Page 1

OSClllOSCOPE

OPERATING

AND

SERVICING MANUAL

Page 2

OPERATING AND SERVICING MANUAL

FOR

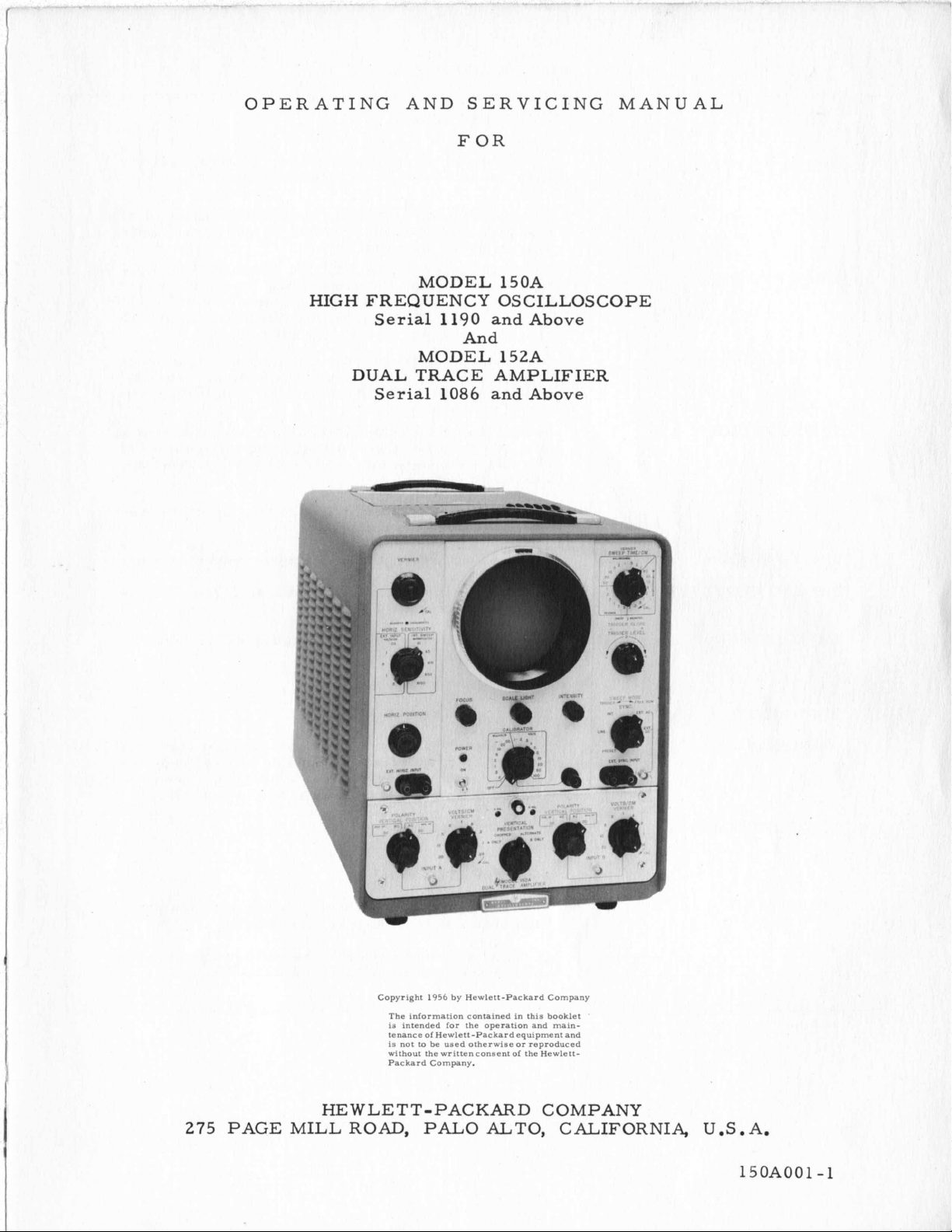

MODEL 150A

HIGH

FREQUENCY OSCILLOSCOPE

Serial

1190

and

Above

And

MODEL 152A

DUAL TRACE AMPLIFIER

Serial

1086

and

Above

,

275

PAGE MILL ROAD,

Copyright

HE

WLET T-PACKARD COMPANY

1956

by Hewlett-Packard Company

The information contained in this booklet

i3 intended for the operation and maintenance of Hewlett-Packard equipment and

is not to be used otherwise or reproduced

without the writtenconsent

Packard Company.

PAL0

of

the Hewlett-

ALTO,

CALIFORNIA, U.S.A.

'

15OAOO1-1

Page 3

INTERNAL SWEEP:

MAGNIFICAT ION:

SYNCHRONIZATION:

SYNC CONTROL:

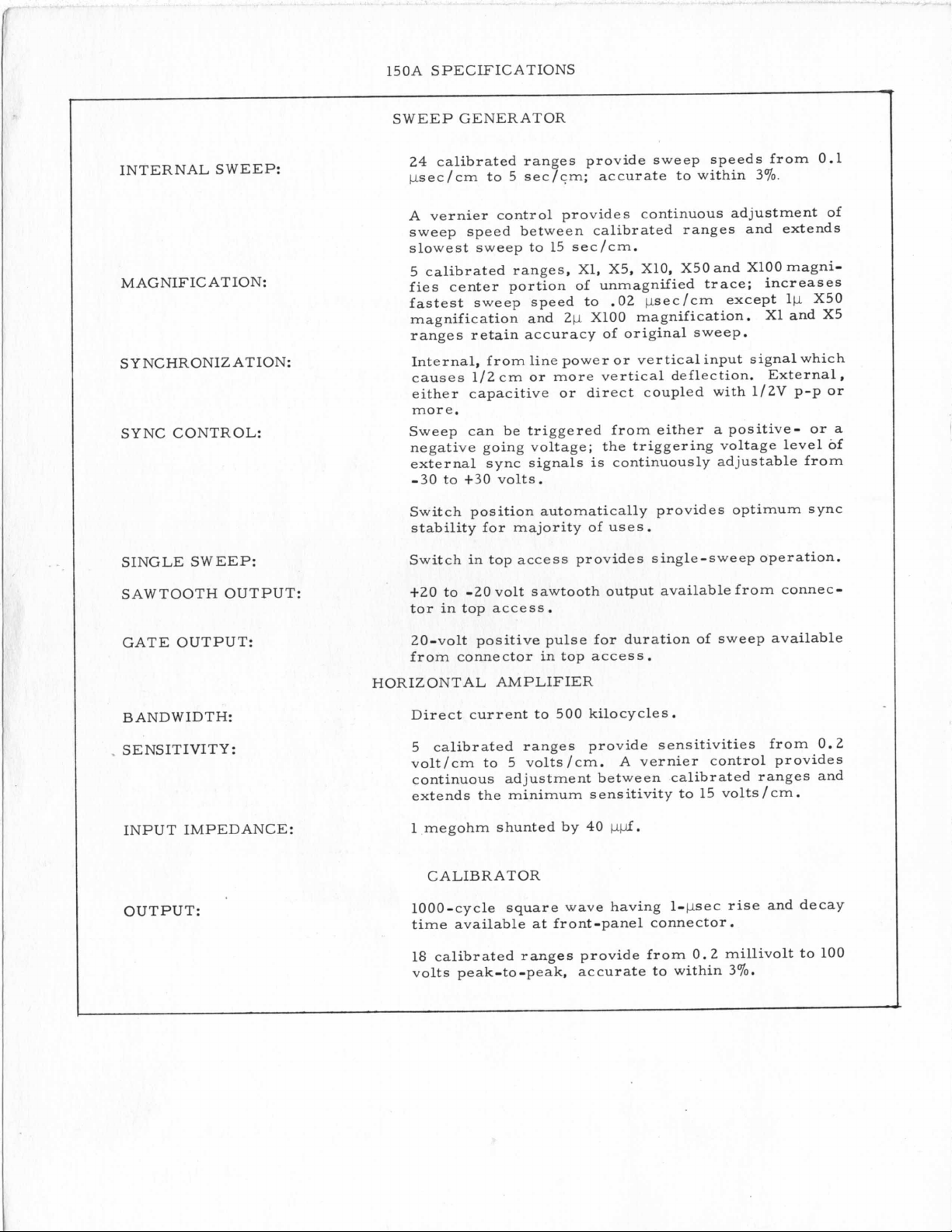

150A SPECIFICATIONS

SWEEP GENERATOR

24

calibrated ranges provide sweep speeds from 0.1

psec/cm to 5 sec/cm; accurate to within

A vernier control provides continuous adjustment of

sweep speed between calibrated ranges and extends

slowest sweep to 15 sec/cm.

5 calibrated ranges, X1, X5, X10, X50 and XlOO magni-

fies center portion of unmagnified trace; increases

fastest sweep speed to

magnification and

ranges retain accuracy of original sweep.

Internal, from line power or vertical input signal which

causes 1/2 cm or more vertical deflection. External,

either capacitive or direct coupled with 1/2V p-p or

more.

Sweep can be triggered from either

negative going voltage; the triggering voltage level of

external sync signals

-30

to

+30

volts.

Switch position automatically provides optimum sync

stability for majority of uses.

2p

.02

XlOO

is

psec/cm except lp X50

magnification. X1 and X5

continuously adjustable from

39%.

a

positive- or

a

SINGLE SWEEP:

SAWTOOTH OUTPUT:

GATE OUTPUT:

BAND WIDTH:

.

SENSITIVITY:

INPUT IMPEDANCE:

OUTPUT:

Switch in top access provides single-sweep operation.

+20

to

-20

volt sawtooth output available from connec-

tor in top access.

20-volt positive pulse for duration of sweep available

from connector in top access.

HORIZONTAL AMPLIFIER

Direct current to 500 kilocycles.

5 calibrated ranges provide sensitivities from

volt/cm to 5 volts/cm. A vernier control provides

continuous adjustment between calibrated ranges and

extends the minimum sensitivity to 15 volts/cm.

1 megohm shunted by

CALIBRATOR

1000-cycle square wave having 1-psec rise and decay

time available

18 calibrated ranges provide from

volts peak-to-peak, accurate to within

at

40

pfl.

front-panel connector

0.2

.

millivolt to 100

370.

0.2

Page 4

I

I

,

I

I

,

!

t

I

!

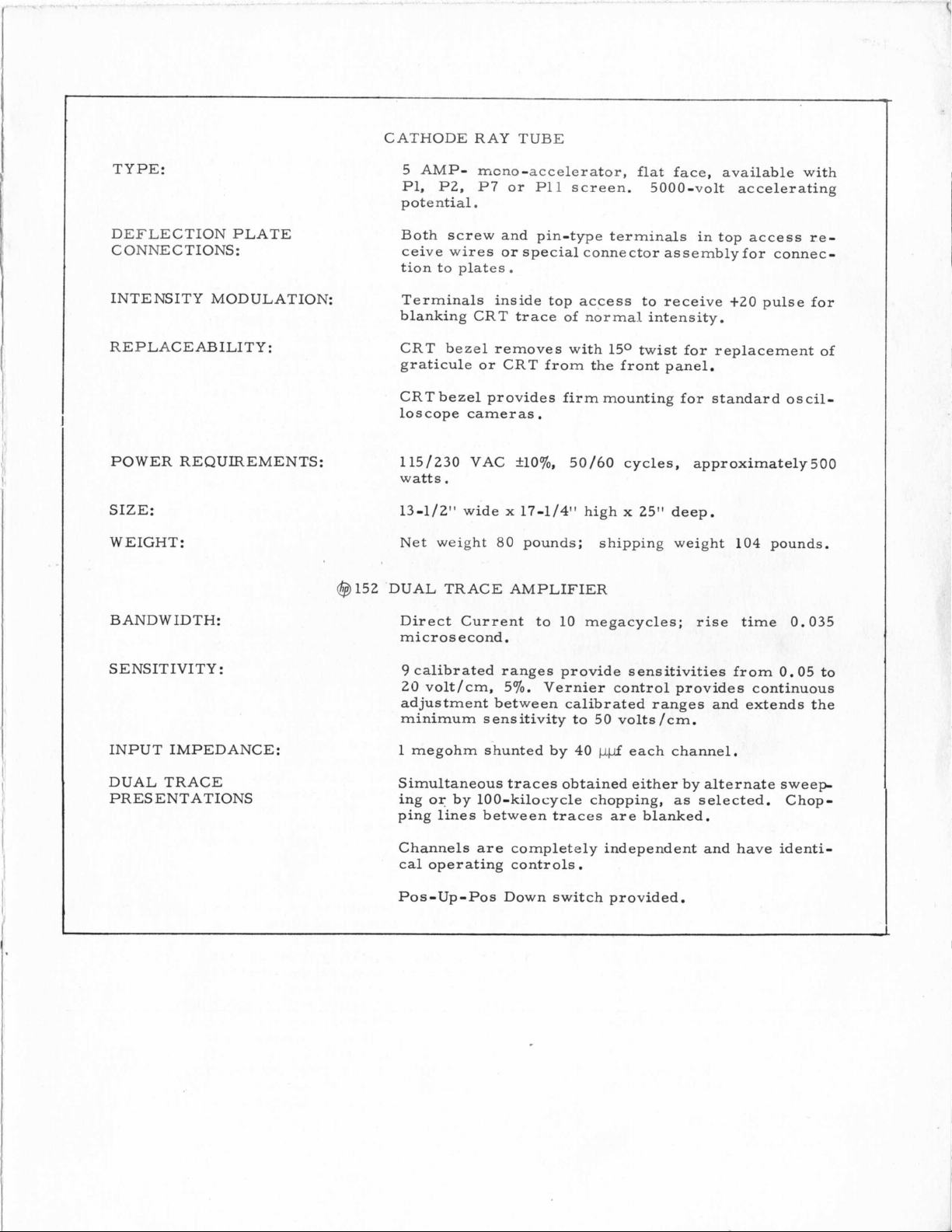

TYPE:

CATHODE RAY TUBE

5 AMP-

P1,

potential

rr-cno-accelerator,

P2,

P7

.

or P11 screen. 5000-volt accelerating

flat face, available with

\

I

i

I

1

I

DEFLECTION PLATE

CONNECTIONS:

INTENSITY MODULATION:

REPLACEABILITY:

POWER REQUIREMENTS:

SIZE:

WEIGHT:

BANDWIDTH:

SENSITIVITY:

Both screw and pin-type terminals in top access re-

or

ceive wires

tion to plates.

Terminals inside top access to receive +20 pulse for

blanking CRT trace of normal intensity.

CRT bezel removes with

graticule or CRT from the front panel.

CRT bezel provides firm mounting for standard oscilloscope cameras

115/230 VAC

watts.

13-1/2" wide

Net weight

@l52 DUAL TRACE AMPLIFIER

Direct Current to

microsecond.

9

calibrated ranges provide sensitivities from

20 volt/cm, 57'0. Vernier control provides continuous

adjustment between calibrated ranges and extends the

minimum sensitivity to 50 volts /cm.

special connector assembly for connec-

.

+lo%,

x

17-1/411

80

pounds; shipping weight

50/60

high x 25" deep.

10

megacycles; rise time 0.035

150

twist for replacement of

cycles, approximately500

104

pounds.

0.05

to

INPUT IMPEDANCE:

I

I

,

1

I

I

I

i

DUAL TRACE

PRESENTATIONS

1'

i

!

I

i

i

I

I

i

i

I

1

megohm shunted by

Simultaneous traces obtained either by alternate sweep

or

ing

ping lines between traces are blanked.

Channels are completely independent and have identical operating controls

Pos-Up-Pos Down switch provided.

by 100-kilocycle chopping,

40

.

ppf

each channel.

as

selected. Chop-

Page 5

TABLE OF CONTENTS

FOR

MODEL 150A AND MODEL 152A

HIGH FREQUENCY OSCILLOSCOPES

Par

1-1

1-2

1-3

1 -4

1-5

1-6

2-1

2 -2

2-2A

2-2B

2-2c

2-2D

2-2E

2-3

2 -4

2-5

3-1

3-2

3 -3

3 -4

3-5

3-6

3-7

3-8

-9

3

3-10

3-1 1

3-12

3-13

4-1

a

.

SECTION

GENERAL DESCRIPTION

General Information.

Damage

Power Line Voltages

Power Cord

Cooling

Overload Relay

OPERATING INSTRUCTIONS

High Voltage Time Delay

Controls and Terminals

Internal Sweep Controls

Horizontal Input Controls.

Dual Channel Amplifier

Controls

CRT Panel Controls

Top Access Controls

Operating Procedures

'Vertical

Use of Chopped or

Alternate Sweep

THEORY

General Content

Overall Operation

Synchronizing Circuit

Sweep Generator

Feedback Integrator and

Diode Switch

Schmitt Trigger Circuit

Horizontal Amplifier.

Main Vertical Amplifier

Model 152 Dual Trace

Amplifier Plug-In Unit

Calibrator

Regulated Low-Voltage

Power Supply

Re gulate d High-Volt age

Power Supply

Single Sweep and Delayed

Sweep Operation

Introductory

in

Transit

.

. . . . . .

.

.

. . . .

. .

SECTION I1

. . .

AC

.

. .

or DC Coupling

. . . . .

SECTION

OF

111

OPERATION

. . .

. .

. .

. .

. .

. . . . . . . .

.

.

. . . . . . .

. . .

SECTION IV

MAINTENANCE

. . . . . . .

I

. .

. . .

. .

.

.

. .

.

. .

.

. . .

. .

. . .

.

. . .

. . .

. .

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

Page

1-1

1-1

1-1

1-1

1-1

1-1

2-1

2-1

2-1

2 -2

2-2

2-3

2-3

2-3

2-3

2 -4

3-1

3-1

3-3

3-5

3-6

3-7

3-7

3-8

-9

3

3-1

3-1 1

3-13

3-13

4-1

Para.

4-2

4-3

-4

4

4-5

4-6

4-7

4-8

4-9

4-10

4-11

4-12

4-12A

4-12B XlOO Magnification

4-12C X5 to XlOO Magnification

4- 12D Main Horizontal Amplifier

4-13 Adjusting the Ext. Horiz.

4- 13A Horiz . Balance

4-13B Ext. Horiz. Input

4-13C Ext. Horiz. Input

4-14 Adjusting the Sync Circuit

4-15 Adjusting the Preset Sensi-

4-16 Calibrating the Sweep

4- 16A Sweep Amplitude

1

4-17 Adjusting Gain and Fre-

4-18 Adjusting Model 152A

4-18A Vertical Centering

4- 18B Neutralizing Adjustments

4-18C Output Frequency

Replacing the Air Filter

Removing the Cabinet

Connecting for 230-Volt

Power Lines

Servicing Etched Circuits

Tube Replacement Chart

Isolating Troubles to

Major Sections

Adjusting the Low-Voltage

Power Supplies

Adjusting the High-Voltage

Power Supply

Replacing and Adjusting

theCRT

Adjusting the Calibrator

Adjusting the Main

Horizontal Amplifier.

Main Horizontal Gain

Adjustment

Calibration

Centering and X1 Centering.

Frequency Response

Adjustment

Input Preamplifier.

Adjustment.

Volts/CM Calibration

tivity of the Sweep

Generator

Generator

Adjustment

quency Response

Vertical Amplifier

Trace Amplifier.

Adjustments

Response Adjustment

. . . .

. . . . .

.

. . . . . .

.

. . . . . .

.

.

. . . . .

.

.

.

.

.

.

. . .

.

.

.

.

. .

. . .

.

.

.

. .

. . .

. . .

.

. . . .

. . . .

. . .

. .

.

.

. .

.

. . .

.

.

of

Main

. . .

Dual

. . . .

. .

.

. .

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Page

1

44-1

4-1

4- 1

4-3

4-3

4-3

4-9

4-9

4-11

4-11

4-11

4-13

4-13

4-14

4-15

4-15

4- 15

4-17

4-17

4-18

4-

18

4-18

4-21

4-2 1

4-21

4-21

4-23

Page 6

1-1

GENERAL INFORMATION

SECTION

I

GENERAL DESCRIPTION

1-4

POWER CORD

The Model 150A dc to 10 MC oscilloscope

a

general purpose oscilloscope employing

5-AMP mono-accelerator type cathode ray

tube, with unitized, plug-in construction for

maximum accessibility and flexibility. It

can be used with either internal or external

sweeps which can be either internally or externally synchronized. The horizontal amplifier incorporates magnification circuitry

is

which

sweeps up

sweep range extends from .02 bsec/cm to

15 sec/cm.

The Model 150A has been designed for use

with

units to perform many different functions

but for the purpose of explaining scope operation in this manual,

the Model 152A Dual Channel Amplifier

employed, Since the control layout on the

front panel has been carefully organized and

labeled for convenient operation, most controls will be self-explanatory. However

major controls will be discussed completely

in the operating section of the manual. A

large fold outview of the panel

Section I1 with

s

cr ibed

capable of expanding basic internal

to

100 times. Thus the internal

a

variety of vertical amplifier plug-in

it

will be assumed that

is

included in

all

operating controls de-

.

is

is

The three conductor power cable supplied

withthe instrument

a

ized three prong male connector recommend-

ed by the National Electrical Manufacturers'

Association. The third contact

round pin added to

plug which grounds the instrument chassis

when used with the appropriate receptacle.

To use this plug in

outlet an adapter should be used to connect

the NEMA plug to the two contact system.

When the adapter

tion becomes

which can be connected to the outlet mounting

box for the protection of operating personnel.

,

1-5

COOLING

The Modell5OA employs a forced draft cooling system to maintain satisfactory operating

temperatures within the case. The

and

air

filter

case, and adequate cooling will take place

,

long

as

the case

ing obstructs the filter. Generally, the height

of the cabinet feet provide such clearance.

Thus the Model150A can be used in

fined bench set-up

of the cabinet

tures are not extreme.

is

is

is

terminated in a polar-

is

a

standard two-blade ac

a

standard two contact

is

used the ground connec-

a

short lead from the adapter

located under the instrument

is

on the instrument and noth-

as

long

as

the underside

clear, and ambient tempera-

an offset,

air

intake

as

a

con-

1-2

DAMAGE IN TRANSIT

After unpacking this instrument should any The Model

shipping damage become evident, refer to the reduces the output voltages

1lClaim for Damage in Shipment" paragraph ply when:

on the warranty sheet in this manual.

1-3

POWER LINE VOLTAGES

The Oscilloscope, like other @ instruments,

is

shippedfrom thefactory wiredfor 115 volt

ac line operation unless otherwise specified

in the order. However, the instrument may

also be operated from a 230 volt ac line source

if

the proper conversion

transformer. This conversion

is

described in the Maintenance section.

is

made to the power

is

simple, and

1-6

OVERLOAD RELAY

150A

1.

)

Any series tube on the d'-c heater

string

strument

2.)

A plug-in vertical amplifier

removed while the instrument

is

on.

3.)

A short circuit or excessive

loading of any positive-voltage

supply occurs.

has an overload-relay which

is

removed while the in-

is

on.

1-1

of

the power

SUP-

is

Page 7

Page 8

i

SECTION

OPERATING INSTRUCTIONS

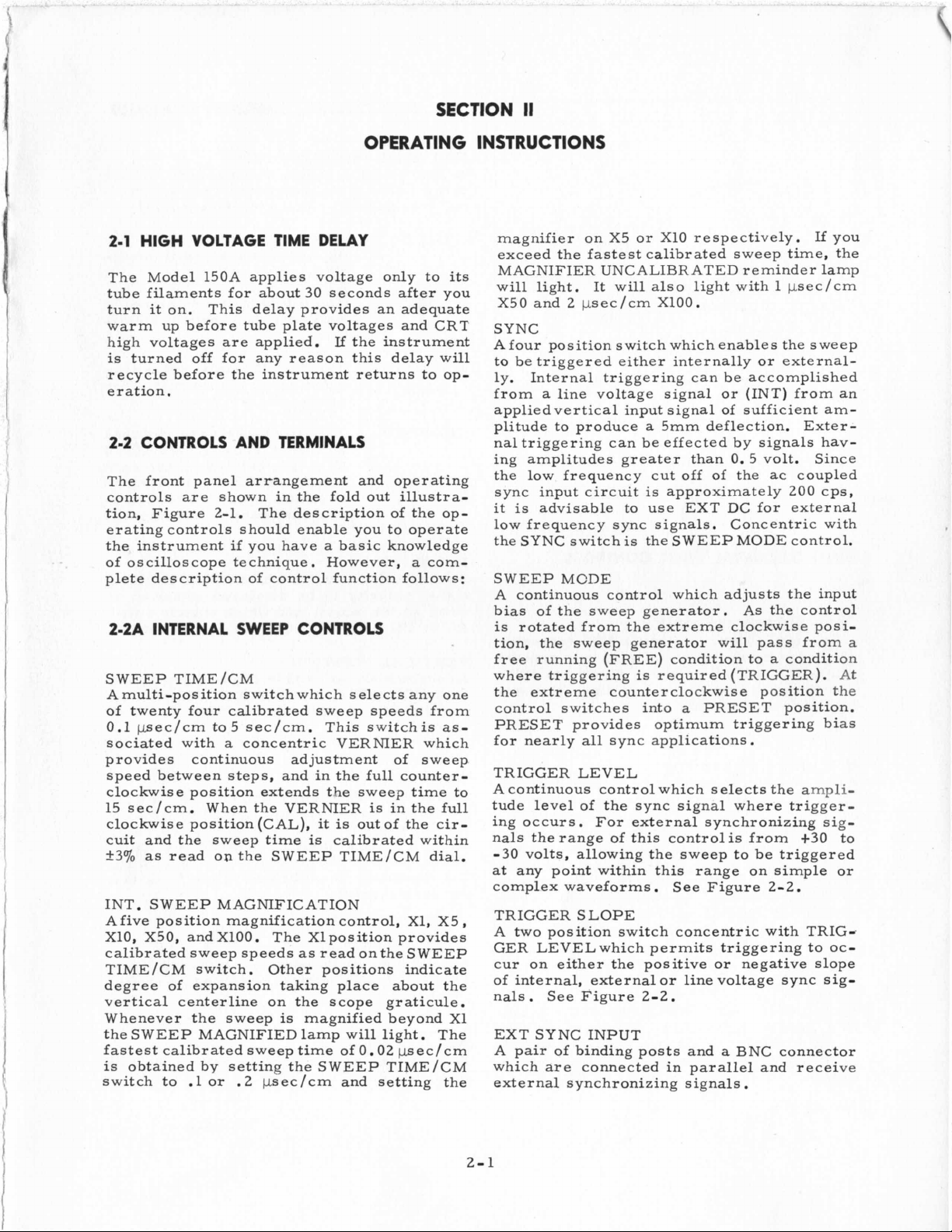

2-1

HIGH VOLTAGE TIME DELAY

The Model 150A applies voltage only to

tube filaments for about

it

turn

warm up before tube plate voltages and CRT

high voltages are applied.

is

recycle before the instrument returns to operation.

2-2

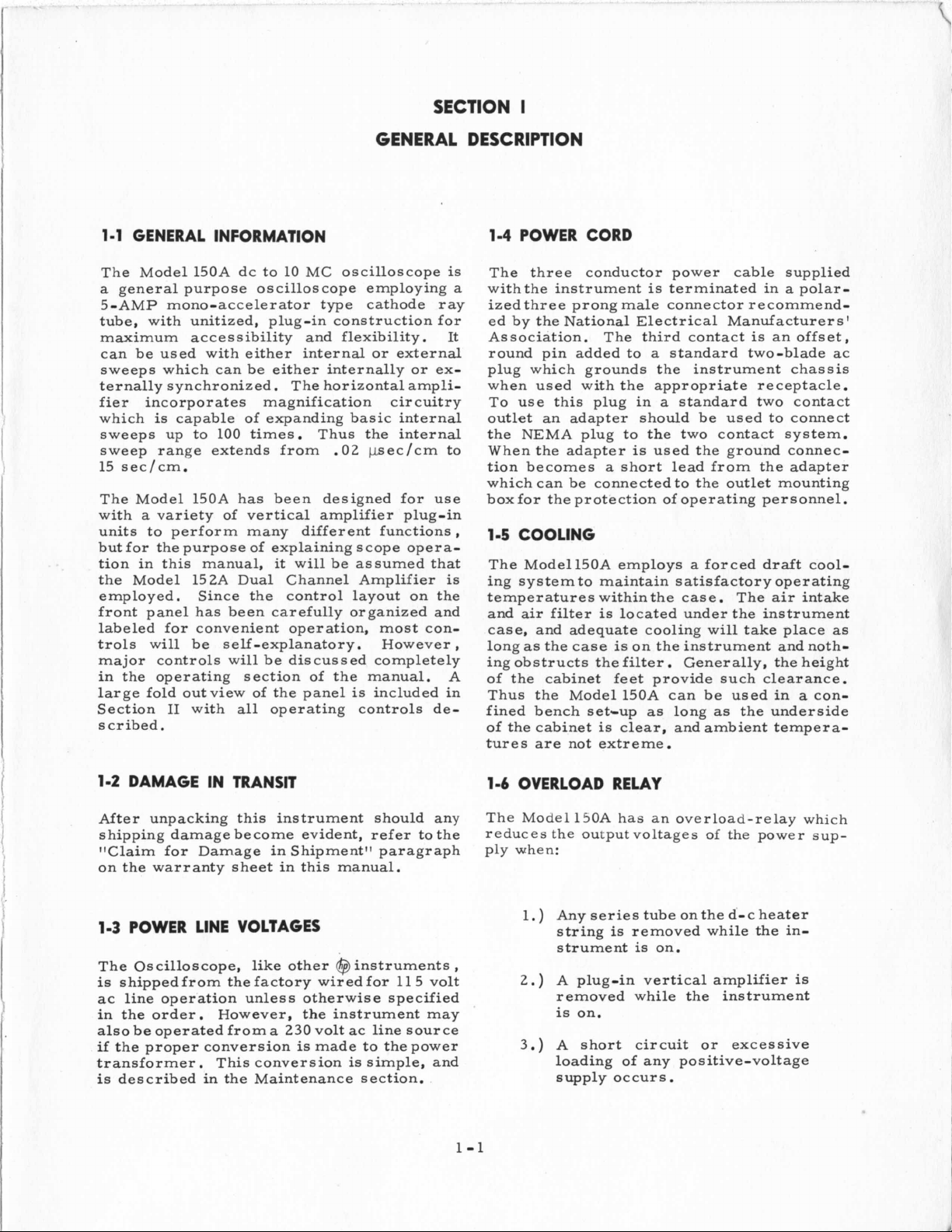

The front panel arrangement and operating

controls are shown in the fold out illustration, Figure 2-1. The description of the operating controls should enable you to operate

the instrument

of oscilloscope technique. However,

plete description of control function follows:

on. This delay provides an adequate

turned off for any reason this delay will

CONTROLS AND TERMINALS

if

you have a basic knowledge

30

seconds after you

If

the instrument

2-ZA INTERNAL SWEEP CONTROLS

SWEEP TIME/CM

Amulti-position switchwhich selects any one

of twenty four calibrated sweep speeds from

0.1 pec/cm to5 sec/cm. This switchis

sociated with a concentric VERNIER which

provides continuous adjustment of sweep

speed between steps, and in the full counterclockwise position extends the sweep time to

is

15 sec/cm. When the VERNIER

clockwise position (GAL),

cuit and the sweep time

k370

as

read

on

the SWEEP TIME/CM dial.

INT. SWEEP MAGNIFICATION

Afive position magnification control,

X10, X50, and X100. The Xlposition provides

calibrated sweep speeds

TIME /CM switch. Other positions indicate

degree of expansion taking place about the

vertical centerline on the scope graticule.

Whenever the sweep

the SWEEP MAGNIFIED lamp will light. The

fastest calibrated sweep time of

is

obtained by setting the SWEEP TIME/CM

switch to

.1

or

.2

psec/cm and setting the

it

is

is

calibrated within

as

read onthe SWEEP

is

magnified beyond X1

in the full

out of the cir-

0.02

pec/cm

a

X1,

its

com-

as-

X5,

II

magnifier on X5 or

exceed the fastest calibrated sweep time, the

MAGNIFIER UNCALIBRATED reminder lamp

will light. It will also light with 1 psec/cm

X50 and 2 psec/cm X100.

SYNC

Afour position switch which enables the sweep

to be triggered either internally or externally. Internal triggering can be accomplished

a

from

applied vertical input signal of sufficient amplitude to produce

nal triggering can be effected by signals having amplitudes greater than

the low frequency cut

sync input circuit

it

low frequency sync signals. Concentric with

the SYNC switch

SWEEP MCDE

A

bias of the sweep generator. As the control

is

tion, the sweep generator will pass from

free running (FREE) condition to a condition

where triggering

the extreme counterclockwise position the

control switches into

PRESET provides optimum triggering bias

for nearly

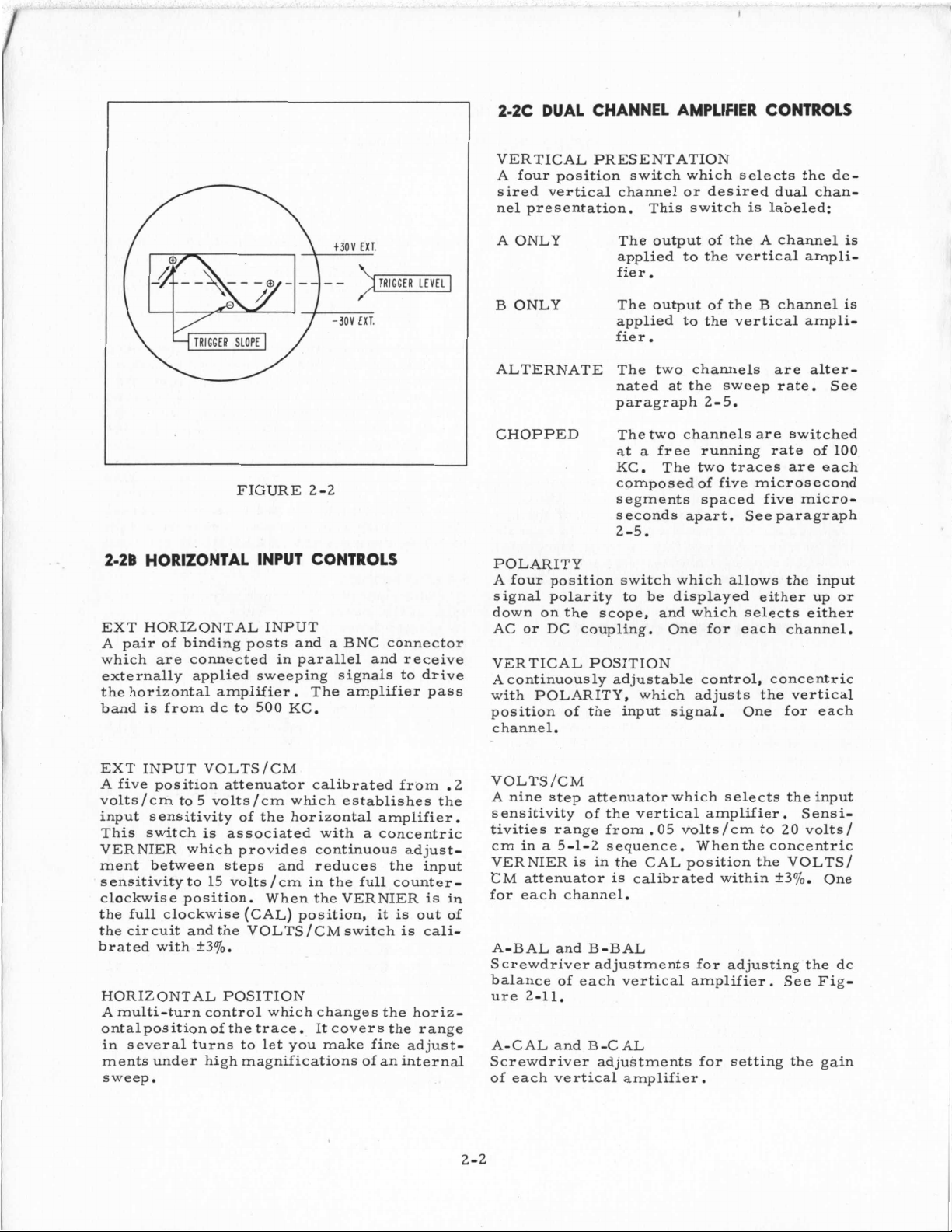

TRIGGER LEVEL

A continuous control which selects the ampli-

tude level of the sync signal where trigger-

ing occurs. For external synchronizing sig-

nals therange of this controlis from

-30

at

complex waveforms. See Figure 2-2.

TRIGGER SLOPE

A two position switch concentric with TRIGGER LEVELwhich permits triggering to occur on either the positive

of internal, external or line voltage sync signals. See Figure 2-2.

EXT

A

which are connected in parallel and receive

external synchronizing signals.

line voltage signal or (INT) from an

is

advisable to use

continuous control which adjusts the input

rotated from the extreme clockwise posi-

all

sync applications.

volts, allowing the sweep to be triggered

any point within this range on simple or

SYNC

pair of binding posts and a BNC connector

INPUT

X1O

respectively. If you

a

5mm deflection. Exter-

0.

5 volt. Since

off

of the ac coupled

is

approximately 200 cps,

EXT

DC for external

is

the SWEEP MODE control.

is

required (TRIGGER). At

a

PRESET position.

or

negative slope

+30

to

a

2-1

Page 9

2-2C

DUAL

VERTICAL PRESENTATION

A four position switch which selects the desired vertical channel or desired dual channel presentation.

CHANNEL AMPLIFIER CONTROLS

This switch

is

labeled:

FIGURE 2-2

2-2B

HORIZONTAL INPUT CONTROLS

EXT HORIZONTAL INPUT

a

A pair of binding posts and

which are connected in parallel and receive

externally applied sweeping signals to drive

the horizontal amplifier. The amplifier pass

is

band

from dc to

500

KC.

BNC connector

A ONLY

B ONLY

ALTERNATE

CHOPPED

POLARITY

A four position switch which allows the input

signal polarity to be displayed either up or

down on the scope, and which selects either

AC or

VERTICAL POSITION

A continuously adjustable control, concentric

with POLARITY, which adjusts the vertical

position of the input signal. One for each

channel.

DC

The output of the A channel

applied to the vertical amplifier.

The output of the B channel

applied to the vertical ampli-

fier.

The two channels are alter-

at

nated

paragraph 2-5.

The two channels

at

a

KC.

composed of five microsecond

segments spaced five microseconds apart. See paragraph

2-5.

coupling. One for each channel.

the sweep rate. See

are

switched

free running rate

The

two

traces are each

of

100

is

is

EXT INPUT VOLTS/CM

A five position attenuator calibrated from .2

volts/cm to 5 volts/cm which establishes the

input

This switch

VERNIER which provides continuous ad just

ment between steps and reduces the input

sensitivity to 15 volts /cm in the full counterclockwise position. When the VERNIER

the full clockwise (CAL) position,

the circuit and the VOLTS/CM switch

brated with

HORIZONTAL POSITION

A multi-turn control which changes the horiz-

ontalpositionof the trace. It covers the range

in several turns to let you make fine adjustments under high magnifications of an internal

sweep.

sensitivity of the horizontal amplifier.

is

associated with a concentric

is

it

is

out of

is

cali-

+30/0.

in

VOLTS /CM

A nine step attenuator which selects the input

sensitivity of the vertical amplifier.

tivities range from. 05 trolts/cm to 20 volts/

a

cm in

-

VERNIER

‘CM

for each channel.

A-BAL and B-BAL

Screwdriver adjustments for adjusting the dc

balance of each vertical amplifier.

ure

A-CAL and B-CAL

Screwdriver adjustments for setting the gain

of each vertical amplifier.

2-2

5-1-2 sequence.

is

in the CAL position the VOLTS/

attenuator is calibrated within

2-11.

Whenthe concentric

Sensi-

+3oJO.

One

See Fig-

Page 10

2-2D

CRT PANEL CONTROLS

FOCUS

01s

Contr

trace resolution,

RESET

A terminal which can receive an external

pulse to rearm the single sweep circuit. Pulse

characteristics required

peakwithno overshoot;

=

+15 to +25 volts

2

to 4 pseconds width.

INTENSITY

Controls trace brightness.

SCALE LIGHT

Adjusts brightness of graticule lines.

CALIBRATOR

a

at

1000

the

rise

A multi-position switch which adjusts

cps square wave from 0.2 millivolts to 100

volts in

+3

of

adjacent terminal and can be used to calibrate the deflection sensitivity of the vertical

and horizontal amplifier

and decay times are each less than 1 micro-

second. The square wave output may also be

used to adjust the divider probe for frequency

response.

a

2-5-10 sequence with an accuracy

70.

The output voltage appears

.

Square wave

2-2E TOP ACCESS CONTROLS

The following controls and terminals are accessible through the top access door of the

instrument cabinet.

Horizontal and vertical deflection plates.

A terminal for CRT intensity (Z-axis) modulation

FUSE

Line fuse

Thermal cutout with resetting button.

2-3

OPERATING PROCEDURES

Basic operating procedures are described by

illustrations

steps in eachcase. The

are complete. Others are arranged to supplement the

tions possible in using the oscilloscope.

index to these illustrations follows:

FIG.

2-3

2 -4

2-5

2-6

2-7

2

-8

2

-9

2-10

2-1 1

2-12

2-13

2-14

2-15

2-16

2-17

(Fl)

6-1/4 amp slo-blo.

which are keyed to procedural

first

twoprocedures

first

two by showing the varia-

TITLE

Internal Sweep

Internal Sweep

Internal Sweep Magnification

External Horizontal Input

Vertical Input

Adjusting Divider Probe

Removing CRT Bezel

Aligning Scope Trace with Graticule

Vertical Balance Adjustment

Direct Connection to

Capacitive Coupling to CRT Plates

Single Sweep Operation

Delayed Sweep Operation

Vertical VOLTS /CM Calibration

External Intensity Modulation

--

Internal Sync

--

External Sync

--

Dual Trace

CRT

Plates

An

SAWTOOTH OUT

A terminal which provides

voltage corresponding to the sweep.

GATE OUT

A terminal which provides

voltage for the duration of the sweep.

SINGLE-NORMAL

A switch which selects either normal or sin-

gle sweep operation. In single sweep posi-

tion the circuits are arrangedto sweep once

a

after

tive until manually or

The ARMED lamp lights when the single sweep

circuit

trigger signal and then remain inopera-

is

ready for a trigger.

a

sawtooth output

a

positive gate

electronically reset.

2-4

VERTICAL AC OR DC COUPLING

Under most conditions AC coupling will be

used.

without regard for the dc levels involved. In

the AC position the input signal (vertical or

external sync)

through

component from the input wave. This coup-

ling circuit has

cps; however, to avoid degrading input pulses

or square waves below 10 cps

to use dc coupling.

When you want to look

to

rundown in circuit work, or in mechanical

work where the output from

a

It permits high gain to be employed

is

coupled to the instrument

a

capacitor which removes the dc

a

low frequency cut off

it

is

advisable

at

waveforms relative

a

dc level; for example, observing a Miller

a

transducer has

dc component; use dc coupling.

2-3

at

2

Page 11

2-5

USE

OF

CHOPPED

OR

ALTERNATE SWEEP

CHOPPED and ALTERNATE VERTICAL PRG

two

SENTATIONare used topresent

electrical phenomona, which are related in

frequency or rate of recurrence, to the

cilloscope CRT for simultaneous viewing.

ALTERNATE may be used whenever sweep

time and rate of recurrence are rapid enough

is

and screenpersistence

vent objectionable flicker. CHOPPED PRESENTATION should be used

NATE position

on the screen as the inputs are switched after

a

flickering effect

long enoughto pre-

if,

separate

os-

in the ALTER-

is

noticeable

each sweep. When two related signals are

being presented to the oscilloscope for

multaneous viewing using either CHOPPED

or ALTERNATE VERTICAL PRESENTATION

the 150A should be synchronized externally.

Insome cases

different input waves not related infrequency.

In this instance the 150A may be synchronized

internally, triggering automatically

one signal then from the other

is

dure

may cause noticeable deterioration of the

quality

may be improved byadjusting the VERTICAL

POSITION controls

not ordinarily recommended since

of

it

may be desirable to view two

first

.

This proce-

the presentation. Quality generally

so

that the traces overlap.

si-

from

it

2-4

Page 12

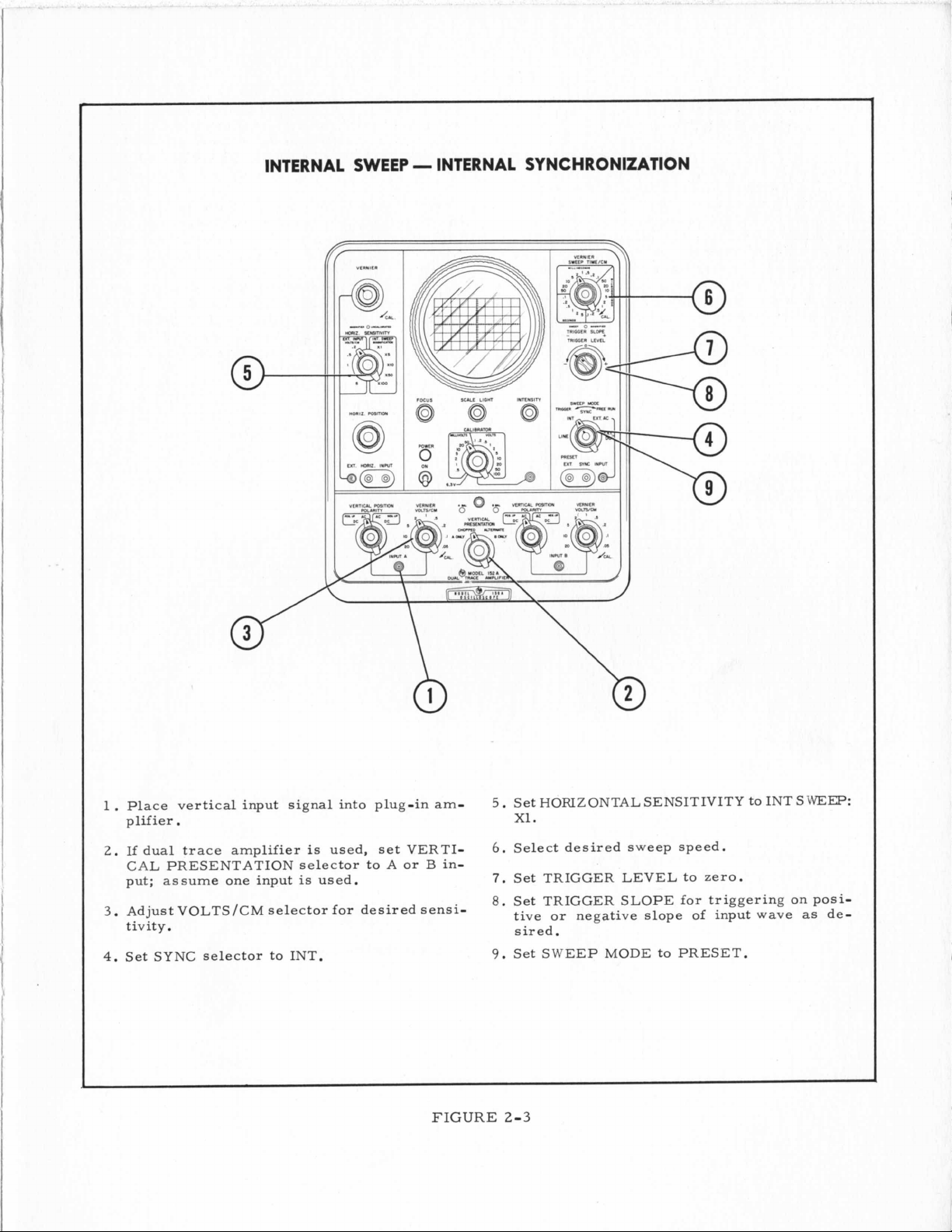

INTERNAL SWEEP - INTERNAL SYNCHRONIZATION

-0-

I

1.

Place vertical input signal into plug-in am-

plifier.

2.

If dual trace amplifier

CAL PRESENTATION selector to

put; assume one input is used.

3

.

Adjust VOLTS/CM selector for desired sensitiv it

y

.

4.

Set SYNC selector to INT.

is

used, set VERTI-

A

or

B

in-

FIGURE

5.

Set HORIZONTAL SENSITIVITY to INT

x1.

6.

Select desired sweep speed.

7.

Set TRIGGER LEVEL to zero.

8.

Set TRIGGER SLOPE for triggering on positive or negative slope

sired.

9.

Set SWEEP MODE to PRESET.

2-3

of

input wave

SWEEP:

as

de-

Page 13

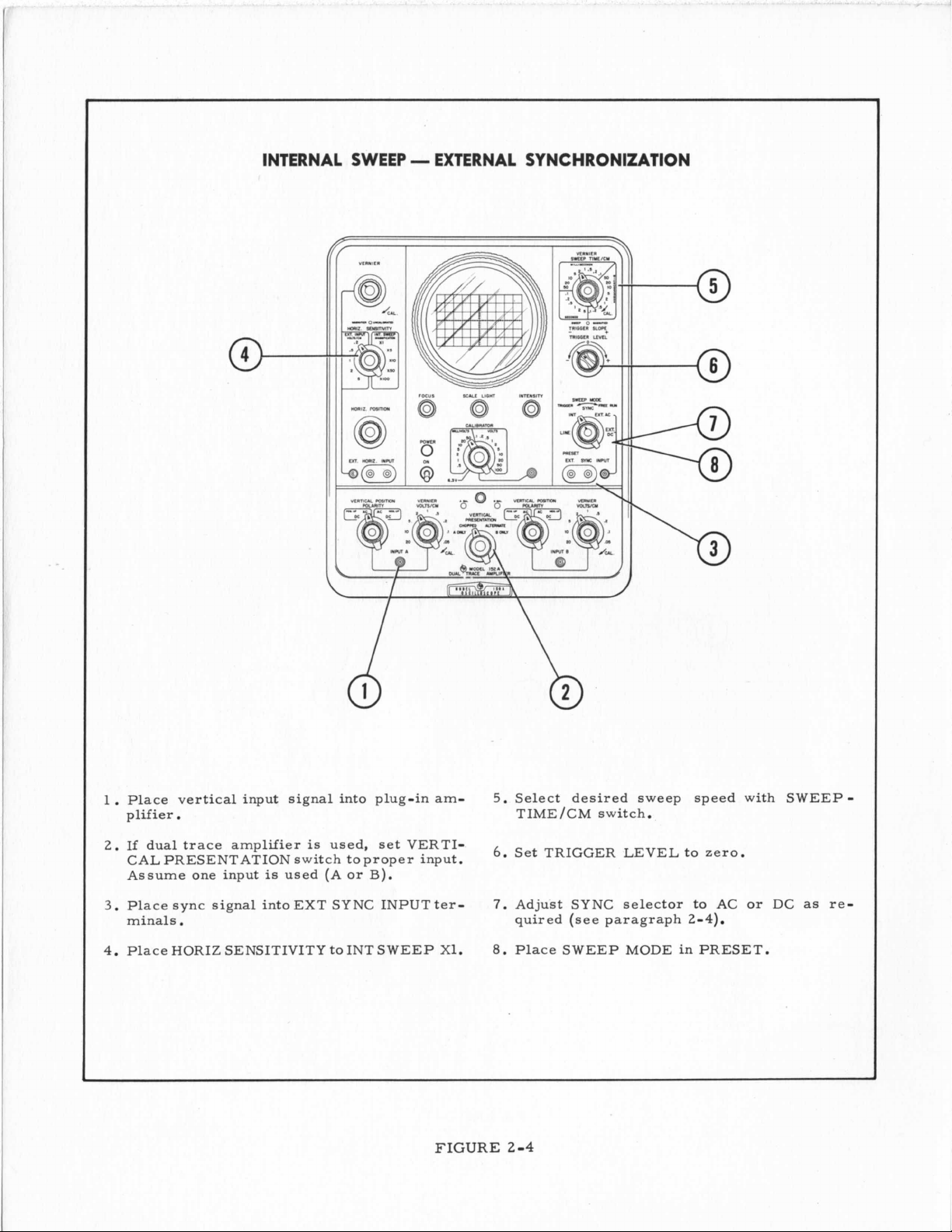

INTERNAL SWEEP - EXTERNAL SYNCHRONIZATION

1.

Place vertical input signal into plug-in am-

plifier.

2.

If dual trace amplifier

CALPRESENTATION switch toproper input.

Assume one input

3

.

Place sync signal into EXT SYNC INPUT terminals

4.

Place HORIZ SENSITIVITY to INT SWEEP X1.

.

is

is

used (A or

used, set VERTI-

B).

FIGURE

5.

Select desired sweep speed with SWEEPTIME/CM switch.

6.

Set TRIGGER LEVEL to zero.

7.

Adjust SYNC selector to AC or DC

quired (see paragraph

8.

Place SWEEP MODE in PRESET.

2-4

2-4).

as

re-

Page 14

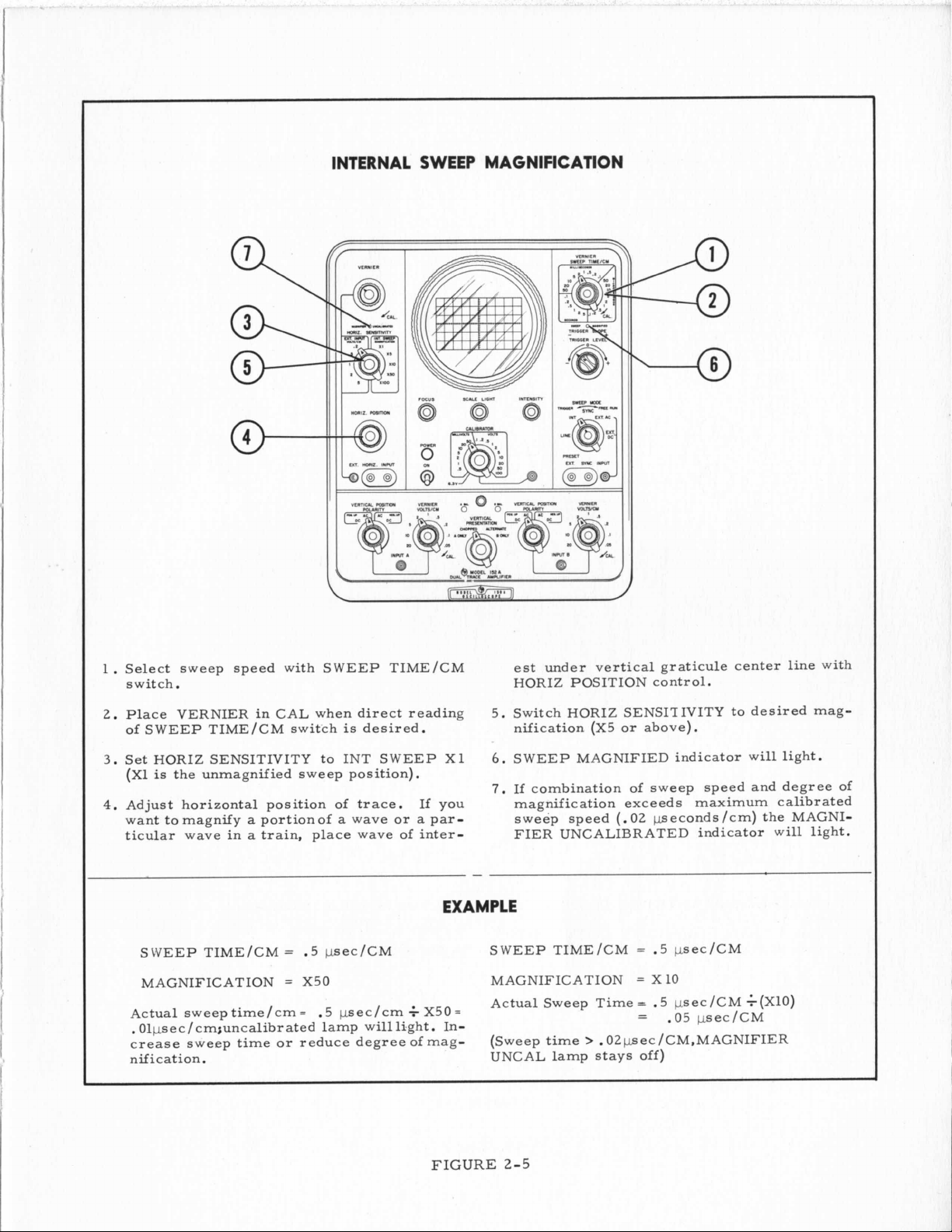

INTERNAL SWEEP MAGNIFICATION

I

1.

Select sweep speed with SWEEP TIME/CM

switch.

Place

2.

of SWEEP TIME/CM switch

3.

Set HORIZ SENSITIVITY to INT SWEEP X1

(X1

4.

Adjust horizontal position of

want

ticular wave in

nification. UNCAL lamp stays off)

VERNIER in CAL when direct reading

is

the unmagnified sweep position).

to

magnify a portionof a wave or a par-

a

train, place wave

SWEEP TIME/CM

MAGNIFICATION

Actual sweeptime/cm=

.

Olpsec / cm;uncalibr ated lamp will light. In-

crease sweep time or reduce degree of mag-

=

=

is

desired.

of

G

If you

inter-

X50=

trace.

.5 psec/CM

X50 MAGNIFICATION

psec/cm

.5

est under vertical graticule center line with

HORIZ POSITION control.

5. Switch HORIZ SENSITIVITY to desired magnification (X5 or above).

6.

SWEEP MAGNIFIED indicator will light.

7.

If

combination of sweep

magnification exceeds maximum calibrated

sweep speed

FIER UNCALIBRATED indicator will light.

SWEEP TIME/CM

Actual Sweep Time

(Sweep

time

>

.02pec/CM,MAGNIFIER

speed and degree of

(.02

peconds/cm) the MAGNI-

=

.5 psec/CM

=

X10

=

.5 psec/CM $(XlO)

=

.05

psec/CM

FIGURE

2-5

Page 15

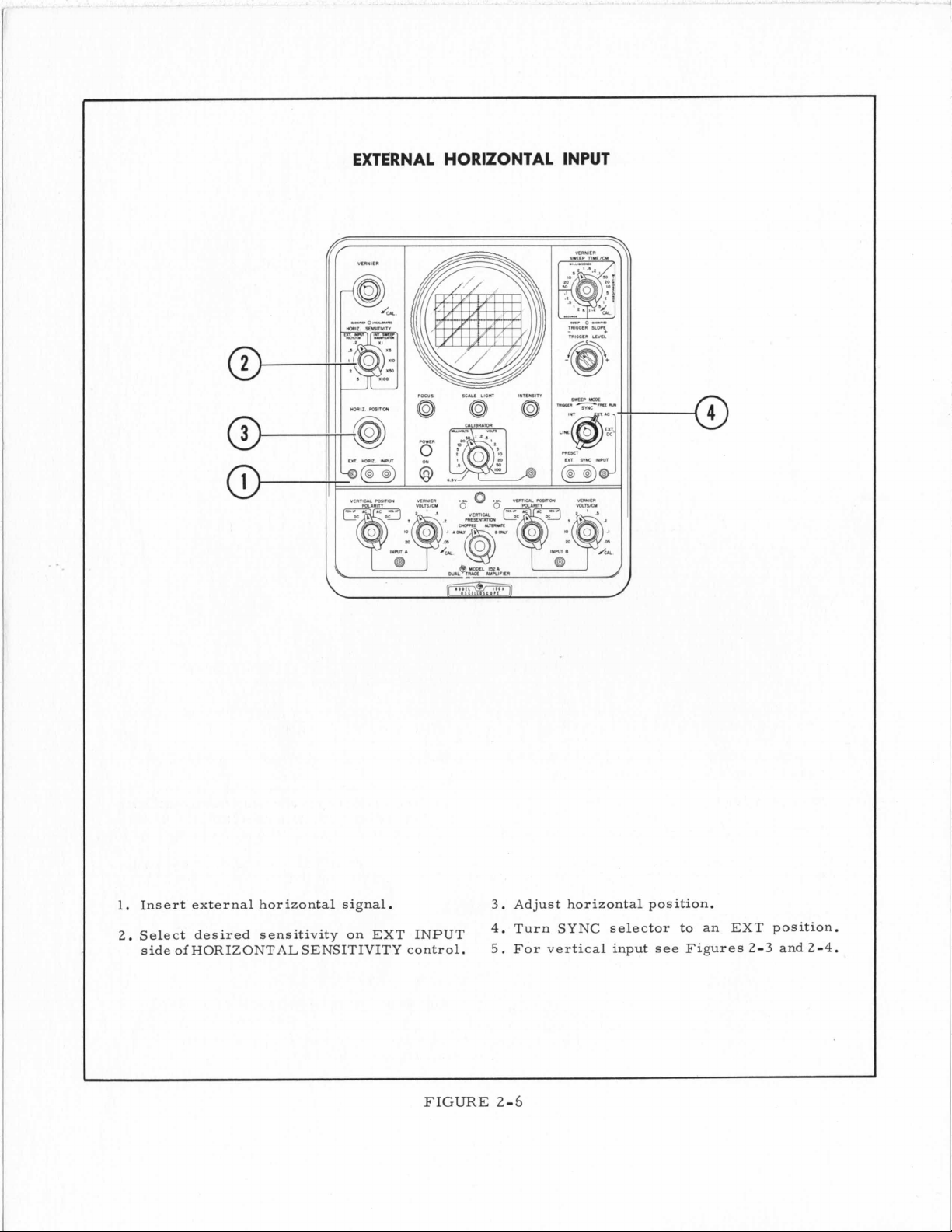

EXTERNAL HORIZONTAL INPUT

(if

VLINILI

1.

Insert external horizontal signal.

2.

Select desired

side

of

HORIZONTAL SENSITIVITY control,

sensitivity

on

EXT

INPUT

FIGURE

3.

Adjust horizontal position.

4.

Turn SYNC selector to an EXT position.

5.

For vertical input see Figures

2-3

2-6

and

2-4.

Page 16

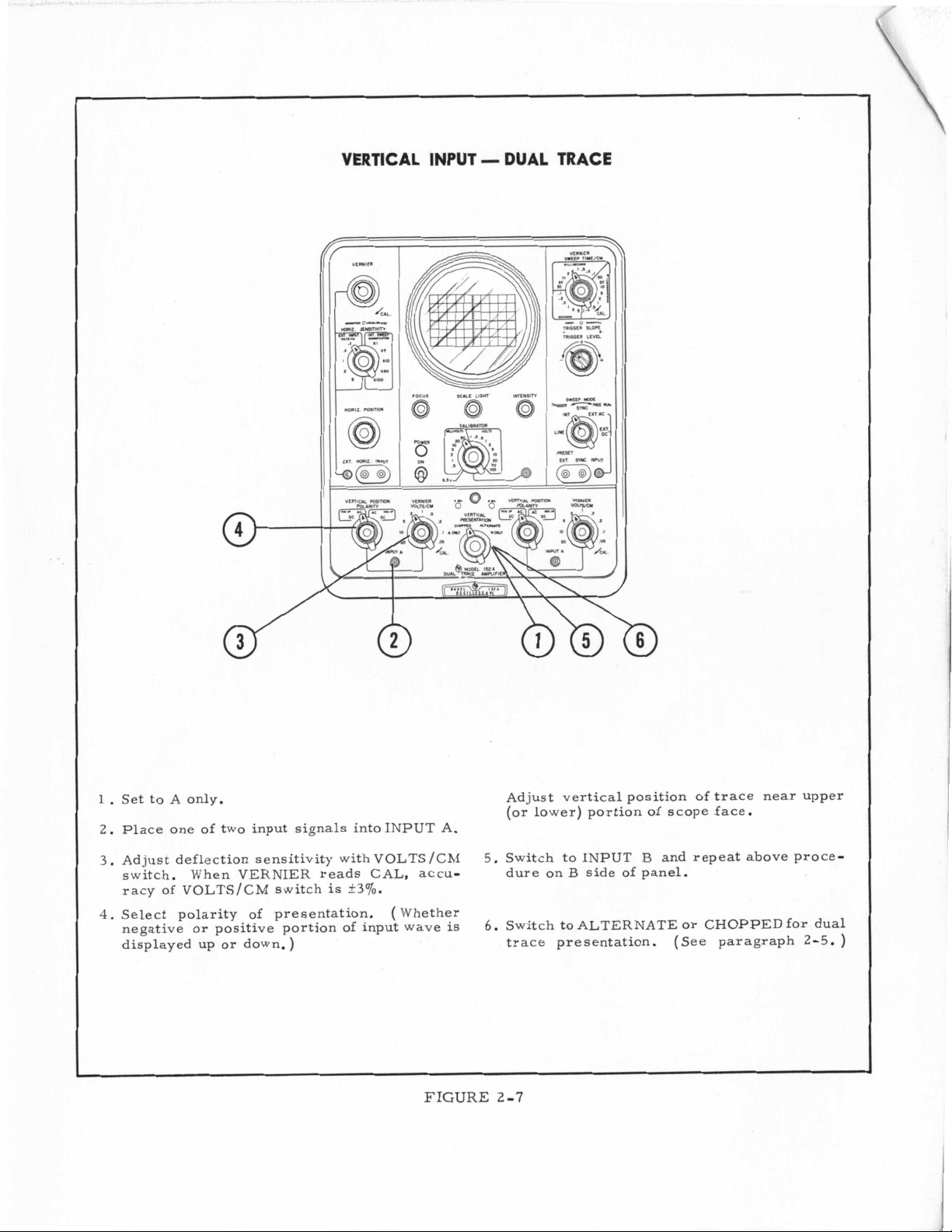

VERTICAL INPUT - DUAL TRACE

1.

Set to A only.

2.

Place one of two input signals intoINPUT A.

3.

Adjust deflection sensitivity with VOLTS /CM

switch. When VERNIER reads CAL, accuracy of VOLTS/CM switch

4.

Select polarity of presentation.

negative or positive portion of input wave

displayed up or down.)

is

+3%.

(

Whether

is

FIGURE

Adjust vertical position of trace near upper

(or lower) portion of scope face.

5.

Switch to INPUT B and repeat above procedure on

6.

Switch to ALTERNATE or CHOPPED for dual

trace presentation.

B

side of panel.

(See paragraph

2-7

2-5.

)

Page 17

..

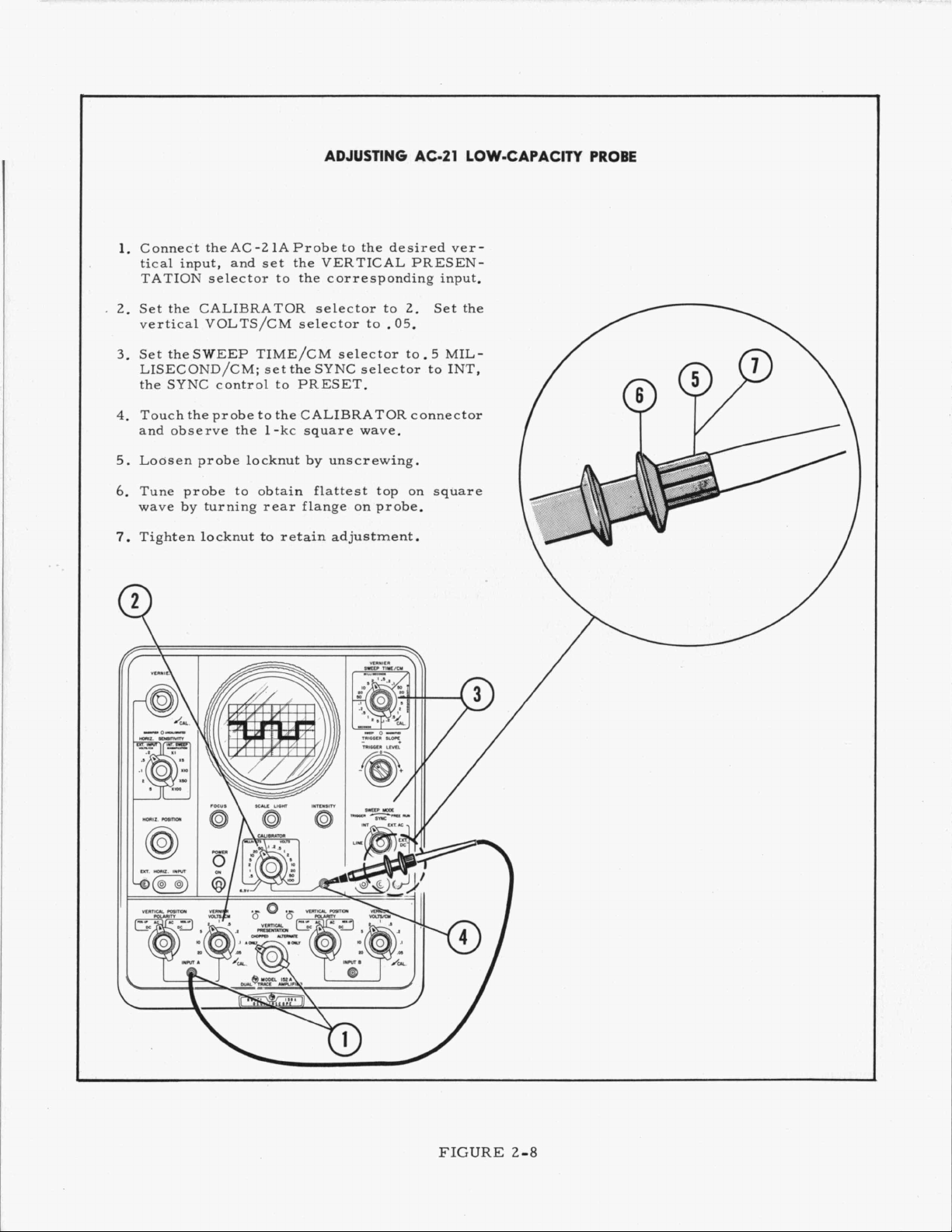

Connect theAC-21AProbe to the desired ver-

lo

tical input, and set the VERTICAL PRESENTATION selector to the corresponding input.

Set the CALIBRATOR selector to

2.

vertical VOLTS/CM selector to

Set the SWEEP TIME/CM selector to. 5 MIL-

3.

2.

.05.

LISECOND/CM; set the SYNC selector to INT,

the SYNC control to PRESET.

Touch the probe to the CALIBRATOR connector

4.

and observe the 1-kc square wave.

I

Set the

.-

Loasen probe locknut by unscrewing.

5.

Tune probe to obtain flattest top on square

6.

wave by turning rear flange

Tighten locknut to retain adjustmenti

7.

on

probe.

t:

/

II

'

FIGURE

2-8

Page 18

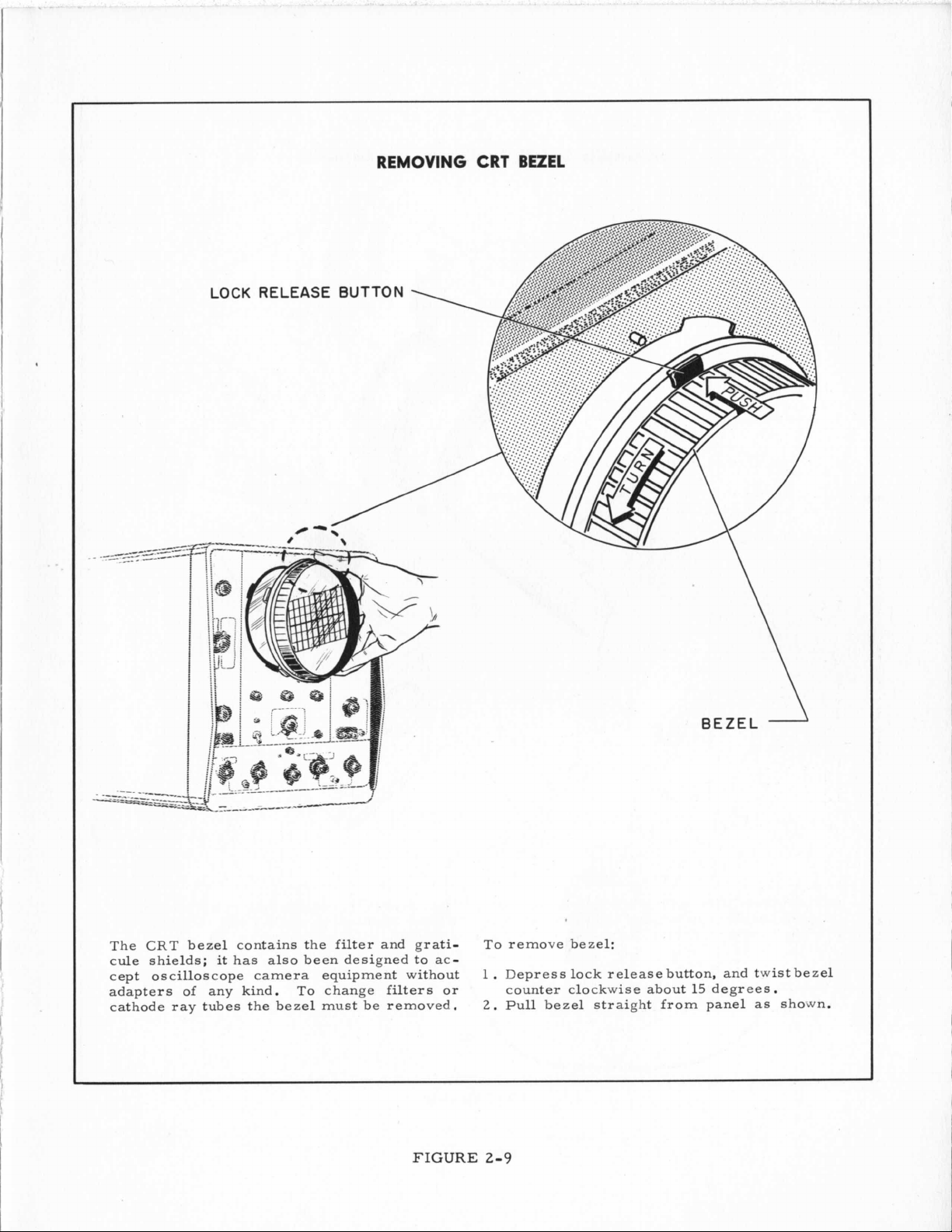

REMOVING CRT BEZEL

LOCK

RELEA

The CRT bezel contains the filter and graticule shields;

cept oscilloscope camera equipment without

adapters of any kind.

cathode ray tubes the bezel must be removed,

it

has also been designed to ac-

To

change filters or

FIGURE

To

remove bezel:

1

.

Depress lock release button, and twist bezel

counter clockwise about 15 degrees

2.

Pull bezel straight from panel

2-9

.

as

shown.

Page 19

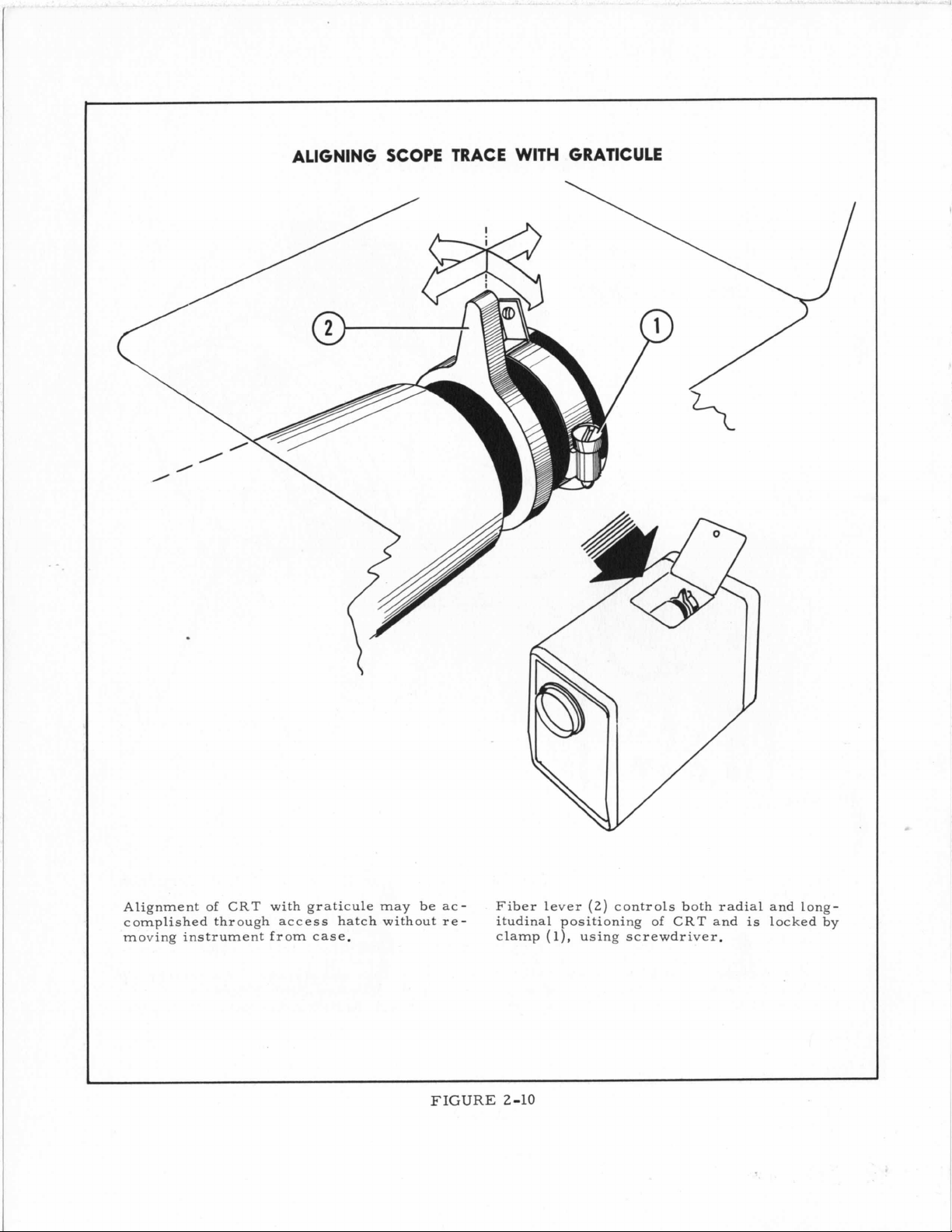

ALIGNING SCOPE TRACE

WITH

GRATICULE

Alignment

complished through access hatch without removing instrument from case.

of

CRT

with graticule may be ac-

FIGURE

(2)

Fiber lever

itudinal positioning

clamp

(l),

controls both radial and

using screwdriver.

2-10

of

CRT

and

is

locked by

long-

Page 20

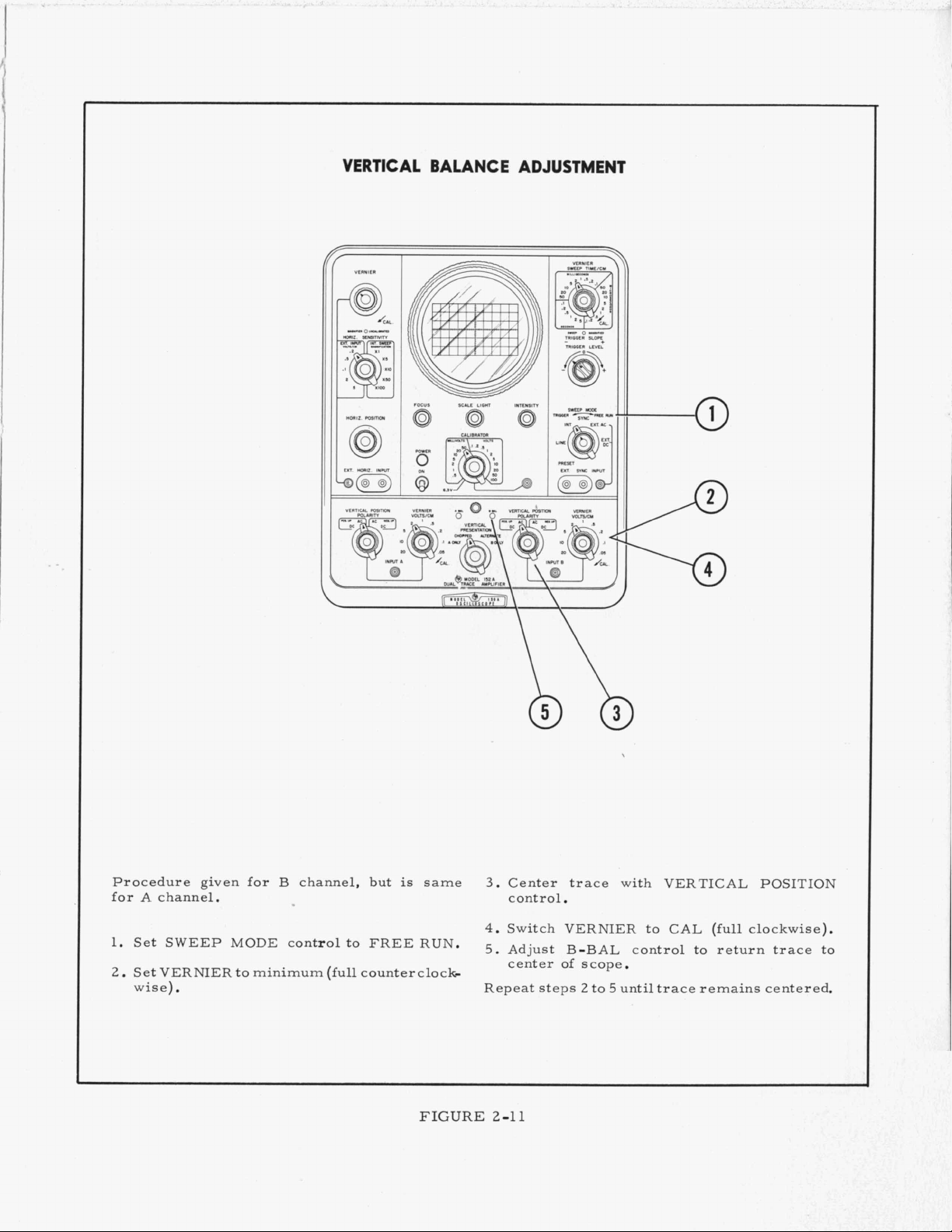

VERTICAL BALANCE ADJUSTMENT

Procedure given for B channel, but

A

for

1. Set SWEEP MODE control to FREE RUN.

2

channel.

.

Set VERNIER to minimum (full counterclock

.

wise)

is

same

FIGURE

3

.

Center trace with VERTICAL POSITION

control.

4.

Switch VERNIER to

5.

Adjust B-BAL control to return trace to

center of scope.

2

Repeat steps

2-11

to 5 until trace remains centered.

CAL

(full clockwise).

Page 21

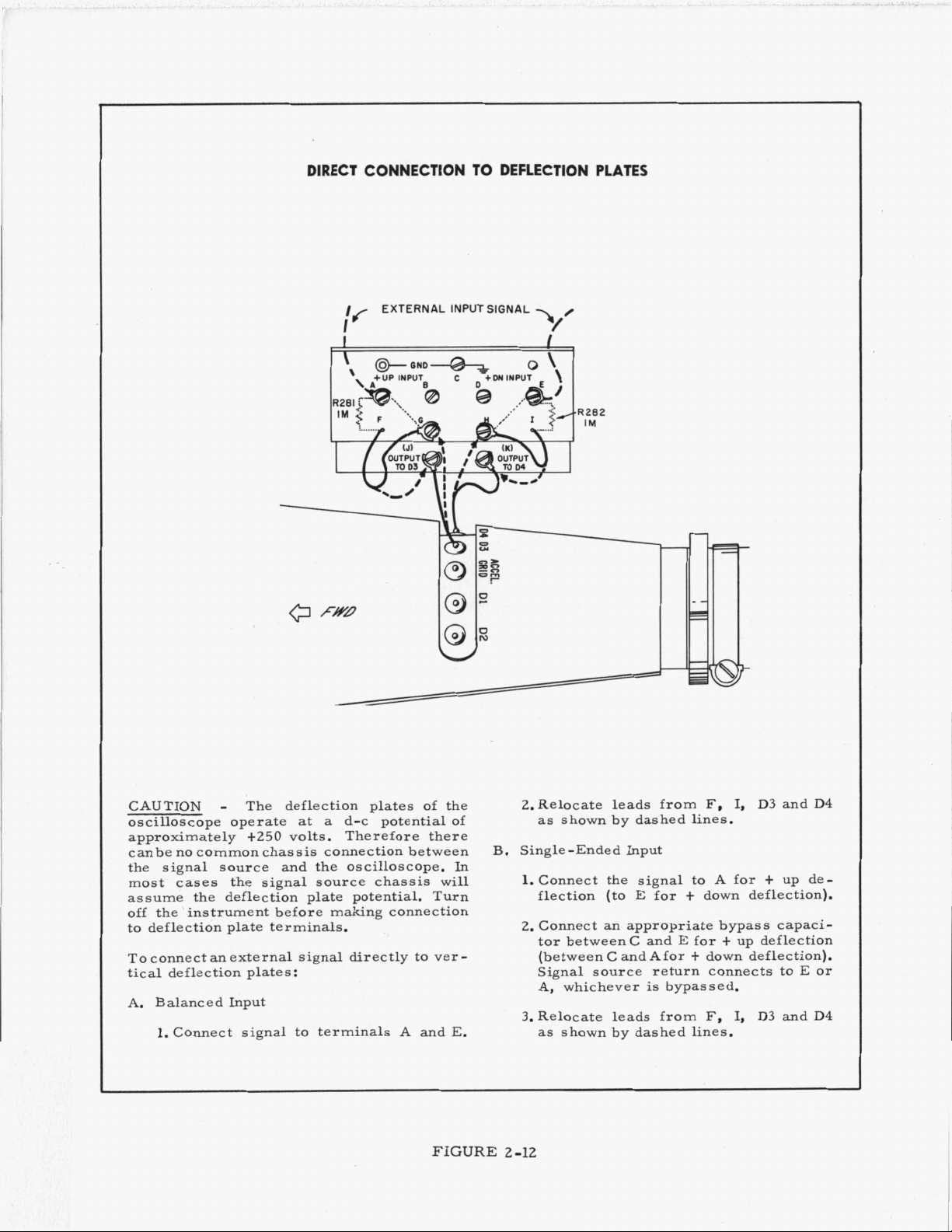

DIRECT CONNECTION

//

EXTERNAL INPUT SIGNAL

I

TO

DEFLECTION

PLATES

'R282

IM

CAUTION

oscilloscope operate

approximately +250 volts. Therefore there

canbe no commonchassis connection between

the signal source and the oscilloscope. In

most cases the signal source chassis

assume the deflection plate potential. Turn

off the

to deflection plate terminals.

To connect an external signal directly to ver

tical deflection plates:

A. Balanced Input

1,Connect signal to terminals A and

-

The deflection plates of the

at

a

d-c potential of

will

'

instrument before making connection

,

E.

FIGURE

-

2.Relocate leads from

as shown by dashed lines.

B.

Single-Ended Input

1.Connect the signal to A for + up deflection (to E for + down deflection).

2.

Connect an appropriate bypass capacitor betweenC and

(between C and Afor

Signal source return connects to

A, whichever is bypassed.

3.

Relocate leads from

as

shown by dashed lines.

2-12

F,

I,

D3

E

for t up deflection

+

down deflection).

F,

I,

D3

and

and

E

D4

or

D4

Page 22

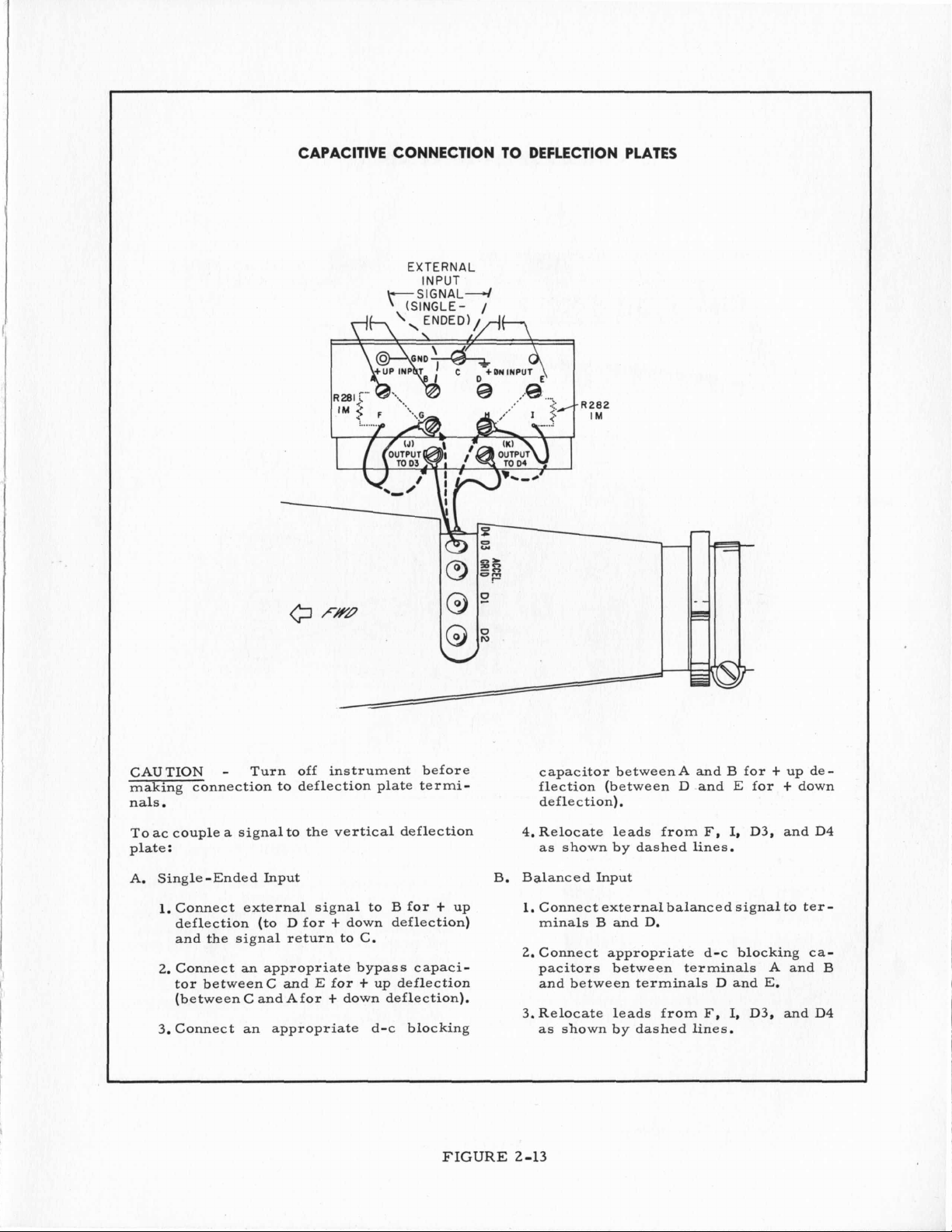

CAPACITIVE CONNECTION

EXTERNAL

INPUT

SIGNAL^

.

(SINGLE-

/

TO

DEFLECTION

-R282

IM

PLATES

CAUTION

-

Turn off instrument before

making connection to deflection plate terminals.

ac

couple a signal to the vertical deflection

To

plate

:

A. Single-Ended Input

1.

Connect external signal to B for t up

deflection (to D for

and the signal return to

2.

Connect an appropriate bypass capaci-

tor betweenC and E for

t

down deflection)

C.

t

up deflection

(between C and Afor t down deflection).

3. Connect an appropriate d-c blocking

FIGURE

capacitor betweenA and B for

flection (between D and

deflection).

F,

4.Relocate leads from

as

shown by dashed lines.

I,

B. Balanced Input

1.

Connect external balanced signal to

minals B and D.

2.

Connect appropriate d-c blocking

pacitors between terminals A and B

and between terminals

3.Relocate leads from

as

shown

by dashed lines.

D and

F,

I,

2-13

t

E

up de-

for t down

D3, and D4

E.

D3, and D4

ter-

ca-

Page 23

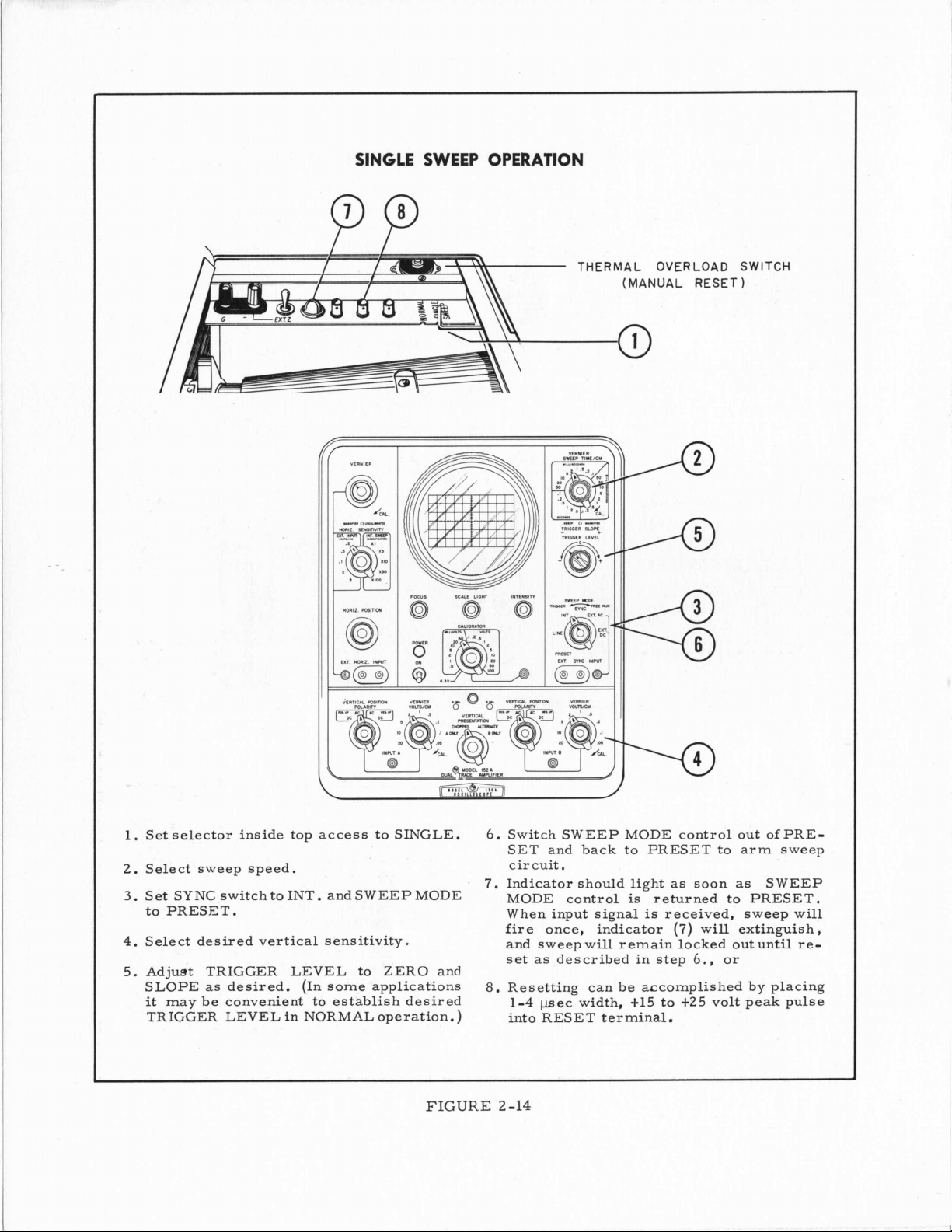

SINGLE SWEEP OPERATION

PP

THERMAL OVERLOAD SWITCH

(MANUAL RESET

1

1.

Set selector inside top access to SINGLE.

2.

Select sweep speed.

3.

Set SYNC switch to INT. and SWEEP MODE MODE control

to PRESET.

4.

Select desired vertical sensitivity.

5.

Adjust TRIGGER LEVEL to ZERO and

SLOPE

it

TRIGGER LEVEL in NORMAL operation.)

as

may be convenient to establish desired

desired.

(In

some applications

FIGURE

6.

Switch SWEEP MODE control out ofPRESET and back to PRESET to arm sweep

circuit

7.

Indicator should light

When input signal

fire

once, indicator

and sweep will remain locked out until re-

set

as described in step

8.

Resetting can be accomplished by placing

1-4

pec

into RES ET terminal

2-14

.

width,

as

soon

as

is

returned to PRESET.

is

received, sweep will

(7)

will extinguish,

6.,

or

t15

to

t25

volt peak pulse

.

SWEEP

Page 24

4

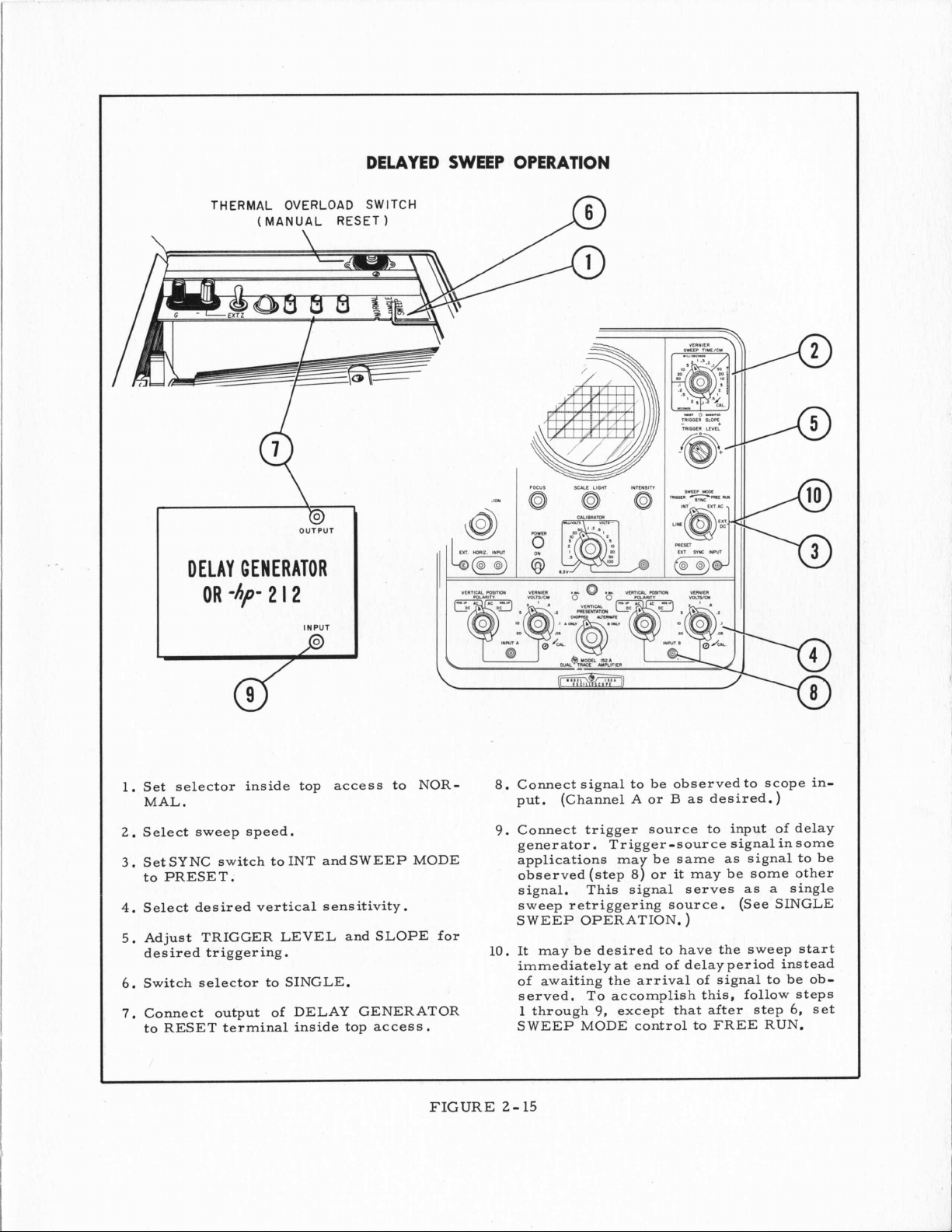

DELAYED SWEEP OPERATION

D

OUTPUT

DELAY GENERATOR

-hp-

2

OR

I2

INPUT

J3

1.

Set selector inside top access to NORMAL.

2.

Select sweep speed.

3.

Set SYNC switch to INT and SWEEP MODE

to PRESET.

4.

Select desired vertical sensitivity.

5.

Adjust TRIGGER LEVEL and SLOPE for

desired triggering.

6.

Switch selector to SINGLE.

7.

Connect output of DELAY GENERATOR

to RESET terminal inside top

access.

8.

Connect signal to be observed to scope in-

(Channel A or

put.

9.

Connect trigger source to input of delay

generator. Trigger-source signal in some

applications may be same

observed(step

signal. This signal serves

sweep retriggering source. (See SINGLE

SWEEP OPERATION.

10.

It may be desired to have the sweep

immediately

of awaiting the arrival of signal to be observed.

1 through

SWEEP MODE control to FREE RUN.

at

To

accomplish this, follow steps

9,

except that after step

8)

end

B

as

desired.)

as

or

it

may be some other

)

of

delayperiod instead

signal

as

a

to

be

single

start

6,

set

FIGURE

2-

15

Page 25

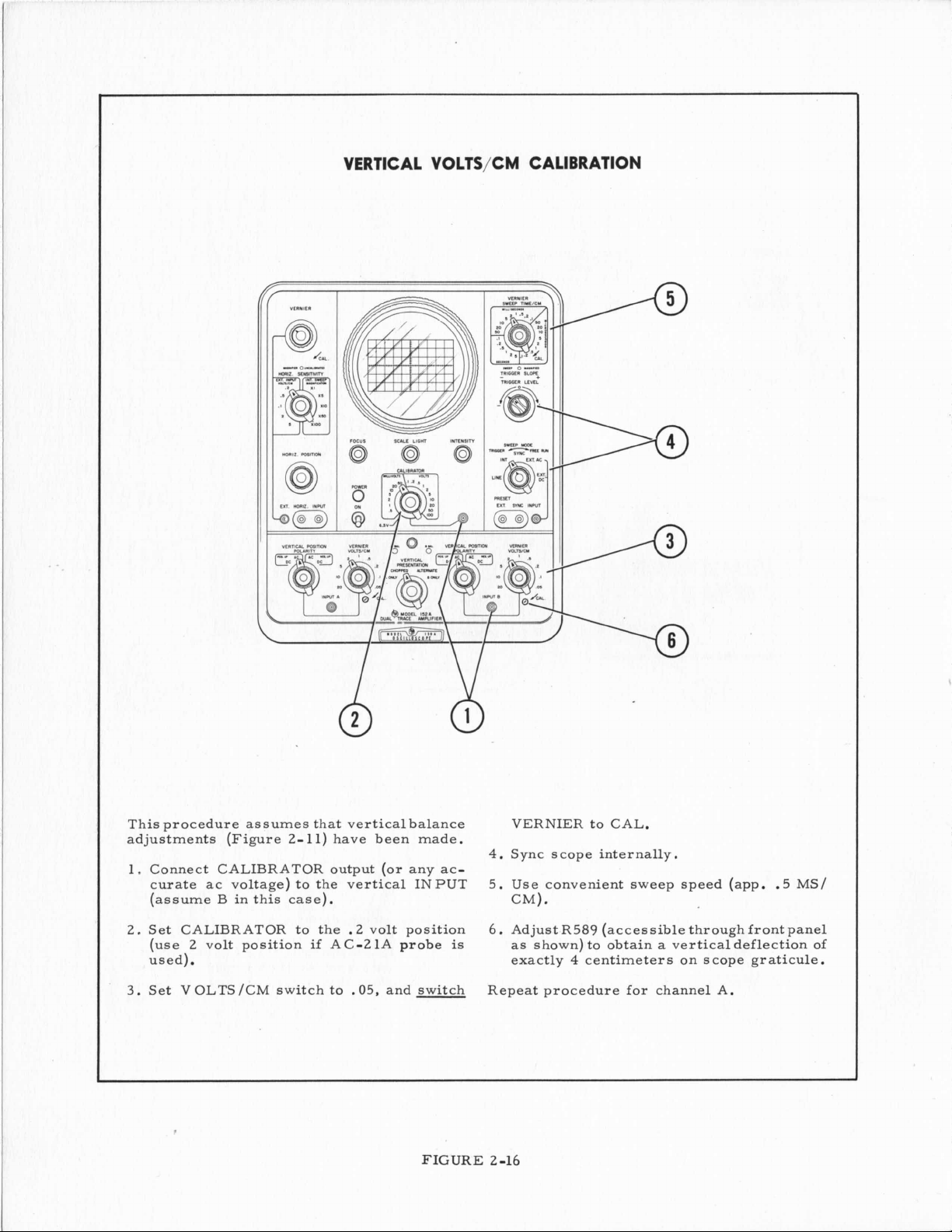

VERTICAL VOLTS/CM CALIBRATION

This procedure assumes that vertical . alance

adjustments (Figure 2- 11) have been made.

1.

Connect CALIBRATOR output (or any accurate ac voltage) to the vertical INPUT

(assume B in this case).

2. Set CALIBRATOR to the .2 volt position

if

2 volt position

(use

AC-21A probe

used).

3.

Set VOLTS/CM switch to

.05,

and switch

FIGURE

VER

TIER to CAL.

4.

Sync scope internally.

5.

Use convenient sweep speed (app. .5 MS/

CM).

6.

is

Adjust R589 (accessible through frontpanel

as shown) to obtain a verticaldeflection of

exactly

4

centimeters on scope graticule.

Repeat procedure for channel A.

2-16

Page 26

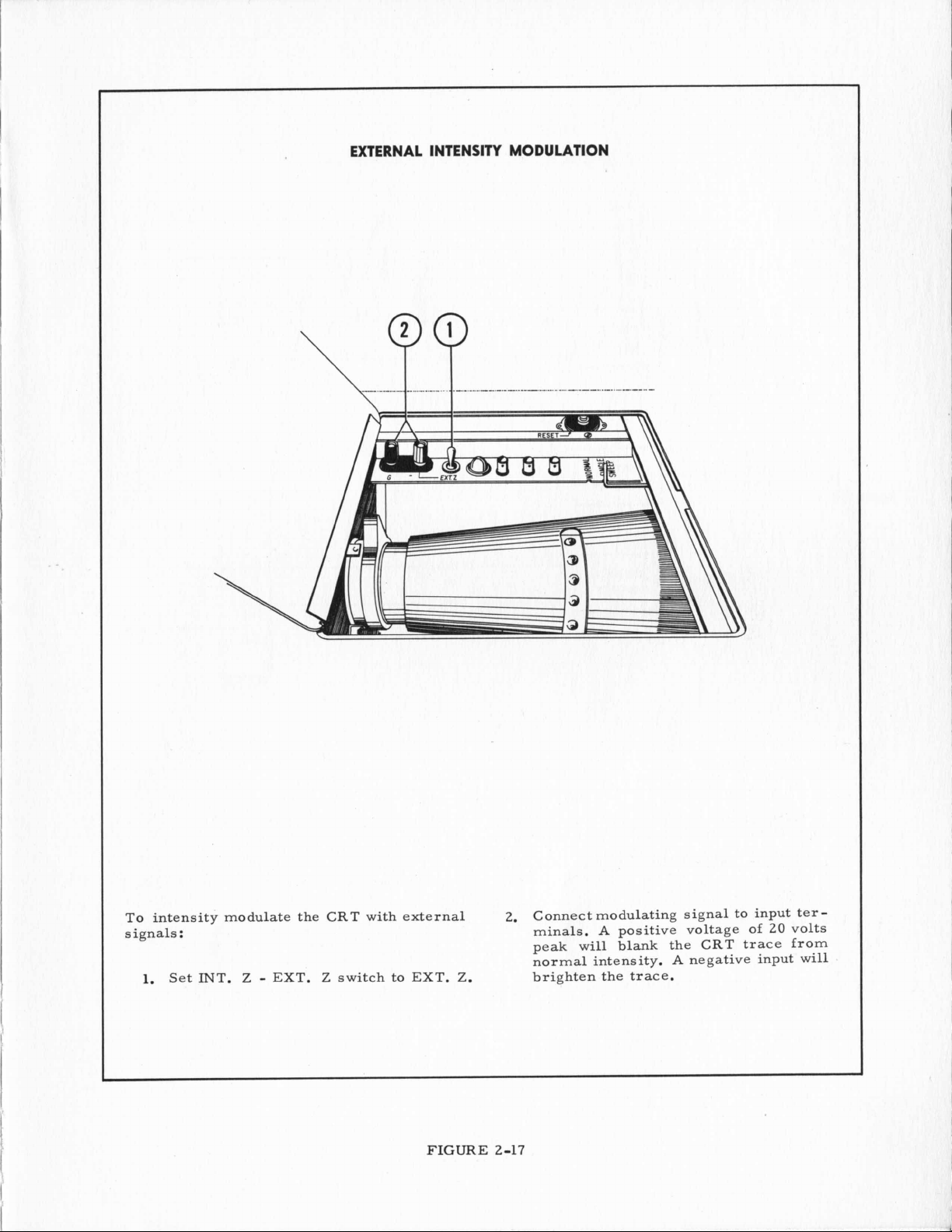

EXTERNAL INTENSITY MODULATION

I

To intensity

signals

:

1.

Set

INT.

modulate the CRT with external

Z

-

EXT. Z switch to EXT.

FIGURE

Z.

Connect modulating signal to input ter-

2.

minals.

peak will

normal intensity.

brighten the trace.

2-17

A

positive voltage of

blank

the CRT trace from

A

negative input will

20

volts

Page 27

1

INT.

SYNC

I

VERTICAL

CRT

PLATES

\

HORIZONTAL

AMPLIFIER

HORIZONTAL

FIGURE

CAT

PLATES

3-1

TO

ASTlCMATlSY

3

-0

Page 28

SECTION

111

THEORY

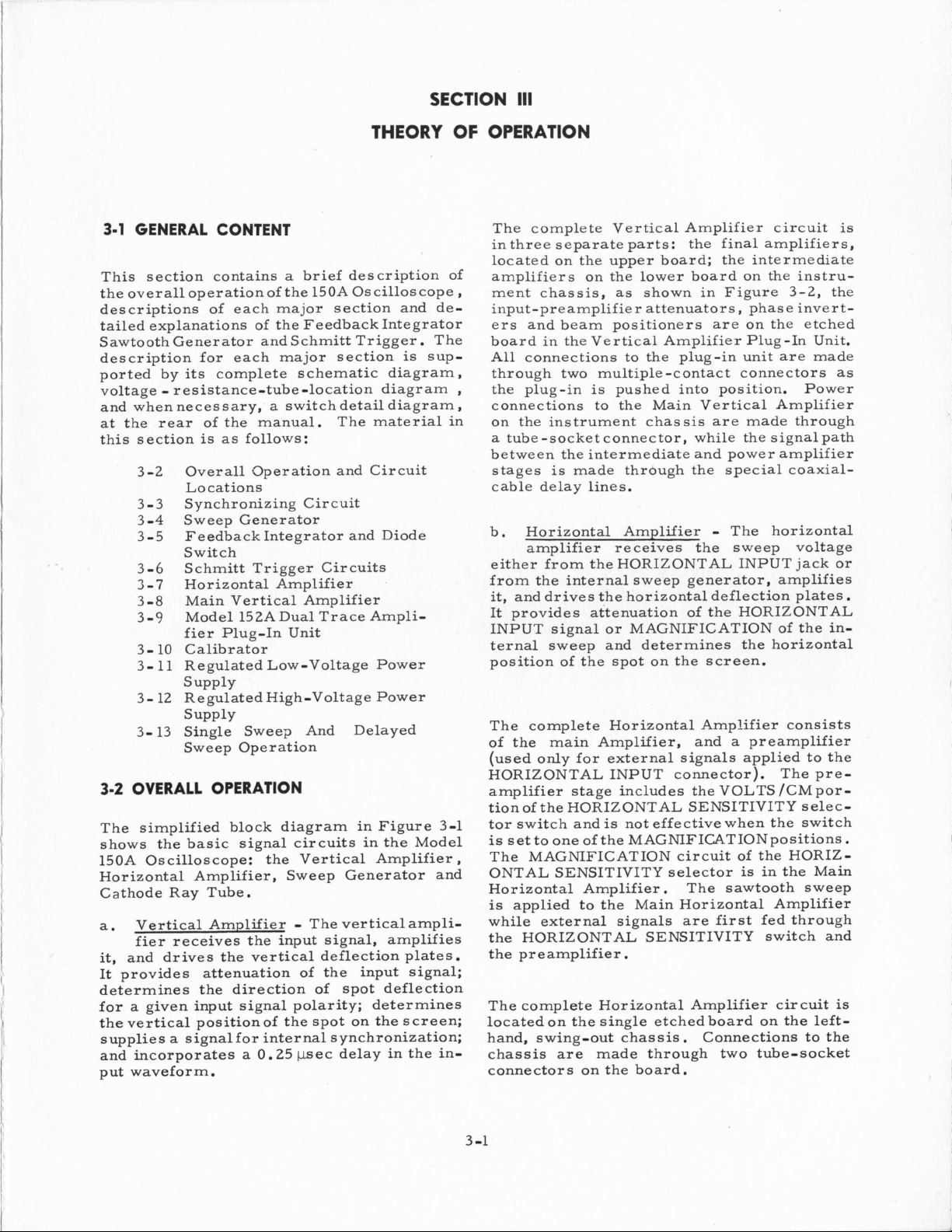

3-1

GENERAL CONTENT

This section contains a brief description of

the overall operationof the 150A Oscilloscope,

descriptions of each major section and detailed explanations of the Feedback Integrator

Sawtooth Generator andSchmitt Trigger. The

is

description for each major section

ported by

voltage

and when necessary, a switch detail diagram,

at

the rear of the manual. The material in

this section

3-2 Overall Operation and Circuit

3-3 Synchronizing Circuit

3-4 Sweep Generator

3-5 FeedbackIntegrator and Diode

3-6

3-7

3-8 Main Vertical Amplifier

3-9

3- 10 Calibrator

3-

3- 12 Regulated High-Voltage Power

3-13 Single Sweep And Delayed

3-2

OVERALL OPERATION

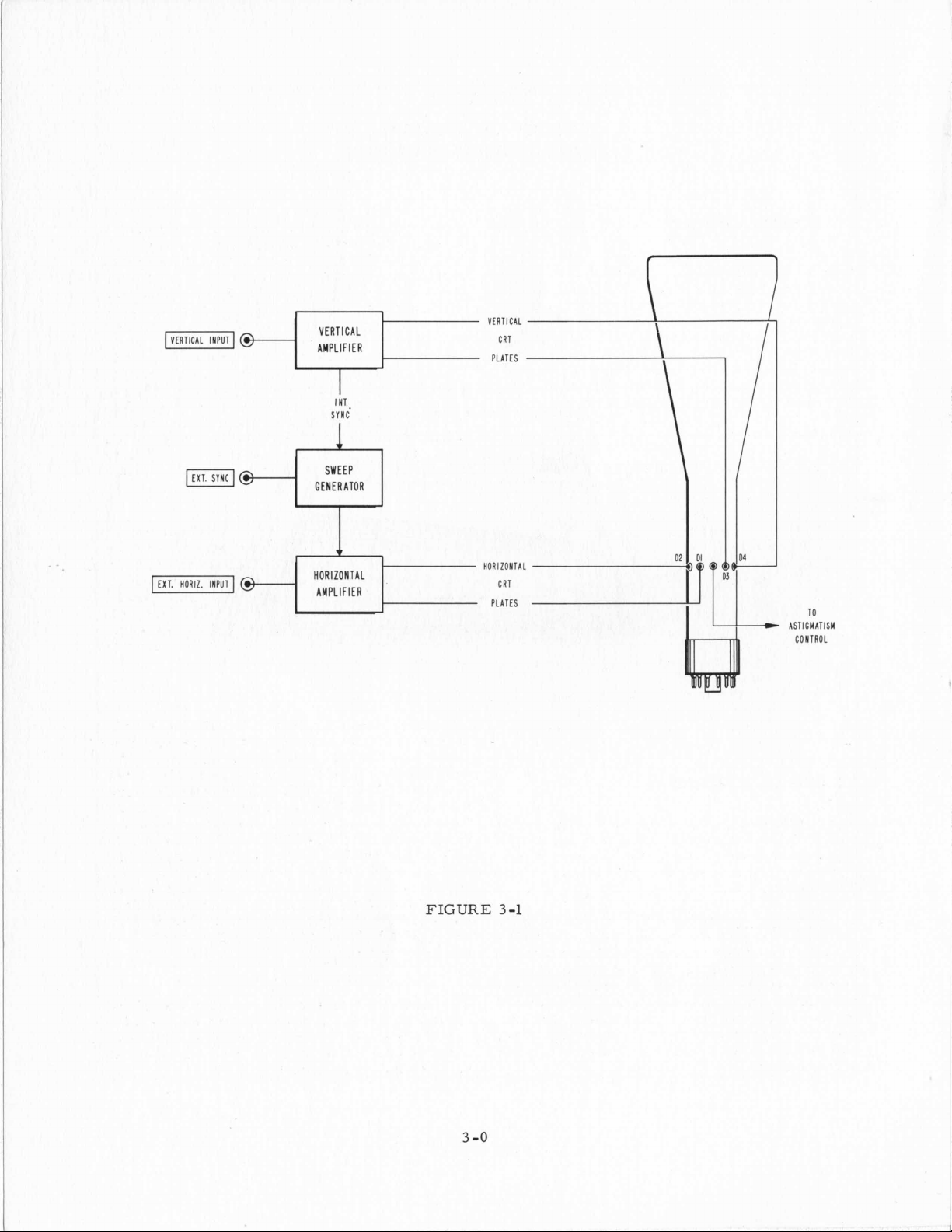

The simplified block diagram in Figure 3-1

shows the basic signal circuits in the Model

150A Oscilloscope: the

Horizontal Amplifier, Sweep Generator and

Cathode Ray Tube.

a.

Vertical Amplifier - The verticalamplifier receives the input signal, amplifies

it,

and drives the vertical deflection plates.

It

provides attenuation of the input signal;

determines the direction of spot deflection

a

for

the vertical positionof the spot on the screen;

supplies

and incorporates

put waveform.

its

complete schematic diagram,

-

resistance-tube-location diagram

is

as

follows:

Locations

Switch

Schmitt Trigger Circuits

Horizontal Amplifier

Model 152A Dual Trace Amplifier

Plug-In Unit

11

Regulated Low-Voltage Power

s

UPPlY

Supply

Sweep Operation

Vertical

given input signal polarity; determines

a

signal for internal synchronization;

a

0.25 pec delay in the in-

Amplifier,

sup-

OF

OPERATION

The complete Vertical Amplifier circuit

in three separate parts: the final amplifiers,

located on the upper board; the intermediate

amplifiers on the lower board on the instru-

ment chassis,

input-preamplifier attenuators, phase inverters and beam positioners are on the etched

board in the Vertical Amplifier Plug-In Unit.

All connections to the plug-in unit are made

through two multiple-contact connectors

,

the plug-in

connections to the Main Vertical Amplifier

on the instrument chassis are made through

a

tube-socket connector, while the signal path

between the intermediate and power amplifier

stages is made thrbugh the special coaxialcable delay lines.

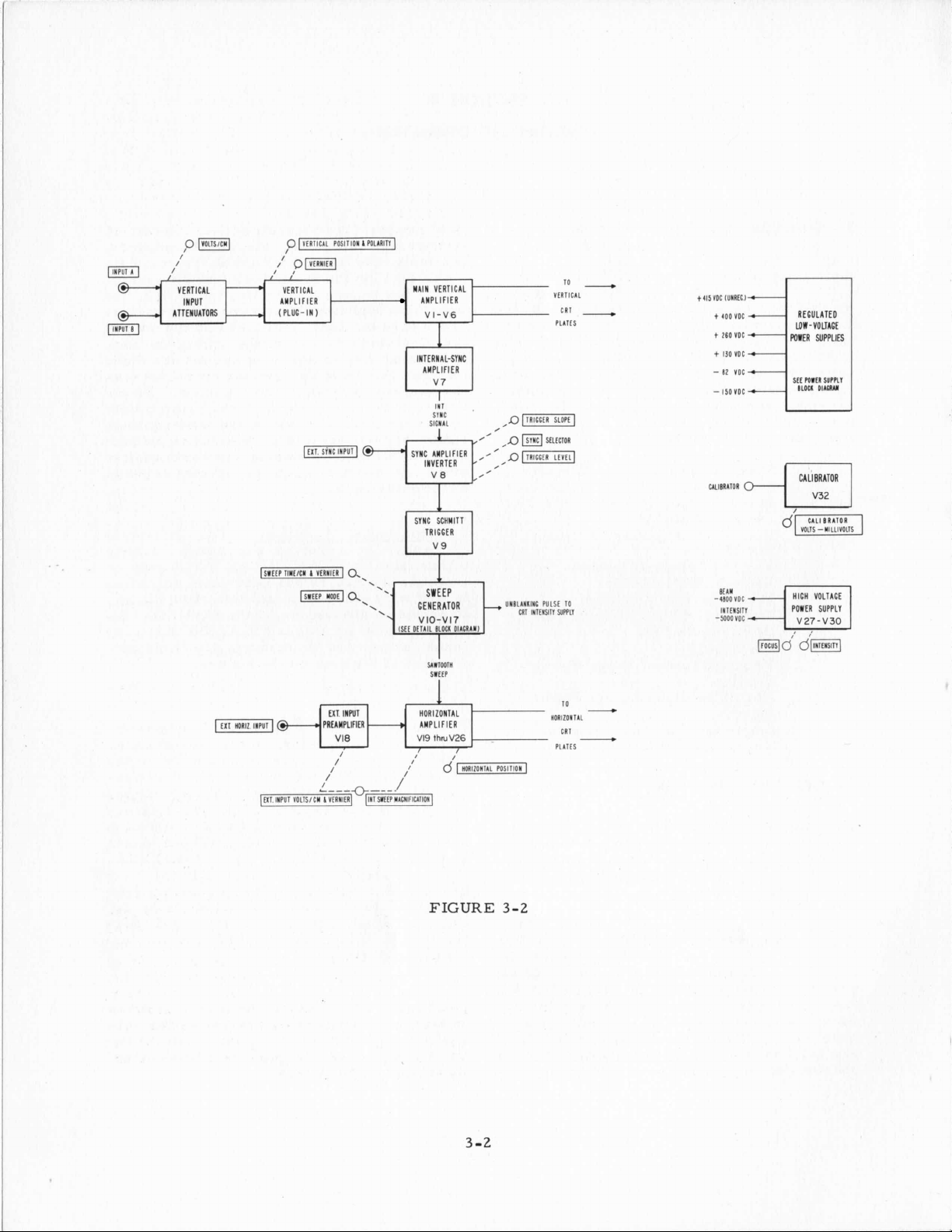

b. Horizontal Amplifier

amplifier receives the sweep voltage

either from the HORIZONTAL INPUT jack or

from the internal sweep generator, amplifies

it,

and drives the horizontal deflection plates.

It provides attenuation of the HORIZONTAL

INPUT signal or MAGNIFICATION of the internal sweep and determines the horizontal

position of the spot on the screen.

The complete Horizontal Amplifier consists

of the main Amplifier, and

(used only for external signals applied to the

HORIZONTAL INPUT connector). The preamplifier stage includes the VOLTS /CMportion of the HORIZONTAL SENSITIVITY selector switch and

is

set

to one of the MAGNIFICATIONpositions.

The MAGNIFICATION circuit of the HORIZONTAL SENSITIVITY selector

Horizontal Amplifier. The sawtooth sweep

is

applied to the Main Horizontal Amplifier

while external signals

the HORIZONTAL SENSITIVITY switch and

the preamplifier.

The complete Horizontal Amplifier circuit

located on the single etched board on the lefthand, swing-out chassis. Connections to the

chassis

connectors on the board.

are

as

shown in Figure

is

pushed into position. Power

-

The horizontal

a

preamplifier

is

not effective when the switch

is

in the Main

are

first fed through

made through two tube-socket

3-2,

is

the

as

is

-1

3

Page 29

INPUT

LTTENUATORS

-

VERTICAL

AMPLIFIER

(PLUG-

(51W

TIUIICU

IN

I

)

VtRUltR

10

MAIN

VERTICAL

AMPLIFIER

VI-V6

INTERNAL-SYNC

AMPLIFIER

TRIGGER

-

YlRTlCIL

CRT

-

t4lSVOC

lUIRtCl

t

400

t

260

t

I30

-

82

-

150

UII8RIIOR

VOC

YOC

VOC

VQC

VOC

REGULATED

UIW-VOLTAGE

POWER

SUPPLIES

SEE

mirn

survu

8LOCl

OIIUU

I

SWEEP

GENERATOR

VlO-Vl7

IStl

Otllll

BLOCI:

UITWTU

SlttP

01IORA1I

UUBLIIIIXt PULSt

CRI

INTlMSlll

WWLl

10

INltISlTl

-5OOOVDC

1,,,,1$

HICH

VOLTAGE

POWFR SUPPLY

V27-VJO

d’(lllTtlSITII

PREAMPLIFIER LMPLlFlER

HORIZONTAL

FIGURE

3-2

3-2

L

UORIZQITIL

cnr

-

Page 30

c.

Sync Circuit - The Synchronizing Circuit

receives a sync signal either from the

Vertical Amplifier for internal synchroniza-

from the EXT. SYNC INPUT connector

tion;

for external synchronization, or from an internal 6.3-volt source for line frequency syn-

chronization. The Sync Circuit amplifies

input signals, determines the input voltage

level and polarity of input sync signal which

start

will

reliable sync pulse for operation of the Saw-

tooth Generator.

a

sweep; and supplies a fast

all

and

switch.

fied and inverted in V8A, or are amplified

without inversion in V8B. The desired polarity of sync signal that

the sweep

plate by the TRIGGER SLOPE control. A

negative-going signal

lowing Schmitt Trigger

positive input-sync signals

from the plate of V8B while negative signals

are

All

incoming sync signals

is

then taken from the appropriate

is

required for the fol-

taken uninverted from

is

tobeusedto

V9;

consequently,

are

taken inverted

V8

A.

are

ampli-

start

-

d. Sweep Generator

receives a negative starting pulse from

the Sync Circuit and generates

be fed to the Horizontal Amplifier. The Feedback Integrator determines the basic sweep

time per centimeter, the Retriggering Bias

Controldetermines the sensitivity of the generator to incoming sync signals and provides

either single or repetitive sweeps. The sweep

generator also supplies an unblanking pulse

a

to the CRT and

sawtooth flyback) to the Dual Channel Verti-

cal

Amplifier Plug-In Unit for ALTERNATE

operation.

The complete Sweep Generator and Sync Cir-

is

cuit

the right-hand, swing-out chassis.

nections to this chassis

three tube-socket connectors and three pin

connectors on the board.

e. The CRT

operated at -5000 volts. The 5AMP may be

obtained with four different phospors:

green medium;

plied with the 150A)

short. All are interchangeable with little

readjustment and the tube

through the front panel. The mono-accelerator anode makes possible

matism adjustment (located inside the access

hole) which requires no resetting when adjusting the FOCUS or INTENSITY. The deflection plate terminals located on the peri-

phery of the tube

movable jumpers directly to the Main Vertical Amplifier.

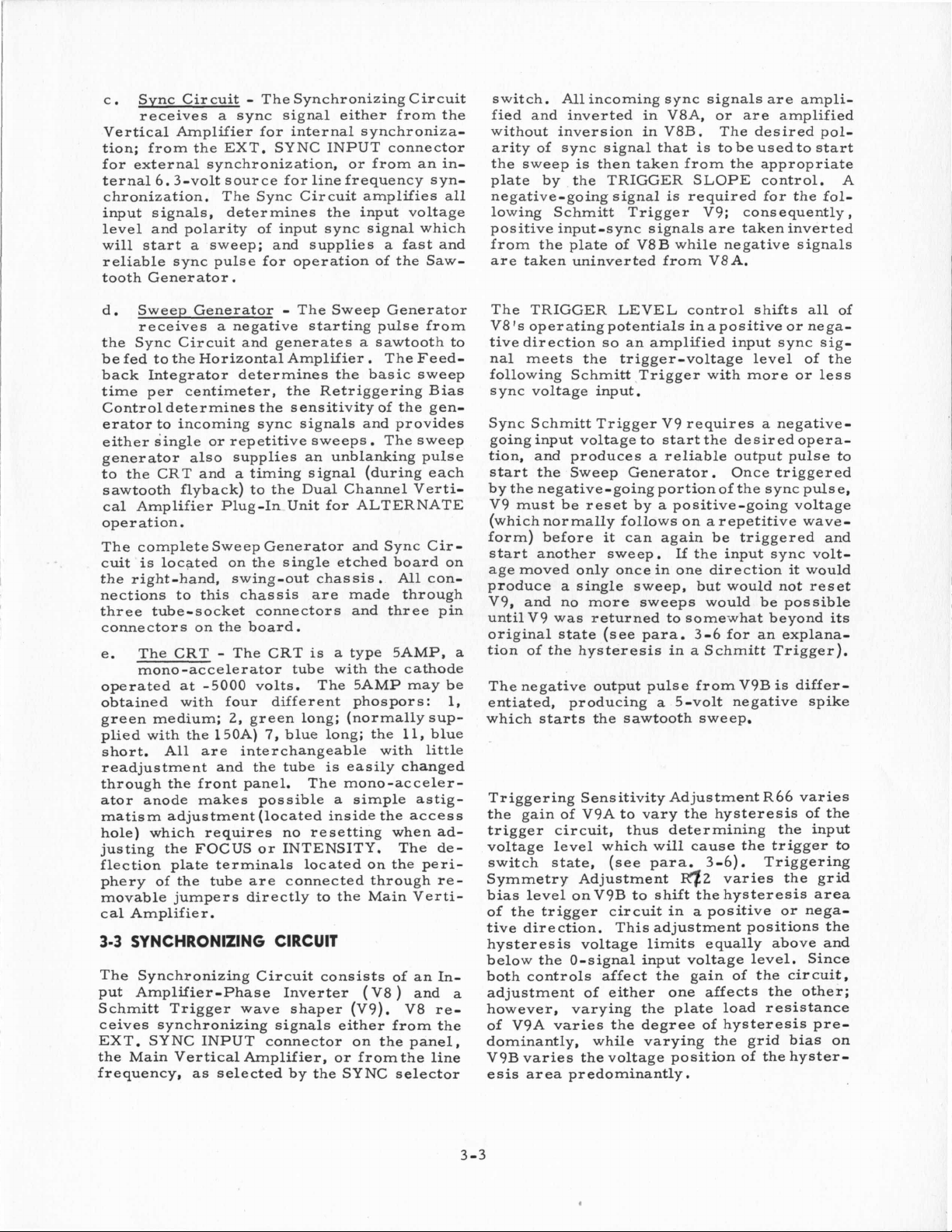

3-3

The Synchronizing Circuit consists

put Amplifier-Phase Inverter (V8) and

Schmitt Trigger wave shaper

ceives synchronizing signals either from the

EXT. SYNC INPUT connector on the panel,

the Main Vertical Amplifier, or from the line

frequency,

located on the single etched board on

mono-accelerator tube with the cathode

SYNCHRONIZING CIRCUIT

as

timing signal (during each

-

The CRT

2,

green long; (normally sup-

are

selected by the SYNC selector

The Sweep Generator

a

sawtooth to

are

made through

is

a

type SAMP,

7,

blue long; the

is

easily changed

a

simple astig-

connected through

(V9).

All

11,

of

V8

con-

1,

blue

re-

an In-

re-

The TRIGGER LEVEL control shifts

V8's operating potentials in apositive or nega-

so

tive direction

nal meets the trigger-voltage level of the

following Schmitt Trigger with more or less

sync voltage input.

Sync Schmitt Trigger

going input voltage to

tion, and produces

start

by the negative-going portionof the sync pulse,

V9

(which normally follows on

form) before

start

age moved only once in one direction

produce

V9, and no more sweeps would be possible

untilV9 was returned to somewhat beyond

original

tion of the hysteresis in

a

The negative output pulse from V9B

entiated, producing

which

Triggering Sensitivity Ad jus tment R 66 varies

the gain of V9A to vary the hysteresis of the

trigger circuit, thus determining the input

voltage level which will cause the trigger to

switch

Symmetry Adjustment

bias level on V9B to shift the hysteresis

of the trigger

tive direction. This adjustment positions the

hysteresis voltage limits equally above and

below the 0-signal input voltage level. Since

both controls affect the gain of the circuit,

a

adjustment of either one

however, varying the plate load resistance

of V9A varies the degree of hysteresis predominantly, while varying the grid bias on

V9B varies the voltage position of the hyster-

esis

the Sweep Generator. Once triggered

must be reset by a positive-going voltage

another sweep.

a

single sweep, but would not reset

state

starts

state,

area

predominantly.

an amplified input sync sig-

V9

requires a negative-

start

the desired opera-

a

reliable output pulse to

a

repetitive wave-

it

can again be triggered and

If

the input sync volt-

(see para. 3-6 for an explana-

a

Schmitt Trigger).

is

a

5-volt negative spike

the sawtooth sweep.

(see para. 3-6). Triggering

e2

varies the grid

circuit in

a

positive or nega-

affects

the other;

all

it

would

differ-

area

of

its

3

-3

Page 31

CATHODE

9-1

FOLLOWER

VIIS

UNBLANKING

PULSE

TO

CRT

SYNC

INPUT

@

/I'

/I

/I

INVERTER

AMPLIFIER TRIGGER

V8

SYNC SWEEP

SCHMITT STA RT-STOP

v9

RETRIGGERING

BIAS

CONTROL

VI7

-

1)

-

1L

INTEGRATOR FEEDBACK

TRIGGER

VIO.VIIA VI3 V14,V15A

RETRIGGERING - SAWTOOTH

HOLD-OFF

VI66

SWITCH INTEGRATOR

INVERTER

V16A

-

/

/

--

T

9

11

SWEEP

OUTPUT

FIGURE

3

-4

3-3

Page 32

3-4

SWEEP

The Sweep Generator consists of tubes V10,

V13, V14, V15 and V16, the sweep sawtooth

slope being created by Feedback Integrator

V14; the sawtooth slope being terminated by

the feedback loop consisting of V16A, B and

V17B. The sensitivity of the Sweep Generator to the trigger pulse from V9

by the front panel SWEEP MODE control

through V17A. The action of the circuit

follows:

GENERATOR

is

adjustable

is

as

The hold-off time

ed to be from

time. During the sweep, V16B acts

normal cathode follower, reproducing

its

cathode the positive sloped sawtooth.

During the retrace V16B

cathode capacitor charged to the most

positive voltage during the sweep, slowly

discharges through the shunt resistors,

providing

a

is

automatically adjust-

3

times to 1/20 of the sweep

is

cut off. The

hold-off voltage for V10.

as

at

a

With no input sync pulse, Sweep StartStop Trigger

voltage which keeps Feedback Integrator

V14 turned

negative sync pulse, it switches state and

produces

permits V14 to generate

creasing voltage. This decreasing volt-

is

age

the input of VlOA through V16B and V17B.

When the positive increasing voltage from

V16A reaches

(which

VlO),

state, shuts off the Feedback Integrator

and terminates the decrease of voltage,

thus creating

3-6 for explanation of hysteresis in the

Schmitt Trigger circuit

During the sawtooth, V10 cannot be retriggered by subsequent negative sync

pulses from V9 because VlOAis inthe

cut-off condition.

To prevent subsequent negative sync

pulses from retriggering V10 immedi-

ately after

circuits to recover,

applied to the input grid of

hold

positive voltage on the grid

the negative-going sync pulses from V9

cannot drive the grid across the lower

hysteresis limit and retrigger

the hold -off voltage drops back to the

normal grid-bias level. The hold-off

bias voltage

discharge circuit, the discharge time beingdetermined by the

lected by theSWEEP TIME/CM selector.

inverted by V16A and fed back to

is

it triggers

-

off bias maintains

V10

produces a low output-

off.

When VlOA receives

a

high positive voltage which

a

linearly de-

a

predetermined level

the upper hysteresis limit of

V10

back to

a

sawtooth. (See para.

its

original

.)

a

sweep and to permit

a

hold-off bias

VlOA.

a

sufficiently

of

V10

is

obtained from a capacitor-

r

and c values se-

VlOA

all

is

The

so

until

To vary the sensitivity of the sawtooth

generator to the incoming negative sync

pulses from V9, the negative grid-bias

5

volts

2

volts

set to

is

a

voltage applied to the grid of VlOA

moved closer to or farther from the low-

If

er trigger level of V10.

is

adjusted with the SWEEP MODE control very close to the trigger point, V10

can be switched by very small negative

voltages,

below the lower trigger point the sweep

generator will free-run.

bias voltage

tion, away from the lower hysteresis

limit,

to trigger

The negative sync pulses from V9 which

trigger the sweep generator

peak or greater for sync signals up to

approximately one megacycle. Since the

sweep generator

put triggers of approximately

peak, !when the

PRESET, the sync pulses from V9 provide very reliable triggering for nearly

all

sync signals encountered. However,

as

the repetition rate of the incoming

sync signal

cycle, the spike from Schmitt Trigger V9

will decrease in size, and the sensitivity

of the Sawtooth Generator must be in-

creased by lowering the bias voltage to

VlOA with the SWEEP MODE control.

V17B serves to combine the variable bias

with the sawtooth and hold-off voltages

whichare fedto the grid ofSchmitt Trig-

ger V10.

if

the bias voltage

is

moved ina positive direc-

a

larger negative pulse

VlO.

is

set to respond to in-

SYNC

is

increased above one mega-

the grid bias

is

If

is

are

control

reduced

the grid-

required

is

-5

3

Page 33

3-5

FEEDBACK INTEGRATOR AND DIODE

SWITCH

The complete Feedback Integrator Circuit

consists of Feedback Integrator V14 which

creates the sawtooth slope, Diode Switch V13

which starts and stops the integrator action,

and Cathode Follower V15A which provides

d-c coupling from the Integrator plate to the

grid. To direct-couple the Integrator plate

to the Cathode Follower grid requires the

three constant voltage lamps, 13, 14, and I5

in series todrop the d-c plate levelto an appropriate value for the grid of V15A. Prior

to the generation of

grid coupling

the integrator-capacitor

the generation of the sawtooth, plate-to-grid

coupling

The operation of the circuit before and dur-

a

sweep

ing

Before a sync signal

Stop Trigger

low, positive output-voltage level, which

is

fed through Cathode Follower V12A to

the cathodes of the Diode Switch V13.

The two diodes conduct, effectively shorting out the Integrator Capacitor (C55

through C63). and effectively connecting

the plate of the Feedback Integrator

the grid through Cathode Follower V15A.

This d-c degenerative feedback locks the

circuit in

put voltage of the sweep generator

tionary and the

tionless. Thus the sweep starts from

fixed position regardless of sweep speed.

When

gers Start-Stop Trigger V10, the Trigger

produces

which biases the Diode Switch V13 beyond cutoff, opens the Switch, and permits the Integrator grid voltage to rise

and begin charging the feedback capa-

citor. While the grid side of the capa-

citor charges toward approx. t130 volts,

the plate-side potential drops 80 volts

for each volt of grid voltage rise.

is

is

through the integrator capacitor.

is

a

a

negative synchronizingpulse trig-

a

a

sawtooth, the plate-to-

through the Diode Switch and

is

shorted. During

as

follows:

is

received, Start-

V10

produces a relatively

stable state holding the out-

sta-

spot on the screen mo-

high, positive output-voltage

to

a

To obtain the graduations in sweep time

beginning on the shortest sweep, the

switch selects one capacity value and

three different total resistance values

1

(in the ratio of

ranges, and repeats this process using

10

x

larger values of capacity; however,

between the 5 and 10 microsecond ranges

and between the .5 and

the capacity remains the same and the

resistance value

tor of 10.

During the generation

the grid-side of the capacitor has risen

only 1/80 of the plate voltage swing,

approximately 1.4 volts.

1% portion of a capacitor charging curve

is

very linear, the resultant plate swing

is

also

very linear. In addition, the de-

generative platsto-grid

the integrator capacitor provides three

important characteristics: it stabilizes

the circuit

characteristics have little affect upon the

slope and linearity of the sawtooth;

improves

able with

by an amplifier;

ent value of the

a

factor equal to the gain of the integra-

tor tube,

simple

fier which multiplies the rate of riseof

the capacitor charging curve by the gain

of the amplifier.

invalue of the timing capacitor

the degenerative feedback inherent in the

Feedback Integrator which reduces the

tendencyof the grid voltage to change by

a

factor equal to the gain of the amplifier.

Aportion of the sawtooth voltage

pled back to the Start-Stop Trigger to

close the Diode Switch and to the sweep

generator when its output has reached

110 volts.

a

sweep

the Diode Switch allows the timing capa-

citor to discharge and commences the

retrace. During the sweep retrace, the

integrator charging resistor

mented by R89 which

volts, thus giving

of

age

same manner

so

the linearity over that obtain-

a

as

integrator followed by an ampli-

110 volts

11

constant slope at the output, in the

:2 :5) for the first three

1

second ranges

is

increased by a fac-

of

the sawtooth,

or

Since the

f

e edback through

that normal changes intube

simple integrator followed

it

increases the appar-

integrator capacitor by

compared to the action of

The apparent increase

is

centimeters long. Closing

sufficient to cause

is

is

returned to -150

a

positive voinq volt-

as

described above.

first

is

due to

is

cou-

supple-

,

it

a

is

The sawtooth slope

values of the grid-to-Bt resistor (R143

through R156) and the grid-to-plate capa-

citor (C55 through C63)

the SWEEP TIME/CM selector switch.

determined by the

as

selected by

For the various SWEEP TIME/CM ranges

the ratioof retrace to sweeptime varies

from1/3 to 1/1000 in accordance with the

ratio of R89 to the particulac charging

resistance in use (R148 to R156).

3-6

Page 34

3-6

SCHMITT TRIGGER CIRCUITS

A Schmitt Trigger consists of two amplifiers

(twin triodes in the 150A) having d-cplate-togrid coupling from A to B amplifier and d-c

cathode - to - cathode coupling. The circuit

has two stable

side cut off;

off. The change-over from one state to the

is

other

decay times from each side of the circuit,

either of which can be used for triggering

subsequent circuits.

The d-c voltage level applied to the A-side

grid determines which state the circuit will

be in. If the grid voltage

.

level, A sidewill conduct and B side will not;

if

below that same level, B side will conduct

and

grid voltage crosses this threshold, the circuit will change state. Inpractice, the threshold voltage

in

a

ing the grid in a negative direction. The two

different voltage levels are called the upper

and lower hysteresis limits of the circuit.

To trigger the circuit,

age must cross the particular hysteresis limit

which will change the state of the circuit.

A side

voltage positive through

limit will have no affect, but driving the grid

voltage negative through

limit will put

side into conduction.

very rapid, producing fast rise and

A

side will not. Each time the A-side

positive direction, and lower when mov-

is

already conducting, driving the grid

states;

B

side conducting, A side cut

is

higher when moving the grid

A

side out of conduction, and B

A side conducting, B

is

above a certain

the A-side grid volt-

its

upper hysteresis

its

lower hysteresis

In the Start-Stop Trigger, A side is conduct-

ing, and the grid voltage can be set by the

SWEEP MODE control to be below the lower

hysteresis limit, in which case the trigger

automatically switches state without an input

trigger pulse and the sawtooth generator free

is

runs. As the bias level

lower hysteresis limit, the circuit requires

increasingly larger input trigger pulses to

switch the trigger. The incoming sync signal

is

not large enough to pass the positive hys-

so

teresis limit,

its

original state. The positive voltage which

resets the trigger

verted sawtooth fed back to the A-side input.

3-7

HORIZONTAL AMPLIFIER

The complete Horizontal Amplifier consists

of the Main Horizontal Amplifier which drives

the deflection plates; and a preamplifier for

signals applied to the EXT. HORIZ. INPUT

permits vernier gain control and gives beam

deflection to the right for negative input signals. The Main Amplifier

the entire amplifier

Main Amplifier contains gain adjustments

for the MAGNIFICATIONranges of the HORIZ

SENSITIVITY switch, frequency response,

balance and centering adjustments. The preamplifier contains an input voltage divider,

If

which inconjunction with the gain selector in

the main am lifier, provides the EXT.

PUT VOLTSAM ranges of the HORIZ. SENSITIVITY selector. The operation of the

Horizontal Amplifier

cannot reset the trigger to

is

is

is

moved above the

obtained from the in-

is

push-pull and

direct-coupled. The

as

follows:

IN-

The initial A-side grid bias can be positioned

anywhere inside or outside the hysteresis

area, thus establishing the input voltage level

required to change A's state. In the Sync

Schmitt Trigger, the A-side grid bias

tioned midway between the upper and lower

hysteresis limits, while in the Stop -Start

Schmitt Trigger the grid bias

from below the lower hysteresis limit up to

about midway between the hysteresis limits.

In the Sync Schmitt Trigger, A side

ducting and

to drive the grid voltage from the midway bias

to below the lower negative hysteresis limit

to switch the circuit. The input sync signal

must then drive the grid beyond the upper

positive hysteresis limit to

for the next incoming sync pulse.

a

negative sync signal

reset

is

is

adjustable

is

is

required

the circuit

posi-

con-

3-7

Horizontal deflection signals are selected

either from the EXT. HORIZ. INPUT

preamplifier or from the Sweep Genera-

tor

by the HORIZ. SENSITIVITY selector

and are then coupled to the grid of V20

through frequency-compensated voltage

dividing networks. V20 and V21

two sides of

phase inverted signal for V21

through amplifier V19A and cathode Follower Vl9B. The inverted signal voltage

is

developed bybringing the two gridreturns from V20 and V21 to

point, and driving the phase inverter from

this junction.

The maximum gain of the Main Horizon-

tal

Amplifier

which varies the gain of Phase Inverter

V19. Varying the gain of the Phase Inverter results in an unbalance in signal

a

push-pull amplifier. The

is

set

by adjusting R199

are

is

obtained

a

common

the

.

Page 35

levels to the grids of V20 and V21, but

the balance

plifier by the common cathode resistors

for V20, V21 and V23, V24.

The MAGNIFICATION and VOLTS/CM

positions of the HORIZ. SENSITIVITY

selector determine the horizontal deflection sensitivity by inserting input attenuators and adjusting the degeneration in

the common cathode circuit of V20 and

V21. In the X1 position, the cathode-to-

cathode resistance

mum) and the sawtooth input to V20

attenuated by a factor of approximately

10. In the X5 MAGNIFICATION position,

the attenuation factor

proximately

sitivity 5 times. In the X10, X50 and

10

0

X

cathode -to

and V21

the deflection sensitivity increased

and

20

times over that present on the X5

position. The XlOO Magnification Gain

Adj. potentiometer, R213, provides minor

adjustment in the cathode-to-cathode resistance to compensate for transconduc-

tance variations and

the XlOO positions, when the cathode-

circuit resistance

Similar operations are performed in the

EXT. INPUT positions. In the

1

VOLT/CM positions of the HORIZ.

and

SENSITIVITY selector, the gain ratios

set

are

as

described above. Attenuation

serted

2 and 5 VOLTS /CM positions.

There

the HORIZ. SENSITIVITY selector between the 5 VOLTS/CM and the XlOO

MAGNIFICATIONpositions. In this position, signals applied to the EXT. HORIZ.

INPUT connector are fed directly to the

Main Horizontal Amplifier without going

through the Ext. Input Preamplifier.

This position

of the gain and frequency response of the

Main Horizontal Amplifier. In this posi-

tion the Main Horizontal Amplifier

connected exactly

CATIONposition. Under these conditions

the deflection sensitivity

The push-pull signals from V20 and

are direct-coupled through Cathode Fol-

lower Drivers V22A and

Amplifiers V23

is

is

restored later in the

is

highest (gain mini-

is

reduced to ap-

2,

increasing deflection sen-

MAGNIFICATION positions the

-

cathode resistance of V20

is

progressively decreased and

is

most effective in

is

lowest.

by cathode-to-cathode resistors

at

the preamplifier input for the

an unlabeled switch position on

is

useful during adjustment

as

in the X5 MAGNLFI-

is

2

VOLTS/CM.

B

to the Output

and

V24. The signals

.2,

is

am-

2,

.5,

in-

V21

is

10

is

from the plates of the Output Amplifiers

are returned through feedback networks

to the input of the Drivers. The feedback networks contain adjustments of the

transient response to assure linear

plification of the sawtooth voltage for

sweep times.

The signals from the Output Amplifiers

are coupled through Output Cathode Followers V25A and

flectionplates. The Capacitance Drivers

V26A and

the Output Cathode Followers during

negative

waveform. Without

the output-tube impedance

during

increasing discharge time of the

circuit capacity prevents the cathode

voltage from accurately following the

grid voltage. This effect

increasing the current thru the Output

Cathode Follower during periods when

its output moves in

The increase in cathode current

about by supplying the capacitance driver

grid with

a

differentiating network (C96, R239, and

C95, R242) from the opposite side of the

circuit. The Capacitance Driver for

particular side

positive-going portion of the output from

that side.

Neonlamps are used in the grid circuits

V19B,

of

coupling without loss of signal amplitude.

Yhe neonlamps are returned

through

reliable lamp operation. A smallbypass

capacitor assures good coupling

frequencies.

3-8

MAIN

The signal from the plug-in vertical amplifier

is

fed through the left-hand connector on the

plug-in unit chassis to the Mainvertical Amplifier on the instrument chassis. The Main

Vertical Amp!.ifier co'nsists of an input amplifier, delay line, buffers and output amplifiers,

entire circuit contains only two adjustments,

a

plification and a frequency response control

to compensate the high frequency end of the

pass band.

all

gain control to standardize the overall

B

-

going portions of the outpyt

a

negative-going swing, and the

a

positive-going voltage through

V23, and V24 to provide direct

a

value of resistance that assures

VERTICAL

push-pull and direct coupled. The

B

to the horizontal de-

improve the performance of

a

capacitance driver

is

increasing

is

prevented by

a

negative direction.

is

is

ineffective during the

at

AMPLIFIER

am-

all

small

brought

-150 volts

at

high

am-

a

3

-8

Page 36

Input amplifiers

mum gain of about 20 db. R5, the gain ad-

justment potentiometer, inserts degeneration

in the cathode-to-cathode coupling between

V1 and V2 to vary their gain over

The signals from V1 and V2

two 0.25 microseconddelay lines (one ineach

side of the amplifier) to the final amplifier

stages. Each delay line consists of a 25inch length of RG-176/U coaxial cable. To

provide satisfactory delay

phase shift in both sides of the amplifier

all frequencies, the physical lengths of the

cables are cut to provide identical electrical

lengths. Both ends of each

ated with the resistance value which matches

the characteristics impedance of the cable.

These terminating resistors are R1, R12, R8

and R13.

At the various frequencies the operation of

the circuit

and up to 25 cycles, the signal from

through R4 through the delay line, then R12

a

and

signal

mately 25 cycles, C1 and C5 become effec-

tive, shunt the two 330K resistors and produce a capacitive

KC

At 3

are equal to the magnitude of the reactance

of C1 and C5 and therefore at the high fre-

quencies the line sees only R4and R12 and is

correctly terminated.

load R4shunted by R12at the other end of the

line, thus cutting the plate load in half. The

effect of the gradual transition from

voltage divider toa 2:l decrease inamplifica-

tion provides

tion with accurate matching over the band.

To prevent capacitive mismatch of the delay

lines

at

V1

and V2 are coupled to the delay lines through

bridged-T networks. To reduce capacitive

loading

cathode followers

of the output amplifiers

gain of output amplifiers

mately 16 db. When replacing the delay lines,

replace in pairs with specially prepared

cables obtained from the Hewlett

Company.

3-9

MODEL

is

second resistor R10, thus giving a 50%

loss

the terminating resistors R4and R12

high frequencies the plate circuits of

at

theoutput end ofthe cables, double

152

V1

and V2 provide a maxi-

a

4 db range.

are

fed through

i.

e.,