Page 1

About this Manual

We’ve added this manual to the Agilent website in an effort to help you support

your product. This manual is the best copy we could find; it may be incomplete

or contain dated information. If we find a more recent copy in the future, we will

add it to the Agilent website.

Support for Your Product

Agilent no longer sells or supports this product. Our service centers may be able

to perform calibration if no repair parts are needed, but no other support from

Agilent is available. You will find any other available product information on the

Agilent Test & Measurement website, www.tm.agilent.com.

HP References in this Manual

This manual may contain references to HP or Hewlett-Packard. Please note that

Hewlett-Packard's former test and measurement, semiconductor products and

chemical analysis businesses are now part of Agilent Technologies. We have

made no changes to this manual copy. In other documentation, to reduce

potential confusion, the only change to product numbers and names has been in

the company name prefix: where a product number/name was HP XXXX the

current name/number is now Agilent XXXX. For example, model number

HP8648A is now model number Agilent 8648A.

Page 2

SERVICE MANUAL

HP 16500A/16501A

Logic Analysis System

SERIAL NUMBERS

This manual applies directly to instruments

For additional information about serial numbers see

INSTRUMENTS COVERED BY THIS MANUAL

ÿ COPYRIGHT HEWLETT-PACKARD COMPANY/COLORADO SPRINGS DIVISION 1990

1900 GARDEN OF THE GODS ROAD, COLORADO SPRINGS, COLORADO U.S.A.

prefixed with serial number:

HP 16500A - 3048A and below

HP 16501A - 3050A

in Section 1.

ALL RIGHTS RESERVED

Manual Part No. 16500-90911 Printed in U.S.A. December1990

Page 3

HP 16500A/16501A - Contents

TABLE OF CONTENTS

Section I

General Information Page

1-1. Introduction .........................................................................................................................1-1

1-2. Instruments Covered by This Manual ................................................................................. 1-1

1-3. Safety Considerations ........................................................................................................1-2

1-4. Product Description ............................................................................................................1-2

1-5. Accessories Supplied .........................................................................................................1-2

1-6. Accessories Available .........................................................................................................1-3

1-7. Operating Characteristics ...................................................................................................1-3

1-8. Recommended Test Equipment .........................................................................................1-3

Section II

Installation Page

2-1. Introduction .........................................................................................................................2-1

2-2. Safety Considerations ........................................................................................................2-1

2-3. Initial Inspection ..................................................................................................................2-1

2-4. Operating Disk Installation ..................................................................................................2-1

2-5. Power Requirements ..........................................................................................................2-1

2-6. Line Voltage Selection ........................................................................................................2-1

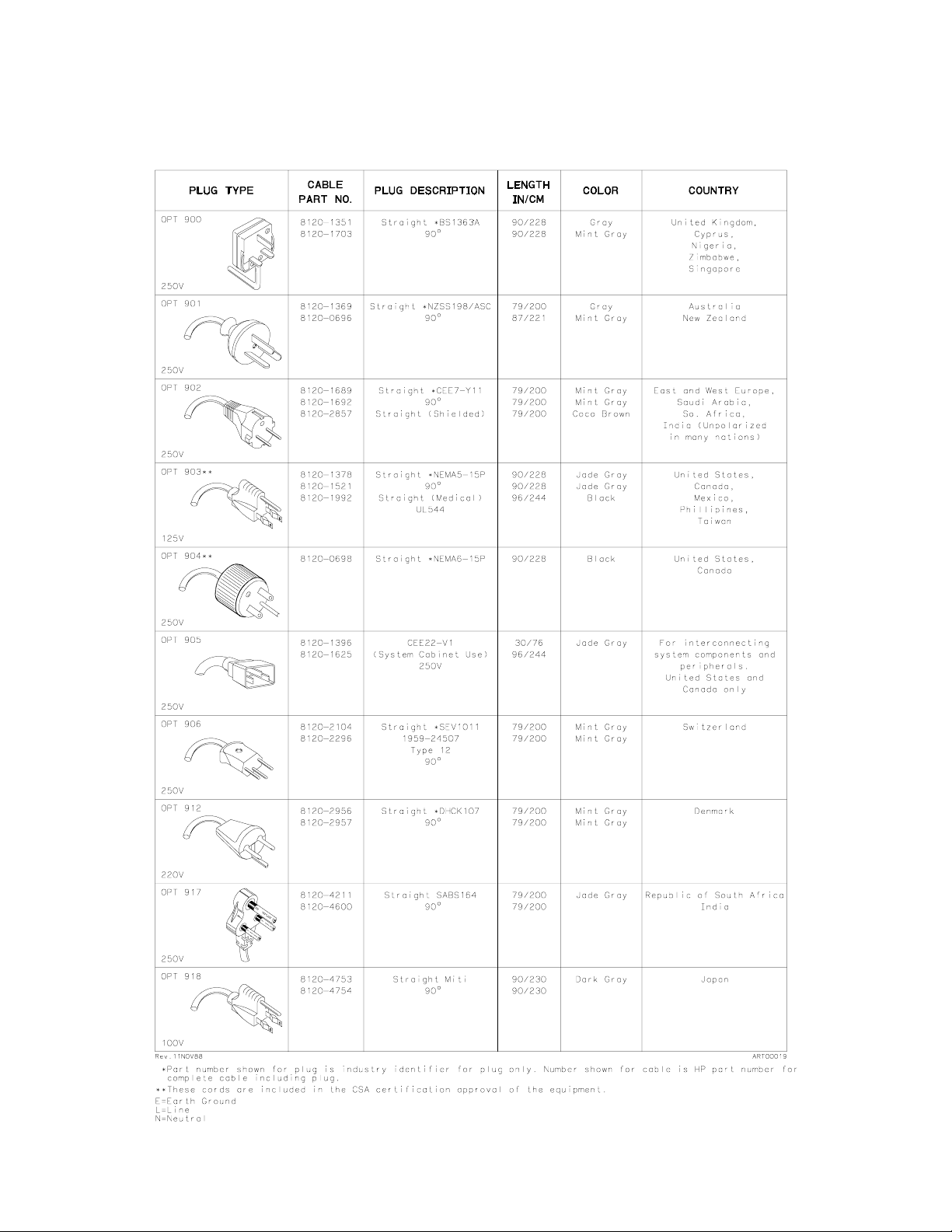

2-7. Power Cable .......................................................................................................................2-2

2-8. User Interface .....................................................................................................................2-4

2-9. HP-IB Interfacing ................................................................................................................2-5

2-10. HP-IB Address Selection ....................................................................................................2-5

2-11. HP-IB Interface Functions .................................................................................................. 2-8

2-12. RS-232C Interface ..............................................................................................................2-8

2-13. Baud Rate Selection ...........................................................................................................2-10

2-14. Degaussing the Display ......................................................................................................2-12

2-15. Operating Environment .......................................................................................................2-12

2-16. Storage and Shipment ........................................................................................................2-12

2-17. Packaging ...........................................................................................................................2-12

2-18. Tagging for Service ............................................................................................................2-12

2-19. Cleaning Requirements ...................................................................................................... 2-12

2-20. HP 16501A Expansion Frame Installation ..........................................................................2-13

Section III

Performance Tests Page

3-1. Introduction .........................................................................................................................3-1

ix

Page 4

HP 16500A/16501A - Contents

Section IV

Adjustments Page

4-1. Introduction .........................................................................................................................4-1

4-2. Degaussing the Display ......................................................................................................4-1

4-3. Safety Considerations ........................................................................................................4-1

4-4. Adjustment Test Patterns ...................................................................................................4-2

4-5. Color Display Module Adjustments .....................................................................................4-7

Section V

Replaceable Parts Page

5-1. Introduction .........................................................................................................................5-1

5-2. Abbreviations ......................................................................................................................5-1

5-3. Replaceable Parts List ........................................................................................................5-1

5-4. Exchange Assemblies ........................................................................................................5-1

5-5. Ordering Information ...........................................................................................................5-1

5-6. Direct Mail Order System ................................................................................................... 5-2

Section VI

Service Page

6-1. Introduction .........................................................................................................................6-1

6-2. Safety Considerations ........................................................................................................6-1

6-3. Service Test Equipment Required ...................................................................................... 6-1

6-4. Theory of Operation ............................................................................................................6-1

6-5. Power- Up Tests ................................................................................................................. 6-6

6-6. Mainframe Tests .................................................................................................................6-8

6-7. Troubleshooting ..................................................................................................................6-19

6-8. Repair .................................................................................................................................6-46

6-9. Tools Required ...................................................................................................................6-47

6-10. Cover Removal ...................................................................................................................6-47

6-11. Power Supply Replacement ...............................................................................................6-48

6-12. Mother Board Replacement ................................................................................................6-50

6-13. Rear Fan Replacement ......................................................................................................6-52

6-14. Side Fan Replacement .......................................................................................................6-54

6-15. Rear Disk Drive Replacement ............................................................................................6-56

6-16. Front Disk Drive Replacement ............................................................................................6-58

6-17. Microprocessor Board Replacement ..................................................................................6-60

6-18. Front-Panel Board Replacement ........................................................................................6-62

6-19. Color Display Module Replacement ...................................................................................6-64

6-20. Expansion Interface Board Replacement ........................................................................... 6-70

6-21. Mainframe Interface Board Replacement ...........................................................................6-72

x

Page 5

HP 16500A/16501A - Contents

LIST OF TABLES

Table Title Page

1-1. Operating Characteristics ...................................................................................................1-4

1-2. Recommended Test Equipment .........................................................................................1-7

2-1. HP 16500A HP-IB Functions ..............................................................................................2-8

2-3. RS-232C Signal Definitions ................................................................................................2-9

5-1. Reference Designator and Abbreviations ........................................................................... 5-3

5-2. HP 16500A Replaceable Parts ........................................................................................... 5-5

5-3. HP 16501A Replaceable Parts ........................................................................................... 5-11

6-1. Cable Pin Numbers ............................................................................................................ 6-34

6-2. Power Supply Voltages ...................................................................................................... 6-38

6-3. Replaceable Assemblies ....................................................................................................6-46

LIST OF FIGURES

Figure Title Page

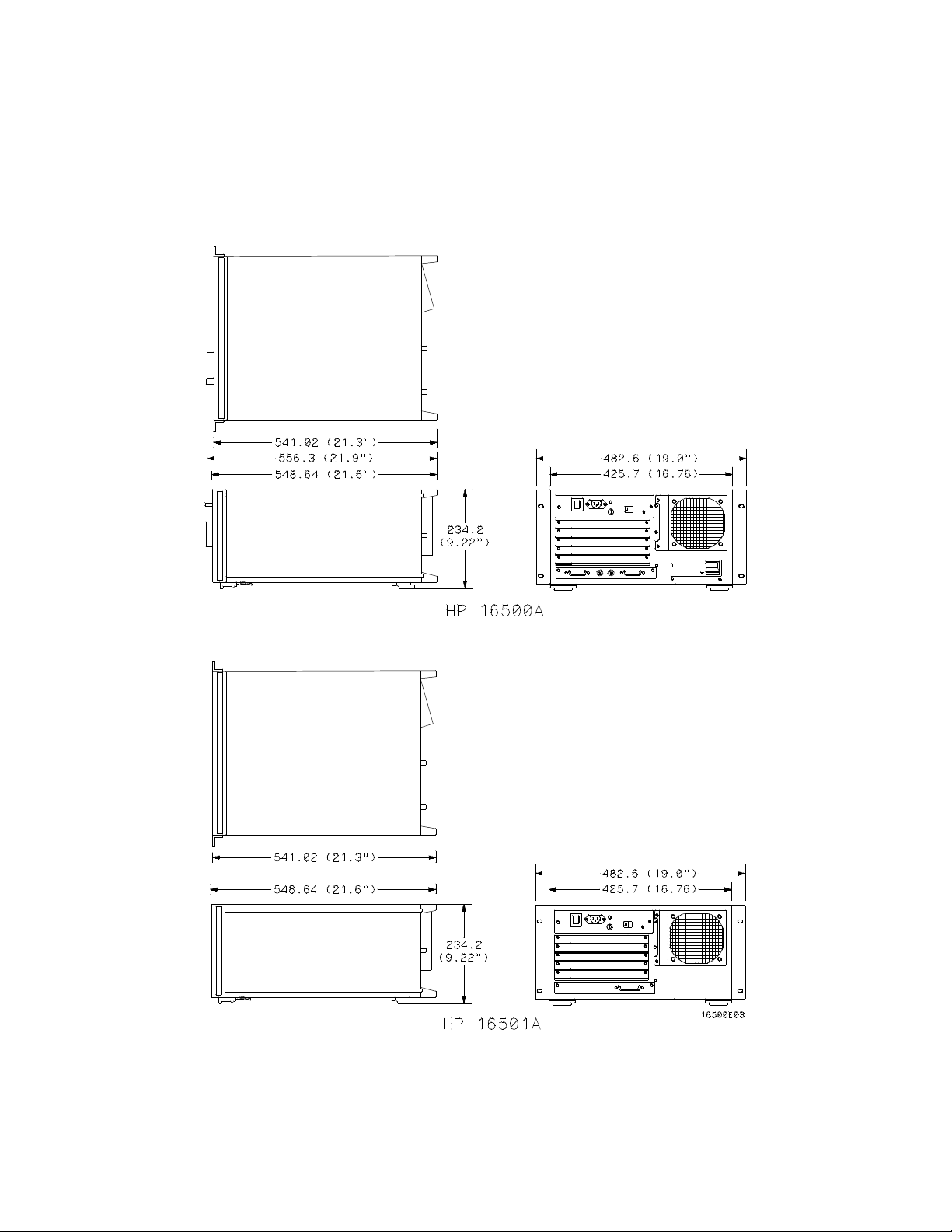

1-1. Dimensional Detail ..............................................................................................................1-6

2-1. Line Voltage Selection ........................................................................................................2-2

2-2. Power Cord Configurations ................................................................................................2-3

2-3. HP 16500A User Interface Devices .................................................................................... 2-4

2-4. HP-IB Interface Connector ................................................................................................. 2-5

2-5. System Configuration Menu ...............................................................................................2-6

2-6. HP-IB Configuration Menu ..................................................................................................2-6

2-7. HP-IB Configuration with Keypad .......................................................................................2-7

2-8. System Configuration Menu ...............................................................................................2-10

2-9. RS-232C Configuration Menu ............................................................................................ 2-10

2-10. Baud Rate Pop-Up Menu ................................................................................................... 2-11

2-11. Configuration ......................................................................................................................2-13

2-12. Endplate Overlap ................................................................................................................2-14

2-13. Endplate Overlap ................................................................................................................2-15

2-14. System Configuration Menu ...............................................................................................2-16

4-1. System Configuration Menu ...............................................................................................4-2

4-2. Accessing the Test System ................................................................................................4-2

4-3. Loading the Test System .................................................................................................... 4-3

4-4. Test System Configuration .................................................................................................4-3

4-5. Selecting Mainframe Test Menu ......................................................................................... 4-4

4-6. Mainframe Test Menu .........................................................................................................4-4

4-7. Selecting the Test Patterns ................................................................................................ 4-5

4-8. Exiting Mainframe Test System .......................................................................................... 4-5

4-9. Exiting Test System Configuration ......................................................................................4-6

xi

Page 6

HP 16500A/16501A - Contents

Figure Title Page

4-10. System Configuration .........................................................................................................4-6

4-11. CRT Module Adjustment Flow Diagram .............................................................................4-8

4-12. PIN AMP Adjustment ..........................................................................................................4-9

4-13. Bottom Rail Removal ..........................................................................................................4-10

4-14. PIN PHASE Adjustment .....................................................................................................4-11

4-15. Purity Magnet Centering .....................................................................................................4-13

4-16. Purity Magnet Adjustment Raster .......................................................................................4-14

4-17. Landing and Purity Adjustment Guide ................................................................................4-15

4-18. Static Convergence ............................................................................................................4-16

4-19. Y BOW Adjustment .............................................................................................................4-17

4-20. Y BOW CROSS Adjustment ...............................................................................................4-17

4-21. V.STAT TOP Adjustment ....................................................................................................4-18

4-22. V.STAT BOTTOM Adjustment ............................................................................................4-18

4-23. H.AMP Adjustment .............................................................................................................4-19

4-24. H.TILT Adjustment ..............................................................................................................4-19

5-1. HP 16500A Assembly Parts ............................................................................................... 5-4

5-2. HP 16500A Chassis Parts ..................................................................................................5-6

5-3. HP 16501A Assembly Parts ............................................................................................... 5-10

5-4. HP 16501A Chassis Parts ..................................................................................................5-12

6-1. HP 16500A/16501A System Overview ............................................................................... 6-2

6-2. Microprocessor Block Diagram ...........................................................................................6-4

6-3. System Configuration .........................................................................................................6-8

6-4. Accessing the Test System ................................................................................................6-9

6-5. Loading the Test System Software .....................................................................................6-9

6-6. Test System Configuration .................................................................................................6-10

6-7. Mainframe Test Menu .........................................................................................................6-10

6-8. All System Test ...................................................................................................................6-11

6-9. Selecting the Color Display Patterns ..................................................................................6-12

6-10. Mainframe Test Menu .........................................................................................................6-13

6-11. ROM Test Screen ...............................................................................................................6-13

6-12. Choosing the Single or Repetitive Mode ............................................................................6-14

6-13. ROM Test with Test Results ............................................................................................... 6-14

6-14. Exiting the Mainframe Test System ....................................................................................6-15

6-15. Exiting Test Configuration ..................................................................................................6-15

6-16. Reloading the Mainframe System ......................................................................................6-16

6-17. Troubleshooting Flowchart 1 ..............................................................................................6-20

6-18. Troubleshooting Flowchart 2 ..............................................................................................6-21

6-19. Troubleshooting Flowchart 3 ..............................................................................................6-22

6-20. Troubleshooting Flowchart 3 (continued) ...........................................................................6-23

6-21. Troubleshooting Flowchart 4 ..............................................................................................6-24

6-22. Troubleshooting Flowchart 5 ..............................................................................................6-25

6-23. Troubleshooting Flowchart 6 ..............................................................................................6-26

6-24. Troubleshooting Flowchart 7 ..............................................................................................6-27

6-25. Troubleshooting Flowchart 8 ..............................................................................................6-28

xii

Page 7

HP 16500A/16501A - Contents

Figure Title Page

6-26. Troubleshooting Flowchart 9 ..............................................................................................6-29

6-27. Troubleshooting Flowchart 10 ............................................................................................6-30

6-28. Troubleshooting Flowchart 11 ............................................................................................6-31

6-29. Troubleshooting Flowchart 12 ............................................................................................6-32

6-30. Color Module to Microprocessor Cable ..............................................................................6-35

6-31. Horizontal and Vertical Sync Signals ..................................................................................6-35

6-32. Power Supply Check ..........................................................................................................6-37

6-33. Power Supply Pins .............................................................................................................6-39

6-34. HP 1651B Format Menu ..................................................................................................... 6-41

6-35. Probe Tip Connections .......................................................................................................6-41

6-36. Expander Test Screen ........................................................................................................6-42

6-37. HP 1651B Test Screen ....................................................................................................... 6-43

6-38. Probe Tip Connections .......................................................................................................6-44

6-39. Power Supply Replacement ...............................................................................................6-49

6-40. Mother Board Replacement ................................................................................................6-51

6-41. Rear Fan Replacement ......................................................................................................6-53

6-42. Side Fan Replacement .......................................................................................................6-55

6-43. Rear Disk Drive Replacement ............................................................................................6-57

6-44. Front Disk Drive Replacement ............................................................................................6-59

6-45. Microprocessor Board Replacement ..................................................................................6-61

6-46. Front-Panel Board Replacement ........................................................................................6-63

6-47. Color Display Module Removal ..........................................................................................6-65

6-48. Transferring Parts ...............................................................................................................6-67

6-49. Color Display Module Installation ....................................................................................... 6-69

6-50. Expansion Interface Board Replacement ........................................................................... 6-71

6-51. Endplate Overlap ................................................................................................................6-72

6-52. Endplate Overlap ................................................................................................................6-72

6-53. Mainframe Interface Board Replacement ...........................................................................6-73

xiii

Page 8

TABLE OF CONTENTS

Section I

General Information Page

1-1. Introduction......................................................................................................................1-1

1-2. Instruments Covered by This Manual..............................................................................1-1

1-3. Safety Considerations.....................................................................................................1-2

1-4. Product Description.........................................................................................................1-2

1-5. Accessories Supplied......................................................................................................1-2

1-6. Accessories Available .....................................................................................................1-3

1-7. Operating Characteristics................................................................................................1-3

1-8. Recommended Test Equipment......................................................................................1-3

Page 9

1-1. Introduction

HP 16500A/16501A - General Information

SECTION I

General Information

This service manual explains how to test, adjust,

and service the Hewlett-Packard 16500A/16501A

Logic Analysis System. This manual is divided

into six sections as follows:

I - General Information

II - Installation

III - Performance Tests

IV - Adjustments

V - Replaceable Parts

VI- Service

The General Information Section includes a

description of the HP 16500A/16501A, its

specifications, options, available accessories, and

recommended test equipment for maintaining the

instrument.

Information for operating, programming, and

interfacing with the HP 16500A/16501A is

contained in the Operating and Programming

manual set supplied with each instrument.

Shipped with this manual are service manuals for

each module ordered with the HP

16500A/16501A. To complete the service

documentation for your system, unpack the

module service manuals and place them in the

3-ring binder of this manual.

1-2. Instruments Covered by This

Manual

The instrument serial number is on the rear panel

of the instrument. Hewlett-Packard uses a

two-part serial number consisting of a four-digit

prefix and a five-digit suffix separated by a letter

(for example, 0000A00000). The prefix is the

same for all identical instruments and the suffix is

different for each instrument. Prefix changes are

for parts compatibility and for instrument tracking.

The only time the manual will be updated to reflect

a new prefix is for parts compatibility. This manual

applies directly to instruments with the serial prefix

shown on the title page.

1-1

Page 10

HP 16500A/16501A - General Information

1-3. Safety Considerations

Review the instrument and manual for safety

markings and instructions before operating it.

Specific warnings, cautions, and instructions are

placed wherever applicable throughout the

manual. These precautions must be observed

during all phases of operation, service, and repair

of the instrument. Failure to comply with these

precautions or with specific warnings elsewhere in

this manual violates safety standards of design,

manufacture, and intended use of this instrument.

Hewlett-Packard assumes no liability for the

customer’s failure to comply with these safety

requirements.

1-4. Product Description

The HP 16500A is the mainframe of the HP Logic

Analysis System. The HP 16501A is an

expansion frame of the HP Logic Analysis System.

The HP 16500A/16501A is of modular structure

using plug-in cards with a wide range of data

acquisition and stimulus capabilities.

This allows the user to configure the system with

only the necessary modules for a particular

application.

Some of the key features of the

HP 16500A/16501A include the following:

• Modular mainframe with five card slots.

• Nine-inch color monitor.

1-5. Accessories Supplied

The following accessories are supplied with the

HP 16500A/16501A:

• One power cord. See section 2,

"Installation," for the available power cords.

• One

• One

• One

• One

• One

• Rear panel filler panels. The quantity of filler

• Disk pouch containing composite software.

• Disk pouch containing systemized operating

• One RS-232C loopback connector.

• One blank disk.

HP 16500A/16501A Logic Analysis

System Operation Reference Manual

.

HP 16500A/16501A Logic Analysis

System Programming Reference Manual

HP 16500A/16501A Logic Analysis

System Service Manual

.

Feeling Comfortable With Logic

Analyzers

guide.

Feeling Comfortable With Digitizing

Oscilloscopes

guide.

panels depends on how many modules are

ordered with the HP 16500A/16501A.

system software.

.

• The touchscreen user interface.

• Dual 3.5-inch disk drives.

• Intermodule triggering and time correlation of

acquired data.

• HP-IB and RS-232C interfaces for hardcopy

output to a printer or controller interface.

• Expansion frame, which expands the total

system card slots to nine.

1-2

Page 11

HP 16500A/16501A - General Information

1-6. Accessories Available

The accessories available for the

HP 16500A/16501A include the following:

• HP 46060A Mouse.

• HP E2427A Keyboard.

• HP-IB Cables: HP 10833A, 10833B,

10833C, 10833D.

• Hewlett-Packard Printers (see table 1-1).

• Extra Operating and Programming Manual

(Option 910).

• HP 1008A Testmobile.

Option 006 Power Strip and Cabinet.

• Extended Repair Service (Option W30).

• RS-232C DTE to DTE Cable. Used for

connecting the HP 16500A to printers and

controllers. HP Part Number 13242-60010.

1-7. Operating Characteristics

Table 1-1 is a listing of the instrument’s operating

characteristics. These are not specifications, but

are typical operating characteristics included as

additional information for you.

1-8. Recommended Test Equipment

The equipment required to test and maintain the

HP 16500A/16501A is listed in table 1-2.

Other equipment may be substituted if it meets or

exceeds the critical specifications listed in the

table.

• RS-232C DTE to DCE Cable. Used for

connecting the HP 16500A to modems and

data switch. HP Part Number 13242-60001.

• HP 74240A/74240B CAE Software.

• Rackmount Kit HP Part Number 5061-9679.

• Transit Case HP Part Number 9211-2658.

• Hewlett-Packard Plug-In Modules with data

acquisition, stimulus, pattern generator, and

oscilloscope capabilities.

• Blank 3.5-inch disks (box of 10) HP Part

Number 92192A.

For more information about plug-in modules or

accessories, contact the nearest Hewlett-Packard

Sales Office.

1-3

Page 12

HP 16500A/16501A - General Information

Table 1-1. HP 16500A/16501A Operating Characteristics

Built-in Disk Drives

File Types: System software; performance verification; configuration (contains instrument configura-

tion, data, pointer to inverse assembler file); inverse assembler; auto-configuration, calibration.

Autoload Designation: A predefined configuration file can be loaded at power-up.

Disk Operations: Store, load, copy, duplicate disk, pack disk, rename, purge, and format disk.

Programmability

Instrument settings and operating modes, including automatic measurements, may be remotely programmed via RS-232C or HP-IB (IEEE-488).

Hardcopy Output

Printers Supported: HP ThinkJet, HP QuietJet, HP LaserJet, HP PaintJet, HP Deskjet, Epson and

Epson-compatible (e. g. Epson FX-80) via RS-232C or HP-IB.

RS-232C Configurations: Protocols: XON/XOFF, Hardware; Data bits: 8; Stop bits: 1, 1 1/2, 2; Par-

ity: none, odd, or even; Baud rates: 110, 300, 600, 1200, 2400, 4800, 9600, 19200.

Input/Output Rear Panel BNCs:

Input BNC: Labeled Port-in. Input signal must drive four LS TTL loads, active high.

Output BNC: Labeled Port-out. Output signal is active high, TTL output level: high ≥ 2V into

50 Ohms, low ≤ 0.4V into 50 Ohms.

1-4

Page 13

Table 1-1. HP 16500A/16501A Operating Characteristics (Continued)

Operating Environment

Temperature:

Instrument: 0 °Cto55 °C(+32°F to 131 °F).

Disk Media: 10 °Cto50 °C(+50 °F to 122 °F).

Probes and Cables: 0 °Cto65°C(+32°F to 149 °F).

Humidity:

Instrument: up to 95% relative humidity at 40 °C (104 °F).

Disk media: 8% to 80% relative humidity at 40 °C (104 °F).

Altitude:

Up to 4600 m (15 000 ft).

HP 16500A/16501A - General Information

Vibration:

Operating: Random vibration 5-500Hz, 10 minutes per axis, ~ 0.3g (rms).

Non-operating: Random vibration 5-500Hz, 10 minutes per axis, ~ 2.4 g (rms);

Weight

HP 16500A

Net: 18.1 kg (40 lbs) + (0.7 kg (1.6 lbs) x number of optional cards installed).

Shipping: 25.9 kg (57 lbs) + (3.6 kg (8 lbs) x number of optional cards installed).

HP 16501A

Net: 12.2 kg (27 lbs) + (0.7 kg (1.6 lbs) x number of optional cards installed).

Shipping: 19.9 kg (44 lbs) + (3.6 kg (8 lbs) x number of optional cards installed).

Power Requirements:

and swept sine resonant search, 5-500Hz, 0.75g (0-peak),

5 minute dwell at 4 resonances per axis.

115 V/230 V, 48 to 66 Hz, 475 W max.

Dimensions:

Refer to figure 1-1 for dimensional detail.

1-5

Page 14

HP 16500A/16501A - General Information

1-6

Figure 1-1. Dimensional Detail

Page 15

HP 16500A/16501A - General Information

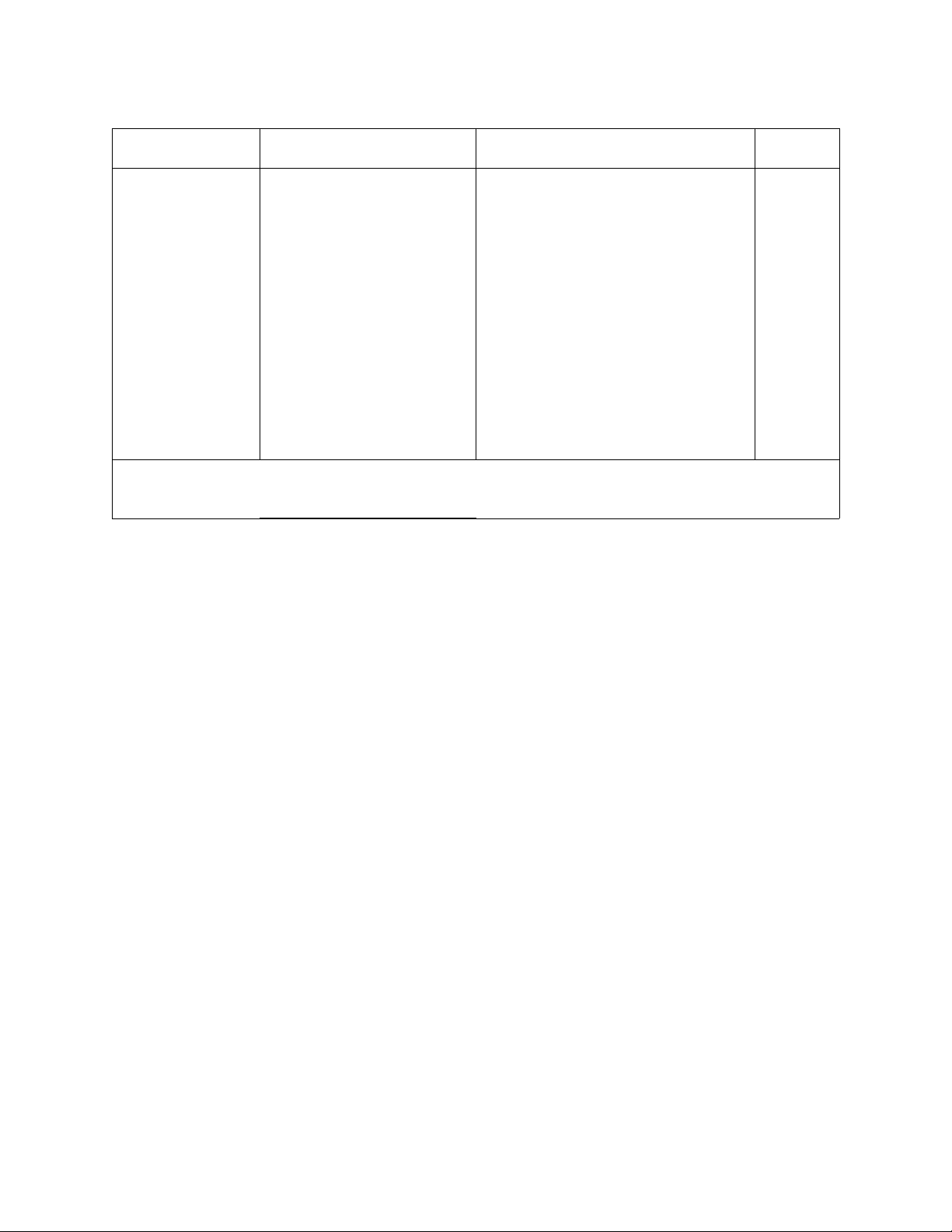

Table 1-2. Recommended Test Equipment

Instrument Critical Specification Recommended Model Use*

State Analyzer 10 MHz Acquisition Speed

22 Channels

Oscilloscope 100 MHz Bandwidth HP 54501A T

RS-232C

Loopback

Connector

Voltmeter 3 1/2 Digit Resolution HP 3468A T

* A=Adjustments P=Performance Tests T=Troubleshooting

HP 1651B T

HP Part No.

01650-63202

T

1-7

Page 16

TABLE OF CONTENTS

Section II

Installation Page

2-1. Introduction......................................................................................................................2-1

2-2. Safety Considerations.....................................................................................................2-1

2-3. Initial Inspection...............................................................................................................2-1

2-4. Operating Disk Installation ..............................................................................................2-1

2-5. Power Requirements.......................................................................................................2-1

2-6. Line Voltage Selection.....................................................................................................2-1

2-7. Power Cable....................................................................................................................2-2

2-8. User Interface..................................................................................................................2-4

2-9. HP-IB Interfacing.............................................................................................................2-5

2-10. HP-IB Address Selection.................................................................................................2-5

2-11. HP-IB Interface Functions...............................................................................................2-8

2-12. RS-232C Interface...........................................................................................................2-8

2-13. Baud Rate Selection........................................................................................................2-10

2-14. Degaussing the Display...................................................................................................2-12

2-15. Operating Environment ...................................................................................................2-12

2-16. Storage and Shipment.....................................................................................................2-12

2-17. Packaging........................................................................................................................2-12

2-18. Tagging for Service.........................................................................................................2-12

2-19. Cleaning Requirements...................................................................................................2-12

2-20. HP 16501A Expansion Frame Installation.......................................................................2-13

Page 17

HP 16500A/16501A - Installation

SECTION II

Installation

2-1. Introduction

This section contains information and instructions

necessary for setting up the HP 16500A/16501A

Logic Analysis System. This includes inspection

procedures, power requirements, hardware

connections and configurations, and packaging

information.

2-2. Safety Considerations

The safety symbols used with Hewlett-Packard

instruments are illustrated in the front of this

manual. WARNING and CAUTION symbols and

instructions should be reviewed before operating

the instrument. These warnings and cautions

must be followed for your own protection and to

avoid damage to the instrument.

2-3. Initial Inspection

Inspect the shipping container for damage. If the

shipping container or cushioning material is

damaged, it should be kept until the contents of

the shipment have been checked for

completeness and the instrument has been

checked mechanically and electrically. The

contents of the shipment should be as listed in

"Accessories Supplied" in section 1. If the

contents are incomplete, if there is mechanical

damage or defect, or if the instrument does not

operate properly, notify the nearest

Hewlett-Packard Sales Office. If the shipping

container is damaged, or the cushioning material

shows signs of stress, notify the carrier as well as

the Hewlett-Packard Sales Office. Keep the

shipping material for carrier’s inspection. The

Hewlett-Packard Sales Office will arrange for

repair or replacement at Hewlett-Packard’s option

without waiting for a claim settlement.

2-4. Operating Disk Installation

The HP 16500A is shipped with yellow protective

disks in each disk drive. Before applying power to

the mainframe, remove the protective disks from

the front and rear disk drives, then install the

operating disk in one of the disk drives. Reinstall

the protective disks whenever the instrument is

transported.

2-5. Power Requirements

The HP 16500A and the HP 16501A each require

a power source of 115 Vac or 230 Vac, 48 to 66

Hz, 475 W maximum.

2-6. Line Voltage Selection

The instrument may be damaged if the Line

Voltage Select switch is not properly set.

When shipped from Hewlett-Packard, the Line

Select switch is set and an appropriate fuse is

installed for operating the instrument in the

country of destination.

2-1

Page 18

HP 16500A/16501A - Installation

To operate the instrument from a power source

other than the one set at Hewlett-Packard,

proceed as follows:

1. Turn the front panel switch to STBY and

turn the rear panel power switch to OFF.

Remove the power cord from the instrument.

2. Replacethemainfusewitha5A/250V

fuse for 230 V operation, or a 10 A/125 V

fuse for 115 V operation.

3. Set the rear panel Line Select switch for the

desired line voltage. See figure 2-1.

4. Reconnect the power cord, turn on the rear

panel power switch, then continue normal

operation.

2-7. Power Cable

This instrument is equipped with a three-wire

power cable. When connected to an appropriate

ac power outlet, this cable grounds the instrument

cabinet. The type of power cable plug shipped

with the instrument depends on the country of

destination. See figure 2-2 for option numbers of

available power cables and plug configurations.

Line Select Switch

2-2

Figure 2-1. Line VoltageSelection

Page 19

Figure 2-2. Power Cord Configurations

HP 16500A/16501A - Installation

2-3

Page 20

HP 16500A/16501A - Installation

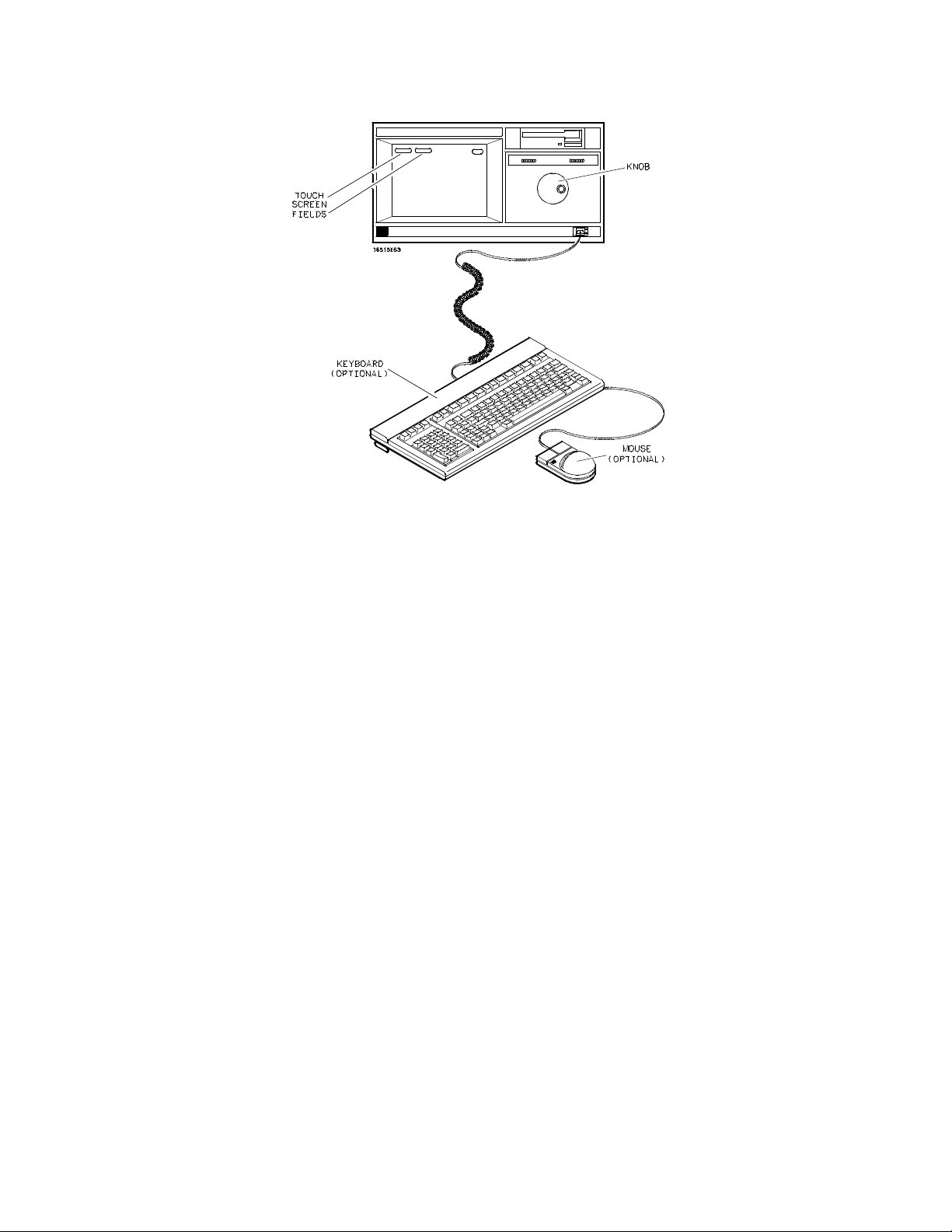

Figure 2-3. HP 16500A User Interface Devices

2-8. User Interface

Four devices may be used to interface with the

HP 16500A and all installed modules, the

touchscreen, the front panel knob, the optional

keyboard, and the optional mouse. See figure 2-3.

For complete operating information refer to the

HP 16500A/16501A Logic Analysis System

Operation Reference Manual

Manual for each module installed.

The Touchscreen.

The touchscreen interface provides the main front

panel control or access to the menus. By touching

the appropriate field, you can access other menus,

configure the HP 16500A for making

measurements, and enter or change alphanumeric

data.

The Front Panel Knob

The front panel knob is used to increment or

decrement numeric fields and to roll the display.

Rolling the display means scrolling through

information on screen.

and the Operating

The Optional Mouse

The mouse is an optional user interface accessory

(HP 46060A). The mouse functions in the same

way as the touchscreen and the knob. Moving it

about on a hard, flat surface will move the cursor

over the entire screen. To select a field, connect

the mouse to the front panel HIL connector and

move the mouse until the cursor rests in the

desired field. Press the left button of the mouse to

complete the selection of the field. To duplicate

the knob function, press and hold the right button

of the mouse and move it over the desktop. When

the correct numerical value or the correct function

has been selected, stop moving the mouse and

release the right button.

The Optional Keyboard

The keyboard is an optional user interface

accessory (HP E2427A). The keyboard can be

used interchangeably with the knob, the

touchscreen, and the mouse for all menu

applications.

2-4

Page 21

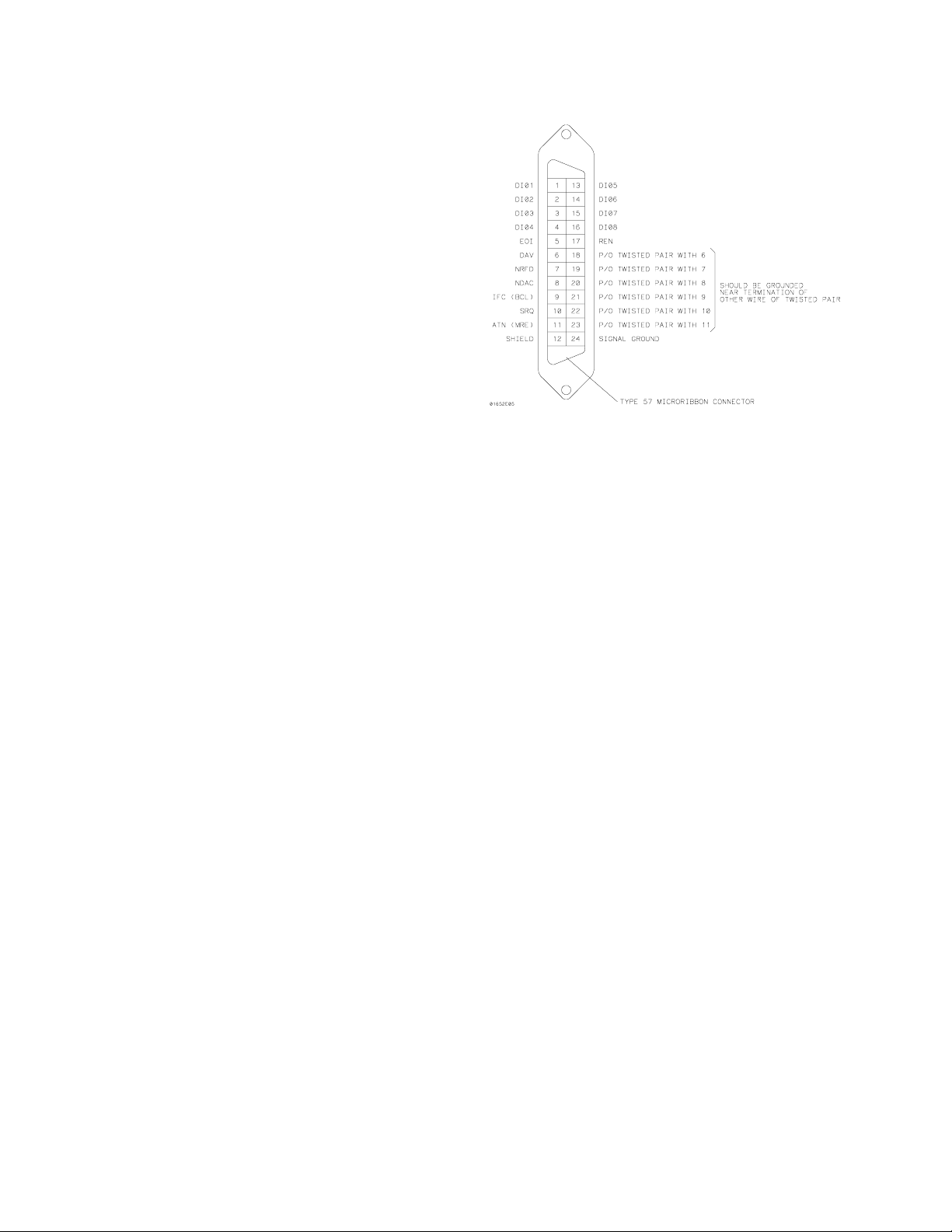

2-9. HP-IB Interfacing

The Hewlett-Packard Interface Bus (HP-IB) is

Hewlett-Packard’s implementation of IEEE

Standard 488-1978, "Standard Digital Interface for

Programmable Instrumentation." HP-IB is a

carefully defined interface that simplifies the

integration of various instruments and computers

into systems. The interface makes it possible to

transfer messages between two or more HP-IB

compatible devices. HP-IB is a parallel bus of 16

active signal lines divided into three functional

groups according to function.

Eight signal lines, called data lines, are in the first

functional group. The data lines are used to

transmit data in coded messages. These

messages are used to program the instrument

function, to transfer measurement data, and to

coordinate instrument operation. Input and output

of all messages, in bit parallel-byte serial form, are

also transferred on the data lines. A 7-bit ASCII

code normally represents each piece of data.

HP 16500A/16501A - Installation

Figure 2-4. HP-IB Interface Connector

2-10. HP-IB Address Selection

Data is transferred by means of an interlocking

"handshake" technique, which permits data

transfer (asynchronously) at the rate of the

slowest active device used in that transfer. The

data byte control lines coordinate the handshaking

and form the second functional group.

The remaining five general interface management

lines (third functional group) are used to manage

the devices connected to the HP-IB. This includes

activating all connected devices at once and

clearing the interface.

The connections to the HP-IB connector on the

rear panel are shown in figure 2-4.

Each instrument connected to the HP-IB interface

bus requires a unique address. The address

provides a method for the system computer to

select individual instruments on the bus. The

address of the HP 16500A defaults at power-on to

decimal "07". The corresponding ASCII code is a

listen address of "’" and a talk address of "G".

2-5

Page 22

HP 16500A/16501A - Installation

To change the address of the HP 16500A, proceed as follows:

1. With the operating system disk in one of the disk drives, turn the instrument on to obtain the System

Configuration menu. See figure 2-5.

Figure 2-5. System Configuration Menu

2. Touch the HP-IB field to obtain the HP-IB Configuration Menu. See figure 2-6.

Figure 2-6. HP-IB Configuration Menu

2-6

Page 23

HP 16500A/16501A - Installation

3. Rotate the knob to select the desired HP-IB address. The address number is shown in the HP-IB

Address field. The address number may also be entered via the keypad. Touch the HP-IB field

again to bring up the keypad. Select the new number using the keypad, then touch Done to enter

Figure 2-7. HP-IB Configuration with Keypad

address. See figure 2-7.

4. Touch Done to exit the HP-IB Configuration menu.

the new selected

2-7

Page 24

HP 16500A/16501A - Installation

2-11. HP-IB Interface Functions

The HP-IB interface offers 10 functions to support communications. Table 2-1 lists the HP-IB functions

that the HP 16500A uses.

Table 2-1. HP 16500A HP-IB Functions

HP 16500A

Mne-

monic Interface Function Name

SH

AH

T

L

SR

RL

PP

DC

DT

C

E

Source Handshake

Acceptor Handshake

Talker (or TE=Extended Talker)

Listener (or LE=Extended Listener)

Service Request

Remote Local

Parallel Poll

Device Clear

Device Trigger

Any Controller

Electrical Characteristics

Implemen-

tation

SH1

AH1

T5

L4

SR1

RL1

PP1

DC1

DT1

C0

E2

2-12. RS-232C Interface

The HP 16500A interfaces with RS-232C communication lines through a standard 25-pin D connector.

The HP 16500A is compatible with RS-232C protocol.

When a hardwire handshake method is used, the Data Terminal Ready (DTR) line (pin 20 on the Computer/Modem connector) is used to signal whether space is available in the logical I/O buffer for more

data. Table 2-2 shows the RS-232C signal definitions.

2-8

Page 25

Table 2-2. RS-232C Signal Definitions

Pin No. Function

1

Protective Ground

HP 16500A/16501A - Installation

RS-232C

Standard Signal Direction and Level

AA

Not applicable

2

3

4

5

6

7

8

Transmitted Data (TD)

Received Data (RD)

Request to Send (RTS)

Clear to Send (CTS)

Data Set Ready (DSR)

Signal Ground (SGND)

Data Carrier Detect (DCD)

BA

BB

CA

CB

CC

AB

CF

Data from Mainframe

High = Space = "0" = +12V

Low = Mark = "1"= -12V

Data to Mainframe

High = Space = "0" = +3V to +25V

Low = Mark = "1" = -3V to -25V

Signal from Mainframe

High = ON = +12V

Low = OFF = -12V

Signal to Mainframe

High = ON = +3V to +12V

Low = OFF = -3V to -25V

Signal to Mainframe

High = ON = +3V to +25V

Low = OFF = -3V to -25V

Not applicable

Signal to Mainframe

High = ON = +3V to +25V

Low = OFF = -3V to -25V

20

23

Data Terminal Ready (DTR)

Data Signal Rate Selector

CD

CH/CI

Signal from Mainframe

High = ON = +12V

Low = OFF = -12V

Signal from Mainframe

Always High = ON = +12V

2-9

Page 26

HP 16500A/16501A - Installation

2-13. Baud Rate Selection

The baud rate of the HP 16500A is set at power-on for 9600 baud. To change the baud rate, proceed as

follows:

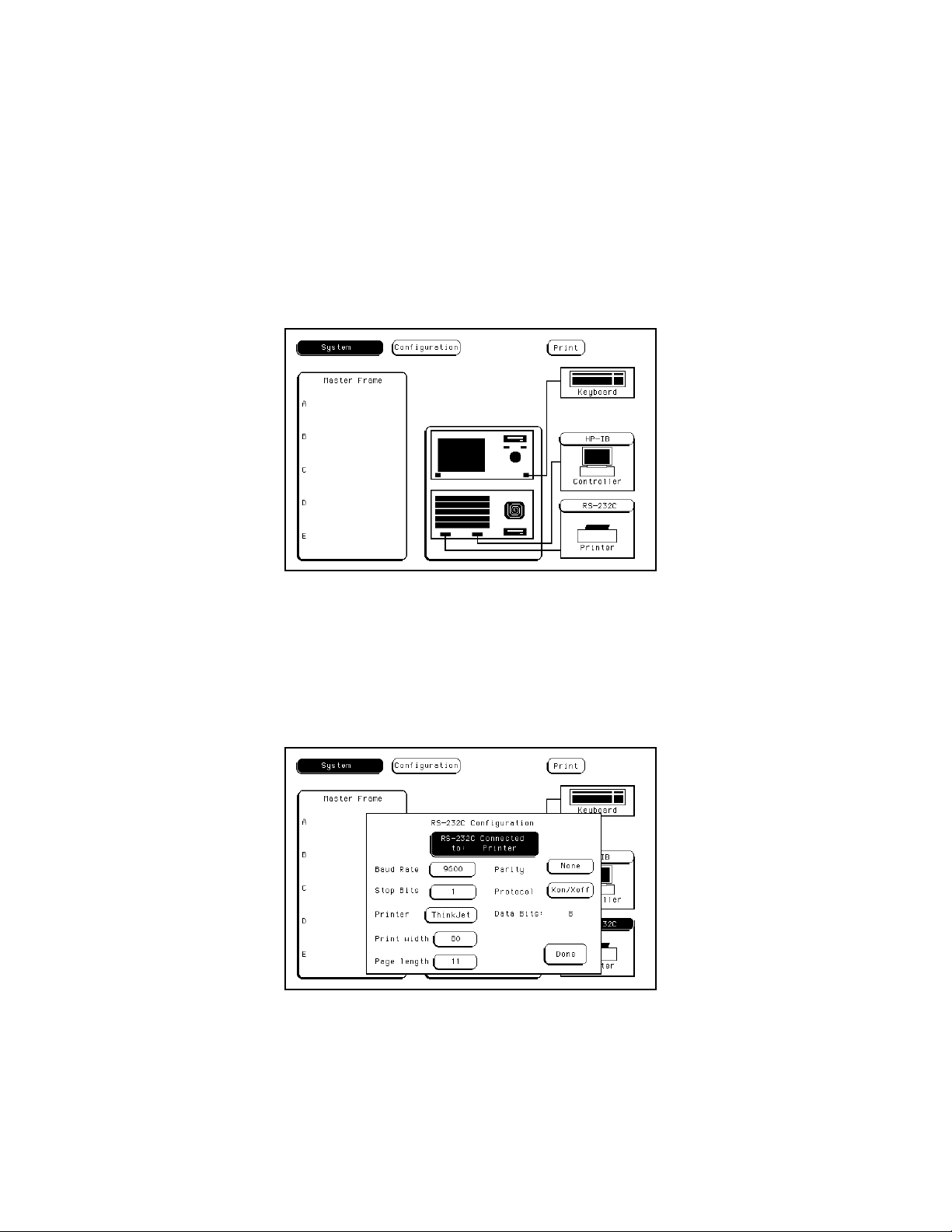

1. With the operating system disk in one of the disk drives, turn on the instrument to obtain the System

Configuration menu. See figure 2-8.

Figure 2-8. System Configuration Menu

2. Touch the RS-232C field in the lower right corner of the screen to obtain the RS-232C configuration

menu. See figure 2-9.

Figure 2-9. RS-232C Configuration Menu

2-10

Page 27

HP 16500A/16501A - Installation

3. Touch the Baud Rate field, then select the required r ate. See figure 2-10. Make any other changes

to the RS-232C configuration while you are in this menu.

Figure 2-10. Baud Rate Pop-Up Menu

4. When the RS-232C configuration is correct, touch the Done field and the System Configuration

screen will be displayed.

2-11

Page 28

HP 16500A/16501A - Installation

2-14. Degaussing the Display

After the HP 16500A has been used for awhile,

the CRT may become magnetized and the color or

other display data may become distorted. To

correct these problems, press the Degauss button

on the power supply rear panel several times. If

the instrument has been subjected to strong

magnetic fields, it may be necessary to degauss

the CRT with a conventional external

television-type degaussing coil or to replace the

CRT.

2-15. Operating Environment

The operating environment is listed in table 1-2.

Note should be made of the non-condensing

humidity limitation. Condensation within the

instrument can cause poor operation or

malfunction. Protection should be provided

against internal condensation.

The HP 16500A/16501A will operate at all

specifications within the temperature and humidity

range given in table 1-2. However, reliability is

enhanced by operating the instrument within the

following ranges.

Temperature: +20 °Cto+35 °C

(+68 °Fto+95 °F)

Humidity: 20% to 80% non-condensing

• Remove the disks from the disk drives and

install the yellow shipping disks.

• Wrap the instrument in heavy paper or plastic.

• Use a strong shipping container. A

double-wall carton made of 350-lb test

material is adequate.

• Use a layer of shock-absorbing material, 70

to 100 mm (3 to 4 inches) thick, around all

sides of the instrument to provide firm

cushioning and to prevent movement inside

the container. Protect the control panel with

cardboard.

• Seal the shipping container securely.

• Mark the shipping container FRAGILE to

ensure careful handling.

• In any correspondence, refer to instrument by

model number and by full serial number.

2-18. Tagging for Service

If the instrument is to be shipped to a

Hewlett-Packard office for service or repair, attach

a tag showing the owner (with address), the

complete instrument serial number, and a

description of the service required.

2-16. Storage and Shipment

The instrument may be stored or shipped in

environments within the following limits:

Temperature: -40 °Cto+75°C

Humidity: Up to 90% at 65 °C

Altitude: Up to 15,300 meters (50,000 feet)

The instrument should also be protected from

temperature extremes which cause condensation

within the instrument.

2-17. Packaging

Use the following general instructions for

repacking the instrument with commercially

available materials.

2-12

2-19. Cleaning Requirements

Use mild soap and water to clean the

HP 16500A/16501A Do not use ammonia-based

products to clean the screen. Ammonia damages

the screen coating.

Clean the CRT display and surrounding area

regularly. Do not place tape or other foreign

material on the screen.

Note

If the CRT display is not clean or if foreign

objects block the edges of the screen,

touchscreen failures can occur.

Vacuum the ventilation slots on the sides of the

instrument and on the rear-panel fan whenever

there is a visible amount of dust on them.

Page 29

HP 16500A/16501A - Installation

2-20. HP 16501A Expansion Frame Installation

The effects of ELECTROSTATIC DISCHARGE can damage electronic

components. Use grounded wriststraps and mats when you are performing any

kind of service to this instrument.

Installation Considerations

• The mainframe interface card can be installed in any available card slot in the HP 16500A main-

frame.

• Cards or filler panels in the HP 16500A located below the empty slot intended for installation do

not have to be moved.

Procedure

1. Turn off the HP 16500A mainframe power switch, then unplug the power cord. Disconnect any input

connections.

2. Verify the correct setting of the Line Select switch located on the rear panel of the HP 16501A. See

section 2-6, "Line Voltage Selection."

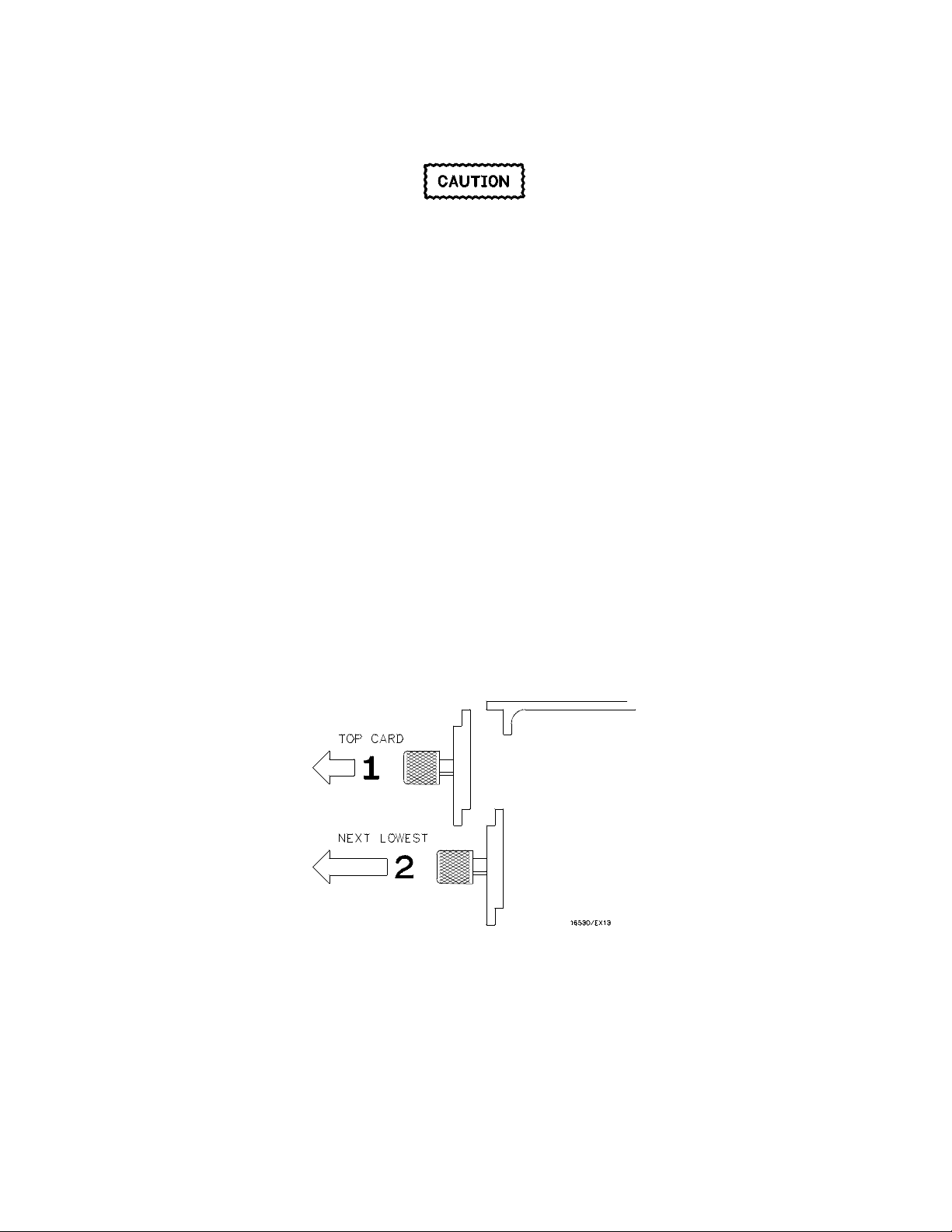

3. Starting from the top, loosenthumb screws on filler panels and cards that need to be moved.

Starting from the top, pull the cards and filler panels half-way out. See figure 2-11.

4. Remove the filler panel or card that is in the slot intended for the mainframe interface card. Slide the

mainframe interface card into the card cage of the HP 16500A mainframe.

Figure 2-11. Endplate Overlap

2-13

Page 30

HP 16500A/16501A - Installation

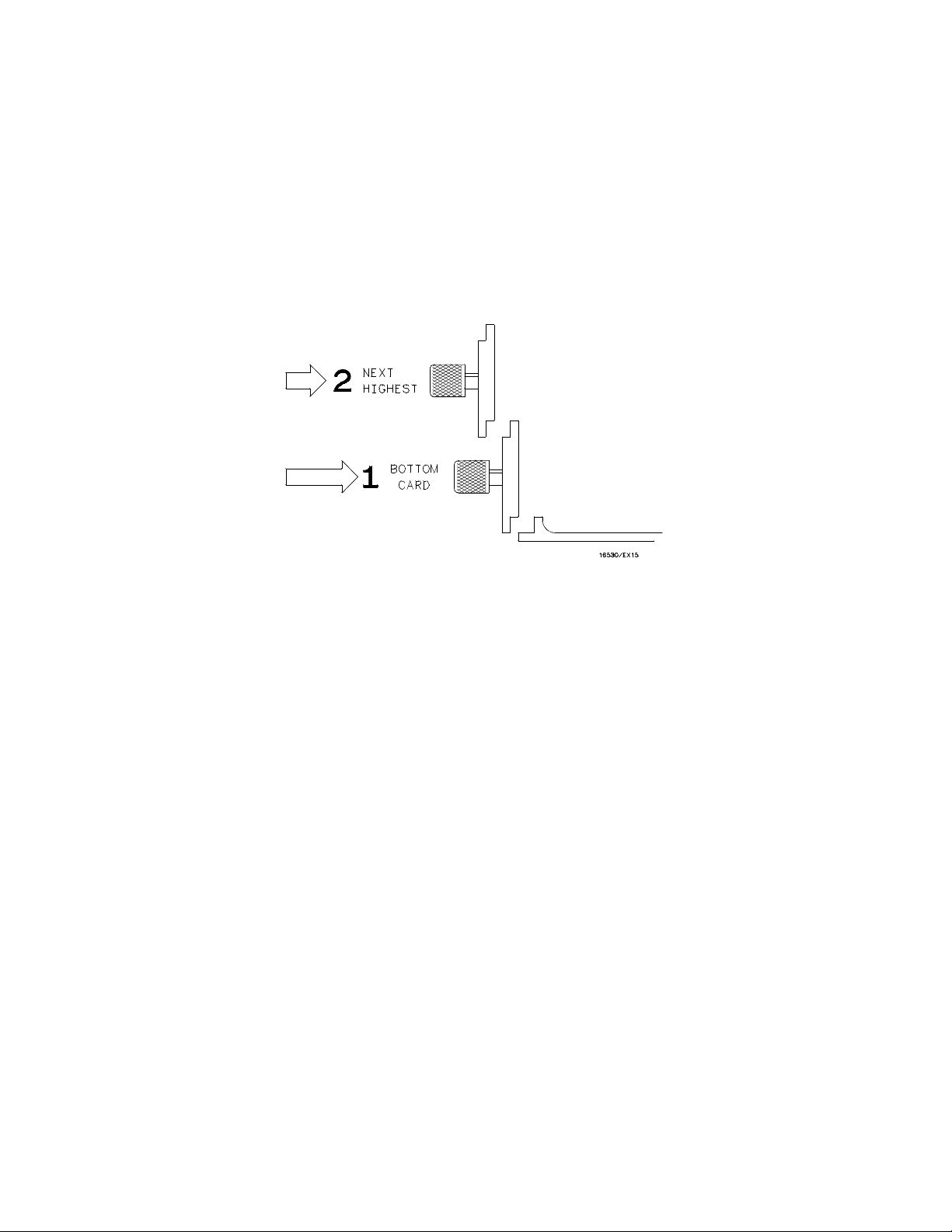

5. Reposition all cards and filler panels so that the endplates overlap properly.

6. Firmly seat the bottom card into the backplane connector of the mainframe. Keep applying

pressure to the center of the card endplate while tightening the thumb screws finger tight.

Repeat for all cards and filler panels in a bottom to top order. See figure 2-12.

Note

Any filler panels that are not used should be kept for future use. Filler panels

must

be installed in all unused card slots for correct air circulation.

Figure 2-12. Endplate Overlap

2-14

Page 31

HP 16500A/16501A - Installation

Note

In order to ensure correct insertion, the 68-pin "D" connectors on each end of the

interface cable are asymmetric in shape. They only fit into their respective ports

on the cards when oriented to match the shape of the ports.

7. Insert one end of the interface cable into the port located on the mainframe interface card in the

HP 16500A. Insert the other end of the interface cable into the port located on the expansion

interface card in the HP 16501A.

Note

When connecting the interface cable, you will hear two clicks. Make sure the

cable connector is properly seated into the port by pulling the connector without

pressing the release tabs. If the connector is properly seated, it will remain

connected to the port.

Figure 2-13 shows the HP 16500A and HP 16501A configuration.

Figure 2-13. Configuration

2-15

Page 32

HP 16500A/16501A - Installation

8. Turn on the HP 16500A/16501A Logic Analysis System.

a. Connect a power cord to each frame.

b. Turn on the line switch located on the rear panel of each frame.

c. Turn on the power standby switch located on the front-panel of the HP 16500A mainframe.

When the power-up tests are complete, the HP 16500A mainframe screen shows the

Mainframe Interface Card in one of the card slots. See figure 2-14.

Figure 2-14. System Configuration Menu

2-16

Page 33

TABLE OF CONTENTS

Section III

Performance Tests Page

3-1. Introduction.......................................................................................................................3-1

Page 34

3-1. Introduction

This section normally contains the performance

verification tests. Because there are no

specifications for the HP 16500A/16501A to test,

there are no performance tests.

HP 16500A/16501A - Performance Tests

SECTION III

Performance Tests

3-1

Page 35

TABLE OF CONTENTS

Section IV

Adjustments Page

4-1. Introduction......................................................................................................................4-1

4-2. Degaussing the Display...................................................................................................4-1

4-3. Safety Considerations.....................................................................................................4-1

4-4. Adjustment Test Patterns................................................................................................4-2

4-5. Color Display Module Adjustments .................................................................................4-7

Page 36

HP 16500/16501A - Adjustments

SECTION IV

Adjustments

4-1. Introduction

The HP 16500A/16501A requires no adjusting

when used in a normal environment. The

procedure given in this section is for the color

module. Do not perform these adjustments as

part of regular maintenance. Observe the

following rules before making any color module

adjustments.

Do not perform this procedure as normal

maintenance.

Make adjustments only if the instrument has

been subjected to extreme magnetic

environments and the colors are incorrect.

Before making any adjustments, try

degaussing the unit using the rear panel

degaussing switch or a color television type

degaussing coil.

4-2. Degaussing the Display

After the instrument has been used for awhile, the

CRT may become magnetized and the color or

other data may become distorted. To correct

these problems, press the Degauss button on the

power supply rear panel several times. If the

instrument has been subjected to strong magnetic

fields, it may be necessary to degauss the CRT

with a conventional external television-type

degaussing coil.

4-3. Safety Considerations

Although this instrument has been designed in

accordance with international safety standards,

general safety precautions must be observed

during all phases of operation, service, and repair

of the instrument. Failure to comply with the

precautions listed in the Safety Summary at the

front of this manual, or with specific warnings

given throughout this manual, could result in

serious injury or death. Service adjustments

should be performed only by qualified service

personnel.

Only qualified personnel who are familiar

with color CRT convergence procedures

should perform this adjustment.

Before adjustments are made, mark the

position of the potentiometers. This process

allows you to return the adjustments to their

original starting position.

Read the Safety Considerations at the front

of this manual before performing

adjustment procedures. Disconnect the

instrument from all voltage sources before it

is opened for any adjustment, replacement,

maintenance, or repair.

4-1

Page 37

HP 16500A/16501A - Adjustments

4-4. Adjustment Test Patterns

Six test patterns are required for adjusting the color module: one white cross hatch pattern, one white full

screen raster, a full screen pattern for each primary color (red, green, blue), and one black full screen

raster.

Access to the test patterns is gained through the Mainframe Test system. To access the test patterns,

proceed as follows:

1. Insert the operating system disk into one of the disk drives, then turn on the instrument to obtain

the System Configuration menu. See figure 4-1.

Figure 4-1. System Configuration Menu

2. Touch the Configuration field, then touch the Test field from the pop-up menu. See figure 4-2.

Figure 4-2. Accessing the Test System

4-2

Page 38

HP 16500A/16501A - Adjustments

3. Verify that test files are on an installed disk. Touch the field close to the center of the screen to load

the Test System. See figure 4-3.

Figure 4-3. Loading the Test System

4. After the Test System has been loaded from the disk, the Test Configuration will be displayed. See

figure 4-4.

Figure 4-4. Test System Configuration

4-3

Page 39

HP 16500A/16501A - Adjustments

5. Touch the Test System field, then select Mainframe Test from the pop-up menu. See figure 4-5.

Figure 4-5. Selecting Mainframe Test Menu

6. The Mainframe Test menu is now displayed. See figure 4-6. Select the Color Display Test field

to display the white cross hatch test pattern, which is the first test pattern in the system. See

figure 4-7.

Figure 4-6. Mainframe Test Menu

4-4

Page 40

HP 16500A/16501A - Adjustments

7. With every touch of the Continue field, the next test pattern will be displayed. See figure 4-7.

Figure 4-7. Selecting the Test Patterns

When Continue is selected from the black raster pattern, the Mainframe Test menu will be

displayed. Notice that the status of the Display Test field has changed to TESTED.

8. To exit the Mainframe Test system and to reload the mainframe operating system, touch the

Mainframe Test field. Then touch the Test System field from the pop-up menu shown in

figure 4-8. The Test System configuration will be displayed.

Figure 4-8. Exiting Mainframe Test System

4-5

Page 41

HP 16500A/16501A - Adjustments

9. Touch the Configuration field, then touch Exit T est. Install the operating system disk into one of

the disk drives, then touch the field close to the center of the screen to reload the mainframe

operating system. See figure 4-9.

Figure 4-9. Exiting Test System Configuration

10. After the operating system has been reloaded, the System Configuration will be displayed. See

figure 4-10.

Figure 4-10. System Configuration

4-6

Page 42

HP 16500A/16501A - Adjustments

4-5. Color Display Module Adjustments

Description:

The Color Display Module is adjusted to compensate for external magnetic influences causing

misconvergence.

Note

DO NOT continue with this procedure before first degaussing the CRT screen

using the rear panel degaussing switch. In extreme cases of magnetism, it may

be necessary to degauss the CRT using a conventional external television-type

degaussing coil. During any of the following adjustments, the CRT module must

face west.

Equipment Required:

Nonmetallic Adjustment Tool.......................................................................HP Part Number 8710-1355

Procedure:

Note

The following adjustments are broken down into adjustment groups. The

sequence of the adjustment groups must be followed due to the interaction and

dependency of one adjustment to another. The adjustment group sequence is

shown in the adjustment flow diagram in figure 4-11. There will be cases where

not all the adjustment groups will be used. For example, if the Geometry

Adjustment Group corrects the problem, this will be the only group used.

4-7

Page 43

HP 16500A/16501A - Adjustments

4-8

Figure 4-11. CRT Module Adjustment Flow Diagram

Page 44

HP 16500A/16501A - Adjustments

Geometry Adjustments

1. From the Mainframe Test System, select the Display Test menu. Select the white cross hatch test

pattern. Refer to section 4-4, "Adjustment Test Patterns," for accessing the test patterns.

2. Preset the front panel BACKGROUND control to mechanical center.

3. Preset the front panel BRIGHTNESS control to maximum.

4. Preset H.SUB SHIFT (RV006) and V.SUB SHIFT (RV008), located on the bottom PC board, to

mechanical center.

5. Using a flexible ruler, adjust H.SIZE (RV504) and V.HEIGHT (RV502), located on the left hand side

PC board, so that the border of the cross-hatch is 120.5 mm (4.74 in.) vertically and 161 mm

(6.34 in.) horizontally.

6. Adjust V.CENT (RV510) and H.CENT (RV503), located on the left hand side PC board, to center

pattern.

7. Adjust PIN AMP (RV506), located on the left hand side PC board, to eliminate pincushion distortion

in the vertical lines of the cross-hatch pattern as shown in figure 4-12.

Figure 4-12. PIN AMP Adjustment

4-9

Page 45

HP 16500A/16501A - Adjustments

Geometry Adjustments (Continued)

8. Set the instrument on its left side, color module side up, then remove the bottom rail. See

figure 4-13.

Note

Leave the instrument standing on its left side until the PIN PHASE adjustment

has been completed.

4-10

Figure 4-13. Bottom Rail Removal

Page 46

HP 16500A/16501A - Adjustments

Geometry Adjustments (Continued)

9. Adjust PIN PHASE (RV505), located on the left side PC board, to eliminate pin phase distortion in

vertical lines of cross-hatch pattern as shown in figure 4-14.

Figure 4-14. PIN PHASE Adjustment

10. Reinstall the bottom rail.

11. Adjust the TOP PIN (RV511), located on the left hand side PC board, so the top horizontal line is

parallel with the center horizontal line.

12. Adjust the BOTTOM PIN (RV512), located on the left hand side PC board, so the bottom horizontal

line is parallel with the center horizontal line.

4-11

Page 47

HP 16500A/16501A - Adjustments

Focus Adjustment

Note

Geometry adjustments must be performed before making the focus adjustment.

1. Remove the rear and side fan. Refer to section 6, "Service," for the fan removal procedures.

2. From the Display Test menu of the Mainframe Test system, select the white cross-hatch test pattern.

3. Adjust FOCUS (RV701), located on the rear PC board, for best overall focus.

Landing and Convergence Adjustment Preparation

1. From the Display Test menu, select a white raster pattern and check for color purity. Repeat this

step using the Red, Green, and Blue raster patterns and check for color purity.

If the color purity is correct, do not perform this Landing and Convergence adjustment.

2. Turn off the instrument, then disconnect the power cord. Loosen the deflection yoke clamp screw.

3. Remove the deflection yoke spacers by moving the deflection yoke towards the rear of the

instrument, then by removing the spacers.

Note

The deflection yoke spacers are tapered rubber blocks located between the front

of the yoke and the rear of the CRT funnel.

4. Plug the power cord into the instrument, then turn on the instrument. For thermal stability, allow the

instrument to warm up for 20 minutes.

Exercise caution when moving purity magnets. Power is applied to the

instrument and high voltages are present around the CRT.

4-12

Page 48

HP 16500A/16501A - Adjustments

Landing Adjustment

1. From the Display Test menu, select the white raster (full screen display).

2. Turn the front panel BRIGHTNESS Control to maximum.

3. Degauss the entire CRT screen by pressing the Degaussing switch located on the rear panel of the

instrument.

Note

In cases where your environment or the shipping environment has caused high

levels of magnetization to take place, you may need to externally degauss the

CRT using a conventional television-type degaussing coil to completely degauss

the CRT.

Figure 4-15. Purity Magnet Centering

magnet tabs to mechanical center. See figure 4-15.

5. Select the green raster from the Display Test menu.

4. Set the purity

4-13

Page 49

HP 16500A/16501A - Adjustments

Landing Adjustment (Continued)

6. Move the deflection yoke towards the rear of the instrument, until the left edge of the raster turns red

Figure 4-16. Purity Magnet Adjustment Raster

and the right edge of the

raster turns blue. See figure 4-16.

7. Adjust the purity magnets until green is in the center of the raster with red and blue bands evenly

distributed on the sides. See figure 4-15. The purity magnets need no more than ±15° movement

from the mechanical center.

8. Move the deflection yoke forward until the entire raster is green.

Note

The landing adjustment is easier if the yoke is moved all the way forward and

then moved backward until the raster is completely green.

9. Replace the green raster with a full screen red raster. Check for proper landing adjustment (color

purity). Select a blue full-screen raster and check it for proper landing adjustment.

4-14

Page 50

HP 16500A/16501A - Adjustments

Landing Adjustment (Continued)

10. If the landing is not correct in step 9, repeat steps 6 through 9 for the best compromise. See

Figure 4-17. Landing and Purity Adjustment Guide

figure 4-17.

11. If the landing is not correct in step 10, readjust the purity magnets for the best landing of each color.

12. Turn off the instrument and remove the power cord. Reinstall the yoke spacers.

13. When the landing adjustment is complete, tighten the deflection yoke clamp screw just enough to

keep the yoke from moving. DO NOT over-tighten.

Note

While moving the deflection yoke forward and backward, rotate the yoke as

necessary to make the vertical edges of the raster parallel to the sides of the

instrument frame.

4-15

Page 51

HP 16500A/16501A - Adjustments

Static Convergence

1. Preset the front panel BACKGROUND control to mechanical center.

2. Preset the front panel BRIGHTNESS control to maximum.

3. Temporarily disconnect the power from the instrument and remove the PC board shield cover from

the rear of the CRT Display Module by prying evenly on all four sides.

4. Reapply the power and from the Display Test menu select the white cross-hatch test pattern.

5. Check the four dots located around the center intersection of the cross-hatch pattern for coincidence

of blue, red, and green dots. If the dots are not coincident, adjust H.STAT (RV703), located on the

rear PC board, to obtain horizontal coincidence and V.STAT (RV803), located on the bottom PC

board, to obtain vertical coincidence. See figure 4-18.

Note

Due to interaction, the BEAM LANDING will need to be readjusted if either

H.STAT or V.STAT adjustments are made. Once the BEAM LANDING is

readjusted, repeat step 5, if necessary, to obtain center-screen coincidence of

the dots.

4-16

Figure 4-18. Static Convergence

Page 52

HP 16500A/16501A - Adjustments

Dynamic Convergence

1. From the Display Test menu, select the white cross-hatch test pattern.

2. Adjust the Y BOW (RV805), located on the bottom PC board, to eliminate red, green, and blue

bowing at the top and bottom of the center vertical line. See figure 4-19.

Figure 4-19. Y BOW Adjustment

3. Adjust the Y BOW CROSS (RV804), located on the bottom of the PC board, to eliminate red, green,

and blue orthogonal misalignment at the top and bottom of the center vertical line. See figure 4-20.

Figure 4-20. Y BOW CROSS Adjustment

4-17

Page 53

HP 16500A/16501A - Adjustments

Dynamic Convergence (Continued)

4. Adjust the V.STAT TOP (RV801) and the V.STAT BOTTOM (RV802), located on the bottom PC

board. These two adjustments allow you to obtain coincidence of red, blue, and green where the

top and bottom horizontal lines intersect with the center vertical line. See figures 4-21 and 4-22.

Figure 4-21. V.STAT TOP Adjustment

Figure 4-22. V.STAT BOTTOM Adjustment

4-18

Page 54

HP 16500A/16501A - Adjustments

Dynamic Convergence (Continued)

5. Adjust the H.AMP (RV807), located on the bottom PC board, for equal amounts of misconvergence

Figure 4-23. H.AMP Adjustment

right and left sides of the screen. See figure 4-23.

Figure 4-24. H.TILT Adjustment

at the

6. Adjust

the H.TILT (RV806), located on the bottom PC board, for coincidence of red, green, and blue at the

right and left sides of the screen. See figure 4-24.

4-19

Page 55

HP 16500A/16501A - Adjustments

White Balance

1. From the Display Test menu, select a blank (colorless) raster.

Note

Any text on the screen will not affect this adjustment.

2. Set the front panel BACKGROUND and SUB BRT (RV901), located on the bottom PC board, to

mechanical center.

3. Set the front panel BRIGHTNESS and SUB CONT (RV902), located on the bottom PC board, to

mechanical center.

4. Set the G. DRIVE (RV921), B. DRIVE (RV931), and R. DRIVE (RV911), located on the bottom PC

board, to mechanical center.

5. Set the G.BKG (RV721), B.BKG (RV731), and R.BKG (RV711), located on the rear PC board, fully

counterclockwise (CCW).

6. Adjust the SCREEN (RV702), located on the rear PC board, until either a red, green, or blue raster

just starts to become visible. Note which color becomes visible first and do not adjust background

control (BKG) for that color in the next step.

7. Adjust the other two background (BKG) controls for the best white balance.

8. From the Display Test menu, select the white raster test pattern.

9. Set the front panel BRIGHTNESS control to maximum.

10. Observe the screen and adjust the DRIVE controls (RV921, RV931, and RV911), located on the

bottom PC board for the best white balance.

Note

Using an average piece of white photocopy paper, compare the white on the

CRT to the paper.

11. Repeat steps 1 through 3 and 6 through 10 until the white balance is acceptable.

12. Reinstall the cooling fans. Refer to section 6, "Service," for the fan installation procedures.

4-20

Page 56

TABLE OF CONTENTS

Section V

Replaceable Parts Page

5-1. Introduction......................................................................................................................5-1

5-2. Abbreviations...................................................................................................................5-1

5-3. Replaceable Parts List ....................................................................................................5-1

5-4. Exchange Assemblies.....................................................................................................5-1

5-5. Ordering Information .......................................................................................................5-1

5-6. Direct Mail Order System................................................................................................5-2

Page 57

HP 16500A/16501A - Replaceable Parts

SECTION V

Replaceable Parts

5-1. Introduction

This section contains information for ordering

parts. Table 5-1 lists abbreviations used in the

parts list. Table 5-2 and table 5-3 list all

replaceable parts in reference designator order.

5-2. Abbreviations

Table 5-1 lists abbreviations used in the parts list

and throughout the manual. In some cases, two