Page 1

User’s Guide

Publication number 16500-97022

August 1997

For Safety information, Warranties, and Regulatory

information, see the pages behind the Index

© Copyright Hewlett-Packard Company 1987, 1990, 1993, 1994, 1996, 1997

All Rights Reserved

HP 16500C /16501A Logic

Analysis System

Page 2

HP 16500C—At a Glance

A system of measurement modules

The HP 16500C is the mainframe of the

Hewlett-Packard Logic Analysis

System. It offers a modular structure for

plug-in cards with a wide range of state,

timing, oscilloscope, and pattern

generator capabilities.

A powerful, easy-to-use interface

The touchscreen interface offers

pop-up menus and color graphics to

lead you through measurement

configurations without having to

remember lots of steps. You can add a

keyboard or mouse to speed data input

and measurement configuration.

The HP 16501A expands module

capacity

The HP 16501 A is the add-on mainframe

for expanding the module capacity of

the HP 165 00C. When the two are

connected, they form a single ten-card

system that is turned on and controlled

by the HP 16500C.

Intermodule measusurement capability

The HP 16500C offers intermodule

measurement features that allow you to

capture complex system activity.

Modules ca n

be armed by an external instrument,

•

be armed by anot her module in the

•

HP16500C or HP16501A frames, or

be used to arm an external

•

instrument.

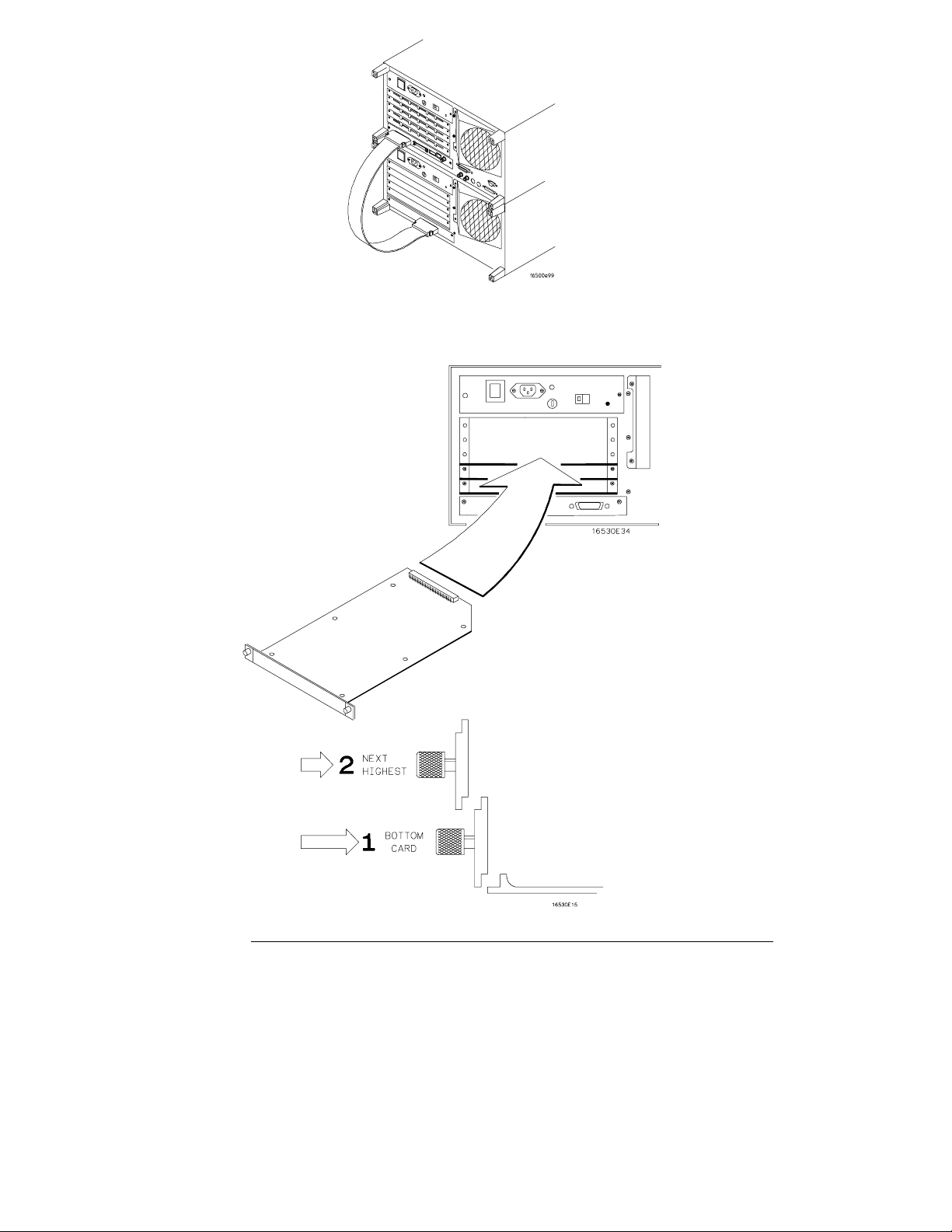

Install measurement modules in any

slot

Single card analyzers, oscilloscopes,

and other options can go in any slot of

the HP 165 00C or HP 16501A. You should

generally begin installing cards starting

with the bottom-most slot and working

up.

Some measurement modules have

multiple cards. A multiple-card module

must be installed into adjacent slots in

the same mainframe—that is, you

cannot install one card of the module

into the HP 16500C and the other into

the HP 16501A.

Calibrate measurement modules af ter

installation

Some measurement modules are

sensitive to temperature and voltage

variations between different

mainframes. Thus, when you install

such a module in the mainframe, you

should calibrate it before using it to

ensure maximum measurement

precision and accuracy.

See the Service Guide for each

measurement module for installation

and calibration procedures.

ii

Page 3

HP 16500C

HP 16501A

iii

Page 4

iv

Page 5

In This Book

This User’s Guide shows you how to use

the HP 16500C Logic Analysis System in

your everyday debugging work.

Chapter 1, “Triggering,” shows you how

to set up the analyzer to trigger on the

various kinds of events present in your

system. Advanced triggering capability

allows you to look at only the program

states of interest when you are solving a

particular problem.

Chapter 2, “Intermodule Measurements,”

shows you how to configure multiple

HP 16500 modules and external

measurement instruments into a single

measurement system in which modules

trigger each other.

Chapter 3, “File Management,” shows you

how to transfer files to and from the

HP 16500C using flexible disks, LAN

interfaces, and other interfaces.

Chapter 4,“Concepts,” gives you a brief

introduction to the ideas underlying the

trigger sequencer and the inverse

assembler, two important components of

sophisticated logic analysis.

Chapter 5, “Solving Problems,” shows you

how to diagnose and correct the more

common types of problems that might

occur while you are making a

measurement.

Chapter 6, “Application Notes,” lists the

various application notes that HP has

published regarding the HP 16500C and

other similar HP logic analyzers. These

notes will give you more information

1

Intermodule Meas urements

2

3

4

5

6

Triggerin g

File Management

Concepts

Solving Problems

Application Notes

Glossary

Index

v

Page 6

about specific application problems and how to solve them using an HP logic

analyzer.

See Also For general information on setup and operation of the HP 16500C, see the

HP 16500C /16501A Logic Analysis System User’s Reference.

For information on programming the HP 16500C using a computer controller

such as a workstation or personal computer, see the HP 16500C/16501A

Logic Analysis System Programmer’s Guide. The Programmer’s Guide is

available from your HP Sales Office.

For information on logic analyzers, oscilloscopes, preprocessors, and other

logic analysis system options, see the User’s Reference manual for those

options.

vi

Page 7

Contents

1 Triggering

To store and time the execution of a subroutine 1–3

To trigger on the nth iteration of a loop 1–5

To trigger on the nth recursive call of a recursive function 1–6

To trigger on entry to a function 1–8

To capture a write of known bad data to a particular variable 1–10

To trigger on a loop that occasionally runs too long 1–11

To verify that all stacks and registers are restored correctly before

exiting a subroutine 1–12

To trigger after all status bus lines finish transitioning 1–13

To find the nth assertion of a chip select line 1–14

To verify that the chip select line of a memory chip is strobed after

the address is stable 1–15

To trigger when expected data does not appear on the data bus from

a remote device when requested 1–16

To test minimum and maximum pulse limits 1–18

To detect a handshake violation 1–20

To detect bus contention 1–21

Cross-Arming Trigger Examples 1–22

To examine software execution when a timing violation occurs 1–23

To look at control and status signals during execution of a routine 1–24

2 Intermodule Measurements

Intermodule Measurement Examples 2–4

To set up a group run of modules within the HP 16500C 2–4

To start a group run of modules from an external trigger source 2–6

To start an external instrument on command from a module within

the HP 16500 and 16501 mainframe 2–8

To see the status of a module within an intermodule measurement 2–10

To see time correlation of each module within an

intermodule measurement 2–12

To use a timing analyzer to detect a glitch 2–14

To capture the waveform of a glitch 2–15

vii

Page 8

Contents

To capture state flow showing how your target system processes

an interrupt 2–16

To test a circuit using stimulus-response 2–17

To use a state analyzer to trigger timing analysis of a count-down on

a set of data lines 2–18

To monitor the activity of two coprocessors in a target system 2–19

Special displays 2–21

To interleave trace lists 2–22

To view trace lists and waveforms together on the same display 2–24

Skew Adjustment 2–26

To adjust for minimum skew between two modules involved in

an intermodule measurement 2–27

3 File Management

Transferring Files Using the Flexible Disk Drive 3–3

To save a measurement configuration 3–4

To load a measurement configuration 3–6

To save a trace list in ASCII format 3–8

To save a menu or measurement as a graphic image 3–10

To load system software 3–12

Using the LAN Interface 3–13

To set up the HP 16500C 3–14

To transfer data files from the HP 16500C system to your computer 3–16

To transfer graphics files from the HP 16500C system to your computer 3–18

viii

Page 9

4 Concepts

The Trigger Sequencer 4–3

The Inverse Assembler 4–10

Configuration Translation for Analyzer Modules 4–13

5 If You Have a Problem

Analyzer Problems 5–3

Intermittent data errors 5–3

Unwanted triggers 5–3

No Setup/Hold field on format screen 5–4

No activity on activity indicators 5–4

Capacitive loading 5–4

No trace list display 5–5

Contents

Preprocessor Problems 5–6

Target system will not boot up 5–6

Slow clock 5–7

Erratic trace measurements 5–7

Inverse Assembler Problems 5–9

No inverse assembly or incorrect inverse assembly 5–9

Inverse assembler will not load or run 5–10

Intermodule Measurement Problems 5–11

An event wasn’t captured by one of the modules 5–11

ix

Page 10

Contents

Messages 5–12

“Default Calibration Factors Loaded” (HP 16540, 16541, and 16542) 5–12

“. . . Inverse Assembler Not Found” 5–12

“Measurement Initialization Error” 5–13

“No Configuration File Loaded” 5–14

“Selected File is Incompatible” 5–14

“Slow or Missing Clock” 5–14

“State Clock Violates Overdrive Specification” 5–15

“Time from Arm Greater Than 41.93 ms” 5–15

“Waiting for Trigger” 5–16

6 Application Notes

Glossary

Index

x

Page 11

1

Triggering

Page 12

Triggering

As you begin to understand a problem in your system, you may realize

that certain conditions must occur before the problem occurs. You

can use sequential triggering to ensure that those conditions have

occurred before the analyzer recognizes its trigger and captures

information.

You set up sequential triggering as follows:

• Select the Trigger menu for the module you are using.

• In the Trigger menu, define terms and associated values to be used

when searching through the sequence.

• In the Trigger menu, select the number of the state sequence level

you want to modify, and enter the appropriate store qualification,

sequence-advance specification, and sequence-Else specification.

If you aren’t familiar with the trigger menus, try working through the

examples in the Logic Analyzer Training Kit manual, or refer to the

User’s Reference for your analyzer.

1–2

Page 13

Triggering

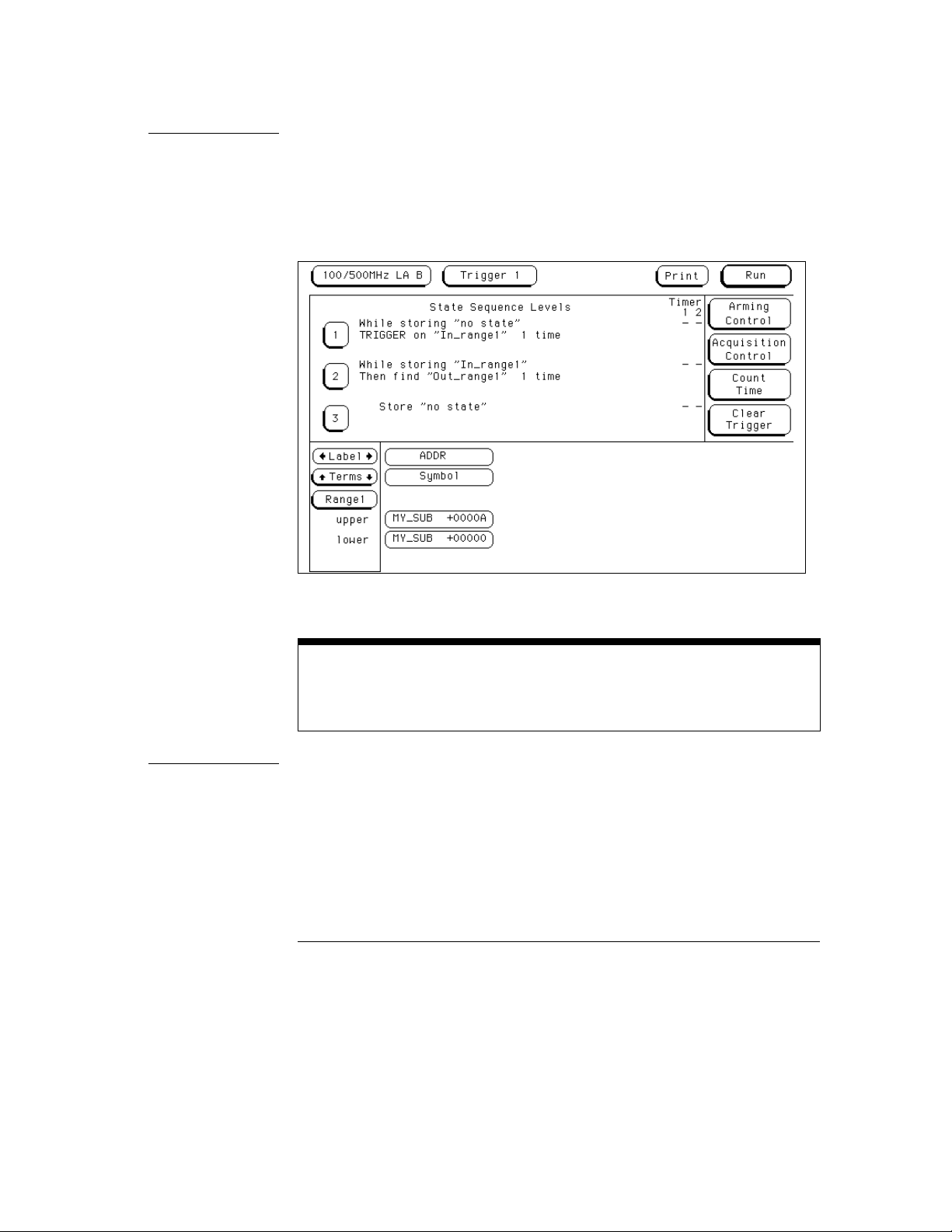

To store and time the execution of a subroutine

To store and time the execution of a subroutine

Most systems software of any kind is composed of a hierarchy of functions

and procedures. During integration, testing, and performance evaluation, you

will want to look at specific procedures to verify that they are executing

correctly and that the implementation is efficient. The analyzer allows you to

do this by triggering on entry to the address range of the subroutine and

counting the elapsed time since the trigger state.

1

Select the state analyzer Trigger menu.

2 Set Count to Time.

Setting the Count to Time causes the state analyzer to store a time stamp for

each data point that is stored in trace memory. The trace list will show these

time stamps next to each state.

3

Define a range term, such as Range1, to represent the address range

of the subroutine of interest.

You may need to examine the structure of your code to help determine this.

If your subroutine calls are really procedure calls, then there is likely to be

some code at the beginning of the routine that adjusts the stack for local

variable allocation. This will precede the address of the first statement in the

procedure. If your subroutine has no local storage and is called by a jump or

branch, then the first statement will also be the entry address.

4

Under State Sequence Levels, enter the following sequence

specification:

While storing “no state” Trigger on “In_range1” 1 time

•

While storing “In_range1” Then find “Out_range1” 1 time

•

Store “no state”

•

1–3

Page 14

Triggering

To store and time the execution of a subroutine

Example Suppose you want to trigger on entry to a routine called MY_SUB. You can

define the address of MY_SUB in the Format menu, allowing you to reference

the symbol name when setting up the trace specification. Assume that

MY_SUB extends for 0A hex locations. You can set up the trigger sequencer

as shown in the display.

Trigger Setup for Storing Execution of a Subroutine

For processors that do prefetching of instructions or have pipelined

architectures, you may want to add part or all o f the depth of the pipeline to the

start address for In_Range1 to ensure that the analyzer does not trigger on a

prefetched but unexecuted state.

1–4

Page 15

Triggering

To trigger on the nth iteration of a loop

To trigger on the nth iteration of a loop

Traditional debugging requires print statements around the area of interest.

This is not possible in most embedded systems designs. But, the analyzer

allows you to view the system’s behavior when a particular event occurs.

Suppose that your system behaves incorrectly on the last iteration of a loop,

which, in this instance, happens to be the 10th iteration. You can use the

analyzer’s triggering capabilities to capture that iteration and subsequent

processor activity.

1

Select the state analyzer Trigger menu.

2 Define the terms LP_START and LP_END to represent the start and

end addresses of statements in the loop, and LP_EXIT to represent

the first statement executed after the loop terminates.

3 Under State Sequence Levels, enter the following sequence

specification:

While storing “no state” Find LP_END 1 time

•

While storing “anystate” TRIGGER on LP_START 9 times; Else on

•

“LP_EXIT” go to level 1

Store “anystate”

•

The above sequence specification has some advantages and a potential

problem. The advantages are that a pipelined processor won’t trigger until it

has executed the loop 10 times. Requiring LP_END to be seen at least once

first ensures that the processor actually entered the loop; then, 9 more

iterations of LP_START is really the 10th iteration of the loop. Also, no

trigger occurs if the loop executes less than 10 times: the analyzer sees

LP_EXIT and restarts the trigger sequence. The potential problem is that

LP_EXIT may be too near LP_END and thus appear on the bus during a

prefetch. The analyzer will constantly restart the sequence and will never

trigger. The solution to this problem depends on the structure of your code.

You may need to experiment with different trigger sequences to find one that

captures only the data you wish to view.

1–5

Page 16

Triggering

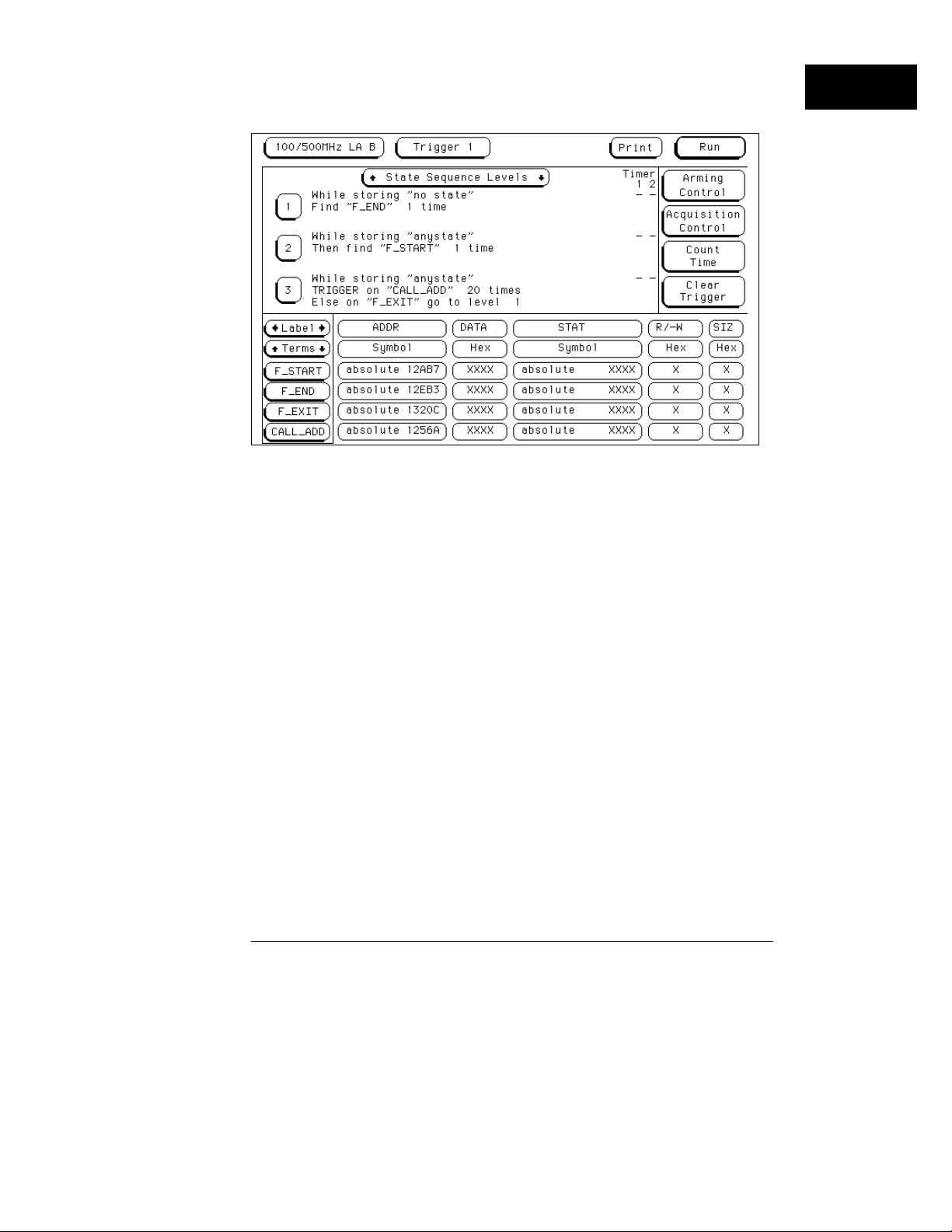

To trigger on the nth recursive call of a recursive function

To trigger on the nth recursive call of a recursive

function

1 Select the state analyzer Trigger menu.

2 Define the terms CALL_ADD, F_START, and F_END to represent the

called address of the recursive function, and the start and end

addresses of the function. Define F_EXIT to represent the address of

the first program statement executed after the original recursive call

has terminated.

Typically, CALL_ADD is the address of the code that sets up the activation

record on the stack, F_START is the address of the first statement in the

function, and F_END is the address of the last instruction of the function,

which does not necessarily correspond to the address of the last statement. If

the start of the function and the address called by recursive calls are the

same, or you are not interested in the function initialization code, you can use

F_START for both CALL_ADD and F_START.

3

Under State Sequence Levels, enter the following sequence

specification:

While storing “no state” Find “F_END” 1 time

•

While storing “anystate” Then find “F_START” 1 time

•

While storing “anystate” TRIGGER on “CALL_ADD” 20 times Else on

•

“F_EXIT” go to level 1

Store “anystate”

•

As with the trigger specification for “To trigger on the nth iteration of a loop,”

this specification helps avoid potential problems on pipelined processors by

requiring that the processor already be in the first recursive call before

advancing the sequencer. Because it is already in the first recursive call, this

example triggers on the 21st recursive call, which is the 22nd entrance to the

function. Depending on the exact code used for the calls, you may need to

experiment with different trigger sequences to find one that captures only

the data you wish to view.

1–6

Page 17

To trigger on the nth recursive call of a recursive function

Triggering on the 22nd Call of a Recursive Function

Triggering

1–7

Page 18

Triggering

To trigger on entry to a function

To trigger on entry to a function

This sequence triggers on entry to a function only when it is called by one

particular function.

1

Select the state analyzer Trigger menu.

2 Define the terms F1_START and F1_END to represent the start and

end addresses of the calling function. Define F2_START to represent

the start address of the called function.

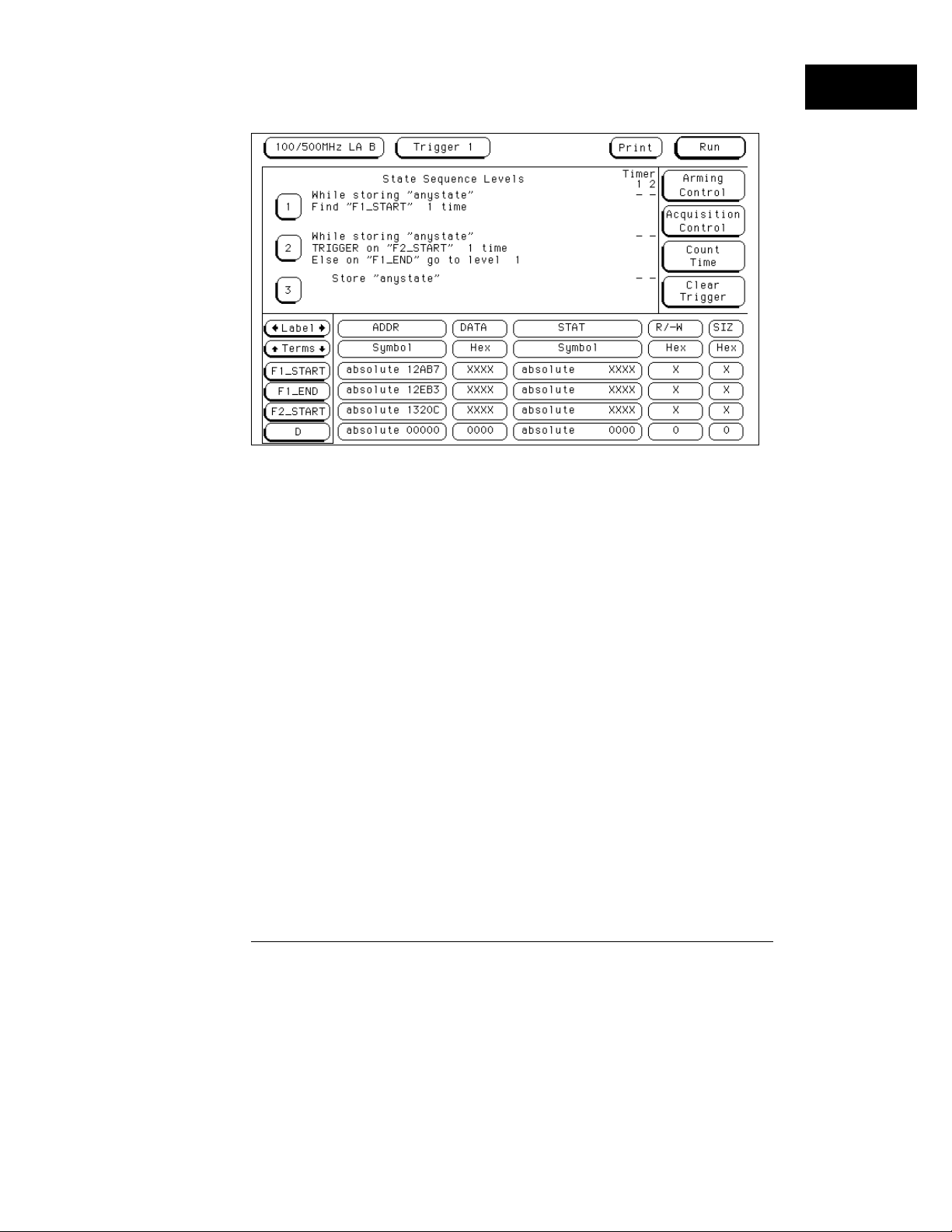

3 Under State Sequence Levels, enter the following sequence

specification:

While storing “anystate” Find “F1_START” 1 time

•

While storing “anystate” TRIGGER on “F2_START” 1 time Else on

•

“F1_END” go to level 1

Store “anystate”

•

This sequence specification assumes there is some conditional logic in

function F1 that chooses whether or not to call function F2. Thus, if F1 ends

without the analyzer having seen F2, the sequence restarts.

The specification also stores all execution inside function F1, whether or not

F2 was called. If you are interested only in the execution of F1, without the

code that led to its invocation, you can change the storage specification from

“anystate” to “nostate” for the second sequence term.

1–8

Page 19

Triggering on Entry to a Function

Triggering

To trigger on entry to a function

1–9

Page 20

Triggering

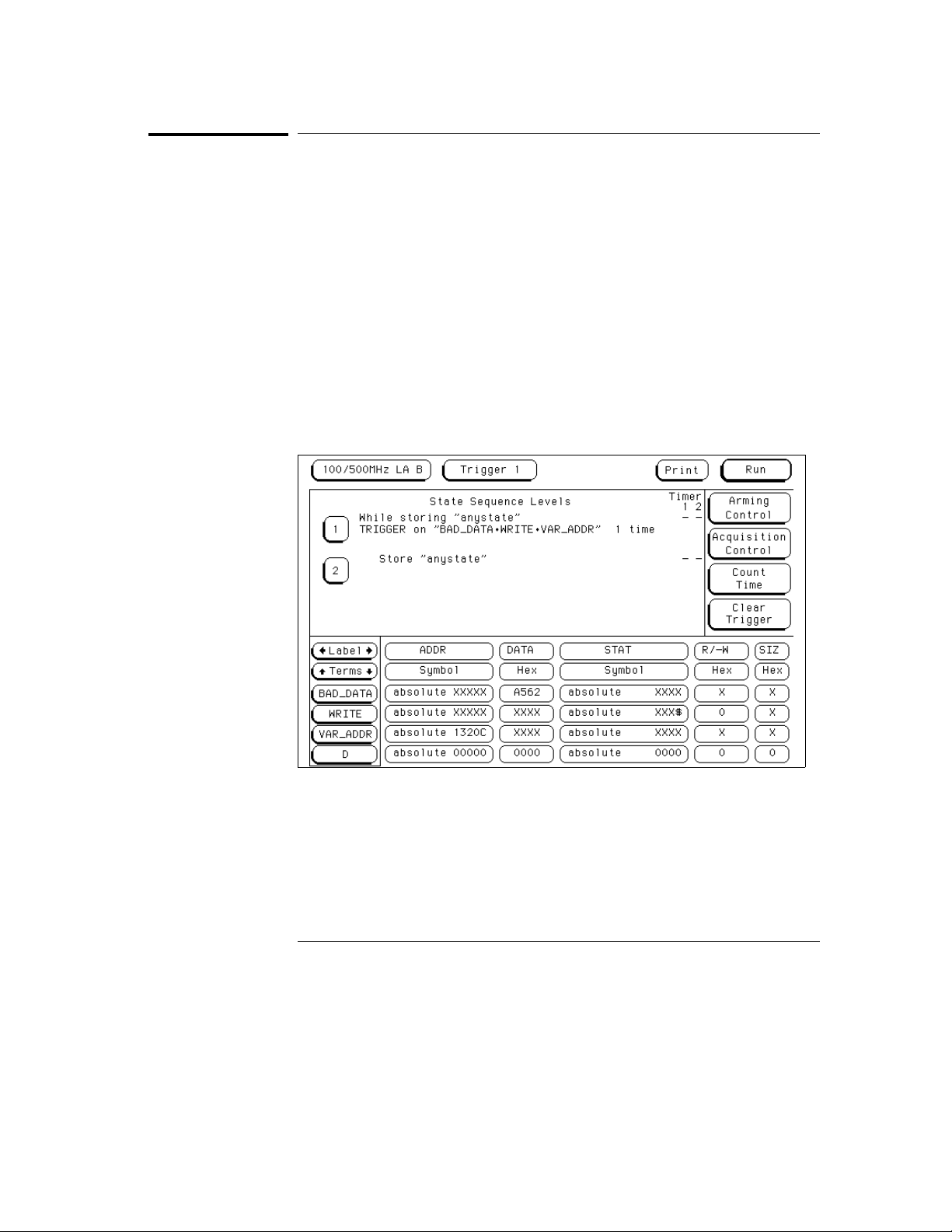

To capture a write of known bad data to a particular variable

To capture a write of known bad data to a particular

variable

The trigger specification ANDs the bad data on the data bus, write

transaction on the status bus, and address of the variable on the address bus.

1

Select the state analyzer Trigger menu.

2 Define the terms BAD_DATA, WRITE, and VAR_ADDR to represent

the bad data value, write status, and the address of the variable.

3 Under State Sequence Levels, enter the following sequence

specification:

While storing “anystate” TRIGGER on “BAD_DATA • WRITE •

•

VAR_ADDR” one time (you use the Combination trigger term to do this)

Store “anystate”

•

Capturing a Bad Write to a Variable

1–10

Page 21

Triggering

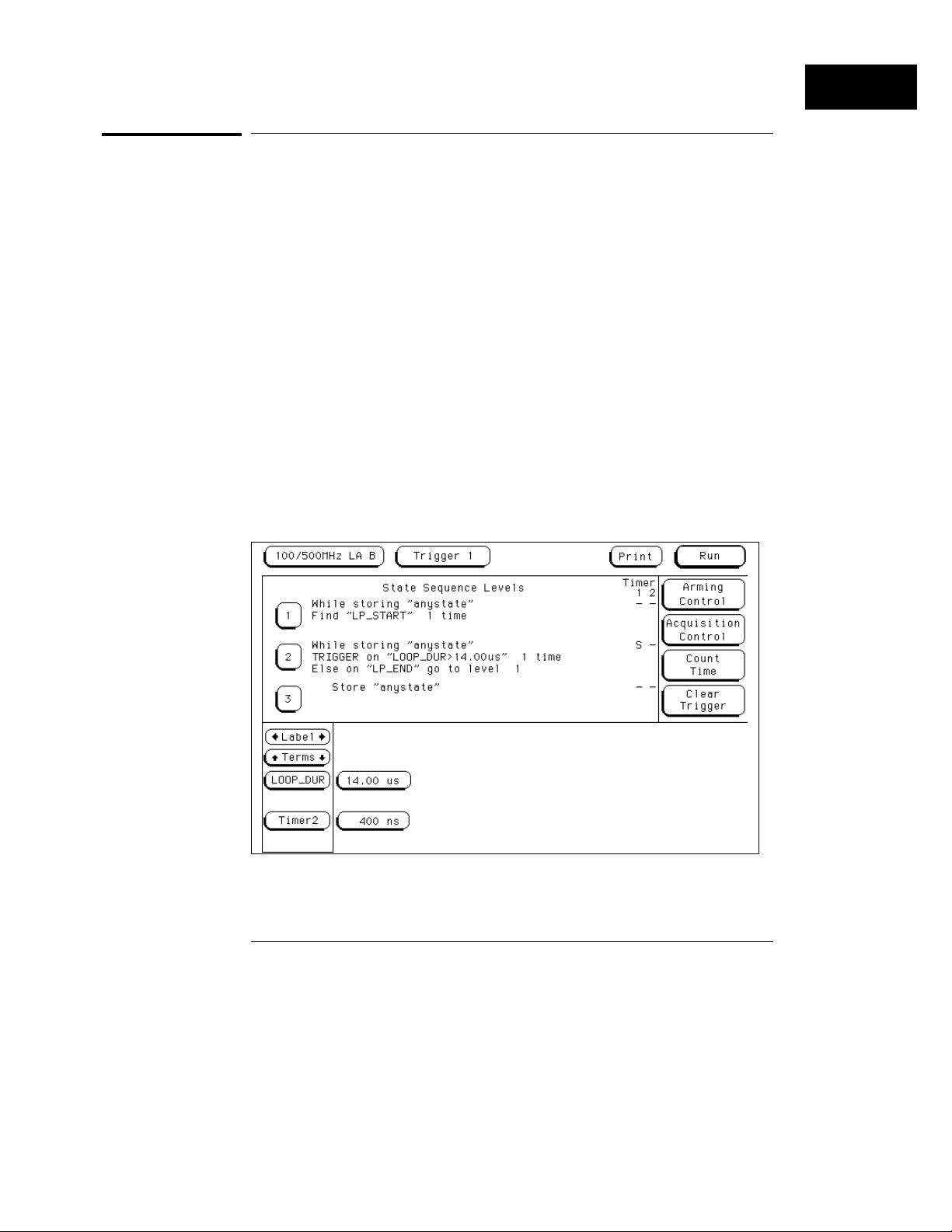

To trigger on a loop that occasionally runs too long

To trigger on a loop that occasionally runs too long

This example assumes the loop normally executes in 14 µs.

1

Select the state analyzer Trigger menu.

2 Define terms LP_START, LP_END, and Timer1 to represent the start

and end addresses of the loop, and the normal duration of the loop.

You can make the sequence specification closer to the problem domain by

renaming Timer1 to LOOP_DUR.

3

Under State Sequence Levels, enter the following sequence

specification:

While storing “anystate” Find “LP_START” 1 time

•

While storing “anystate” TRIGGER on “LOOP_DUR 14.00 µs” 1 time Else

•

on “LP_END” go to level 1

You will need to start the LOOP_DUR timer (Timer1) upon entering

this state. You do this using the Timer Control field in the menu for

sequence level 2.

Store “anystate”

•

Triggering on a Loop Overrun

1–11

Page 22

Triggering

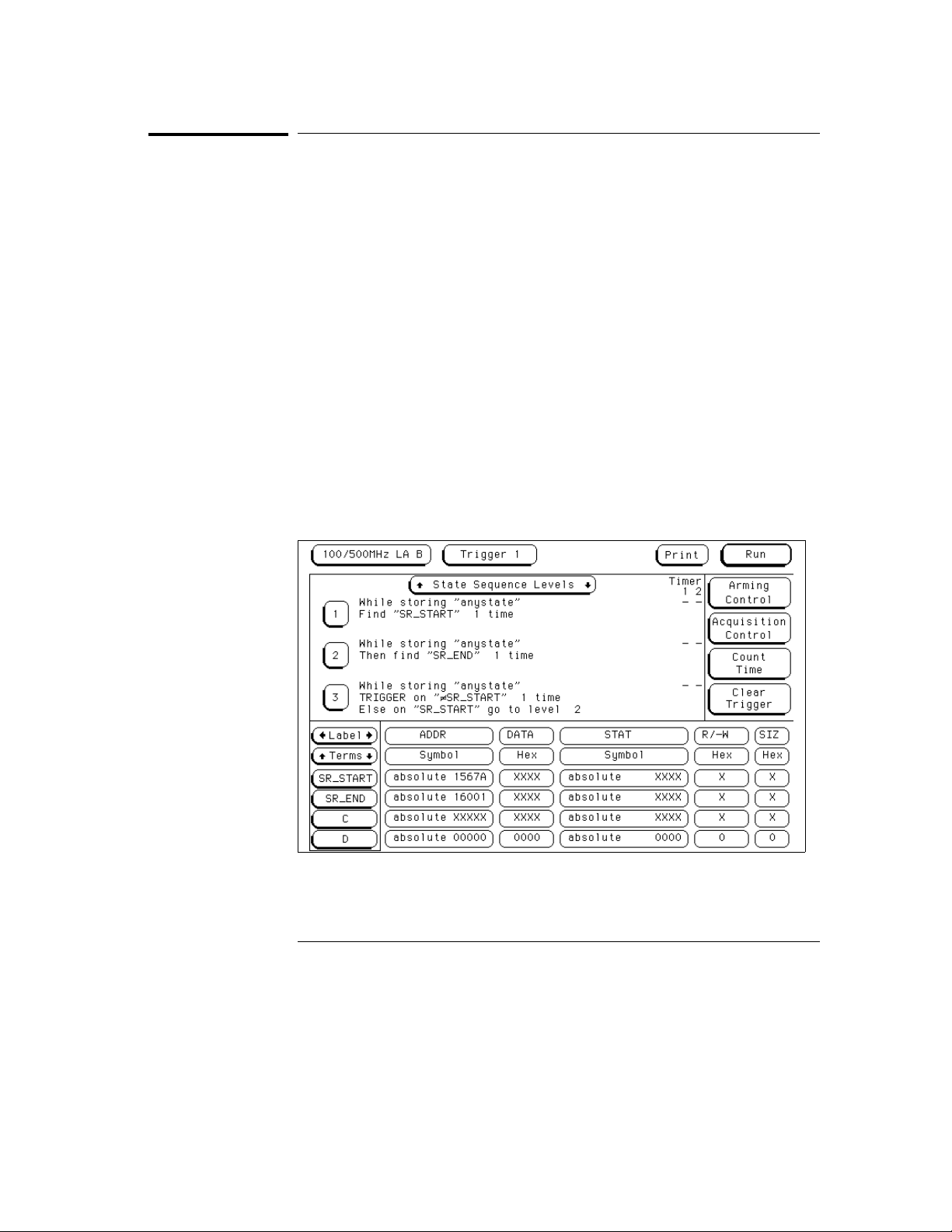

To verify that all stacks and registers are restored correctly before exiting a subroutine

To verify that all stacks and registers are restored

correctly before exiting a subroutine

The exit code for a function will often contain instructions for deallocating

stack storage for local variables and restoring registers that were saved

during the function call. Some language implementations vary on these

points, with the calling function doing some of this work, so you may need to

adapt the procedure to suit your system.

1

Select the state analyzer Trigger menu.

2 Define terms SR_START and SR_END to represent the start and end

addresses of the subroutine.

3 Under State Sequence Levels, enter the following sequence

specification:

While storing “anystate” Find “SR_START” 1 time

•

While storing “anystate” Then find “SR_END” 1 time

•

While storing “anystate” TRIGGER on “≠ SR_START” 1 time Else on

•

“SR_START” go to level 2

Store “anystate”

•

Verifying Correct Return from a Function Call

1–12

Page 23

Triggering

To trigger after all status bus lines finish transitioning

To trigger after all status bus lines finish transitioning

In some applications, you will want to trigger a measurement when a

particular pattern has become stable. For example, you might want to trigger

the analyzer when a microprocessor’s status bus has become stable during

the bus cycle.

1

Select the timing analyzer Trigger menu and define a term called

PATTERN to represent the value to be found on the label

representing the status bus lines.

2 Under Timing Sequence Levels, enter the following sequence

specification:

TRIGGER on “PATTERN” > 40 ns

Triggering after lines are done transitioning

1–13

Page 24

Triggering

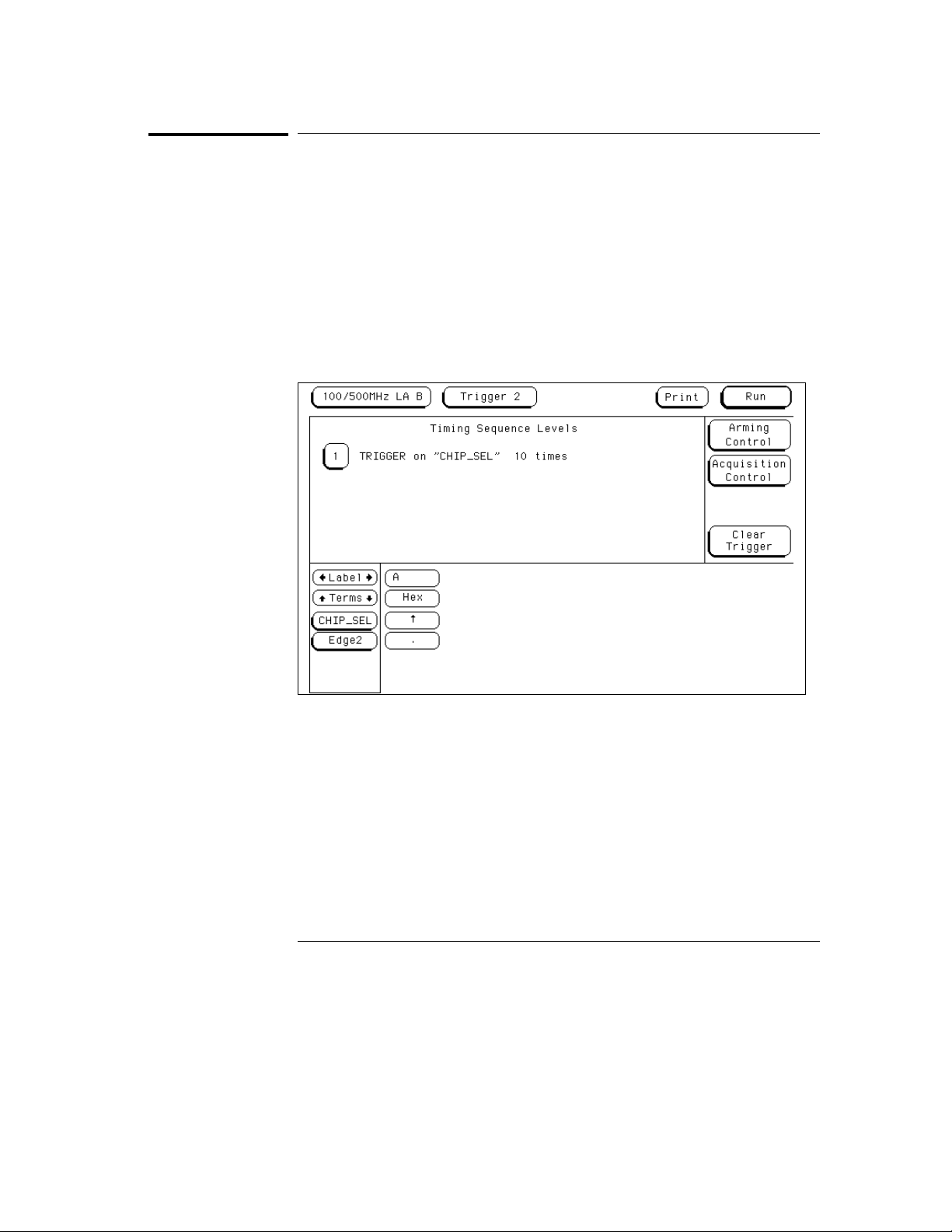

To find the nth assertion of a chip select line

To find the nth assertion of a chip select line

1 Select the timing analyzer Trigger menu.

2 Define the glitch/edge1 term to represent the asserting transition on

the chip select line.

You can rename the Edge1 term to make it correspond more closely to the

problem domain, for example, to CHIP_SEL.

3

Under Timing Sequence Levels, enter the following sequence

specification:

TRIGGER on “CHIP_SEL” 10 times

Triggering on the 10th Assertion of a Chip Select Line

1–14

Page 25

Triggering

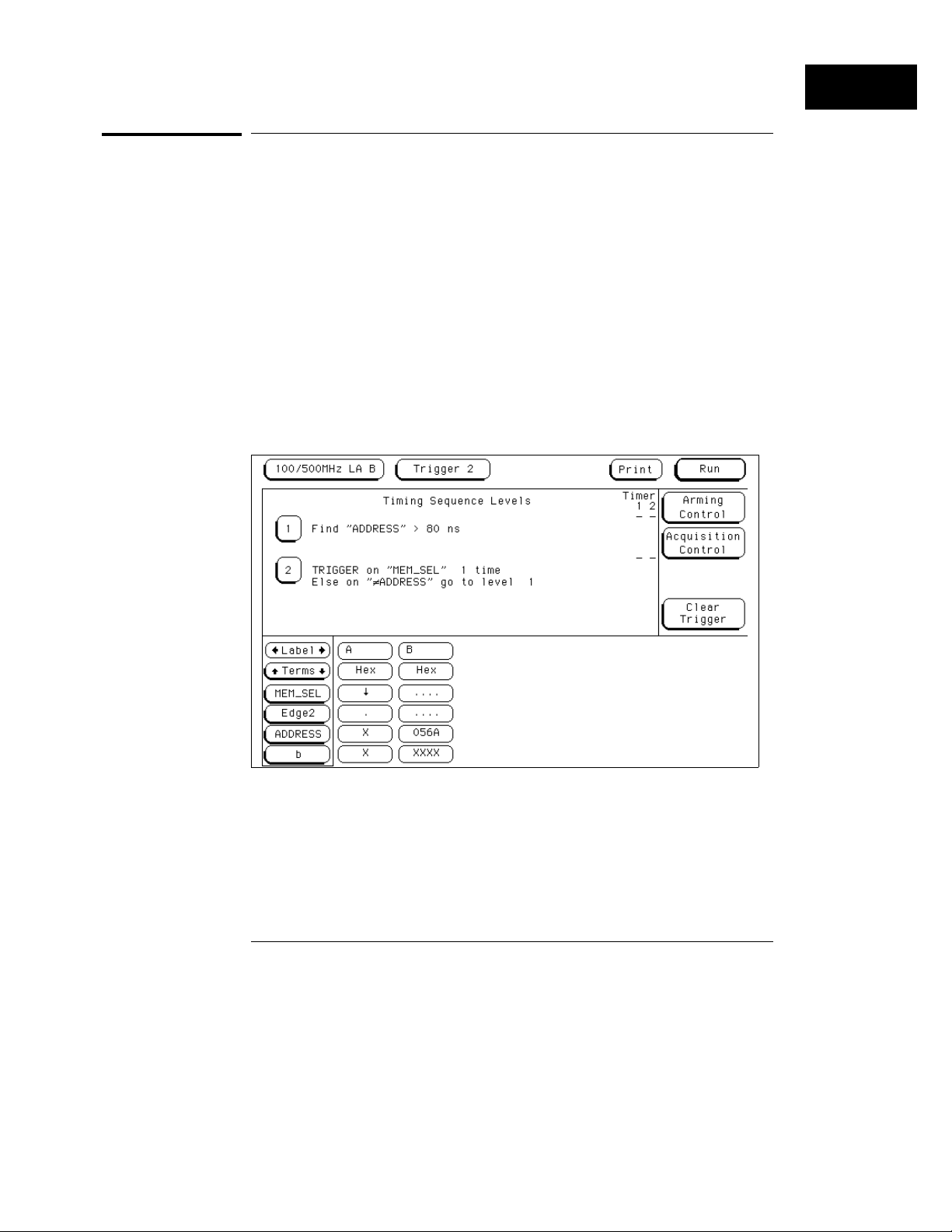

To verify that the chip select line of a memory chip is strobed after the address is stable

To verify that the chip select line of a memory chip is

strobed after the address is stable

1 Select the timing analyzer Trigger menu.

2 Define a term called ADDRESS to represent the address in question

and the Edge1 term to represent the asserting transition on the chip

select line.

You can rename the Edge1 term to suit the problem, for example, to

MEM_SEL.

3

Under Timing Sequence Levels, enter the following sequence

specification:

Find “ADDRESS” > 80 ns

•

TRIGGER on “MEM_SEL” 1 time Else on “≠ ADDRESS” go to level 1

•

Verifying Setup Time for Memory Address

1–15

Page 26

Triggering

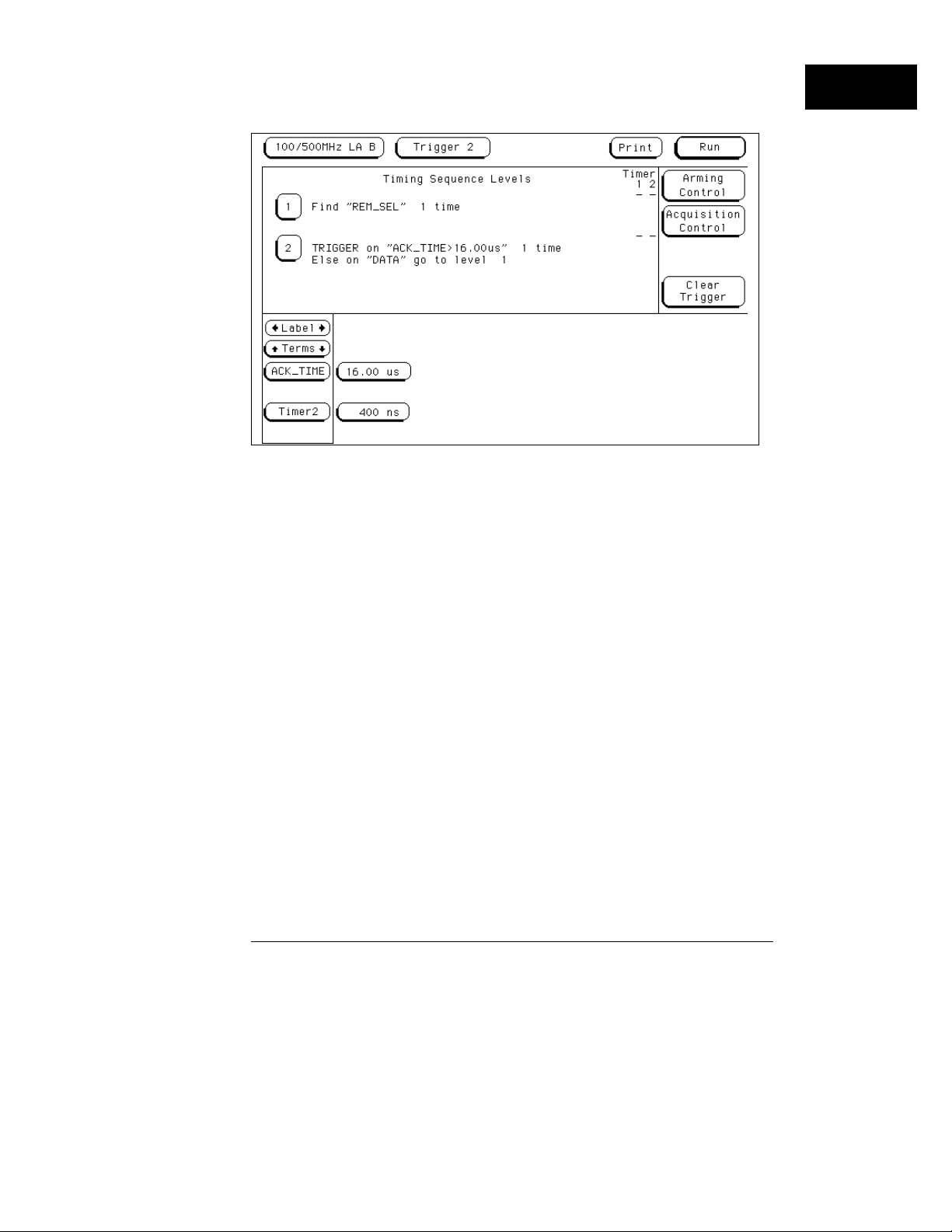

To trigger when expected data does not appear on the data bus from a remote device when requested

To trigger when expected data does not appear on the

data bus from a remote device when requested

1 Select the timing analyzer Trigger menu.

2 Define a term called DATA to represent the expected data, the Edge1

term to represent the chip select line of the remote device, and the

Timer1 term to identify the time limit for receiving expected data.

You can rename the Edge1 and Timer1 terms to match the problem domain,

for example, to REM_SEL and ACK_TIME.

3

Under Timing Sequence Levels, enter the following sequence

specification:

Find “REM_SEL” 1 time

•

TRIGGER on “ACK_TIME > 16.00 µs” 1 time Else on “DATA” go to level 1

•

You will need to use the Timer Control field in the sequence setup for

sequence level 2 to start the ACK_TIME timer upon entering that sequence

level.

This sequence specification causes the analyzer to trigger when the data does

not occur in 16 µs or less. If it does occur within 16 µs, the sequence restarts.

Specifications of this type are useful in finding intermittent problems. You

can set up and run the trace, then cycle the system through temperature and

voltage variations, using automatic equipment if necessary. The failure will be

captured and saved for later review.

1–16

Page 27

Triggering

To trigger when expected data does not appear on the data bus from a remote device when requested

Triggering When I/O Data Not Returned

1–17

Page 28

Triggering

To test minimum and maximum pulse limits

To test minimum and maximum pulse limits

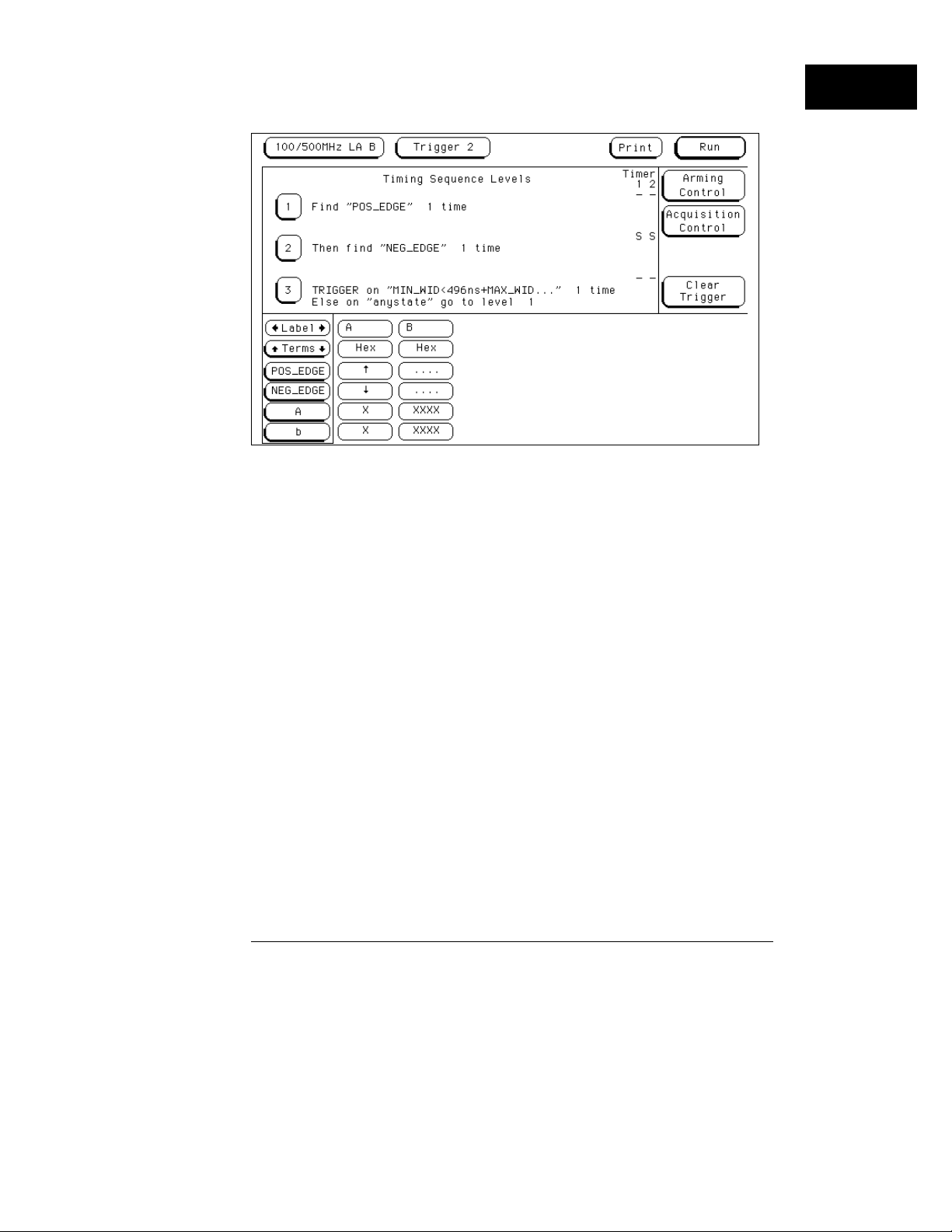

1 Select the timing analyzer Trigger menu.

2 Define the Edge1 term to represent the positive-going transition, and

define the Edge2 term to represent the negative-going transition on

the line with the pulse to be tested.

You can rename these terms to POS_EDGE and NEG_EDGE.

3

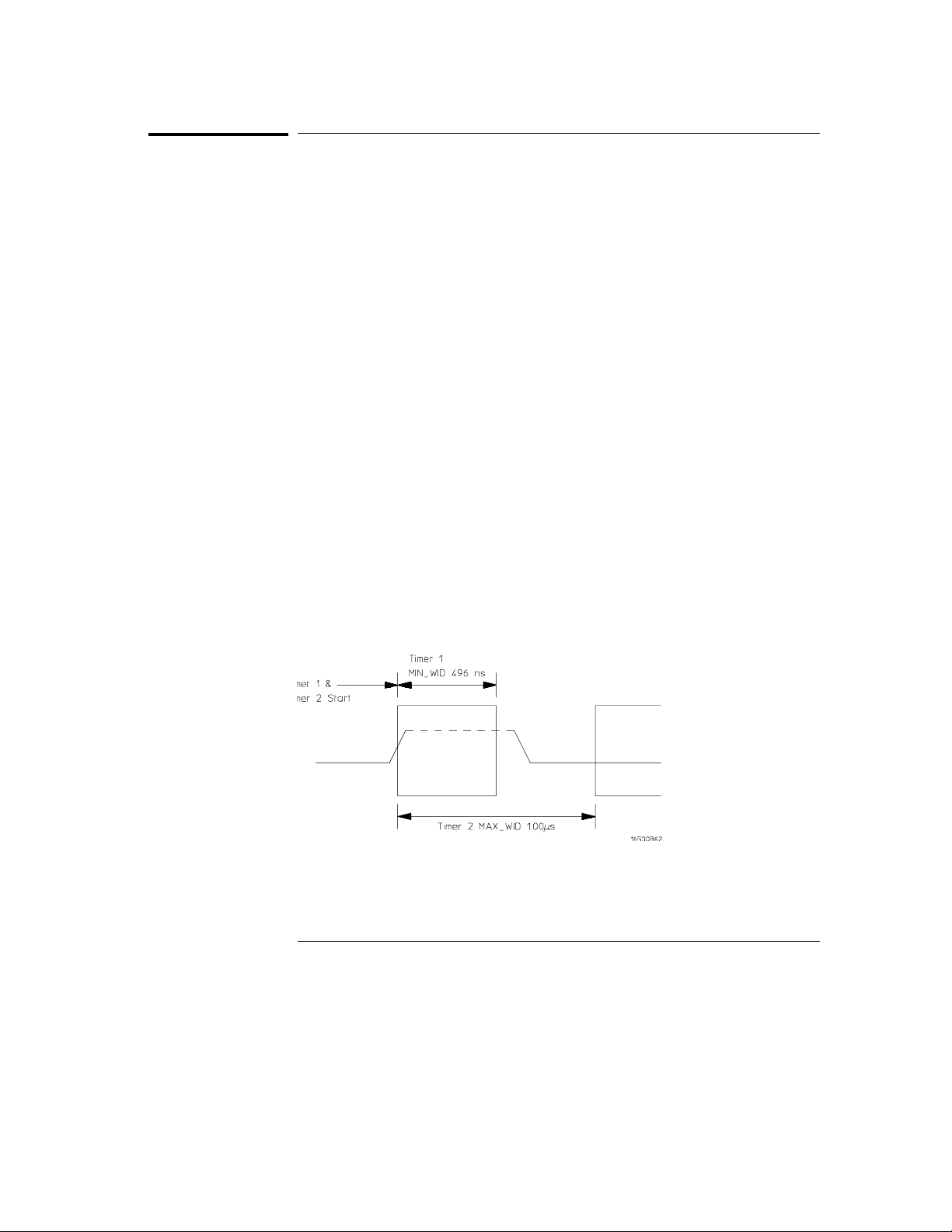

Define the Timer1 term to represent the minimum pulse width, and

the Timer2 term to represent the maximum pulse width.

You can rename these terms to MIN_WID and MAX_WID. In this example,

Timer1 was set to 496 ns and Timer2 was set to 1 µs. Both timers start when

sequence level 2 is active.

4

Under Timing Sequence Levels, enter the following sequence

specification:

Find “POS_EDGE” 1 time

•

Then find “NEG_EDGE” 1 time

•

TRIGGER on “MIN_WID 496 ns + MAX_WID 1.00 µs” 1 time Else on

•

“anystate” go to level 1

Because both timers start when entering sequence level 2, they start as soon

as the positive edge of the pulse occurs. Once the negative edge occurs, the

sequencer transitions to level 3. If at that point, the MIN_WID timer is less

than 496 ns or the MAX_WID timer is greater than 1 µs, the pulse width has

been violated and the analyzer should trigger. Otherwise, the sequence is

restarted.

Measurement of Minimum and Maximum Pulse Width Limits

1–18

Page 29

To test minimum and maximum pulse limits

Triggering when a Pulse Exceeds Minimum or Maximum Limits

Triggering

1–19

Page 30

Triggering

To detect a handshake violation

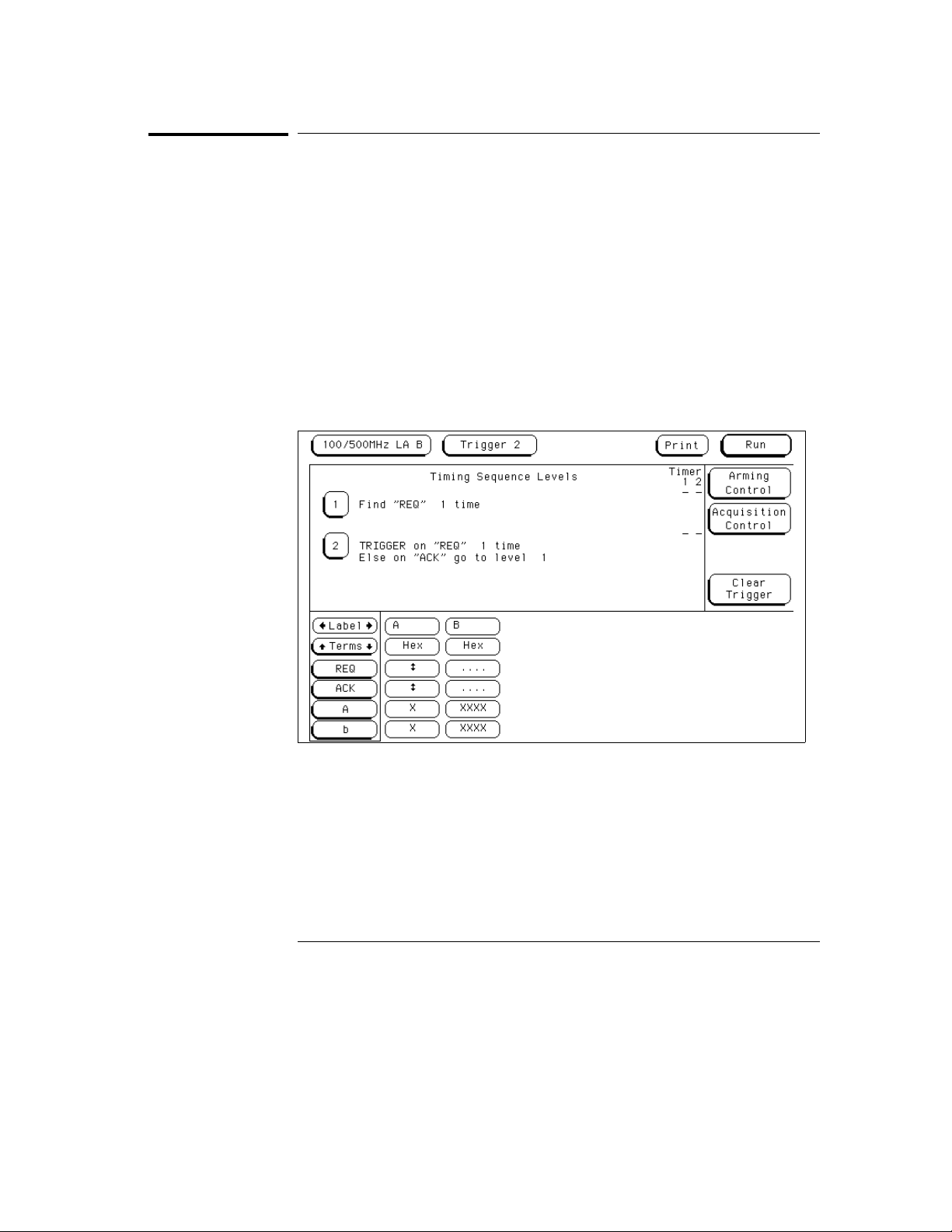

To detect a handshake violation

1 Select the timing analyzer Trigger menu.

2 Define the Edge1 term to represent either transition on the first

handshake line, and the Edge2 term to represent either transition on

the second handshake line.

You can rename these terms to match your problem, for example, to REQ

and ACK.

3

Under Timing Sequence Levels, enter the following sequence

specification:

Find “REQ” 1 time

•

TRIGGER on “REQ” 1 time Else on “ACK” go to level 1

•

Triggering on a Handshake Violati on

1–20

Page 31

Triggering

To detect bus contention

To detect bus contention

In this sequencer setup, the trigger occurs only if both devices assert their

bus transfer acknowledge lines at the same time.

1

Select the timing analyzer Trigger menu.

2 Define the Edge1 term to represent assertion of the bus transfer

acknowledge line of one device, and Edge2 term to represent

assertion of the bus transfer acknowledge line of the other device.

You can rename these to BTACK1 and BTACK2.

3 Under Timing Sequence Levels, enter the following sequence

specification:

TRIGGER on “BTACK1 • BTACK2” 1 time

Triggering on Bus Contention

1–21

Page 32

Cross-Arming Trigger Examples

The following examples use cross arming to coordinate measurements

between two instruments. The cross-arming is set up in the Arming

Control menu (obtained by selecting Arming Control in the Trigger

menu). When coordinating measurements between two or more

analyzers, select Count Time so you can correlate the measurements

made by the two analyzers.

See Also Chapter 2, “Intermodule Measurements.”

1–22

Page 33

Triggering

To examine software execution when a timing violation occurs

To examine software execution when a timing

violation occurs

The timing analyzer triggers when the timing violation occurs, and when it

triggers, it also sets its “arm” level to true. When the state analyzer receives

the arm signal, it triggers immediately on the present state.

1

Select the timing analyzer Trigger menu.

2 Define the Edge1 term to represent the control line where the timing

violation occurs.

3 Under Timing Sequence Levels, enter the following sequence

specification:

TRIGGER on “glitch/edge1” 1 time

4

Select the state analyzer Trigger menu and accept the default

(anystate) definition for term a.

5 Under State Sequence Levels, enter the following sequence

specification:

While storing “anystate” TRIGGER on “arm • a” 1 time

•

Store “anystate”

•

1–23

Page 34

Triggering

To look at control and status s ignals during execution of a routine

To look at control and status signals during execution

of a routine

The state analyzer will trigger on the start of the routine whose control and

status signals are to be examined with finer resolution than once per bus

cycle. When it triggers, it will switch its “arm” level true. The timing analyzer

will trigger when it receives the true arm level and detects the transition

represented by glitch/edge1.

1

Select the state analyzer Trigger menu and define term R_START to

represent the starting address of the routine.

2 Under State Sequence Levels, enter the following sequence

specification:

While storing “anystate” TRIGGER on “R_START” 1 time

•

Store “anystate”

•

3

Select the timing analyzer Trigger menu.

4 Define the Edge1 term to represent a transition on one of the control

signals.

5 Under Timing Sequence Levels, enter the following sequence

specification:

TRIGGER on “arm • Edge1” 1 time

1–24

Page 35

2

Intermodule Measurements

Page 36

Intermodule Measurements

An intermodule measurement is a measurement that is coordinated

between two or more modules to capture different types of

information related to a problem you are trying to solve. This chapter

shows you how to make several kinds of intermodule measurements.

Intermodule measurements can involve state analyzers, timing

analyzers, oscilloscopes, and pattern generators. The measurement

may be as simple as coordinating the startup of several modules

during a measurement; it may be quite complex and include multiple

arming sequences between modules and external equipment.

For example, you may have a timing analyzer detect the occurrence of

a glitch, and at the same time, have an oscilloscope capture the glitch

waveform and a state analyzer capture the program flow before and

after the occurrence of the glitch. With several types of information

obtained from various analysis modules, you can discover problems

that would otherwise be difficult to identify.

The figure on the opposite page shows how intermodule bus arming

signals are connected between modules inside the HP 16500C and

HP 16501A. Note that any arm input can be driven by any slot, and

that the port input line can drive any slot.

If you are unfamiliar with the basic operation of the Intermodule

Menu, try working the examples in the Logic Analyzer Training Kit.

2–2

Page 37

Intermodule Bus Block Functional Diagram

Intermodule Measurements

2–3

Page 38

Intermodule Measurement Examples

To set up an intermodule measurement, you must use the

Intermodule menu. All modules that will participate in the

intermodule measurement must be represented in this menu and their

relationships must be shown under the Group Run field.

To set up a group run of modules within the HP 16500C

Modules are armed in the configuration tree by either an individual module or

the Group Run field. When armed, a module begins searching for the input

that will satisfy its trigger specification. To obtain a specification that triggers

on the arm signal, specify to trigger on “anystate.”

1

Select the Intermodule menu.

2 Select the second field down from the top on the left, then select

Group Run.

3 Select the name of each module you want to include in the

measurement.

The modules are listed under “Modules” on the right side of the menu.

a Select Group Run if you want to arm this module immediately when

the Group Run begins.

b Select the name of another module if you want the other module to

arm the present one when the other module finds its trigger.

c Select Independent if this module should not be included in the

intermodule measurement.

4

Select the Group Run field in the upper right hand corner.

The group run begins. The modules attached directly to the Group Run field

immediately begin searching for their respective trigger conditions. When a

module finds its trigger, it arms any modules attached to it in the Group Run

tree.

2–4

Page 39

The analyzer in slot

B is armed when

the oscilloscope in

slot D finds its

trigger condition.

Intermodule Measurements

To set up a group run of modules within the HP 16500C

Oscilloscope Arms State Analyzer in Group Run

2–5

Page 40

Intermodule Measurements

To start a group run of modules from an external trigger source

To start a group run of modules from an external

trigger source

1 Connect the arm signal from the external instrument or system to the

PORT IN BNC connector on the rear panel of the HP 16500 frame.

2 Select the Intermodule menu.

3 Set up the group run specification.

4 Select the PORT IN/OUT field.

a Select the field under PORT IN Level, then select the level that

matches the external signal that will be applied to the PORT IN BNC

on the HP 16500C rear panel.

The choices are TTL, ECL, and User. The latter allows you to specify a

voltage from −4.00 V to +5.00 V using an onscreen keypad.

b Select the field under PORT IN Edge to change from Rising to Falling

edge and vice-versa for the rear-panel input signal.

c Select Done to leave the PORT IN/OUT Setup menu.

5 Select the Group Run field in the upper right hand corner.

The modules attached directly to the Group Run Armed from PORT IN field

wait for a signal from the PORT IN field.

6

Start the external instrument or system.

When the external instrument sends the proper signal to the PORT IN BNC,

the internal modules attached directly to the Group Run Armed from PORT

IN field are armed and begin searching for their respective trigger conditions.

Modules are armed by modules above them, eit her an individual module or the

field named Group Run Armed from PORT IN. That is, in the intermodule display,

an arrow pointing to a module to be armed originates in the module providing

the arm signal. See the figure “Oscilloscope A rms State Ana lyzer in Group Run”

on page 2-5. When armed, a module begins searching for the input that will

satisfy its trigger specification. To obtain a specificat ion of “trigger on the arm

signal,” specify a trigger that equates to “trigger on anything.”

See Also “To set up a group run of modules within the HP 16500C.”

2–6

Page 41

Both the analyzer in

slot B and the

oscilloscope in slot D

are armed when the

PORT IN signal

arrives.

Intermodule Measurements

To start a group run of modules from an external trigger source

State Analyzer and Oscilloscope armed from PORT IN

2–7

Page 42

Intermodule Measurements

To start an external instrument on command from a module within the HP 16500 and 16501 mainframe

To start an external instrument on command from a

module within the HP 16500 and 16501 mainframe

You can set up a module in a group run so that it sends a pulse through the

PORT OUT rear panel BNC. The pulse can be used to start or stop a

measurement in an external instrument or system.

1

Set up the group run specification.

See “To start a group run of modules within the HP 16500C” or “To start a

group run of modules from an external trigger source.”

2

Select PORT IN/OUT.

The PORT IN/OUT Setup menu appears.

3 Select the PORT OUT Source field.

Select Off if no module should drive PORT OUT.

•

or

Select the name of the module you want to have drive PORT OUT.

•

If you are using Group Run with OR TRIGGER, Port Out is automatically

assigned to the OR TRIGG ER group.

4

Set the Type, Polarity, and Output fields to generate the type of signal

the external instrument expects.

To generate the same signal as a 16500B would, set Type to Feedthrough,

Polarity to Active High, and Output to Normal. Normal sends out a standard

TTL signal; Open Collector sinks 128 milliamps in its low state.

5

Select Done in the PORT IN/OUT Setup menu.

See Also “To set up a group run of modules within the HP 16500C” or “To start a

group run of modules from an external trigger source” in this chapter.

“Configuring Port In/Out” in chapter 2, “Correlating Measurements,” of the

16500C User’s Reference.

2–8

Page 43

Intermodule Measurements

To start an external instrument on command from a module within the HP 16500 and 16501 mainframe

The analyzer in

slot B drives port

out after finding

its trigger.

Driving the Port Out BNC in an Intermodule Measurement

2–9

Page 44

Intermodule Measurements

To see the status of a module within an intermodule measurement

To see the status of a module within an intermodule

measurement

1 Select the Intermodule menu.

2 Find the name of the module under the “Modules” list, and read the

status under the module name.

The status can be either Running or Stopped. You can interpret these

indications as follows:

If a module was running and is now stopped, assume it received its arming

•

signal, triggered, and finished its measurement properly.

If a module located below a stopped module on the intermodule

•

configuration tree has received an arming signal and is still running, either

it is still waiting to satisfy its trigger specification or it has not captured

enough information to fill its memory.

If a module below a running module on the intermodule configuration tree

•

has not received its arming signal, it will not begin running until the upper

module finds its trigger condition.

2–10

Page 45

Both modules are

running because

neither has found

its respective

trigger condition.

Intermodule Measurements

To see the status of a module within an intermodule measurement

Module Status

2–11

Page 46

Intermodule Measurements

To see time correlation of each module within an intermodule measurement

To see time correlation of each module within an

intermodule measurement

Time correlation in the intermodule menu can help you see when the trigger

occurred for each module and the relative time range of data captured by

that module.

1

Select Time in the Count field of the trigger menu of each logic state

analyzer whose measurement will be time-correlated with the other

modules.

Timing analyzers and digitizing oscilloscopes implicitly count time because

their sampling is driven by an internal clock, rather than an external state

clock. See the User’s Reference for your logic state analyzer for details on

how to count time with the analyzer.

2

Select the Intermodule menu.

3 Select the Group Run field in the upper right hand corner.

Once the measurement has started, view the time correlation bars at the

bottom of the Intermodule Menu. The “T” in each bar indicates the relative

time at which that module found its trigger condition. The yellow portion of

each bar indicates the start and stop points of the acquisition window of the

associated module relative to the other modules in the measurement.

2–12

Page 47

This portion of the bar

indicates the relative

time range of data

acquired by this

module.

T indicates the time

at which the trigger

was found.

Intermodule Measurements

To see time correlation of each module within an intermodule measurement

Module Time Correlation

2–13

Page 48

Intermodule Measurements

To use a timing analyzer to detect a glitch

To use a timing analyzer to detect a glitch

The following setup uses a state analyzer to capture state flow occurring at

the time of the glitch. This can be useful in troubleshooting. For example, you

might find that the glitch is ground bounce caused by a number of

simultaneous signal transitions.

1

Select the Intermodule menu.

2 Select the timing analyzer from the Modules list and set it to Group

Run. Select the state analyzer and set it to respond to the arm signal

from the timing analyzer.

You must have fully independent state and timing analyzers to make this type

of measurement. For example, though the HP 16550A can be configured to

use some of its channels for a state analyzer and some for a timing analyzer, it

cannot present those analyzers independently for intermodule measurements.

3

Select the timing analyzer Trigger menu.

4 Select an Edge term. Then assign glitch detection “*” to the channels

of interest represented by the Edge term.

5 Select the state analyzer Trigger menu.

6 Set the analyzer to trigger on any state and store any state.

7 Select Group Run in the upper right corner of the display.

If you don’t see the activity of interest in the state trace, try changing the

trigger position using the Acquisition Control field in the Trigger menu of the

state analyzer. By changing the Acquisition mode to manual, you can position

the trigger at any state relative to analyzer memory.

The timing analyzer can detect glitch activity on a waveform. A glitch is defined

as two or more transitions across the logic threshold between adjacent timing

analyzer samples.

2–14

Page 49

Intermodule Measurements

To capture the waveform of a glitch

To capture the waveform of a glitch

The following setup uses the triggering capability of the timing analyzer and

the acquisition capability of the oscilloscope.

1

Select the Intermodule Menu.

2 Select the timing analyzer from the Modules list and set it to Group

Run. Select the oscilloscope module and set it to respond to the arm

signal from the timing analyzer.

3 Select the timing analyzer module.

4 Select the Trigger menu, and within the menu, select an Edge term.

5 Assign glitch detection "*" to the channel of interest represented by

the Edge term.

This will usually be the same channel monitored by the oscilloscope.

6 Select the oscilloscope Trigger menu, and set Mode to Immediate.

7 Select the Group Run field in the upper right corner.

If you have trouble capturing the glitch waveform on the oscilloscope, try

adjusting the skew in the Intermodule menu, so the oscilloscope triggers

earlier.

A timing analyzer can trigger on a glitch and capture it, but a timing analyzer

doesn’t have the volt age or timing resolution to display the glitch in detail. An

oscilloscope can display a glitch waveform with fine resolut ion, but cannot

trigger on glitches, combinations of glit ches, or sophisticated patterns involving

many channels .

2–15

Page 50

Intermodule Measurements

To capture state flow showing how your target system processes an interrupt

To capture state flow showing how your target system

processes an interrupt

Use an oscilloscope with a sample rate faster than the microprocessor clock

rate to trigger on the asynchronous interrupt request.

1

Select the Intermodule menu.

2 Select the oscilloscope from the Modules list and set it to Group Run.

Select the state analyzer module and set it to respond to the arm

signal from the oscilloscope module.

3 Select the oscilloscope module.

4 Select the Trigger menu, and set the mode to Edge trigger.

5 Select the state analyzer module.

6 Select the Trigger menu of the state analyzer, and set the analyzer to

trigger on any state and store any state.

7 Select Group Run from the upper right corner of the display.

When the interrupt occurs, the oscilloscope will trigger, subsequently

triggering the state analyzer.

If the analyzer doesn’t capture the expected interrupt activity, ensure that

the interrupt isn’t masked due to the actions of other program code.

This setup can help you answer questions like the following:

• Does the process or branch to the proper interrupt handling routine?

• Are registers and status information sa ved properly?

• How long does it take to service the interrupt?

• Is the interrupt acknowledged properly?

• After the interrupt is serviced, does the processor restore registers and

status information and continue with the interrupted routine as expected?

You can use the state analyzer to check the address of the interrupt routine as

well as to see if interrupt processing is done as expected. Using a preprocessor

and inverse assembler with the state analyzer will make it easier to read the

program flow.

2–16

Page 51

Intermodule Measurements

To test a circuit using stimulus-response

To test a circuit using stimulus-response

1 Select the Intermodule menu.

2 Select the pattern generator from the Modules list and set it to Group

Run. Select the oscilloscope module and set it to respond to the arm

signal from the pattern generator. Select the state analyzer and set it

to respond to the arm signal from the pattern generator.

3 Load the pattern generator with the proper patterns to simulate the

signals from the driving hardware.

4 Insert the “Signal IMB” instruction at the desired point in the pattern

generator program.

The arm signal is programmable. It can occur anywhere in the pattern

generator cycle.

5

Select the oscilloscope Trigger Menu. Set the oscilloscope to trigger

on signals of interest in the circuit under test.

6 Select the state analyzer Trigger Menu. Set the analyzer to trigger on

addresses, data, or status conditions of interest, and to store any

state or states of interest.

7 Select Group Run from the upper right corner of the display.

The pattern generator will begin its cycle, and will arm the oscilloscope and

state analyzer.

In the early stages of system design and integration, you may want to test a

circuit when the driving hardware that will stimulate it has not yet been

designed or fabricated. You can also use t he pattern generators with the logic

analyzer to test PC boards when no board-test system is available.

The HP 16522A pattern generator for the HP 16500C avoids the inconvenience of

having to stack several signal generators on top of each other, with all of the

cable connections required for those signal generators. Additionally, you have a

single interface to acces s all the test modules in your measure ment.

See Also The HP 16522A User’s Reference for the procedures for operating the

pattern generator.

2–17

Page 52

Intermodule Measurements

To use a state analyzer to trigger timing analysis of a count-down on a set of data lines

To use a state analyzer to trigger timing analysis of a

count-down on a set of data lines

1 Select the Intermodule menu.

2 Select the state analyzer from the Modules list and set it to Group

Run. Select the timing analyzer and set it to respond to the arm signal

from the state analyzer.

3 Select the state analyzer Trigger menu.

4 Set the state analyzer to trigger on the label and term that identify the

start of the count-down routine.

If you are not familiar with the procedures for setting up a trigger condition,

see chapter 1.

5

In the timing analyzer Trigger Menu, set the timing analyzer to trigger

on any state and store any state.

6 Select Group Run from the upper right corner of the display.

Your target system may include various state machines that are started by

system events: interrupt process ing, I/O activity, and the like. The state analyzer

is ideal for recognizing the system events; the timing analyzer is ideal for

examining the step-by-step operation of the state machines.

2–18

Page 53

Intermodule Measurements

To monitor the activity of two coprocessors in a target system

To monitor the activity of two coprocessors in a target

system

Debugging coprocessor systems can be a complex task. Replicated systems

and contention for shared resources increase the potential problems. Using

two state analyzers with preprocessors can make it much easier to discover

the source of such problems. For example, you may wish to set up one

analyzer to trigger only when a certain problem occurs, and set up the other

analyzer to be armed by the first analyzer so that it takes its trace only when

the first analyzer recognizes its trigger. This will let you observe the behavior

of both coprocessors during the occurrence of a problem.

1

Select the Intermodule menu.

2 Select the first state analyzer from the Modules list and set it to

Group Run. Select the second state analyzer and set it to respond to

the arm signal from the first analyzer.

3 Select the Trigger menu of the first analyzer.

4 Set the first analyzer to trigger on the problem condition.

Some problems may involve complex sequences of conditions. See chapter 1,

“Triggering,” for more information on defining a trigger sequence.

5

Select the Trigger menu of the second analyzer.

6 Set the second analyzer to trigger on any state and store any state.

2–19

Page 54

Intermodule Measurements

To monitor the activity of two coprocessors in a target system

7 Select Group Run from the upper right corner of the display.

After the measurement is complete, you can interleave the trace lists of both

state analyzers to see the activity executed by both coprocessors during

related clock cycles.

You can use a similar procedure if you have only one processor, but wish to

monitor its activity with that of other system nodes, such as chip-select lines,

I/O activity, or behavior of a watchdog timer. In some instances it may be

easier to look at related activity with a timing analyzer.

See Also “Special Displays” in this chapter.

“To use a state analyzer to trigger timing analysis of a count-down on a set of

data lines” in this chapter.

2–20

Page 55

Special displays

Interleaved Trace Lists

Interleaved trace lists allow you to view data captured by two or more

analyzers in a single trace list. When you interleave the traces, you see

each state that was captured by each analyzer. These states are

shown on consecutive lines.

You can interleave state listings from HP 16510B, 16540A, 16540D,

and 16550A state analyzers, when two or more are used together in a

group run. Interleaved state listings are useful when you are using

multiple analyzers to look at interaction between two or more

processors. They are also useful when you need more analysis width

than is available in one analyzer.

Mixed Display Mode

The Mixed Display mode allows you to show state listings and

waveforms together on screen, if all were obtained by modules within

the HP 16500C and 16501A frame. State listings are shown at the top

of the screen and waveform displays are shown at the bottom. You can

interleave state listings from two analyzers at the top of the screen, if

desired. You can display waveforms from two oscilloscopes or timing

analyzers at the bottom of the screen.

2–21

Page 56

Intermodule Measurements

To interleave trace lists

To interleave trace lists

1 Set up the analyzers whose data you wish to interleave as part of a

group run.

You won’t need to do this if the two measurement modules for which you

want mixed display are really part of the same module. For example, you

might have an HP 16550A state/timing analyzer configured as two separate

analyzers, one a state analyzer, the other a timing analyzer. You can use

mixed display to view the timing analyzer waveform with the trace lists from

the state analyzer.

2

Select the first state analyzer whose trace list will be shown in the

interleaved display.

3 Select Trigger from the menu field and set Count to Time.

The system uses the time stamps stored with each state to determine the

ordering of states shown in an interleaved trace list.

4

Repeat steps 2 and 3 for the second state analyzer.

5 Select Listing Display from the Menu field.

6 Select one of the label fields in the trace list display, then select

Interleave.

7 Select the name of the analyzer whose trace list will be interleaved

with the first analyzer. Then choose the label that you want to

interleave from the selected analyzer.

Interleaved data is displayed in yellow. Trace list line numbers of interleaved

data are indented. The labels identifying the interleaved data are shown

above the labels for the current analyzer, and are displayed in yellow.

If you have problems with the procedure, and you are using two independent

analyzers, first ensure that the analyzers are set up as part of a group run.

Ensure that each analyzer is set to Count Time and that each analyzer has an

independent clock from the target system.

You can interleave trace lists from state analyzers that were configured as part

of a group run or from state analyzers that are configured as separate analyzers

within the same measurement module. In the first case, y ou might have two

HP 16550A analyzers configured in a grou p run; in the second, you might have a

single HP 1 6550A configured as two state analyzers. The interleaved t race lists

are shown as a time-correla ted, state-to-state display.

2–22

Page 57

Labels for the

interleaved states are

shown above those for

the primary analyzer.

Interleaved states

are shown in yellow

with line numbers

indented from those

of the primary

analyzer.

Intermodule Measurements

To interleave trace lists

Interleaved Trace Lists on the HP 16550A

See Also “To set up a group run of modules within the HP 16500C” in this chapter.

2–23

Page 58

Intermodule Measurements

To view trace lists and waveforms together on the same display

To view trace lists and waveforms together on the

same display

1 Set up the modules whose data you wish to view as part of a group

run.

You won’t need to do this if the two measurement modules for which you

want mixed display are really part of the same module. For example, you

might have an HP 16550A state/timing analyzer configured as two separate

analyzers, one a state analyzer, the other a timing analyzer. You can use

mixed display to view the timing analyzer waveform with the trace lists from

the state analyzer.

2

Select the module for which you wish to show waveforms.

This might be an oscilloscope module or a timing analyzer.

3 Select the label field to the left of the waveform display area twice,

then choose the waveforms to be shown.

When you double-select the label field to the left of the waveform display

area, a new menu appears that allows you to insert and delete signals and

choose the relative display size and position for the signals.

4

Select the state analyzer.

5 Set the Trigger menu of the state analyzer and set the Count field to

Time.

Timing analyzers and digitizing oscilloscopes implicitly count time because

their sampling is driven by an internal clock, rather than an external state

clock. See the manual for your logic state analyzer for details on how to count

time with the analyzer.

6

To insert state listings, select any label field from the state listing.

From the popup that appears, select the desired label to insert.

7 Select Mixed Display from the menu field.

8 Select Group Run from the upper right corner of the display.

You can position X and O Time markers on the waveform display, if desired.

Once set, the time markers will be displayed in both the listing and the

waveform display areas. Note that even if you set X and O Time markers in

another display, you must also set the Time markers in the Mixed Display if

Time markers are desired.

2–24

Page 59

X and O markers from

the waveform display

are shown in their

relative position on the

state display.

Intermodule Measurements

To view trace lists and waveforms together on the same display

You can use the Mixed Display feature in the state analyzer menus to show both

waveforms and trace lists in the same display, making it easier to correlate the

events of interest.

If you are using mixed display as part of a group run, you may need to adjust

intermodule skew to ensure proper time correlation and display results.

Mixed Display using the HP 16550A and HP 16532A

See Also “To set up a group run of modules within the HP 16500C” in this chapter.

“Skew Adjustment” in this chapter.

2–25

Page 60

Skew Adjustment

You can modify the skew or timing deviation between modules within

the intermodule measurement. This allows you to compensate for any

known delay of the system under test, or to compare two signals by

first removing any displayed skew between the signal channels.

Skew adjustments can correct module delays to within 2 ns of other

modules. Note that the module or channel that is used as the trigger is

normally the reference channel, and adjustments are normally made

to deskew the nonreference channels.

2–26

Page 61

Intermodule Measurements

To adjust for minimum skew between two modules involved in an intermodule measurement

To adjust for minimum skew between two modules

involved in an intermodule measurement

1 Connect an input signal from each module to the same signal.

An ideal signal for testing skew is a single-shot signal with fast risetime. Such

a signal simplifies triggering and makes it easier to correlate the input event

between the modules. Ensure that you use proper probe grounding for

maximum signal fidelity.

2

Select the Intermodule menu.

3 Set up both modules so they will begin searching for the trigger

immediately when a group run begins.

This setup focuses mostly on trying to eliminate probe skew and internal

triggering delays. You can use other intermodule setups as well. For example,

you may be interested in nullifying the effects of the internal arming delay in

a setup where one module arms another.

4

Set up the trigger conditions for each module.

This will depend upon your input signal. For example, if you are adjusting

intermodule skew using a single-shot pulse with a rising edge, set a timing

analyzer to trigger on a rising edge using the Edge1 term, and the

oscilloscope to trigger on a positive slope.

5

Select the Display or Waveform menu in one of the modules.

6 Set up the display so that both input waveforms are displayed

simultaneously.

You do this by selecting the label field to the left of the display twice. The

second selection brings up a new menu that allows you to insert or delete

waveforms. You can delete all but the waveform of interest from the first

module, then add the waveform of interest from the second module. Select

Done when finished.

7

Select Group Run.

You may now need to trigger the signal of interest, if, for example, it is

activated by a push button. You may need multiple events to capture good

waveforms for both measurement modules. Remember that the oscilloscope

captures far more accurate waveform data than the timing analyzer. Thus, if

the waveforms do not match exactly, it may only be because the waveform

edge did not meet the timing analyzer’s setup and hold time specifications for

a particular sampling period.

2–27

Page 62

Intermodule Measurements

To adjust for minimum skew between two modules involved in an intermodule

measurement

8 Record the differences shown by the two modules.

You can use the X and O markers to measure the differences in delays.

9 Select the Intermodule Menu.

10 Select Skew, then enter a skew correction value for one of the

modules using the knob or the keyboard.

11 Return to the module waveform display and recheck the skew

adjustment.

You will need to repeat steps 7 through 11 as needed until the trigger events

on the two waveforms match as closely as possible.

Before making an intermodule measurement, you should remove skew between

the modules to ensure that a simultaneous arm signal to both modules results in

captures of the same events around the trigger.

Skew Removal Between Timing Analyzer and Oscilloscope

2–28

Page 63

3

File Management

Page 64

File Management

A host computer such as a PC or UNIX workstation can enhance the

HP 16500C in many ways. You can use the host to store configuration

files or measurement results for later review. Screen images from the

HP 16500C can be saved in bitmap files for inclusion in reports

developed using word processors or desktop publishing tools. Or, you

can develop programs on the PC that manipulate measurement results

to satisfy your problem-solving needs.

This chapter shows you some examples of how to transfer files

between a host computer and the HP 16500C, using the flexible disk

drive and the LAN Interface. If you aren’t familiar with basic flexible

disk drive operations or if you need help setting up or understanding

the use of the LAN Interface, see the HP 16500C/16501A User’s

Reference.

You can also use a host computer to send the HP 16500C complex

command sequences—allowing you to automate your measurement

tasks. If you want to program the HP 16500C using a host computer,

see the HP 16500C/16501A Logic Analysis System Programmer’s

Guide, available from your HP Sales Office.

3–2

Page 65

Transferring Files Using the Flexible Disk Drive

Because the flexible disk drive on the HP 16500C will read and write

double-sided, double density or high-density disks in MS-DOS format,

it is a useful tool for transferring images to and from IBM

PC-compatible computers as well as other systems that can read and

write MS-DOS format. You can save measurement configuration files,

measurement results, and even menu and measurement images from

the screen.

This section shows you how to use the flexible disk drive to:

• save a measurement configuration

• load a measurement configuration

• save a trace list in ASCII format

• save a screen image (such as an oscilloscope display or menu)

• load system software

If you need more information on the basic flexible disk drive

operations, see the HP 16500C/16501A Logic Analysis System

User’s Reference.

3–3

Page 66

File Management

To save a measurement configuration

To save a measurement configuration

You can save measurement configurations on a 3.5-inch disk or on the

internal hard disk for later use. This is especially useful for automating

repetitive measurements for production testing.

1

Select System from the module field.

2 Select Hard Disk or Flexible Disk from the menu field.

3 Select Store from the disk operations field.

4 Select the module for which you want to save the configuration from

the module list.

You can save the configuration for individual modules. The choice “System”

saves only the mainframe configuration. The choice “All” saves the

mainframe configuration and that of all measurement modules.

5

Specify a file name into which to save the configuration using the “to

file” field.

6 Specify a descriptive comment for the file using the “file description”

field.

7 Select Execute.

3–4

Page 67

To save a measurement configuration

Saving the Oscilloscope Configuration for Skew Testing

File Management

If you want to save your file in a directory other than the root, you can select

Change Directory from the disk operations field. Then type the name of the

desired directory in the directory name field, or select it from the list of v isible

directories using the knob.

3–5

Page 68

File Management

To load a measurement configuration

To load a measurement configuration

You can quickly load a previously saved measurement configuration, saving

the trouble of manually setting up the measurement parameters for each

module.

1

Select System from the module field.

2 Select Hard Disk or Flexible Disk from the Menu field.

Your choice here depends on where you saved the configuration.

3 Select Load from the disk operations field.

4 Select the module for which you want to load a configuration from

the module list.

You can load configurations for individual modules. The choice “System”

loads only the mainframe configuration. The choice “All” loads the mainframe

configuration and that of all measurement modules.

However, you can only load configurations that are defined in the

configuration file itself. Thus, if you select System, then select a file that

contains only an analyzer configuration, the configuration will fail.

If you save an analyzer configuration as “All,” then attempt to reload that

configuration into a particular measurement mo dule, configuration will fail.

Also, configurations are slot dependent. If you save a configuration for a

particular module, rearrange the modules within the HP 16500C, then try to

reload the configuration, the configuration will n ot load.

5

Specify a file name from which to load the configuration using the

“from file” field.

6 Select Execute.

3–6

Page 69

To load a measurement configuration

Loading Configuration for all HP 16500C Modules and the System

File Management

3–7

Page 70

File Management

To save a trace list in ASCII format

To save a trace list in ASCII format

Some HP 16500C displays, such as file lists and trace lists, contain columns of

ASCII data that you may want to move to a PC for further manipulation or

analysis. You can save these displays as ASCII files, using a procedure similar

to that for creating graphics images. While a graphics capture saves only the

data shown onscreen, saving the display as an ASCII file captures all data in

the list, even if it is offscreen.

1

Insert a DOS-formatted 3.5-inch disk in the flexible disk drive.

2 Set up the menu you want to capture, or run a measurement from

which you want to save data.

Remember that only displays that present lists of textual data can be

captured as ASCII files.

3

Select Print Disk from the Print menu.

4 Select the Filename field and specify a file name to which the screen

will be printed.

5 Select ASCII (ALL) from the Output Format field.

If the current display contents can’t be saved as an ASCII file, this option will

not be present in the Output Format field.

6

Select Flexible Disk from the Output Disk menu.

7 Select Execute.

3–8

Page 71

File Management

To save a trace list in ASCII format

68332EVS - State Listing

Label ADDR CPU32 Mnemonic STAT

__________ _____ ______________________________________ _________________

0 406F4 ANDI.L #********,(A6)+ Opcode Fetch

1 0FF7A 0004 data write Data Write

2 0FF7C 06F6 data write Data Write

3 40992 BSR.B 0004093E Opcode Fetch

4 40994 nu MOVE.B ********,(****,A7) Opcode Fetch

5 0FF76 0004 data write Data Write

6 0FF78 0994 data write Data Write

7 4093E MOVE.W #03FF,00FFFA46 Opcode Fetch

8 40940 03FF pgm read Opcode Fetch

9 40942 00FF pgm read Opcode Fetch

10 40944 FA46 pgm read Opcode Fetch

11 40946 MOVE.W #6B70,00FFFA72 Opcode Fetch

12 40948 6B70 pgm read Opcode Fetch

13 4094A 00FF pgm read Opcode Fetch

14 4094C FA72 pgm read Opcode Fetch

15 4094E RTS Opcode Fetch

16 40950 nu MOVE.L D1,-(A7) Opcode Fetch

17 0FF76 0004 data read Data Read

18 0FF78 0994 data read Data Read

19 40994 MOVE.B 00020001,(0004,A7) Opcode Fetch

20 40996 0002 pgm read Opcode Fetch

21 40998 0001 pgm read Opcode Fetch

22 4099A 0004 pgm read Opcode Fetch

Part of a Trace Listing Saved as an ASCII File

3–9

Page 72

File Management

To save a menu or measurement as a graphic image

To save a menu or measurement as a graphic image

You can save menus and measurements to disk in one of four different

graphics formats.

1

Insert a DOS-formatted flexible disk in the flexible disk drive.

2 Set up the menu whose image you want to capture, or run a

measurement from which you want to save data.

3 Select Print Disk from the Print menu.

4 Select the Filename field and specify a file name to which the screen

will be printed.

5 Select the Output Format field and specify the output format for the

graphics file.

Choose one of the following formats:

B/W TIF (SCREEN) is a black and white Tagged Image File Format file in

•

TIFF version 5.0 format

Color TIF (SCREEN) is a color TIFF file in TIFF version 5.0 format

•

PCX (SCREEN) is a color PCX file (PCX is the PC Paintbrush and

•

Publisher’s Paintbrush format from ZSoft)

EPS (SCREEN) is a black and white Encapsulated PostScript file

•

6 Select Flexible Disk from the Output Disk menu.

7 Select Execute.

3–10

Page 73

To save a menu or measurement as a graphic i mage

An Oscilloscope Display Saved as a TIF Image

File Management

3–11

Page 74

File Management

To load system software

To load system software

1 Insert the first disk containing the system software.

2 Select System from the module field.

3 Select Hard Disk from the menu field.

4 Select Change Directory from the disk operation field.

5 Select the directory SYSTEM using the knob, and select Execute.

6 Select Flexible Disk from the menu field.

7 Select Copy from the disk operation field.

8 Select the file you want to update using the knob, then select Execute.

The selected file is copied to the \SYSTEM directory on the hard disk.

Repeat steps 7 and 8 for all files you need to update. If you have more than

one disk from which you want to copy files, turn the knob after changing

disks. This ensures that the HP 16500C will read the directory on the new

disk.

3–12

Page 75

Using the LAN Interface

The LAN Interface of the HP 16500C extends the Logic Analysis

System by making it look like a NFS (Network File System) node.

Using NFS utilities for the PC or NFS on a UNIX workstation, you can

transfer files to and from the HP 16500C as if it were a disk drive

attached to your machine. The LAN Interface also creates virtual

directories and files for measurement configurations and results, so

you can store and retrieve these as though they were ordinary files.

This section shows you how to use the LAN interface do the following:

• set up the HP 16500C configuration

• retrieve measurement data from a module in the HP 16500C

• transfer images of HP 16500C menu and result screens to your host

computer

If you have not connected your HP 16500C to the network, installed

network software, or learned basic network commands, see the

chapter on connecting to your LAN in the HP 16500C/16501A User’s

Reference before performing the tasks in this chapter.

3–13

Page 76

File Management

To set up the HP 16500C

To set up the HP 16500C

You can set up the HP 16500C from the front panel, or via the LAN. To set up

the system via the LAN, you can use one of three methods:

Copy a configuration file from your PC or workstation to one of the files

•

called setup.raw in the HP 16500C directory tree.

Remotely load a configuration file into the system from one of the local

•

disk drives of the HP 16500C.

Program the system directly, using the programming commands described

•

in the optional HP 16500C System Programmer’s Guide.

Example You want to load a configuration file called “486_bus” from your local

computer into an HP 16550A state/timing module. The HP 16550A is installed

in slot B of the HP 16500C mainframe. The mainframe is mounted on your

network as disk drive L: (assuming you are using a PC as the host).

To load the configuration file, enter the following at the DOS prompt:

C:\> copy 486_bus L:\slot_b\setup.raw

If you are using a UNIX system, you might use the cp command. In the

Microsoft Windows environment, you can use the File Manager.

3–14

Page 77

File Management

To set up the HP 16500C

Example You want to load a configuration file called “486_bus” from the hard disk of

the HP 16500C into an HP 16550A state/timing module. The HP 16550A is

installed in slot B of the HP 16500C mainframe. To load the configuration file

from the HP 16500C hard disk, you need to send the programming command

to the analyzer. The syntax of the command is:

:MMEMory:LOAD:CONFig <filename>[,<disk drive>][,<slot number>]

In this case, the disk drive parameter, will be “INT0,” which indicates the

hard disk. The slot number will be 2, because the HP 16550A is installed in

slot B. To load the configuration file, enter the following command at the

DOS prompt:

C:\> echo :MEM:LOAD:CON ’486_BUS’,INT0,2 L:\system\program

If you are using a UNIX system, you can use the UNIX echo command.

See Also The HP 16500C System Programmer’s Guide for more information on

programming command syntax.

To copy files to the setup.raw file locations , or to send commands to the system

at the \system\program file location, you must be connected to the HP 16500C

system as the control user.

3–15

Page 78

File Management

To transfer data files from the HP 16500C system to your computer

To transfer data files from the HP 16500C system to

your computer

You can transfer data from the HP 16500C system to your PC or workstation

by copying files. Data files in binary format are available in file locations