Page 1

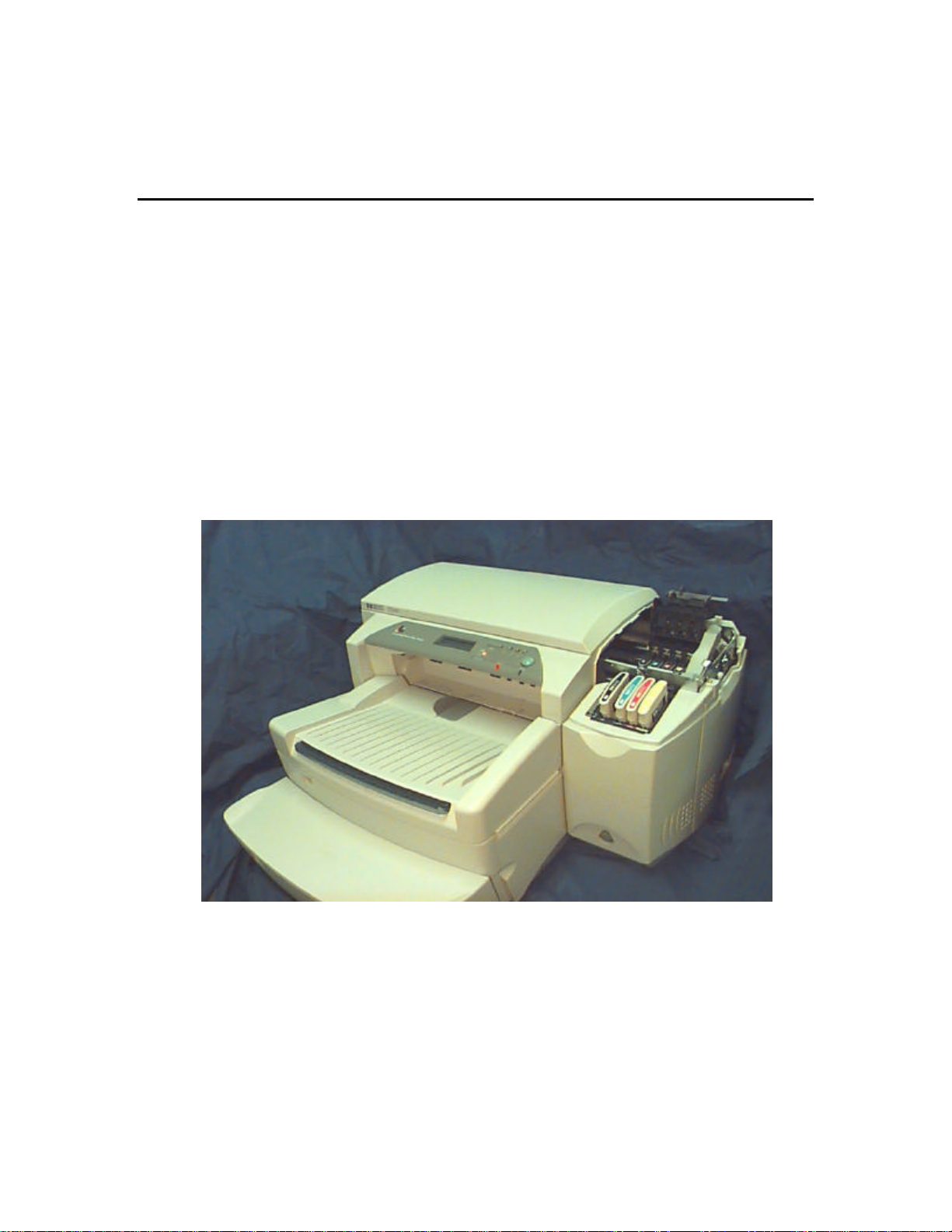

HP 2500C Series Printer

Service Manual

Page 2

ii

Version History

Version 2.0 January 1, 1999

Notice

The information contained in this document is subject to change without notice.

Hewlett-Packard makes no warranty of any kind with regard to this material,

including, but not limited to, the implied warranties of merchantability and fitness

for a particular purpose.

Hewlett-Packard shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance or use of this

material.

No part of this document may be photocopied, reproduced, or translated to another

language without the prior written consent of Hewlett-Packard Company.

Page 3

iii

Contents

Chapter 1

Production Information

Technology Update......................................................... ...............1-1

Modular Ink Delivery System ................................... ...............1-1

Specifications .................................................................................1-4

Data Sheet ................................................................................1-4

Cable Specifications..................................................................1-8

Reliability Specifications ..........................................................1-14

Interface Specifications.............................................................1-15

Physical Specifications..............................................................1-16

Packaging Dimensions Specifications .......................................1-17

Electrical Specifications............................................................1-18

Environmental Specifications ....................................................1-19

Product Certifications................................................................1-20

Media Sizes Supported..............................................................1-21

Recommended Media Weight...................................................1-22

Paper Handling .........................................................................1-23

Printable Area...........................................................................1-24

Media Margins ..........................................................................1-25

Hewlett-Packard Ink Cartridge Specifications...........................1-27

System Requirement.................................................................1-28

Product Overview...........................................................................1-29

Printer External View................................................................1-29

Model and Serial Number .........................................................1-29

Supplies and Accessories................................................................1-30

Product Structure......................................................................1-30

Power Cord ...............................................................................1-31

Network Interface .....................................................................1-32

Print Cartridge ..........................................................................1-33

Media........................................................................................1-34

Other Accessories .....................................................................1-35

Replaceable Parts......................................................................1-35

Warranty and Support.....................................................................1-36

Hewlett-Packard Limited Warranty Statement...........................1-37

Extent of Limited Warranty.......................................................1-37

Limitations of Warranty............................................................1-38

Limitations of Liability .............................................................1-39

Obtaining Printer Drivers..........................................................1-40

Service Support Contracts.........................................................1-41

Service and Support Resource ...................................................1-42

Worldwide Customer Support Numbers....................................1-49

Page 4

iv

Chapter 2

Operating Overview

Using the Control Panel................................................................... 2-1

Control Panel Layout................................................................. 2-1

Indicator Lights.......................................................................... 2-3

Settings and Defaults ................................................................. 2-4

Restoring Factory Defaults ......................................................... 2-7

Control Panel Menus.................................................................. 2-8

Paper Handling Menu........................................................... 2-9

Diagnostics Menu................................................................2-11

Information Menu ...............................................................2-12

Self-Test Menu....................................................................2-13

Print Quality Menu..............................................................2-14

Printing Menu .....................................................................2-15

I/O Menu.............................................................................2-16

Resets Menu........................................................................2-17

Configuration Menu............................................................2-17

MIO Menu..........................................................................2-18

Aligning Printheads...................................................................2-19

Printhead Diagnostic Process....................................................2-20

Error Codes ....................................................................................2-21

Recoverable Error Codes................................................................2-21

Unrecoverable Codes..................................................................2-23

Printer Diagnostic Pages.................................................................2-33

Diagnostic Page...........................................................................2-33

Extended Diagnostic Page............................................................2-35

Page 5

v

Chapter 3

Loading Paper and Paper Behavior

Chapter 4

Install / Uninstall

Loading the Trays............................................................................ 3-1

Loading Commonly-Used Media in Tray 2...................................... 3-2

Loading Commonly Used Media in Tray 3 ...................................... 3-4

Loading Paper in Tray1.................................................................... 3-6

Loading Paper through the Rear Manual Feed.................................. 3-7

Paper Behavior ................................................................................ 3-8

Print Job Selected Tray 2 .............................................................. 3-8

Print Job Selected Tray 3 .............................................................. 3-8

Print Job Selected Autoselect........................................................ 3-9

Print Job Selected Manual Feed .................................................... 3-9

Unexpected Paper Size.................................................................. 3-9

Printer is Idle ................................................................................ 3-9

Printer is Printing from Tray 1 or Tray 2....................................... 3-9

Printer is Printing from Tray 3 .....................................................3-10

Paper Jam at Output Bin During Paper Loading...........................3-10

Paper Jam at Output Bin During Printing.....................................3-10

Paper Jam Internal During Paper Loading....................................3-11

Installing Printer Software from CD................................................. 4-1

Installing PCL Software from CD in Windows ................................ 4-2

Installing PCL Software from Floppy Diskettes in Windows......... 4-3

Installing PostScript Software in Macintosh.................................. 4-4

Installing PostScript Software in Windows ................................... 4-4

Uninstalling Printer Software ........................................................... 4-5

For Windows 3.1x ........................................................................ 4-5

For Windows 95 / 98 / NT4.0 ....................................................... 4-5

Copy Printer Software from CD to Disk or Server ........................... 4-6

Page 6

vi

Chapter 5

Maintenance and Ink Cartridge Safety

Chapter 6

Functional Overview

Cleaning the Printer and Accessories ............................................... 5-1

Cleaning Spilled Ink ..................................................................... 5-1

Printhead ...................................................................................... 5-2

Ink Cartridge Safety ......................................................................... 5-3

For HP No.10 Color/Black Ink Cartridges..................................... 5-3

For Service Station Assembly ....................................................... 5-5

Potential Health Effects ................................................................ 5-6

First Aid Measures ........................................................................ 5-7

Note to Physician.......................................................................... 5-7

Handling Precautions.................................................................... 5-7

Additional Information ................................................................. 5-8

Material Safety Data Sheet (MSDS).............................................. 5-8

Writing System................................................................................ 6-1

Introduction.................................................................................. 6-1

Part Numbers................................................................................ 6-2

Ink Cartridge and Printhead Specifications.................................... 6-3

Thermal InkJet Technology........................................................... 6-4

Paper Paths and Components........................................................... 6-6

Chassis.......................................................................................... 6-6

Output Management ..................................................................... 6-7

Output Mechanism........................................................................ 6-8

Swivel PCA.................................................................................6-18

Dual Bin Pick and Feed Mechanism.............................................6-21

HP 2500C Electronics .....................................................................6-24

HP 2500C PCA Overview............................................................6-24

Motor Control Overview ..............................................................6-25

Firmware........................................................................................6-26

Physical Layer.............................................................................6-27

Data Link Layer ...........................................................................6-27

Application Layer........................................................................6-28

Interface with Mechanism............................................................6-28

Interface with Key Panel..............................................................6-29

Page 7

vii

Chapter 7

Removal and Replacement of Parts (without Calibration)

Introduction..................................................................................... 7-1

Removal and Replacement Tools.................................................. 7-1

Before You Begin......................................................................... 7-2

Important Notes about Printer Components and Disassembly ........ 7-3

Replacement of Parts....................................................................... 7-4

Removing the PCA....................................................................... 7-4

Installing the PCA......................................................................... 7-6

Removing the Service Station....................................................... 7-7

Installing the Service Stations....................................................... 7-9

Removing the LED PCA..............................................................7-10

Installing the LED PCA...............................................................7-12

Removing the LCD Panel ............................................................7-13

Installing the LCD Panel..............................................................7-14

Removing the Power Knob..........................................................7-15

Installing the Power Knob ............................................................7-16

Removing the Power Supply........................................................7-19

Installing the Power Supply .........................................................7-20

Removing the MIDS....................................................................7-21

Installing the MIDS .....................................................................7-22

Removing the Ink Supply System ................................................7-23

Installing the Ink Supply System..................................................7-24

Removing the Main Case.............................................................7-25

Installing the Main Case...............................................................7-26

Removing the Paper Knob ...........................................................7-27

Installing the Paper Knob.............................................................7-28

Removing the Fan........................................................................7-29

Installing the Fan .........................................................................7-30

Removing the Carriage Motor......................................................7-31

Installing the Carriage Motor.......................................................7-32

Removing the Assembly Harness Cover ......................................7-33

Installing the Assembly Harness Cover........................................7-34

Removing the Rear Door .............................................................7-35

Installing the Rear Door ...............................................................7-36

Removing the Encoder Strip ........................................................7-37

Installing the Encoder Strip..........................................................7-38

Removing the Primary Star Wheel...............................................7-39

Installing the Primary Star Wheel.................................................7-40

Removing the Secondary Star Wheel ...........................................7-41

Installing the Secondary Star Wheel .............................................7-42

Removing the Rubber Foot..........................................................7-43

Installing the Rubber Foot............................................................7-44

Removing the Absorbers ..............................................................7-45

Installing the Absorbers ...............................................................7-48

Page 8

viii

Chapter 8

Troubleshooting

Chapter 9

Parts and Diagrams

Troubleshooting Concepts ............................................................... 8-1

LED.............................................................................................. 8-2

Standard Procedures ..................................................................... 8-3

No Power...................................................................................... 8-4

LED or LCD.................................................................................8-6

Unrecoverable Error Messages...................................................... 8-9

Print Quality ................................................................................8-11

Broken or Missing Parts...............................................................8-12

No Pick or Multiple Pick or Other Mechanism Problems .............8-13

Troubleshooting Tools.................................................................8-14

Parts List ......................................................................................... 9-1

Parts Leveraged form HP2000C (C4503A)...................................... 9-2

Exploded Views............................................................................... 9-3

Page 9

1-1

Chapter 1 Product Information

Technology Update

Modular Ink Delivery System

A modular ink delivery system is the separation of ink cartridges and printheads into

individual, single-color components. Traditional inkjet printers use one black and one tricolor ink cartridge, each with integrated printheads. HP's modular ink delivery system

features four separate ink cartridges--one for each primary printing color--and four

corresponding long-life printheads, with tubes connecting the components. Including the

standard and high-capacity black ink cartridges, there are actually nine consumables, with

only eight used in the printer at one time.

Product Information

Page 10

1-2

Technology Update

How It Works

By separating the ink cartridge from the printheads, a modular ink delivery system allows

the ink supply to remain in a permanent, fixed position. The printheads remain attached

to the carriage and move back and forth, delivering ink to the page as the paper advances

through the printer. Each printhead and ink cartridge is embedded with a tiny memory

device called a smart chip that recognizes and stores the unique operating characteristics

of the component to create a totally integrated printing system that ensures consistent,

high-quality printing at the lowest cost available.

A unique pressurization system maintains a constant supply of ink to the printheads.

Smart chips monitor the amount of ink used by counting every drop that passes through

each printhead. When the smart chips sense more ink is needed to maintain continuous

printing, a plunger in each cartridge temporarily pressurizes the cartridges to deliver more

ink to the printheads. With the modular ink delivery system, ink supply is instantly

replenished, even at top speeds.

The new, individually replaceable printheads are designed for long life and each should

print 12,000 pages in black, 24,000 pages in color. As a result, you'll go through many

ink cartridges before the corresponding printhead will need replacement. With their

modular design, ink cartridges contain twice the ink supply of current HP cartridges, so

you'll also get longer lasting cartridges. When a component approaches the end of its

print life, the smart chip notifies the user through on-screen messages so a replacement

can be purchased prior to the part expiring.

By separating the printheads and ink cartridges, you only replace the component that is

no longer usable. Printheads can be replaced one at a time without the need for costly or

extensive servicing and aren't discarded when the ink is expended. HP printheads also use

a wet wiping system to eliminate nozzle clogging that plagues other permanent printhead

designs. Component replacement is easy. Simply pull out the used part and snap in a

replacement.

Product Information

Page 11

1-3

Technology Update

The Benefits

Cuts up to 30 percent off the printing costs of other methods

§ Modular design means only the component that is no longer useful is replaced.

§ Longer-life printheads and higher-capacity ink cartridges means less frequent

replacement.

Achieves color laser speed in a personal desktop printer

§ Printheads have 304 nozzles apiece (1,216 total, the most in the industry)

resulting in faster print speeds.

§ Prints in 1/2-inch swath as opposed to the 1/5- or 1/3-inch swaths of integrated

print cartridges.

§ Ink cartridge pressurization system keeps constant flow of ink to printhead. Smart

chips store component information and alert user to low-ink, ink-out and

printhead failure status.

Product Information

Page 12

1-4

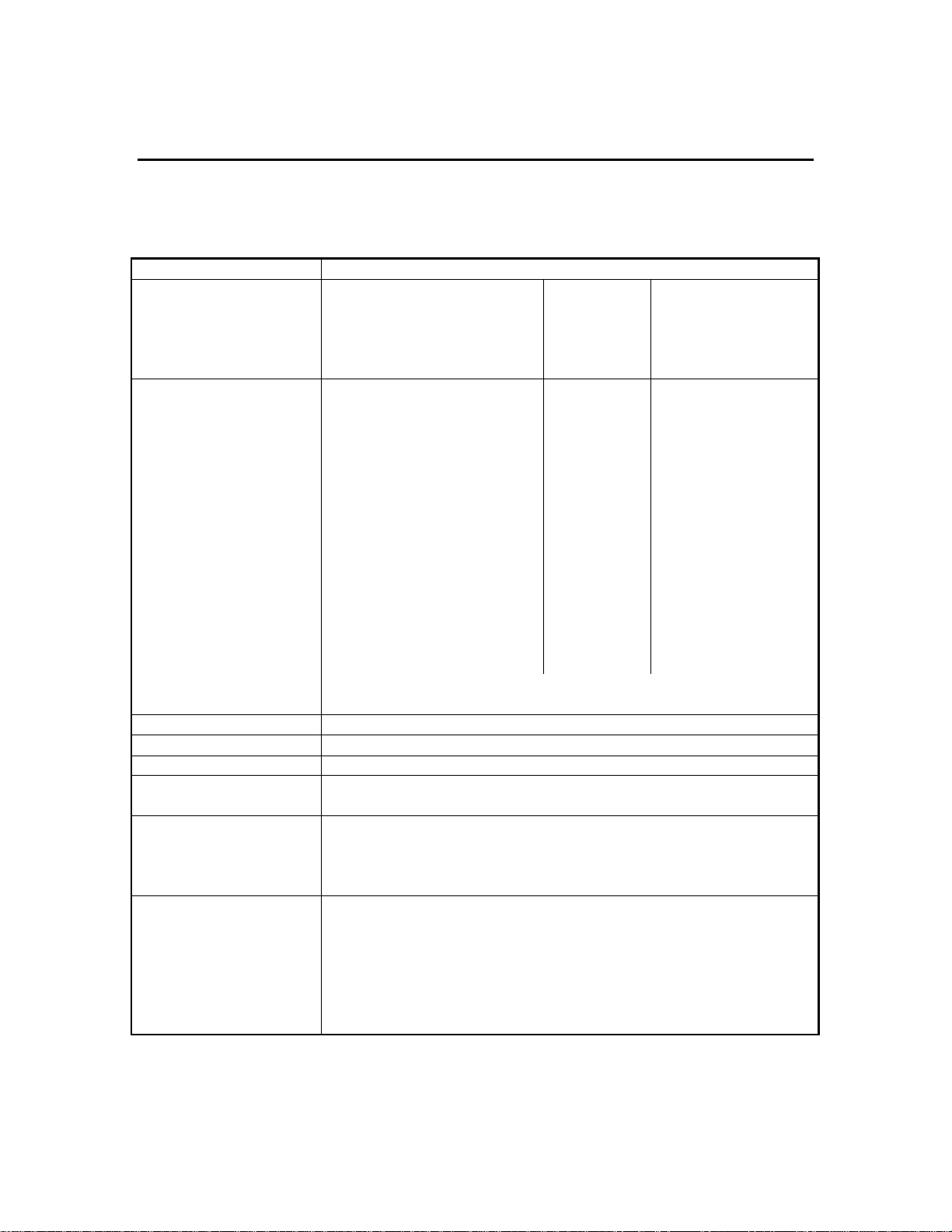

Specifications

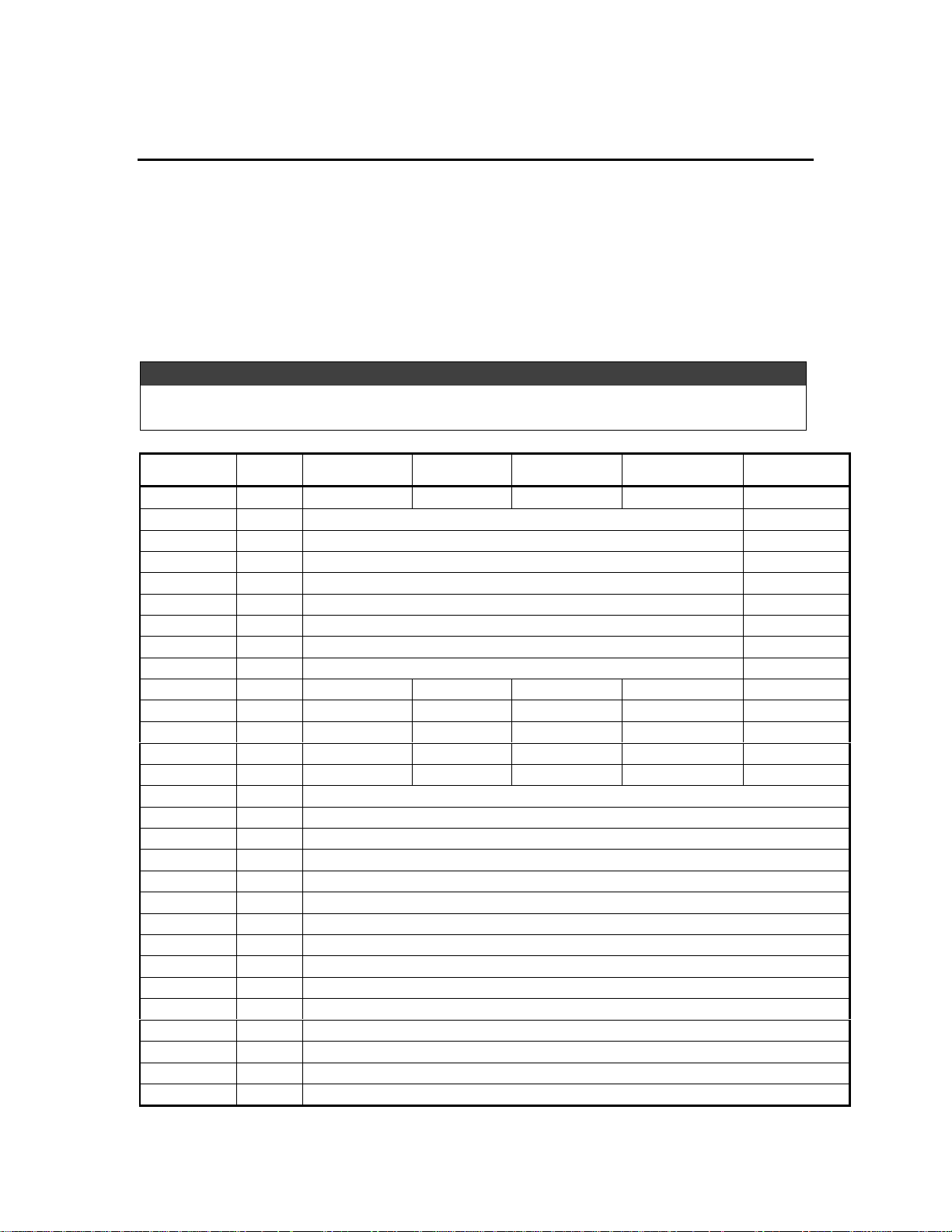

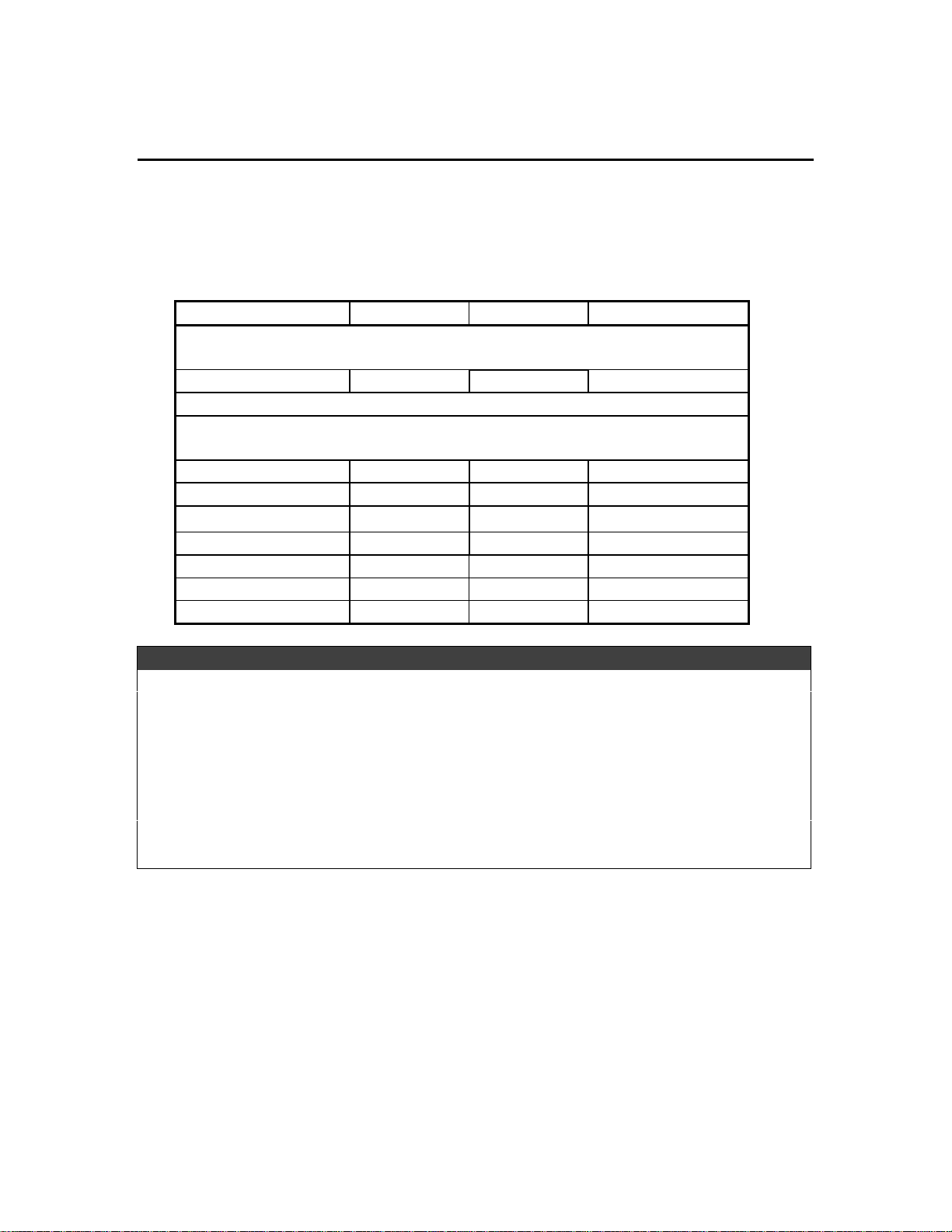

Data Sheet

Print Method

Print Speed 1 Black Black Text

Print Speed 1 Color

Black Resolution

Color Resolution

Printhead Nozzles

Printer Command

Language

Font Capability

Memory HP 2500C

Plain paper drop on-demand thermal inkjet printing.

Econofast Mode

Normal Mode

Best Mode

Color Highlights

Econofast Mode

Normal Mode

Best Mode

Mixed Text & Graphics

Econofast Mode

Normal Mode

Best Mode

Full Page Color

Econofast Mode

Normal Mode

Best Mode

1

Approximate figures. Exact speed dependent on the system

configuration, software program, and document complexity

Up to 600x600 dpi

PhotoREt II for photo quality

304 black, 912 color (304 per color printhead)

HP PCL 3 enhanced

Adobe PostScript 3 (With HP 2500CM only)

HP FontSmart v2.5 (110 TrueType fonts for windows)

HP FontSmart software provides easy-to-use font management

capabilities

136 PostScript fonts with Adobe PostScript 3

4 Mbytes standard RAM

Letter / A4

9 ppm

7 ppm

7 ppm

Letter / A4

9 ppm

6 ppm

5 ppm

Letter / A4

7 ppm

3.5 ppm

1.2 ppm

Letter / A4

3.5 ppm

1.8 ppm

0.4 ppm

11x17 / A3

5 ppm

3 ppm

3 ppm

11x17 / A3

5 ppm

3 ppm

2 ppm

11x17 / A3

4 ppm

2 ppm

0.5 ppm

11x17 / A3

1 ppm

0.8 ppm

0.2 ppm

HP2500CM

20 Mbytes standard RAM

Two 72-pin SIMM slots for additional memory (EDO, 60ns)

expansion up to a total of 76 Mbytes

Product Information

Page 13

1-5

Connectivity /Network

Management

HP2500C

Network-capable printer for DOS and Windows environments

Enhanced HP PCL 3e Windows Driver Support for Windows NT 4.0,

Windows 3.1x/95/98

Centronics parallel, IEEE 1284 compliant

One network interface slot accepts optional HP MIO Print Servers

with support for Novell Netware, Microsoft LAN Manager, Windows

for Workgroups, Windows for NT, IBM LAN Server, Unix

environment and Apple Talk (Ether Talk)

HP2500CM

Network-ready printer for DOS, Windows and Macintosh

environments

Enhanced HP PCL 3e Windows Driver Support for Windows NT 4.0,

Windows 3.1x/95/98

Centronics parallel, IEEE 1284 compliant

HP MIO 10/100Base-TX print server with support for Novell

Netware, Microsoft LAN Manager, Windows for Workgroups,

Windows NT, IBM LAN Server, Unix environment and AppleTalk

(EtherTalk)

Supports networking protocols IPX/SPX, TCP/IP, DLC/LLC,

AppleTalk and NetBEUI

Adobe PostScript 3 drivers for Windows and Macintosh QuickDraw

Paper Handling

Automatic switching between languages and ports.

HP JetAdmin printer management software provides easy printer

setup and configuration. Latest versions available from HP’s web

site (http://www.hp.com/go/jetadmin)

HP WebJetAdmin printer management software available from HP’s

web site (http://www.hp.com/go/webjetadmin) for simple

installations and configuration from a common web browser.

Standard input capacity of 400 sheets through two trays (Tray 2 & 3)

of 150 sheet and 250 sheet capacity.

Standard output capacity of 150 sheets (face-up)

Rear Manual feed – single sheet only

Tray 1 (Input / Output Tray) – Sheets: up to 10, Cards: up to 4

Tray 2 (Upper Tray) – Sheets: up to 150, Cards: up to 60

Tray 3 (Lower Tray) – Sheets: up to 250

All input paths handle standard media sizes (as listed below) up to

13 in.x19 in. (Supper A3)

Additionally, Tray 1 and the rear manual feed support all media sizes

as small as 4 in.x6 in. (101.6mmx152.4mm)

Built-in media size sensors prevents printing on the wrong size of

media

Product Information

Page 14

1-6

Paper Size Handling

Maximum Print Width

Recommended Media

Weight

Minimum Width: 76.2 mm (4in.) x 127.0 mm (6 in.)

Maximum Width: 330.2 mm (13in.) x 482.6 mm (19 in.)

320 mm (12.61 in.) x 470 mm (18.49 in.) on 13 in. x 19 in. media

All input paths handle the following paper weights with the rear

straight-through paper path handling up to 0.3 mm thickness of paper

Paper / Labels: 60 to 135 g/m2 (16 to 36 lb. Bond)

Cards: 110 to 200 g/m2 (110 lb. Index)

Straight-through path: up to 0.3 mm thickness (0.012 in.) or approx.

200 g/m2 (110 lb. Index)

Smart Software

Features

Media Size / Type

Control Panel

Built-in printer driver features:

HP ZoomSmart scaling technology, Billboard, Handout (N-up

printing), Mirror, Watermark, Print Preview, Quick Sets, LaserJet

Margin Emulation

Paper: Super B 13 x 19 in., U.S. Tabloid 11 x 17 in.,

U.S. Legal 8.5 x 14 in., U.S. Letter 8.5 x 11 in.,

European A3 297 x 420 mm, European A4 210 x 297 mm,

European B4 257 x 364 mm

Transparencies: U.S. Letter 8.5 x 11 in., European A4 210 x 297mm

Cards: U.S. Index card 4 x 6 in., Index card 5 x 8 in.,

European A5 card 105 x 148.5 mm, Postcard 100 x 148 mm

Labels: U.S. Labels, 8.5 x 11 in.; European A4 Labels, 210 x 297mm

Intuitive operation and complete, easy-to-understand messages

Two-line 32 character LCD display and 2 LEDs

Buttons: (Go), Job Cancel, Menu, Item, Value, Select

Indicators: Attention, Ready

Operating

Environment

Power Supply

Power Requirements

Power Consumption

Product Information

Messages can be displayed in 14 languages: English, French, Italian,

German, Spanish, Portuguese, Dutch, Norwegian, Finnish, Swedish,

Danish, Polish, Czech and Russian

Operating temperature: 5o to 40oC (41o to 104oF)

Recommended operating conditions: 15o to 35oC (59o to 95oF)

Storage temperature: -40o to 60oC (-40o to 140oF)

Relative Humidity: 20 to 80% RH non-condensing

Noise levels per ISO 9614-1: Sound Pressure, LwAm 62 dB(A)

Built-in Universal Power Supply

Input Voltage 100 – 240 AC (±10%), 50/60 Hz (±3 Hz)

Less than 2 watts when off, 8 watts maximum non-printing, 35 watts

average printing, 65 watts maximum printing

Page 15

1-7

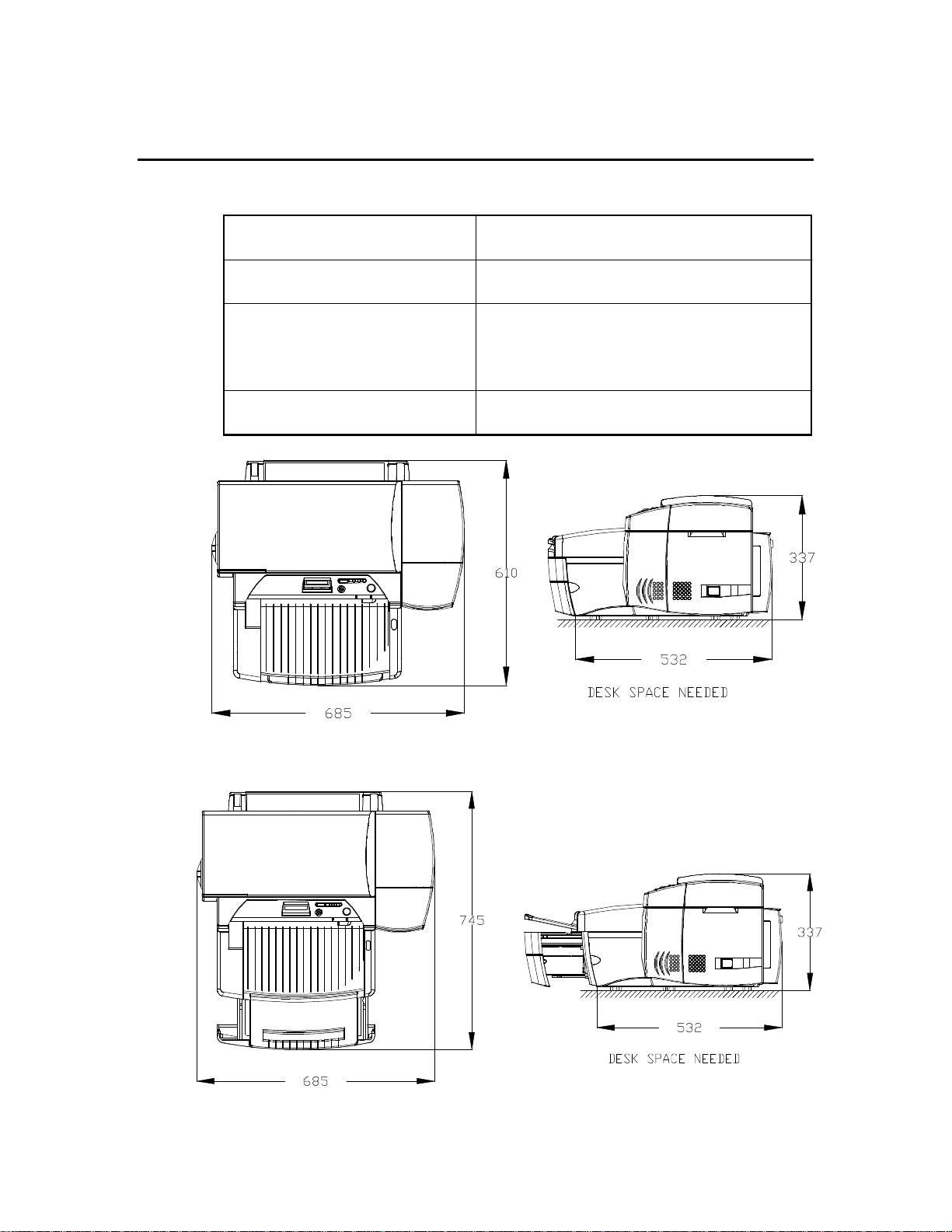

Dimensions

With paper tray closed

685 mm (26.97in.) W x 610 mm (24.02in.) D x 337 mm (13.27in.) H

With paper tray fully extended

685 mm (26.97in.) W x 745 mm (29.33in.) D x 337 mm (13.27in.) H

Desk Space Required

685 mm (26.97 in.) W x 532 mm (20.94 in.) D

Weight

Reliability & Estimated

Usage

System Requirements

Warranty

Product Certifications

26.5 kg (58.48 lb.) without printheads and ink cartridges

27.0 kg (59.52 lb.) with printheads and ink cartridges

Up to 12,000 pages / month

Minimum:

Recommended:

50 Mb Free HardDisk space for 11 x 17 or A3 size printing.

Graphics intensive files may require more disk space.

1 year on site warranty

Safety Certifications: CCIB (China), CSA (Canada), PSB (Singapore),

UL (USA), NOMi(Mexico), TUV-GS (Germany), SABS (South

Africa), JUN (Korea)

EMI Certifications: FCC Part 15B Class B when used with a Class B

computing device (USA), FCC Part 15B Class A when connected to

Local Area Network (LAN) Devices, CTICK (Australia & New

Zealand), VCCI (Japan), CE (European Union), B mark (Poland), Gost

(Russia), BCIQ (Taiwan), RRL (Korea)

Windows 3.1x: 486DX-66, 8Mb RAM

Windows 95/98: 486DX-100, 8Mb RAM

Windows NT 4.0: 486DX-100, 16Mb RAM

Macintosh System 7.5.3: 68040 – 8Mb RAM

Windows 3.1x: Pentium 150/166, 16Mb RAM

Windows 95/98: Pentium 150/166, 16Mb RAM

Windows NT 4.0: Pentium 150/166, 32 Mb RAM

Macintosh System 8 or later: Power PC – 16 Mb

Brands and product names listed are trademarks or registered trademarks of their

respective companies.

Information in this document is subject to change without notice – for more information

or the latest updates, please go to the HP2500C/CM’s web site located at

http://www.hp.com/go/hp2500

Product Information

Page 16

1-8

Specifications

Cable Specifications

1284-B Connector Pin Assignments

The pin numbers and their assigned signal names for the 1284-B connectors are given

below.

Note

The abbreviations used in the "Source" column:

H = host; P = printer; Bi-Di = bi-directional

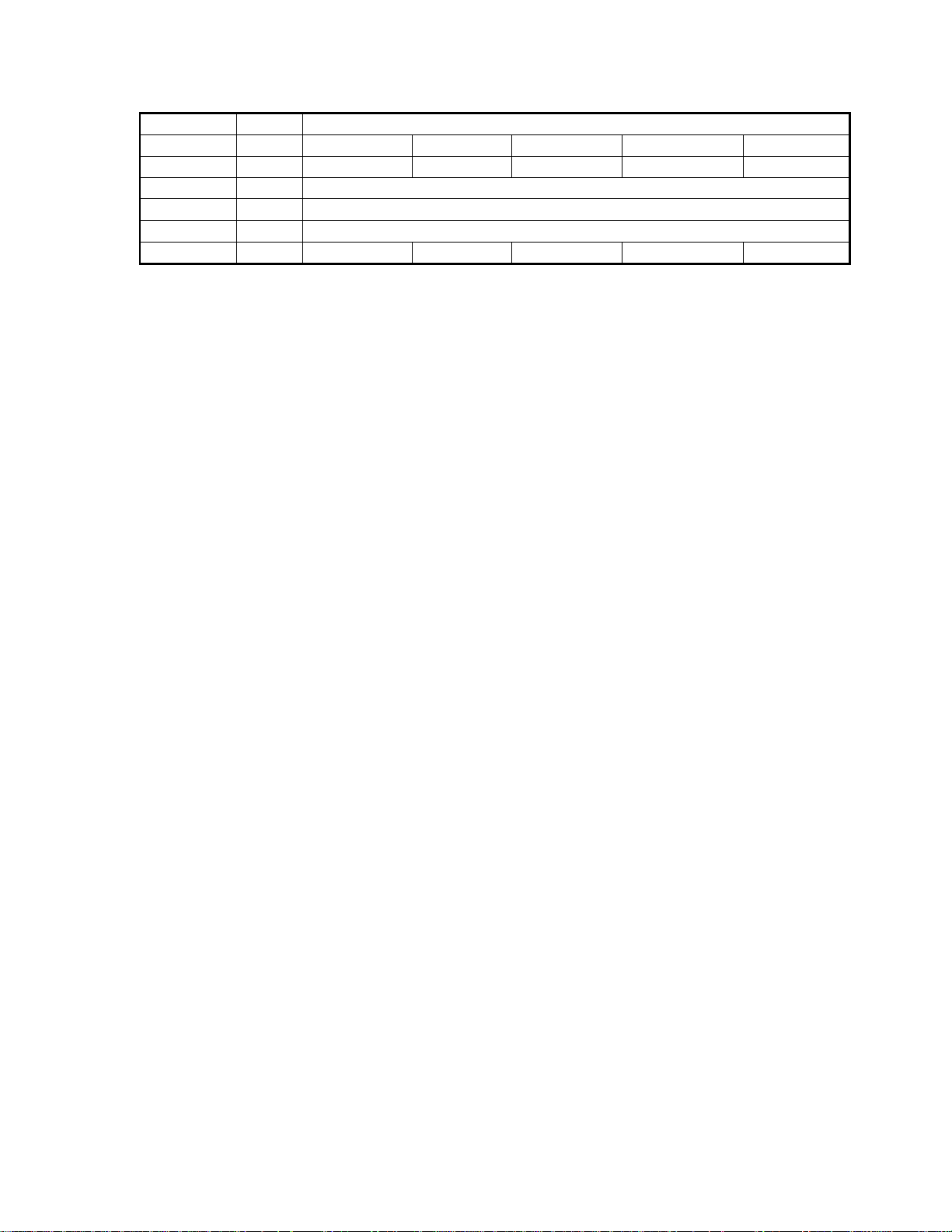

PIN# SOURCE COMPATIBLE NIBBLE BYTE ECP EPP

1 H nStrobe HostClk HostClk HostClk nWrite

2 Bi-Di* Data 1 (Least Significant Bit) AD1

3 Bi-Di* Data 2 AD2

4 Bi-Di* Data 3 AD3

5 Bi-Di* Data 4 AD4

6 Bi-Di* Data 5 AD5

7 Bi-Di* Data 6 AD6

8 Bi-Di* Data 7 AD7

9 Bi-Di* Data 8 (Most Significant Bit) AD8

10 P nAck PtrClk PtrClk PeriphClk Intr

11 P Busy PtrBusy PtrBusy PeriphAck nWait

12 P PError AckDataReq AckDataReq nAckReverse User Defined 1

13 P Select Xflag Xflag Xflag User Defined 3

14 H nAutoFd HostBusy HostBusy HostAck nDStrb

15 Not Defined

16 Logic Gnd

17 Chassis Gnd

18 P Peripheral Logic High

19 Signal Ground (nStrobe)

20 Signal Ground (Data 1)

21 Signal Ground (Data 2)

22 Signal Ground (Data 3)

23 Signal Ground (Data 4)

24 Signal Ground (Data 5)

25 Signal Ground (Data 6)

26 Signal Ground (Data 7)

27 Signal Ground (Data 8)

28 Signal Ground (PError, Select, nAck)

29 Signal Ground (Busy, nFault)

Product Information

Page 17

1-9

30 Signal Ground (nAutoFd, nSelectIn, nInit)

31 H nInit nInit nInit nReverseRequest nInit

32 P nFault nDataAvail nDataAvail nPeriphRequest User Defined 2

33 Not Defined

34 Not Defined

35 Not Defined

36 H nSelectIn 1284 Active 1284 Active 1284 Active nAStrb

∗ Data signals will be driven by some but not all peripheral devices.

∗ Pins not defined by this spec are used by manufacturers at their own risk.

Product Information

Page 18

1-10

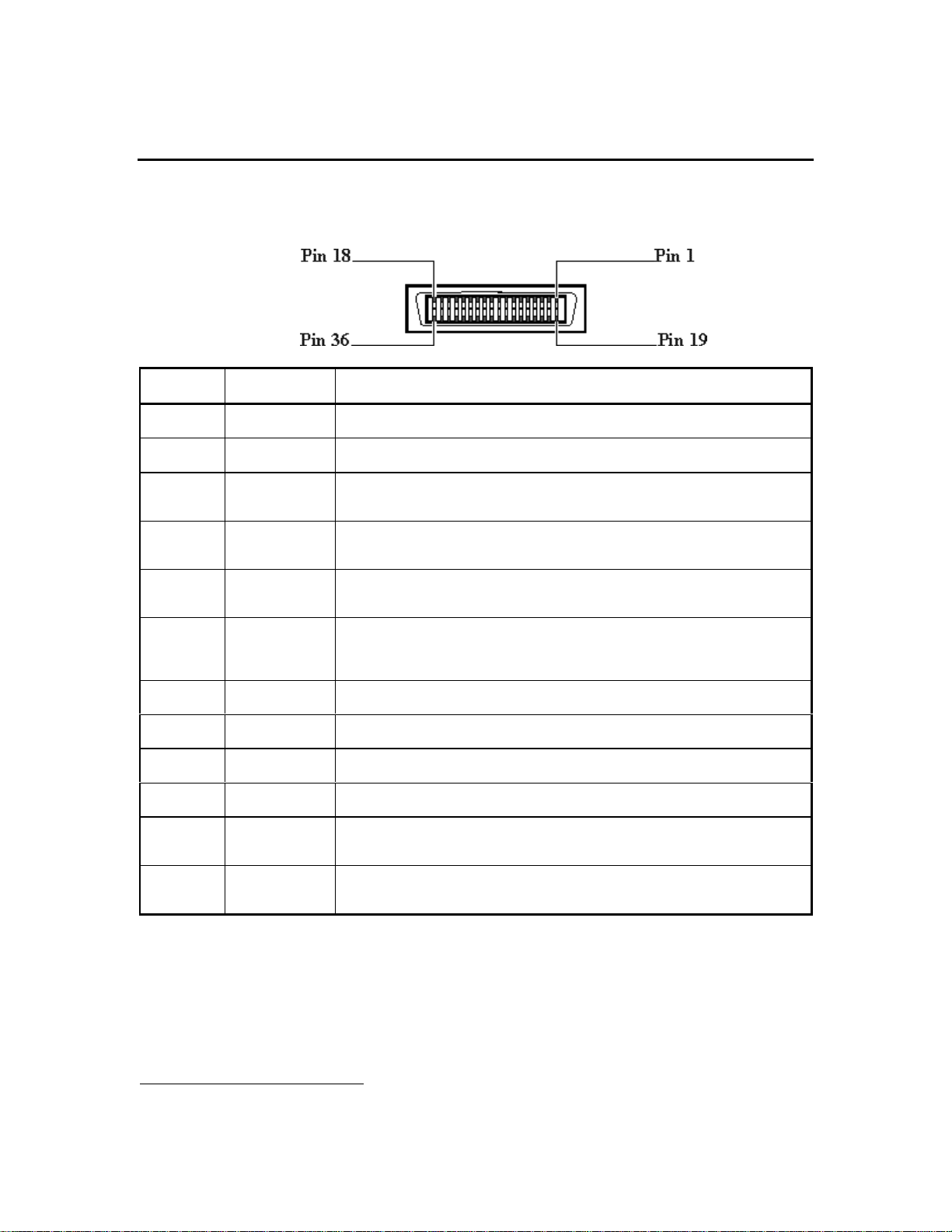

Specifications

Centronics Parallel Pinout Information

PIN NUMBER PIN ID DESCRIPTION

Clear

1

1

A low pulse causes the printer to read one byte of data

ready for more data.

receive data due to data entry, a full buffer or error status.

paper.

condition. The printer sends a low logic level to indicate that it is offline or that the

input buffer is full.

A low pulse sent by the computer resets the printer and clears the print buffer. The

reset occurs on the trailing edge of the pulse

1 Strobe

2 - 9 Data 0 - Date 7 These pins are the data lines. Data 0 is the least significant bit (LSB)

10 Acknowledge The printer sends a low pulse to indicate that it has accepted a byte of data and is

11 Busy The printer sends a high logic level to indicate to the computer that it cannot

12 Paper Error The printer sends a high logic level to indicate to the computer that it is out of

13 Ready The printer sends a high logic level to indicate to the computer that it is in an online

16 Signal Ground Signal interface ground.

17 Chassis Ground Chassis ground.

18 +5 V The printer outputs a +5 volt high logic level through a 2.2K ohm resistor.

19 - 30 Ground These pins are tied to signal ground

31 Reset/Input

32 Error

1

The printer sends a low logic level to the computer to indicate that it is in an error

state.

1

Active low

Product Information

Page 19

1-11

Specifications

The Centronics Parallel Cable has only 8 data lines, 5 status lines, 4 ground lines and

ground connections between the host PC and the peripheral. Each of the signal lines has a

corresponding bit position in a memory address (register) in the host where data is read or

written. Sending data to the printer follows the sequence below:

§ Host places data in Data Out register

§ Host sends pulse on Strobe line

§ Printer sends pulse on Busy in response to pulse on Strobe

§ Printer reads data on Data Out lines

§ Printer sends pulse on ACK (Acknowledge) line after data is read

This method of data transfer is also known as the Compatibility mode and the transfer

rate of data is slow. The printer while operating in compatibility mode is capable of

indicating limited printer error feedback to the host computer. Such feedback includes:

§ Paper jam

§ Out of paper

§ Printer on or off line

§ Time out

Product Information

Page 20

1-12

Specifications

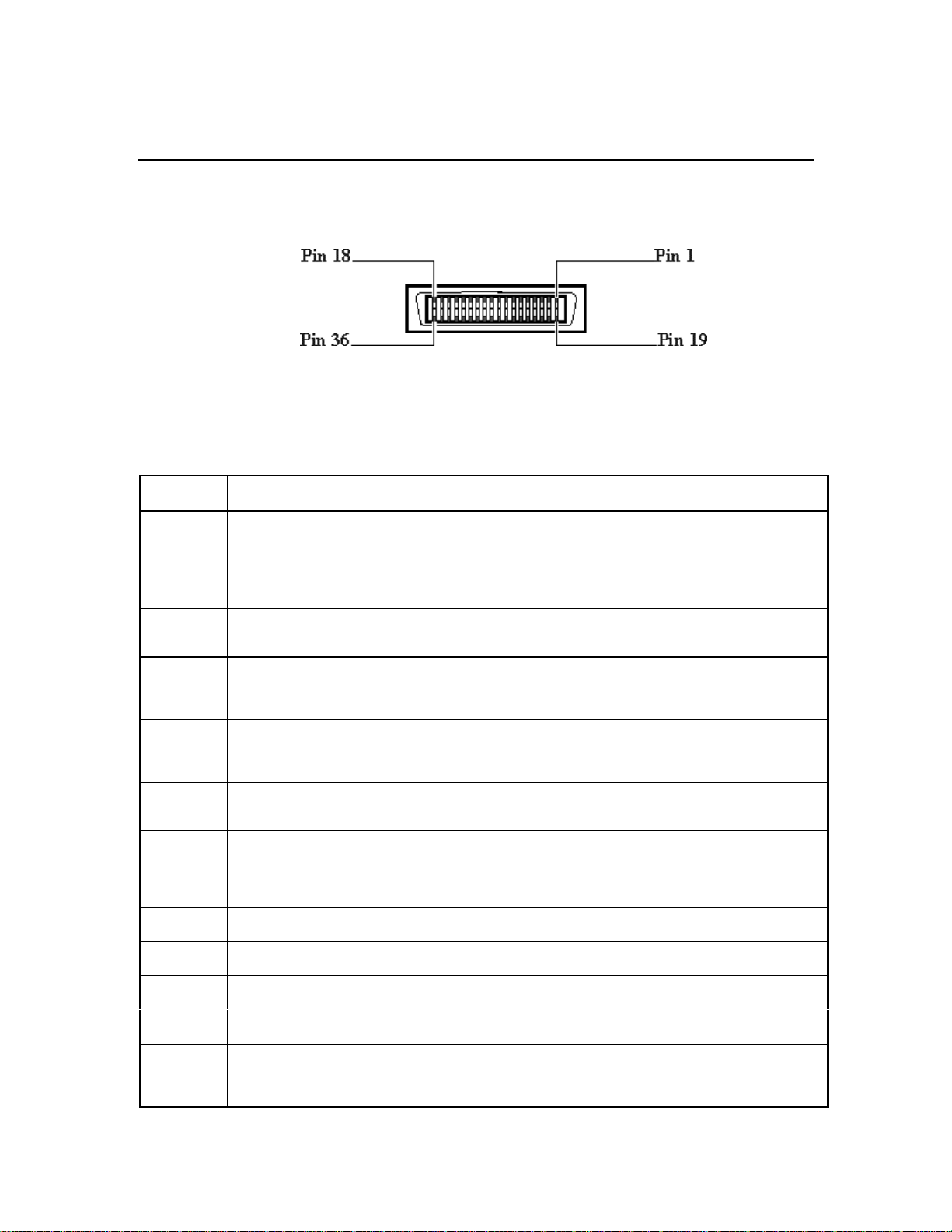

IEEE 1284 Pinout Information

Any standard IEEE 1284 compliant printer cable will work with the printer. The

customer can order the HP IEEE 124 Compliant Parallel Interface Cable C2950A (2

meters) or C2951A (3 meters). See Ordering Parts in Chapter 12 for ordering

information.

PIN NUMBER PIN ID DESCRIPTION

1 HostClk Used in a closed-loop handshake with PeriphAck to transfer data or address

2 - 9 AD1 - AD8 Host to peripheral device or peripheral device to host address or data. Data 1 is

10 PeriphClk Used in a closed-loop handshake with HostAck (nAutoFd) to transfer data from

11 PeriphAck The peripheral uses this signal for flow control in the forward direction.

12 nAckReverse The peripheral drives this signal low to acknowledge nReverseRequest. The

13 Xflag This is used by the peripheral device to reply to the requested extensibility byte

14 HostAck The host drives this signal for flow control in the reverse direction. It is used in

16 Logic Ground Logic board ground.

17 Chassis Ground Chassis Ground.

information from the host to the peripheral device.

the least significant bit (bit 0).

the peripheral device to host.

PheriphAck also provides a ninth data bit to determine whether command or

data information is present on the data signals in the reverse direction.

host relies upon nAckReverse to determine when it is permitted to drive the

data signals.

during the negotiation phase.

an interlocked handshake with PeriphClk. Host Ack also provides a ninth data

bit used to determine whether command or data information is present on the

data signals in the forward direction.

18 Peripheral Logic High This signal is used to provide +5V high logic.

19-30 Ground These pins are tied to signal ground

31 nReverseRequest This signal is driven low to place the channel in the reverse direction. While in

ECP mode, the peripheral is only allowed to driver the bi-directional data

signals when nReverseRequest is low and 1284 Active is high.

Product Information

Page 21

1-13

32 nPeriphRequest During ECP mode the peripheral may drive this pin low to request

communications with the host. This request merely “hints” to the host; the host

has ultimate control over the transfer direction. This signal provides a

mechanism for peer-to-peer communication. This signal is valid in the forward

and reverse directions.

36 1284 Active Driven high by host while in ECP mode. Set low by the host to terminate ECP

mode and return the link to the Centronics (uni-directional) mode

The 1284 compliant cable supports the ECP (Extended Capabilities Port) mode in the

transfer of data. The ECP protocol includes a series of protocols that differ from standard

Centronics parallel port operation. These additional signaling methods allow the host and

peripheral to negotiate any of faster transfer modes (e.g. DMA, FIFO and RLE

decompression). The protocol is hardware driven and the performance is limited by the

ISA bus bandwidth. The primary advantage is that once data transfer is negotiated, data

can flow without the need of an acknowledge or a return status signal. This can result in a

transfer rate of up to 10 times faster than that of the compatibility mode that the

Centronics parallel cable supports.

To transfer data, the host first goes through a negotiation phase, which allows the host

and peripheral to select a mutually-supported communications mode. During the

negotiation phase, the host indicates which communication mode and options it would

like to use via the Extensibility Request Value. If the peripheral device does not support

the requested mode or options, it sets the Extensibility Flag low and the interface returns

to Compatibility Mode.

Product Information

Page 22

1-14

Specifications

Reliability Specifications

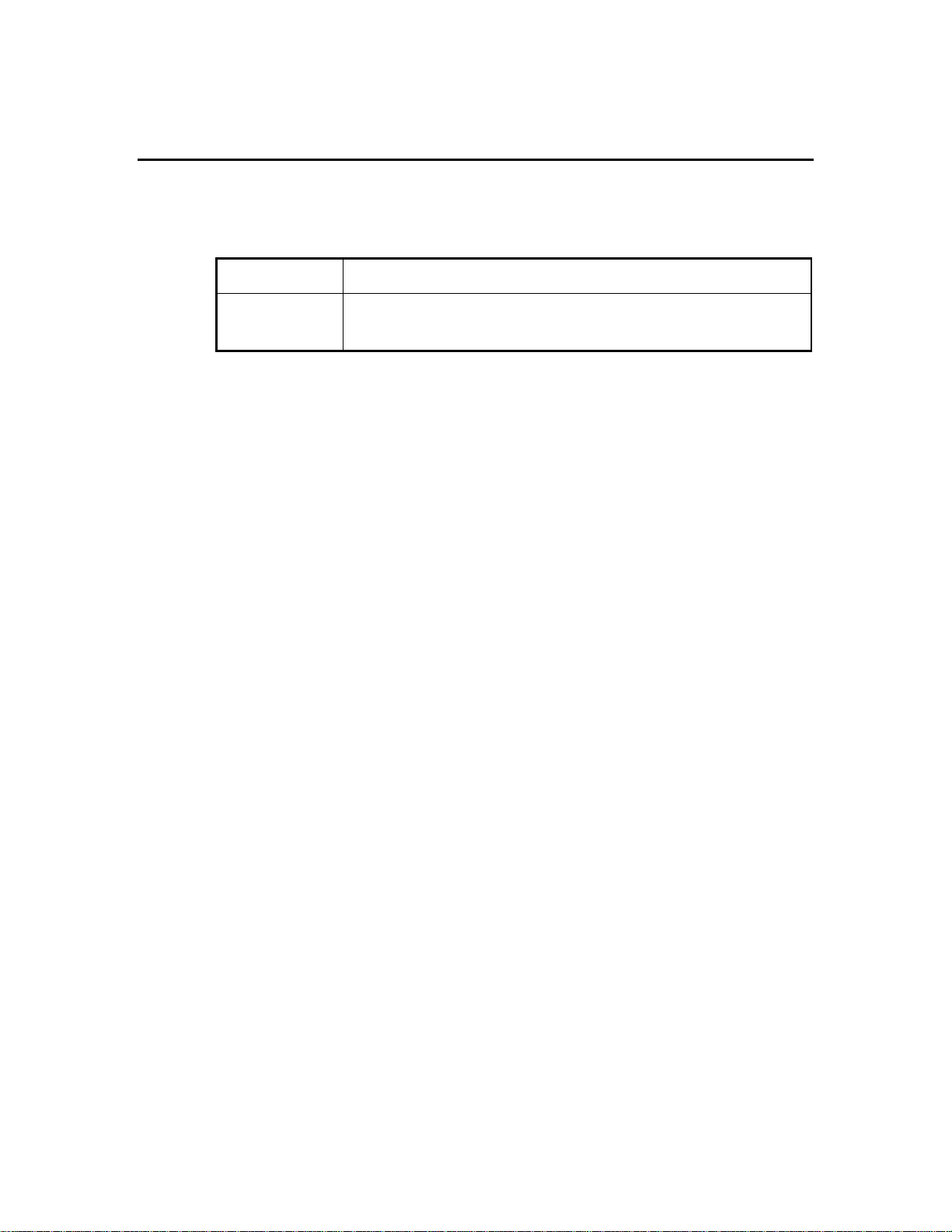

Category Specifications

Printer Usage Up to 12,000 pages / month

Mechanism Life 150,000 A size pages / 5 years

Product Information

Page 23

1-15

Specifications

Interface Specifications

Category Specifications

Interface Specification

§ Centronics parallel, IEEE 1284

Compliant with 1284-B

receptacle (ECP)

§ 64KB buffer size

Product Information

Page 24

1-16

Specifications

Physical Dimensions

With paper tray closed

(W x D x H)

With paper tray fully extended

(W x D x H)

Weight 26.5 kg (58.48 lb.) without printheads and

Desk space needed

(W x D)

27.0 x 24.0 x 13.3 inches

685 x 610 x 337 mm

27.0 x 29.3 x 13.3 inches

685 x 745 x 337 mm

ink cartridges

27.0 kg (59.52 lb.) with printheads and

ink cartridges

27.0 x 21.0 inches

685 x 532 mm

Product Information

Printer with paper tray closed

Printer with paper tray fully extended

Page 25

1-17

Specifications

Packaging Dimensions Specifications

792 mm (31.3 in.) W x 731 mm (28.8 in.) D x 457 mm (18.0 in.) H

Product Information

Page 26

1-18

Specifications

Electrical Specifications

Category Specification

Input Voltage

Frequency

Interface

Specification

Power Consumption

§ Idle

§ Printing

Transient Spike Immunity

§ Amplitude

§ Pulse width

§ Rise time

100 to 240 Vac (±10%)

50/60 Hz (±3 Hz)

Centronics parallel,

IEEE 1284 Compliant with 1284-B receptacle (ECP)

4.4 watts

35 watts max.

1 kV

50 µseconds

1.2 µseconds

Product Information

Page 27

1-19

Specifications

Environmental Specifications

Category Specifications

Temperature

§ Operating

§ Storage condition

§ Recommended operating

Humidity

§ Operating

§ Storage condition

§ Recommended operating

Altitude

§ Operating

§ Non-operating

5 °C to 40 °C (41 °F to 104 °F)

-40 °C to 60 °C (-40 °F to 140 °F)

15 °C to 35 °C (59 °F to 95 °F)

10%-80% RH non-condensing

10%-80% RH non-condensing

20%-80% RH non-condensing

0 to 3100 meters

0 to 4600 meters

Mechanical Vibration

§ Frequency range

§ Operating (Random)

§ Non-operating (Random)

§ Swept Sine

Noise Levels per ISO 9296

§ Sound power L

pAm

5 to 500 Hz

Approximately 0.21 G rms

Approximately 2.09 G rms

0.5 (0 to peak)

49 dB(A) (By-stander position)

Product Information

Page 28

1-20

Specifications

Product Certifications

Safety Certifications EMI Certifications

CCIB (China) C TICK (Australia and New Zealand)

CSA (Canada) VCCI (Japan)

NOM1 (Mexico) CE (European Union)

PSB (Singapore) GOST (Russia)

TUV-GS (Germany) B mark (Poland)

UL (USA) GOST (Russia)

SABS (South Africa) BCIQ (Taiwan)

JUN (Korea) RRL (Korea)

EMI FCC Class B when used with a Class B computing

device (USA)

Product Information

Page 29

1-21

Specifications

Media Sizes Supported

The following are the media sizes supported by the printer.

General type Sizes (mm) Sizes (inch) Remarks

Tray 1 (Input / Output Tray)

Post Card 100x148 3.94x5.83 Minimum Size

Including all media sizes in Tray 2 (Upper Tray) / Tray 3 (Lower Tray)

Tray 2 (Upper Tray) / Tray 3 (Lower Tray)

ISO-A4 210x297 8.27x11.7

US-Letter 215.9x279.4 8.5x11

US-Legal 215.9x355.6 8.5x14

JIS-B4 257x364 10.11x14.33

US-B (Ledger) 279.4x431.8 11x17

ISO-A3 297x420 11.69x16.53

Super B 330.2x482.6 13x19 Maximum Size

Note

1. There are sensors mounted on Tray 2 (Upper Tray) and Tray 3 (Lower Tray) of the

printer to detect the sizes of paper in use on each tray.

2. The printer is capable of printing on custom-sized media provided that its

dimensions conform to the minimum and maximum size definition.

3. Envelopes are not supported on the HP2500C/CM.

Product Information

Page 30

1-22

Specifications

Recommended Media Weight

Paper

Cardstock 110 to 200 g/m2 (110 lb. Index)

60 to 135 g/m2 (16 to 36 lb. Bond)

(up to 0.012 in. or 0.3 mm thickness for straight paper path)

Product Information

Page 31

1-23

Specifications

Paper Handling

Tray 1 (Input / Output Tray)

Sheets 10

Cards 4

Tray 2 (Upper Tray)

Sheets 150

Cards 60

Tray 2 (Upper Tray)

Sheets 250

Media Type Capacity (Pages)

Rear Manual Feed

All media sizes from 4x6 inches (101.6x152.4mm)

to 13x19 inches (330.2x482.6mm) and maximum

thickness of 0.3mm (0.012 inches)

Output Tray

Sheets (face-up) 150

Note

1. There is a sensor mounted on the bypass paper feed to indicate whether it is in use.

1

Product Information

Page 32

1-24

Specifications

Printable Area

Printable area

(Portrait

orientation)

The table as follows will show the minimum margin of each media type (portrait

orientation) for the HP 2500C Series Printer.

Please note that the printable area is smaller than that of HP LaserJets. However in the

HP2500C/CM printer driver software there is a new utility that can automatically adjust

the margins of LaserJet formatted documents so that they can be printed without the loss

of any formatting.

Printable area

(Landscape orientation)

Product Information

Page 33

1-25

Specifications

Media Margins (in portrait orientation)

Media Type

US Letter

8.5 x 11 in.

215.9 x 279.4 mm

Tabloid / Ledger

11 x 17 in.

279.4 x 431.8 mm

A4

8.27 x 11.69 in.

210.00 x 296.9 mm

A3

11.69 x 16.53 in.

296.9 x 419.9 mm

B4

10.12 x 14.33 in.

257.0 x 364.0 mm

Legal

8.5 x 14 in.

215.9 x 355.6 mm

Executive

7.25 x 10.50 in.

184.2 x 266.7 mm

A5

5.83 x 8.27 in.

148.0 x 210.0 mm

B5

7.16 x 10.12 in.

181.9 x 257.0 mm

4x6 Index Card

4.00 x 6.00

101.6 x 152.4

5x8 Index Card

5.00 x 8.00

127.0 x 203.2

Left Right Top Bottom Comments

0.25 in.

6.4 mm.

0.20 in.

5.1 mm.

0.13 in.

3.4 mm.

0.20 in.

5.1 mm.

0.20 in.

5.1 mm.

0.25 in.

6.4 mm.

0.25 in.

6.4 mm.

0.12 in.

3.1 mm.

0.12 in.

3.1 mm.

0.12 in.

3.1 mm.

0.12 in.

3.1 mm.

0.25 in.

6.4 mm.

0.20 in.

5.1 mm.

0.13 in.

3.4 mm.

0.20 in.

5.1 mm.

0.20 in.

5.1 mm.

0.25 in.

6.4 mm.

0.25 in.

6.4 mm.

0.12 in.

3.1 mm.

0.12 in.

3.1 mm.

0.12 in.

3.1 mm.

0.12 in.

3.1 mm.

Margins

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

Landscape

Orientation

Product Information

Page 34

1-26

A6 Card

4.13 x 5.83

105.0 x 148.0

Hagaki Card

3.94 x 5.83

100.0 x 148.0

Super B

13.00 x 19.00

330.2 x 482.6

Statement

5.50 x 8.50

139.7 x 215.9

C Size

17.00 x 22.00

431.8 x 558.8

A2

16.53 x 23.38

419.9 x 593.9

Hagaki

7.87 x 5.83

200.0 x 148.0

A3 Nobi

13.00 x 19.00

330.2 x 482.6

Custom

3.94 to 13.00 x 5.83 to 19.00

100 to 330 x 148 to 482

0.12 in.

3.1 mm.

0.12 in.

3.1 mm.

0.20 in.

5.1 mm.

0.20 in.

5.1 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.12 in.

3.1 mm.

0.20 in.

5.1 mm.

0.20 in.

5.1 mm.

0.12 in.

3.1 mm.

0.12 in.

3.1 mm.

0.20 in.

5.1 mm.

0.20 in.

5.1 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.12 in.

3.1 mm.

0.20 in.

5.1 mm.

0.20 in.

5.1 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.40 in.

10.2 mm.

0.40 in.

10.2 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.12 in.

3.0 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.50 in.

12.7 mm.

0.40 in.

10.2 mm.

0.40 in.

10.2 mm.

0.51 in.

13.0 mm.

0.51 in.

13.0 mm.

0.50 in.

12.7 mm.

*NEC only

*NEC only

Note

For the printable regions of landscape orientation, just reverse the matrix on the table

above. For example, the matrix for US Letter size in portrait is 8.5 x 11 inches, so in

landscape the matrix is 11 x 8.5 inches.

Product Information

Page 35

1-27

Specifications

Hewlett-Packard Ink Cartridge Specifications

Category Specification

Type

Printhead Nozzles

Black Resolution

Color Resolution

Ink Drop Volume

Print Speed1 Black Black Text

Plain paper drop on-demand thermal inkjet printing

304 black, 912 color (304 per color printhead)

Up to 600x600 dpi

PhotoREt II for photo quality

35ng black, 8ng color drop volume for high resolution printing

Econofast Mode

Normal Mode

Best Mode

Letter / A4

9 ppm

7 ppm

7 ppm

11x17 / A3

5 ppm

3 ppm

3 ppm

Print Speed1 Color

Color Highlights

Econofast Mode

Normal Mode

Best Mode

Mixed Text & Graphics

Econofast Mode

Normal Mode

Best Mode

Full Page Color Highlights

Econofast Mode

Normal Mode

Best Mode

1

Approximate figures. The exact speed is dependent on the

Letter / A4

9 ppm

6 ppm

5 ppm

Letter / A4

7 ppm

3.5 ppm

1.2 ppm

Letter / A4

3.5 ppm

1.8 ppm

0.4 ppm

11x17 / A3

5 ppm

3 ppm

2 ppm

11x17 / A3

4 ppm

2 ppm

0.5 ppm

11x17 / A3

1 ppm

0.8 ppm

0.2 ppm

system configuration, software program and document

complexity.

Product Information

Page 36

1-28

Specifications

System Requirement

The following CPUs and memory are required :

Minimum: Windows 3.1x: 486DX-66, 8 Mb RAM

Windows 95/98: 486DX-100, 8 Mb RAM

Windows NT 4.0/5.0: 486DX-66, 16 Mb RAM

Macintosh System 7.5.3 or later: 68040 – 8 Mb RAM

Recommended: Windows 3.1x: Pentium 150/166, 16 Mb RAM

Windows 95/98: Pentium 150/166, 16 Mb RAM

Windows NT 4.0/5.0: Pentium 150/166, 32 Mb RAM

Macintosh System 8 or later: Power PC – 16 Mb RAM

50 Mb free hard disk space for 11x17 or A3 size printing.

Graphics intensive files may require more disk space.

Product Information

Page 37

1-29

Product Overview

Printer External View

Model and Serial Number

The serial number of the HP 2500C Series Printers can be found on the labels at the back

of each printer and at the top of the main case (concealed by the top cover). The figure

below shows how the serial number is interpreted.

Serial Number = CCYMDVL###

CC (Country) The country show where the printer was manufactured.

Y (Year) The year the printer was manufactured.

M (Month) The month the printer was manufactured.

D (Day) The day the printer was manufactured.

V (Version) The printer model version 1 indicates HP 2500C, other version numbers

will be assigned as needed. Contact a technical support engineer if you

need to know which version a new number refers to.

L (Line) The factory assembly line which manufactured this printer.

### These three digits allow a maximum of 27,000 unique serial numbers per

line per day. This unit number is in base 30.

Product Information

Page 38

1-30

Supplies and Accessories

Product Structure

The following items will be shipped in the box:

Basics

Printer

Extended Tray Cover (a)

Driver Kit

Starter CD (b)

HP JetDirect CD (HP 2500CM printer only)(b)

User’s Guide (d)

Hardcopy Kit

Setup Poster (c)

Getting Started Guide (Not available in U.S.)

Quick Reference Guide (e)

User’s Guide (Available in U.S. only)

Accessory Kit

Power Cord (f)

Four HP No. 10 Ink Cartridges (h)

(Black, Cyan, Magenta and Yellow)

Four HP No. 10 Printheads (g)

(Black, Cyan, Magenta and Yellow)

Product Information

Page 39

1-31

Supplies and Accessories

Power Cord

US 8120-6805 #ABB, #ABM, #AC4, #AKY, #A2L, #ABA

Europe 8120-6802 #ABS, #AKB, #ACB, #ABT, #AKC, #ACT,

#AB7, #ABB, #ARG, #ARP, #AKY

Australia 8120-6803 #ABG, #AKY

Singapore / Malaysia 8120-6809 #AB4

SA 8120-6808 #ACQ

UK 8120-6801 #ABU

Product Information

Page 40

1-32

Supplies and Accessories

Network Interface

The following cards have been tested with the HP 2500C and HP 2500CM Color Printer.

JetDirect MIO print server card

(Bundled with HP 2500CM)

JetDirect MIO print server card

300X Print Server J3263A Ethernet

J4100A Ethernet

RJ-45 (10/100 base-TX)

BNC

J2556B Ethernet

RJ-45 (10/100 base-TX)

J2550B Ethernet

RJ-45 (10 Base-T)

J2552B Ethernet

BNC (Thin Coax)

RJ-45 (10 Base-T)

LocalTalk System 7

J2555B Token Ring

DB9, RJ-45

RJ-45 (10/100 base-TX)

Parallel Port

Product Information

Page 41

1-33

Supplies and Accessories

Print Cartridge

No. 10 Cyan Ink Cartridge C4841A

No. 10 Magenta Ink Cartridge C4842A

No. 10 Yellow Ink Cartridge C4843A

No. 10 Hi Capacity Black Ink Cartridge C4844A

No. 10 Cyan Pen C4801A

No. 10 Magenta Pen C4802A

No. 10 Yellow Pen C4803A

No. 10 Black Pen C4800A

Note

The HP 2500C/CM Printers are shipped with a Low Capacity Black Ink Cartridge

(C4840A).

Product Information

Page 42

1-34

Supplies and Accessories

Media

HP Bright White Paper (500 / A size) C1824A

HP Bright White Paper (500 / A4 size) C1825A

HP Bright White Paper (200 / 11x17 size) C1857A

HP Bright White Paper (200 / A3 size) C1858A

HP Premium InkJet Coated Paper (200 / A) 51634Y

HP Premium InkJet Coated Paper (200 / A4) 51634Z

HP Premium InkJet Coated Paper (100 / 11x17) C1855A

HP Premium InkJet Coated Paper (100 / A3) C1856A

HP Premium InkJet Heavyweight Paper (100 / A) C1852A

HP Premium InkJet Heavyweight Paper (100 / A4) C1853A

HP Premium Photo Paper (20 / 11x17) C6058A

HP Premium Photo Paper (20 / A3) C6059A

HP Premium Photo Paper (15 / A) C6039A

HP Premium Photo Paper (15 / A4) – European C6040A

HP Premium Photo Paper (15 / A4) – Asian C6043A

HP Premium InkJet Transparency Film (20 / A) C3828A

HP Premium InkJet Transparency Film (20 / A4) C3832A

HP Premium InkJet Transparency Film (50 / A) C3834A

HP Premium InkJet Transparency Film (50 / A4) C3835A

HP Premium InkJet Rapid-Dry Transparency Film (A) C6051A

HP Premium InkJet Rapid-Dry Transparency Film (A4) C6053A

HP Iron-On T-Shirt Transfers (10 / A) C6049A

HP Iron-On T-Shirt Transfers (10 / A4) C6050A

HP Greeting Card Paper C1812A

HP Greeting Card Paper (Europe Only) C6042A

HP White Labels 1”x2.5/8” Addressing Labels 92296A

HP White Labels 1.1/3”x4” Addressing Labels 92296B

HP White Labels 1”x4” Addressing Labels 92296C

HP White Labels 2”x4” Shipping Labels 92296D

HP White Labels 3.1/3”x4” Shipping Labels 92296E

HP White Labels 1/2”x1.3/4” Return Address Labels 92296F

HP White Labels 8.1/2”x11” White Full Sheet Labels 92296K

HP White Labels 99.1x38.1mm Addressing Labels 92296L

HP White Labels 99.1x38.8mm Addressing Labels 92296M

HP White Labels 63.5x38.1mm Addressing Labels 92296N

HP White Labels 100x51mm Addressing Labels 92296P

HP White Labels 199.6x289mm Full Sheet Labels 92296R

HP White Labels 99.1x67.7mm Parcel Labels C4296A

HP White Labels 63.5x46.6mm Addressing Labels C4297A

Product Information

Page 43

1-35

Supplies and Accessories

Other Accessories

HP 64MB (2x32MB) 60ns EDO SIMM D4543A

HP 32MB (2x16MB) 60ns EDO SIMM D3648B

HP 16MB (2x8MB) 60ns EDO SIMM D3647B

HP 2500C Postscript 3 Upgrade Kit C3289A

Customer Replaceable Parts

Note

The following parts are customer replaceable parts. Replacing these parts require no

technical expertise. These parts can be sent directly to the customer by the Customer

Care Centers after qualification. This process is based on the premise that customers

agree to replace the parts themselves.

The exceptions to this process are the PCA Logic and Service Station. These two parts

require some technical capability and will only be sent to customers that have the

capabilities to replace these two modules.

PCA-Logic C2684-60200

Name Plate (HP 2500C) C2684-60203

Cover Main PCA C2684-60206

Side Cover Service Station C2684-60210

Assembly Secondary Access Door C2684-60212

Assembly Output Tray C2684-60214

Removable Trough C2684-60215

Assembly Dual Bin Tray C2684-60224

Adjuster Width Dual Bin C2684-60225

Adjuster Length Dual Bin C2684-60226

Media Plate C2684-60227

Adjuster Length I/O C2684-60232

Adjuster Width I/O C2684-60233

Tray Cover C2684-60108

Cover Front C2684-60239

Service Station C2684-60273

Plate Media 2 C2684-60274

Foot C2684-60275

Product Information

Page 44

1-36

Warranty and Support

The warranty for HP 2500C Series Printers varies depending on the product, the date and

the country of purchase.

For products returned under warranty, Hewlett-Packard may :

§ Provide on-site repair,

§ Replace the product with a remanufactured unit,

§ Replace the product with a product of equal or greater functionality or

§ Refund the purchased price.

Product Information

Page 45

1-37

Warranty and Support

Hewlett-Packard Limited Warranty Statement

HP Product Duration of Limited Warranty

Software 1 year

Print Cartridges 90 days

Printer 1 year

Printheads 1 year

Extent of Limited Warranty

1. Hewlett-Packard (HP) warrants to the end user customer that HP products will be free

from defects in materials and workmanship, for a specified time after the date of

purchase by the customer. The duration of this limited warranty is stated above.

Certain additional conditions and limitations of HP’s warranty are stated in the user’s

guide. Those conditions and limitations include:

a. For software products, the warranty applies only to the media upon which the

product is recorded; and

b. HP does not warrant the operation of any product to be uninterrupted or error free.

2. HP’s limited warranty covers only those defects which arise as a result of normal use

of the product, and do not apply to any:

a. Improper or inadequate maintenance;

b. Software or interfacing not supplied by HP;

c. Unauthorized modification or misuse;

d. Operation outside the product’s environment specifications, including duty cycle

abuse or use of a mechanical switch-box without a designated surge protector;

e. Use of non-supported printing media or memory boards; or

f. Improper site preparation or maintenance.

3. For HP printer products, the use of a non-HP print cartridge or a refilled print

cartridge does not affect either the warranty to the customer or any HP support

contract with the customer; print cartridge includes both toner cartridges and ink

cartridges. However, if printer failure or damage is attributable to the use of a nonHP or refilled print cartridge, HP will charge its standard time and materials charges

to service the printer for the particular failure or damage.

4. If any software media product or print cartridge product proves defective during the

applicable warranty period, and if the product is covered by HP’s warranty, the

customer shall return the product for replacement.

Product Information

Page 46

1-38

5. If HP receives, during the applicable warranty period, notice of a defect in a hardware

product which is covered by HP’s warranty, HP shall either repair or replace the

product, at its option. Any replacement product may be either new or like-new,

provided that it has functionality at least equal to that of the product being replaced.

6. If HP is unable to repair or replace, as applicable, a defective product which is

covered by HP’s warranty, HP shall within a reasonable time after being notified of

the defect, refund the purchase price for the product, provided the customer returns

the product.

7. The warranty is valid in any country where this product is distributed by Hewlett-

Packard. Contracts for additional services such as on-site service are available from

any authorized HP service facility in countries where this product is distributed by HP

or an authorized importer.

8. This limited Warranty Statement gives the customer specific legal rights. The

customer may also have other legal rights which vary from state to state in the United

States, from province to province in Canada, and from country to country elsewhere

in the world.

Limitations of Warranty

1. NEITHER HP NOR ANY OF ITS THIRD PARTY SUPPLIERS MAKES ANY

OTHER WARRANTY OF ANY KIND, WHETHER EXPRESS OR IMPLIED,

WITH RESPECT TO HP PRODUCTS. HP AND ITS THIRD PARTY SUPPLIES

SPECIFICALLY DISCLAIM THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

2. To the extent that this Limited Warranty Statement is inconsistent with the law of the

locality where the customer uses the HP product, this Limited Warranty Statement

shall be deemed modified to be consistent with such local law. Under such local law,

certain limitations of this Limited Warranty Statement may not apply to the customer.

For example, some states in the United States, as well as some governments outside

the United States (including provinces in Canada), may:

a. Preclude the disclaimers and limitations in this Warranty Statement from limiting

the statutory rights of a customer (e.g. Australia and the United Kingdom);

b. Otherwise restrict the ability of a manufacturer to make such disclaimers or

impose such limitations; or

c. Grant the customer additional warranty rights, specify the duration of implied

warranties which the manufacturer cannot disclaim, or not allow limitations on

how long an implied warranty lasts.

3. To the extent allowed by local law, the remedies provided in this Warranty Statement

are the customer’s sole and exclusive remedies.

Product Information

Page 47

1-39

Limitations of Liability

1. EXCEPT FOR THE OBLIGATIONS SPECIFICALLY SET FORTH IN THIS

WARRANTY STATEMENT, IN NO EVENT SHALL HP BE LIABLE FOR ANY

DIRECT, INCIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER

LEGAL THEORY AND WHETHER ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES.

Product Information

Page 48

1-40

Warranty and Support

Obtaining Printer Drivers

The HP 2500C Series Printer Driver Software is updated periodically. The latest versions

can be obtained from authorized Hewlett-Packard dealers or any of the sources listed

below.

24-hour Modem Access

Internet

HP 2500C Series Printer drivers and product support information can be obtained through

the World Wide Web at:

http://www.hp.com/go/hp2500

HP BBS Library

The HP 2500C Series Printer drivers can also be obtained at HP’s electronic bulletin

board library service. Refer to HP BBS Library under Service and Support

Resources for the list of phone numbers.

Set modem communications software to: no parity, 8 bits, and 1 stop bit.

Product Information

Page 49

1-41

Warranty and Support

Service Support Contracts

In the U.S.

HP SupportPack

The HP SupportPack is an enhancement to the customer’s original one-year warranty

repair service. The HP SupportPack provides next business day on-site support for the

duration of an additional two years of warranty. This service enhancement provides

customers with a cost-effective and timely way to achieve quality support. The HP

SupportPack (ordered like any other HP product) is sold exclusively through resellers and

is not available directly from Hewlett-Packard. Customers MUST purchase this service

enhancement within 30 days of purchasing the printer. The HP SupportPack is not

transferable from one piece of equipment to another. Additional information on HP

SupportPack and the prices for the service upgrade are available through HPNN and the

In-Touch newsletter.

Non-U.S.

HP SupportPack

The HP SupportPack enhances the service offering during the warranty period by

upgrading warranty repair service to a next day exchange service. This service

enhancement provides customers with a cost-effective and timely way to achieve quality

support. HP SupportPack is sold exclusively through resellers (ordered like any other HP

product) and is not available directly from Hewlett-Packard. Additional information on

HP SupportPack and the prices for the service upgrade is available through HPNN.

For other service and support contracts, contact the Hewlett-Packard office or Response

Center for that country.

Product Information

Page 50

1-42

Warranty and Support

Service and Support Resources

Hewlett-Packard News Network (HPNN)

HPNN is an electronic bulletin board service available only to HP authorized resellers.

This service provides the following information:

§ Presales Information

§ Printer Drivers

§ HP SupportPack Information

§ Software Notes

§ Postsales Information

For more information, call 1 (408) 553-7303.

HP Customer Information Center

The HP Customer Information Center provides presales product information. This

service is available for resellers and end-users.

For more information, call 1 (800) 752-0900, Monday – Friday, 6:00 AM – 5:00 PM U.S.

Pacific Time.

HP Reseller Response Line

The HP Reseller Response Line provides pre-sales and post-sales technical support for

HP authorized resellers.

For more information, call 1 (800) 544-9976, Monday – Friday, 8:00 AM – 4:00 PM U.S.

Pacific Time.

Product Information

Page 51

1-43

Warranty and Support

HP BBS Library

The HP electronic bulletin board library service, which is available 24 hours a day, 7

days a week, contains drivers and support information which can be downloaded to your

PC via modem.

Country Number Baud Rates

Austria + 43 (222)251658 2400 to 28800 or ISDN

Belgium + 32 (2) 778-3819 1200 to 28800

Denmark + 45 (45) 991905 300 to 28800

Finland (9600) 7280 2400 to 28800

France 3616 HP MICRO 1200 to 28800 (Service Minitel)

Italy + 39 (2) 9210-4244 Up to 28800

Netherlands + 31 (20) 647-5433 2400 to 28800

Norway + 47 (2) 273-5697 2400 to 28800

Sweden + 46 (8) 750-6262 2400 to 28800

Switzerland + 41 (64) 560200 Up to 28800 or ISDN

United Kingdom + 44 (1344) 361891 Up to 28800

Worldwide Int Code + 1 (208) 344-1691 300 to 28800

Set the modem for no parity, 8 data bits and 1 stop bit (N,8,1).

Product Information

Page 52

1-44

Warranty and Support

HP FAXback on Demand – HP FIRST

You can use this service to select documents, such as product descriptions and technical

information. To access this service, use the handset on your fax machine and dial the

appropriate number from the table in this section.

Use the following steps to use HP FIRST:

1. Call the system. You will need to use a touch-tone telephone or the phone set of your

fax machine. A voice prompt will welcome you and guide you to the information you

need. You will also need to give the phone number of the fax machine where you

wish to receive the documents you select.

2. We suggest you initially request the index which lists all available documents.

3. Once you receive the HP FIRST index, choose the documents you need.

4. Call HP FIRST again. A voice prompt will ask you for the index number of the

documents you have selected and would like to have faxed to you.

5. Selected documents will be sent immediately to the fax number you have specified.

Note

To obtain documents in English from outside the UK, dial your international access

code and then (31) 20 681 5792 (international toll rates applicable).

Product Information

Page 53

1-45

Warranty and Support

HP FIRST Telephone Numbers

Country Telephone Number

For US and Canada

For Customers in Europe:

U.K. 0800 96 02 71

For service in English outside U.K. + 31 20 681 5792

Austria 0600 8128

Belgium (Dutch) 0800 11906

Belgium (French) 0800 17043

Denmark 800 10453

Finland 800 13134

France 0800 905900

Germany 0130 810061

Italy 1678 59020

Norway 800 11 319

Portugal 05 05 31 33 42

Spain 900 993123

Sweden 020 795743

Switzerland (French) 0800 551 526

Switzerland (German) 0800 551 527

Netherlands 0800 022 2420

(800) 333-1917

For Customers in Asia-Pacific:

Australia 613 9272 2627

China 86 10 6564 5735

Hong Kong 2506 2422

India 9111 622 6420

Indonesia 21-352 2044

Korea 822 769 0543

Malaysia 03 298 2478

New Zealand 64 09 356 6642

Philippines (65) 275 7251

Singapore 275 7251

Taiwan (02) 719 5589

Thailand 662 661 3511

Product Information

Page 54

1-46

Warranty and Support

HP Telephone Support

Technical Phone Support for Customers

The HP Customer Support Center provides free technical assistance for peripherals

within the hardware warranty period.

For the product under warranty, call (208) 323-2551.

For the product out of warranty, call :

§ 1 (900) 555-1500 at $2.50 per minute, or

§ 1 (800) 999-1148 at $25.00 per call using VISA / MasterCard.

(The above prices are subjected to change without notice)

To ensure the call is dealt with quickly, have the following information ready:

§ The product model number and serial number.

§ The operating system version and the configuration.

§ A description of the software installed and the accessories used.

HP North American Customer Support Center

Assistance from the Hewlett-Packard North American Customer Support Center is

available Monday to Friday, 7:00 AM to 6:00 PM Mountain Time, except Wednesday,

(7:00 AM to 4:00 PM).

§ 1 (303) 635-1000

HP European Customer Support Center

Assistance from the Hewlett-Packard European Customer Support Center is available in

English, Monday to Friday, 8:30 AM to 6:00 PM Central European time, except

Wednesday, (8:30 AM to 4:00 PM).

§ Int Code + 31 (20) 682-8291

HP provides free telephone support during the warranty period. After the warranty has

expired, support is available through the same telephone number for a fee. The fee is

charged on a per incident basis. When calling HP, please have the following information

ready:

§ The product model number and serial number.

§ The operating system version and the configuration.

§ A description of the software installed and the accessories used.

Product Information

Page 55

1-47

Warranty and Support

Warranty and Out-of-Warranty Support Telephone Numbers

Country (Language) Telephone Number

Austria (German) 0660-6386

Belgium (Dutch) 02 626 8806

Belgium (French) 02 626 8807

Denmark (Danish) 3929 4099

Finland (Finnish) 0203 47288

France (French) 04 50 43 9853

Ireland 01 622 5525

Germany (German) 0180 5 25 81 43

Italy (Italian) 02 26410350

Netherlands (Dutch) 020 606 8751

Norway (Norwegian) 22 11 6299

Portugal 01 441 7199

Spain (Spanish) 902-321 123

Sweden (Swedish) 08 619 2170

Switzerland (French) 0848 80 11 11

Switzerland (German) 0848 80 11 11

UK 0171 512 5202

English language support for other European countries +44 171 512 5202

Product Information

Page 56

1-48

Warranty and Support

Contacting Hewlett-Packard

To contact HP, check your local telephone directory for the HP Sales and Service Office

near you. If you cannot find an HP office, contact one of the major HP Sales and Service

Offices or one of the following Worldwide Marketing Headquarters.

Asia Far East Sales Region Headquarters

Hewlett-Packard Asia Ltd.

22/F Peregrine Tower

Lippo Centre

89 Queensway, Central

Hong Kong

Canada Hewlett-Packard Ltd.

6877 Goreway Drive

Mississauga

Ontario L4V 1M8, Canada

Europe European Operations Headquarters

Hewlett-Packard S.A.

150, route du Nant-d’Avril

PO Box 1217

Meyrin 2/Geneva, Switzerland

Latin America Hewlett-Packard Latin Am. Headquarters

Monte Pelvoux 111

Lomas de Chapultepec

11000 Mexico D.F.

Middle East / Asia Middle East / Central Africa Sales Headquarters

Hewlett-Packard S.A.

Rue de Veyrot 39

CH-1217 Meyrin 1/Geneva, Switzerland

U.S. Intercon Operations Headquarters

Hewlett-Packard Company

3495 Deer Creek Road

PO Box 10495

Palo Alto, CA 94303-0896, USA

Product Information

Page 57

1-49

Warranty and Support

Worldwide Customer Support Numbers

Customer Support Centers provide technical information via telephone directly with

online agents who are trained to assist with setup, configuration, startup and

troubleshooting of HP products.

Customer Support Center assistance can be obtained by calling one of the following

country-specific telephone numbers:

Note

Check the world wide web at http://www.hp.com/go/hp2500 for the most up-to-date

customer support telephone numbers.

Country Telephone Number

For U.S.

For Latin America

Argentina (541) 787 4061/69

Brazil 55 11 709 1444

Chile 562 800 360999

Mexico City 01-800-22147000/1-800-9052900

Mexico Guadalajara (525) 264 2075

Mexico Monterey 91800 22147

Venezuela 582 239 5664

(208) 323-2551

Product Information

Page 58

1-50

For Europe

Africa/Middle East 41 22/780 71 11

Austria 0660 6386

Belgium (Dutch) 02 6268806

Belgium (French) 02 6268807

Czech Republic 42 (2) 471 7327

Denmark 3929 4099

Finland 203 47288

France 01 43 62 34 34

Germany 180 5258 143

Greece 0168 96 411

Hungary 36 (1) 252 4505

Ireland 01662 5525

Italy 02 264 10350

Norway 22 11 6299

Poland 48 22 37 50 65

Portugal 01 441 7199

Russia 7095 923 50 01

Spain 902 321 123

Sweden 08 619 2170

Switzerland 0848 80 11 11

Netherlands 020 606 8751

Turkey 90 1 224 59 25

United Kingdom 0171 512 5202

For Asia-Pacific

Australia (61-3) 9272-8000

China 86 10 6564 5959

Hong Kong 800 96 7729

India 9111 682 6035

Indonesia 21 350 3408

Korea (82-2) 3270-0700

Malaysia 03 295 2566

New Zealand 09 356-6640

Philippines 2 867 3551

Singapore 272 5300

Taiwan 866-2-7170055

Thailand 02 661 4011

Vietnam 8823 4530

Product Information

Page 59

Chapter 2 Operating Overview

Using the Control Panel

The Control Panel allows you to perform most major tasks with the printer, including

controlling print status, resetting from recoverable errors and changing the printer's

default settings.

Control Panel Layout

The Control Panel on the front of the printer consists of six buttons on the panel, two

LEDs and a LCD multi-function display panel:

Operating Overview 2-1

Page 60

Using the Control Panel

The functions of each of the buttons are as follows :

Control Panel Key Function

[ GO ]

[ Cancel Job ]

[ Menu ]

[ Item ]

[ Value ]

[ Select ]

§ Puts the printer either online or offline.

§ Allows the printer to resume printing after going

offline. Also clears most printer messages and puts

the printer online.

§ Allows the printer to continue printing after a non-

critical warning message such as UNEXPECTED

PAPER SIZE or TRAY x LOAD [ TYPE ] [ SIZE ].

§ Exits the control panel menus. (To save the control

panel selection, press the [ Select ] button first.)

§ Displays unrecoverable error codes.

Press this only once to cancel the print job that the printer

is processing. The duration required to cancel the job will

depend on the size of the print job. Pressing the Cancel

Job button repeatedly will not cancel the next job on the

print queue.

Press this to cycle through the control panel menus.

To print a menu map from the control panel :