Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Page 2

HP 16520A/16521A

PATTERN GENERATION MODULE

Service Manual

Flin-

~e.II

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HEWLETT

PACKARD

Page 3

rlin-

~~

HEWLETT

PACKARD

SERVICE MANUAL

HP

Pattern Generator

16520A 50 MBit/s

Master

Card

AND

HP

16521A 50 MBit/s

Pattern Generator Expansion Card

© COPYRIGHT HEWLETT-PACKARD COMPANY/COLORADO DIVISION 1987

OF

1900 GARDEN

THE GODS ROAD, COLORADO SPRINGS, COLORADO U.S.A.

Manual Part No. 16520·90901

Microfiche Part No. 16520·90801

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

ALL

RIGHTS RESERVED

PRINTED: SEPTEMBER 1987

Page 4

CERTIFICATION

Hewlett-Packard Company certifies that this product met its published specifications at the time

shipment from the factory. Hewlett-Packard further certifies that its calibration measurements are

traceable to the

calibration facility, and to the calibration facilities of other International Standards Organization

members.

United States National Bureau of Standards, to the extent allowed

by

the Bureau's

of

WARRANTY

This Hewlett-Packard product

period of one year from date of shipment. During the warranty period, Hewlett-Packard

will, at its option, either repair or replace products which prove to

For warranty service or repair, this product must

Buyer

shall prepay shipping charges to

product to Buyer. However,

HP

returned to

HP

warrants that its software and firmware deSignated by

from another country.

execute its programming instructions when properly

warrant that the operation of the instrument or software, or firmware will

free.

is

warranted against defects in material and workmanship for a

be

defective.

be

returned to a service faCility deSignated by HP.

HP

and

HP

shall pay shipping charges to return the

Buyer shall pay

all

shipping charges, duties, and taxes for products

HP

for

use

with

an

instrument will

installed on that instrument.

be

uninterrupted or error

HP

Company

does not

LIMITATION

OF

WARRANTY

The foregoing warranty shall not apply to defects resulting from improper or inadequate

maintenance by Buyer, buyer-supplied software or interfacing, unauthorized modification or

misuse, operation outside the environmental specifications for the product, or improper site

preparation or maintenance.

NO OTHER WARRANTY

IMPLIED WARRANTIES

THE REMEDIES PROVIDED HEREIN ARE BUYER'S SOLE AND EXCLUSIVE REMEDIES.

SHALL NOT BE LIABLE

CONSEQUENTIAL DAMAGES, WHETHER BASED

THEORY.

IS

EXPRESSED

OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

FOR

ANY

OR

IMPLIED. HP SPECIFICALLY DISCLAIMS THE

DIRECT, INDIRECT, SPECIAL, INCIDENTAL,

ON

CONTRACT, TORT,

OR

ANY

OTHER LEGAL

HP

OR

ASSISTANCE

Product maintenance agreements and other customer assistance agreements are available for

Hewlett-Packard products.

For any

provided at the back of this manual.

aSSistance, contact your nearest Hewlett-Packard Sales and Service Office. Addresses are

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

CWA584

Page 5

SAFETY CONSIDERATIONS

GENERAL - This

with terminal for protective earthing).

OPERATIO~

power transformer primary.

voltage, the correct fuse

are taken

Instrument's external markings which are described under

"Safety Symbols."

(see

Is

a Safety Class I Instrument (provided

- BEFORE APPLYING POWER verify that the

Is

matched to the available line

Is

Installed, and Safety Precautions

the following warnings). In addition, note the

I WARNING I

o Servicing Instructions are for use by service-trained

personnel. To avoid dangerous electric shock, do

perform any servicing unless qualified to do

o BEFORE SWITCHING

protective earth terminal of the Instrument must

connected to the protective conductor

powercord. The mains

socket outlet provided with a protective earth contact. The

protective action must not be negated by the use of

extension cord (power cable) without a protective

conductor (grounding). Grounding one conductor of a twoconductor outlet

Is

ON

THE INSTRUMENT, the

plug shall only

not sufficient protection.

so.

of

be

Inserted

the (mains)

not

be

In

an

Do

not Install substitute parts or perform any unauthorized

o

modification to the Instrument.

o Adjustments described

power

supplied to the Instrument while protective covers

are removed. Energy available at many

contacted, result In personal Injury.

o Any adjustment, maintenance, and repair

Instrument under voltage should be avoided

possible, and when

a skilled person who

CapaCitors Inside the Instrument may stili be charged even

o

If the Instrument has been disconnected from Its source

supply.

a

Instruction manual symbol. The product will

In

Inevitable, should

Is

aware of the hazard Involved.

SAFETY SYMBOLS

ill marked with this symbol when It

the user to refer to the Instruction manual

to protect against damage to the product.

the manual are performed with

pOints may, If

of

the opened

as

much as

be

carried

out

only

by

of

be

Is

necessary for

In order

If this Instrument

o

auto-transformer (for voltage reduction) make sure the

common terminal is connected to the earth terminal of the

power source.

o Any Interruption of the protective (grounding) conductor

(Inside or outside the Instrument)

protective earth terminal will cause a potential shock

hazard that could

It

Is

o Whenever

the Instrument must

against any unintended operation.

Only fuses with the required rated current, voltage, and

o

specified type (normal blow, time delay, etc.) should be

used. Do not use repaired fuses or short circuited

fuseholders. To do so could cause a shock or fire hazard.

o Do not operate the Instrument in the presence of flammable

gasses or fumes. Operation of any electrical Instrument

such

an

likely that the protection has been Impaired,

environment constitutes a definite safety hazard.

Is

to

be

energized

or

disconnecting the

result In personal Injury.

be

made Inoperative and be secured

via

an

~

Indicates hazardous voltages.

-L

Earth terminal (sometimes used In manual to

indicate circuit common connected

chassis).

The WARNING sign denotes a hazard. It

attention to a procedure, practice,

I WARNING I

performed or adhered to, could result

not proceed beyond a

conditions are

':::~:::::~:~~;:~!

~i

I

. correctly performed or adhered to, could result

or destruction

In

beyond a

fully understood

CAUTION sign until the Indicated conditions are

calls

or

the like, which, If

WARNING sign until the Indicated

fully understood and met.

The CAUTION sign denotes a hazard. It

calls attention to an operating procedure,

practice, or the like, which,

of

part or

all

of the product. Do not proceed

or

met.

to

grounded

not

correctly

In personal Injury. Do

If

not

In

damage to

S010984

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 6

HP

16520/21 A-Table of Contents

TABLE OF CONTENTS

SECTION

I.

GENERAL INFORMATION

1-1. Introduction

1-2. Modules Covered By Manual

1-3. Safety Requirements

1-4. Product Description

1-5. Accessories Supplied

1-6. Accessories

1-7. Specifications

1-8. Operating Characteristics

1-9. Recommended Test Equipment

II.

INSTALLATION

2-1. Introduction

2-2. Initial Inspection

2-3. Preparation

2-4. Power Requirements

2-5. Safety Requirements

2-6. Probe Cable Replacement

...................................................................................

2-7. Installation

2-8. Module Installation

2-9. Adding Expansion Cards

2-10. Operating Environment

2-11. Storage

2-12. Packaging

2-13. Tagging

For

........................................................................

...........................................................................

.......... ~ ..............................................

..................................................................

...................................................................

.................................................................

Available

.........................................................................

...........................................................................

For

.............................................................................

.............................................................................

..........................................................................

Service

.................................................................

.............................................................

......................................................

.......................................................................

Use

..................................................................

.................................................................

..................................................................

............................................................

....•.............•...................................................

.............................................................

............................................................

................................................................

PAGE

1-1

1-1

1-1

1-1

1-2

1-2

1-2

1-2

1-2

1-2

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-2

2-8

2-10'

2-10

2-10

2-10

III. PERFORMANCE

3-1. Introduction

3-2. Recommended Test Equipment

3-3. Test Record

3-4. Performance Test Interval

3-5. Performance Test Procedures

3-6.

Data

3-7. Duty Cycle Test

iv

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

TESTS

Period Accuracy Test

..................................

...........................................................................

...........................................................................

.......................................................................

:

......................................

......................................................

............................................................

""""",.,""""""""""""",.".,.,

.......................................

,

...................

.•

,"',.,'

3-1

3-1

3-1

3-1

3-1

3-1

3-2

3-8

Page 7

HP

16520/21 A-Table of Contents

SECTION

IV.

ADJUSTMENTS

4-1. Introduction

4-2. Calibration Interval

4-3. Safety Requirements

4-4. Recommended Test Equipment

4-5. Extender Board Installation

4-6. Instrument Warmup

4-7. Adjustment And

V.

REPLACEABLE

5-1. Introduction

5-2. Abbreviations

5-3. Replaceable Parts List

5-4. Exchange Assemblies

5-5. Ordering Information

5-6. Direct Mail order System

VI.

SERViCE

..................................................................................

...........................................................................

....................................................................

..................................................................

......................................................

...........................................................

...................................................................

PARTS

Calibration Check

..........................................................................

...................................................

............................................................................

..........................................................................

................................................................

................................................................

..................................................................

.............................................................

..........................................................................................

PAGE

4-1

4-1

4-1

4-1

4-1

4-1

4-4

4-4

5-1

5-1

5-1

5-1

5-1

5-1

5-2'

6-1

6-1. Introduction

6-2. Safety Requirements

6-3. Recommended Test Equipment

6-4. Module Block Diagram and Theory Of Operation

............................................................................

...........................•......................................

......................................................

...................................

6-5. Pattern Generator Master Card Theory of Operation

6-6. Expansion

6-7.

Self Tests

Card Theory Of Operation

..............................................................................

6-8. Troubleshooting

6-9.

Card Replacement

6-10. Probe

Cable Replacement

.......................................................................

....... -...........................................................

.........................................................

................................................

................................

6-1

6-1

6~1

6-1

6-3

6-4

6-5

6-9

6-32

6-35

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

v

Page 8

HP

16520/21 A-Table of Contents

LIST OF TABLES

TABLE TITLE

1-1.

HP

16520/21 A Specifications

"HP

1-2.

16520/21 A Operating Characteristics

1-3. Recommended Test Equipment

3-1. Performance Test Record

.................................................................

........................................................

.0

•••••••••

0

••••••••••••••••••••••••••••••••••••••••••••••••••••••••

5-1. Reference Designators and Abbreviations

5-2. Replaceable Parts

.............................................................................

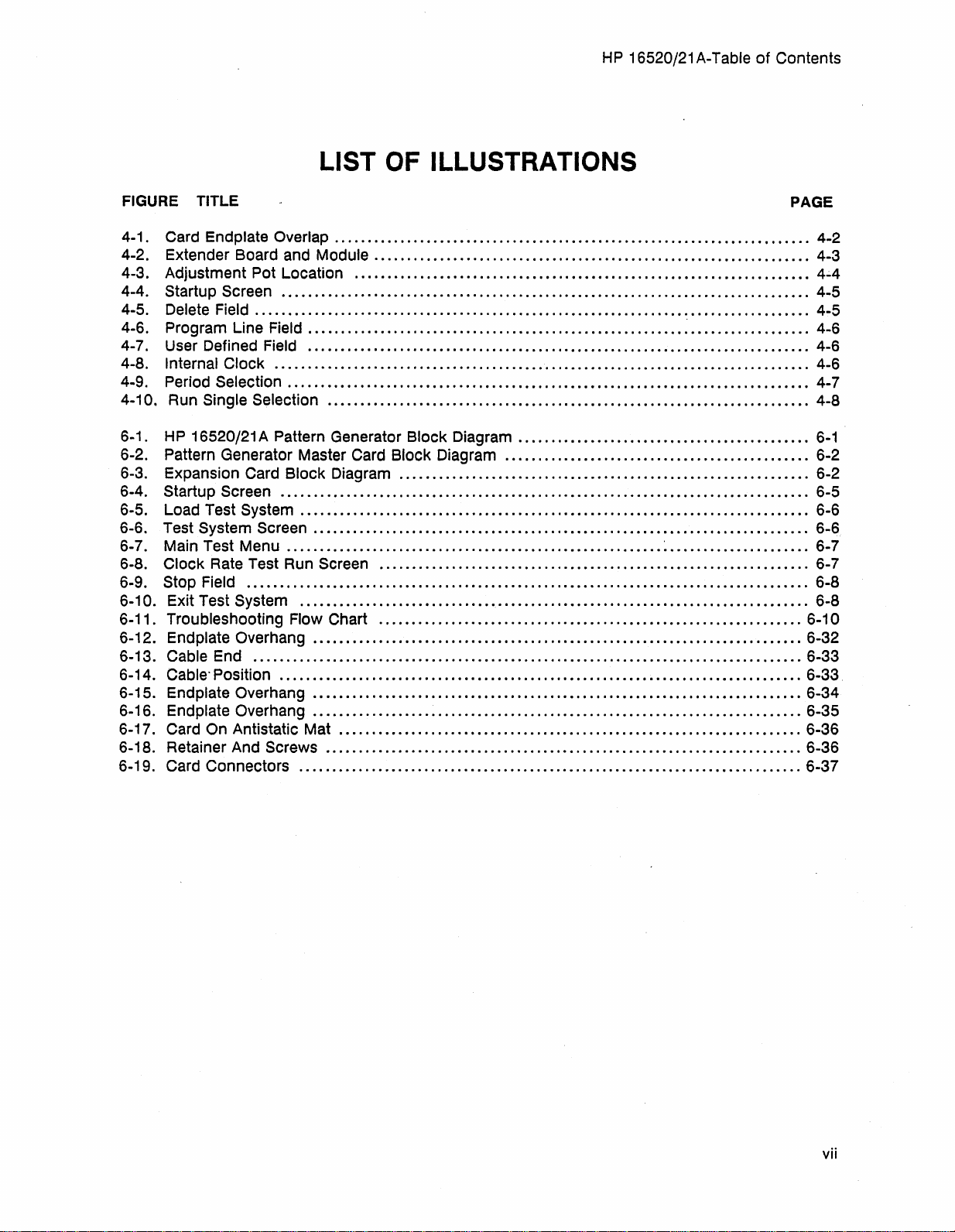

LIST OF ILLUSTRATIONS

FIGURE

2-1. Installation Guide

2-2. Endplate

2-3.

2-4.

2-5. One Master and three Expansion Cards

2-6. One Master and Four Expansion Cards

2-7.

2-8.

2-9. Endplate

2-10. Endplate

2-11. Configuration Guide

TITLE

Overlap

..............

................................................•......................•......

0

••• 0 •••••••••••••••••••••••••••••••••••

One Master and One Expansion Card

One Master and Two Expansion Cards

Cable End

Cable Position

..............................................................................

............ : ....................................................................

Overlap

Overlap

..............................................................................

....................................................

........................................................

....................................................

....................................................

0

•••••••••••••••

................................................

....

0

.................................................

.....................................................

......................................................

~

.................

0 • • • • • • • • • • • • • • •

00000

0

••••••

0

......

0 0 • • •

0

••••••

PAGE

1-3

1-4

••

1-8

3-13

5-3

5-4

PAGE

2-2

2-3

2-4

2-4

2-5

2-5

••

2-6

2-6

2-7

2-9

••

2-9

3-1

. Data Period Accuracy Test Equipment Hookup

3-2. Startup Screen

3-3.

Clock Field

Clock Period Screen

3-4.

3-5.

Channel Assignment Field

3-6. Data

Channel Select

3-7. Program Field

3-8. Numeric Entry

3-9.

Insert New Program Line

3-10. Program

3-11. Numeric Entry

3-12. Example Program

3-13. Run Repetitive Mode

3-14. Duty

3-15.

Cycle Test Equipment Hookup

Startup Screen

3·16. Set TTL Level

3-17.

Clock Field

3-18. Divide By 1 Field

3-19.

3-20. Data

Channel Assignment Field

Output Select

3-21. Example Program

3-22. Run Repetitive Mode

3-23. 25 MHz Square

................................................................................

.....................

0

•••• 0 •••••••••••••••••••••••••••••••••••••••

..........................................................................

........

0........................................................... 3-4

................................................

..............................

....

0

••••••••••••••••••••••••••••••••••••

..................

Field

..

0 0

•••••

0

•••••••••••••••••••

...

0

•••••

0

•••••••••••••••••••

.........................

.......................................................

.........................................................

...

0

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

..............................•................................

.................................•................

.....................................

..........

0

•••••••••••••••••••••••••••••••••••••••••••••••••••••••

.................................................................

.........................

......................

Wave

.......................................................................

.... . ..

0

•••••••••••••••••••••••••••

o

•••••••••••••••••••

0

•••••••••••••

0 0

•••••••••••••••••••••••••••••••

0

•••••••••••••••••••••••••••••••••••••••••

0

•••••••••••••••••••••••••••••••••••••••••••••••••

0

•••••••••••••••••••••••••••••••••••••••••••••••••

..

..

0

••••••••••••••••••

0

•••• " •••••••••••••••••••••••

0

••••••••••••••••••••••••••••••••••••••

..

0

••••••••••••••••••••••

..

.. .. ..

0

••••••••••••••••••••••••••••••

0

••••••••••••••••••

..

..

..

.. . ..

0 • • • • • • • • • • • • • • •

0

•••••••••••••••

0

•••••••••••

0

••••••

0

•••••••••••••••••

0

•••••••••••••••••

..

..

.. .. ..

00

0 • 0 • • • •

0.

• • • • • • •

0

0 0 • • • • • •

0 • • • • • • • •

o

••••••••

0 • • • •

0 • • • •

•••••••

••••••••

...

••

••

••

••

••

••

••

3-2

3-3

3-3

3-4

3-4

3-5

3-5

3-5

3-6

3-6

3-6

3-7

3-8

3-9

3-9

3-9

3-10

3-10

3-10

3-11

3-11

3-11

vi

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 9

HP

16520/21 A-Table

of

Contents

LIST

FIGURE TITLE

4-1

. Card Endplate Overlap

4-2. Extender Board and Module

4-3. Adjustment

4-4. startup Screen

4-5.

Delete Field

Program Line Field

4-6.

4-7. User Defined Field

4-8.

Internal Clock

Period Selection

4-9.

4-10, Run Single Selection

HP

6-1.

6-2. Pattern Generator Master Card Block Diagram

6-3. Expansion Card

6-4. Startup

6-5. Load Test

6-6. Test

6-7. Main Test Menu

6-8.

6-9.

6-10. Exit Test System

6-11. Troubleshooting Flow Chart

6-12. Endplate Overhang

6-13.

6-14.

6-15. Endplate Overhang

6-16. Endplate Overhang

6-17. Card

6-18. Retainer And

6-19. Card Connectors

16520/21 A Pattern Generator Block Diagram

System Screen

Clock Rate Test Run Screen

Stop Field

Cable End

Cable"

On Antistatic Mat

Pot Location

................................................................................

....................................................................................

.................................................................................

...............................................................................

Block Diagram

Screen

Position

................................................................................

System

.........................................................

.....................................................................................

...................................................................................

...............................................................................

Screws

........................................................................

............................................................................

............................................................................

.........................................................................

.............................................................................

...........................................................................

...................•.........................................................

..........................................................................

..........................................................................

..........................................................................

......................................................................

........................................................................

............................................................................

OF

ILLUSTRATIONS

..................................................................

................................

..............................................................

.................................................................

................................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

............................................

..............................................

~

.....................

PAGE

4-2

4-3

..

4.;.4

4-5

4-5

4-6

4-6

4-6

4-7

4-8

6-1

6-2

6-2

6-5

6-6

6-6

6-7

6-7

6-8

6-8

6-10

6-32

6-33

6-33,

6-34

6-35

6-36

6-36

6-37

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

vii

Page 10

GENERAL INFORMATION

TABLE

OF

CONTENTS

1-1. Introduction

1-2. Modules Covered By Manual

1-3. Safety Requirements

1-4. Product Description

1-5. Accessories Supplied

1-6. Accessories Available

1-7. Specifications

1-8. Operating Characteristics

1-9. Recommended Test Equipment

............................................................................

..........................................................

...................................................................

....................................................................

..................................................................

..................................................................

..........................................................................

........ ; .....................................................

.......................................................

1-1

1-1

1-1

1-2

1-2

1-2

1-2 .

1-2

1-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 11

HP

16520/21 A - General Information

SECTION I

1-1. INTRODUCTION

This service manual contains information for

testing, adjusting, and servicing the

16520A

the

Expansion Card. This manual

six sections

Information

interfacing the

Generator Module

16520/16521 A Pattern Generator Operating

and Programming Manual

module.

The General

safety requirements, a product description,

and a

cessories available. Also included

listing specifications and operating characteristics, and a list of recommended test

equipment.

Listed on the title page of this manual

Microfiche part number. This number can

used to order 4 X 6 inch microfilm transparencies of the manual. Each microfiche contains

up to

pages. The microfiche package also includes

the latest Manual Changes supplement

as

50

MBit/s Pattern Generator Card,

HP

16521 A 50

as

- General Information

II

- Installation

III

- Performance Tests

IV

- Adjustments

V - Replaceable Parts

VI

- Service

for operating, programming,

list of accessories supplied

96

photo-duplicates of the manual

pertinent Service Notes.

MBit/s Pattern Generator

follows:

HP

16520A/16521 A Pattern

is

contained

supplied with each

Information Section includes

HP

is

divided into

in

the

HP

and

of ac-

are

tables

is

as

and

and

a

be

well

GENERAL

To complete the service documentation for

your system, place this service manual in the

3-ring binder with your Logic Analysis

Mainframe Service Manual.

INFORMATION

System

1-2. MODULES COVERED BY THIS

MANUAL

The

information covered

the

HP

16520A/16521 A Pattern Generator

Module.

module

be

panied

This supplement explains the changes and

how to adapt the manual to the newer card.

In

addition to the change information, the supplement may contain information for correcting errors

as

current

Hewlett-Packard recommends that you

periodically request the latest Manual Changes

Supplement.

If either of the two cards in the

have

changed, a new card number will

assigned and the manual will

by

a Manual Changes Supplement.

in

the manual. To keep this manual

and

accurate

in

this manual

as

possible,

be

is

accom-

for

1-3. SAFETY REQUIREMENTS

Specific warnings, cautions, and instructions

are

placed wherever applicable throughout the

manual. These must

phases

module. Failure to comply with them violates

safety standards of design, manufacture, and

intended use of this module. Hewlett-Packard

assumes no

tomer to comply with these safety

requirements.

of

operation, service, and repair of the

liability for the failure of the cus-

be

observed during all

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1-1

Page 12

HP 16520/21 A - General Information

1-4. PRODUCT DESCRIPTION

The HP 16520A/16521 A Pattern Generator

Module is a general purpose digital stimulus.

The module consists

one master card and one or more expansion

cards. The HP

minimum

strobe channels, a clock out channel and three

dedicated input qualifier channels.

The HP 16521 A Expansion

dability with 48 additional data out channels.

Up to four expansion boards (192 channels)

can be connected to a single master board.

Some of the module's main features are:

configuration of 12 data and three

• Three strobe output channels (10 ns

minimum

• Three input qualifier channels, and

one input clock

• 50 MBit/s programmable pattern

generatation

of

one master card or

16520A master card offers the

Card offers expan-

resolution)

• Intercard Connecting Cable Kit

(HP 16521-88701)

• Input Qualifier Probe Cable

(HP

16520-61601)

•

8 Channel Data Probe Cable

16520-61602)

(HP

•

Clock Probe Cable (HP 16520-61603)

HP

16521A:

• 8 Channel Data Probe Cables

(HP

16520-61602) Qty 6

1-6. ACCESSORIES AVAILABLE

• 8 Channel

10345A)

(HP

• 8 Channel

(HP

10346A)

• Grabbers

• Service

(16520-90903)

ECl

Differential Driver Pod

TTL

Tristate Buffer Pod

(HP

5959-0288 Qty 20)

Data Supplement

• 4 k bit per channel memory depth

• Expandable to 204 data out channels

(1

HP 16520A and 4

•

TTL

and

ECl

interface levels

• Internally available clock rates between 5 kHz and 50 MHz

• Intermodule

trigger capability

HP

16521

As)

1-5. ACCESSORIES SUPPLIED

The following accessories are supplied with

the H P 16520A/16521 A Pattern Generator

Module. Quantity one unless shown otherwise.

HP

16520A:

• Operating and Programming Manual

Set

'Service Manual

•

•

lead

Set Qty 2

10347A purple tip)

(HP

• Input Qualifier Probe Kit

16520-69501 grey tip)

(HP

1-7. SPECIFICATIONS

Module specifications are listed in table 1-1.

These specifications are the performance

standards against which the module is tested.

1

..

8.

OPERATING CHARACTERISTICS

Table 1-2 lists the module operating characteristics. The operating characteristics are

specifications, but are typical operating

characteristics included

tion for the user.

as

additional

not

informa-

1-9. RECOMMENDED TEST

EQUIPMENT

. Equipment for testing and maintaining the HP

16520A/16521 A Pattern Generator Module is

listed in table 1-3.

substituted if it meets or exceeds the critical

specifications listed in the table.

Other equipment

may

be

1-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 13

Table 1-1. HP 16520/21 A SpecifIcations.

HP 16520A/21A SPECIFICATIONS

CLOCK SOURCES (HP 16520A ONLY)

INTERNAL CLOCK

HP

16520/21 A - General Information

Clock Period: Programmable from 20 ns to 200

Data Period Accuracy:

EXTERNAL

CLOCK (provided by user)

±

2%

(of period) ± 1 ns

Input Clock Period:

1 Hz to

50 MHz (20 ns min period)

frequency divide (/1, /5, or /10) provided.

Duty cycle:

minimum

high time, 10 ns

10 ns

STROBES (HP 16520A ONLY)

Number

Bits/Channel:

Maximum Bit Rate: 20 MBit/s (50 ns Period)

Edge Placement:

of

Strobes: 3

4095

(Eel

or TTL)

~

10M

Bits/s: tenths of period

> 10 MBits/s to 20 MBits/s: fifths of Period

(DELAY + WIDTH ~ PERIOD)

J1.s

in a 1-2-5 sequence.

Eel

minimum

low time

or TTL, internal

Minimum

Minimum

period

delay is

width is 1/10 (1/5) of data period,

0/10

(0/5),

maximum

delay

maximum

is

9/10 (4/5) data period.

width is the data

(values in parentheses apply to 20 MBits/s timebase setting).

If strobes are desired while operating with external clock, the data rate

will be divided to

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1/5

or 1/10 the external

clock

rate.

1-3

Page 14

HP

16520/21 A - General Information

Table

1-2.

HP 16520/21 A Operating Characteristics

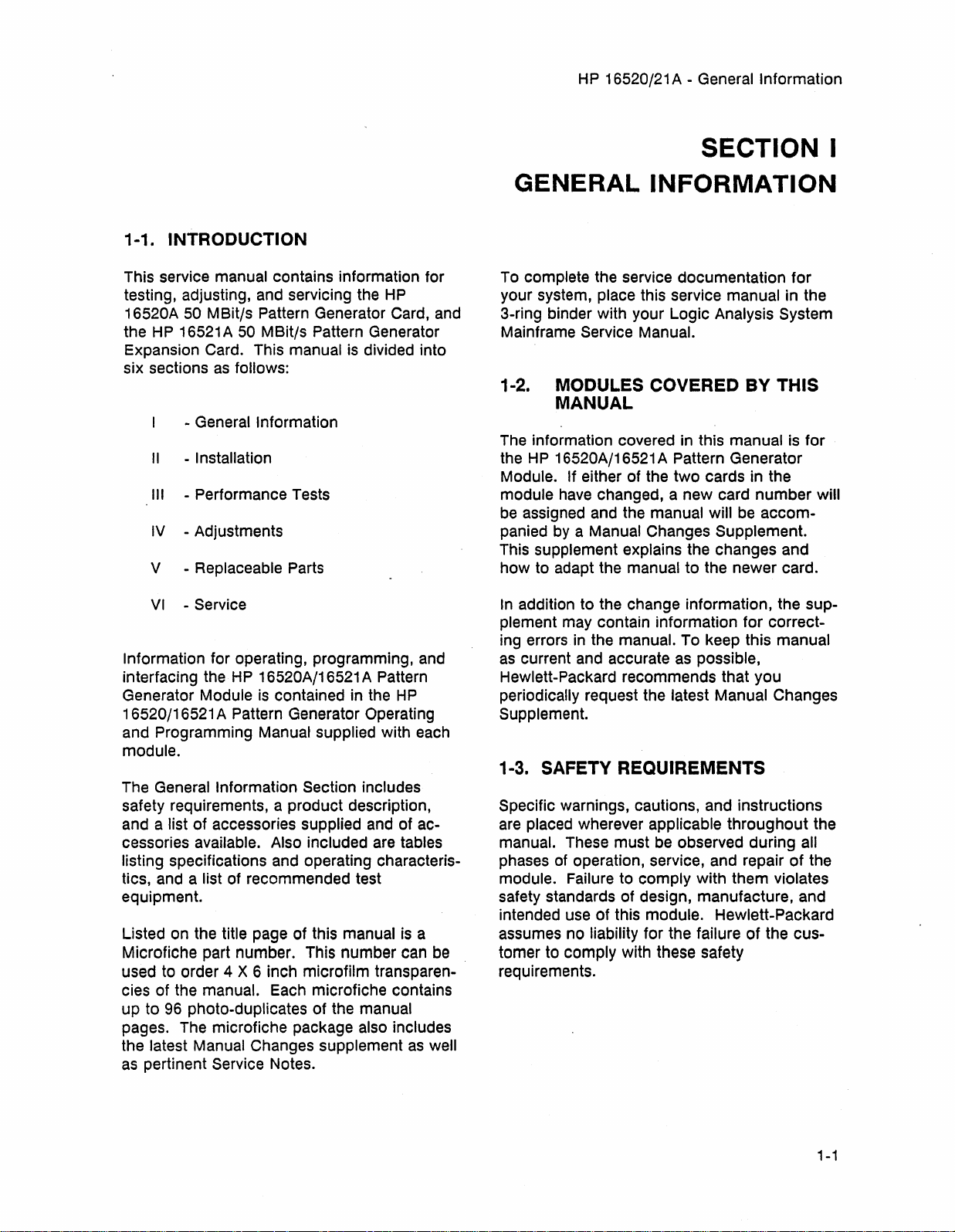

HP 16520/21A OPERATING CHARACTERISTICS

OUTPUT

Eight channel pods can

All characteristics

are

valid at the probe tip.

PARAMETER

VOH

VOL

(steady

(steady

state)

state)

Risetime/

Falltime

(typ)

Channel-to-

channel

(same

Skew*

card)

be

assigned

I

as

either standard

Eel

or TTL levels.

ECl

- 0.98V

- 1.55V 0.6V

2.3 ns

V

to

5 ns

-1.55

V)

(

(-0.98

<=

0.6

TTL

2.7V

2.5

V

to

<=

ns

2.7

5 ns

V)

Channel-to-

<10

channel

Skew*

ns

(card-to-card)

of

std

No.

(Output measurements made into a load consisting of 10 kn

ground.)

(*)

Skew measured at (+1.6

1-4

loads

3

(10

V)

TTL and (-1.3

KH

@

Vnh=IS0

ECl,

V)

Eel

mY)

levels.

<10

ns

3 (lSTTl, @ Vnl=2S0

in

series shunted with 10 pF to

mY)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 15

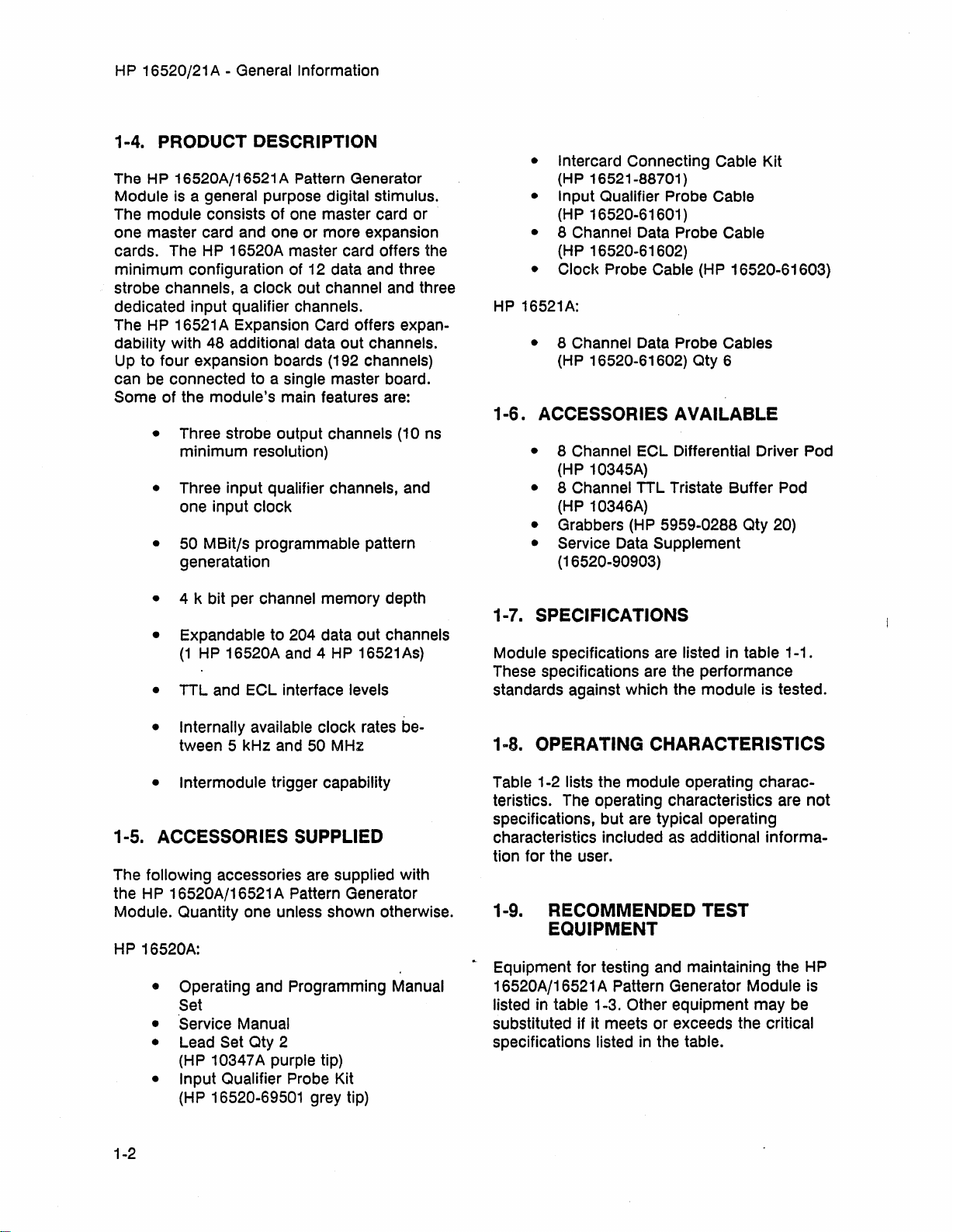

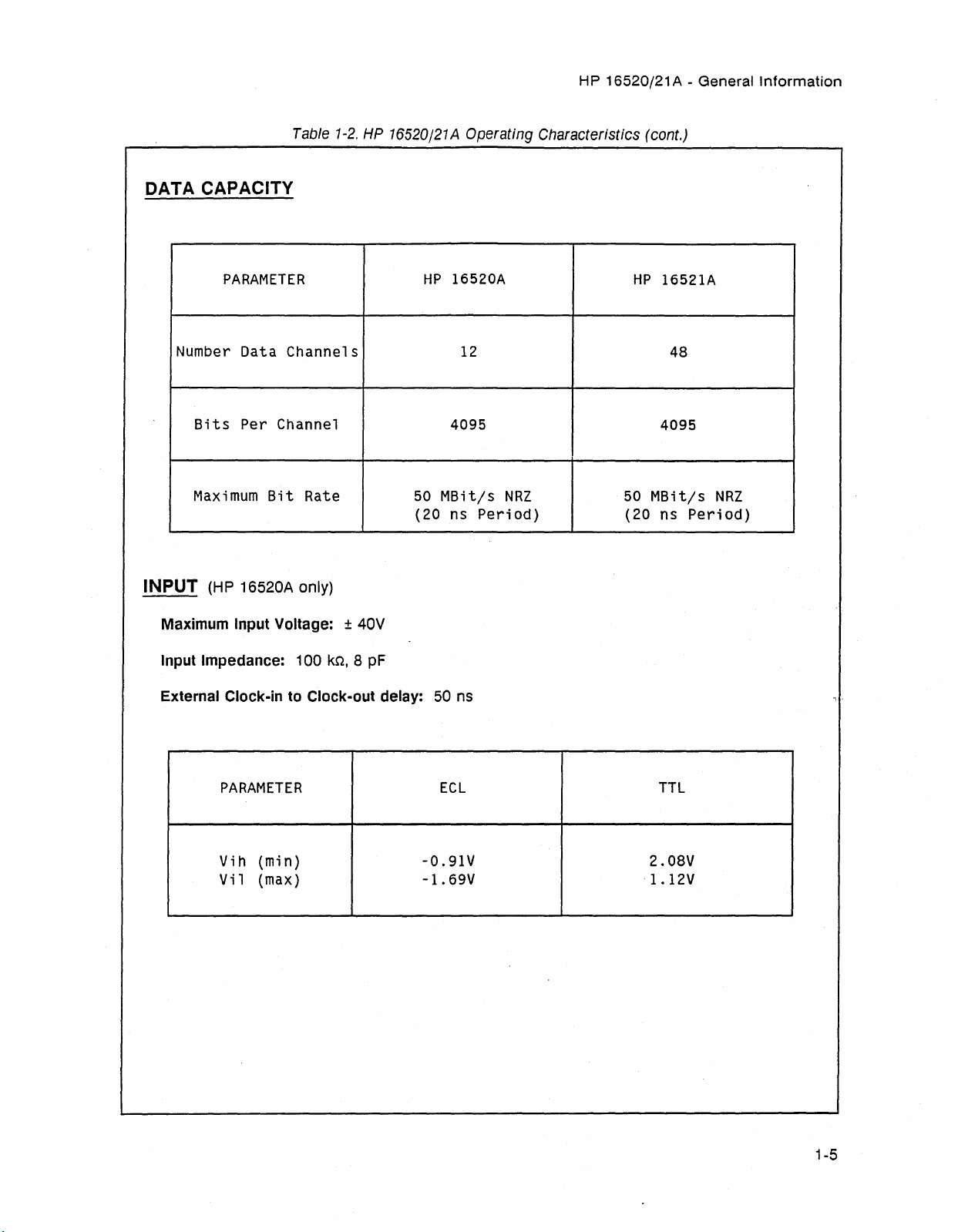

DATA CAPACITY

PARAMETER

Table

1-2.

HP

16520/21

HP

HP 16520/21 A - General

A Operating Characteristics (cont.)

16520A

HP

16521A

Information

Number

Bits

Maximum

Data Channels

Per Channel

Bit

Rate

50

(20 ns

INPUT

Maximum Input Voltage: ± 40V

Input Impedance: 100

External Clock-in to Clock-out delay: 50 ns

(HP

16520A only)

kn,

8

pF

PARAMETER

12

4095

MBit/s

Period)

ECl

NRZ

4095

50

MBit/s

(20 ns

TTL

48

NRZ

Period)

Vih

(min)

Vil

(max)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

-O.91V

-1.

69V

2.08V

1.12V

1-5

Page 16

HP

16520/21 A - General Information

Table

1-2.

HP 16520/21 A Operating Characteristics (cont.)

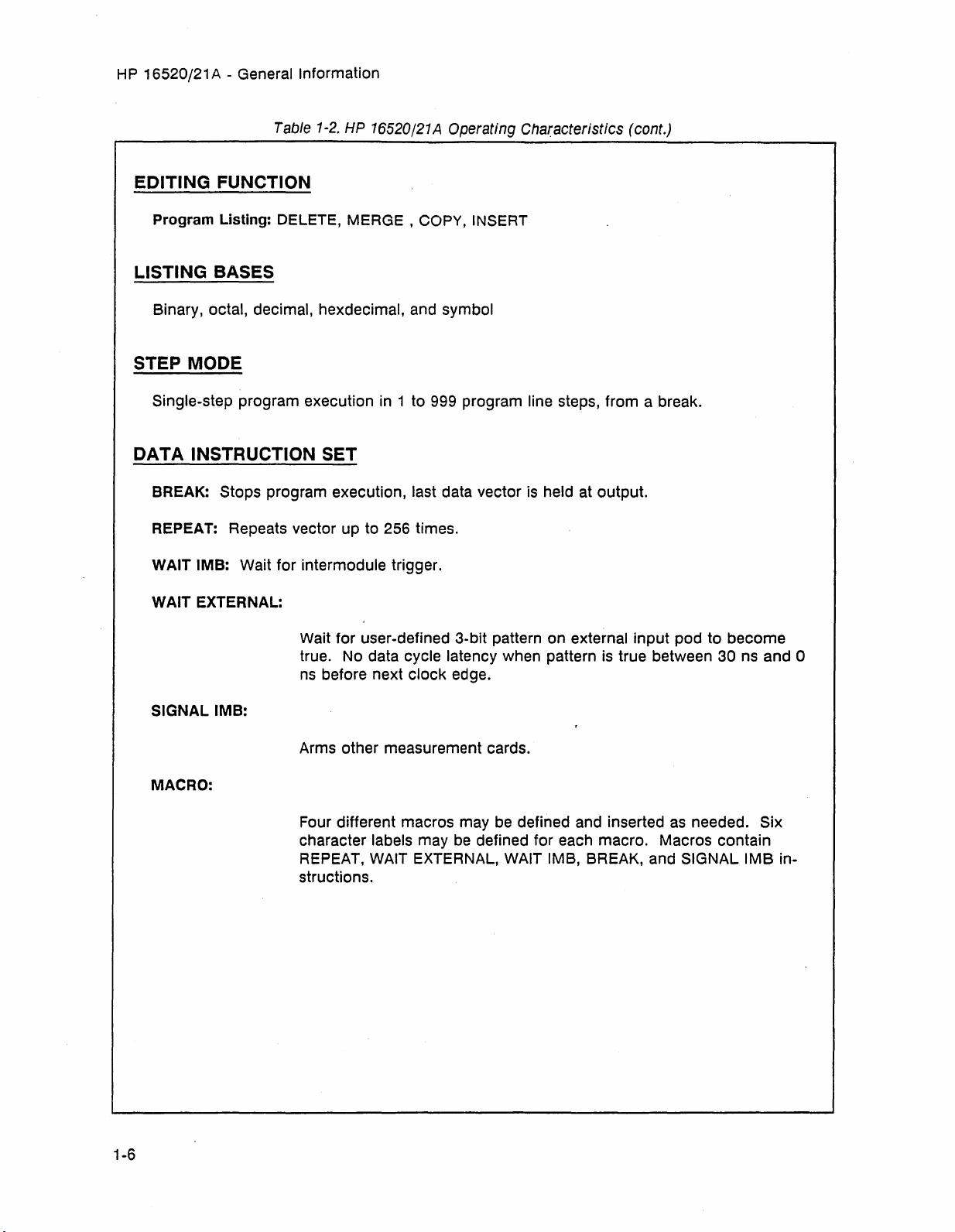

EDITING FUNCTION

Program Listing: DELETE, MERGE, COPY, INSERT

LISTING

Binary, octal, decimal, hexdecimal, and symbol

BASES

STEP MODE

Single-step program execution

in

1 to 999 program line steps, from a break.

DATA INSTRUCTION SET

BREAK:

REPEAT: Repeats vector up to 256 times.

WAIT

WAIT EXTERNAL:

SIGNAL

Stops program execution, last data vector

1MB:

Wait for intermodule trigger.

Wait for user-defined 3-bit pattern on external input pod to become

true.

No

data cycle latency when pattern

ns

before next clock edge.

1MB:

is

held at output.

is

true between 30 ns and 0

1-6

MACRO:

Arms other measurement cards.

be

Four different macros may

character labels may

REPEAT, WAIT EXTERNAL,

structions.

be

defined and inserted

defined for each macro. Macros contain

WAIT

1MB,

BREAK, and SIGNAL

as

needed. Six

1MB

in-

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 17

HP

16520/21 A - General Information

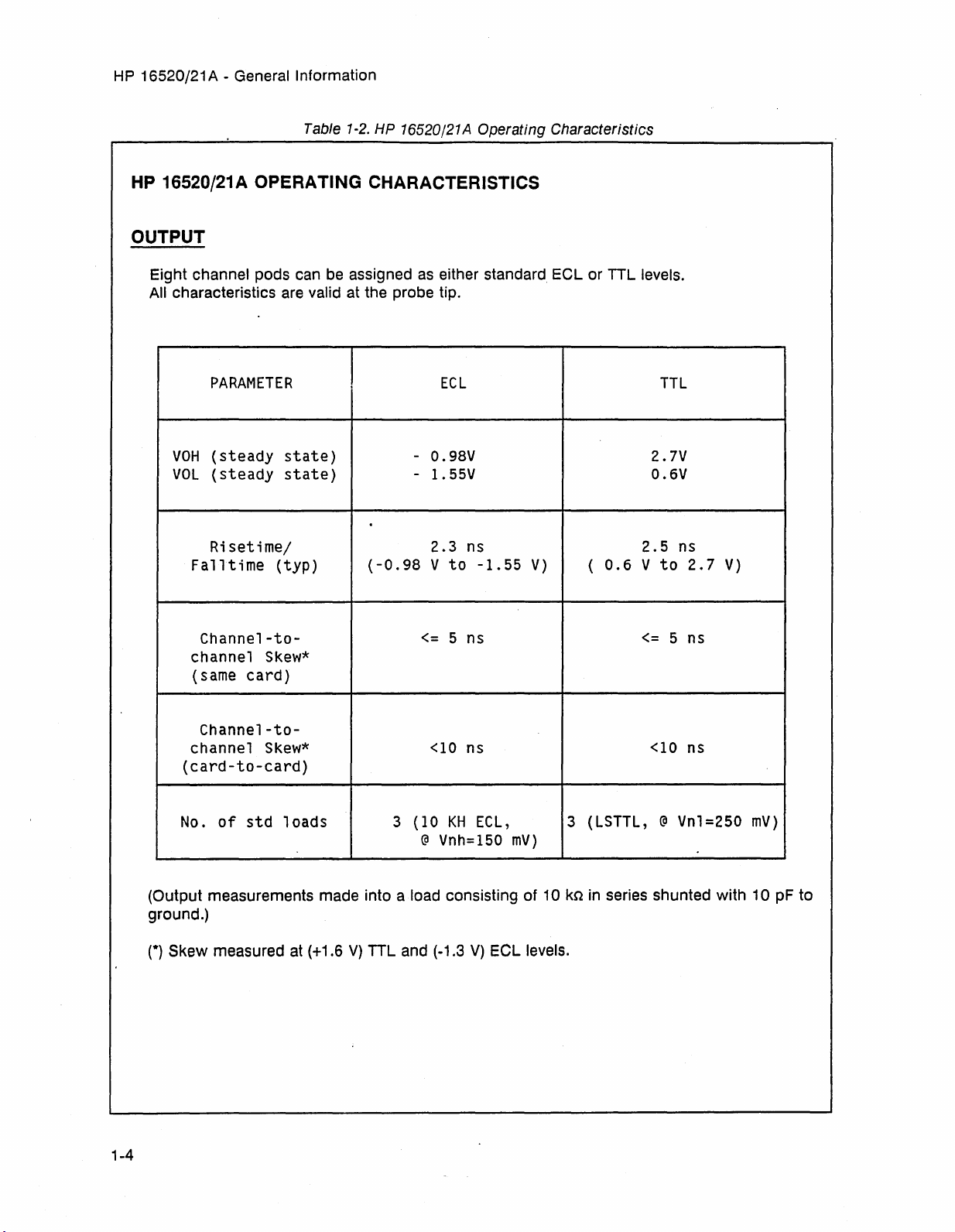

Table 1-2. HP 1G520/21A Operating Characteristics (cont.)

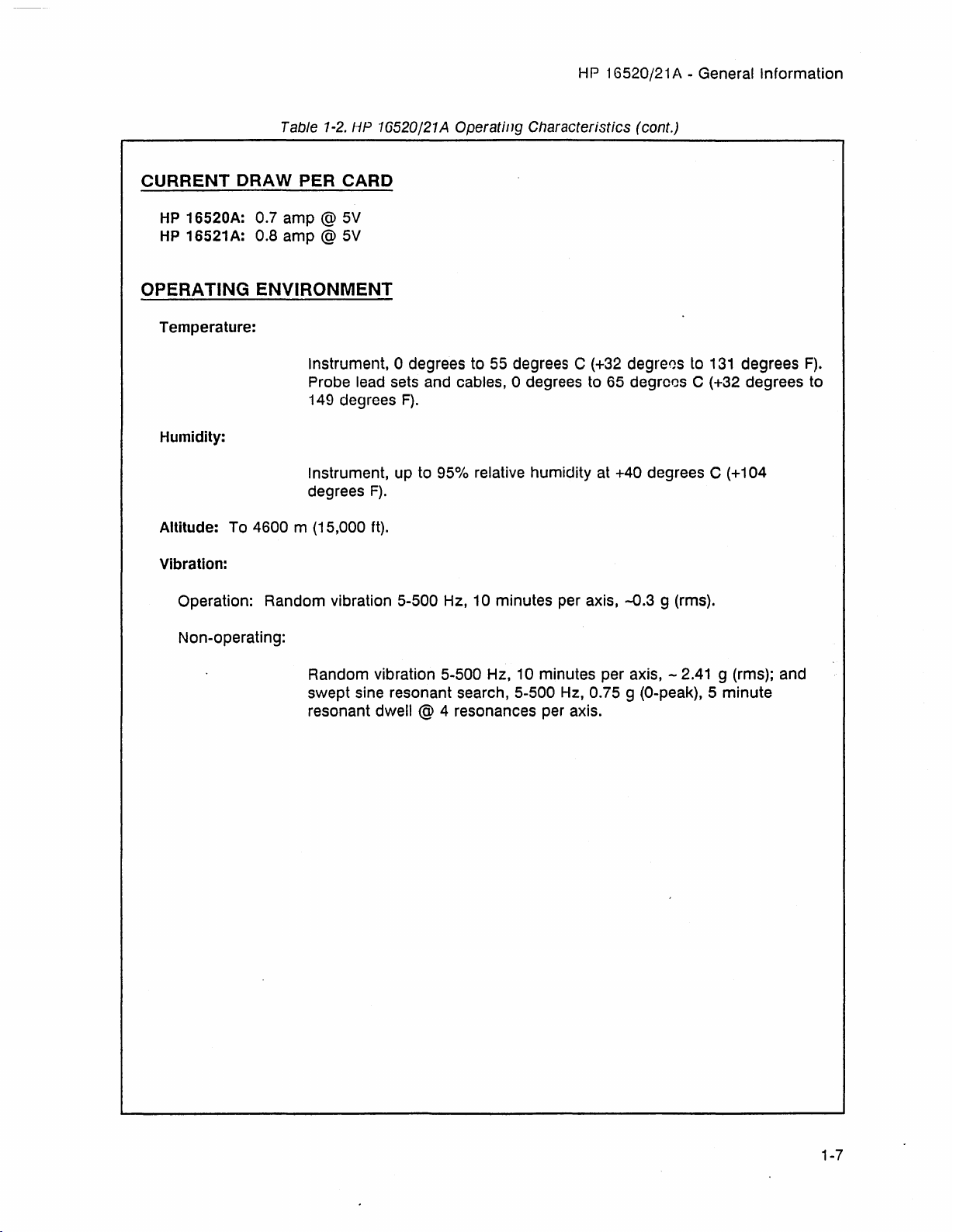

CURRENT

HP

16520A: 0.7

HP

16521 A: 0.8

ORA

W PER

amp

@ 5V

amp

@ 5V

CARD

OPERATING ENVIRONMENT

Temperature:

Instrument, 0 degrees to 55 degrees C (+32 degrees to

Probe lead sets and cables, a degrees to 65 degrees C (+32 degrees to

149 degrees

Humidity:

Instrument, up to

degrees

Altitude: To 4600 m (15,000 ft).

Vibration:

Operation: Random vibration 5-500 Hz, 10 minutes per axis,

F).

F).

95%

relative humidity at +40 degrees C (+104

-0.3

9 (rms).

131

degrees

F).

Non-operating:

Random vibration

swept sine resonant search,

resonant dwell @ 4 resonances per axis.

5-500 Hz, 10 minutes per axis, - 2.41 9 (rms); and

5-500 Hz, 0.75 9 (O-peak), 5

minute

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1-7

Page 18

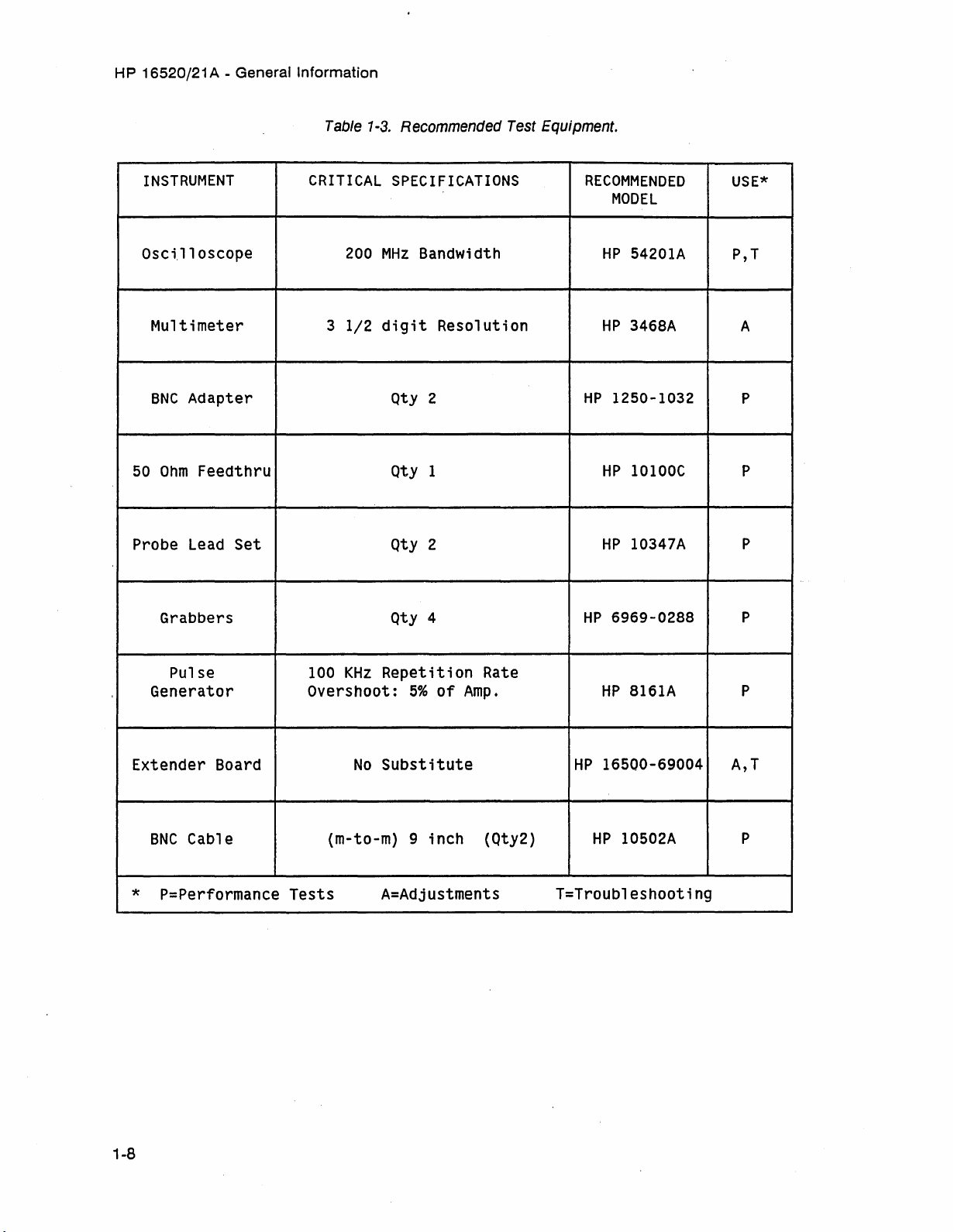

HP 16520/21 A - General Information

Table

1-3.

Recommended

Test

Equipment.

INSTRUMENT

Osci.l

loscope

Multimeter

BNC

Adapter

50

Ohm

Feedthru

Probe

Lead

Grabbers

Set

CRITICAL

200

3

1/2

SPECIFICATIONS

MHz

Bandwidth

digit

Qty

Qty

Qty

Resolution

2

1

2

Qty 4

RECOMMENDED

MODEL

HP

54201A

HP

3468A

HP

1250-1032

HP

10100C

HP

10347A

HP

6969-0288 P

USE*

P,T

A

P

P

P

Pulse

Generator

Extender Board

BNC

Cable

P=Performance

*

100

KHz

Repetition

Overshoot:

No

5%

of

Substitute

(m-to-m) 9 inch (Qty2)

Tests

A=Adjustments

Rate

Amp.

HP

B161A

HP

16500-69004

HP

10502A

T=Troubleshooting

P

A,T

P

1-8

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 19

INSTALLATION

TABLE OF CONTENTS

2-1. Introduction

2-2. Initial Inspection

2-3. Preparation For

2-4. Power Requirements

2-5. Safety Requirements

............................................................................

........................................................................

Use

...................................................................

.............................

...................................................................

2-6. Probe Cable Installation

2-7. Installation

2-8. Module Installation

..............................................................................

....... ' ..............................................................

2-9. Adding Expansion Cards

2-10. Operating Environment

2-11. Storage

2-12. Packaging

2-13. Tagging For Service

...............................................................................

............................................................................

..................................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...............................................................

..............................................................

..............................................................

..

2-10

2-10

2-10

2-10

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-2

2-8

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 20

HP

16520/21 A - Installation

2-1. INTRODUCTION

This section explains, how to initially inspect

the

HP

16520/21 A Pattern Generator Module,

how to prepare it for use, storage and ship-

are

ment. Also included

installation.

procedures for module

2-2. INITIAL INSPECTION

Inspect the shipping container for damage. If

the shipping container or cushioning material

is

damaged, it should

tents of the shipment have been checked for

completeness and the module

checked mechanically and electrically. The

contents of the shipment should

the "ACCESSORIES SUPPLIES" paragraph located in Section

be

kept until the con-

has

been

be

as

listed

I.

in

SECTION

INSTALLATION

2-4. POWER REQUIREMENTS

All

power supplies required for operating the

HP

16520/21 A Pattern Generator Module are

supplied to the module through the backplane

connenctor.

2-5. SAFETY REQUIREMENTS

Specific warnings, cautions, and instructions

are

placed wherever applicable throughout the

be

manual. These must

phases

module. Failure to comply with them violates

safety standards of deSign, manufacture, and

intended use of this module. Hewlett-Packard

assumes no liability for the failure of the cus-

tomer to comply with these safety

requirements.

of

operation, service, and repair of the

observed during all

·11

Procedures for checking electrical perfor-

are

mance

container

damage or defect, or the instrument does not

pass the performance tests, notify the nearest

Hewlett-Packard office.

If the shipping container

cushioning material shows signs of stress,

notify the carrier

Hewlett-Packard office.

material

Hewlett-Packard office will arrange for repair

or replacement at Hewlett-Packard's option

without waiting for claim settlement.

in Section III. If the contents of the

are

incomplete, there

is

as

well

as

Keep

so

the carrier can inspection it. The

is

mechanical

damaged, or the

the

the shipping

2-3. PREPARATION FOR USE

I

WARNING

Read the Safety Considerations in the

of

front

before

module.

this manual and in Section I

installing or operating this

I

2-6. PROBE CABLE INSTALLATION

The

HP

16520/21A Pattern Generator Module

comes with probe cables installed by the fac-

If a cable

tory.

and

ECl,

REPLACEMENT" in Section

is

to

be

switched between TTL

refer to "PROBE CABLE

VI

of this manual.

2-7. INSTALLATION

Do

not install, remove or replace the

module in the instrument unless the in-

is

strument power

The HP16520A Pattern Generator Card will

take up one slot in the card cage. For

HP

16521

A Expansion Card you connect to

the

HP

16520A Pattern Generator Card you

an

will need

four expansion cards may

HP

16520A Pattern Generator Card.

Installation procedures for the module and additional expansion cards

step-by-step

additional slot. A maximum of

in

turned off.

be

connected to the

are

shown

paragraphs 2-6 and 2-7.

every

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-1

Page 21

HP

16520/21 A - Installation

2·8. MODULE INSTALLATION

If you

are

installing the

card and one or more expansion cards),

an

cards to

existing module, follow the procedure "ADDING

2-9.

The

effects of

ponents.

service

HP

16520/21 A Pattern Generator Module (one master card or one master

ELECTROSTATIC

Use

grounded wrists traps

to

this

module.

follow this procedure. If you

EXPANSION

DISCHARGE

and

mats

can

when

damage

performing

are

adding more expansion

CARDS" in paragraph

electronic

any

com-

kind of

INSTALLATION

CONSIDERATIONS:

• Cards or filler panels below the empty slots intended for the module installation do not

have to

•

You

• If previously installed modules prevent proper installation, they must

card cage.

be

removed.

will need only one intercard connecting cable for any installation configuration.

be

repositioned in the

See

figure

2-1

.

• To maintain the channel-to-channel skew and adequate intercard signal quality, the short-

be

est intercard connecting cable should

more than two slots away from the master card.

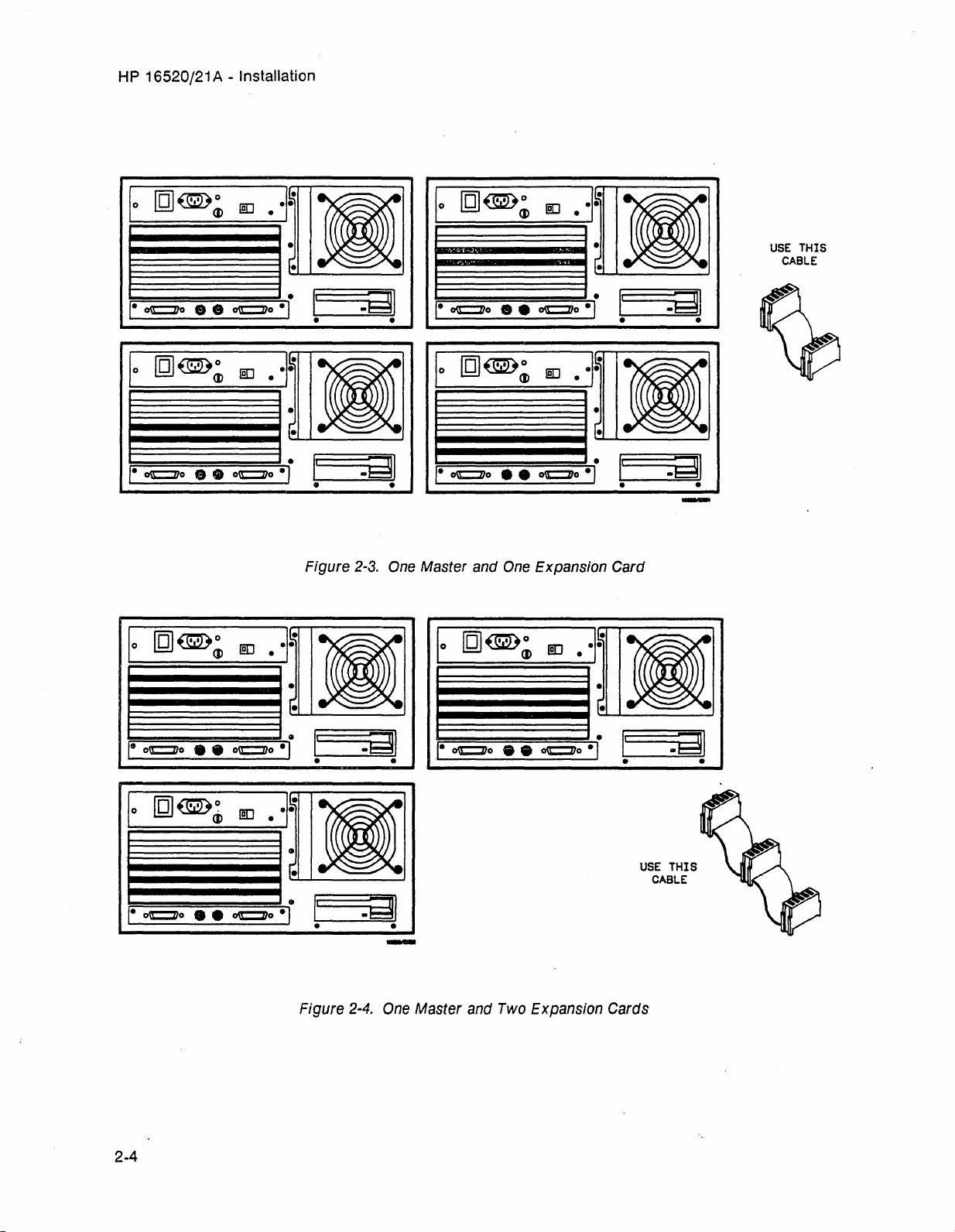

Figure

2-1

is

a guide in choosing the correct intercard connecting cable and illustrates the expan-

sion card position relative to the master card.

MASTER

ANO

EXPANSION

CARD

ORIENTATION

E~_I~J

EXPANSION

used and the expansion cards should

See

figure 2-1.

Use

this guide at step d in the following procedure.

EXPANSION

EXPANSION

EXPANSION

be

no

2-2

MASTER

AHV

SLOT

SLOT

SELECTION

WASTER

J

IlASTER

EXPANSION

At((

TWO

ADJACENT

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

SLOTS

WASTER

EXPANSION

ANY

ADJACENT

Figure

THREE

2-1.

SLOTS

Installation

WASTER

EXPANSION

ADJACENT

Guide

EXPANSION

EXPANSION

At((

FOUR

SLOTS

WASTER

ALL

SLOTS

18520/EX07

Page 22

HP

PROCEDURE:

a.

Turn instrument power switch off, unplug power cord and disconnect any input or output connections.

b. Starting from the top, loosen thumb screws on filler panel(s) and card(s).

16520/21 A - Installation

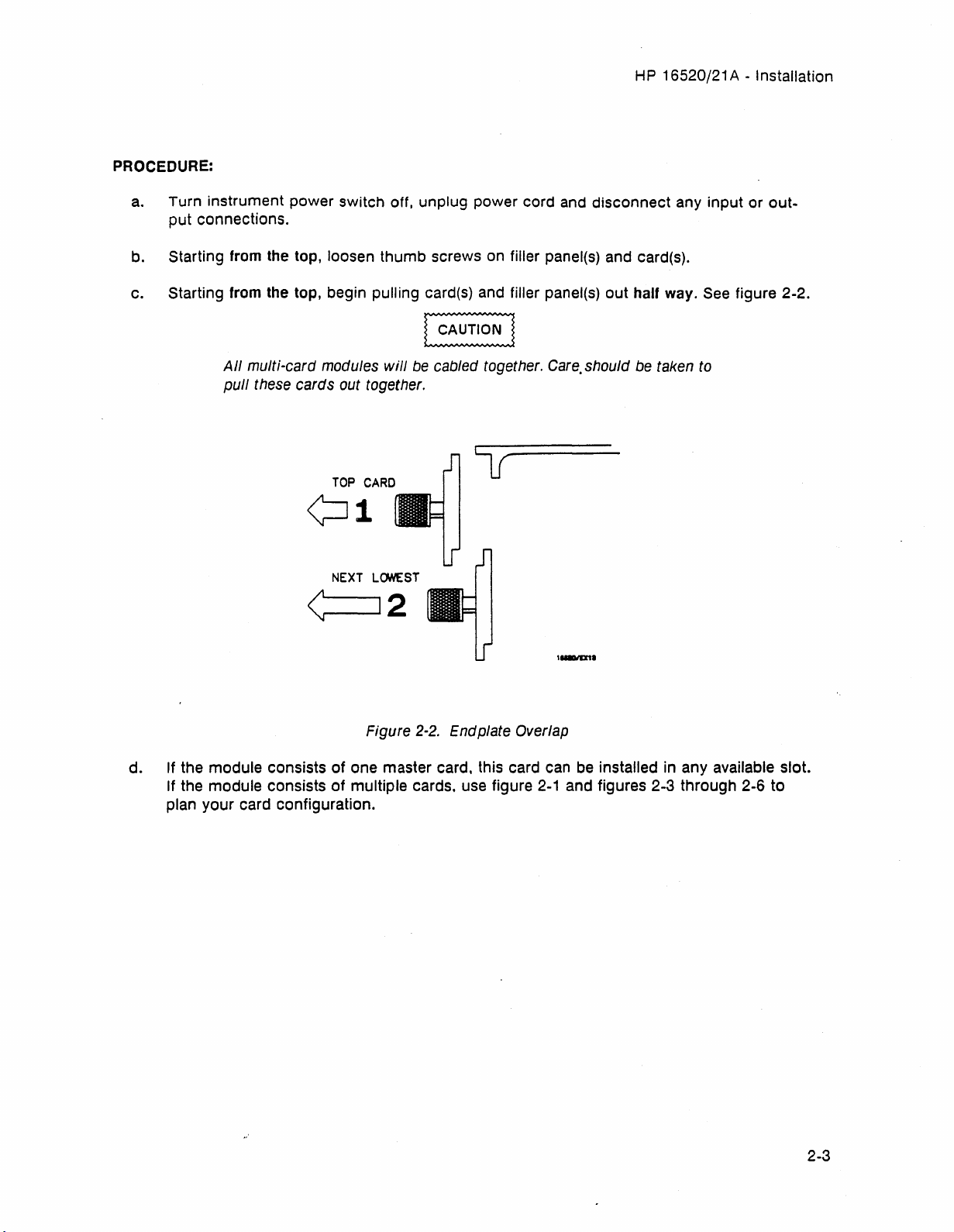

c. Starting from the top, begin pulling card(s) and filler panel(s) out half way.

All

multi-card modules

pull

these cards out together.

TOP

will

CARD

be

cabled together.

Care.

should be taken to

¢:J1

NEXT

LCNlEST

<:

12

Figure

2-2.

Endplate Overlap

lu.ID11

See

figure 2-2.

d. If the module consists

If the module consists

plan your card configuration.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

of

one master card, this card can

of

multiple cards, use figure

be

installed in any available slot.

2-1

and figures 2-3 through 2-6 to

2-3

Page 23

HP

16520/21 A - Installation

[Q]~o

I·

I

,.

~o

[Q]~o

I·

I

I·

~o

[Q](IDo

I·

<D

sa

<D

8..

CD

m

·

·I~

•

r.

I.

~o·l.

m

·

·I~

•

~

I.

oc::::J}o

·1.

m

·

·I~·

-

Irc::::==,

~.~I

• •

-

Irr:::::=:,

o •

Figure

~.

~.=nl

B.

2-3.

One

I·

-1III

I·

Master

I·

[Q]~o

[Q]~o

[Q]~o

and

<D

<D

One

Expansion

<D

lID

.

·I~

•

r.

-

lID

.

·I~

•

r.

-

Card

lID

.

·I~·

-

USE

CABLE

THIS

I

Ie

oc::::::l1o

[Q]~~

I·

••

<D

oc::::J}o

lID

·

•

r·

-

I.

P'

·1.

·I~·

•

r.

~.4\1

• •

E3.

I.

~.

..

~.l

•

[.

-

i

Ic::::'

===;.EJ::::iji

• •

USE

I

THIS

CABLE

-

~,.

~oc::::J}~o

~.~.~oe:::::l1~o~l

i

reI'

==.==EJ:n11

• •

Figure

2-4.

-

One

Master

and

Two

Expansion

Cards

2-4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 24

HP

16520/21 A - Installation

(g]~o

I·

(I)

lID

.

'I~'

-

r-

1

~

~~I.

,-

oc::::J1o

CD CD

oc::::J1o

-,.

-

f==i

=:=nl.'1

E3.

- -

[QJ(Wo

I·

CD

lID

.

·I~·

-

[-

-

,- oc::::J1o

••

oc::::J1o

Figure

-,

2-5.

-

One

Master

-

-

and

Three

USE

THIS

CABLE

Expansion Cards

[QJ~o

I·

1

..

----I.

,-

oc.t=:J1o •

lID

CD

0)

oe::::l1o

Figure

.

2-6.

'I~

.-

r-

-

,rc::::.

-,.

==.:::Iil'1

E3.

. -

-

One

Master

and

USE

CABLE

Four

Expansion Cards

THIS

2-5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 25

HP

16520/21 A - Installation

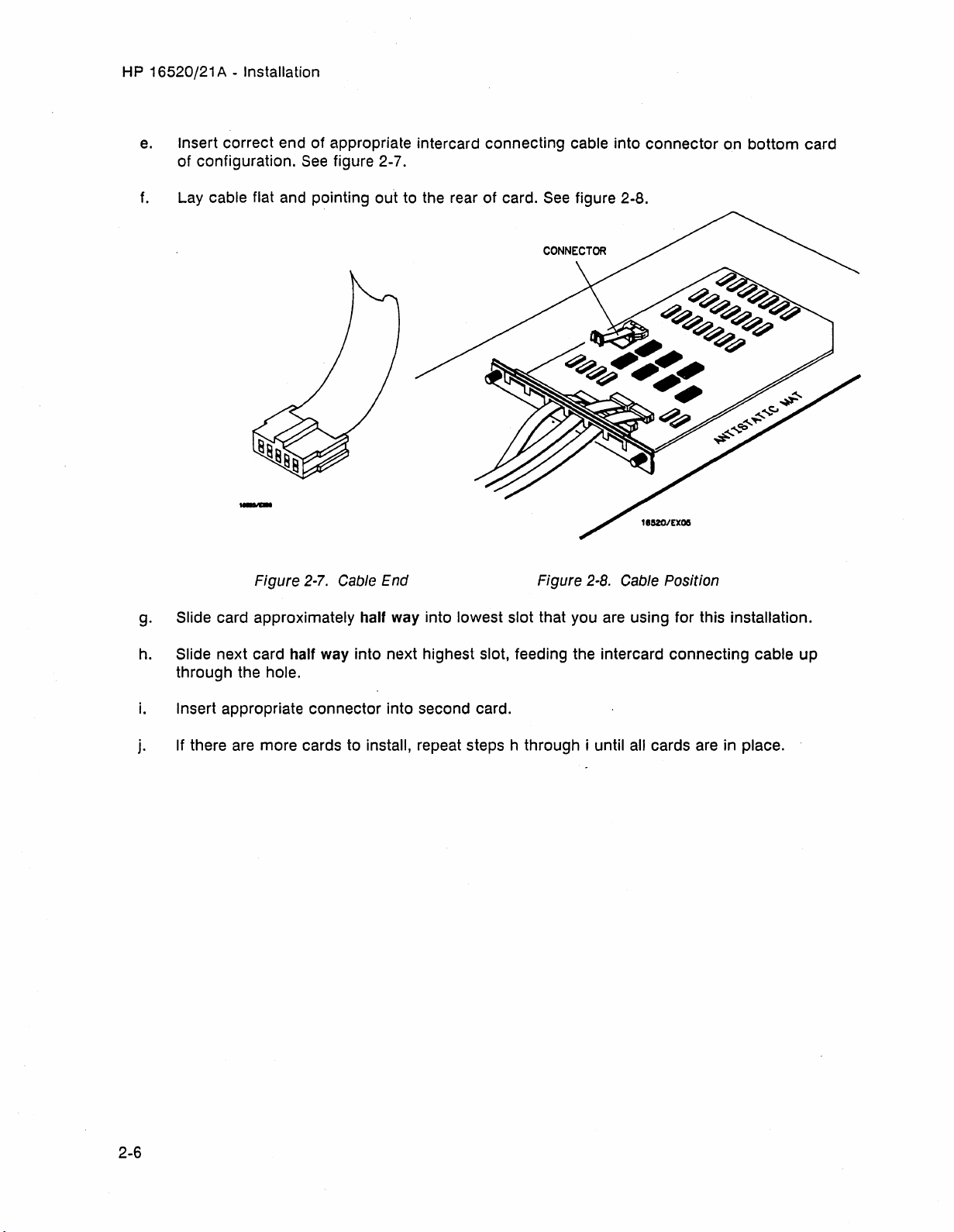

e.

Insert correct end of appropriate intercard connecting cable into connector on bottom card

of configuration.

f.

Lay cable flat and pointing out to the rear of card.

See

figure 2-7.

See

figure 2-8.

Figure

2-7.

Cable End Figure

2-8.

Cable Position

g. Slide card approximately half way into lowest slot that you are using for this installation.

h. Slide next card half way into next highest slot, feeding the intercard connecting cable up

through the hole.

i.

Insert appropriate connector into second card.

j. If there

are

more cards to install, repeat steps h through i until all cards are in place.

2-6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 26

HP

16520/21 A - Installation

k.

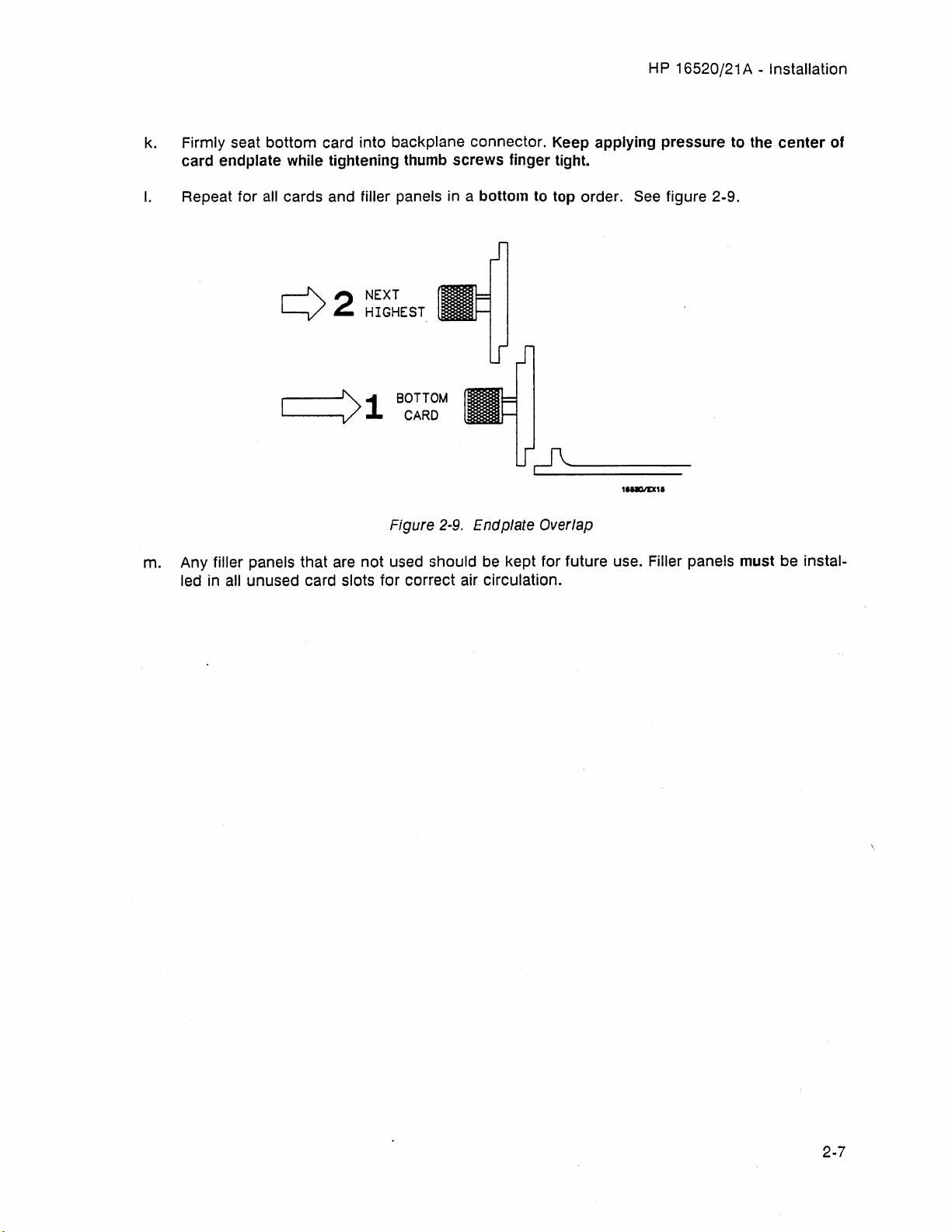

Firmly seat bottom card into backplane connector. Keep applying pressure to the

card endplate while tightening thumb screws finger tight.

I.

Repeat for

all

cards and filler panels in a bottom to top order.

See

figure 2-9.

NEXT

HIGHEST

BOTTOM

CARD

11AD1D1.

center

of

m. Any filler panels that are

all unused card slots for correct air circulation.

led in

Figure

not

used should be kept for future use. Filler panels must be instal-

2-9,

Endplate Overlap

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-7

Page 27

HP

16520/21 A - Installation

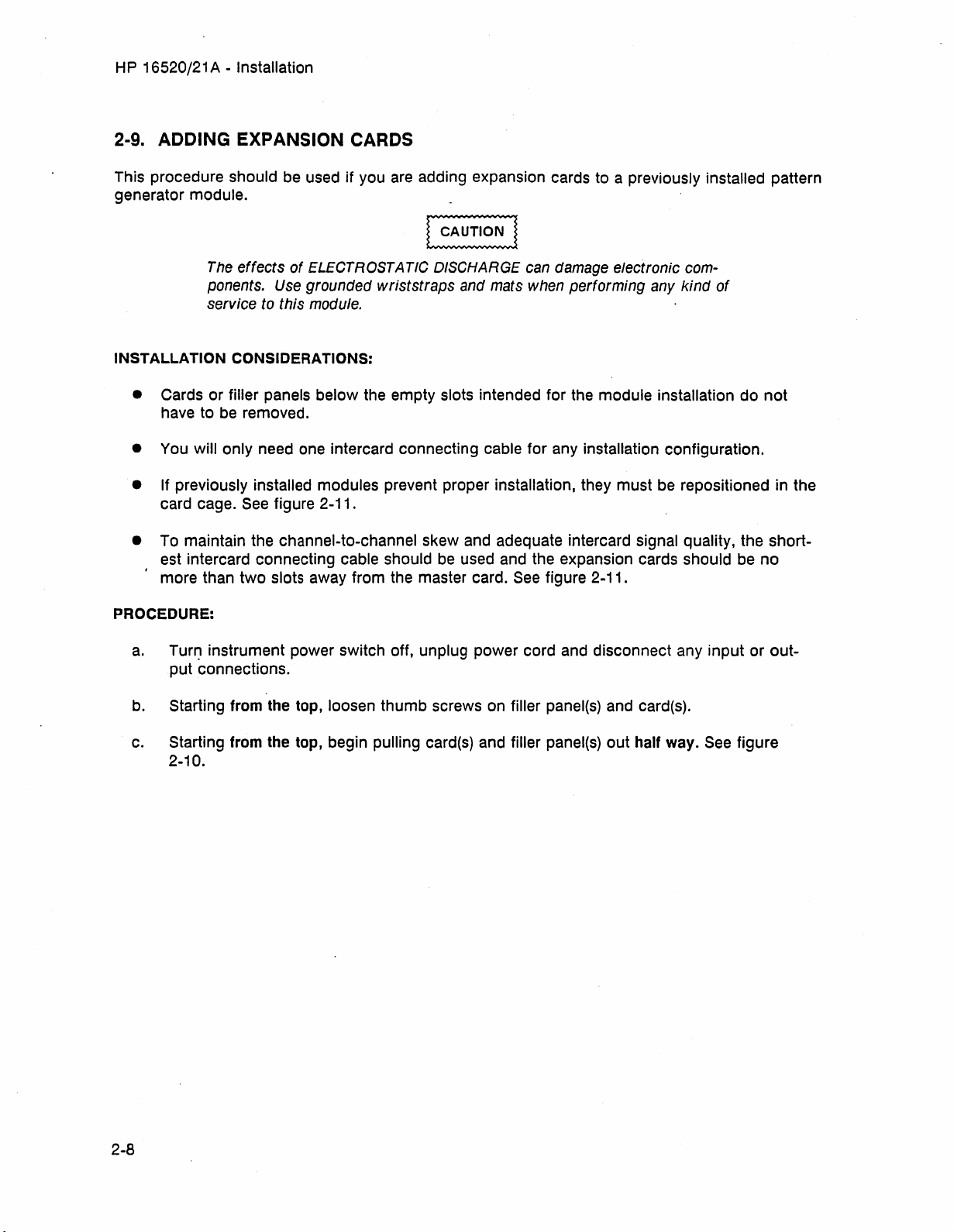

2·9. ADDING EXPANSION CARDS

This procedure should be used if you

are

adding expansion cards to a previously installed pattern

generator module.

The effects

ponents. Use grounded

service to this module.

INSTALLATION CONSIDERATIONS:

• Cards or filler panels below the empty slots intended for the module installation do

have to

be

removed.

of

ELECTROSTA

TIC

DISCHARGE can damage electronic com-

wriststraps

and

mats

when performing any

kind

of

not

• You will only need one intercard connecting cable for any installation configuration.

• If previously installed modules prevent proper installation, they must be repositioned in the

card cage.

See

figure

2-11

.

• To maintain the channel-to-channel skew and adequate intercard signal quality, the shortest intercard connecting cable should

more than two slots away from the master card.

PROCEDURE:

be

used and the expansion cards should

See

figure 2-11.

be

no

a.

Turr~

instrument power switch off, unplug power cord and disconnect any input or out-

put connections.

b. Starting from the top, loosen thumb screws on filler panel(s) and card(s).

c. Starting from the top, begin pulling card(s) and filler panel(s) out half way.

2-10.

See

figure

2-8

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 28

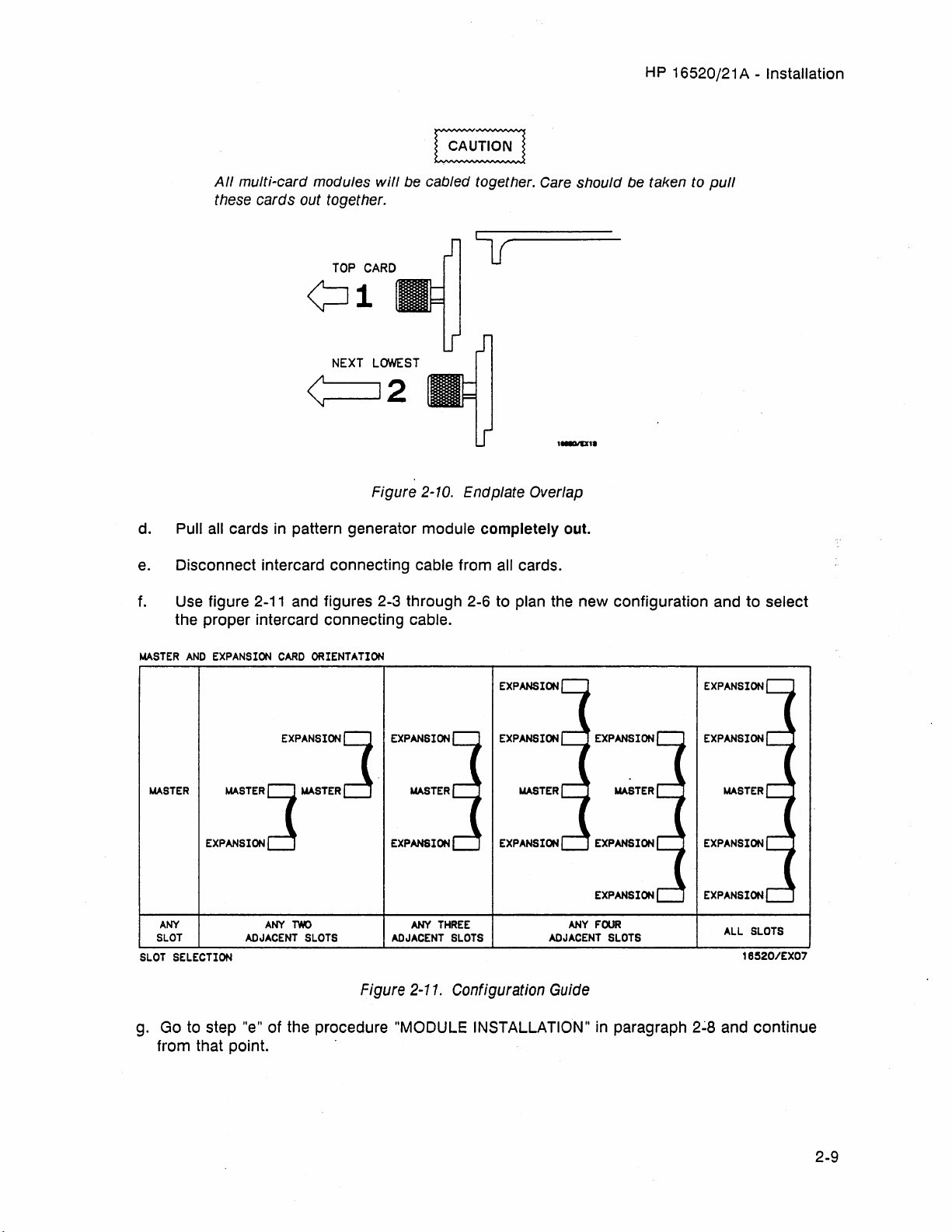

All

multi-card modules

these cards out together.

will

¢Jl

NEXT

LOWEST

HP

be

cabled together. Care should be taken to

16520/21 A - Installation

pull

<

d. Pull

e.

f.

MASTER

MASTER

all

cards

in

pattern generator module completely out.

Disconnect intercard connecting cable from

Use

figure

2-11

and figures 2-3 through 2-6 to plan the new configuration and to select

the proper intercard connecting cable.

AND

EXPANSION

MASTER

EXPANSION

CARD

ORIENTATION

EXPANSION

LJ

.......

c!

TER

12

Figure 2-10. Endplate Overlap

LJ

EXPANSION

c!

EXPANSION

.......

TER

aI/

cards.

EXPANSION

EXPANSION EXPANSION

MASTER MASTER

EXPANSION

EXPANSION

At-N

SL.OT

SLOT

SELECTION

g. Go to step "e" of the procedure "MODULE INSTALLATION"

from that pOint. .

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

At-N

ADJACENT

TWO

SLOTS

At-r(

ADJACENT

Figure 2-11. Configuration Guide

THREE

SLOTS

ANY

ADJACENT

EXPANSION

FOUR

SLOTS

in

paragraph

ALL

16520/EX07

2~8

and continue

SLOTS

2-9

Page 29

HP

16520/21 A - Installation

2-10. OPERATING ENVIRONMENT

The operating environment

1-2.

Note the non-condensing humidity limitation. Condensation within the instrument can

cause poor operation or malfunction.

Protection should

condensation.

The

HP

16520/21 A will operate

tions within the temperature and humidity

range given in table 1-2. However, reliability

enhanced by operating the instrument within

the

following ranges.

Temperature:

Humidity:

be

+20 to +35° C

20%

to

80%

is

listed

in

table

provided against internal

at

all

specifica-

(+68

to +95°

non-condensing

F)

2-11. STORAGE

The module may

vironments within the

Temperature:

Humidity:

Altitude:

Feet)

The module should also

temperature extremes, which cause condensation on the module.

be

stored or shipped

following limits:

_40°

C to +75° C

Up

to 90% at 65°C

Up

to 15,300 meters (50,000

be

protected from

in

en-

is

2-12. PACKAGING

Follow these general instructions for repacking

the module with commercially available

materials.

• Wrap module in anti-static plastic.

•

Use

a strong shipping container. A

double-wall carton made of

is

material

•

Use

70-to-100 mm (3-to- 4 inch) thick around

all

sides of the module to provide firm

cushioning and prevent movement inside

the container.

•

Seal

• Mark shipping container FRAGILE to ensure careful handling.

•

In

any correspondence, refer to module

by model number and board number.

2-13. TAGGING

If the module

Hewlett-Packard office for service or repair, attach a tag with your name and address, the

complete board number, and a description of

the service required.

adequate.

a layer of shock-absorbing material

shipping container securely.

FOR

SERVICE

is

to

be

shipped to a

350 lb. test

2-10

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 30

PERFORMANCE TESTS

TABLE

OF

CONTENTS

3-1. Introduction

3-2. Recommended Test Equipment

3-3. Test Record

3-4. Performance Test Interval

3-5. Performance Test Procedures

3-6. Data Period Accuracy Test

3-7. Duty

Cycle Test

............................................................................

............................................................................

............................................................

............................................................

........................................................................

.......................................................

.........................................................

3-1

3-1

3-1

3-1

3-1

3-2

3-8

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 31

H P 16520/21 A - Performance Tests

SECTION III

3·1. INTRODUCTION

The procedures

generator's electrical performance using the

specifications listed in Section I

mance standards.

without access to the interior of the instrument.

can

results.

At

the end of this section

be

used

in

this section test the pattern

as

the perfor-

All

tests can

as

a record of performance test

be

performed

is

a form that

3·2. RECOMMENDED TEST

EQUIPMENT

Equipment recommended for performance

tests

is

listed in table 1-3. Any equipment that

satisfies the critical specifications given in the

table may

models.

be

substituted for the recommended

PERFORMANCE

all

of the tested specifications and their acceptable limits. The results recorded in the

test record may

periodic maintenance and troubleshooting or

after repairs and adjustments have been made.

be

used for comparison in

TESTS

3·4. PERFORMANCE TEST INTERVAL

Periodic performance verification of the H P

16520/21 A Pattern Generator Module is

required

strument's performance should

ter it has been serviced, or if improper operation

formed before any performance verification

tests. Further checks requiring access to the

interior of the instrument are included in the

adjustment section, but are not required

the performance verification.

at

two year intervals. The in-

be

verified af-

is

suspected. Calibration should be per-

for

3·3. TEST RECORD

Results of performance tests may

in the Performance Test Record (table 3-1)

the end of the procedures. The test record lists

be

tabulated

at

3·5. PERFORMANCE TEST

PROCEDURES

All performance tests should

the instrument's environmental operating temperature and after a

is-minute

be

performed at

warm up.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3-1

Page 32

H P 16520/21 A - Performance Tests

3-6. Data Period Accuracy Test

SPECIFICATION: ±

EQUIPMENT:

Oscilloscope

BNC Cable

BNC Adapter

Probe Lead Set

Grabber

DESCRIPTION:

The purpose of this test

slowest and fastest clock ranges. (For

PROCEDURE:

a.

(2)

Connect data output channel 0 and the corresponding ground from a selected output

data cable, to the oscilloscope

nally connected for either TTL or

2%

(of period) ± 1

...........................................................................

....................................................

......................................................................

........................................................................

........................

is

to verify the data period accuracy of the internal clock at its

ns

:.............

bes.t

as

shown

EeL.

"

.......................

. . . .

..

. . . . .

.. .. ..

. . . . . .

...

. .

results, terminate

in

figure 3-1. The output cables can

in~o

10

kQ,

OSCILLOSCOPE

...

10

..

pF)

..

HP

HP

HP

54201 A

HP

10502A

1250-1032

H P 10347 A

5959-0288

be

inter-

b.

Apply power to the

DATA

CABLE

Figure

D

~

..,/

DATA

CHANNEL

3-1.

Data

Period

HP

16500A and wait for system bootup.

Accuracy

ADAPTER

Test

Equipment

INPUT

Hookup

3-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 33

HP

16520/21 A - Performance Tests

c. From the startup screen shown in figure 3-2, touch the following

below:

1.

System

2.

Pattern Gen (If multiple

.....

_S.;.y_st_e_m_--'J

Cards

A

PATTERN

GENERATOR

MASTER

- 50

Mbit/s

6

PATTERN

C

D

E

GENERATOR

EXPANDER

HP

(configuratiOn)

Figure

3-2.

16520A Cards, pick one to

Controller

RS-232C

~

Printer

Startup Screen

fields in the sequence

be

tested)

d. In the Format screen, touch Clock field and set to Internal

Pat

tern

Gen

..-="""""

......

(PO"ij'S)

l.!....!J

A ) (

Pol

(

ITTLnpu t )..

P d

ht.

2.0 3 ..

Figure

Format

A3

0 7

P d

ht.

......

3-3.

A2

----..

'--

__

P d

65

DE¥ACHED

0 7

......

Clock Field

.,/

0 7

E)

r;::::::)

~

Pod

DETACHED

......

as

shown in figure 3-3.

( Run

( ]

Symbols

65

Pod

64

DETACHED

0 7

......

0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3-3

Page 34

HP

16520/21 A - Performance Tests

e.

Touch Period and

set

Pettern

Internal clock to 200

Gen

A ) ( Formet

J.Ls

as

20

50

100

200

500

2 us

5 us

Figure 3-4. Clock Period Screen

shown

ns

ns

ns

ns

ns

1 us

in

figure 3-4.

f. Touch channel assignment field for the selected input cable.

Pet

tern

Gen

~

STROBE

DATA

Off

g.

Select data output channel 0

Pe t tern

A ) ( Formet

Pod

A3

•

Pol

tE

TTL

•

2.0 3 ..

•

••

•••

G"'§§§

Figure

3-5.

as

Gen

A )

Formet

'--_--'

Pod

TTL

7

.....

0

Channel

shown

r----

_____

A2

Pod

DETACHED DETACHED DETACHED

0 7

......

I I • • • • • • •

Assignment Field

in

figure 3-6. Touch Done.

B6

......

0 7

~

(Strobes)

Pod

B5

......

•••••

~

0

I I • I

;:;==:-:=---..

Off

1"':::c::i:;;;:j;:::)...c.hr~d1

aD

(--C-LE-A--"'R)

( DONE) § §

(

Strobes)

Pod

65

.

~~:~~~~g

See

figure 3-5.

(

Run

(Symbols)

Pod

B~

7

......

0

•••••

I

(

Run

(SymbO

IS)

Pod

64

~~:~~~~g

Figure

h. Touch Format, then touch Listing.

3-4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3-6.

Data

Channel

Select

Page 35

i.

From the listing screen, program the pattern generator

HP

16520/21 A - Performance Tests

as

follows:

Touch program field

1.

8

EJ

c::D

B

2.

Touch 1

as

shown

Autoroll

EJ

as

Instr

shown

(

)

(STROBE

Listing

in

figure 3-7.

)~

~~

***

:TART

I

.*.

QFb~:k:RAMI

10_

No

OF

P M *

in

figure 3-8, then touch Done.

Instr

***

••

Figure 3-7. Program Field

~~

~~

Run

(

Run

(

3.

Touch Insert

as

c::D

-

Figure

shown in figure 3-9.

Listing

Instr ) (STROBE

)

~

~~

u.

:TART

I

**.

No

OF

Figure

OF~RAM

~

0

M

•••

3-9.

.**

c::E::J

3-8.

Numeric

Insert New Program Line

Entry

3-5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 36

HP

16520/2'1 A - Performance Tests

4. Touch program

~=~:===::..~(~L=l=s=t1~ng~

EJ

B

CJJ

5.

Enter

Os

as

shown in figure 3-11, then touch

(

Pettern

field

•••

Ln

Ins

START

END

Gen

Ins

as

shown

tr

) (

STROBE

~~

Or

PROGRAM

OF

~~.~

Figure

A ) (

tr

Listing

)

(STROBE)

in

figure 3-10.

)

~

•••

3-10.

._

~~

Program Field

Done.

..

(

Run

Run

6.

Repeat steps 1 through 5 until there

ding with a zero

Pettern

(0).

See

Gen

Ins

A ) (

tr

figure 3-12.

) (

STROBE

~~

•••

START

Or

PROGRAM

Merge u 00

B

~I

~

•••

~~cb

END

bF~

Figure

Figure

Listing

0

3-11.

Numeric Entry

is

a short program starting with a one

)

~

•••

01

01

00

••

.3-12.

Example Program

~~

(

Run

(1)

and en-

3-6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 37

HP

16520/21 A - Performance Tests

j. Touch

Run,

then drag finger to Repetitive

Pottern

Gen A ) (

'---

_____

listing

J~

~

as

shown in figure 3-13.

~,...:..:...:...:..:....:

..........

_

~

Figure 3-13. Run Repetitive Mode

k. Using the oscilloscope, measure pulse period at 50% point on waveform.

I.

The pulse high time and low time should each measure between 196

m. Touch Stop.

n. Touch Listing, then touch Format.

o. Touch Period.

p. Change period to

q. Touch

Run,

20 ns.

then drag finger to Repetitive.

J.Ls

and 204

J..Ls.

r.

Using the oscilloscope, measure pulse period at 50% point on waveform.

s.

Pulse high time and low time should each measure between 18.6 ns and 21.4 ns.

t. Touch Stop.

Note

This test arbitrarily selects data channel 0 on

If

desired, other output channels and cables may

one

of

the data output cables.

be

substituted or added to

this procedure.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3-7

Page 38

HP

16520/21 A - Performance Tests

3-7. Duty Cycle Test

SPECIFICATION: 10 ns minimum high time; 10 ns minimum low time

EQUIPMENT:

Oscilloscope

Pulse Generator

BNC Cable

BNC

Adapter

50 Ohm

Probe Lead Set

Grabbers

DESCRIPTION:

The purpose of this test

high and low times of the user supplied clock. (For best results, terminate into 10 kn,

PROCEDURE:

a.

Connect test equipment

...........................................................................

........................................................................

(2)

.........................................................................

(2)

...............................................................

Feedthru

(4)

.....................................................................

........................................................................

.......................................................................

is

to

verify that the internal clock circuits will respond to the

as

shown in figure 3-14.

,

....

OSCILLOSCOPE

D

PULSE

GENERATOR

HP 54201 A

H P 8116A

HP

10502A

HP

1250-1032

HP

10100C

HP

10347A

HP

5959-0288

minimum

10

INPUT

pF)

OUTPUT

-

GROUND

CLOCK

INPUT

Figure 3-14. Duty

b. Apply power to the 16500A and wait for system bootup.

c. Set pulse generator for a 50 MHz square wave, 50% duty cycle, and an amplitute of 5

Volts.

3-8

Cycle

Test

Equipment

Hookup

BNC

ADAPTER

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 39

HP

16520/21A - Performance Tests

d. From the startup screen shown

sequence below:

1. System

2.

Pattern

(,-

__

S_ys_t_em

A

PATTERN

MASTER -50

B

PATTERN

EXPANDER

C

D

E

Gen

(If multiple

__

Cerds

GENERATOR

GENERATOR

.,)

Mbit/s

(cant

Figure 3-15. Startup Screen

in

figure 3-15, touch the following field

HP

16520A Cards, pick one to

iguretion)

Controller

RS-232C

LJ

Printer

be

in

tested)

the ordered

e.

Touch Input field to set input level to

(

Pe t tern

Gen A ) (

r-==="""I(

f.

Touch Clock field and set to External

(

r===-",(

P')t

tern

:Od!)

Pol

Gen A ) (

:Od!)

Pol

2.0 3 ..

2.03

TIL

as

shown

Formet

_

Pod A3 Pod

TTL TTL

0 7

Clack

Interne!

......

A2

0 7

,-----.

"--

__

Pod

66

DETACHED

......

Figure 3-16. Set TTL Level

as

shown

Formet

(I~t

P~

A3

..

0 7

)_

P~

......

,----"'"

A2

D"~-~~-C-~~-D--'D~~~C~~D

0 7

......

in

figure 3-16.

~

~

r'

~

PoC!

65 Pod

DETACHED

0 7

......

in

figure 3-17.

~

0 7

......

0 7

0

( Run

( )

Symbols

6.:1

DETACHED

......

( Run

(

Symbol

Pod

6.:1

DETACHED

7

......

0

s)

0

Figure 3-17. Clock Field

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3-9