Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Page 2

Errata

Title & Document Type: 41952A/B Transmission/Reflection Operating Note

Title & Document Type: 41952A/B Transmission/Reflection Operating Note

Manual Part Number: 41952-90000

Manual Part Number: 41952-90000

Revision Date: December 1988

Revision Date: December 1988

About this Manual

About this Manual

We've added this manual to the Agilent website in an effort to help you support your

We’ve added this manual to the Agilent website in an effort to help you support your

product. This manual provides the best information we could find. It may be incomplete

product. This manual provides the best information we could find. It may be incomplete

or contain dated information, and the scan quality may not be ideal. If we find a better

or contain dated information, and the scan quality may not be ideal. If we find a better

copy in the future, we will add it to the Agilent website.

copy in the future, we will add it to the Agilent website.

HP References in this Manual

HP References in this Manual

This manual may contain references to HP or Hewlett-Packard. Please note that Hewlett-

This manual may contain references to HP or Hewlett-Packard. Please note that Hewlett-

Packard's former test and measurement, life sciences, and chemical analysis

Packard's former test and measurement, life sciences, and chemical analysis

businesses are now part of Agilent Technologies. The HP XXXX referred to in this document is

businesses are now part of Agilent Technologies. The HP XXXX referred to in this document is

now the Agilent XXXX. For example, model number HP8648A is now model number Agilent

now the Agilent XXXX. For example, model number HP8648A is now model number Agilent

8648A. We have made no changes to this manual copy.

8648A. We have made no changes to this manual copy.

Support for Your Product

Support for Your Product

Agilent no longer sells or supports this product. You will find any other available

Agilent no longer sells or supports this product. You will find any other available

product information on the Agilent Test & Measurement website:

product information on the Agilent Test & Measurement website:

www.aqilent.com

www.agilent.com

Search for the model number of this product, and the resulting product page will guide

Search for the model number of this product, and the resulting product page will guide

you to any available information. Our service centers may be able to perform calibration

you to any available information. Our service centers may be able to perform calibration

if no repair parts are needed, but no other support from Agilent is available.

if no repair parts are needed, but no other support from Agilent is available.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 3

HP 41452A/la

TRANSMISSION/REFL1aCTION

TEST SET

•

1114. 19118

9/VZ56 I ta dH

Ipal HEWLETT

PACKARD

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

WARRA NTY AND ASSISTANCE '

All Hewlett-Packard products are warranted against defects In materials and

workmanship. This warranty applies for one year from the,date of delivery, or, in

the case of certain major components listed in the operating manual, for the

specified,perlod. We will repair or replac6, products which prove to be defective

during the warranty period provided they are returned to Hewlett-Packard. No

other warranty is expressed or implied. We are not liable for consequential

damages:

For any assistance, contact your nearest Hewlett-Packard Sales and Service

Office. Addresses are provided at the back of this manual.

1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 5

HEWLETT

PACKARD

OPERATION NOTE,

MODEL 41952A/I3

TRANSMISSION/REFLECTION

TEST SET

SERIAL NUMBERS

This manual applies directly to HP 41952A or HP 41952B Transmis-

sion/Reflection Test Set with serial number prefixed 2850J.

.0 COPYRIGHT: YOKOGAWA-HEWLETT-PACKARD, LTD„ 1988

9.1, TAKAKURA-CHO, HACHIOJI•SHI, TOKYO, JAPAN

Manual Part Number: 41952-90000

Microfiche Part Number: 41952-90050 Printed: December 1988

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 6

TABLE ,,OF CONTENTS

ri

SECTION 1:

"

GENERAL INFORMATION

INTRODUCTION

PRODUCT DESCRIPTION

SAFETY CONSIDERATIONS

UNITS COVERED BY THIS OPERATION NOTE

PRODUCT CONTENTS

SPECIFICATIONS

ACCESSORIES AVAILABLE

SECTION 2: INSTALLATION

I

I

'I

SECTION CONTENTS

INITIAL INSPECTION

ENVIRONMENTAL REQUIREMENTS

PACKAGING

Original Packaging

Other Packaging

110111111111111.111111111111

SECTION 3:'

OPERATION

SECTION CONTENTS 3-1

OVERVIEW 3-1

OPERA TOR'S CHECK 3-4

TYPICAL MEASUREMENT SETUPS 3-6

Transmission/Reflection Measurements 3-7

S-Parameter Measurements 3-9

CALIBRA TION CONSIDERATIONS 3-11

SECTION 4:

I

PERFORMANCE TESTS

'INTRODUCTION

EQUIPMENT REQUIRED

CALIBRATION CYCLE

PREPARATION

DIRECTIVITY TEST.

EFFECTIVE SOURCE MATCH TEST

PORT MATCH TEST, '

2-1

2-1

2-3

2-3

2-3

2-3

4-1

4-1

4-2

4-2

4-5

4-9

4-13

1.1

SECTION 5:

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

SERVICE

INTRODUCTION 5-1

REPLACEABLE PARTS 5-1

Page 7

GENERAL INFORIVIATION

SECTION 1

INTRODUCTION This section provides the specification and the InforrhaZion neces-

' sary for receiving, performing an incoming Inspec',Ion, preparing

the HP 41952A/8 for use.

11113111111111111111101111111111

PRODUCT

DESCRIPTION The HP 41952A and HP 41952B Transmission/Reflection Test

Sets are used with the HP 4195A to perform both transmission

and reflection measurements. The HP 41952A Is used for 50(1

applications and the HP 41952B is used for 75n applications.

Using two HP 41952A or HP 41952B test sets, full ¶meter

measurements can be performed. The following are the main

feature of the HP 41952A/B.

• Frequency rat* : 100 kHz to 500 MHz

• Directivity : 40 dB (HP 41952A, 300 kHz to 200 MHz)

• Effective Source Match : Z 20 dB (300 kHz)

• Direct connection to the HP 4195A

• •

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

1.1111111111111111111411=11

SAFETY

CONSIDERATIONS The HP 41952A/B Transmisslon/Reflection Test Sets conform to

the safety requiremcnts for IEC 348, and CSA 556B instruments,

and is 'shipped from the factory in a safe condition. This opera-

tion note contains information, CAUTIONS and WARNINGS which

must be followed by the user to ensure safe operation,

UNITS COVERED BY

THIS OPERATION

NOTE

Hewlett-Packard uses a two-part, nine character serial number

which is stamped on the serial number plate (see Figure 1-1)

attached to the inside of the carrying case. The first four digits

and a letter are the prefix and the last five digits are the suffix of

the serial number, The letter in the serial, number identifies the

country where the instrument was manufactured. The prefix is

same for all identical instruments, it changes only when a change

Is made to the instrument. The suffix, however, is assigned

sequentially and is different for each Instrument. This operation

note applies to instruments with serial number prefixes listed

under Serial Numbers on the title page.

Figure 1-1. Serial Number Plate

Units manufactured after this operation note was printed may

have a serial number prefix which is not listed on the title page.

An unlisted serial number prefix indicates that the instrument may

be different from those described in this operation note. Opera-

tion notes for new instruments may be accompanied by a yellow

Manual Supplement page, or have a different part number, This

supplement contains "Change Information" explaining how to

adapt this operation note to newer instruments.

1-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 9

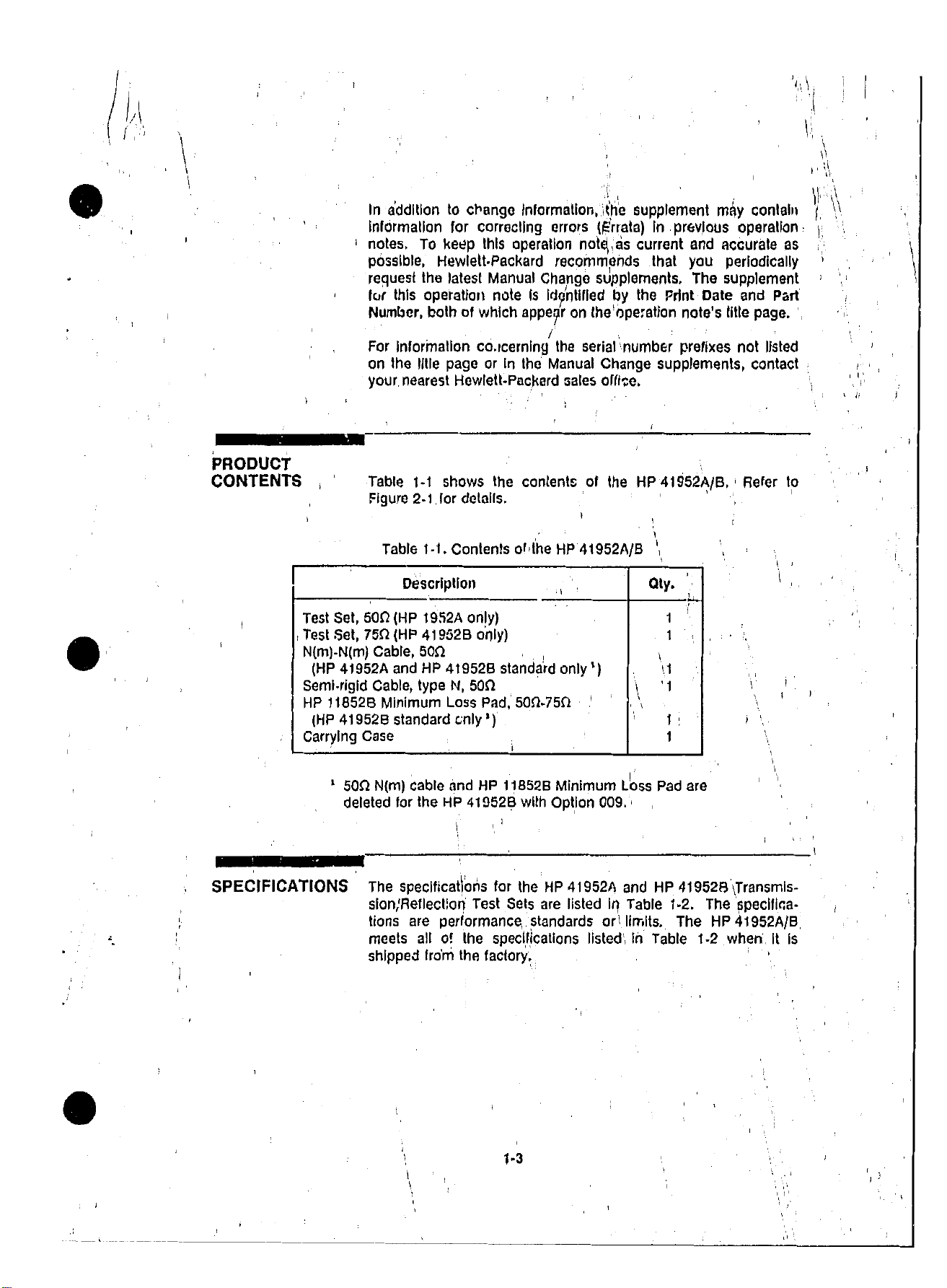

PRODUCT

CONTENTS ,

Te st Set, 500 (HP 1952A only)

Te st Set, 7552 (HP 41952B only)

N(m)-N(m) Cable, 5052

Semi-rigid Cable, type N, 5052

HP 118 52B Minimum Loss Pad. 5052-7551

Carrying Case

In addition to change information, ,t'he supplement may contain (,

information for correcting errors (gnats) in previous operation r,

notes, To keep this operation notiA,as current and accurate as

possible, Hewlett-Packard recommends that you periodically

request the latest Manual Change supplements. The supplement

fur this operation note is id?ntifled by the Print Date and Part

Nur*3er, both of which eppeF on the'opEation note's title page. ',

For information co.icerning the serial 'number prefixes not listed

on the title page or In the Manual Change supplements, contact

your. nearest Hewlett-Packard sales offie.

Ta ble 1-1 shows the contents of the HP 41952A/B, , Refer to

Figure 2-1 for details.

Ta ble 1-1. Contents o▶=the HP 41952A/B

Description Qty.

(HP 41952A and HP 4195213 standard only ;)

(HP 41952B standard only')

,

, 1'

j

1

505IN(m) cable and HP 11852B Minimum Loss Pad are

deleted for the HP 4195219 with Option 009.,

SPECIFICATIONS The specifications for the HP 41952A and HP 419528 \Transmis-

sion:Reflectlon Test Sets are listed in Table 1-2. The specifica-

tions are performance, standards or1 limits. The HP 41952A/B

meets all of the specifications listed', in Table 1-2 when. It is

shipped frdm the factory.

1.3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 10

/ •

Taye 1-2. SpecificOons (1 of 2)

1\'

•

•

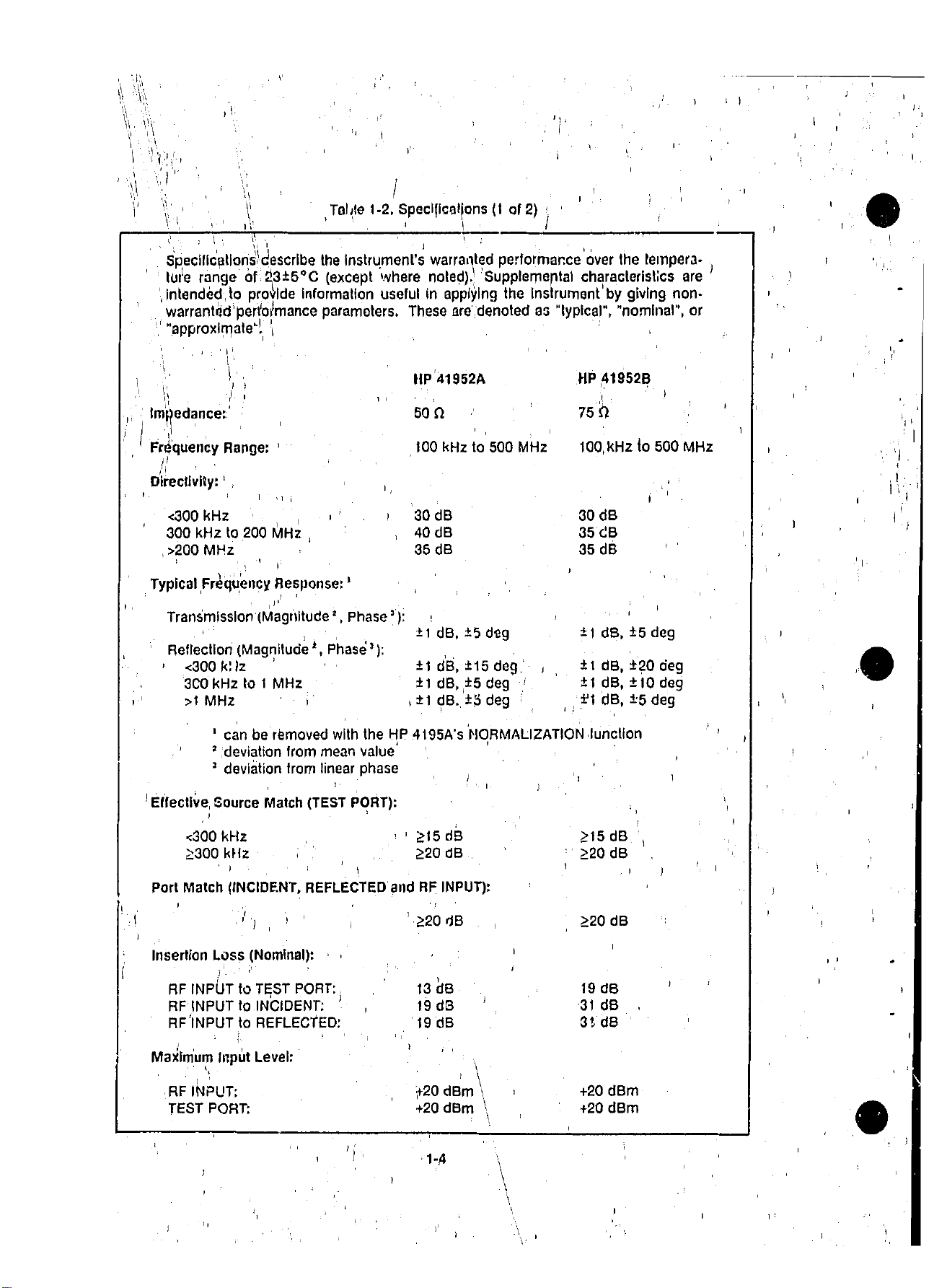

. SpecificationSdescribe the Instrument's warranted performance over the tempera-

tui'e range of • 3-15°C (except where noted). 'Supplemental characteristics are

intended, to provide information useful in applying the Instrument by giving non-

warranted'perfolimance parameters. These are denoted as "typical", "nominal", or

"approximate., '1

•

I

•

1 •

I

ledance:

Frequency Range:

11P 41952A

50 fl

100 kHz to 500 MHz 100,kHz to 500 MHz

HP 1-1952p

75'

/11

Directivity:

•

<300 kHz

300 kHz to 200 MHz

•

>200 MHz

30 dB

40 dB

35 dB

30 dB

35 dB

35 dB

Typical Frequency Response:

TranSmission (Magnitude , Phase'):

±1 dB, ±5 deg ±1 dB, ±5 deg

Reflection (Magnitude k, Phase' ):

<300 k:lz ±1 dB, ±15 deg ±1 dB, ±20 cieg

3C0 kHz to 1 MHz ±1 dB, 3±5 deg ±1 dB, ±10 deg

>1 MHz • ±1 dB. ,±$ deg t1 dB, ±5 deg

can be removed with the HP 4195A's NORMALIZATION function

deviation from mean value

deviation from linear phase

•

' EffectiVe, source Match (TEST PORT):

<300 kHz X15 dB

:z300 klIz Z20 dB

•

Port Match (INCIDENT, REFLECTED and RF INPUT):

• •1 •

' >20 dB >20 dB

Insertion Loss (Nominal): • ,

)

RF INPUT to TEST PORT:

RF INPUT to INCIDENT:

RF'INPUT to REFLECTED:

13 'dB

19 dB

19 dB

•

Mailmum Input Level:

• \

• RF INPUT:

TEST PORT:

dBm \ •

+20 dem \

1.4

•

dB

20 dB

19 dB

31 dB •

31, dB

+20 dBm

+20 dBm

•

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 11

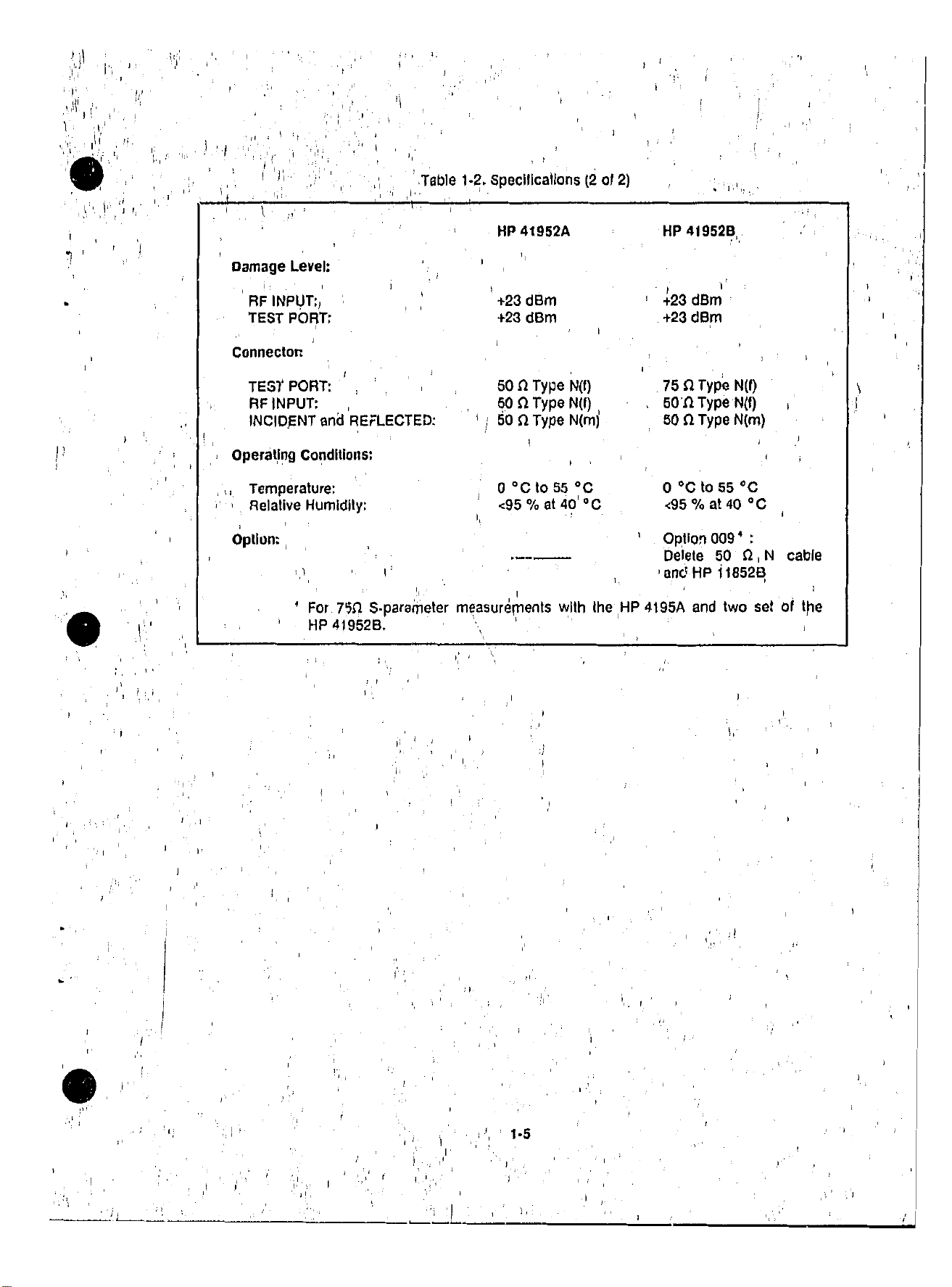

Tabl e 1-2. Specifications (2 of 2)

Damage Level:

RF INPUT:)

TEST PORT:

Connector:

TEST PORT:

RF INPUT:

INCIDENT and REFLECTED:

Operating Conditions:

, „. Temperature:

Relative Humidity:

Option: ,

4 For 78S1 S-pararheter measurements with the HP 4195A and two set of the

HP 41952B.

HP 41952A

+23 dBm

+23 dBm

HP 419528,.

+23 dBm

+23 dBm

50 CI Type N(i) 75 CI Type N(f)

50 n Type N(f) , 50T1 Type N(f) ,

' i 60 a Type N(mi 50 CI Type N(m)

0 °C to 55 °C

<95 % at 40' °C

0 °C to 55 °C

<95 % at 40 °C

Option 009'

Delete 50 R , N cable

and HP 11852B

,

J1,

•

1.5

• .,1

1, .

1,:

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 12

111111101111=1111111•11111

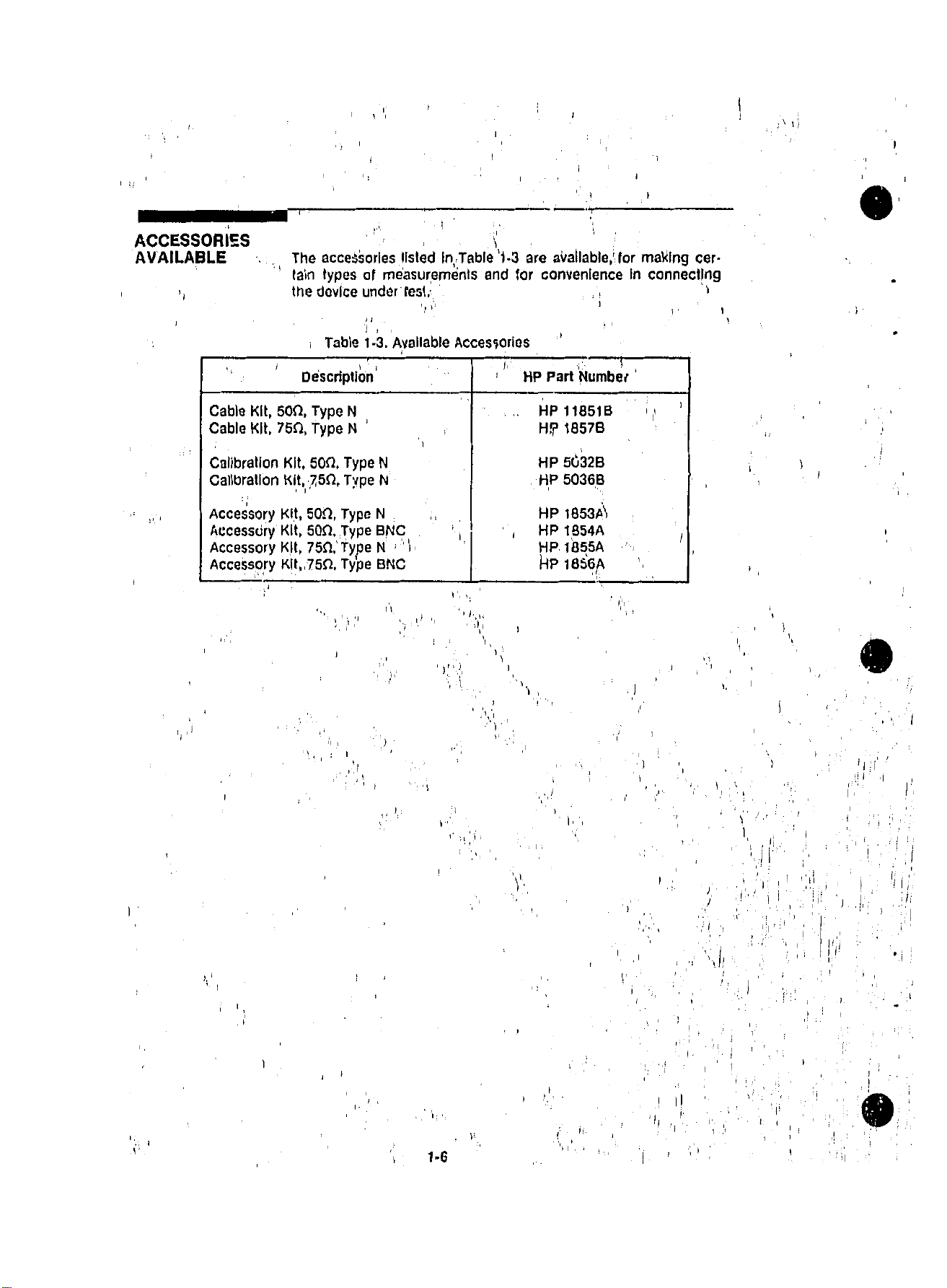

ACCESSORIES

AVAILABLE

The accessories listed Injable '1-3 are airallable,' for making cer-

tain types of measurements and for convenience in connecting

the device under rest; ' ti

;%

Tabl e 1-3. Available Acces5ories

Description

Cable Kit, 500, Type N

Cable Kit, 75), Type N

Calibration Kit, 500, Type N

Calibration Kit, 750, Type N

Accessory Kit, 50n, Type N

Accessdry Kit, 50f/, Type BNC

Accessory Kit, 75D, Type N'

Accessory Kit, 750, Type BNC

Il

1 ,

:

HP Part Number

HP 11851B

18576

HP 5032E

HP 5036B

HP 1853A1

HP 1854A

HP. 1855A

kp 18561

1.6

1 1

• • 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 13

INSTALLATION

SECTION

CONTENTS

INiT AL

INSPECTION

This section provides the following information.

The HP 41952A/B Transmission/RefrectIon Test Sets meet all of

the specifications listed in Table 1.3. Upon receipt, Inspect the

shipping container for damage. If the shipping container or the

cushioning material has been damaged, beep the' container and

packing material until the contents have been checked for com-

pleteness and the test set has been checked oit mechanically

and electrically. Figure 2-1 shows the product, overview., The

proCeduies for checking the general electrical operation are given

19 SECTION 4, PERFORMANCE TEST.

SECTION 2

•, ,Initial Inspection

• Mating Connectors

• Environmental Requirements

• Packaging

If anything is missing, damaged (scratches, dents, broken con-

nectors, etc.), or If performance does not meet the perfOrmance

test limits, notify the nearest HP sales office (see the list at the

back of this operation note). The HP sales office will immediately

arrange for repair or replacement without waiting for a claim

settlement.

2-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 14

g.

1

/ (3)

I

i

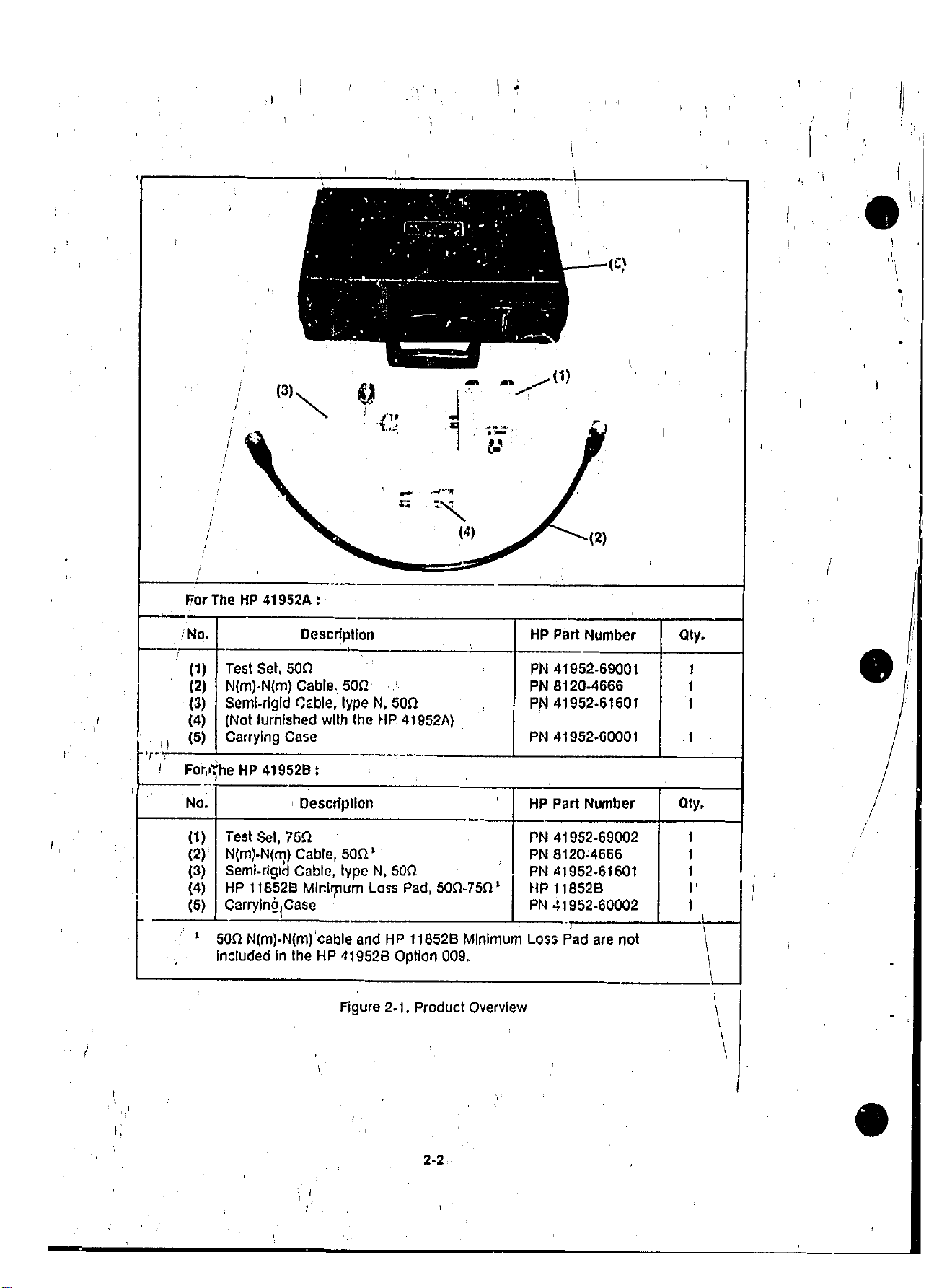

For The HP 41952A :

jNo.

• '

Description

, .

....,....

:,-

sommuw

' .. - " •

.

r

— - •

(4) (2)

..---

(1)

HP Part Number Qty.

•

(Cs,

,

Test Set, 5012

(1)

(2)

N(m)-N(m) Cable, 50f1

(3)

Semi-rigid Cable, type N, 50f/

(4)

,(Not furnished with the HP 41952A)

.I1 (5)

tt

Carrying Case

Forine HP 41952B:

No.

Test Set, 75n

(1)

(2)'

N(m)-N(m) Cable, 50n'

Semi-rigid Cable,, type N, 50a

(3)

(4)

HP 118528 Minimum Loss Pad, 500.-750`

Carrying Case

(5)

50a N(m)-N(m)'cable and HP 118528 Minimum Loss Pad are not

Included in the HP 419528 Option 009.

PN 41952-69001

PN 8120-4666

PN 41952-61601

PN 41952-00001

Description HP Part Number

PN 41952-69002

PN 812C.4666

PN 41952-61601

HP 118528

PN 41952-60002

7

Figure 2-1. Product Overview

1

1

1

Qty.

1

1

1

1

1 ,

2-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 15

21111/111111.11110111111111111111

ENVIRONMENTAL .1

REQUIREMENTS The HP 4 l'952A/B inay be stored or shipped under'Ide following

• environmental ,:ondition..

• TemPerature : -40*C to +70°C,

The unit must be protected from temperature extremes which Can

cause condensation.

1111111111111•1•111=1111 ,,

1 1

PACKAGING Thii paragraph describes how.tolrepackage the HP 41952A/B for

shipment when necessary. 1

Original

Pakaging Containers and packing material Identical to those'used in factory

packaging are available from Hewlett-Packard. if the unit Is being

returned to Hewlett-Packard for servicing, attach,a tag Indicating

the type of service required, return address, model number and

full serial number,

Other

Packaging The following general instructions should be used for repacking

; with commercially available materials.

1. Wrap the unit in hea(ey paper or plastic. It shipping to a

HP sales office or service center, attach a tag indicating

the type of service required, return address, model num-

ber and full serial number.

2. Use a strong shipping container. A double-walled carton

made of 350 pound test material Is adequate.

3. Use enough shock absorbing material (a 3 to 4 inch layer)

around all sides of the' unit to provide a film cushion and

to prevent the unit, from moving inside the container.

4. Seal the shipping container securely.

5. Mark the shipping container FRAGILE to ensure careful

handling.

6. In any correspondence, refer to unit by Its model number

and the full serial number.

2-3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

\

OPERATION

SECTION

;CONTENTS Tiffs section provides the following information.

• Overview

• Operator's Check

Typica' Measurement Setups

•

• Calibratfon Considerations

ECTION 3

OVERVIEW

(TO OUTPUTS), ,

Figure 3-1 shows the main features of the HP 41952A/13 test sets

end their simple block diagramd, and the lollowing description Is ,

dorresponded to each features. , I

(2) INCIDENT connector 3) REFLECTED connector

(TO INPUT R) (TOINPUT T)

, •

(1) RF INPUT

connector

(4) TEST PORT connector

(5) Semi-rigid Cable

Figure 3-1. HP 41952A/B Test Sets Features (1/2)

3.1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 17

r,:

HP 41952A

50 ohm

(1) RF INPUT>

(0dB

I 50 ohm

(2) INCIDENT

(-19dB*)

12dB

Pad

(6dB)

(6dB)

60 ohm

(3) REFLECTED

+ _ _

Directional

Bridge

(4) TEST PORT

A (119dB*

When TEST PORT is)

opened or shorted.

6dB

Coupling

13de*

(When TEST PORT is)

50 ohm

50 ohm terminated.

(DC COUPLED)

HP 41952E3

60 ohM

(2) INCIDENT

(-31d13*)

24dBI

Pad —

50 ohm

(1) RF INPUT>

(0dB in)

(6dB)

Directional

(6dB)

6dB

,Pad ,

* Levels applied to each connector when a OdB level

is applied to the RF INPUTconnecter.

50 ohm

I (3) REFLECTED

A

-31dB*

(When TEST PORT Is)

nOned or shorted.

6dBiPad j

Bridge

6dB

Coupling

75 ohmi 75 ohm terminated.

(4) TEST PORT

(DC COUPLED)

- -

19dB*

l(_

When TEST PORT s

Mb

Figure 3-1. HP 41952A/13 Test Sets Features (2/2)

3-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 18

(1) RF INPUT connector : 600 N(f) connector

The output signal from HP 4195A's OUTPUT Si , or S2 Is input

through the RF ,INPUT connector, the signal is then split and fed

to the INCIDENT and TEST PORT / REFLECTED connectors

(2) INCIDENT connector : 600 N(m) connector

This connerttor is used to route a portion (INCIDENT) of the OUT-

PUT S1 or S2 signal to the HP 4195A's INPUT R1 or R2. This

signal Is Used as the refejence sIgnal for ratio measurements.

(3) REFLECTED connector : 500 N(m) connector

This connector is used to route' the REFLECTED sigmil from the

DUT to the HP 4195A's INPUT T1 or '1"2.

(4) TEST PORT connector :HP 41952A :500 NO) connector

:HP 41952B :750 N(I) connector

This connector' Is used to route the OUTPUT signal to the OUT

and to receive the REFLECTED signal from the OUT.

(5) Semi-rigid cable :1.00 N(m)-N(m) cable

This cable is used to connect HP 4195A OUTPUT S1 or S2 to the

HP 41952A/13's RF1NPUT.

CAUTION1

Do not apply signals with power levels exceeding +23 dBm

to the RF INPUT and TEST PORT connectors, or damage

may result.

ICAUTION

Do not mate a 500 type-N connector to a ma type-N con-

nector or damage may result.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 19

OPERATOR'S

CHECK

This paragraph describes the HP 41952A/B operator's check,

This check procedure is intended only to ensure, that the

HP 41952A/B is functional, If the HP 41952A/B falls this check, it

must be repaired. To verify (hat the HP 41952A/B meets the ,

specifications, run the PERFORMANCE TEST described in SEC-

TION 4.

HP 4195A

r•-..

0000

0000

°CM°

000

0000

PO

.1:4

0

____

...1-=

00 0000

, 0 00 00

o

000

0

0

0

0 0 00000

10 C-5I

0 ,a

000

000

000 0

,-,

0

0 0

• , r

0 0 0

. 0 r

0

0 C C

0 0 0

P 0 0 0

® ® ®

Figure 3-2. Operator's Check Setup

lEquIpmentj

• Network Analyzer HP 4195A

•

5052 Termination

(for HP 41952A only)

HP PN 85032-60004

or HP 909C/F opt.012

• 750 Termination

(for HP 419521 only) HP PN 85036-60008

[Procedure)

1. Connect the HP 41952A/B to the network analyzer as shOwn

In Figure 3-2. Do not connect the termination to the TEST

PORT connector of the HP 41952A/B.

3-4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 20

2. Set the network analyzer's start frequency to 10 MHz and its

stop frequency to 600 MHz,,,

3. Set the network analyzer's output level to 0 dBm.

4. The network an•qier's magnitude ratio reading should be

approximately 0 dB.

5. Conned a termination (50 CI termination fiiir the HP 41052A or

75 CI termination for the HP 41952B), to the HP 41952A/B's

TEST PORT connector.

6. The network analyzer's magnitude ratio reading shquld be

less than -30 dB,

I

3.5:

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 21

TYPICAL

MEASUREMENT

SETUPS

This paragraph provides typical measurement setups using the

HP 41952A/B. The following setups are described,

o Transmission/Reflection Measurement

• Using HP 41952A (50 CI)

• Using HP 41952B (75 D)

• S-parametor Measurement

• Using HP 41952A (50 CI)

• Using HP 41952E (75 cl)

CAUTION

Do not mate a 50n type-N connector to a 7511 type-N con-

nector or damage may result,

CAUTION1

Do not apply signals with power levels exceeding +23 dBm

to the RF INPUT and TEST PORT connectors or damage

may result,

3.6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 22

Transmission/

Reflection

Measurements (Using the HP 41952A (500)]

Figure 3-3 shows typical measurement setup' for a Transmission/

Reflection measurement of a 500 system.

HP 4195A

co

0000

00

0

a

00

t=3

0 0

0 0

00

ca

000

000

0000000

00

0 0 cl

HP,41952A

OUT

o

0 0 0 0

0000

0000

000

0000

10 6)

Figure 3.3. TransmissIon/Rellection Measurement Setup Example

Using the HP 41952A (500)

3-7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 23

[Using 11P 41.9528 (750)]

Figure 3.4 shows typical measurement setup for the Transmis-

sion/Reflection measurement of a 15) system. Set the character-

istic Impedance setting of the HP 4195A to 750 using the ‘ZO 5001

715f1 soney.

HP 4195A

o

0

0

0

(i. 4) 0 "3

JHP 419526

C300

COCO

0 0 0

000 00

0

P

pqr

fl

0

0

oprzoo

oct000

00000

U 000

0

0

• 6

()

50 fl Cable

6. HP ltP52.B.

Minanorn Loss Pad

Figure 3-4. Transmission/Reflection Measurement Setup Example

Using the HP 41952B (75f1)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 24

•

S-Parameter

Measurements [Using the HP 41862A (600)1

Figure 3-5 shows a typical measurement setup for making ,S-

pare/Meter measurements of a 500 system.

0

0

0

a

0

0

000

0

0

000

000

00000 0000

0

C

0000

0

0000

"CI°

b

000

Figure 3-5. &Parameter Measbrement Setup Example

' Using the HP 41952A (500)

t • •

• 1 )

3.9

-

ft' ' i.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

I .1

1

I I

Page 25

[t.15Ing HP 41952B (75f1)]

• Figure •3=6 showsla typicgI measurement setup for making a S-

•

parameter measurement'of a 75C1 system.", Set the characteristic

Impedance setting of: the HP 4195A1 to 75n using- the 10 50S1

• 75f1' eaftkev,

HIP'4195A

#, •

1 po ooao

0

, ...ca.

,

0 0,

I •

(II

—

.

0 0

0 0 O 10 0

'

I. ,

o rao

Ei

t:3°._1

0

0

00'0 0

0 0 0 0 0

•

op

.,

o

"r)°

000

0000

,

■ HP 41^5B

DLIT

Figure 3-6. s-p :meter Measurement Setup E>campie

Using the HP 41952B (750)

1-10

11

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 26

11111=1111111111111111=111111

CALIBRATION

CONSIDERATIONS The HP 4195A provides calibration capabilities for enhancing

measurement accuracy. You can select from the following call-

bration functions (appropriate for your measurement) to compen-

sate for errors due to the test set. Refer to the HP 4195A Opera-

tion Manual for details.

• For Transmission Measrements

• Normalize (Through) Calibration:

Compensates frequency response errors.

• Normalize & Isolation Calibration:

Compensates frequency response and crosstalk

errors. 1

• For Reflection Measurements

• NorMalize (Open\ Calibration:

ComOnsates trequency response lors.

• One Pail Partial Calibration:

Compensate, frequency response and directivity

errors.

1

f

Calibration

Standard Values

HP 85032B

N(m) connector

HP 85032B ,

N(t) connector

HP 8503613

N(m) connector

• One Port Full Caliblation;

Compensates frequency response, directivity, and

source mismatching errors.

The standard values Tor reflection alit—eon are stored In the

HP 4195A's, memory, and those values can be modified to match

your standards, , Use the values listed in Table 3-1 for the stan-

dard values when using the HP 8503213 or HP 85036B calibration

kit.

Ta b l e 3.1. Standard Values

OPEN

0 [SI,

0 [SI, 108E-15 [FJ

0 [SJ, 275E-15 [Ff

413E-15 IFI , 0 [Oh 876E-12 [Hi 50 [fll, 0 [HI

SHORT

.0 pi,

0 [0J, 1317E-12 [HI 75 [al, 0 fHI

0 [HI 50 [0]. 0 [HI

LOAD

HP 85036E

N(f) connector

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

0 [SI, 635E-14 [FI

0 pl,

3-11

0 [HI

75 [C11, 0 [HJ

Page 27

SECTION 4

PERFORMANCE TESTS

111=11111111111.1.111111IN

INTRODUCTION This section provides the performance test procedure to ensure

that the HP 41952A/B meets the specifications listed in Table 1-3,

Specifications. The performance test can be performed without

accessing the interior of the HP 41952A/B.

The test results should be recorded into the Performance Test

Record located at the end of this section.

EQUIPMENT REQUIRED

The equipment required for performance testing is listed in Table

4-1. Substitutions can be made for the equipment in this list if

the specifications meet or exceed the specifications listed in the

Requirements column.

Tabl e 4-1, Recommended Test Equipment

Equipment i

Recommended Model

Network Analyzer No substitute

'HP 4195A

T/R Test Set

HP 41952A

Calibration Kit i 1

HP 85032B

Calibration Kit i I

HP 85036B ' I

Termlnatitin 1

HP 909C•Opt.200, 0p1012 ' 2

I Return Loss: 52 dB

Termination

HP 909F Opt.012 ' 2 Frequency: 100 kHz to 500 MHz

,

Qty. Requirements

,

1 No substitute

I

No substitute

(use open/sho'tI50 (1 termination)

1

1 Typ e N(m), 50 fl

Na substitute

(use open/short/75 it termination)

Type N(m), 50 C

Frequency: S 200 MHz

Return Loss: Z 47 dB

Adapter

Note: Used for performance testing the HP 41952B.

2 Used for performance testing the HP 41952A.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1 N(f)-N(f), 50 ft

1 N(m)-N(m), 50 SI

4-1

Page 28

CALIBRATION CYCLECYCLE

The HP 41952A/3 requires periodic performance Verification. The''

HP 41952A/B bliould be checked out using the performance test

at least once a year or more depending on the frequency of use. ,

Preventive maintenance should be performed at least twice a year

to keep dowtt-time to a minimum, and to insure optimum

operation.

PREPARATION This paragraph provides the information you need to know, and

the steps you must perform before starting the performance test.

1, The test equipment must be allowed to warm-up and stabilize

for at least 30 minutes.

2. An HP 4195A Is required to performance test the HP 41952A/

B, In the remainder of this manual, the HP 4195A's softkeys

are indicated in boldface type and are enclosed In single

quotes (e.g., 'NETWORK' soltkey), and keys are indicated in

bold face type only (e,g., PRESET key).

3. The HP 4195A's calibration capability Is used to performance

test the HP 41952A/B. Perform the procedure given below to

change the calibration standard data stored In the HP 4195A

before running the performance test. If you are testing a

HP 41952A, perform steps a and b. I: you are testing a

HP 41952B, perform steps a through d,

a, Turn the HP 4195A ON, and sequentially press the PRE-

SET and CAL keys, and the 'more 112' and 'CAL STD

modify' softkeys.

b. Sequentially press the following keys.

'OPEN CAL STD', 0, green shiltkey, , (comma)

4 , 1 , 3 EEX, - (minus), 1 , 5 , ENTER/EXECUTE

'SHORT CAL STD', 0 , green shiltkey„ (comma)

8 , 7 , 8 , EEX, - (minus) , 1 , 2 , ENTER/EXECUTE

'LOAD CAL STD', 70 , green shiftkey„ (comma)

0 , ENTER/EXEC....

4-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 29

c.. Sequentially press the HP 4195A's CA key, and the

'more 1/2', 'ZO 5011 7512' and the 'CA STD modify'

softkeys.

d. Sequentially press the following keys.

'OPEN CAL STD', 0, green shlitkey, (ccin ma)

,1

2 , 7 , 5 , EEX, • (minus) , 1 , 5 , ENTER/E ECUTE

'SHORT CAL STD', 0 , green shiftkey, (c• mma)

1 , 3 , 1 , 7 ,tEX, • (minus) , 1 , 2 , ENTE /EXECUTE

'LOAD CAL STD', 7 , 6 green shiltkey, comma)

0 , ENTER/EXECUTE

•

I

4.3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 30

PERFORMANCE TESTS

DIRECTIVITY TEST

SPECIFICATIONS: (at 23 °C *5 °C)'‘

HP 41952A: 30 dB at < 300 kHz

HP 41952B: Z 30 dB at <300 kHz

40 dB at 300 kHz to 200 MHz

Z35dBat>200MHz

35 dB at 300 kHz ,

SETUP:

HP 4195A

8

c-)

ci

11

0 a i 0 0

. p‘

frf (I.3

1 j

....

=1"

1,4; .:..1;:',. 0 .19,•]2E

--ir-r---

1

toAct

Figure 4-1. Directivity Test Setup

EQUIPMENT:

Network Analyzer HP 4195A

Calibration Kit HP 85032B

HP 8503613' 2

Term in at io n HP 909C Opt. 200 Opt. 012*

Term in at io n HP 909F Opt. 012"

Note: Used for testing the HP 41952A

• z Used for testing the HP 41952B

PROCEDURE:

1. Connect the HP 41952A/B to the HP 4195A, as shown in Figure 4-1.

4.5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 31

PERFORMANCE TESTS

2, Sequentially press the following HP 4195A front panel keys,

CONFIG, 'NETWORK', PRESET

AMPLITUDE (CHANNEL 1 side), 1 , 0 , ENTER/EXECUTE,

REF ATTEN (CHANNEL 1 side), 1 , 0 , ENTER/EXECUTE

TEST ATTEN (CHANNEL i Side), 1 , 0 , ENTER/EXECUTE

START, 1 , 0 , 0 kHz/dBrn

RES BW, 1 , kHz/dBm

MENU, 'TRIGGER menu', 'SINGLE mode', 'return'

'TYPE lin tog'

(log" In the 'TYPE lin log' sioltkey will change to

Intensified green.)

DISPLAY, 'TRACE B on oft'

("off" In the 'TRACE B on oft' sottkey will change

to intensified green,)

NOTE

If you are testing the HP 41952B, skip step 3.

3. Press tha following keys, and skip step 4,

STOP, 2 , 0 , 0 , MHz/V

4, Press the following keys (only for testing the HP 41952B).

STOP, 5 , 0 , 0 , MHz/V

CAL, 'more 1/2', 'ZO 509 75f2',

("M' in the '7.0 Bon 7551' softkey will change to intensified ween.)

5. Connect the N(m) SHORT standard to the HP 41952A/B's TEST PORT connector.

6. Press the TRIG/RESET key on the HP 4195A's front panel, to makeia single sweep

measurement.

7. Enter the HP 4195A "C=A" command using the following keystrokes.

CLR LINE, blue shiftkey, C , = , A , ENTER/EXECUTE

8. Connect the N(m) LOAD standard (HP 909C Opt, 200, Opt. 012 for testing

HP 41952A, HP 85036B's 75 CI standard (85036-60008) for testing HP 41952B) to the

HP 41952A/B's TEST PORT connector.

9. Press the HP 4195A's TRIG/RESET key.

4.61

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 32

PERFORMANCE TESTS

10. Enter The HP 4195A 'A=C-A" command using the following keystrokes to have the

HP 4195A display the Directivity Test, results. '

CLR LINE, blue shittkey, A , = , C , • (minus) , A ENTER/EXECUTE

11. Press the SCALE REF key and the 'A AUTO SCALE' soltkey for auto scaling.

12. Sequentially press the following keys to set the HP 4195A's analysis range between

100 kHz and e00 kHz,

MORE, 'ANA RNG'

(move the • marker to the point as close as possible to 300 kHz by rotating the

HP 4195A's rotaryiknob.)

'active oMKR .MKR' ("oMKR" in this soltkey will change to Intensified

green.)

(muve the o marker to the 100 kHz point)

'STORE ANA RNG'

'PART ANA on off' ("on" in this softkey will change to intensified

green.)

13. Press the MKR-0 key and 'MKR-*MIN' softkey,

14. Confirm that the T/R data displayed on the upper right corner of the HP 4195A's

display (Directivity Test result) Is within the test limits listed In Table 4-Z Directivity

Test Limit,

15. Sequentially press the following keys to set the HP 4195A's analysis range between

300 kHz, and the stop frequency point (200 MHz for testing a HP 41952A, or

500 MHz for testing a HP 41952B).

MORE, 'ANA RNG'

(move o marker to the STOP frequency point)

'STORE ANA RNG'

16. Press the MKR- key and 'MKR-*MIN' soltkey.

17, Confirm that the T/R data displayed on the upper right corner of the HP 4195A's

display (Directivity Test result) Is within the test limits listed in Table 4-2, Directivity

Test Limits.

NOTE

If you are testing a HP 41952B, do not perform step 18,

4.7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 33

PERFORMANCE TESTS

18, Perform steps a throUgh j only when testing a HP 41952A.

a, Sequentially press the following HP 4195A keys.

START, 2 , 0 , 0 , MHz/V

STOP, 5 , 0 , 0 , MHz/V

b. Connect the HP 85032B's N(m) SHORT standard (HP 11512A) to the

HP 41952A's TEST PORT connector.

c. Press the HP 4195A front panel TRIG/RESET key to perform a single sweep

measurement,

d. Enter the HP 4195A "C=A" command using the following keystrokes.

CLR LINE, blue shiftkey, C , a , A , ENTER/EXECUTE

e. Connect a the 50 11 Termination (HP 909F Opt. 012) to, the HP 41952A's TEST

PORT connector.

f. Press the HP 4195A TRIG/RESET key.

g. Enter the HP 4195A "A=C-A" command using the following keystrokes to have

the HP 4185A display the Directivity Test results.

,CLR LINE, blue shiflkey, A , = , C , - (minus) , A , ENTER/EXECUTE

h. Press the SCALE REF key and 'A AUTQ SCALE' softkey for auto scaling.

Sequentially press the MKR-* key and the 'MICR-HOIN' soltkey.

Confirm that the T/R data displayed in the upper right corner of the HP 4195A's

1.

display (Directivity Test result) is within the test limits listed in Table 4-2, Directivi-

ty Test Limits.

Tabl e 4-2. Directivity Teit Limits

HP 41952A:

Frequency Test Limit

< 300 kHz

300 kHz to 200 MHz

> 200 MHz

HP 419526:

a 30 dB

Z 40 dB

Z35dB

Frequency

< 300 kHz

a 300 kHz

4.8

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Test Limit

Z30dB

35 dB

Page 34

PERFORMANCE TESTS

EFFECTIVE SOURCE MATCH TEST

SPECIFICATIONS: eat 23 °C °C)

TEST PORT: a 15 dB at < 30( •••

a 20 dB at r:3(2,1, gz

SETUP: tip 4196A

_.....

0.002

car

0

0 0 0 0

,i) ® i

.

a

0

0 0

.. It

_4 u E3

0 0 0

„ • 1

n '-• I j-(....,)

0. .0

0 0 €11

8

8

Ez,,"„1=',,, la

ciao

0 0 0 0 0

0 0 a

: 0

AP 41952A a .1t952E

St•rof tro LCAr)

Figure 4-2. Effective Source Mat •t1 Test Setup

',';re,data

EQUIPMENT:

Network 14Inalyzer

Calibration Kit

HP 4195A

HP 85032W

Hp 85030B"

Note:

Used for testing the HP 41952A

• 3

Used for testing the HP 41952B

PROCEDURE:

1. Connect the HP 41952A/B to the HP 4195A, as shown in Figure 4-2.

4.9

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 35

PERFORMANCE TESTS

2, Sequentially press the lollowing HP 4195A front panel keys,

CONFIG, 'S-PRMTR', '511', PRESET

AMPLITUDE (CHANNEL 1 side), 1 , 0 , ENTER/EXECUTE

REP ATTEN (CHANNEL 1 side), i ; ENTER/EXECUTE

TEST ATTEN (CHANNEL I side), 1 , 0 , ENTER/EXECUTE

START, 1 , 0 , 0 , kHr/dBm

STOP, 5 , 0 , 0 , MHz/V

RES BW, 1 , kHz/dBm

MENU, 'TRIGGER menu', 'SINGLE mode'

.'TYPE lin log'

(log" in the 'TYPE lin log' soltkey will change to

'return'

intensified green.)

DISPLAY, 'TRACE B on off'

("off" in the 'TRACE B on off' softkey will change

to intensified green.)

NOTF

If you are testing a HP 41952A, skip step 3.

3. Press the following keys (only when testing a HP 41952B).

CAL, more 1/2 , 'ZO 50Q 7511'

(the "75cr in the 'ZO 50f1 75cr soltkey will change to intensified green)

4. Sequentially press the HP 4195A's CAL key, and the 'S-PRMTR CAL menu' and 'ONE

PORT FULL CAL' soltkeys.

5. Connect the N(m) OPEN standard to the HP 41952A/B's TEST PORT connector.

3. Press the 'OPEN' softkey and the ENTER/EXECUTE key. Wait until the single sweep

measurement Is completed,

7. Connect the N(m) SHORT standard to the HP 41952A/B's TEST PORT connector.

8. Press the 'SHORT' sollkey and the ENTER/EXECUTE key. Walt until the single

sweep measurement is completed.

9. Connect the N(m) LOAD standard to the HP 41952A/B's TEST PORT connector.

110. Press the 'LOAD' soRkey and the ENTER/EXECUTE key. Wait until the single sweep

measurement is completed.

4-10

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 36

I i

PERFORMANCE TESTS

I I. Press the 'CAL' key and the 'CORRECTN on off' solthey. "on" I i this softkey will

l' change to intensiflad green. /

, 1

1,2,) Press the PROGRAM key, the 'EDIT' softkey and the UNTER/17XECUTE key, In se-

qudnCe. The HP 4195A'a display will change to the user progrep editor display,

,13. Enter the followl,ig HP 4195A program to have It display the Effective Source Match

test results. Ii you need more Information on how to enter a HP 4195A program,

refer to the HP 4195A's Operation Manual, paragraph 6-4, USER PROGRAM (Auto

Sequence Program:ASP).

10 <RA,RB> = <MFOR,MFOI> • <TFSR,TFS$>

20 <RA,RB> = <RA,RB> <MFSR,MFSI> ‹TFOR,TFOI>

30 <RA,RB> a <RA,RB> + <MFLR,MFLI> • (<TFOR,TFOI> <TFSR,TESI>)

40 <RC,RD> = <MFOR,MFOI> • ‹TFOR,TFOI> • ‹TFSR,TFSI>

50 <PC,RD> = <RC,RD> <MFSR,MFSI> • <TFSR,TFSI> . <TFOR,TFOI>

60 <RE,RF> <RA,RB> / <RC,RD>

70 A = - 20 • LOG ( SOP,(RE • RE + RF • RF ) )

60 END

Note; To display " < ", press the green shiftkey and < key.

To display " > ", press the green shiftkey and > key.

To display " , '', press the green shiftkey and , (comma) key.

To display " . '', press the MATH OPERATOR key and • . softkey,

To display " ", press the MATH OPERATOR key and +' softkey.

To display " / ", press the MATH OPERATOR key and /' softkey

To display " ( ", press the MATH OPERATOR key and ( ' sollkey,

To display " ) ", press the MATH OPERATOR key and ) ' softkey.

To display any alphabet key, let the LED indicator in the blue shiftkey

light, and press any alphabet key.

14. Sequentially press the PROGRAM key and the 'QUIT editor' and 'RUN' soft!.

Wait until the OP' softkey changes to. intensified green.

15, Press the SCALE REF key and the 'A AUTO SCALE' softkey for auto scaling.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 37

16. Sequentially press the following keys iol set the HP L'195A's analysis range between

100 kHJ and 3op kHz,

MORE. JANA 11N(1)

(move the . marker to a point as close as possible to 300 kHz by rotating the

HP 4195A's rotary knob)

'active oMKR .MKR' ("oMKR" In this soltkey will change to ,intensified

(move the o marker to the 100 kHz point)

'STORE ANA RNG'

'PART ANA on off' ("on" in this softkey will change to intensified

17, Press the MKR-▶ key and the `MKR-•MIN' softkey,

18. Confirm that the data RL displayed on the upper right corner of the HP 4195A's

display (Effective Source Match Test result) is within the test limits listed in Table 4.3,

Effective Source Match'Test Limits.

19. Press the following• keys in sequence, to set the HP 4195A's analysis range between

300 kHz and 500 MHz.

1

green.)

green.)

MORE, 'ANA RNG'

(move o marker to 500 MHz point)

'STORE ANA RNG'

20. Press the MKR-+ key and the 'MKR-*MIN' softkey.

21, Confirm that the data RL displayed on the upper right corner of the HP 4195A's

displ4 (Effective Source Match Test result) is within the test limits listed in Table 4.3,

Effective Source Match Test Limits.

Ta bl e 4-3. Effective Source Match Test Limits

Frequency Test Limit

< 300 kHz

300 kHz ,

' Z 15 dB

Z20dB

4-12

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

•

Page 38

PORT. MATCH TEST

SPECIFICATIONS: (at 2J' °C ±5 °C)

PERFORMANCE TESTS

INCIDENT, REFLECTED, HF INPUT:

SETUP: 1-11) 41,36A

on 0 0 0

1-53

Ll

00o0 Latnao coin;

nalp-.)

8

ci a

MO

00 0 IL,

a n o CI

0 0 0 0

4•IMIONIS MINIMMMI

® 0

41,f,2A

a 20 dt3

001

0000

0000

000

4000

Figure 4-3. HP 41952A Calibration Setup

EQUIPMENT:

Network Analyzer HP 4195A

T/R Test Set HP 41952A'

Calibration Kit HP 85032B

50 a Termination HP 909F Opt. 012'

Adapters as necessary

Note: •

PROCEDURE:

1. Connect the HP 41952A to the HP 4195A.

Test equipment required to test the HP 41952A/B under test

•

Used for testing the HP 41952B

.7

Used for testing the HP 41952A

HP 85036B'

4.13

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 39

PERFORMANCE TEST'S'

, „ t •

2, Toni the HP 4195A.OFF and ON .to Initialize It„-and then sequentially press the fol-

lowIng)HP 4195A front panelkeys;

CONF1G, 'S-PRMTR', 'S11', PRESET

AMPLITUDE (CHANNEL 1,sIde),1,, 1 ENTER/EXECUTE

REFi'ATTEN (CHANNEL, I side), 1 , 0 , ENTER/EXECUTE

TEST'IMEN (CHANNEL 1 side), 1 0 ,ENTER/EXECUTE

START, 1,, 0 , 0 , ktiz/dBm, ' •

STOP, 51,10 , 0 , MHz/V

RES. BW, 1 , kHz/dBm•

•

MENU, 'TRIGGER menu', 'SINGLE,mode'

DISPLAY, 'TRACE B on off':.'

("off' iri the 'TRACE B on off' softkey will change

to intensified green.)

3. Perform the following procedure (steps a through h), to perform a 1 PORT FULL

CALIBRATION for the TEST' PORT connector of the HP 41952A (test equipment).

a. Sequentially press the HP 4t95A's CAL key, and the `S-PRMTR CAL menu' and

`ONE PORT FULL CAL' softkeys. '

b. Connect the HP 85032B's N(m) OPEN standard to the TEST PORT connector of

the HP 41952A (test equipment).

c. Press the 'OPEN' softkey end the ENTER/EXECUTE key. Wait until the single

sweep measurement is completed.

d. Connect the HP 85032B's N(m) SHORT standard to the TEST PORT connector

of the HP 41952A (let equipment).

e. Press the 'SHORT' softkey and ENTER/EXECUTE key. Wait until the single

sweep measurement is completed.

f. Connect the HP 85032B's N(m) LOAD standard to the TEST PORT connector of

the HP 41952A (test equipment).

Press the 'LOAD' softkey and the ENTER/EXECUTE key. Wait until the single

9.

sweep measurement is completed.

h. Press the CAL key and the 'CORRECTN on off' softkey. The "on" In this softkey

will change to Intensified green.

)

4-14

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 40

PERFORMANCE TESTS

4, Perform the following procedure (steps a through I) to test the Port Match for the

INCIDENT (R) connector of tho HP 41952A/B (under test),

To HP .1,notromt)

TEST ponr cd:rn,cter

50A LOAD, fl(t)

CriC

60A LORD. Wm/

9,09 F rpt. Ot2 Itcr test+rt; 41'352A1

76A LOAD, Niti Ilat teitan 4126213;

Figure 4-4, INCIDENT connector Port Match Test Setup

a. Connect the N(m) LOAD standard (909F Opt. 012 for testing the HP 41952A,

HP 85036B's 75 CI standard for testing the HP 41952B) to the TEST PORT con-

nector of the HP 41952A/B (under test).

b. Connect the HP 850328's N(f) LOAD standard to the REFLECTED (T) connector

of the HP 41952A/B (under test).

c. Connect the HP 85032B's N(m) LOAD standard to the RF .NPUT connector of

the HP 41952A/B (under test), as shown In Figure 4-4.

d. Conned the INCIDENT (R) connector of the HP 41952A/B (under test) to the

TEST PORT connector of the HP 41952A (test equipment).

e. Press the HP 4195A's TRIG/RESET key, to make a single sweep measurement.

f. Enter the HP 4195A command using the following key stroke sequence to

have the HP 4195A display the Port Match test results,

CLR LINE, blue shiftkey, A , - (minus), A , ENTER/EXECUTE

g. Press the SCALE REF key and the 'A AUTO SCALE' softkey for auto scaling.

h. Press the MKR-> key and the 'MKR-,MIN' softkey to move the o marker to the

minimum point.

I. Confirm that the RL data displayed on the upper right corner of the HP 4195A's

display (Port Match test result) is greater than or equal to 20 dB.

5. Disconnect the HP 41952A/B (under test) from the HP 41952A (test equipment).

6. Disconnect the HP 85022B's N(f) LOAD standard from the REFLECTED (T) connec-

tor of the HP 41952A'B (under test).

4-15

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 41

PERFORMANCE TESTS

7. Perform the following procedure (steps a through g) to test the Port Match for the

REFLECTED (T) connector of the HP 41952A/B (under test).

To HP 41952A (test ec,tipmerA

TEST PORT Connector

60A LOAD, No)

50A LOAD, litrn)

0

CO

0 909 F epl. 012 (tot testing 41952A)

76A LOAD, 11trn) (for testing 41952E)

QD

Figure 4-5. REFLECTED connector Port Match Test Setup

a. Connect the HP 85032B's N(t) LOAD standard to the INCIDENT (R) connector of

'the HP 41952A/B (under test), as shown in Figure 4-6.

b. Connect the REFLECTED (T) connector of the HP 41952A/B (under test) to the

TEST PORT connector of the HP 41952A (test equipment).

c. Press the HP 4195A's TRIG/RESET key to make a single sweep measurement.

d. Enter the HP 4195A "A=-A" command uskig the following key sequence to have

the HP 4195A display the Port Match test result.

CLR LINE, blue shift!. ey, A = , - (minus), A , ENTER/EXECUTE

e. Press the SCALE REF key and the 'A AUTO SCALE' softkey for auto scaling.

. Press the MKR-▶ key and the 'MKE-VPMIN' soflkey to move the o marker to the

minimum point.

g. Confirm that the RL data displayed on the upper right corner of the HP 4195A's

display (Port Match test result) is greater than or equal to 20 dB.

8. Disconnect the HP 41952A/B (under test) from the HP 41952A (test equipment).

9. Disconnect the HP 85032B's N(m) LOAD standard and N(f) LOAD standard from the

RF INPUT connector and the INCIDENT connector of the HP 41952A/B (under test),

respectively.

10. Connect the N(m)-N(rn) Adapter lo the TEST PORT connector of the HP ;1952A (test

equipment).

4-16

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 42

PERFORMANCE TESTS

11. Uoe the following procedure (steps a through kb to perform a 1 PORT FULL CALI-

BRATION for the adapter on the TEST PORT connector of the HP 41952A (test

equipment).

a. Sequentially press the HP 4195A's CAL key, and the 'CORRECTN ors off', 'more

1/2', and 'CAL STD modify' softkeys,

b. Sequentially press the following keys to change the HP 4195A's stored standard,

calibration data,

'OPEN CAL STD', 0 , green shlftkey„ (comma), 1 , 0 , 8

EEX, - (minus), 1 , 5 , ENTER/EXECUTE

'SHORT CAL STD', 0 , green shiftkey„ (comma), 0 , ENTER/EXECUTE

c. Press the MENU key (once) and the 'TYPE tin log' softkey (twice).

d. Sequentially press the HP 4195A's CAL key, and the, 'S-PRMTR CAL menu' and

the 'ONE PORT FULL CAL' softkeys.

e. Connect the HP 850326's N(f) OPEN standard to the adapter on the TEST PORT

connector of the HP 41962A (test equipment),

f, Press the 'OPEN' sollkey and the ENTER/EXECUTE key. Wait until the single

sweep.measurement is completed,

Connect the HP 850326's N(f) SHORT standard to the adapter on the TEST

g.

PORT 'connector of the HP 41952A (test equipment).

Press the 'SHORT' soflkey and the ENTER/EXECUTE key. Walt until, the single

v‘ieep measurement is completed.

i. Connect tnie HP 850326's NW LOAD standard to the adapter on the TEST PORT

connector of the HP 41952A (test equipment).

Press the 'LOAD' softkey and the ENTER/EXECUTE key, Wait until the single

sweep measurement is completed.

k. Press the CAL key and the 'CORRECTN on oft' softkey.

12. Perform the following procedure (steps a through h) to test the Port Match for the RF

INPUT connector of the HP 41952A/B (under test).

4.17

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 43

PERFORMANCE TESTS

To HP 41952A Rest equpinen0

TEST PORT Connector

tilm1-Ntni) adapter

/

[_ Nlt)-Nit} adapte;

DOD

o'

CI /

/ 6071 LOAD, NW

60A LOAD, Mt

® 909 F opt. 012 (for lesPng 41952A1

76/1 LOAD, MN ttor testing 41952D1

Figure 4.6. RF INPUT connector Port Match Test Setup

a. Connect the HP 85032B's N(f) LOAD standard to the REFLECTED (T) connector

of the HP 41952A/B (under test).

I. Connect the HP 85032B's N(m) LOAD standard to the INCIDENT (R) connector

of the HP 41952A/B (under test) using the N(f)-N(f) Adapter, as shown in Figure

4-6.

c, Connect the RF INPUT connector of the HP 41952A/B (under test) to the adapter

on the TEST PORT connector of the HP 41952A (test equipment).

d. Press the HP 4195A's TRIG/RESET key to make a single sweep measurement.

e. Enter the HP 4195A "A=-A" command using the following key stroke sequence

to have the HP 4195A display the Port Match test results.

CI.R LINE, blue shiftkey, A , , - (minus), A , ENTER/EXECUTE

f. Press the SCALE REF key and the 'A AUTO SCALE' softkey for auto scaling.

g. Press the MKR+ key and the softkey to move the o marker to the

minimum point.

h. Confirm that the RL data displayed on the upper right corner of the HP 4195A's

display (Port Match test result) Is greater than or equal to 20 dB.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 44

PERFOFIMANC

TEST RECORD

Hewlett-Packard

Model 41952A

Tra nsmission/Reflection Test Set

DIRECTIVITY:

Min. at f < 300 kHz:

Min, at 300 kHz 5 f 5 200 MHz:

Min. at f > 200 MHz:

EFFECTIVE SOURCE MATCH:

Min. at f < 300 kHz:

Specification

'a 30 dB

40 dB

3b dB

Specification

Z 15 dB

Test ed by

Date

Serial No,

Temp erat ure

Humidity

Actual

dB

dB

dB

Actual

dB

Min, at f 300 kHz:

PORT MATCH:

Min. for INCIDENT:

Min. for REFLECTED:

Min, for RF INPUT:

20 dB

Specification

20 dB

20 dB

20 dB

dB

Actual

dB

dB

dB

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 45

PERFORMANCE TEST RECORD

Hewlett•Packard Tested by

' Model 419520 Date

Tra nsm ission/ Reflect ion Test Set Serial No.

Temp er at ur e

DIRECTIVITY:

Humidity

Specification

Min. at f <300 kHz: a 30 dB

Min, at f 300 kHz: Z 35 dB

Actual

EFFECTIVE SOURCE MATCH:

Specification Actual

Min, at f < 300 kHz: 15 dB dB

Min. at f Z 300 kHz: 2 20 dB dB

PORT MATCH:

Specification Actual

Min. for INCIDENT: Z 20 dB dB

Min. for REFLECTED: 20 dB dB

dB

dB

•

Min. for RF INPUT: Z 20 dB dB

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 46

SECTION 5

SERVICE

•

INTRODUCTION This section contains Information about replaceable parts,

REPLACEABLE PARTS

The HP 41952A/B's replaceable parts are listed in Table 5-1,

Replaceable Parts. Table 5-1 lists the Hewlett-Packard part num-

ber, quantity (Oty,), and gives a description.

To order a part listed in Table 5-1, Indicate the Hewlett-Packar

part number and quantity desired. Address the order to your

nearest Hewlett-Packag 3 office.

5-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 47

Ta bl e 5-1. Replaceable Parts

Reference

Designator

2 41952-69001

3

4 11852B

Part Number

41952-61601

41952-69002

8120-4666

cart -:smfrill,

ZdtikZ

Qty.

1 Cable Semi-rigid

1

1

1

1

Test Set 5052 (for HP 41952A)

Test Set 7552 (for HP 41952B)

Cable Coaxial

Minimum Loss Pad

(furnished with HP 41952B)

Description

5.2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 48

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Loading...

Loading...