Page 1

About this Manual

We’ve added this manual to the Agilent website in an effort to help you support

your product. This manual is the best copy we could find; it may be incomplete

or contain dated information. If we find a more recent copy in the future, we will

add it to the Agilent website.

Support for Your Product

Agilent no longer sells or supports this product. Our service centers may be able

to perform calibration if no repair parts are needed, but no other support from

Agilent is available. You will find any other available product information on the

Agilent Test & Measurement website, www.tm.agilent.com.

HP References in this Manual

This manual may contain references to HP or Hewlett-Packard. Please note that

Hewlett-Packard's former test and measurement, semiconductor products and

chemical analysis businesses are now part of Agilent Technologies. We have

made no changes to this manual copy. In other documentation, to reduce

potential confusion, the only change to product numbers and names has been in

the company name prefix: where a product number/name was HP XXXX the

current name/number is now Agilent XXXX. For example, model number

HP8648A is now model number Agilent 8648A.

Page 2

User’s Guide

Publication Number 01660-97017

First Edition, November 1995

For Safety Information, Warranties, and Regulatory Information, see the

pages at the end of this manual.

Copyright Hewlett-Packard Company 1991 - 1995

All Rights Reserved.

HP 1660CS-Series

Logic Analyzers

Page 3

HP 1660CS-Series Logic Analyzers

The HP 1660CS-series logic analyzers are 100-MHz state/500-MHz

timing logic analyzers and 1 GSa/s digitizing oscilloscopes.

Logic Analyzer Features

• 130 data channels and 6 clock/data channels in the HP 1660CS

• 96 data channels and 6 clock/data channels in the HP 1661CS

• 64 data channels and 4 clock/data channels in the HP 1662CS

• 32 data channels and 2 clock/data channels in the HP 1663CS

• 3.5-inch flexible disk drive and 540 MB hard disk drive

• HP-IB, RS-232-C, and Centronics interfaces

• Variable setup/hold time

• 4 K memory on all channels with 8 K in half-channel mode

• Marker measurements

• 12 levels of trigger sequencing for state and 10 levels of trigger

sequencing for timing

• 100 MHz time tagging and number-of-states tagging

• Full programmability

• DIN mouse and keyboard support

Oscilloscope Features

• 8000 samples per channel

• Automatic pulse parameters

displays time between markers, acquires until specified time

between markers is captured, performs statistical analysis on

time between markers

• Lightweight miniprobes

Options include Ethernet LAN Interface, Programmer’s Guide, and

Service Guide

ii

Page 4

In This Book

The Logic An alyzer at a Glance

1

This User’s Guide shows you how to

use the HP 1660CS-series logic

analyzer. It contains measurement

examples, field and feature

definitions, and a basic service guide.

Refer to this manual for information

on what the menu fields do and how

they are used. This manual covers all

HP 1660CS-series analyzers.

The User’s Guide is divided into four

parts. The first part, chapters 1

through 4, covers general product

information you need to use the logic

analyzer. The second part, chapters

5 and 6, contains detailed examples

to help you use your analyzer in

performing complex measurements.

The third part, chapters 7 through 9,

contains reference information on the

hardware and software, including the

analyzer menus and how they are

used. There are sections for each

analyzer menu and a separate

chapter on System Performance

Analysis. The fourth part, chapters 10

through 12, provides a basic service

guide.

2

3

4

5

6

7

8

9

10

11

12

Connecting Peripherals

Using the Logic Analyzer

Using the Trigger Menu

Triggering Examples

File Management

Reference

System Performance Analysis

(SPA) Software

Concepts

Troubleshooting

Specifications

Operator’s Service

Glossary

Index

iii

Page 5

Introduction

iv

Page 6

Contents

1 Logic Analyzer Overview

To make a measurement 1–4

2 Connecting Peripherals

To connect a mouse 2–3

To connect a keyboard 2–4

To connect to an HP-IB printer 2–5

To connect to an RS-232-C printer 2–7

To connect to a parallel printer 2–8

To connect to a controller 2–9

3 Using the Logic Analyzer

Accessing the Menus 3–3

To access the System menus 3–4

To access the Analyzer menus 3–6

To access the Scope menus 3–8

Using the Analyzer Menus 3–10

To label channel groups 3–10

To create a symbol 3–12

To examine an analyzer waveform 3–14

To examine an analyzer listing 3–16

To compare two listings 3–18

The Inverse Assembler 3–20

To use an inverse assembler 3–20

v

Page 7

Contents

4 Using the Trigger Menu

Specifying a Basic Trigger 4–3

To assign terms to an analyzer 4–4

To define a term 4–5

To change the trigger specification 4–6

Changing the Trigger Sequence 4–7

To add sequence levels 4–8

To change macros 4–9

Setting Up Time Correlation between Analyzers 4–10

To set up time correlation between two state analyzers 4–11

To set up time correlation between a timing and a state analyzer 4–11

Arming and Additional Instruments 4–12

To arm another instrument 4–12

To arm the oscilloscope with the analyzer 4–13

To receive an arm signal from another instrument 4–15

Managing Memory 4–16

To selectively store branch conditions (State only) 4–17

To place the trigger in memory 4–18

To set the sampling rates (Timing only) 4–19

vi

Page 8

5 Triggering Examples

Single-Machine Trigger Examples 5–3

To store and time the execution of a subroutine 5–4

To trigger on the nth iteration of a loop 5–6

To trigger on the nth recursive call of a recursive function 5–8

To trigger on entry to a function 5–10

To capture a write of known bad data to a particular variable 5–11

To trigger on a loop that occasionally runs too long 5–12

To verify correct return from a function call 5–13

To trigger after all status bus lines finish transitioning 5–14

To find the nth assertion of a chip select line 5–15

To verify that the chip select line is strobed after the address is stable 5–16

To trigger when expected data does not appear when requested 5–17

To test minimum and maximum pulse limits 5–18

To detect a handshake violation 5–20

To detect bus contention 5–21

Contents

Cross-Arming Trigger Examples 5–22

To examine software execution when a timing violation occurs 5–23

To look at control and status signals during execution of a routine 5–24

To detect a glitch 5–25

To capture the waveform of a glitch 5–26

To view your target system processing an interrupt 5–27

To trigger timing analysis of a count-down on a set of data lines 5–28

To monitor two coprocessors in a target system 5–29

Special displays 5–30

To interleave trace lists 5–31

To view trace lists and waveforms on the same display 5–32

vii

Page 9

Contents

6 File Management

Transferring Files Using the Flexible Disk Drive 6–3

To save a configuration 6–4

To load a configuration 6–6

To save a listing in ASCII format 6–7

To save a screen’s image 6–8

To load additional software 6–9

7 Reference

Configuration Capabilities 7–3

Probing 7–5

General-purpose probing system description 7–8

Oscilloscope probes 7–11

Assembling the probing system 7–12

Keyboard Shortcuts 7–16

Moving the cursor 7–16

Entering data into a menu 7–17

Using the keyboard overlays 7–17

Common Menu Fields 7–18

Print field 7–19

Run/Stop field 7–20

Roll fields 7–21

Disk Drive Operations 7–22

Disk operations 7–22

Autoload 7–24

Format 7–24

Pack 7–24

Load and Store 7–25

viii

Page 10

The RS-232-C, HP-IB, and Centronics Interfaces 7–26

The HP-IB interface 7–27

The RS-232-C interface 7–27

The Centronics interface 7–28

System Utilities 7–29

Real Time Clock Adjustments field 7–29

Update FLASH ROM field 7–29

Shade adjustments 7–30

The Analyzer Configuration Menu 7–31

Type field 7–31

Illegal configuration 7–31

Contents

The Analyzer Format Menu 7–32

Pod threshold field 7–32

State. acquisition modes (state only) 7–32

Timing acquisition modes (timing only) 7–33

Clock Inputs display 7–34

Pod clock field (State only) 7–34

Master and Slave Clock fields (State only) 7–37

Symbols field 7–40

Label fields 7–41

Label polarity fields 7–42

The Analyzer Trigger Menu 7–43

Trigger sequence levels 7–43

Modify trigger field 7–43

Timing trigger macro library 7–44

State trigger macro library 7–46

Modifying the user macro 7–48

Resource terms 7–51

Arming Control field 7–54

Acquisition Control field 7–56

Count field (State only) 7–57

ix

Page 11

Contents

The Analyzer Listing Menu 7–58

Markers 7–58

The Analyzer Waveform Menu 7–60

sec/Div field 7–60

Accumulate field 7–60

Delay field 7–60

Waveform label field 7–61

Waveform display 7–62

The Analyzer Mixed Display Menu 7–63

Interleaving state listings 7–63

Time-correlated displays 7–64

Markers 7–64

The Analyzer Chart Menu 7–65

Min and Max scaling fields 7–66

Markers/Range field 7–66

The Analyzer Compare Menu 7–67

Reference Listing field 7–68

Difference Listing field 7–68

Copy Listing to Reference field 7–69

Find Error field 7–69

Compare Full/Compare Partial field 7–69

Mask field 7–70

Bit Editing field 7–70

Oscilloscope Common Menus 7–71

Run/Stop options 7–71

Autoscale 7–72

Time base 7–73

x

Page 12

The Scope Channel Menu 7–74

Offset field 7–74

Probe field 7–75

Coupling field 7–75

Preset field 7–75

The Scope Display Menu 7–76

Mode field 7–76

Connect Dots field 7–77

Grid field 7–77

Display Options field 7–78

The Scope Trigger Menu 7–79

Trigger marker 7–79

Mode/Arm menu 7–79

Level field 7–81

Source field 7–82

Slope field 7–83

Count field 7–83

Auto-Trig field 7–84

When field 7–85

Count field 7–87

Contents

The Scope Marker Menu 7–88

Manual time markers options 7–88

Automatic time markers options 7–90

Manual/Automatic Time Markers option 7–94

Voltage Markers options 7–94

Channel Label field 7–96

The Scope Auto Measure Menu 7–97

Input field 7–97

Automatic measurements display 7–97

Automatic measurement algorithms 7–99

xi

Page 13

Contents

8 System Performance Analysis (SPA) Software

System Performance Analysis Software 8–2

What is System Performance Analysis? 8–4

Getting started 8–6

SPA measurement processes 8–8

Using State Overview, State Histogram, and Time Interval 8–21

Using SPA with other features 8–30

9 Concepts

The File System 9–3

Directories 9–4

File types 9–5

Transitional Mode Theory 9–7

125-MHz transitional mode 9–7

250-MHz transitional mode 9–8

Other transitional timing considerations 9–11

The Trigger Sequence 9–12

Trigger sequence specification 9–13

Analyzer resources 9–15

Timing analyzer 9–18

State analyzer 9–18

Configuration Translation Between HP Logic Analyzers 9–19

The Analyzer Hardware 9–21

HP 1660CS-series analyzer theory 9–22

Logic acquisition board theory 9–25

Oscilloscope board theory 9–28

Self-tests description 9–32

xii

Page 14

10 Troubleshooting

Analyzer Problems 10–3

Intermittent data errors 10–3

Unwanted triggers 10–3

No activity on activity indicators 10–4

Capacitive loading 10–4

No trace list display 10–4

Preprocessor Problems 10–5

Target system will not boot up 10–5

Slow clock 10–6

Erratic trace measurements 10–7

Contents

Inverse Assembler Problems 10–8

No inverse assembly or incorrect inverse assembly 10–8

Inverse assembler will not load or run 10–9

Error Messages 10–10

". . . Inverse Assembler Not Found" 10–10

"No Configuration File Loaded" 10–10

"Selected File is Incompatible" 10–10

"Slow or Missing Clock" 10–11

"Waiting for Trigger" 10–11

"Must have at least 1 edge specified" 10–12

"Time correlation of data is not possible" 10–12

"Maximum of 32 channels per label" 10–12

"Timer is off in sequence level n where it is used" 10–13

"Timer is specified in sequence, but never started" 10–13

"Inverse assembler not loaded - bad object code." 10–13

"Measurement Initialization Error" 10–14

"Warning: Run HALTED due to variable change" 10–14

xiii

Page 15

Contents

11 Specifications

Accessories 11–2

Specifications (logic analyzer) 11–3

Specifications (oscilloscope) 11–4

Characteristics (logic analyzer) 11–5

Characteristics (oscilloscope) 11–5

Supplemental characteristics (logic analyzer) 11–6

Supplemental characteristics (oscilloscope) 11–9

Operating environment 11–13

12 Operator’s Service

Preparing For Use 12–3

To inspect the logic analyzer 12–4

To apply power 12–4

To set the line voltage 12–5

To degauss the display 12–6

To clean the logic analyzer 12–6

To test the logic analyzer 12–6

Calibrating the oscilloscope 12–7

Set up the equipment 12–7

Load the default calibration factors 12–8

Self Cal menu calibrations 12–9

Troubleshooting 12–11

To use the flowcharts 12–12

To check the power-up tests 12–14

To run the self-tests 12–15

To test the auxiliary power 12–22

xiv

Page 16

1

Logic Analyzer Overview

Page 17

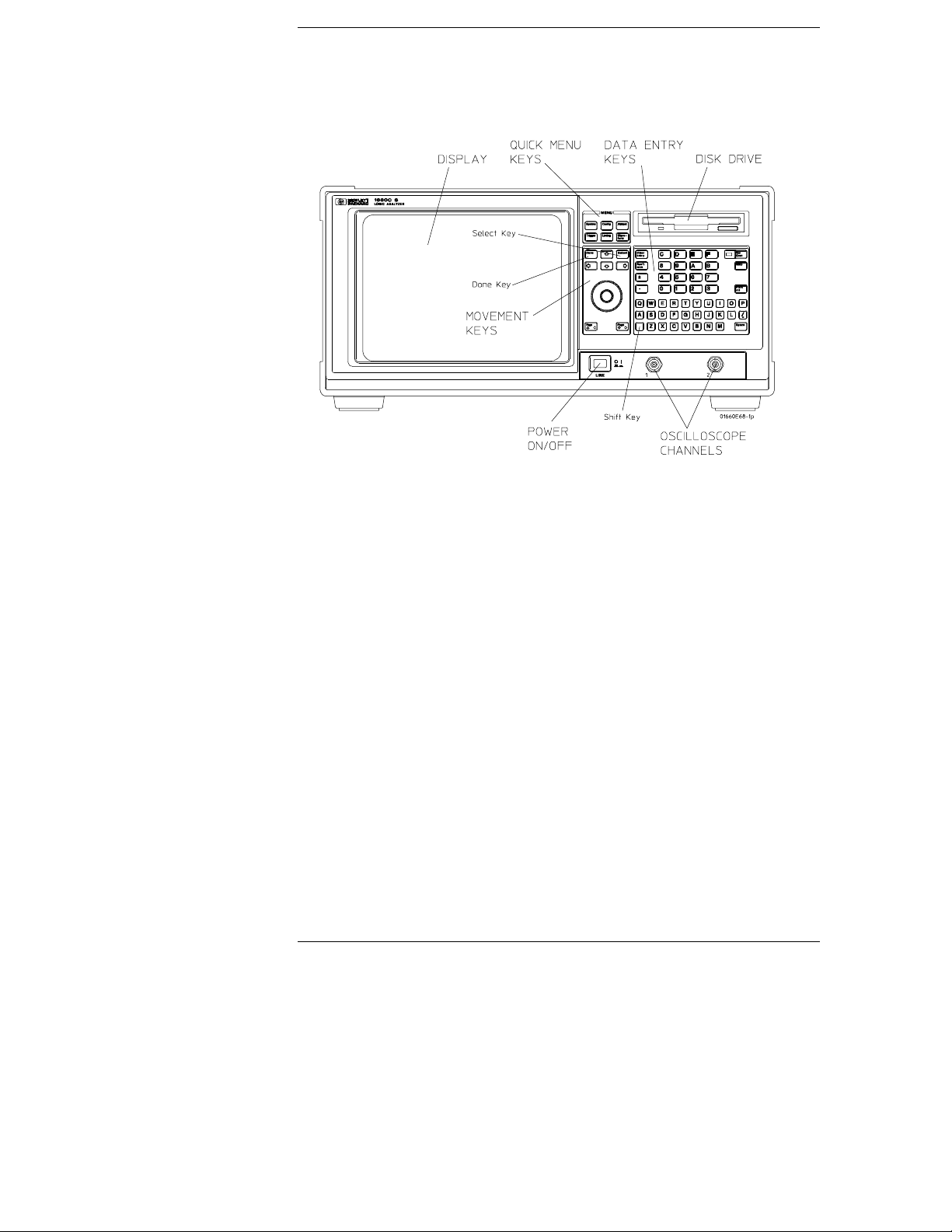

HP 1660CS-Series Logic Analyzer

Select Key

The Select key action depends on the type of field currently highlighted. If

the field is an option field, the Select key brings up an option menu or, if

there are only two possible values, toggles the value in the field. If the

highlighted field performs a function, the Select key starts the function.

Done Key

The Done key saves assignments and closes pop-up menus. In some fields, its

action is the same as the Select key.

Shift Key

The shift key, which is blue, provides lowercase letters and access to the

functions in blue on some of the keys. You do not need to hold the shift key

down while pressing the other key — just press the shift key first, and then

the function key.

Knob

The knob can be used in some fields to change values. These fields are

indicated by a side view of the knob placed on top of the field when it is

selected. The knob also scrolls the display and moves the cursor within lists.

If you are using a mouse, you can do the same actions by holding down the

right button of the mouse while dragging.

1-2

Page 18

Logic Analyzer Overview

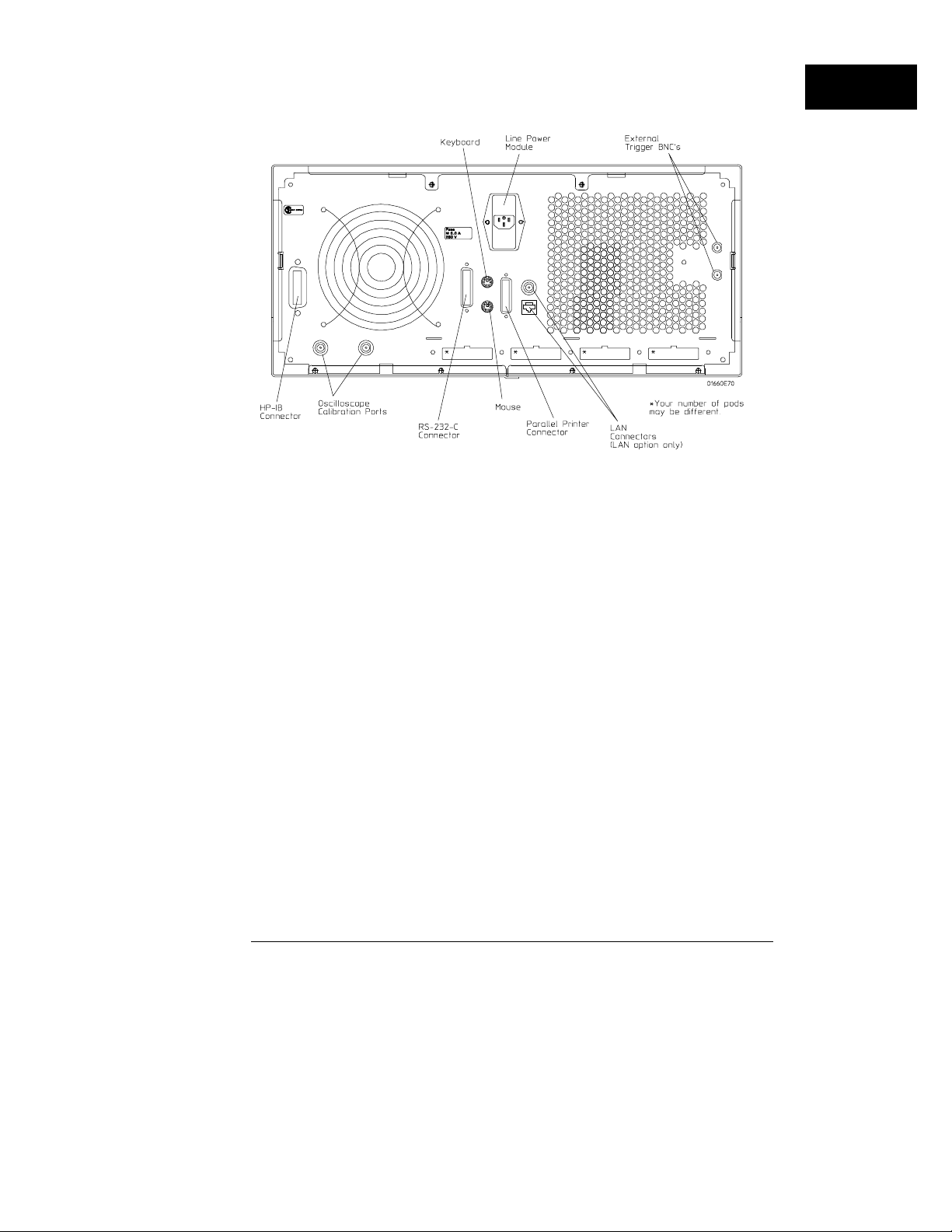

Line Power Module

Permits selection of 110-120 or 220-240 Vac and contains the fuses for each

of these voltage ranges.

External Trigger BNCs

The External Trigger BNCs provide the "Port In" and "Port Out" connections

for the Arm In and Arm Out of the Trigger Arming Control menu.

RS-232-C, HP-IB, and Parallel Printer Connectors

The RS-232-C connector is a standard DB-25 connector for RS-232-C printer

or controller. The HP-IB connector is a standard HP-IB connector for

connecting an HP-IB printer or controller. The Parallel Printer connector is a

standard Centronics connector for connecting a parallel printer.

Oscilloscope Calibration Ports

Provides signals for operational accuracy calibration for the oscilloscope and

the oscilloscope/probe together to optimize performance.

LAN Connectors (with LAN option only)

Connects the logic analyzer to your local Ethernet network. The BNC

connector on top accepts 10Base2 ("thinlan"). The UTP connector below the

BNC connector accepts 10Base-T ("ethertwist").

1-3

Page 19

Logic Analyzer Overview

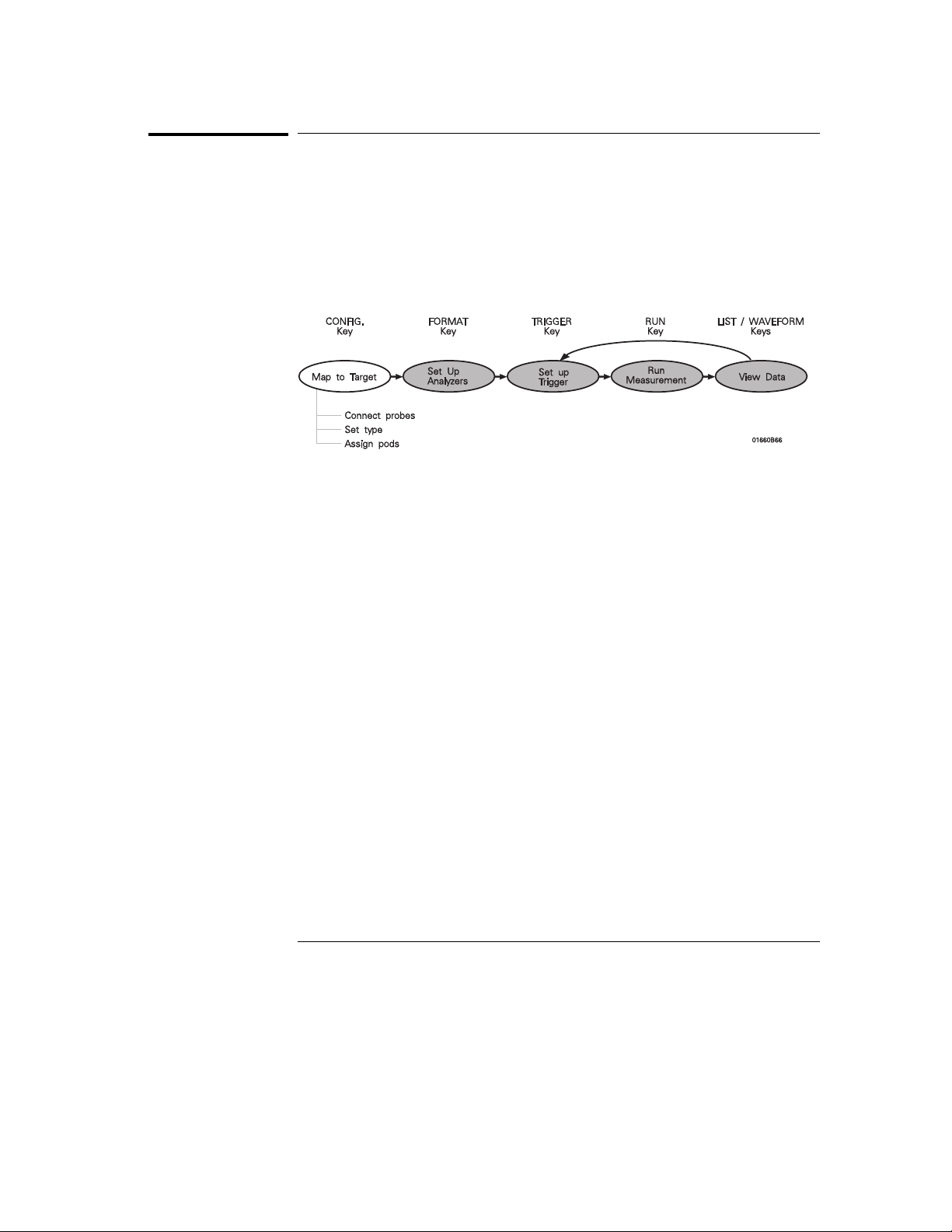

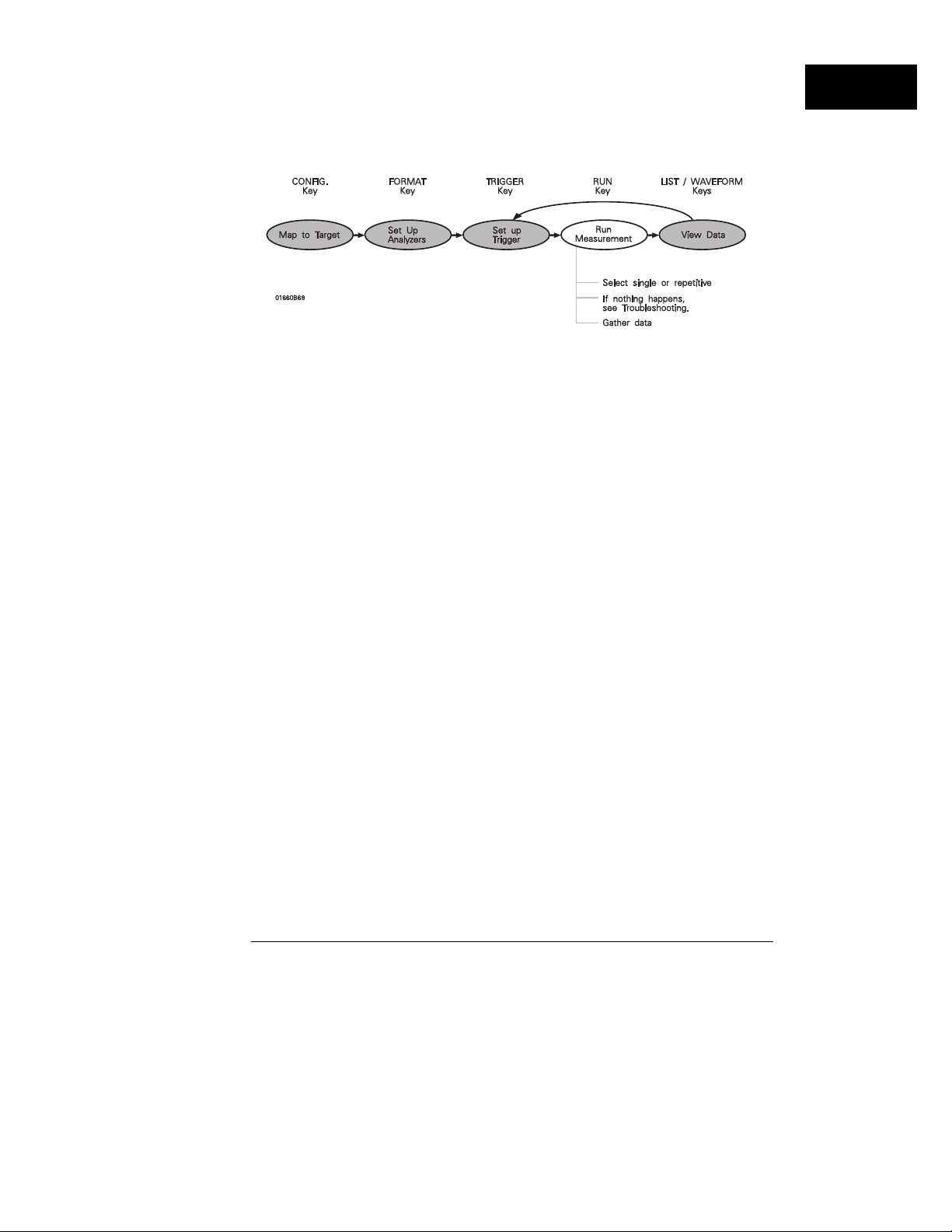

To make a measurement

To make a measurement

For more detail on any of the information below, see the referenced chapters

or the Logic Analyzer Training Kit. If you are using a preprocessor with the

logic analyzer, some of these steps may not apply.

Map to target

Connect probes Connect probes from the target system to the logic

analyzer to physically map the target system to the channels in the logic

analyzer. Attach probes to a pod in a way that keeps logically-related

channels together. Remember to ground the pod.

See Also "Probing" in Chapter 7 for more detail on grounding and constructing probes.

Set type* When the logic analyzer is turned on, Analyzer 1 is named

Machine 1 and is configured as a timing analyzer, and Analyzer 2 is off.

To use state analysis or software profiling, you must set the type of the

analyzer in the Analyzer Configuration menu. You can only use one

timing analyzer at a time.

Assign pods* In the Analyzer Configuration menu, assign the

connected pods to the analyzer you want to use. The number of pods on

your logic analyzer depends on the model. Pods are paired and always

assigned as a pair to a particular analyzer.

* If you load a configuration file, this step is not necessary.

1-4

Page 20

Logic Analyzer Overview

To make a meas urement

Set up analyzers*

Set modes and clocks Set the state and timing analyzers using the

Analyzer Format menu. In general, these modes trade channel count for

speed or storage. The state analyzer also provides for complicated

clocking. If your state clock is set incorrectly, the data gathered by the

logic analyzer might indicate an error where none exists.

See Also "The Format Menu" in Chapter 7 for more information on modes and clocks.

Group bits under labels The Analyzer Format menu indicates active

pod bits. You can create groups of bits across pods or subgroups within

pods and name the groups or subgroups using labels.

* If you load a configuration file, this step is not necessary.

1-5

Page 21

Logic Analyzer Overview

To make a measurement

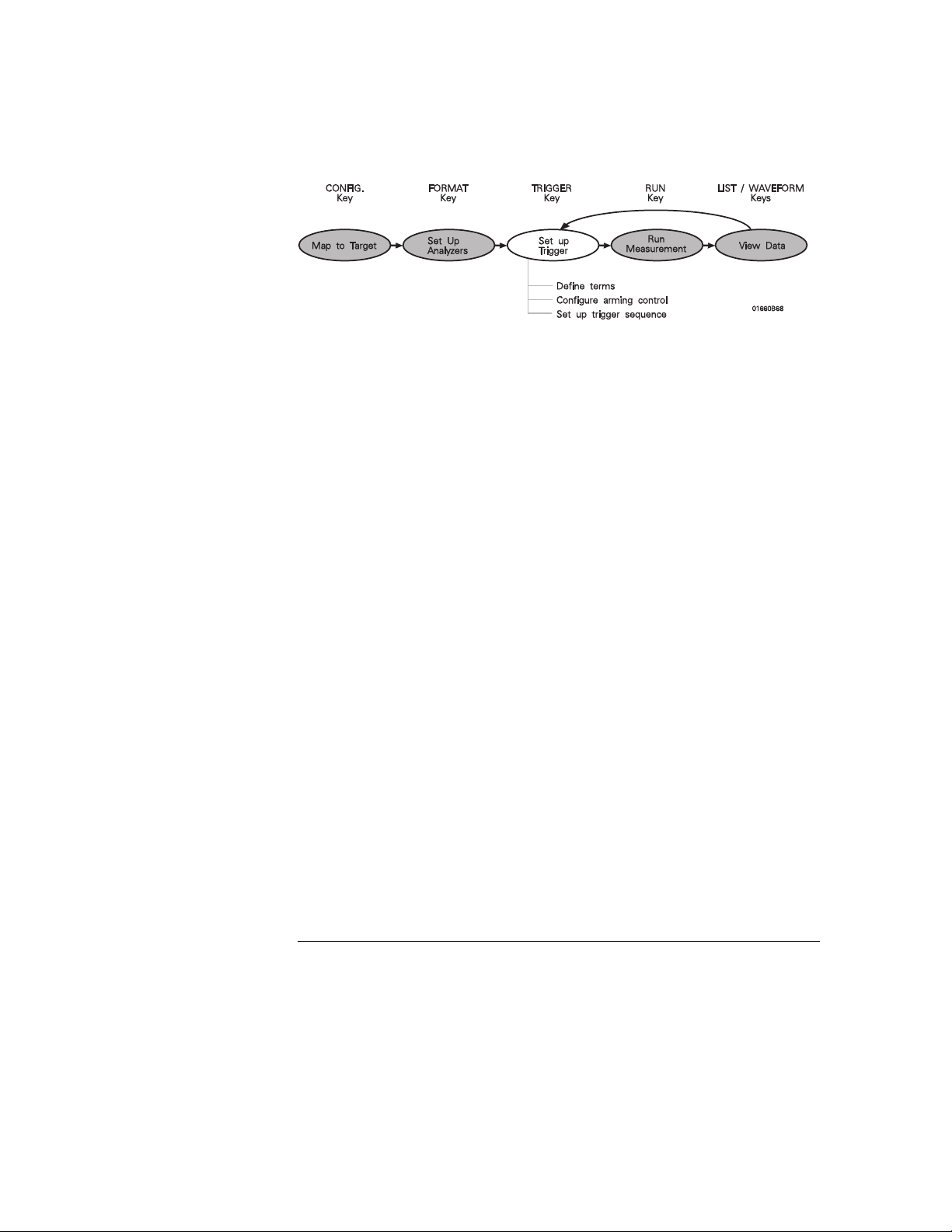

Set up trigger*

Define terms In the Analyzer Trigger menu, define trigger variables

called terms to match specific conditions in your target system. Terms

can match patterns, ranges, or edges across multiple labels.

Configure Arming Control Use Arming Control if

you want to correlate the triggers and data of both analyzers

•

you want to use the logic analyzer to trigger an external instrument or

•

the built-in oscilloscope, or

you want to use an external instrument or the built-in oscilloscope to

•

trigger the logic analyzer.

Set up trigger sequence Create a sequence of steps that control when

the logic analyzer starts and stops storing data and filters which data it

will store. For common tasks, you can use a trigger macro to simplify the

process or use the user-defined macros to loop and jump in sequence.

You can also set the oscilloscope to trigger on a complex pattern.

See Also Chapter 4,"Using the Trigger Menu" and Chapter 5, "Triggering Examples" for

more information on setting up a trigger.

"The Trigger Sequencer" in Chapter 9 for more information about the trigger

sequence mechanism.

"To save a configuration" and "To load a configuration" in Chapter 6 for

instructions on saving and loading the setup so you don’t have to repeat

setting up the analyzer and trigger.

* If you load a configuration file, this step is not necessary.

1-6

Page 22

Logic Analyzer Overview

To make a meas urement

Run measurement

Select single or repetitive From any Analyzer or Scope menu, select

the field labeled Run in the upper right corner to start measuring, or

press the Run key. A single run will run once, until memory is full; a

repetitive run will go until you select Stop or until a stop measurement

condition that you set in the markers menu is fulfilled.

See Also "Markers Field" and "Scope Markers" in Chapter 7 for more information on

markers and stop measurement conditions.

If nothing happens, see Troubleshooting. When you start a run,

your analyzer menu changes to one of the display menus or a status

message pops up. If nothing happens, press the Stop key or select

Cancel. If the analyzer still does not display any measurements, see

Chapter 10, "Troubleshooting."

Gather data You can gather statistics automatically by going to a

Waveform or Listing menu, turning on markers, and setting patterns for

the X and O markers. You can set the logic analyzer to stop if certain

conditions are exceeded, or just use the markers to count valid runs.

See Also "Markers Field," "Scope Markers," and "Scope Auto-measure" in Chapter 7 for

more information on markers.

1-7

Page 23

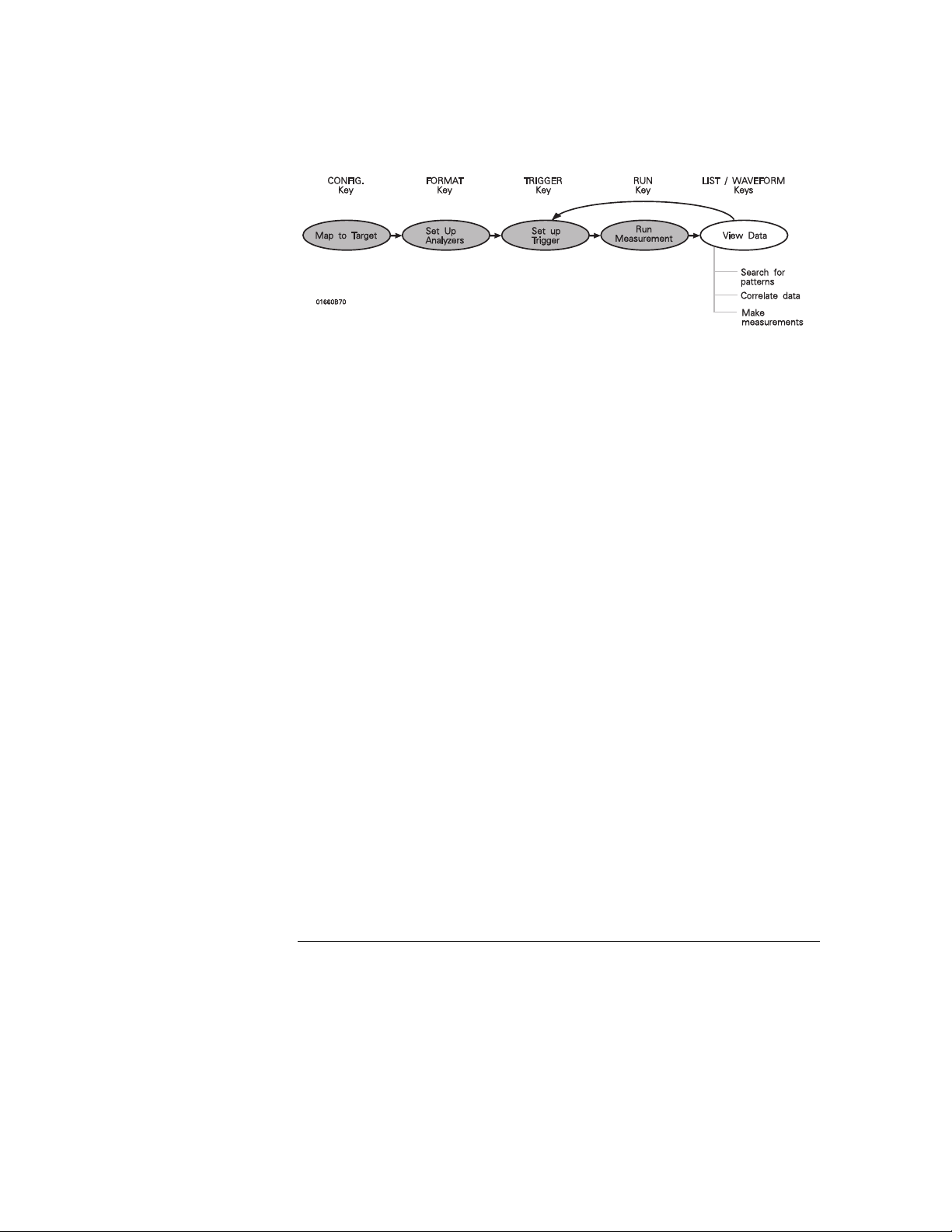

Logic Analyzer Overview

To make a measurement

View data

Search for patterns In both the Waveform and Listing menus you can

use symbols and markers to search for patterns in your data. In the

Analyzer Waveform or Analyzer Listing menu, toggle the Markers field to

turn the pattern markers on and then specify the pattern. When you

switch views, the markers keep their settings.

Correlate data You can correlate data by setting Count Time in your

state analyzer’s Trigger menu and then using interleaving and mixed

display. Interleaving correlates the listings of two state analyzers. Mixed

display correlates a timing analyzer waveform and a state analyzer listing,

or a state analyzer and an oscilloscope waveform, or a state analyzer and

both timing and oscilloscope waveforms. To correlate oscilloscope data,

the oscilloscope arm mode must be set to Immediate. The System

Performance Analysis (SPA) Software does not save a record of actual

activity, so it cannot be correlated with either timing or state mode.

Make measurements The markers can count occurrences of events,

measure durations, and collect statistics, and SPA provides high-level

summaries to help you identify bottlenecks. To use the markers, select

the appropriate marker type in the display menu and specify the data

patterns for the marker. To use SPA, go to the SPA menu, select the

most appropriate mode, fill in the parameters, and press Run.

See Also Chapter 8, "System Performance Analysis (SPA) Software" for more

information on using SPA.

"The Waveform Menu" and "The Listing Menu" in Chapter 7 for additional

information on the menu features.

1-8

Page 24

2

Connecting Peripherals

Page 25

Connecting Peripherals

Your HP 1660CS-series logic analyzer comes with a PS2 mouse. It also

provides connectors for a keyboard, Centronics (parallel) printer, and

HP-IB and RS-232-C devices. This chapter tells you how to connect

peripheral equipment such as the mouse or a printer to the logic

analyzer.

Mouse and Keyboard

You can use either the supplied mouse and optional keyboard, or

another PS2 mouse and keyboard with standard DIN connector. The

DIN connector is the type commonly used by personal computer

accessories.

Printers

The logic analyzer communicates directly with HP PCL printers

supporting the printer control language or with other printers

supporting the Epson standard command set. Many non-Epson

printers have an Epson-emulation mode. HP PCL printers include the

following:

• HP ThinkJet

• HP LaserJet

• HP PaintJet

• HP DeskJet

• HP QuietJet

You can connect your printer to the logic analyzer using HP-IB,

RS-232-C, or the parallel printer port. The logic analyzer can only

print to printers directly connected to it. It cannot print to a

networked printer.

2-2

Page 26

Connecting Peripherals

To connect a mouse

To connect a mouse

Hewlett-Packard supplies a mouse with the logic analyzer. If you prefer a

different style of mouse you can use any PS2 mouse with a standard PS2 DIN

interface.

Plug the mouse into the mouse connector on the back panel. Make

1

sure the plug shows the arrow on top.

2 To verify connection, check the System External I/O menu for a

mouse box.

The mouse box is on the right side above the Settings fields. If the logic

analyzer was displaying the System External I/O menu when you plugged in

the mouse, the menu won’t update until you exit and then return to it.

The mouse pointer looks like a plus sign (

pointer over it and press the left button. To duplicate the front-panel knob,

hold down the right button while moving the mouse. Moving the mouse up or

to the right duplicates turning the knob clockwise. Moving the mouse down

or to the left duplicates turning the knob counterclockwise.

+). To select a field, move the

System External I/O menu showing mouse installed

2-3

Page 27

Connecting Peripherals

To connect a keyboard

To connect a keyboard

You can use either the HP-recommended keyboard, HP E2427B, or any other

keyboard with a standard DIN connector.

Plug the keyboard into the keyboard connector on the back panel.

1

2 To verify, check the System External I/O menu for a keyboard box.

The keyboard box is on the right side, above the Settings fields. If the logic

analyzer was displaying the System External I/O menu while you plugged the

keyboard in, the menu won’t update until you exit and then return to it.

The keyboard cursor is the location on the screen highlighted in inverse

video. To move the cursor, use the arrow keys. Pressing Enter selects the

highlighted field. The primary keyboard keys act like the analyzer’s

front-panel data entry keys.

See Also "Keyboard Shortcuts" in the Chapter 7 for complete key mappings.

System External I/O menu showing keyboard installed

2-4

Page 28

Connecting Peripherals

To connect to an HP-IB printer

To connect to an HP-IB printer

Printers connected to the logic analyzer over HP-IB must support HP-IB and

Listen Always. When controlling a printer, the analyzer’s HP-IB port does not

respond to service requests (SRQ), so the SRQ enable setting does not have

any effect on printer operation.

Turn off the analyzer and the printer, and connect an HP-IB cable

1

from the printer to the HP-IB connector on the analyzer rear panel.

2 Turn on the analyzer and printer.

3 Make sure the printer is set to Listen Always or Listen Only.

For example, the figure below shows the HP-IB configuration switches for an

HP-IB ThinkJet printer. For the Listen Always mode, move the second

switch from the left to the 1 position. Since the instrument doesn’t respond

to SRQ EN (Service Request Enable), the position of the first switch doesn’t

matter.

Listen Always switch setting

2-5

Page 29

Connecting Peripherals

To connect to an HP-IB printer

4 Go to the System External I/O menu and configure the analyzer’s

printer settings.

a If the analyzer is not already set to HP-IB, select the field under

Connected To: in the Printer box and choose HP-IB from the menu.

b Select the Printer Settings field.

c In the top field of the pop-up, select the type of printer you are using.

If you are using an Epson graphics printer or an Epson-compatible

printer, select Alternate.

d If the default print width and page length are not what you want,

select the fields to toggle them.

If you select 132 characters per line when using a printer other than

QuietJet, the listings are printed in a compressed mode. QuietJet

printers can print 132 characters per line without going to compressed

mode, but require wider paper.

e Press Done.

Printer Settings menu

2-6

Page 30

Connecting Peripherals

To connect to an RS-232-C prin ter

To connect to an RS-232-C printer

1 Turn off the analyzer and the printer, and connect a null-modem

RS-232-C cable from the printer to the RS-232-C connector on the

analyzer rear panel.

2 Before turning on the printer, locate the mode configuration switches

on the printer and set them as follows:

For the HP QuietJet series printers, there are two banks of mode function

•

switches inside the front cover. Push all the switches down to the 0

position.

For the HP ThinkJet printer, the mode switches are on the rear panel of

•

the printer. Push all the switches down to the 0 position.

For the HP LaserJet printer, the factory default switch settings are okay.

•

3 Turn on the analyzer and printer.

4 Go to the System External I/O menu and configure the analyzer’s

printer settings.

a If the analyzer is not already set to RS-232-C, select the field under

Connected To: in the Printer box and choose RS-232C from the menu.

b Select the Printer Settings field.

c In the top field of the pop-up, select the type of printer you are using.

If you are using an Epson graphics printer or an Epson-compatible

printer, select Alternate.

d If the default print width and page length are not what you want,

select the fields to toggle them.

If you select 132 characters per line when using a printer other than

QuietJet, the listings are printed in a compressed mode. QuietJet

printers can print 132 characters per line without going to compressed

mode, but require wider paper.

e Press Done.

5 Select the RS232 Settings field and check that the current settings are

compatible with your printer.

See Also "The RS-232-C Interface" section in Chapter 7 for more information on

RS-232-C settings.

2-7

Page 31

Connecting Peripherals

To connect t o a parallel printer

To connect to a parallel printer

1 Turn off the analyzer and the printer, and connect a parallel printer

cable from the printer to the parallel printer connector on the

analyzer rear panel.

2 Before turning on the printer, configure the printer for parallel

operation.

The printer’s documentation will tell you what switches or menus need to be

configured.

Turn on the analyzer and printer.

3

4 Go to the System External I/O menu and configure the analyzer’s

printer settings.

a If the analyzer is not already set to Parallel, select the field under

Connected To: in the Printer box and choose Parallel from the menu.

b Select the Printer Settings field.

c In the top field of the pop-up, select the type of printer you are using.

If you are using an Epson graphics printer or an Epson-compatible

printer, select Alternate.

d If the default print width and page length are not what you want,

select the fields to toggle them.

If you select 132 characters per line when using a printer other than

QuietJet, the listings are printed in a compressed mode. QuietJet

printers can print 132 characters per line without going to compressed

mode, but require wider paper.

e Press Done.

There are no settings specific to the parallel printer connector.

2-8

Page 32

Connecting Peripherals

To connect t o a controller

To connect to a controller

You can control the HP 1660CS-series logic analyzer with another

instrument, such as a computer running a program with embedded analyzer

commands. The steps below outline the general procedure for connecting to

a controller using HP-IB or RS-232-C.

Turn off both instruments, and connect the cable.

1

If you are using RS-232-C, the cable must be a null-modem cable. If you do

not have a null-modem cable, you can purchase an adapter at any electronics

supply store.

Turn on the logic analyzer and then the controller.

2

3 In the System External I/O menu, select the field under Connected

To: in the Controller box and set it appropriately.

The figure below is for HP-IB.

4 Select the appropriate Settings field and configure the values in the

pop-up menu to be compatible with the controller.

See Also HP 1660C/CS-Series Logic Analyzers Programmer’s Guide and the LAN

User’s Guide for more information on connecting controllers.

2-9

Page 33

2-10

Page 34

3

Using the Logic Analyzer

Page 35

Using the Logic Analyzer

This chapter shows you how to perform the basic tasks necessary to

make a measurement. Each section uses an example to show how the

task fits into the overall goal of making a measurement.

3–2

Page 36

Accessing the Menus

When you power up the logic analyzer, the first screen after the

system tests is the Analyzer Configuration menu. Menus are identified

by two fields in the upper left corner. The leftmost field shows

Analyzer. This field is sometimes referred to as the "mode field" or the

"module field" because it controls which other set of menus you can

access. The second field, just to the right of the mode field, accesses

menus within the mode and so is called the "menu field". Menus are

referred to by the titles that appear in the mode and menu fields, for

example, the Analyzer Configuration menu.

The figure below shows the top of the first screen. The mode field,

item 1, displays "Analyzer." The menu field, item 2, displays

"Configuration." Because menus are identified by the titles in these

two fields, this menu is referred to as the Analyzer Configuration

menu. When there is no risk of confusion, the menu is sometimes

referred to just by the title showing in the second field, for example,

the Configuration menu.

3–3

Page 37

Using the Logic Analyzer

To access the System menus

To access the System menus

The System menus allow you to perform operations that affect the entire

logic analyzer, such as load configurations, change colors, and perform

system diagnostics.

Select the mode field.

1

Use the arrow keys to highlight the mode field, then press the Select key. Or,

if you are using the mouse, click on the field. This operation is referred to as

"select".

A pop-up menu appears with the choices System, Analyzer, and Scope. (If

you have installed any optional software, there may be other choices as well.)

Select System.

2

3 Select the menu field.

The pop-up lists five menus: Hard Disk, Flexible Disk, External I/O, Utilities,

and Test.

3–4

Page 38

Using the Logic Analyzer

To access the System menus

Hard Disk allows you to perform file operations on the hard disk

•

Flexible Disk allows you to perform file operations on the flexible disk.

•

External I/O allows you to configure your HP-IB, RS-232-C, and LAN

•

interfaces and connect to a printer and controller.

Utilities allows you to set the clock, update the operating system software,

•

and adjust the display.

Test displays the installed software version number and loads the self

•

tests.

See Also For more information on operations available in the Disk menus, "File

Management" chapter and "Disk Drive Operations" in Chapter 7.

For more information on the External I/O, "Connecting Peripherals" chapter

and "The RS-232-C, HP-IB, and Centronics Interfaces" in Chapter 7.

For more information on the system utilities, "System Utilities" in Chapter 7.

For information on running the self-tests, "Operator’s Service" chapter.

3–5

Page 39

Using the Logic Analyzer

To access the Anal yzer menus

To access the Analyzer menus

The Analyzer menus allow you to control the analyzer to make your

measurement, perform operations on the data, and view the results on the

display.

Select the mode field.

1

A pop-up menu appears with the choices System, Analyzer, and Scope. (If

you have installed any optional software, there may be other choices as well.)

Select Analyzer.

2

3 Select the menu field.

The figure on the next page shows all possible menus. Your analyzer will

never have all of them available at once, because certain menus are only

accessible with the analyzer configured in a particular mode. For instance,

the Compare menu is only available when you set an analyzer to state mode,

and the SPA menu requires an analyzer set to SPA.

Configuration is always available in Analyzer mode. Use Configuration to

•

assign pods and set the analyzer type.

Format is available whenever an analyzer is set to a type other than "Off."

•

Use Format to create data labels and symbols, adjust the pod threshold

level, and set modes and clocks.

Trigger is available when an analyzer is set to State or Timing. Use Trigger

•

to specify a trigger sequence which will filter the raw information into the

measurement you want to see.

Listing is available when an analyzer is set to State or Timing. Use Listing

•

to view your measurement as a list of states. Using an inverse assembler, a

state analyzer can display the measurement as though it were assembly

code.

Compare is available only when an analyzer is set to State. Use Compare to

•

compare two listings and quickly scroll to the sections where they differ.

3–6

Page 40

Using the Logic Analyzer

To access the Analyzer menus

Mixed Display always appears in the menu list when an analyzer is set to

•

State or Timing, but it requires a State analyzer with time tags enabled.

Waveform is available when an analyzer is set to State or Timing. Use

•

Waveform to view the data as logic levels on discrete lines.

Chart is available only when an analyzer is set to State. Use Chart to view

•

your measurement as a graph of states versus time.

SPA is available only when an analyzer is set to SPA. Use SPA to gather

•

and view overall statistics about your system performance.

See Also Chapter 7, "Reference" for details on the State and Timing menus and

Chapter 8, "System Performance Analysis (SPA) Software" for information on

the SPA menu.

"Using the Analyzer Menus" in this chapter for how to use the menus.

3–7

Page 41

Using the Logic Analyzer

To access the Scope menus

To access the Scope menus

The Scope menus allow you to control the analyzer to make your

measurement, perform operations on the data, and view the results on the

display.

Select the mode field.

1

A pop-up menu appears with the choices System, Analyzer, and Scope. (If

you have installed any optional software, there may be other choices as well.)

Select Scope.

2

3 Select the menu field.

The pop-up lists six menus: Scope Channel, Scope Display, Scope Trigger,

Scope Marker, Scope Auto Measure, and Scope Calibration.

Scope Channel lets you select the channel input. It lets you set values that

•

control the vertical sensitivity, offset, probe attenuation factor, input

impedance, and coupling of the input channel currently shown in the Input

field. The Channel menu also gives you preset vertical sensitivity, offset,

and trigger level values for ECL and TTL logic levels.

Scope Display controls how the oscilloscope acquires and displays

•

waveforms. You can acquire and display the waveforms in one of the

following modes: Normal, Average, or Accumulate. The Display options

also control the connect-the-dots display and grid display features.

3–8

Page 42

Using the Logic Analyzer

To access t he Scope menus

Scope Trigger allows you to choose the method you want to use to trigger

•

the oscilloscope for a particular application. The three trigger modes are

Edge, Pattern, and Immediate.

Scope Markers has two sets of markers that allow you to make time and

•

voltage measurements. These measurements can be made either manually

(voltage and time markers) or automatically (time markers only).

Scope Auto Measure provides nine automatic measurements to fit the

•

acquired waveform to the display. These measurements are Period,

Risetime, Falltime, Frequency, +Width, −Width, Vp_p, Preshoot, and

Overshoot.

Scope Calibration allows you to calibrate the oscilloscope or the

•

oscilloscope/probe system.

See Also Chapter 12, "Operator’s Service," for details on calibrating the oscilloscope.

3–9

Page 43

Using the Analyzer Menus

The following examples show how to use some of the Analyzer menus

to configure the logic analyzer for measurements. These examples

assume that you have already determined which signals are of interest

and have connected the logic analyzer to the target system. Some of

the examples use data from a Motorola 68360 target system, acquired

with an HP E2456A Preprocessor Interface.

To label channel groups

Hewlett-Packard logic analyzers give you the ability to separate or group data

channels and label the groups with a name that is meaningful to your

measurement. Labels also assist you in triggering only on states of interest.

Labels can only be assigned in the Analyzer Format menu. Once assigned, the

labels are available in all display menus, where they can be added to or

deleted from the display. Use labels when you want to group data channels

by function with a name that has meaning to that function.

The default label names are Lab1 through Lab126. However, you can modify

a name to any six-character string. If you are using an HP preprocessor

interface, the configuration file has predefined labels for your specific

processor.

To create or modify a label and assign channel groups, use the following

procedure.

Press the Format key to go to the Format menu.

1

2 Select a label under the Labels heading. In the pop-up menu, select

Modify Label.

3 Use the keyboard to type in a name for the label and press Done.

In this example, the label is called CYCLE.

3–10

Page 44

Using the Logic Analyzer

To label channel groups

4 Select the pod containing the channels for the label. Use the knob or

the arrow keys to position the selector over a channel you want to

change.

An asterisk indicates the channel is selected; a dot indicates the channel is

not part of the current group.

Toggle the channel’s group status by pressing Select.

5

The indicator changes and the selector moves to the next channel.

In this example, the channels 3, 1, and 0 (Pod A1) are assigned to label

CYCLE and the channels 6 and 3 (Pod A2) are assigned to the label Lab2.

3–11

Page 45

Using the Logic Analyzer

To create a symbol

To create a symbol

Symbols are alphanumeric mnemonics that represent specific data patterns

or ranges. When you define a symbol and set the the base type to Symbol in

the Listing menu, the symbol is displayed in the data listing where the bit

pattern would normally be displayed. The symbols also appear in the

Waveform menu when you view a label in bus form. Symbols allow you to

quickly identify data of interest.

To create a symbol, use the following procedure.

In the Analyzer Format menu, select Symbols.

1

The symbol table menu appears. The symbol table is where all user symbols

are created and maintained. If you get a message, "No labels specified," check

that you have at least one label turned on with channels assigned to it.

In the Symbol menu select the Label field. In the pop-up menu select

2

the label that contains the channel groups you want.

When you open the symbol table menu, the Label field displays the name of

the first active label.

If the label you want does not appear in the pop-up menu, the label is

probably off. Return to the Format menu, select the label you want, and

select Turn Label On. Another possibility is that the label is on the other

analyzer. The two analyzers manage resources separately.

Select the Base field. In the pop-up menu, select the base for the

3

pattern.

In this example, binary is used since CYCLE only contains three channels.

4 Select the field below Symbol. Select Add a Symbol, type in the

symbol name, then press Done.

3–12

Page 46

Using the Logic Analyzer

To create a symbol

5 If additional Symbols are needed, repeat step 4 until you have added

all symbols.

In this example three symbols are added: MEM RD, MEM WR, and DATA RD.

6 Toggle the Type field to "range" or "pattern".

When Type is range, a third field appears under the Stop column. To fully

specify a range, you need to enter a value for it, too.

Select the Pattern/Start field and use the keypad to enter an

7

appropriate value in the selected base. Use X for "don’t care."

8 When the pattern is specified, press Done. If you created additional

Symbols, repeat steps 6 and 7 until all symbols are specified.

9 To close the symbol table menu, select Done.

Symbol ta ble menu showing three symbols

You can also download symbol tables created by your programming

environment using HP E2450A Symbol Utility. The Symbol Utility is shipped

with the HP 1660CS-series logic analyzers.

See Also HP E2450A Symbol Utility User’s Guide for more information on the

Symbol Utility.

3–13

Page 47

Using the Logic Analyzer

To examine an analyzer waveform

To examine an analyzer waveform

The Analyzer Waveform menu allows you to view state or timing data in a

format similar to an oscilloscope display. The horizontal axis represents

states (in state mode) or time (in timing mode) and the vertical axis

represents logic highs and lows.

In Analyzer mode, press the Run key to acquire data.

1

In any mode other than Analyzer or Scope, pressing the Run key has no

effect. The menus which ignore Run lack the Run field onscreen. In Analyzer

mode with Run available, the menu changes to a display menu.

Go to the Analyzer Waveform menu.

2

3 To adjust the horizontal axis (sec/Div or states/Div) use the knob.

If nothing happens when you turn the knob, make sure the Div field has a roll

indicator above it, as in the figures on the next page. When you first enter

the Waveform menu, the knob adjusts the horizontal axis but if you select

another rollable field, the knob will control that field instead.

To adjust the display relative to the trigger, select the Delay field and

4

enter a value or use the knob.

The portion of memory being displayed is indicated by a white bar along the

bottom of the display area. The position of the trigger in memory is indicated

by a white dot on the same line. When the bar includes the dot, then the

trigger is visible on the display as indicated by a vertical line with a "t"

underneath.

To scroll through waveforms, select the large rectangle below the Div

5

field and use the knob.

The roll indicator appears at the top of the rectangle and the name of the first

waveform is highlighted. The highlight moves as you turn the knob.

To insert waveforms, select the large rectangle under the Div field. In

6

the pop-up, select Insert, and then select the labels and channels.

The Sequential field inserts all the channels of the label as individual

waveforms; the Bus field groups the waveforms; the Bit N field inserts just

the Nth bit. Waveforms are inserted after the currently highlighted one.

3–14

Page 48

7 To take measurements, select the Markers field and choose the

appropriate marker type.

The markers available depend on the type of analyzer and whether or not

tagging is enabled. Use markers to locate patterns quickly.

See Also "Count Field" and "Markers Field" in Chapter 7.

roll indicator

trigger in dicator

memory displayed

indicator

Using the Logic Analyzer

To examine an analyzer waveform

Example

The following example shows a state waveform from the Hewlett-Packard

preprocessor interface for the Motorola 68360. Notice how the bus

waveforms insert symbols or state data.

3–15

Page 49

Using the Logic Analyzer

To examine an analyzer listing

To examine an analyzer listing

The Analyzer Listing menu displays state or timing data as patterns (states).

The Listing menu uses any of several formats to display the data such as

binary, ASCII, or symbols. If you are using an inverse assembler and select

Invasm, the data is displayed in mnemonics that closely resemble the

microprocessor source code.

See Also "The Inverse Assembler" at the end of this chapter for additional information

on using an inverse assembler.

In Analyzer mode, press the Run key to acquire data.

1

In any mode other than Analyzer or Scope, pressing the Run key has no

effect. The menus which ignore Run lack the Run field onscreen. In Analyzer

mode with Run available, the menu changes to a display menu.

Go to the Analyzer Listing menu.

2

All labels defined in the Analyzer Format menu appear in the listing. If there

are more labels than will fit on the screen, the Label/Base field is shaded like

a normal field.

To scroll the labels, select the Label/Base field and use the knob.

3

If the Label/Base field is selectable, the roll indicator appears over the field as

in the example. To move the labels one full screen at a time, press Shift and

a Page key.

To scroll the data, use the Page keys or select the data roll field and

4

use the knob.

If you select the data roll field, the roll indicator moves to it. No matter

which field is currently controlled by the knob, however, the Page keys page

the data up or down.

The numbers in the data roll column indicate how many samples the data is

from the trigger. Negative numbers occurred before the trigger and positive

numbers occurred after.

If the labels have symbols associated with them, set the base to

5

Symbol.

The symbols you defined appear in the listing.

3–16

Page 50

6 To insert a label, select one of the label fields, then select Insert from

the pop-up and the label you want to insert.

The last label cannot be deleted, so there is always at least one label. You can

insert the same label multiple times and display it in different bases.

To take measurements, select the Markers field and choose the

7

appropriate marker type.

The markers available depend on the type of analyzer and whether or not

tagging is enabled. Use markers to locate states quickly.

See Also "Count Field" and "Markers Field" in Chapter 7.

The following illustration shows a listing from the Hewlett-Packard

Example

preprocessor interface for the Motorola 68360. The ADDR label has the base

set to Hex to conserve space on the display. The DATA label has the base set

to Invasm for inverse assembly. The FC label has the base set to Symbol.

Additional labels are located to the right of FC, and can be viewed by

highlighting and selecting Label, then using the knob to scroll the display

horizontally.

Using the Logic Analyzer

To examine a n analyzer listing

roll indicator

data roll field

3–17

Page 51

Using the Logic Analyzer

To compare two listings

To compare two listings

The Compare menu allows you to take two state analyzer acquisitions and

compare them to find the differences. You can use this function to quickly

find all the effects after changing the target system or to quickly compare the

results of quality tests with results from a working system.

In Analyzer mode, press the Run key to acquire data.

1

In any mode other than Analyzer or Scope, pressing the Run key has no

effect. The menus which ignore Run lack the Run field onscreen. In Analyzer

mode with Run available, the menu changes to a display menu.

Go to the Analyzer Compare menu, select Copy Listing to Reference,

2

and then select Execute.

The Compare menu initially is empty, but when you select Execute the data

appears.

Set up the other test that you want to compare to the first.

3

This can be a change to the hardware, or a different system. Do not change

the trigger, however, or all the states will be different.

Run the test again, then select the Reference listing field to toggle to

4

Difference listing.

The Difference listing is displayed on the next page.

3–18

Page 52

Using the Logic Analyzer

To compare t wo listings

The Difference listing displays the states that are identical in dark typeface,

and the states that are different in light typeface (indistinguishable in the

above illustration). The light typeface shows the data from the compare file

that is different from the data in the reference file.

Select the Find Error field and use the knob to scroll through the

5

errors.

The display jumps past all states that are identical, and shows the number of

errors through the current state in the Find Error field. In the above

illustration, there are 37 errors through state 44 of the listing.

3–19

Page 53

The Inverse Assembler

When the analyzer captures a trace, it captures binary information.

The analyzer can then present this information in symbol, binary,

octal, decimal, hexadecimal, or ASCII. Or, if given information about

the meaning of the data captured, the analyzer can inverse assemble

the trace. The inverse assembler makes the trace list more readable

by presenting the trace results in terms of processor opcodes and data

transactions.

To use an inverse assembler

Most preprocessors include an inverse assembler in their software. Loading

the configuration file for the preprocessor sets up the logic analyzer to

provide certain types of information for the inverse assembler. This section

is provided in case you ever have to set up an analyzer for inverse assembly

yourself.

The inverse assembly software needs at least these five pieces of information:

Address bus. The inverse assembler expects to see the label ADDR, with

•

bits ordered in a particular sequence.

Data bus. The inverse assembler expects to see the label DATA, with bits

•

ordered in a particular sequence.

Status. The inverse assembler expects to see the label STAT, with bits

•

ordered in a particular sequence.

Start state for disassembly. This is the first displayed state in the trace list,

•

not the cursor position. See the figure on the next page.

Tables indicating the meaning of particular status and data combinations.

•

The particular sequences that each label requires depends on the type of

chip the inverse assembler was designed for. Because of this, inverse

assemblers cannot generally be transferred between platforms.

To run the inverse assembler, you must be sure the labels are spelled

correctly as shown here, or as directed in your inverse assembler

documentation. Even a minor difference such as not capitalizing each letter

will cause the inverse assembler to not work.

3–20

Page 54

The inverse assembler

sync hroni z es at the

first line in the trace

list...

not at the cursor

position

Using the Logic Analyzer

To use an inverse assembler

Inverse assembly synchronization

When you press the Invasm key to begin inverse assembly of a trace, the

inverse assembler begins with the first displayed state in the trace list. This is

called synchronization. It looks at the status bits (STAT) and determines

the type of processor operation, which is then displayed under the STAT

label. If the operation is an opcode fetch, the inverse assembler uses the

information on the data bus to look up the corresponding opcode in a table,

which is displayed under the DATA label. If the operation is a data transfer,

the data and corresponding operation are displayed under the DATA label.

This continues for all subsequent states in the trace list.

If you roll the trace list to a new position and press Invasm again, the inverse

assembler repeats the above process. However, it does not work backward in

the trace list from the starting position. This may cause differences in the

trace list above and below the point where you synchronized inverse

assembly. The best way to ensure correct inverse assembly is to synchronize

using the first state you know to be the first byte of an opcode fetch.

See Also The Preprocessor User’s Guide for more information on controlling inverse

assembly.

"Troubleshooting," Chapter 10, if you have problems using the inverse

assembler.

3–21

Page 55

3–22

Page 56

4

Using the Trigger Menu

Page 57

Using the Trigger Menu

To use the logic analyzer efficiently, you need to be able to set up your

own triggers. This book provides examples of triggering in the next

chapter. Those examples assume you already know where to find

fields in the trigger menu. This chapter explains how to use those

fields.

This chapter shows you how to:

• Specify a basic trigger

• Change a trigger sequence

• Set up time correlation between analyzers

• Arm from another instrument, or arm another instrument

• Manage memory

Much of the information here is also covered in the Logic Analyzer

Training Kit, but this chapter presents the information in a more

general form.

4–2

Page 58

Specifying a Basic Trigger

The default analyzer triggers are

While storing "anystate" TRIGGER on "a" 1 time

Stor e "a ny state"

for state analyzers and

TRIGGER on "a" > 8 ns

for timing analyzers. The oscilloscope triggers separately from the

logic analyzers. If you want to simply record data, these will get you

started. They can quickly be tailored by specifying a particular pattern

to look for instead of the general case.

Customizing a trigger generally requires these steps:

• Assign terms to both analyzers

• Define the terms

• Change the trigger to use the new terms

The oscilloscope can be used in complex triggering sequences

managed by the logic analyzer, but its inherent trigger mechanism is

much simpler. Using the oscilloscope in conjunction with one or both

of the analyzers is covered in "Arming and Additional Instruments" in

this chapter. The different modes of triggering the oscilloscope are

covered in "The Scope Trigger Menu" in Chapter 7.

4–3

Page 59

Using the Trigger Menu

To assign terms to an analyzer

To assign terms to an analyzer

When you turn the logic analyzer on, Analyzer 1 is named Machine 1 and

Analyzer 2 is off. Trigger terms can only be used by one analyzer at a time,

so all the terms are assigned to Analyzer 1. If you plan to use both analyzers

in your measurement, you need to assign some of the terms to Analyzer 2.

Go to the Trigger Machine 1 menu.

1

If you have renamed Machine 1 in the Analyzer Configuration menu, the

name you changed it to will appear in the menu instead of Machine 1.

Select a term.

2

The terms are the fields below the roll field "Terms". See the figure below.

Terms

Select Assign from the list that appears.

3

The Resource Term Assignment menu appears. It is divided into two

sections, one for each analyzer. All the terms are listed.

To change a term assignment, select the term field.

4

The term fields toggle from one section to the other. You can get all your

terms assigned at once, or just change a few to meet immediate needs.

To exit the term assignment menu, select Done.

5

4–4

Page 60

Using the Trigger Menu

To define a term

To define a term

Both default triggers trigger on term "a". If you only need to look for the

occurrence of a certain state, such as a write to protected memory, then you

only need to define term "a" to make the measurement you want.

In the Trigger menu, select the field at the intersection of the term

1

and the label whose value you want to trigger on.

You set labels in the Analyzer Format menu. If the channels you want to

monitor are not attached to a label, they will not appear in the trigger menu.

Enter the value or pattern you want to trigger on.

2

If the label’s base is Symbol, a pop-up menu appears offering a choice of

symbols. For other bases, use the keypad. An "X" stands for "don’t care".

If there are two conditions that need to be present at the same time, for

example a protected address on the address bus and a write on the read/

write line, define both values on the same term. See the figure below.

Press Done.

3

Term "a" defined as a data write to read-only memory

4–5

Page 61

Using the Trigger Menu

To change the trigger specification

To change the trigger specification

Most triggers use terms other than "a." Even a simple trigger might use

additional terms to set conditions on the actual trigger. To use these terms,

you must include them in the trigger sequence specification.

In the Trigger menu, select the number beside the specific level you

1

want to modify.

A Sequence Level menu pops up. It shows the current specification for that

trigger level.

Select the field you want to change.

2

In the top row of the pop-up are three action fields: Insert Level, Select New

Macro, and Delete Level. The next section goes into detail on them. The

fields after "While storing," "TRIGGER on," and "Else on" are completed with

trigger terms. Selecting these fields pops up a menu of terms(see below).

Select the term you want to use from the pop-up, or enter a new

3

value, as appropriate to the field.

Selecting "Combination" pops up a menu to define a term combination. The

combination mechanism is discussed in "Resource Terms" in Chapter 7 and

"The Trigger Sequencer" in Chapter 9.

If you have renamed a term, that name is automatically used everywhere the

term would appear.

Select Done until you are back at the Trigger menu.

4

Term selection pop-up menu

4–6

Page 62

Changing the Trigger Sequence

Most measurements require more complicated triggers to better filter

information. From the basic trigger, you can

• Add sequence levels

• Change macros

Your logic analyzer provides a macro library to make setting up the

trigger easier. There are 12 state macros and 13 timing macros. Most

macros take more than one level internally to implement, and can be

broken down into their separate levels. Once broken down, the levels

can be used to design your own trigger sequences.

4–7

Page 63

Using the Trigger Menu

To add sequence levels

To add sequence levels

You can add sequence levels anywhere except after the final one.

1 In the Trigger menu, select the number beside the sequence level just

after where you want to insert.

For example, if you want to insert a sequence level between levels 1 and 2,

you would select level 2. To insert levels at the beginning, select level 1.

A Sequence Level pop-up appears. Its exact contents depend on the analyzer

configuration and the level specification. However, all Sequence Level

pop-ups have an Insert Level field in the upper left corner.

Select Insert Level.

2

Another pop-up offers the choices of Cancel, Before, or After. If the level you

started from was the last level, After will not appear.

Select Before.

3

The Trigger Macro pop-up replaces the Sequence Level pop-up. The macros

available depend on whether the analyzer is configured as state or timing.

Use the knob to highlight a macro, and select Done.

4

A new Sequence level pop-up appears. Its contents reflect the macro you just

selected. The figure below shows a user macro for a state analyzer.

Fill in the fields and select Done.

5

Sequence Lev el pop-up menu

4–8

Page 64

Using the Trigger Menu

To change macros

To change macros

You do not need to add and delete levels just to change a level’s macro. This

can be done from within the Sequence Level pop-up.

From the Trigger menu, select the sequence level number of the

1

sequence level you want to modify.

A Sequence Level pop-up appears. Its contents reflect the current macro.

Select Select New Macro.

2

The Trigger Macro pop-up replaces the Sequence Level pop-up. The macros

available depend on whether the analyzer is configured as state or timing.

Use the knob to highlight the macro you want, and select Done.

3

A new Sequence Level pop-up appears. Its contents reflect the macro you

just selected. The wording of this screen is very similar to the macro

description, and the line drawing demonstrates what the macro is measuring.

Select the appropriate assignment fields and insert the desired

4

pre-defined terms, numeric values, and other parameter fields

required by the macro. Select Done.

See Also "Timing Trigger Macro Library" and "State Trigger Macro Library" in

Chapter 7 for a complete listing of macros.

4–9

Page 65

Setting Up Time Correlation between Analyzers

There are two possible combinations of analyzers: state and state, and

state and timing. Timing and timing is not possible because the

Analyzer Configuration menu only permits one analyzer at a time to

be configured as a timing analyzer. For either combination, time

correlation is necessary for interleaving and mixed display.

Time correlation is useful when you want to store different sorts of

data for each trace, but see how they are related. For instance, you

could set up a timing and a correlated state analyzer and see if setup

and hold times are being met. Or, you could set up two state analyzers

and have one watch normal program execution and the other watch

the control and status lines.

Time correlation requires that state analyzers store time tags. You set

the state analyzer to store time tags by turning on Count Time in the

Analyzer Trigger menu. The timing analyzer already stores time tags

when it samples data.

See Also "Special Displays" in Chapter 5 for more information on interleaving

and mixed display.

4–10

Page 66

Using the Trigger Menu

To set up time correlation between two state analyzers

To set up time correlation between two state analyzers

To correlate the data between two state analyzers, both must have Count

Time turned on in their Trigger menus. Although both have Count State

available, it is not possible to correlate data based on states even when they

are identically defined.

In the Analyzer Trigger menu, select Count.

1

Count may be Count Off, Count Time, or Count States. Selecting the field

causes a pop-up to appear.

Select the field after Count: and select Time.

2

A warning may appear about reduced memory. It will not prevent you from

changing Count to Count Time.

Select Done.

3

4 Repeat steps 1 through 3 for the other state analyzer.

Now when you acquire data you will be able to interleave the listings.

To set up time correlation between a timing and a state analyzer

To set up time correlation between a timing and a state analyzer, only the

state analyzer needs to have Count Time turned on. The timing analyzer

automatically keeps track of time.

In the state Analyzer Trigger menu, select Count.

1

Count may be Count Off, Count Time, or Count States. Selecting the field

causes a pop-up to appear.

Select the field after Count: and select Time.

2

A warning may appear about reduced memory. It will not prevent you from

changing Count to Count Time.

Select Done.

3

Now when you acquire data you will be able to set up a mixed display.

4–11

Page 67

Arming and Additional Instruments

Occasionally you may need to start the analyzer acquiring data when

another instrument detects a problem. Or, you may want to have the

analyzer itself arm another measuring tool. This is accomplished from

the Arming Control field of the Analyzer Trigger menu.

To arm another instrument

1 Attach a BNC cable from the External Trigger Output port on the

back of the logic analyzer to the instrument you want to trigger.

The External Trigger Output port is also referred to as "Port Out." It uses

standard TTL logic signal levels, and will generate a rising edge when trigger

conditions are met.

In the Analyzer Trigger menu, select Arming Control.

2

Arming Control is below the Run button.

3 Select the Port Out field, and choose Analyzer from the list.

4 If you are using both analyzers, set the Arm Out Sent From field in

the upper right corner.

This field does not appear if only one analyzer is configured.

The selected analyzer will send the arm signal when it finds its trigger.

Select Done.

5

When you make a measurement, the analyzer will send an arm signal through

the External Trigger Output when the analyzer finds its trigger.

4–12

Page 68

Using the Trigger Menu

To arm the oscilloscope with the analyzer

To arm the oscilloscope with the analyzer

If both analyzers and the oscilloscope are turned on, you can configure one

analyzer to arm the other analyzer and the oscilloscope. An example of this

is when a state analyzer triggers on a bit pattern, then arms a timing analyzer

and the oscilloscope which capture and display the waveform after they

trigger.

In the Analyzer Trigger menu, select Arming Control.

1

2 Select the Analyzer Arm Out Sent From field, and choose from the

list the Analyzer that will generate the arm.

3 Select the Analyzer Arm In field, and choose Group Run.

This allows you to time-correlate the data from the analyzers and the scope.

The Scope Trigger Mode must be Immediate for correlation.

Select the field of the instrument which will arm the others, and in

4

the pop-up set it to run from Group Run.

The Scope field is not selectable. To set how the scope is run, select the field

under Scope Arm In.

Select the other instrument fields and choose the mechanism which

5

will arm them.

The Analyzer Arm Out field determines which analyzer sends the arming

signal to Port Out and to the oscilloscope if the oscilloscope is being armed

by an analyzer.

As you set each machine, the arrows connecting the fields in the Arming

Control menu change. The arrows show the order in which the instruments

are armed.

See the example on the next page.

Select Done until you are back at the Trigger menu.

6

4–13

Page 69

Example

Using the Trigger Menu

To arm the oscilloscope with the analyzer

In this example STATE MACH triggers from Group Run, then arms TIME

MACH and Scope.

To duplicate this, set STATE MACH to run from Group Run, TIME MACH to

run from STATE MACH, and Scope Arm In to Analyzer.

Arming with two analy zers and an oscillscope

When the run starts, the state analyzer automatically begins evaluating its

trigger sequence instruction. When the trigger sequence is satisfied, the

state analyzer sends an "Arm" signal to the timing analyzer, the oscilloscope,

and the external trigger.

4–14

Page 70

To receive an arm signal from another instrument

To receive an arm signal from another instrument

When you set the analyzer to wait for an arm signal, it does not react to data

that would normally trigger it until after it has received the arm signal. The

arm signal can be sent to any of the Trigger Sequence levels, but will go to

level 1 unless you change it. Setting up the analyzer to receive an arm signal

is more efficient when the sequence levels are already in place.

Connect a BNC cable from the instrument which will be sending the

1

signal to the External Trigger Input port on the back of the logic

analyzer.

CAUTION Do not exceed 5.5 volts on the External Trigger Input.

The External Trigger Input port is also referred to as "Port In." It uses

standard TTL logic signal levels, and expects a rising edge as input.

2 In the Analyzer Trigger menu, select Arming Control.

Arming Control is below the Run button.

Select the Analyzer Arm In field, and choose PORT IN.

3

4 To change the default settings, select the analyzer field.

A small pop-up menu appears. To change which device the analyzer is

receiving its arm signal from, select the Run from field. To change which

sequence level is waiting for the arm signal, select the Arm sequence level

field.

Select Done until you are back at the Trigger menu.

5

Using the Trigger Menu

4–15

Page 71

Managing Memory

Sometimes you will need every last bit of memory you can get on the

logic analyzer. There are three simple ways to maximize memory

when specifying your trigger:

• Selectively store branch conditions (State only)

• Place the trigger relative to memory

• Set the sampling rates (Timing only)

4–16

Page 72

Using the Trigger Menu

To selectively store branch conditions (State only)

To selectively store branch conditions (State only)

Besides setting up your trigger levels to store anystate, no state, or some

subset of states, you can also choose whether or not to store branch

conditions. Branch conditions are always stored by default, and can make

tracing the analyzer’s path through a complicated trigger easier. If you really

need the extra memory, however, it is possible to not store the branch

conditions.

You cannot set the analyzer to store only some branches in a trigger

sequence specification.

In the Analyzer Trigger menu, select Acquisition Control.

1

The Acquisition Control menu pops up. If the acquisition mode is set to

Automatic, the menu contains a single field and an explanation. If Acquisition

has been customized, it has 3 fields and a picture showing where the trigger

is currently placed in memory.

If the mode is Automatic, select the field to toggle it to Manual.

2

The menu now shows three fields and a picture.