Page 1

Errata

16500B/16501A Logic Analysis System Service Guide

16500-97011

August 1994

Title & Document Type:

Manual Part Number:

Revision Date:

HP References in this Manual

This manual may contain references to HP or Hewlett-Packard. Please note that HewlettPackard's former test and measurement, semiconductor products and chemical analysis

businesses are now part of Agilent Technologies. We have made no changes to this

manual copy. The HP XXXX referred to in this document is now the Agilent XXXX.

For example, model number HP8648A is now model number Agilent 8648A.

About this Manual

We’ve added this manual to the Agilent website in an effort to help you support your

product. This manual provides the best information we could find. It may be incomplete

or contain dated information, and the scan quality may not be idea l. If we find a better

copy in the future, we will add it to the Agilent website.

Support for Your Product

Agilent no longer sells or supports this product. You will find any other available

product information on the Agilent Test & Measurement website:

www.tm.agilent.com

Search for the model number of this product, and the resulting product page will guide

you to any available information. Our service centers may be able to perform calibration

if no repair parts are needed, but no other support from Agilent is available.

Page 2

Service Guide

Publication number 16500-97011

First edition, August 1994

For Safety information, Warranties, and Regulatory

information, see the pages at the end of the book.

Copyright Hewlett-Packard Company 1987 – 1994

All Rights Reserved.

HP 16500B/16501A

Logic Analysis System

Page 3

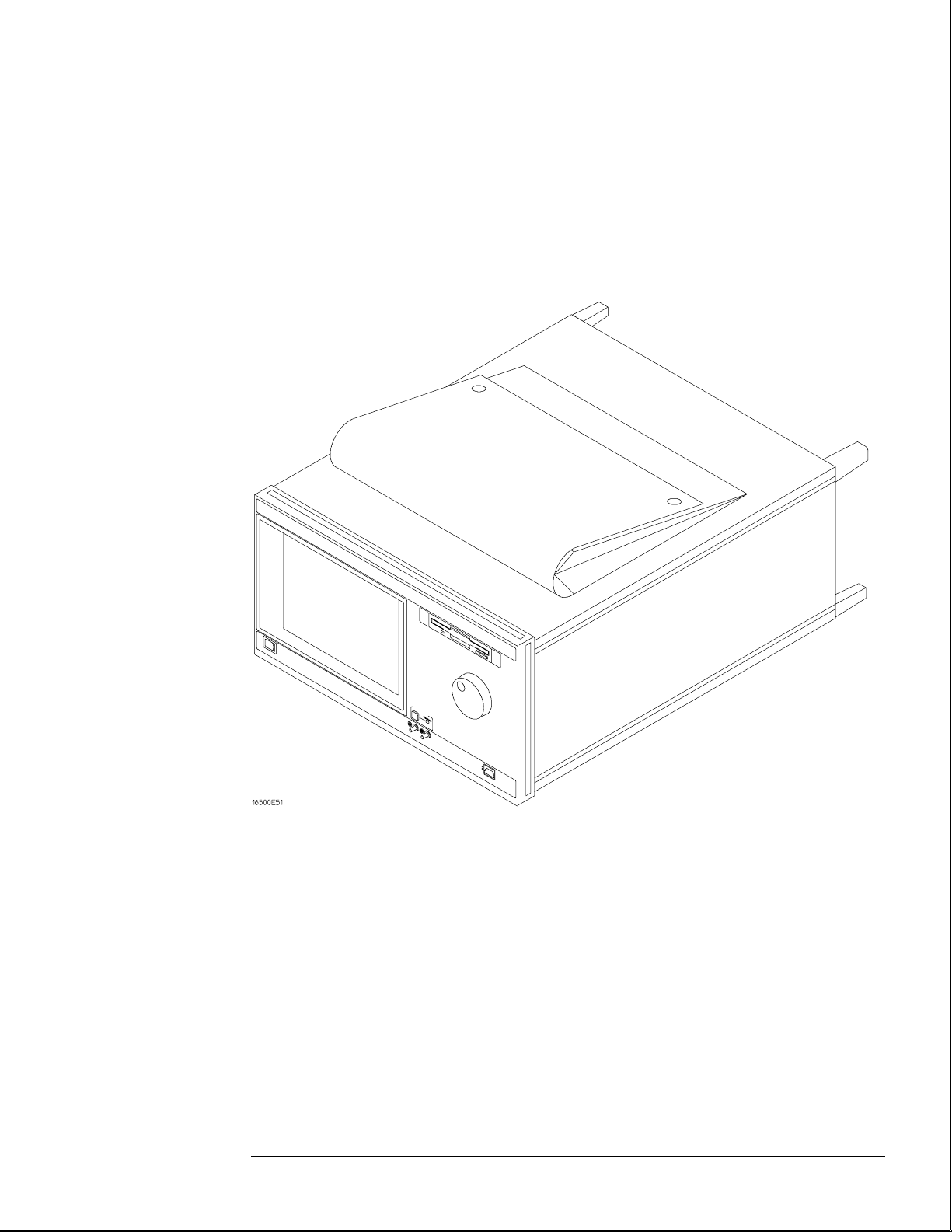

HP 16500B/16501A Logic Analysis System

The HP 16500B is the mainframe of the Logic Analysis System, and the HP 16501A is

the expansion frame. The HP 16500B/16501A is of modular structure using plug-in

cards with a wide range of data acquisition and stimulus capabilities.

Features

Some of the main features of the HP 16500B/16501A are as follows:

• Modular mainframe with five card slots

• Expansion frame, which expands the total system card slots to ten

• Touchscreen user interface

• 86 Mbyte hard disk drive

• High-density 3.5-inch flexible disk drive

• Color monitor

• Intermodule triggering and time correlation of acquired data

• HP-IB, RS-232C or optional LAN interfaces for hardcopy output to a printer or

controller interface

Service Strategy

The service strategy for this instrument is the replacement of defective assemblies.

This service guide contains information for finding a defective assembly by testing

and servicing the HP 16500B/16501A.

This instrument can be returned to Hewlett-Packard for all service work, including

troubleshooting. Contact your nearest Hewlett-Packard Sales Office for more details.

ii

Page 4

The HP 16500B Logic Analysis System

iii

Page 5

In This Book

This book is the service guide for the HP 16500B/16501A Logic Analysis System and is divided

into eight chapters.

Chapter 1 contains information about the instrument and includes accessories for the

instrument, specifications and characteristics of the instrument, and a list of the equipment

required for servicing the instrument.

Chapter 2 tells how to prepare the instrument for use.

Chapter 3 gives instructions on how to test the performance of the instrument.

Chapter 4 contains calibration instructions for the instrument.

Chapter 5 contains self-tests and flowcharts for troubleshooting the instrument.

Chapter 6 tells how to replace the instrument and assemblies of the instrument, and how to

return them to Hewlett-Packard.

Chapter 7 lists replaceable parts, shows an exploded view, and gives ordering information.

Chapter 8 explains how the instrument works and what the self-tests are checking.

This book also contains information about the HP 16500L interface module when using an

expansion frame or an external monitor. For information about using the interface module

with a local area network, refer to the manuals for the HP 16500L.

iv

Page 6

Contents

1 General Information

Accessories 1–2

Specifications 1–3

Characteristics 1–3

Recommended Test Equipment 1–6

2 Preparing for Use

To inspect the logic analysis system 2–2

To apply power 2–3

To operate the user interface 2–3

To set the line voltage 2–4

To degauss the display 2–5

To clean the logic analysis system 2–5

To test the logic analysis system 2–5

To install modules 2–6

To install the HP 16500L interface module 2–7

To connect the HP 16501A Expansion Frame 2–9

To connect an external monitor 2–10

3 Testing Performance

To perform the power-up tests 3–3

To perform the self-tests 3–4

4 Calibrating and Adjusting

To prepare the instrument 4–3

To access the test patterns 4–4

To adjust geometry 4–5

To adjust focus, landing, and convergence 4–6

To adjust white balance 4–13

5 Troubleshooting

To use the flowcharts 5–2

To check the power-up self-tests 5–18

To run the self-tests 5–19

To check the video signals 5–22

To check the power supply LEDs 5–23

To check the power supply voltages 5–24

To test the flexible disk drive voltages 5–25

To test the hard disk drive voltages 5–27

To test the expansion frame interface 5–29

v

Page 7

Contents

6 Replacing Assemblies

To remove and replace the

Optional modules or filler panels 6–3

Covers 6–4

Flexible disk drive 6–5

Power supply 6–6

Rear fan 6–8

Side fan 6–9

HP 16500L interface module 6–10

Hard disk drive 6–12

Microprocessor board (CPU) 6–13

SIMM memory 6–14

Expansion interface board 6–15

Mother board 6–16

Front-panel board 6–18

Color display assembly 6–19

To return assemblies 6–22

7 Replaceable Parts

Replaceable Parts Ordering 7–2

Replaceable Parts List Description 7–3

HP 16500B Exploded View and Replaceable Parts 7–4

HP 16501A Exploded View and Replaceable Parts 7–9

8 Theory of Operation

Block-Level Theory 8–3

The HP 16500B Logic Analysis System 8–3

The Microprocessor Board 8–6

The Power-Up Routine 8–9

The Power-Up Screen 8–9

Power-Up Self-Tests 8–10

Power-Up Tasks 8–10

The System Configuration Menu 8–12

Self-Tests Description 8–13

Power-Up Self-Tests 8–13

Functional Performance Verification Tests 8–15

HP-IB 8–18

RS-232C 8–19

vi

Page 8

1

Accessories 1–2

Specifications 1–3

Characteristics 1–3

Recommended Test Equipment 1–6

General Information

Page 9

General Information

This chapter lists the accessories, the specifications and characteristics, and the

recommended test equipment.

Accessories

The following accessories are supplied with the HP 16500B/16501A Logic Analysis System.

Accessories Supplied Qty

Training Kit 1

Setting Up The System Guide 1

User’s Reference 1

Programming Reference 1

Service Guide 1

RS-232C Loopback Connector 1

Power cord 1

Disk pouch containing backup composite software 1

Feeling Comfortable With Logic Analyzers

Feeling Comfortable with Digitizing Oscilloscopes

Filler Panels Quantity depends on how many modules are

1

1

ordered wi th the HP 16500B/16501A

Accessories Available

Other accessories available for the HP 16500B/16501A Logic Analysis System are listed in the

Accessories for HP Logic Analyzers brochure.

1–2

Page 10

General Information

Specifications

The specifications are the performance standards against which the product is tested. There

are no specifications for the HP 16500B or the HP 16501A.

Characteristics

These characteristics are not specifications, but are included as additional information. The

following characteristics are typical for the HP 16500B/16501A system.

Hard Disk Drive Capacity 86 Mbyte unformatted; Formatted as a Microsoft DOS disk drive IDE Interface

Bus.

Flexible Disk Drive Capacity 1.44 Mbyte formatted Microsoft DOS or LIF supported.

Specifications

Programmability Instrument settings and operating modes, including automatic measurements, may be

remotely programmed via RS-232C, HP-IB (IEEE-488), or optional HP 16500L (Ethernet).

Hardcopy Output Printers Supported HP ThinkJet, HP QuietJet, HP LaserJet, HP PaintJet, HP Deskjet,

HP Deskjet C, Epson and Epson-compatible (for example, Epson FX-80) via RS-232C or

HP-IB.

RS-232C Configurations Protocols: XON/XOFF, Hardware; Data bits: 8; Stop bits: 1, 1

1/2, 2; Parity: none, odd, or even; Baud rates: 110, 300, 600, 1200, 2400, 4800, 9600, 19200.

HP-IB Interface Functions SH1, AH1, T5, TE0, L3, LE0, SR1, RL1, PP1, DC1, DT1, C0

and E2.

Input/Output

Rear Panel BNCs:

Intermodule Bus (IMB)

Characteristics

Port-in

1.5 mA to +6 V at 1.6 mA.

Port-out

into 50 Ω.

Run Control Oscilloscope, timing, state, and pattern generation can be armed by Group

Run. Modules can run concurrently or be armed in series. Each module can arm one or

more modules.

Mixed Display Mode Any timing or oscilloscope waveform displays can be mixed.

State listings can be included with waveforms in the State/Timing Mixed Mode display.

User selectable: TTL, ECL or user defined; Zin = 4 kΩ ; Maximum Vin = -6.0 V at

Output signal is active high, TTL output level, high > 2 V into 50 Ω, low < 0.4 V

Acquiring Data for Mixed Displays To obtain a mixed display, multiple modules must

be armed through the IMB. To include state listings in mixed mode displays, state time

tagging must be on.

1–3

Page 11

General Information

Characteristics

Time Interval Accuracy Between Modules Equals the sum of the channel-to-channel

time interval accuracies of each module used in the measurement, for a deskewed

measurement.

Time Correlation Resolution 2 ns (500 MHz).

Operating

Environment

Weight HP 16500B

Temperature

Instrument

Disk Media

Probes and Cables

Humidity

Instrument

Disk media and hard drive

Altitude Up to 4600 m (15 000 ft). Hard drive to 300 m (10,000 ft.).

Vibration

Operating Random vibration 5-500Hz, 10 minutes per axis, ~ 2.41 g (rms).

Non-operating Random vibration 5-500Hz, 10 minutes per axis, ~ 2.4 g (rms); and

swept sine resonant search, 5-500Hz, 0.75g (0-peak), 5 minute dwell at 4 resonances

per axis.

Net 18.1 kg (40 lbs) + [0.7 kg (1.6 lbs) x number of optional cards installed].

Shipping 25.9 kg (57 lbs) + [3.6 kg (8 lbs) x number of optional cards installed].

HP 16501A

Net 12.2 kg (27 lbs) + [0.7 kg (1.6 lbs) x number of optional cards installed].

Shipping 19.9 kg (44 lbs) + [3.6 kg (8 lbs) x number of optional cards installed].

0 °C to 50 °C (+32 °F to 122 °F).

10 °C to 40 °C (+50 °F to 104 °F).

0 °C to 65 °C (+32 °F to 149 °F).

up to 95% relative humidity at 40 °C (104 °F).

8% to 80% relative humidity at 40 °C (104 °F).

Power Requirements HP 16500B 115 V/230 V, -22% to +10%, 48 to 66 Hz, 475 W max.

HP 16501A 115 V/230 V, -22% to +10%, 48 to 66 Hz, 420 W max.

1–4

Page 12

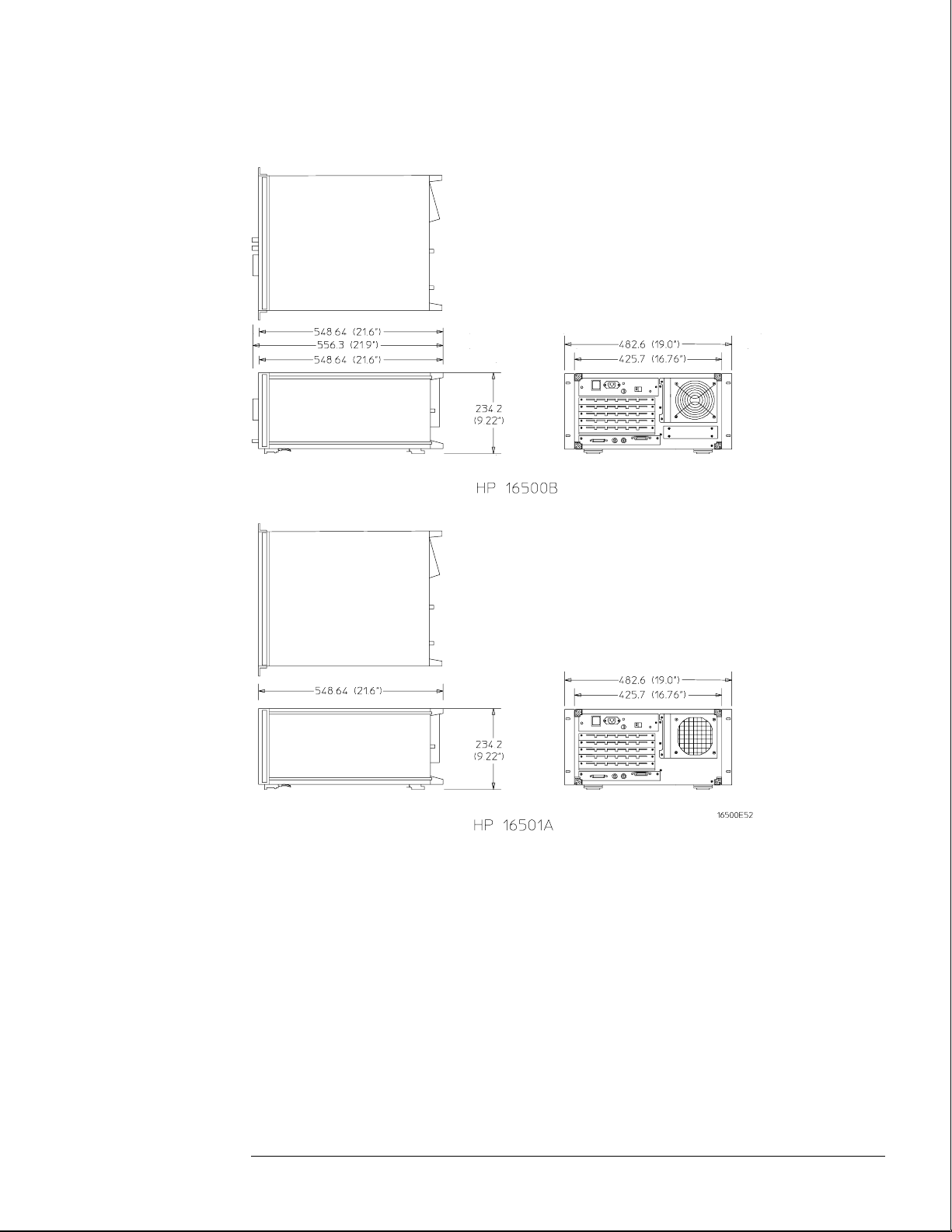

Dimensions Refer to the following figure for dimensional detail.

General Information

Characteristics

Dimensional Detail

1–5

Page 13

General Information

Recommended Test Equipment

Recommended Test Equipment

Equipment Required

Equipment Critical Specifications Recommended

Model/Part

Oscilloscope 100 MHz Bandwidth HP 54600A T

Voltmeter HP 3478A T

RS-232C Loopback

Connector

*A = Adjustment P = Performance Tests T = Troubleshooting

HP Part Number

01650-63202

Use

T

*

1–6

Page 14

2

To inspect the logic analysis system 2–2

To apply power 2–3

To operate the user interface 2–3

To set the line voltage 2–4

To degauss the display 2–5

To clean the logic analysis system 2–5

To test the logic analysis system 2–5

To install modules 2–6

To install the HP 16500L interface module 2–7

To connect the HP 16501A Expansion Frame 2–9

To connect an external monitor 2–10

Preparing for Use

Page 15

Preparing For Use

This chapter gives you instructions for preparing the logic analysis system for use.

Power Requirements

The logic analysis system mainframe requires a power source of either 115 Vac or 230

Vac, –22 % to +10 %, single phase, 48 to 66 Hz, 475 W maximum power.

The logic analysis system expansion frame requires a power source of either 115 Vac

or 230 Vac, –22 % to +10 %, single phase, 48 to 66 Hz, 420 W maximum power.

Operating Environment

The operating environment is listed in chapter 1. Note the noncondensing humidity

limitation. Condensation within the instrument can cause poor operation or

malfunction. Provide protection against internal condensation.

The logic analysis system will operate at all specifications within the temperature and

humidity range given in chapter 1. However, reliability is enhanced when operating it

within the following ranges:

WARNING

• Temperature: +20 °C to +35 °C (+68 °F to +95 °F)

• Humidity: 20% to 80% noncondensing

Storage

Store or ship the logic analysis system in environments within the following limits:

• Temperature: -40 °C to + 75 °C

• Humidity: Up to 90% at 65 °C

• Altitude: Up to 15,300 meters (50,000 feet)

Protect the system from temperature extremes which cause condensation on the

instrument.

To inspect the logic analysis system

1 Inspect the shipping container for damage.

If the shipping container or cushioning material is damaged, keep them until you have

checked the contents of the shipment and checked the instrument mechanically and

electrically.

Hazardous voltages exist in this instrument. To avoid electrical shock, do not apply power to

a damaged instrument.

2–2

Page 16

2 Check the supplied accessories.

Accessories supplied with the logic analysis system are listed in "Accessories" in chapter 1.

3 Inspect the product for physical damage.

Check the logic analysis system and the supplied accessories for obvious physical or

mechanical defects. If you find any defects, contact your nearest Hewlett-Packard Sales

Office. Arrangements for repair or replacement are made, at Hewlett-Packard’s option,

without waiting for a claim settlement.

To apply power

1 Check that the line voltage selector, located on the rear panel, is on the correct

setting and the correct fuse is installed.

See also, "To set the line voltage" in this chapter.

2 Connect the power cord to the instrument and to the power source.

This instrument is equipped with a three-wire power cable. When connected to an

appropriate ac power outlet, this cable grounds the instrument cabinet. The type of power

cable plug shipped with the instrument depends on the country of destination. Refer to

chapter 7, "Replaceable Parts," for option numbers of available power cables.

Turn on the instrument line switch located on the rear panel, then turn on the power

3

standby switch located on the front panel.

Preparing for Use

To apply power

To operate the user interface

• To select a field on the mainframe screen, use the touchscreen.

For more information about the logic analysis system interface, refer to the

HP 16500B/16501A Logic Analysis System User’s Reference.

• To set the HP-IB address or to configure for RS-232C, refer to the

HP 16500B/16501A Logic Analysis System User’s Reference.

2–3

Page 17

Preparing for Use

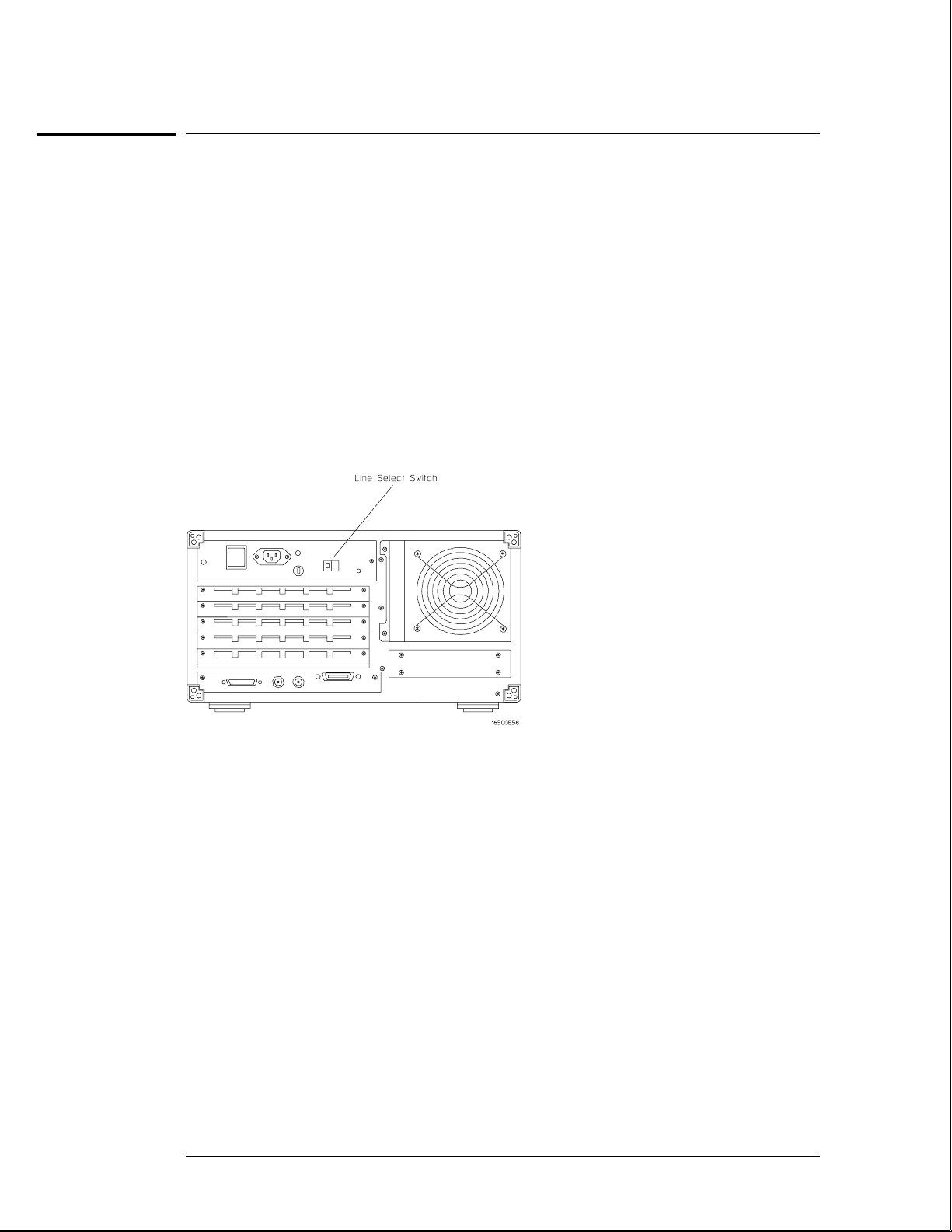

To set the line voltage

To set the line voltage

When shipped from HP, the line voltage selector is set and an appropriate fuse is installed for

operating the instrument in the country of destination. To operate the instrument from a

power source other than the one set, perform the following steps.

Turn the front panel power switch to the STBY position, then turn the power switch

1

to the Off position. Remove the power cord from the instrument.

2 Replace the main fuse with a 5 A/250 V fuse for 230 V operation, or a 10 A/125 V fuse

for 115 V operation.

3 Set the rear panel line select switch for the desired voltage.

4 Reconnect the power cord, turn on the rear panel power switch, then continue

normal operation.

5 If your system includes an HP 16501A Expansion Frame, repeat this procedure for it.

The expansion frame has only one power switch, and that switch is located on the rear panel.

Line Voltage Selection

2–4

Page 18

Preparing for Use

To degauss the display

To degauss the display

• If the mainframe has been subjected to strong magnetic fields, the CRT might

become magnetized and display data might become distorted. To correct this

condition, degauss the CRT with a conventional, external-television-type degaussing

coil.

To clean the logic analysis system

• With the instrument turned off and unplugged, use mild soap and water to clean the

front and cabinet of the system. Harsh soap might damage the water-base paint.

To test the logic analysis system

The logic analysis system does not require calibration or adjustment.

• If you require a test to initially accept the operation, perform the self-tests in

chapter 3, "Testing Performance."

• If the logic analysis system does not operate correctly, go to the beginning of

chapter 5, "Troubleshooting."

2–5

Page 19

CAUTION

Preparing for Use

To install modules

To install modules

The following steps give general instructions for installing modules into the mainframe or the

expansion frame of the system.

Electrostatic discharge can damage electronic components. Use grounded wriststraps and

mats when performing any service to modules.

1

Turn off the frame power switch, then unplug the power cord. Disconnect any input

or output connections.

2 Plan your module configuration.

Refer to the manuals of individual modules for configuration information.

Loosen the thumb screws.

3

Cards or filler panels below the slots intended for installation do not have to be removed.

Starting from the top, loosen the thumb screws on filler panels and cards that need to be

moved.

Starting from the top, pull the cards and filler panels that need to be moved halfway

4

out.

All multicard modules will be cabled together. To prevent damage to the cables and

connectors, pull these cards out together.

Remove the cards and filler panels.

5

Remove the cards or filler panels that are in the slots intended for the module installation.

Some modules for the logic analysis system require calibration if you move them to a different

slot. Refer to the manuals of individual modules for calibration information.

6

Install the module.

You may need to push all other cards into the card cage, but not completely in, to get them

out of the way for installing the module.

Refer to the manuals of individual modules for cabling information.

Slide the complete module into the frame, but not completely in.

7

Each card is firmly seated and tightened one at a time in step 9.

8 Position all cards and filler panels so that the endplates overlap.

9 Seat the cards and tighten the thumbscrews.

Starting with the bottom card, firmly seat the cards into the backplane connector of the

mainframe. Keep applying pressure to the center of the card endplate while tightening the

thumbscrews finger-tight. Repeat this for all cards and filler panels starting at the bottom and

moving to the top.

CAUTION

See Also Service Guides for the individual modules.

For correct air circulation, filler panels must be installed in all unused card slots. Correct air

circulation keeps the instrument from overheating. Keep any extra filler panels for future use.

10

Plug in the system, then turn it on.

When you turn on the power switch, the logic analysis system performs power-up tests. After

the power-up tests are complete, the screen will show your system configuration.

2–6

Page 20

WARNING

CAUTION

Preparing for Use

To install the HP 16500L interface module

To install the HP 16500L interface module

The HP 16500L interface module is required to connect the HP 16501A Expansion Frame to

the HP 16500B mainframe.

Hazardous voltages exist on the power supply, the CRT, and the CRT driver board of the

HP 16500B mainframe. To avoid electrical shock, disconnect the power from the instrument

before performing the following procedures. After disconnecting the power, wait at least six

minutes for the capacitors on the power supply board and the CRT driver board to discharge

before servicing the instrument. However, if the AC LED on the power supply has any

illumination, a significant charge remains on the power supply capacitors.

Electrostatic discharge can damage electronic components. Use grounded wriststraps and

mats when performing any service to this module or to the HP 16500B Logic Analysis System.

For correct orientation of the cables, match the slots on the cable connectors and on the

board connectors.

Remove power from the HP 16500B mainframe, then remove the optional modules,

1

the four rear feet, and the top and bottom covers of the mainframe.

2 Remove the sheetmetal plate on the rear of the mainframe covering the slot where

the HP 16500L interface module will be installed.

With the interface module installed, you will not use the plate. Save the plate to use in case

the interface module is removed.

Remove the cable connecting the CRT module to the CPU board.

3

To release the cable, push the tabs on the board connector to the outside of the connector.

With the interface module installed, you will not use this cable. Save the cable to use in case

the interface module is removed.

If you need more room to replace the CRT cable, you can remove the hard disk drive. Removing

the hard disk is not necessary, but gives you more room for replacing the CRT cable. The hard

disk is connected with four screws.

4

Connect one end of the new 40-pin cable to the CRT module.

Push the cable connector into the board connector until the tabs lock in the cable.

If you removed the hard disk drive, replace it before going to the next step.

2–7

Page 21

Preparing for Use

To install the HP 16500L interface module

5 Slide the interface module into the mainframe through the slot in the rear panel.

6 Install the screws connecting the interface module to the mainframe.

Two screws through the top of the interface module connect it to the sheetmetal plate, and

four screws through the rear plate of the interface module connect it to the rear panel of the

mainframe.

Connect the end of the 40-pin CRT cable to the interface module.

7

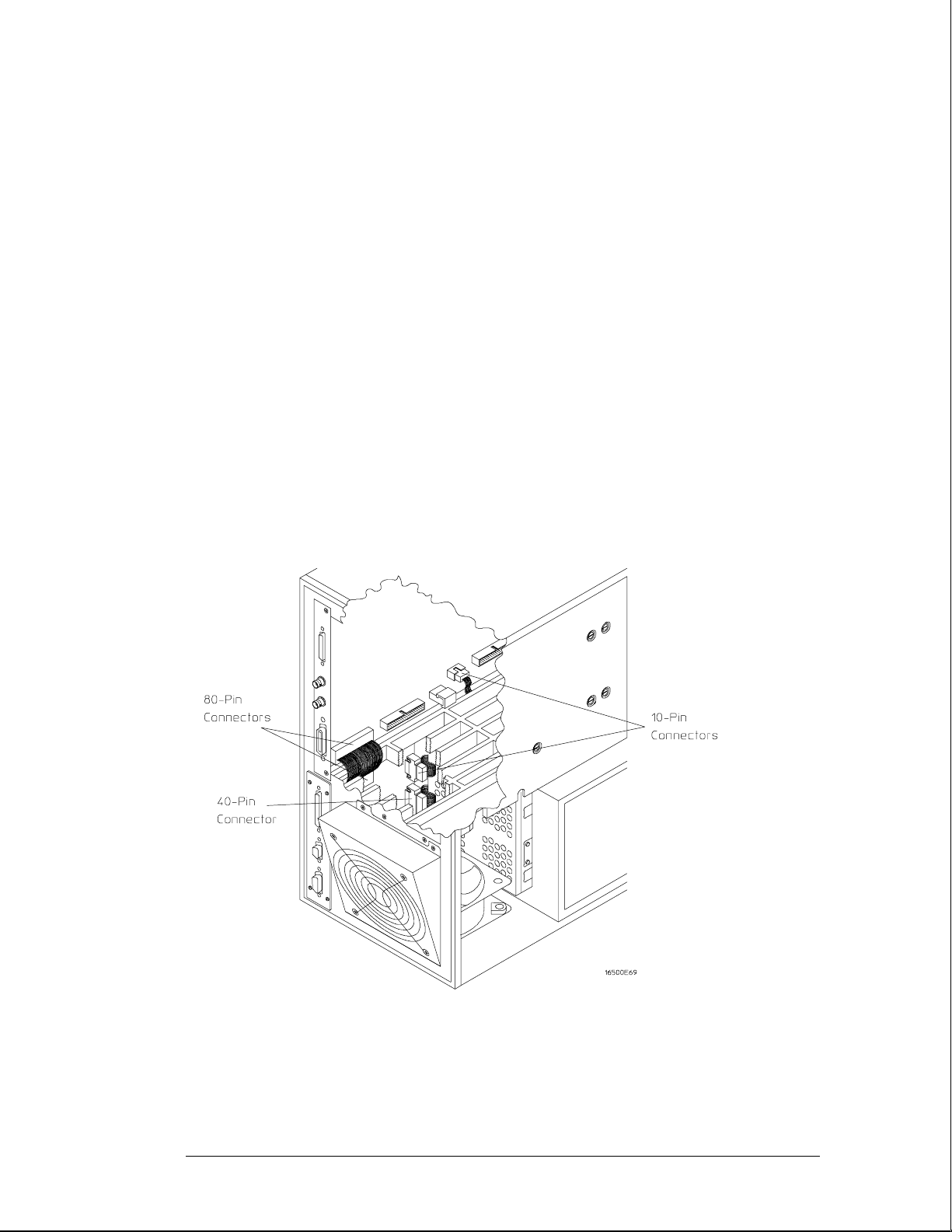

8 Connect the 80-pin cable to the CPU board and to the interface module.

a Slide the 80-pin cable halfway through the rear slot of the card cage between the

interface module and the CPU board.

b Connect the cable to the CPU board.

c Connect the cable to the interface module.

Connect the 10-pin cable to the CPU board and to the interface module.

9

10 Replace the top and bottom covers, the optional modules, and the rear feet of the

mainframe.

11 Turn on the system.

a Connect a power cord to the frame.

b Turn on the line switch located on the rear panel the frame.

c Turn on the power standby switch located on the front panel of the mainframe.

When the power-up tests are complete, the mainframe screen shows "Ethernet" in the

Communications menu.

2–8

Page 22

CAUTION

Preparing for Use

To connect the HP 16501A Expansion Frame

To connect the HP 16501A Expansion Frame

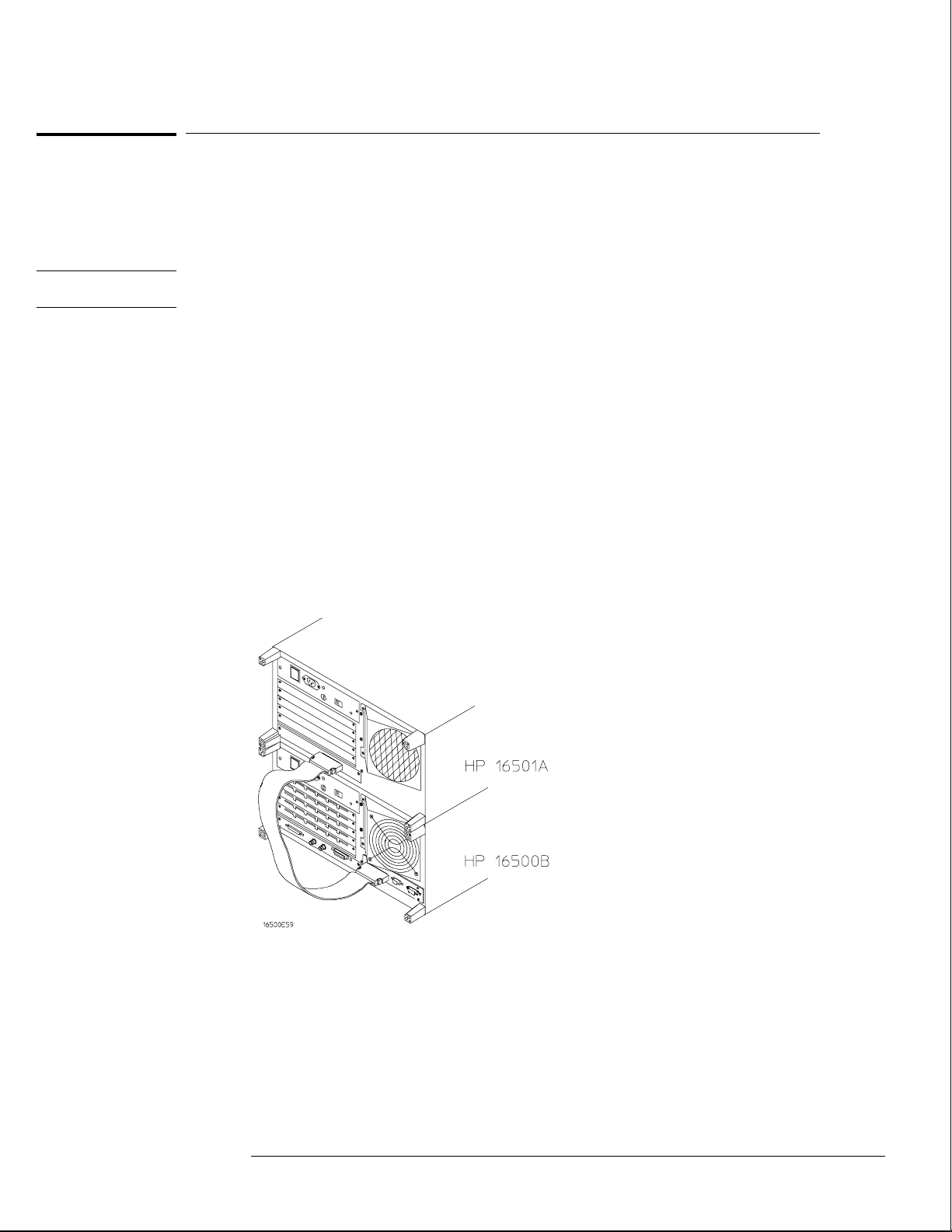

The HP 16501A Expansion Frame includes an interface cable and requires an HP 16500L

interface module to connect to the HP 16500B mainframe. To install the expansion frame,

you need to install the interface module into the mainframe, then connect the cable from the

module to the expansion frame.

Electrostatic discharge can damage electronic components. Use grounded wriststraps and

mats when performing any service to this card.

1

Turn off the mainframe power switch, then unplug the power cord. Disconnect any

input connections.

2 Verify that the line select switch located on the rear panel of the expansion frame is

in the off position.

3 Install the HP 16500L interface module into the mainframe.

The procedure for installing the HP 16500L is on page 2–7.

4 Connect the interface cable to the expansion frame and to the interface module in

the mainframe.

To ensure correct insertion, the 68-pin "D" connectors on each end of the interface cable are

asymmetric in shape. They only fit into their respective ports on the cards when oriented to

match the shape of the ports.

When connecting the interface cable, you will hear two clicks. Make sure the cable connector

is properly seated into the port by pulling the connector without pressing the release tabs. If

the connector is properly seated, it will remain connected to the port.

Turn on the system.

5

a Connect a power cord to each frame.

b Turn on the line switch located on the rear panel of each frame.

c Turn on the power standby switch located on the front panel of the mainframe.

When the power-up tests are complete, the mainframe screen shows "Master

Frame" in a blue field.

2–9

Page 23

Preparing for Use

To connect an external monitor

To connect an external monitor

The following tables define the signal available for external monitors at the HP 16500L

connector and pin numbers.

HP 16500L Output Signal For External Monitors

Horizontal deflection (fh) 25.0 kHz

Vertical deflection (fv) 59.95 Hz

Resolution 576 x 368 x dots x lines (WxH)

RGB video 0.714 VP-P, positive

Impedance 75 ohm , analog

External Sync Signal

Connector Pins

H TTL, negative 3.2 µS;

W TTL, negative, 120 µS

Pin number Signal Pin number Signal

1 Red 6,7,8,10 Ground

2 Green 13 Horizontal Sync

3 Blue 14 Vertical Sync

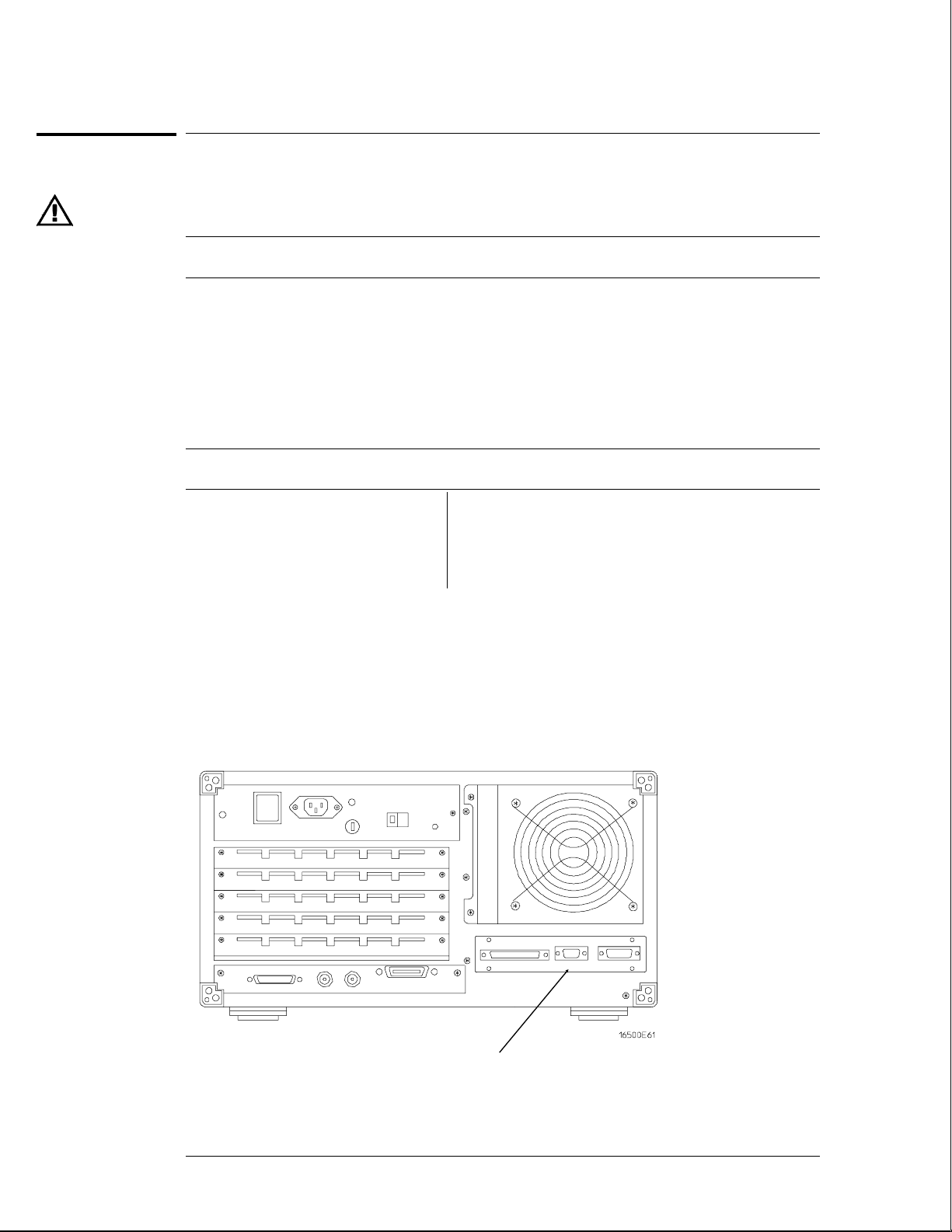

1 Connect your monitor to the HP 16500L interface module installed into the

HP 16500B mainframe.

2 If your monitor needs adjusting, follow the manufacturer’s instructions.

2–10

Connector for

external monitor

Page 24

3

To perform the power-up tests 3–3

To perform the self-tests 3–4

Testing Performance

Page 25

Testing Performance

To ensure the logic analysis system is operating correctly, you can perform software

tests (self-tests) on the system. Directions for performing the software tests are

given in this chapter.

This chapter normally tells you how to test the performance of the logic analysis

system against the specifications listed in chapter 1. Because there are no

specifications for the HP 16500B/16501A, there are no performance verification tests.

Self-Tests

The self-tests listed in this chapter check the functional operation of the mainframe

and the expansion frame. Self-tests for the optional modules installed in the frames

are listed in the individual module Service Guides.

There are two types of self-tests: self-tests that automatically run at power-up, and

self-tests that you select on the screen. For descriptions of the tests, refer to chapter

8, "Theory of Operation."

Perform the self-tests as an acceptance test when receiving the logic analysis system

or when the logic analysis system is repaired.

If a test fails, refer to chapter 5, "Troubleshooting."

Test Interval

There is no recommended test interval for the HP 16500B mainframe or the

HP 16501A expansion frame. However, each of the HP 16500-series option modules

has performance verification tests and therefore require a periodic verification of

specifications. Refer to the Service Guides of the individual modules for more

information.

The Logic Analysis System Interface

To select a field on the HP 16500B screen, use the touchscreen. For more

information about the logic analysis system interface, refer to the

HP 16500B/16501A Logic Analysis System User’s Reference.

3–2

Page 26

Testing Performance

To perform the power-up tests

To perform the power-up tests

The logic analysis system automatically performs power-up tests when you apply power to the

instrument. The revision number of the boot ROM shows in the upper-right corner of the

screen during these power-up tests. As each test completes, either "passed" or "failed" prints

on the screen in front of the name of each test.

Disconnect all inputs, then insert a formatted disk into the flexible disk drive.

1

2 Let the instrument warm up for a few minutes, then cycle power by turning off then

turning on the power switch.

If the instrument is not warmed up, the power-up test screen will complete before you can

view the screen.

As the tests complete, check if they pass or fail.

3

The Flexible Disk Test reports No Disk if a disk is not in the disk drive.

If a power-up self-test fails, refer to chapter 5, "Troubleshooting."

Performing Power-Up Self-Tests

passed ROM Test

passed RAM Test

passed Interrupt Test

passed Display Test

passed HIL Controller Test

passed Front-Panel Test

passed Touchscreen Test

passed Correlator Test

passed Hard Disk Test

passed Flexible Disk Test

Loading Module Files

3–3

Page 27

Testing Performance

To perform the self-tests

To perform the self-tests

The self-tests verify the correct operation of the logic analysis system. Self-tests can

be performed all at once or one at a time. While testing the performance of the logic

analysis system, run the self-tests all at once.

1 If you just did the power-up self-tests, go to step 2.

If you did not just do the power-up self-tests, disconnect all inputs, then turn on the

power switch. Wait until the power-up tests are complete.

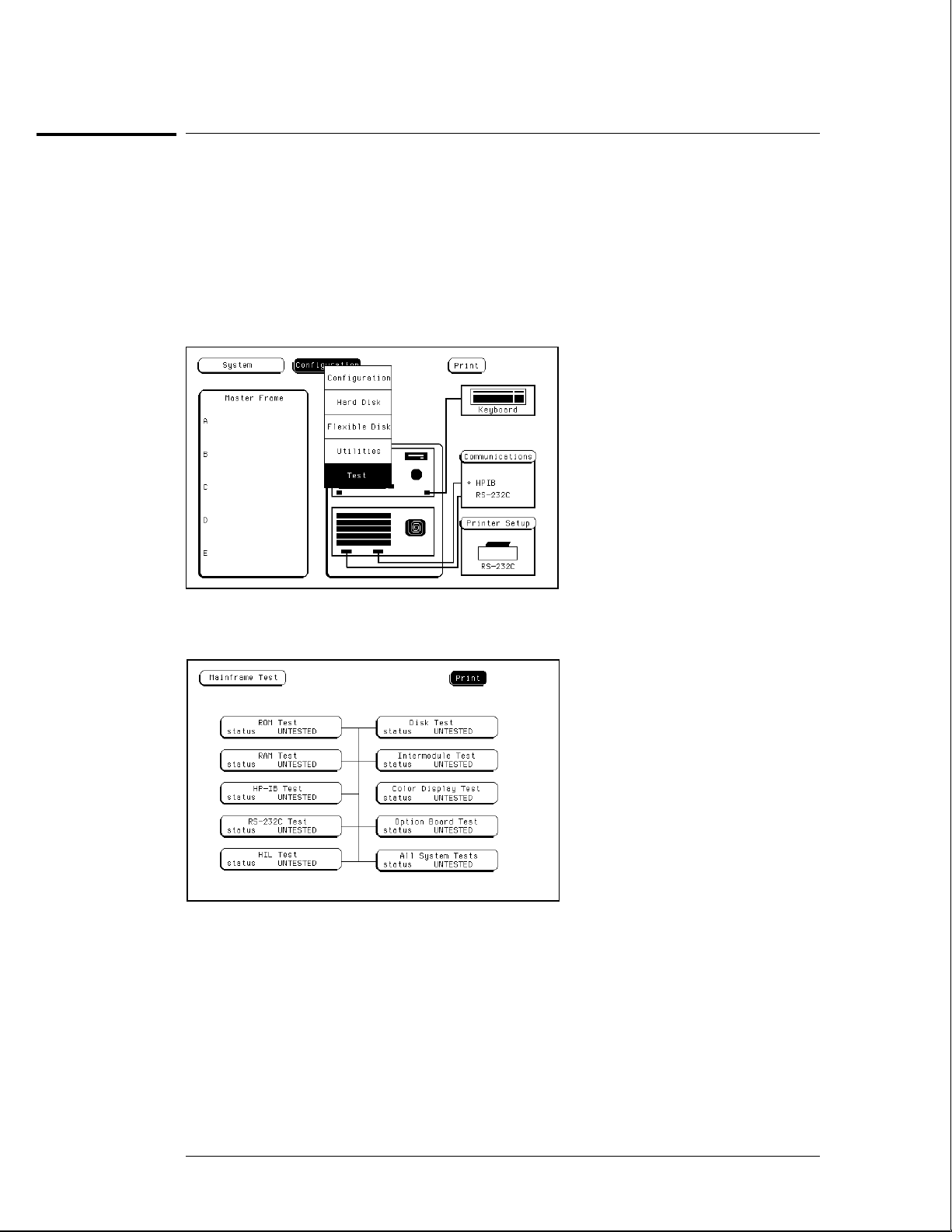

2 In the System Configuration menu, select Configuration, then select Test.

3 Select the box labeled Load Test System.

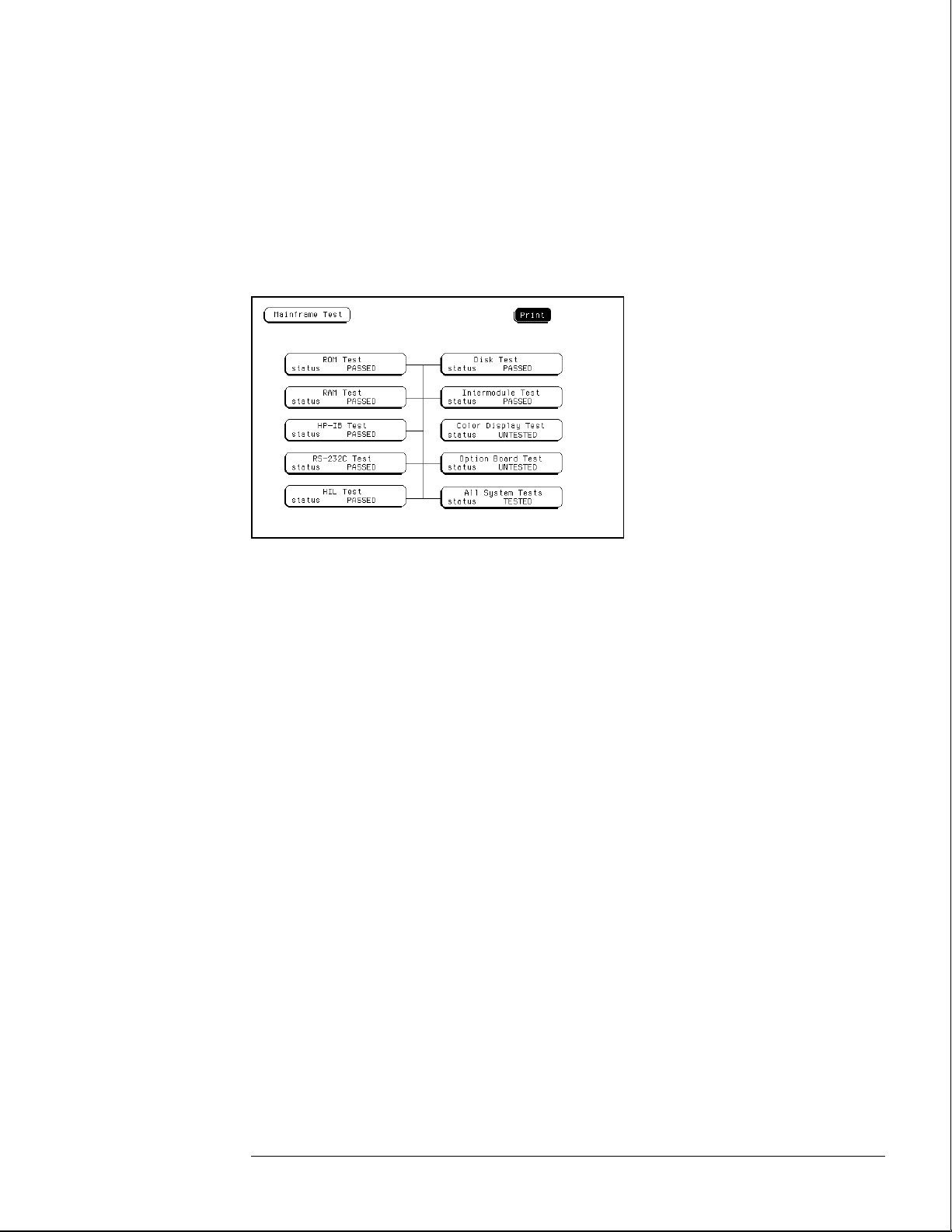

4 Select Test System, then select Mainframe Test from the pop-up menu.

3–4

Page 28

Testing Performance

To perform the self-tests

5 Install a formatted disk that is not write protected into the flexible disk drive.

Connect an RS-232C loopback connector onto the RS-232C port.

6 Select All System Tests.

You can run all tests at one time by running All System Tests. To see more details about each

test, you can run each test individually. This step shows how to run all tests at once.

The status of the tests will change from Untested to Passed or Failed. If a test fails, refer to

chapter 5, "Troubleshooting."

The Color Display Test is not normally needed. The screens are primarily used when the

color display assembly requires adjusting. For the adjustment procedure, refer to chapter 4,

"Calibrating and Adjusting."

Exit the mainframe tests.

7

a In the Mainframe Test menu, select Mainframe Test, then select Test System.

b Select Configuration, then select Exit Test in the pop-up menu.

c Select the field close to the center of the screen to exit the test system and to load the

mainframe operating system.

After the operating system is loaded, the System Configuration menu is displayed.

3–5

Page 29

3–6

Page 30

4

To prepare the instrument 4–3

To access the test patterns 4–4

To adjust geometry 4–5

To adjust focus, landing, and convergence 4–6

To adjust white balance 4–13

Calibrating and Adjusting

Page 31

Calibrating and Adjusting

This chapter normally gives you instructions for calibrating and adjusting the logic

analysis system. Because the HP 16500B/16501A requires no calibration, only

adjustment instructions are included.

Adjustments

The only adjustments to the logic analysis system are adjustments to the color CRT

monitor assembly.

Use the following procedures to adjust the CRT module to compensate for magnetic

influences causing misconvergence.

WARNING

Hazard voltages exist on the power supply, the CRT, and the CRT driver board. To avoid

electrical shock, read and follow the Safety and Warning considerations at the end of this

manual before performing adjustment procedures.

Adjustment Interval

DO NOT PERFORM THESE ADJUSTMENTS AS A PART OF ROUTINE

CALIBRATIONS. The following procedures are provided only for the few extreme

cases where either the earth’s magnetic field or the user’s environment cause an

unusable display due to misconvergence that cannot be corrected by degaussing the

entire CRT screen.

DO NOT perform the procedures in this chapter before first degaussing the CRT

screen using the rear-panel degaussing switch. In extreme cases of magnetism, it

may be necessary to degauss the CRT using a conventional external television-type

degaussing coil.

Adjustment Personnel

It is recommended that these adjustments be performed only by qualified personnel

who are familiar with color CRT convergence procedures.

Equipment Required

The instrument firmware supplies the display patterns necessary for adjustment.

The only tool required is a nonmetallic adjustment tool:

• Sony Part Number 4-367-065-01

• HP Part Number 8710-1355

4–2

Page 32

Calibrating and Adjusting

To prepare the instrument

To prepare the instrument

1 Remove the rear feet and the covers from the mainframe.

2 Before starting the adjustments, mark the position where the potentiometers are set.

This helps in returning the adjustments to their original positions if it becomes necessary to

restart the procedure.

During any of the following CRT adjustments, the CRT module must face west.

3

4 Use the following chart to guide you with the CRT adjustment procedure.

The following CRT adjustments are broken down into adjustment groups. The adjustment

group sequence must be followed in order because of interaction and dependency. The

adjustment group sequence is shown in the adjustment flow diagram below. There will be

cases where not all of the adjustments groups will be used. For example, if the Geometry

Adjustment Group corrects the problem, this will be the only group used.

Colo

r

CRT

Mod

ule

Adju

stme

nt

Flow

Diag

ram

4–3

Page 33

Calibrating and Adjusting

To access the test patterns

To access the test patterns

Some procedures on the following pages ask you to access test patterns. This procedure tells

you how to access them and how to exit the test.

In the System Configuration menu, touch Configuration, then select Test in the

1

pop-up menu.

2 Touch the field near the center of the screen to load the Test System.

3 In the Test System Configuration menu, touch Test System, then select Mainframe

Test in the pop-up menu.

The screen displays the Mainframe Test menu.

4 Touch the Color Display Test field to display the first test pattern, which is the

white, cross-hatch pattern.

5 Touch Continue to see the next test pattern.

With every touch of the Continue field, the next test pattern will be displayed. When

Continue is selected from the black raster pattern, the Mainframe Test menu will be displayed.

Notice that the status of the Display field changes to Tested.

To exit the test system, touch the Mainframe Test field, then touch the Test System.

6

Touch Configuration, select test, then touch the field near the center of the screen to

exit the test system.

4–4

Page 34

Calibrating and Adjusting

To adjust geometry

To adjust geometry

1 Display the white cross-hatch test pattern on the CRT.

From the Color Display Test menu, select the white, cross-hatch pattern.

2 Preset the front panel brightness control, the top of the two controls to the left of

the display, maximum clockwise.

3 Preset the front panel contrast control, the bottom of the two controls to the left of

the display, to the mechanical center.

4 Preset H.SUB SHIFT (RV006) and V.SUB SHIFT (RV008), located on the bottom PC

board, to the mechanical centers.

All of the following adjustment potentiometers are located on the PC board on the left side of

the display.

Adjust the display size. Measure with a flexible ruler.

5

Adjust H.SIZE (RV504) for a 161 mm (6.34 in.) width.

•

Adjust V.HEIGHT (RV50) for a 120.5 mm (4.74 in.) height.

•

Center the pattern.

6

Adjust V.CENT (RV510) for vertical centering.

•

Adjust H.CENT (RV503) for horizontal centering.

•

Adjust PIN AMP (RV506) to eliminate pincushion distortion in the vertical lines of

7

the cross-hatch pattern as shown in the next figure.

8 Remove the left, bottom rail of the mainframe.

The left, bottom rail must be removed in order to access the next adjustment.

9 Adjust PIN PHASE (RV505) to eliminate pin phase distortion in the vertical lines of

the cross-hatch pattern as shown in the next figure.

10 Reinstall the bottom rail.

11 Adjust TOP PIN (RV511) so that the top horizontal line is parallel with the center

horizontal line.

12 Adjust BOTTOM PIN (RV512) so that the bottom horizontal line is parallel with the

center horizontal line.

4–5

Page 35

Calibrating and Adjusting

To adjust focus, landing, and convergence

To adjust focus, landing, and convergence

Once you have started, you will have to do all three of the procedures in this group: the focus,

the landing, and the convergence adjustments.

Initial Preparation

Loosen the deflection yoke clamp screw.

1

2 Remove the rear and side fans.

Refer to chapter 6, "Replacing Assemblies."

Focus Adjustment

Geometry adjustments must be performed before making the focus adjustment.

Display the white, cross-hatch test pattern on the display.

1

From the Color Display Test menu, select the white, cross-hatch pattern.

2 Adjust FOCUS (RV701), located on the rear PC board, for best overall focus.

4–6

Page 36

Calibrating and Adjusting

To adjust focus, landing, and convergence

Landing Adjustment

Turn the front panel BRIGHTNESS control fully clockwise.

1

2 Degauss the CRT by momentarily pressing the DEGAUSS switch located on the

instrument rear panel.

In some cases, the user’s environment or shipping environment may have caused high levels of

magnetization in the CRT. In this case, to completely degauss the CRT you may need to use a

conventional television-type degaussing coil.

Red

Green

Blue

Set the purity magnet tabs to the mechanical center. Refer to the next figure.

3

4 Display a green raster test pattern on the display.

From the Color Display Test menu, select the green raster.

In the next steps, while moving the deflection yoke forward and rearward, rotate the yoke as

necessary to keep the edges of the raster parallel to the sides of the display.

Move the deflection yoke rearward until the left edge of the raster turns red and the

6

right side of the raster turns blue.

7 Adjust the purity magnets until green is in the center of the raster with red and blue

bands evenly distributed on the sides.

4–7

Page 37

Purity control

corrects this area

Deflection yoke

position corrects

these areas

Calibrating and Adjusting

To adjust focus, landing, and convergence

8 Move the deflection yoke forward until the entire raster is green.

Landing adjustment is easier if the yoke is moved all the way forward and then moved back

until the raster is completely green.

Using the Color Purity key, replace the green raster with red and then blue raster,

9

each time checking for proper landing adjustment (color purity of each).

10 If the landing is not correct in step 9, repeat steps 6 through 9 for the best

compromise.

11 If the landing is not correct in step 10, readjust purity magnets for best landing of

each color.

12 When the landing adjustment is complete, tighten the deflection yoke clamp screw

just enough to keep the yoke from moving. DO NOT over tighten or you might

damage the CRT.

4–8

Page 38

Calibrating and Adjusting

To adjust focus, landing, and convergence

Static Convergence

Temporarily disconnect the power from the instrument.

1

2 Remove the PC board shield cover from the rear of the Color CRT Module by prying

evenly on all four sides.

3 Reapply power.

4 Display the white, cross-hatch test pattern on the CRT.

From the Color Display Test menu, select the white, cross-hatch pattern.

5 Preset front panel brightness control, the top of the two controls to the left of the

display, maximum clockwise.

6 Preset front panel contrast control, the bottom of the two controls to the left of the

display, to the mechanical center.

7 Check the four dots which are located around the center intersection of the

cross-hatch pattern for coincidence of the blue, red, and green dots. If the dots are

not coincident, adjust H.STAT (RV703) located on the rear PC board to obtain

horizontal coincidence and V.STAT (RV803) located on the bottom PC board to

obtain vertical coincidence.

V.STAT

Center dot

H.STAT

Due to interaction, the BEAM LANDING will need to be readjusted if either the H.STAT or

V.STAT adjustments are made. Once the BEAM LANDING is re-adjusted, repeat step 7 above

if necessary to obtain the center screen coincidence of the dots.

4–9

Page 39

Calibrating and Adjusting

To adjust focus, landing, and convergence

Dynamic Convergence

Display the white, cross-hatch test pattern on the CRT.

1

From the Color Display Test menu, select the white, cross-hatch test pattern.

2 Adjust Y BOW (RV805) located on the bottom PC board to eliminate red, green, and

blue bowing at the top and bottom of the center vertical line.

3 Adjust Y CROSS (RV804) located on the bottom PC board to eliminate red, green,

and blue orthogonal misalignment at the top and bottom of the center vertical line.

4–10

Page 40

Calibrating and Adjusting

To adjust focus, landing, and convergence

4 Adjust V TOP (RV801) and V BOTTOM (RV802) to obtain coincidence of the red,

blue, and green at the intersection of the top and bottom horizontal lines with the

center vertical line. The VTOP and VBOTTOM adjustments are located on the

bottom PC board. Use the next two figures for V TOP and V BOTTOM respectively.

4–11

Page 41

Calibrating and Adjusting

To adjust focus, landing, and convergence

5 Adjust H.AMP (RV807) located on the bottom PC board for equal amounts of

misconvergence at the right and left sides of the screen.

6 Adjust H.TILT (RV806) located on the bottom PC board for coincidence of red,

green, and blue at the right and left sides of the screen.

7 If you are finished with the CRT adjustments, replace the fans.

If you need to adjust the white balance, which is the next procedure, you will

replace the fans after completing that procedure.

4–12

Page 42

Calibrating and Adjusting

To adjust white balance

To adjust white balance

1 Provide a blank display on the CRT.

From the Color Display Test menu, select a blank (colorless) raster.

2 Preset the front panel brightness and contrast controls to their mechanical centers.

3 On the bottom PC board, set the following adjustments to their mechanical centers.

SUB BRT (RV901)

•

SUB CONT (RV902)

•

4 On the bottom PC board, set the following adjustments to their mechanical centers.

G. DRIVE (RV921)

•

B. DRIVE (RV931)

•

R. DRIVE (RV911)

•

5 On the rear PC board, set the following adjustments fully counterclockwise.

G. BKG (RV721)

•

B. BKG (RV731)

•

R. BKG (RV711)

•

6 Adjust the SCREEN (RV702) located on the rear PC board until either the red, green,

or blue raster just starts to become visible. Note which color becomes visible first

and do not adjust the background control (BKG) for that color in the next step.

7 Adjust the other two background controls for the best white balance.

8 From the Color Display Test menu, select the white raster test pattern.

9 Set the front panel brightness control to maximum.

10 On the bottom PC board, adjust the DRIVE controls (RV921, RV931 and RV911) for

the best white balance.

For a white balance reference, use an average piece of white photocopy paper and compare

the white on the CRT to the paper.

Repeat steps 1-3 followed by 6-10 until satisfied with the white balance.

11

Essentially, from this point the procedure is as follows:

a With a blank screen, the front panel brightness set to center, and SCREEN (RV702) set

for minimum background, adjust the BKG controls (G.-RV721, B.-RV731, and

R.-RV711) for the best white balance.

b With a white raster and the front panel brightness set to maximum, adjust the DRIVE

controls (G.-RV921, B.-RV931, and R.-RV911) for best white balance.

c Repeat until satisfied with the white balance.

Replace the side and rear fans.

12

Refer to chapter 6, "Replacing Assemblies."

4–13

Page 43

4–14

Page 44

5

To use the flowcharts 5–2

To check the power-up self-tests 5–18

To run the self-tests 5–19

To check the video signals 5–22

To check the power supply LEDs 5–23

To test the power supply voltages 5–24

To test the flexible disk drive voltages 5–25

To test the hard disk drive voltages 5–27

To test the expansion frame interface 5–29

Troubleshooting

Page 45

Troubleshooting

This chapter helps you troubleshoot the logic analysis system to find defective

assemblies. The troubleshooting consists of flowcharts, self-test instructions, and

tests. This information is not intended for component-level repair.

If you suspect a problem, start at the top of the first flowchart. During the

troubleshooting instructions, the flowcharts will direct you to perform other tests.

The other tests are located in this chapter after the flowcharts.

The service strategy for this instrument is the replacement of defective assemblies.

This instrument can be returned to Hewlett-Packard for all service work, including

troubleshooting. Contact your nearest Hewlett-Packard Sales Office for more details.

CAUTION

Electrostatic discharge can damage electronic components. Use grounded wriststraps and

mats when you perform any service to this instrument or to the cards in it.

To use the flowcharts

Flowcharts are the primary tool used to isolate defective assemblies. The flowcharts refer to

other tests to help isolate the trouble. The circled letters on the charts indicate connections

with the other flowcharts. Start your troubleshooting at the top of the first flowchart.

5–2

Page 46

Troubleshooting

To use the flowcharts

Main Troubleshooting Flowchart 1

5–3

Page 47

Note: The HP 16500L

is in the System

Configuration menu if

"Master Frame" is in a

blue field and

"Ethernet" is in the

Communications field.

Troubleshooting

To use the flowcharts

Main Troubleshooting Flowchart 2

5–4

Page 48

Troubleshooting

To use the flowcharts

Color Module Troubleshooting Flowchart 3

5–5

Page 49

Troubleshooting

To use the flowcharts

Color Module Troubleshooting Flowchart 3A (continued)

5–6

Page 50

Troubleshooting

To use the flowcharts

Power-Up Troubleshooting Flowchart 4

5–7

Page 51

Troubleshooting

To use the flowcharts

System Start Troubleshooting Flowchart 5

5–8

Page 52

Troubleshooting

To use the flowcharts

Mainframe Tests Troubleshooting Flowchart 6

5–9

Page 53

Troubleshooting

To use the flowcharts

Power Supply Troubleshooting Flowchart 7

5–10

Page 54

Troubleshooting

To use the flowcharts

HIL Troubleshooting Flowchart 8

5–11

Page 55

Troubleshooting

To use the flowcharts

Flexible Disk Drive Troubleshooting Flowchart 9

5–12

Page 56

Troubleshooting

To use the flowcharts

Hard Disk Drive Troubleshooting Flowchart 10

5–13

Page 57

Troubleshooting

To use the flowcharts

RS-232C Troubleshooting Flowchart 11

5–14

Page 58

Troubleshooting

To use the flowcharts

Intermodule Troubleshooting Flowchart 12

5–15

Page 59

Troubleshooting

To use the flowcharts

Expansion Frame Troubleshooting Flowchart 13

5–16

Page 60

Troubleshooting

To use the flowcharts

Note: Compare the

specifications of the

monitor against the

specifications of the

video signal as a way

to determine

compatibility (ability

to synch). Video

signal specifications

are listed in "To

connect an external

monitor" in chapter 2.

External Monitor Troubleshooting Flowchart 14

5–17

Page 61

Troubleshooting

To check the power-up self-tests

To check the power-up self-tests

The logic analysis system automatically performs power-up self-tests when you apply power

to the instrument. The revision number of the operating system shows in the upper-right

corner of the screen during these power-up tests. As each test completes, either "passed" or

"failed" appears on the screen in front of the name of each test.

Disconnect all inputs, then insert a formatted disk into the flexible disk drive.

1

2 Let the instrument warm up for a few minutes, then cycle the power by turning off

and turning on the power switch.

If the instrument is not warmed up, the power-up test screen will complete before you can

view the screen.

As the tests complete, check if they pass or fail, then return to the flowcharts.

3

The Flexible Disk Test reports No Disk if a disk is not in the disk drive. Refer to the tables

below for the screen listing after the tests are complete and for power-up error messages.

Power-Up Self-Test Screen Listing

Performing Power-Up Self-Tests

passed ROM Test

passed RAM Test

passed Interrupt Test

passed Display Test

passed HIL Controller Test

passed Front-Panel Test

passed Touchscreen Test

passed Correlator Test

passed Hard Disk Test

passed Flexible Disk Test

Loading Module Files

Error Messages at Power-Up

Message Cause Remedy

FATAL ERRORS ENCOUNTERED,

BOOT HALTED

SYSTEM DISK NOT FOUND The mainframe operating system

Touchscreen power-up test

impaired

A power-up test failed. Follow the troubleshooting

flowcharts.

Install the operating system

cannot be found on the hard disk

drive.

The touchscreen operation is

impaired.

software onto the hard disk drive.

Follow the troubleshooting

flowcharts. The touchscreen might

still operate with a minimal loss of

functionality.

See Also "The Power-Up Routine" in chapter 8.

5–18

Page 62

To run the self-tests

Self-tests identify the correct operation of major, functional subsystems of the instrument.

You can run all self-tests without accessing the interior of the instrument. If a self-test fails,

the troubleshooting flowcharts instruct you to change a part of the instrument.

If you just did the power-up self-tests, go to step 2.

1

If you did not just do the power-up self-tests, disconnect all inputs, then turn on the

power switch. Wait until the power-up tests are complete.

2 In the System Configuration menu, select Configuration, then select Test.

Troubleshooting

To run the self-tests

3 Select the box labeled Load Test System.

4 Select Test System, then select Mainframe Test from the pop-up menu.

5–19

Page 63

Troubleshooting

To run the self-tests

5 Select ROM Test. The ROM Test screen is displayed.

You can run all tests at one time by running All System Tests. To see more details about each

test, you can run each test individually. This example shows how to run an individual test.

Select Run, then select Single.

6

To run a test continuously, select Repetitive. Select Stop to halt a repetitive test.

For a Single run, the test runs one time, and the screen shows the results.

5–20

Page 64

Troubleshooting

To run the self-tests

7 To exit the ROM Test, select Done. Note that the status changes to Passed or Failed.

8 Install a formatted disk that is not write-protected into the flexible disk drive.

Connect an RS-232C loopback connector onto the RS-232C port. Run the remaining

All System Tests in the same manner.

The Color Display Test is not part of this troubleshooting. The Color Display Test is used in

chapter 4, "Calibrating and Adjusting," to adjust the color display.

The Option Board Test is used later in this chapter to check signals to the HP 16501A

Expansion Frame.

Exit the mainframe tests.

99

a Select Done from any test screen.

b Select Mainframe Test, then select Test System in the pop-up menu.

c Select Configuration, then select Exit Test in the pop-up menu.

d Select the box near the center of the screen to exit the test system.

If you are performing the self-tests as part of the troubleshooting flowchart, return

10

to the flowchart.

5–21

Page 65

WARNING

Troubleshooting

To check the video signals

To check the video signals

Refer to chapter 6, "Replacing Assemblies," for instructions on how to remove or replace

covers and assemblies.

Hazard voltages exist on the power supply, the CRT, and the CRT driver board. This

procedure is to be performed by service-trained personnel aware of the hazards involved,

such as fire and electrical shock.

Turn off the instrument, then remove the bottom cover.

1

2 On the color assembly, disconnect the cable that connects the microprocessor

board to the color display assembly.

3 Turn on the instrument, then wait for it to power up.

4 Probe the cable for the horizontal sync, vertical sync, and display data signals.

The horizontal and vertical sync signals are TTL levels that resemble the figure.

The display data signals have a baseline of approximately −1.7 V and vary in amplitude from

the baseline voltage to approximately 125 mV, depending on the characteristics of the colors

displayed.

Reconnect the cable, then return to the color display assembly flowchart.

5

Vertical

Horizontal

Cable Pin Numbers

Pin Numbers Signal

3 Vertical Sync

7 Horizontal Sync

21 Red Display Data

29 Green Display Data

37 Blue Display Data

Sync Signals

5–22

Page 66

WARNING

To check the power supply LEDs

To check the power supply LEDs

Refer to chapter 6, "Replacing Assemblies," for instructions to remove or replace covers and

assemblies.

Hazard voltages exist on the power supply, the CRT, and the CRT driver board. This

procedure is to be performed by service-trained personnel aware of the hazards involved,

such as fire and electrical shock.

Turn off the instrument, then remove the top cover.

1

2 Apply power to the instrument.

3 Check the power supply LEDs.

4 Note problems with the power supply, then return to the power supply flowchart.

Troubleshooting

5–23

Page 67

WARNING

Troubleshooting

To check the power supply voltages

To check the power supply voltages

Refer to chapter 6, "Replacing Assemblies," for instructions to remove or replace covers and

assemblies.

Hazard voltages exist on the power supply, the CRT, and the CRT driver board. This

procedure is to be performed by service-trained personnel aware of the hazards involved,

such as fire and electrical shock.

Turn off the instrument, disconnect the power cord, then remove the top cover.

1

2 Apply power to the instrument.

3 Using a DVM, measure the power supply voltages.

4 Note problems with the power supply, then return to the power supply flowchart.

Power Supply Voltages

Pin Supply/Signal Voltage Pin Supply/Signal Voltage

1-5 5 volt +5 V 21 Ground sense 0 V

6 +5 volt remote sense +5 V 22 Power valid +5 V

7-9 +3.5 volt +3.5 V 23

10 +3.5 volt remote sense +3.5 V 24-30

11 +12 volt +12 V 31

12

13 Not connected 33-37

14-20 Ground 0 V 38 Remote on/off +12 V

−12 volt −12 V

32

−3.25 volt remote sense −3.25 V

−3.25 volt −3.25 V

−5.2 volt current limit

−5.2 volt remote sense −5.2 V

−5.2 volt −5.2 V

+2.5 V

5–24

Page 68

WARNING

Troubleshooting

To test the flexible disk drive voltages

To test the flexible disk drive voltages

Refer to chapter 6, "Replacing Assemblies," for instructions to remove or replace covers and

assemblies.

Hazard voltages exist on the power supply, the CRT, and the CRT driver board. This

procedure is to be performed by service-trained personnel aware of the hazards involved,

such as fire and electrical shock.

Equipment Required

Equipment Critical Specification Recommended

Model/Part

Digitizing Oscilloscope > 100 MHz Bandwidth HP 54600A

1 Turn off the instrument, then remove the power cable. Remove the instrument

cover and the flexible disk drive.

2 Reconnect the disk drive cable to the rear of the disk drive. Turn the disk drive over

so that the solder connections of the cable socket are accessible.

3 Connect the power cable, then turn on the instrument.

4 In the Mainframe Test menu, select the Flexible Disk Test. Insert a disk that has

enough available bytes to run the test in the disk drive, then select Run-Repetitive.

Refer to "To run the self-tests" in this chapter if you need help accessing the test menu.

5–25

Page 69

Troubleshooting

To test the flexible disk drive voltages

5 Check for the following voltages and signals using an oscilloscope.

Disk Drive Voltages

Pin Signal

Description

1 NC 13 Ground 24 Write Gate

2 Disk Change 14 NC 25 Ground

3 NC 15 Ground 26 Track 00

4 High Density 16 Motor On 27 Ground

5 NC 17 Ground 28 Write Protect

6 NC 18 Direction 29 Ground

7 +5 V 19 Ground 30 Read Data

8 Index 20 Step 31 Ground

9 +5 V 21 Ground 32 Side Select

10 Drive Select 22 Write Data 33 Ground

11 +5 V 23 Ground 34 Ready

12 NC

Pin Signal

Description

Pin Signal Description

6 Select Stop, and turn off the logic analyzer. Remove the power cable.

7 Disconnect the disk drive cable and reinstall the disk drive in the mainframe.

8 Reconnect the disk drive cable and install the cover on the mainframe.

5–26

Page 70

WARNING

Troubleshooting

To test the hard disk drive voltages

To test the hard disk drive voltages

Refer to chapter 6, "Replacing Assemblies," for instructions to remove or replace covers and

assemblies.

Hazard voltages exist on the power supply, the CRT, and the CRT driver board. This

procedure is to be performed by service-trained personnel aware of the hazards involved,

such as fire and electrical shock.

Equipment Required

Equipment Critical Specification Recommended

Model/Part

Digitizing Oscilloscope > 100 MHz Bandwidth HP 54600A

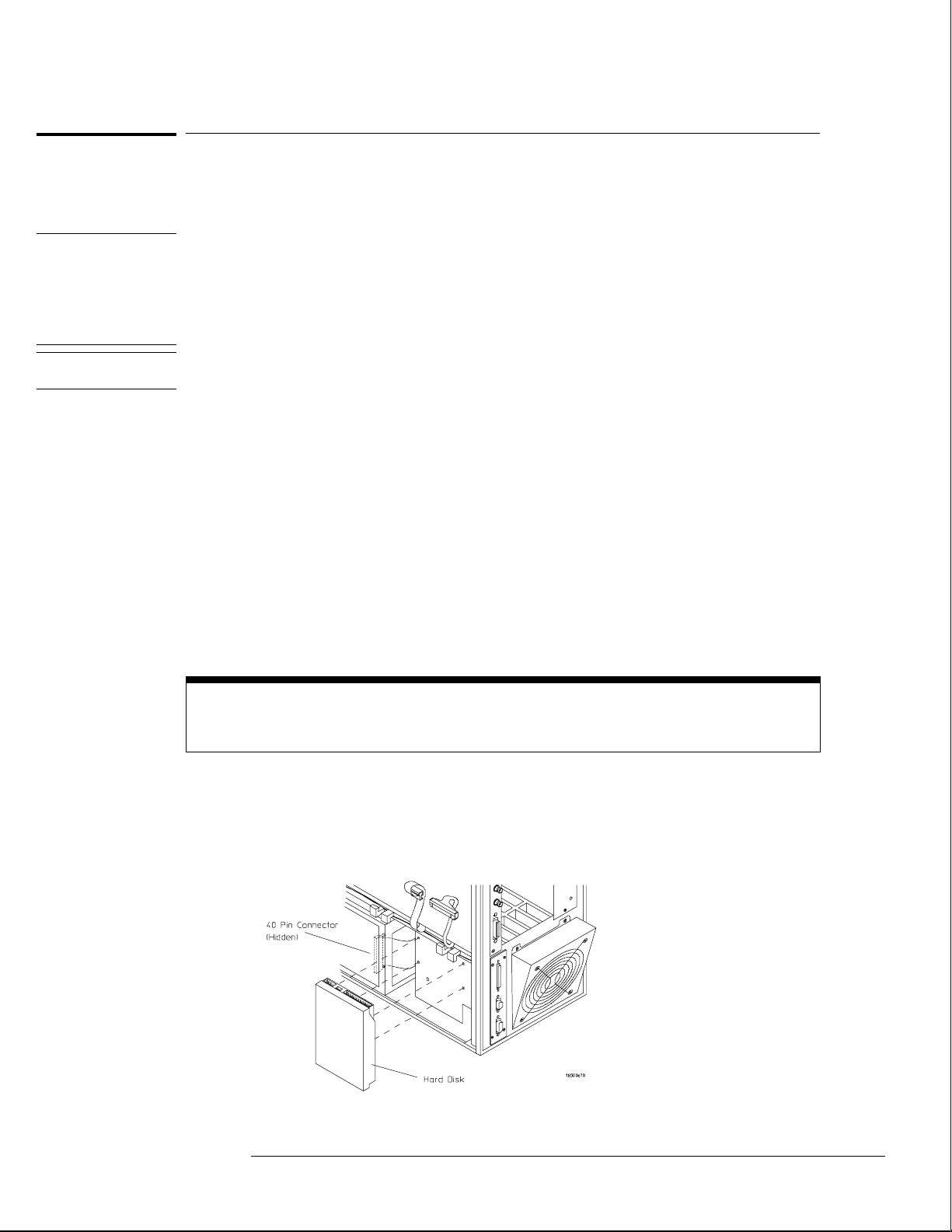

1 Turn off the instrument, then remove the power cable. Remove both the top and

bottom covers of the mainframe and set the mainframe on its side with the strap

handle facing up.

2 If an HP 16500L module is installed, then remove it from the mainframe.

a Disconnect the three cables plugged into the HP 16500L by reaching through the top

of the mainframe and removing the plugs.

b Remove the screws attaching the HP 16500L to the mainframe. Refer to chapter 6 for

more complete instructions to remove the HP 16500L.

Remove the four screws holding the hard disk drive and let the hard disk drive hang

3

by the power and the data cables. Do not let the hard disk drive contact the CPU

board.

4 Connect the power cable and apply power to the mainframe. When the hard disk

drive begins spinning, ensure the disk drive does not contact the CPU board. When

the mainframe has powered up, enter the Test System.

5 When the System Test menu appears, select Mainframe Test, then select Disk Test.

When the disk test menu appears, select Run-Repetitive.

6 Using an oscilloscope, check for activity on the pins. Probe the voltages on the hard

disk drive circuit board where the data cable connector is soldered. Pin 1 of the

connector is marked on the circuit board and is on the side of the connector closest

to the power cable.

5–27

Page 71

Troubleshooting

To test the hard disk drive voltages

Disk Drive Voltages

Pin Signal Description Pin Signal Description Pin Signal Description

1

2 Ground 16 Data 30 Ground

3 Data 17 Data 31 Interrupt Request

4 Data 18 Data 32 NC

5 Data 19 Ground 33 Address

6 Data 20 (connector key pin) 34 NC

7 Data 21 NC 35 Address

8 Data 22 Ground 36 Address

9 Data 23

10 Data 24 Ground 38

11 Data 25

12 Data 26 Ground 40 Ground

13 Data 27 I/O Cycle Extend

14 Data 28 NC

Reset 15 Data 29 +5 V

Write Strobe 37 Register Select

Register Select

Read Strobe 39 NC

7 If the hard disk drive signals appear as indicated, then the hard disk drive should be

replaced. If the signals do not appear, then either the data cable or the CPU board is

suspect. J12 of the CPU board can be probed in the same manner as described

above to check for the same signals.

8 Select Stop, and turn off the mainframe. Remove the power cable and replace the

faulty assembly.

9 Reassemble the mainframe.

5–28

Page 72

WARNING

Troubleshooting

To test the expansion frame interface

To test the expansion frame interface

This procedure is used during troubleshooting to isolate a failed interface component, the

interface cable, the expansion frame interface card, or the HP 16500L. The Option Board Test

in the performance verification software generates bit patterns across the data, address, and

strobe lines of the interface. Isolation is done by using an oscilloscope to check activity on the

address and data buses and the strobe signal lines.

Refer to chapter 6, "Replacing Assemblies," for instructions to remove or replace covers and

assemblies.

Hazard voltages exist on the power supply, the CRT, and the CRT driver board. This

procedure is to be performed by service-trained personnel aware of the hazards involved,

such as fire and electrical shock.

Equipment Required

Equipment Critical Specification Recommended

Model/Part Number

Oscilloscope 100MHz Bandwidth HP 54600A

Before beginning this procedure, verify that the HP 16500L interface is properly installed and that

the expansion frame interface card and interface cable are properly seated.

Set up the Expansion Frame

1

Remove power from the HP 16500B system and unplug the power cords from both

the mainframe and the expansion frame.

2 Set the expansion frame on its side with the strap handle facing up. Remove the

bottom cover from the expansion frame.

3 Plug the power cords into both the mainframe and expansion frame, then apply

power.

4 In the System Configuration menu, select Configuration. Select Test , then touch the

box to load the test system.

5 Select Test, then select Mainframe Tests in the pop-up menu. Select Option Board

Tests, then select Run-Repetitive.

5–29

Page 73

Troubleshooting

To test the expansion frame interface

Test the Expansion Interface Card

Ground the oscilloscope probe to the metal portion of the frame near the rear panel

1

of the expansion frame and check for TTL activity on the following pins.

U7 pins 11 through 18

•

U8 pins 2 through 9

•

U9 pins 5 through 9

•

If there is TTL activity on all of the pins indicated, then the signal paths from the

mainframe CPU board and the end of the expansion frame interface card are

considered working. Go to the next step.

If one or more of the signal lines do not show activity, then go to "Test the

Mainframe CPU Board" on the next page.

2 With the oscilloscope probe still grounded to the expansion frame, probe the

following pins.

U7 pins 2 through 9

•

U8 pins 11 through 18

•

U9 pins 11 through 15

•

If all of the signal lines show TTL activity, then go to the next step.

If one or more of the signal lines do not show TTL activity, then replace the

expansion frame interface board.

Bottom Side of Expansion Interface Card

5–30

Page 74

To test the expansion frame interface

3 Remove the probe ground from the frame, and reattach the probe ground to the

metal portion of the expansion frame near the front panel.

4 Probe the following pins.

U1 pins 2 through 9

•

U2 pins 2 through 9

•

U3 pins 5 through 9

•

If all of the signal lines show TTL activity, then go to the next step.

If one or more of the signal lines do not show TTL activity, then replace the

expansion frame interface board.

5 With the oscilloscope probe still grounded to the frame, probe the following pins.

U1 pins 11 through 18

•

U2 pins 11 through 18

•

U3 pins 11 through 15

•

If one or more of the signal lines do not show TTL activity, then replace the

expansion frame interface board.

Troubleshooting

Bottom Side of Expansion Interface Card

5–31

Page 75

Troubleshooting

To test the expansion frame interface

Test the Mainframe CPU Board

Remove power from the HP 16500B system and unplug the power cords from both

1

the mainframe and the expansion frame.

2 Reinstall the bottom cover on the expansion frame. Set the mainframe on its side

with the strap handle facing up, then remove the bottom cover.

3 Plug the power cords into both the mainframe and expansion frame, then apply

power.

4 In the System Configuration menu, select Configuration. Select Test, then touch the

box to load the test system.

5 Select Test, then select Mainframe Tests. Select Option Board Tests, then select

Run-Repetitive.

6 Ground the oscilloscope probe to the metal portion of the frame near the rear panel

of the mainframe and check for TTL activity on the following pins. Reference

designator J10 is indicated on the bottom side of the CPU board.

J10 pins 11 through 18

•

J10 pins 21 through 28

•

J10 pins 48 through 50

•

If there is TTL activity on all of the pins indicated, then the mainframe CPU board is

operational.

If one or more of the signal pins on the expansion frame interface board did not

show TTL activity, then the HP 16500L or the interface cable are suspect. Using an

ohm meter, check continuity of the interface cable.

If the interface cable is good, then replace the HP 16500L circuit board.

7 Remove power from the HP 16500B system, and unplug the power cords from both

the mainframe and expansion frame. Replace the faulty components, then

reassemble the mainframe.

5–32

Page 76

6

To remove and replace the

Optional modules or filler panels 6-3

Covers 6–4

Flexible disk drive 6–5

Power supply 6–6

Rear fan 6–8

Side fan 6–9

HP 16500L interface module 6–10

Hard disk drive 6–12

Microprocessor board (CPU) 6–13

SIMM memory module 6–14

Expansion interface board 6–15

Mother board 6–16

Front-Panel board 6–18

Color display assembly 6–19

To return assemblies 6–22

Replacing Assemblies

Page 77

Replacing Assemblies

This chapter contains the instructions for removing and replacing the assemblies of

the logic analysis system. Also in this chapter are instructions for returning

assemblies.

WARNING

CAUTION

CAUTION

Hazardous voltages exist on the power supply, the CRT, and the CRT driver board. To avoid

electrical shock, disconnect the power from the instrument before performing the following

procedures. After disconnecting the power, wait at least six minutes for the capacitors on

the power supply board and the CRT driver board to discharge before servicing the

instrument. However, if the AC LED on the power supply has any illumination, a significant

charge remains on the power supply capacitors.

Damage can occur to electronic components if you remove or replace assemblies when the

instrument is on or when the power cable is connected. Never attempt to remove or install

any assembly with the instrument on or with the power cable connected.

Replacement Strategy

These replacement procedures are organized as if disassembling the complete

instrument, from the first assembly to be removed to the last. Some procedures say

to remove other assemblies of the instrument, but do not give complete instructions.

Refer to the procedure for that specific assembly for the instructions.

Electrostatic discharge can damage electronic components. Use grounded wriststraps and

mats when performing any service to this logic analyzer.

Tools Required

#10, #15, #25 TORX screwdrivers

#2 posidrive screwdriver

8-mm nut driver

6–2

Page 78

Replacing Assemblies

To remove and replace optional modules or filler panels

To remove and replace optional modules or filler panels

1 To reconfigure your system later in this procedure, note the configuration of your

system.

Some modules for the Logic Analysis System require calibration if you move them to a

different slot.

Starting from the top, loosen the thumb screws on filler panels and cards in the

2

mainframe or the expansion frame. Starting from the top, pull the cards and filler

panels out.

All multicard modules will be cabled together. To prevent damage to the cables and

connectors, pull all multicard modules out together.

To replace the modules, reposition all cards and filler panels so that the endplates

3

overlap properly.

4 Firmly seat the bottom card into the backplane connector of the mainframe. Keep

applying pressure to the center of the card endplate while tightening the thumb

screws finger tight. Repeat for all cards and filler panels in a bottom to top order.

For correct air circulation, filler panels must be installed in all unused card slots. Correct air

circulation keeps the instrument from overheating. Keep any extra filler panels for future use.

See Also Service Guides for each individual module.

6–3

Page 79

Replacing Assemblies

To remove and replace the covers

To remove and replace the covers

There are four outside covers on the HP 16500B and on the HP 16501A, a top cover, a bottom

cover, and two side covers.

When removing the covers, note where the shielding braid is located. If the shielding braid

separates from the covers, reinstall it when replacing the covers. The shielding braid helps

the instrument meet EMI (electromagnetic interference) specifications.

Remove the four rear feet.

1

The screws connecting the feet to the frame are accessible through the holes in the end of the

feet.

Remove the top and bottom covers.

2

To remove the covers, loosen the screw in the rear of the covers. If a captive screw was used,

loosening the screw will pull the cover back. When the screw is completely loose from the

frame, slide the cover off. To remove the bottom cover, turn the instrument on its side, then

loosen the screw in the rear of the bottom cover.

Remove the side strap handle and side covers.

3

To remove the side strap handle, remove the two strap retaining screws. Slide the strap

handle cover off.

Note that the handle is rounded on the side closest to the instrument. Reinstall the handle

with the same side toward the instrument.

To remove a side cover, loosen the screw in the rear of the cover. (The side cover with a

strap handle will not have a rear screw.) If a captive screw was used, loosening the screw will

pull the cover back. When the screw is completely loose from the frame, slide the cover off.

Replace the covers by reversing this procedure.

4

6–4

Page 80

Replacing Assemblies

To remove and replace the flexible disk drive

To remove and replace the flexible disk drive

HP 16500B

Using previous procedures, remove the following assemblies:

1

Top cover

•

Remove the two disk drive mounting screws.

2

3 Slide the flexible disk drive assembly toward the rear panel until the assembly is out

of the instrument.

4 Disconnect the control cable for the disk drive.

5 Remove the mounting bracket from the bottom of the assembly.

6 Reverse this procedure to replace the flexible disk drive.

6–5

Page 81

Replacing Assemblies

To remove and replace the power supply

To remove and replace the power supply

WARNING

Hazardous voltages exist on the power supply. To avoid electrical shock, disconnect the

power from the instrument before performing the following procedures. After disconnecting

the power, wait at least six minutes for the capacitors on the power supply board to

discharge before servicing the instrument. However, if the AC LED on the power supply has

any illumination, a significant charge remains on the capacitors.

HP 16500B

Using previous procedures, remove the following assemblies:

1

Top cover

•

Flexible disk drive assembly

•

Optional module card or filler panel in the top slot of the card cage

•

2 Remove the power supply rear panel.

3 Disconnect the color display to power supply cable from the power supply.

4 Remove the four power supply mounting screws.

5 Pull the power supply towards the rear panel of the mainframe until the power