Page 1

HP SureStore

Fibre Channel SCSI Bridge 2100 ER

User Guide

Edition 3

Part Number C6340-90003

February 2000

Printed in: Greeley, CO USA

© Copyright 2000 Hewlett-Packard Company

Page 2

Notice

This document contains information that is protected by copyright. All

rights are reserved. No part of this document may be photocopied,

reproduced, or translated to another language. The information

contained in this document is subject to change without notice.

See Appendix C for important safety and regulatory information.

Warranty

HP PRODUCT: HP SureStore 2100 ER SCSI Fibre Channel Bridge

C6340F

DURATION OF LIMITE D WARRANTY: Two Years

1. HP warran ts HP hardware, acce ssories, and supplies against defects

in materials and workmanship for the period specified above. If

Hewlett-Packard receives notice of such defects during the warranty

period, Hewlett-Packard will, at its option, either repair or replace

products which prove to be defective. Replacement products may be

either new or like-new.

2. HP warrants that HP software will not fail to execute its

programming instructions, for the period specified above, due to

defects in material and workmanship when properly installed and

used. If HP receives notice of such defects during the w arranty period,

HP will replace software media that does not execute its

programming instructions due to such defects.

3. HP does not warrant that the operation of HP products will be

uninterrupted or error free. If HP is unable, within a reasonable time ,

to repair or replace any product to a co ndition as warranted, customer

will be entitled to a refund of the purchase price upon prompt return

of the product.

4. HP products may contain remanufactured parts equivalent to new in

performance or may be been subject to incidental use.

ii

Page 3

5. The warranty period begins on the date of delivery or on the date of

installation if installed by HP. If customer schedules or delays HP

installation more than 30 days after delivery, warranty begins on the

31st day from delivery.

6. Warranty does not apply to defects resulting from (a) improper or

inadequate maintenance or calibration, (b) software, interfacing,

parts or supplies not s upplied by H P, (c) unauthorized modificati on or

misuse, (d) operation outside of the published environmental

specifications for the products, or (e) improper site preparation or

maintenance.

7. TO THE EXTENT ALLOWED BY LOCAL LAW, THE ABOVE

WARRANTIES ARE EXCLUSIVE AND NO OTHER WARRANTY

OR CONDITION, WHETHER WRITTEN OR ORAL, IS EXPRESSED

OR IMPLIED AND HP SPECIFICALL Y DISCLAIMS ANY IMPLIED

WARRANTIES OR CONDITIONS OF MERCHANTABILITY,

SATISFACTORY QUALITY, AND FITNESS FOR A PARTICULAR

PURPOSE.

8. HP will be liable for damage to tangible property per incident up to

the greater of $300,000 or the actual amount paid for the product that

is the subject of the claim, and for damages f or bodily injury or deat h,

to the extent that all such damages are determined by a court of

competent jurisdiction to have been directly caused by a defe ctive HP

product.

9. TO THE EXTENT ALLOWED BY LOC AL LA W, THE REMEDIES IN

THIS WARRANTY STATEMENT ARE THE CUSTOMER’S SOLE

AND EXCLUSIVE REMEDIES. EXCEPT AS INDICATED ABOVE,

IN NO EVENT WILL HP OR ITS SUPPLIERS BE LIABLE FOR

LOSS OF DATA OR FOR DIRECT, SPECIAL, INCIDENTAL,

CONSEQUENTIAL (INCLUDING LOST PROFIT OR DATA), OR

OTHER DAMAGE, WHETHER BASED IN CONTRACT, TORT, OR

OTHERWISE.

iii

Page 4

Printing History

This guide is the first edition of all included material. The guide printing

date and part number indicate the current edition. The printing date

changes when a new edition is printed. (Minor corrections and updates

incorporated at reprint do not change this date.)

Edition 1: July 1998

Edition 2: December 1998: Added textual enhancements and

revised illustrations

Edition 3: February 2000: Added references to magneto-optical

devices and revised illustrations

iv

Page 5

Typographical Conventions

The following typographical conventions are used in this guide:

Italic font: Denotes important information.

KEYCAP : Denotes keystrokes.

Computer Output: Denotes information displayed in the control panel

and screen menu items that you select.

WARNING Warnings call attention to a procedure or practice that could

result in personal injury if not correctly performed. Do not

proceed until you fully understand and meet the required

conditions.

CAUTION Cautions call attention to an operating procedure or practice that could

damage the product if not correctly performed. Do not proceed until you

fully understand and meet the required conditions.

NOTE Notes provide information that can be helpful in understanding the

operation of the product.

v

Page 6

In This Guide

In this guide, the following areas are described:

Chapter 1 Introduction: Contents of the parts kit, supported

products, environmental requirements for the Fibre

Bridge, and sample configurations.

Chapter 2 Setting Up the Fibre Bridge: How to install the Fibre

Bridge, including rackmounting and cabling.

Chapter 3 Operating the Fibre Bridge: The Fibre Bridge start

sequence, default settings (and how to change them),

and verification of the system setup.

Chapter 4 Troubleshooting Guide: Possible start sequence errors,

instructions for starting diagnostic procedures, and

how to proceed.

Appendix A Fibre Channel Overview: Background information

about the Fibre environment, including specifics

relating to the Fibre Bridge.

Appendix B Support and Customer Service: Resource information

about access to Hewlett-Packard customer support and

service.

Appendix C Safety and Regulatory Informat ion: Safety and

regulatory information for the Fibre Bridge.

Glossary A list of terms with definitions.

vi

Page 7

Contents

1. Introduction

Chapter Overview ....................................................................... 1-2

Fibre Bridge Components and Supported Products.................... 1-3

Product Components.............................................................. 1-3

Supported Products ................................................................ 1-5

Choosing a Location ................................................................... 1-6

Physical Specifications .......................................................... 1-6

Environmental Specifications ................................................ 1-6

Fibre Channel Configurations..................................................... 1-7

Basic Configuration ..............................................................1-7

Expanded Configuration (DLT libraries only) ...................... 1-8

Table of Contents

2. Setting Up the Fibre Bridge

Chapter Overview ....................................................................... 2-2

Mounting the Fibre Bridge in a Rack ......................................... 2-3

Assemble the L-brackets to the Fibre Bridge ........................ 2-4

Install the Fibre Bridge in the Rack ....................................... 2-5

Installing Cables ........................................................................ 2-6

Fibre Bridge Connection, Basic Configuration Example

(DLT and MO Libraries) .................................................... 2-6

Fibre Bridge Connection, Expanded Configuration Example

(DLT libraries only)............................................................ 2-8

Optical Fibre Channel Cable Options.................................... 2-11

3. Operating the Fibre Bridge

Chapter Overview ....................................................................... 3-2

Powering on the System ............................................................3-3

Changing the Default Settings .................................................... 3-5

Connecting the Serial Cable .................................................. 3-5

Serial Port Setup .................................................................... 3-7

Serial Port Operation ............................................................. 3-7

vii

Page 8

Contents

Making Configuration Changes.................................................. 3-9

Reconfigure the Fibre Channel Address ................................ 3-11

Change the Trace Settings ....................................................3-13

Fibre Channel to SCSI Mapping Configuration .................... 3-14

4. Troubleshooting Guide

Chapter Overview ....................................................................... 4-2

Troubleshooting .......................................................................... 4-3

Problem: Cannot Turn On the DLT Library ....................... 4-3

Problem: Cannot Turn On the MO Library ........................ 4-3

Problem: Cannot Turn On the Hub (DLT Only) ................ 4-4

Problem: Cannot Turn On the Fibre Bridge .........................4-4

Problem: Cannot Confirm the Library Connection ............ 4-4

A. Fibre Channel Overview

Overview..................................................................................... A-2

Defining Fibre Channel .............................................................. A-3

Implementing Fibre Channel ...................................................... A-5

Distributed Devices................................................................ A-5

Cabling Advantages............................................................... A-5

Working With Fibre Channel .................................................... A-6

Problems with Fibre Channel ..................................................... A-9

Physical Connections............................................................. A-9

Laser Power Control Systems................................................ A-11

Device Addressing ................................................................. A-11

B. Support and Customer Service

Chapter Overview ....................................................................... B-2

Supplies and Accessories............................................................ B-3

Hewlett-Packard Customer Support ........................................... B-4

Support Pack Service Contract .............................................. B-5

viii

Page 9

Contents

HP FIRST/QUICK FAX Faxback Services........................... B-5

Electronic Support Services................................................... B-8

Customer Care Centers .......................................................... B-9

Telephone Support After Warranty ....................................... B-11

C. Safety and Regulatory Information

Chapter Overview ....................................................................... C-2

CDRH Regulations (USA Only)............................................ C-3

United Kingdom Telecommunications Act 1984 .................. C-3

Herstellerbescheinigung......................................................... C-5

English Translation of German Sound Emission Directive... C-5

Turvallisuusyhteenveto.......................................................... C-6

English Translation of Finland Regulatory Information........ C-7

Japanese VCCI Statement...................................................... C-8

Table of Contents

Glossary

Index

ix

Page 10

Contents

x

Page 11

Tables

Table 1-1. Supplied Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Table 1-2. Supported Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table 1-3. Physical Specifications of the Fibre Bridge . . . . . . . . . . . . . 1-6

Table 1-4. Location Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Table 2-1. Assembly Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Table 2-2. Fiber-Optic Cable Options . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Table 3-1. Fibre Bridge Default Configuration Settings . . . . . . . . . . . . 3-8

Table A-1. Fibre Channel Supported Fabric Topologies . . . . . . . . . . . .A-4

Table of Tables

xi

Page 12

Tables

xii

Page 13

Figures

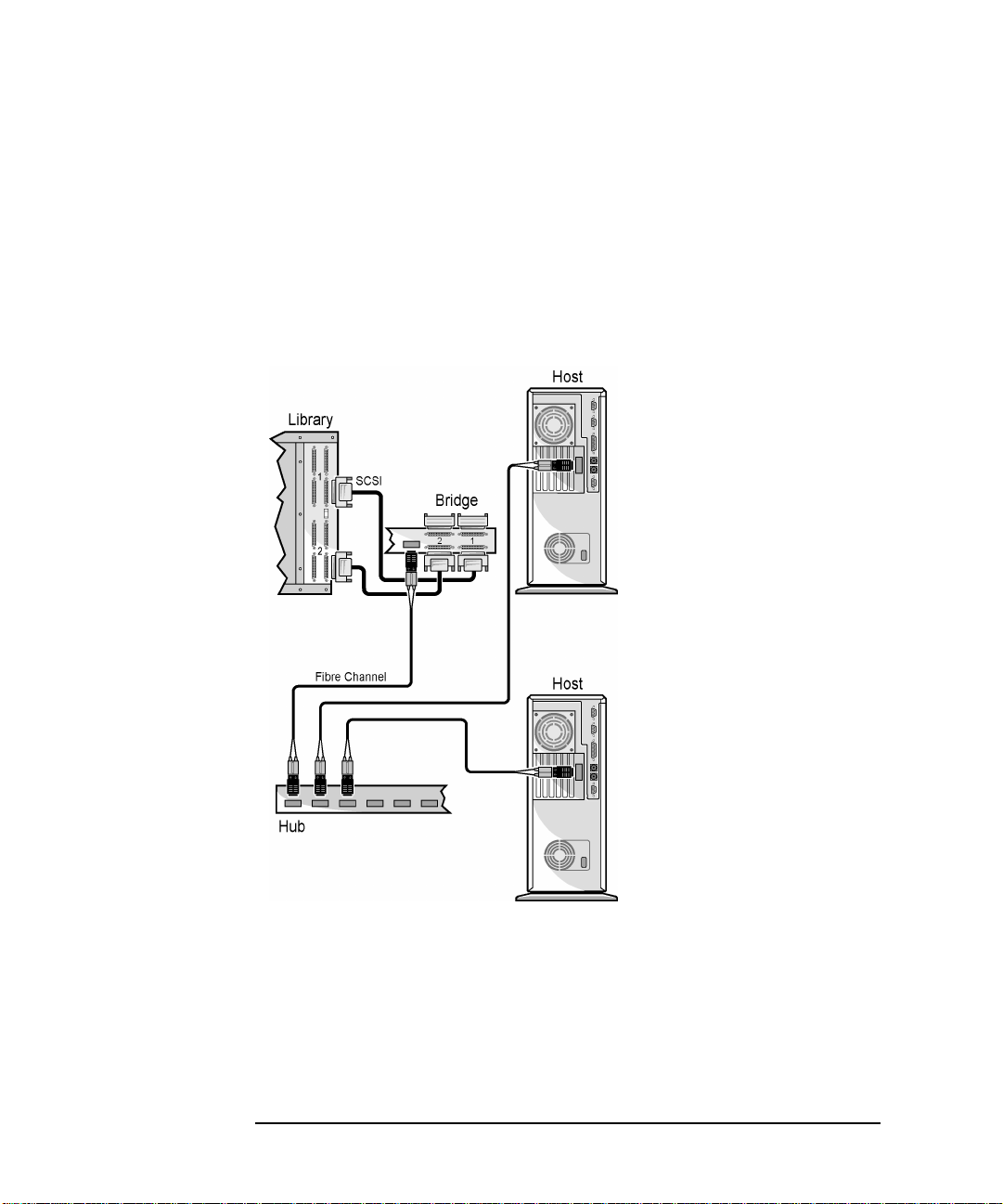

Figure 1-1. Sample Fibre Channel Configuration—Basic. . . . . . . . . . . 1-7

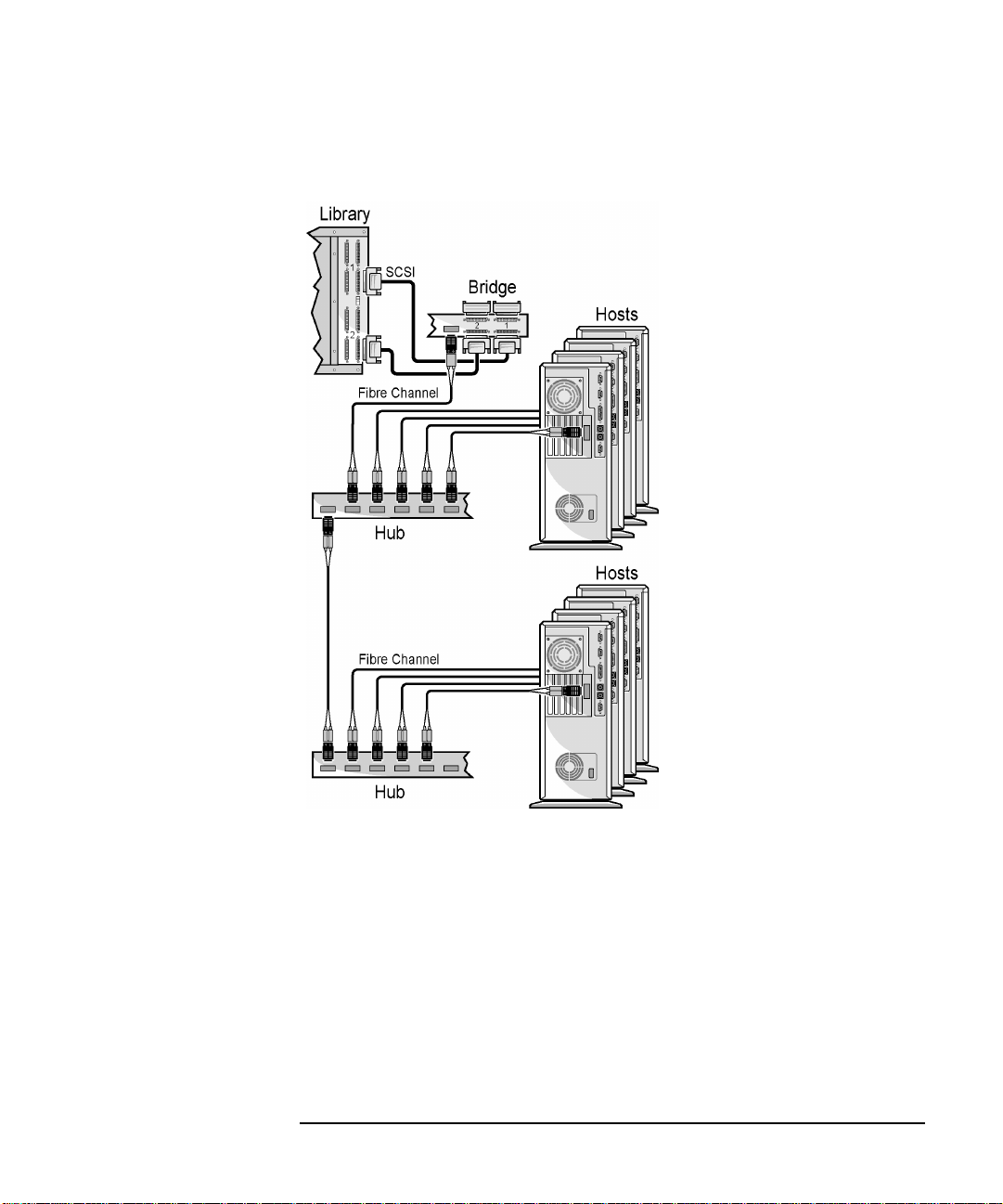

Figure 1-2. Sample Fibre Channel Configuration—

Minimum Expansion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Figure 1-3. Sample Fibre Channel Configuration—

Maximum Expansion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Figure 2-1. Assembling L-brackets to the Fibre Bridge . . . . . . . . . . . . 2-4

Figure 2-2. Mount the Fibre Bridge in the Rack . . . . . . . . . . . . . . . . . . 2-5

Figure 2-3. Fibre Bridge Connection, Basic Configuration

(DLT and MO Libraries). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Figure 2-4. Fibre Bridge Connection, Expanded Configuration

(Minimum) (DLT Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Table of Figures

Figure 2-5. Fibre Bridge Connection, Expanded Configuration

(Maximum) (DLT Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Figure 3-1. Fibre Bridge, Back View . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Figure 3-2. Connecting the Serial Cable . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Figure 3-3. Fibre Bridge Configuration, Main Menu . . . . . . . . . . . . . . 3-9

Figure 3-4. Fibre Bridge Configuration Menu . . . . . . . . . . . . . . . . . . . 3-10

Figure 3-5. Fibre Channel Configuration Menu . . . . . . . . . . . . . . . . . 3-11

Figure 3-6. Fibre Channel Addresses. . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Figure 3-7. Trace Settings Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

xiii

Page 14

Figures

xiv

Page 15

Introduction

1 Introduction

1-1

Page 16

Introduction

Chapter Overview

Chapter Overview

This chapter provides the following information:

• Fibre Bridge Components and Supported Products

• Choosing a Location

• Fibre Channel Configurations

1-2 Chapter 1

Page 17

Fibre Bridge Components and Supported Products

Fibre Bridge Components and

Supported Products

This section includes a list of all parts supplied with the Fibre Bridge,

products that Hewlett-Packard supports for use with the Fibre Bridge,

environmental considerations, and sample system configurations.

Product Components

Table 1-1 lists the parts that are supplied with the Fibre Bridge.

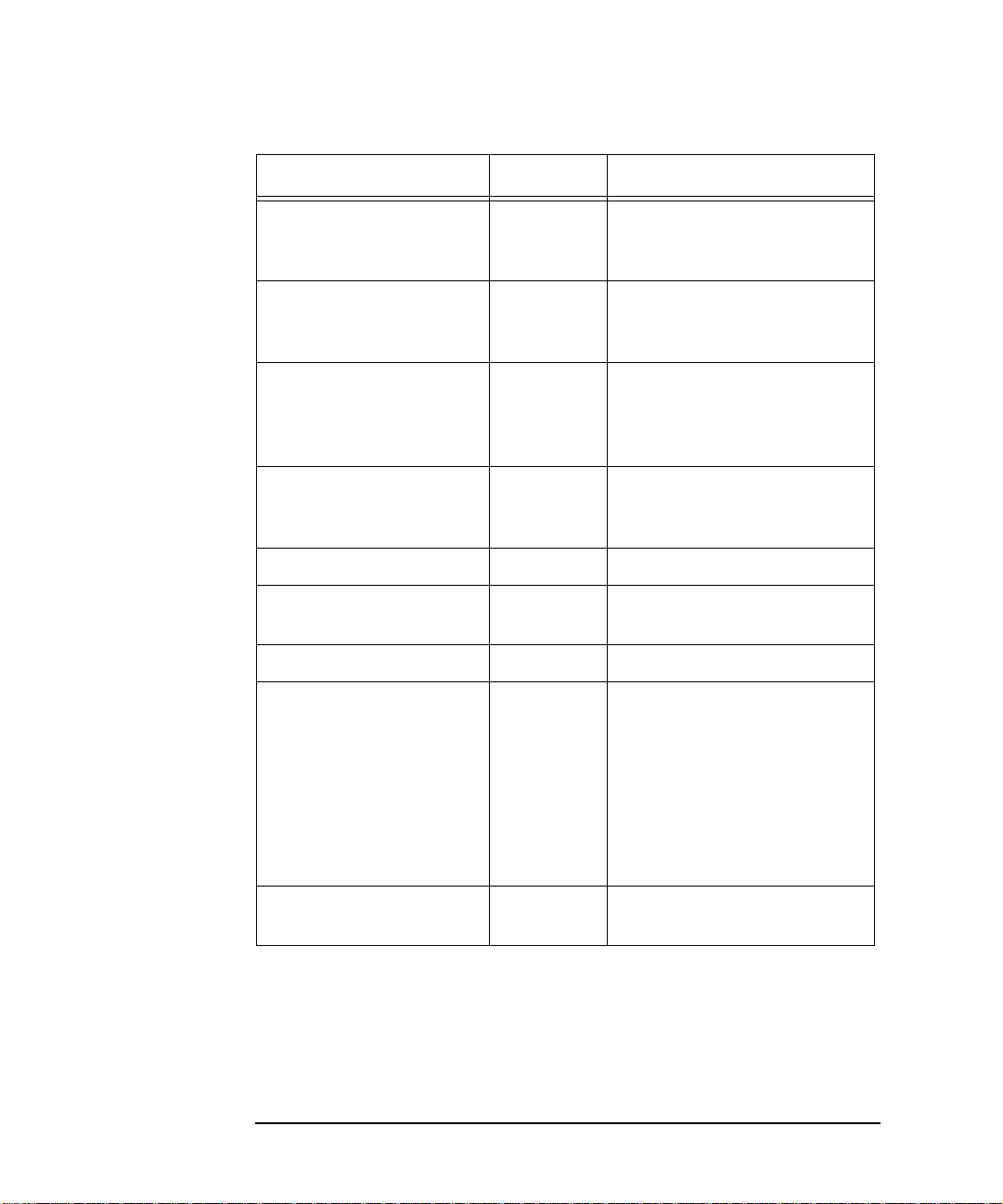

Table 1-1 Supplied Components

Item Quantity Description

Fe et 4 Rubber pads for bottom of

Introduction

Introduction

Fibre Bridge. (Not required

for rackmount installation.)

Fibre Channel SCSI

Bridge 2100 ER User

Guide CD-ROM

Filler Panel Decal 1 Adhesive-backed decal for

French Statement 1 A French regulatory

HP SureStore Fibre

Channel SCSI Bridge

2100 ER

Rackmount Hardware 2 Two L-brackets that fasten

Chapter 1 1-3

1 User Guide in English,

French, German, and

Japanese.

CD also contains a Fibre

Share Primer, and

Application Notes

filler panel, provided by rack

manufacturer.

requirement.

1 Fibre Bridge.

to the Fibre Bridge and

mount in a rack.

Page 18

Introduction

Fibre Bridge Components and Supported Products

Item Quantity Description

SCSI Cables

(for Digitial Linear T ape

libraries)

SCSI Cable

(for Magneto-Optical

libraries)

Serial Cable 1 RJ-11 to RJ-11 cable,

SW Optical FC Cable 1 Short Wave Optical Fibre

SW Optical GBIC 2 Gigabit Interface Converter.

Te rminator 2 Single-ended 68-pin D

User Guide 1 English manual.

Rackmount screws and

nuts

2 Two Single-ended, 2 meter

length - 68 pin high density.

2 Two Single-ended, 2 meter

length - 50-to-68 pin, high

density.

included for troublesh ooti ng

and reconfiguration

purposes only.

Channel Cable, 16 meter

length.

connector with screws.

1 package

(Includes

extra

parts)

Six (6) 6x 32 screws with

lock-washers, for mounting

the Fibre Bridge to

L-brackets.

Six (6) 10x32 screws and six

(6) clipnuts for installing the

L-brackets with Fibre

Bridge into a rack.

RJ-11 to DB9 Adapter 1 Adapter to use with the

RJ-11 to RJ-11 Serial Cable.

1-4 Chapter 1

Page 19

Introduction

Fibre Bridge Components and Supported Products

Supported Products

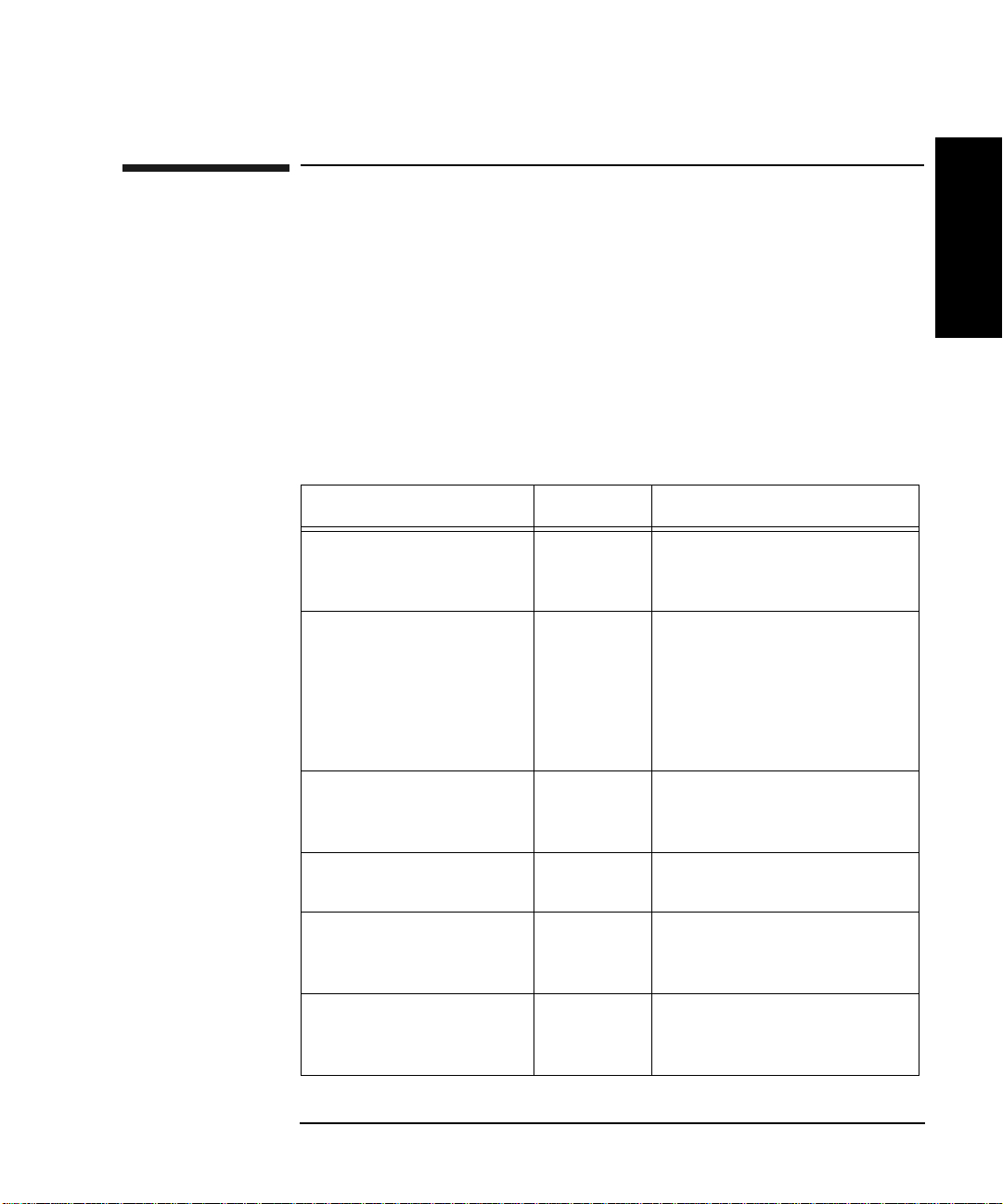

Table 1-2 shows the products that Hewlett-Packard supports for

connection with the Fibre Bridge:

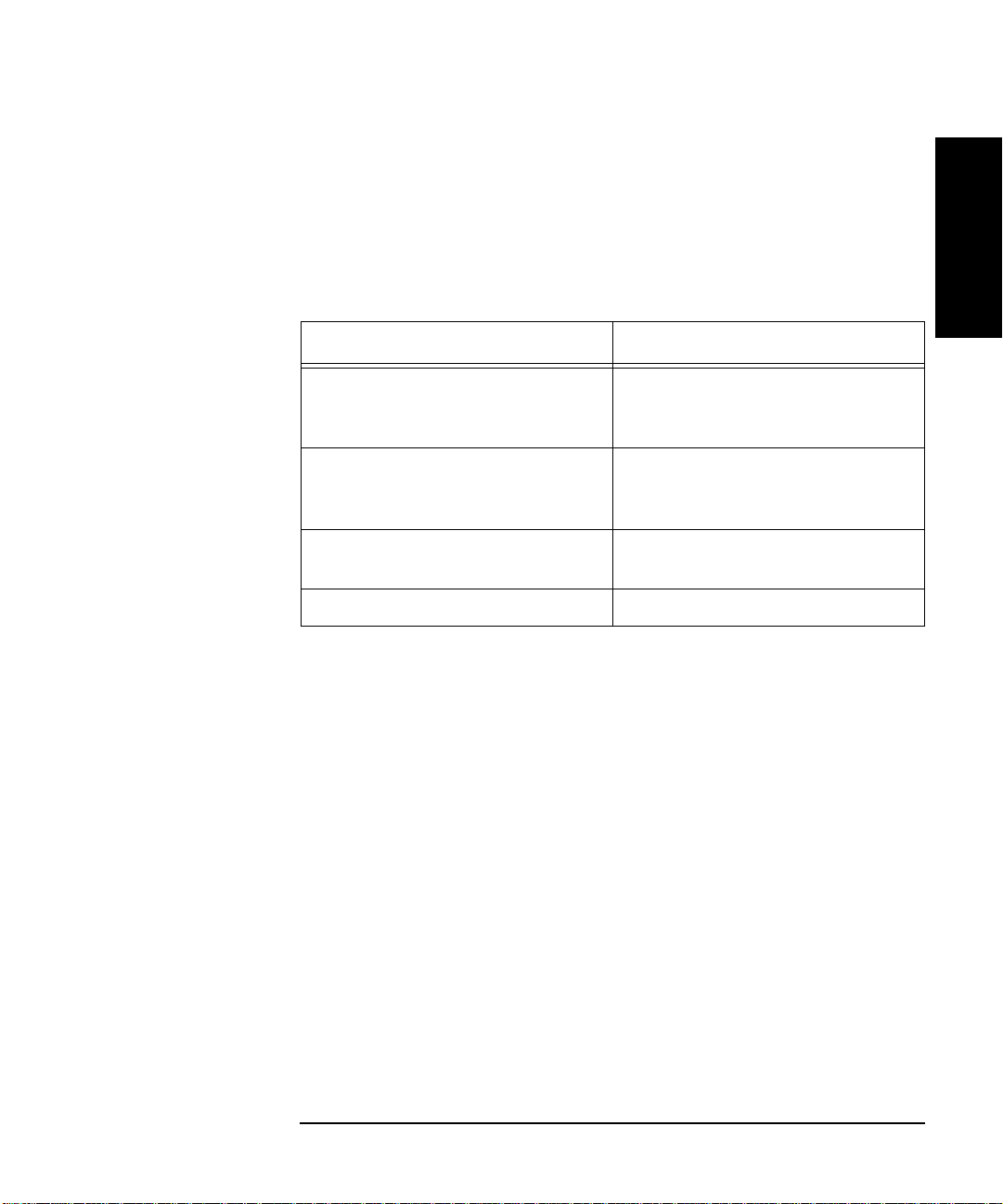

Table 1-2 Supported Products

Product Description

HP DLT libraries and autoloaders

with single-ended SCSI

interfaces

HP magneto-optical (MO)

libraries with single-ended SCSI

interfaces

HP Fibre Channel hub Consult with your sales

HP Host bus adapter HHBA-5101B for NT Systems.

Introduction

Library models are subject to

change. Consult with your sales

representative.

Library models are subject to

change. Consult with your sales

representative.

representative for model of hub.

Chapter 1 1-5

Page 20

Introduction

Choosing a Location

Choosing a Location

Physical Specifications

The Fibre Bridge is des igned for rackmoun ting . The unit can b e mounted

in most standard 19-inch rack configurations. The physical

characteristics are as follows:

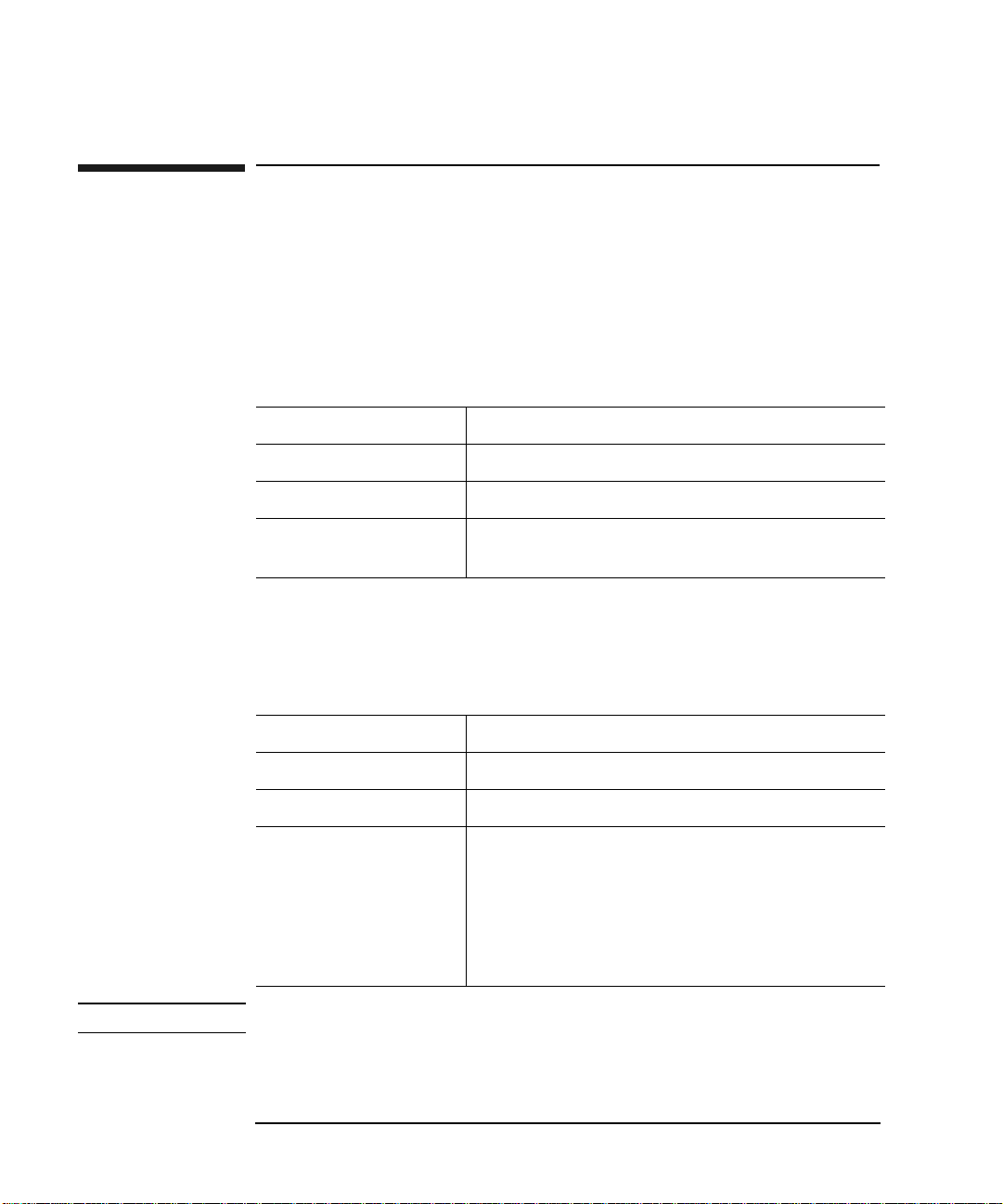

Table 1-3 Physical Specifications of the Fibre Bridge

Height 1.7 inches (4.2 cm)

Width 16.9 inches (42.9 cm)

Depth 9 inches (22.8 cm)

Physical package

weight

Approximately 8 pounds (3.6 kg)

Environmental Specifications

Choose a location that meets the following criteria:

Table 1-4 Location Criteria

Room temperature 40–104° F (5–40° C).

Humidity 5% to 80% relative humidity, non-condensing.

Power source AC power voltage: 100/120V to 220/240 V.

Clearance Rackmount configuration—requires 1 EIA

unit in a rack. 1 EIA = 1.75 inches (44 mm).

Requires 5 inches (125 mm ) cle arance be tween

the rear edge of the Fibre Bridge and the

backplane of the rack, to allow adequate room

for cables.

NOTE See Chapter 2 for rackmounting instructions.

1-6 Chapter 1

Page 21

Introduction

Fibre Channel Configurations

Fibre Channel Configurations

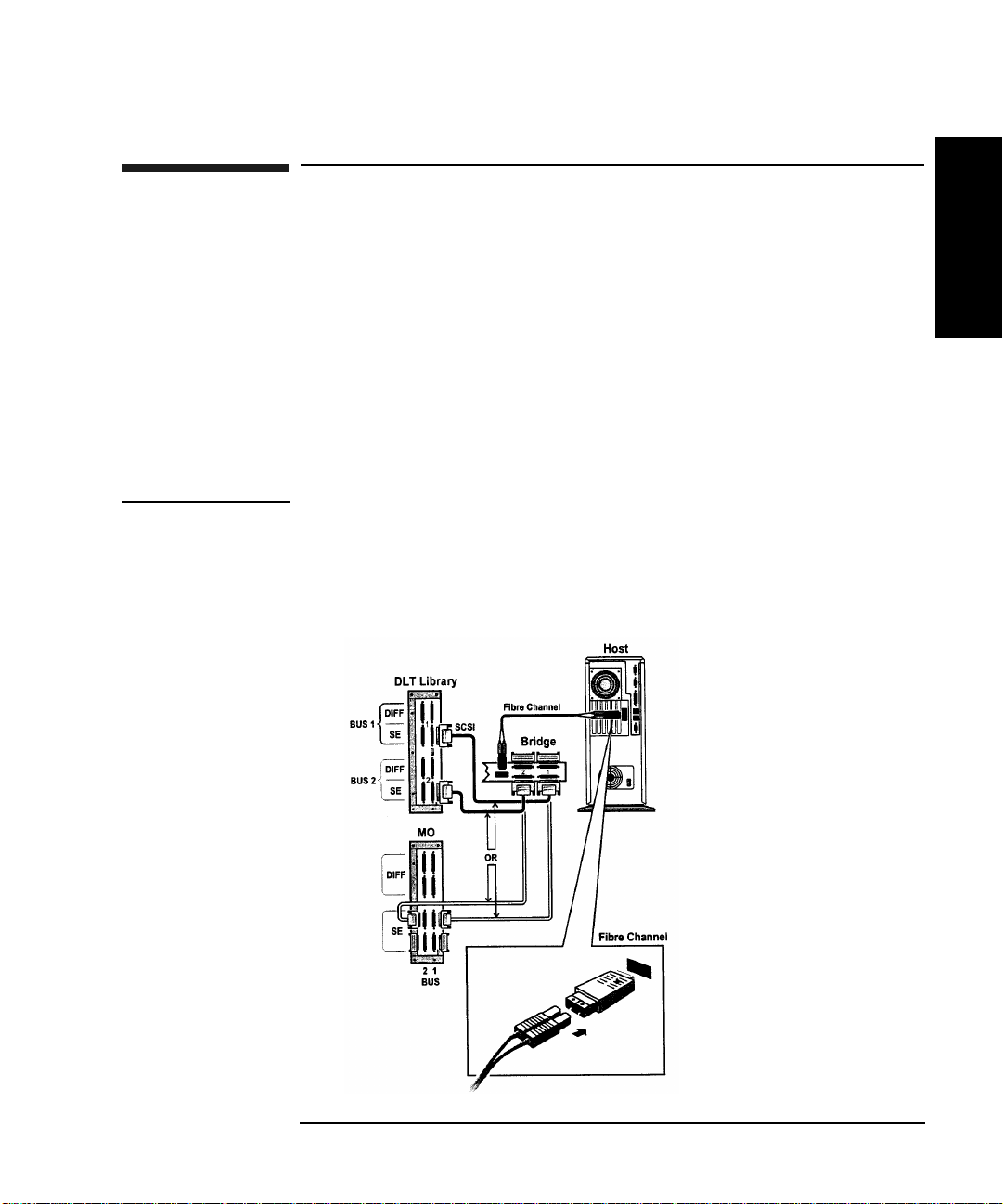

The Fibre Bridge is supported in a basic configuration on Digital Linear

Tape (DL T) and Magneto-Optical (MO) libraries. The bridge is support in

expanded configurations on DLT libraries. A basic configuration is

comprised of only one Fibre Bridge (two SC SI buses available) and a

host. Expanded configurations may include multiple hubs and hosts,

usually connected to one or more networks.

Basic Configuration

Figure 1-1 shows the Fibre Bridge in a basic configuration, including one

host or server, one Fibre Bridge, and one library.

NOTE Magneto-optical libraries are supported only on the basic configuration.

You may connect a maximum of two MO libraries (one on each SCSI bus

from the bridge).

Introduction

Figure 1-1 Sample Fibre Channel Configuration—Basic

Chapter 1 1-7

Page 22

Introduction

Fibre Channel Configurations

Expanded Configuration (DLT libraries only)

Figure 1-2 and Figure 1-3 shows the Fibre Bridge in two possible

expanded configurations . These configurations are supported on DLT

libraries only.

Figure 1-2 Sample Fibre Channel Configuration— Minimum Expansion

1-8 Chapter 1

Page 23

Introduction

Fibre Channel Configurations

Figure 1-3 Sample Fibre Channel Configuration—Maximum Expansion

Chapter 1 1-9

Page 24

Introduction

Fibre Channel Configurations

1-10 Chapter 1

Page 25

Setting Up the

Fibre Bridge

2 Setting Up the Fibre Bridge

2-1

Page 26

Setting Up the Fibre Bridge

Chapter Overview

Chapter Overview

This chapter provides instructions on completing the following setup

procedures:

• Mounting the Fibre Bridge in a Rack

• Installing Cables

2-2 Chapter 2

Page 27

Setting Up the Fibre Bridge

Mounting the Fibre Bridge in a Rack

Mounting the Fibre Bridge in a Rack

Mounting the Fibre Bridge in a rack requires assembling L-brackets to

the Fibre B ri d ge a nd t he n mou n ti ng the L - br ackets to a r ac k . L- br ackets

allow the Fibre Bridge to be mounted in a fixed position, near the back of

a rack.

NOTE All connections and user displays are located on the back of the Fibre

Bridge. Consequently, mount toward the back of a rack.

Before you begin, verify you have the a ssembly components listed in

Table 2-1.

Table 2-1 Assembly Components

Tool 1 #2 Phillips screwdriver (not supplied).

Setting Up the

Fibre Bridge

Mounting

brackets

Rackmount

screws and

nuts

Filler panel

decal

1 pair L-brackets, for assembly with Fibre

Bridge.

1 package

(Includes

extra

parts)

1 Decal for filler panel, provided by

Six (6) 6x32 screws t o attac h Fibre B ridge

to L-brackets.

Six (6) 10x32 screws and six (6) clip nuts

for installing the Fibre Bridge (with

L-brackets attached) into a rack.

customer (supplied separately by rack

manufacturer).

Chapter 2 2-3

Page 28

Setting Up the Fibre Bridge

Mounting the Fibre Bridge in a Rack

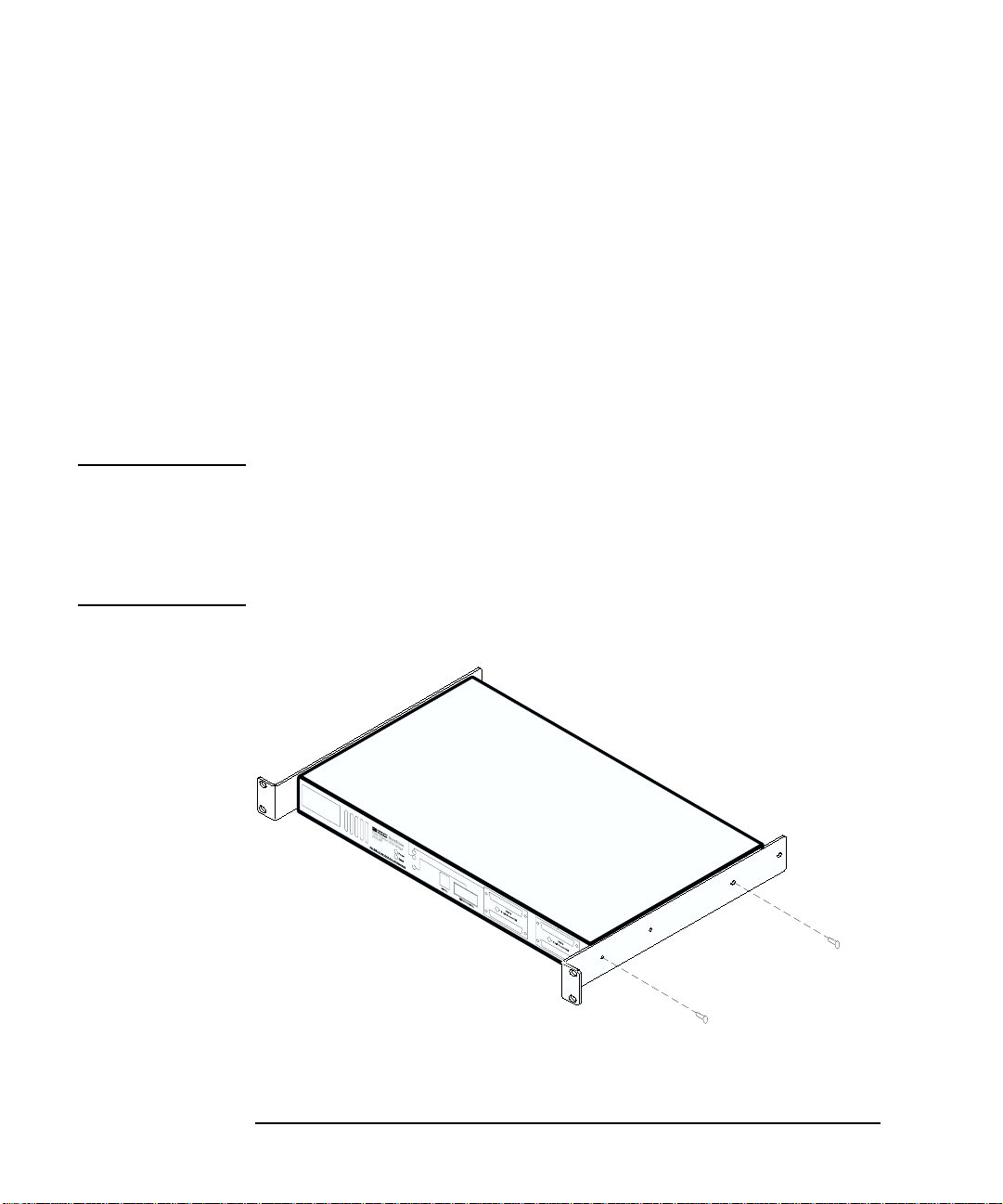

Assemble the L-brackets to the Fibre Bridge

1. Facing the back of the Fibre Bridge, position the first L-bracket with

the mounting tab toward the back of the rack and pointing away from

the unit, as shown in Figure 2-1.

2. Insert 6x32 screws through the first and third holes from the

mounting tab and tighten. Use the first and third holes (from the

mounting tab end of the bracket) for mounting in a Hewlett-Packard

rack. (Non-HP racks may require mounting holes number two and

four. See note below.)

3. Follow the same procedure for the second L-bracket.

NOTE For non-HP racks, allow for cable turn: A minimum distance of 5 inches

(125 mm) is required between the back of the Fibre Bridge and the

backplane of the rack. When installing in racks where the mounting

holes in step 2 produces a distance less than 5 inches (125 mm), use the

second and fourth holes when attaching the mounting bracket to the

Fibre Bridge.

Figure 2-1 Assembling L-brackets to the Fibre Bridge

H

N

o

t

S

u

i

t

a

b

l

e

f

o

r

H

a

r

d

D

r

i

v

e

S

u

b

s

y

s

t

e

m

s

2-4 Chapter 2

Page 29

Setting Up the Fibre Bridge

Mounting the Fibre Bridge in a Rack

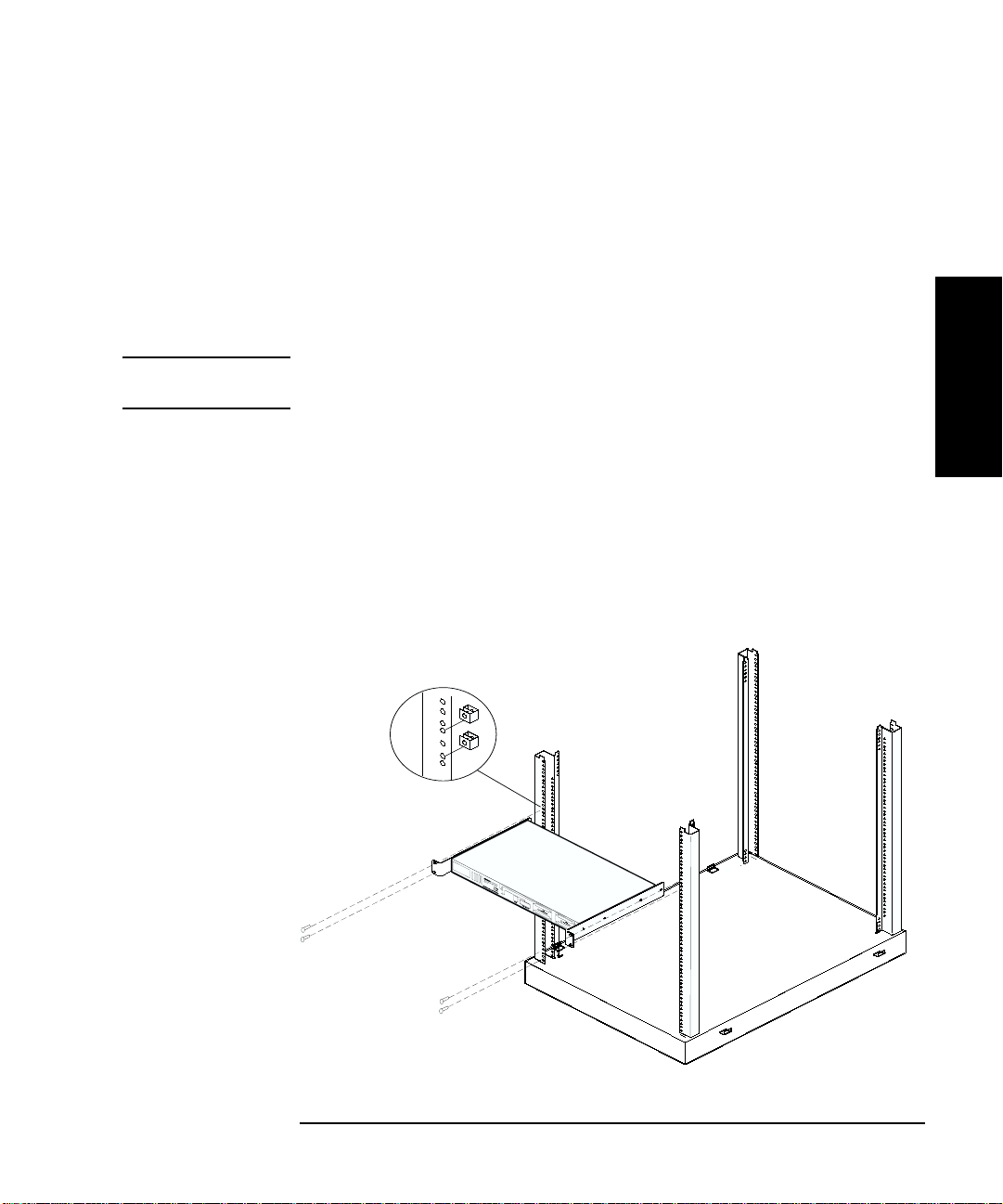

Install the Fibre Bridge in the Rack

1. Facing the back of the rack, install a total of four clip nuts above any

existing product, two into each of the rails. Install the clip nuts so

that the top nut aligns with the top hole of the L-bracket and the

other with the bottom hole. (Figure 2-2).

To ensure level mounting, verify that the clip nuts are in the same

position on the right and left rails.

NOTE The Fibre Bridge mounts from the bac k of the rac k. All user functio nality

is located on the back of the unit; no access to the front is required.

2. Holding the Fibre Bridge in position, align the holes in the mounting

brackets with the holes in the clip nuts.

3. Install four 10x32 screws into the clip nuts and hand-tighten.

4. Tighten all four screws.

5. Install the front filler panel (supplied by the rack vendor) and apply

the decal.

Figure 2-2 Mount the Fibre Bridge in the Rack

Setting Up the

Fibre Bridge

H

N

o

t

S

u

i

t

a

b

l

e

f

o

r

H

a

r

d

D

r

i

v

e

S

u

b

s

y

s

t

e

m

s

Chapter 2 2-5

Page 30

Setting Up the Fibre Bridge

Installing Cables

Installing Cables

The Fibre Bridge can be used in either basic or expanded system

configurations. This section provides the steps to install cables in both

configurations.

NOTE The following section explains overall configuration cabling. For

complete installation procedures, refer to the INSTALL subdirectory on

the CD-ROM shipped with the bri d ge.

Fibre Bridge Connection, Basic Configuration Example (DLT and MO Libraries)

CAUTION Be sure all devices in the configuration have been turned off and

disconnected from the power source before making any connections.

F ailure to disconnect all power could result in damage to the devices.

1. Properly shut down all peripheral devices that will be connected to

the Fibre Bridge, i ncluding the host. If the host compu ter is connected

to a network, check with the system administrator before switching

off power.

2. Connect the SCSI cable from bus 1 on the Fibre Bridge to bus 1 on the

library.

For a two-drive DLT library, connect a SCSI cable from bus 2 on the

Fibre Bridge to bus 2 on the library.

For a two-bus MO library, connect a SCSI cable from bus 2 on the

Fibre Bridge to bus 2 on the library.

NOTE A basic, point-to-point configuration is “One HBA to one bridge to one or

two SCSI buses.”

A two-drive DLT library uses both SCSI buses, so only one t w o-drive

DLT library may be connected to one HBA.

An MO library may be connected to each SCSI bus on a bridge, so two

MO libraries (maximum) may be connected to one HBA.

2-6 Chapter 2

Page 31

Setting Up the Fibre Bridge

3. Connect one end of the optical cable into the GBIC on th e Fibre

Bridge and the other end into the GBIC on the Fibre Channel HBA in

the host.

4. Connect the power cord from the Fibr e Bridge to an grounded outlet.

5. Confirm that all cable ends are connected securely and both ends of

the SCSI bus are properly terminated, as shown in F igure 2-3 on p age

2-7.

6. Go to “Powering on the System” in Chapter 3.

Figure 2-3 Fibre Bridge Connection, Basic Configuration

(DLT and MO Libraries)

Installing Cables

Setting Up the

Fibre Bridge

Chapter 2 2-7

Page 32

Setting Up the Fibre Bridge

Installing Cables

Fibre Bridge Connection, Expanded Configuration Example (DLT Libraries Only)

1. Properly shut down all peripheral devices that will be connected to

the Fibre Bridge, including the hub(s). Check with the system

administrator before turning off power to either hubs or libraries.

CAUTION Failure to turn off all power could result in damage to the devices.

2. Connect a S CSI cable from bus 1 on the Fibre Bridge to bus 1 on the

library one. For a two-drive library, connect a SCSI cable from bus 2

on the Fibre Bridge to bus 2 on the library.

3. Connect the optical cable from the Fibre Bridge to the hub.

4. Connect an optical cable from the hub to each host syste m.

If you have a 6-8 host system, you will need an additional hub. (See

Figure 2-3 and Figure 2-4 for examples of expanded configurations.)

5. Connect the power cord from Fibre Bridge one to an grounded outlet.

6. Confirm that all cable ends are connected securely and both ends of

each SCSI bus are properly terminated, as shown in Figure 2-4 or

Figure 2-5 on page 2-10.

7. See poweron instructions in Chapter 3.

2-8 Chapter 2

Page 33

Setting Up the Fibre Bridge

Installing Cables

Figure 2-4 Fibre Bridge Connection, Expanded Configuration (Minimum)

(DLT Only)

Setting Up the

Fibre Bridge

Chapter 2 2-9

Page 34

Setting Up the Fibre Bridge

Installing Cables

Figure 2-5 Fibre Bridge Connection, Expanded Configuration (Maximum)

(DLT Only)

2-10 Chapter 2

Page 35

Setting Up the Fibre Bridge

Installing Cables

Optical Fibre Channel Cable Options

The Fibre Bridge uses fiber-optic cables available in the lengths listed in

Figure 2-2:

Table 2-2 Fiber-Optic Cable Options

Product Number Length

D6980A 164 ft (50 m)

D6981A 328 ft (100 m)

NOTE For additional information regarding the Fibre Channel environment,

configuration, and other Fibre issues, refer to Appendix A, “Fibre

Channel Overview.”

Chapter 2 2- 11

Page 36

Setting Up the Fibre Bridge

Installing Cables

2-12 Chapter 2

Page 37

3 Operating the Fibre Bridge

Operating the

Fibre Bridge

3-1

Page 38

Operating the Fibre Bridge

Chapter Overview

Chapter Overview

This chapter provides the following information:

• Powering on the System

• Changing the Default Settings

• Making Configuration Changes

3-2 Chapter 3

Page 39

Operating the Fibre Bridge

Powering on the System

Powering on the System

The HP SureStore Fibre Channel SCSI Bridge 2100 ER is configured for

most Fibre Channel installations without intervention. The basic

configuration uses one Fibre Bridge connected directly to a Fibre

Channel Host Bus Adapter (HBA) within a host computer. In expanded

configurations (DLT libraries only), the Fibre Bridge may be connected to

either a Fibre Ch annel HBA or a Fibre Channel hub . Th e F ibre Bridge is

set up to support an HP single-ended SCSI library on a Fibre Channel

arbitrated loop.

Use the following sequence when powering on the sys tem:

NOTE Powering on each device in the proper sequence is important. When

devices are turned on out of order, communication failures may result.

1. Power on the library, which allows the Fibre Bridge to connect

properly to the library when it scans the SCSI bus.

2. Power on the F ibre Bridge. When you do, notice that the power

indicator comes on immediately. The Fault indicator may flash

momentarily. After about 30 seconds, the SCSI activity indicator will

flash once. The Fibre Channel activity indicator will not flash until

other devices have been attached and powered on.

3. Power on the hub, if required.

4. Power on the host.

(If DLT) If there are multiple hosts , power them on sequentially.

Order is important. Wait for for each host to finish booting before

powering on the next host.

NOTE If any fault indicators are encountered on the Fibre Bridge or other

equipment, consult the appropriate user gui de.

5. (If DLT) Install backup software.

Operating the

Fibre Bridge

Chapter 3 3-3

Page 40

Operating the Fibre Bridge

Powering on the System

Figure 3-1 Fibre Bridge, Back View

3-4 Chapter 3

Page 41

Operating the Fibre Bridge

Changing the Default Settings

Changing the Default Settings

The basic Fibre Bridge configuration assumes there is only one Fibre

Bridge included in the system. If this is a DLT installation and more

than one Fibre bridge will be installed, or if there is another Fibre

Channel device using the same address, you must change the fib re

channel address, using the serial port of the Fibre Bridge.

Connecting the Serial Cable

Using the serial cable is not necessary in most installations. The default

settings work in most configurations. Use the serial cable only if one of

the following situations occurs:

• The default configuration must be changed.

• A failure has occurred that requires diagnostic procedures. See

“Chapter 4: Troub les h o ot ing.”

If any of these scenarios occur , attach the serial cable and RJ-11 to DB9

adapter as shown in Figure 3-2 on page 3-6.

Operating the

Fibre Bridge

1. Plug the RJ-11 connector into the Fibre Bridge.

2. Plug the DB9 adapter into the Com1 or Com2 port of the computer.

3. Verify that the RJ-11 serial cable is properly plugged into the RJ-11

to DB9 adapter.

Chapter 3 3-5

Page 42

Operating the Fibre Bridge

Changing the Default Settings

Figure 3-2 Connecting the Serial Cable

4

H

N

o

t S

u

it

a

b

l

e

fo

r

H

a

rd

D

riv

e

S

u

b

s

ys

t

e

m

3

2

s

1

1Fibre Bridge

2 RJ-11 connector

3 Serial cable

4 RJ-11 to DB9 adapter

3-6 Chapter 3

Page 43

Operating the Fibre Bridge

Changing the Default Settings

Serial Port Setup

Before communicating, the PC serial port must be connected to t he Fibre

Bridge and terminal emulation software (Hyperterminal, or similar)

must be installed on the ho st. Configure t he terminal emulat ion program

to use the settings in Table 3-1 on page 3-8 for the PC’s serial port.

NOTE When initially powered on, the Fibre Bridge uses the default (or

previously set) baud rate during self-tests. After completing the

self-tests, pressing

itself to the baud rate used by the host.

ENTER several times causes the Fibre Bridge to reset

Serial Port Operation

The serial port on the Fibre Bridge connects to a terminal or computer

that is running a terminal emulator such as Hyperterminal on Windows

NT. The operator can then perform the following:

• Change the system addresses and address modes

Operating the

Fibre Bridge

• Check the results of the POST tests

• Change the operating leve l of diag nos tic rout in es

NOTE The serial port cannot be used to transfer data to devices on the SCSI

buses or on the Fibre Channel loop.

An EEPROM inside the Fibre Bridge stores configuration changes.

Because the Fibre Bridge stores its original settings, it can be reset to the

original configuration at any time. See Table 3-1 on page 3-8 for the

default configuration settings.

NOTE If there is trouble communicating between the serial port and the Fibre

Bridge, contact an HP service representative.

Chapter 3 3-7

Page 44

Operating the Fibre Bridge

Changing the Default Settings

Table 3-1 Fibre Bridge Default Configuration Settings

Serial Port • Baud rates: 9600, 19200, 38400, 57600, 115200

(baud rate will auto-configure).

• No handshake.

• No parity.

• 8 data bits.

• 1 stop bit.

Fibre

Channel

SCSI Initiator address 7.

Trace Debug

Level

• Hard address mode uses addres s 0x82.

• User may change both address mode and hard

address.

Bus automatically negotiates for wide ultra SCSI

performan ce, per AN SI SCSI specifications.

Only the initiator addr esses may be changed.

Each bus can be set to its own initiator address

independently of the other b u s.

Level 0, 1, 2, and 3.

3-8 Chapter 3

Page 45

Operating the Fibre Bridge

Making Configuration Changes

Making Configuration Changes

To mak e configuration changes, follow these steps:

1. Start your terminal emulation application software.

2. Press the

ENTER key. The following menu will display:

NOTE The user may need to press ENTER several times to prompt the Fibre

Bridge to recognize the serial port settings.

Figure 3-3 Fibre Bridge Configuration, Main Menu

3. Use the

the configuration. To select the option, type

press

Perform Configuration menu option to make changes to

1 on the keyboard and

ENTER to display the Fibre Bridge configuration menu.

Operating the

Fibre Bridge

Chapter 3 3-9

Page 46

Operating the Fibre Bridge

Making Configuration Changes

Figure 3-4 Fibre Bridge Configuration Menu

4. To initiate a change, enter the number of any item on the list. After

all changes have been complete d, save the changes by pressing

a on

the keyboard. To make changes take effect, restart the Fibre Bridge.

CAUTION Making changes under options B or C does not change the settings in

memory. Before closing the configuration menu and restarting the Fibre

Bridge, always select option A, “Save Configuration”.

3-10 Chapter 3

Page 47

Operating the Fibre Bridge

Making Configuration Changes

Reconfigure the Fibre Channel Address

Use the Fibre Channel Configuration menu to change from the hard

address mode to the soft address mode.

NOTE The Fibre Bridge de fault set ting is ha rd addressing , where the address is

preset to 71 (0x82). Use this procedure when an additional bridg e is

installed in a system or to resolve a Fibre Channel device ID conflict.

1. From the Configuration menu (Figure 3-4 on page 3-10), select option

2, Fibre Channel Configuration.

2. To toggle between hard addressing and soft addressing, select option

1.

3. To choose a new address, select option 2 and enter a new address from

the table in Figure 3-6 on page 3-12.

NOTE The “Change ALPA Valu e” option is not available when the so ft address

mode has been selected.

Figure 3-5 Fibre Channel Configuration Menu

Operating the

Fibre Bridge

Chapter 3 3- 11

Page 48

Operating the Fibre Bridge

Making Configuration Changes

Selecting the “Change ALPA Value (option 2 in the previous menu)

produces the following list of addresses:

Figure 3-6 Fibre Channel Addresses

4. Select an address by entering the number before the colon.

Pressing any key , except a valid number, will display an invalid entry

message. The address will not be changed. The firmware will return

to the Fibre Channel Configurati on menu.

NOTE Confirm that the Fibre Channel device address selected is unique on the

FC-AL.

3-12 Chapter 3

Page 49

Operating the Fibre Bridge

Making Configuration Changes

Change the Trace Settings

CAUTION Changing options in the Trace Settings menu directly affects the current

operation of the Fi bre Bridge. Pressing

parameters without restarting the Fibre Bridge.

The Trace Level menu is included for troubleshooting purposes. The

Trace Settings menu enables options in the Fibre Bridge firmware.

Changing the trace level does not affect the Fibre Bridge’s operation, but

can affect the performance.

The HP service technician may require that you c hange one or more

settings. Do not use the Trace Settings menu unless an HP service

technician requests that you do so.

Figure 3-7 Trace Settings Menu

U changes the current operating

Operating the

Fibre Bridge

Chapter 3 3-13

Page 50

Operating the Fibre Bridge

Making Configuration Changes

Fibre Channel to SCSI Mapping Configuration

Use the Fibre Channel to SCSI Mapping Configuration menu to display

the SCSI devices that are present on the Fibre Bridge.

3-14 Chapter 3

Page 51

4 Troubleshooting Guide

Troubleshooting

Guide

4-1

Page 52

Troubleshooting Guide

Chapter Overview

Chapter Overview

This chapter provides the following information:

• Possible problems that a user may encounter when installing the

Fibre Bridge.

• Recommended procedures for analyzing and solving problems.

• What to do when problems cannot be resolved using the documented

approach.

4-2 Chapter 4

Page 53

Troubleshooting Guide

Troubleshooting

Troubleshooting

This section describes potential problems and solutions. If you are

unable to diagnose and solve a problem using these guidelines, contact

an HP service representative or your sales representative. By using

these suggested procedures, you can determine in advance some of the

information that a service technician will need .

Problem: Cannot Turn On the DLT Library

If the library will not power-up, use the following steps before taking

further action:

1. Verify all power connections, breakers, and switch settings are

working and correct.

2. Confirm that the indicator is on and green.

3. Check to see that the indicator is not amber, which indicates a

self-test failure.

4. Consult the library user guide for additional troubleshooting steps

and support options.

Problem: Cannot Turn On the MO Library

If the library will not power-up, use the following steps before taking

further action:

1. Verify all power connections, breakers, and switch settings are

working and correct.

2. Confirm that

3. Consult the library user guide for additional troubleshooting steps

and support options.

READY is displayed in the control panel.

Troubleshooting

Guide

Chapter 4 4-3

Page 54

Troubleshooting Guide

Troubleshooting

Problem: Cannot Turn On the Hub (DLT

Only)

If the hub will not power -up, use the fo llowing steps before taki ng further

action:

1. Verify all power connections, breakers, and switch settings are

working and correct.

2. Confirm that the power indicator is illuminated.

3. Verify that the fault indicator is not illuminated.

4. If the fault indicator is illuminated, the hub is inoperable; further

diagnostic procedures cannot be performed. Contact the sales

representative or an HP service representative.

Problem: Cannot Turn On the Fibre Bridge

If the Fibre Bridge will not power on, use the following procedures to

diagnose the problem:

1. Verify that all power connections, breakers, and switch settings are

powered on and are set correctly.

2. Confirm that the power indicator is illuminated gree n.

3. Verify that the fault indicator (amber) is not illuminated.

4. If the fault indicator is illuminated, the unit is inoperable; further

diagnostic procedures cannot be performed. Contact the sales

representative or an HP service representative.

Problem: Cannot Confirm the Library

Connection

1. Confirm the library connection by using the control panel menu on

the NT server to review the SCSI device folder.

NOTE The NT discovery process is not dynamic. When SCSI devices are

powered on after the host, the control panel will not display their

connection.

4-4 Chapter 4

Page 55

Troubleshooting Guide

Troubleshooting

2. Make sure the libraries, Fibre B ridge, and hubs (DLT only) are

powered on and connected appropriately before powering on

workstations. If they were not connecte d, powered o n, and configu red

properly before the NT workstat ion was powered on, restart the

workstation (and any other on the loop, one at a time) so they can

re-discover the library.

NOTE (DLT On ly) Do not restart multiple NT workstations on a Fibre Channel

loop at the same time. Allow each workstation to complete the process

and display the NT login prompt before turning on the next computer. If

more than one workstation is powered on at the same time, only one will

locate devices on the Fibre Channel loop. This sequential process is

particularly critical when recovering from a power failure.

Troubleshooting

Chapter 4 4-5

Guide

Page 56

Troubleshooting Guide

Troubleshooting

3. If the workstation does not display the SCSI devices under the Fibre

Channel HBA in the control panel, restart the workstation and then

recheck for the appearance of the library SCSI devices.

4. (If DLT) Run the tape diagnostic utility from the NT workstation to

verify that the library and drives are detected and pass all self-tests.

NOTE (If DLT) If the tape diagnostic utility has not been installed, install this

software from the DIA G subdirectory on the User Guide CD-ROM.

5. Verify SCSI Bus Configuration: Check all appropriate devices for the

following conditions:

• Termination: Problems with termination can cause intermittent or

hard failure. Two connectors are implemented for each SCSI bus,

supporting middle of bus configurations.

Terminate the SCSI bus on both ends, and only at the ends of the

bus. Check each terminator and connector for bent pins.

• Bus Type: Single-ended devices cannot be combined with

differential de vices on the same bus. Similarly, differenti al

terminators cannot be used on the single-ended Fibre Bridge.

• Device ID: Each device on a SCSI bus must have a unique ID. The

default SCSI ID of the Fibre Bridge is 7. Make sure that this ID is

not in use on the bus. Check the library user guide for the default

SCSI IDs. Verify that other IDs on the bus are not in conflict.

• Cabling: Check SCSI cables to verify that they are functional, then

perform the following procedures:

a. Be sure the maximum cable length on the single-ended SCSI

cable connected to the F ib re B rid ge does not exc e ed a to ta l of 3

meters.

b. Check all cable connections and pins on the connectors. Reseat

the connections if necessary.

4-6 Chapter 4

Page 57

Troubleshooting Guide

Troubleshooting

6. Verify SCSI bus operation: Use the serial connection between the NT

workstation and the Fibre Bridge. See Chapter 3, “Fibre Bridge

Default Configuration Settings,” on page 3-8 for default settings and

for steps to initiate the following procedures:

• Perform a Fibre Bridge self-test.

• Verify device locations using the Fibre Channel to SCSI Mapping

menu. See Chapter 3, “Fibre Channel to SCSI Mapping

Configuration,” on page 3-14.

NOTE If you experience communication difficulty with the Fibre Bridge,

confirm that the terminal emulation software (Hyperterminal, or

similar) has been configured properly. See Chapter 3, page 6.

7. Verify Fibre Bridge Configuration: Configurati on changes may result

in an invalid configuration. If you are in doubt about the

configuration, refer to “Making Configuration Changes” on page 3-9.

If this procedure fails, contact an HP service representative.

8. Verify devices: If the previous diagnostic procedure have not resulted

in a functional connection between the Fibre Bridge and each device,

use the following steps :

a. Connect the library to a SCSI HBA on the host and restart the

workstation. Verify functionality with the SCSI connection.

b. Confirm that the library is visible in the SCSI devices folder of the

control panel.

c. (If DLT) Confirm that there are no error indicators illuminated on

the front panel of the library.

Chapter 4 4-7

Page 58

Troubleshooting Guide

Troubleshooting

4-8 Chapter 4

Page 59

A Fibre Channel Overview

Fibre Channel

Overview

A-1

Page 60

Fibre Channel Overview

Overview

Overview

In this appendix, we will describe the following:

• Defining Fibre Channel

• Implementing Fibre Channel

• Working With Fibre Channel

• Problems with Fibre Channel

A-2 Appendix A

Page 61

Fibre Channel Overview

Defining Fibre Channel

Defining Fibre Channel

This overview of Fibre Channel is intended to briefly explain the

technology, its potential uses, and possible problems that a user should

consider. Individuals requiring more information should consider

additional publications, seminars, and Fi bre Channel user groups.

Fibre Channel is an information transport protocol that can be used to

send information between computers and computer sub-systems.

Defined by the American National Standards Institute (ANSI), Fibre

Channel supports the following:

• Internet Protocol (IP)

• Transmission Control Protocol/Internet Protocol (TCP/IP)

• Small Computer System Interface (SCSI)

• High-Performance Parallel Interface (HIPPI)

• Asynchronous Transfer Mode (ATM)

• Other high-level protocols

Using Fibre Channel, these protocols can run at the same time. For

example, a host bus adapter (HBA) can simultaneously send Local Area

Network (LAN) information to another computer and read or write data

to a Redundant Array of Inexpensive Disks (RAID). Fibre Channel was

defined with multiple initiators in mind. In addition to supporting a

number of protocols on the same connection, Fibre Channel offers users

the following advantages:

• High speed data transmission

• Long distance support

• Large address space

• Multiple device configuration opportunities

Appendix A A-3

Fibre Channel

Overview

Page 62

Fibre Channel Overview

Defining Fibre Channel

A fully implemented Fabric system supports over 16 million device

addresses, allowing a user to send data from each device at 100 MB per

second. Using fiber optic cable, Fibre Channel devices can be spaced at

maximum intervals of 10 km, supporting distributed hosts in a campus

environment, with centralized st orage systems. Fibre Channel uses

three connection topologies, illustrated in the following table:

Table A-1 Fibre Channel Supported Fabric Topologies

Topology Description

Point to point Dedicated connection

between two devices.

Fibre Channel

Arbitrated Loop

(FC-AL)

Fabric A switching concept,

Supports up to 126

devices, distributing

the 100 MBps data

bandwidth among all

devices on the loop.

similar to a telephone

system, providing

simultaneous

data-transmission

among multiple

devices at 100 MBps.

Advantages/

Disadvantages

Low cost, high

performance.

Supports more

devices.

Increasing the

number of devices

reduces performance.

Supports multiple

devices without

performance

reduction.

Higher cost.

A-4 Appendix A

Page 63

Fibre Channel Overview

Implementing Fibre Channel

Implementing Fibre Channel

Whether designing a new system or enhancing a system that is in place,

Fibre Channel offers significant speed and distance and cost advantages.

Fibre Channel works with existing systems and software, with the

addition of a Fibre Channel HBA; new systems are not required to take

advantage of Fibre Channe l technology.

Distributed Devices

Computer and storage systems can be separated and distributed more

efficiently because of the distance capability of Fibre Channel.

Contrasting with the address range and distance limitations of SCSI,

adding storage with a Fibre Channel system does not require adding

servers, except when extra performance is needed.

Supporting distributed configurations, Fibre Channel improves dis aster

recovery planning. Faster speeds and greater transmission distances

allow for remotely located backup systems.

Cabling Advantages

Using less cable-associated hardware than a typical SCSI environment,

Fibre Channel reduces total system costs and supports greater

performance. Easily added, and often using LAN cables, Fibre Channel

cable is smaller and lighter than SCSI cable, making it easier to install

and manage.

Fibre Channel supports copper and optical cables. Optical cable, while

more expensive, will carry data further than copper and is not

susceptible to noise interference. Although current HBA drivers use

SCSI commands, future driver enhancements will support other

protocols specified for Fibre Channel, including LAN. Optical cables,

carrying LAN protocols, will be used in place of existing LAN cabling in

the future.

Appendix A A-5

Fibre Channel

Overview

Page 64

Fibre Channel Overview

Working With Fibre Channel

Working With Fibre Channel

Fibre Channel is a transport protocol. Differing from protocols such as

SCSI, Fibre Channel does not use data manipulation commands. An

addressing scheme with advance handshaking requirements verifies

that data was transferred correctly.

Fibre Channel specifications are divided into multi-layered, functional

levels. The five layers define the physical media and transmission rates,

encoding scheme, framing protocol and flow control, common services,

and the upper-level protocol interfaces. Each section of the Fibre

Channel specification can be changed without affecting other sections.

Upper level specifications for Fibre Channel map commands and data

from different supported protocols to the Fibre Channel system. The

mapped commands and data are then segmented into frame sequences.

Each frame is encoded and sent to the desi red target device. At the target

device, the frames are decoded and reassembled into the original

sequence. The data in the sequence is extracted and then processed by

the target system. This whole process is done without knowledge of the

contents of the information being transferred.

Because Fibre Channel supports many different communication

protocols, the highest level of the Fibre Channel specifications identify

the type of communication protocol encoded. As information is divided

into sequences of frames, Fibre Channel attaches address and sequence

information to each packet. This transport protocol is required to

reconstruct the original information into its original form.

More complex than simply dividing information up into frames and

sending it to an address, Fibre Channel also has special frames to pass

the following Fibre Channel-specific information between devices:

• New devices added to the system

• All device addresses

• How and when data can be transferred

• Problem detection

A-6 Appendix A

Page 65

Fibre Channel Overview

Working With Fibre Channel

The Fibre Channel protocol will work when devices are connected or

disconnected while data is being transferred because of this additional

information. Error detection and recovery at all levels of the protocol are

also provided.

A fairness algorithm is built into the FCAL protocol so that all devices

have equal access to the system. To keep the phase lock loops

synchronized, Fibre Channel continually communicates, even between

frames, supporting device arbitration for access to the loop. Fibre

Channel devices also use this communication to report on buffer size

available for communication. If there is nothing to report, the Fibre

Channel protocol fills up the space between frames with idle characters.

Characters must be present on the bus at all times to keep the high

frequency circuits working correctly, reconstructing data clocks and

detecting data on the bus. Even the data encoding is arranged so that

there is never a continuous string of ones or zeros.

The lower levels of Fibre Channel protocol is handled in the hardware

and, to a minor extent, by the low level HBA drivers. System and

application software does not need to be aware of any low level protocol

operations. Additional features exi st in the protocol that more advanced

applications can use.

Fibre Channel addressing int roduces three major advantages:

• Provides large number of addresses

• Detects address conflicts

• Automatically reassigns new addresses when conflicts occur

With Fibre Channel, the data network can be distributed and very large .

The ANSI Fibre Channel committee developed a method that devices

must use to check and report addresses before data can be sent or

received. ANSI also added the ability to semi-dynamically assign address

devices on the loop. Addresses are only checked and conflicts resolved

when a Fibre Channel device is added or removed. During normal

operations (i.e. no devices being connected or disconnected), device

addresses are not changed. When a Fibre Channel bus configuration

changes, each device on the bus verifies and reports its address.

Appendix A A-7

Fibre Channel

Overview

Page 66

Fibre Channel Overview

Working With Fibre Channel

Fibre Channel devices may use either of two modes: soft or hard

addressing. Hard addressing is similar to the existing SCSI approach.

Fibre Channel device s can o nly us e t he assi gned a ddre ss. If that address

is already being used by another device, the Fibre Channel device will

not respond to any bus activity. Soft addressing is similar to LAN

addressing, where the system determines device addresses. As part of

the addressing protocol, all Fibre Channel devices have one or more

unique addresses that are not duplicated any where in the world. These

addresses are provided by ANSI to manufactures of Fibre Channel

products.

A-8 Appendix A

Page 67

Fibre Channel Overview

Problems with Fibre Channel

Problems with Fibre Channel

Fibre Channel accommodates many protocols and physical interfaces.

Problems result in the attempt to do many things with one solution.

Awareness of the potential problems helps users create and maintain

reliable systems. This section addresses three of the main problems:

• Physical Connections

• Laser Power Control Systems

• Device Addressing

Physical Connections

Physical problems arise from connecting devices with different types of

cables. Fibre Channel supports copper and optical interfaces.

ANSI specifies types of copper cable. The maximum distance between

devices depends on the type of cable being used, but is limited to less

than 20 meters. As with all electrical media, Fibre Channel copper media

can radiate RF interference and can be affected by external RF noises.

Because of the distance limitation and noise problems, copper media

should be used only inside a cabinet or rack.

An optical interface should be used to send data farther. ANSI specifies

multiple optical interfaces that use lasers, light-emitting diodes (LED’s),

and different types of optical cable. Generally, cable that supports

greater distance transmission commands is more expensive than cables

that support shorter distances.

Using a Fibre Channel hub allows multiple cable types within a system.

For ex ample , all devices in a rack can be connect ed to a hub usin g coppe r

cable. The hub can be connected to a F ibre Channel l oop or Fabric using a

fiber optic cable.

Appendix A A-9

Fibre Channel

Overview

Page 68

Fibre Channel Overview

Problems with Fibre Channel

Additional optical cable considerations are as follows:

• Cable between two nodes must use the same core size.

NOTE The limitation on mixing core sizes applies only to cable between two

nodes and is only a concern when splicing or connecting optical cables

directly together. Different size optical cable can be used in the same

Fabric between different sets of nodes.

• Three core sizes supported by Fibre Channel are: 62.5 micron, 50

micron, and 9 micron.

A-10 Appendix A

Page 69

Fibre Channel Overview

Problems with Fibre Channel

Laser Power Control Systems

There are two types of systems approved for use: OFC and non-OFC.

These two types of control systems can exist on the same network, but

are not optically compatible and cannot be hooked up to the same optical

cable.

Device Addressing

The two modes of addressing use d in Fibre Channel, included on page

A-7, are hard and soft addressing. In small, controlled environments,

hard addressing works well. Also, s ome operating systems and host bus

adapters do not support soft addressing. Large Fabric networks,

connecting many devices, require the flexibility of soft addressing; hard

addressing is not supported in a Fabric environment.

HBA drivers cannot dynamically track device addresses that can change

after the system is turned on. Physical addresses change while the

operating system uses the same logical name for the device. Applications

that always use the same phy sical dev ice may use the World-Wide Name

(WWN). For ex ample, backup p rograms must locate the library and all of

its drives regardless of the bus address. Fibre Channel resolves these

issues.

Proper system pla nning a nd r ese arc h p rio r t o i nst all ing a F i bre C hannel

system will help avoid these problems. Configured properly, Fibre

Channel is as reliable and easy to use as current SCSI systems.

Appendix A A-11

Fibre Channel

Overview

Page 70

Fibre Channel Overview

Problems with Fibre Channel

A-12 Appendix A

Page 71

B Support and Customer Service

Customer Service

Support and

B-1

Page 72

Support and Customer Service

Chapter Overview

Chapter Overview

This chapter contains information to help users obtain supplies and

obtain support. In this section you will find the following:

• Supplies and Accessories

• Hewlett-Packard Customer Support

B-2 Appendix B

Page 73

Support and Customer Service

Supplies and Accessories

Supplies and Accessories

A full range of supplies may be ordered through a Hewlett-Packard

authorized dealer, sales office, or through HP Direct. To contact HP

Direct, call 1-800-227-8164.

Call 1-800-752-0900 for the location of the nearest authorized

Hewlett-Packard dealer.

Appendix B B-3

Customer Service

Support and

Page 74

Support and Customer Service

Hewlett-Packard Customer Support

Hewlett-Packard Customer Support

If a Fibre Bridge fails during the warranty period, and the

troubleshooting guide a nd user ma nual do not sol ve the prob lem, you can

receive support by doing the following:

• Consult HP FIRST or QUICK FAX for faxback services. See “HP

FIRST/QUICK FAX Faxback Services” on page B-5.

• Consult one of the computer/ modem connectivity services available,

such as America Online or CompuServe. See “Electronic Support

Services” on page B-8.

• Consult one of the customer support centers in your area for standard

or post warranty work. See “Customer Care Centers” on page B-9. If

you have upgraded your support to on-site service, call the number

listed on the Support Pack or Service Contract.

If the Fibre Bridge fails after the warranty period, contact your

authorized HP dealer/distributor or the nearest HP sales and service

office. Customers in the US and Europe can also use a credit card for

phone assistance.

B-4 Appendix B

Page 75

Support and Customer Service

Hewlett-Packard Customer Support

Support Pack Service Contract

If you purchased a Support Pack from Hewlett-Packard to upgrade the

support level, make sure that you immediately send in the registration

card. Fa ilure to submit the Support P ac k registration card may delay th e

on-site response time.

NOTE Registering allows the local repair office to prepare f or the proper

response level needed.

HP FIRST/QUICK FAX Faxback Services

QUICK FAX and HP FIRST are automated systems that fax requested

product information and/or technical support documents to you. These

faxback services are available 24 hours/day.

To use this service, dial the appropriate fax number below for your

country from a touch-tone phone. Follow the voice prompts to select an

index of available support and product documents.

NOTE Remember to dial the country code before these numbers.

NOTE HP FIRST/QUICK FAX was discontinued in many countries. To obtain

product information and/or technical support documents, go to

“www.hp.com”. Select “HP Services and Support” and then select your

product type.

Appendix B B-5

Customer Service

Support and

Page 76

Support and Customer Service

Hewlett-Packard Customer Support

Asia-Pacific

Australia (03) 9272 2627

China (81610) 65055280

Hong Kong 800-96- 772 9

India +91 (0) 11 682 6031

Indonesia 6221-350-3408

Japan (3) 3335-8622

Korea (02) 769-0543

Malaysia 800-1611

New Zealand (09) 356 6642

Philippines 632-867-3551

Singapore (65) 291-7951

Taiwan (02) 719 5589

Thailand (02) 661 4011

Vietnam 001- (84) 823-4530

B-6 Appendix B

Page 77

Europe

Austria 06 60 63 86

Belgium, Dutch 0800 11906

Belgium, French 0800 17043

Denmark 800 10453

Finland 0800 13134

France 05 905900

Germany 0130 810 061

Ireland 01 662 5525

Italy 1678 59020

Netherlands 06 022 2420

Norway 800 11319

Portugal 01 441 7199

Support and Customer Service

Hewlett-Packard Customer Support

Spain 900 993123

Sweden 020 795743

Switzerland,

German 0800 55 1527

Switzerland,

French 0800 55 1526

United Kingdom 0800 960271

Other locations

in Europe 31 20 681 5792

North and South America (includes Canada)

(800) 368-9673 or (970) 635-1510

Other Countries

(970) 635-1510

Appendix B B-7

Customer Service

Support and

Page 78

Support and Customer Service

Hewlett-Packard Customer Support

Electronic Support Services

For 24-hour access to information over your modem:

On-line Service Providers

Technical information is available on CompuServe and America Online.

Service

Provider

CompuServe To download software, firmware,

and support documents, and to

discuss issues in user forums.

America

Online

To download software, firmware,

and support documents, and to

discuss issues in user forums.

Description Address

Go HPSYS

Go HPSTOR

Hewlett-Packard Web Site

Product and support information is available on the Hewlett-Packard

web site www.hp.com.

B-8 Appendix B

Page 79

Support and Customer Service

Hewlett-Packard Customer Support

Customer Care Centers

NOTE Contact the Customer Care Center in your area for technical assistance

during the warranty of your product.

North and South America (includes Canada)

Monday - Friday, 7 am - 5 pm MST

(970) 635-1500

European Customer Care Centers

Monday - Friday, 8:30 - 18:00 (C.E.T)

NOTE Language or country support might not be available for all products.

Austria 0711 420 1080

Belgium, Dutch 02 626 8806

Belgium, French 02 626 8807

Denmark 3929 4099

Finland 0203 47 288

France 01 43 62 34 34

Germany 0180 52 58 143

Ireland 01 662 5525

Italy 02 264 10350

Netherlands 020 606 8751

Norway 22 11 6299

Portugal 21 317 6333

South Afreica 086 000 1030

Spain 902 321 123

Sweden 08 619 2170

Switzerland 0848 80 11 11

United Kingdom 0870 842 2339

Appendix B B-9

Customer Service

Support and

Page 80

Support and Customer Service

Hewlett-Packard Customer Support

Israel 09 952 4848

Russia 095 797 3520

Turkey 0212 221 6969

Asia-Pacific

Australia . +61 (3) 8877 8000

China . +86 10 656 45959

Hong Kong . 800 96 7729

India . + 91 (0) 11 682 6035

Indonesia . +62 21 350 3408

Japan . +81 3 3335 8333

Korea . +82 (0) 2 3270 0700

Outside Seoul: 080 999 0700

Malaysia . +60 3 295 2566

New Zealand . +64 (9) 356 6640

Philippines . +63 2 867 3551

Singapore . +65 272 5300

Taiwan . +886 2 2717 0055

Thailand . +66 2 661 4000

Elsewhere

Contact your authorized HP dealer/distributor or the nearest HP sales

and service office.

B-10 Appendix B

Page 81

Support and Customer Service

Hewlett-Packard Customer Support

Telephone Support After Warranty

Before Calling

Before calling, please complete the following information so that you will

have it ready for the support center representative:

• Serial number of product ____________________

• Brand and model of host computer ________________________

• Version of software used; driver selected ________________________

US and Canada

Using a VISA or MasterCard, call one of the following:

• (800) 810-0130: Per incident fee of $25.00 will be charged to the credit

card.

• (900) 555-1800: $2.50 per minute with a maximum of $25.00 will be

charged to the credit card.

Europe

Call the appropriate number listed under “European Customer Care

Centers” on page B-9. A per incident fee will be charged for

after-warranty support. Please have a credit card, PO number, or billing

number address ready.

Elsewhere

Contact your authorized HP dealer/distributor or the nearest HP sales

and service office for after-warranty support.

HP Reseller Locator Numbers

US (800) 752-0900

Canada (800) 387-3867

Mexico and

South America (305) 267-4220

Appendix B B-11

Customer Service

Support and

Page 82

Support and Customer Service

Hewlett-Packard Customer Support

B-12 Appendix B

Page 83

C Safety and Regulatory

Information

C-1

Regulatory

Safety and

Page 84

Safety and Regulatory Information

Chapter Overview

Chapter Overview

This section contains important safety and regulatory information for

the United States, Finland, Sweden, Germany, United Kingdom,

European Union, and Japan.

C-2 Appendix C

Page 85

Safety and Regulatory Information

Chapter Overview

CDRH Regulations (USA Only)

The Center for Devices and Radio logi cal Hea lth ( CDRH) of the U.S. Food

and Drug Administration implemented regulations for laser products on

August 2, 1976. These regulations apply to laser products manufactured

from August 1, 1976. Compliance is mandatory for products marketed in

the United States. The labels and artwork shown below indicate

compliance with CDRH regulations and must be attached to laser

products marketed in the United States.

WARNING Use of controls, adjustments or performing procedures other

than those specified in this manual may result in hazardous

laser radiation exposure.

NOTE Complies with 21 CFR Chapter 1 Subchapter J.

Laser Class Information: A label which reads, "Class 1 Laser Product"

printed in English, German, Finnish.

United Kingdom Telecommunications Act 1984

The HP SureStore Fibre Channel SCSI Bridge is approved un der

Approval Number NS/G/1234/J/100003 for indirect connection to Public

Telecommunication Systems within the United Kingdom.

Appendix C C-3

Regulatory

Safety and

Page 86

Safety and Regulatory Information

Chapter Overview

C-4 Appendix C

Page 87

Safety and Regulatory Information

Chapter Overview

Herstellerbescheinigung

Diese Information steht im Zusammenhang mit den Anforderungen der

Maschinenlärn information sverordnung vo m 18 Januar 1991.

Schalldruckpegel Lp < 70 dB(A)

• am arbeitsplatz

• normaler betrieb

• nach ISO 7779:1988/EN 27779:1991 (Typprüfung)

English Translation of German Sound Emission Directive

This statement is provided to comply with the requirements of the

German Sound Emission Directive, from 18 January 1991.

Sound pressure Lp < 70 dB(A)

• at operator position

• normal operation

• according to ISO 7779: 1988/EN 27779: 1991 (type test)

Appendix C C-5

Regulatory

Safety and

Page 88

Safety and Regulatory Information

Chapter Overview

Turvallisuusyhteenveto

Laserturvallisuus

LUOKAN 1 LASERLAITE

KLASS 1 LASER APPARAT

HP SureStore Fibre Channel SCSI Bridge - l aitteesee n on asennet tu

optista tiedonsiirtoa varten laserlähetin, joker lähettää signaalit siihen

kytketyn optisen kuidun kautta.

Optisessa lähetinmoduulissa ei ole huollettavia kohteita eikä sen

tehtaalla tehtyjä säätöjä tule muuttaa.

Lähetinmoduulin turvallisen toiminnan varmistamiseksi on

noudatettava tarkoin sen asentamisesta ja toiseen vastaanottavaan

laitteistoon kytkemis e st ä annettuja ohjeita.

Tie-dye optisessa lähetinmoduulissa käytettävien laserdiodien

säteilyominaisuuksista:

Aallonpituus 780 - 680 nm

Teho 3 mW

Luokan 3B laser

C-6 Appendix C

Page 89

Safety and Regulatory Information

Chapter Overview

English Translation of Finland Regulatory Information

Laser Safety

CLASS 1 LASER DEVICE

HP SureStore Fibre Channel SCSI Bridge has a laser transmitter

module installed for optical data transmission. Optical fibre connected to

the module is used for data transmission.

Under normal operating conditions the transmitter is a safe Class 1 laser

device for the user and the user cannot be exposed to the laser radiation

it generates. The safety class of the tran smitter has been defined

according to the EN 60825-1 (1994) standard.

The are no user serviceable parts inside the laser transmitter module

and the factory settings should not be adjusted.

In order to ensure safe operation of the transmitter module all the

instructions about installing and connecting to receiving equipment

should be closely followed.

Information about radiation characteristics of the laser diode used in the

transmitter module:

Wavelength 780 - 860 nm

Power 3 mW (Typic al)

Class 3B laser

Appendix C C-7

Regulatory

Safety and

Page 90

Safety and Regulatory Information

Chapter Overview

Japanese VCCI Statement

This equipment is in the Class A category information technology

equipment based on the rules of Voluntary Control Council For

Interference by Information Technology Equipment (VCCI). When used

in a residential area, radio interference may be caused. In this case, user

may be required to take appropriate corrective actions.

C-8 Appendix C

Page 91

Glossary

A

ANSI An acronym for the

American National Standards

Institute, the coordinating

organization for voluntary

standards in the United States.

Arbitrated loop topology Fibre Channel topology that provides a low-cost solution to attach multiple communicating ports in a loop without switches.

Asynchronous SCSI signals are transmitted one at a time down the SCSI communication path.

ATM Asynchronous Transfer Mode

C

CDB An acronym for the

Command Descriptor Block.

CRC An acronym for Cyclic

Redundancy Check. An errorcorrecting code used in Fibre

Channel.

F

Fabric Fibre Channel-defined

interconnection methodology that

supports high-speed data routing

in Fibre Channel networks.