I.

I

\

I'

-

SPtClAL

NOTE

-

..

.

,

t

RACK

With

two

installation. This permits the chass.is to slide

RACK

LARGE

MOUNT Model

screws at

ward

MOUNT

the

for-

he,rvicing.

MODEL

150A's

rear

of

ONLY

only, remove

the

cabinet before

the

for-

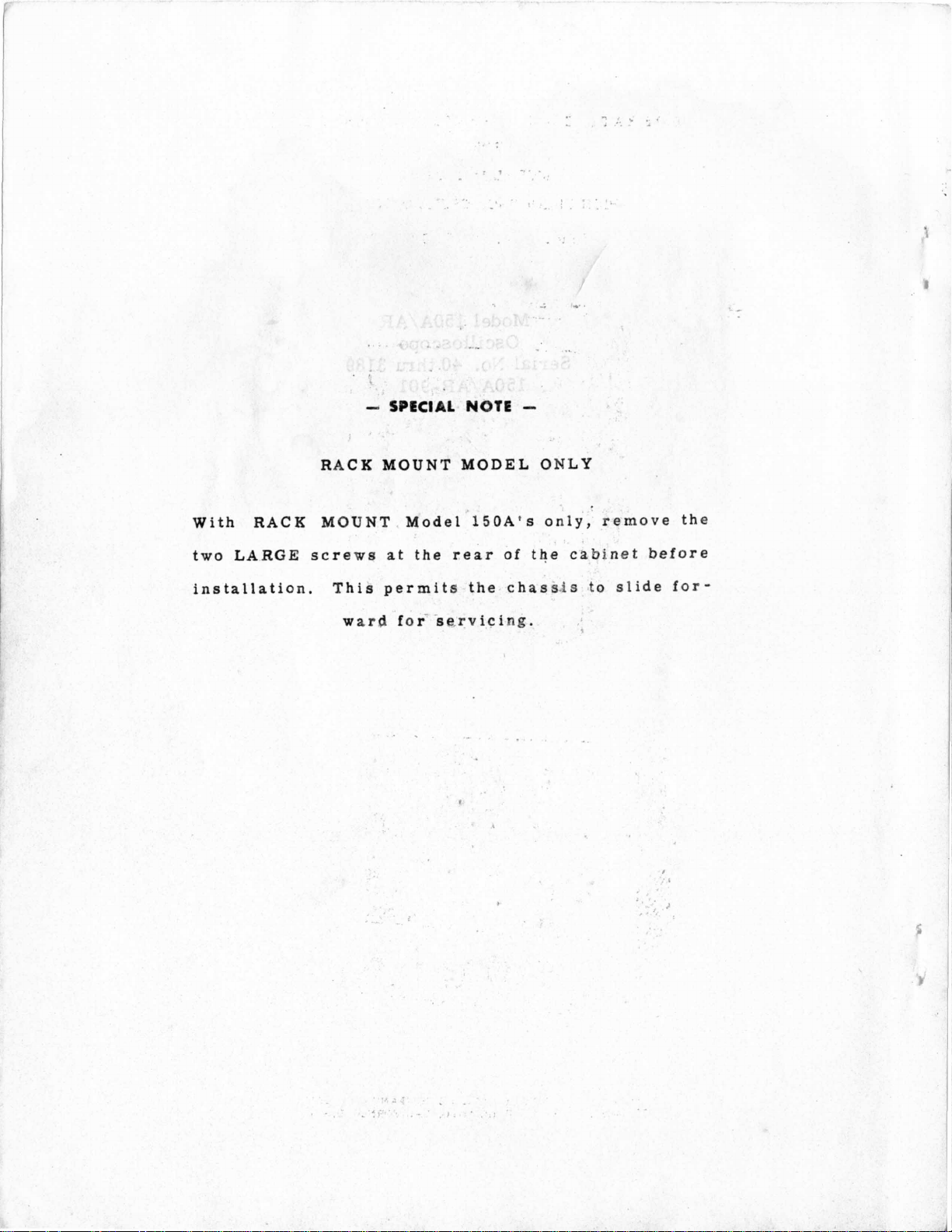

OPERATING AND SERVICING MANUAL

FOR

MODEL 150A/AR

HIGH FREQUENCY OSCILLOSCOPE

SERIAL

40

THROUGH

3189

Copyright

275

PAGE MILL

H

EWL

ROAD,

ETT

-PA CKA

PAL0 ALTO, CALIFORNIA. U.S.A.

R

D

COMPANY

1950

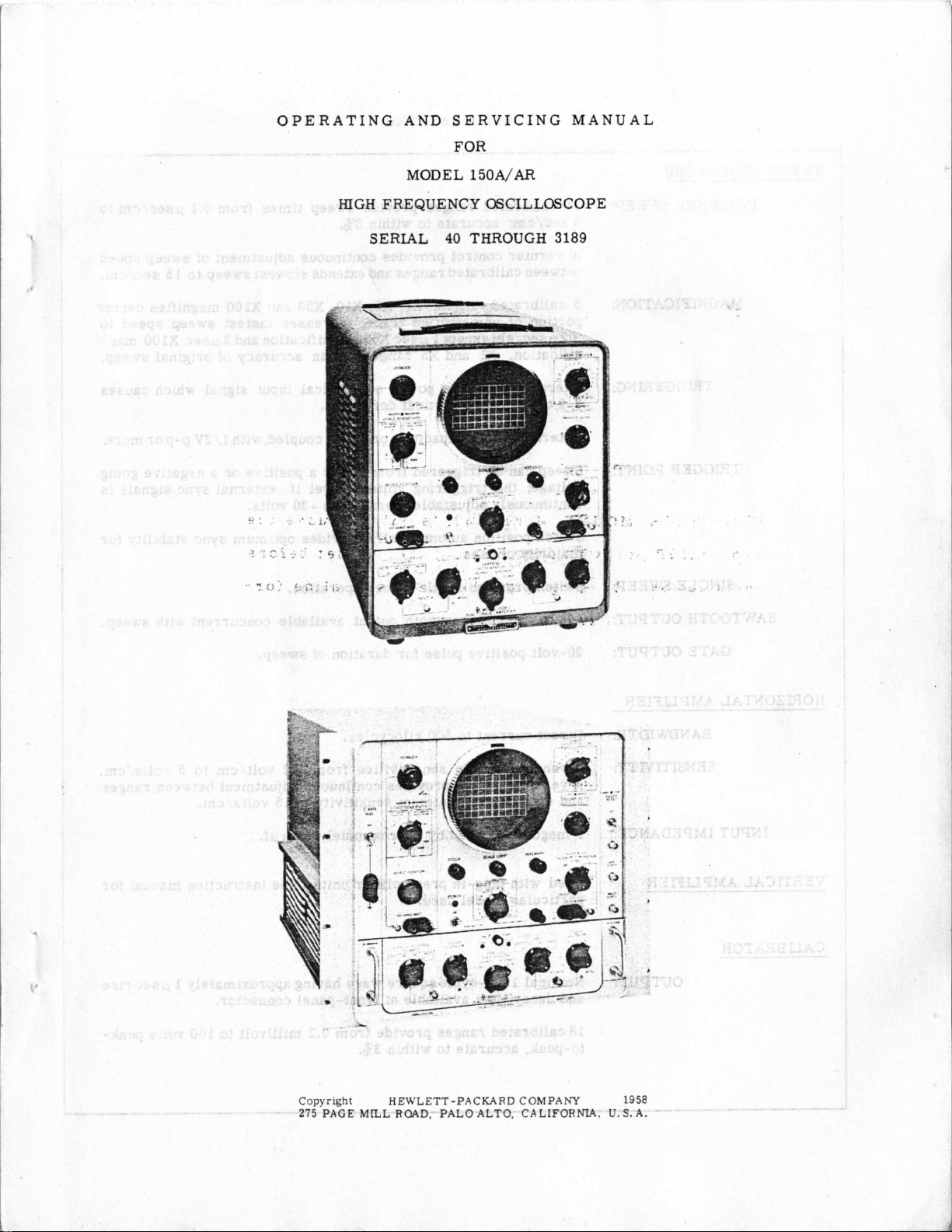

SWEEP GENERATOR

SPECIFICATIONS

INTERNAL SWEEP

MAGNIFICATION

TRIGGERING:

TRIGGER POINT:

SINGLE

SWEEP

SAWTOOTH OUTPUT:

GATE OUTPUT:

24

calibrated

range$

pr&de $weep times from

0.1

psec/cm to

5 s&c/cm; accurate to within.3%..

A vernier control provides continuous adjustment of sweep speed

between calibrated ranges and extends slowest sweep to 15 sec/cm.

5 cabrated ranges; X1, X5,

XlO,

X50 and

XlOO

magnifies center

portion of unmagnified trace, increases fastest sweep speed to

.02

psec/cm except

nification.

Inter

mal,

1/2

(

:m

Externa,

Sweep can

X1 and X5 rahges retain accuracy of original sweep.

from line

or

more vert

eitnec

be

voltage; the triggering voltage level

continuonsly adjustable from

1

psec

X50 magnification and 2 psec XlOO mag-

mwer

I

or

vertical input signal which causes

ical deflection.

capacitive

or

direct coupled,with 1/2V p-por

triggered from either a positive

if

external sync signals

-30

to

+30

volts.

or

a

negative going

more

is

Switch position automatically provides optimum sync stability for

majority of uses.

Switch provides single-sweep operation.

+20

to

-20

volt. sawtooth output. available concurrent with sweep.

pulse

20-volt positive

for duration of swekp.

,-

,I

_-

,

.

I,

HORIZONTAL AMPLIFIER

BANDWIDTH:

SENSITIVITY

INPUT IMPEDANCE:

VERTICAL AMPLIFIER

CALIBRATOR

OUTPUT

Direct current to 500 kilocycles.

0.2

5 ranges provide sensitivities from

volt/cm to 5 volts/cm.

A vernier control provides continuous adjustment between ranges

and extends the minimum sensitivity to 15 volts/cm.

1

megohm Shunted

by

approiimately

27

ppfi

,

used with plug-in preamplifier units. See instruction manual for

particular model used.

Nominal 1000-cycle square wave having approximately

and decay time available

18 calibrated ranges provide from

at

front-panel connector.

0.2

millivolt to 100 volts

1

psec rise

peak-

to-peak, accurate to within 3%.

SECTION

L

*:

-

I

-

GENERALDEZCRIPT~ON

CONTENTS

-.

..

..

Page

'.

I

't

..

I-

.......

..

-.

'

7

..

I

-

.

.I

->.'

,.

>.

.<-:.

.I

..

.I

if

ib-f

-/

1..

.

,^,

.I

.

..

'n

'

z

.:,T.

..

*.^-

.

.

._

'

1

..

-SECTION

I

SkCTIONfII

+,

'.G,;,,l

,,

.

-

1-

2

.

--:

._

._

..

1.

,.

~ 3

1-4

,:-.

.5

...

1':"6'-';' ' Overlaad~Reiay

1,-

7

......

~.

OPERATING

-1

2,l

i'2

2-3 Vertical Amplifiers

2-4

.-

2

5

Power Cord.

,Cooling

230-Volt.Operation

..

Instrument Safety Devices

:

Controls aniiTe,rminals

.

AC or DC Coupling

.

AC-2lA Low-Capacity Probe

.I

INSTRW

............................

.....

..

CTIONS

..

THEORY

3-1 Over-All Operation

-:3ic.$'

3-3 Horizontal Amplifier

3 - 4

3

.

3-6 Single Sweep Operation

"

2

3

-

3

-:qc:<

3-8

3-9

OF

OPERATION

.

'

'Vertical -Amplifier

Synchronizing Circuit

5

e''

SW~

7A:-

7B Protective Circuits

Regulated Low-Voltage Power Supply

Protective Circuits

Regulated High-Voltage Power Supply

Calibrator

Generator

.............................

...

I..

...

............................

....................

,

...

......

.........................

....................

:

,

,.

.

..

-.:

,

i'

I

...

.............

.'

...

....

................

,

-,-.

.-

.

,

,.,

:*

.,.

............

..

.......

.........................

.

;

.................

.........................

.........................

........................

..........

.

1

...

;

....................

._.

...........

........................

...............

...

..

--

Serial

--

Serial

40

through 339

340

'and above

...........

...............

.......

.-

I

-

-

..

1-1

1-1

1-1

1-2

11-1

411

-

1

I1

-

1

11-1

11 - 1

-

1

III

-

1

111

-

2

III

-

2

III - 2

III - 3

LII

-

3

111

-

4

111

.

5

111

-

6

111

-

6

SECTION

I

*'

.

SECTION

I

I

i'

.

.I.

-

........

rv

.

-

c

.I-;

_A\-

.

<-

V

.1

r.

-

MAINTENAN~E

.

4'

4

''4

4-4

4 - 5

4-6

.

4

..

4

4-9

4

.TABLE

'

5-1 Table

..............

.

I'r

:

s

Gene'fd Information

-

2

-

,-'

'-

-

"Routine Servicing

3 Condensed Test And Adjustment P-rocedure

Trouble,-Shooting Procedure

Detarled Test And Adjustment Procedures.

Low Voltage Power Supply

7

.

High Voltage Power Supply And Calibrator

8

.

Horizontal Amplifier

Main Vertical AmplifieF

10 Sweep Generator

OF

-.

,.

REPLACEABLE PARTS

of

'Replaceable Paits'

-.

.................

..........................

.....................

.....................

..........................

And

Sync Circuits

,

_.

~

..

_____.___.__._...I-.

..

......................

................

,

~

.

....................

.

A-

8.

.....

.......

............

............

.............

...

-.*

-..-

......

-

....

IV

IV

IV

..

IV

-

1

IV

-

1

IV

-

5

IV - 7

IV

-

8

IV

-

8

-

10

-

12

IV - 16

-

17

V-1

SPECIFICATIONS

(CONT'D.)

CATHODE

RAY

TUBE

TYPE:

FILTER SUPPLIED:

GRATICULE:

DEFLECTION PLATE

CONNECTIONS:

DEFLECTION 'SENSITIVITY

INTENSITY

.

MODULATION:

REP'LACEABILITY:

GENERAL

POWER REQUIREMENTS:

1.

5AMP- mono-accelerator,

or

P11

screen. 5000-volt accelerating potential.

Compatible

and blue with

10 cm long

with

phosphor, green with

P11

.

x

6

cmhigh marked incentimeter squares; 2 mm sub-

divisions on horizontal and vertical

Both &crewand

pin

type

flat

face,

available

P1

and P2,

axes.

Controlled

terminals to receive

wires

with

P1,

amber

edge

or

special con-

with

lighting.

nector assdmbly for connection to plates.

20 volts/cm approxhnately.

c20 volt pulse required to bla& CRT

CRT bezel removes with 15"

or

for replacement of the CRT without removing the cabinet of the

150A

or

without removing the 150AR from the rack.

CRT bezel provides

firm

twist

mounting for standard oscilloscope

cameras.

11

5/230 vac

*l@&

50/60

cps,

approximately

trace

of normal intensity.

for replacement of graticule

.

:1

-,

,

.-.

.&

,.

*y..:.

500**&ttts.

>.

,

.-,

.

"

P2,

J

.-

-

,-

.

.

P?

P?,

.

..I

"-

2s

DIMENSIONS:

WEIGRT:

PLUG-IN AMPLIFIERS:

ACCESSORIES AVAILABLE:

ACCESSORIES

FURNISHED:

Cabinet Mount: 13-3/4Iv-wide,

l?".higfi,

2&3/4" deep.'

Rack Mount: 19" wide, 15-314" high,-24:3/4"

Depth behind panel

Cabinet

Mount:

Rack Mount: Net

Net

65

85

lbs.,

shipping 105 Ibs.

ibs.,

approximately..

Model 151A High Gain Amplifier, dc to 10

Model

152A

Dual

Trace Amplifier,

Model 152B Dual Trace Amplifier, dc

Model

153A HighGainDifferential Amplifier, dc to 500 kc, 1 mv/cm.

is

23 inches;

mc,

dc

tr,

10 mc,

to

lO.mc,differential input,

Model-115A Testmobile,

Model 116A Testmobile Storage Unit,

Model AC-Ll7A Accessory Storage Drawer,

AC-8SA Viewing

460B-95A, Oscilloscope

Hood,

adapter

for connecting the output of

~

Fast Pulse Amplifier to the 150A/AFt Deflection Plates,

AC-21A Probe, 10:

AC-2lC

Probe,

AC-76A BNC to binding

Two

AC-21A Probes.

Two

A076A

1,

specify grey

5&1, specify grey

post

BNC

to binding

-,

1.

I'

or

or

adapter.

post

adapters.

black lead,

black lead,

deep.'

..

5 mvtcm.

50

mv/cm.

'

.

I'

.~

a

460B

L

-

,

-i

Sect. I Page

1

I:

.T

?

%:;

,

purpose osci~loscope employing

type

accelerator

cathode ray

".

.

,.

a

tube

withunitized,

cope

5

-.

is

+general

AMP-

7

(*

i

mono- whenuse'dwith the appropriate recepticle. An adap-

plug-,-

in construction for maximum accessibitityand flexi-

It

ca~.be

bility.

sweeps

which

synchronized.

magmficationclrcuitry which

used with either internal

can

be

either internally

,*

horizontal amplifier incorporates _able ground for the ProtectioR QfpPera.t.bg personnel

is

ing basic internal sweegqup to

term1 sweep range extends fn>m

sec/cm.

The Model 150A uses

plug-in units

-+.&

-..-...

1

*?:;

a

to

perform different functions. The

:-

variety of vertical amplifier operation.

capable of expand-

100

-02

09

external

or

externally from the adapter which should be connected to a suit-

times.,

The in-

psec/cm to 15

>

c,

._

various plug-in amplifiers available are described

in the table of spec,lf,&a.a@on~.

!;*,.->,(-*.>-

r

*

SECTION

GENERAL

LC

.#.

trical M-mufacturers' Association.

.

tact

.

blade,iac-plug, which grounds

.

ter

standard

,used, the ground connection beoomes,

.

.On

is

.

means of a,retracting coil cord. This permits

instrument,.to

:

1-5:

,'.-e

.>

.is

an

offset round

,should

;be

used

t60

contact output. men the adapter

to connect

..

the .r.ack 'mount Model 15OAR, the instrument

connected to the ac receptacle in

I.

,Slide out of the cabinet while stil

COOLING,

DESCRIPTION

*

-1.

The third con-

pin,

added, ta- a standard

the

instrument chassis

the

.NEM4

~

e*.

a

short lead

the

cabinet

I.

two-

plug to

.-

1

a

is

.

h~

Since operation of the rmcb

model

is

sirnilartto

that

of the cabinet modelf the.operatian&the instrument

willbedescribedwithbutregasdto~Style:of

j

<.

1-2

DAMAGE

Should any shipping

to the "Claim

on the warranty sheet-in thismanual,

1-3

POWER LINE VOLTAGES

The Oscilloscope

for

115

volt ac line operation, unless otherwise

specified.' Kov.teve.r14 the

operated

fmnh

IN

TRANSIT..

fm-

*I

is

damage

Damage

-I

I-

shipped from

became evidmt

in

fiipment"-paragraph set-up

.,

-I

.

instrumnt

230-voltpdC line sburce

e

1

&-*:'

the

mmnting

-.,

.

,

4.

it,

._

refer

-

.

:

-

If

.

factory wired

may

abo

if

the.

proper

-,-

-'

$,5,

be

conversionis made to the power.trmsforrner. Refer

to the conversion instructims

the appropriate schematic diagram

1-4

POWER CORD

The three conductor power cable supplied with

instrument

male

is

terminated in a polarized three prong

connector recommended by the National Elec-

in

paragsaptr.1-3 and

in

Section

.A.

'

IN,

v,.

the

'

.The.Model15OA empWs aforced draft cooling

.

tern

to maintain satisfactory operating temperah

:;

within the case. The

air

intake and filter are

cated under the instrument case and adequate cooling

-

will

.take

place

a8

.

long asrthe

L-

-

.

mentand nothingobstructs the filter. Generally, the

case

is

on the instru-

height of the cabinet feet provides such clearance,

:

Thus,khe.Model.l50A caQMuspdin a confined bench

as

.Ion&

as

clear,

:-<-

1-6

TheMoaeI'

.rupts

.

~

-.lJ

-

-

i2,

-5

:

3.f

and ambient temperatures are not extreme.

t

\.-

.OVE~LQAD

*

.I.

150A

op&ration when:

-,

-,

-$series

is

remaved while the instrument

.-

.*

k

plug-in+er$ieal amplifier

...

instrument

;;-

'*

~

-

'A'

&oi.tai-rculior excessive loading of any posi-

the underside of the cabinet

62,

2-

RELAY

has

an

overload relay which inter-

tube

on the regulated dc heater string

is

on.

1'

.

-.

'

is

is

removed while the

tive-voltage supply occurs.

To reset the overload relay remove the cause, and

turn the instrument off for one minute

or

s

10-

on.

,

r_

1

more. The

is

Sect. I Page

instrument may then

2

be

turned on again and oper-

ated normally.

1-7

The

230-VOLT

150A

is

OPIERATION

normally shipped from the factory with

the dual primary windings of the two power trans-

formers connected in parallel for use

on

115-volt

ac lines. The windings can easily be reconnected

in

series for use on 230-volt

pimary connections to both

dentical, and each

requires

power,

power

if

desired.

transformers are

the same change

in

The

con-

nections. To reconnect the primary windings of T2

and T3

disconnect the jumpers which join terminals

ad

to

Replace the

2

T2

for

use

on

230

volts, on each transformer

to

5.

Connect 10-ohm disk thermistors, RT301

and

RT302 to T3, between terminals 4 and 5.

6-1/4

amp fuse with a 3-amp fuse and

1

to

the 150Acan now be operated from 230 volt lines with

no change in operation.

4

~-

..

.-

..

I-

.,

,I

.

.-4

.

...

..

..

.,

!

I.'.

..

.

.I_.

...

;

.'

......

,.

.....

._

,.

)I

..

.,

..

..

..

)I

.~.

,..-.'>

,._

..

.......

"

......

....

'1

,

, . ,-

..

...

>,a

4

..,.

-

I

.-i

.

I

_,

-

.

~

..

.

,

I

..

.r.

..

::

.,

.I

..

,.

.

...

...

,

..

,_..

.......

....

.

-

,I..

.j.

.."',''

I

'I

I.,

...

.,.

..

',

'

:.

....

.I

',

,

...

-

1

'.

"I

...

..

.-

..

,

..

...

I

,.

.I

.

.,

..

,.

-

...

..

'

8.

.

.:

....

..

.I

.......

,

:

..

7

.....

-

'

l,,'.,

..

;

,

I.

',!

I..,..'

.

,.

..

..

.,

_.

....

_.

.

.-

..

,.

<.

.

...

.

..

.

,I

.,

..

Sect.

I1

Page

1

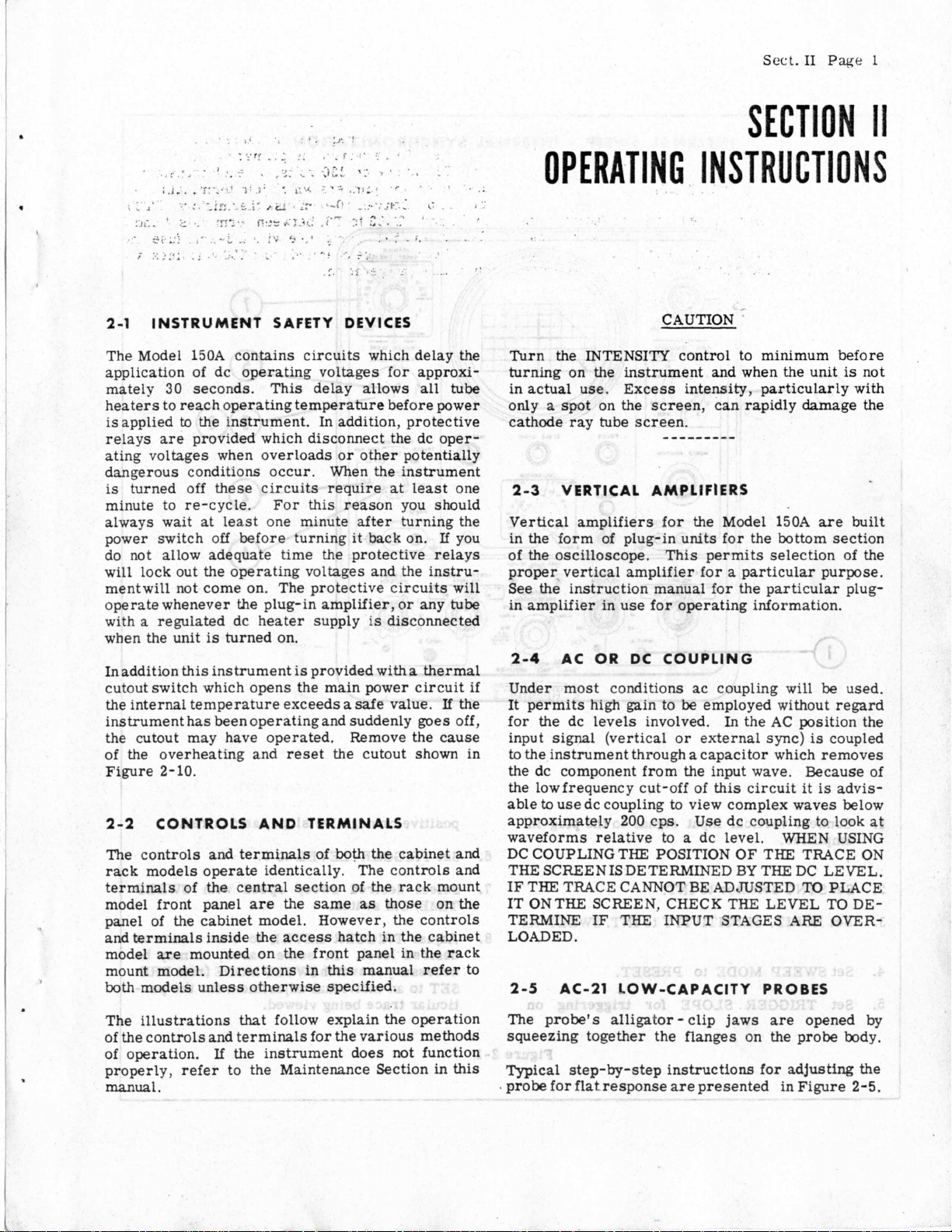

2-1 INSTRUMENT SAFETY DEVICES

The Model 150A contains circuits which delay the

application of dc operating voltages for approximately

heaters to reach operating temperature before power

is

relays are provided which disconnect the dc operating voltages when overloads

dangerous conditions occur. When the instrument

is turned off these circuits require at least one

minute to re-cycle.

always wait at least one minute after turning the

power switch

do

will lock out the operating voltages and the instru-

mentwill not come on. The protective circuits will

operate whenever

with a regulated dc heater supply

when the unit

Inaddition this instrument

cutout switch which opens the main power circuit

the internal temperature exceeds a safe value.

instrument has been operating and suddenly goes off,

the cutout may have operated. Remove the cause

of the overheating and reset the cutout shown in

Figure 2-10.

2-2

The controls and terminals of both the cabinet and

rack models operate identically. The controls and

terminals of the central section of the rack mount

model front panel are the same

panel of the cabinet model. However, the controls

and terminals inside the access hatch in the cabinet

model

mount model. Directions in this manual refer to

both models unless otherwise specified.

30

seconds. This delay allows all tube

applied

not allow adequate time the protective relays

to

the

instrument. In addition, protective

or

other potentially

For

this

reason you should

off

before turning it back on.

the

plug-in amplifier,

is

turned on.

is

provided witha thermal

CONTROLS AND TERMINALS

are

mounted on the front panel in the rack

or

is

disconnected

as

those on the

any

If

you

tube

If

if

the

SECTION

0

PERATIN

Turn the INTENSITY control to minimum before

turning on the instrument and when the unit

in actual

only

cathode ray tube screen.

2-3

Vertical amplifiers for the Model

in the form of plug-in units for the bottom section

of the oscilloscope. This permits selection of the

proper. vertical amplifier for

See the instruction manual for the particular plugin amplifier in use for operating information.

2-4

Under most conditions ac coupling will be

It

permits high gain to

for the dc levels involved.

input signal (vertical

to the instrument through

the dc component from the input wave. Because of

the lowfrequency cut-off of this circuit it

able

approximately 200 cps.

waveforms relative to a dc level. WHEN USING

DC COUPLINGTHE POSITION

THE SCREENISDETERMINED

IF THE TRACE CANNOT BE ADJUSTED

IT ONTHE SCREEN, CHECK THE LEVEL TO DE-

TERMINE

LOADED.

2-5

use.

a

spot on

VERTICAL AMPLIFIERS

AC OR DC COUPLING

to

use dc coupling to view complex waves below

AC-21 LOW-CAPACITY PROBES

the

IF

THE INPUT STAGES ARE

G I NSTRUCTI

CAUTION.

Excess intensity, particularly with

screen, can rapidly damage the

0

NS

is

not

---------

150A

are

built

a

particular purpose.

used.

be

employed without regard

In

the AC position the

or

external sync)

a

capacitor which removes

Use

dc coupling to look at

OF

THE TRACE ON

BY

THE

is

DC

TO

coupled

is

advis-

LEVEL.

PLACE

OVER-

II

.

The illustrations that follow explain the operation

of the controls and terminals for the various methods

of operation.

properly, refer to the Maintenance Section

manual.

If

the instrument does not function

in

this

The

probe's

squeezing together the flanges on the probe body.

Typical

probe for flatresponse

alligator-clip jaws

step-by-step instructions

are

presented in Figure 2-5.

are

opened

for

adjusting the

by

Sect.

II

Page

2

\

INTERNAL

I

*OlZ

LOYIIO.

SWEEP

-

INTERNAL SYNCHRONIZATION

I

Connect vertical input

1.

amplifier.

Set SYNC selector to INT.

2.

Set HORIZ. SENSITMTY

3..

4.

SetSWEEP MODE to PRESET,

5.

Set

TRIGGER

SLOPE

signal

to

INT.

for

triggering

to the plug-in

SWEEP

'

.^

X1

on

Figure

,

--.

.

1

,....

slope,

O;'c:.

sp6&'3Vith

to

as

desired.

start

*-

-. ~

,~

positive

6.

Set

TRIGGER.

7.

Select desired

TIME/CM

Adjust

8.

,

-1

or

negative

LEVELko

sw'eep

switch.

TWGGER~

LEVEL

desired level. In some cases, it may be

necessary

SET

ticular trace

toswitchWEEP

to

an

individual adjustment

being

MODEfrom

viewed.

2-1,

fbr

r

-.

)_.

'SWEEP

trace at

PRFr

the

par-

,

Sect.

II

Page

3

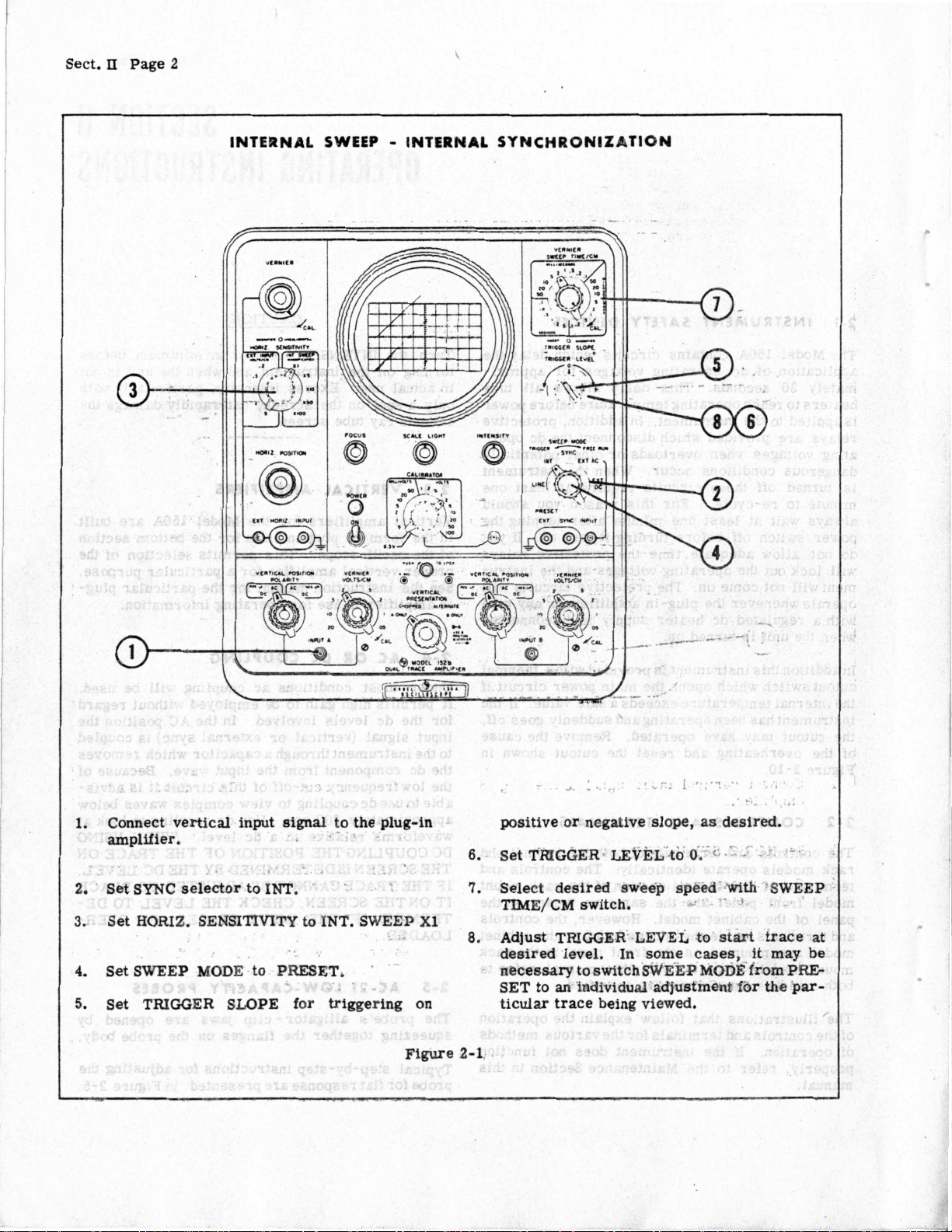

INTERNAL

I

SWFEP - EXTERNAL SYNCHRONIZATION

i

i

1.

Connect vertical input

signal

amplifier.

~=-:.?9,

2.

Set HORIZ. SE.MIVWTY to

:3.

:Compect

2s-

3

extema

.o.

-

syrq.

.*.L*,7;

signal-toEJq SYNC' TIME/CM switch,

INPUT terminals.

4.

.

Set

SWEgE!

5..

-'Set:TRI-G&R:SI$WE:for -t-riggering

tive-or negbiye sfopebCaq

MQDE to-PRESET,

-9.b:

?c,

7.

deskred.

"...',

-

I_

e.

to the plug-in

.-

lm

fTpEEPc?cl.

.;r

.

4.

J - 5L?'

,on

-.-*

&'

-.

-1

gosi-

-

~

6.

Set SYNC selector to EXT AC or EXT DC,

as

required.

7.

Sit

TRI&~R

0.

Select desired sweep speed

9.,\

OAdfust

.)

desired level. In some cases it may

TRIGGER-LEVEL'bo

essary to switch SWEEP MODE

SET to an3ndividual~a~stment

ticular trace being viewed.

1.-

2:

:c,.

,-

..

~EVEIL

to

-

.

-

.A_

.

,

.

..

0.

,

7,

with

.

.i

.

start

fOF

~

--,

~

.

SWEEP

I

.

trace at

be

from

the par-

,

.

._

nec-

PRE-

.,

.

sect.

IJ

Page

4

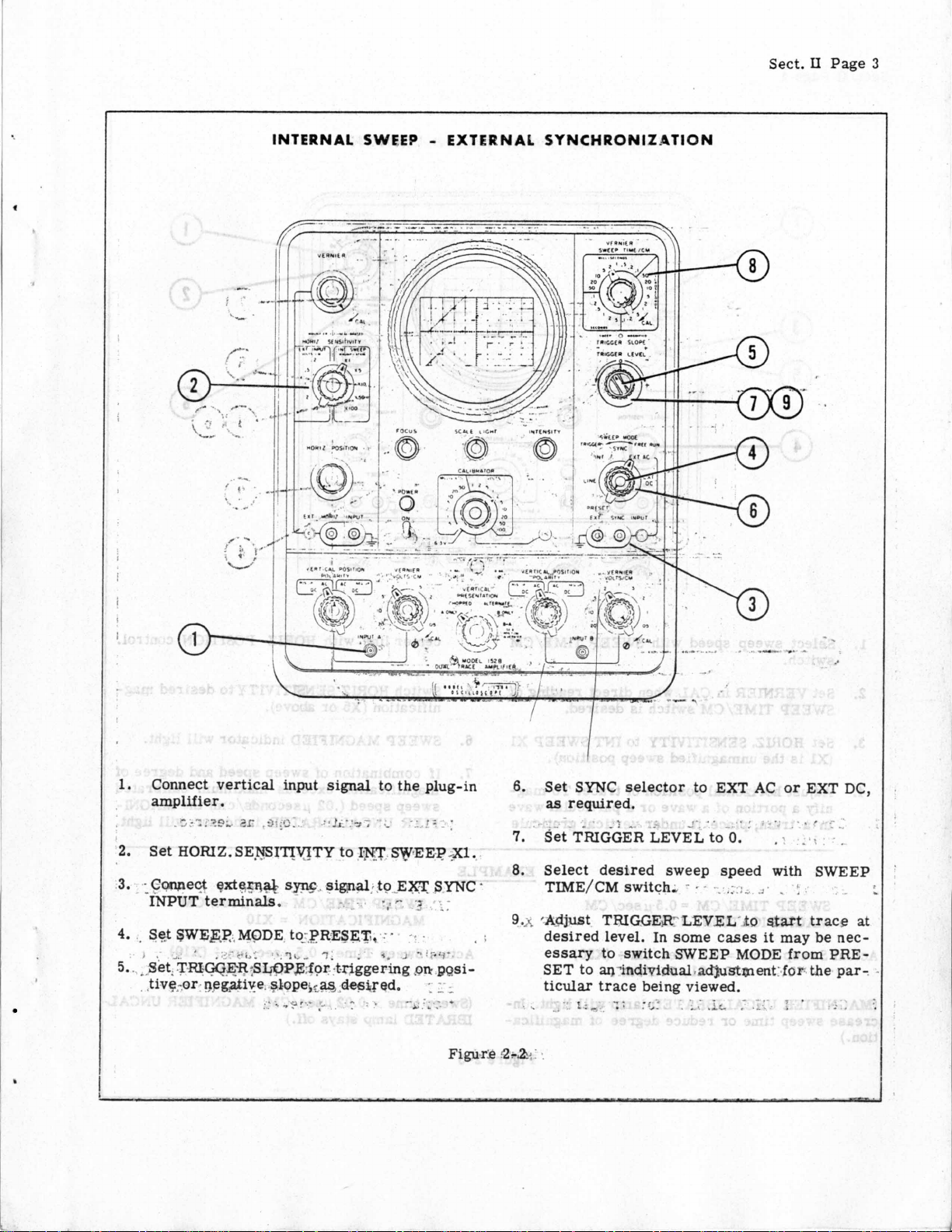

INTERNAL SWEEP MAGNIrICATION

..

Select

1.

switch.

Set

2.

SWEEP

Set

3.

(Xl

Adjust horizontal position of

1.

nify

in

SWEEP TIME/CM

MAGNIFICATION

sweep speed with SWEEP TIME/CM

VERNXER

TIME/CM

HORIZ.

is

the unmagnified sweep position).

a

portion

a

train, place

-.

in

CAL

SENsfiivr'I'Y

of

a

it

when

direct reading

switch

is

desired.

to

IN"

trace.

wave

or

a

particular wave

under vertical

=

0.5

JL

sec/CM

=BO

SWEEP

To mag-

graticule

of

XI

5.

.

6.

7.

EXAMPLE

center line with

Switch

nification (X5

--

SWEEP MAGNIFIED indicator

If

magnification exceeds maximum calibratec

sweep

FIER UNCALIBFUTED indicator

HORIZ

-.

combination of sweep speed and degree

speed

SWEEP TIME/CM

MAGNlFICATlON

HOFtIZ

POSITION control.

SENSITIVITY

or

above).

-

(.02

pseconds/cm) the

=

0.5

psec/CM

=

X10

to desired mag-

will

light.

MAGNI-

will

01

light,

ictual

Sweep Time

MAGNIFIER

rease

ion.)

sweep time

=

0.5

bsec/cm

=

0.01psedcm

UNCALIBRATED.lamp will light.

or

reduce degree

I

(X50)

of

magnifica-

.In-

Fibre

Actual

(Sweep time

IBRATED

Sweep-Tfme"='

2-3

=

>

0.0'2

psec/CM,

lamp stays

0.5

bsecjcm

0.05

off.)

psec/cm

I&&GkJ?IER

.

;

(XlO)

UNCA

Sect.

II

Page

5

..'

EXTERNAL

..

.

-.

-

.

. . . - .

..

-

..

---.

f

_.

..

._

-

..

..

A

*

.

:I-

.

,

-.

.

HORIZONTAL

..

.-

-.

.

INPUT

,

..

.

...

,

,,

.

.

(;y

4

I-

.

,...

.

I

,,

~

,._.

:..

.;

'

.

I

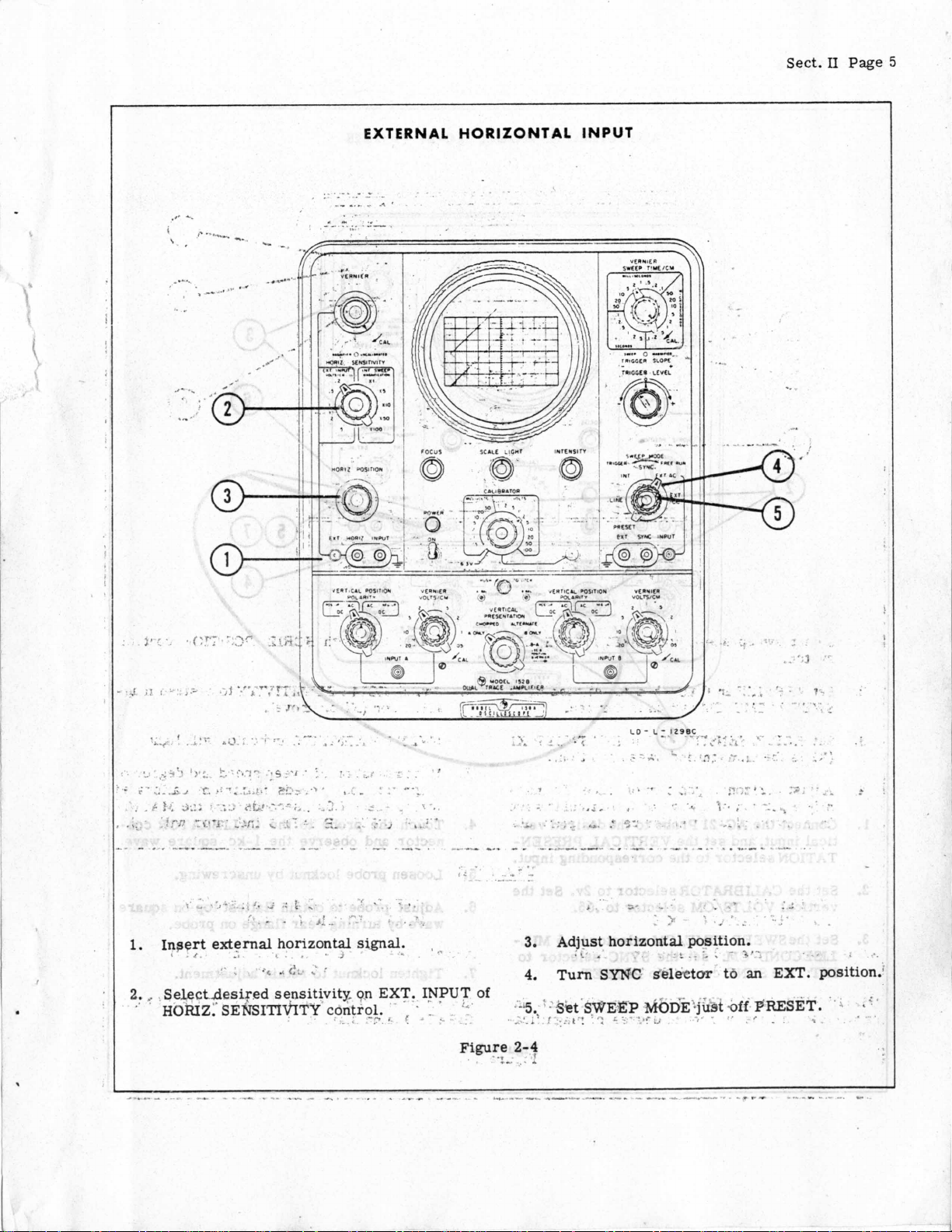

1.

Invert

s

/.

external

..

I.

horizontal

.

.

'c

2.

,

Selectdesired sensitivity,

.

HORIZ.'

SENSITIVITY

L

.L

,.

..

.

.

.

r

1,.

__

'i

.\

.

,!.

.

.

.--':

.

.:

t

-

i

,

*

(::.

controi.,

.,

signal.

on

EXT.

.

.

..

,

:

..

-.

*j

'

..

INPUT

.<

I_

Figure

of

.-

,

.

=-

'.'.

3.

Adjust horizontal position.

,I

._

4.

Turn

-5.,

'

:Skt SWEEP

^'.b

'

2-4

.

t

:

SYNC

<

seeleetor

*DE.;j;;?5t

..

.

._

'

,

.i.-.

'.

*,,:*.

..

-

-

,

tb

-off

'.

.-

._

..

.

2'-

._

an

EXT.

PmSET.

,

.I

position.'

..

Sect.

I1

Page

6

ADJUSTING

@MODEL

AC-21

PROBES

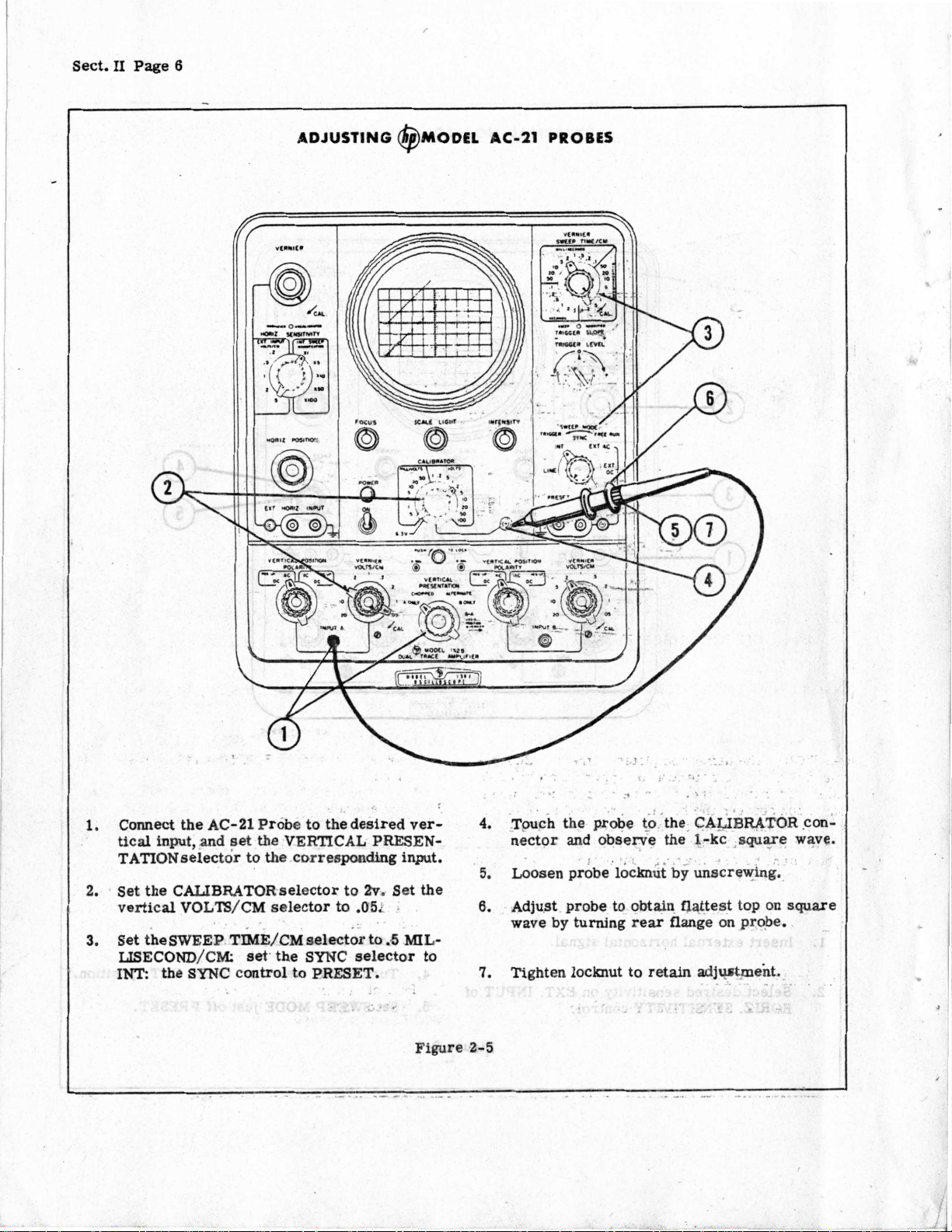

Connect the AC-21 Probe to thedeslred ver-

1.

tical input, and set the

VERTICAL

TATIONselector to the corresponding input.

Set the CAJJBRATORselector to

2.

vertical

Set theSWEEP TIME/CM selector to

3.

VOLTS/CM

selector to

2v.

.05i

LISECOND/CM: set the SYNC selector to

INT:

the SYNC control to PRESET.

PRESEN-

Set the

4

MIL-

Figure

I

Touch the

4.

pr&e

to

'the.

CALIRRA'XbR

nector and observe the 1-kc 'square wave.

by

Loosen probe locknut

5.

Adjust probe to

6.

wave

by

Tighten lochut to

7.

2-5

obtain

turning rear flange

unscrewing.

flattest top on square

on

probe.

retain

adjustment.

.con-

I.

DIRECT CONNECTION TO DEFLECTION PLATES

.-

--

i

.*

/f

EXTERNAL INPUT SIGNAL

I

,

--

-.

'/'

--

a

Sect.

I1

Page

7

1

~

i

I

.

*.

..

-.

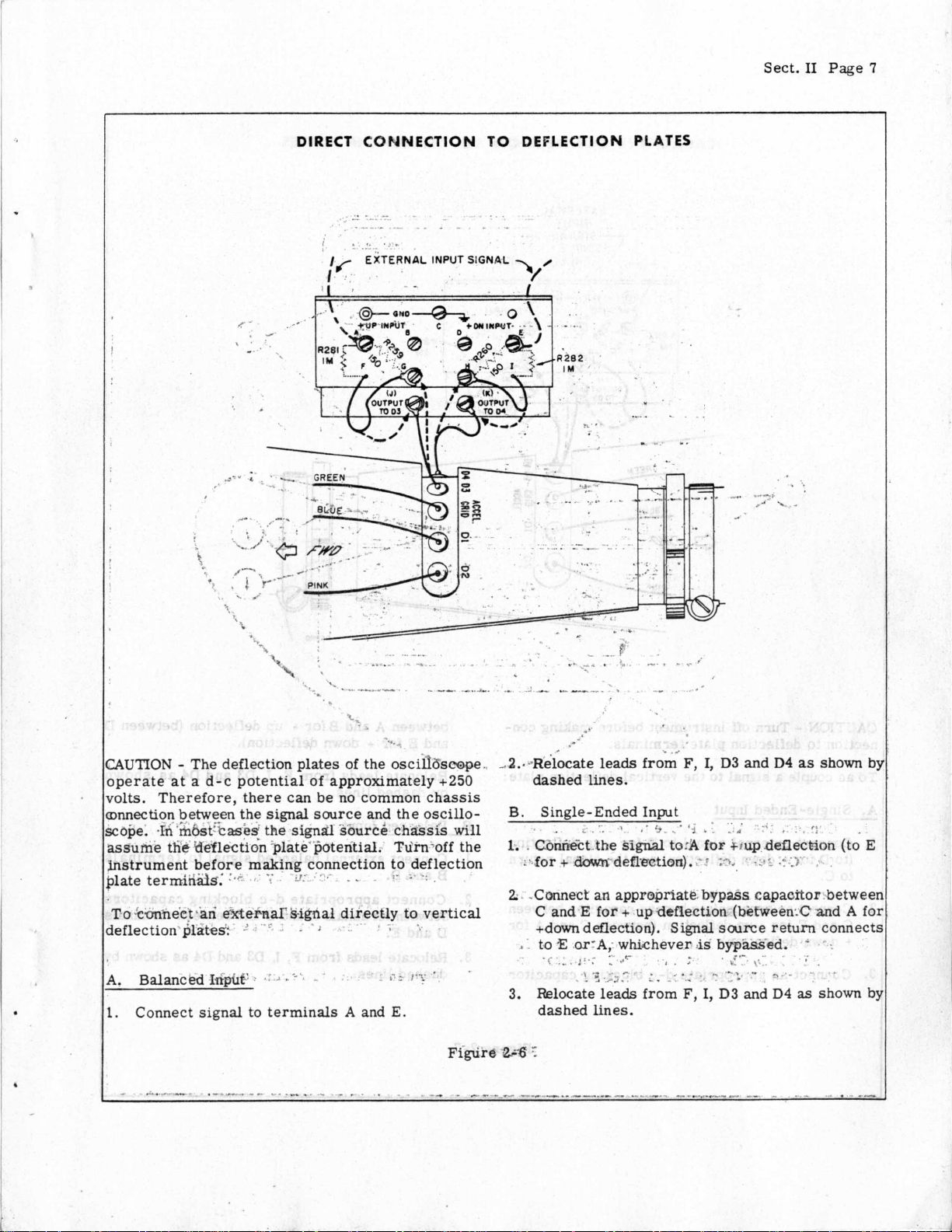

XUTION

iperate at

-

The deflection plates of the osciilf~sscoge..

a

d-c potential of approximately

rolts. Therefore, there can

Dnnection between the

cope. .In'mbst'tases the

signal

signa

--.I-

t.

be

no common chassis

source and the oscillo-

sourci chassis

._

--

_..-.

***

I

+250

will

ssulne the ;deflection plate potential. Turn-off the

tnstrument before making connection to deflection

)late terminals.'

To

.%unhe'e:tLan

leflection' plates:

'

f.

extehaI'4ignal

.

-1

_.

directly to vertical

I.

-

A2..-Relocate leads from

dashed

B.

Single-Ended Input

I.

.

Cbnh&t the

:.for

2

-Connect an appropriate bpp&s capacitor betweer

C and

lines.

,

I ; .I

signal

+

dmmi

deflection).

E

for + updeflection (bB€ween.Cmd A for

+dm detledion). Signal source return connects

I

to

-E

ar*A,

whichever .is bypasskd.

1

- J .-

:d'

,..

I

L.

.I.

3.

Relocate leads from

F,

.

.

tori9

I,

.

...,

-. .

F,

I,

D3

I.

. .

$b

-A

for

wup

-.

:%

i,

*-.-

I,

D3

and

D4

.

..

.'

deflection (to

.

sr

.

2

.-

.

--

and

D4

as

-

I.

as

shown

E

shown by

bj

i

I

i

Sect.lI Page8

.-

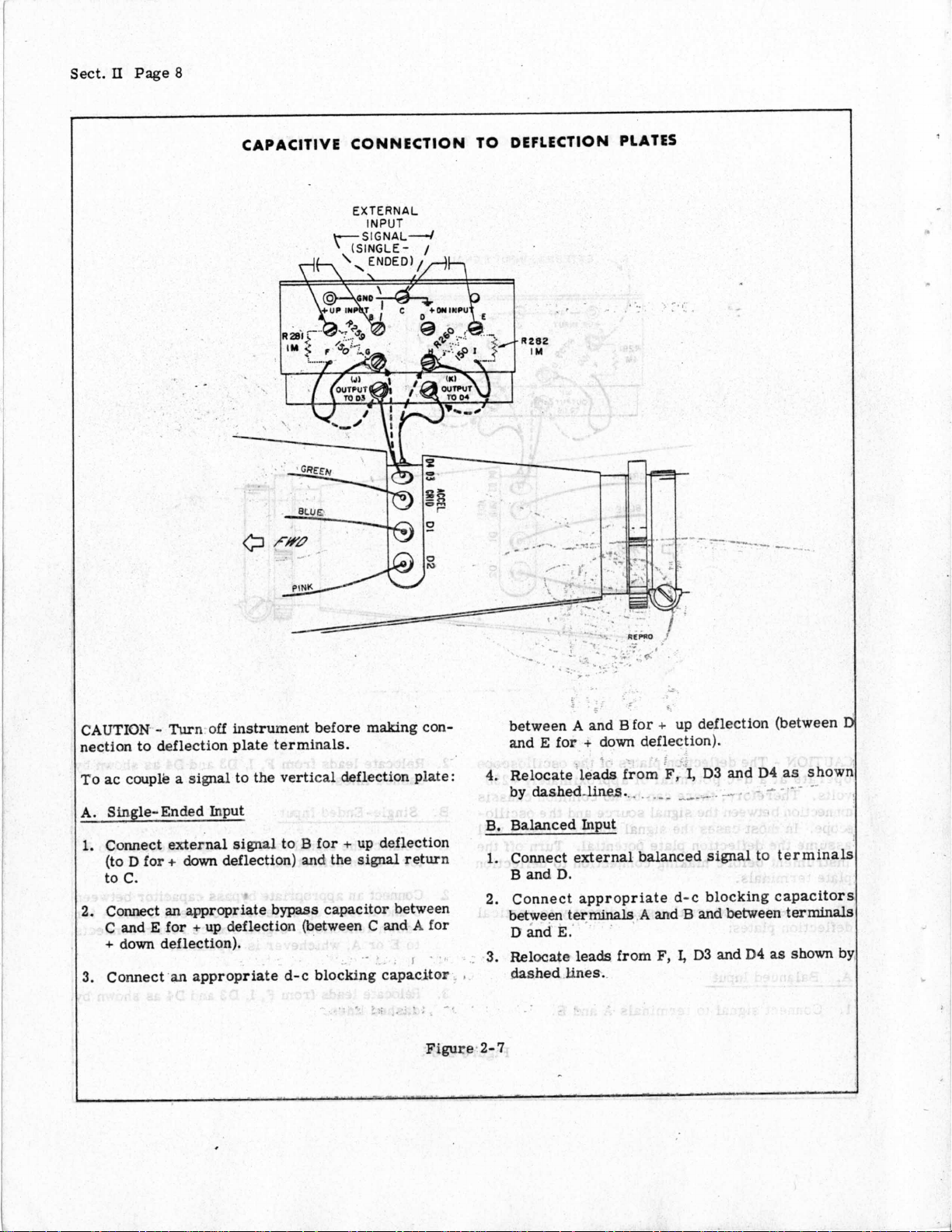

CAPACITIVE CONNECTION

EXTERNAL

INPUT

L.

,.

I,

TO

DEFLECTION PLATES

.

..

..

..

--

ZAUTION

iection to deflection plate terminals.

ro

ac couplk a signal to the vertical deflection plate:

9.

Single-Ended Input

I.

Connect external

(to

to

2.

Connect

C and

+

3.

Connect an appropriate d-c blocking capacitor

+

-

Turn

off

instrument before making con-

signal

D

for

+

c.

down deflection).

down deflection) and the

an

appropriate bypass capacitor between

E

for + up deflection (between

to B for + up deflection

signal

C

return

and

A

for

1.

,

Figure.2-

between

and

4.

Relocate

by

B.

Balanced Input

1.

Connect external balanced signal to terminal

B

2. Connect appropriate

between terminals

D

3.

Relocate

dashed lines.

A

and

E

for

+

down deflection).

leads

dashd-lines.

and

D.

and

E.

leads

Bfor

+

up deflection (between

from

F,

I,

D3

and

D4

..

.

__-

_-._

d-c

blocking capacitor

A

and B and between terminal

from

F,

I,

D3

._.-

and

-

D4

as

_-_

as

7

show

--

~

shown

1

b

Sect.

II

Page

9

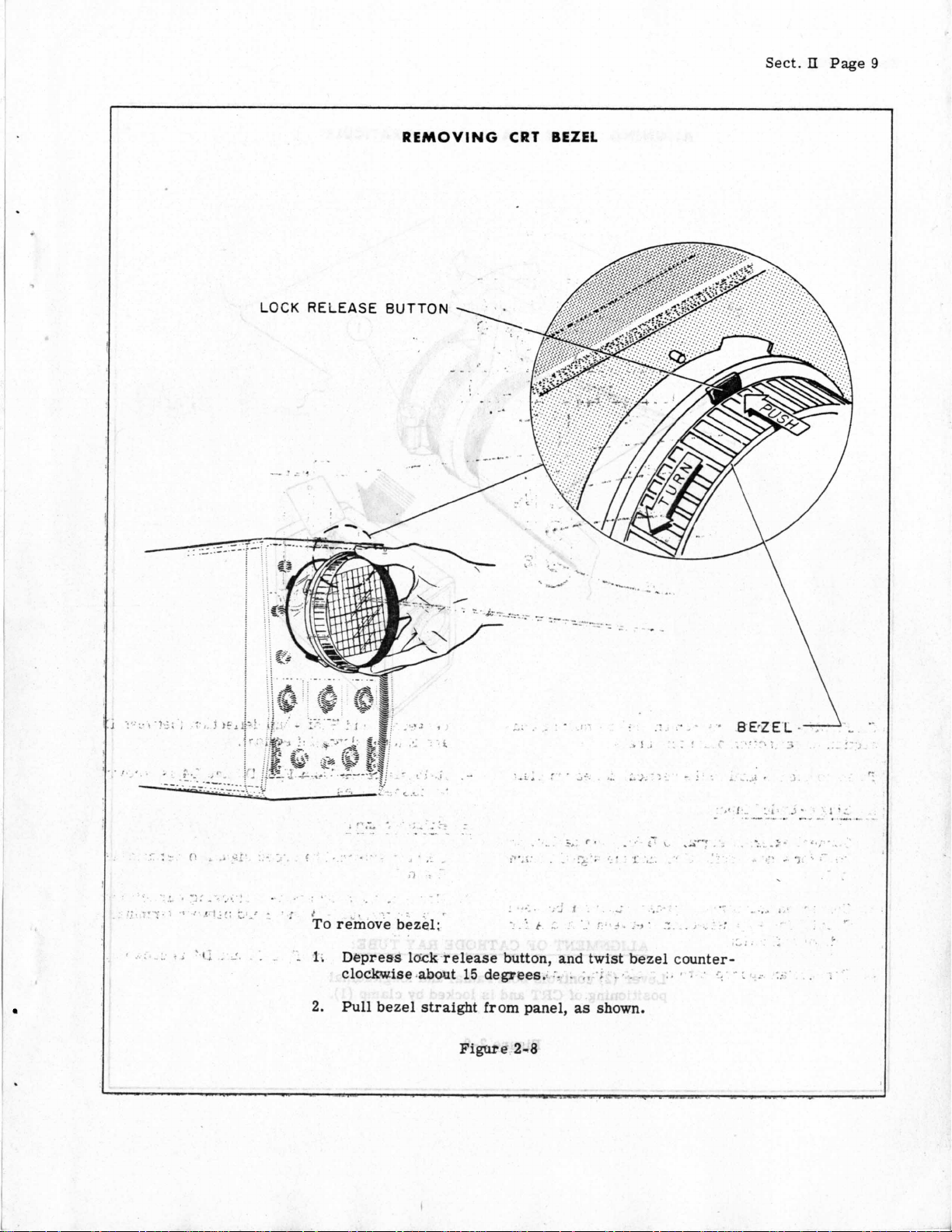

LOCK RELEASE

.....

---

REMOVING

BUTTON

CRT

BEZEL

......

..

.

.....

(.

.,

0

...

.,-.,

...........

.:

,

.

c

1;:;

:.

+;

%I.:

.-

..,.

.

..

...

.

.

-:

,_

-

.

.......

.,

.

2:'

:.

:'

<

...

.,

:,

.

,

:.

-r

.

:.

. .

.

.,

'

:

..

,.

c

To

remove

':

1;

2.

,.

-

._..r

bezel:

DepreaS lack release button, and twist bezel counterclockwisedabout

Pull

bezel straight

.-

..

.-.

-

,.

,

.

15

Figwe

-I.,

..

......

.

.i

.....

.

-.

...

degrees..

from

panel,

248

I-

-

....

-.

.

.-

-,,

r'

.

.

,,.

.,

f

..

....

"

t.:

:.

.

;,

as

...

:.

';

shown.

.!'

..,

.-

..

<.

..

...

*-

....

+,

;.,

.

.....

.....

.....

'I.

<

-\.

.

1.

.i"!

-.

::.

.

;

;

.........

-

.......

:;

.

-

-

,..<

..

I.

..

...

........

3.

:,

-.- - ._

..

-.

=.

..

.

.

I

I.

....

......

,

;

c

,.

.

.

_-

-

..

,.

......

.

1

..

I.

-.

..

._

i,;

I

~

.....

..

c

.

Sect.

II

Page

10

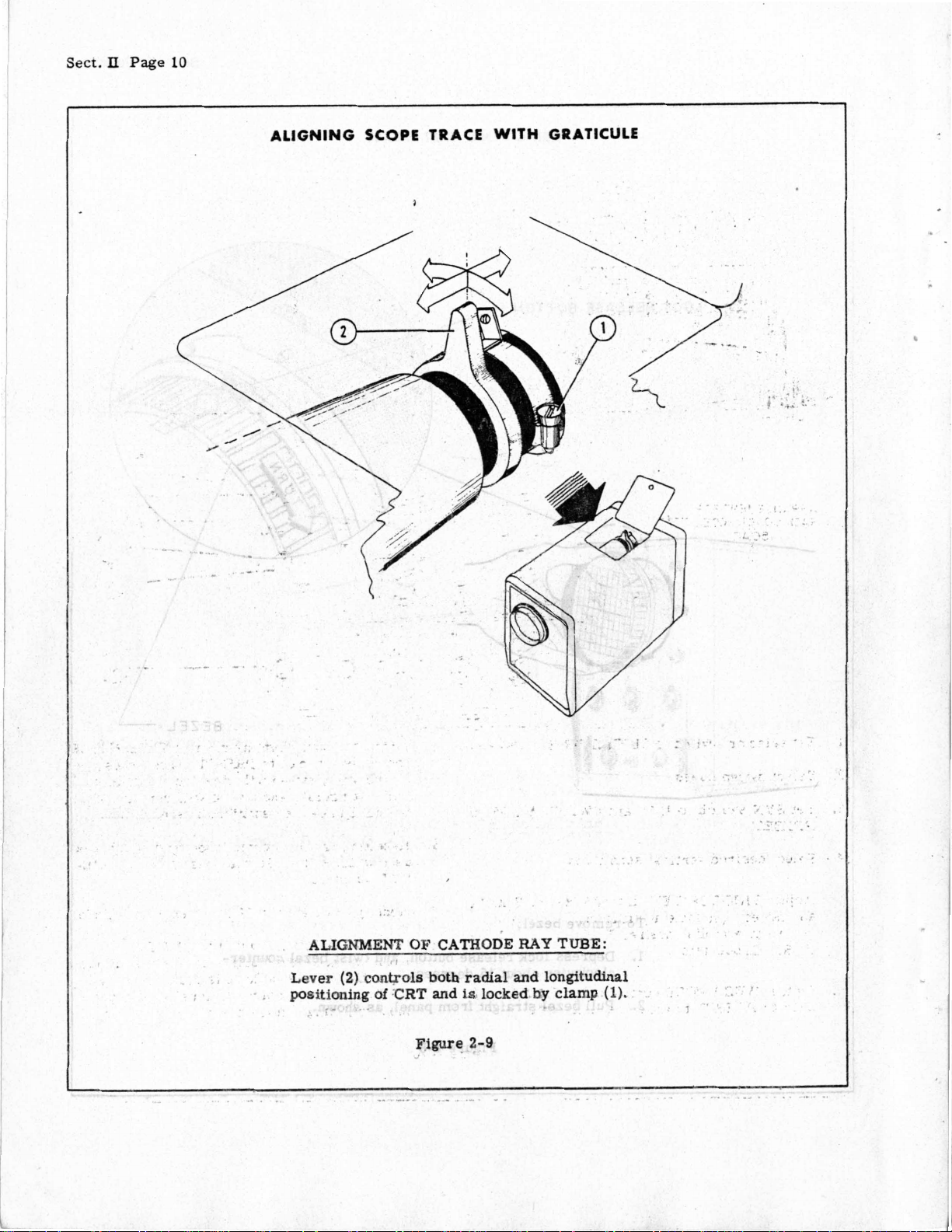

ALIGNING SCOPE TRACE

1

WITH

GRATICULE

.

,

...

.I

,,

..

.I

.,"

.>!

%,

.:

. , .

,

,

.

,.-

Lever

positioning

..

....

..

.....

.

,

-.

;

I.

...

ALIGNMENT

(2)

controls both

_-

-.

!'

I

'

of

CRT

.........

OF

CATHODE

and

Figure

..-

..

...

radial

is

locked

2-9

.

-

RAY

and

.

.

.

.'

__

...

..

.,

....

.

..i'

TUBE:

longitudinal

clamp

(1).

..

..

,

,.

..

.

-,

..,

.

:,

....

...........

.

.,

_.

...

...

;

..

?

.....

.

...........

.>-

..,

..

..

~ ...

,

.

..

........

..

..

.JS.

".

:

.,

.I'

.

(.,

.,

1

1

..

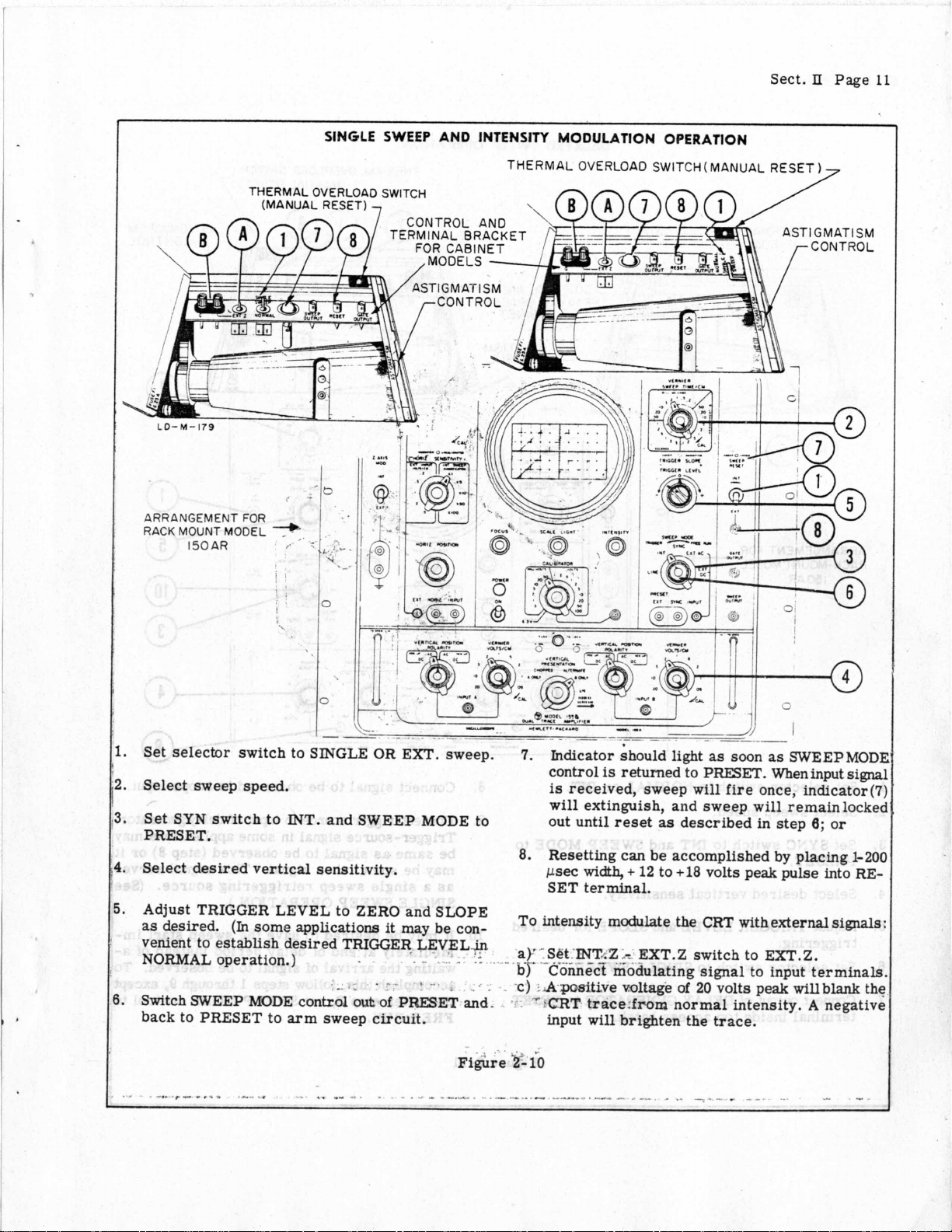

SINGLE SWEEP AND INTENSITY MODULATION OPERATlON

Sect.

II

Page

11

ARRANGEMENT

RACK MOUNT MODEL

150AR

FOR

THERMAL OVERLOAD

SWITCH(

MANUAL RESET9

0

-

Set selector switch to SINGLE OR EXT. sweep.

Select sweep speed.

Set

SYN

switch to INT. and SWEEP MODE to

PRES ET.

Select

Adjust

as

venient

NORMAL

Switch SWEEP MODE control

back to PRESET to arm sweep circuit.

desired

desired.

to

vertical sensitivity.

LEVEL

(In

some applications it

establish desired TRIGGER LEVEL@

operation.)

to

-.

and

SLOPE To intensity modulate the CRT withexternalsignals:

may

be

con-

.

.-_

.

Ouc

(...

,

. I .

of

PRESET and. 'CRT trace;from normal intensity. A negative

..

Indicator should light

7.

is

control

is

received, sweep will fire once, indicator(7)

will extinguish, and sweep will remain locked

out until reset

8.

Resetting can be accomplished

psec

SET terminal.

=?

-s6t,.INT4zR

-

-_-

-

1.

-

Conned

b)

.

-c) :IApositi.ve voltage

.

input will brighten the trace.

returned to PRESET. Wheninput

as

width,

+

12

to

EXT.Z

modulating

as

soon

as

described in step

by

+18

volts peak pulse into RE-

switch

of

20

to

signal

volts peak

m.z.

to input terminals.

SWEEPMODE

signal

6;

or

placing

willblank

1-200

the

Sect.

II

Page

12

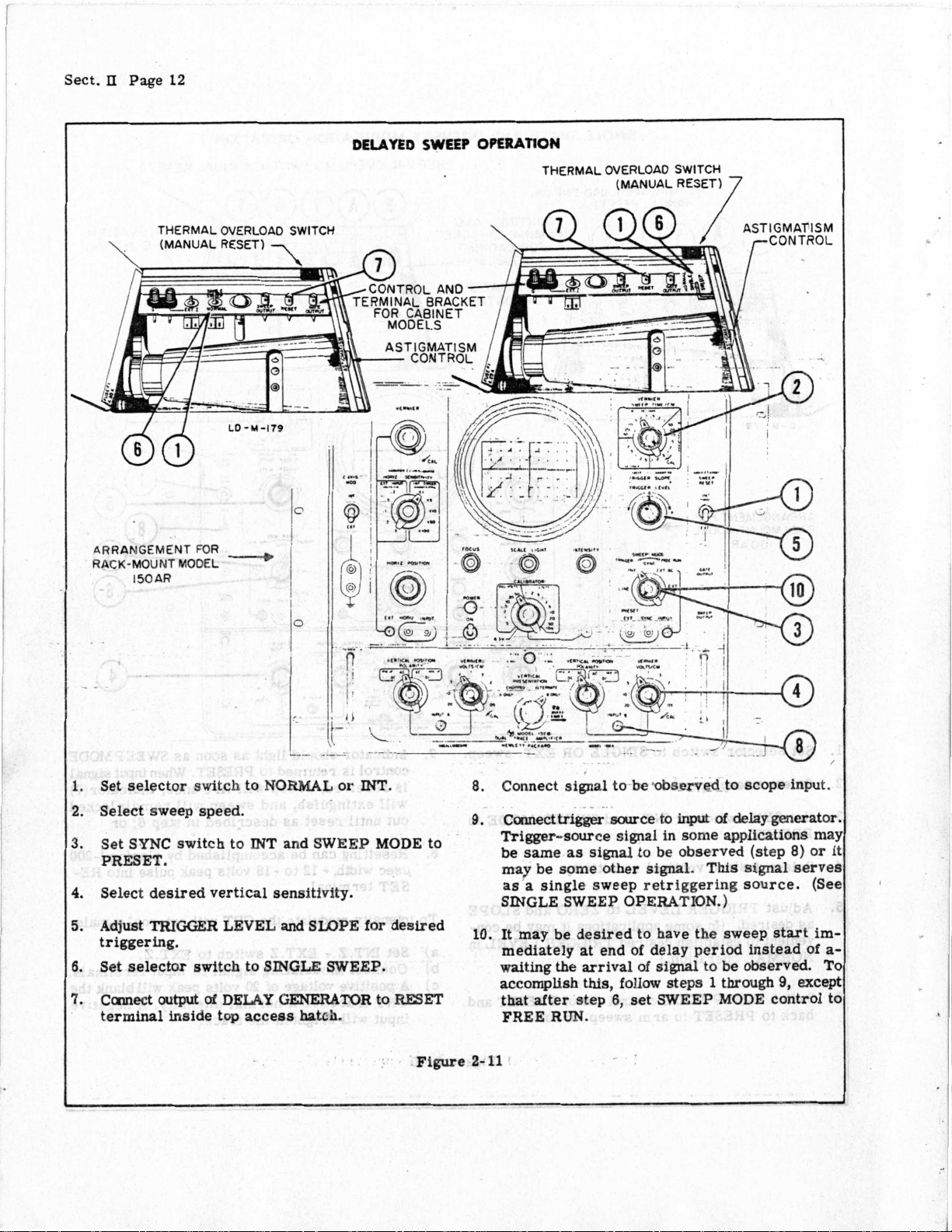

Q

d

ARRANGEMENT

RACK-MOUNT

MODEL

150AR

FOR

LD-LI-'79

-

DELAYED

SWEEP

OPERAnON

THERMAL OVERLOAD

(MANUAL RESET)

SWITCH

7

-

1.

2.

3.

4.

5.

6.

7.

..

Set selector switch to NORMAL

Select sweep speed.

Set

SYNC

PRESET.

Select desired vertical sensitivity.

Adjust

triggering.

Set selector switch to

Cam&

terminal inside top

switch to

output

LEVEL

d

DELAY

INT

and !WEEP MODE to

and

SINGLE

GENERATOR

access

--

SLOPE

hatch.

or

DIT.

for

SWEEP.

to

,.

RESET

Figure

Connect signal to

8.

cmnecttrig& mce to

9.

Trigger-source signal in some applications ma

be same

may

as

SINGLE

10.

It

may be desired to have the sweep start

mediately at end

waiting

accomplish this, follow steps

that after step

FREE

2-11

as

be

some other

a

single sweep retriggering source. (Se

SWEEP

the arrival

RUN.

bewbserved

input

signal to be observed (step

signal.

OPERATION.)

of

delay period instead

of

signal

6,

set SWEEP

to scope input.

of

delay

This

signal

to be observed. T

1

through

MODE

generato1

8)

or

serve

im

of

9,

excel:

control t

i

,

a

Sect.

Page

0

,.

?-'.

....

.-

.I-

,.

4

-,

..

t

400

t

?a0

+

..

__

.

q,..

L.

130

-71

-

11QVQC

*IU

-4800VOC

11111s111

-5000

VQC

VQC

WC

VQC

rQL

RECULITED

LOW-VOUAEE

ROAR

SUPPLIES

vi

mvin

wmr

lLOC1

QllclU

HlCW

C-

-c-

VOLTI$f

POWER

SUPPLY

v27-v

30

..

-.

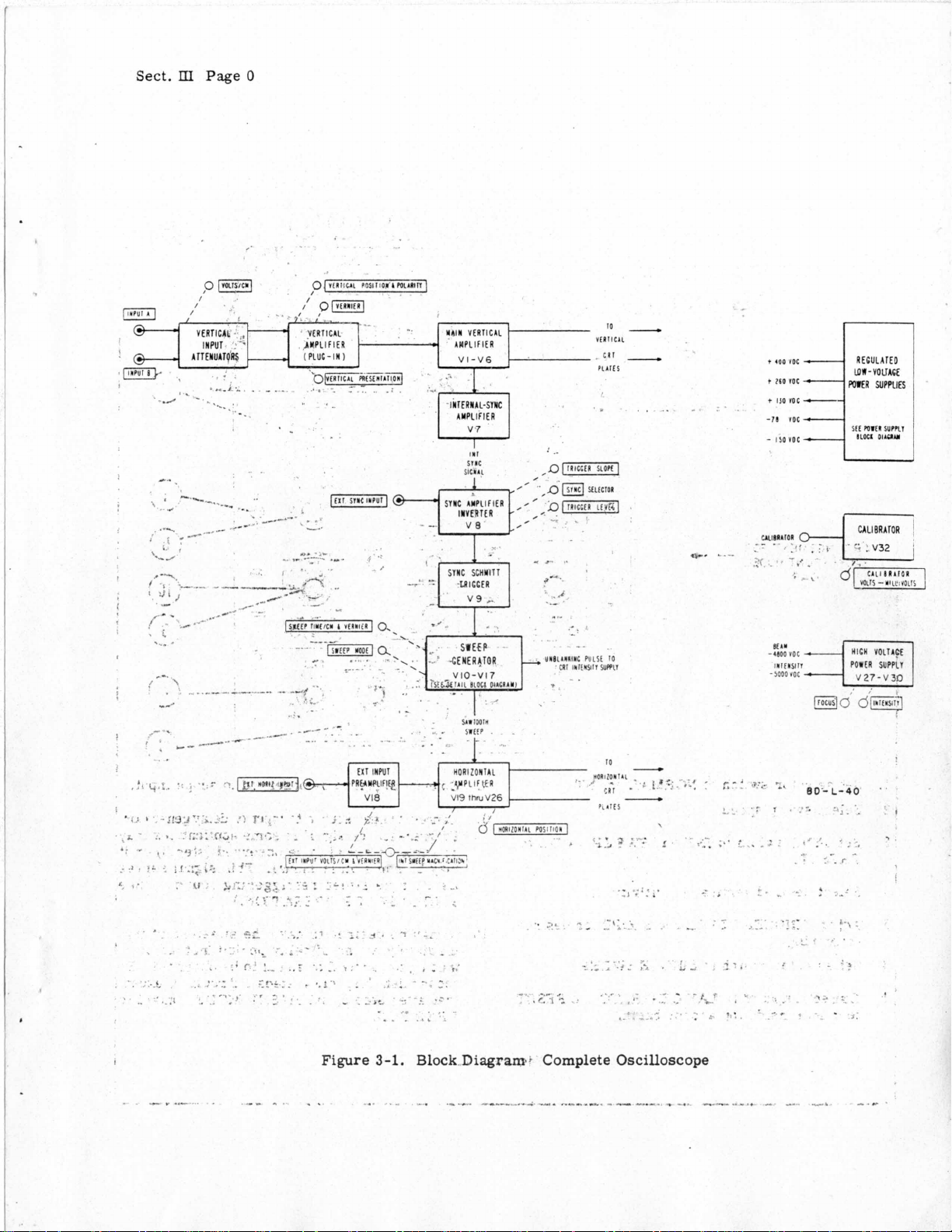

Figure

c

*.-

..

.--

.....

3-1.

Block Diagram. Complete Oscilloscope

..............

-_

.......

i

-.

..--.-.

.

-

-.-.

~

*.

--

.....

*_

-.

.

+

I.

...

..-,

-

...

.

Sect.

III

Page

1

.

3-1

OVER-ALL OPERATION

The block diagram in

signal circuits in the Model 150A Oscilloscope: the

Vertical Amplifier, Horizontal Amplifier, Sweep

Generator and Cathode Ray Tube.

a. Vertical Amplifier

plifier receives the input

and

drives

vides attenuation of the input

.

determines the direction of spot deflection for

given input signal polarity; determines ‘the vertical position of the spot on the screen: supplies

signal for internal synchronization; and incor-

porates

The complete Vertical Amplifier circuit

separate parts:

inverter, vertical position controls and amplifiers in the Vertical Amplifier Plug-In Unit, and

second the intermediate and final amplifiers on

the instrument chassis.

b.

Horizontal Amplifier - The horizontal amplifier

is

driven either from the HORIZ. INPUT jack

from the internal sweep generator.

The complete Horizontal Amplifier consists of

the main amplifier, and

for external signals applied to the HORIZ.

PUT connector). The preamplifier stage includes

the VOLTS/CM portion

ITY selector switch and

switch

sitions. The MAGNIFICATION circuit

HORIZ. SENSITIVITY selector

Horizontal Amplifier. The sawtooth sweep

applied directly to the Main Horizontal Amplifier

while external signals are first applied to the

HORIZ. SENSITIVITY switch and the preamplifier.

c. Sync Circuit - The Synchronizing Circuit re-

ceives

the

a

0.25 psec delay

is

set to one of the MAGNIFICATION po-

,

a

signal either from the Vertical Ampli-

Figure

-

vertical deflection plates. It

first

3-1

shows the basic

The complete vertical am-

signal,

signal

in

the input waveforms.

the input attenuators, phase

a

preamplifier (used only

of

the

is

not in

amplifies it,

if

HORIZ.

use

is

necessary;

SENSITW-

when the

in the

pro-

is

IN-

of

the

Main

or

is

SECTION

THEORY

fier

for internal synchronization, from the EX”.

SYNC INPUT

source. The Sync Circuit amplifies

nals,

and determines the level and polarity which

will

start a sweep.

d. Sweep Generator

on receiving

and generates

Amplifier. The Feedback Integrator determines

the basic sweep time per centimeter, and the

a

a

in

SWEEP MODE control selects triggered or freerunning operation.

provides either single

sweep generator also supplies unblanking pulses

to the CRT,

tooth flyback) to the Dual Channel Vertical Amplifier Plug-In Unit for ALTERNATE operation,

and sweep and gate signals to output connectors.

e. The CRT

accelerator tube with the cathode operated at

-4800

volts. The mono-accelerator anode makes

possible

cated inside the access hatch) which requires no

resetting when adjusting the FOCUS

ITY. The deflection plate terminals located on

the periphery

through removable jumpers directly to the Main

Vertical Amplifier, Horizontal Amplifier, and

Astigmatism control.

3-2

The signal from the plug-in vertical amplifier

coupled through a connector on the plug-in unit chas-

sis

chassis

Input amplifiers

of approximately 20

tiometer R5 has

tained by varying

eration.

VERTICAL AMPLIFIER

to the Main Vertical Amplifier on the instrument

.

or

a

sync pulse from the Sync Circuit

a

a

timing signal (during each

-

The CRT

a

simple astigmatism adjustment (lo-

of

V1

and

a

range of approximately 4 db ob-

V1

OF

OPERATION

from an internal power line

all

-

The Sweep Generator starts

sawtooth to drive the Horizontal

A

SINGLE SWEEP switch

or

repetitive sweeps. The

is

a

type 5AMP - mono-

the. tube neck are connected

V2 provide a maximum

db.

The gain adjustment poten-

and

V2

cathode circuit degen-

input sig-

or

INTENS-

Ill

saw-

is

gain

Sect. IV Page

1

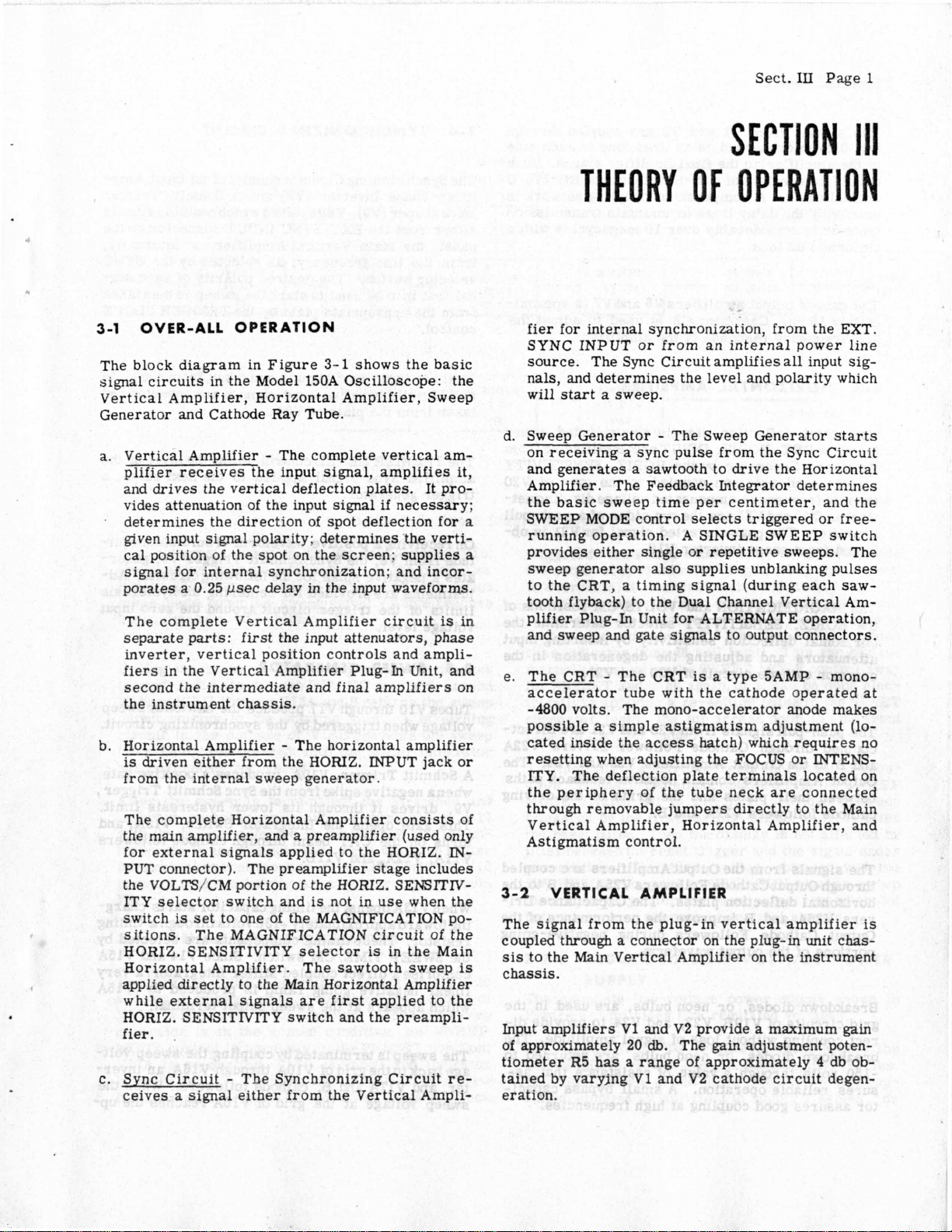

4-1

GENERAL INFORMATION

This section contains instructions for testing, ad-

justing and trouble-shooting the Model 150A Oscil-

If

loscope.

densed Test and Adjustment Procedure, paragraph

is

4-3,

ments and operation. The Trouble-Shooting Procedure, paragraph 4-4,

a

section of the instrument that

Paragraph 4-2 deals with

instrument and routine maintenance procedures.

Schematic Diagrams and the Table of Replaceable

Parts

The following test equipment

adjusting the Model 150A Oscilloscope during manufacture. Equivalent test equipment may

A

test oscilloscope such

1)

equipped with

fier.

the instrument

a

fast method of checking the basic adjust-

are

located

at

the end of this section.

an

@

Model 152 Dual Trace Ampli-

is

operating, the Con-

is

a

rapid means of isolating

is

not functioning.

the

physical layout of the

is

used for testing and

be

as

the

@

Model 150A

used.

SECTION

IV

MAINTENANCE

9)

A

frequency response generator such

Specification 23679.

4-2

Routine servicing covers

removal, adjustments required when tubes are

changed, and CRT replacement.

Each of the major sections

cated in

location of these sections. The Horizontal Amplifier

sections will swing out when the instrument

of

fasteners near the panel.

A.

scope

ROUTINE SERVICING

air

filter cleaning, cabinet

of

the instrument

a

particular

and the Sweep Generator and Sync Amplifier

the

cabinet. These sections

CLEANING THE

Inspect the

is

in constant use.

area.

Figure 4- 1 indicates the

are

AIR

FILTER

air

filter often when the Oscillo-

as

an

@

is

lo-

is

out

held in place by

2)

A

high impedance dc vacuum tube voltmeter cal-

ibrated to

410B with an

3)

A

such

4)

A

mum rating of 7.5 amps, equipped

accurate within

A

5)

211A.

6)

A

of

at

7)

An accurate time mark generator suitable for

sweep speed calibration.

8)

A

Specification 23678.

an

accuracy of

@

Model 459A DC Voltage Mcitiplier.

high impedance ac vacuum tube voltmeter,

as

an @ Model 400D/WL.

variable power line transformer with a mini-

1

volt.

square wave generator such

sine wave o scillator

least

50,000

voltmeter calibration generator such

cycles, such

A%,

with

a

as

such

with

m

aximum

an

as

an @ Model

a

voltmeter,

as

an

@

Model

$3

frequency

Model

200CD.

as

an

@

The air-filter element in

type.

cabinet and

the

the filter element, wash in warm water and detergent, then recoat with an adhesive made for this

purpose. Filter Coat No.

ducts Corp., Madison

you have difficulty obtaining it,

Packard Field Sales Engineer.

Apply Filter Coat

applicator directed at the intake side of the filter

until visible baffles are liberally coated. Do not

spray

the surface of the filter. Filter

service.

B.

When the cabinet

are

It

is

located in the bottom of the instrument

is

removed

rack mount pull the filters to the rear. To clean

No.

to

the extent that adhesive runs

REMOVING THL CABINET

CAUTION

is

exposed. Observe adequate safety precautions.

----------

the

150A

is

a

reuseable

by

pulling straight down. In

3

made by Research

10,

Wisconsin

3

with the HANDIKOTER spray

removed, dangerous voltages

is

suitable.

see

your Hewlett-

or

is

now ready for

Pro-

drips off

If

i

I

!

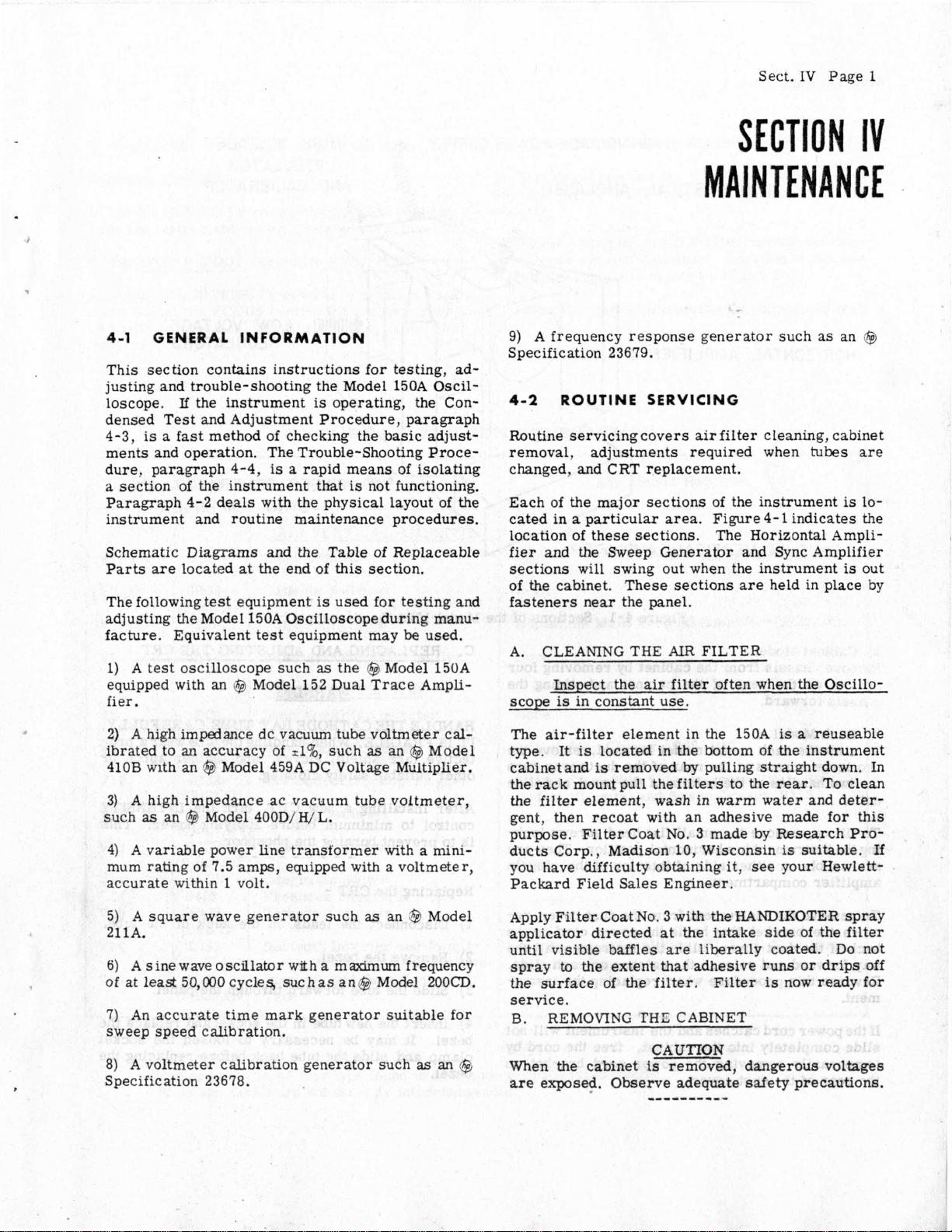

Sect. IV

Page

4

1

4

I

1

I

I

Circuit

Reference

V18

Vl9

v20,21

v22

V23,24

v25

V26

V27

v28

V29

V3

0

V31

6AN8

(6BQ7A)

6DJN6BQ7A)'

6485

6D

(

6 BQ74

6CL6

6D J8(6 BQ7A)

6DJ8( 6BQ7A)

6AU5GT

6D

5AMP

58

J8(

6 BQ7 A):

*

*

TABLE 4-1.

HORIZONTAL AMPLIFIER

Ext. Horizontal Input

Preamplifier

Amplifier-Phase Inverter

Push-Pull

Cathode Followers

Output Amplifier

Output Cathode Follower

Capacitance Driver

HIGH VOLTAGE SUPPLY

60 kc, High Voltage

Oscillator

High Voltage Control

High

High Voltage Rectifier

Cathode

TUBE

Function

Voltage Rectifier

REPLACEMENT CHART (CONTD)

Amplifier

Ray Tube

Tube

Adjustment Required

Adjust Preamplifier Gain, R178 and

Preamplifier Balance, R185

Adjust Horizontal Gain R199

Horizontal Balance, R189,

None

Adjust Horizontal

Horizontal Balance, R189,

None

AND

CRT CIRCUIT

None

Adjust High Voltage, R275, Ft267

None

Adjust Astigmatism, R283

Adjust Vertical Gain, R5; Horizontal Gain,

R199 and Horizontal Balance, R189,R207

Gain,

and

R207

R199 and

R207

V3 2

v33,34,3 5

V36

V37,3 8,39

V40

V41,42

v43

V44,45,46

v47

V4

8

v49

EO

*

Replace with

and 6BK7

**3A2 used in

6U8

12B4A

6BH6

12%

6BH6

12B4A

6BH6

126BH6

5651

12AX7

12-

same

are

some

CALIBRATOR

1

kc Multivibrator

LOW VOLTAGE POWER

400

Volt Regulator

400

Volt Control

+260 Volt Regulator

+260 Volt Control

+130 Volt Regulator

+130 Volt Control

-150 Volt Regulator

-150 Volt Control

Power Supply

-78 Volt Control

-78

Volt Regulator

tube

type

found in instrument.

not directly interchangeable.

instruments.

Reference

None

SI

'PLY

None

'I

Check -150 Volt Output

Check -78 Volt Output

1

None

Tube

types

6BQ7A, 6DJ8

I

;I

Sect.IV

Page

5

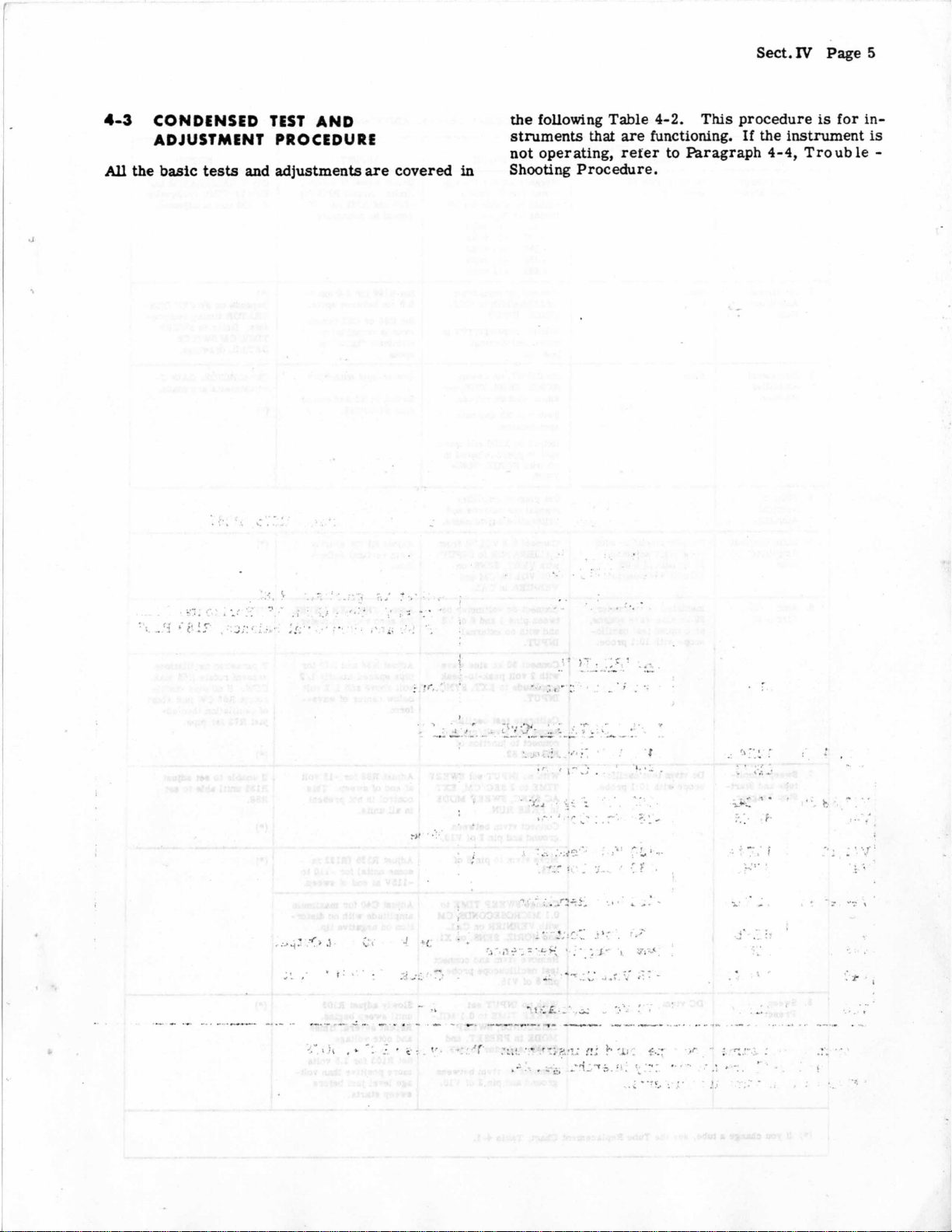

4-3

All

CONDENSED TEST AND

ADJUSTMENT PROCEDURE

the

basic

tests

and

adjustments

are

covered

in

the

following Table

struments

that

4-2.

are

functioning.

This

procedure is

If

not operating, refer to Paragraph

Shooting

Procedure.

for

the instrument

4-4,

Trouble

in-

is

-

1

I

.;...,.*

..

.,.

?+A

'

'

.

,

.I

.:.,

....

*:-"

..

.......

.,I>...

.,-.

._:

.

.,..-.

-

;>

J

"1. '*

:

.

.

::

,.-

.

.

+..

,

..

,.

;

,

-,..

,

3

...

,,

T

'

1-

i

,.-

-.

...

z

"-

'

-

,

...

...

.,

.

,,

.'

....

:J.

..

.......

I.

,..,

.,.~

,

.

:.'

-1

?

..

,P

,.

.,:

......

..

i',

:.._

.

<

-

..

,-

=+-

.I

.

:,.

r.

.

-.

.

r

...

....

<. -.

.....

..

..

.

,

I

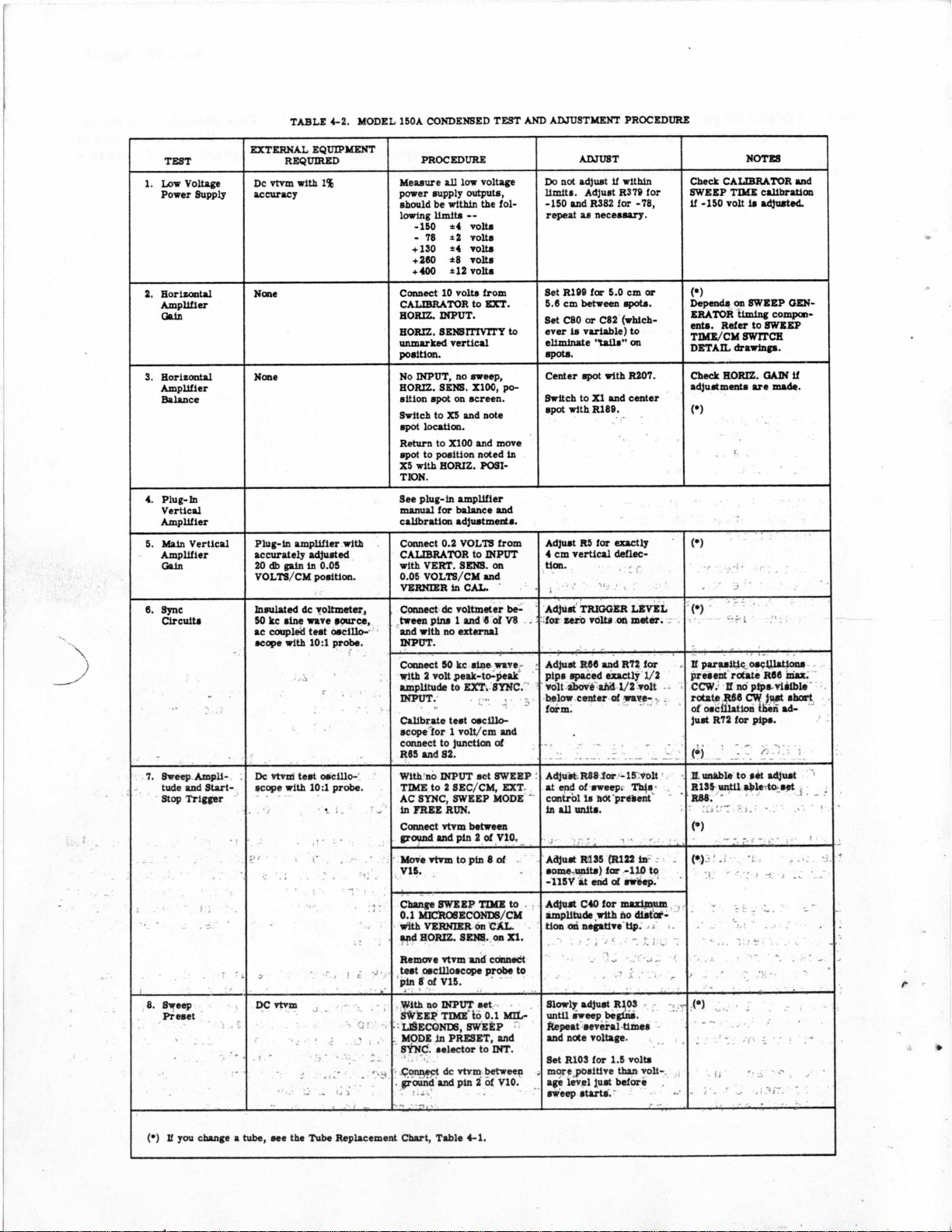

'.P

1.

Lor

vow

Power

supply

2.

Eorizcdal

Ampllfler

ooin

3.

Eoriumtrl

Ampllfler

Balance

4.

Plug-ln

Vertical

Amplifier

Amplifier

opin

6.

Sqnc

ctrcllit.

I-

TABLE

42.

NaaC

Nme

plug-in

unpwier.lltb

accurately

20

VOLTS/CM

lnwlated

50

LC

scape

Dc

.cape

adjusted

dh

gah

in

0.05

position.

dc

yoltmeter,

kc

shte

wave

corrpled test oscllkw

vfth

1O:l

*hm

test

mcillo-.

with

1O:l

t

MODEL 150A CONDENSED

Cam& 10 voltr

CALIBRATOR

EOIUZ

EORIZ.

unmarked

postt1on.

INPUT,

No

HORIZ.

sltlon

Srltch to

.pot loution.

Fzeturn

.pot

to

X5

with

TION.

See plug-in

mprmpl

calibration adfwtmerdr.

Cmnect

CALIBRATOR to

wlth VERT.

0.05 VOLTB/CM and

VERNIER

Cmnect dc voltmeter

www.

probe.

hPccnpinrland6dW

and wlth

INPUT.

Conaeet

Wth

2

unplltude

IWT.

Wbrlte

scope lor 1 mlt/cm

connect to junction

R65

and

probe.

e.

'*

TEST

from

to

EXT.

INPUT.

SENSITIVITY

vertid

no moep,

SENS.

X100,

.pot

on

rcreen.

XS

md note

to XlOO md

posltlon noted

EORIZ.

for

0.2

no

so

volt peak-to-peak'

t..t

82.

POSI-

unpllifer

balance

VOLTS from

MPUT

SENS.

on

in

CAL.

atml

kc

mine

WWe-

to

EXT,

8YNC.'

acillo-

mwe

pad

of

AND

ADJUBTMENT

Do

not

limits. Adjust R379 for

-150 urd RS82

repeat necessmry.

Bct RlDD

5.6

cm

Set

C80

ever

to

ellmirute

spots.

Center

p

[hitch

spot

in

Adjust

4

cm vertid

tion.

.I

AdfudTRIGGER

be-

,101

zero

,

AWE?

PIP.

Wlt

belm

-3

form.

aod

AnmaT

adjut

for

between

or

is

rulable)

spot

to

with

R5

,

volt.

R66

rpled

dwve

center

PROCEDURE

ti

rfthin

for

5.0

cm

Ipot..

C82'(rhieh-

'WB"

rith

X1

and

R18D.

..

lor

Q.ett

ddlec-

,I

on

,-

8ad

R72

anctb

rhbl

1/2 volt

oi

wave-

-78,

or

to

on

R207.

center

.

LEVEL

mater.

for

1/2

..

Check

SWEEP

if

-150 Volt

(*I

Depandr

ERATOR

ent..

TLbWCMSWfiCE

DETAIL

Check

adjustments

(*I

(*I

.2

(*)

-

IpuuiUc-cW-

prermt rd.tc R66

.

.

CCW. I no

rotate

.

of

oscillation

just

R72

CALlBRAlOR

TIME

calibr.Uon

i.

@rut&

0

8wEEP

thhg

to

drawings.

are

'.>,

pes

CW

for

pips.

compon-

MEP

mrde.

rllible-

111.1

then

Refer

EORIZ.

R66

ud

ow-

if

mu.

short

ad-

(*)

I

you

change

a

tube,

..

s

nee

'

the

3.

Tube

.I

....

..

_.

;

.

Replacement

grdandpfn2dVlQ-

.

Mwe~tvmtopin8ol

v15.

'.

.

.. .

I.

.

Remore

oscillorcopc

test

in

l7

~~~ ~

With

SWEEP TIME

LIflECQNDS, SWEEP

MODE

SYNC. selector

COIIQWA

ground and pin

-.

7,.

Cbut,

rhm

of

V15.

no

INPUT

in

dc

Table

and

cd

probe

rct

to

0.1

PRESET,

to

INT.

rhm

between

2

of

4-1.

IbtIf.~

and

V10.

.

,

~eu.tm~5

.

MIU&db)fOr-1Wt?

-115V

at

end

to

SlWl?

wb

until

beep

kepsat

several

and

note

voltage.

set

Rlos

for

more

paritlve

.

age

level

just

weep starts.'

..

mn1p

of

#weep.

.>

RIOS

kgl~.

timer

1.5 volta

tb.a

before

.

~

volt-

._

L

I

-

.

--

r

..

-

(*).e.

(*)

-

-

._

_-

.>

-

-.

,I

#*

-<-,

a.

'12

r

. .-

a,-

-.

~

.~

~

.

Sect.

IV

Page

7

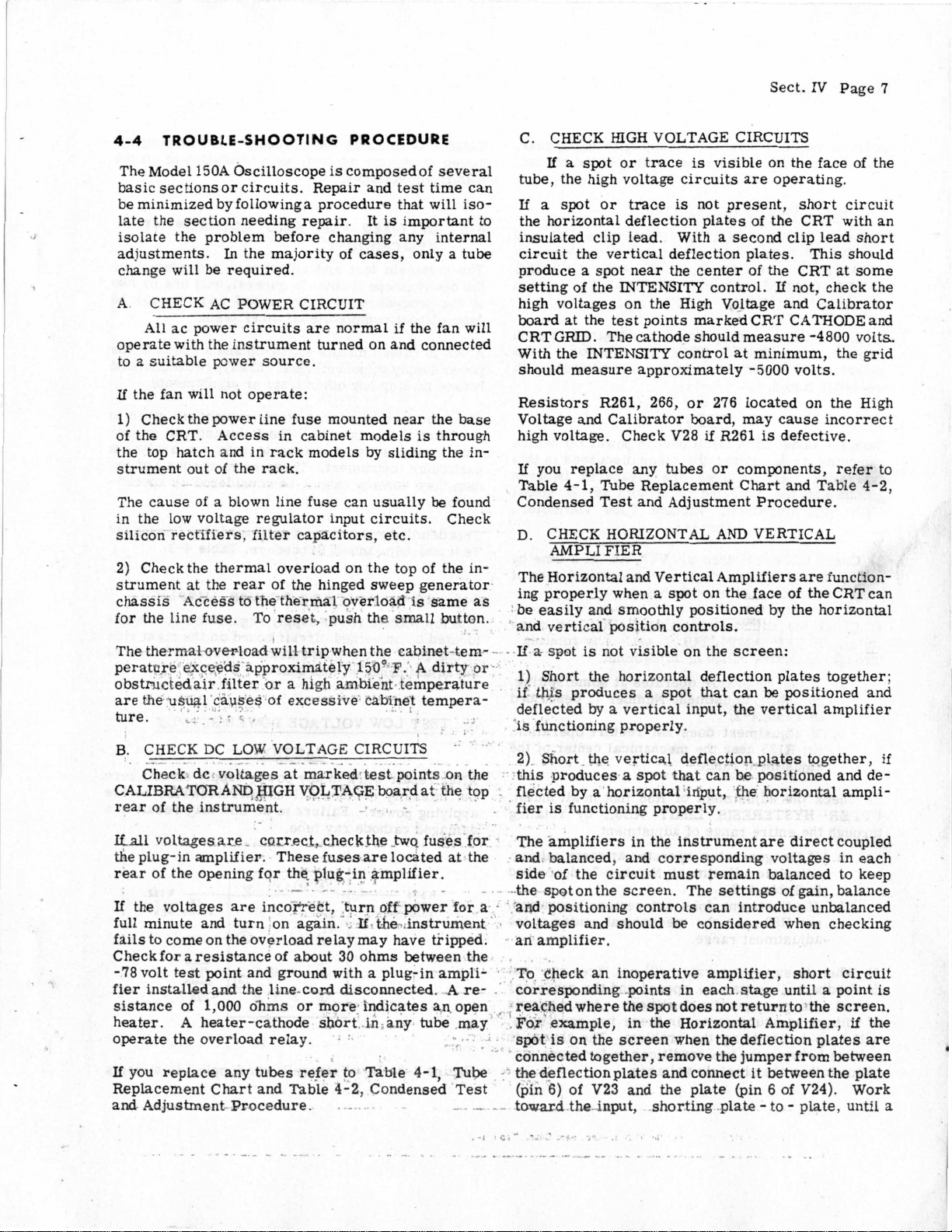

4-4

TROUBLE-SHOOTING PROCEDURE

The Model 150A Oscilloscope

is

composed of several

basic sectionsor circuits. Repair and test time can

be

minimized by followinga procedure that will iso-

late the section needing repair.

It

is

important to

isolate the problem before changing any internal

adjustments.

change will

A

CHECK AC POWER CIRCUIT

All

ac power circuits

In

the majority of cases, only a tube

be

required.

are

normal

if

the fan will

operate with the instrument turned on and connected

a

suitable power source.

to

If

the fan will not operate:

1)

Check the power line fuse mounted near the

of the CRT. Access in cabinet models

the top hatch

and

in rack models

by

sliding the in-

is

through

base

strument out of the rack.

The cause of

in the low voltage regulator input circuits.

silicon rectifiers

a

blown line

,

filter capacitors, etc

fuse

can usually

.

be

found

Check

2) Check the thermal overload on the top of the instrument at the rear of the hinged sweep generator

chassis AcXeSs

for

the

line fuse. To reset, push the small button.

The

thermalmepload

perature excee'ds approximately 15'"

obstmctedair filter

are thsu$uirl causes of excessive

ture.

B.

'

CHECK DC

Check

to

€be thermal overload

wilJ trip when the cabinet-tern-

'*

or

a

high ambient temperature

cabwet

-.

.

LOW

VOLTAGE CIRCUITS

dc

voltages atmarked-test points on

is

Same

A

tempera-

.

as

Or.

.<

the

CALIBRATORANDJI'IGH VOLTAGEboardat €he top

rear

of

the instrument.

CHECK

C

If

tube, the high voltage circuits

If

a

spot

a

spot

or

HIGH

VOLTAGE CIRCUITS

or

trace

trace

is

visible

is

not present, short circuit

on

are

operating.

the face of the

the horizontal deflection plates of the CRT with an

insulated clip lead. With

circuit the vertical deflection plates.

a

produce

setting of the

spot near the center of the CRT at some

INTENSITY

a

second clip lead short

This should

control.

If

not, check the

high voltages on the High Voltage and Calibrator

board at the test points marked CRT CATHODE and

CRTGRID. The cathode should measure -4800 volts.

With the INTENSITY control at minimum, the grid

should measure approximately -5000 volts.

or

Resistors R261, 266,

276 located on the High

Voltage and Calibrator board, may cause incorrect

if

R261

is

high voltage. Check V28

If

you replace any tubes

Table 4-1,

Tube

Replacement Chart and Table 4-2,

or

defective.

components, refer to

Condensed Test and Adjustment Procedure.

D. CHECK HORIZONTAL AND VERTICAL

AMPLIFIER

The Horizontal and Vertical Amplifiers

ing properly when

:be easily

and

a

spot on the face of theCRTcan

smoothly positioned by the horizontal

are

function-

and vertical position controls.

-

-

If

a-

spot

is

not visible on the screen:

Short the horizontal deflection plates together;

1)

if

this

produces

deflected

'is

functioning properly.

by

a

vertical

a

spot

that

input,

can

the

be

positioned

vertical

amplifier

2)- Short. the vertical deflection-plates together,

this produces a spot

-

flected by a horizontal iriput, the horizontal ampli-

.

fier

is

functioning properly.

that can

be

positioned and de-

and

if

Iflall

voltages are - cmr-ectScheckthe

the plug-in amplifiep. These fuses

the

rear of the opening for

If

the voltages

full

minute and turn on again.-, If7theo.instrument,

are

incoMCt,

plug-in amplifier. side of the circuit must remain balanced to keep

-

-

'turn off-

-twq

are

located at the

._

fuses for The amplifiers in the instrument are direct coupled

and

balanced,

-

.the spotonthe screen. The settings of gain,balance

power

for

a

-

.

-and positioning controls can introduce unbalanced

3

voltages and should be considered when checking

fails to come on the overload relay may have tripped. an amplifier.

Checkforaresistanceof about

-78 volt test point and ground with

fier

installedand the line-cord disconnected.

sistance of 1,000 olms

heater.

A heater-cathode shbrt in any tube may

operate the overload reiay.

If

you replace any tubes

Replacement Chart and Table 4-2, Condensed Test

and Adjustment. Procedure.

30

ohms between the

a

plug-in ampli-

..A

re-

or

more indicates an, open , reached where the

r,

refer

to

Table

4-1,

Tube

-

To

Check an inoperative amplifier, short circuit

.

corresponding "points in each

,For

1

I

_I_

example, in the Horizontal Amplifier, if the

spot

is

on the screen when thedeflection plates are

connected together, remove the jumper from between

thedeflectionplates andconnect it between the plate

(pin

6)

-.

--

toward the--input, shorting plate

of V23 and the plate (pin 6 of V24). Work

and

corresponding voltages in each

stage

until a point

spot

does not return to the screen.

-to-

plate, until

is

a

Sect.

IV

Page

8

point

is

reached where the

spot

does

not

appear.

This locates the unbalanced portion of the circuit.

E. CHECK SWEEP GENERATOR

1)'Set the

the

FREE RUN

SWEEP-NORMAL

models set the SWEEP RESET switch to

2)

A repetitive sweep should be obtained in each

position of the SWEEP TIME/CM selector.

generator

HORIZ.

SWEEP

is

SENSITIVITYseIector

to

X1

and

MODE control maximum clockwise to

.

In cabinet models, set

switch at

NORMAL

the

;or

INT.

SINGLE

in rack

If

the

inoperative, try the following steps in

the order listed.

4-3

Table

sweep generator

contains the procedure for forcing the

as

well

as

a

tabulation of

all

the

significant voltages.

4-5

DETAILED TEST AND ADJUSTMENT

PROCEDURES

The complete test and adjustment procedures for

the oscilloscope follow.

of the procedures

done without completing

A ten

to

fifteen minute warm-up and a check of the

power supply output voltages

before making any other tests

will

In

general, only one

be

needed and they can

all

other

tests.

is

always recommended

or

adjustments.

or

two

be

NOTE

Turn

the Model 150A Oscilloscope power off before

or

removing

installing the

procedure. All voltages

tubes

discussed in this

are

measured between

ground and the indicated point with an

410B

High Impedance Vacuum

3)

Check tubes

V10

-------

through V17, one

Tube

Voltmeter.

at

a

substitution. Always replace the original

proper operation

4)

Check the adjustment of

units), SWEEP AMPLITUDE

through the entire range of adjustment.

a.

If

the generator operates

complete adjustment Number

in Table

b.

If

adjustment does not restore operation,

is

not restored.

4-2.

R135 (R122

ADJ.,

by

at

some setting,

7;

described.

rotating

-.

@

Model

time

tube

in some

The specifications for your instrument

this

the front of

manual. The following test procedure contains extra checks to help you analyze

particular instrument. These extra checks and the

be

data they contain cannot

,considered

cations.

This

by

if

detailed procedure

Test

and

Adjustment Procedure, Table

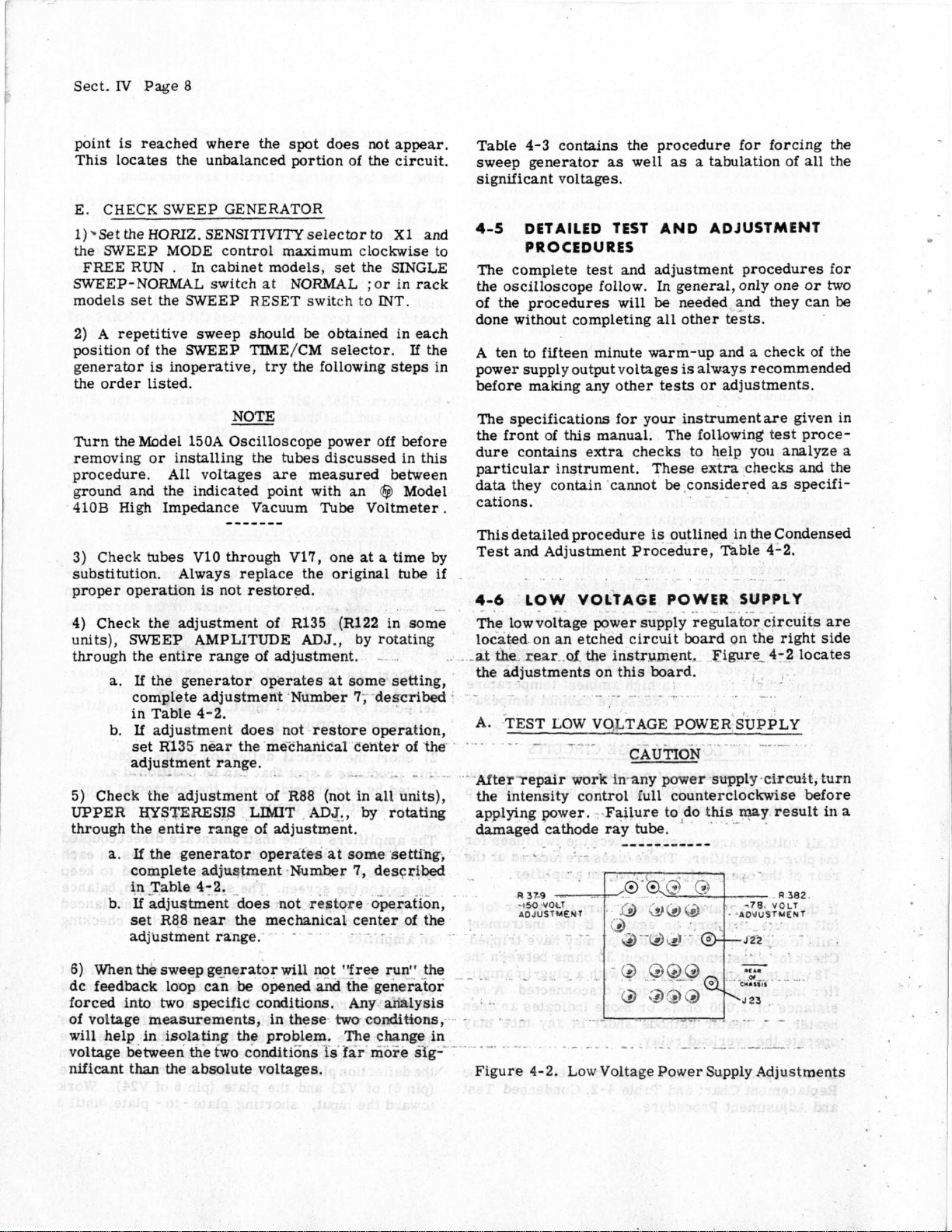

4-6

LOW VOLTAGE POWER SUPPLY

is

outlined in the Condensed

The low voltage power supply regulator circuits

located on an etched circuit board on the right side

-

-at

rear..of the instrument, Figure-

the

the adjustments on this board.

-

A.

TEST

LOW

.-

-.

-.

-

VOLTAGE

.

.

.-

POWERSUPPLY

are

as

4-2.

4-2

given in

a

specifi-

are

locates

in -Table

b.

If

adjustment does not retatore &&ion,

set

4-2.

R88

near the mechanical center of the

adjustment range.

6)

When

the

sweep generator

dc feedback loop can

two

forced into

specific conditions. Any analysis

be

.

will

opened

not "free run" the

and

the generalor

-.

R37-9

-.

-tw

VOtT

ADJUSTMENT

,@''Q-$

-@

@(r,

'

&'-@et

@

@@-@

3

;3,a3Q\JPJ

I

@

@

-78,

..

~ADWUSTMENT

L

@--JZ2

-

-

0

C*.$,,*

R

3.92

VOLT

Q-

-

The

REMOVE

The

ftsWr

'SWEEP

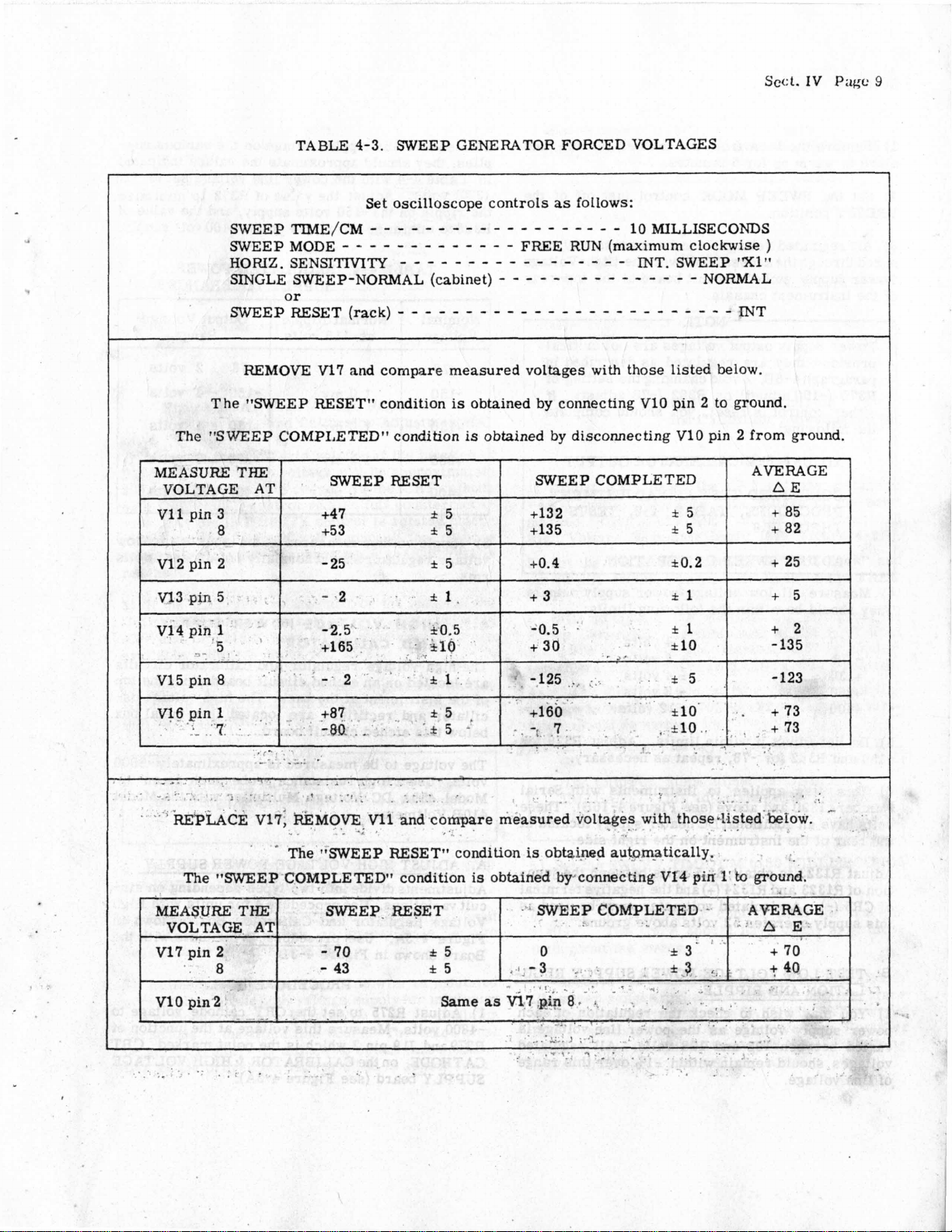

TABLE 4-3. SWEEP GENERATOR FORCED VOLTAGES

VI7

and compare measured voltages

ZEP RESET" condition

COMPLETED" condition

is

obtained by connecting

is

obtained by disconnecting V10 pin 2 from ground.

with

those listed below.

VlO

pin 2 to ground.

Sccl.

IV

9

I

I

MEASURE

VOLTAGE AT

I

vll

pin

V12 pin 2

V13 pin 5

.-

.......

,.

..*

.

''kE!FhCE V17; *MOVE

The "SWEEP COMPLETED*' condition

THE

8

~ ~ ~ ~

'

-

25

-

s2

.........

i

.

.I

..

Vl1

.

-;

*

fie

"SWEEP RESET" condition

1

>"

..

1'

b

.

AVERAGE

AE

+82

+85

+

25

+5

+2

-123

ground.

SWEEP COMPLETED SWEEP RESET

*5

*5

*5

'

*l.

+132

+135

+0.4

+3

'0.5

+

30

*5

*5

*0.2

*1

.

r

.,e

*l

*10 -135

..

and cotnpare measured voltages with those-listed'derow.

is

obtai-md auto@tically.

is

obtaind

byckcting VI4

pin

I

I

..'.

....

..

....

A:,.)

:.*-.

,.,

-._.

':;

,11

...

....

..

..:

....

.

-

..,

...

....

Sect. IV

Page

12

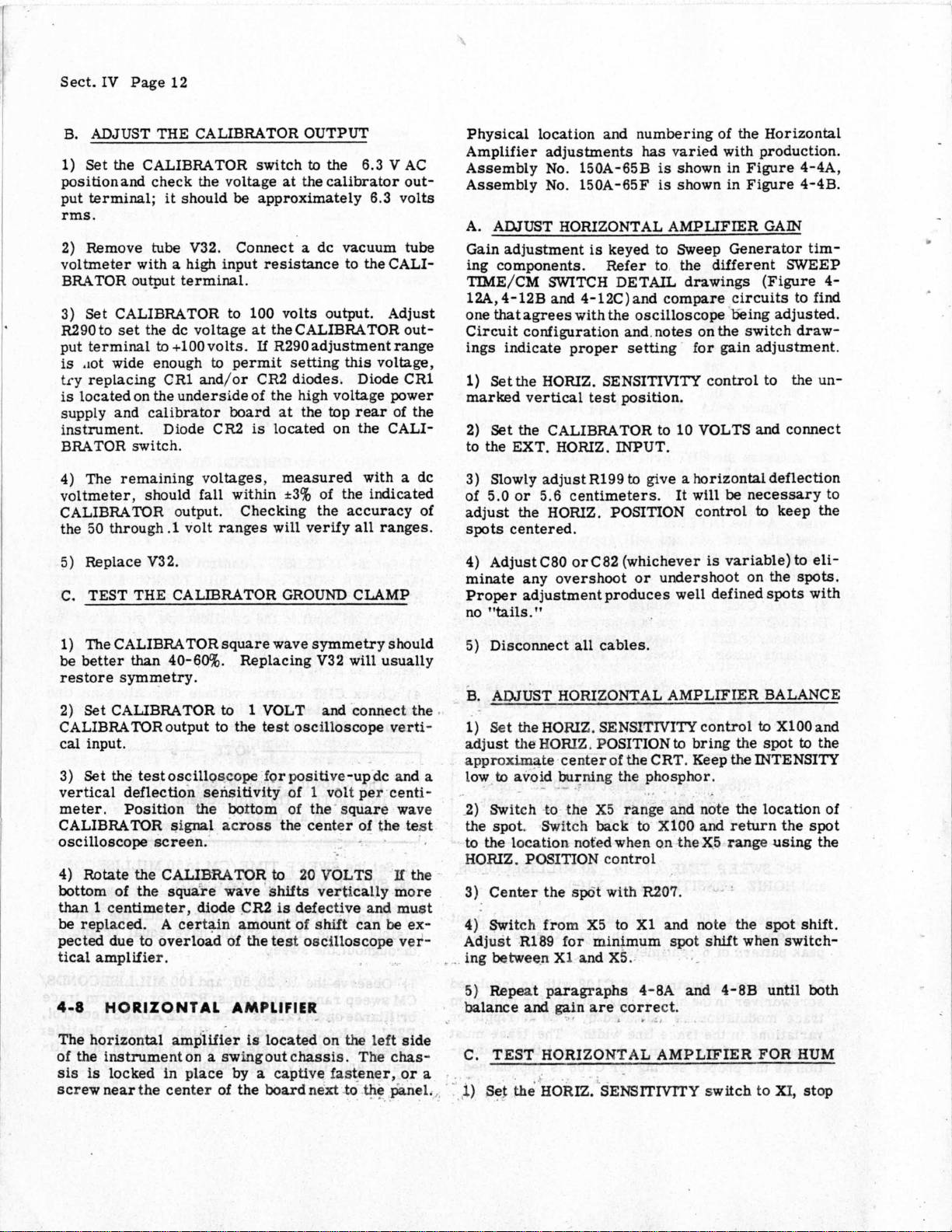

B. ADJUST THE CALIBRATOR OUTPUT

1)

Set the CALIBRATOR switch

positionand check the voltage at the calibrator out-

be

put terminal; it should

rms.

2) Remove

voltmeter with a high input resistance to theCALI-

BRATOR output terminal.

3) Set CALIBRATOR to 100 volts output. Adjust

R290to set the dc voltage

put terminal

is

.lot wide enough

try replacing CR1 and/or CR2 diodes.

is

located on the underside

supply and calibrator board at the top rear

instrument. Diode CR2

BRATOR switch.

4) The remaining voltages, measured with

voltmeter, should fall within

CALIBRATOR output. Checking the accuracy of

50

the

5) Replace V32.

C.

TEST THE CALIBRATOR GROUND CLAMP

tube

through

V32. Connect a dc vacuum

to

+100volts.

.1

volt ranges

approximately 6.3 volts

at

If

to

permit setting this voltage,

of

is

to

the 6.3 V AC

tube

theCALIBRATOR out-

R290adjustmentrange

Diode

CR1

the high voltage power

of

the

located on

*3%

will

verify

the

CALI-

a

dc

of the indicated

all

ranges.

Physical location and numbering of the Horizontal

Amplifier adjustments

Assembly No. 150A-65B

Assembly No. 150A-65F is shown in

A. ADJUST HORIZONTAL AMPLIFIER GAIN

Gain adjustment

ing

components.

TIME/CM SWITCH DETAIL drawings (Figure 412A,4-12B and 4-12C)and compare circuits to find

one that

Circuit configuration and.notes on the switch drawings indicate proper setting for gain adjustment.

1) Setthe HORIZ. SENSITIVITY control to the unmarked vertical test position.

2) Set the CALIBRATOR to

to the EXT. HORIZ. INPUT.

3) Slowly adjustR199

of

adjust the HOFUZ. POSITION control

spots centered.

4) Adjust C80

minate any overshoot

Proper adjustment produces

no

5.0

or

"tails."

agrees

5.6 centimeters.

is

with the oscilloscope being adjusted.

or

C82 (whichever

has

varied with production.

is

shown in Figure 4-4A,

Figure

keyed to Sweep Generator tim-

Refer

to, the different SWEEP

10