Page 1

HP 1910 Fast Ethernet Switch Series

Getting Started Guide

Part number: 5998-3955

Document version: 5W100-20130620

Page 2

Legal and notice information

© Copyright 2013 Hewlett-Packard Development Company, L.P.

No part of this documentation may be reproduced or transmitted in any form or by any means without

prior written consent of Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice.

HEWLETT-PACKARD COMPANY MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS

MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE. Hewlett-Packard shall not be liable for errors contained

herein or for incidental or consequential damages in connection with the furnishing, performance, or use

of this material.

The only warranties for HP products and services are set forth in the express warranty statements

accompanying such products and services. Nothing herein should be construed as constituting an

additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

i

Page 3

Contents

Product overview ·························································································································································· 1

1910-8 panel views ·························································································································································· 1

1910-24 panel views ······················································································································································· 2

1910-48 panel views ······················································································································································· 2

1910-8-PoE+ panel views ················································································································································ 3

1910-24-PoE+ panel views ·············································································································································· 3

Preparing for installation ············································································································································· 1

Safety recommendations ·················································································································································· 1

Examining the installation site ········································································································································· 1

Temperature/humidity ············································································································································· 1

Cleanness ·································································································································································· 2

EMI ············································································································································································· 2

Installing the switch ······················································································································································ 1

Mounting the switch in a 19-inch rack with mounting brackets ··················································································· 1

Mounting the switch on a workbench ····························································································································· 3

Connecting cables ···························································································································································· 4

Connecting network cable ······································································································································ 4

Installing SFP transceiver module and connecting optical fiber ·········································································· 4

Connecting the console cable ································································································································· 5

Connecting the AC power cord ······························································································································ 6

Verifying the installation ··················································································································································· 7

Accessing the switch for the first time ························································································································· 1

Setting up the configuration environment ······················································································································· 1

Connecting the console cable ········································································································································· 1

Console cable ··························································································································································· 1

Connection procedure ············································································································································· 2

Setting terminal parameters ············································································································································· 2

Powering on the switch····················································································································································· 5

Verification before power-on ·································································································································· 5

Powering on the switch ············································································································································ 5

Appendix A Troubleshooting ······································································································································ 6

Appendix B Technical specifications ·························································································································· 1

Appendix C LED description ······································································································································· 1

Power LED ································································································································································· 1

Ethernet copper port LEDs ······································································································································· 1

SFP transceiver module link LED ····························································································································· 1

SFP transceiver module active LED ························································································································· 2

PoE LED ······································································································································································ 2

i

Page 4

Regulatory Model Name

HNGZA-HA0001

HNGZA-HA0002

HNGZA-HA0003

HNGZA-HA0004

HNGZA-HA0005

Product overview

The HP 1910 Switch Series includes the models in Table 1.

Table 1 HP 1910 Switch Series models

Product code HP description Alias

Non-PoE

JG536A HP 1910-8 Switch 1910-8

JG538A HP 1910-24 Switch 1910-24

JG540A HP 1910-48 Switch 1910-48

PoE

JG537A HP 1910-8-PoE+ Switch 1910-8-PoE+

JG539A HP 1910-24-PoE+ Switch 1910-24-PoE+

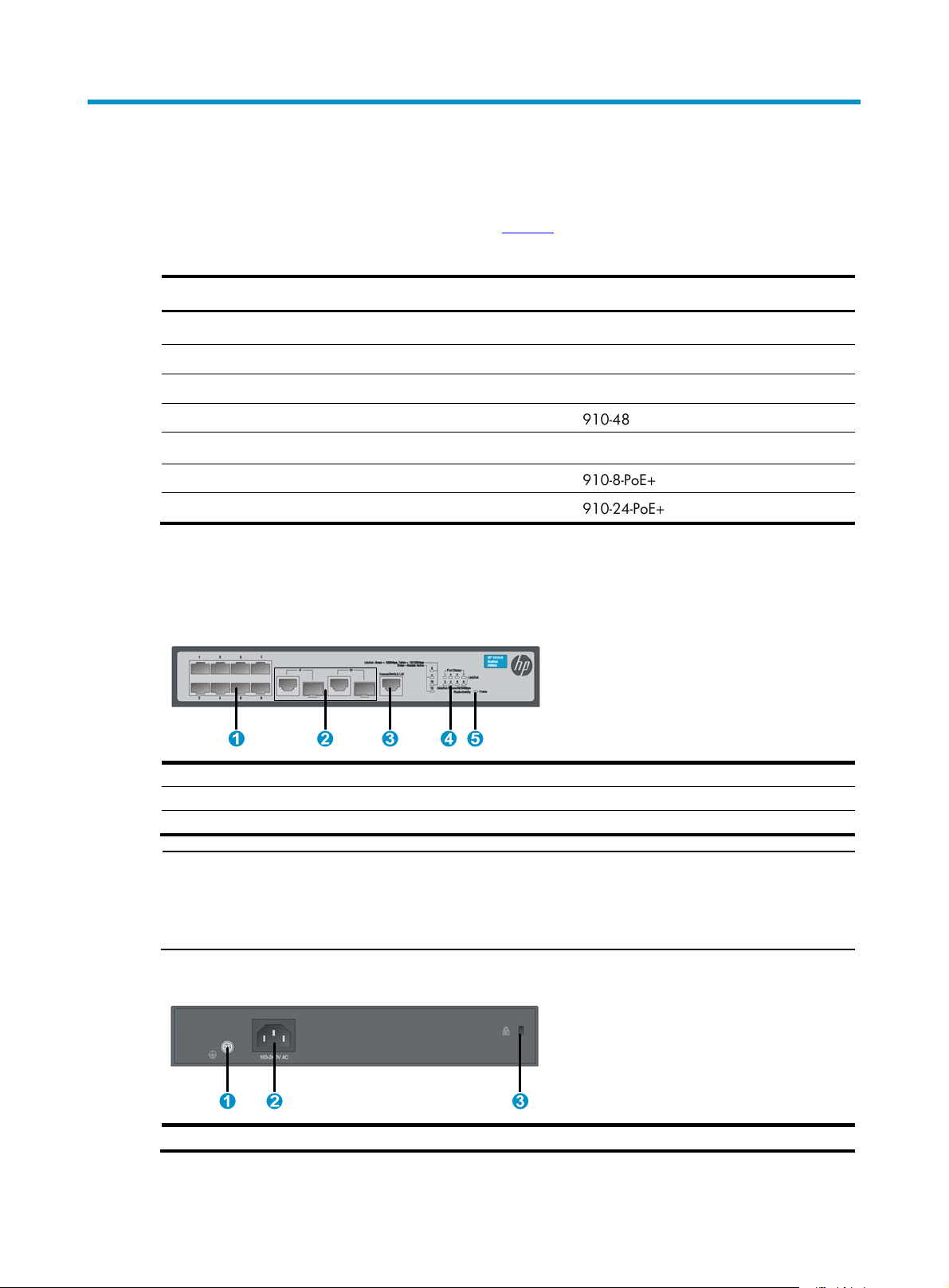

1910-8 panel views

Figure 1 Front panel

(1) 10/100Base-T auto-sensing Ethernet port

(3) Console port (4) Port LED

(5) Power LED (Power)

NOTE:

The 10/100Base-T Ethernet ports of the HP 1910 switch are numbered from the upper left to the lower

right. From left to right, the ports in the upper line are numbered odd numbers 1, 3, 5, and so on, and

those in the lower line are numbered even numbers 2, 4, 6, and so on.

Figure 2 Rear panel

(2) Combo interface

(1) Grounding screw (2) AC-input power receptacle (3) Anti-theft hole

1

Page 5

A

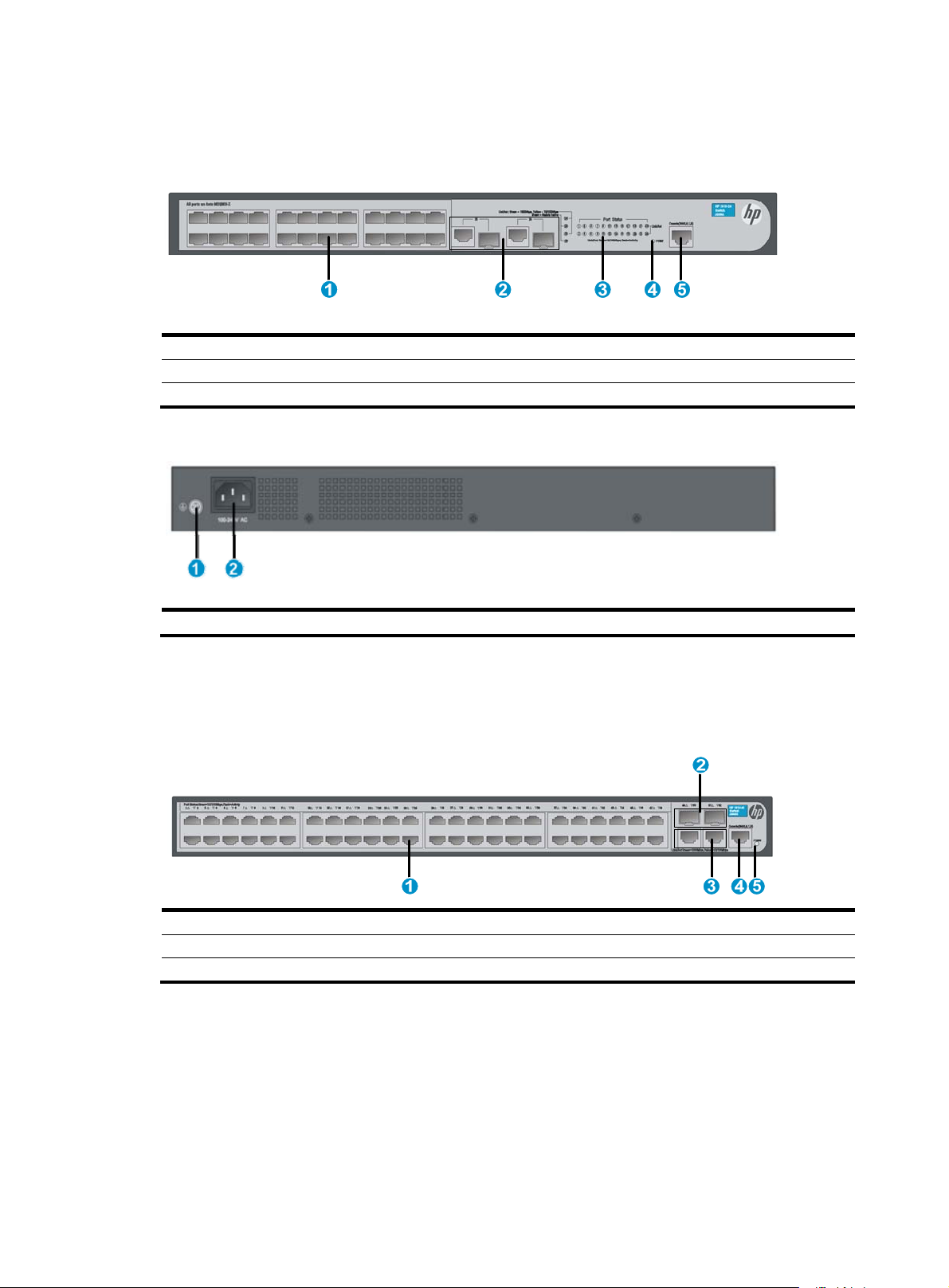

1910-24 panel views

Figure 3 Front panel

(1) 10/100Base-T auto-sensing Ethernet port

(3) Port LED (4) Power LED (Power)

(5) Console port

Figure 4 Rear panel

(1) Grounding screw (2)

1910-48 panel views

Figure 5 Front panel

(2) Combo interface

C-input power receptacle

(1) 10/100Base-T auto-sensing Ethernet port

(3) 100/1000Base-T auto-sensing Ethernet port

(5) Power LED (Power)

(2) 1000Base-X SFP port

(4) Console port

2

Page 6

A

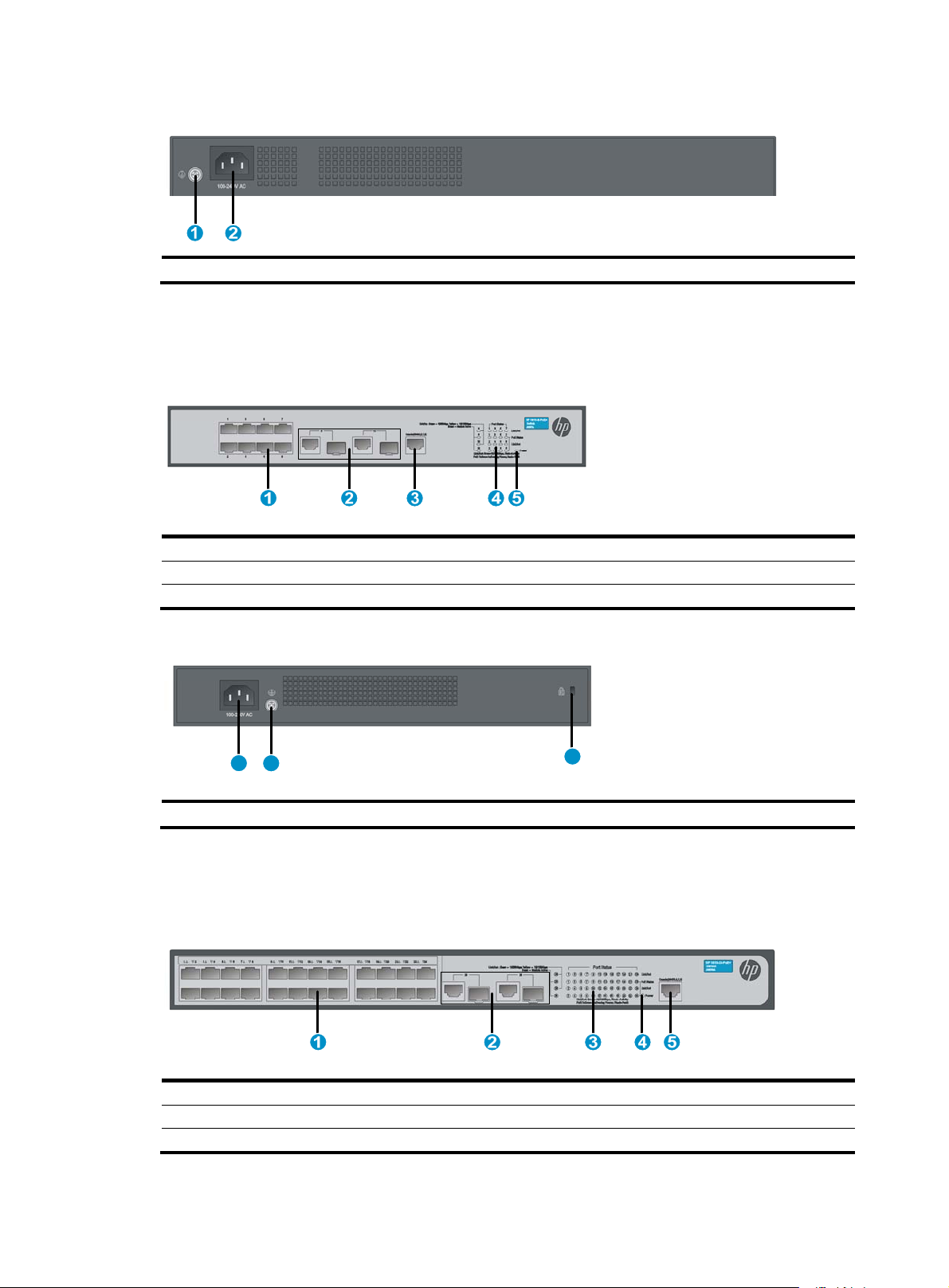

Figure 6 Rear panel

(1) Grounding screw (2) AC-input power receptacle

1910-8-PoE+ panel views

Figure 7 Front panel

(1) 10/100Base-T auto-sensing Ethernet port

(3) Console port (4) Port LED

(5) Power LED (Power)

Figure 8 Rear panel

21

(1) AC-input power receptacle (2) Grounding screw

1910-24-PoE+ panel views

Figure 9 Front panel

(2) Combo interface

3

(3)

nti-theft hole

(1) 10/100Base-T auto-sensing Ethernet port

(3) Port LED (4) Power LED (Power)

(5) Console port

(2) Combo interface

3

Page 7

A

Figure 10 Rear panel

(1) Grounding screw (2)

C-input power receptacle

4

Page 8

Preparing for installation

Safety recommendations

To avoid any equipment damage or bodily injury caused by improper use, read the following safety

recommendations before installation. The recommendations do not cover every possible hazardous

condition.

• Do not store the switch without power too long due to the storage requirement for the electrolytic

capacitor in the switch.

• Take proper anti-interference measures because the switch might cause radio interference as a

class-A product.

• Before cleaning the switch, remove all power cords from the switch. Do not clean the switch with wet

cloth or liquid.

• Do not place the switch near water or in a damp environment. Prevent water or moisture from

entering the switch chassis.

• Do not place the switch on an unstable case or desk. The switch might be severely damaged in case

of a fall.

• Ensure proper ventilation of the equipment room and keep the air inlet and outlet vents of the switch

free of obstruction.

• Make sure that the operating voltage is in the required range.

• To avoid electrical shocks, do not open the chassis while the switch is operating or when the switch

is just powered off.

• The accessories shipped with the switch, including but not limited to power cables, are intended

only for the switch. Please do not use them for other products.

Examining the installation site

The HP 1910 switches must be used indoors. You can mount your switch in a rack or on a workbench, but

make sure:

• Adequate clearance is reserved (at least 5 cm or 1.97 in) at the air inlet and exhaust vents for

ventilation.

• The rack or workbench has a good ventilation system.

• The rack or workbench is sturdy enough to support the switch and its accessories.

• The rack or workbench is well earthed.

To ensure normal operation and long service life of your switch, install it in an environment that meets the

requirements described in the following subsections.

Temperature/humidity

Maintain appropriate temperature and humidity in the equipment room.

• Lasting high relative humidity can cause poor insulation, electricity creepage, mechanical property

change of materials, and metal corrosion.

1

Page 9

• Lasting low relative humidity can cause washer contraction and ESD and bring problems including

loose captive screws and circuit failure.

• High temperature can accelerate the aging of insulation materials and significantly lower the

reliability and lifespan of the switch.

For the temperature and humidity requirements of different switch models, see "Appendix B Technical

specifications.

Cleanness

Dust buildup on the chassis may result in electrostatic adsorption, which causes poor contact of metal

components and contact points, especially when indoor relative humidity is low. In the worst case,

electrostatic adsorption can cause communication failure.

Table 2 Dust concentration limit in the equipment room

Substance Concentration limit (particles/m³)

EMI

Dust

NOTE:

Dust diameter ≥ 5 μm

≤ 3 x 104 (no visible dust on the tabletop over three days)

The equipment room must also meet strict limits on salts, acids, and sulfides to eliminate corrosion and

premature aging of components, as shown in Table 3

.

Table 3 Harmful gas limits in the equipment room

Gas Maximum concentration (mg/m

SO

2

H2S 0.006

NH3 0.05

Cl2 0.01

0.2

3

)

All electromagnetic interference (EMI) sources, from outside or inside of the switch and application

system, adversely affect the switch in a conduction pattern of capacitance coupling, inductance coupling,

electromagnetic wave radiation, or common impedance (including the grounding system) coupling. To

prevent EMI, take the following actions:

• If AC power is used, use a single-phase three-wire power receptacle with protection earth (PE) to

filter interference from the power grid.

• Keep the switch far away from radio transmitting stations, radar stations, and high-frequency

devices.

• Use electromagnetic shielding, for example, shielded interface cables, when necessary.

• Route interface cables only indoors to prevent signal ports from getting damaged by overvoltage or

overcurrent caused by lightning strikes.

2

Page 10

W

g

Installing the switch

The HP 1910 switch can be installed in a 19-inch rack or on a workbench.

ARNING!

Before installing or moving the switch, remove the power cord.

Mounting the switch in a 19-inch rack with mounting brackets

To install the switch with mounting brackets:

1. Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is well

grounded.

2. Ensure the rack is securely grounded and stands stably.

3. Fix the mounting brackets on the sides of the front panel with screws.

NOTE:

The mounting brackets are used only for fixing the switch instead of bearing the switch wei

on the rack is used to bear the switch weight.

Figure 11 Installing the mounting brackets to the HP 1910-8 switch

Figure 12 Installing the mounting brackets to the HP 1910-8-PoE+ switch

ht. A holder

1

Page 11

Figure 13 Installing the mounting brackets to the HP 1910-24-PoE+/1910-24/1910-48 switch

4. Place the switch on a holder in the rack, and push the switch in along the guide rails until the oval

holes in the brackets aligns with the mounting holes in the rack posts.

5. Fix the mounting brackets to the rack posts with screws.

Figure 14 Mounting the HP 1910-8 switch in the rack

2

Page 12

Figure 15 Mounting the HP 1910-8-PoE+ switch in the rack

Figure 16 Mounting the HP 1910-24-PoE+/1910-24/1910-48 switch in the rack

Mounting the switch on a workbench

3

Page 13

IMPORTANT:

• Ensure good ventilation and 10 cm (3.9 in) of clearance around the chassis for heat dissipation.

• Avoid placing heavy objects on the switch.

To mount the switch on a workbench:

1. Check that the workbench is sturdy and well grounded.

2. Place the switch with bottom up, and clean the round holes in the chassis bottom with dry cloth.

3. Attach the rubber feet to the four round holes in the chassis bottom.

4. Place the switch with upside up on the workbench.

Figure 17 Attaching rubber feet (1910-24-PoE+)

Connecting cables

Connecting network cable

Use crossover cable or straight through cable to connect a PC or other network devices to the Ethernet

port of the switch.

Figure 18 Connecting network cable

Installing SFP transceiver module and connecting optical fiber

4

Page 14

W

NOTE:

CAUTION:

• Hold the SFP transceiver module by its two sides when you install or remove the module. Do not touch

the golden finger of the module.

• Remove the optical fiber, if any, from a transceiver module before installing it.

To install an SFP transceiver module and connect the optical fiber:

1. Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is well

grounded.

2. Pivot the clasp of the module up. Holding the module, gently push the module into the slot until it

has firm contact with the slot (when the top and bottom spring tabs catch in the slot).

3. Remove the protection covers from the optical fiber and the transceiver module, and connect the LC

connector of the optical fiber to the transceiver module.

Keep the protection covers for future use.

Figure 19 Installing SFP transceiver module and connecting optical fiber

Connecting the console cable

ARNING!

Do not connect or remove the console cable to or from the PC if the switch has been powered on.

To connect a terminal, for example, a PC, to the switch:

1. Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is well

grounded.

2. Plug the DB-9 female connector of the console cable to the serial port of the PC.

3. Connect the RJ-45 connector to the console port of the switch.

Figure 20 Connecting the console cable

5

Page 15

NOTE:

To disconnect the console cable, plug out the RJ-45 connector of the cable and then the DB-9 female

connector.

Connecting the AC power cord

To connect the AC power cord:

1. Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is well

grounded.

2. Make sure the correct power source is used.

3. Connect one end of the AC power cord to the AC-input power receptacle on the switch.

Figure 21

4. Connect the other end of the AC power cord to the AC power outlet.

5. Check the Power LED. If it is ON, it means the power connection is correct.

Figure 21 Connecting the AC power cord

shows the power cord connection on the switch.

6

Page 16

Verifying the installation

After you complete the installation, verify that:

• There is enough space for heat dissipation around the switch, and the rack or workbench is stable.

• The grounding cable is securely connected.

• The correct power source is used.

• The power cords are properly connected.

• All the interface cables are cabled indoors. If any cable is routed outdoors, verify that the socket

strip with lightning protection and lightning arresters for network ports have been properly

connected.

7

Page 17

Accessing the switch for the first time

Setting up the configuration environment

The first time you access the switch you must use a console cable to connect a console terminal, for

example, a PC, to the console port on the switch.

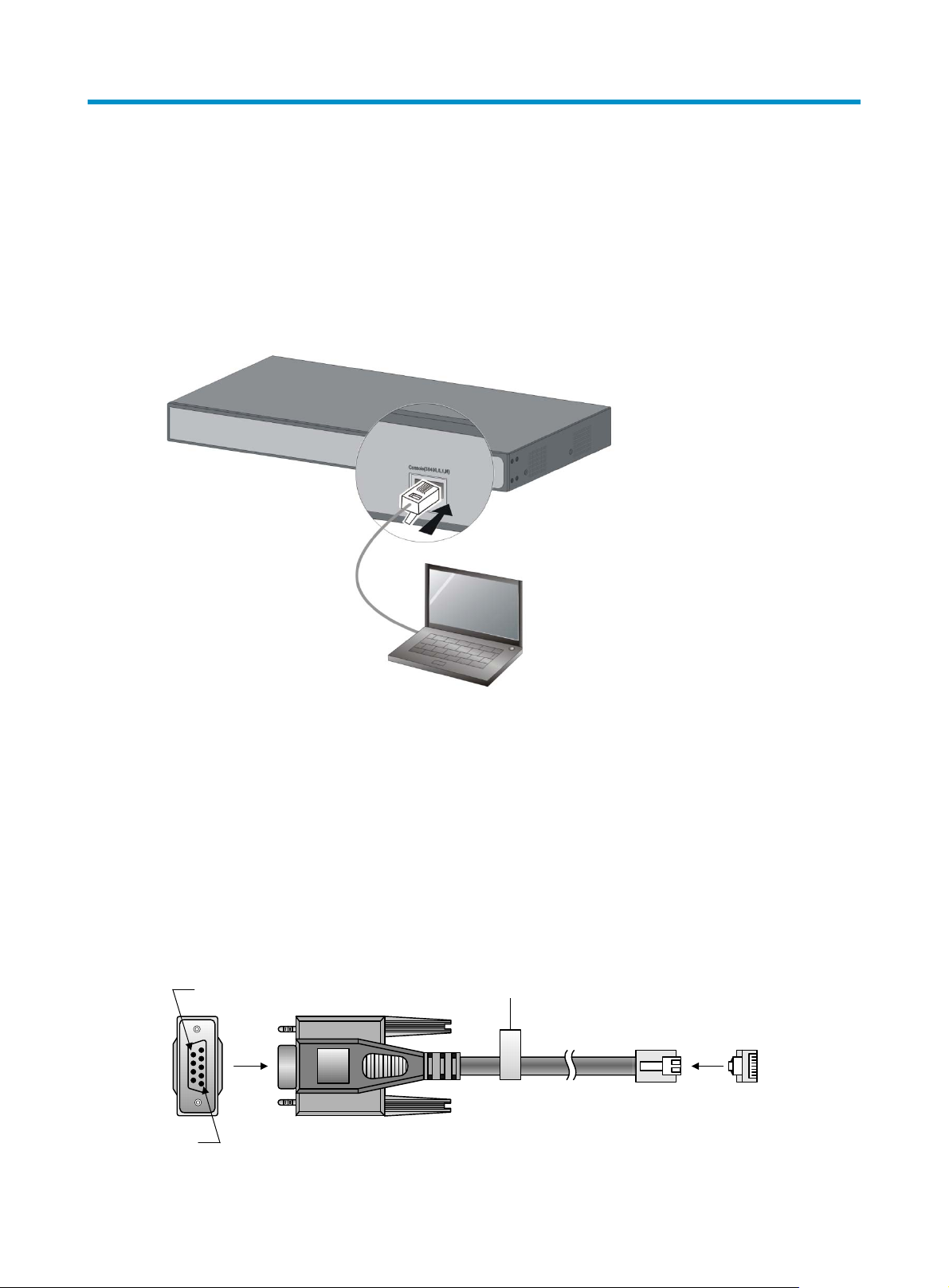

Figure 22 Connect the console port to a terminal

Connecting the console cable

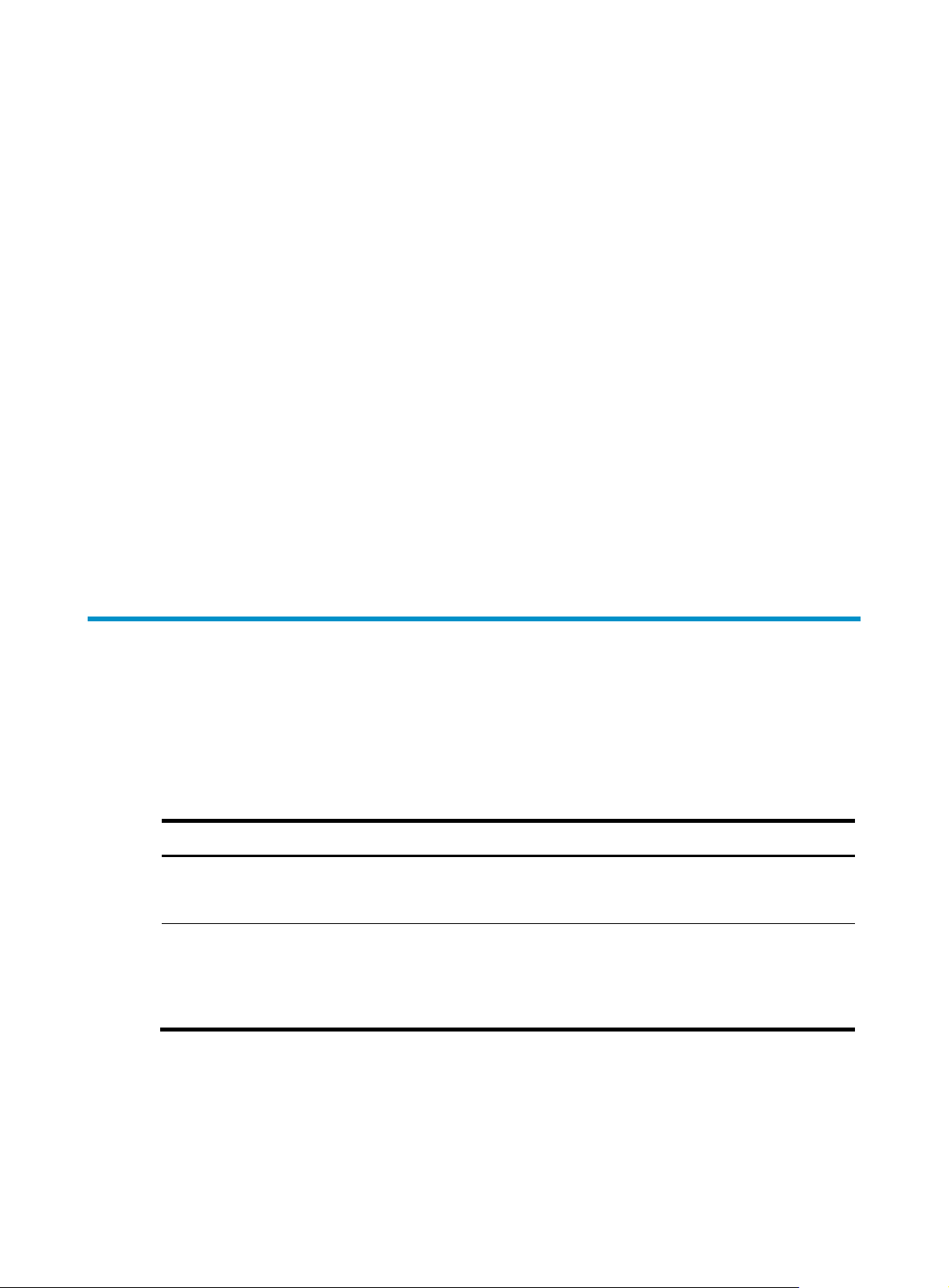

Console cable

A console cable is an 8-core shielded cable, with a crimped RJ-45 connector at one end for connecting

to the console port of the switch, and a DB-9 female connector at the other end for connecting to the

serial port on the console terminal.

Figure 23 Console cable

A side

Pos.9

A

Pos.1

Main label

8

1

B side

B

1

Page 18

Connection procedure

To connect a terminal, for example, a PC, to the switch:

1. Plug the DB-9 female connector of the console cable to the serial port of the PC.

2. Connect the RJ-45 connector to the console port of the switch.

NOTE:

• Identify the mark on the console port and make sure that you are connecting to the correct port.

• The serial ports on PCs do not support hot swapping. If the switch has been powered on, connect the

console cable to the PC before connecting to the switch, and when you disconnect the cable, first

disconnect from the switch.

Setting terminal parameters

To configure and manage the switch, you must run a terminal emulator program on the console terminal.

The following are the required terminal settings:

• Bits per second—38,400

• Data bits—8

• Parity—None

• Stop bits—1

• Flow control—None

• Emulation—VT100

To set terminal parameters, for example, on a Windows XP HyperTerminal:

1. Select Start > All Programs > Accessories > Communications > HyperTerminal.

The Connection Description dialog box appears.

2. Enter the name of the new connection in the Name field and click OK.

Figure 24 Connection description

2

Page 19

Select the serial port to be used from the Connect using list, and click OK.

3.

Figure 25 Set the serial port used by the HyperTerminal connection

4. Set Bits per second to 38400, Data bits to 8, Parity to None, Stop bits to 1, and Flow control to

None, and click OK.

Figure 26 Set the serial port parameters

5. Select File > Properties in the HyperTerminal window.

3

Page 20

Figure 27 HyperTerminal window

6. On the Settings tab, set the emulation to VT100 and click OK.

Figure 28 Set terminal emulation in Switch Properties dialog box

4

Page 21

Powering on the switch

Verification before power-on

Before powering on the switch, verify that:

• The power cord is properly connected.

• The input power voltage meets the requirement of the switch.

• The console cable is properly connected, the terminal or PC used for configuration has started, and

the configuration parameters have been correctly set.

Powering on the switch

Power on the switch, for example, an 1910-24-PoE+ switch, and you can see the following information:

Starting......

****************************************************************************

* *

* HP 1910-24-PoE+ Switch JG5389 BootWare, Version 1.02 *

* *

****************************************************************************

Copyright (c) 2010-2013 Hewlett-Packard Development Company, L.P.

Compiled Date : Mar 20 2013 17:00:53

CPU Type : MIPS4kec

CPU L1 Cache : 16KB

CPU Clock Speed : 500MHz

Memory Type : DDR3 SDRAM

Memory Size : 128MB

Memory Speed : 300MHz

BootWare Size : 3MB

Flash Size : 32MB

BootWare Validating...

Press Ctrl+B to enter extended boot menu...

Starting to get the main application file--flash:/hp1910_24_poe.bin!........

..............

The main application file is self-decompressing.............................

............................................................................

............................................................................

............................................................................

............................................................................

............................................................................

............................................................................

............................................................................

............................................................................

............................................................................

5

Page 22

............................................................................

............................................................................

............................................................................

............................................................................

............................................................................

............................................................................

............................................................................

............................................................................

............................................................................

........................................................Done!

System application is starting...

User interface aux0 is available.

Press ENTER to get started.

Press Enter and the system displays the following prompt:

<Hp>

This prompt indicates that the switch is ready to configure.

Appendix A Troubleshooting

This chapter lists some issues that you may encounter while using and managing the switch, with

corrective action to take.

If you encounter an issue that is not listed here and you cannot solve it, please contact your local

technical support representative.

Table 4 Troubleshooting

Symptom Troubleshooting method

1. Verify that the correct power source is used and the power cords are

Power LED off

LAN interface LED off

properly connected.

2. Verify that the power source side provides power supply normally.

1. Verify that the network cable is properly connected to the network

port of the switch.

2. Plug the two ends of a network cable into two network ports of the

switch. If the port LEDs are on, it indicates that the network cable is

well. Otherwise, please replace the network cable.

6

Page 23

Symptom Troubleshooting method

1. Use the ping command to check the network connectivity:

a. Ping 127.0.0.1 to verify that TCP/IP has been installed.

b. Ping the management IP address of the switch to verify that the

management PC is connected to the switch. If not, perform the

following check:

{ For local configuration, verify that the IP addresses of the

management PC and the switch are in the same subnet.

Unable to log on to the Web

interface of the HP 1910 switch

{ For remote configuration, verify that the route from the

management PC to the switch is reachable.

2. Check the LED status to verify that the cables are connected

properly.

3. Verify that the switch's port that connects to the management PC is

enabled and belongs to the management VLAN.

4. Verify that the Web browser is not configured with proxy or dial-up

connection.

5. Disable and then enable the local network after you complete local

network settings.

7

Page 24

Appendix B Technical specifications

Table 5 Technical specifications

Item 1910-8 1910-24 1910-48 1910-8-PoE+ 1910-24-PoE+

44 × 266 ×

Dimensions (H

× W × D)

Weight ≤ 1 kg (2.20 lb)

Management

port

Ethernet port

Input AC

voltage

Power

consumption

(full

configuration)

162 mm (1.73

× 10.47 × 6.38

in)

One console port

Eight

10/100-Mbps

auto-sensing

Ethernet ports

and two GE

combo

interfaces

Rated voltage range: 100 VAC to 240 VAC @ 50 Hz or 60Hz

8 W 12 W 22 W

44 × 440 ×

173 mm (1.73

× 17.32 × 6.81

in)

≤ 2.2 kg (4.85

lb)

24 ×

10/100-Mbps

auto-sensing

Ethernet ports

and two GE

combo

interfaces

44 × 440 ×

173 mm (1.73

× 17.32 × 6.81

in)

≤ 2.3 kg (5.07

lb)

48 ×

10/100-Mbps

auto-sensing

Ethernet ports,

two

10/100/1000Mbps

auto-sensing

Ethernet ports,

and two GE

fiber ports

44 × 330 ×

230 mm (1.73

× 12.99 × 9.06

in)

≤ 2.1 kg (4.63

lb)

Eight

10/100-Mbps

auto-sensing

Ethernet ports

and two GE

combo

interfaces

A single PoE

port provides

power

consumption up

to 30 W and the

switch provides

up to 65 W for

PoE

port-connected

devices in total.

The overall

power

consumption of

the switch is 90

W.

44 × 440 ×

238 mm (1.73

× 17.32 × 9.37

in)

≤ 3.3 kg (7.28

lb)

24 ×

10/100-Mbps

auto-sensing

Ethernet ports

and two GE

combo

interfaces

A single PoE

port provides

power

consumption up

to 30 W and the

switch provides

up to 180 W for

PoE

port-connected

devices in total.

The overall

power

consumption of

the switch is

220 W.

Operating

temperature

Relative

humidity

Cooling

system

0°C to 40°C (32°F to 104°F)

5% to 95%, noncondensing

No fans for heat ventilation

Two fans for

heat ventilation

1

Page 25

Appendix C LED description

Power LED

The power LED shows the operation status of the switch.

Table 6 Power LED description

LED mark Status Description

Steady green The switch is operating properly.

Power

Flashing green The system is performing power-on self test (POST).

Off The switch has been powered off or the power supply failed.

Ethernet copper port LEDs

Table 7 Ethernet copper port LED description

LED mark Status Description

Steady green The port is operating at 10/100 Mbps.

10/100BAS

E-T port

Link/Ac

t

10/100/10

00BASE-T

port

Flashing green The port is sending or receiving data at 10/100 Mbps.

Off No link is present on the port.

Steady green The port is operating at 1000 Mbps.

Flashing green The port is sending or receiving data at 1000 Mbps.

Steady yellow The port is operating at 10/100 Mbps.

Flashing yellow The port is sending or receiving data at 10/100 Mbps.

Off No link is present on the port.

SFP transceiver module link LED

Table 8 SFP transceiver module LED description

LED mark Status Description

Steady yellow The port is operating at 100 Mbps.

Flashing yellow The port is sending or receiving data at 100 Mbps.

SFP transceiver module

link LED

Steady green The port is operating at 1000 Mbps.

Flashing green The port is sending or receiving data at 1000 Mbps.

Off No link is present on the port.

1

Page 26

SFP transceiver module active LED

Table 9 SFP transceiver module active LED

LED mark Status Description

Module

Active

PoE LED

Only the HP 1910-8-PoE+ and HP 1910-24-PoE+ switches support PoE.

Table 10 PoE LED

LED mark Status Description

PoE Power

SFP port

Steady green The SFP transceiver module is in the slot and recognized.

Off The SFP transceiver module is not in the slot or not recognized.

Steady green PoE power supply is normal.

Flashing green PoE power supply is abnormal.

Off The port is not supplying power.

2

Loading...

Loading...