Page 1

Product Service Manual

Page 2

HP LaserJet 3100 Product

Service Manual

Page 3

Copyright Information

1997 Hew lett- Packard

©

Company

All Rights Reserved.

Reproduction, adaptation, or

trans lation without prior written

permis sion is p rohibited except

as allowed under copyright

laws.

Part Number: C3948-90958

First Edition, March 1998

Warranty

The inf ormation contained in

this document is subject to

change without notice .

Hewlett-Packar d makes no

warranty of any kind with

respect to this information.

HEWLETT-PACKARD

SPECIFICALLY DISCL AIMS

THE IMPLIED WARRANTY OF

MERCHANTABILITY AND

FITNESS FOR A

PARTICULAR PURPOSE

Hewlett-Packard shall not be

liable for an y direct, indir ect,

incidental, consequential, or

other damage alleged in

connect ion w ith the fu rni shin g or

use of this information.

NOTICE TO U.S.

GOVERNMENT USERS:

RESTRICTED RIGHTS

COMMERCIAL COMPUTER

SOFTWARE: “Use, duplication,

or disclosure by t he

Government is subject to

restrictions as set forth in

subparagraph (c)(1)(ii) of the

Rights in Technical Data Clause

at DFARS 52.227-7013.”

Material scanned by this

product may be protected by

governmental laws and ot her

regulations, such as copyright

laws. The customer is solely

responsible for complying with

all such laws and regulations.

This product may be serviced

only in the country for which

it was designed to be used.

Trademark Credits

JetSuite Pro Desktop for

Hewlett-Packard is a trademark

of JetFax, Inc.

Microsoft, Windows, and

MS-DOS are U.S. registered

trademarks of Microsoft

Corporation.

Iris is a registered trademark of

the Caere Corporation.

NERGY STAR is a U.S.

E

registered service mark of the

United States Environmental

Protection Agency.

CompuSe rve is a tr ademark of

CompuServe, Inc.

All other products mentioned

herein may be trademarks of

their r espective companies.

Hewlett-Packard Company

11311 Chinden Boulevard

Boise, Idaho 83714 U.S.A.

Page 4

Contents

1 Product Information

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Product features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Product specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Model and serial numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Product overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Regulatory information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Laser statement for Finland . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

FCC regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Telephone consumer protection act (U.S.). . . . . . . . . . . . . . . . 27

IC CS-03 requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Canadian DOC regulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Environmental product stewardship program . . . . . . . . . . . . . . 30

Material safety data sheet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2 Installation and operation

EN

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Operating environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Media requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Toner cartridge information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Storage conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Storing opened toner cartridges . . . . . . . . . . . . . . . . . . . . . . . . 38

Toner Recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Control panel messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Menu tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3 Maintenance

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Life expectancies of consumables . . . . . . . . . . . . . . . . . . . . . . . . . 54

Cleaning and maintaining the equipment . . . . . . . . . . . . . . . . . . . . 55

Cleaning the document scanner path . . . . . . . . . . . . . . . . . . . . . . . 56

Cleaning the print path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Using a cleaning page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Recalibrating the document scanner. . . . . . . . . . . . . . . . . . . . . . . . 63

Contents

3

Page 5

4 Functional overview

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Basic functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Printer functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

ECU/power system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Print engine control system. . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Power system (on ECU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Formatter system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Central processing unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Parallel interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Draft mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Image formation system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Toner cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Step 1: Primary charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Step 2: Scanning exposure. . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Step 3: Developing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Step 4: Transferring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Step 5: Separating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Step 6: Drum cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Fixing stage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Printer feed system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Paper jam detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Solenoid, photosensors, and switches . . . . . . . . . . . . . . . . . . . 80

Document scanner system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Basic sequence of operation (formatter-to-printer) . . . . . . . . . . . . . 83

Contents

4

5 Removal and replacement

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Removal and replacement strategy. . . . . . . . . . . . . . . . . . . . . . . . . 86

Required tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Back cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Right side cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Left side cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Left front cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Top cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

RFI shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Document scanner assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Printer door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Document release door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Upper guide assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Contact image sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Document scanner assembly/motor . . . . . . . . . . . . . . . . . . . . 104

Document scanner pickup roller . . . . . . . . . . . . . . . . . . . . . . . 106

EN

Page 6

Internal assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

LIU board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Formatter board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Metal side plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Exit roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Delivery assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Fuser pressure plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Front casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Heating element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Pressure roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Face-up/face-down lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Fuser exit roller assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Paper exit sensor flag. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Laser/scanner assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Pickup roller assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Paper feed frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Transfer roller guide and transfer roller. . . . . . . . . . . . . . . . . . 132

Kick plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Separation pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Subpads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Feed assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Bottom assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Cable guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Main Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

ECU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Feet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

EN

6 Troubleshooting

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Basic troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Error messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Image formation troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . 156

Check the toner cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Solving image quality problems . . . . . . . . . . . . . . . . . . . . . . . 157

Solving paper feed problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Functional checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Engine test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Internal reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Printing all reports at once . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Half-self test functional check. . . . . . . . . . . . . . . . . . . . . . . . . 171

Drum rotation functional check . . . . . . . . . . . . . . . . . . . . . . . . 172

Heating element check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

High-voltage power supply check. . . . . . . . . . . . . . . . . . . . . . 174

Paper curl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Paper path check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Contents

5

Page 7

Troubleshooting tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Paper path and components. . . . . . . . . . . . . . . . . . . . . . . . . . 177

Document path and components . . . . . . . . . . . . . . . . . . . . . . 178

Repetitive image defect ruler . . . . . . . . . . . . . . . . . . . . . . . . . 179

Main wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Service menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Control panel service menu . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Extended service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Softswitches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

To change the country code softswitch. . . . . . . . . . . . . . . . . . 189

Firmware download. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

7 Parts and diagrams

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

How to use the parts lists and diagrams . . . . . . . . . . . . . . . . . . . . 194

Ordering parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Consumables and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Ordering consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Common hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Alphabetical parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Numerical parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Contents

6

EN

Page 8

Figures

Figure 1. Model and serial number label . . . . . . . . . . . . . . . . . 18

Figure 2. Document scanner path . . . . . . . . . . . . . . . . . . . . . . 19

Figure 3. Printer path (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 4. Printer path (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 5. Rear view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 6. Control panel layout . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 7. Basic configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 8. Printer unit functional block diagram . . . . . . . . . . . . . 67

Figure 9. ECU loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 10. High-voltage power supply circuit . . . . . . . . . . . . . . . 71

Figure 11. Image formation block diagram . . . . . . . . . . . . . . . . . 74

Figure 12. Simplified paper path . . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 13. Solenoid, photosensors, and switches . . . . . . . . . . . 80

Figure 14. Simplified document path . . . . . . . . . . . . . . . . . . . . . 82

Figure 15. General timing diagram . . . . . . . . . . . . . . . . . . . . . . . 84

Figure 16. Back cover removal (1 of 2) . . . . . . . . . . . . . . . . . . . . 88

Figure 17. Back cover removal (2 of 2) . . . . . . . . . . . . . . . . . . . . 89

Figure 18. Right side cover removal . . . . . . . . . . . . . . . . . . . . . . 90

Figure 19. Left side cover removal . . . . . . . . . . . . . . . . . . . . . . . 91

Figure 20. Left front cover removal . . . . . . . . . . . . . . . . . . . . . . . 92

Figure 21. Top cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Figure 22. RFI shield removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Figure 23. Printer door removal (1 of 3) . . . . . . . . . . . . . . . . . . . 95

Figure 24. Printer door removal (2 of 3) . . . . . . . . . . . . . . . . . . . 96

Figure 25. Printer door removal (3 of 3) . . . . . . . . . . . . . . . . . . . 97

Figure 26. Document release door removal (1 of 2) . . . . . . . . . . 98

Figure 27. Document release door removal (2 of 2) . . . . . . . . . . 99

Figure 28. Upper guide assembly removal (1 of 2) . . . . . . . . . . 100

Figure 29. Upper guide assembly removal (2 of 2) . . . . . . . . . . 101

Figure 30. Contact image sensor removal (1 of 2) . . . . . . . . . . 102

Figure 31. Contact image sensor removal (2 of 2) . . . . . . . . . . 103

Figure 32. Document scanner assembly/motor removal (1 of 2) 104

Figure 33. Document scanner assembly/motor removal (2 of 2) 105

Figure 34. Document scanner pickup roller removal . . . . . . . . 106

Figure 35. LIU board removal . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Figure 36. Formatter board removal (1 of 2) . . . . . . . . . . . . . . . 108

Figure 37. Formatter board removal (2 of 2) . . . . . . . . . . . . . . . 109

Figure 38. Metal side plate removal . . . . . . . . . . . . . . . . . . . . . 110

Figure 39. Exit roller removal . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Figure 40. Delivery assembly removal (1 of 2) . . . . . . . . . . . . . 112

Figure 41. Delivery assembly removal (2 of 2) . . . . . . . . . . . . . 113

EN

Contents-7

Page 9

Figure 42. Fuser pressure plate removal . . . . . . . . . . . . . . . . . 114

Figure 43. Fuser pressure plate replacement . . . . . . . . . . . . . . 115

Figure 44. Front casing removal . . . . . . . . . . . . . . . . . . . . . . . . 116

Figure 45. Heating element removal (1 of 2) . . . . . . . . . . . . . . 117

Figure 46. Heating element removal (2 of 2) . . . . . . . . . . . . . . 118

Figure 47. Pressure roller guide removal . . . . . . . . . . . . . . . . . 119

Figure 48. Face-up/face-down lever replacement . . . . . . . . . . 120

Figure 49. Fuser exit roller assembly removal . . . . . . . . . . . . . 121

Figure 50. Paper exit sensor flag replacement . . . . . . . . . . . . . 122

Figure 51. Laser/scanner assembly removal . . . . . . . . . . . . . . 123

Figure 52. Solenoid removal (1 of 2) . . . . . . . . . . . . . . . . . . . . 124

Figure 53. Solenoid removal (2 of 2) . . . . . . . . . . . . . . . . . . . . 125

Figure 54. Pickup roller assembly removal (1 of 2) . . . . . . . . . 126

Figure 55. Pickup roller assembly removal (2 of 2) . . . . . . . . . 127

Figure 56. Paper pickup roller assembly replacement . . . . . . . 128

Figure 57. Paper feed frame removal (1 of 3) . . . . . . . . . . . . . . 129

Figure 58. Paper feed frame removal (2 of 3) . . . . . . . . . . . . . . 130

Figure 59. Paper feed frame removal (3 of 3) . . . . . . . . . . . . . . 131

Figure 60. Transfer roller guide and transfer roller removal . . . 132

Figure 61. Kick plate removal . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Figure 62. Kick plate spring replacement . . . . . . . . . . . . . . . . . 134

Figure 63. Separation pad removal . . . . . . . . . . . . . . . . . . . . . 135

Figure 64. Subpad removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Figure 65. Feed assembly removal (1 of 3) . . . . . . . . . . . . . . . 137

Figure 66. Feed assembly removal (2 of 3) . . . . . . . . . . . . . . . 138

Figure 67. Feed assembly removal (3 of 3) . . . . . . . . . . . . . . . 139

Figure 68. Cable guide removal . . . . . . . . . . . . . . . . . . . . . . . . 140

Figure 69. Motor removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Figure 70. ECU removal (1 of 4) . . . . . . . . . . . . . . . . . . . . . . . . 142

Figure 71. ECU removal (2 of 4) . . . . . . . . . . . . . . . . . . . . . . . . 143

Figure 72. ECU removal (3 of 4) . . . . . . . . . . . . . . . . . . . . . . . . 144

Figure 73. ECU removal (4 of 4) . . . . . . . . . . . . . . . . . . . . . . . . 145

Figure 74. Feet removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Figure 75. Engine test switch location . . . . . . . . . . . . . . . . . . . 168

Figure 76. Toner cartridge high-voltage connection points . . . . 174

Figure 77. High-voltage connector assembly . . . . . . . . . . . . . . 175

Figure 78. Overriding SW101 . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Figure 79. Paper path and components . . . . . . . . . . . . . . . . . . 177

Figure 80. Document path and components . . . . . . . . . . . . . . . 178

Figure 81. Repetitive image defect ruler . . . . . . . . . . . . . . . . . . 179

Figure 82. General circuit diagram (1 of 2) . . . . . . . . . . . . . . . . 180

Figure 83. General circuit diagram (2 of 2) . . . . . . . . . . . . . . . . 181

Figure 84. Major assembly locations . . . . . . . . . . . . . . . . . . . . 197

Figure 85. Supports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Figure 86. External covers and panels . . . . . . . . . . . . . . . . . . . 200

Figure 87. Printer door (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . 202

Figure 88. Printer door (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . 204

8

EN

Page 10

Figure 89. Document scanner assembly . . . . . . . . . . . . . . . . . 206

Figure 90. Internal components (1 of 3) . . . . . . . . . . . . . . . . . . 208

Figure 91. Internal components (2 of 3) . . . . . . . . . . . . . . . . . . 210

Figure 92. Internal components (3 of 3) . . . . . . . . . . . . . . . . . . 212

Figure 93. Electrical components assembly . . . . . . . . . . . . . . . 214

Figure 94. Paper pickup assembly . . . . . . . . . . . . . . . . . . . . . . 216

Figure 95. Feed assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Figure 96. Separation guide assembly . . . . . . . . . . . . . . . . . . . 220

Figure 97. Delivery assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 222

EN

9

Page 11

10

EN

Page 12

Tables

Table 1. Product features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 2. Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 3. Performance specifications . . . . . . . . . . . . . . . . . . . . 16

Table 4. Power specifications. . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 5. Operating acoustical emissions . . . . . . . . . . . . . . . . . 17

Table 6. Environmental requirements. . . . . . . . . . . . . . . . . . . . 36

Table 7. Media requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 8. Control panel messages. . . . . . . . . . . . . . . . . . . . . . . 40

Table 9. Menu tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 10. Life expectancies of consumables . . . . . . . . . . . . . . . 54

Table 11. DC power distribution . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 12. Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Table 13. Control panel service menu . . . . . . . . . . . . . . . . . . . 182

Table 14. Extended service menu tree. . . . . . . . . . . . . . . . . . . 184

Table 15. Extended service mode self-test failures . . . . . . . . . 185

Table 16. Extended service mode tests . . . . . . . . . . . . . . . . . . 186

Table 17. Extended service mode reports . . . . . . . . . . . . . . . . 187

Table 18. Country code softswitch sequences. . . . . . . . . . . . . 190

Table 19. Consumables and accessories. . . . . . . . . . . . . . . . . 195

Table 20. Common fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Table 21. Supports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Table 22. External covers and panels . . . . . . . . . . . . . . . . . . . 201

Table 23. Printer door (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . 203

Table 24. Printer door (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . 205

Table 25. Document scanner assembly . . . . . . . . . . . . . . . . . . 207

Table 26. Internal components (1 of 3). . . . . . . . . . . . . . . . . . . 209

Table 27. Internal components (2 of 3). . . . . . . . . . . . . . . . . . . 211

Table 28. Internal components (3 of 3). . . . . . . . . . . . . . . . . . . 213

Table 29. Electrical components assembly . . . . . . . . . . . . . . . 215

Table 30. Paper pickup assembly . . . . . . . . . . . . . . . . . . . . . . 217

Table 31. Feeder assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Table 32. Separation guide assembly . . . . . . . . . . . . . . . . . . . 221

Table 33. Delivery assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Table 34. Alphabetical parts list . . . . . . . . . . . . . . . . . . . . . . . . 224

Table 35. Numerical parts list. . . . . . . . . . . . . . . . . . . . . . . . . . 230

EN

Contents-11

Page 13

12

EN

Page 14

1

Product Information

Chapter contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Product features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Product specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Model and serial numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Product overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Regulatory information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

EN

Chapter contents 13

Page 15

Introduction

The HP LaserJet 3100 product is a powerful business tool with the

capabilities of a full range of office equipment. With the HP LaserJet

3100 product, you can:

●

●

●

●

●

Print—Easily print documents with the laser quality you have

come to expect from an HP LaserJet printer.

Fax—Use the HP LaserJet 3100 product as a standalone fax

machine to send and receive faxes, as well as perform advanced

tasks such as forwarding faxes to other locations. Use the

software to send faxes from and receive them to your computer.

Copy—Make superior laser-quality copies. You can make up to

99 copies of a 30-page original. You can also enlarge, reduce,

adjust contrast and collate.

Scan—Scan important documents to create electronic files.

Use Software—Use the software to print, fax, copy, or scan. Also

use the software to store and organize scanned documents.

Product Information

14

EN

Page 16

Product features

Table 1. Product features

Feature Description

Print speed 6 pages per minute (ppm)

Copy speed 6 ppm

Fax transmission speed 6 seconds per page

Margins for scanned items 0.16 in (4.06 mm) at leading and trailing edges

0.12 in (3.05 mm) at sides

Margins for printed pages 0.20 in (5.08 mm) at sides

0.25 in (6.35 mm) at leading and trailing edges

Fax compatibility International Telecommunications Union (ITU) Group 3

Fax coding schemes MR, MMR, MH, and JBIG

Modem speed 14,400 bits per second (bps)

Speed dialing Yes

Distinctive ring detect Yes

Multiple copies Up to 99 per job

Copy Reduction/

Enlargement

Memory 2 megabytes (MB) (approximately 150 pages)

Printer Duty Cycle 6,000 single-sided pages per month

Document Scanner Duty

Cycle

EN

50% to 200%

2,500 single-sided items per month

Product features 15

Page 17

Product specifications

Table 2. Physical specifications

Category Specification

Height 10.71 in (272 mm) without supports attached;

15.91 in (404 mm) with supports attached

Depth 15.36 in (390 mm) without supports attached;

23.55 in (598 mm) with supports attached

Width 15.12 in (384 mm)

Weight (cartridge installed) 23.37 pounds (10.6 kilograms)

Table 3. Performance specifications

Category Specification

Print resolution 600 dots per inch (dpi)

Scan resolution 600 dpi enhanced; 300 dpi optical, with 256 levels of gray

Fax resolution Standard: 203 by 98 dpi

Fine: 203 by 196 dpi

Superfine: 300 by 300 dpi (no halftone)

Photo: 300 by 300 dpi (halftone enabled)

Print speed 6 ppm

Copy speed 6 ppm

16 Product Information

EN

Page 18

Table 4. Power specifications

Category Specification

Power requirements 100 to 127 Volts alternating current (Vac) +/-10%; 50 to 60 hertz

220 to 240 Vac +/-10%; 50 hertz

Power consumption (in

continuous copy mode)

Power consumption (idle) 9 watts

Minimum recommended

circuit capacity

135 watts

4.2 amps (110 volts)

2 amps (220 volts)

(4.2 amps maximum pull)

Table 5. Operating acoustical emissions (per International Standards

Organization 9296) specifications

Category Specification

Sound Power Level,

L

(1 bel = 10 decibels)

WAd

Sound Pressure Level,

L

(Operator Position)

pAm

5.7 bels (B)

52 decibels (dB)

Sound Pressure Level,

L

(Bystander Position)

pAm

EN

43 dB

Product specifications 17

Page 19

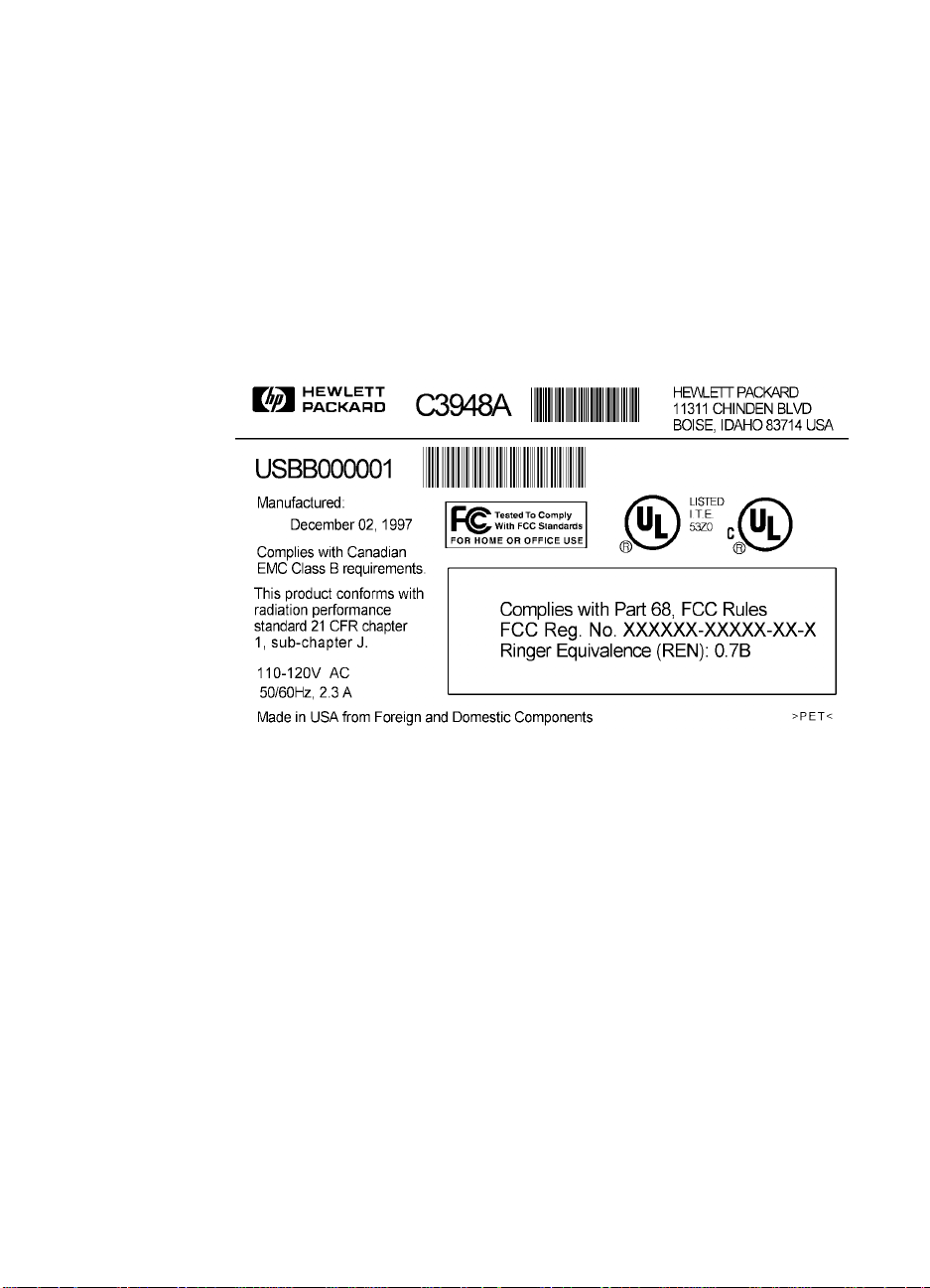

Model and serial numbers

The model number and serial number are listed on an identification

label located on the back of the printer. The model number of the HP

LaserJet 3100 product is C3948A.

The serial number contains information about the Country of Origin,

the Revision Level, the Production Code, and production number of

the HP LaserJet 3100 product.

The label also contains power rating and regulatory information.

Figure 1. Model and serial number label

18 Product Information

EN

Page 20

Product overview

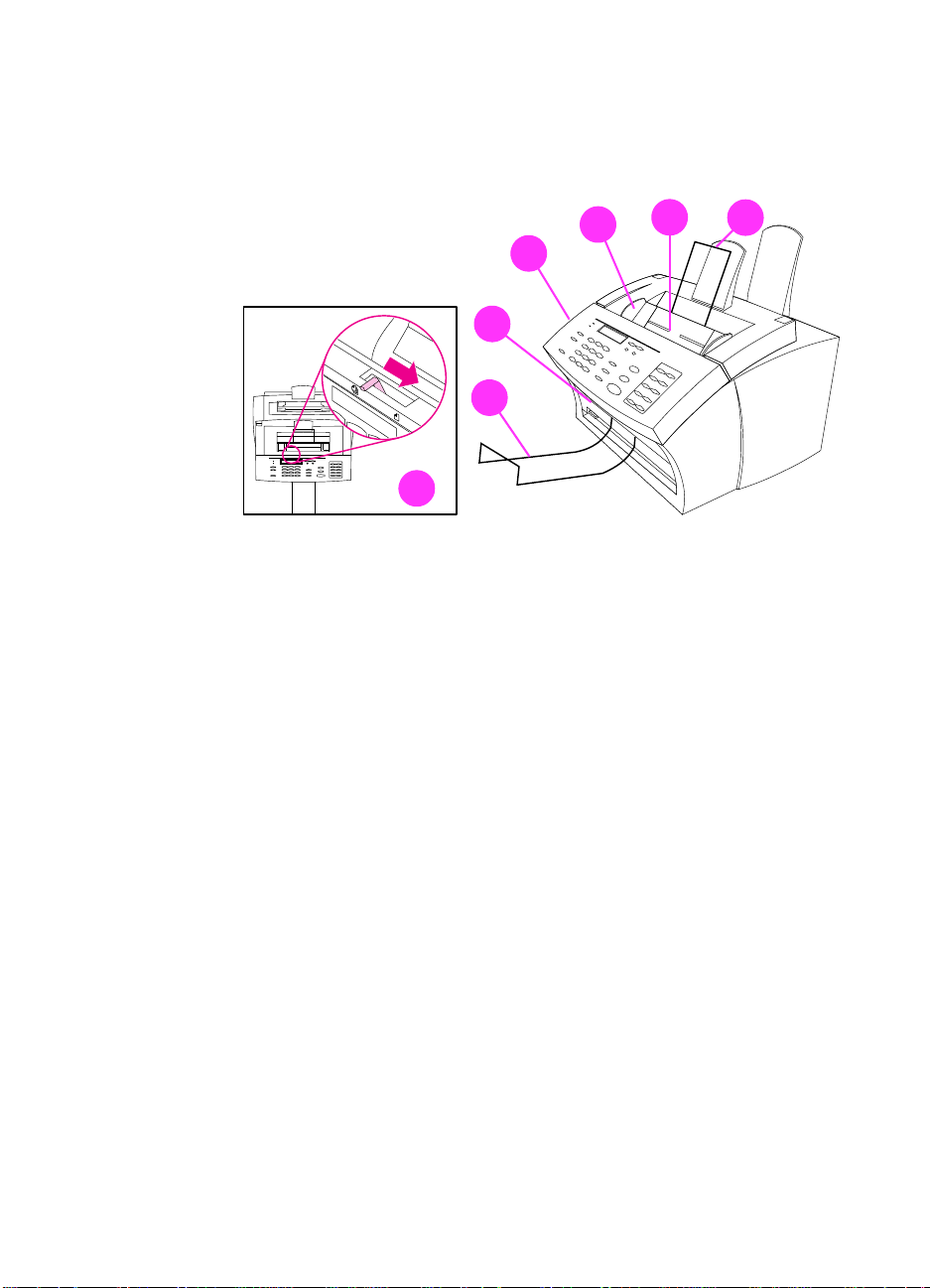

3

2

1

7

Figure 2. Document scanner path

Document output support

1

Document output slot

2

Document release door/control panel

3

Document feeder tray guides

4

Document feeder tray

5

4

5

6

EN

Document feeder support

6

Special media lever

7

Product overview 19

Page 21

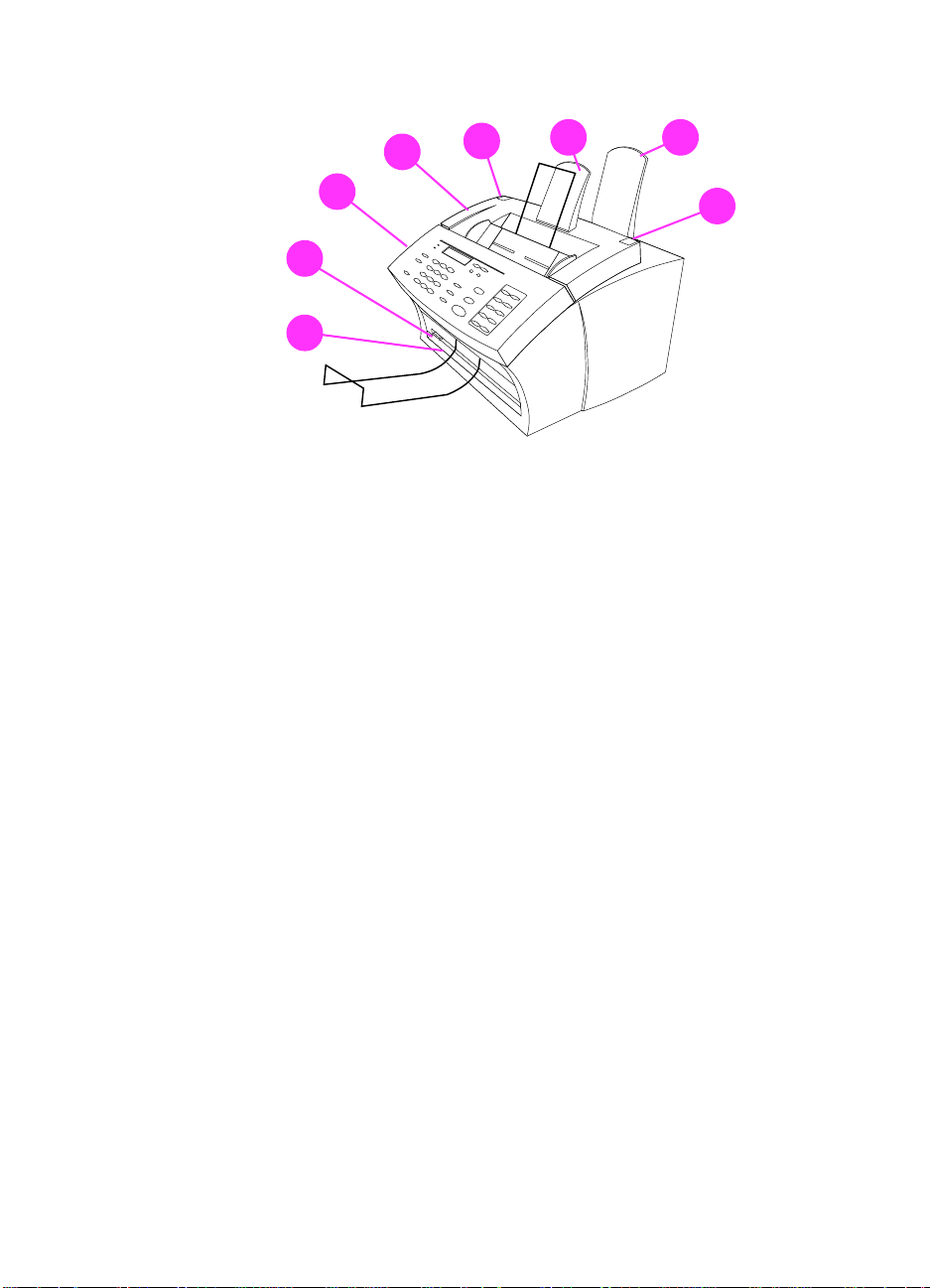

4

5

6 7

3

2

1

Figure 3. Printer path (1 of 2)

Front paper output

1

Paper path lever

2

Control panel

3

Printer door

4

Printer door release latches

5

Paper output support

6

Paper input support

7

5

Product Information

20

EN

Page 22

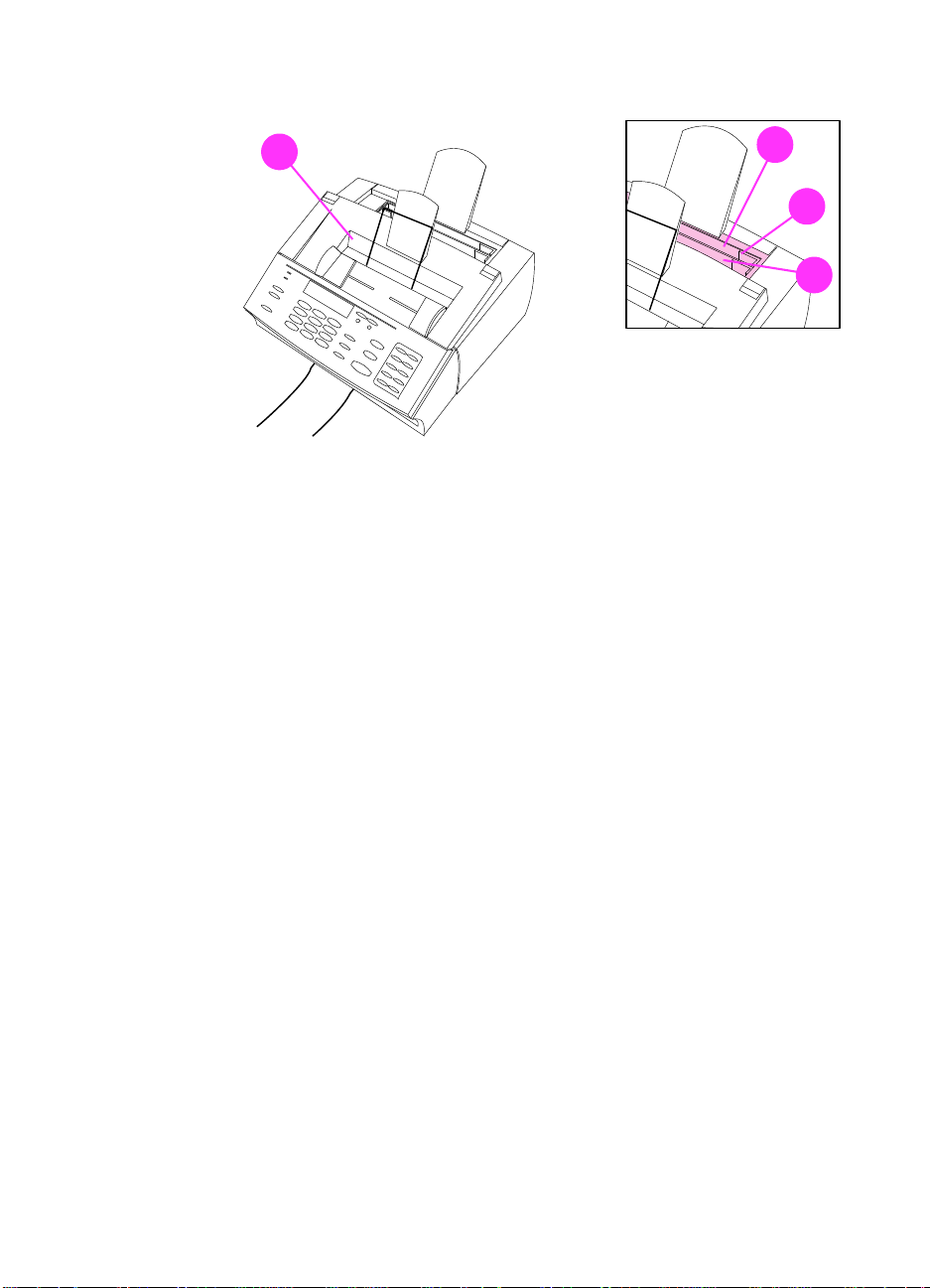

1

Figure 4. Printer path (2 of 2)

Output bin

1

Input bin

2

Paper guides

3

Single-sheet input slot

4

2

3

4

EN

Product overview 21

Page 23

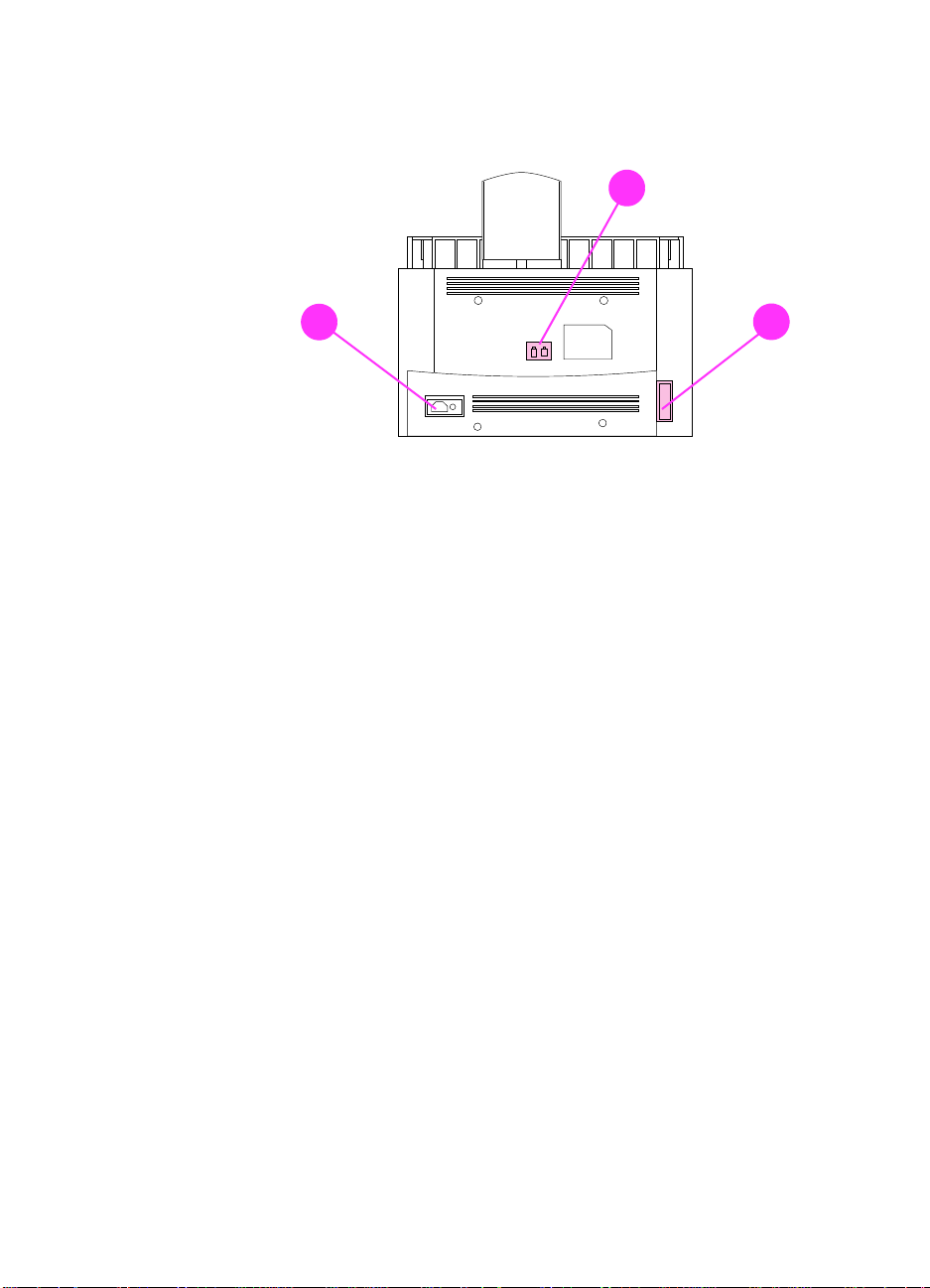

2

1

Figure 5. Rear view

Power cable connector

1

Phone line connector (or connectors, depending on country)

2

Parallel cable connector

3

3

Product Information

22

EN

Page 24

Regulatory information

Safety

Transportation

Non-operating Magnetic Field Emissions, IATA Packaging

Instructions 902

Laser safety statement

The Center for Devices and Radiological Health (CDRH) of the U.S.

Food and Drug Administration has implemented regulations for laser

products manufactured since August 1, 1976. Compliance is

mandatory for products marketed in the United States. This printer is

certified as a “Class 1” laser product under the U.S. Department of

Health and Human Services (DHHS) Radiation Performance

Standard according to the Radiation Control for Health and Safety Act

of 1968. Since radiation emitted inside this printer is completely

confined within protective housings and external covers, the laser

beam cannot escape during any phase of normal user operation.

WARNING!

Using controls, making adjustments, or performing procedures other

than those specified in this manual may result in exposure to hazardous

radiation.

EN

Regulatory information 23

Page 25

Laser statement for Finland

Luokan 1 laserlaite

Klass 1 Laser Apparat

HP LaserJet 3100 laserkirjoitin on käyttäjän kannalta turvallinen

luokan 1 laserlaite. Normaalissa käytössä kirjoittimen suojakotelointi

estää lasersäteen pääsyn laitteen ulkopuolelle.Laitteen

turvallisuusluokka on määritetty standardin EN 60825-1 (1994)

mukaisesti.

Varoitus!

Laitteen käyttäminen muulla kuin käyttöohjeessa mainitulla tavalla

saattaa altistaa käyttäjän turvallisuusluokan 1 ylittävälle

näkymättömälle lasersäteilylle.

Varning!

Om apparaten används på annat sätt än i bruksanvisning

specificerats, kan användaren utsättas för osynlig laserstrålning, som

överskrider gränsen för laserklass 1.

HUOLTO

HP LaserJet 3100 -kirjoittimen sisällä ei ole käyttäjän huollettavissa

olevia kohteita. Laitteen saa avata ja huoltaa ainoastaan sen

huoltamiseen koulutettu henkilö. Tällaiseksi huoltotoimenpiteeksi ei

katsota väriainekasetin vaihtamista, paperiradan puhdistusta tai

muita käyttäjän käsikirjassa lueteltuja, käyttäjän tehtäväksi

tarkoitettuja ylläpitotoimia, jotka voidaan suorittaa ilman

erikoistyökaluja.

Varo!

Mikäli kirjoittimen suojakotelo avataan, olet alttiina näkymättömälle

lasersäteilylle laitteen ollessa toiminnassa. Älä katso säteeseen.

Varning!

Om laserprinterns skyddshölje öppnas då apparaten är i funktion,

utsättas användaren för osynlig laserstrålning. Betrakta ej strålen.

Tiedot laitteessa käytettävän laserdiodin säteilyominaisuuksista:

Product Information

24

Aallonpituus 775-795 nm

Teho 5 mW

Luokan 3B laser

EN

Page 26

FCC regulations

This equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment

generates, uses, and can radiate radio frequency energy. If is not

installed and used in accordance with the instructions, it may cause

harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

●

Increase separation between equipment and receiver.

●

Connect equipment to an outlet on a circuit different from that to

●

which the receiver is located.

Consult your dealer or an experienced radio/TV technician.

●

Note

Note

Any changes or modifications to the printer that are not expressly

approved by HP could void the user’s authority to operate this

equipment.

Use of a shielded interface cable is required to comply with the Class

B limits of Part 15 of FCC rules.

FCC part 68 requirements

This equipment complies with FCC rules, Part 68. On the back of this

equipment is a label that contains, among other information, the FCC

registration number and ringer equivalence number (REN) for this

equipment. If requested, this information must be provided to the

telephone company.

The REN is used to determine the quantity of devices which may be

connected to the telephone line. Excessive RENs on the telephone

line may result in the devices not ringing in response to an incoming

call. In most, but not all, areas, the sum of the RENs should not

exceed five (5.0). To be certain of the number of devices that may be

connected to the line, as determined by the total RENs, contact the

telephone company to determine the maximum REN for the calling

area.

EN

Regulatory information 25

Page 27

This equipment uses the following USOC jacks:

RJ11C

An FCC-compliant telephone cord and modular plug is provided with

this equipment. This equipment is designed to be connected to the

telephone network or premises wiring using a compatible modular

jack which is Part 68 compliant.

This equipment cannot be used on telephone company-provided coin

service. Connection to Party Line Service is subject to state tariffs.

If this equipment causes harm to the telephone network, the

telephone company will notify you in advance that temporary

discontinuance of service may be required. If advance notice isn’t

practical, the telephone company will notify the customer as soon as

possible. Also, you will be advised of your right to file a complaint with

the FCC if you believe it is necessary.

The telephone company may make changes in its facilities,

equipment, operations, or procedures that could affect the operation

of the equipment. If this happens, the telephone company will provide

advance notice in order for you to make the necessary modifications

in order to maintain uninterrupted service.

If trouble is experienced with this equipment, please see the numbers

in the front of this manual for repair and (or) warranty information.

If the trouble is causing harm to the telephone network, the telephone

company may request you remove the equipment from the network

until the problem is resolved.

The following repairs can be done by the customer:

Replace any original equipment that came with the HP LaserJet 3100

product. This includes the toner cartridge, the supports for trays and

bins, the power cord and the telephone cord.

It is recommended that the customer install an AC surge arrestor in

the AC outlet to which this device is connected. This is to avoid

damage to the equipment caused by local lightning strikes and other

electrical surges.

Product Information

26

EN

Page 28

Telephone consumer protection act (U.S.)

The Telephone Consumer Protection Act of 1991 makes it unlawful

for any person to use a computer or other electronic device, including

fax machines, to send any message unless such message clearly

contains, in a margin at the top or bottom of each transmitted page or

on the first page of the transmission, the date and time it is sent and

an identification of the business, other entity, or individual sending the

message and the telephone number of the sending machine or such

business, other entity, or individual. (The telephone number provided

may not be a 900 number or any other number for which charges

exceed local or long-distance transmission charges.)

In order to program this information into your facsimile, please see

“Setting the fax header” and “Setting the time and date” in the user

guide.

EN

Regulatory information 27

Page 29

IC CS-03 requirements

NOTICE: The Industry Canada label identifies certified equipment.

This certification means that the equipment meets certain

telecommunications network protective, operational and safety

requirements as prescribed in the appropriate Terminal Equipment

Technical Requirement document(s). The Department does not

guarantee the equipment will operate to the user’s satisfaction.

Before installing this equipment, users should ensure that it is

permissible to be connected to the facilities of the local

telecommunications company. The equipment must also be installed

using an acceptable method of connection. The customer should be

aware that compliance with the above conditions may not prevent

degradation of service in some situations.

Repairs to certified equipment should be coordinated by a

representative designated by the supplier. Any repairs or alterations

made by the user to this equipment, or equipment malfunctions, may

give the telecommunications company cause to request the user to

disconnect the equipment.

Users should ensure for their own protection that the electrical ground

connections of the power utility, telephone lines and internal metallic

water pipe system, if present, are connected together. This

precaution may be particularly important in rural areas.

Caution:

themselves, but should contact the appropriate electric inspection

authority, or electrician, as appropriate.

The Ringer Equivalence Number (REN) of this device is 0.7.

NOTICE: The Ringer Equivalence Number (REN) assigned to each

terminal device provides an indication of the maximum number of

terminals allowed to be connected to a telephone interface. The

termination on an interface may consist of any combination of devices

subject only to the requirement that the sum of the Ringer

Equivalence Number of all the devices does not exceed 5.

The standard connecting arrangement code (telephone jack type) for

equipment with direct connections to the telephone network is

CA11A.

Product Information

28

Users should not attempt to make such connections

EN

Page 30

Declaration of conformity

according to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name

Manufacturer’s Address

declares, that the product

Product Name:

Model Number

Product Options

conforms to the following Product Specifications

Safety: IEC 950:1991+A1+A2+A3 / EN 60950:1992+A1+A2+A3

EMC: CISPR 22:1993+A1 / EN 55022:1994 Class B1

Supplementary Information

The product herewith complies with the requirements of the following Directives and carries the CEmarking accordingly:

- the EMC directive 89/336/EEC

- the Low Voltage Directive 73/23/EEC

1

This product was tested in a typical configuration with Hewlett-Packard Personal Computer Systems.

2

This Device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cau s e undesired operation.

For Compliance Information ONLY, contact:

Australia Contact: Product Regulations Manager, Hewlett-Packard Australia Ltd., 31-41 Joseph Street,

: Hewlett-Packard Company

: 11311 Chinden Boulevard

Boise, Idaho 83714-1021, USA

HP LaserJet 3100 product

: C3948A

: ALL

EN 41003:1993

IEC 825-1:1993 / EN 60825-1:1994 Class 1 (Laser/LED)

EN 50082-1:1992

IEC 801-2:1991 / prEN 55024-2:1992-3kV CD, 8kV AD

IEC 801-3:1984 / prEN 55024-3:1991-3 V/m

IEC 801-4:1988 / prEN 55024-4:1992-0.5 kV Signal Lines

IEC 1000-3-2:1995 / EN61000-3-2:1995

IEC 1000-3-3:1994 / EN61000-3-3:1995

FCC Title 47 CFR, Part 15 Class B2 / ICES-003, Issue 2

AS / NZS 3548:1995 / CISPR 22:1993 Class B

:

March 25, 1997

Blackburn, Victoria 3130, Australia

:

1.0 kV Power Lines

1

European Contact: Your Local Hewlett-Packard Sales and Service Office or Hewlett-Packard Gmbh,

Department HQ-TRE / Standards Europe, Herrenberger Strasse 130, D-71034

Böblingen (FAX: +49-7031-14-3143)

USA Contact: Product Regulations Manager, Hewlett-Packard Company, PO Box 15, Mail Stop 160,

Boise, ID, 83707-0015 (Phone: 208-396-6000)

EN

Regulatory information 29

Page 31

Canadian DOC regulations

Complies with Canadian EMC Class B requirements.

Conforme á la classe B des normes canadiennes de compatibilité

électromagnétiques. << CEM>>.

Environmental product stewardship program

Protecting the environment

Hewlett-Packard Company is committed to providing quality products

in an environmentally sound manner. This HP LaserJet printer has

been designed with several attributes to minimize impacts on our

environment.

This HP LaserJet printer design eliminates:

Ozone production

The printer does not use high-voltage corona wires in the

electrophotographic process and therefore generates no appreciable

ozone gas (O3). Instead, this printer uses charging rollers in the toner

cartridge and in the print engine.

This HP LaserJet printer design reduces:

Energy consumption

Energy usage drops to as little as 9 watts while in idle mode. Not only

does this save natural resources, but it also saves money without

affecting the high performance of this product. This product qualifies

for the E

voluntary program established to encourage the development of

energy-efficient office products. E

service mark of the U.S. Environmental Protection Agency.

Product Information

30

NERGY STAR

Program (U.S. and Japan). E

NERGY STAR

As an E

NERGY STAR

is a U.S. registered

partner, HewlettPackard Company has determined that

this product meets E

Guidelines for energy efficiency.

NERGY STAR

NERGY STAR

is a

EN

Page 32

Toner consumption

Depending on the type of printer driver you have, you may be able to

select a “draft” mode which uses about 50% less toner, thereby

extending the life of the toner cartridge. This is only available using

printer driver properties when printing or making copies from the

software.

Paper use

Depending on the type of program you use, you may be able to print

2 or 4 document pages on each printed page. This “N-up” printing

practice and the printer’s manual duplex capability (two-sided

printing) reduce paper usage and the resulting demands on natural

resources.

The design of this HP LaserJet printer facilitates the recycling

of:

Plastics

Plastic parts have marking according to international standards that

enhance the ability to identify plastics for recycling purposes at the

end of the product’s life. The plastics used in the product housing and

chassis are technically recyclable.

HP toner cartridges/photoconductive drum

In many countries, this product’s toner cartridge/drum can be

returned to HP using the prepaid shipping label and instructions

included inside each new HP toner cartridge box. If your country is

not listed in the recycling guide, call your local HP Sales and Service

Office for further instructions.

HP cartridge recycling program

Since 1990, the HP LaserJet Toner Cartridge Recycling Program has

collected more than 12 million cartridges that otherwise would have

been discarded into landfills or similar facilities. Once a cartridge is

returned through the prepaid return program, it is disassembled, and

reusable components and the plastic housing are cleaned and

inspected for quality conformance. After passing strict inspection

procedures, materials such as nuts, screws, and clips are reclaimed

and used to produce new cartridges. Remaining materials are melted

down and used as raw materials for a variety of other products. Over

95 percent of the weight of returned materials is recycled. For more

information in the U.S., contact the HP LaserJet Supplies Website at:

http://LJsupplies.com/planetpartners

International customers can call the local HP Sales and Service

Office for further information regarding the HP Toner Cartridge

Recycling Program.

EN

Regulatory information 31

Page 33

Printer and parts

Design for recycling has been incorporated into this printer and its

accessories. The number of materials has been kept to a minimum

while ensuring proper functionality and high product reliability.

Dissimilar materials have been designed to separate easily.

Fasteners and other connections are easy to locate, access, and

remove with common tools. High priority parts have been designed to

be accessed quickly for efficient disassembly and repair. Plastic parts

have been primarily designed in two colors to enhance recycling

options. A few small parts are colored specifically to highlight

customer access points.

HP provides a product return system for customers in Germany.

Many of the functional parts are recovered, tested, and reused as

fully warranted service parts. Used parts are not placed into new

product manufacturing. Remaining product parts are recycled, if

possible. For product return information, contact:

Hewlett-Packard GmbH

Wertstoffzentrum

Fronackerstr .30

71063 Sindelfingen

Paper

This printer is suited for the use of recycled papers when the paper

meets the guidelines outlined in the HP LaserJet Printer Family Paper

Specification Guide, HP part number 502-8956. This printer is suited

for the use of recycled paper according to DIN 19 309.

To ensure longevity of your HP LaserJet printer, HP provides the

following:

Extended warranty

HP SupportPack provides coverage for the HP hardware product and

all HP-supplied internal components. The hardware maintenance

covers a three-year period from date of the HP product purchase. HP

SupportPack must be purchased by the customer within 90 days of

the HP product purchase. Information on HP SupportPack is

available in a fax format by calling the U.S. HP FIRST (Fax

Information Retrieval Support Technology) at (800) 333-1917.

After connecting, press 1, and then press 1 again. The document

number is 9036. International customers can contact the nearest

HP-authorized reseller about this service.

Spare parts and consumables availability

Spare parts and consumable supplies for this product will be made

available for at least five years after production has stopped.

Product Information

32

EN

Page 34

Material safety data sheet

The Material Safety Data Sheet for the toner can be obtained by

calling U.S. HP FIRST (Fax Information Retrieval Support

Technology) at (800) 231-9300. After connecting, press 1. Then,

request document number 10164.

EN

Regulatory information 33

Page 35

Product Information

34

EN

Page 36

Installation and

2

operation

Chapter contents

Operating environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Media requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Toner cartridge information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

EN

Chapter contents 35

Page 37

Operating environment

The environmental requirements listed below must be maintained to

ensure the proper operation of the HP LaserJet 3100 product.

Table 6. Environmental requirements

Category Requirement

Operating (working or

standby)

Non-operating Temperature (toner cartridge): -4 to 104°F (-20 to 40°C);

Normal storage Temperature: 32 to 95°F (0 to 35°C)

Temperature: 59 to 90.5 degrees Fahrenheit

(15 to 32.5 degrees Celsius)

Humidity: 10 to 80 percent relative humidity (no condensation)

Temperature (product): -4 to 140°F (-20 to 60°C)

Humidity: 10 to 90 percent relative humidity (no condensation)

Humidity: 35 to 85 percent relative humidity

Consider the following before installing the printer:

●

Install in a well-ventilated, dust-free area.

●

Install on a hard, flat, continuous surface, with all four feet level.

Do not install on carpet or other soft surfaces.

●

Ensure adequate power is supplied. Uninterruptible power

supplies (UPS) should not be used with the HP LaserJet 3100

product.

CAUTION Using uninterruptible power supplies can damage the fuser.

● Install away from direct sunlight, open flames, or ammonia fumes.

If the HP LaserJet 3100 product is placed near a window, make

sure the window has a curtain or blind to block direct sunlight.

● Install with enough space around the product for proper access

and ventilation.

● Install away from the direct flow of exhaust from air ventilation

systems.

Installation and operation

36

EN

Page 38

Media requirements

Media must be in good condition. Do not use media that is torn, worn,

or irregular. The table below details media requirements of the HP

LaserJet 3100 product.

Table 7. Media requirements

Input for paper input bin and single-sheet input slot (for printer path)

Media size Maximum: 8.5 by 14 in (216 by 356 mm)

Minimum: 3 by 5 in (76.2 by 127 mm)

Media weight

For paper output bin: 16 to 28 lb; (60 to 105 g/m

For front output slot: 16 to 42 lb (60 to 157 g/m

Paper input bin capacity

Up to 100 sheets of media at 20 lb (75 g/m

(fewer than 100 sheets of heavier media) or up to 10 envelopes

Input for document feeder tray (for document scanner path)

Item size Maximum width: 8.5 in (216 mm)

Maximum length: 39 in (991 mm); up to 118 in (2997.2 mm) with

“long pages” enabled

Minimum size: 2 by 3.5 in (51 by 89 mm)

Item weight

Document feeder tray

capacity

Maximum: 28 lb (105 g/m

up to 67 lb (252 g/m

Minimum: 12 lb (44 g/m

Up to 30 pages of an item at 20 lb (75 g/m

Fewer than 30 pages of items up to 28 lb (105 g/m

2

) for normal use;

2

) when using special media lever

2

)

One page at a time of 12 to 67 lb (44 to 252 g/m

special media lever

Output capacities

2

)

2

)

2

) weight or lighter

2

) weight or lighter

2

) weight

2

) weight using

Paper output bin

Front paper output slot

Document output tray

EN

Up to 100 sheets of 20 lb (75 g/m

Up to 20 pages of 20 lb (75 g/m

2

) or lighter paper

2

) or lighter paper

Up to 30 pages of an item at 28 lb (105 g/m

Media requirements 37

2

)

Page 39

Toner cartridge information

Toner cartridges contain components that are sensitive to light,

temperature, and humidity. Follow the recommendations in this

section to ensure the highest quality and longest life of HP toner

cartridges.

Keep the HP LaserJet 3100 product within the following

environmental conditions for optimum performance.

Storage conditions

Toner cartridges are affected by their environment. Packaging

protects toner cartridges from light and increases storage life. It is

important to store cartridges in their original packaging until ready for

installation.

When storing cartridges in a warehouse or work area, make sure the

storage place meets the conditions specified in Table 6.

Storing opened toner cartridges

Because cartridges do not have shutters to cover the laser beam

access slot, they should be kept inside the HP LaserJet 3100 product

until empty. Toner cartridges that have had the toner sealing tape

removed are also more vulnerable to environmental extremes.

If a toner cartridge must be removed from the HP LaserJet 3100

product, always store the cartridge:

● Inside the protective bag in which it was originally packaged.

● In a dark cabinet, away from direct sunlight.

● Correct side up and in a horizontal position (not standing on end).

● Away from ammonia or organic solvent fumes.

CAUTION Never ship the HP LaserJet 3100 product with a toner cartridge

installed. Excessive vibration during shipping can cause toner to leak,

contaminating the product and possibly damaging the drum. Never

expose a cartridge to direct sunlight or to room light for more than a

few minutes. Bright light can permanently damage a toner cartridge.

Toner Recycling

See recycling information in Chapter 1.

38 Installation and operation

EN

Page 40

Control panel

1

2

3

4

5

8

9

18

6

7

17

16

12

15

Figure 6. Control panel layout

1. Ready light 7. Forward arrow key 13. Speed-dial key

2. Error light 8. Stop/clear key 14. Redial/pause key

3. Control panel display 9. Copy key 15. Numeric keys

4. Enter/menu key 10. One-touch keys 16. Volume key

5. Backspace key 11. Start key 17. Resolution key

14

13

11

10

6. Back arrow key 12. Manual dial key 18. Contrast key

EN

Control panel 39

Page 41

Control panel messages

These control panel messages are listed alphabetically, and are

accompanied by the cause for the message and steps to take to

resolve the problem.

Table 8. Control panel messages

Message Cause Solution

(number) is a Group

Group not Allowed

Already in Group While programming a group-dial code,

Blacklisted

(France only)

Busy While sending a fax, receiving fax line was

Cancel Group Edit

ENTER to Confirm

The group-dial code you entered is

assigned to a group, but a group cannot

be dialed at this point.

Entries assigned as groups cannot be

assigned into other groups.

you have tried to add a fax number that is

already in the group.

The fax number you are trying to dial has

received a voice answer or no answer,

was busy on the first dial and redials, or

was busy with redials pending.

busy for all redial attempts.

You pressed Back Space while in a

group-dial code in the Group Dial Setup

Menu level.

Enter a different one-touch key or

speed-dial code that is not assigned.

Continue by adding the next fax number

you want to the group.

To clear the blacklist, unplug the fax

machine’s power cord from the power

strip or outlet and plug it back in.

Check the fax number and try resending

the fax. If the message appears again,

try sending to another fax machine or try

again later.

TART

Press S

code and continue editing.

Press E

Dial Setup level of the Menu. (Press

NTER/MENU

E

group-dial code.)

Press S

settings.

to return to the group-dial

NTER/MENU

TOP/CLEAR

to go to the Group

again to choose a different

to exit the Menu

40 Installation and operation

EN

Page 42

Table 8. Control panel messages

Message Cause Solution

Clear Document

From Scanner

Your document jammed while being fed

through the document feeder tray or the

HP LaserJet 3100 product loaded multiple

sheets of the document.

The special media lever was in the wrong

position for the document you sent.

The control panel configuration was set

incorrectly.

Pull the document release door open,

remove the jammed item, and then

close the door.

Remove the jammed item as detailed

above. Then, check the special media

lever. It should be to the left for regularweight items or to the right for thick

items, which must be fed one at a time.

Check the control panel configuration

for outgoing faxes, including the “send

long pages” setting.

EN

Control panel 41

Page 43

Table 8. Control panel messages

Message Cause Solution

Communication Error An error occurred while trying to transmit

a fax. Brief descriptions of communication

errors are listed below:

60 no RTC at end of fax

81 memory filled up

82 fax was too short

84 power fail while receiving

85 failed to train

86 in ECM, fax data had error(s)

87 NEC failed to decode (T.4 or T.6

coding error

88 received scan line exceeds 13 sec

(T.4-3.2)

89 modem setup timeout

90 low speed command time out

91 bad low speed command

92 transmit error: no DIS

93 transmit error: no answer

94 transmit error: canceled by operator

95 transmit error: failed to train

96 transmit error: busy

97 transmit error: no dial tone

100 poll-in error: no document to poll

101 document jam

102 receive error: too many mailbox

logs

103 receive error: had poll document but

no memory for receive

104 transmit error: no MCF

105 image processing chip fell behind

106 transmit: modem output buffer error

107 PIN received

108 RR/RNR timeout

109 generic ECM error

110 possible missing/partial pages in

ECM

111 T4 bit not set in DIS

112 wrong password

113 communications error in remote

setup (JetFax only)

114 fax document was lost (JetFax only)

115 blacklist

116 SUB/PWD error

117 timeout waiting for image

processing chip

118 no fax detected

119 remote access

120 caller disconnected prematurely

Try resending the fax.

If the call fails again, check that the

telephone cord is securely connected.

Then, check for a dial tone on the phone

line by pressing M

Wait and try resending the fax later.

ANUAL DIAL

.

42 Installation and operation

EN

Page 44

Table 8. Control panel messages

Message Cause Solution

Configuration

Err # (number 1-4)

Config. Stuck Addr In Service Mode only, SRAM stuck

Config. Tied Addr. In Service Mode only, SRAM tied address

Decoding Error

#(number 1-3)

Documents Were

Lost START to

Continue

An error was detected in the static

random-access memory (SRAM).

address test.

test.

There was an error in decoding with the

image processing chip.

Power to the HP LaserJet 3100 product

was interrupted, and documents in

memory were lost.

Unplug the power cord from the power

source, wait 10 seconds, and replug in

the power cord. If the error persists, see

Chapter 6, “Troubleshooting.”

Unplug the power cord from the power

source, wait 10 seconds, and replug in

the power cord. If the error persists, see

Chapter 6, “Troubleshooting.”

Unplug the power cord from the power

source, wait 10 seconds, and replug in

the power cord. If the error persists, see

Chapter 6, “Troubleshooting.”

Unplug the power cord from the power

source, wait 10 seconds, and replug in

the power cord. If the error persists, see

Chapter 6, “Troubleshooting.”

TART

Press S

product prints a report. Check the fax

log status column for the “Fax

Document was Lost” message. Resend

the associated outgoing faxes and, for

incoming faxes, ask the sender to

resend them.

. The HP LaserJet 3100

Encoding Error There was an error in encoding with the

image processing chip.

Errors Likely in

Pages: (page range)

EN

The fax transmission was completed, but

there are likely to be errors in the pages

specified.

Unplug the power cord from the power

source, wait 10 seconds, and replug in

the power cord. If the error persists, see

Chapter 6, “Troubleshooting.”

Try resending the fax or asking the

sender to resend the fax to you.

Control panel 43

Page 45

Table 8. Control panel messages

Message Cause Solution

Fax Document was

Lost

Fax Memory Error

#(number 1-5)

Faxes in memory were lost due to a power

failure.

An error was detected in dynamic

random-access memory (DRAM).

If you set up faxes to be sent at a future

time or to be polled, print a fax log to

identify which faxes were lost. Then,

enter the faxes again.

If the HP LaserJet 3100 product was set

to receive faxes to memory (instead of

printing), any documents received to

memory also have been lost. Check with

the sender and request that the fax be

resent.

Unplug the power cord from the power

source, wait 10 seconds, and replug in

the power cord. If the error persists,

service may be required. See Chapter 6,

“Troubleshooting.”

If you set up faxes to be sent at a future

time or to be polled, print a fax log to

identify which faxes may have been lost.

Then, re-enter the faxes. If the HP

LaserJet 3100 product was set to

receive faxes to memory (instead of

printing), any documents received to

memory also may have been lost. If you

were expecting a fax, check with the

sender and request that the fax be

resent.

Group is Empty, Use

ONE-TOUCH/

SPEED DIAL

Input Limit Reached Too many fax numbers were dialed when

Invalid Date or Time An invalid time or date was entered, such

Keypad Test Failed In Service Mode only, the keypad test

Appears when you are creating a groupdial code.

trying to send to an ad-hoc group.

as 25:99 PM or June 35

failed.

44 Installation and operation

Begin adding fax numbers the groupdial code by pressing each number’s

one-touch key or pressing S

entering the fax number’s speed-dial

code, and pressing E

The maximum number of fax numbers

that can be added to an ad-hoc group is

100. Resend the fax, but only to 100 fax

numbers or fewer.

Re-enter the date and time. If the error

persists, see Chapter 6,

“Troubleshooting.”

Try running the keypad test again.

PEED DIAL

NTER/MENU

.

EN

,

Page 46

Table 8. Control panel messages

Message Cause Solution

Long Page?

START to Continue

The HP LaserJet 3100 product senses a

document over 39 inches (991 mm), such

as a banner, may be feeding through the

document feeder tray or that a paper jam

has occured.

Memory Full - Send

Unscanned Pages

During the fax job the memory filled. All

pages of the fax have to be in memory for

a fax job to work correctly. Only the pages

that fit into memory were sent.

Memory is Full The HP LaserJet 3100 product’s memory

has been completely filled during a copy

or a scan.

Modem Error #

An error was detected with the modem. Unplug the power cord from the power

(number 1-3)

TART

Press S

you do not press S

to continue scanning. If

TART

within three

seconds, the message disappears and

the document scanner stops scanning

because it thinks the page has jammed.

If you are sending a fax or copying a

document longer than 39 inches (991

mm), you can also set the control panel

configuration to “Send long pages,”

which ensures that long pages feed

without having to monitor the task and

TART

press S

before the document

scanner shuts off.

Reload the unscanned pages and resend them to finish the fax job.

Or, scan the unscanned pages to the

computer and fax them from the

computer.

This message should clear

automatically when the next task starts

(for example when you start a copy or

receive a fax).

source, wait 10 seconds, and replug in

the power cord.

No Answer You tried to send a fax, but the receiving

fax line did not answer for all redial

attempts.

No Dial Tone You tried to send a fax, but your phone

line is not operational.

No Fax in (number)

Tries

The HP LaserJet 3100 product failed to

connect to the receiving fax machine in

the number of redials specified.

EN

Check the fax number and try resending

the fax. If the message appears again,

try sending to another fax machine or try

again later.

Check that the telephone cord is

securely connected. Then, check for a

dial tone on the phone line by pressing

ANUAL DIAL

M

. If necessary, check the

wall outlet by plugging in a phone and

attempting to place a phone call.

Check the fax number and try resending

the fax. If the message appears again,

try sending to another fax machine or try

again later.

Control panel 45

Page 47

Table 8. Control panel messages

Message Cause Solution

No Memory for

Report

Erase/Print

Document

No Modem Installed There is a problem with the line interface

No Room in Fax Log The fax log was unable to print due to an

Not Enough Memory There is not enough memory to complete

Out of Memory

Switching to ONE

COPY

Memory needed to print a report may be

being used to store faxes that have been

received to memory.

Needed memory may be being used to

store faxes set up to be sent at a future

time or to be polled.

unit (LIU).

error, such as out of paper.

the job indicated.

The HP LaserJet 3100 product does not

have enough memory to complete the

copy job.

Print faxes that have been received to

memory.

If you have several faxes set up to be

sent at a future time or to be polled, try

clearing these faxes using job status.

Unplug the power cord from the power

source, wait 10 seconds, and replug in

the power cord. If the error persists, see

Chapter 6, “Troubleshooting.”

Load paper in the paper input bin so the

HP LaserJet 3100 product can print the

log.

Try resending the job. If the error

persists, try reducing the amount of

activity on the HP LaserJet 3100

product and cancel jobs in memory

before resending the job.

The HP LaserJet product continues to

copy, but only one copy is output.

Divide the copy job into smaller sections

and then try copying again.

If you are collating the job, turn off the

collation feature, only make one copy of

the document at a time, or see the user

guide for instructions about using the

Document Assistant to make the copies.

No Fax Pages in

Memory to Reprint

Nov-22-93 06:30 PM

(This date is

incorrect.)

The HP LaserJet 3100 product attempted

to execute “Reprint Last Fax” when

nothing was in memory.

The battery inside the HP LaserJet 3100

product has failed, causing all Menu

features to revert to the factory settings.

Settings that contained alphabetic and

numeric characters you entered, such as

header information and speed-dial names

and numbers, have been erased.

46 Installation and operation

Wait for a fax, then as soon as a fax is in

the memory, the HP LaserJet 3100

product will reprint the fax.

The battery should be replaced. You

can continue to use the HP LaserJet

3100 product without replacing the

battery, but if you re-enter the Menu

settings and then turn off the power, the

settings are erased again.

EN

Page 48

Table 8. Control panel messages

Message Cause Solution

Paper Bin is Empty

Please Add Paper

Password must be 4

Digits

Paused (Memory

Full)

PC Print Timed Out The print job took too long to print, and the

Phone Number Error Too many characters were entered when

The paper input bin is empty. Load paper. If paper is already loaded,

Attempt was made to enter a password

that was not four digits.

The HP LaserJet 3100 product’s memory

is full, and the current job in the document

feeder tray is paused to wait for memory

to become available.

HP LaserJet 3100 product timed out.

dialing a phone number.

remove it. Check for and remove any

jammed sheets and discard them. Then,

reload the paper.

Re-enter four-digit password.

Reduce activity on the HP LaserJet

3100 product, or wait for other jobs to

finish so memory will be freed.

If there are faxes set up to be polled or

sent at a future time, you may want to

cancel these jobs to free memory.

Let the “print jobs retry” continue for five

minutes. If the HP LaserJet 3100

product still does not print, resend the

print job.

The maximum number of characters

that can be entered is 40. If you have a

number longer than 40 characters,

break the number into smaller chunks.

Enter the first part of the number, and

EDIAL/PAUSE

press R

character in the first number. Then,

enter the second part of the number as if

it were a second number going to a

group. When the product dials, it will

treat both numbers as if they are one.

as the last

Polling-In Error The HP LaserJet 3100 product tried to poll

another fax machine. The poll failed

because there was no answer, the line

was busy, or the other fax machine was

not ready to be polled.

EN

Make sure the sender’s fax machine is

ready to be polled, and check the fax

number. Then, set up to poll again.

Control panel 47

Page 49

Table 8. Control panel messages

Message Cause Solution

Printer Comm Error There was an error in communicating with

the HP LaserJet 3100 product.

Printer Comm Error ^1In Service Mode only. There was an error

in communicating with the HP LaserJet

3100 product.

Printer Cover Open

or No Cartridge

Printer Fixing Error

Replace Fixing Unit

The printer door is open or the toner

cartridge is not installed properly.

There is an error with the print engine. See Chapter 6, “Troubleshooting.”

Check that the parallel cable is securely

connected between the HP LaserJet

3100 product and the computer.

If the problem persists, unplug the HP

LaserJet 3100 product’s power cord

from the power source for 5 seconds,

and then replug it in.

If neither of these solutions works, see

Chapter 6, “Troubleshooting.”

Check that the parallel cable is securely

connected between the HP LaserJet

3100 product and the computer.

If the problem persists, unplug the HP

LaserJet 3100 product’s power cord

from the power source for 5 seconds,

and then replug it in.

If neither of these solutions works, see