Page 1

@

OPERATING AND

MODEL

SERIALS

OSCILLOSCOPE

SERVICE

13OB/BR

PREFIXED:

201

MANUAL

)

00013-3

Copyright HEWLETT-PACKARD COMPANY

1501

PAGE

MILL

ROAD, PAL0 ALTO, CALIFORNIA,

U.

1959

S.

A.

Printed:

JAN

1862

Page 2

Model 130B

Table of Contents

List

of

Illustrations

)

TABLE

Section Page

I

GENERAL DESCRIPTION

1 . 1

.

General

1.2 . Damage in Transit

1.3

.

Power Line Voltages

1.4 . Power Cord

1.5 . Installation

1.6 . Cathode Ray

I1

OPERATINGINSTRUCTIONS

2.1

.

Controls and Terminals

2.2

.

Rear-Access Terminals

2.3

.

Warm-up Drift

2.4

.

AC

2.5

.

Balanced Inputs

2.6

.

Operating Procedures

111

THEORY OF OPERATION

3-

1

.

General Content

3.2 . Over-All Operation

3.3

.

Vertical Amplification Channel

3.4 . Horizontal Amplification

3.5

.

Sweep Generator

3.6

.

Low Voltage Power Supply

...............

............

of

Tube

or

DC Coupling

Channel

.............

........

.........

.......

Rack Mount

Warranty

.....

....

......

......

......

..........

........

..........

.......

........

..........

........

.........

....

. .

1-1

1 . 1

1-1

1 . 1

1-1

1-1

1-2

2-1

2-1

2-1

2-1

2-2

2-2

2-2

3-1

3-

3-1

3-1

3-2

3-2

3-3

OF

CONTENTS

Section

111

THEORY OF OPERATION (cont’d)

3.7

.

3.8

.

IV MAINTENANCE

4-

1

.

4.2

.

4.3 . Removing the Cabinet

4.4

.

4.5 . Connecting

4.6 . Tube Replacement

4.7

.

4.8 . Adjustment Procedure

4.9 . Turn On

4-

10

4.11

4.12 . Checking and Adjusting the

1

4.13 . Adjusting the Vertical Amplifier

4- 14 . Adjusting the Horizontal Amplifier

4.15

4.16 . Adjusting Preset

4.16 . Adjusting the Sawtooth Generator

High Voltage Power Supply

Calibrator

.............

.............

Introduction

Simple Check Procedure

............

.......

Isolating Troubles to Major

Sections

.............

for

230Volt

Operation

........

Condensed

Procedures

Test

and Adjustment

..........

......

..............

.

Power Supplies

.

ReplacingandAdjustingthe

Calibrator

.

Phase Shift Adjust

..........

...........

........

.........

and Sweep Amplifier

......

Page

....

.....

.

CRT

.

.

.

3-4

3-4

4-1

4-1

4-1

4-3

4-3

4-3

4-4

4-5

4-9

4-9

4-9

4-11

4-13

4-13

4-15

4-15

4-17

4-17

1

/

i

/

LIST

OF

Number Page

1.1

.

Model 130B/BR Oscilloscope

1

.

2

.

Cathode Ray Tube Warranty

1.3

.

Model

Operating Controls and Terminals

2.1

.

Vertical Balance Adjustment

2.2

.

Horizontal Balance Adjustment

2.3

.

2.4

.

Internal Sweep.

Internal Sweep.

2.5

.

External Horizontal Input

2.6

.

AC Coupling Balanced Input

2.7

.

Connection to CRT Deflection Plates

2.8

.

External Intensity Modulation

2.9

.

.

Aligning ScopeTracewithGraticule

2.10

3.1

.

4.1

.

Location Diagram

4.2

.

Line Voltage Connection

4.3

.

Power Supply Location Diagram

4.4 . Servicing Etched Circuit Boards

4.1 . Condensed

4.2

.

Tube Replacement Chart

00013-2

130BR

Internal Synchronization

External Synchronization

130B

Procedures

Installation

Diagram

for

Major Circuits

Test

and Adjustment 4.3 . Regulated Power SupplyTolerances

..............

.....

......

........

...

......

....

.......

......

.......

......

.

.

.....

.

.

......

.

.......

....

....

LIST

........

1-0

1

.

2

1-3

2-0

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

2-11 4.15 . Power Supply Regulator.

3-0

4-2 4.17 . Filament and Primary Detail.

4-4 Schematic Diagram 4-29

4-8 4.18 . Sweep Time/CM Switch.

OF

4-6

4-7 5.2 . Table

ILLUSTRATIONS

Number Page

.

4.5

4.6

4.7

4.8

4.9

4.10

4.11

4.12

4.13

4.14

4.16 . Power Supply. Schematic

Vertical Amplifier Adjustment

Locations

.

Horizontal Amplifier Adjustment

Locations

.

SweepGenerator Adjustment Locations . 4-16

.

Vertical Amplifier.

Voltage Resistance Diagram

.

Vertical Amplifier. Schematic

.

Horizontal Amplifier.

Voltage Resistance Diagram

.

Horizontal Amplifier. Schematic

.

Sweep Generator.

Voltage Resistance Diagram

.

Sweep Generator. Schematic

Sweep Time/CM Switch

.

Voltage Resistance Diagram

...............

...............

.....

.....

.....

....

.....

......

.........

.....

........

..........

Assembly Diagram

TABLES

5.1

.

Reference Designator

of

Replaceable Parts

..........

. .

..........

.......

4-12

4-14

4-20

4-21

4-22

4-23

4-24

4-25

4-26

4-27

4-28

4-30

4-9

5-2

5-13

iii

Page 3

SPECIFICATIONS

Model

130B

SWEEP

Sweep Range:

0.2

,usec/cm to at least

ibrated sweeps, accurate within

1-2-5-10

Vernier permits continuous adjustment of sweep

time between calibrated steps and extends

slowest sweep time to at least

Magnifier:

X5

Magnifier may

expands fastest sweep to

curacy within

Synchronization:

Internally from line voltage or from signals

causing

sequence, 1 ,usec/cm to 5 sec/cm.

10%.

1/2

centimeter or more vertical deflec-

tion.

or more.

Trigger Point:

Continuously adjustable from approximately

-30

to

+30

volts on either positive or negative

slope of external synchronizing signal, or from

any point of the vertical signal presented on the

screen.

Preset Triggering:

Switch position on sweep mode control selects

optimum setting for automatic triggering.

INPUT AMPLIFIERS

Vertical and horizontal amulifier

characteristics.

Sensitivity:

1

mv/cm to at least

ranges, accurate within

sequence, 1 mv/cm to

mits continuous adjustment between ranges and

decreases sensitivity of

least

125

volts/cm. Input voltage rating

volts dc or rms.

12.5

sec/cm.

12.5

be

used on all ranges and

0.2

pec/cm.

from

5

125

v/cm.

*5%,

50

v/cm. Vernier per-

50

Peakmto-peak impedance 2 megohms, approximately

s

15

in a

v/cm range to at

21

fs%,

sec/cm.

have' same

calibrated

1-2-5-10

calin a

Ac-

600

Phase Shift:

Within

up to

lifiers with verniers in cal.

Stability:

1

Bandwidth

DC

to

of sensitivity setting.

Balanced Input:

On

Mount

with approximately

f

lo

relative phase shift at frequencies

50

kc

between vertical and horizontal amp-

mv/hr after warmup.

Coupling: dc to

300

kc.

Specified bandwidth

1,2,5,10,20

input

impedance: megohms shunted

and

300

50

25

kc.

AC Coupling: 2 cps

is

independent

mv/cm ranges. Cabinet

pf. Rack Mount input

125

shunt capacity. Disconnecting the

front panel which connect to the

reduces the input capacity to approximately

25

pf.

Common Signal Rejection:

(Balanced input only):

Rejection at least

not exceed

Single Ended Input:

Cabinet Mount input impedance:

shunted with approximately

input impedance:

pf shunt capacity. Disconnecting the

the front panel connecting to the rear terminals

reduces the input capacity to approximately

50

pf.

Internal Calibrator:

300

millivolts peak-to-peak

squarewave applied to vertical or horizontal

amplifiers

1.5

by

40

volts.

1

megohm, approximately

CAL position of input attenuators.

Common signal must

db.

50

wires

rear

terminals

1

megohm

pf. Rack Mount

wires

f

2%,

300

cycles

pf

at the

200

at

iv

00013-2

Page 4

Model

130B

SPECIFICATIONS

GENERAL

External Graticule (Standard):

Edge lighted graticule with controlled illumination, 10 cm

x

10 cm, marked

in

centimeter

squares with 2 mm subdivisions, on major horizontal and vertical axes.

Internal Graticule (Optional):

10 cm x 10 cm, major horizontal.

CRT Plates:

Direct connection to deflection plates via

minals on rear. Sensitivity approximately 20

volts/cm.

Intensity Modulation:

Terminals on

rear;

20 volts positive signal

blanks CRT at normal intensity.

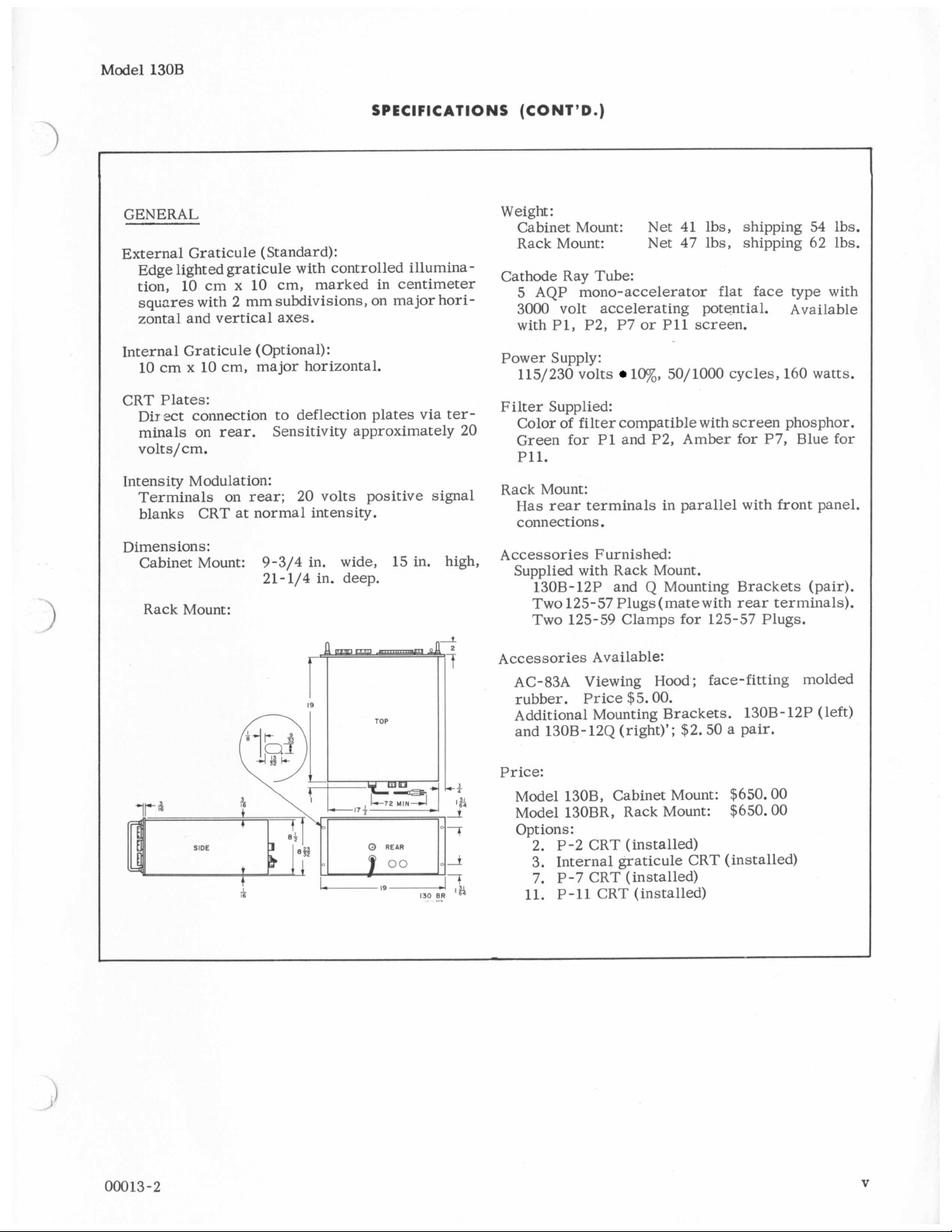

Dimensions:

Cabinet Mount: 9-3/4 in. wide, 15 in. high,

Rack

21-1/4

Mount:

in.

deep.

ter-

(CONT’D.)

Weight:

Cabinet Mount:

Rack

Mount:

lbs, shipping

Net 47 lbs, shipping 62 lbs.

54

Net

41

Cathode Ray Tube:

5

AQP mono-accelerator flat face type with

3000 volt accelerating potential. Available

with P1, P2, P7 or P11 screen.

Power Supply:

115/230 volts

lo%, 50/1000 cycles, 160 watts.

Filter Supplied:

Color of filter compatible with screen phosphor.

Green for P1 and P2, Amber for P7, Blue for

P11.

Rack Mount:

Has

rear

terminals in parallel with front panel.

connections.

Accessories Furnished:

Supplied with

Rack

Mount.

130B-12P and Q Mounting Brackets (pair).

Two 125-57 Plugs (mate with

rear

terminals).

Two 125-59 Clamps for 125-57 Plugs.

lbs.

Accessories Available:

AC-83A Viewing Hood; face-fitting molded

TOP

rubber. Price

Additional Mounting Brackets. 130B-12P (left)

$5.00.

and 130B-12Q (right)’; $2.50 a pair.

Price:

Model 130B, Cabinet Mount: $650.00

Model 130BR, Rack Mount: $650.00

Opt ions

:

2. P-2 CRT (installed)

3. Internal graticule CRT (installed)

7. P

-

-

6

i

J

1-19-1

Ik

130

BR

11.

7 CRT (installed)

P-11 CRT (installed)

00013-2

V

Page 5

Sect. I Page0

Model 130B

)

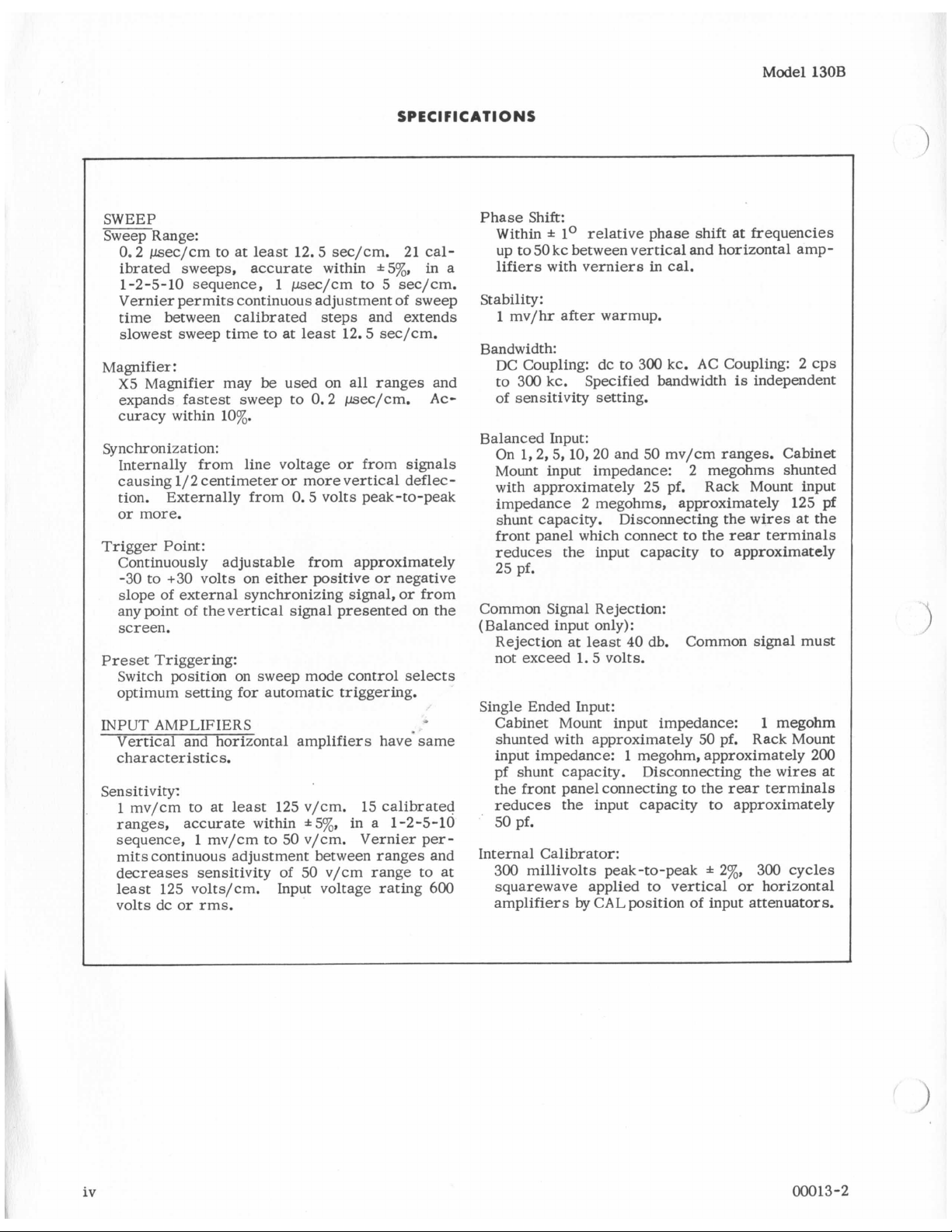

Figure

1-1.

Model 13OB/BR Oscilloscope

00013-2

,I

Page 6

Model

130B

Sect.1

Page

1

i

1-1

GENERAL

The Hewlett-Packard Model 130B Oscilloscope

general purpose oscilloscope.

either internal

either internally

it

can

be

type mounting. Because

balanced input, the Model 130B may often

directly with transducers, enabling you

direct

having

Some of the

are

A.

tained from

insures

type of sweep generator,

independent

of sweep generator.

B.

sients by expanding

the

detail.

all

sweep time

C. CALIBRATED AMPLIFIERS

are

*5%.

in

ization

Phase shift measurements can

with this oscilloscope over

frequencies.

00013-2

presentation of phenomena

to

resort

as

follows:

LINEAR INTEGRATOR SWEEP GENERATOR

The accurate direct reading sweeps

a

X5 SWEEP EXPANSION

You speed observation and analysis

trace

This X5 sweep expander, may

sweep time settings and expands the fastest

Voltage measurements of various waveforms

quickly made with the 130B, accurate within

A built-in calibrator which

*2%

permits quick verification and standard-

of

the amplifier gain.

or

external sweeps which can

or

externally synchronized and

obtained in either the cabinet

of

to

preamplifiers.

special

a

Miller-integrator sweep circuit which

high

of

tube characteristics than other types

to

10

to

.2

features

order

linearity and stability.

a

two centimeter segment

centimeters

microsecond/cm.

it

can

be

used with

or

its

high sensitivity and

be

to

desired

of

this oscilloscope

are

is

more reliable and

of

for

easy viewing

be

used on

is

accurate with-

be

made accurately

a

wide range of input

without

is

be

rack

used

see

ob-

This

tran-

SECTION

GENERAL DESCRIPTION

1-2

a

This instrument should

when

refer

graph

1-3

a

The Oscilloscope

wired

otherwise specified. However, the instrument

may

source

power transformer. This conversion

in the Maintenance Section (Section

1-4

The three conductor power

instrument

prong male connector recommended by the National

Electrical

contact

two-blade

chassis when used with the appropriate receptacle.

of

An adapter should

of

plug

adapter

short lead from the adapter which should be connected

operating personnel.

1-5

The @ 130BR

ported in

usual manner;

mounted in the rack with brackets

Figure

supported by the dust cover and may

DAMAGE

it

is

to

the “Claim

on

POWER LINE VOLTAGES

for

also

be

if

the proper conversion

POWER CORD

Manufacturers’ Association. The third

is

an offset round pin, added to a standard

ac

to

a

standard two contact output.

is

used, the ground connection becomes

to

a

INSTALLATION

a

1-1.

IN

TRANSIT

be

thoroughly inspected

received. If any damage

for

Damage in Shipment”

the Warranty sheet in this manual.

is

shipped from the factory

115

volts

ac

line operation, unless

operated from a 230 voIts

is

IV).

cable

supplied with the

is

terminated in a polarized three

plug, which grounds the instrument

be

used

to

connect the NEMA

suitable ground

is

designed

19 inch rack by the front panel in the

or,

the dust cover may

In the

OF

latter

for

the protection

RACK MOUNT

so

that

it

case,

the chassis

is

evident,

made

is

described

When the

can

be

be

as

shown in

be

slipped in

para-

ac

line

to

the

a

of

sup-

rigidly

is

I

Page 7

Sect. I Page

or

out easily; the screws through the front panel

merely holding the chassis in place.

mount the

1)

Mount the bracket

2

130BR

using the brackets:

as

shown in Figure

To

1-3

rack

with

screws through the outside holes of the brackets.

The length of these screws may

the front panel from the panel

The brackets

at

the

rear

are

installations but can be used

required. These

brackets

Hewlett-Packard Company

2)

Remove the dust cover from the

The

cathode

ny

date

not Included

You?

glad to process

Whenever

oui

rival,

ray

bbes

prchased

01

sale by

ln

local Hewletl-Packard

a

bbe is

in

full

and

since m eredlt

1)

Carefully wrnp

pddlng material.

2)

Wrap the

3)

Pack

the

4)

Prmund

almllir

tlght ail around

5)

mbes

be

E)

Shipprepaid preferably

We

CATHODf RAY

tube

supplied

from

theHewlett-PackrdCompany.

this

guarantee.

your

warnnty clalm

returned

returned with the tube. Follawshi&lng instructions carefuilyto

can

be

above

In

a

rlgid

tube In each dimension.

the

tube

shockabsorbing

returned

packed

I"

a

do

not

recommend

TUB1

In

your

Hnvlett-Packud

9

are

-ranteed

representative

for

allowed

SHIPPING

the

tube

in

heavy krdt

mntalner

withal leaat four lmhes afpekedexcelslor

the

from

wooden

maintalna

for

you. Please

L

warranty claim the

on

broken

INSTRUCTIONS

In

1/4"

thick

pper

which

Is

material.

bbe.

outside

the

eontlnental

box.

by

AIR

FRElGHTor

parcel

p~st

be

chosen

rails

to

as

desired.

notnecessaryin most

if

added support

are

available from the

as

an accessory item.

130BR

WARRANTY

Oselllodeope

agllmt

electrical

Broken

bbes

a

stock

conwl1

reverse

tubes.

cotton

batting

at

least

4

Be

certain

United

RAILWAY EXPRESS.

or

air

preel post shlpment.

nnd

replacement

failure

for

or

tubes withtmrned phosphor

of

him.

slde

Inches

that

thepcklng

Sate8

one

replacementtubes and

of

this sheet must

or

other

soft

larger

ULVl

or

Is

should

insure

space

and

csWa

year

from

be

de

is

wlll

filled

mount it in the brackets with the

10-32

screws provided.

3)

Slip the

130BR

into the dust cover and fasten in

place with screws through the front panel.

1-6

CATHODE RAY TUBE WARRANTY

The cathode ray tube (crt) supplied with the oscil-

loscope and replacement crt'

Hewlett-Packard company

s

purchased from

are

guaranteed against

electrical failure for one year from the date of sale

by Hewlett-Packard. Cathode Ray Tube Warranty

sheet is illustrated in figure

use

is included in the appendix of this manual.

FROM:

NAME:

COMPANY:

ADDRESS:

Perm"

to contact

for

the

are

NAHE:

TITLE:

kt

COMPANY:

ADDRESS:

ar-

rn

pceaa

1)

@MsTRuMENT

2)

TUBE TYPE SERIAL

3)

ORIGINAL TUBE REPLACEMENT TUBE

4)

YOUR

5)

DATE PURCHASED

8)

PURCHASED

7) COMPIAINT (Plawe describe mbre

8)

OPERATING CONDITIONS:

further

-

govr

clDlm

quickly please enter the

MODEL

PURCHASE ORDER

FROM

ZIT

Irdormatlon:

NO.

(Please

deacrlbe condltlona prlor

WARRANTY

of

Information

trouble)

1-2.

CLAIM

indicated

SERUL

A

sheet for your

below

to

nnd

at

Model

trusshead

DATE

___

Ume

of faflure

130B

-

HEWLETT-PACKARD

CO.

PAGE

MILL

ROAD,

PAL0

Figure

ALTO, CALIF. U.S.A.

1-2.

Cathode Ray Tube Warranty

i

00013-2

Page 8

Model

130B

Sect.11 Page

1

\

1

OPERATING INSTRUCTIONS

2-1

Front panel operation controls

ure

enables you to operate

a

tailed operating procedures

ating plates.

INTERNAL SWEEP CONTROLS

SWEEP TIME/CM

This switch determines the speed at which the Horizontal or Sync INPUT

crt beam crosses the screen. HORIZ. SENSlTIVITY

tion or internal sweeps are not generated. Associ- sweeping voltages. On

ated with the SNEEP TIME/CM switch

centric VERNIER which provides continuous ad- rear of

justment of sweep speed

sweep magnifier operates

CONTROLS AND TERMINALS

2-1.

This description of the operating controls

the

instrument

basic

knowledge of oscilloscope technique.

are

-

switch must be in

an

INT. SWEEP posi- external

between

on

all ranges.

are

shown in Fig-

if

given

in

steps.

you have

De-

the

oper-

is

a con-

A

X5

TRIGGER LEVEL

This continuous control selects the level

sync waveform where triggering

the TRIGGER LEVEL control

trigger circuits

TRIGGER SLOPE

This two-position switch, concentric with TRIGGER

LEVEL, permits triggering to occur on either

positive or negative slope of internal, external or

line voltage sync signals.

A

set

of three binding posts used for receiving

sync

a

3-conductor receptacle

the

with the binding posts.

-

are

the most sensitive.

-

voltages and

instrument,

the

SECTION

on

is

to occur. When

is

set

to zero, the

-

external

rack mount model only,

5102,

is

connected

generated

mounted at the

in

parallel

II

the

the

SYNC

This three position switch lets

gered

triggering can be accomplished from a line

quency signal or from an applied

signal of sufficient amplitude to produce a one- Horizontal and vertical deflection plates, and a

half centimeter deflection. External triggering terminal for crt intensity (Z-axis) modulation.

can be produced by signals havingamplitude greater

than

SWEEPMODE

As

wise

an

dition through a condition

operation

in

counterclockwise position the control switches

into

optimum triggering bias for nearly all waveforms.

-

the

sweep be trig-

either

0.5

internally or externally. Internal

vertical

volt, peak-to-peak.

-

this control

position,

un-synchronized free-running (FREE

which sweeps

a

PRESET position.

is

rotated from the extreme clock-

the

sweep

is

possible (TRIGGERED) to a position

will

generator will pass from

where

not occur.

This

only triggered

At

the

position provides

input

RUN)

extreme

fre-

con-

2-2

The following terminals

the

See

2-3

When

the

at high sensitivities,

immediately following turn-on, becoming slower

as

drift,

not be attempted until the instrument

warm. For most purposes a

will be adequate.

REAR-ACCESS TERMINALS

------DANGER-

rear access plate of

Figures

trace

the

2-8

WARM-UP DRIFT

the

oscilloscope

will

instrument warms up, Because of this

fine

adjustment of amplifier balance should

HIGH

VOLTAGE-----

are

accessible through

the

instrument cabinet:

and

2-10.

is

first

turned

be

quite noticeable, particularly

the

trace drift

5

on,

is

thoroughly

minute warm-up

is

drift

fastest

in

Page 9

Sect.11 Page

2-4

AC OR DC COUPLING

2

AC coupling permits high gain to be employed

without regard for

the

dc level involved.

In

the

AC position the input signal (vertical or horizontal)

is

coupled to

which removes the dc component from

the

amplifier through a capacitor

the

input.

This coupling circuit has a low frequency cut-off

at

2

cps. To avoid degrading input pulses or square

waves below

ling. WHEN USING

AGE VALUE

POSITION

200

cps it

is

advisable to

DC

COUPLING THE AVER-

OF

THE DC DETERMINES THE

OF

THE SWEEP ON THE OSCILLO-

use

dc coup-

SCOPE. IF YOU ARE UNABLE TO FIND THE

TRACE WITH THE VERTICAL POSITION CONTROL WHEN USING

DC

COUPLING, TRY AC

COUPLING. When AC coupled the maximum dc

that may be applied

2-5

BALANCED INPUTS

is

600

volts.

The instrument will accept balanced input signals

on

the

six

most sensitive ranges. This arrange-

ment

is

shown

in

Figure

2-7.

Driving the instrument from a balanced source

can be

stray pickup that would otherwise obscure

desired information. To take advantage of

noise reduction that

input, you must be

the source

conductor shielded cable

oscilloscope. The input cable shield must

connected to a suitable ground,

loscope or some other

cautions

very

effective in removing

is

possible

sure

that neither terminal of

is

connected to ground, and

between

point.

in

the external input circuit, any stray

the

with

a balanced

use

the source and

either

at the oscfl-

With these pre-

unwanted

the

the

double

be

signals (noise, hum, etc.) will be coupled equally

to

the

two input terminals, and be cancelled by

the

differential amplifiers. Since

formation

is

applied between

nals, it will be amplified and displayed

normal manner. Since

the

the

noise

the

two

is

desired

input

termi-

in

a problem

in-

the

Model

at

mainly

is

available only on the most sensitive ranges

low level, the fact that balanced input

generally not a serious limitation.

The common-mode signal rejection will be at

least

40

db

(1/100

of

the

input signal).

using a balanced input certain limitations must

be considered. The proper operating levels must

be maintained

on

the

input

amplifier: The COMMON-MODE SIGNAL VOLTAGE MUST NOT EXCEED

TIVE,

this

1.5

VOLTS EITHER POSITIVE ORNEGA-

ON

EITHER INPUT TERMINAL. Note that

is the sum of all voltages (dc plus peak ac).

NOTE

If

balanced ac coupling

to connect a capacitor

is

desired, it is necessary

in

the external signal path

to the middle terminal, since a dc voltage on this

terminal only unbalances

arrangement

is

shown

in

Figure

the

amplifier. This

2-7.

-----------

2-6

Basic operating procedures are described

following illustrations. Positions of controls are

different on

are identical to those of the rack model.

Figure DescriDtion

2-2

2-3

2-4

2-5

2-6

2-7

2-8

.

2-9

2-10

OPERATING PROCEDURES

the

cabinet model but their functions

VERTICAL BALANCE ADJUSTMENT

HORIZONTAL BALANCE ADJUSTMENT

INTERNAL SWEEP-INTERNAL SYNCHRONIZATION

INTERNAL SWEEP-EXTERNAL SYNCHRONIZATION

EXTERNAL HORIZONTAL INPUT

AC COUPLING BALANCED INPUT

CONNECTION TO CRT DEFLECTION

PLATES

EXTERNAL INTENSITY MODULATION

ALIGNING SCOPE TRACE

WITH

GRATICULE

130B

When

in

the

is

Page 10

Model 130B Sect.

VERTICAL BALANCE ADJUSTMENT

I1

Page

3

After

Warm-up:

Turn

1.

2.

3.

4.

5.

6.

SWEEP MODE control to FREE

Set HORIZ. SENSITIVITY switch to

SNEEP X1.

Set SWEEP TIME/CM switch

venient

faster than

factory.)

Short vertical input terminals together.

Set AC-DC switch to

Set VERT. SENSITIVITY to CAL.

VERNIER to CAL.

base

line

is

formed.

50

MILLISECONDS/CM

DC.

so

(Any

RUN.

INT.

that a consweep

time

is

satis-

Turn

RO

b

7.

Center bottom portion of calibration signal trace using VERT. POS. control.

8.

Set VERT. SENSITIVITY to 1 MILLIVOLTS/

CM.

9.

Center trace with coarse (screwdriver)

VERT.

control if unbalance

10.Repeat steps

NOTE:

etched board)

VERNIER.

DC

BAL, control or with

is

slight.

6,

7,8

and

A

separate adjustment (Bal. Adj. on

is

provided to balance

9

if

fine

necessary.

/

(knob)

the

the

Figure

2-2

Page 11

Sect.

I1

Page

4

HORIZONTAL BALANCE ADJUSTMENT

Model

130B

After warm-up:

1.

Short together the horizontal INPUT terminals.

2.

Set AC-DC switch

3.

Set HORIZ. SENSITIVITY to CAL. Turn

VERNIER

4.

Adjust the HORIZ. POS. control

to

left edge of the calibrating signal

CAL.

to

DC.

to

place the

trace

the major vertical axis.

JUMPER

5.

6.

7.

NOTE: A separate adjustment (Bal. Adj. on the

etched

on

VERNIER.

Set HORIZ. SENSITIVITY

VOLT/CM.

Return the spot

with the

coarse

BAL. control

if the unbalance

Repeat steps

board)

to

the major vertical axis

(screwdriver) HORIZ.

or

with the fine (knob) control

is

slight.

2,

3

4,

and 5 if necessary.

is

provided

RO

1

to

to

balance the

MILLI-

DC

Figure

2-3

Page 12

Model 130B

@-

0-

Sect.11 Page 5

INTERNAL SWEEP - INTERNAL SYNCHRONIZATION

1.

Set HORIZ. SENSITIVITY switch

SWEEP

2.

Set SYNC switch to INT.

3.

Set SWEEP MODE to PRESET.

4.

Connect vertical input signal into vertical

input terminals.

5.

Set AC-DC switch for

6.

Adjust VERT. SENSITIVITY

sensitivity.

X1

(or

to

X5

for

magnified sweeps)

type

coupling desired.

to

for

INT.

desired

Figure

7.

Set TRIGGER SLOPE switch for triggering

on

positive

as desired.

8.

Set TRIGGER LEVEL control

9.

Select desired sweep speed with SWEEP

TIME/CM switch.

10.Adjust TRIGGER LEVEL

desired level. In some cases, it may

necessary to switch SWEEP MODE from

PRESET

particular trace being viewed.

2-4

or

negative

to

an individual adjustment

slope

of

to

input signal,

to

start trace at

0.

for

be

the

Page 13

Sect.11 Page

6

Model 130B

INTERNAL SWEEP - EXTERNAL SYNCHRONIZATION

1.

Set HORIZ. SENSITIVITY switch

SWEEP

2.

Set SYNC switch to EXT.

3.

Set SWEEP MODE

4.

Feed synchronizing signal

more) to the horizontal input terminals.

5.

Set AC-DC switch

6.

Set TRIGGER LEVEL to

7.

Feed vertical input signal into vertical input

terminals.

X1

(or

to

X5

for magnified sweeps).

.

to

PRESET.

(0.5

for

type coupling desired.

0.

volts p-p or

to

IfiT.

Figure

8.

Adjust VERT. SENSITIVITY for desired

sensitivity.

9.

Select desired sweep speed with SWEEP

TIME/CM switch.

10. Set TRIGGER SLOPE for triggering on posi-

or

tive

11.Adiust TRIGGER LEVEL

desired level. In some cases, it may

found necessary to switch SWEEP MODE

from PRESET to an individual adjustment for

the particular trace being viewed.

negative slope, as desired.

to

start trace at

2-5

be

Page 14

Model

130B

EXTERNAL HORIZONTAL INPUT

Sect.

I1

Page

7

?

1.

Feed horizontal signal to horizontal input

terminals.

2.

Set AC-DC switch

des ired.

3.

Set

HORIZ.

sensitivity. ing Lissajous patterns,

SENSITIVITY switch

for

type of input coupling

for

desired

Figure

4.

Adjust horizontal position

HORIZ.

This type

POS. control.

of

input

2-6

will

be

etc.

found

of

pattern with

useful

for

view-

Page 15

Sect.11 Page

8

Model

130B

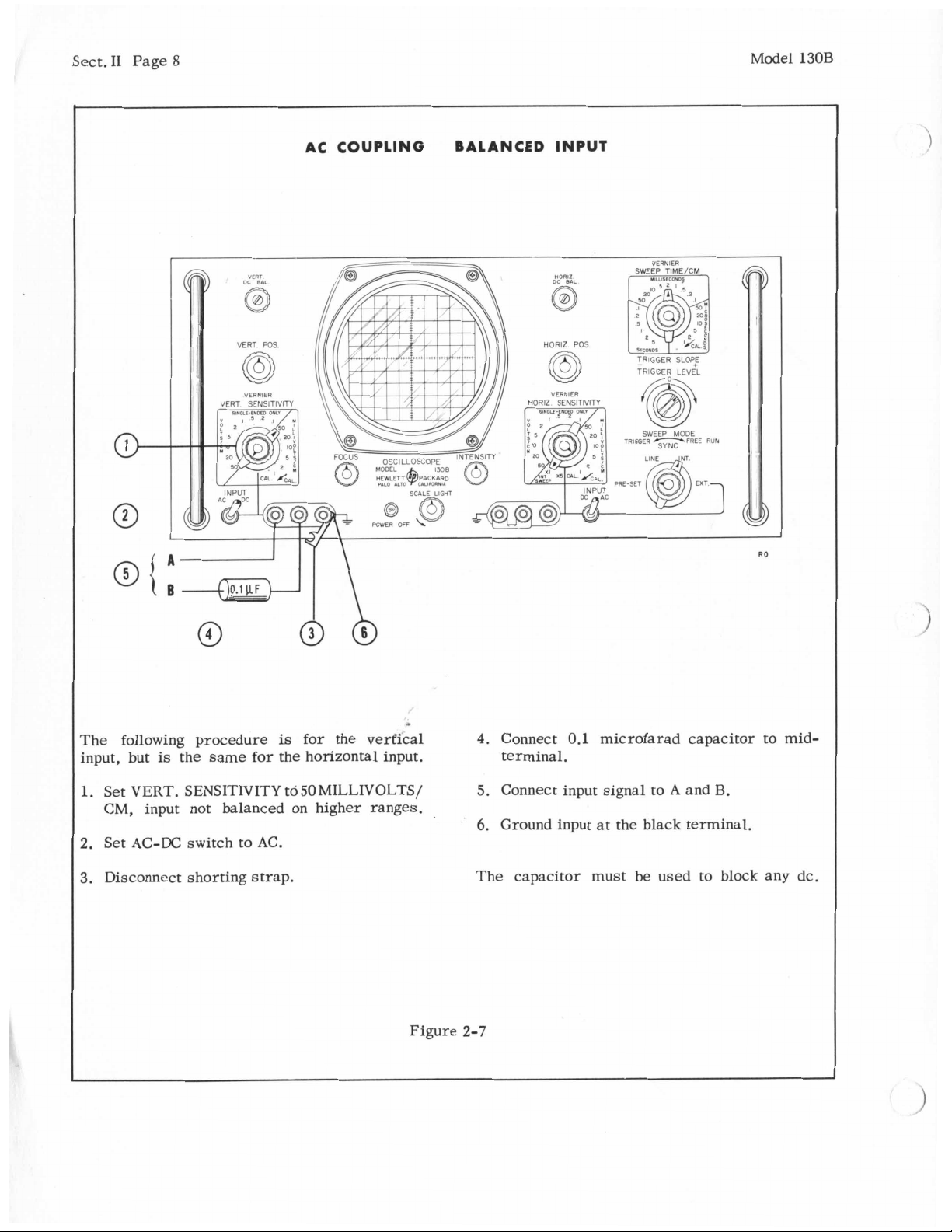

AC COUPLING BALANCED INPUT

VERT

POS

The following procedure

input, but

1.

Set VERT. SENSITIVITY to

is

the same for the horizontal input.

is

for the vertical

50

MILLIVOLTS/

CM, input not balanced on higher ranges.

2.

Set AC-DC switch to AC.

3.

Disconnect shorting strap.

4.

Connect

0.1

microfarad capacitor to mid-

terminal.

5.

Connect input signal

6.

Ground input at the black terminal.

The capacitor must

to

A

and

be

used to block any dc.

RO

B.

Figure

2-7

Page 16

Model

130B

CONNECTION TO CRT DEFLECTION PLATES

Sect.

I1

Page 9

The following procedure

ternal signals to

but

is

the

1.

Remove rear access plate fastened by four

the

same for the horizontal plates.

is

for connecting ex-

vertical deflection plates,

screws.

2.

Remove

cal

replace them with

the

shorting bars between

Amplifier and terminals

1

megohm,

D3

the

and

1/2

resistor.

Verti-

D4

and

watt

Figure

For balanced AC coudinp:

3.

Connect balanced signal through appropriate

capacitor to

D3

and

D4.

For single-ended AC coupling:

4.

Bypass

D4

to chassis

with

capacity.

5.

Connect

the

signal to

D3

through an appro-

priate capacitor.

NOTE:

deflect

and connect

If

the

it

is

desired to have positive voltage

beam

downward, bypass

the

signal to

D4.

2-8

an

adequate

D3

tochassis

Page 17

Sect.11

Page

10

EXTERNAL INTENSITY MODULATION

Z

AXIS

02

POSlTNE

DEFLECTS

RT

d

D3

POSITIVE DEFLECTS UP

VERT

I

RO

CA

Model

L

130B

d

CAUTION: Dangerous Voltages

this terminal board. Be sure the instrumekt

turned

To

signals:

1.

off

when making this connection.

intensity modulate the CRT with external

Remove

small screws

rear

access

at

rear

plate fastened

of

are

present-on

dust cover.

by

four

is

2.

Remove shorting

3.

Connect modulating signal

A

positive voltage

the CRT trace from normal intensity.

bar.

of

to

20

volts peak will blank

these terminals

Figure

2-

9

Page 18

Model

130B

Sect.11 Page

11

ALIGNING SCOPE TRACE

WITH

GRATICULE

RO

CAUTION: DANGEROUS VOLTAGES ARE

PRESENT INSIDE THE INSTRUMENT

Remove two screws at rear of dust cover and

slide cover off to rear. Fiber lever

both

radial and longitudinal positioning of CRT

and

is

locked by clamp

(1).

(2)

controls

Figure

To align sweep trace with graticule loosen clamF

(1)

with a screwdriver. Rotate fiber arm

until

the

trace

is

parallel to horizontal lines

graticule. Tighten clamp

(1)

after adjustment

has been made.

2-10

(2)

on

Page 19

Sect.

111

Page

0

Model

130B

r--

I

I

J

I

c

0

L

a

FW

3-

a5

+-I

3n

or

a

E

(d

k

bn

(d

8

c

0.

-I

a

4

al

k

3

bn

iz

OU

I

I

Page 20

Model 130B

J

Sect.111 Page

1

3-1

GENERAL CONTENT

This section contains a brief description of the

over-all operation of the Model 130B Oscilloscope,

description of each major section and detailed

description

3-2

The block diagram in Figure

circuits of the Model 130B Oscilloscope.

A.

VERTICAL AMPLIFIER

The Vertical Amplifier receives the input

signal, amplifies it, and drives the vertical deflection plates of the cathode ray tube. In addition,

this

amplifier determines the vertical position of

the spot on

chronizing

B. HORIZONTAL AMPLIFIER

The Horizontal Amplifier receives

either from

Sweep Generator, amplifies

zontal deflection plates of

Except for

fier

for amplifying the internally- generated sawtooth voltage,

Vertical Amplifier.

SflEEPGENERATOR

The Sweep Generator forms a sawtooth volt-

to control

across

Generator

generator,

the

sawtooth. The trigger generator controls

allow

sawtooth sweep begins.

of

a Schmitt trigger.

OVER-ALL OPERATION

3-1

the

screen

the

sweep

the

the

provisions in

the

the

face of

is

divided into two parts:

2)

the

operator to choose

and supplies a signal for syn-

with

the vertical input signal.

horizontal INPUT jack or from the

it

and drives

the

cathode ray

the

Horizontal Ampli-

it

is

essentially

horizontal movement of the spot

the

cathode ray tube. The Sweep

a

trigger generator, which starts

the

point at which the

shows the basic

its

signal

the

hori-

tube.

the

same as

1)

a

sawtooth

the

SECTION

THEORY

In addition to forming the 'internal sweep of the

oscilloscope,

the required unblanking pulse

trace during

D.

CALIBRATOR

An

nominal frequency of 300 cps,

ting

the

either

to CAL., turns

and connects

E. CATHODE

accelerator type. It

P1 phosphor screen but

P11 phosphors also and P2 upon special order.

All are electrically interchangeable and the tube

easily changed.

makes possible

which requires no resetting when adjusting the

FOCUS or INTENSITY controls.

plate terminals are connected through removable

jumpers at

rect connections to the plates

3-3

The vertical amplification channel consists of

three parts:

ator,and the amplifier section proper.

A.

is

capacitor

DC

attenuator.

the VERT. or HORIZ. SENSITIVITY switches

The cathode ray tube

VERTICAL AMPLIFICATION CHANNEL

AC - DC

The signal comes into the input terminals and

fed to

position, the signal goes directly to

the

each

sweep.

internal square-wave calibrator, with

basic gain of the amplifiers. Turning

on

its

output to the appropriate amplifier.

RAY

a

the

rear of the instrument

the

SWITCH

the

AC-DC switch. For ac coupling,

is

switched into

OF

Sweep Generator also supplies

the

calibrator supply voltage

TUBE

is

normally supplied

is

The

simple astigmatism adjustment

OPERATION

which

brightens

is

provided for

is

a SAQP - mono-

available

mono-accelerator anode

in

The

the

deflection

so

can

be made easily.

AC-DC

switch,

the

signal path.

the

input attenu-

set-

with

P7 and

that di-

In

the

input

111

the

a

a

is

a

the

Page 21

Sect.

111

Page 2 Model 130B

B. INPUT ATTENUATOR

is

a

The input attenuator

switch having fifteen calibrated ranges (1 MILLIVOLT/CM

sition. When the switch

the input of the amplifier

to

the output

less

ended frequency -compensated attenuators

inserted ahead of the Vertical Amplifier.

six most sensitive ranges, balanced-type attenu-

ators

amplifier (V2) and the third differential amplifier

(V3).

input signals may

after

The sensitivity may

ranges by means of the VERNIER control.

C.

VERTICAL AMPLIFIER

The Vertical Amplifier consists

of

balanced differential amplifiers* in cascade.

The first stage (Vl) has the VERT. DC BAL. adjustment (RlOA,

adjusts the current division between the two halves

of

the stage. The second

control in the cathode circuit which varies the

gain

SENSITIVITY switch, and another dc balance adjustment (R20)

stages,

the coupling

of

the amplifier arising from the inter-electrode

capacitances. The output

fed

to the balanced attenuator

SITIVITY switch. The output

tenuator

ential amplifier (V3). The .third stage has two

potentiometers in its cathode circuit, one controls

the vertical position of the pattern (VERT. POS)

and the other adjusts the basic gain of the Vertical

Amplifier (R40, Gain Adj.). The fourth balanced

differential amplifier (V4)

The neon lamps in the grid-cathode circuit

protect the tube when the Model 130B

turned

deflection plates

dition, synchronization signals

to

50

VOLTS/CM) and a calibrate po-

is

of

the internal calibrator.

sensitive than

are

inserted between the second differential

On

the six most sensitive ranges, balanced

removing the jumper

of

the amplifier between ranges

neutralizing capacitors

effects

is

connected

on.

The output

50

MILLIVOLTS/CM, single-

be

applied

to

be

varied continuously between

B)

in its cathode

is

also

provided.

between the input and output

of

to

the third balanced differ-

of

V4 drives the vertical

of

the cathode ray tube.

sixteen position

in the CAL. position,

is

directly connected

On

ranges

On

to

the input terminals

the ground terminal.

of

four

stages

circuit

stage

has a VERNIEK

of

In

the

are

used

the second

of

the VERT-. SEN-

of

the balanced

is

the output stage,

are

coupled from

which

the VERT.

last

three

to

cancel

stage

of

is

first

In

are

the

is

at-

V4

ad-

the plates

erator

TERNAL

a

precaution against drift and hum, a regulated

dc

supply

stages.

3-4

The Horizontal Amplifier

to the Vertical Amplifier, except in the INT.

SWEEP

SITIVITY switch.

signal from the Sweep Generator

the sweep attenuator to the grid

third balanced differential amplifier.

X5 position, R164, X5 Mag. Adj., in the cathode

circuit

obtain sweep magnification

V104 drives the horizontal deflection plates

cathode ray tube.

3-5

The sweep generator provides a sawtooth voltage

to produce linear horizontal movement

spot

the HORIZ. SENSITIVITY switch

SWEEP (X1

erator

the cathode ray tube during each sweep.

The sweep generator consists

erator,

Cathode Follower.

A. TRIGGER GENERATOR

The purpose

receive

into

the Sawtooth Generator.

The Trigger Generator consists

lector

and

selector

1) the Vertical Amplifier (internal synchro-

nization,

of

V4 and coupled into the Sweep Gen-

to

trigger the sweep during either IN-

+

or

INTERNAL - synchronization. As

is

used

for

the heaters

HORIZONTAL AMPLIFICATION

CHANNEL

is

X1

and

X5

position of the

In

these positions, the sawtooth

of

V104 sets the gain

SWEEP GENERATOR

of

the first three

essentially identical

of

the amplifier

of

X5.

HORIZ.

is

of

The output of

SEN-

fed through

V103, the

In

the INT.

of

of

across

a

a

the

face

of

the cathode ray tube when

is

set

to

or

X5). In addition, the sweep gen-

furnishes the pulse required to unblank

of

a

Trigger Gen-

a

Sawtooth Generator, and a Gate Out

of

the Trigger Generator

a

synchronizing signal and convert

fast,

constant-amplitude pulse

of a SYNC

switch (S201), a Trigger Amplifier (V201),

Trigger Generator (V202). The SYNC

switch accepts a signal from:

+

or

-),

to

to

the

the

INT.

is

to

it

start

se-

*

Valley and Wallman, “Vacuum Tube Amplifier”,

Massachusetts Institute

Series, vol.

Company, Inc., New York, 1948.

18,

pp 441-451. McGraw-Hill Book

of

Technology Radiation

2) an internal

synchronization),

3) the horizontal INPUT terminals (external syn-

chronization).

6.3

volt source (line-frequency

or

Page 22

)

Model 130B

is

fed

to

The synchronizing signal

amplifies the signal and delivers

phase,

to the Trigger Generator. Adjustment

TRIGGER LEVEL control

V201, determining the point on the input waveform

that

Trigger Generator (V202)

cuit: a discussion

A

and B, having both plate-to-grid and cathode-tocathode coupling. The

states:

conducting,

action the change-over from one state to the other

is

in the square-wave output. The levels

the change-over takes place (hysteresis limits)

can be adjusted to

ger Generator (V202)

Start-Stop Trigger (V203).

the A side grid voltage must

hysteresis limit to change the

For

the grid voltage positive through the upper hysteresis limit

grid voltage negative through the

limit

side into conduction.

as

selected by the TRIGGER SLOPE switch,

sets

will

trigger the Trigger Generator (V202).

is

of

the Schmitt trigger follows:

Schmitt trigger consists

circuit

A

side conducting, B side

A

side cut

very rapid, producing fast

example,

will

if

the A side

will

put the A side out of conduction and B

off.

be

close

or

have no

together as in the Trig-

widely spaced

effect,

a

Schmitt trigger

of

two amplifiers,

Due to regenerative

rise

To

trigger the

cross

state

is

conducting, driving

V201 which

it

in the proper

of

the output level

cir-

has

two

stable

cut

off; B side

and decay times

at

which

as

in the

circuit,

a

particular

of

the circuit.

but driving the

lower

hysteresis

the

of

A

Sect.

111

Page

of

the cathode ray tube. The rate

sweep takes place

of

the RC network in the grid circuit

These values

switch. The output

neon lamp (1203) to the Integrator Cathode

lower (V206A). I203

improve the high-frequency response

and a

series

ency toward oscillation. I204 through I206

tective neons

time switch.

The output

(V206A)

sweep attenuator to the Horizontal Amplifier

and 2)

lower

back

ducts and the

charges. However,

V207B

charges, maintaining

of

between sweeps

cover. The bias which determines the triggering

level

plied by the Retriggering Bias Control (V207A).

The bias

R218, in the grid

to

(V207B) in the Sawtooth Generator feed-

circuit.

V203A. This hold-off bias allows sufficient time

of

‘are

resistor

for

of

is

fed

the Retriggering Hold-Off Cathode Fol-

is

cut

the Start-Stop Trigger (V203A)

is

adjusted by the SWEEP MODE control,

is

determined by the values

varied by the SWEEP TIME

of

V206B

is

shunted with a capacitor to

is

used to eliminate any tend-

the timing capacitor in the sweep

the Integrator Cathode Follower

to

two

circuits:

During the Sweep, V207B con-

capacitor

at

off

and the cathode

for

circuit

in

its

the termination

a

positive bias on the grid

the Sweep Generator

of

V207A.

at

which this

of

V206B.

is

fed througha

Fol-

of

the circuit,

are

pro-

1)

through the

cathode circuit

of

the sweep,

capacitor

is

to

dis-

re-

sup-

3

j

B. SAWTOOTH GENERATOR

of

The Sawtooth Generator consists

Stop Trigger (V203), and Integrator Switch ‘(V205),

a

Feedback Integrator (V206B), and Integrator

Cathode Follower (V206A), and

Hold-Off Cathode Follower (V207B).

Start-Stop Trigger (V203).

cuit,

is

fed by Trigger Generator (V202). The

square wave output

Integrator Switch (V205), which in turn controls

the action

V203 produces

cut

off

Feedback Integrator (V206B), a Miller integrator

circuit*, generates essentially

rising waveform, which

tal Amplifier to sweep the trace across the face

*

Millman and Taub, “Pulse and Digital Circuits”

pp 216-228, McGraw-Hill Book Company, Inc.,

New

00013-2

of

Feedback Integrator (V206B). When

permitting V206B

York, 1956.

of

a

negative pulse,it

a

V203

to

is

applied to the Horizon-

a

Retriggering

Schmitt trigger

is

fed directly to the

causes

commence operation.

a

positive linearly

Start-

cir-

V205

to

C. GATE OUT CATHODE FOLLOWER

of

Another function

is

to

furnish a pulse

tube. The

couples the required positive unblanking pulse

from the Start-Stop Trigger

crt

for

3-6

The low-voltage power supply consists

regulated voltage supplies, three positive (+585V,

+300V,

nishing the plate voltages and dc filament voltages

required

The operation

similar; only the -150 volt supply

cussed. V306, V307 and V308 constitute the

voltage regulator circuit

V308,

erence voltage

Gate

Out Cathode Follower (V204),

the duration

LOW VOLTAGE POWER SUPPLY

+lOOV)

for

the instrument.

a

glow discharge tube, probides

of

and one negative (-15OV), fur-

of

each

for

the Start-Stop Trigger

to

unblank the cathode ray

to

the grid of the

the sweep.

of

the four regulators

will

for

the -150 volt supply.

the cathode

of

V307, the

of

be

a

four

is

dis-

ref-

Page 23

Sect.

111

Page

4

is

Control Tube. V306, a Series Regulator,

trolled by the voltage at the plate of V307.

output voltage from the

rectifier

increases,

con-

If

the

the

bias of V307 decreases, causing V307 todraw more

current.

the

This

lowers the plate voltage

grid voltage of V306, resulting

of

V307 and

in

greater plate

resistance for V306. Increased plate resistance

causes a greater voltage drop across V306, compensating for

rectifier

output

.

If

the

output voltage from the rectifier decreases,

the

reverse

supply voltage due to changes

minimized

voltage

the

-150

for

the

3-7

The

HIGH-VOLTAGE POWER SUPPLY

high-voltage power supply provides regulated

dc voltage to the cathode and control grid of

the

increased output voltage from the

and resulting

in

substantially constant

of the above action occurs. Changes

in

load current are

in

the same manner. Thus,

is

held essentially constant. The output of

volt supply

three

positive-voltage supplies.

serves

as

the

reference voltage

the

in

output

the

cathode ray tube. The high-voltage power supply

consists of

an

RF Oscillator tube (V313). a high-

voltage transformer (T302), high-voltage recti-

fiers

(V310.311) and a High-Voltage Control Tube

(V312). The RF Oscillator, a Hartley circuit,

oscillates at a frequency of approximately

100

kc.

The high-voltage transformer has two separate

secondaries which feed the High-Voltage Rectifiers.

The output of V310

the

cathode ray

is

fed to

a

dc-coupled amplifier. The output

fed back to

in

proper phase to oppose any change

the

the

voltage output. The INTENSITY control

output of

cathode of

The output of

of

the

is

cut off. During

this

supply determines the voltage

the

V311

cathode ray tube, and normally

is

connected to the cathode of

tube.

A

fraction of this voltage

High-Voltage Control Tube V312,

of

V312

screen of RF Oscillator tube (V313)

in

the

high-

in

the

on

the

cathode ray tube.

is connected to

the

sweep operation, a positive

the

control grid

the

crt beam

is

Model 130B

pulse from

in

the Sweep Generator circuit overrides

tive crt grid cutoff voltage and unblanks

ray

tube.

justed with the

(R343).

3-a

The

Calibrator, a square-wave oscillator, pro-

the

Gate Out Cathode Follower (V204)

The

brilliance of the trace may be ad-

Intensity

in

series

CALIBRATOR

with grid-voltage supply.

the

nega-

the

cathode

Adjust potentiometer

duces an accurate voltage across R244 for application to either amplifier for setting the basic

gain. Turning either

SENSITlVITY

switches

brator and connects its output to

the

VERT. or HORIZ.

to CAL. turns

the

on

the

Cali-

appropriate

amplifier.

The Calibrator consists of two neon lamps (I207

and 1208) in a relaxation oscillator circuit. Operation of the Calibrator

When

the

+300 volt supply

is

as follows:

is

applied to

the

Calibrator, 1207 will ionize first due to higher potential across it compared to

1208.

When

I207 fires

R243. However,

it

the

voltage at

R242, C213 and R243 will build

the

voltage across a capacitor cannot change

stantaneously.

change,

the

As

C213 allows this voltage to

voltage at

I207 and I208 will also change, since

drop across the ionized neon lamp

(approximately 60 volts).

the

potential across

will draw

the

current

the

junction of

up

slowly because

common junction of

the

is

As

the voltage at

through

in-

voltage

constant

the

common junction of I207 and I208 reaches approximately +70 volts, I208 will

current through R240 and

age across I207 and

it

will de-ionize. I208 remains

fire.

R241

This additional

will reduce

the

volt-

lit until the voltage across C213 charges through

R243

to a voltage approximately 70 volts below the

voltage that appears at

and 1208. I207 will now

the

common junction of I207

fire

and the action will

repeat itself.

I208

is

thus

alternately turned off and on at a rate

of approximately 300 cps. The output of

brator

is

taken from the current passing through

the

Cali-

R244 and 1208. The output is approximately a

square wave

300 millivolts

which

in

amplitude.

can be

set

with

R240 to obtain

Page 24

Model

130B

Sect. IV Page

1

1

4-1

INTRODUCTION

This. section contains instructions for testing, ad-

justing, and trouble shooting the Model

Oscilloscope.

Standard, readily available components are used

for manufacture

sible. Special components are available through

your

local

stock

for

your convenience.

When ordering parts, specify instrument model

serial

and

and stock number appearing in the Table of Replaceable

Your

facilities

you with any problems you may have with

instruments.

Parts.

local

and specially trained personnel to assist

of

@

instruments whenever

@

Representative who maintains a part

number plus the component description

@

Representative maintains complete

130B

pos-

@

SECTION

IV

MAINTENANCE

The following

and adjusting the Model

manufacture. Equivalent test equipment may

be

used.

1)

A

high impedance dc vacuum tube voltmeter,

such

as

DC

Voltage Multiplier.

2)

A

high impedance

such

as

an @ Model

3)

A

variable power line transformer with a mini-

mum rating of

4)

A

square-wave generator such

211A.

5)

A

sine-wave oscillator with a maximum

quency

@

of

Model

test

equipment

an @ Model

3

amps.

at least

200CD.

is

used for testing

130B

Oscilloscope during

410B

with an @ Model

ac

vacuum tube voltmeter,

400D/H/L.

as

500,000

cycles, such as

459A

an @ Model

fre-

an

\

1

The material in this section

to circuit functions, each section having a com-

plete

set

of

adjustment instructions. The material

in this section

4-2

Simple Check Procedure

4-3

Removing the Cabinet

4-4

Isolating Troubles

Connecting

4-5

4-6

Tube

Condensed

4-7

4-8

Adjustment Procedure

4-9

Turn On

4-10

Power

4-11

Replacing and Adjusting the CRT

4-12

Checking and Adjusting the Calibrator

4-13

Adjusting the

4- 14

Adjusting the Horizontal Amplifier

4-15

Phase Shift Adjust

4-16

Adjusting

4-17

Adjusting the Sawtooth Generator and Sweep

Amplifier

00013-2

is

as

follows:

for

230

Replacement

Test

Supplies

Vertical

Preset

and Adjustment Procedure

is

divided according

to

Major Sections

Volt

Operation

Amplifier

6)

An accurate time mark generator suitable

sweep speed calibration.

4-2

This check should

strument malfunction

sary to remove the instrument from the cabinet.

Set both VERT. and HORIZ. SENSITIVITY switches

on

tilted at

should

zontal and vertical directions.

If the proper pattern

both the Vertical and Horizontal Amplifier, the

Power Supplies and the Calibrator

properly.

as

SIMPLE CHECK PROCEDURE

be

performed

is

suspected.

CAL. The pattern should

45

degrees. In addition, the deflection

he

a

total of six centimeters in the hori-

is

obtained,

To

check the Sweep Generator proceed

follows:

first

whenever in-

It

is

be

a

straight line

it

is

are

not neces-

likely that

functioning

for

.

Page 25

Sect.

IV

Page 2

HORIZONTAL AMPLIFIER

BOARD

POWER SUPPLY BOARD-

/

HIGH VOLTAGE RF OSCILLATOR,

TRANSFORMER

AND CONTROL CIRCUIT

SENSITIVITY

SWITCH

SWEEP TIME/CM SWEEP GENERATOR,

SELECTOR SWITCH SYNC CIRCUIT AND

S204

\

CALIBRATOR BOARD.

(SWINGS OUT)

Model

VERTICAL AMP1

BOARD

S2

130B

.I

FlER

\

POWER SUPPLY BOARD

I

j2

IN

5102

IN PARALLEL WITH TiE

HORIZONTAL INPUT TERMINALS VERTICAL INPUT TERMINALS.

PARALLEL

WITH

THE

HORIZONTAL AMPL

BOARD

VERTICAL AMPLIFIER

BOARD

VERTICAL SENSITIVITY

SELECTOR SWITCH

LO

- L -

2198

I

FlER

S2

1

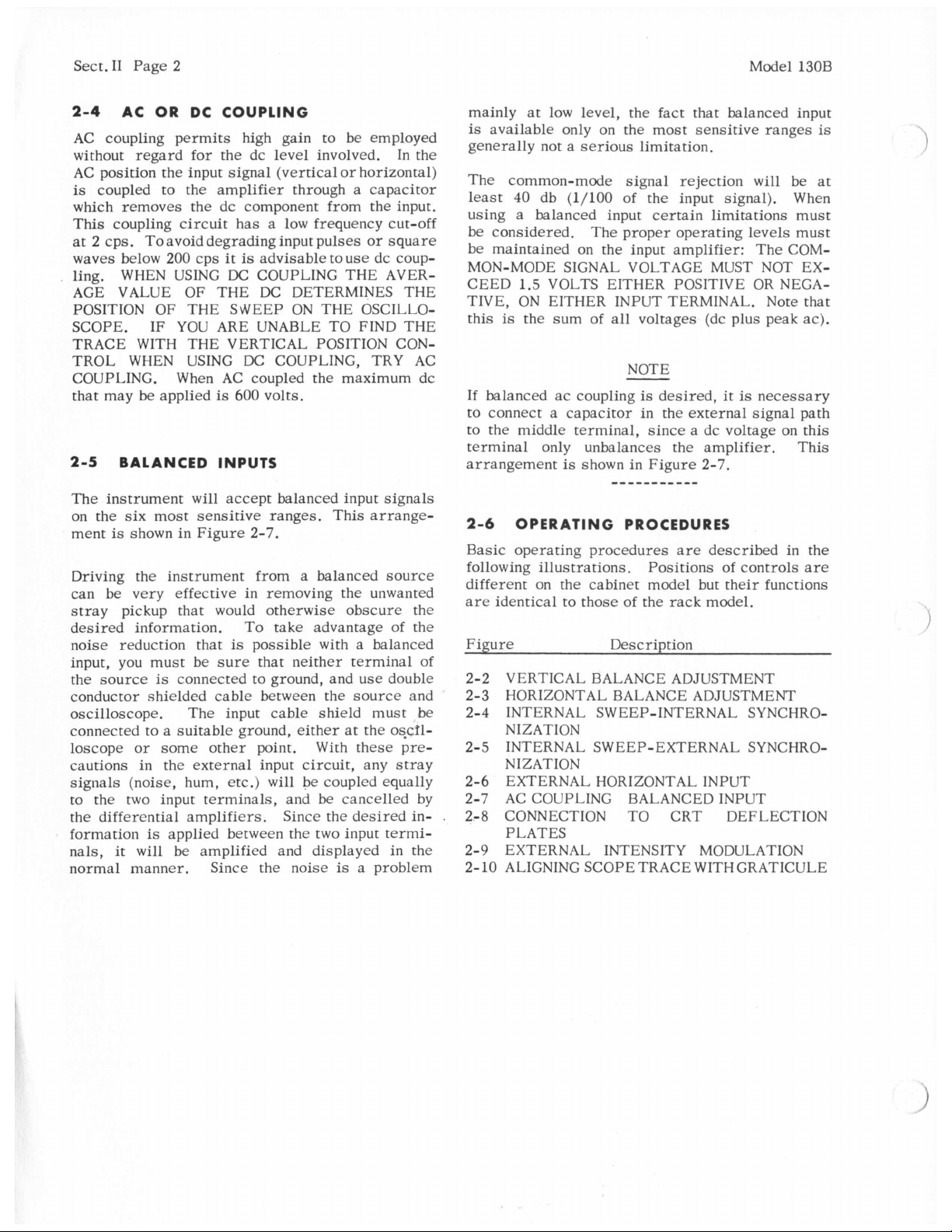

Figure

4-1.

Location Diagram

for

Major Circuits

1

/

Page 26

)

?

Model

1)

CAL, switch HORIZ. SENSITIVITY switch

SWEEPX1.

2)

SECOND.

should appear on the screen.

tained

switch

to

malfunction

4-3

In the cabinet model, remove the

the rear

ment forward.

If the

as

which pass through the front panel, and withdraw

the chassis. If the instrument

turn

trols), remove the two

lift

4-4

Determining which major section contains a malfunction

following general rules are remembered.

1)

usually be traced

2)

Horizontal Amplifier also

generated sweeps, while

stages affects only the Horizontal Amplifier.

3)

generated sweeps only, and does not

Horizontal Amplifier.

130B

Leaving the VERT. SENSITIVITY switch in

to

INT.

Switch SWEEP TIME/CM switch to 1 MILLI-

A

six centimeter square-wave pattern

If no pattern

be

sure SWEEP MODE

is

in INT., and adjust TRIGGER LEVEL

trigger. If a pattern cannot be obtained, the

is

most likely in the Sweep Generator.

REMOVING THE CABINET

is

in PRESET, SYNC

two

of

the cabinet, and push the instru-

130BR

described in Figure

it

off

ISOLATING TROUBLES TO MAJOR

S

A

failure affecting all major sections can

A

failure occurring in the last

A

sweep Generator failure affects internally

has been rack-mounted with brackets

1-3,

remove the

is

out

on

its

face (handles

the dust cover.

ECTlO NS

is

usually not a difficult process,

to

the power supply.

will

screws

protect the con-

at the rear, and

two

will

affect internally

a

failure in

stages

screws

of

the rack,

the

first

affect

is

ob-

screws

if

the

of

the

two

the

at

Sect.IV Page

plates has unbalanced voltages,

control must

center

in that amplifier. If both

have unusual voltages, look

power supply.

5)

major sections

6)

amplifier, such as are used in the Vertical and

Horizontal Amplifiers on the:

and, unless

motionless in the center

whether this signal

or

positioning

move from the center

strument ages

occur which must be compensated by internal adjustments. However, should there be a component

failure in either amplifier the spot

off

ment

isolate the trouble, begin by shorting together the

grids

trace

ahead

the amplifier. If shorting the grids of one stage

does not return the spot to the screen, the

in this stage, or

this stage,

7)

SWEEP TIME/CM switch

SECONDS/CM, turn the SWEEP MODE control to

FREE RUN, and observe

These are the three neon lamps near V206 (6AW8)

on the Sweep Generator etched

these lamps flicker regularly, the Sweep Generator

the TRIGGER region should stop the generation

of sweeps and, hence, the flickering

lamps.

to

If the

The

two

is

supplied by an internal source, such as a

the screen and usually out

of

of

(spot) returns

of

To

check the Sweep Generator quickly,

is

sweeping. Turning the SWEEP MODE into

be

turned

balance these voltages, look

series

sides

or

the balance and positioning controls.

the amplifier closest

this stage. Proceed towards the front of

it

heater string should open, all

will

of

a

signal

balance control, causes the spot to

it

is

if

may be out

far

sets

be

inoperative.

the direct-coupled differential

is

present, the spot

of

is

applied

of

the screen.

to

be expected that a drift

to

the screen, the fault

there

is

of

or

if

the position

from

its

mechanical

for

trouble

of

deflection plates

for

trouble in the

130B,

the screen. Any signal,

to

to

a balancing control in

adjustment.

to

1201, I202

are balanced

will

be

the input terminals

As

the in-

will

will

be

thrown

of

range

of

adjust-

To

If

the output.

5

or

10

and

circuit

board.

of

the

fault

set

the

MILLI-

1203.

the neon

is

is

3

If

.j

4)

If following the Simple Check Procedure does

not produce a trace or spot on the screen, measure the voltages on the deflection plates

Cathode-Ray Tube (deflection plate terminal board

is

a convenient place

VERT. and HORIZ. SENSITIVITY switches

50

MILLIVOLTS/CM, these voltages can

to approximately 480 vdc using the position controls, look for trouble in

of

the power supplies. If one

to

measure).

the

high voltage section

set

of

the

If,

with both

set

to

be

set

of deflection

00013-2

4-5

CONNECTING FOR

Unless otherwise requested by the customer,

instruments are shipped with their power transformer primaries connected in parallel for operation on

To

ment from

the

115

convert

two

screws

volt (nominal) power lines.

to

230

its

cabinet

at

230

VOLT OPERATION

@

volt supply, remove the instru-

or

dust cover by removing

the rear of the chassis, and

Page 27

Sect.

IV

Page 4

Model 130B

push the chassis forward. At the primary of the

power transformer (marked A), remove the

connecting terminals 2 and

connect

1

to 2 as shown in Figure 4-2, and

5,

and 1 and

4.

wires

Then

re-

place the 2 amp slow-blow fuse (F301)witha 1-1/4

amp slow-blow

fuse.

The instrument may now be

connected to the 230 volt line.

115

V

CONNECTION

230V

CONNECTION

Figure 4-2. Line Voltage Connection

4-6

In many

rected by replacing

fore changing the setting

TUBE REPLACEMENT

cases

instrument malfunction can be cor-

a

weak or defective tube. Be-

of

any internal adjust-

ment, check the tubes. Adjustments made in an

attempt to compensate

for

a defective

tube

will

often complicate the repair problem.

It

is a good practice to check tubes by substitution

rather than by using a “tube checker”. The

re-

sults obtained from the “tube checker” can be misleading. Before removing a tube, mark it

if

the tube

is

good it can be returned to the same

so

that

socket. Replace only tubes proved to be weak or

defective.

Any tube with corresponding standa.rd EIA

characteristics can

be

used as a replacement.

Where variation in tube characteristics

circuit

performance, an adjustment

(JEDEC)

will

is

provided.

affect

The following table lists the tests and adjustments

which should be performed

if

such tubes are

re-

placed.

The chart in Table 4-2 lists

all

tubes in the 130B

with their functions and adjustments required when

replacing tubes. The heaters

operated in

series

from a regulated dc voltage

of

some tubes

are

obtained from the Low-Voltage Power Supply.

These tubes are identified in the chart with an

asterisk and their heaters

are

shown in the

Fila-

ment and Primary Detail Schematic. If a tube in

the dc string

the string

is

pulled or burned out, all tubes in

will

be turned off.

Page 28

Model

130B

Sect.IV Page

5

4-7

All basic

CONDENSED TEST AND ADJUSTMENT

PROCEDURE

tests

and adjustments are covered in graphs

the following Table

table will cover

all

normal adjustment needs for

the oscilloscope. For

tailed

If

4-1.

In most cases, this

If

a

more complete and de- complete the indicated adjustments.

test

the

instrument

4-3

a

tube

procedure

and

4-6.

is

replaced,

refer

is

not operating,

to paragraph

refer

refer

to Table

4-8.

to para-

4-2

and

Page 29

I

I

Test

1.

LowVoltage

Power Supply

2. Vertical ampli-

fier

balance

3.

Vertical

VERNIER

balance

4. Vertical ampli-

fier

gain

6. Horizontal

amplifier

balance

7.

Horizontal

VERNIER

balance

8.

Horizontal NONE

10. Sweep

preset

11.

Sweep

I

External Equipment Required

DC

vtvm with

1%

accuracy

,

NONE

NONE

400 cycle

Voltage Calibration Generator

Square Wave

Generator

NONE

NONE

NONE

Square wave

generator

Time Marker

Generator