Page 1

SERVICE MANUAL

HP 16532A

1 GSa/s Di g i t i zing

Oscilloscope

COPYRIGHT HEWLETT-PACKARD COMPANY,

COLORADO SPRINGS DIVISION 1991-1993

1900 GARDEN OF THE GODS ROAD, COLORADO SPRINGS, COLORADO U.S.A.

ALL RIGHTS RESERVED

Manual Part No. 16532-97002 PRINTE D: JULY 1993

Page 2

SAFETY CONSIDERATIONS

GENERAL - This is a Safety Class I instrument ( provided with

terminal for protective earthing).

OPERATION - BEFORE APPLYING POWER verify that the

power transformer primary is matched to the available line

voltage, the correct fuse is installed, and Safety Precautions

are taken (see the following warnings). In addition, note the instrument’s external markings which are described under

"Safety Symbols."

• Ser vicing instructions are for use by service-trained personnel. To avoid dangerous electric shock, do not perform

any servicing unless qua lified to do so.

• BEFORE SWITCHING ON THE INSTRUMENT, the protective earth terminal of the instrument must be connected to

the protective conductor of the (mains) powercord. The

mains plug shall only be inserted in a socket outlet provided with a protective earth contact. The protective action

must not be negated by the use of an e x tension cord

(power cable) without a protective conductor (grounding).

Gr ou nding one conductor of a two-con duc tor outlet is not

sufficie nt protec tion.

• If this instrument is to be e nergized vi a an auto-transformer (for v oltage reduction) make sure the common terminal is connected to the earth terminal of the power

source.

• Any interruption of the protective (grounding) conductor

(ins i de or outside th e instrument) or disconnecting the protective earth terminal will cause a potential shock hazard

that could result in personal injury.

• W henever it is lik ely that the protection has been impaired, the instrument must be made inoperative and be

sec ur ed against any unintended operation.

• Only fuses with the required rated current, voltage, and

specified type (normal blow, time delay, etc.) should be

used. Do not us e repaired fuses or shor t circuited fus eholders. To do so could cause a shock or fire hazard.

• Do not operate the instrument in the presence of flammable gasses or fumes. Operation of any electrical instrument in such an environment constitutes a definite safe ty

hazard.

• Do not in stall substitute parts or perfor m any unauthorized

modification to the instrument.

• A djustments described in the manual are performed with

power supplied to the instrument while protective covers

are r e move d. E ne rgy available at many points may, if contacted, result in personal injury.

• A ny adjustment, maintenance, and repair of the opened instrument under voltage should be avoided as much as

possible, and when inevitable, should be carried out only

by a skilled person who is aware of the hazard involved.

• Capacitors inside the instrument may still be charged

even if the ins trument has been disconnected from its

source of supply.

SAFETY SYMBOLS

Ins tr uction manual sy mbol. The product will be

marked with this symbol when it is necessary for

the user to refer to the instruction manual in order

to protect against damage to the product.

Indicates hazardous voltages

Earth terminal (sometimes used in manual to indicate circuit common connected to grounded

chassis).

The WARNING sign denotes a hazard. It

calls attention to a procedure, practice,

or the like, which, if not correctly performed or adhered to, could result in personal injury. Do not

proceed beyond a WARNING sign until the indicated conditions are fully understood and met.

The CAUTION sign denotes a hazard. It

calls attention to an operating procedure,

practice, or the like, which, if not correctly performed or adhered to, could result in damage to or

destruction of part or a ll of the product. D o not proceed beyond a CAUTION sign until the indicated conditions are fully

understood or met.

SC1D98 4

Page 3

HP 16532A - Table of Contents

CONTENTS

SECTION I

General Informatio n

1-1 . I ntroduction .............................................................................................................................. 1-1

1-2. Module Covered by This Manua l ............................................................................................ 1-1

1-3. S a fe ty R e quirements ............................................................................................................... 1-1

1-4. P roduct Description ................................................................................................................. 1-2

1-5. A ccessories Supplied .............................................................................................................. 1-2

1-6. A ccessories Available............................................................................................................... 1-2

1-7. S pecifications ........................................................................................................................... 1-2

1-8. Operating Characteristics ....................................................................................................... 1-2

1-9. Recommended Test Equipment ............................................................................................. 1-2

SECTION II

Installation

2-1 . I ntroduction ............................................................................................................................. 2-1

2-2. Initial Inspection ...................................................................................................................... 2-1

2-3. P reparation for Use ................................................................................................................ 2-1

2-4. P ower R e quirements .............................................................................................................. 2-1

2-5. S a fe ty R e quirements .............................................................................................................. 2-1

2-6. Module Installation ................................................................................................................. 2-1

2-7. Operating Environment .......................................................................................................... 2-4

2-8. S torage .................................................................................................................................... 2-4

2-9. P a ckaging ............................................................................................................................... 2-4

2-10. Tagging for Service ................................................................................................................ 2-4

SECTION III

Performance Tests

3-1 . I ntroduction .............................................................................................................................. 3-1

3-2. Recommended Test Equipment ............................................................................................. 3-1

3-3. Test Record .............................................................................................................................. 3-1

3-4. P e rformance Test Interval ....................................................................................................... 3-1

3-5. P e rformance Test Procedures ................................................................................................ 3-1

3-6. DC C AL OUTPUT Test ............................................................................................................. 3-2

3-7. A C C AL OUTPUT Test ............................................................................................................. 3-3

3-8. Input Resistance ...................................................................................................................... 3-4

3-9. Voltage Measurement Accuracy ............................................................................................. 3-6

3-10. Offse t A ccuracy ....................................................................................................................... 3-9

3-11. Ba ndwidth ................................................................................................................................ 3-11

3-12. Time Measurement Accuracy .................................................................................................. 3-13

3-13. Trigger Sen s itivity .................................................................................................................... 3-15

v

Page 4

HP 16532A - Table of Contents

SECTION I V

Calibration

4-1 . I ntroduction............................................................................................................................... 4-1

4-2. S a fe ty R e quirements................................................................................................................ 4-1

4-3. Ca libration Interval.................................................................................................................... 4-1

4-4 . M aintaining System Integrity.................................................................................................... 4-1

4-5 . Calibration Protection Switch................................................................................................... 4-1

4-6. Recommended Test Equipment..............................................................................................4-2

4-7 . I ns trument Warmup.................................................................................................................. 4-2

4-8. Ca libration................................................................................................................................. 4-2

4-9 . Setting the PROTECT/UNP ROTECT Switch to UNPROTECT................................................ 4-3

4-10. Equipment Required for Calibration ....................................................................................... 4-4

4-1 1. Loading the D efault Calibration Factors................................................................................. 4-4

4-12. Self Cal Menu Calibrations...................................................................................................... 4-5

4-1 3. Setting the PR O TEC T/UNP ROTECT Switch to PROTECT.................................................... 4-8

4-14. Sealing the Mainframe............................................................................................................. 4-8

Section V

Replaceable Parts

5-1 . I ntroduction .............................................................................................................................. 5-1

5-2. A bbreviations ........................................................................................................................... 5-1

5-3. Replaceable Parts List ............................................................................................................. 5-1

5-4. Ordering Information ............................................................................................................... 5-1

5-5. E xchange Assemblies ............................................................................................................. 5-1

5-6. Direct Mail Order System ........................................................................................................ 5-2

SECTION VI

Service

6-1 . I ntroduction .............................................................................................................................. 6-1

6-2. S a fe ty R e quirements ............................................................................................................... 6-1

6-3. Recommended Test Equipment ............................................................................................. 6-1

6-4. Module Block Diagram and Theory of Operation ................................................................... 6-1

6-5. A ttenuator Theory of Operation............................................................................................... 6-1

6-6. Main A s se mbly Theory of Operation ....................................................................................... 6-1

6-7. S e lf-Tests .................................................................................................................................. 6-4

6-8. Troubleshooting ....................................................................................................................... 6-10

6-9. Oscilloscope Module R e moval and R e placement ................................................................. 6-18

6-10. Trigger Cable Removal and R e placement ............................................................................. 6-20

6-11. Attenuator Removal and Replacement .................................................................................. 6-21

vi

Page 5

HP 16532A - Table of Contents

LIST OF TABLES

TABLE TITLE PAGE

1-1. HP 16532A Specifications........................................................................................................ 1-3

1-2. HP 16532A Operating Characteristics..................................................................................... 1-4

1-3. Recommended Test Equipment..............................................................................................1-9

3-1. P e rformance Test R e cord ........................................................................................................ 3-17

4-1. Ca libration Sequence............................................................................................................... 4-2

5-1. Reference Designator and Abbreviations................................................................................ 5-3

5-2. Replaceable Parts List.............................................................................................................. 5-5

LIST OF FIGURES

FIGURE TITLE PAGE

2-1. E ndplate Overlap - Top Sequence........................................................................................... 2-2

2-2. E ndplate Overlap - Bottom Sequence..................................................................................... 2-3

3-1. Voltage Measurement Accuracy Test........................................................................................ 3-7

4-1. E ndplate Overlap - Top Sequence........................................................................................... 4-3

4-2 . Location of the PROTECT/UNP ROTECT Switch..................................................................... 4-3

4-3 . Default Calibration Dis pla y....................................................................................................... 4-4

4-4. E xt T rig Null Calibration Connections......................................................................................4-7

4-5. E nd of Calibration Display........................................................................................................ 4-8

4-6. E ndplate Overlap - Top Sequence .......................................................................................... 4-8

5-1. Pa rts I de ntification.................................................................................................................... 5-4

6-1. HP 16532A Oscilloscope Block Diagram................................................................................ 6-2

6-2 . Startup Screen.......................................................................................................................... 6-4

6-3. Load Te st S ystem Screen........................................................................................................6-5

6-4. Test System Screen.................................................................................................................. 6-5

6-5. Functional Tests Screen........................................................................................................... 6-6

6-6. Main Test Menu ........................................................................................................................ 6-6

6-7. A /D Test Run Screen................................................................................................................ 6-7

6-8. S top Field.................................................................................................................................. 6-7

6-9. Exit Tes t System Screen..........................................................................................................6-8

6-10. Troubleshooting Flowchart ...................................................................................................... 6-13

6-11. Endplate Overlap - Top Sequence........................................................................................... 6-18

6-12. Endplate Overlap - Bottom Sequence..................................................................................... 6-19

6-13. Oscilloscope Module Exploded View...................................................................................... 6-20

vii

Page 6

TABLE OF CONTENTS

General Informatio n

1-1 . I ntroduction...........................................................................................................................1-1

1-2. Module Covered by Manual.................................................................................................1-1

1-3. S a fe ty R e quirements.............................................................................................................1-1

1-4. P roduct Description..............................................................................................................1-2

1-5. A ccessories Supplied ...........................................................................................................1-2

1-6. A ccessories Available...........................................................................................................1-2

1-7. S pecifications........................................................................................................................1-2

1-8. Operating Characteristics.....................................................................................................1-2

1-9. Recommended Test Equipment ..........................................................................................1-2

Page 7

1-1. Introduction

HP 16532A - General Information

SECTION I

General Information

Th e service policy for this instrument is replacement of defective asse mblies. This service guidel

contains information for finding a defective

assembly by testing and servicing the HP 16532A

1 GS a/s Oscilloscope Module. Also included in

the guide are installation procedures and a list of

recommended test equipment. This guide is

divided into six sections as follows:

I - General Information

II - Installation

III - Performance Tests

IV - C a libration

V- Replaceable Parts

V I - Service

Th e G e ne ra l I nformation S e ction includes safety

requirements, a product description, and a list of

accessories supplied and of accessories available.

Also included are table s lis ting specifications and

operating characteristics, and a list of

recommended test equipment.

To complete the service documentation for your

HP 16500 Logic Analysis System, place this

serv ice manu a l in the 3 - ring binder with your other

logic analysis system Service Guides.

1-2. Mo d ule Covered by This Ma nual

Th e inf ormation covered in this ma n ual is for the

HP 16532A 1 GSa/s Oscilloscope Module.

1-3. Safety Requirements

Specific warnings, cautions, a nd instructions are

placed wherever applicable throughout the

manual. These must be observe d during all

pha ses of opera tion, s ervi ce, and repa i r of the

module. Failure to comply with them violates

safety standards of design, manufa cture, a n d

intended use of this module.

Hewlett-Packard assumes no liability for the failure

of the customer to comply with these safe ty

requirements.

1-1

Page 8

HP 16532A - General Information

1-4. Product Description

The HP 16532A Oscilloscope Module is a 1 GS a /s

digitizing oscilloscope. Some of the main f e atures

are:

• 1 GSa/s digitizing for 250 MHz bandwidth sin-

gle shot analysis.

• 8000 samples per channel.

• Automatic pulse parame te rs , dis plays time be-

tween ma rke rs , acquires until s pecifi e d time

between ma rke rs is captured, performs statistical analys is on time betwee n ma rke rs .

• Lightweight miniprobes.

1-5. Accessories Supplied

Th e following accessories are supplied with the

HP 16532A Oscilloscope module. Quantity one

unless shown otherwise.

• Use r’s Refere nce and Programming R e f er-

ence set

• 24-pin IC test clip (HP 10211A)

• BNC-to-BNC ac coupling capacitor

(HP 10240B)

10:1 Probe:

• 1-MΩ, 7.5- pf miniprobe, 1 m (HP 10435A )

1:1 Probes:

• 40-pf miniprobe, 1 m (HP 10438A)

• 64-pf miniprobe, 2 m (HP 10439A)

• 50-Ω miniprobe, 2 m (HP 10437A)

100:1 Probe:

• 10-MΩ, 2.5- pf miniprobe, 2 m (HP 10440A )

1-7. Specifications

Module specifications are listed in table 1-1. These

specifications are the performance standards

against which the module is tested.

• Service G uide

• HP 10441A 10:1 probes, Qty 2

• Right angle BNC adapters, Qty 2

• BNC miniprobe adapter

• Mas te r- slave trigger cable

• Operating Sys tem Software

1-6. Accessories Available

• 10:1, 100:1, 50 Ω, 10 pf resistive divider probe

set, 1.2 m (HP 10020A)

• BNC-to-BNC cable, 1.2 m (HP 10503A)

1-8. Operating Characteristics

Ta ble 1 - 2 is a listing of the module operating

characteristics. The operating characteristics are

not specifications, but are the typical operating

characteristics included as a dditional information

for the user.

1-9. Recomme nded Test

Equipment

Equipment required to test and maintain the

HP 16532A Oscilloscope Module is listed in table

1-3. Other equi pment may be substituted if it

meets or e xceeds the critical specifications listed

in the table.

1-2

Page 9

HP 16532A - General Information

Table 1-1. HP 16532A S pecifications

HP 16532A SPECIFICATIONS

Type: 2- chann el s imulta ne ous a cquisition

(* ,1)

Bandwidth

Maximum Sample Rate: 1 Gigasample per second

Number of Channels: 2, 4 , 6, 8 simultaneous channels usi ng the s ame time base s etting(s)

OR

Up to 10 chan nels with independent time bases f or e ach pair of channels.

Up to 18 chann e ls with the HP 16501A Expansion Frame.

Rise Time

ADC: 8-bit real time

Vertical Resolution: 8 bits ov er 4 vertica l div i s i ons (± 0.4%)

Waveform Record Length: 8000 points

Time Interval Measurement Accuracy

Vertical (dc) Gain Acc ura c y

DC Offset Accurac y

Voltage Measurement Accuracy

Trigger Sensitivity

: dc to 250 MHz (real time, dc-coupled)

(2)

: 1.4 ns

(*,3,6)

(4)

: ± 1.5% of full scale

(* )

: ± (1.0 % of channel offset + 2.0% of full s cal e )

(* ,5)

: ± [(1.5% of full scale + offset accuracy) + (0.008 x V/div)]

(* )

: dc to 50 MHz: 0.063 x full scale, 5 0 to 250 MHz: 0.125 x full scale

: ± [(0.005% X ∆t)+ (2 x 10

6

−

x delay se tting)+ 150 ps]

Input Coupling: 1 MΩ: ac and dc, 50 Ω: dc only

(*)

Input R (selectable)

: 1 MΩ: ± 1%, 50 Ω: ± 1%

Input C: Approximately 7 pF

___________________________________________________________________________________________

NOTES:

* Specifications (valid within ± 10° C of auto-calibration temperature, excluding bandwidth− see

note 1 for bandwidth specification.)

1. Upper bandwidth reduces by 2.5 MHz for every degree C above 35° C.

=

bandwid th

0.35

1

sample rate

2. Rise time is calculate d from the formula:

3. S pe cification applies to the maximum s ampling rate. At lower rates, the s pecification is:

± [(0.005% x ∆t)+ (2 x 10

= 1.4 x sa mple inte rv a l). Sample interva l is defi ne d as

(t

r

-6

x delay setting) + (0.15 x sa mple interv a l)] for bandwidth limited signals

t

r

4. Vertical gain accuracy decreas es 0.0 8% per degree C from software cal ibra tion temper a ture.

5. D i gitizi ng le vel = (#vertical divisions)(

1

)(

), where LS B = 2

LSB

2

# bits in ADC

1

6. The T ime Inte rval Mea s ure me nt Accuracy deteriorates across multiple modules connected as one

unit with ea ch a dded module.

1-3

Page 10

HP 16532A - General Information

Table 1-2. HP 16532A Operating Characteristics

HP 16532A OPERATING CHARACTERISTICS

VERTICAL (at BNC)

Vertical Sensitivity Range (1:1 Probe):

4 mV/div to 10 V/div in 1-2-4 increments

DC Offset Range (1:1 Probe):

V e rtical Sensitiv ity Availa ble Offse t

4 mV/div to 100 mV/div ± 2 V

> 100 mV/div to 500 mV/div ± 10 V

> 500 mV/div to 2.5 V/div ± 50 V

> 2.5 V/div to 10 V/div ± 250 V

Probe Factors:

Any integer ratio from 1:1 to 1000:1

Maximum Safe Input Voltage:

1 MΩ: ± 250 V [dc + peak ac (< 10 KHz)]

50 Ω: ± 5 VRMS

Channel-to-Channel I solation:

dc to 50 MHz: 40 dB, 50 MHz to 250 MHz: 30 dB

TIM EBASE

Range:

1 ns/div to 5 s/div

Resolution:

20 ps

Delay Pre-trigger Range:

Ti me /div Setting Available Delay

1 µs to 5 s/div -8 x (s/div)

1 ns to 500 ns/div -4 µs

Delay Post-trigger Range:

1-4

Ti me /div Setting Available Delay

100 ms to 5 s/div 2.5 ks

1 µs to 50 ms/div 33,500 x (s/div)

1ns to 500 ns/div 16.7 ms

Page 11

TRIGGERING

Trigger Level Range:

Trigger Modes:

Immediate:

Edge:

Pattern:

HP 16532A - General Information

Table 1-2. HP 16532A Operating Characteristics (cont.)

Within display window (full scale an d offset)

Triggers imme diate ly a f ter a rming condition is met.

Triggers on rising or falling edge of any internal channel or external trigger,

count adjustable f rom 1 to 32,000.

Triggers on ente ring, e xiting, duration greater tha n, duration less than, and

duration in range for a specified pattern of both internal channels an d external

trigger, count adjustable from 1 to 32,000. Duration time range is a djustable

from 20 ns to 160 ms in 10 ns steps. Duration accuracy is approximately ± 3%

± 2 ns.

Auto-Trigger:

If enabled, the module will self-trigger if no trigger condition is found within

approximately 50 ms after arming.

Events Dela y:

Th e trigger can be s et to occur on the nth edge or pattern, as specified by the

user. The number of events (n) can be s et from 1 to 32,000 events. Maximum

count frequency is 7 0 MH z .

Intermodule:

Arms a n other mea sure me nt module or triggers the re a r pane l B NC .

Exte rn a l:

If ena bled, the oscilloscope will trigger on an ECL l ev e l s ignal (-1 . 3 V).

DIGITIZER

Resolution: 8 bits (1 part in 256)

Digitizing Rate: Up to 1 Gigasample per second

Digitizing Technique: Re al-time digitizing; each 8000 samples are acquired on a single acquisition

Acquisition Memory Size: 8000 samples per channel

1-5

Page 12

HP 16532A - General Information

Table 1-2. HP 16532A Operating Characteristics (cont.)

WAVEFORM DISPLAY

Displayed Wavefo rms:

Eight wave f orm windows maximum, with scrolling across 96 wav e f orms.

Display Forma ts:

W aveforms can be di splay ed in an ove rlapping and/or non-ov erla pping format.

Displa y capability of A − B and A+ B is also provided.

Display Resolution:

500 points horizontal, 240 points vertical

DISPLAY M ODES

Normal (Single):

New acquisition replaces old acquisition on screen.

Accu mu l at e:

New acquisition is displayed in addition to previous acquisitions until screen is

erased.

Average:

New a cquisitions are a veraged with old acquisitions, with the updated wav e f orm

displayed until era s e d. M a ximum number of a v e rages is 256.

Overlay:

Up to 8 acquired waveforms from separate channels can be ove rla ye d in the

same display area.

Connect-the-dots:

Provides a displa y of the s ample points connected by straight lines.

Waveform Reconstr uction:

Wh e n the re is insufficient data to fill e v ery horizontal location, a post acquisition

reconstruction filter fills in missin g data points for time bas e < 50 ns/div.

Waveform Math:

1-6

Displa y capability of A − B and A+ B functions is provided.

Page 13

Table 1-2. HP 16532A Operating Characteristics (cont.)

MEASUREMENT AIDS

Time Markers:

Tw o vertical markers, X and O, are provided for mea surements of time and

voltage. Capabilities are: measure voltage at point where X and O markers

cross each a n alog waveform; me asure time f r om trigger to X, trigger to O, and

X to O; automatic marker placement by specifying percentage of edge, edge

number, and rising or falling edge type; run until X to O > than, < than, in

range, and not in range provides selective event search; X to O statistics (mean,

max, an d min) provide analysis of time interval deviation.

Automatic Search:

Se arches for a percentage or an absolute voltage lev el at a positive or ne gative

edge, count adjusta ble from 1 to 100.

Auto Search Statistics:

HP 16532A - General Information

Mea n, maximum, an d minimum values for el apsed time from X to O ma rke rs for

multiple runs. Number of val id runs a n d total number of runs av a i la ble .

Automatic Measurements:

The following pulse parameter mea s ure me nts can be perf ormed automatically:

Freque ncy R is e time + pulse width

Pe riod Fall time − pulse width

V p-p Preshoot V

Overshoot

Grid:

Gr aticules ca n be displaye d i n backrou nd of wa vefor m.

Voltage Markers:

Tw o horizontal marke rs, A an d B, are provided for voltage measure me nts.

Th e se markers can each be placed on any acquisition channel trace. A delta

volt age display pr ovides delta V betwe en ma r k ers on t h e sa me cha nnel or

between two channels .

amplitude

*

(*gives difference between top and base

voltages; only available over bus)

1-7

Page 14

HP 16532A - General Information

Table 1-2. HP 16532A Operating Characteristics (cont.)

SETUP AIDS

Autoscale:

Autoscale s the vertical an d horizontal ra n ges , off s et, and trigger level to display

the input signals. Requires a frequency between 50 Hz and 250 MHz.

Presets:

Scale s the vertical ra n ge, offset, and trigger level to predetermined values for

displaying ECL or T TL waveforms.

Calibration:

V e rtica l, trigger, del a y, and all defaults . C alibration factors stored in NV-RAM on

the circuit board.

Probe Compensation Source:

External BNC su pplies a square wave approximately 0. 0 mV to -800 mV into the

open circuit at approximately 1000 Hz.

OPERATING ENVIRONMENT

Temperature:

Instrument, 0° to 5 5 ° C (+ 32° to 131° F). Probes and cables, 0° to 65° C (+ 32°

to 149° F).

Humidity:

Instrument, u p to 95% relativ e humidity a t + 4 0 ° C (+ 104° F). Recommended

disk media, 8% to 80 % relative humidity at + 4 0° C (+ 104° F).

Altitude:

To 4600 m (15,000 ft).

Vibration

Operation:

Random vibration 5-500 Hz, 10 minutes per a xis , ~ 0 . 3 g (rms).

Non-operating:

Random vibration 5-500 Hz, 10 minutes per a xis , ~ 2 . 41 g (rms); and swept

sine resonant search, 5-500 Hz, 0.75 g (0- peak), 5 minute resona nt dwell @ 4

resonances per axis.

1-8

Page 15

HP 16532A - General Information

Table 1-3. Recommended Test Equipment

EQUIPMENT CRITICAL SPECIFICATIONS RECOMMENDED MODEL USE*

Signal Generator Frequency: 1 - 250 MHz at approx .

170 mV RMS resolution

Output Accuracy: ± 1 dB

1 MHz time bas e accuracy 0.2 5 ppm

Dc Power Supply Range: − 35.000 to + 35.000 Vdc, ± 1 mV HP 6114A P

Digital Multime ter 0.1 mV resolution

Accuracy: better than 0.005%

R esistance mea s u rement: bette r th a n

0.25% accuracy

Power Meter/Sensor 1 - 250 MHz ± 3% accuracy HP 436/8482A P

Power Splitter Outputs differ by < 0.1 5 dB HP 11667B P

Blocking Capacitor 50 Ω BNC (m-to-f), 0.18 µF, ± 200 V HP 10240B P

Adapter 50 Ω BNC (m)(m) HP 1250-1236 C

Adapter 50 Ω Type N(m)- to-B N C (m) HP 1250-0082 P

Adapter 50 Ω BNC(f)-to-Dual Banana Plug HP 1251-2277 P

HP 8656B Option 001 P

HP 3458A P

Adapter 50 Ω Type N(m)-to-BN C (f ) HP 1250-0780 P

Tee Adapter 50 Ω BNC (m)(f)(f ) HP 1250-0781 P,C

Cable Type N(m-to-m) 24- i nch HP 11500B P

Cable 50 Ω BNC (m-to-m) 48-inch HP 10503A P

Cable 50 Ω BNC (m-to-m) 9 inch HP 10502A C

Cable 50 Ω BNC-SMB HP 16532-61601 C

*P= Performance Tests C= Calibrations

1-9

Page 16

1-10

Page 17

TABLE OF CONTENTS

Installation

2-1 . I ntroduction ......................................................................................................................... 2-1

2-2. Initial Inspection .................................................................................................................. 2-1

2-3. P reparation for Use ............................................................................................................. 2-1

2-4. P ower R e quirements .......................................................................................................... 2-1

2-5. S a fe ty R e quirements ........................................................................................................... 2-1

2-6. Module Installation .............................................................................................................. 2-1

2-7. Operating Environment ................................................................................................. ..... 2-4

2-8. S torage ................................................................................................................................ 2-4

2-9. P a ckaging ........................................................................................................................... 2-4

2-10. Tagging for Service ............................................................................................................. 2-4

Page 18

Page 19

HP 16532A - Installation

SECTION II

Installation

2-1. Introduction

This section explains how to initially inspect the

HP 16532A Oscilloscope Module, then how to

prepare it for use, storage, and shipment. Also

included are procedures for module installation.

2-2. Initial Inspection

Inspect the shipping container for damage. If the

shipping container or cushioning material is

damaged, it should be kept until the contents of

the shipment have been checked for

completeness and the module has been checked

mechanically and electrically. T h e contents of the

shipment should be as lis te d in the "Accessories

Supplie d" par agraph l ocated in Secti on I.

Procedures for checking electrical performance

are in Section III. If the contents of the container

are incomplete, there is mechanical damage or

defect, or the instrume nt does not pass the

performance tests, notify the nearest

Hewlett-Packard sales office.

2-4. Power Requirements

All power supplies required for operating the

HP 16532A Oscilloscope Module are supplied to

the module through the backplane connector in

the mainfra me .

2-5. Safety Requirements

Specific warnings, cautions, a nd instructions are

placed wherever applicable throughout the

manual. These must be observe d during all

pha ses of opera tion, s ervi ce, and repa i r of the

module. Failure to comply with them violates

safety standards of design, manufa cture, a n d

intended use of this module.

Hewlett-Packard assumes no liability for the failure

of the customer to comply with these safe ty

requirements.

2-6. Module Installation

If the shipping container is damaged, or the

cushioning material shows signs of stress, notify

the carrier as w e ll a s the Hewlett-P a ckard sa l e s

office. Keep the shipping material so the carrie r

can inspect it. Th e H e wle tt-P a ckard office will

arrange for repair or replacement at

Hewlett-Packard’s option without waiting for claim

settlement.

2-3. Preparation for Use

Rea d the Safety Considerations in the front of

this man u al and in Section I be f or e ins talling

or operating this module.

Do not inst all, remove , or replace the module

in the instrument unless the instrument power

is turned off.

The HP 16532A Oscilloscope Module will take up

one slot in the card cage. For ev e ry a dditional

HP 16532A Oscilloscope Module you install, you

will need an a dditional slot. Th e y may be insta lle d

in any slot and in any order. The install a tion

procedure for the module is continued,

step-by-step, on the next page.

2-1

Page 20

HP 16532A - Installation

Module Insta llation (cont. )

The effects of ELECTR OST ATIC D ISCHARG E can damage electronic components. U se grounded wrist straps and mats when you are performing any kind of

service to this module.

Installation Considerations

• The HP 16532A Oscilloscope Modules can be installed in any available card slot.

• For multiple modules connected as one unit, the ma s te r card must be placed in the s lot above the

expander cards. The ma s ter card and expander cards must be in adjoining slots.

• Cards or filler panels below the e mpty slots intended for module installation do not have to be re-

moved to install a module above them.

Proced u r e:

1. T urn i ns trume nt power switch off, unplug power cord and disconnect any input connections.

2. Starting from the top, loosen the thumb screws on the fille r pane ls and cards.

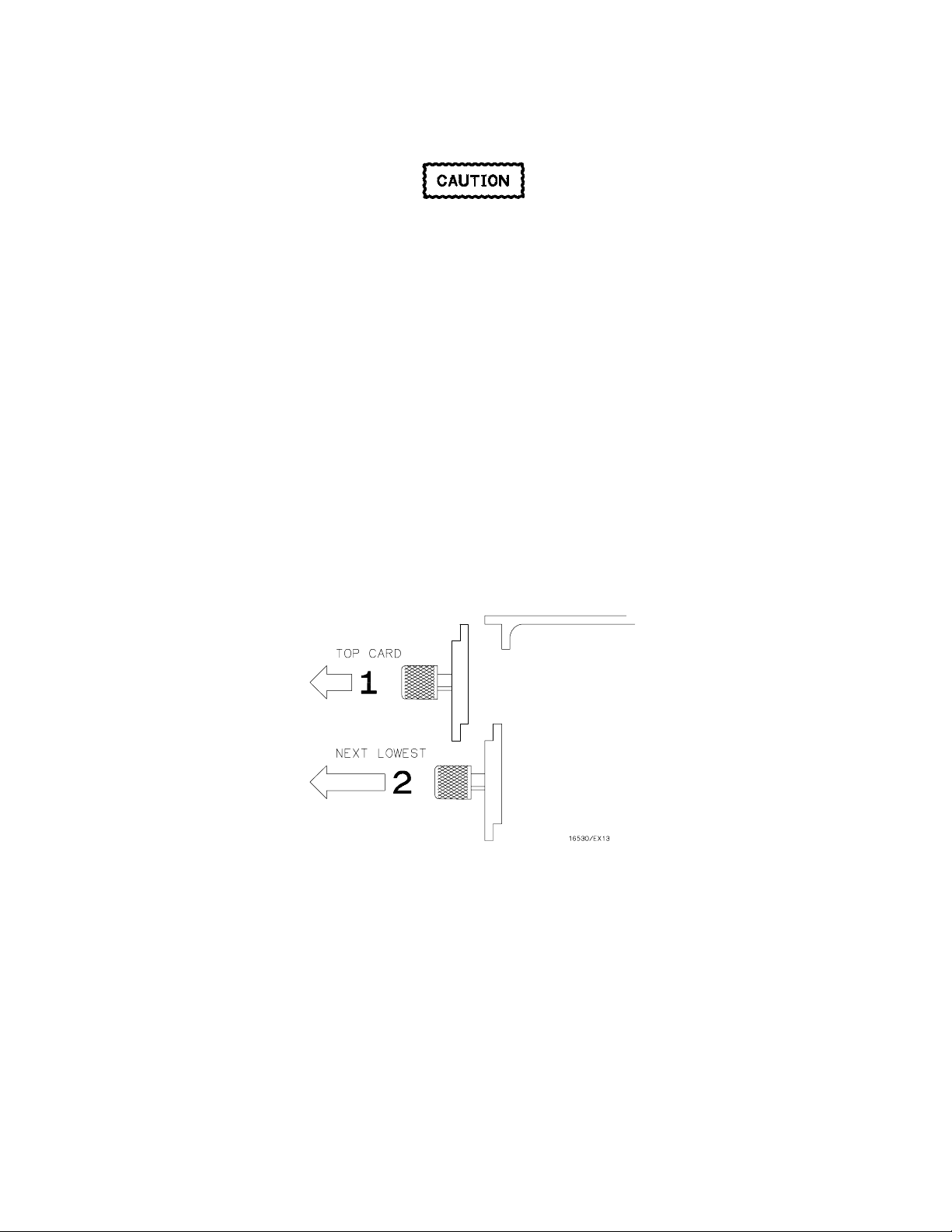

3. Starting from the top, begin pulling out the cards and filler panels halfway. See figure 2-1.

Figure 2-1. Endplate Ov erlap - Top Sequence

2-2

Page 21

HP 16532A - Installation

4. S lide the oscilloscope module into the card cage approximately halfway.

5. If you hav e more oscilloscope cards to install, slide them into the card cage approximately halfway.

6. F irmly s eat the bottom card into the backplane connector. Keep applying pressure to the center

of the card endplate while tightening the thumb screws finger tight.

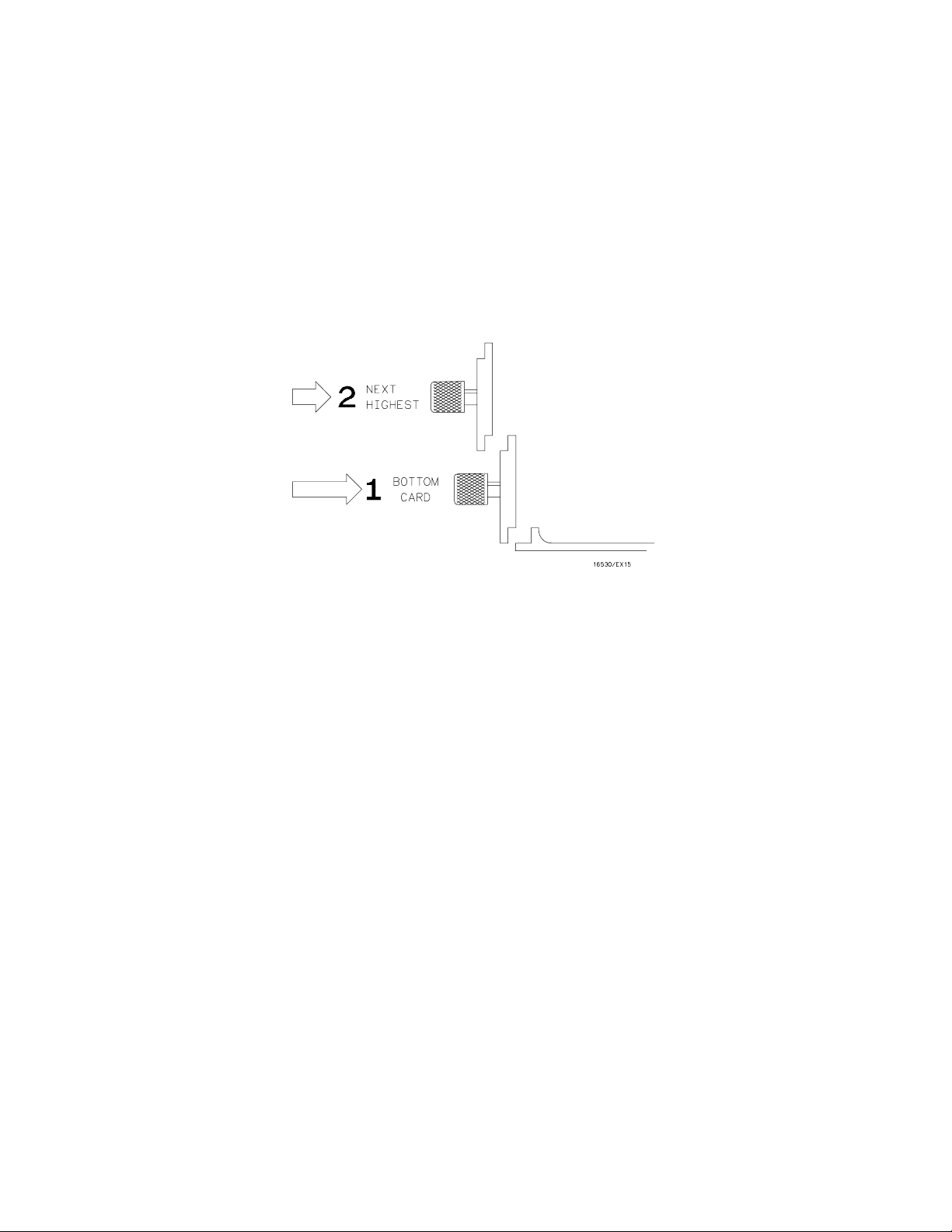

7. Repeat step 6 for all cards and filler panels in a bottom-to-top order. See figure 2-2.

8. A ny fille r pane ls tha t a re not used should be kept for future use. Fille r pane ls must be ins t alle d i n all

unused card slots for correct air circulation.

F igure 2-2 . Endplate Overlap - Bottom Sequence

2-3

Page 22

HP 16532A - Installation

2-7. Operating Environment

Th e operating env ironment is lis te d in table 1-2 of

Se ction I of this manu a l. N ote s h ould be made of

the non-condensing humidity limitation.

Condensa tion within the instrume nt can cause

poor oper ation or malfun ct ion . Protect i on should

be provided against internal condensation.

The HP 16532A Oscilloscope Module will operate

at all specifications within the te mpera ture an d

humidity range giv en in table 1-2. H owe ver,

reliability is enhanced when operating the module

within the following ranges.

• Temperature: + 20 °C to + 35 °C (+ 68 °F to

+ 95 °F)

• Humidity: 20% to 80% non-condensing

2-8. Storage

T h e module m ay be s tor e d or shippe d i n

environments within the following limits:

2-9. Packaging

The following general instructions sh ould be us ed

for repacking the module with commercially

availa ble ma teria ls .

• Wrap the module in antis tatic plastic.

• Use a strong shipping container. A double-

walled carton made of 350-lb test material is

adequate.

• Use a layer of shock-absorbing material 70 to

100 mm (3- to 4-inch) thick around all sides of

the module to provide firm cushioning and to

prevent movement within the container.

• Seal the shipping container securely.

• Mark the shipping container FRAGILE to en-

sure proper handling.

• In any correspondence, refer to the module

by its model number and serial number.

• Temperature: − 40 °C to + 75 °C

• Humidity: Up to 90% at 65 °C

• Altitude: Up to 15,300 meters (50,000 feet)

The module should also be protected from

temperature extremes which cause condensa tion

on the instrument.

2-10. Tagging for Service

If the module is to be shipped to a

Hewlett-Packard sales office for service or repair,

attach a tag showing owner (with address),

complete se ria l number, a n d a des cription of the

service required.

2-4

Page 23

TABLE OF CONTENTS

Performance Tests

3-1 . I ntroduction ......................................................................................................................... 3-1

3-2. Recommended Test Equipment ........................................................................................ 3-1

3-3. Test Record ......................................................................................................................... 3-1

3-4. P e rformance Test Interval .................................................................................................. 3-1

3-5. P e rformance Test Procedures ........................................................................................... 3-1

3-6. DC C AL OUTPUT Test ........................................................................................................ 3-2

3-7. A C C AL OUTPUT Test ........................................................................................................ 3-3

3-8. Input Resistance ................................................................................................................. 3-4

3-9. Voltage Measurement Accuracy ........................................................................................ 3-6

3-10. Offse t A ccuracy .................................................................................................................. 3-9

3-11. Ba ndwidth ........................................................................................................................... 3-11

3-12. Time Measurement Accuracy.............................................................................................. 3-13

3-13. Trigger Sen s itivity ............................................................................................................... 3-15

Page 24

Page 25

HP 16532A - Performance Tests

SECTION III

Pe rformance Tests

3-1. Introduction

Th e procedures in this section test the

oscilloscope module’s electrical performance

using the specifications listed in Se ction I as the

performance standards. All tests can be

performed without access to the inte rior of the

instrument. At the end of this section is a f orm that

can be used as a record of performance test

results.

3-2. Recomme nded Test Equipment

Equipment recommended for performance tests is

listed in table 1-3. Any equipment that satisfies the

critical specifications given in the ta ble ma y be

substituted for the re commended models .

3-3. Test Record

R esults of performance tests ma y be ta bula te d on

the Performance Test Record (table 3-1) at the end

of the procedures. The test record lists all of the

tested spe cifications an d their acceptable limits.

Th e re s ults re corded on the test record may be

used for comparison in periodic maintenance a nd

troubleshooting or after repairs a n d adjustments

have been made.

3-4. Performance Test Interval

Pe riodic performance verification of the

HP 16532A Oscilloscope Module is required at

one-yea r inte rv als. Th e instrument’s performance

should be verified after it has been serviced, or if

improper operation is suspected. Calibration

sh ou ld be performe d before any performance

verif ication checks.

3-5. Performance Test Procedures

Al l perform a n ce tes ts should be performed at the

environmental opera ting temperature of the

instrument, af te r a 30-minute w a rmup period.

3-1

Page 26

HP 16532A - Performance Tests

3-6. DC CAL OUTPUT Test

Th e DC CAL OUTPUT port on the rear pane l is used for instrument cali bration an d probe calibration.

Th ough calibrator accuracy is not specified in the performance specifications, it must be within limits in order t o p rovi de accurat e calibration.

Test Limits:

5.000 V ± 10 mV

Equipment Required:

The f ollowing equipment is required for the test.

Recommended

Equipment Required Critical Specification

Model/ Part Number

Digital Multime te r

Cable

Adapter

Procedure:

1. Us e the BNC-to-bana n a a da pter to connect the BNC cable between the multime te r a n d the oscillo-

scope module DC CAL OUTPUT connector.

2. On the oscilloscope module set the following parameters in the order given:

Menu Selection Setting

Calibration Mode

3. The DVM should read close to 0.0000 V. Record the reading to four decimal places.

V1 = __________ .

0.1 mV resolution, better than 0 .005% accuracy

50 Ω BNC (m to m) 48- in ch

50 Ω BNC (f) to Dual Banana Plug

Service Calibration

Procedure

DC Volts

DC Cal BNC

0 V

HP 3458A

HP 10503A

HP 1251-2277

4. In the Calibration menu se t the DC V olts to 5 V.

5. The DVM should read close to 5.0000 V. Record the reading to four decimal places.

V2 = __________ .

6. In the Calibration menu se t the DC V olts to 0 V.

7. Subtract V1 from V2. The difference should be between 4.990 and 5.010 V. Record the reading in

the performance test record.

3-2

Page 27

HP 16532A - Performance Tests

3-7. AC CAL OUTPUT Test

Th e AC CAL OUTPU T port on the rear pane l is used for instrument cali bration an d probe compensation.

Th ough calibrator accuracy is not specified in the performance specifications, it must be within limits in order t o p rovi de accurat e calibration.

Test Limits:

1000 Hz ± 10%, 0.8 V p_p ± 10%

Equipment Required:

The f ollowing equipment is required for the test.

Recommended

Equipment Required Critical Specification

Cable 50 Ω BNC (m to m) 48-inch HP 10503A

Model/ Part Number

Procedure:

1. Use the BNC cable to connect the AC C AL OUT PUT to channel 1 input of the oscilloscope module.

2. On the oscilloscope module set the following parameters in the order given:

Menu Selection Setting

Calibration

Channel

3. In the Calibration menu select AUTOSCALE.

4. In the Auto-Meas ure me nu verify that the wa v eform is approximately 0 . 8 Vp_ p at a pproximately

1000 Hz. Record the reading in the performance test record.

Mode

Procedure

Signal

Coupling

Probe

Service Calibration

Oscillator Output

Probe Compensation

1 MΩ/DC

1:1

3-3

Page 28

HP 16532A - Performance Tests

3-8. INPUT RESISTANCE

This tes t verifies the input resistance of the oscilloscope module. A four-wire meas ure me nt is us ed for accuracy at 50 Ω.

Specification:

1 M Ω ± 1% and 50 Ω ± 1%

Equipment Required:

The f ollowing equipment is required for the test. Procedures are base d on the model or part numbers recommended.

Recommended

Equipment Required Critical Specification

Model/ Part Number

Digital Multime te r

Cables (2)

Adapter

Adapte rs ( 2 )

Procedure:

1. S et up the multimeter to make a 4- wire re s is ta nce me asurement.

2. Us e the B N C - to-banana adapters to connect one end of each BNC cable to the 4-wire re s is ta nce

connections on the multimete r, a n d connect the free e n ds of the cable s to the BNC T ee.

3. Connect the male end of the BNC tee to the channel 1 input of the oscilloscope module. Set up the

oscilloscope module according to the following parameters in the order given:

Menu Selection Setting

Channel

Meas ure res is tance (4- wire ) better than 0.2 5 %

accuracy

50 Ω BNC (m to m) 48 - i nch

50 Ω BNC Tee (m)(f)(f)

50 Ω BNC (f) to Dual Banana Plug

Input

Probe

V/Div

Offset

Coupling

1

1:1

20 mV

0 V

50 Ω / DC

HP 3458A

HP 10503A

HP 1250-0781

HP 1251-2277

Trigger

3-4

Mode

Immediate

Page 29

HP 16532A - Performance Tests

4. Select RUN - SINGLE . The clicking of attenuator relays sh ould be audible. Verify res is tance rea dings on the digital multimeter of 50 Ω ± 0.5 Ω (49.5 to 50.5 Ω).

5. In the Channel menu change the Coupling field to 1 MΩ/DC.

6. S e l ect RUN. The clicking of attenuator relays should be audible. Verify resistance readings on the

digital multimeter of 1 MΩ ± 10 kΩ (0.990 to 1.010 MΩ).

7. In the Channel menu change the Coupling field to 50 Ω/DC and V/Div to 200 mV/Div. Repeat steps

4 through 6.

8. In the Channel menu change the Coupling field to 50 Ω /DC and V/Div to 1 V/Div. Repeat steps 4

through 6.

9. In the Channel menu change the Coupling field to 50 Ω /DC and V/Div to 4 V/Div. Repeat steps 4

through 6.

10. Connect the male end of the BNC tee to the channel 2 input of the oscilloscope module.

11. Repeat ste ps 3 through 9 for channel 2 , r e placing channe l 1 with channel 2 w h e r e applicable.

Note

If a reading is not within limits, then the attenua tor for the out-of-bounds channel

shou ld be r eplaced. See "Serv ice" in Section VI.

3-5

Page 30

HP 16532A - Performance Tests

3-9. VOLTAGE MEASUREMENT ACCURACY

Thi s te st verifie s the DC voltage me asurement a ccuracy of the instrume nt. This procedure use s a dual cursor measureme nt that nullifies offse t e rror, resulting in the following measure me nt:

± [(1.5% of full s cale) + (0.016 x V/div)].

Specification:

± [(1.5% of full s cale + offset accuracy) + (0.008 x V/div)]

Equipment Required:

The f ollowing equipment is required for this test. Procedures are bas ed on the model or part numbers recommended.

Recommended

Equipment Required Critical Specification

Model/ Part Number

DC Power Supply

Digital Multime te r

Cable

Adapter

(cable to power supply)

Adapter

Blocking Capacitor

-14 Vdc to + 14 Vdc, 0.1 mV resolution

Better than 0.1% accuracy

50 Ω BNC (m to m) 48-i nch

50 Ω BNC (f) to Dual Banana Plug

50 Ω BNC tee (m)(f)(f)

50 Ω BNC (m to f) 0.18 µF, 200 V

HP 6114A

HP 3458A

HP 10503A

HP 1251-2277

HP 1250-0781

HP 10240B

3-6

Page 31

HP 16532A - Performance Tests

Proced ure:

1. Using a BNC adapter, connect one end of the cable to the power supply. Connect the BNC tee,

the blocking capacitor, and the s h orting endcap to the other end of the cable. R efer to figure 3-1.

Figure 3-1 . Voltage Measurement Accuracy Test

2. In the Wav e form Selection menu delete channel 2. If channel 1 is not inserted, insert channel 1. Set

the following parameters in the order given.

Menu Selection Setting

Channel

Trigger

Display

Input

Probe

Coupling

s/Div

Mode

Mode

Average #

Grid

Markers

1

1:1

1 MΩ / DC

500 ns

Immediate

Average

8

On

On

Set the C ha nnel

result.

Coupling

field to 1 MΩ/DC or damage to the equipment will

3-7

Page 32

HP 16532A - Performance Tests

Use the f ollowing table for steps 3 through 9.

V/Div Offset Supply Upper Limit Lower Limit

4 V/Div

1 V/Div

400 mV/Div

40 mV/Div

40 mV/Div

400 mV/Div

1 V/Div

4 V/Div

3. With the power supply disconnected from the channel input, se t the C h a nn e l me nu to the V/Div

range and offset values shown in the first line of the table.

4. On the oscilloscope, select RUN - REPETITIVE and wait for approximately fiv e seconds, then select

STOP. Read the voltage displaye d under the chan nel label on the lef t of the dis play. Enter this

value on the performance test record in the "Ze r o Input" column.

5. Set the power supply to the first supply value listed in the table. Connect the power supply to the

channel input as s hown in figure 3 - 1 .

6. On the oscilloscope, select RUN - REPETITIVE and wait for approximately fiv e seconds, then s elect

STOP. Read the voltage displaye d under the chan nel label on the lef t of the dis play. Enter this

value on the pe rformance te s t re cord in the "Measured" column.

7. To obtain the tes t re s ults , subtract the Zero Input voltage from the Measured voltage listed in the

performance test record. For ex a m ple: (M easured) - (Z ero Input) = (Actual). When calculating the

results, observ e the plus or minus value of the v oltage measurements . Record the results in the pe rformance test record in the "Actual" column.

-7.0 V

-1.75 V

-700.0 mV

-70.0 mV

70.0 mV

700.0 mV

1.75 V

7.0 V

-14.0 V

-3.50 V

-1.40 V

-140.0 mV

140.0 mV

1.40 V

3.50 V

14.0 V

-13.7 V

-3.43 V

-1.37 V

-137.0 mV

143.0 mV

1.43 V

3.57 V

14.3 V

-14.3 V

-3.57 V

-1.43 V

-143.0 mV

137.0 mV

1.37 V

3.43 V

13.7 V

8. Repeat ste ps 3 through 8 for the second line of the table, then f or the res t of the line s of the ta ble f or

channel 1.

9. In the Wav e form Selection menu, select Input channel 2. Delete channel 1 and insert channel 2. Repeat steps 2 through 8 for channe l 2, replacing channel 1 with channe l 2 where applicable.

3-8

Page 33

HP 16532A - Performance Tests

3-10. OFFSET ACCURACY

This test verifies the offset accuracy.

Specification:

± (1.0% of chann e l offset + 2.0% of full scale)

Equipment Required:

The f ollowing equipment is required for the test. Procedures are base d on the model or part numbers recommended.

Recommended

Equipment Required Critical Specification

Model/ Part Number

DC Power Supply

Digital Multime te r

Cable

Adapter

Procedure:

Zero-Input Offset

1. Disconnect all cables and probes from the oscilloscope inputs. In the Waveform Selection menu delete channel 2. If channel 1 is not inserted, insert channel 1. Then set up the oscilloscope module

according to the following parameters in the order given:

Menu Selection Setting

Channel

− 35.000 to + 35.000 Vdc, ± 1 mV resolution

Better than 0.1% accuracy

50 Ω BNC (m to m) 48-i nch

50 Ω BNC (f) to Dual Banana Plug

Input

Probe

v/Div

Offset

Coupling

s/Div

1

1:1

4 V

0 V

1 MΩ / DC

500 ns

HP 6114A

HP 3458A

HP 10503A

HP 1251-2277

Trigger

Display

2. With the DC power supply disconnected from the channel input, make sure the m a rke rs are ne ar

the center of the display.

Mode

Mode

Average #

Grid

Markers

Immediate

Average

32

On

On

3-9

Page 34

HP 16532A - Performance Tests

3. Select RUN - REPETITIVE. Wait approximately 1 5 seconds (avera ging complete), then select

ST OP. The display should read 0.00 V ± 320.0 mV as read from the markers voltage field. Record

the reading in the performance test record.

4. In the Channel menu, change the vertical sensitivity to 1 V/Div. Select RUN - REPETITIVE and wait

approximately 15 s econds (ave ra ging complete), then select ST O P. Th e displa y s h ould rea d 0. 00 V

± 80.0 mV. Record the reading in the performance test record.

5. In the Channel menu, change the vertical sensitivity to 100 mV/Div. Select RUN - REPETITIVE and

wait approximately 15 seconds (avera ging complete), then select ST O P. Th e displa y s h ould rea d

0.00 V ± 8.0 mV. Record the reading in the performance test record.

6. In the Channel menu, change the vertical sensitivity to 10 mV/Div. Select RUN - REPETITIVE and

wait approximately 15 seconds (avera ging complete), then select ST O P. Th e displa y s h ould rea d

0.00 V ± 800.0 µV . Record the reading in the performance test record.

DC Input Offset

Set the C ha nnel

Coupling

field to 1MΩ / DC or damage to the equipment will

result.

7. Use the BNC-to-banana adapter to connect the BNC cable between the power supply and channel

1 input. Monitor the power supply using a voltmete r.

8. Use the following table for the next steps:

V/Div Offs et Supply Min Max

1 V/Div

100 mV/Div

20 mV/Div

20 mV/Div

100 mV/Div

1 V/Div

9. In the Channel menu se t the V/Div range and offset per the first line of the table. Set the power

supply per the first line of the table.

10. On the oscilloscope, select RU N - REPETITIVE and wait approximately 15 seconds (avera ging

complete), then ST OP.

− 35.00 V

− 10.00 V

− 2.00 V

+ 2.00 V

+ 10.00 V

+ 35.00 V

− 35.00 V

− 10.00 V

− 2.00 V

+ 2.00 V

+ 10.00 V

+ 35.00 V

− 35.4 V

− 10.1 V

− 2.02 V

+ 1.98 V

+ 9.90 V

+ 34.6 V

− 34.6 V

− 9.90 V

− 1.98 V

+ 2.02 V

+ 10.1 V

+ 35.4 V

11. Read the voltage from the marke rs v oltage f ield. It should be within the limits given in the table. R ecord the reading in the performance test record.

12. Repeat steps 7 through 10 for the remaining lines of the table using the V/Div range, offse t, a n d supply voltages given in the table.

13. In the Channel menu sele ct channel 2. In the Waveform Selection menu delete channel 1 and insert

channel 2.

14. Repeat ste ps 1 through 12 for channe l 2, replacing channel 1 with channe l 2 where a pplicable .

3-10

Page 35

HP 16532A - Performance Tests

3-11. BANDWIDTH

This tes t checks the bandwidth of the oscilloscope module.

Specification:

Bandwidth (dc coupled) dc to 250 MHz

Equipment Required:

The f ollowing equipment is required for this test. Procedures are bas ed on the model or part number recommended.

Recommended

Equipment Required Critical Specification

Model/ Part Number

Signal Generator

Powe r Meter/Sensor

Power Splitter

Cable

Adapter

Procedure:

1. With the N cable, connect the si gna l ge n e r a tor to the power splitter in put. C onn e ct the power

sens or to one output of the power splitter.

2. U s i ng a n N- to-B N C adapter, connect the other power splitter output to the Channel 1 in put of the

oscilloscope module.

3. In the Waveform Selection menu delete channel 2. If channel 1 is not inserted, insert channel 1.

Set the following parameters.

Menu Selection Setting

1 - 250 MHz at approx 170 mVrms

1 - 250 MHz ± 3 % accur acy

Out put s diffe r by < 0.1 5 dB

Ty pe N (m to m) 2 4-inch

50 Ω Type N (m) to BN C (m)

HP 8656B

HP 436/8482A

HP 11667B

HP 11500B

HP 1250-0082

Channel

Trigger

Display

Input

Probe

v/Div

Offset

Coupling

s/Div

Mode

Level

Mode

Average #

Grid

Markers

1

1:1

80 mV

0 V

50 Ω / DC

200 ns

Edge

0 V

Average

32

On

Off

3-11

Page 36

HP 16532A - Performance Tests

4. Set the signal generator for 1MHz at − 2.4 dBm. On the oscilloscope, select RUN - REPETITIVE. The

signal on the scree n s h ould be two cycles a t thre e divisions amplitude.

5. After the measurement settles (averaging complete, about 15 seconds), select STOP. In the

Auto-Me asure menu note the V

reading. V

p-p

= __________ mV.

1MHz

6. S e t the power me ter C a l Factor % to the 1MHz va l ue from the calibration chart on the power splitter.

Then press dB[REF] to set a 0 dB reference.

7. Change the signal generator to 250 MHz. Set power meter Cal Factor % to the 250 MHz value from

the chart.

8. A djust the s i gnal gen e ra tor amplitude for a power rea ding as close a s possi ble to 0. 0 dB[REL].

Reading = __________ dB.

9. Se t the oscilloscope s/Div for 2 ns/Div and select RUN- REPETITIVE.

10. After the measurement settles (averaging complete), select STOP. In the Auto-Measure menu note

the V

reading. V

p-p

= ________mV.

250MHz

11. Calculate the re s ponse us in g the formula:

V

250

response (dB

) = 20 log

10

Mhz

1

MHz

= 20

V

(_____) = ______

log

10

dB

12. Correct the result from step 1 1 with any diffe re n ces in the power m e te r f r om ste p 8. O bserve si gns.

For example:

R esult from step 1 1 = − 2.3 dB

Pow er mete r r eading = − 0.2 dB[RE L]

then true re s ponse = (− 2.3) − (− 0.2) − 2.1dB

(__________) − (__________) = ____________ dB

13. The result fr om ste p 1 2 should be ≤ − 3.0 dB. Record the result in the Performance Test Record.

14. In the Channel menu select channel 2. In the Waveform Selection menu delete channel 1 and

insert channel 2.

15. Repeat ste ps 2 through 14 for channe l 2, replacing channel 1 with channe l 2 where a pplicable .

Note

F a ilure of the bandwidth test can be caused by a fa u lty at tenua tor or main

assembly.

3-12

Page 37

HP 16532A - Performance Tests

3-12. TIME MEASUREMEN T ACCURACY

This te s t us e s a precise frequency source to check the accuracy of time measurement functions.

Specification:

−

± [(0.005% x ∆t) + (2 x 10

Equipment Required:

The f ollowing equipment is required for this test. Procedures are bas ed on the model or part number recommended.

Equipment Required Critical Specification

6

x delay se tting) + 150 ps]

Recommended

Model/ Part Number

Signal Generator

Cable

Adapter

200 MHz, timebase accuracy 0.25 ppm

50 Ω BNC (m to m) 48-inch

50 Ω Type N (m) to BN C (f)

HP 8656B Opt. 001

HP 10503A

HP 1250-0780

Procedure:

1. Set the signal generator to 181.81818 MHz (5.5 ns period) and approximately 600 mV rms.

2. Use the N-to-BNC adapter to connect the cable to the signal generator. Connect the free end of the

BNC cable to the channel 1 input.

3. In the Wav e form Selection menu delete channel 2. If channel 1 is not inserted, insert channel 1. Set

the following parameters in the order given:

Menu Selection Setting

Channel

Input

Probe

v/Div

Offset

Coupling

s/Div

1

1:1

400 mV

0.0 V

50 Ω / DC

2.00 ns

Trigger

Display

Mode

Source

Level

Slope

Mode

Grid

Edge

Chan 1

0.0 V

Positive

Normal

On

3-13

Page 38

HP 16532A - Performance Tests

4. Se le ct the Markers Auto menu, and set the following parameters:

Menu Selection Setting

Markers

Auto

5. Se le ct DONE. On the oscilloscope module select RUN - REPETITIVE. If the waveform is clipping,

reduce the signal ge n e ra tor output voltage level until the waveform no longer clips. All ow the oscilloscope module to run approximately two minutes, the n s elect ST O P.

6. In the statistics fiel d, check to see tha t the M EAN X-O fie l d is a pproximately 5.500 ns. Check that

both the MIN X -O and the MA X X-O a re within 150 ps of the MEAN X-O. Record the results in the

performance test record.

7. Se le ct the Markers Auto menu, and set the following parameters:

Menu Selection Setting

X →

O→

Statistics

Set on cha n 1

at Level 50%

Slope Positive

Occur 1

Set on cha n 1

at Level 50%

Slope Positive

Occur 2

On

Markers

Auto

8. Sele ct DONE. In the Display menu, set MODE AVERAGE #8 and DEL AY 99.00 ns. Select R U N-REPE TITIV E and allow the oscilloscope module to run approximately two minutes. Select ST O P.

9. In the statistics fiel d, check to see tha t the M EAN X-O fie l d is a pproximately 99.000 ns. Check that

both the MIN X -O and the MA X X-O a re within 155 ps of the MEAN X-O. Record the results in the

performance test record.

X →

O→

Statistics

Manual

Set on cha n 1

at Level 50%

Slope Positive

Occur 1

On

Note

Failure of the time measurem ent accuracy test can be caused by a defective

main assem bly.

3-14

Page 39

HP 16532A - Performance Tests

3-13. TRIGGER SENSITIVITY

Th is te s t checks chan ne l triggers for sensitivity a t rate d ban dwidth.

Specification:

dc to 50 MHz : 0.063 x full scale (0.25 division)

50 to 250 MHz : 0.125 x full scale (0. 5 divis i on)

Equipment Required:

The f ollowing equipment is required for this test. Procedures are bas ed on the model or part number recommended.

Recommended

Equipment Required Critical Specification

Model/ Part Number

Signal Generator

Cable

Adapter

50 and 250 MHz, 30-80 mV

50 Ω BNC 48-inch

50 Ω Type N (m) to BN C (f)

rms

output

HP 8656B Opt. 001

HP 10503B

HP 1250-0780

Procedure:

1. In the Wav e form Selection menu delete channel 2. If channel 1 is not inserted, insert channel 1. On

the oscilloscope module set the following parameters in the order given:

Menu Selection Setting

Channel

Trigger

Input

Probe

v/Div

Offset

Coupling

s/Div

Mode

Source

Level

1

1:1

400 mV

0 V

50 Ω / DC

20 ns

Edge

Chan 1

0 V

Display

Mode

Average #

Grid

Markers

Average

8

On

Off

2. With an N- to-B N C adapter and BNC cable, connect the signa l ge n e r a tor to channe l 1 input.

3-15

Page 40

HP 16532A - Performance Tests

3. Se t the signal generator for a 50 MHz a nd 35 mV rms signal. On the oscilloscope module select

RUN - REPETITIVE.

4. In the Auto-Measure menu read V

close to and not more than 100 mV

. Adjust the signal generator output level so that the signal is

p_p

.

p_p

5. In the Trigger menu a djust the trigger lev el for a stable displa y. The test passe s if the trigger is stable. Record whether the trigger is sta ble or is n ot stable.

6. On the oscilloscope module select STOP. Se t the signal generator frequency to 250 MHz and

70 mV rms signal level.

7. In the Channel menu change s/Div to 5 ns/Div and select RUN.

8. In the Auto-Measure menu read V

close to and not more than 200 mV

. Adjust the signal generator output level so that the signal is

p_p

.

p_p

9. In the Trigger menu a djust the trigger lev el for a stable displa y. The test passe s if the trigger is stable. Record whether the trigger is sta ble or is n ot stable in the performance te s t re cord.

10. On the oscilloscope module select STOP. In the Channel menu sele ct channel 2. In the Trigger

menu select Source channel 2. In the Waveform Selection menu delete channel 1 and insert

channel 2.

11. Repeat ste ps 1 through 9 for channel 2 , r e placing channe l 1 with channel 2 w h e r e applicable.

Note

Failure of the trigger sensitivity t est can be caused by a defective m ain

assembly.

3-16

Page 41

HP 16532A - Performance Tests

Hewlett-Packard

Table 3-1. Performance Test Record

Tested by ______________________________

Model 16532A

Oscilloscope Module

Serial No.:

____________________

R ecommended Pe rf ormance

V e rif ication Inte rv a l:

12 M onths

Work Order No. _________________________

Date Tested ____________________________

Paragraph No. Test Results

3-6 DC CAL OUTPUT

5.000Vdc

3-7 AC CAL OUTPUT

3-8 Input Resistance

0.8Vp_p

1000Hz

Ω± 0.5Ω (49.5 to 50.5Ω)

50

1M

Ω± 10KΩ (0.990 to

1.010M

± 10mV

± 10%

± 10%

Ω)

Minimum Maximum Actual

4.990Vdc 5.010Vdc ____________Vdc

Minimum Maximum Actual

0.72Vp_p 0.88Vp_p ____________Vp_p

Minimum Maximum Actual

900Hz 1100Hz ____________Hz

Channel 1 Reading

Ω @ 20mV/Div _____________Ω

50

1M

Ω @ 20mV/Div _____________Ω

Ω @ 200mV/Div _____________Ω

50

1M

Ω @ 200mV/Div _____________Ω

50

Ω @ 1V/Div _____________Ω

Ω @ 1V/Div _____________Ω

1M

50

Ω @ 4V/Div _____________Ω

1M

Ω @ 4V/Div _____________Ω

3-9 Voltage Measurement Accuracy

Upper Limit Lower Limit

-13.7V -14.3V

-3.43V -3.57V

-1.37V -1.43V

-137.0mV -143.0mV

143.0mV 137.0mV

1.43V 1.37V

3.57V 3.43V

14.3V 13.7V

Channel 2 Reading

50

Ω @ 20mV/Div _____________Ω

1M

Ω @ 20mV/Div _____________Ω

50

Ω @ 200mV/Div _____________Ω

Ω @ 200mV/Div _____________Ω

1M

50

Ω @ 1V/Div _____________Ω

1M

Ω @ 1V/Div _____________Ω

Ω @ 4V/Div _____________Ω

50

1M

Ω @ 4V/Div _____________Ω

Channel 1

Zero Input Measured Actual

__________ __________ __________V

__________ __________ __________V

__________ __________ __________V

__________ __________ __________mV

__________ __________ __________mV

__________ __________ __________V

__________ __________ __________V

__________ __________ __________V

3-17

Page 42

HP 16532A - Performance Tests

Ta ble 3-1. Performance Test Record (Continued)

Paragraph No. Test Results

3-9 Voltage Measurement Accuracy

(continued)

Upper Limit Lower Limit

-13.7V -14.3V

-3.43V -3.57V

-1.37V -1.43V

-137.0mV -143.0mV

143.0mV 137.0mV

1.43V 1.37V

3.57V 3.43V

14.3V 13.7V

3-10 Offset Accuracy

Zero-input Offset-Channel 1

Offset Accuracy

DC Input Offset-Channel 1

Channel 2

Zero Input Measured Actual

__________ __________ __________V

__________ __________ __________V

__________ __________ __________V

__________ __________ __________mV

__________ __________ __________mV

__________ __________ __________V

__________ __________ __________V

__________ __________ __________V

V/Div Setting Reading Actual

4V/Div 0.00V

1V/Div 0.00V

100mV/Div 0.00V

10mV/Div 0.00V

Supply Min Max Actual

-35.00V -35.4V -34.6V -__________V

-10.00V -10.1V -9.90V -__________V

-2.00V -2.02V -1.98V -__________V

+2.00V +1.98V +2.02V +__________V

+10.00V +9.90V +10.1V +__________V

+35.00V +34.6V +35.4V +__________V

± 320.0mV ___________V

± 80.0mV ___________V

± 8.0mV ___________V

± 800.0µV ___________V

Offset Accuracy

Zero-input Offset-Channel 2

Offset Accuracy

DC Input Offset-Channel 2

3-11 Bandwidth

≤−3.0dB

V/Div Setting Reading Actual

4V/Div 0.00V

1V/Div 0.00V

100mV/Div 0.00V

10mV/Div 0.00V

Supply Min Max Actual

-35.00V -35.4V -34.6V -__________V

-10.00V -10.1V -9.90V -__________V

-2.00V -2.02V -1.98V -__________V

+2.00V +1.98V +2.02V +__________V

+10.00V +9.90V +10.1V +__________V

+35.00V +34.6V +35.4V +__________V

Channel 1:

Actual Reading= ________ dB

Channel 2:

Actual Reading = ________ dB

± 320.0mV ___________V

± 80.0mV ___________V

± 8.0mV ___________V

± 800.0µV ___________V

3-18

Page 43

HP 16532A - Performance Tests

Ta ble 3-1. Performance Test Record (Continued)

Paragraph No. Test Results

3-12 Time Measurement Accuracy

5.500ns

99.00ns

3-13 Trigger Sensitivity Channel 1:

± 150ps

± 155ps

MEAN X-O __________ns

MIN X-O __________ns

MEAN X-O - MIN X-O = _________ps

MAX X-O __________ns

MAX X-O - MEAN X-O = _________ps

MEAN X-O __________ns

MIN X-O __________ns

MEAN X-O - MIN X-O = _________ps

MAX X-O __________ns

MAX X-O - MEAN X-O = _________ps

Trigger Stable @ 100mVp_p Yes ____ No ____

Trigger Stable @ 200mVp_p Yes ____ No ____

Channel 2:

Trigger Stable @ 100mVp_p Yes ____ No ____

Trigger Stable @ 200mVp_p Yes ____ No ____

3-19

Page 44

3-20

Page 45

TABLE OF CONTENTS

Calibration

4-1 . I ntroduction..........................................................................................................................4-1

4-2. S a fe ty R e quirements............................................................................................................4-1

4-3. Ca libration Interval...............................................................................................................4-1

4-4 . M aintaining System Integrity...............................................................................................4-1

4-5 . Calibration Protection Switch..............................................................................................4-1

4-6. Recommended Test Equipment .........................................................................................4-2

4-7 . I ns trument Warmup.............................................................................................................4-2

4-8. Ca libration............................................................................................................................4-2

4-9 . Setting the PROTE C T/UNPR O TECT Switch to UNPROTECT...........................................4-3

4-10. Equipment Required for Calibration...................................................................................4-4

4-1 1. Loading the D efault Calibration Factors............................................................................4-4

4-12. Self Cal Menu Calibrations .................................................................................................4-5

4-1 3. Setting the PR O TEC T/UNP ROTECT Switch to PROTECT................................................4-8