Page 1

HPE 3PAR StoreServ 9000 Storage Customer Self Install Guide

Abstract

This document provides information and instructions to guide you through the installation of

your HPE 3PAR StoreServ 9000 Storage system without the assistance of an authorized

service provider. If installation assistance is needed, contact your HPE sales representative or

HPE Channel Partner to purchase the HPE Deployment Services.

Part Number: QL226-99978a

Published: January 2019

Edition: 4

Page 2

©

Copyright 2018-2019 Hewlett Packard Enterprise Development LP

Notices

The information contained herein is subject to change without notice. The only warranties for Hewlett

Packard Enterprise products and services are set forth in the express warranty statements accompanying

such products and services. Nothing herein should be construed as constituting an additional warranty.

Hewlett Packard Enterprise shall not be liable for technical or editorial errors or omissions contained

herein.

Confidential computer software. Valid license from Hewlett Packard Enterprise required for possession,

use, or copying. Consistent with FAR 12.211 and 12.212, Commercial Computer Software, Computer

Software Documentation, and Technical Data for Commercial Items are licensed to the U.S. Government

under vendor's standard commercial license.

Links to third-party websites take you outside the Hewlett Packard Enterprise website. Hewlett Packard

Enterprise has no control over and is not responsible for information outside the Hewlett Packard

Enterprise website.

Acknowledgments

Microsoft® and Windows® are either registered trademarks or trademarks of Microsoft Corporation in the

United States and/or other countries.

Revision history

Part Number Publication

date

QL226-99978a January 2019 4

QL226-99978 December 2018 3

QL226-99888 June 2018 2

Q0E92-90703 February 2018 1

Edition Summary of changes

• Updated "Guidelines for redundant power

cabling"

• Added "Checking enclosure power redundancy

(optional)"

• Updated "Controller node LEDs and ports"

• Updated "Guidelines for cabling"

• Support for a new physical service processor,

HPE ProLiant DL360 Gen10 Server

• HPE StoreFront Remote (SFRM) content

replaced with HPE InfoSight content

With HPE 3PAR OS 3.3.1 (MU1) Patch 09, Patch

11, and Patch 18 software, also known as HPE

3PAR OS 3.3.1 EMU1, and HPE 3PAR Service

Processor 5.0.2.1 software or later software

versions, CSI supported for the HPE 3PAR

StoreServ 9000 Storage

Page 3

Contents

Guidelines for the Customer Self Install of the HPE 3PAR

StoreServ 9000........................................................................................ 6

About the HPE 3PAR StoreServ 9000 Storage system........................ 8

Preparing: Process overview...............................................................10

Unpacking the factory-integrated-in-rack option: Process

overview.................................................................................................12

Installation media.......................................................................................................................... 9

Serial number location.................................................................................................................. 9

Forum for the storage system....................................................................................................... 9

Site planning............................................................................................................................... 10

Customer Self Install videos........................................................................................................11

Acclimatizing............................................................................................................................... 11

Tools for the installation...............................................................................................................11

Unpacking the HPE rack factory-integrated with the storage system......................................... 12

Positioning and stabilizing the HPE rack.................................................................................... 20

Installing the drives: Process overview....................................................................................... 21

Guidelines for the drive installation.................................................................................. 22

Installing the SFF drives...................................................................................................23

Cabling the factory-integrated-in-rack option: Process overview... 24

Guidelines for cabling................................................................................................................. 24

Guidelines for redundant power cabling..................................................................................... 26

Cabling the physical service processor (if installed)................................................................... 27

Cabling the controller nodes: Process overview......................................................................... 28

Cabling for the management connection......................................................................... 28

Cabling for the host connection........................................................................................29

Cabling for the Remote Copy connection (optional feature)............................................ 31

Cabling for the File Persona connection (optional feature).............................................. 31

Cabling the power cords of the power distribution units to the power receptacles at the

operating site.............................................................................................................................. 32

Powering on: Process overview.......................................................... 33

Precautions for powering on the storage system........................................................................33

Checking AC power cable connections...................................................................................... 33

Powering on the storage system.................................................................................................34

Checking enclosure power redundancy (optional)......................................................................35

Setting up the service processor connection: Process overview....37

About the service processor....................................................................................................... 37

3

Page 4

Network and firewall support access.......................................................................................... 38

Firewall and proxy server configuration........................................................................... 38

Setting up the physical service processor connection: Process overview.................................. 40

Assigning an IP address to the physical service processor with a functional network

using the Guided Setup—SP5.x...................................................................................... 40

Setting up the virtual service processor connection with VMware ESXi: Process overview.......42

Deploying the virtual service processor on a host with VMware ESXi............................. 42

Locating or assigning an IP address to the virtual service processor with VMware

ESXi................................................................................................................................. 43

Setting up the virtual service processor connection with Hyper-V: Process overview................44

Deploying the virtual service processor on a host with Hyper-V...................................... 44

Assigning an IP address to the virtual service processor with Hyper-V........................... 45

Setting up the service processor and storage system software:

Process overview..................................................................................46

Prerequisites for the HPE 3PAR Guided Setup.......................................................................... 46

Setting up the service processor using the HPE 3PAR Guided Setup........................................47

Setting up the storage system using the HPE 3PAR Guided Setup........................................... 48

Installing and setting up the HPE 3PAR StoreServ Management

Console software: Process overview..................................................49

Post-installation tasks.......................................................................... 50

Accessing the HPE InfoSight platform and registering the storage system: Process

overview......................................................................................................................................50

About the HPE InfoSight platform.................................................................................... 50

Creating an account to access the HPE InfoSight web portal..........................................50

Registering the storage system with the HPE InfoSight web portal using the HPE

3PAR StoreServ Management Console...........................................................................51

Adding workstations to the public firewall rules.......................................................................... 52

Configuring the host and SAN: Process overview...................................................................... 53

Configuring a host using a host-OS implementation guide.............................................. 53

Enhancing security with data encryption.....................................................................................53

Validating the HPE 3PAR Remote Support connectivity to HPE 3PAR Central..........................54

Testing the service processor connectivity to the storage system using the Service

Console............................................................................................................................ 54

More information...................................................................................56

Component information ..............................................................................................................56

Adapter information..........................................................................................................56

Backup battery unit information........................................................................................56

Controller node information..............................................................................................57

Controller node internal components information............................................................ 58

Drive enclosure information............................................................................................. 59

Drive information.............................................................................................................. 61

Fan module information, controller node enclosure......................................................... 61

Fan module information, drive enclosure......................................................................... 62

I/O module information.....................................................................................................62

Power supply unit information, controller node enclosure................................................62

Power supply unit information, drive enclosure................................................................63

Power distribution unit information................................................................................... 63

4

Page 5

Rack information.............................................................................................................. 64

Service processor information..........................................................................................64

Physical service processor information, HPE ProLiant DL120 Gen9 Server........ 64

Physical service processor information, HPE ProLiant DL360 Gen10 Server...... 65

System information front view (typical component configuration).................................... 66

Component LEDs........................................................................................................................68

Adapter LEDs...................................................................................................................68

NVMe SCM Module LEDs.....................................................................................69

Two-port 32 Gb FC HBA LEDs..............................................................................70

Two-port 10 Gb iSCSI CNA LEDs.........................................................................71

Two-port 10 Gb Ethernet NIC adapter LEDs.........................................................72

Four-port 16 Gb FC HBA LEDs.............................................................................73

Four-port 12 Gb SAS HBA LEDs...........................................................................74

Backup battery unit LEDs.................................................................................................75

Controller node LEDs and ports.......................................................................................76

Drive enclosure LEDs.......................................................................................................77

Drive LEDs....................................................................................................................... 78

Fan module LEDs.............................................................................................................79

Fan module LEDs, controller node enclosure....................................................... 79

Fan module LEDs, drive enclosure....................................................................... 80

I/O module LEDs..............................................................................................................80

Power supply unit LEDs................................................................................................... 82

Power supply unit LEDs, controller node enclosure..............................................82

Power supply unit LEDs, drive enclosure..............................................................83

Service processor LEDs...................................................................................................83

Physical service processor LEDs, HPE ProLiant DL120 Gen9 Server................. 83

Physical service processor LEDs, HPE ProLiant DL360 Gen10 Server............... 85

System status LEDs—controller node enclosure.............................................................87

Troubleshooting.................................................................................... 89

Alerts issued by the storage system and processed by the service processor...........................89

Browser warning when connecting to the service processor...................................................... 89

Checking the system health, HPE 3PAR Service Processor 5.x software, Service Console

interface...................................................................................................................................... 93

Failed installation of a virtual service processor with Hyper-V....................................................93

Identifying drive enclosure (cage) numbering in the software.....................................................93

HPE 3PAR StoreServ 9000 Storage Software Set up Worksheet......95

Websites................................................................................................ 97

Support and other resources...............................................................98

Accessing Hewlett Packard Enterprise Support......................................................................... 98

Accessing updates......................................................................................................................98

Customer self repair....................................................................................................................99

Remote support.......................................................................................................................... 99

Warranty information...................................................................................................................99

Regulatory information..............................................................................................................100

Documentation feedback.......................................................................................................... 100

Acronyms.............................................................................................101

5

Page 6

Guidelines for the Customer Self Install of the HPE 3PAR StoreServ 9000

IMPORTANT:

• The customer self install (CSI) option is the self-installation of your storage system without the

assistance of an authorized service provider. If installation assistance is needed, contact your

Hewlett Packard Enterprise sales representative or channel partner to purchase Hewlett Packard

Enterprise deployment services.

• When the initial installation is completed according to the rules provided in this CSI guide, the

storage system is fully supported by the warranty.

• After the initial installation, the system might be ungradable to add specific components. Some

components are designated as customer self upgrade (CSU) components. All non-CSU

components require installation by an authorized service provider to satisfy the warranty.

CSI guidelines:

The CSI option is only available for the HPE 3PAR StoreServ 9000 system that meets the following

criteria:

• Two-node or four-node configurations

• Factory integrated in a single HPE Rack

The factory integration configuration option includes the assembly of components, cabling, labeling,

the installation of software and licenses, the installation in an HPE rack, and then testing the storage

system as a whole at the factory. The storage system is shipped in the HPE Rack, ready for

installation at the customer site.

• The CSI of the HPE 3PAR StoreServ 9000 must be performed using the HPE 3PAR Guided Setup that

is a feature of the HPE 3PAR OS 3.3.1.

CSI installer technical profile:

To install the HPE 3PAR StoreServ 9000 system, Hewlett Packard Enterprise recommends using an

installer experienced in the following:

• Have a good understanding and knowledge of SANs, Fiber Channel (FC) fundamentals, and a basic

understanding of TCP/IP and other networking protocols (DNS/NTP).

• Have a good understanding of server virtualization technology, in particular of hypervisors such as

VMware ESXi and Microsoft Hyper-V.

• Be able to maintain and install server hardware and Windows and/or Linux OSs.

• Have experience creating storage LUNs, presenting and/or exporting LUNs to a server, and formatting

the LUNs to make them usable for applications.

• Be able to troubleshoot hardware and software issues using logs and documentation.

• Have the required tools and mechanical skills to unpack, roll, and install a heavy rack, up to ~900 kg

(2,000 pounds). Three people are recommended to remove the racked system from its shipping

container.

6 Guidelines for the Customer Self Install of the HPE 3PAR StoreServ 9000

Page 7

If the installer does not meet the profile or is not comfortable with the CSI process, Hewlett Packard

Enterprise recommends contacting your Hewlett Packard Enterprise sales representative or HPE Channel

Partner to purchase HPE Deployment Services

CSI installer responsibilities:

• Review all the relevant documentation for the HPE 3PAR StoreServ 9000 prior to initiating the

installation.

• Ensure that the host and SAN environment is supported and compliant with HPE recommendations

and best practices. Resolve any problems with the host and SAN environment prior to installing the

HPE 3PAR StoreServ 9000. The HPE 3PAR Implementation Guides and the HPE 3PAR Smart SAN

User Guide are available at the Hewlett Packard Enterprise Information Library website:

www.hpe.com/info/storage/docs

The Support Matrix is available at the Single Point of Connectivity Knowledge (SPOCK) website:

www.hpe.com/storage/spock

• Gather the required network and password information as indicated in the HPE 3PAR StoreServ

Software Setup Worksheet.

• Use the HPE 3PAR Guided Setup and HPE 3PAR StoreServ Management Console (SSMC) to set up

and configure the storage system.

Guidelines for the Customer Self Install of the HPE 3PAR StoreServ 9000 7

Page 8

About the HPE 3PAR StoreServ 9000 Storage system

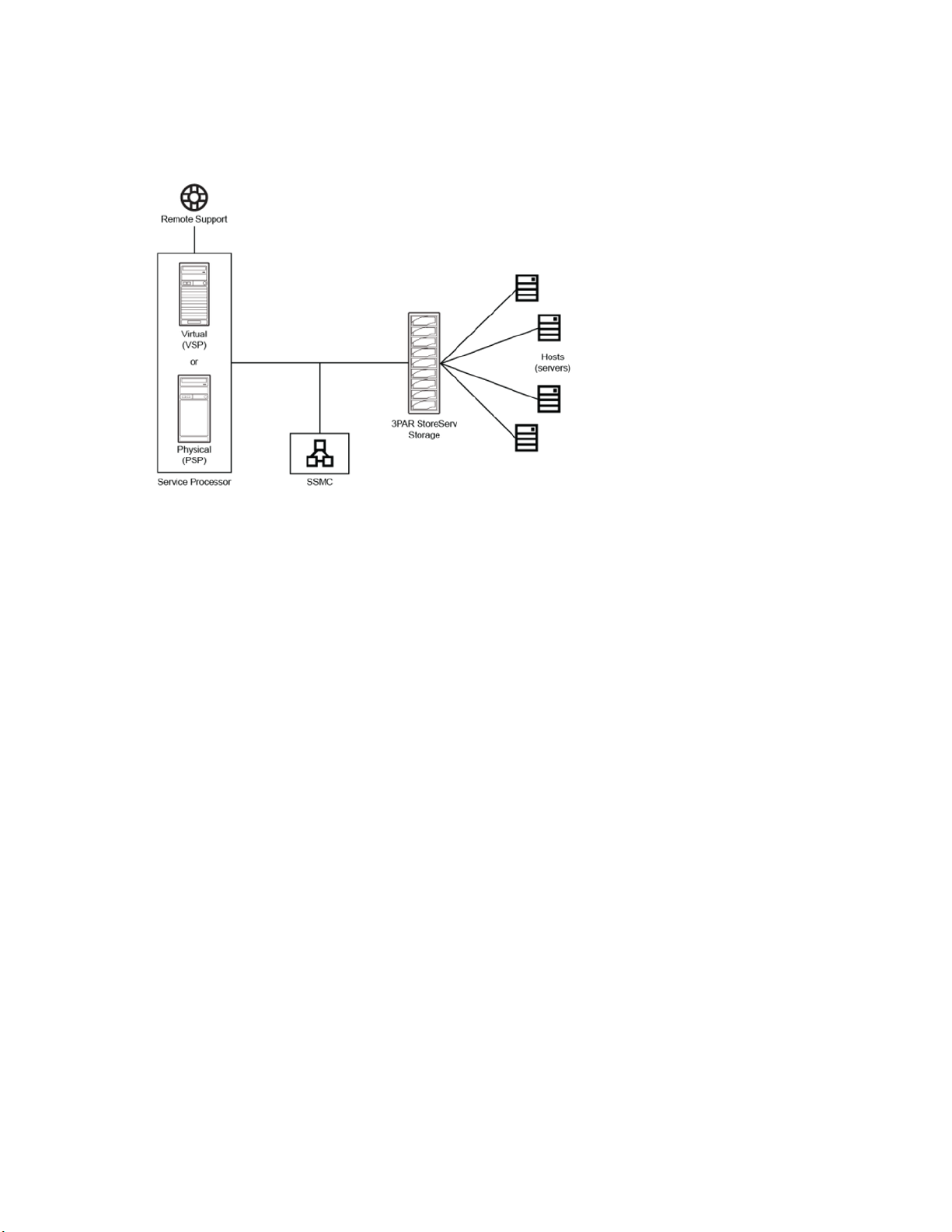

Figure 1: Architecture of the storage system

HPE 3PAR StoreServ 9000 Storage system:

The HPE 3PAR StoreServ 9000 Storage is an enterprise-class flash array. The storage system is

made up of a Controller Node Enclosure (two or four Controller Nodes), SAS Adapters, Host

Adapters; 2 to 48 Drive Enclosures with up to 24 small form factor (SFF) Solid-State Drives (SSDs)

each, and a Service Processor. The Controller Nodes include network ports to provide administrative

data-paths to the storage system.

Hosts (servers):

The host servers connect to the HPE 3PAR StoreServ 9000 Storage system directly or through a

switch with the following types of connections: FC, iSCSI, FCoE, or File Services.

HPE 3PAR StoreServ Management Console (SSMC) software:

The HPE 3PAR SSMC software defines, creates, and exports storage to your host servers. The HPE

3PAR SSMC also provides tools to monitor the health of your storage system.

HPE 3PAR Service Processor (SP) software:

Each HPE 3PAR StoreServ 9000 Storage system requires either an HPE 3PAR physical SP or HPE

3PAR virtual SP. The HPE 3PAR SP software is designed to provide remote monitoring, error

detection, error reporting, and support of diagnostic and maintenance activities involving the storage

system. The SP only sends support data to HPE 3PAR Remote Support. The HPE 3PAR virtual SP is

deployed as a virtual machine (VM) and runs on a customer-owned, customer-provided server and

communicates with the storage system over its Ethernet connection.

HPE 3PAR Remote Support connectivity:

HPE 3PAR Remote Support connectivity to HPE 3PAR Central is a utility that monitors the health of

your storage system. Information about the system health and configuration is transferred securely to

Hewlett Packard Enterprise. If HPE 3PAR Remote Support connectivity is enabled, it can also provide

critical software updates to your storage system.

8 About the HPE 3PAR StoreServ 9000 Storage system

Page 9

For additional HPE 3PAR StoreServ 9000 Storage architecture information, see the HPE 3PAR StoreServ

Storage Concepts Guide available at the Hewlett Packard Enterprise Information Library website:

www.hpe.com/info/storage/docs

For information about supported hardware and operating system (OS) platforms, see the Hewlett Packard

Enterprise Single Point of Connectivity Knowledge (SPOCK) website:

www.hpe.com/storage/spock

Installation media

Installation DVDs are not typically shipped with the HPE 3PAR StoreServ 9000 Storage system, and

instead the following delivery methods are used:

• If you selected the License to Use (LTU) delivery method of physical delivery during ordering,

installation media is shipped at the time of your order.

• If you selected electronic delivery, see the HPE e-Software Delivery Confirmation email for detailed

instructions for downloading the software. The e-Software Delivery Confirmation email was sent at the

time of purchase to your IT administrator, product manager, or purchasing agent.

If you require installation media, contact the Hewlett Packard Enterprise Support Center:

www.hpe.com/support/hpesc

Website for software downloads

Locate the software-receipt email that has the download link, or download the latest software from the

Hewlett Packard Enterprise Software updates and licensing website:

www.hpe.com/downloads/software

An HPE Passport profile and a valid Service Agreement ID (SAID) are required to access downloads.

Serial number location

The HPE 3PAR StoreServ 9000 Storage system has a 10-character serial number that is used with the

software setup.

The storage system serial number can be found in these locations:

• A label at the top-left-rear of the controller node enclosure

• The outside of the corrugated shipping material

Forum for the storage system

For the latest HPE 3PAR StoreServ 9000 Storage Customer Self Install (CSI) information, see the official

HPE 3PAR StoreServ Storage forum website in the Hewlett Packard Enterprise community:

www.hpe.com/forum/3PARCSIHELP

Use this forum to ask for help, share your installation experience, provide feedback, and search for

solutions to issues encountered during the installation process.

About the HPE 3PAR StoreServ 9000 Storage system 9

Page 10

Preparing: Process overview

Procedure

1. Review

2. Review Regulatory information on page 100.

3. Review Customer Self Install videos on page 11.

4. Complete the HPE 3PAR StoreServ 9000 Storage Software Set up Worksheet on page 95.

5. Review Acclimatizing on page 11.

6. Obtain the Tools for the installation on page 11.

7. Review Unpacking the factory-integrated-in-rack option: Process overview on page 12 and

complete the process.

Site planning on page 10.

Site planning

Successful installation of the HPE 3PAR StoreServ 9000 Storage system requires careful planning and

supervision and may require collaboration with authorized Hewlett Packard Enterprise representatives.

Proper site planning will help provide for a more efficient installation and greater reliability, availability, and

serviceability.

Environment—For optimal performance at a specific location, controlled environmental conditions are

recommended, and they can best be facilitated through raised flooring and under-floor air conditioning. It

is the responsibility of the customer to monitor this environment to ensure continued conformance with

the recommended environmental specifications.

Power—Adequate power is necessary for the reliable functioning of electronic equipment and for the

safety of the installation. The customer is responsible for procuring, installing, and maintaining adequate

power to the equipment.

• Provide suitable space for unpacking, installing, and operating the storage system.

• Review the power and the heating, ventilation, and air-conditioning (HVAC) requirements. Provide

adequate power facilities for the storage system and maintain proper environmental conditions for the

storage system. Order any additional support equipment indicated by the power and HVAC review.

• Verify that the electrical service wiring has been installed at the predetermined location before

installing the storage system. For detailed requirements, see the respective product specifications.

• Supply the network connections and external cabling required by the storage system.

• Ensure that all units in the specified configuration and all cables of the required length have been

ordered.

• Make a layout for the installation.

• Enable the appropriate HPE 3PAR Remote Support strategy.

10 Preparing: Process overview

Page 11

Procedure

Review the specific information concerning server-room environments and for input electrical power and

grounding requirements in the HPE 3PAR StoreServ 9000 Storage Site Planning Manual available at the

Hewlett Packard Enterprise Information Library website: www.hpe.com/info/storage/docs

Customer Self Install videos

The HPE 3PAR StoreServ 9000 Storage Customer Self Install (CSI) videos are available at the HPE

3PAR StoreServ 9000 Storage Customer Self Install Video website:

www.hpe.com/support/3PAR9000CSIVideo

NOTE: The video may take a minute to load.

Acclimatizing

CAUTION: To prevent potential damage to storage system hardware, do not power on the storage

system until it is fully acclimatized. The maximum acceptable rate of temperature change for a

nonoperating storage system is 36° F/hour (20° C/hour). If the storage system or its components

have experienced environmental changes during transit, allow enough time for the storage system

to acclimatize before proceeding with the power-on sequence.

Before powering on the HPE 3PAR StoreServ 9000 Storage system, the storage system might require up

to 24 hours to acclimatize to the new operating environment when outside-to-inside conditions vary

significantly.

Procedure

If condensation is present even after the 24-hour acclimatization period, wait for all condensation to fully

evaporate before completing the power-on sequence.

Tools for the installation

Table 1: Tools for the installation

Purpose Tools

Safety

Rack unpacking

Physical Service

Processor (SP)

connection setup

• ESD mat

• ESD grounding strap

• Scissors or snips

• Box cutter

• Socket wrench with 13 mm (1/2 in) and 17 mm (11/16 in) sockets for

removing L-bracket shipping clamps

• Adjustable wrench for leveling feet on the rack

Laptop for configuration of a physical Service Processor

Preparing: Process overview 11

Page 12

Unpacking the factory-integrated-in-rack option: Process overview

Prerequisites

Review the information about the placement of the HPE 3PAR StoreServ 9000 Storage system and

reserving room for service access in the HPE 3PAR StoreServ 9000 Storage Site Planning Manual

available at the Hewlett Packard Enterprise Information Library website:

www.hpe.com/info/storage/docs

Procedure

1. Complete Unpacking the HPE rack factory-integrated with the storage system on page 12.

2. Complete Positioning and stabilizing the HPE rack on page 20.

3. Drives are installed at the factory. However, if additional drives were received and not installed,

complete: Installing the drives: Process overview on page 21.

4. Review

complete the process.

Cabling the factory-integrated-in-rack option: Process overview on page 24 and

Unpacking the HPE rack factory-integrated with the storage system

During this procedure, refer to the unpacking diagrams on the outside of the cardboard shipping

container.

For more information about placement of the HPE 3PAR StoreServ Storage system and reserving room

for service access, see the HPE 3PAR StoreServ 9000 Storage Site Planning Manual available at the

Hewlett Packard Enterprise Information Library website:

www.hpe.com/info/storage/docs

NOTE: The illustrations in this procedure are examples and might not be an exact representation of your

HPE rack (cabinet).

12 Unpacking the factory-integrated-in-rack option: Process overview

Page 13

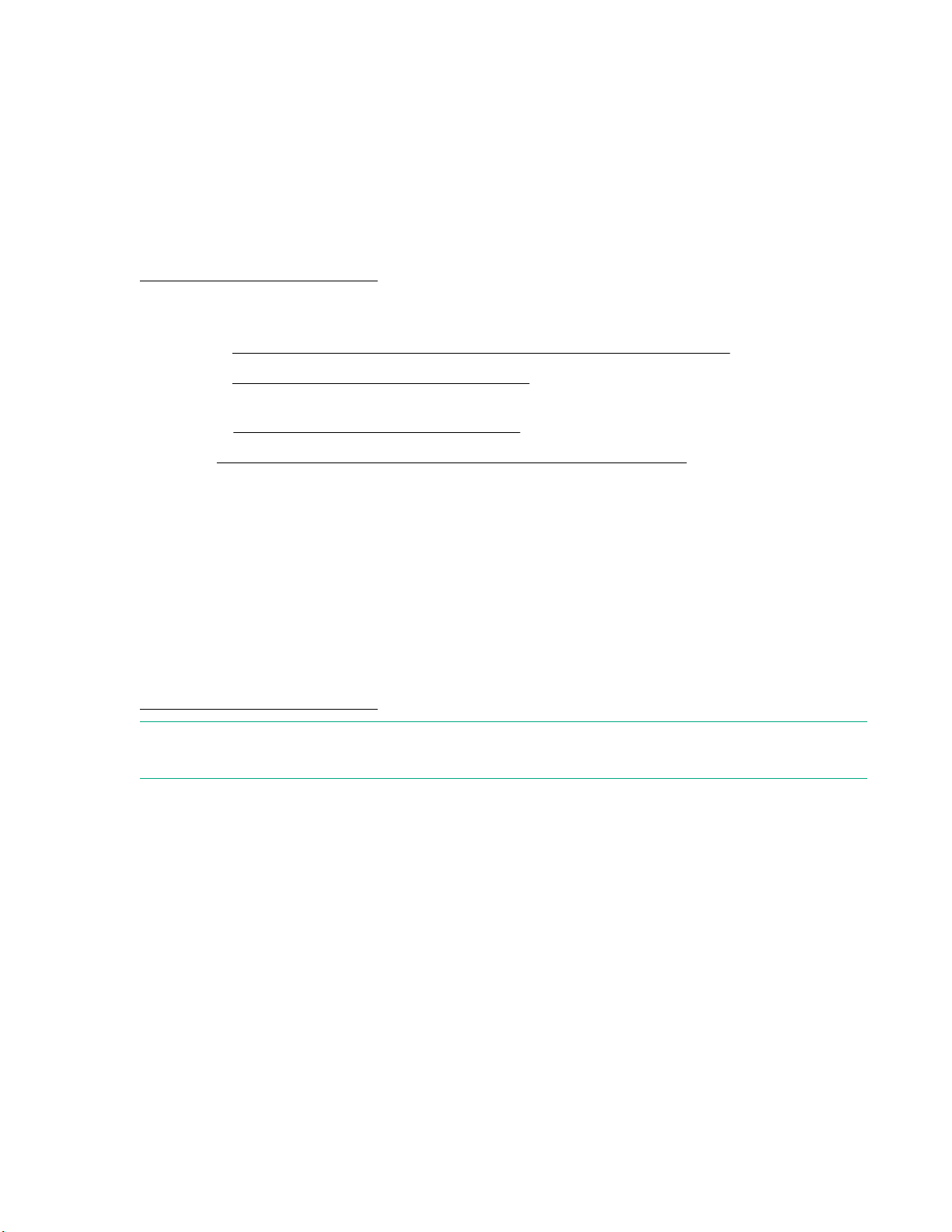

Figure 2: Items for unpacking an HPE rack

1. Rack (cabinet)

2. Ramps

3. Caster guides

4. Ramp supports

5. Pallet

Unpacking the factory-integrated-in-rack option: Process overview 13

Page 14

Prerequisites

CAUTION: Ensure that precautions have been taken to ensure rack stability and safety. Observe all

cautions and warnings included in the installation instructions.

• When the equipment arrives, verify that there is enough space to unload and unpack the HPE

3PAR StoreServ Storage system. The specific amount of space for unpacking the storage

system is based on the dimensions of the container, ramp, and room. This space is required to

access the storage system so that it can be removed from the crate and moved to its final

location.

• Verify that the delivered shipment matches the order by referring to the packing slip and SKUs.

• Observe local occupational safety requirements and guidelines for heavy equipment handling.

• Verify that the total weight of the rack is within the floor loading limit.

• Due to the weight of the rack, use extreme caution when unpacking and moving the rack to avoid

tipping the rack.

• When unloading the rack from the pallet, always use at least three people and do not stand in

front of the rack.

• To make the rack bottom-heavy and more stable, always load the heaviest item first from the

bottom of the rack and up.

Procedure

1. Inspect the packaging for damage and report any issues to the Hewlett Packard Enterprise Support

Center.

2. From the cardboard shipping container, remove the banding and top cover.

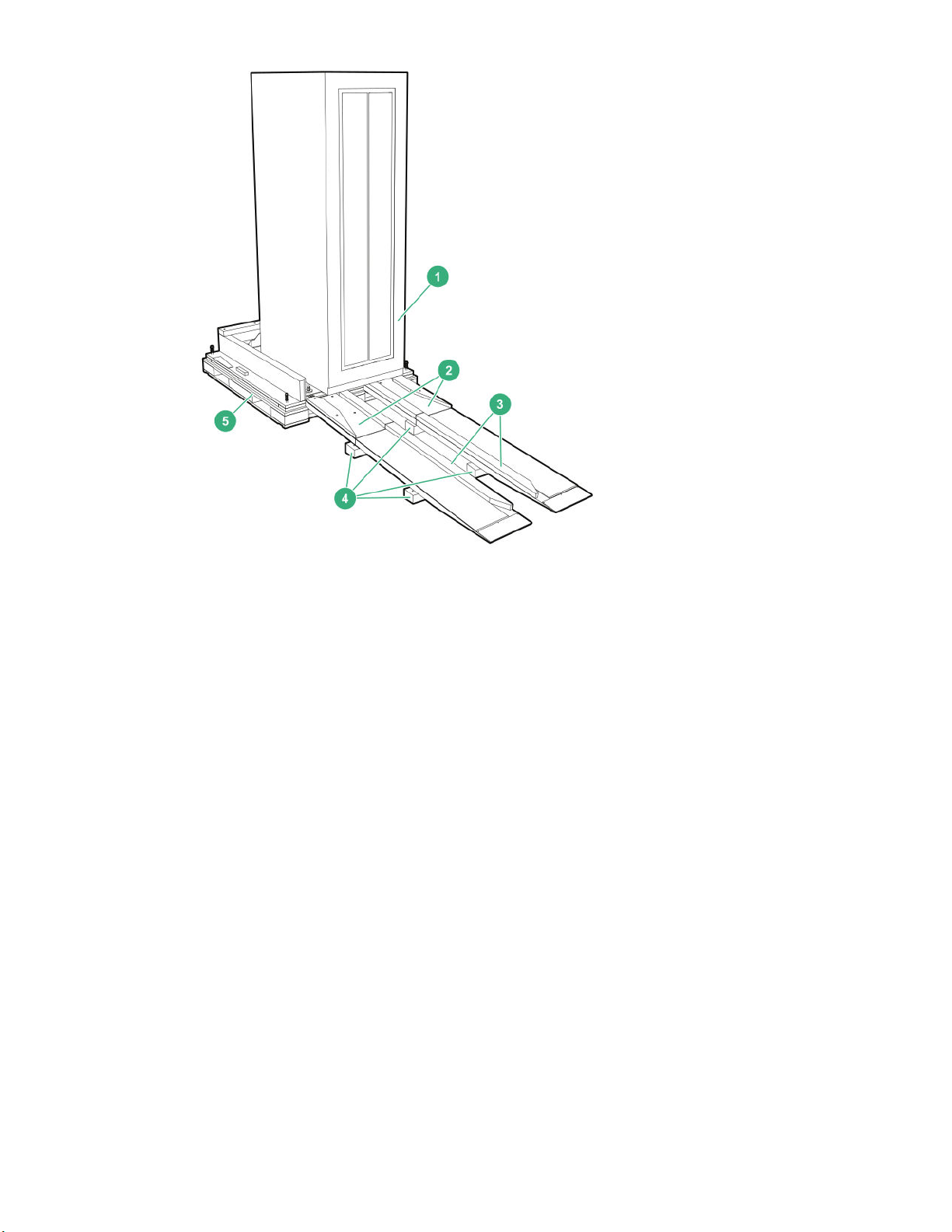

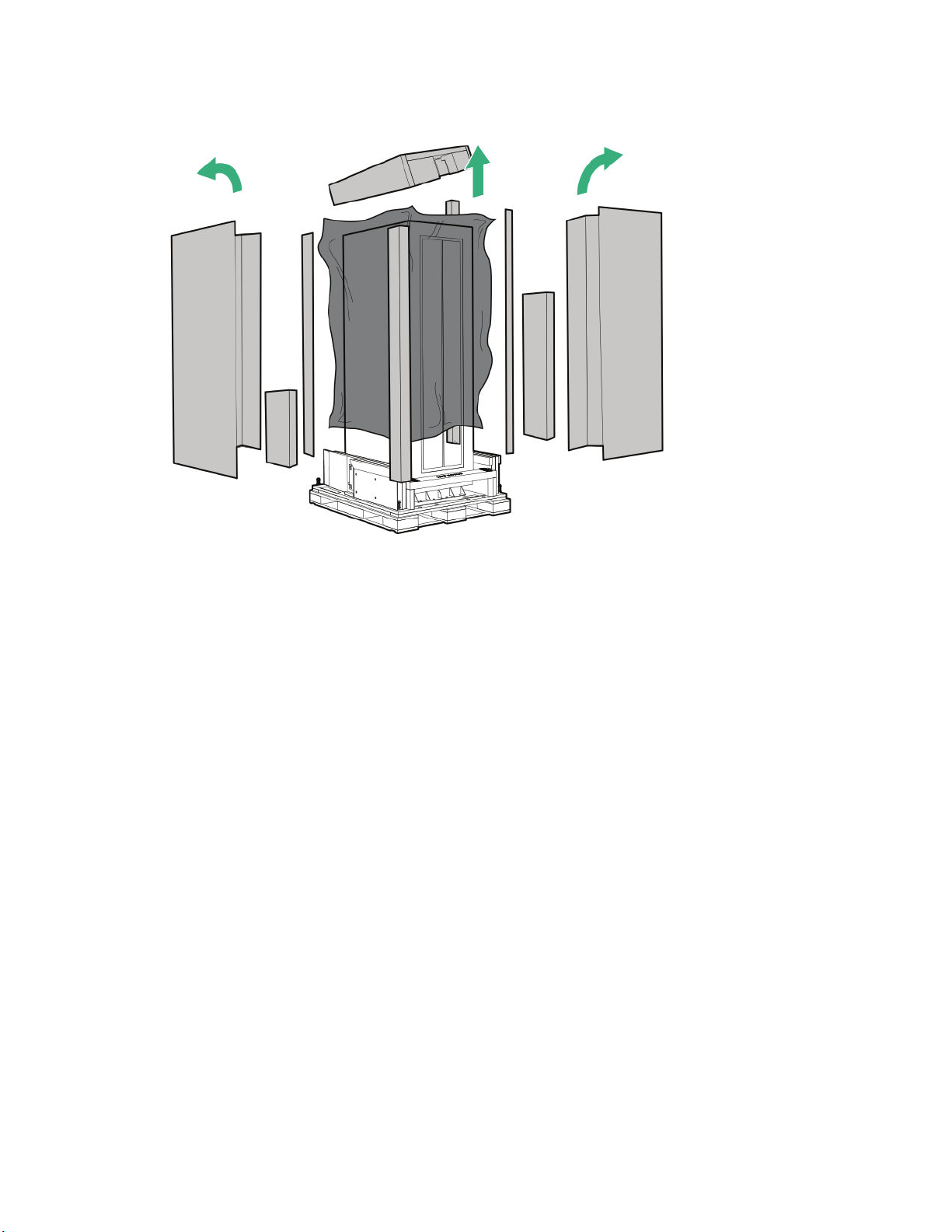

Figure 3: Removing the banding, HPE rack shipping container

14 Unpacking the factory-integrated-in-rack option: Process overview

Page 15

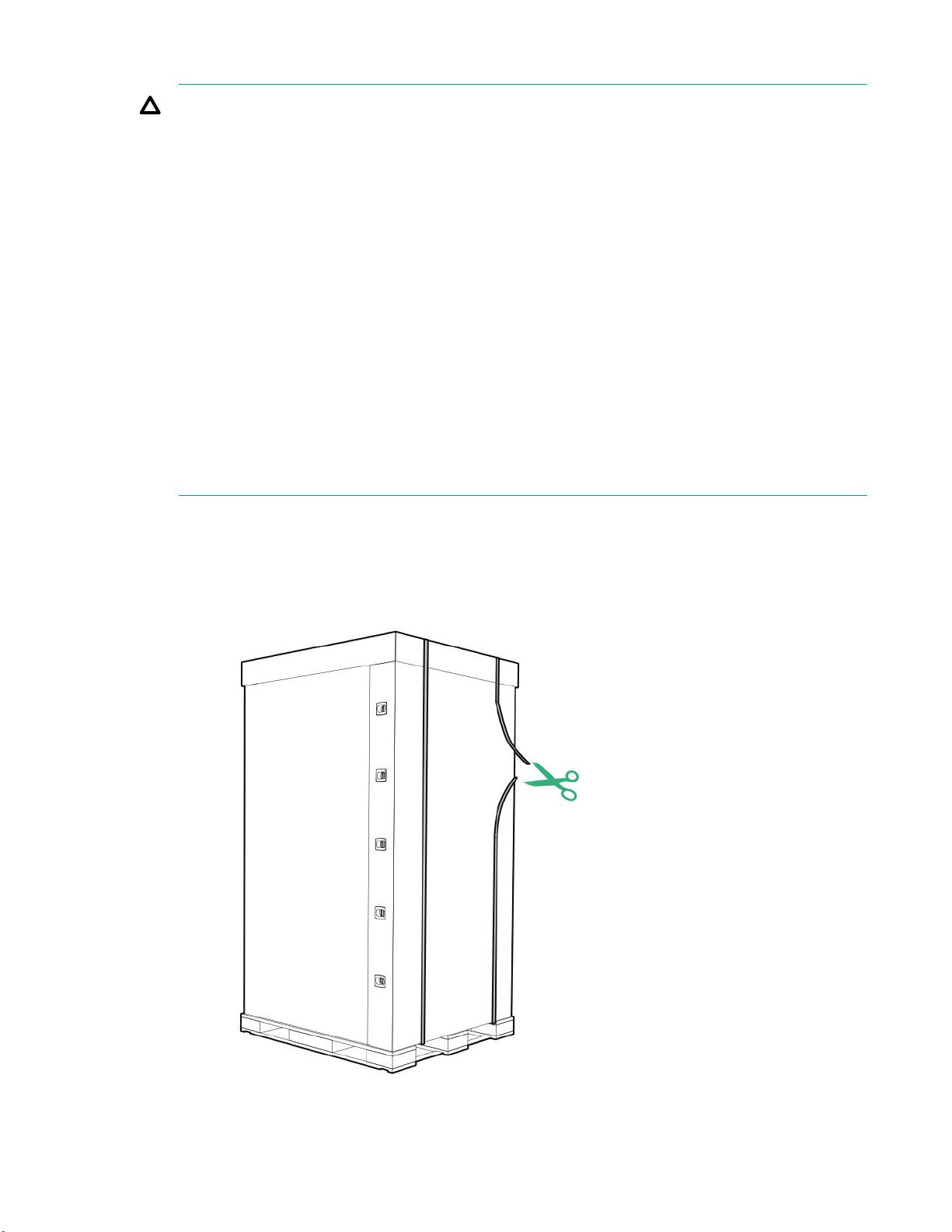

Figure 4: Removing the top, HPE rack shipping container

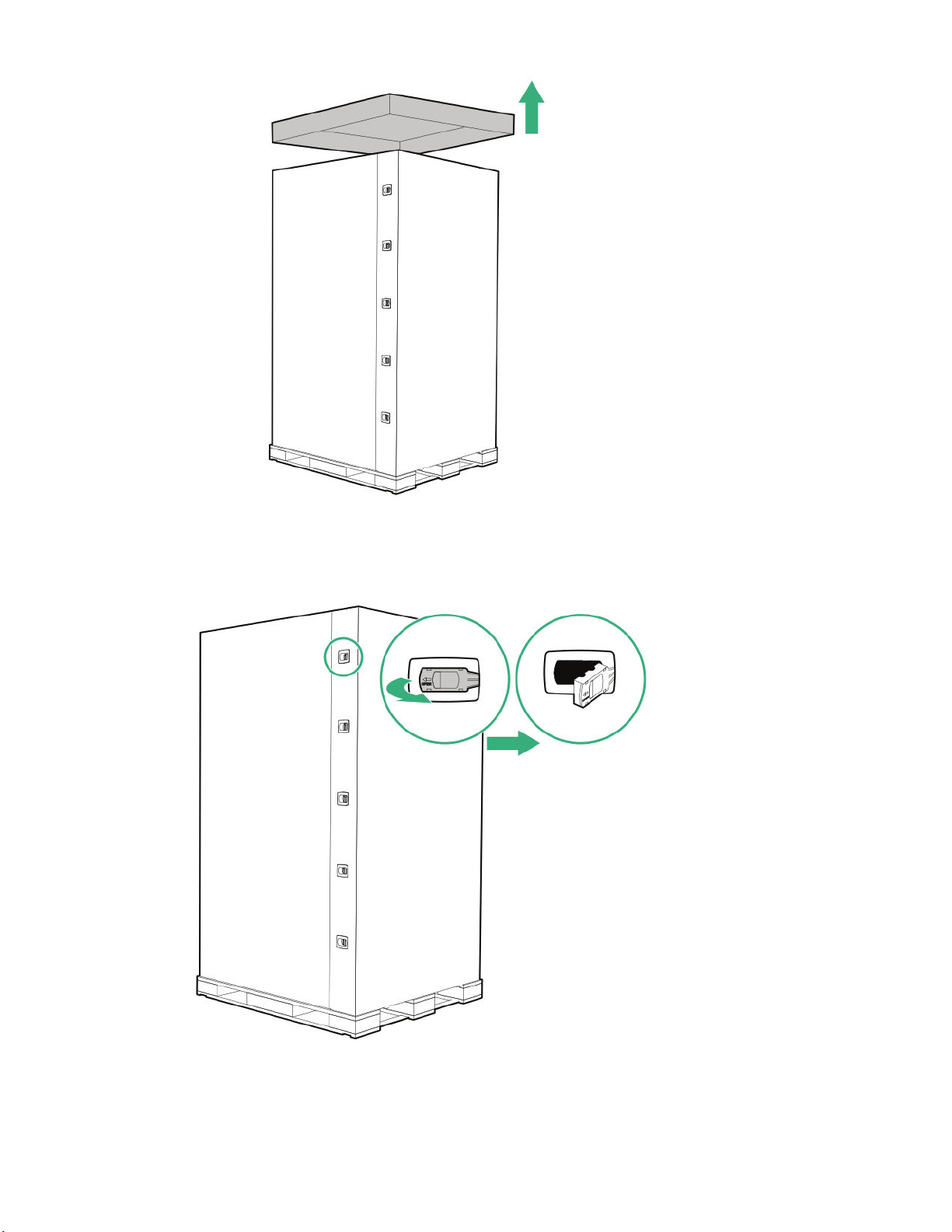

3. Remove the clips along the corrugated fiber board (CFB) walls and separate the CFB walls. Place the

separated walls away from the storage system.

Figure 5: Removing the clips, HPE rack shipping container

Unpacking the factory-integrated-in-rack option: Process overview 15

Page 16

4. Remove the packing material (wrapping material, foam pieces, plastic ESD cover), and then set aside

the boxes that hold the ramps and additional installation hardware.

Figure 6: Removing the packing material, HPE rack shipping container

5. Remove the four shipping L-brackets that attach the rack to the pallet using a socket wrench with 13

mm (1/2 in) and 17 mm (11/16 in) sockets.

a. Starting at the rack front, open the door and locate the two L-brackets.

b. Remove the two 13 mm (1/2 in) bolts that secure the L-bracket to the rack.

c. Remove the two 17 mm (11/16 in) bolts that secure the L-brackets to the pallet.

d. At the rack rear, repeat this same procedure to remove the remaining two L-brackets.

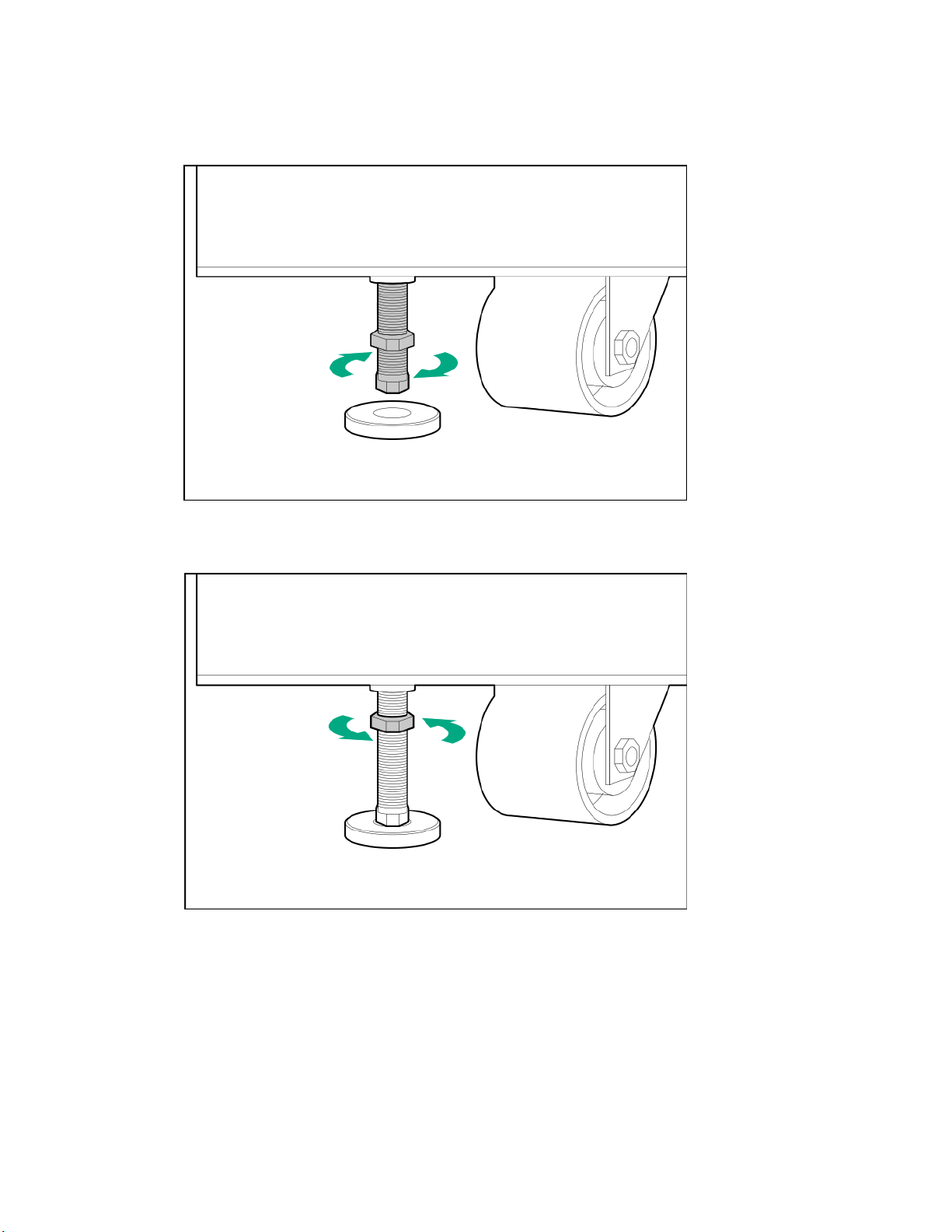

6. Check that the leveling bolts are raised to provide sufficient clearance for removing the rack from the

pallet.

a. If it is necessary to raise a leveling bolt, use an adjustable wrench and turn the upper locking nut

clockwise to loosen.

16 Unpacking the factory-integrated-in-rack option: Process overview

Page 17

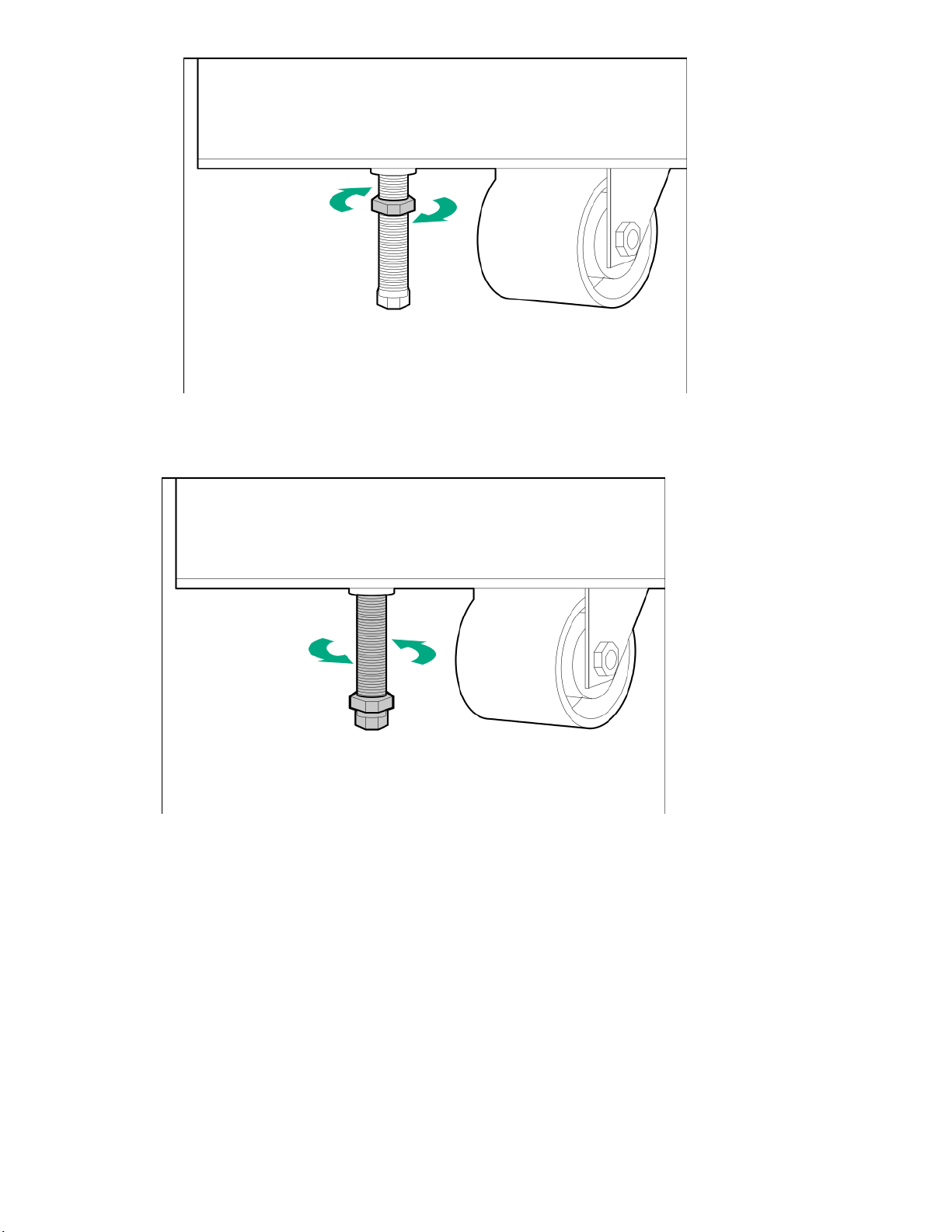

Figure 7: Releasing the locking nut, HPE rack leveling bolt

b. With an adjustable wrench, turn the leveling bolt counterclockwise until fully raised.

Figure 8: Raising the leveling bolt, HPE rack

7. Close and secure the rack front and rear doors.

8. Unpack the Ramp Assembly Kit and install the ramps and ramp supports at the front of the pallet.

a. Unpack the two ramps and four wooden supports.

b. Extend the ramps to their full length.

Unpacking the factory-integrated-in-rack option: Process overview 17

Page 18

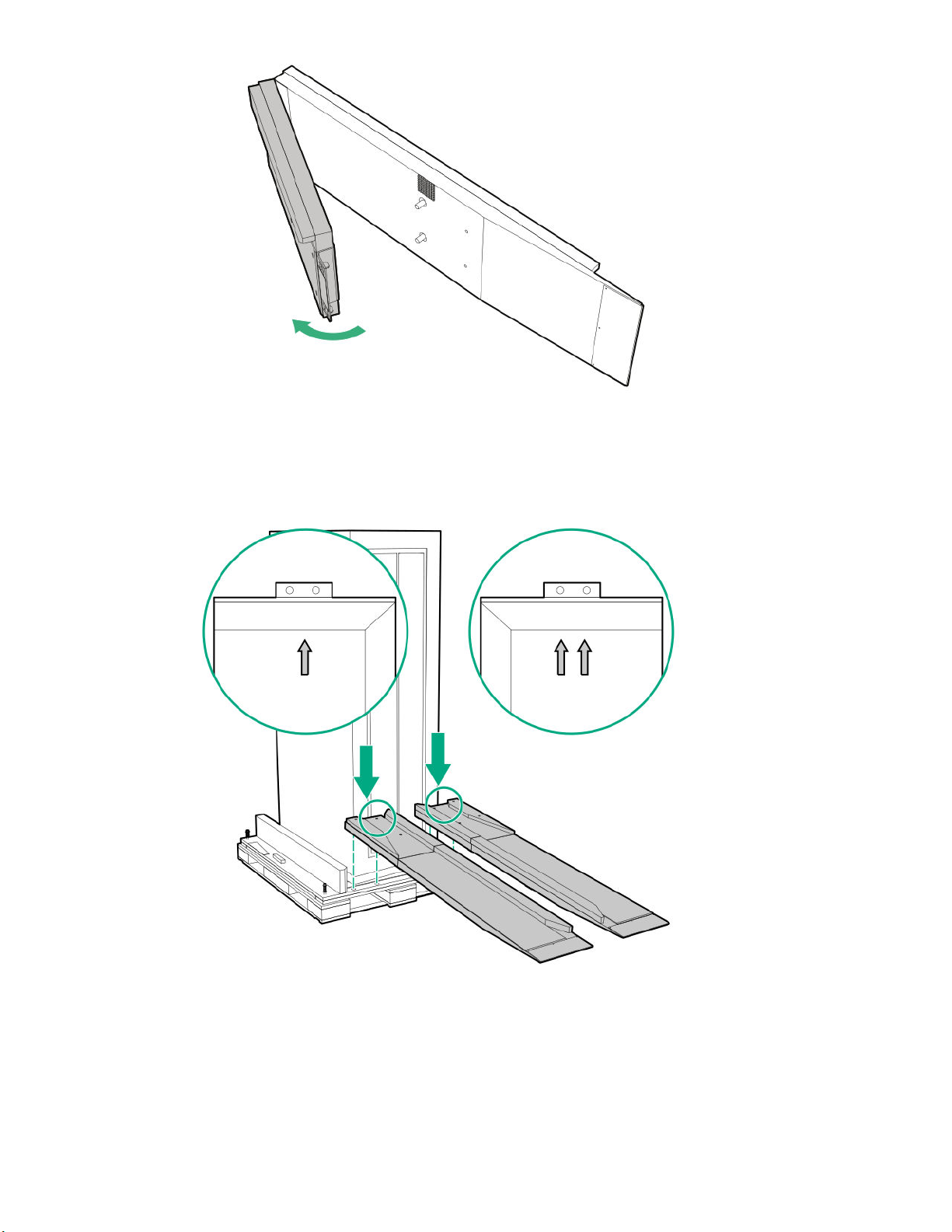

Figure 9: Extending the ramps, HPE rack shipping container

c. To install the ramps, match up the single arrow and double arrows on the pallet and ramps. The left

ramp has the single arrow, and the right ramp has double arrows. Attach the metal brackets with

the mounting holes along the front edge of the pallet, and then step firmly on the ramp and ensure

that the ramp is secure to the pallet.

Figure 10: Installing the ramps onto the pallet, HPE rack shipping container

18 Unpacking the factory-integrated-in-rack option: Process overview

Page 19

WARNING: Before rolling the rack from the pallet to the floor, correctly install the ramp

supports underneath the ramps, which will prevent the ramps from collapsing or causing the

rack to tip as it is moved down the ramps.

d. Attach the wooden ramp supports designated A and B to the locations on the ramps designated A

and B. Ensure that the angle of the wooden ramp support is attached to the ramps at the same

angle. The letters are marked on the ramp inside edge and support edge. Install support A beneath

the general area marked A on the rack, and do the same for support B. Insert the ramp support

beneath the ramp where the bottom of the ramp support touches the ground and the velcro on the

top of the ramp support is secure to the velcro underneath the ramp. The wooden ramp supports

must fit snugly between the ramp and the floor.

Figure 11: Installing the ramp supports, HPE rack shipping container

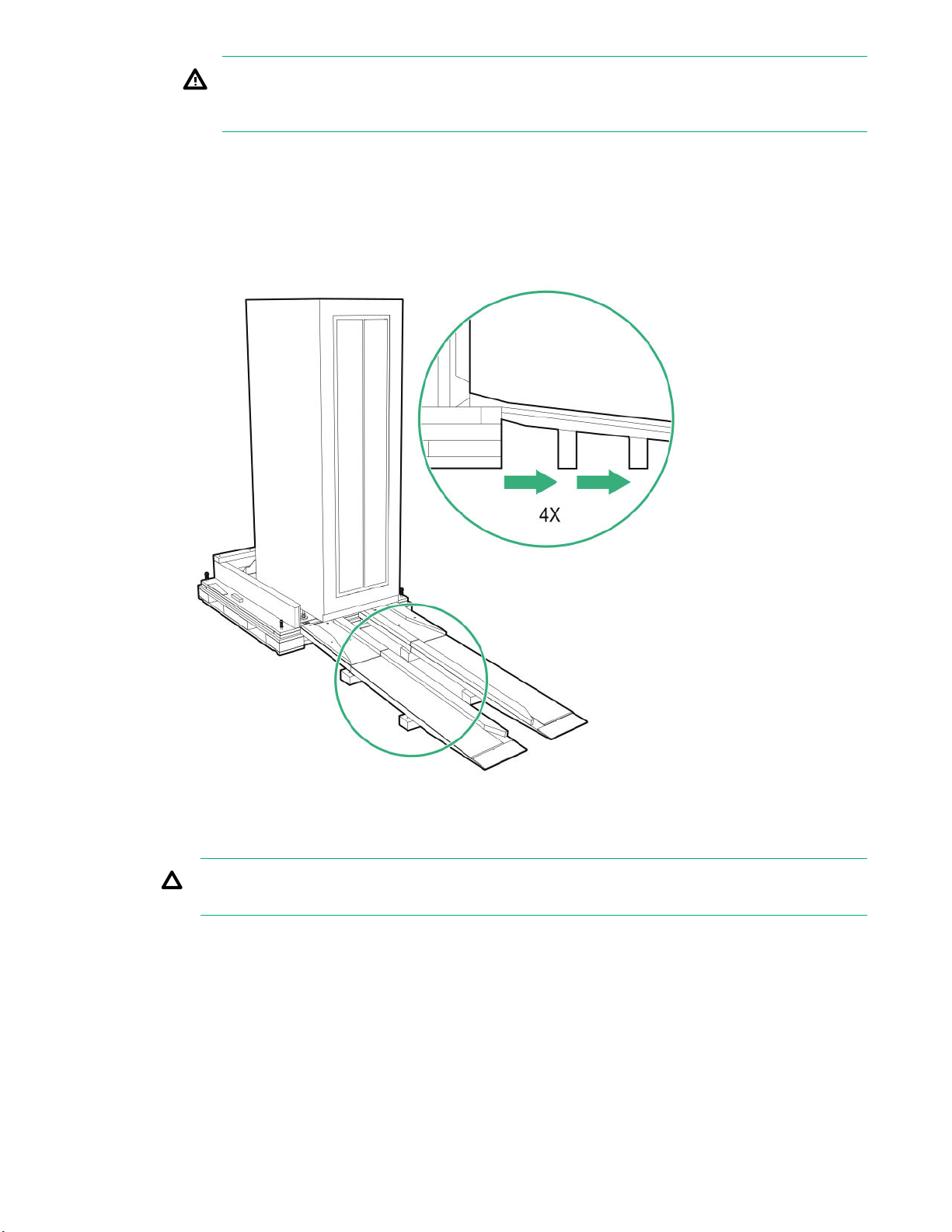

9. Roll the rack from the pallet to the floor.

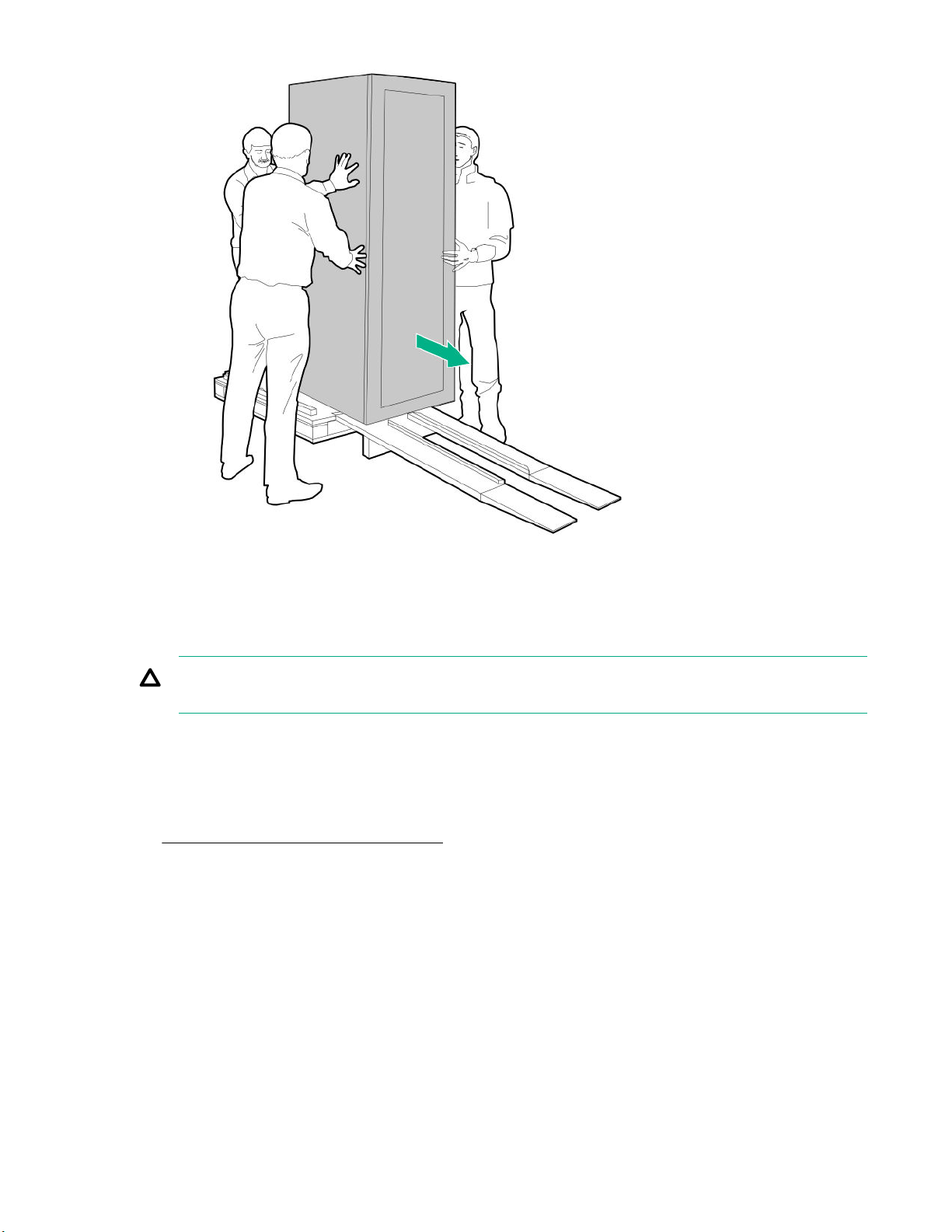

CAUTION: When unloading the rack from the pallet, always use at least three people and do not

stand in front of the rack.

To roll the rack off the pallet to the floor, each person must grasp the rack corners with two people

guiding the rack down the ramp while a third person slowly pushes the rack from behind. Based on the

weight of the rack, it may be necessary to have both people on the side carefully push the rack until it

is completely on the ramp and adjust to guiding the rack the rest of the way down the ramps and onto

the floor.

Unpacking the factory-integrated-in-rack option: Process overview 19

Page 20

Figure 12: Unloading the HPE rack from the pallet

Positioning and stabilizing the HPE rack

CAUTION: To prevent potential damage to the storage system equipment, do not adjust the position

of the HPE rack when the power is on.

Prerequisites

• Read and complete all the configuration specifications and installation requirements in the HPE 3PAR

StoreServ 9000 Storage Site Planning Manual available at the Hewlett Packard Enterprise Information

Library website:

http://www.hpe.com/info/storage/docs

• Obtain an adjustable wrench for leveling the feet on the HPE rack.

Procedure

1. Roll the HPE rack to the final operating location. If the operating location has raised floor tiles with

cutouts to facilitate cable routing, position the rack over the cutouts in the tiles.

2. Stabilize and level the HPE rack.

After properly positioning the storage system, four leveling pads must be installed underneath the four

leveling bolts to stabilize the HPE rack and prevent movement during operation. The leveling pads are

normally located in a plastic bag in the box that contains rack keys and accessory material. The

leveling pads provide a wider base for supporting the rack and protecting the floor.

20 Unpacking the factory-integrated-in-rack option: Process overview

Page 21

a. Position a leveling pad underneath the leveling bolt.

b. Using an adjustable wrench, turn the leveling bolt clockwise to extend the bolt until the entire

weight of the rack rests on the leveling pad instead of the caster. The caster must be slightly off the

floor, so it can swivel slightly by hand.

Figure 13: Lowering an HPE rack leveling bolt

c. Lock the leveling pad in place by turning the locking nut counterclockwise until tight.

Figure 14: Tightening the locking nut on an HPE rack leveling bolt

d. Repeat for each leveling pad.

Installing the drives: Process overview

This process overview is for installing the drives.

If it is necessary to install additional drives, complete the following process:

Unpacking the factory-integrated-in-rack option: Process overview 21

Page 22

Procedure

1. Review Guidelines for the drive installation on page 22.

2. Complete Installing the SFF drives on page 23.

Guidelines for the drive installation

IMPORTANT: The guidelines for how the drives are installed, allocated, and balanced are critical to

the performance and reliability of your storage system.

CAUTION:

• To ensure proper thermal control, slot-filler blanks are provided with the enclosures and must be

inserted in all unused drive bays in the enclosure. Operate the enclosure only when all drive

bays are populated with either a drive or a blank.

• If the storage system is enabled with the Data-at-Rest (DAR) encryption feature, only use

Federal Information Processing Standard (FIPS) capable encrypted drives.

• Before installing drives into enclosures, make sure that the enclosures are free of obstructions

(such as loose screws, hardware, or debris). Inspect the drives before installing them in the

enclosure to make sure that they are not damaged.

• To avoid errors when powering on the storage system, all enclosures must have at least one pair

of identical drives installed by following the guidelines for installing, allocating, and balancing

drives.

• A pair or pairs of drives must be installed in consecutively numbered slots in a drive enclosure and

must be of the same capacity and speed.

• The recommended initial quantity is eight SSDs per controller node pair, with a required minimum of

six SSDs per controller node pair.

• With a four-node configuration, the best practice is to attach the same number of drives to each

controller node pair.

• All drive enclosures must contain an even number of drives, with a minimum of two.

• Try to distribute an equal number of drives in all drive enclosures. If an equal distribution is not

possible, get as close as possible while still following the guidelines for the drives.

• RAID 6 is strongly recommended for all drive types.

SFF drive loading guidelines and examples:

The small form factor (SFF) drives are loaded starting at bay 0, left to right, leaving no empty space

between drives. The bays are numbered 0 through 23.

NOTE: The top right bay in the SFF drive enclosure must not be used and is populated with a blank

panel.

22 Unpacking the factory-integrated-in-rack option: Process overview

Page 23

Table 2: Example slot order, SFF drive enclosure

20 (...) 21 (...) 22 (...) 23 (...) 24 (Do not use)

15 (...) 16 (...) 17 (...) 18 (...) 19 (...)

10 (...) 11 (...) 12 (...) 13 (...) 14 (...)

5 (SSD) 6 (SSD) 7 (SSD) 8 (...) 9 (...)

0 (SSD) 1 (SSD) 2 (SSD) 3 (SSD) 4 (SSD)

Installing the SFF drives

Prerequisites

• Determine an installation plan for allocating and loading the drives based on the provided guidelines,

number of drives, and drive types to install.

• To avoid damaging any circuitry, wear an ESD grounding strap.

• Prepare a surface with an ESD safe mat for staging components for installation.

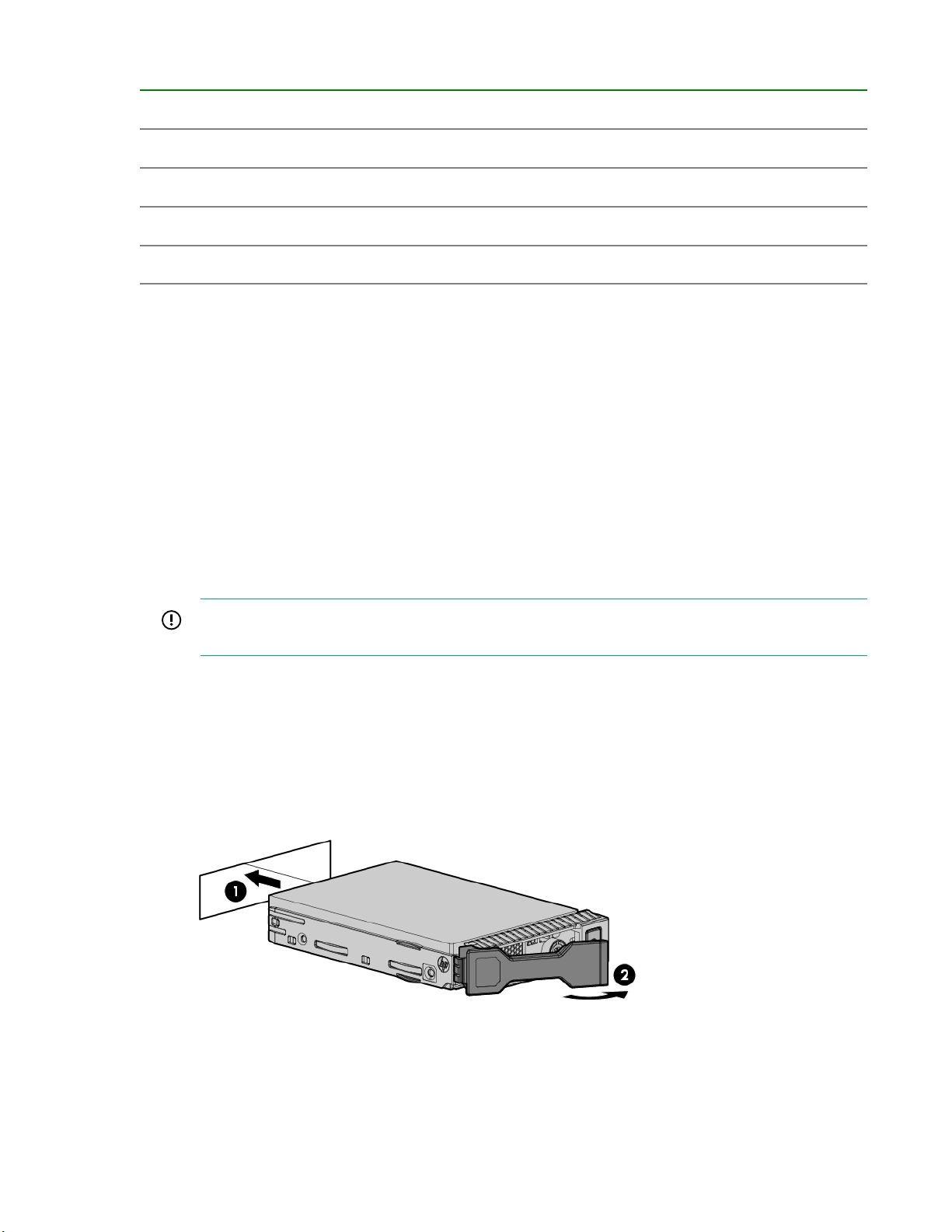

Procedure

1. Unpack the component and place on an ESD safe mat.

2. Remove the slot-filler blanks from where you will be installing the pairs of drives.

IMPORTANT: For proper airflow and cooling, a slot-filler blank must remain installed in all

unused drive bays.

3. Install the pair or pairs of drives.

a. On the drive, press the release button to open the handle.

b. With the latch handle of the drive fully extended, align and slide the drive into the bay until the

handle begins to engage (1).

c. To seat the drive into the drive bay, close the handle (2).

Figure 15: Installing an SFF drive

Unpacking the factory-integrated-in-rack option: Process overview 23

Page 24

Cabling the factory-integrated-in-rack option: Process overview

IMPORTANT: Do not turn on power to the components at this time. Connect the power cables and

keep the power off until you power on the components.

IMPORTANT: To enable access to components for servicing, neatly route and secure the cables

along the sides of the rack.

For an HPE 3PAR StoreServ 9000 Storage system that is factory integrated in an HPE rack, the internal

cabling for the data cables and power cables has been completed before shipment; however, you must

complete the following additional cabling process:

Procedure

1. Review Guidelines for cabling on page 24.

2. Review

3. Complete Cabling the physical service processor (if installed) on page 27.

4. Complete Cabling the controller nodes: Process overview on page 28.

5. Complete Cabling the power cords of the power distribution units to the power receptacles at

the operating site on page 32.

6. Review Powering on: Process overview on page 33 and complete the process.

Guidelines for redundant power cabling on page 26.

Guidelines for cabling

Guidelines for the minimum bend radius of the cable

Bend radius is defined as the minimum radius to which the cable may safely be bent during installation

without the risk of permanent damage resulting in excessive attenuation or even breakage.

Use the manufacturer guidelines for the minimum bend radius of a cable. If manufacturer guidelines have

not been provided, use the general guidelines provided in the following table.

CAUTION: Bending optical cables tightly can damage the internal fibers, causing signal loss,

reduced reliability, and performance problems.

IMPORTANT: Minimum bend radius is not the same as minimum bend diameter.

Table 3: General minimum bend radius by cable type

Cable type Minimum bend radius

Standard power cable 1 in (2.5 cm)

Active optical cable (AOC) 2 in (5.08 cm)

Fiber optical cable 1.75 in (4.44 cm)

24 Cabling the factory-integrated-in-rack option: Process overview

Table Continued

Page 25

Cable type Minimum bend radius

Network Cat 5/6 (Unshielded) 1.75 in (4.44 cm)

Network Cat 5/6 (Shielded) 3.5 in (8.90 cm)

Coaxial (50W) 1.2 in (3 cm)

Coaxial (75W) 1.7 in (4.31 cm)

R1 InfiniBand - at connector 4.6 in (11.68 cm)

R2 InfiniBand - away from connector 2.6 in (6.60 cm)

• Power cable: Minimum bend radius prevents disconnection from power socket and possible arcing

under high-voltage conditions. When there is a high voltage or high current on the cable, sharp edges

or turns can cause puncturing of the cable jacket or arcing to equipment at local potential.

• Copper cable: Too sharp a radius will stress the center conductor, and may cause the cable outer

conductor to collapse or buckle. A sharp radius will cause impedance discontinuities at the bends

resulting in reflections and leads to signal degradation and circuit problems. An excessive bending of

cable can affect the geometry of the twists and increase the sensitivity to external noise and cause

stress on cable terminations.

• Fiber optic: Tighter bends may cause micro-bending of individual fibers that allow light to escape the

signal path, resulting in signal attenuation. More severe bends can break fiber strands completely,

resulting in signal loss.

General guidelines for cabling

• If not already applied by the factory, label all cables.

• Use the shortest possible cable between devices. Shorter cables reduce the possibility of signal

degradation over longer distances and are easier to route along the rear of the rack.

• Cables cannot have any obvious kinks, deformation, or damage to the connector housing or

sheathing. To prevent these issues, use extra care when unpacking, unwinding, routing, and storing

cables.

• To prevent mechanical damage or depositing contaminants from your hands, do not touch the ends of

the cable connectors.

• Before connecting a cable to a port, lay the cable in place to verify the length of the cable.

• Some data cables are prebent. Do not unbend or manipulate the cables.

• For components that must be movable while powered on, ensure that a full range of motion (frequently

called a service loop) is possible without cable interference or disconnection.

• Leave some slack in the cable (service loop). The slack provides room to remove and replace

components, allows for minor, inadvertent movement of the rack, and helps prevent the cables from

being bent to less than the minimum bend radius. The slack can be addressed by forming loops or

using a take-up spool as long as the minimum bend radius is maintained.

Guidelines for connecting, routing, and restraining cables

• When routing cables, always be sure that the cables are not in a position where they can be pinched

or crimped.

• When routing cables onto a management arm, secure the cables enough to prevent interference or

pinch areas during movement, yet not so tight as to cause binding.

Cabling the factory-integrated-in-rack option: Process overview 25

Page 26

• Restrain and support cables in a manner that eliminates stress on connectors and eliminates tight

bends of the cables.

• Secure fiber and AOC cables with loose fitting Velcro straps, instead of wire or cable ties.

• For cable ties, ensure that the cables are not compressed when cinching the tie, and cut the cable ties

flush with the cable tie head to prevent scratches or cuts during future service interactions.

• When the cables are restrained together, verify that storage system components and LED indicators

are easily visible and accessible for operation and maintenance.

Guidelines for disconnecting cables

To prevent damage to the internal wires of the cable or the port pins, operate the release latch on the

cable connector, and then grip the body of the cable connector to disconnect the cable instead of pulling

on the cable.

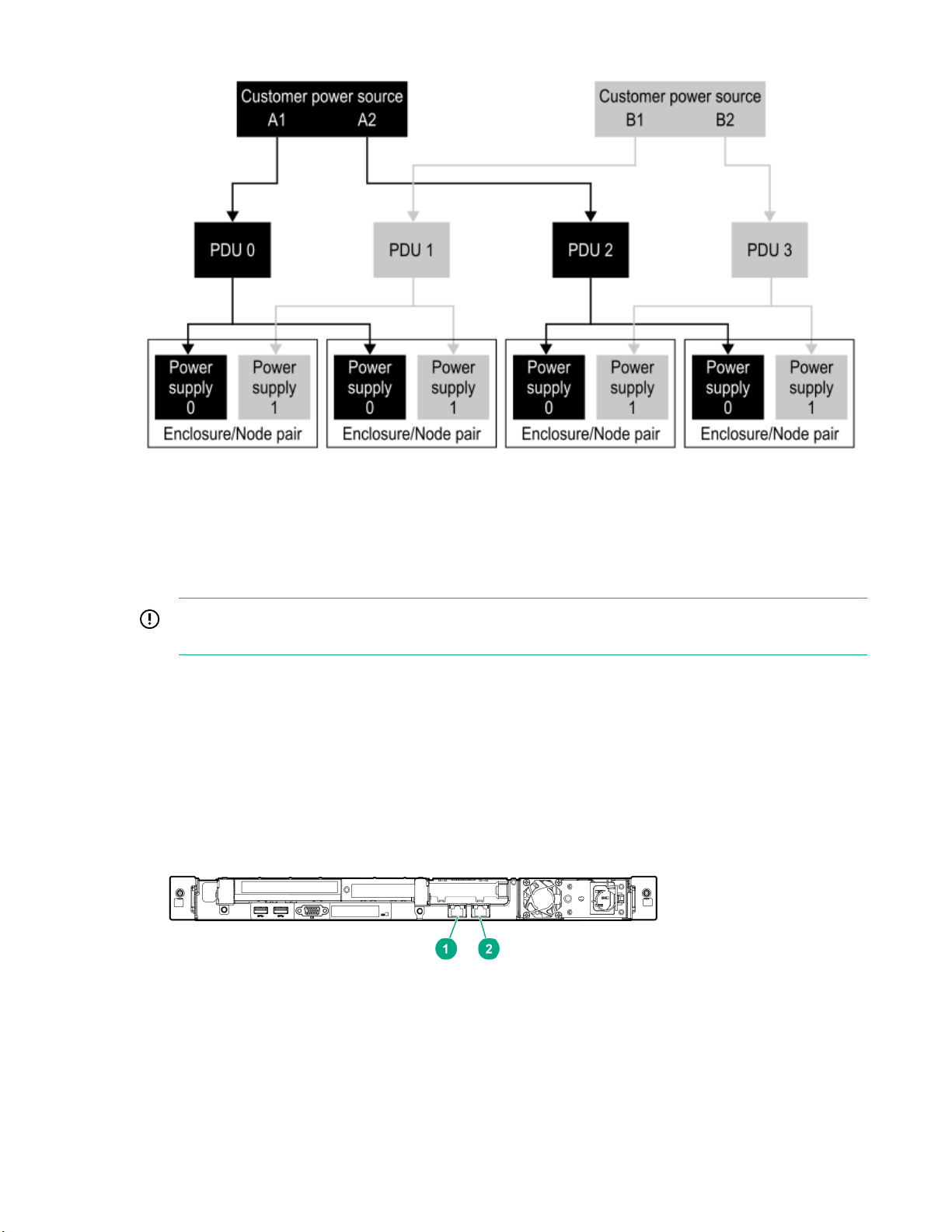

Guidelines for redundant power cabling

Power should be supplied to each component of the storage system using redundant power supplies and

redundant power distribution units (PDUs). If the power connections for the system are correctly

configured for power redundancy, the system will stay operational if a power failure occurs with an input

power source, a PDU, or a power supply.

WARNING: To avoid possible injury, damage to storage system equipment, and potential loss of

data, do not use the surplus PDU outlets. Never use PDU outlets to power components that do not

belong to the storage system or that reside in other racks.

To achieve redundant power, the storage system must have the following redundant power configuration.

See Figure 16: Redundant power configuration on page 27.

• Customer power source: Each main, independent, grounded-electrical power source should be

controlled and protected by its own circuit breaker.

• PDU:

◦ The even-numbered PDUs should be connected to customer power source (A)

◦ The odd-numbered PDUs should be connected to customer power source (B).

NOTE: The number of PDUs in a rack can vary depending on the rack and power type (such as,

single- or three-phase power).

• Power supply:

NOTE: The generic term "power supply" refers to various types of power components, such as a

power supply unit (PSU), power cooling module (PCM), or a power cooling battery module (PCBM).

◦ Controller node pair: Each power supply should be connected to a separate PDU.

◦ Drive enclosure: Each power supply should be connected to a separate PDU.

◦ Even-numbered power supplies: Each power supply 0 should be connected to an even-

numbered PDU using a black power cable.

◦ Odd-numbered power supplies: Each power supply 1 should be connected to an odd-numbered

PDU using a gray power cable.

26 Cabling the factory-integrated-in-rack option: Process overview

Page 27

Figure 16: Redundant power configuration

Cabling the physical service processor (if installed)

The physical service processor is an optional component that can be used with the HPE 3PAR StoreServ

9000 Storage system instead of using a virtual service processor.

IMPORTANT: Do not turn on power to the components at this time. Connect the power cables and

keep the power off until you power on the components.

Procedure

1. Connect the cable for the management connection.

a. Connect an Ethernet cable between the Management port and the network using the same subnet

as the storage system.

b. At the rack rear, neatly route and secure the cables along the right side of the rack.

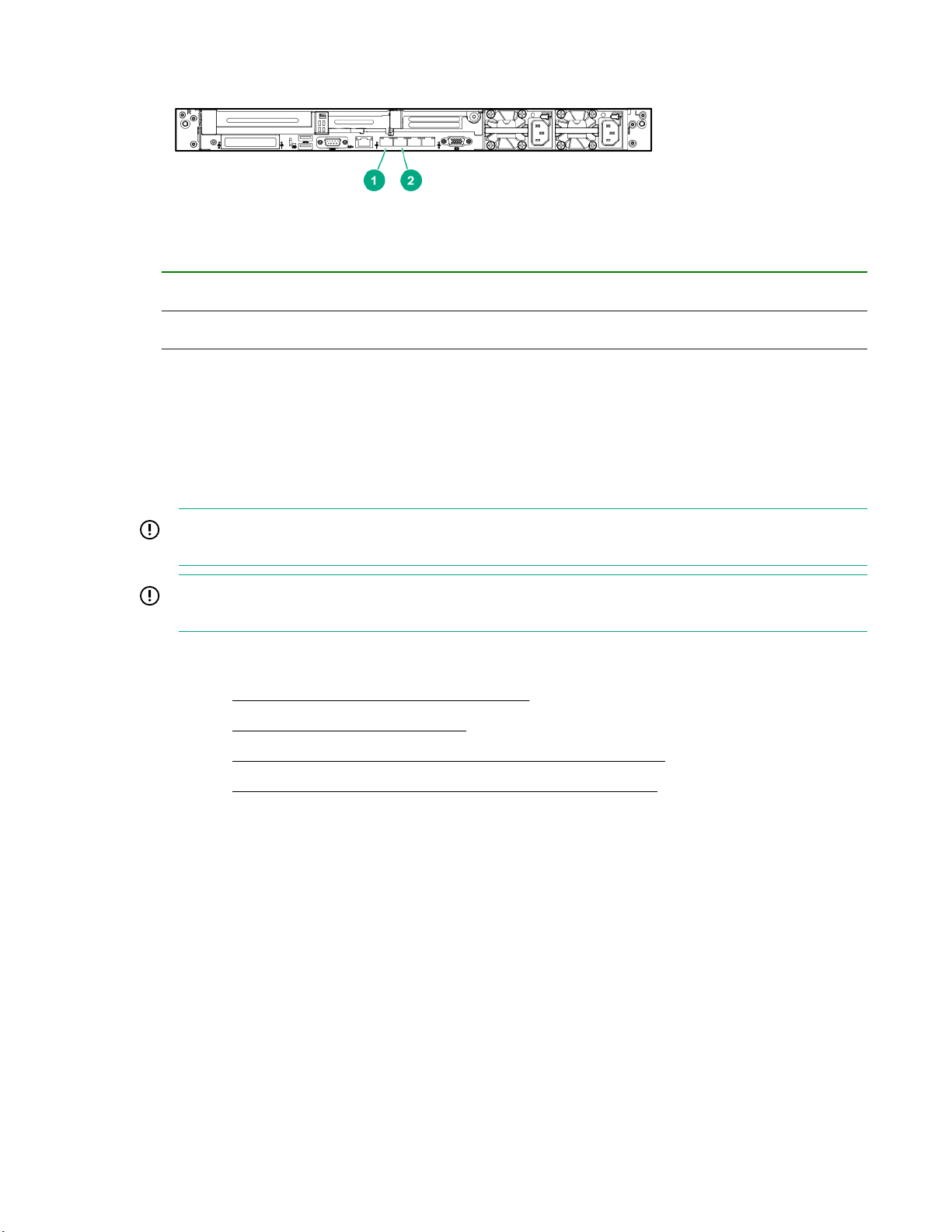

Figure 17: Physical service processor ports, HPE ProLiant DL120 Gen9 Server

Cabling the factory-integrated-in-rack option: Process overview 27

Page 28

Figure 18: Physical service processor ports, HPE ProLiant DL360 Gen10 Server

1 Management (MGMT) port; NIC 1

2 Service port; NIC 2

2. Connect and secure the cable for the power connection.

Power connection—Connect a power cable to a power source, but do not turn on the power yet.

For dual power supplies, connect power cables to both power supplies and each to an independent

power source.

Cabling the controller nodes: Process overview

IMPORTANT: Do not turn on power to the components at this time. Connect the power cables and

keep the power off until you power on the components.

IMPORTANT: To enable access to components for servicing, neatly route and secure the cables

along the sides of the rack.

Procedure

1. Complete Cabling for the management connection on page 28.

2. Complete Cabling for the host connection on page 29.

3. Complete Cabling for the Remote Copy connection (optional feature) on page 31.

4. Complete Cabling for the File Persona connection (optional feature) on page 31.

Cabling for the management connection

Procedure

• Connect a CAT-5e or Cat 6 Ethernet cable between the onboard MGMT port on each controller node

and the network. At the rack rear, neatly route and secure the cables along the right side of the rack.

Each controller node supports one Ethernet connection to a switch or hub. Separate connections from

the Ethernet switch or hub to at least two controller nodes are required to support redundancy. One IP

address is shared between the two connections, and only one network connection is active at a time. If

the active network connection fails, the IP address is automatically moved to the surviving network

connection.

28 Cabling the factory-integrated-in-rack option: Process overview

Page 29

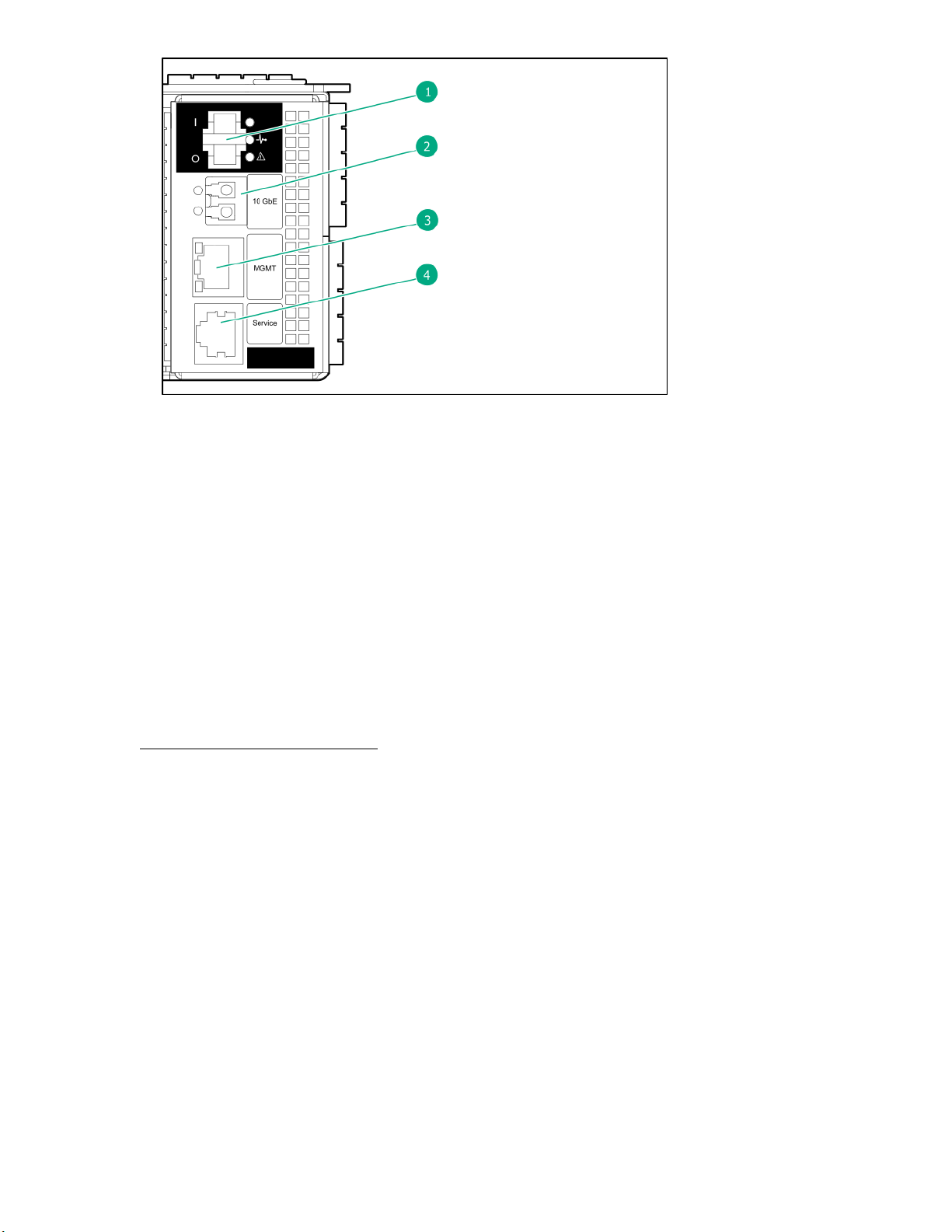

1. Power switch

2. 10 GbE port (RCIP)

3. 1 GbE Management (MGMT) port

4. Service port (Console)

Figure 19: Controller node ports

Cabling for the host connection

Prerequisites

Before connecting any FC or iSCSI cables, follow the guidelines provided for your host OS that are

available in an HPE 3PAR host-OS implementation guide available at the Hewlett Packard Enterprise

Information Library website:

www.hpe.com/info/storage/docs

For instance, the following are some of the available HPE 3PAR host-OS implementation guides:

• HPE 3PAR AIX and IBM Virtual I/O Server Implementation Guide

• HPE 3PAR Apple OS X Implementation Guide

• HPE 3PAR Citrix XenServer Implementation Guide

• HPE 3PAR HP-UX Implementation Guide

• HPE 3PAR Solaris Implementation Guide

• HPE 3PAR SUSE Linux Enterprise Implementation Guide

• HPE 3PAR Red Hat Enterprise Linux and Oracle Linux Implementation Guide

• HPE 3PAR VMware ESX/ESXi Implementation Guide

• HPE 3PAR Windows Server 2016/2012/2008 Implementation Guide

Cabling the factory-integrated-in-rack option: Process overview 29

Page 30

Procedure

• Connect a cable between a port on a host adapter (FC/iSCSI) and a switch or directly to the host; one

or more cables per controller node. Hewlett Packard Enterprise recommends connecting each host to

both controller nodes in a controller nodes pair (node pair: 0/1 or 2/3) using the same port number on

the FC/iSCSI host adapters to provide redundancy. At the rack rear, neatly route and secure the

cables along the left side of the rack. When possible, route and secure host cables towards the rear of

the rack, separated from the internally routed SAS cables.

Recommended configurations for FC/iSCSI host connectivity

For optimal redundancy and I/O load balancing, Hewlett Packard Enterprise recommends the

guidelines for connectivity from any given host-server (host) to the controller node pair (node pair) on

the storage system:

◦ Depending on the number of host ports available, balance the host-server ports across both

controller nodes in the node pair of the storage system at a minimum.

◦ From any given host, make a pair of connections from any given host to the same numbered slot

and port (partner port) on each controller node in the node pair.

◦ If more than one host connection can be made per controller node, distribute connections of the

same type (for example, FC) from any given host across host adapters in different slots (where

available) on any given controller node.

NOTE: To provide redundancy and to permit online software upgrades, both controller nodes in a node

pair (for example, controller nodes 0 and 1 or controller nodes 2 and 3) must maintain connections to

each host server.

Host connectivity using a switch

◦ For an Ethernet switch, the recommended configuration for the connection is from the Ethernet

switch or hub to two controller nodes (node pair).

◦ For an FC switch, you must set up FC fabric zoning to restrict WWNs seen by the system.

NOTE: With HPE 3PAR File Persona or HPE 3PAR Remote Copy, an additional Ethernet connection

is required.

See “Supported Network Topologies” in the HPE 3PAR StoreServ 9000 Storage Site Planning Manual

available at the Hewlett Packard Enterprise Information Library website:

www.hpe.com/info/storage/docs

30 Cabling the factory-integrated-in-rack option: Process overview

Page 31

FC cable limitations for host connectivity

Cable size Speed Maximum cable length limit

50 micron 16 Gb/s 50 meters

The maximum supported Fibre Channel cable length is based on the cable size and port speed.

Cabling for the Remote Copy connection (optional feature)

Hewlett Packard Enterprise

For the optional HPE 3PAR Remote Copy connection with the HPE 3PAR StoreServ 9000 Storage, see

the HPE 3PAR Remote Copy Software User Guide available at the Hewlett Packard Enterprise

Information Library website:

www.hpe.com/info/storage/docs

Procedure

Connect a cable between the onboard 10 GbE (RCIP) port or four-port 16Gb FC HBA (RCFC) and

another HPE 3PAR StoreServ 9000 system. To provide redundancy, connect two or more controller

nodes per storage system.

Cabling for the File Persona connection (optional feature)

Hewlett Packard Enterprise

For the optional HPE 3PAR File Persona connection with the HPE 3PAR StoreServ 9000 Storage, see

the HPE 3PAR File Persona User Guide available at the Hewlett Packard Enterprise Information Library

website:

www.hpe.com/info/storage/docs

Cabling the factory-integrated-in-rack option: Process overview 31

Page 32

Procedure

Connect a cable between a port on a two-port 10Gb Ethernet NIC adapter and the network. To provide

redundancy, connect two or more controller nodes per storage system.

Cabling the power cords of the power distribution units to the power receptacles at the operating site

IMPORTANT: Do not turn on power to the components at this time. Connect the power cables and

keep the power off until you power on the components.

Each AC power cord on the PDUs must connect to an appropriate outlet based on the cord type and

power requirements for supplying power to the storage system.

Prerequisites

WARNING: Before connecting a main power cable, confirm that the circuit breakers for all internal

PDUs are set to the OFF position to prevent danger of electric shock and potential damage to

equipment.

IMPORTANT: Verify that the operating site provides redundant power.

Procedure

1. Based on the location of the power receptacles at the operating site, route the PDU power cords

through the top or bottom of the rack.

2. Connect the even-numbered PDUs to power receptacles from one power source (source A) and

connect the odd-numbered PDUs to power receptacles from another power source (source B) with

each power receptacle controlled and protected by its own circuit breaker.

32 Cabling the factory-integrated-in-rack option: Process overview

Page 33

Powering on: Process overview

Procedure

1. Review Precautions for powering on the storage system on page 33 .

2. Review Checking AC power cable connections on page 33 .

3. Complete Powering on the storage system on page 34 .

4. (Optional) Complete Checking enclosure power redundancy (optional) on page 35 .

5. Review Setting up the service processor connection: Process overview on page 37 and

complete the process.

Precautions for powering on the storage system

To reduce the risk of electric shock or damage to the equipment, follow these precautions.

CAUTION:

• Do not disable the power cable grounding plug. The grounding plug is an important safety

feature.

• Plug the power cable into a grounded (earthed) electrical outlet that is easily accessible at all

times.

• Do not route the power cable where it can be walked on or pinched by items placed against it.

Pay particular attention to the plug, electrical outlet, and the point where the cable extends from

the storage system.

• Verify that there is clear access to all components for servicing by tying all power cables to

restrain them behind the rack column.

• To avoid potential damage to equipment, do not adjust the positioning of the rack after powering

on the HPE 3PAR StoreServ Storage.

Checking AC power cable connections

A factory-integrated storage system arrives with all internal power cables configured and connected.

Procedure

1. Ensure that the alternating-current (AC) power cables are properly configured and connected to the

components.

2. Ensure that the cable locks and cable ties on the AC power cables are properly connected on the

power distribution units (PDUs) and power supplies.

3. Ensure that all of the power cables are properly secured with restraints.

Powering on: Process overview 33

Page 34

Powering on the storage system

Prerequisites

• The acclimatization process has completed for the storage system components. Do not power on the

storage system until it is fully acclimatized. Allow up to 24 hours, and if condensation is still present,

wait until fully evaporated before powering on. If small drops of water can be seen on any of the

surfaces, condensation is present.

• The storage system does not exceed the ratings of the power sources and adheres to the guidelines in

the HPE 3PAR StoreServ 9000 Storage Site Planning Manual available at the Hewlett Packard

Enterprise Information Library website:

www.hpe.com/info/storage/docs

• Drives or slot-filler blanks are in all bays for proper thermal control.

• If power connections are underneath the rack, route the PDU power cables under the bracket at the

bottom rear of the rack.

Procedure

1. On all PDUs, turn on the power by setting all circuit breakers to the ON position.

For a physical service processor (SP), the power starts automatically when the PDUs are powered on.

Alternatively, use the power reset button. For the drive enclosures, the power starts automatically,

because there is no power switch.

2. On each controller node, turn on the power by setting the power switch to the ON position.

Figure 20: Controller node power switch

3. Wait approximately 10 minutes for completion of the storage system power-on/boot sequence.

4. At the rear of the storage system, verify that all status LEDs are illuminated green. If any of the LEDs

are amber, troubleshoot the issue before continuing to power on. There is an LED status for the

controller nodes, drive enclosures, and power supply units.

34 Powering on: Process overview

Page 35

IMPORTANT: The Status LED at the storage system front is not illuminated green at this time.

Instead, after the power on sequence, the UID/Service LED is illuminated blue and the Fault LED

is illuminated amber. Later during the software Guided Setup, these LEDs turn off and the Status

LED becomes illuminated green.

Checking enclosure power redundancy (optional)

To verify that the storage system has been correctly configured to achieve power redundancy, complete

the following procedure:

CAUTION:

• Hewlett Packard Enterprise recommends checking for power redundancy before the system is

initialized. If the system is already initialized, checking the power redundancy could cause an

outage.

• To maintain power to the storage system during this procedure, only one power distribution unit

(PDU) should be powered off at a time.

NOTE: The generic term "power supply" refers to various types of power components, such as a power

supply unit (PSU), power cooling module (PCM), or a power cooling battery module (PCBM).

Prerequisites

Ensure that the power cabling for the storage system follows the guidelines for redundant power cabling.

See Guidelines for redundant power cabling on page 26.

Figure 21: Redundant power configuration

Powering on: Process overview 35

Page 36

Procedure

1. Ensure that all power supplies (power supply units) for the enclosures (controller node enclosure and

drive enclosure) have a solid-green status LED indicating a normal operation state.

• Review Power supply unit LEDs, controller node enclosure on page 82 .

• Review Power supply unit LEDs, drive enclosure on page 83 .

2. Turn off the power source at the panel that provides input power to one PDU. Alternatively, the circuit

breaker(s) on the PDU can be set to the OFF position.

For example, as represented in Figure 21: Redundant power configuration on page 35:

• When Customer power source A1 is turned off, the power supplies connected to PDU-0 turn off.

• When Customer power source B2 is turned off, the power supplies connected to PDU-3 turn off.

3. Ensure that the following expected behavior has occurred:

• Every enclosure: At least one power supply is operating normally.

• Every power supply without input power: The LEDs turn off.

4. After confirmation of the expected behavior, turn back on the power source at the panel for the PDU

and wait 30-60 seconds.

5. Before moving to the next PDU, ensure that the green status LED is illuminated on all components.

6. For each PDU, repeat the prior steps.

36 Powering on: Process overview

Page 37

Setting up the service processor connection: Process overview

For detailed service processor (SP) connection setup instructions, see the HPE 3PAR Service Console

and StoreServ Management Console Quick Setup Guide and HPE 3PAR Service Processor Software

User Guide available at the Hewlett Packard Enterprise Information Library website:

www.hpe.com/info/storage/docs

Procedure

1. Review About the service processor on page 37.

2. Ensure Network and firewall support access on page 38.

3. Based on your service processor, complete one of the following processes:

a. Setting up the physical service processor connection: Process overview on page 40

b. Setting up the virtual service processor connection with VMware ESXi: Process overview on

page 42

Setting up the virtual service processor connection with Hyper-V: Process overview on page

c.

44

4. Review Setting up the service processor and storage system software: Process overview on

page 46 and complete the process.

About the service processor

Each storage system requires a service processor (SP), which can be either physical or virtual. Both the

physical SP and the virtual SP provide remote monitoring and report storage system errors, and can

perform diagnostic and maintenance activities involving the storage system. With HPE 3PAR SP 5.x

software, only one standalone HPE 3PAR StoreServ 9000 Storage system can be added to the service

processor.

The preferred service processor setup method is to connect to the service processor using the

preconfigured, nonroutable IP address through a local network using a browser, which starts the HPE

3PAR Guided Setup automatically.

For service events performed by a service technician, the customer must provide the following to the

technician:

• For a physical SP, access to the physical SP for a direct connection to the Service port.

• For a virtual SP, access to their network and the IP address to the virtual SP.

For detailed information about the service processor, see the documents available at the Hewlett Packard

Enterprise Information Library website:

www.hpe.com/info/storage/docs

Service processor types

Physical SP

A physical SP is a dedicated service appliance located within the storage rack providing proximity to the

storage system. For access to the physical SP by an authorized service provider, a direct connection to

Setting up the service processor connection: Process overview 37

Page 38

the physical SP is required. If you choose a physical SP at the time of ordering, your storage system will

include a physical SP installed in the same rack as the controller nodes.

A physical SP has two physical network connections:

• The Management (MGMT) port requires a connection to the network to communicate with the storage

system.

• The Service port is for maintenance purposes only and is not connected to the network.

Virtual SP

A virtual SP is deployed as a virtual machine. For access to the virtual SP by an authorized service

provider, a network connection to the virtual SP is required. The virtual SP software is provided in an

Open Virtual Format (OVF) for VMware vSphere Hypervisor and self-extractable virtual hard disk (VHD)

package for Microsoft Hyper-V.

CAUTION: To ensure that the management of the storage system by the virtual SP is independent

of other host servers connected to the storage system, do not install the virtual SP software on a

host server that is also using storage from the storage system. The virtual SP must use the local

boot disk of the assigned VMware server and not boot from the storage system LUNs.

The HPE 3PAR Text-based User Interface

The HPE 3PAR Text-based User Interface (TUI) is a utility on the HPE 3PAR SP that enables limited

configuration and management of the SP and access to the HPE 3PAR CLI of an attached storage

system. The intent of the HPE 3PAR TUI is not to duplicate the functionality of the HPE 3PAR SP Service

Console interface, but to allow a way to fix problems that may prevent you from using the Service

Console interface.

The TUI appears when you log in to the Linux console opened from the VMware vSphere Client or

through a terminal emulator using SSH to a physical or virtual SP. Prior to SP initialization, you can log in

to the TUI with the user name admin and no password. To access the TUI after the SP has been

initialized, you will need to log in to the console with the admin user name and the password you created

during the initialization.

The SP ID and model are always displayed in the heading. Before the SP is initialized, the SP ID is

displayed as SP00000. After initialization, the actual ID assigned to the SP during initialization is

displayed.

Network and firewall support access

Before performing the service processor (SP) connection setup, ensure that there are no customer

firewall restrictions to the existing HP servers and the new HPE servers on port 443. Firewall and proxy

server configuration must be updated to enable outbound connections from the service processor to the

existing HP servers and the new HPE servers.

For a list of HP and HPE server host names and IP addresses, see Firewall and proxy server

configuration on page 38.

Firewall and proxy server configuration

Firewall and proxy server configuration must be updated on the customer network to enable outbound

connections from the service processor to the existing HP servers and the new HPE servers.

HP and HPE server host names and IP addresses

• HPE Remote Support Connectivity Collector Servers:

38 Setting up the service processor connection: Process overview

Page 39

◦ https://storage-support.glb.itcs.hpe.com (16.248.72.63)

◦ https://storage-support2.itcs.hpe.com (16.250.72.82)

• HPE Remote Support Connectivity Global Access Servers:

◦ https://c4t18808.itcs.hpe.com (16.249.3.18)

◦ https://c4t18809.itcs.hpe.com (16.249.3.14)

◦ https://c9t18806.itcs.hpe.com (16.251.3.82)

◦ https://c9t18807.itcs.hpe.com (16.251.4.224)

• HP Remote Support Connectivity Global Access Servers:

◦ https://g4t2481g.houston.hp.com (15.201.200.205)

◦ https://g4t2482g.houston.hp.com (15.201.200.206)

◦ https://g9t1615g.houston.hp.com (15.240.0.73)

◦ https://g9t1616g.houston.hp.com (15.240.0.74)

• HPE RDA Midway Servers:

◦ https://midway5v6.houston.hpe.com (2620:0:a13:100::105)

◦ https://midway6v6.houston.hpe.com (2620:0:a12:100::106)

◦ https://midway7v6.houston.hpe.com (2620:0:a13:100::108)

◦ https://midway9v6.houston.hpe.com (2620:0:a13:100::109)

◦ https://midway8v6.houston.hpe.com (2620:0:a12:100::109)

◦ https://g4t8660g.houston.hpe.com (15.241.136.80)

◦ https://s79t0166g.sgp.ext.hpe.com (15.211.158.65)

◦ https://s79t0165g.sgp.ext.hpe.com (15.211.158.66)

◦ https://g9t6659g.houston.hpe.com (15.241.48.100)

◦ https://g9t7157g.houston.hpe.com (15.241.48.251)

◦ https://g9t7158g.houston.hpe.com (15.241.48.252)

◦ https://g4t9581g.houston.hpe.com (15.241.136.208)

◦ https://s54t0109g.sdc.ext.hpe.com (15.203.174.94)

◦ https://s54t0108g.sdc.ext.hpe.com (15.203.174.95)

◦ https://s54t0107g.sdc.ext.hpe.com (15.203.174.96)

• HPE InfoSight Servers:

◦ https://sfrm-production-llb-austin1.itcs.hpe.com (16.252.64.51)

◦ https://sfrm-production-llb-houston9.itcs.hpe.com (16.250.64.99)

◦ https://infosight1.itcs.hpe.com (16.248.65.16)

Setting up the service processor connection: Process overview 39

Page 40

• For communication between the service processor and the HPE 3PAR StoreServ Storage system, the

customer network must allow access to the following ports on the storage system.

◦ Port 22 (SSH)

◦ Port 5781 (Event Monitor)

◦ Port 5783 (CLI)

• For communication between the browser and the service processor, the customer network must

enable access to port 8443 on the SP.

• For communication between the vCenter instance and the service processor, the customer network

must enable access to port 443 (default port) on the SP and vCenter server.

Setting up the physical service processor connection: Process overview

Procedure

Complete Assigning an IP address to the physical service processor with a functional network

using the Guided Setup—SP5.x on page 40.

Assigning an IP address to the physical service processor with a functional network using the Guided Setup—SP5.x

Prerequisites

• The physical service processor (SP) and the HPE 3PAR StoreServ Storage are connected to a

network with a gateway.

• The service processor must be on the same subnet as the HPE 3PAR StoreServ Storage system.

Procedure

1. Connect a service laptop to the physical service processor.

With an Ethernet cable, connect a private Ethernet switch/hub between an Ethernet port on a service

laptop and the service port on the physical service processor.

IMPORTANT: Hewlett Packard Enterprise recommends using a private Ethernet switch/hub for

connection between a service laptop and a physical service processor to ensure that the service

laptop does not lose its network connection during the procedure. The loss of a network

connection can result in a failure of the procedure. Any Ethernet switch/hub with four to eight

ports is supported, such as the HPE 1405-5G Switch (J97982A).

40 Setting up the service processor connection: Process overview

Page 41

Figure 22: Physical service processor ports, HPE ProLiant DL120 Gen9 Server