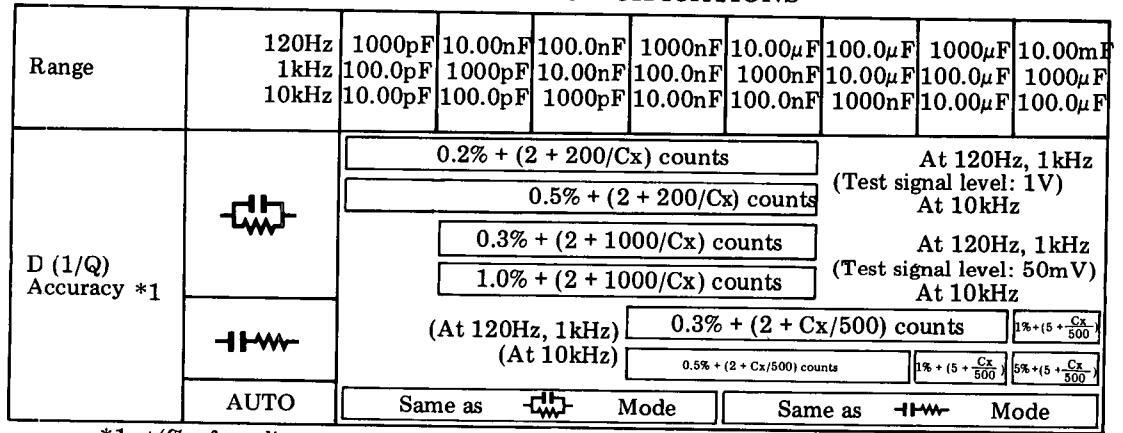

Table 1-1. Specifications (Sheet 2 of 4).

| C·D, C·Q MEASUREMENT | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ranges | с |

120Hz

1kHz 10kHz |

1000pF

100.0pF 10.00pF |

10.00nF

1000pF 100.0pF |

100.0nF

10.00nF 1000pF |

1000nF

100.0nF 10.00nF |

10.00µF

1000nF 100.0ņF |

100.0μF

10.00μF 1000nF |

1000μF

100.0μF 10.00μF |

10.00mF

1000μF 100.0μF |

|

| 8 | D | .001~19.9 (2 Ranges) | |||||||||

| Q *1 | 0.05~1000 (4 Ranges) | ||||||||||

| - | ╬ | 1V or 50mV (LOW LEVEL) | |||||||||

| Test Signal | - | II | 10µA | 100µA | 1mA | 10mA | 40mA | ||||

| Level *2 | A | AUTO | Same | eas -[ | ₩Ъ- М | ode | Same | eas ⊣⊦ | •••- N | lode | |

| 0.2 | % + 1 co | unts | (Test si | gnal level | ;1V) | ||||||

|

0.5% +

3 counts |

0.3% + 2 | 2 counts | (Test signal level; 50mV) | ||||||||

| C Accuracy *3 | -11 | (At 120Hz, 1kHz) 0.3% + 2 counts 1% + 2 counts 1% + 2 counts 2 counts |

1% + *4

2 counts |

||||||||

| (At 10kHz) 0.3% + 2 counts 1% + 2 5% - | 5% + 2 | ||||||||||

| AUTO | Same | eas -C | ₩ - М | ode | Same | eas -IF | •••- M | lode | |||

| 0.2% + (2 | 2 + 200/C | x) count | 5 | A | t 120Hz | , 1kHz | |||||

| ᆐᠲ | 0.5% + (2 + 200/Cx) counts (Test signal level; 1V) | 1V) | |||||||||

| 0.3% + (2 + 1000/Cx) counts At 120H | t 120Hz | ,1kHz | |||||||||

|

D(1/Q)

Accuracy *3 |

1.0% + (2 + 1000/Cx) counts(Test signal level; 50m)At 10kHz | 50mV) | |||||||||

| ( | At 120H | z, 1kHz) | 0.3% | 5 + (2 + C | x/500) c | ounts |

1% + (5 +

Cx

500 ) |

||||

| 11 | (At | 10kHz) | 0.5% + | (2 + Cx/500 | ) counts | 1% + (5 + Cx ) | 5% + (5 + Cx ) | ||||

| AUTO | Same | as -C | ъ м | ode | Same | as -II | ₩- M | lode | |||

*1 Calculated from D value as a reciprocal number. *2 Typical data, varies with value of D and number of counts. *3 ±(% of reading + counts). Cx is capacitance readout in counts. This accuracy only applies for D values to 1.999. (For higher D values, refer to General Information). *4 (5% + 2 counts) at 1kHz.

Accuracy applies over a temperature range of 23°C ± 5°C (At 0°C to 55°C, error doubles).

Note: C accuracy for higher D values are unspecified.

| L-D, L-Q N | 1EASUREI | MENT | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ranges |

120Hz

L 1kHz 10kHz |

1000μH

100.0μH 10.00μH |

10.00mH

1000μH 100.0μH |

100.0mH

10.00mH 1000µH |

1000mH

100.0mH 10.00mH |

10.00H

1000mH 100.0mH |

100.0H

10.00H 1000mH |

1000H

100.0H 10.00H |

|||

| Touriges | D | .001~19.9 (2 Ranges) | |||||||||

| Q*1 | 0.05~1000 (4 Ranges) | ||||||||||

| -@ | 1 | v | |||||||||

|

Test Signal

Level *2 |

-00-00- | 40mA | 10mA | 1mA | 100µA | 10µA | |||||

| AUTO | Same as | -787-99- | Mode | Same a | s -∰- | Mode | |||||

| an | (At 120H | z, 1kHz) | 0.3% + 2 | 2 counts | counts | ||||||

| -L₩ | (At 10 | kHz) | 0.3% + 2 | 2 counts | 1% + 2 | 5% + 2 | |||||

| L Accuracy*3 | 0. | 2% + 2 cou | ints (At 120Hz, 1kHz | 1kHz) | |||||||

| 0.3% + 2 | 0.2% + | 2 counts | (At 10kHz) | ) | |||||||

| AUTO | Same as | -787-99- | Mode | Same a | s | Mode | |||||

| അ | (At 120H | z, 1kHz) | 0.3% + (3 | + Lx/500) | 1% + (3 + | Lx/500) | |||||

| Ҷѿ҉Ҏ | (At 10) | kHz) | 0.5% + (3 | + Lx/500) |

1% + (3 +

Lx

500) |

5% + (5 + Lx ) | |||||

|

D(1/Q)

Accuracy |

0.2% + ( | 3 + 200/L | x) counts | (At 120Hz | , 1kHz) | ||||||

| - | - 00 | 0.5% + ( | 3 + 200/L | x) counts | (At 1kHz) | ||||||

| AUTO | Same as | -780-444- | Mode | Same a | s -CMD- | Mode | |||||

Table 1-1. Specifications (Sheet 3 of 4).

*1 Calculated from D value as a reciprocal number.

*2 Typical data, varies with value of D and number of counts.

*3 ±(% of reading + counts). Lx is inductance readout in counts. This accuracy only applies for D values to 1.999.

Accuracy applies over a temperature range of 23°C ± 5°C. (At 0°C to 55°C, error doubles).

| Ranges |

120Hz

R/ESR 1kHz 10kHz |

1000mΩ | 10-00Ω | 100.0Ω | 1000 Ω | 10.00kΩ | 100.0kΩ | 1000kΩ | 10.00MΩ | ||

|

$

₽ |

1V | ||||||||||

|

Test Signal

Level *1 |

-1 ⊢ ₩ | 40mA | 10mA | 1mA | 100µA | 10µA | |||||

| AUTO | Sa | me as 🕂 | ~-~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ | Mode | ode Same as Mode | ||||||

| - | 0.3% + 2 counts *3 | ||||||||||

| Accuracy *2 | -11 | 0.2 | % + 2 cou | ints | |||||||

| AUTO | San | ne as -II-w |

~ -

|

Mode | Same | eas – C | Ъ Мо | ode | |||

R/ESR MEASUREMENT

*1 Typical data, varies with number of counts.

*2 ±(% of reading + counts).

*3 (0.5% + 2 counts) on 10.00MΩ range at 10kHz.

** Measurement range for ESR (equivalent series resistance) is from 1mΩ to 19.99kΩ (typical), which varies with series capacitance and inductance value . refer to "REFERENCE DATA".

Accuracy applies over a temperature range of 23°C ± 5°C. (At 0°C to 55°C, error doubles.)

OPTIONS

- Option 001: Simultaneous BCD output of LCR and DQ data (positive true). Max. sink current 16mA. Mating connector (P/N 1251-0086). (Alternate BCD output of LCR and DQ data selectable by switch on internal board).

- Option 004: Digital comparator (can not be used with OPT 101). Compares measured value with high and low limit settings for LCR or DQ and provides HIGH, IN, LOW comparison outputs.

Limit setting range: 0000 - 1999 for each limit switch.

Comparison output: Visual, relay contact, and TTL level.

Visual: 3 LED's indicate HIGH(red), IN (green), or LOW (red).

Relay contacts: SPST contacts to circuit common for each HIGH, IN and LOW output. TTL level:

Open collector circuits to high level (open) for each HIGH, IN and LOW outputs (fanout max. 30mA).

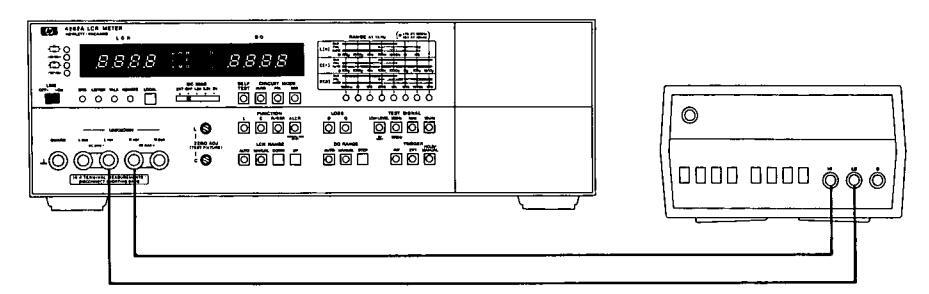

Option 101: HP-IB data output & remote control.

Remotely controllable functions: Function (L, C, R/ESR, △LCR) Loss (D, Q) LCR range DQ range Circuit mode Test frequency & level Trigger Self test Data output: C - D/Q, L - D/Q, R/ESR

Internal function allowable subsets: SH1, AH1, T5, L4, RL1, DC1, SR1 and DT1. Data output format: Either of two formats

Data output format: Eitner of two formats may be selected. Switchable at rear panel (no + sign outputs). Format A.

SFFT±N.NNNE+NN, SF±N.NN(CR)(LF)

Format B.

SFFT±N.NNNE±NN(CR)(LF)

SF±N.NN(CR)(LF)

FT Test Frequency

----Measurement Equivalent Circuit

–Measurement Status

Measurement status

Option 010: 100Hz test frequency instead of 120Hz.

ACCESSORIES AVAILABLE

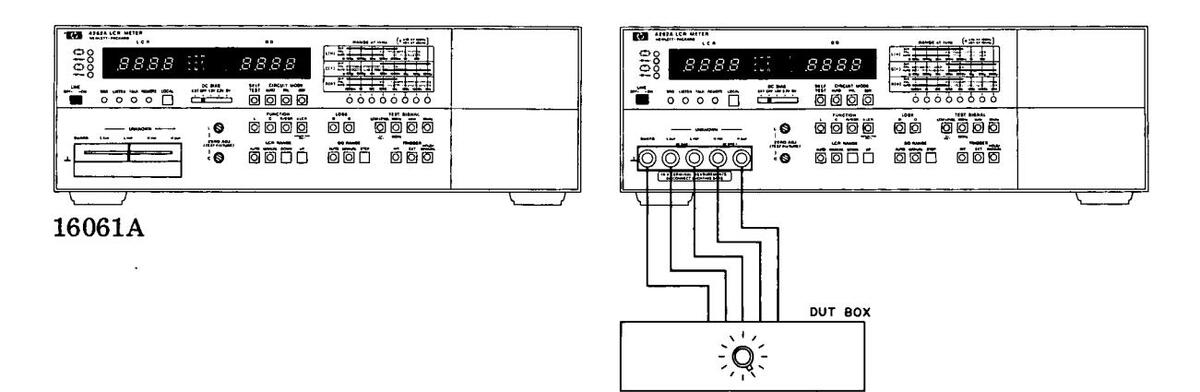

- 16061A: Test fixture, direct coupled, 5-terminal Two kinds of inserts are included for components with either axial or radial leads. Usable on all ranges of 4262A.

- 16062A: Test cable with alligator clips, 4-terminal. Useable for low impedance measurements. Measurement range at 1kHz is L ≤ 2H, C ≥ 200nF and R ≤ 10kΩ. [For L and C measurements, these ranges increase by x10 at 120 (100)Hz and decrease by same factor at 10kHz].

16063A: Test cable with alligator clips, 3-terminal. Useable for high impedance measurements. Measurement range at 1kHz is L ≥ 3mH, C ≤ 10µ F and R ≥ 200Ω. [For L and C measurement, these ranges increase by x10 at 120(100)Hz and decrease by same factor at 10kHz].

Table 1-2. General Information.

Sum of Counts on LCR and DISSIPATION FACTOR Displays

)00 (Counts)

Time

1kHz and 10kHz and about 900 milliseconds at 120Hz. The wide range capability of the 4262A enables a measurement range from small capacitances such as mica capacitors and the parasitic capacitance of a semiconductor device through high capacitances such as the measurement of electrolytic capacitors to be covered. A wide range of inductance measurements from the inductance of a high frequency transformer to that of a power transformer can be measured. The wide resistance range permits the measurement of solid resistors. In parallel capacitance measurements, either a test signal level of 1Vrms, or 50mVrms can be selected.

1-7. The 4262A has the capability of making capacitance, inductance, and resistance deviation measurements. This function is enabled by pushing the A LCR switch to display the deviation of a reference value. When the \(\Delta\) LCR switch is depressed the reference value is obtained and memorized from the preceding measurement. The practical use of this feature is evident when it is desired to make a measurement on a variable capacitor: First, the minimum value is measured, then the A LCR button is pushed. Minimum to maximum capacitance is now displayed as the capacitor is rotated through its range. For parallel capacitance measurements, test signal levels of either 1Vrms or 50mVrms may be selected. Other versatile 4262A capabilities and features are, for example, the use of internal and external dc bias voltages. LC zero adjustment, and options providing BCD output. HP-IB interfacing capability, or a comparator function.

1-8. SPECIFICATIONS.

1-9. Complete specifications of the Model 4262A LCR Meter are given in Table 1-1. These specifications are the performance standards or limits against which the instrument is tested. The test procedures for the specifications are covered in Section IV Performance Tests. Table 1-2 lists gen-

Figure 1-2. Serial Number Plate.

eral information. General information is not specifications but is typical characteristics included as additional information for the operator. When the 4262A LCR Meter is shipped from the factory, it meets the specifications listed in Table 1-1.

1-10. SAFETY CONSIDERATIONS.

1-11. The Model 4262A LCR Meter has been designed to conform to the safety requirements of an IEC (International Electromechanical Committee) Safety Class I instrument and is shipped from the factory in a safe condition.

1-12. This operating and service manual contains information, cautions, and warnings which must be followed by the user to ensure safe operation and to maintain the instrument in a safe condition.

1-13. INSTRUMENTS COVERED BY MANUAL.

1-14. Hewlett-Packard uses a two-section nine character serial number which is marked on the serial number plate (Figure 1-2) attached to the instrument rear panel. The first four digits and the letter are the serial prefix and the last five digits are the suffix. The letter placed between the two sections identifies country where instrument was manufactured. The prefix is the same for all identical instruments; it changes only when a change is made to the instrument. The suffix, however, is assigned sequentially and is different for each instrument. The contents of this manual apply to instruments with the serial number prefix(es) listed under SERIAL NUMBERS on the title page.

1-15. An instrument manufactured after the printing of this manual may have a serial number prefix that is not listed on the title page. This unlisted serial number prefix indicates the instrument is different from those described in this manual. The manual for this new instrument may be accompanied by a yellow Manual Changes supplement or have a different manual part number. This supplement contains "change information" that explains how to adapt the manual to the newer instrument.

1-16. In addition to change information, the supplement may contain information for correcting errors (called Errata) in the manual. To keep this manual as current and accurate as possible, Hewlett-Packard recommends that you periodically request the latest Manual Changes supplement. The supplement for this manual is identified with this manual's print date and part number, both of which appear on the manual's title page. Complimentary copies of the supplement are available from Hewlett-Packard. If the serial prefix or number of an instrument is lower than that on title page of this manual, see Section VII Manual Changes.

1-17. For information concerning a serial number prefix that is not listed on the title page or in the Manual Changes supplement, contact your nearest Hewlett-Packard office.

1-18. OPTIONS.

1-19. Options for the Model 4262A LCR Meter are available for adding the following capabilities:

Option 001: BCD Parallel Data Output.

- Option 004: Comparator. A comparator function providing GO/NO-GO judgement with HIGH and LOW limits for LCR and D/Q.

- Option 101: HP-IB Interface.

-

Option 010: 100Hz Test Frequency.

- (instead of 120Hz)

- Options 907, 908 or 909 are handle or rack mount kits. See paragraph 1-29 for details.

Option 910: Extra Manual.

1-20. OPTION 001.

1-21. The 4262A option 001 provides separate BCD parallel data output for L, C, R/ESR and dissipation factor or quality factor simultaneously from the two rear panel connectors. With this option, external data processing devices such as a digital printer can be used with the 4262A.

1-22. OPTION 004,

1-23. The 4262A Option 004 provides for GO/NO-GO judgement by comparing L, C, R/ESR and D/Q values to HIGH and LOW limits. Three judgement outputs are provided: LED lamp display, relay contacts, or TTL level voltages (open collectors):

- HIGH . .measured value is not less than HIGH limit.

- IN . measured value is less than HIGH limit and not less than LOW limit.

LOW ... measured value is less than LOW limit.

1-24. OPTION 101.

1-25. The 4262A Option 101 provides interfacing functions to both transfer L, C, R/ESR and D/Q data to HP Interface Bus line and to receive remote control signals from HP Interface Bus line.

1-26. OPTION 010.

1-27. The 4262A Option 010 provides test frequencies of 100Hz, 1kHz, and 10kHz (100Hz is used instead of standard 120Hz). All other electrical performance is the same as that of standard instrument.

1-28. OTHER OPTIONS.

1-29. The following options provides mechanical parts necessary for rack mounting and hand carrying:

Option 907: Front Handle Kit. Option 908: Rack Flange Kit. Option 909: Rack Flange and Front Handle Kit.

The installation procedures for these options are detailed in section II.

1-30. The 4262A Option 910 provides an extra copy of the operating and service manual.

1-31. ACCESSORIES SUPPLIED.

1-32. Figure 1-1 shows the HP Model 4262A LCR Meter, power cord (HP Part No. 8120-1378), and fuses (HP Part No. 2110-0007 and 2110-0202).

1-33. ACCESSORIES AVAILABLE.

1-34. For effective and easy measurement, three styles of fixtures and leads for the measurement of various components are available. These are listed in Table 1-1. A brief description of each of these fixtures and leads is given in Table 1-3. Refer to Section III Figure 3-3 on page 3-8 for detailed information on these devices.

Model 4262A

Table 1-3. Accessories Available.

| Model | Description |

|---|---|

| HP 16061A |

Test Fixture (direct coupled type) for

general measurement of both axial and vertical lead components. |

| нр 16062А |

Test Leads (with alligator clips) useful

for low inductance, high capacitance or low resistance (less than 10kΩ) measure- ments. |

| HP 16063A |

Test Leads (with alligator clips) for

general component measurement and especially useful for high impedance measurements. |

| HP P/N 5060-4017 |

Extender Board used for

4262A

troubleshooting. |

| Instrument | Critical Specifications |

Recommended

Model |

*Use |

|

Frequency Counter Frequency Range: 40Hz to 10kHz

Sensitivity: 50mVrms min. |

HP 5300A/

w 5306A |

Р | |

|

Capacitance Standard

(See para. 4-3)Capacitance Values: 100pF, 1000pF, 10nF, 100nF, 1000nF and 10µF |

GR Type 1413

GR Type 1417 |

P, A | |

|

Resistance Standard

(See para. 4-3)Resistance Values: 1kΩ, 10kΩ, 100kΩ and 10MΩ |

GR Type 1443-Y | P, A | |

|

Inductance Standard

(See Para. 4-3) |

Inductance Value: 100mH | GR Type 1482-L | Р |

|

DC Voltmeter Voltage Range: 1V to 10V

Sensitivity: 10mV min. |

HP 5300A/

w 5306A |

P, A | |

| Oscilloscope |

Bandwidth: 10MHz min.

Vertical Sensitivity: 5mV/div. Horizontal Sweep Rate: 1µs/div. |

HP 180C/

w 1801A/ w 1821A |

A, T |

| Signature Analyzer | HP 5004A | Т | |

| Current Tracer | HP 547A | Т | |

| Service Kit | Signature Analysis Test Board |

HP P/N:

04262-87002 |

Т |

| DUT Box | Comprises L, C and R components whose values are calibrated at 120Hz and 1kHz. | HP 16361A | P, A |

| DUT Box | Comprises L, C and R components whose values are calibrated at 10kHz. | HP 16362A | P, A |

| *P=Performar | ice Test A=Adjustments T=Troubleshootir | ng | |

Table 1-4. Recommended Test Equipment.

SECTION II

2-1. INTRODUCTION.

2-2. This section provides installation instructions for the Model 4262A LCR Meter. The section also includes information on initial inspection and damage claims, preparation for using the 4262A, packaging, storage, and shipment.

2-3. INITIAL INSPECTION.

2-4. The 4262A LCR Meter, as shipped from the factory, meets all the specifications listed in Table 1-1. On receipt, inspect the shipping container for damage. If the shipping container or cushioning material is damaged, notify the carrier as well as the Hewlett-Packard office and be sure to keep the shipping materials for carrier's inspection until the contents of the shipment have been checked for completeness and the instrument has been checked mechanically and electrically. The contents of the shipment should be as shown in Figure 1-1. The procedures for checking the general electrical operation are given in Section III (Paragraph 3-5 Basic Operating Check) and the procedures for checking the 4262A LCR Meter against its specifications are given in Section IV. Firstly. do the self test. If the 4262A LCR Meter is electrically questionable then do the Performance Tests to determine whether the 4262A has failed or not. If contents are incomplete, if there is mechanical damage or defects (scratches, dents, broken switches, etc.), or if the performance does not meet the self test or performance tests, notify the nearest Hewlett-Packard office (see list at back of this manual). The HP office will arrange for repair or replacement without waiting for claim settlement.

2-5. PREPARATION FOR USE.

2-6. POWER REQUIREMENTS.

2-7. The 4262A requires a power source of 100, 120, 220 Volts ac ±10%, or 240 Volts ac ±5%, -10%, 48 to 66Hz single phase. Power consumption is approximately 55 watts.

WARNING

IF THIS INSTRUMENT IS TO BE ENERGIZED VIA AN EXTER-NAL AUTOTRANSFORMER FOR VOLTAGE REDUCTION, BE SURE THAT THE COMMON TERMINAL IS CONNECTED TO THE NEUTRAL POLE OF THE POWER SUPPLY.

2-8. LINE VOLTAGE AND FUSE SELECTION.

CAUTION

BEFORE TURNING THE 4262A LINE SWITCH TO ON, VERIFY THAT THE INSTRUMENT IS SET TO THE VOLTAGE OF THE POWER SUPPLIED.

2-9. Figure 2-1 provides instructions for line voltage and fuse selection. The line voltage selection card and the proper fuse are factory installed for the voltage appropriate to instrument destination.

CAUTION

USE PROPER FUSE FOR LINE VOLTAGE SELECTED.

CAUTION

MAKE SURE THAT ONLY FUSES FOR THE REQUIRED RATED CURRENT AND OF THE SPECI-FIED TYPE ARE USED FOR RE-PLACEMENT. THE USE OF MENDED FUSES AND THE SHORT-CIRCUITING OF FUSE-HOLDERS MUST BE AVOIDED.

2-10. POWER CABLE.

2-11. To protect operating personnel, the

Figure 2-1. Voltage and Fuse Selection.

National Electrical Manufacturer's Association (NEMA) recommends that the instrument panel and cabinet be grounded. The Model 4262A is equipped with a three-conductor power cable which, when plugged into an appropriate receptacle, grounds the instrument. The offset pin on the power cable is the ground wire.

2-12. To preserve the protection feature when operating the instrument from a two contact outlet, use a three prong to two prong adapter (HP Part No. 1251-8196) and connect the green grounding tab on the adapter to power line ground.

CAUTION

THE MAINS PLUG MUST ONLY BE INSERTED IN A SOCKET OUTLET PROVIDED WITH A PROTECTIVE EARTH CONTACT. THE PROTECTIVE ACTION MUST NOT BE NEGATED BY THE USE OF AN EXTENSION CORD (POWER CABLE) WITH-OUT PROTECTIVE CONDUCTOR (GROUNDING).

2-13. Figure 2-2 shows the available power cords, which may be used in various countries including the standard power cord furnished with the instrument. HP Part number, applicable standards for power plug, power cord color, electrical characteristics and countries using each power cord are listed in the figure. If assistance is needed for selecting the correct power cable, contact nearest Hewlett-Packard office.

2-14. Interconnections.

2-15. When an external bias is applied to the sample capacitor through DC BIAS input connectors on the 4262A rear panel, both plus and minus sides of the external power supply should be connected to the plus and minus sides of the 4262A EXT DC BIAS connector, respectively.

CAUTION

THE MAINS PLUG MUST BE IN-SERTED BEFORE EXTERNAL CONNECTIONS ARE MADE TO MEASURING AND/OR CON-TROL CIRCUITS.

2-16. Operating Environment.

2-17. Temperature. The instrument may be operated in temperatures from 0°C to +55°C.

2-18. Humidity. The instrument may be operated in environments with relative humidities to 95% to 40°C. However, the instrument should be protected from temperature extremes which cause condensation within the instrument.

2-19. Installation Instructions.

2-20. The HP Model 4262A can be operated on the bench or in a rack mount. The 4262A is ready for bench operation as shipped from the factory. For bench operation a two-leg instrument stand is used. For use, the instrument stands are designed to be pulled towards the front of instrument.

2-21. Installation of Options 907, 908 and 909.

2-22. The 4262A can be installed in a rack and be operated as a component of a measurement system. Rack mounting information for the 4262A is presented in Figure 2-3.

2-23. STORAGE AND SHIPMENT.

2-24. Environment.

2-25. The instrument may be stored or shipped in environments within the following limits:

Temperature -40°C to +75°C Humidity to 95% Altitude 50,000ft

The instrument should be protected from temperature extremes which cause condensation inside the instrument.

2-26. Packaging.

2-27. Original Packaging. Containers and materials identical to those used in factory packaging are available through Hewlett-Packard offices. If the instrument is being returned to Hewlett-Packard for servicing, attach a tag indicating the type of service required, return address, model number, and full serial number. Also mark the container FRAGILE to assure careful handling. In any correspondence, refer to the instrument by model number and full serial number.

2-28. Other Packaging. The following general instructions should be used for re-packing with commercially available materials:

- a. Wrap instrument in heavy paper or plastic. If shipping to Hewlett-Packard office or service center, attach tag indicating type of service required, return address, model number, and full serial number.

- b. Use strong shipping container. A double-wall carton made of 350 pound test material is adequate.

- c. Use enough shock absorbing material (3 to 4 inch layer) around all sides of instrument to provide firm cushion and prevent movement inside container. Protect control panel with cardboard.

- d. Seal shipping container securely.

- e. Mark shipping container FRAGILE to ensure careful handling.

- f. In any correspondence, refer to instrument by model number and full serial number.

Section II Figure 2-2

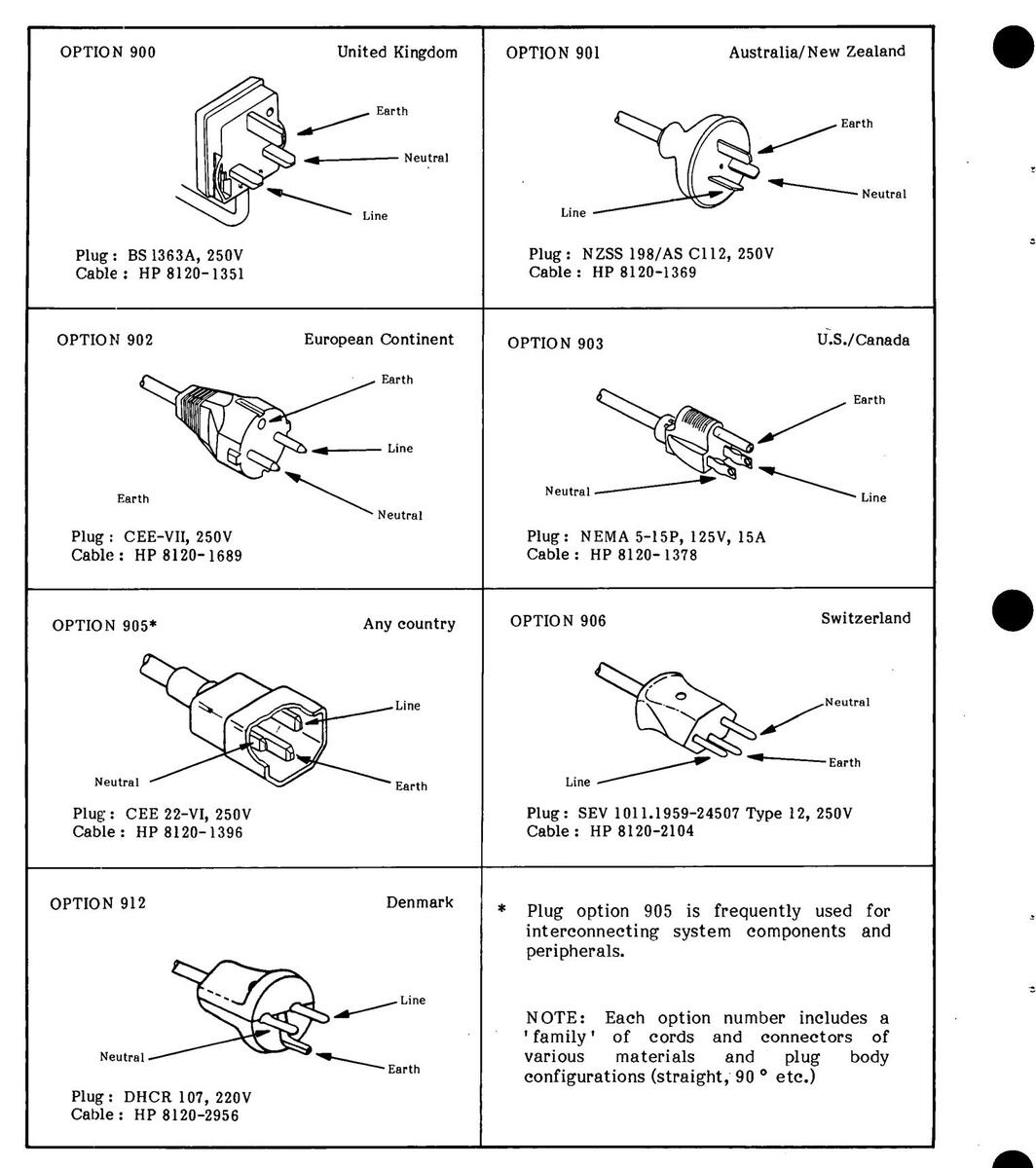

Figure 2-2. Power Cables Supplied.

| Option |

Kit

Part Number |

Parts Included | Pårt Number | Q'ty | Remarks |

|---|---|---|---|---|---|

| 907 |

Handle Kit

5061-0089 |

Front Handle

Trim Strip #8-32 x 3/8 Screw |

(3) 5060-9899

(4) 5060-8896 2510-0195 |

2

2 6 |

9.525mm |

| 908 |

Rack Flange Kit

5061-0077 |

Rack Mount Flange

#8-32 x 3/8 Screw |

② 5020-8862

2510-0193 |

2

6 |

9.525mm |

| 909 |

Rack Flange &

Handle Kit 5061-0083 |

Front Handle

Rack Mount Flange #8-32 x 3/8 Screw |

(3) 5060-9899

(5) 5020-8874 2510-0194 |

2

2 6 |

15.875mm |

- 1. Remove adhesive-backed trim strips (1) from side at right and left front of instrument.

- 2. HANDLE INSTALLATION: Attach front handle ③ to sides at right and left front of instrument with screws provided and attach trim ④ to handle.

- 3. RACK MOUNTING: Attach rack mount flange (1) to sides at right and left front of instrument with screws provided.

- 4. HANDLE AND RACK MOUNTING: Attach front handle ③ and rack mount flange ⑤ together to sides at right and left front of instrument with screws provided.

- 5. When rack mounting (3 and 4 above), remove all four feet (lift bar at inner side of foot, and slide foot toward the bar).

Figure 2-3. Rack Mount Kit

2-29. OPTION INSTALLATION.

2-30. When it is desired to add one or two of the available optional features to a standard 4262A instrument, perform the installation as follows:

Refer to option installation illustrations on facing page.

- a. Push LINE switch to off.

- b. Remove instrument top cover.

- c. Follow the appropriate paragraph below.

-

2-31. OPTION 001 BCD DATA OUTPUT INSTALLATION.

- a. Remove the left side middle and lower blind covers from the rear panel.

- b. Install two 50-pin connector assemblies in the openings.

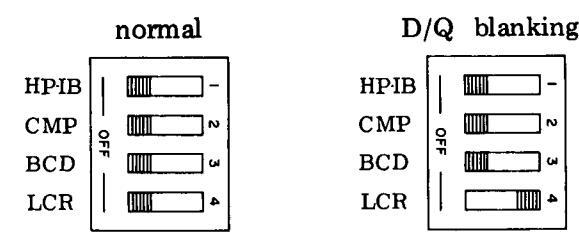

- c. Set BCD switch of SW1 on A23 board assembly (RED/ORANGE GUIDE, P/N: 04262-66523 or 04262-66623) from OFF to opposite position. This board is located third from front on the right side.

- d. Connect cable attached to A23 board (shown below) between A23 and A35 BCD Option board assemblies (P/N: 04262-66535). Install A35 in RED/GREEN GUIDE option receptacle.

- e. Plug 2 each flat cable assemblies from A35 BCD Option board into connector boards of rear panel connector assemblies.

- f. Install instrument top cover.

2-32. OPTION 004 COMPARATOR INSTALLATION.

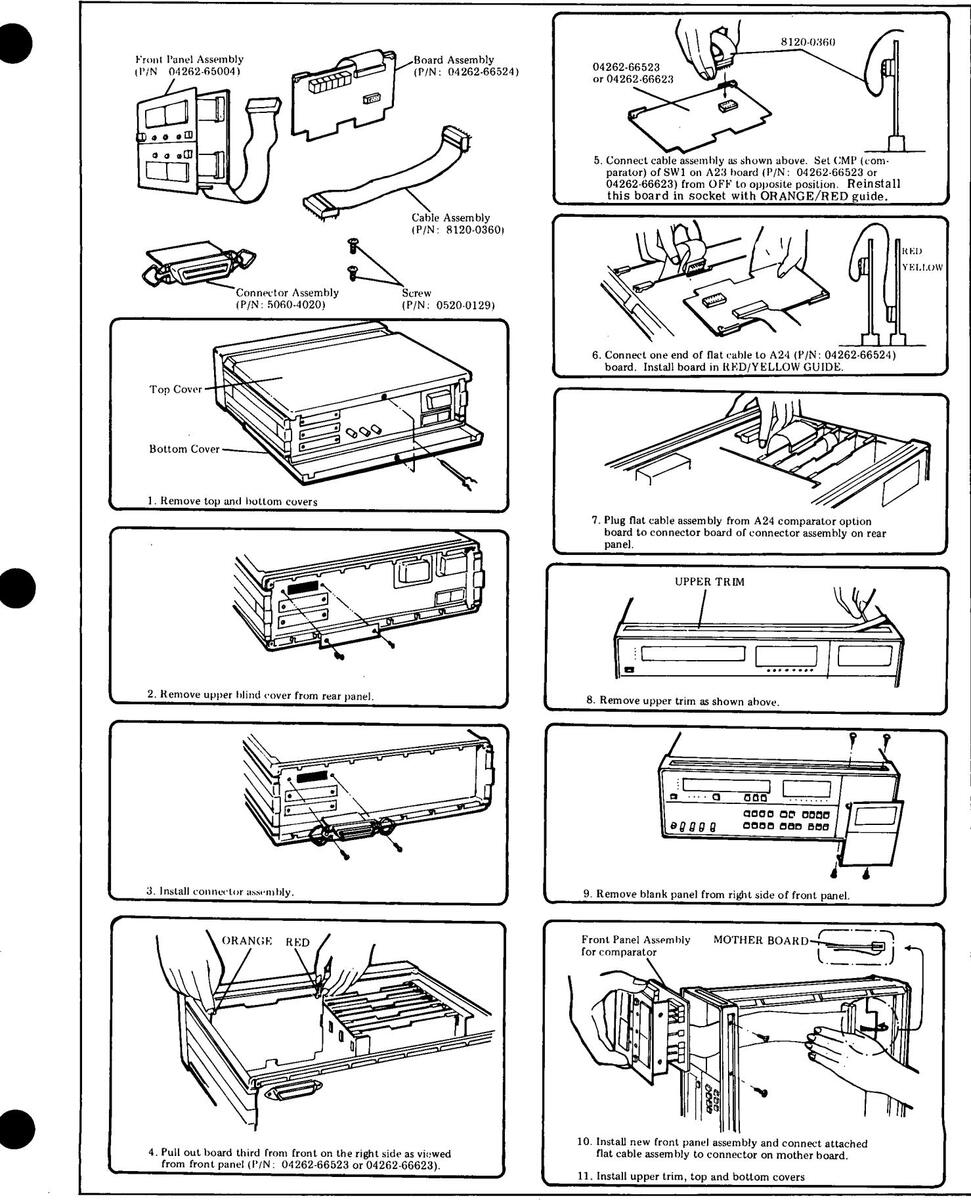

Refer to Fig 2-4 for installation procedure.

-

2-33. COUPLING OPTION 004 COMPARATOR WITH OPTION 001 BCD DATA OUTPUT INSTALLATION.

- a. Set CMP (comparator) and BCD option switches of SW1 ON A23 board assemblies (RED/ORANGE GUIDE, P/N: 04262-66523 or 04262-66623) from OFF to opposite position. This board is located third from front on the right side.

- b. Connect cables attached to A23 board between A23 and A24 comparator option BCD board assembly. No other cable assembly change is necessary for this combination of options.

- c. Refer to Paragraphs 2-31 and 2-32 for other installation procedures.

-

2-34. OPTION 101 HP-IB REMOTE CONTROL AND DATA OUTPUT INSTALLATION.

- a. Remove right side blind covers from rear panel.

- b. Install connector board assembly (P/N: 04262-66503) in the opening and mount with washers and nuts included with assembly.

- c. Set the HP-IB switch of SW1 on A23 board assembly from OFF to opposite position. The A23 board is located on the right side third from front.

- d. Connect cable assembly attached to A25 board between A23 and A25 HP-IB option board assemblies (P/N: 04262-66525). Install A25 in RED/GREEN GUIDE option receptacle.

- e. Plug flat cable assembly from connector board assembly P/N: 04262-66503 into A25 board assembly (installed in RED/GREEN GUIDE receptacle).

OPTION 101 IS NOT COMPATIBLE WITH OPTIONS 001 AND 004.

Figure 2-4. Option Installation Illustrations.

| Onting | E un et i en | Components | ||||||

|---|---|---|---|---|---|---|---|---|

| HP Part No. | Q'ty | Description | ||||||

| 001 |

BCD Data

Output |

04262-66535

5060-4020 8120-0360 |

1

2 1 |

A35 Board Assembly

Connector Board Assembly Flat Cable Assembly |

||||

| 004 | Comparator |

04262-66544

04262-66505 04262-66524 3100-1201 5060-4020 8120-0360 04262-24003 |

1

1 2 1 1 1 |

A4 Board Assembly

A5 Board Assembly A24 Board Assembly Thumbwheel Switch Connector Board Assembly Flat Cable Assembly Standoff |

||||

| 010 |

100Hz Test

Frequency |

04262-66911

04262-66914 |

1

1 |

All Board Assembly

Al4 Board Assembly |

||||

| 101 | HP-IB |

04262-66525

04262-66503 8120-0360 0380-0644 |

1

1 1 2 |

A25 Board Assembly

A3 Board Assembly Flat Cable Assembly Stud for A3 Board Assemlby |

||||

Table 2-1. Option Components

Note: To mount Connector Board assemblies, use rear panel blank plate retaining screws (Part No. 0520-0129) removed for the option installation.

SECTION III OPERATION

3-1. INTRODUCTION.

3-2. This section provides the operating information to acquaint the user with the 4262A LCR Meter. Basic product features and characteristics, measurement procedures for various applications, an operational check of the fundamental electrical functions, and operator maintenance information is presented in this section. Operating cautions throughout the text should be carefully observed.

3-3. PANEL FEATURES.

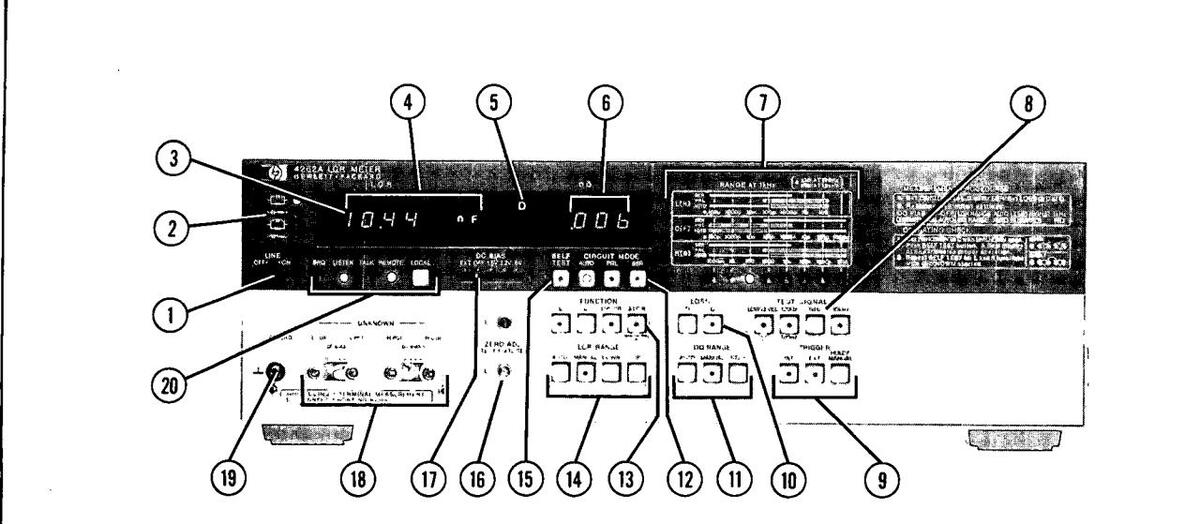

3-4. Front and rear panel features for the 4262A are described in Figures 3-1 and 3-2. Description numbers match the numbers on the photographs. Other detailed information for panel displays and controls are covered in the Operating Instructions (paragraph 3-7).

3-5. SELF TEST (Basic Operating Check).

WARNING

ANY INTERRUPTION OF THE PROTECTIVE GROUNDING CON-DUCTOR INSIDE OR OUTSIDE THE INSTRUMENT OR DISCON-NECTION OF THE PROTECTIVE EARTH TERMINAL IS LIKELY TO CAUSE THE INSTRUMENT TO BE DANGEROUS. INTENTIONAL INTERRUPTION IS PROHIBITED.

WARNING

WHENEVER IT IS LIKELY THAT THE PROTECTION OFFERED BY FUSES HAS BEEN IMPAIRED, THE INSTRUMENT MUST BE MADE INOPERATIVE AND BE SECURED AGAINST ANY UNIN-TENDED OPERATION.

BEFORE ANY OTHER CONNEC-TION IS MADE, THE PROTEC-TIVE EARTH TERMINAL MUST BE CONNECTED TO A PROTEC-TIVE GROUNDING CONDUCTOR.

3-6. Functional operation of the Model 4262A should be confirmed by the SELF TEST switch before measuring samples of interest. This test can

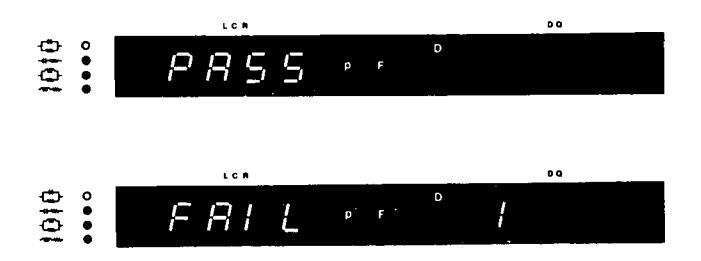

be done under all conditions of FUNCTION and TEST SIGNAL settings. Tests under certain combined conditions of FUNCTION and TEST SIGNAL settings are done for five ranges. A test for a range ends with a display of PASS (normal operation) or FAIL (abnormal operation) and then next range test is started. Range shifting for this test is done automatically from lower to higher.

All the combinations of FUNCTION and TEST SIGNAL switch settings are listed below. Even if the FUNCTION or TEST SIGNAL switch settings are limited for proposed sample measurement, all combined conditions should be tested.

| Pushbutton Switch Setting * |

UNKNOWN**

Connectors |

|---|---|

|

(

C

), (

120Hz

), (

SELF TEST

)***

(C), ( 1 kHz ), ( SELF TEST ) (C), ( 10 kHz ), ( SELF TEST ) |

Open between

HIGH side and Low side |

|

|

|

(

L

), (120 Hz), (

SELF TEST

)

(L), ( 1 kHz ), ( SELF TEST ) (L), ( 10 kHz ), ( SELF TEST ) |

Short between

HIGH side and LOW side. |

|

(

R⁄ESR

), (10 kHz), (

SELF TEST)

(R∕ESR), ( 1 kHz ), ( SELF TEST ) (R∕ESR), ( 120Hz ), ( SELF TEST ) |

* When FUNCTION or TEST SIGNALS switch setting is changed, the SELF TEST switch is automatically disabled. Therefore, whenever a new setting is made, push the SELF TEST switch again.

For ** see page 3-5

- ① LINE ON/OFF switch: Turns instrument on and readies instrument for measurement

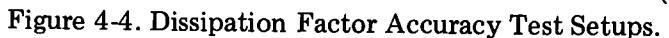

- Circuit Mode Indicator: LED lamp, next to equivalent measuring circuit being used, lights. Sample connected to UNKNOWN terminals (18) is measured in an equivalent circuit selected by FUNCTION (13) and CIRCUIT MODE (12) switches and is indicated by appropriate LED lamp. Equivalent circuits are shown as electronic circuit symbols at the left of indicator lamps. Desired circuit parameter of component is measured in one of the following selected circuit modes:

|

Parallel capacitance

Parallel resistance |

- C |

|---|---|

|

Series capacitance

Series resistance |

|

| Parallel inductance | -[**-] |

|

Series inductance

Series resistance |

-787-444- |

Trigger Lamp: Turns on during sample measuring period. Turns off during period when instrument is not taking measurement (or hold period). There is one turn-on-and-off cycle per measurement. This lamp turns on and off repeatedly when TRIGGER (9) is set to INT.

- LCR Display: Inductance, capacitance or resistance value including the decimal point and unit is displayed in 3-½ digit decimal number from 0000 to 1999. If the sample value exceeds 1999 in a selected range, O-F(Over-Flow) appears in this display. This display also shows PASS or FAIL when SELF TEST is performed.

- D/Q Indicator: In a capacitance or inductance measurement, this indicator indicates which of D (dissipation factor) or Q (quality factor) is displayed in D/Q display 6. In resistance measurement, this indicator is also lit (however, D or Q indication has no meaning and D/Q display 6 is left blank).

- (6) D/Q Display: Value for dissipation factor or quality factor is displayed in capacitance and/or inductance measurement. In resistance measurement, this display is kept blank.

- (1) RANGE Indicator: The range automatically or manually selected is indicated by LED lamp. The table printed above the LED array shows the measurement ranges of the Model 4262A.

- TEST SIGNAL These pushbuttons enable selection of measurement frequency—120Hz, 1kHz or 10kHz and that of low test voltage of the signal applied to sample to be tested. LOW LEVEL switch is effective only in parallel capacitance measurements, supplying a test voltage of 50mVrms. For units equipped with option 010, arrow on pushbutton (120Hz) points to 100Hz.

- IRIGGER: These pushbuttons select trigger mode, INT, EXT or HOLD/MANUAL. INT key provides internal trigger which enables instrument to make repeated automatic measurements. In external trigger mode (EXT), trigger signal should be applied to either of following two connectors: (1) EXT TRIGGER input connector on the rear panel (2) 50 pin connector of Option 001 or 004 on the rear panel. HOLD/MANUAL trigger mode provides trigger signal for one measurement cycle when this key is depressed.

- LOSS: These pushbuttons select whether D or Q value is displayed in the D/Q display (6) in capacitance or inductance measurements.

- D/Q RANGE: These pushbuttons select ranging method for loss measurement. AUTO: Optimum D/Q range is selected by internal logic circuit. MANUAL: D/Q range is fixed to a range. Range change is done by depressing the STEP key on the right.

- (1) CIRCUIT MODE: Appropriate circuit mode for taking a measurement is selected and set with these pushbuttons. A parallel equivalent circuit is selected by PRL key and series equivalent circuit by SER key. When AUTO key is pushed, the instrument automatically selects the appropriate parallel or series equivalent circuit.

-

(13) FUNCTION: These pushbuttons select electrical circuit parameter to be measured as follows:

- C: Capacitance together with dissipation factor (D) or quality factor (Q).

- L:Inductance with dissipation factor (D) or quality factor (Q).

- R/ESR: Resistance or Equivalent Series Resistance.

- △LCR: Difference in L, C, or R value between the value of the sample under test and the internally stored value obtained by a measurement just before △LCR key is depressed.

-

(1) LCR RANGE: These pushbuttons select ranging method for LCR measurement.

- AUTO: Optimum range for the sample value is automatically selected.

- MANUAL: Measurement range is fixed (even when the sample connected to the UNKNOWN terminals is changed). Range change is done by depressing DOWN or UP key on the right.

- (15) SELF TEST: This pushbutton performs automatic check for checking the basic operation of Model 4262A. If normal operation is confirmed, "PASS" is displayed in LCR display ④. If wrong performance is detected, a display of "FAIL" appears. See paragraph 3-5 for details.

- (B) ZERO Adjustment Controls: These adjustments provide proper compensation for cancelling stray capacitance and residual inductance which are present when a test fixture is mounted on the UNKNOWN terminals. Connectors are kept open for cancelling stray capacitance and shorted for cancelling residual inductance.

- 1) DC BIAS Selector Switch: This switch permits selection of internal DC bias voltage applied to sample (1.5Vdc, 2.2Vdc, or 6.0Vdc). When switch is set to EXT, it is used to apply external bias voltage from rear DC BIAS input connectors. OFF position is selected if no bias voltage is necessary.

- (B) UNKNOWN Terminals: Consist of four terminals: High current terminal (Hcure), High potential terminal (HPOT), Low potential terminal (LPOT) and Low current terminal (LCUR). A five-terminal configuration is constructed by adding the GUARD terminal (9). A three-terminal configuration is constructed by shorting High terminals and Low terminals together with shorting bars. Under DC Bias operation, the high terminals have a positive DC voltage with respect to LOW terminals.

- (9) GUARD Terminal: This is connected to chassis ground of instrument and can be used as Guard terminal for increasing accuracy in certain measurements.

- (2) HP-IB Status Indicator and LOCAL switch. LED lamps for SRQ, LISTEN, TALK, and REMOTE which indicate status of interface between the 4262A (Option 101) and HP-IB controller. LOCAL switch enables front panel controls instead of remote control signals from HP-IB line.

** Two HIGH side terminals and two LOW side terminals should be connected with the shorting strap, for each configuration of the UNKNOWN terminals. When the UNKNOWN terminal configuration is not appropriate, for example, shorted (C) or open (L), display will show FAIL 1 (because they result from different causes, FAIL 2 or FAIL 3 are rarely displayed).

*** Setting change required is only the underlined switch setting.

If FAIL is displayed, check the UNKNOWN terminal configurations as follows:

- (1) That the two HIGH side terminals (HCUR HPOT) and the two LOW side terminals (LCUR LPOT) are properly shorted.

- (2) That short or open conditions properly exist between HIGH and LOW side terminals.

- (3) That GUARD terminal is isolated (open) from both of HIGH and LOW terminals.

If FAIL is still displayed (under the above condition), notify the nearest Hewlett-Packard office with information detailing which combination of settings show FAIL.

During SELF TEST, other controls are automatically set as follows:

| CIRCUIT MODE | SER when FUNCTION |

|---|---|

| is set to L or R/ESR. | |

| PRL when FUNCTION | |

| is set to C. | |

| LOSS | D |

| LCR RANGE | |

| D/Q RANGE | MANUAL |

| TRIGGER | INT |

NOTE

TO ENSURE CORRECT RESULTS OF SELF-TEST OPERATION IN L AND R MEASUREMENT FUNCTIONS, CON-NECT ALL (HIGH AND LOW SIDE) UN-KNOWN TERMINALS TOGETHER WITH A LOW IMPEDANCE STRAP (IF THIS SHORT-CIRCUIT IS MADE AT THE ENDS OF THE TEST LEADS, COR-RECT RESULTS MAY NOT OCCUR).

3-7. TEST SIGNALS.

3-8. Three test signal frequencies are available: these are 120Hz, 1kHz and 10kHz sinusoidal waveforms which have a frequency accuracy of 3%. The typical voltage applied to the sample or current flowing through the sample is specified in Table 3-1 for all test signal frequencies. A constant test voltage is supplied to the sample when measuring parallel parameters Lp, Cp, and Rp. The constant current method is adopted for the measurement of Ls, Cs, and Rs. The 50mVrms test voltage is used only for Cp measurement.

3-9. MEASUREMENT RANGE.

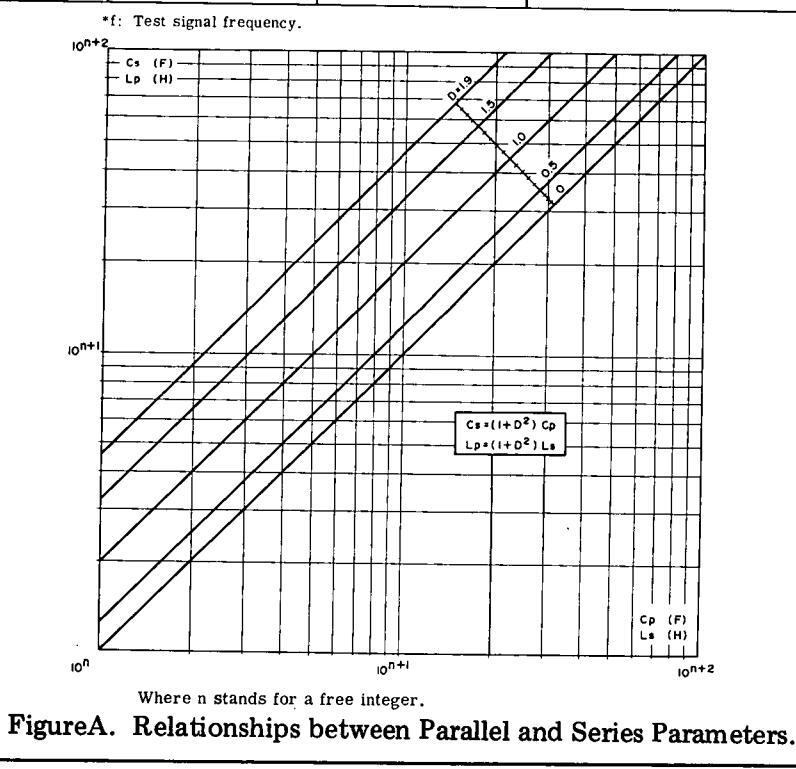

3-10. As given in Table 3-2, the 4262A has wide measurement ranges. Seven or eight ranges are available (depending upon measurement function) and the appropriate range is automatically selected for the value of sample connected to the 4262A UNKNOWN terminals. For applications which require a fixed measurement range (such applications are sometimes needed for example in inductance measurements) manual range control is pushbutton selectable. Four or five ranges, however, are used in the series and parallel equivalent circuit measurement modes. When the CIRCUIT MODE is set to AUTO, the 4262A will automatically select the appropriate circuit mode, range over the measurement ranges shadowed in Table 3-2, settle on the proper range, and measure the sample.

Table 3-1. Sample Voltage or Current.

| PANCE | CIRCUIT | MODE | ||||

|---|---|---|---|---|---|---|

| RANGE | Ls | Lp | Cs | Ср | Rs | Rp |

| 1 | 40mA rms | 1Vrms(50mVrms)* | 40mA rms | |||

| 2 | 10mA rms | _ | 1Vrms (50mVrms)* | 10mA rms | ||

| 3 | 1mA rms | 1Vrms(50mVrms)* | 1mA rms | |||

| 4 | 100 µA rms | 1V rms | 10 µA rms | lVrms (50mVrms)* | 100 µA rms | 1V rms |

| 5 | 10 µA rms | 1V rms | 100 µA rms | 1Vrms (50mVrms)* | 10 µA rms | 1V rms |

| 6 | 1V rms | 1 μA rms | 1V rms | |||

| 7 | 1V rms | 10mA rms | 1V rms | |||

| 8 | 40mArms | 1V rms |

*When TEST SIGNAL is set to LOW LEVEL.

| CIRCUIT | TEST | Ra | inge | ||||||

|---|---|---|---|---|---|---|---|---|---|

| MODE | Frequency | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Lp |

120 Hz

1 kHz 10 kHz |

0000 mH

000.0 mH 00.00 mH |

00,00 H

0000 mH Hm 0,000 |

000.0 H

00.00 H 0000mH |

0000 H

000.0 H 00.00 H |

||||

| Ls |

120 Hz

1 kHz 10 kHz |

14 0000

Hμ 0.000 Hμ 00.00 |

00,00 mH

0000 μH 000,0 μH |

000,0mH

00,00mH 0000 μH |

0000 mH

000.0 mH 00.00 mH |

00.00 H

0000 mH 000.0 mH |

|||

| Ср |

120 Hz

1 kHz 10 kHz |

0000 pF

000.0 pF 00.00 pF |

00.00 nF

0000 pF 000.0 pF |

000.0 nF

00.00 nF 0000 pF |

0000 nF

000.0 nF 00.00 nF |

00.00 μF

0000 nF 000.0 nF |

|||

| Cs |

120 Hz

1 kHz 10 kHz |

0000 nF

000.0 nF 00.00 nF |

00.00 μF

0000 nF 000.0 nF |

000.0μF

00.00μF 0000 nF |

0000 μF

000.0 μF 00.00 μF |

00,00mF

0000 μF 000.0 μF |

|||

| Rp |

120 Hz

1 kHz 10 kHz |

Ω 0000

Ω 0000 Ω 0000 |

00.00 kΩ

00.00 kΩ 00.00 kΩ |

000.0 kΩ

000.0 kΩ 000.0 kΩ |

0000 kΩ

0000 kΩ 0000 kΩ |

00,00 ΜΩ

00,00 ΜΩ 00,00 ΜΩ |

|||

| Rs |

120 Hz

1 kHz 10 kHz |

Ωm 0000

Ωm 0000 Ωm 0000 |

Ω 00.00

Ω 00.00 Ω 00.00 |

000.0Ω

000.0Ω 000.0Ω |

Ω 0000

Ω 0000 Ω 0000 |

00.00 kΩ

00.00 kΩ 00.00 kΩ |

|||

| Note: 0 | 0000µH inc | licates a ra | inge of 000 | )1µH to 19 | 99µH ( an | d similarly | for F and | Ω). |

Table 3-2. Measurement Ranges.

Model 4262A

3-11. INITIAL DISPLAY TEST.

3-12. The Model 4262A automatically performs a front panel LED display test for a few seconds after instrument is tuned on (after LINE button is depressed). The display test sequence is:

- 1. All front panel indicator lamps, except numeric segments and multiplier indicator lamps will illuminate. (SRQ, LISTEN, TALK and REMOTE lamps illuminate only when HP-IB option is installed).

- 2. Front panel pushbutton LED's and indicator lamps indicate that automatic initial settings (see Paragraph 3-13 which follows) have been set. Simultaneously, the LCR DISPLAY and DQ DISPLAY readouts are tested. All numeric displays show figures of 8 ( ) and multiplier indicators (p n μ m k M) light in turn.

- 3. Range indicator lamps step from right (upper range) to left (lower range). When steps 1, 2 and 3 have been completed, the trigger lamp begins to flash. Figures on numeric displays change to meaningful numbers showing that the 4262A is ready to take a measurement.

3-13. INITIAL CONTROL SETTINGS.

3-14. One of the sophisticated features of the 4262A is its automatic initial control setting function. After the instrument is turned on, the front panel control functions are automatically set as follows:

| SELF TESTOFF | |

|---|---|

| CIRCUIT MODE AUTO | |

| FUNCTIONC | |

| LCR RANGE AUTO | |

| LOSS D | |

| DQ RANGE AUTO | |

| TEST SIGNAL 1kHz | |

| TRIGGER INT |

As these initial settings provide the general capacitance measurement conditions applicable to a broad range of capacitance measurements, a capacitance can be usually measured by merely connecting the sample to the UNKNOWN terminals. Inductance or resistance can be measured by pressing the L FUNCTION or R/ESR FUNCTION buttons, as appropriate. When a different measurement is to be attempted, press appropriate pushbuttons and select desired functions.

3-15. D/Q MEASUREMENT.

3-16. The Model 4262A makes a loss measurement along with capacitance or inductance measurements on each measurement cycle. The measured loss factor is displayed in the form of the dissipation (D) or quality (Q) factor of the sample. The D or Q function is pushbutton selectable in both L and C measurements. D and Q measurement ranges are:

| D: | 2 ranges | .001 to 1.999 |

|---|---|---|

| - | 0.01 to 19.9 | |

| Q: | 4 ranges | .050 to 1.996 |

| 0.05 to 19.61 | ||

| .00.1 to 166.7 | ||

| 001 to 1000 |

The D range, appropriate to the value of the sample is automatically selected. Alternately, a manual D range control is pushbutton selectable. Quality factor (Q) is calculated as a reciprocal dissipation number from the measured D value. Hence, the Q readout display will skip some numbers when low dissipation samples are measured. For example, when the dissipation measured is .010, the quality factor display is 100. When dissipation is .009, the quality factor reading is 111 (Q readings of 101 to 110 are not obtained). On the high D measurement range, the readout is displayed in 3 digits.

3-17. △ LCR MEASUREMENT.

3-18. When many components of similar value are to be tested, it is sometimes more practicable to measure the difference between the value of the sample and a predetermined reference value. The △LCR function permits repetitive calculation of the difference between the reference and each individual sample and to display the result on the LCR DISPLAY. When the ALCR FUNCTION button is pressed, the inductance, capacitance, or resistance value of the sample is stored in an internal memory. The 4262A will now display the difference between the stored value and the measured value of a sample connected to UNKNOWN. The LCR RANGE is automatically held in MANUAL for the duration of ALCR measurements (if another pushbutton is inadvertently pressed, the ALCR measurement function will be reset and will require reactivating).

| Section | ш |

|---|---|

| Figure | 3-3 |

| Accessory Model | Characteristics | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 16061A Test Fixture |

This fixture facilitates easy measurement of general

type components with axial or vertical leads. To install fixture, disconnect shorting bars between high terminals and between low terminals. Insert fix- ture screws to firmly attach fixture to instrument. Two kinds of inserts are included (for components with either axial or vertical leads). |

l

n fix- |

|||||||||

| D | UT ra |

inge (a

F |

at 1k |

Hz)

n |

F | μF | |||||

| e entre |

μ

S |

H

2 1 |

0 1 |

m

00 k |

Η

Ω + |

10 1 | 00 N |

Η

/Ω |

10 1 | .00 | |

| 1 | С | ||||||||||

| Five terminal construction test fixture. |

L

R |

||||||||||

| 16062A Test Leads | T |

|

he 16 |

|

062A |

is esp |

pecial |

|

ly use |

|

ful wl |

hen m | neasu |

ring le |

bw |

|

in

ar m 10 po |

npeda

e diag ore th 00µH otenti leasur |

nces.

gramm aan ap at 1 k al lead able E bF |

DUI

ped b prox Hz, if ds and DUT 1 |

value

elow. . 300/ ; is red d curr canges n m |

es me

If th uF at comm ent le (at 1 uF |

asurai

e mea 1kHz endec ads b kHz) |

ble wi

isurin or le d that e twis |

uth the same set of the set of th |

ae 160

nple is an app respec cogeth |

orox.

etive er. |

|

| _ | Ω 1 | 0 1 | 00 k |

Ω :

| |

00 N |

/Ω

| |

10 1 | 00 | |||

| Test Leads for four terminal measurement (does not contain guard conductor). |

L

R |

||||||||||

| 16063A Test Leads The 16063A is particularly useful when measuring impedances. DUT values measurable with the 16 are diagrammed below. This test lead set is not in tended to be used for the accurate measurement small capacitances (less than approx. 100pF) due the residual capacitance of the leads. Measurable DUT ranges (at 1kHz) pF nF μF U mH H |

suring

le 160 not in- nent o due t |

high

63A f :0 |

|||||||||

| c |

μ

S |

1 1 | 0 1 | .0 1( | 10 1 | 00 | |||||

| Coaxial test leads with guard conductor | L | - | - | + | |||||||

| for three terminal measurement. | R | ╞ | |||||||||

Figure 3-3. Test Fixture and Leads.

3-19. D/Q Blanking Function (Switch selectable function inside cabinet).