Page 1

OPERATING AND SERVICE MANUAL

Scans by ArtekMedia © 2007

MODEL 1349AlD

DIGITAL DISPLAY

SERIAL NUMBERS

This manual applies directly to instruments with serial

numbers prefixed

For additional important information about serial numbers,

see INSTRUMENTS COVERED

2437A.

BY

MANUALin Section

I.

OCOPYRIGHT HEWLETT-PACKARD COMPANYICOLORADO SPRINGS DIVISION

Manual Part Number 01349-90901

Microfiche Part Number 01349-80901

1900

GARDEN OF THE GODS ROAD, COLORADO SPRINGS, COLORADO, U.S.A.

ALL RIGHTS RESERVED

1984

PRINTED AUGUST

1984

Page 2

Page 3

I

Scans by ArtekMedia © 2007

This product has been designed and tested according to International Safety Requirements. To

ensure safe operation and to keep the product safe, the information, cautions, and warnings in this

manual must be heeded. Refer to Section Iand the Safety Summary forgeneral safety considerations

applicable to this product.

SAFETY

CERTIFICATION

Hewlett-Packard Company certifies that this product met its published specifications at the time of

shipment from the factory. Hewlett-Packard further certifies that its calibration measurements are

traceable to the United States National Bureau of Standards, to the extent allowed by the Bureau's

calibration facility, and to the calibration facilities of other International Standards Organization

members.

WARRANTY

This Hewlett-Packard product is warranted against defects in material and workmanship for a period

of one year from date of shipment. During the warranty period, Hewlett-Packard Company will, at its

option, either repair or replace products which prove to be defective.

The cathode-ray tube (CRT) in the instrument and any replacement CRT purchased from HP are also

warranted against electrical failure for a period of one year from the date of shipment from Colorado

Springs. BROKEN TUBES

NOT INCLUDED UNDER THIS WARRANTY.

ANDTUBES WITH PHOSPHOR ORMESH BURNS, HOWEVER, ARE

For warranty service or repair, this product must be returned to a service facility designated by HP.

However, warranty service for products installed by HP and certain other products designated by HP

will be performed at Buyer's facility at no charge within the HP service travel area. Outside HP

service travel areas, warranty service will be performed at Buyer's facility only upon HP's prior

agreement and Buyer shall pay HP's round trip travel expenses.

For products returned to HP for warranty service, Buyer shall prepay shipping charges to HP and HP

shall pay shipping charges to return the product to Buyer. However, Buyer shall pay all shipping

charges, duties, and taxes for products returned to HP from another country.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper or inadequate maintenance

operation outside of the environmental specifications for the product, or improper site preparation or

maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. HP SPECIFICALLY DISCLAIMS THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE.

THE REMEDIES PROVIDED HEREIN ARE BUYER'S SOLE AND EXCLUSIVE REMEDIES. HP

SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER

LEGAL THEORY.

by Buyer, Buyer-supplied software or interfacing, unauthorized modification or misuse,

EXCLUSIVE REMEDIES

Product maintenance agreements and other customer assistance agreements are available for

Hewlett-Packard products.

For any assistance, contact your nearest Hewlett-Packard Sales and Service Office. Addresses are

provided at the back of this manual.

ASSISTANCE

S C W

8 A 9/78

(CRT)

Page 4

SAFETY SUMMARY

Scans by ArtekMedia © 2007

The followlng general safety precautlons must be observed

and repalr of thls Instrument.

elsewhere

Instrument. Hewlett-Packard Company assumes no

wlth these

GROUND THE INSTRUMENT.

To mlnlmlze shock hazard, the Instrument chassls and cablnet must be connected to an electrlcal

ground The Instrument

must

to two-contact adapter

(safety ground) at the power outlet The power jack and

lnternatlonal Electrotechnlcal Comm~ss~on (IEC) safety standards

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE.

Do not operate the Instrument In the presence of flammable gases or fumes

electrlcal Instrument

KEEP AWAY FROM LIVE CIRCUITS.

Operating

adjustments must be made by quallfled malntenance personnel Do not replace components w~th

power cable connected Under certaln condltlons, dangerous voltages may exist even wlth the

power cable removed To

touchlng them

In

thls manual vlolates safety standards of deslgn, manufacture, and Intended use of the

requirements.

elther be plugged Into an approved three-contact electrlcal outlet or used wlth a three-contact

wlth the

In such an

personnel must not remove Instrument covers Component replacement and Internal

Fallure to comply wlth these precautlons or wlth speclflc warnlngs

llablllty for the customer's fallure to comply

1s equlpped w~th a three-conductor ac power cable The power cable

grounding

environment

avold lnjurles always

wire (green) flrmly connected to an electrlcal ground

constitutes

a deflnlte safety hazard

disconnect

durlng

matlng plug of the power cable meet

all phases of

power and discharge clrcults before

operation,

Operation

servlce,

of any

DO NOT SERVICE OR ADJUST ALONE.

Do not attempt Internal servlce or adjustment unless another person capable of

and

resuscitation

USE CAUTION WHEN EXPOSING OR HANDLING THE CRT.

Breakage of the Cathode-ray Tube (CRT) causes a hrgh-veloclty

To prevent CRT ~mploslon, avoid rough handling or jarrlng of the Instrument Handllng of the CRT shall

be done only by

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT.

Because of the danger of lntroduclng add~tlonal hazards do not Install

any

unauthorized

Sales and

DANGEROUS PROCEDURE WARNINGS.

Warnings,

manual lnstruct~ons

Serv~ce Offlce for servlce and repalr to ensure that safety features are malvtained

IS

present

scattering

quallfled malntenance personnel uslng approved safety mask and gloves

modlflcation of the ~nstrument Return the Instrument to a Hewlett-Packard

such as the example below precede potent~ally dangerous procedures throughout thls

contained

In the warnings must be followed

WARNING

of glass fragments (~mploslon)

substitute

rendering

parts or perform

first ald

u

Dangerous voltages, capable of causing death, are present in this instrument.

Use extreme caution when handling, testing, and adjusting.

SS

2

1176

Page 5

Table of Contents Model 1349A/D

Scans by ArtekMedia © 2007

TABLE

Section Page Section Page

.

GENERAL INFORMATION 4.5 . Calibration Cycle

I

1.1

.

Introduction

1.4

.

Specifications

1.6 . Safety Considerations 1-1

1.8 . Instruments Covered by Manual

1.13 . Descri~tion

1.15

.

Accessories Supplied

1.19 . Recommended Test Equipment

I1 . INSTALLATION

Introduction

Initial Inspection 2-1

Preparation for Use 2-1

Power Requirements 2-1

Power Connector

1/0 Connector 2-2

Analog Outputs 2-3

Operating Environment 2-3

Storage and Shipment 2-3

Packaging 2-3

I11 . OPERATION

3.1

.

Introduction

.

3.3

3.4 . Handshake Timing for 1349D 3-1

3.6 Refresh Modes 3-4

3.10

IV . PERFORMANCE VERIFICATION

Signal Line Definitions

3.5 . Picture Refresh Requirements

for 1349D 3-4

.

.

Memory Initialization

3.7

3.8

.

1349A/D Command Set

3.9

.

Vector Drawing Examples

.

Programming the 1349D

3.11 . Write Operation

.

3.12

3.13

3.14

3.15

3.16

3.17 . Operating Considerations for the

3.18 . Signal Line Definitions

3.19 . Handshake Timing for the 1349A 3-12

3.20

3.21

4.1

4.3

Read Operation

.

Programming Summary

.

Using the Jump Instruction

.

Optimizing Picture Quality

Octal and Hexadecimal Range

.

1349A/D Commands

for

1349A

.

Transfer Sequence

.

Restrictions

.

Introduction

.

Equipment Required

.....................

....................

...........

......................

.............

.....................

................

.............

.............

................

...................

..................

..........

...........

.......................

.....................

..........

....

......................

...................

............

..........

.......

.........

.................

..................

.........

.....

......

.......

.........................

..........

...............

......................

.....................

.............

OF

1-1

1-1

.

1-1

1-4

1-4

. .

1-4

2-1

2-2

3-1

3-1

3-5

3-6

3-10

3-10 VI

3-10

3-11

3-11

3-12

3-12

3-12

3-12 VII

3-12

3-13

3-13

4-1

4-1

CONTENTS

4.9

.

4.10 . Resolution Verification

.

ADJUSTMENTS

V

5.1 Introduction 5-1

5.3

REPLACEABLE PARTS

.

6.1

6.3

6.5 Replaceable Parts List 6-1

6.7 Ordering Information 6-1

6.10 Direct Mail Order System 6-1

MANUAL CHANGES

.

7.1

SERVICE

VIII

.

8.1

8.4

8.8 . Recommended Test Equipment

................

Performance Verification

.

.

Safety Requirements

Equipment Required

Adjustments

Adjustment Procedures

Low Voltage Power Supply

Adjustment

High Voltage Power Supply

Adjustment

Z-Axis Drive Adjustment and

Test Pattern Set-up

Preliminary Focus and

Astigmatism Adjustment

Intensity Cut-off Level

Trace Alignment and Writing

Speed Adjustment

Stroke Generator Adjustments

Stroke Intensity Adjustments

Image Size and Position

Vector Closure

Fine Focus and Astigmatism

Adjustment and Resolution

Check

Auxiliary X-Y-Z Output Check

.

Introduction

.

Abbreviations

.

.

.

.

Introduction

.

Introduction

.

Theory of Operation

.....................

.....................

....................

....................

...................

.........................

.....................

....................

.....................

.....................

........

..........

.............

.............

..........

............

......

...........

.............

...

....

.........

...

...........

............

.......

.............

.

.

4-1

4-1

4-4

5-1

6-1

6-1

7-1

8-1

8-1

8-1

Page 6

Model 1349A/D

Scans by ArtekMedia © 2007

Table of Contents

TABLE OF CONTENTS (Cont'd)

Section Page Section Page

Repair

CRT Removal Procedure

Troubleshooting

Service Sheet

Vector Processor

X-Y Stroke Generator

Low Voltage and High Voltage

Memory Circuit

Figure Title

1349A Digital Display

1349A Dimensional Detail 1-5

Power Connector for 1349A 2-2

1349A

Read Command Timing

Write Command Timing

Refresh Mode Selection

Synchronous Refresh Example

Asynchronous Refresh Example

Vector Drawing Area

Graphing Example

Example of Character Spacing

Drawing a Square on the Display

Drawing Two Horizontal Lines on

1349A Power Connections 4-2

1349A Primary Test Pattern 4-2

1349A Command Check-out 4-3

Memory Fail Test Pattern 4-3

1349A Focus and Resolution Test

1349A Assembly Location

Low Voltage Power Supply

High Voltage Power Supply

1349A Primary Test Pattern

1349A Primary Test Pattern

1349A/D Primary Test Pattern

Z-Axis Drive and Preliminary Focus

Writing Speed Adjustment

Intensity Cut-off Level. Trace

1/0

the Display

Pattern 4-4

Identification

Adjustment Locations

Adjustment Locations

Adjustment Locations

Alignment and Writing Speed

Adjustment Locations

...........................

Operation

Power Supplies

Connector

......................

.........................

.............................

.......................

.........

.................

1. Theory of

.................

............

................

..................

LIST OF ILLUSTRATIONS

................

............

...........

.................

...............

..............

...............

........

.......

.................

....................

........

....

.............

..........

...........

............

...............

...............

..........

..........

.......

...............

............

...............

Page Figure

1-0

2-2

3-2

3-3

3-4

3-4

3-5

3-7

3-7

3-8

3-10

3-10

8.22 . Service Sheet 2, Theory of

Operation 8-10

8.23 . Service Sheets 3A. 3B. 3C

Theory of Operation 8-12

Service Sheet 4. Theory of

8.24

.

Operation

8.25

Service Sheet 5. Theory of

.

Operation

Service Sheet 6. Theory of

8.26

.

Operation

Stroke Generator Adjustment

Stroke Length Adjustment

Stroke Intensity Adjustment

Stroke Generator. Stroke Length and

Stroke Intensity Adjustment

Locations

X-Y Vector Closure

P/O Fine Focus Adjustment

P/O Fine Focus Adjustment

Vector Closure. Focus and Astigmatism

Adjustment Locations

X-Amplifier Auxiliary Output 5-14

Y-Amplifier Auxiliary Output 5-14

Z-Amplifier Auxiliary Output 5-14

Chassis Parts and Board Assembly

Identification

CRT Removal

Schematic Diagram Symbols

Basic Logic Symbols

Service Sheet

Vector Processor Troubleshooting

Flow Chart

Vector Processor Component Locator

Service Sheet

Vector Processor Component Locator

Service Sheet

Simplified Block Diagram of Analog

Multiplier

Current Definition for Ramp

Generator

Analog X-Y-Z Troubleshooting Flow

Chart

Service Sheet 3A. P/O X-Y-Z Amp/

Stroke Generator

Analog X-Y-Z Component Locator

Service Sheet 3B. P/O X-Y-Z Amp/

Stroke Generator

...............................

......................

...........

......................

......................

......................

Title

Page

.........

............

..........

...........................

....................

..........

..........

...............

.........

.........

..........

........................

.........................

..........

..................

1.

Block Diagram

.........................

2A. P/O Vector Processor 8-11

2B. P/O Vector Processor 8-13

...........................

...........................

....................

....................

.......

...

.

.

.....

8-10

8-10

8-12

8-14

8-14

8-14

8-15

8-16

8-17

8-18

8-20

8-24

5-8

5-9

5-9

5-10

5-11

5-12

5-12

5-13

6-3

8-2

8-3

8-4

8-9

Page 7

Table of Contents

Scans by ArtekMedia © 2007

Model

1349A/D

Figure

Table

LlST OF ILLUSTRATIONS

Title Page Figure Title Page

Analog X-Y-Z Component Locator

Service Sheet 3C. P/O X-Y-Z Amp

Stroke Generator 8-19

Low Voltage Power Supply

Troubleshooting Flow Chart 8-20

Low Voltage Power Supply Component

Locator

Service Sheet 4. Low Voltage Power

Supply

High Voltage Power Supply

Troubleshooting Flow Chart 8-22

High Voltage Power Supply Component

Locator

.............................

..............................

.............................

.....................

.....

........

........

8-18

8-20

8-21

8-22

8.23 . Service Sheet 5. High Voltage Power

8.24

8.25

8.26

8.27 . Memory Circuit Troubleshooting Flow

8.28 . Memory Circuit Component Locator 8-26

8.29

LlST OF TABLES

Title

Specifications

1349A Functions

Supplemental Characteristics

Recommended Test Equipment

1349A Power Requirements

1349A Character Set

Truth Table for 1349A Instructions 5.10

and Commands

Power Supply Requirements

Sequence of Adjustments

+

105V Adjustment

High Voltage Power Supply

Adjustment

2-Axis Drive Adjustment and Test 8.1

Pattern Set-up 5-5 8.2

.........................

......................

.........

........

...........

..................

.....................

...........

..............

....................

.........................

......................

Page Table

1-2 5.5

1-3

1-3 5.6

1-5 5.7

2-1 5.8

3-9 5.9

3-11 5.11

5.12

4-1

6.1

5-1

5-3 6.2

6.3

5-4

(Cont'd)

Supply

.

Read/Write Mode

.

Picture Refresh Mode

.

Service Sheet 6A, P/O Memory Circuit

(1349D Only)

Chart

.

Service Sheet 6B, P/O Memory Circuit

(1349D Only)

Preliminary Focus and Astigmatism

.

Adjustment

.

Intensity Cut-off Level Adjustment

Trace Align and Writing Speed

.

Adjustment

Stroke Generator and Stroke Length

.

Adjustment

.

Stroke Intensity Adjustment

Image Size and Position Adjustment

.

Vector Closure Adjustment

.

Fine Focus and Astigmatism

.

Adjustment

.

Reference Designators and

Abbreviations

.

Replaceable Parts

.

List of Manufacturer's Codes

.

Service Sheet Quick Reference

.

Function Labels

..............................

.....................

.................

........................

...............................

........................

Title Page

.........................

.........................

.........................

............

.........................

.......................

.....................

.......................

...

....

..........

.

.

.........

........

8-23

8-24

8-24

8-25

8-26

8-27

5-6

5-7

5-8

5-9

5-10

5-10

5-11

5-13

6-2

6-5

6-19

8-1

8-7

Page 8

General Information

Scans by ArtekMedia © 2007

ARTE

K

MEDIA

Digitally signed

by ARTEK

MEDIA

DN: cn=ARTEK

MEDIA, c=US,

o=DC Henderson

Date: 2007.04.15

15:15:11 -05'00'

Model

1349A/D

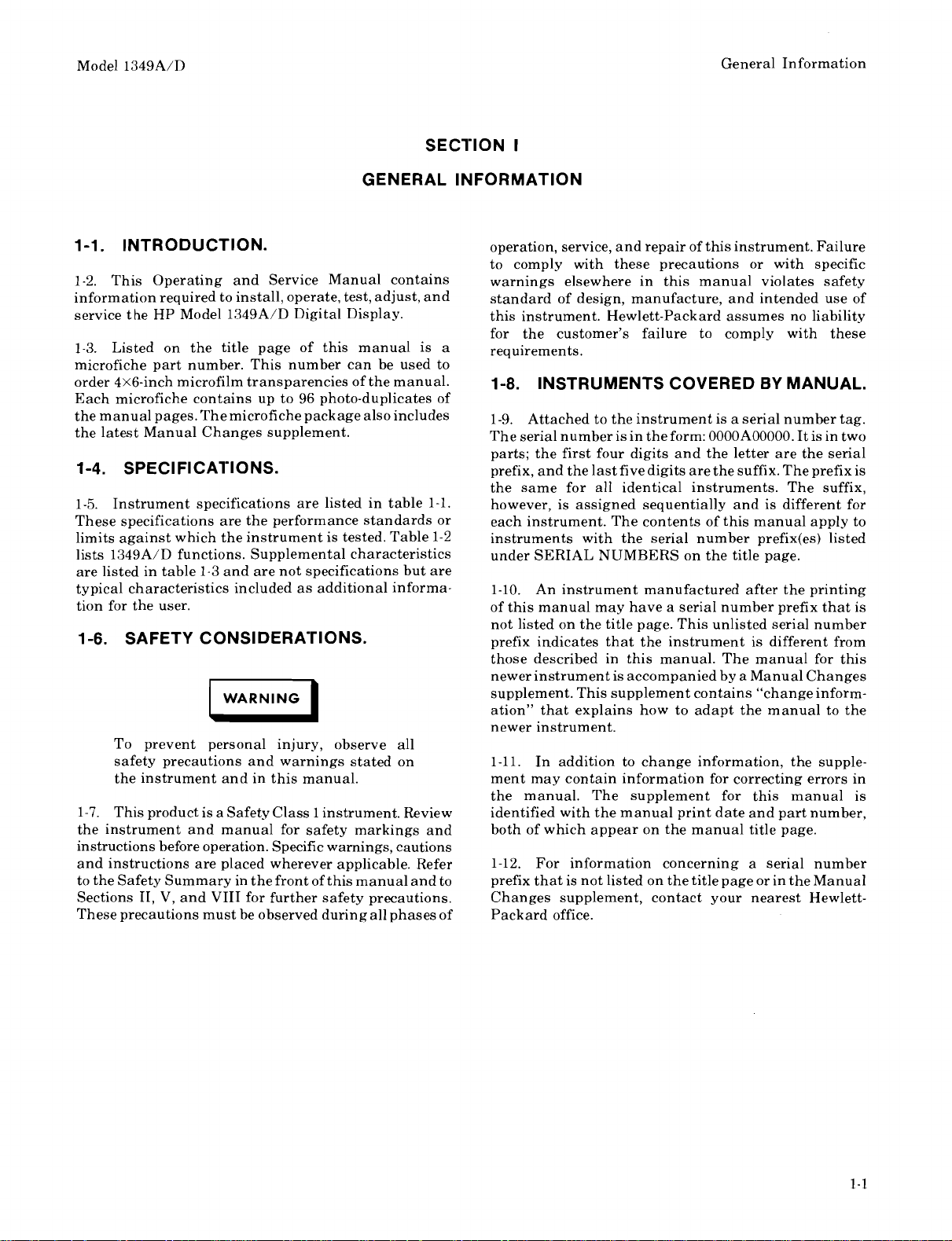

Figure 1-1. 1349A/D Digital Display

Page 9

Model 1349A/D

Scans by ArtekMedia © 2007

General Information

SECTION

GENERAL INFORMATION

1-1. INTRODUCTION.

1-2. This Operating and Service Manual contains

information required to install, operate, test, adjust, and

service the HP Model

1-3. Listed on the title page of this manual is a

microfiche part number. This number can be used to

order 4x6-inch microfilm transparencies of the manual.

Each microfiche contains up to 96 photo-duplicates of

the manual pages. Themicrofiche package also includes

the latest Manual Changes supplement.

1349A/D Digital Display.

1-4. SPECIFICATIONS.

Instrument specifications are listed in table 1-1.

1-5.

These specifications are the performance standards or

limits against which the instrument is tested. Table

lists 1349A/D functions. Supplemental characteristics

are listed in table

typical characteristics included as additional informa-

tion for the user.

1-3 and are not specifications but are

1-2

1-6. SAFETY CONSIDERATIONS.

To prevent personal injury, observe all

safety precautions and warnings stated on

the instrument and in this manual.

1-7.

This product is a Safety Class 1 instrument. Review

the instrument and manual for safety markings and

instructions before operation. Specific warnings, cautions

and instructions are placed wherever applicable. Refer

to the Safety Summary in the front of this manual and to

Sections

These precautions must be observed

11, V, and VIII for further safety precautions.

duringall phases of

I

operation, service, and repair of this instrument. Failure

to comply with these precautions or with specific

warnings elsewhere in this manual violates safety

standard of design, manufacture, and intended use of

this instrument. Hewlett-Packard assumes no liability

for the customer's failure to comply with these

requirements.

1-8. INSTRUMENTS COVERED BY MANUAL.

Attached to the instrument is a serial number tag.

1-9.

The serial number is in the form:

parts; the first four digits and the letter are the serial

prefix, and the last five digits are the suffix. The prefix is

the same for all identical instruments. The suffix,

however, is assigned sequentially and is different for

each instrument. The contents of this manual apply to

instruments with the serial number

under SERIAL NUMBERS on the title page.

An instrument manufactured after the printing

1-10.

of this manual may have a serial number prefix that is

not listed on the title page. This unlisted serial number

prefix indicates that the instrument is different from

those described in this manual. The manual for this

newer instrument is accompanied by a Manual Changes

supplement. This supplement contains "change information" that explains how to adapt the manual to the

newer instrument.

1-11.

In addition to change information, the supplement may contain information for correcting errors in

the manual. The supplement for this manual is

identified with the manual print date and part number,

both of which appear on the manual title page.

1-12. For information concerning a serial number

prefix that is not listed on the title page or in the Manual

Changes supplement, contact your nearest HewlettPackard office.

0000A00000. It is in two

prefix(es) listed

Page 10

General Information Model 1349A/D

Scans by ArtekMedia © 2007

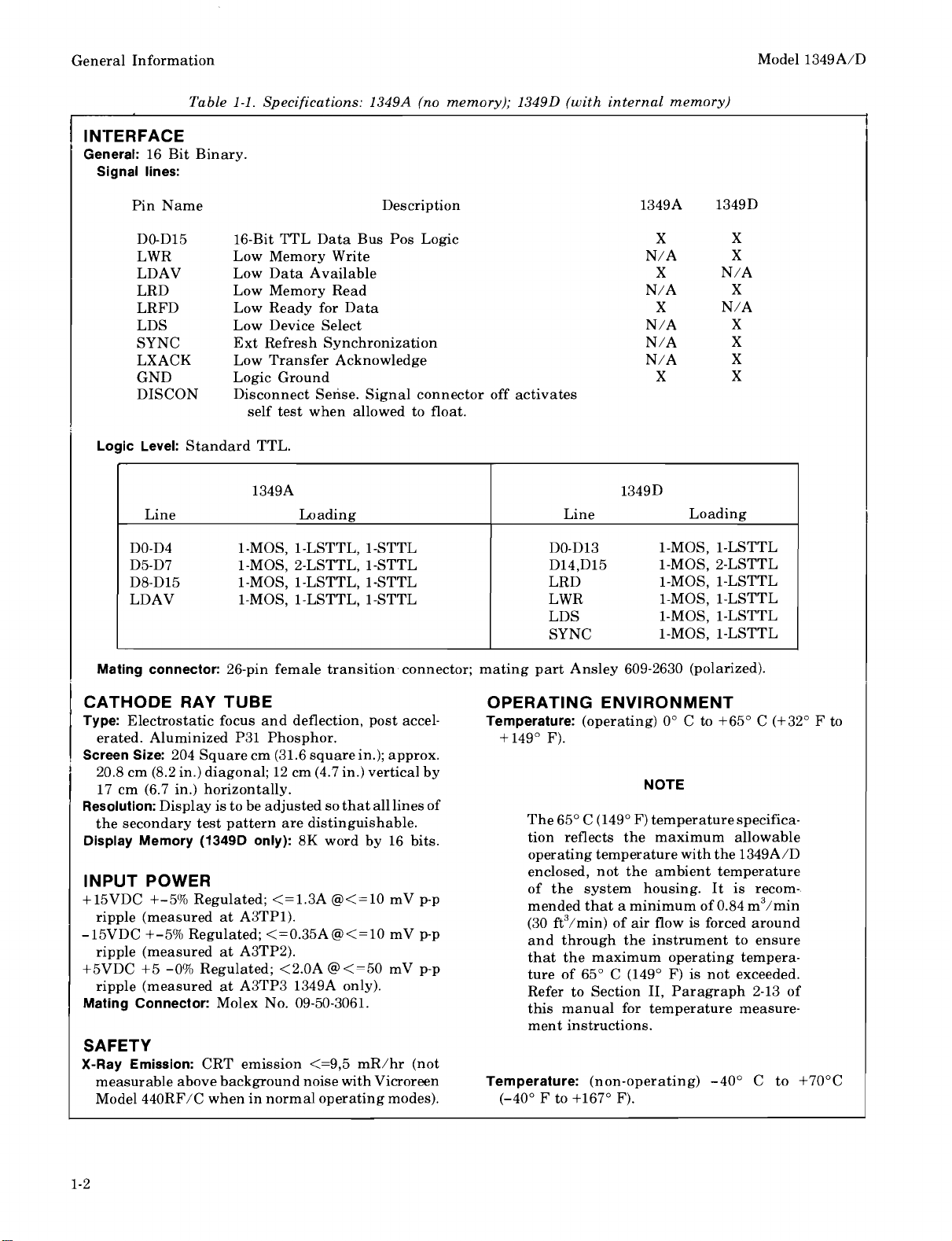

Table

1-1.

Specifications: 1349A (no memory); 13490 (with internal memory)

INTERFACE

General: 16 Bit Binary.

Signal lines:

Pin Name Description

DO-Dl5

LWR

LDAV

LRD

LRFD

LDS

SYNC

LXACK

GND

DISCON

16-Bit TTL Data Bus Pos Logic

Low Memory Write

Low Data Available

Low Memory Read

Low Ready for Data

Low Device Select

Ext Refresh Synchronization

Low Transfer Acknowledge

Logic Ground

Disconnect Sense. Signal connector off activates

self test when allowed to float.

Logic Level: Standard TTL.

1349A

Line Loading

1

DO-D4

D5-D7

-MOS, 1 -LSTTL, 1 -STTL

1

-MOS, 2-LSTTL, 1 -STTL

D8-Dl5 1-MOS, 1-LSTTL, 1-STTL

LDAV 1-MOS, 1-LSTTL, 1-STTL

Line Loading

DO-Dl3 1-MOS, 1-LSTTL

D14,D15 1-MOS, 2-LSTTL

LRD 1-MOS, 1-LSTTL

LWR 1-MOS, 1-LSTTL

1349D

LDS 1-MOS, 1-LSTTL

SYNC 1-MOS, 1-LSTTL

Mating connector: 26-pin female transition connector; mating part Ansley 609-2630 (polarized).

CATHODE RAY TUBE OPERATING ENVIRONMENT

Type: Electrostatic focus and deflection, post accel-

erated. Aluminized P31 Phosphor.

Screen Size: 204 Square cm (31.6 square in.); approx.

20.8 cm (8.2 in.) diagonal; 12 cm (4.7 in.) vertical by

17 cm (6.7 in.) horizontally.

Resolution:

Display is to be adjusted so that alllines of

the secondary test pattern are distinguishable.

Display Memory (1349D only): 8K word by 16 bits.

INPUT POWER

+

15VDC +-5% Regulated;

ripple (measured at

-15VDC +-5% Regulated; <=0.35A@<=10 mV p-p

ripple (measured at

+5VDC +5 -0% Regulated; <2.OA @ <=50 mV p-p

ripple (measured at

Mating Connector: Molex No. 09-50-3061.

<=

1.3A @<=lo mV p-p

A3TP1).

A3TP2).

A3TP3 1349A only).

Temperature: (operating) 0' C to +65' C (+32' F to

+14g0 F).

NOTE

The

65' C (149' F) temperaturespecifica-

tion reflects the maximum allowable

operating temperature with the

enclosed, not-the ambient temperature

of the system housing. It is recommended that a minimum of 0.84 m3/min

(30 ft3/min) of air flow is forced around

and through the instrument to ensure

that the maximum operating temperature of

Refer to Section

65' C (149' F) is not exceeded.

11, Paragraph 2-13 of

this manual for temperature measure-

ment instructions.

SAFETY

X-Ray Emission: CRT emission <=9,5 mR/hr (not

measurable above background noise with

Vicroreen

Model 440RF/C when in normal operating modes).

Temperature: (non-operating) -40' C to +70°C

(-40' F to +167' F).

1349A/D

Page 11

Model 1349A/D General Information

Scans by ArtekMedia © 2007

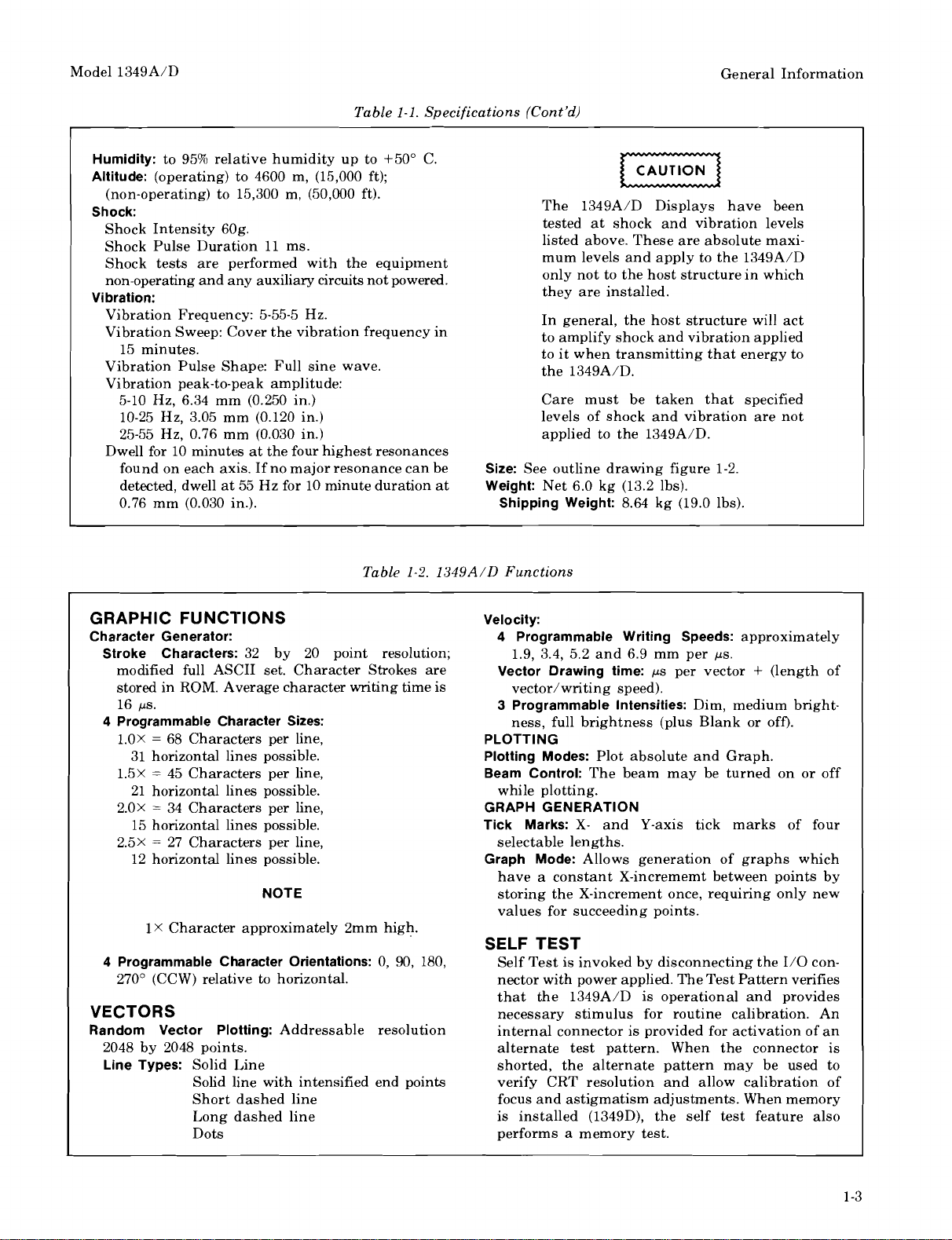

Table

1-1. Specifications (Cont'd)

Humidity:

Altitude:

to 95%) relative humidity up to +50° C.

(operating) to 4600 m, (15,000 ft);

(non-operating) to 15,300 m, (50,000 ft).

Shock:

Shock Intensity 60g.

11

Shock Pulse Duration

ms.

Shock tests are performed with the equipment

non-operating and any auxiliary circuits not powered.

Vibration:

Vibration Frequency: 5-55-5 Hz.

Vibration Sweep: Cover the vibration frequency in

15 minutes.

Vibration Pulse Shape: Full sine wave.

Vibration peak-to-peak amplitude:

5-10 Hz, 6.34 mm (0.250 in.)

10-25 Hz, 3.05 mm (0.120 in.)

25-55 Hz, 0.76 mm (0.030 in.)

Dwell for 10 minutes at the four highest resonances

found on each axis. If no major resonance can be

detected, dwell at 55 Hz for 10 minute duration at

0.76 mm (0.030 in.).

-

Table

Size:

Weight:

Shipping Weight:

-

-

1-2.

1349A/D Functions

1349A/D Displays have been

The

tested at shock and vibration levels

listed above. These are absolute maximum levels and apply to the

1349A/D

only not to the host structure in which

they are installed.

In general, the host structure will act

to amplify shock and vibration applied

to it when transmitting that energy to

1349A/D.

the

Care must be taken that specified

levels of shock and vibration are not

applied to the

1349A/D.

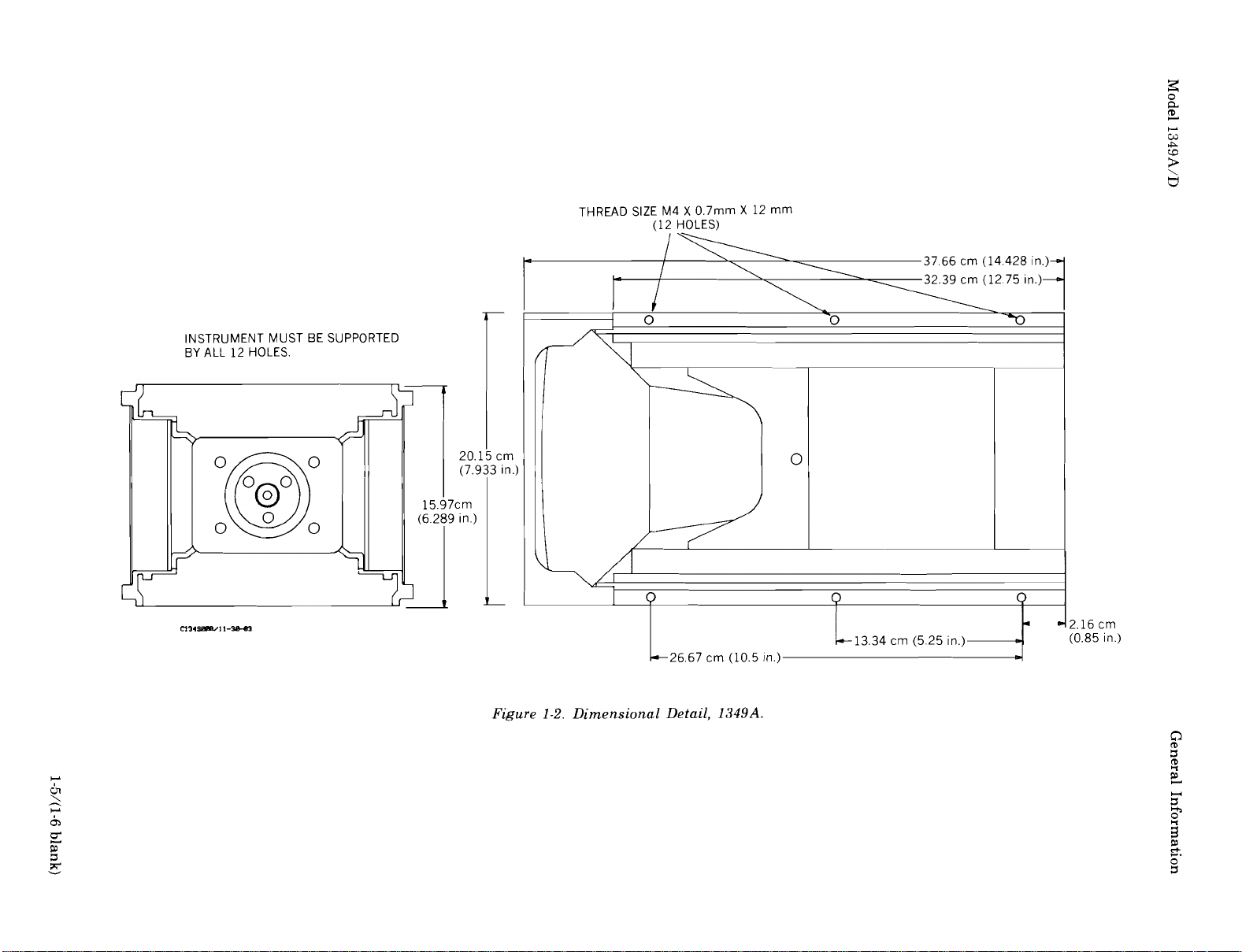

See outline drawing figure 1-2.

Net 6.0 kg (13.2 lbs).

8.64 kg (19.0 lbs).

GRAPHIC FUNCTIONS

Character Generator:

Stroke Characters:

modified full ASCII set. Character Strokes are

stored in ROM. Average character writing time is

16 ps.

4 Programmable Character Sizes:

1.0X = 68 Characters per line,

31 horizontal lines possible.

1.5X = 45 Characters per line,

21 horizontal lines possible.

2.0x = 34 Characters per line,

15 horizontal lines possible.

32 by 20 point resolution; 1.9, 3.4, 5.2 and 6.9 mm per ps.

Velocity:

4 Programmable Writing Speeds:

Vector Drawing time:

ps per vector + (length of

vector/writing speed).

3

Programmable Intensities:

Dim, medium bright-

ness, full brightness (plus Blank or off).

PLOTTING

Plotting Modes:

Beam Control:

Plot absolute and Graph.

The beam may be turned on or off

while plotting.

GRAPH GENERATION

Tick Marks:

X-

and Y-axis tick marks of four

approximately

2.5X = 27 Characters per line, selectable lengths.

12 horizontal lines possible.

Graph Mode:

Allows generation of graphs which

have a constant X-incrememt between points by

NOTE

storing the X-increment once, requiring only new

values for succeeding points.

lx

Character approximately 2mm high.

SELF TEST

4 Programmable Character Orientations:

270' (CCW) relative to horizontal.

VECTORS

Random Vector Plotting:

2048 by 2048 points. alternate test pattern. When the connector is

Line Types:

Solid Line shorted, the alternate pattern may be used to

Solid line with intensified end points verify CRT resolution and allow calibration of

Short dashed line

Long dashed line is installed

Dots performs a memory test.

Addressable resolution internal connector is provided for activation of an

0, 90, 180,

Self Test is invoked by disconnecting the

I/O connector with power applied. The Test Pattern verifies

that the

1349A/D is operational and provides

necessary stimulus for routine calibration. An

focus and astigmatism adjustments. When memory

(1349D), the self test feature also

Page 12

General Information Model 1349A/D

Scans by ArtekMedia © 2007

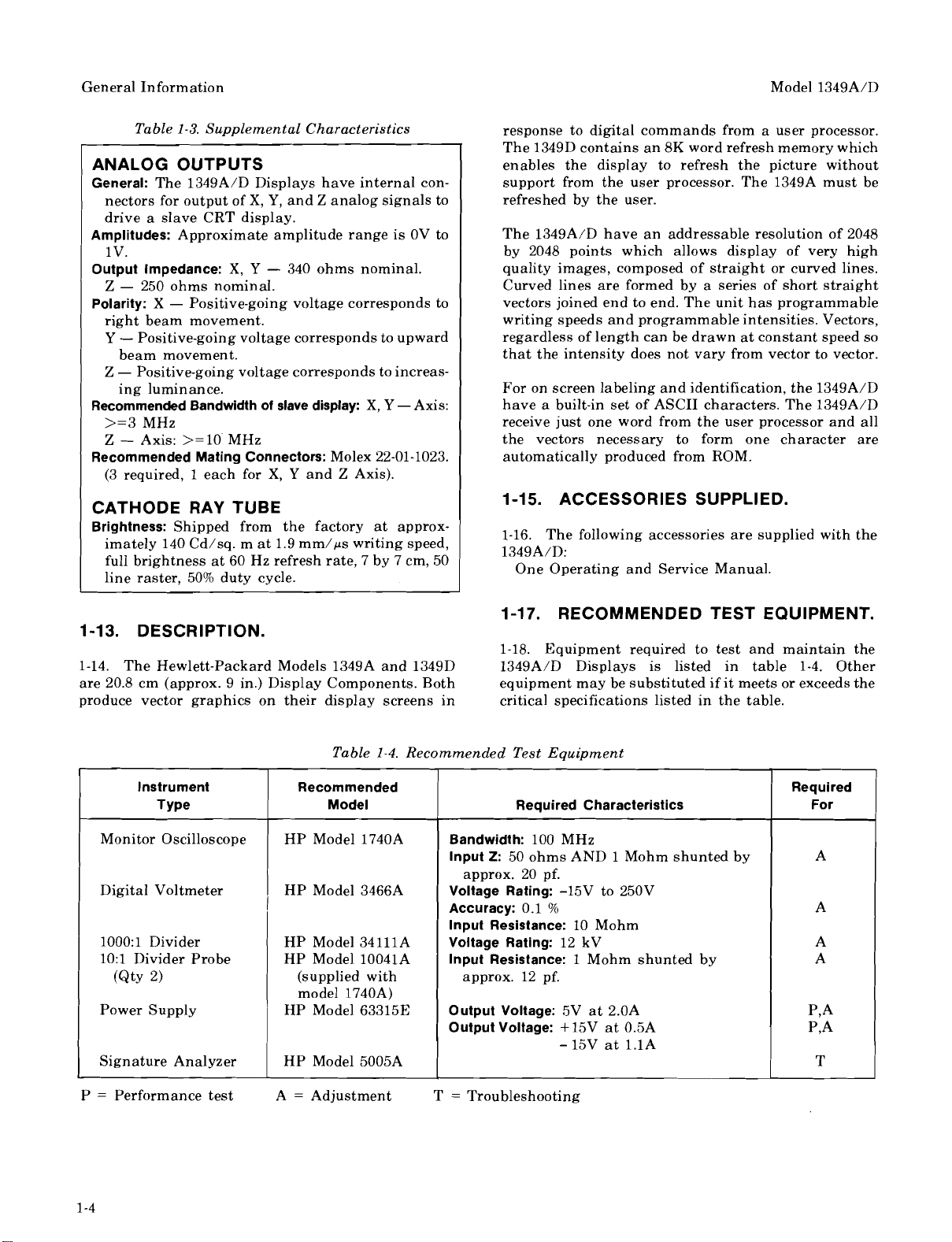

Table

1-3.

Supplemental Characteristics

ANALOG OUTPUTS

General: The 1349A/D Displays have internal con-

nectors for output of

drive a slave CRT display.

Amplitudes: Approximate amplitude range is OV to

1 v.

Output Impedance:

Z

-

250 ohms nominal.

Polarity: X -

right beam movement.

Y

-

Positive-going voltage corresponds to upward

beam movement.

Z

-

Positive-going voltage corresponds to increas-

ing luminance.

Recommended Bandwidth of slave display:

>=3 MHz

Z

-

Axis:

Recommended Mating Connectors: Molex 22-01-1023.

(3 required,

Positive-going voltage corresponds to

>=

1 each for

X,

X,

Y

10 MHz

Y,

and Z analog signals to

-

340 ohms nominal.

X,

Y

-Axis:

X,

Y

and Z Axis).

CATHODE RAY TUBE

Brightness: Shipped from the factory at approx-

imately 140

full brightness at 60 Hz refresh rate, 7 by 7 cm, 50

line raster, 50% duty cycle.

Cd/sq. m at 1.9 mm/ps writing speed,

response to digital commands from a user processor.

1349D contains an 8K word refresh memory which

The

enables the display to refresh the picture without

support from the user processor. The

refreshed by the user.

1349A/D have an addressable resolution of 2048

The

by 2048 points which allows display of very high

quality images, composed of straight or curved lines.

Curved lines are formed by a series of short straight

vectors joined end to end. The unit has programmable

writing speeds and programmable intensities. Vectors,

regardless of length can be drawn at constant speed so

that the intensity does not vary from vector to vector.

For on screen labeling and identification, the

have a built-in set of ASCII characters. The 1349A/D

receive just one word from the user processor and all

the vectors necessary to form one character are

automatically produced from ROM.

1-15.

1-16. The following accessories are supplied with the

1349A/D:

ACCESSORIES SUPPLIED.

One Operating and Service Manual.

1349A must be

1349A/D

1-17.

RECOMMENDED TEST EQUIPMENT.

1-13. DESCRIPTION.

1-18. Equipment required to test and maintain the

1-14. The Hewlett-Packard Models

are 20.8 cm (approx. 9 in.) Display Components. Both equipment may be substituted if it meets or exceeds the

produce vector graphics on their display screens in critical specifications listed in the table.

Instrument

Monitor Oscilloscope

Digital Voltmeter

1000:l Divider

10:l Divider Probe

(Q~Y 2)

Power Supply

1

Signature Analyzer

-

P = Performance test

I

I

HP Model 1740A

HP Model 3466A

HP Model 34111A

HP Model 10041A

HP Model 633153

HP Model

A = Adjustment

1349A and 1349D 1349A/D Displays is listed in table 1-4. Other

Table

1-4.

Recommended Test Equipment

Recommended

Model

(supplied with

model

1740A)

5005A

Required Characteristics

Bandwidth: 100 MHz

lnput

2:

50 ohms AND 1 Mohm shunted by

approx. 20 pf.

Voltage Rating: -15V to 250V

Accuracy: 0.1

lnput Resistance: 10 Mohm

Voltage Rating: 12 kV

lnput Resistance:

approx. 12 pf.

Output Voltage: 5V at 2.OA

Output Voltage:

r

=

Troubleshooting

96

1

Mohm shunted by

+

15V at 0.5A

-

15V at 1.lA

Required

For

Page 13

INSTRUMENT MUST BE SUPPORTED

Scans by ArtekMedia © 2007

12

BY ALL

HOLES.

20.1

(7.9

7c

m

9 in.)

I

3

crn

in.)

THREAD SIZE M4

(12

X

0.7rnrn

HOLES)

X

12

rnrn

Figure

1-2.

Dimensional Detail,

1349A.

Page 14

Model 1349A/D

Scans by ArtekMedia © 2007

Installation

SECTION II

INSTALLATION

2-1. INTRODUCTION.

This section provides installation instructions for

2-2.

the Model

includes information about initial inspection, damage

claims, preparation for use, and storage and shipment.

1349A/D Digital Displays. This section also

2-3. INITIAL INSPECTION.

2-4. Inspect the shipping container for damage. If the

shipping container or cushioning material is damaged,

it should be kept until the contents of the shipment

have been checked for completeness and the instrument

has been checked mechanically and electrically. The

contents of the shipment should be as listed in the

"Accessories Supplied" paragraph in Section I. Procedures for checking electrical performance are given

in Section IV. If the contents are incomplete, if there is

mechanical damage or defect, or if the instrument does

not pass the Performance Tests, notify the nearest

Hewlett-Packard office. If the shipping container is

damaged, or the cushioning material shows signs of

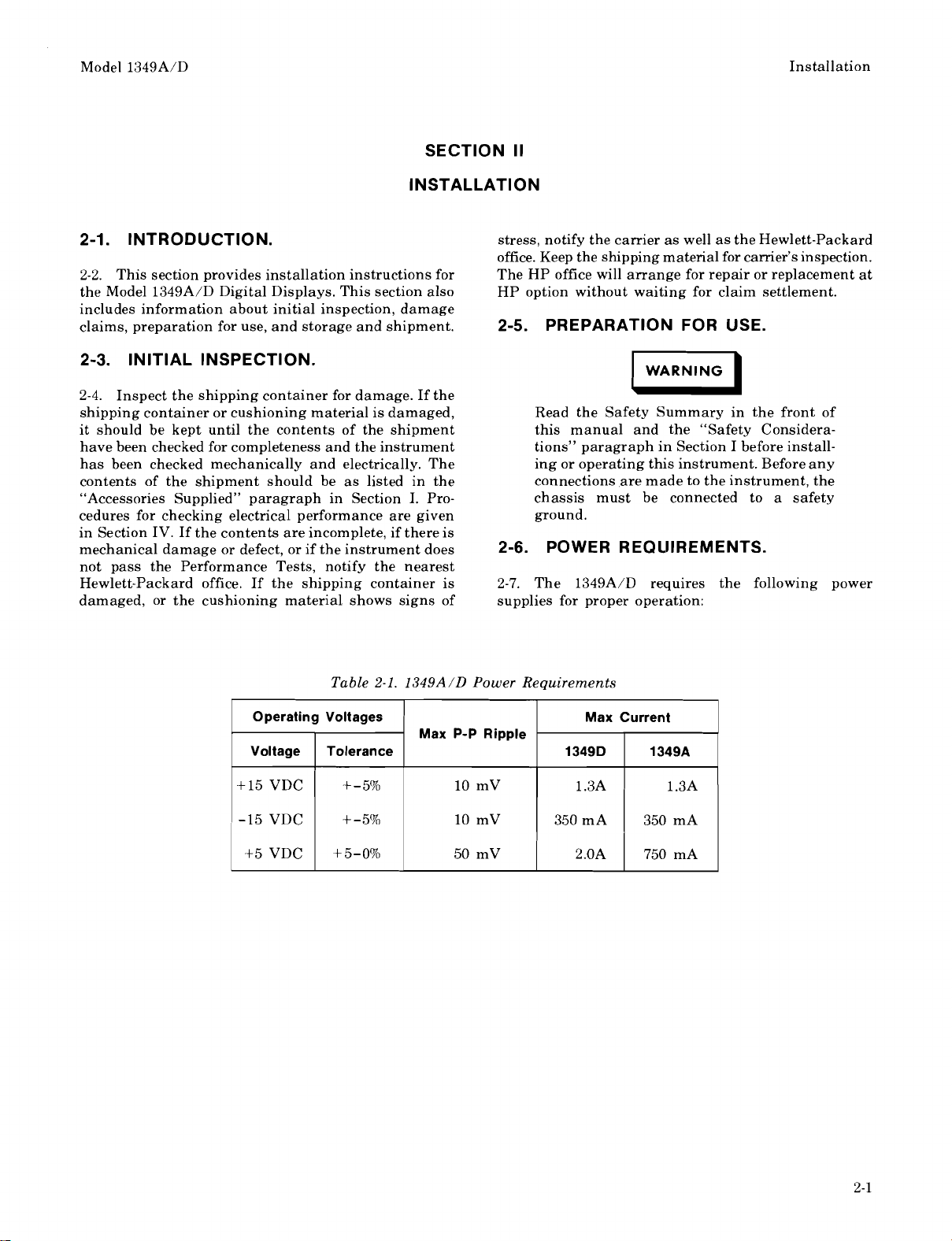

Table

2-1. 1349A/D

stress, notify the carrier as well as the Hewlett-Packard

office. Keep the shipping material for carrier's inspection.

The HP office will arrange for repair or replacement at

HP option without waiting for claim settlement.

2-5. PREPARATION FOR USE.

WARNING

u

Read the Safety Summary in the front of

this manual and the "Safety Considerations" paragraph in Section I before installing or operating this instrument. Before any

connections are made to the instrument, the

chassis must be connected to a safety

ground.

2-6. POWER REQLIIREMENTS.

2-7. The 1349A/D requires the following power

supplies for proper operation:

Power

Requirements

Operating Voltages

Voltage

+15 VDC

-15 VDC

+5 VDC

Tolerance

+5-0%

+-5%

+-5%

Max

P-P

Ripple

10 mV

10 mV

50 mV

Max Current

1349D

1.3A

350 mA

2.OA

1349A

1.3A

350 mA

750 mA

Page 15

Installation Model 1349A/D

Scans by ArtekMedia © 2007

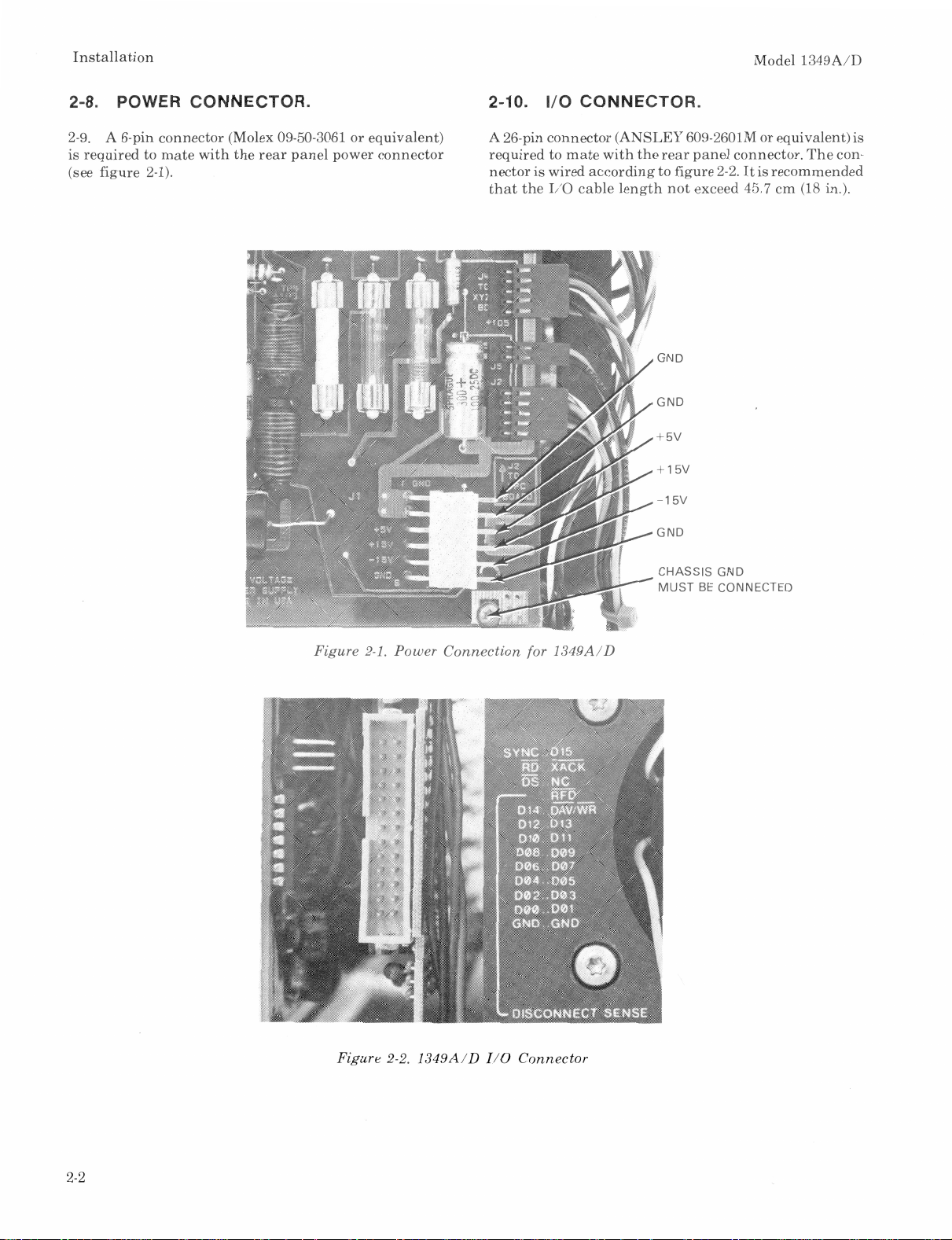

2-8.

2-9.

POWER CONNECTOR.

A 6-pin connector (Molex 09-50-3061 or equivalent)

is required to mate with the rear panel power connector

(see figure 2-1).

2-10.

1/O CONNECTOR.

A 26-pin connector (ANSLEY 609-2601M or equivalent) is

required to mate with the rear panel connector. The connector is wired according to figure 2-2. It is recommended

that the

I/O

cable length not exceed 45.7 cm (18 in.).

Figure 2-1. Power Connection for 1349A/D

SIS

GND

-

BE CONNECTED

Figure 2-2. 1349A/D

Z/O

Connector

Page 16

Model 1349A/D

Scans by ArtekMedia © 2007

Installation

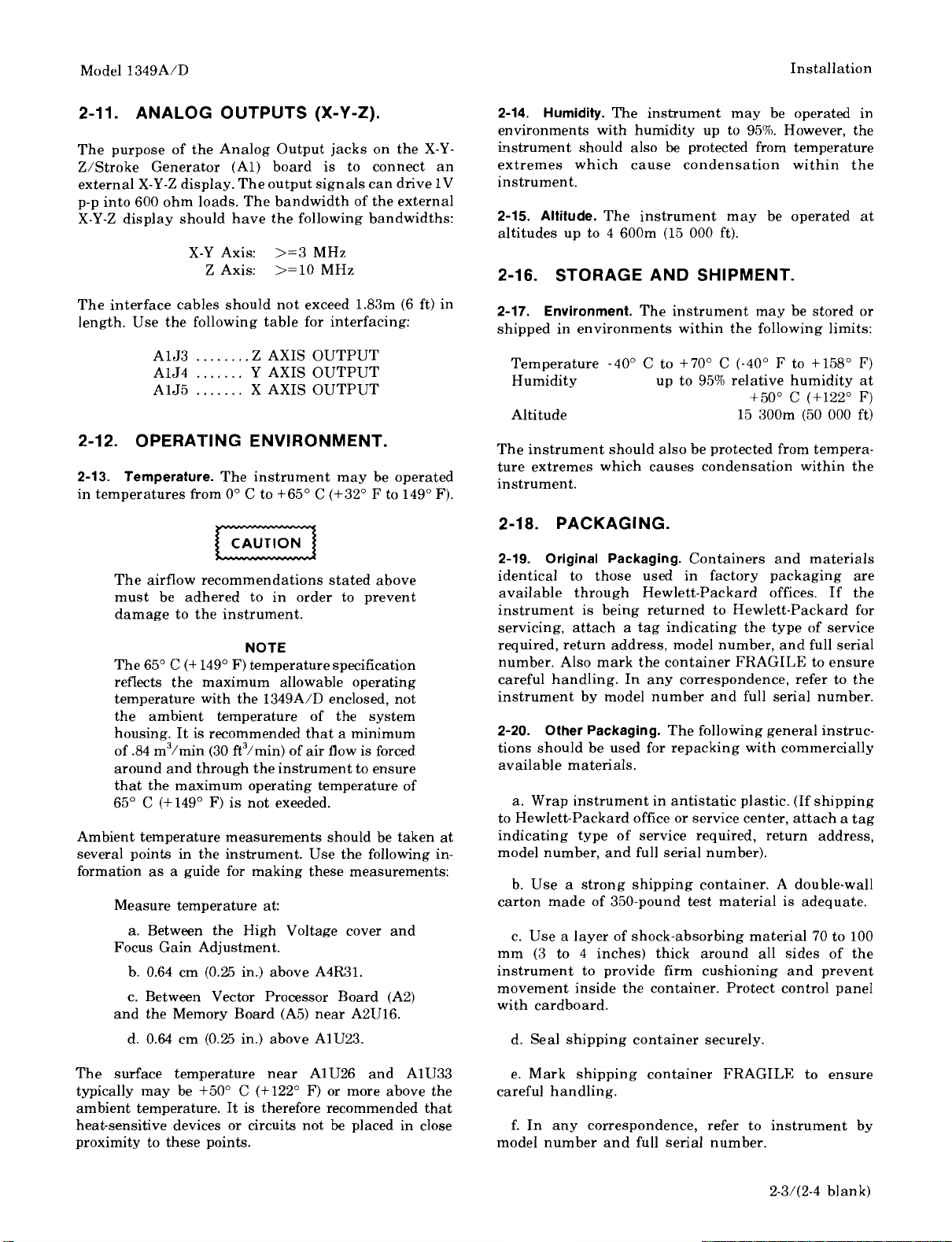

2-1 1. ANALOG OUTPUTS

The purpose of the Analog Output jacks on the X-YZ/Stroke Generator (Al) board is to connect an

external X-Y-Z display. The output signals can drive

p-p into 600 ohm loads. The bandwidth of the external

X-Y-Z display should have the following bandwidths:

X-Y Axis: >=3 MHz

Z Axis: >=lo MHz

The interface cables should not exceed

length. Use the following table for interfacing:

A1J3

A1J4

A1J5

........

.......

.......

Z AXIS OUTPUT

Y AXIS OUTPUT

X AXIS OUTPUT

(X-Y-Z).

1V

1.83m (6 ft) in

2-12. OPERATING ENVIRONMENT.

2-13. Temperature.

in temperatures from

The airflow recommendations stated above

must be adhered to in order to prevent

damage to the instrument.

The 65"

reflects the maximum allowable operating

temperature with the

the ambient temperature of the system

housing. It is recommended that a minimum

of .84

around and through the instrument to ensure

that the maximum operating temperature of

65"

Ambient temperature measurements should be taken at

several points in the instrument. Use the following information as a guide for making these measurements:

Measure temperature at:

Focus Gain Adjustment.

and the Memory Board (A5) near

C

m3/min (30 ft3/min) of air flow is forced

C

(+14g0 F) is not exeeded.

a. Between the High Voltage cover and

b. 0.64 cm (0.25 in.) above

c. Between Vector Processor Board (A2)

d. 0.64 cm (0.25 in.) above AlU23.

The instrument may be operated

0" C to f65" C (+32" F to 149" F).

NOTE

(+

149" F) temperature specification

1349A/D enclosed, not

A4R31.

A2U16.

2-14. Humidity.

environments with humidity up to

instrument should also

extremes which cause condensation within the

instrument.

2-15. Altitude.

altitudes up to 4 600m (15 000 ft).

The instrument may be operated in

95%. However, the

be

protected from temperature

The instrument may be operated at

2-16. STORAGE AND SHIPMENT.

2-17. Environment.

shipped in environments within the following limits:

Temperature

Humidity up to

Altitude

The instrument should also be protected from temperature extremes which causes condensation within the

instrument.

The instrument may be stored or

-40" C to $70" C (-40" F to +158" F)

95g1 relative humidity at

+50° C (+122" F)

15 300m (50 000 ft)

2-18. PACKAGING.

2-19. Original Packaging.

identical to those used in factory packaging are

available through Hewlett-Packard offices. If the

instrument is being returned to Hewlett-Packard for

servicing, attach a tag indicating the type of service

required, return address, model number, and full serial

number. Also mark the container FRAGILE to ensure

careful handling. In any correspondence, refer to the

instrument by model number and full serial number.

2-20. Other Packaging.

tions should be used for repacking with commercially

available materials.

a. Wrap instrument in antistatic plastic. (If shipping

to Hewlett-Packard office or service center, attach a tag

indicating type of service required, return address,

model number, and full serial number).

b. Use a strong shipping container. A double-wall

carton made of 350-pound test material is adequate.

c. Use a layer of shock-absorbing material 70 to 100

mm (3 to

instrument to provide firm cushioning and prevent

movement inside the container. Protect control panel

with cardboard.

d. Seal shipping container securely.

4

inches) thick around all sides of the

Containers and materials

The following general instruc-

The surface temperature near AlU26 and AlU33

typically may be +50° C (+12Z0 F) or more above the

ambient temperature. It is therefore recommended that

heat-sensitive devices or circuits not

proximity to these points.

be

placed in close

e. Mark shipping container FRAGILE to ensure

careful handling.

f. In any correspondence, refer to instrument by

model number and full serial number.

2-3/(2-4 blank)

Page 17

Model 1349A/D

Scans by ArtekMedia © 2007

Operation

SECTION

OPERATION

3-1. INTRODUCTION.

3-2. The purpose of this section is to give detailed

information concerning the operation and programming

1349A/D. It includes a list of the programming

of the

instructions and a section containing a brief

explanation of "bit programming". The end of this

section contains several programming examples.

WARNING

SHOCK HAZARD

Before operating the instrument, connect the

chassis of the display to a safety ground in

the system.

3-3. SIGNAL LINE DEFINITIONS.

DO-Dl5

DO through Dl4 are the vector data lines (TTL

positive logic).

instruction. When

recognized as a memory command. When

"0" then all the input data forms the picture.

DISCONNECT SENSE

This line must be grounded to the display chassis

when the data lines are active. The internal

Performance Verification pattern will be displayed

if the 26-pin connector is disconnected.

SYNC

External display refresh synchronization signal

line. The line provides an external refresh clock

when external sync mode has been selected via a

jumper wire on the Vector Memory board.

LXACK

Acknowledge signal line. When low, this line

indicates that the Vector Memory has completed

the Read or Write operation requested by the user

processor.

Dl5 is used as a Vector Memory

Dl5 is a"1" then theinput data is

Dl5 is a

Ill

LDS

Device Select signalline. When low this line enables

the Vector Memory to communicate with the user

processor

LWR

Memory Write signal line. When low, this line

indicates that the 16-bit Data Bus contents

written into either the current Vector Memory

location

(D15=1).

LRD

Memory Read signal line. When low, this line

indicates that the contents of the current Vector

Memory location (as specified by the User Address

Pointer) are to be placed on the 16-bit Data Bus for

transmission back to the user processor.

Whenever a Vector Memory location has

been either written into or read from by the

user processor, the User Address Pointer

auto-increments to the next Vector Memory

location (address).

3-4. HANDSHAKE TIMING FOR 1349D.

The TTL digital interface to the Vector Memory (1349D)

is compatible with most microprocessor peripheral

interface adaptor chips (the Motorola

Vector Memory digital interface consists of:

1. A 16-bit bidirectional Data Bus.

2. A Read Signal line LRD (input).

3. A Write signal line LWR (input).

4. A Device Select signal line

5. An Acknowledge signal line LXACK (output).

6. An External display Synchronization signal line

SYNC (input use is optional).

(write/read).

areto be

(D15=0) or into the User Address Pointer

NOTE

63

6821).

LDS (input).

Page 18

Operation

Scans by ArtekMedia © 2007

Model

1349A/D

A

Tdss

READ

COMMFWD

4

TIMING

Tdsh

4

Tdh

MI349001

Read Command Timing

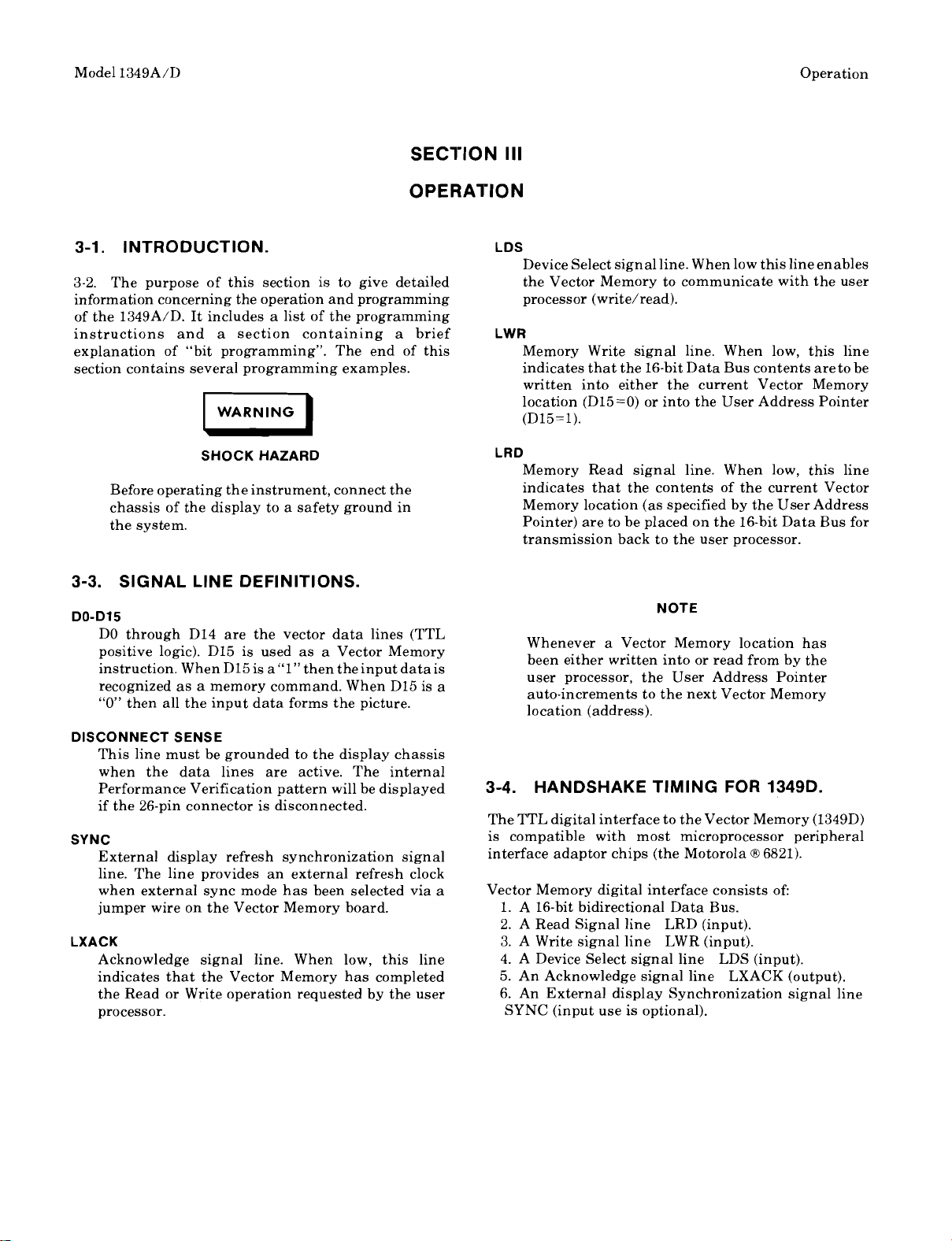

Tdss

-

Device Select Setup Time

Tdsh - Device Select Hold Time

-

Trd

Trdp - Read Precharge Time

Tac - Read Access Time

Tdh - Read Data Hold Time

Tah - Acknowledge Hold Time

Tack - Acknowledge Delay Time

Read Pulse Time (ACK not used) 495 nsec min

(ACK used) 760 nsec min

..........

............

..........

Figure

3-1.

Read Command Timing

.......

........

760 nsec max

........

130 nsec max

455 nsec min

.....

855 nsec max

0 nsec min

0 nsec min

25

nsec min

30 nsec min

40 nsec min

Page 19

Model 1349A/D

Scans by ArtekMedia © 2007

Operation

4

Tdss

HRITE

1-

COMmWD

TCY

TIMING

4

Tdsh

4

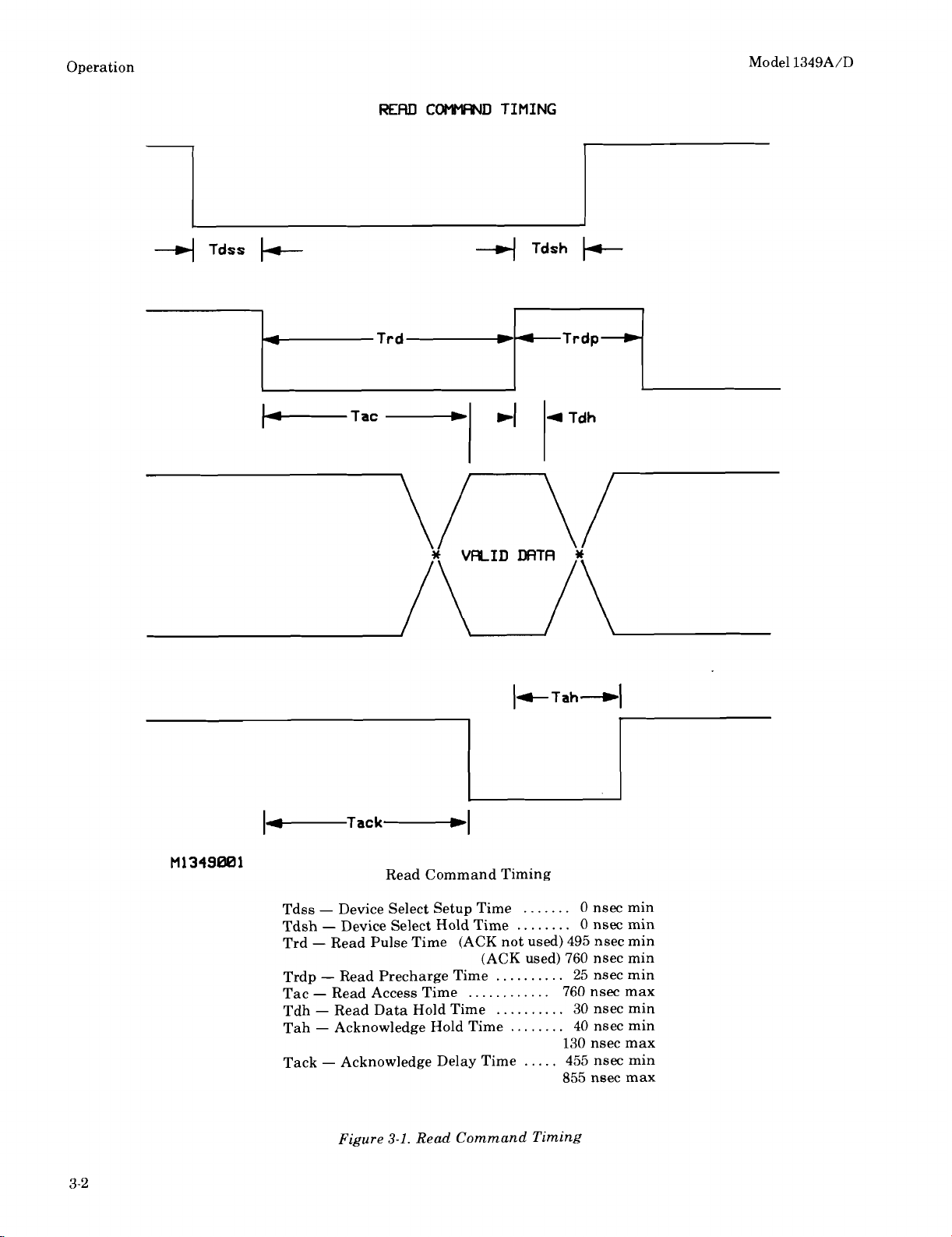

Write Command Timing

Tdss

-

Device Select Setup Time

Tdsh

-

Device Select Hold Time

-

Tcy

Twe

Tds

Tdh - Data In Hold Time 0 nsec min

Tack

Tah

Write Cycle Time

-

Write Command Active Time

-

Data In Setup Time

-

acknowledge Delay Time

-

Acknowledge Hold Time..

Figure

3-2.

Write Command Timing

..............

........

........

820 nsec min

. .

795 nsec rnin

.............

..............

.....

455 nsec min

855 nsec max

.......

130 nsec max

0 nsec min

0 nsec min

0 nsec max

40 nsec min

Page 20

Operation

Scans by ArtekMedia © 2007

P/O

RS

(MEMORY

BD.

1349D)

SWITCHES SET

FOR

INT SYNC

1349A/D

Model

SWITCHES SET

FOR

EXT

SYNC

Figure

3-3.

Refresh Mode Selection

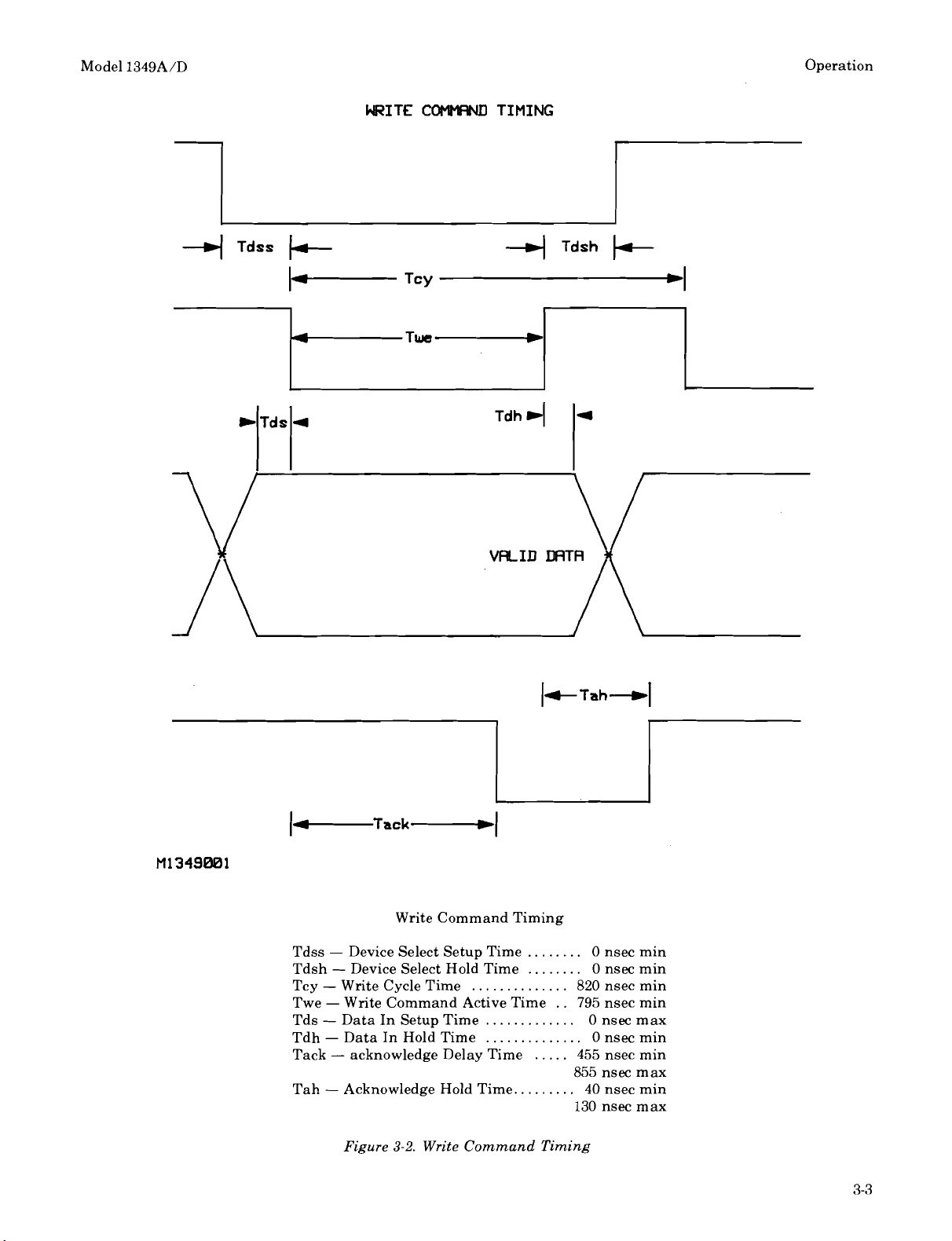

3-5. PICTURE REFRESH REQUIREMENTS

1349D.

FOR

Each time that the picture is redrawn by the 1349D, the

display is refreshed. This prevents the phosphor light

output from expiring. The refresh sync signal may be

provided by either the internal refresh circuit, or an

external source. To select the required mode of operation

for refresh mode, set the

Memory Board (A5) as shown in figure 3-3.

INTERNAL SYNC. When the jumper is

Internal position, an on-board oscillator

provides sync pulses at approximately a

user processor can send all picture producing data to the

Vector Memory at one time. The Vector Memory will

then continuously refresh the display screen by

redrawing the picture at regular intervals. This reduces

overhead time for the user processor.

EXTERNAL

supplied from an external source in the user system via

SYNC.

Int/Ext switch (A5S1) on the

ir, the

(A5U1)

60

Hz rate. The

Sync

pulses (?TL)

must

be

the SYNC input signal line. This signal is useful when

the display is used in electromagnetic fields which can

cause the picture to "swim". Synchronizing the display

with the interfering signal can stabilize the picture.

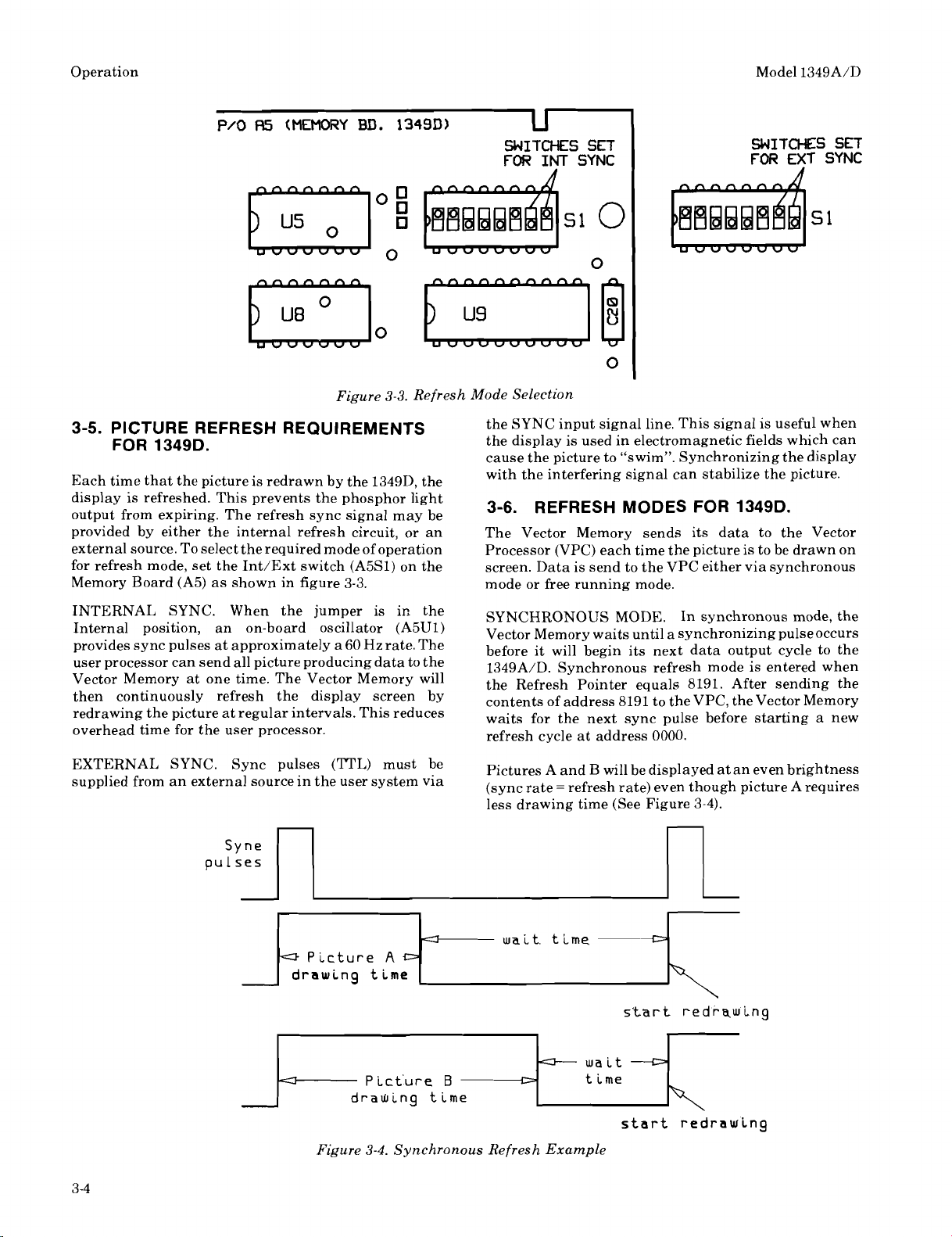

3-6. REFRESH MODES FOR 1349D.

The Vector Memory sends its data to the Vector

Processor (VPC) each time the picture is to be drawn on

screen. Data is send to the VPC either via synchronous

mode or free running mode.

SYNCHRONOUS MODE.

Vector Memory waits until a synchronizing pulseoccurs

before it will begin its next data output cycle to the

1349A/D. Synchronous refresh mode is entered when

the Refresh Pointer equals 8191. After sending the

contents of address 8191 to the VPC, the Vector Memory

waits for the next sync pulse before starting a new

refresh cycle at address

Pictures A and B will be displayed atan even brightness

=

(sync rate

less drawing time (See Figure

refresh rate) even though picture A requires

In synchronous mode, the

0000.

3-4).

-

-

5

Picture

drawing time

4

Figure

Pict'ure

drauing time

3-4.

4

ruait. time

A

B

LS

Synchronous Refresh Example

-0

rua

it

time

start

redrsrulng

start redrawing

\

Page 21

Model 1349A/D

Scans by ArtekMedia © 2007

Operation

I=-

1

-a

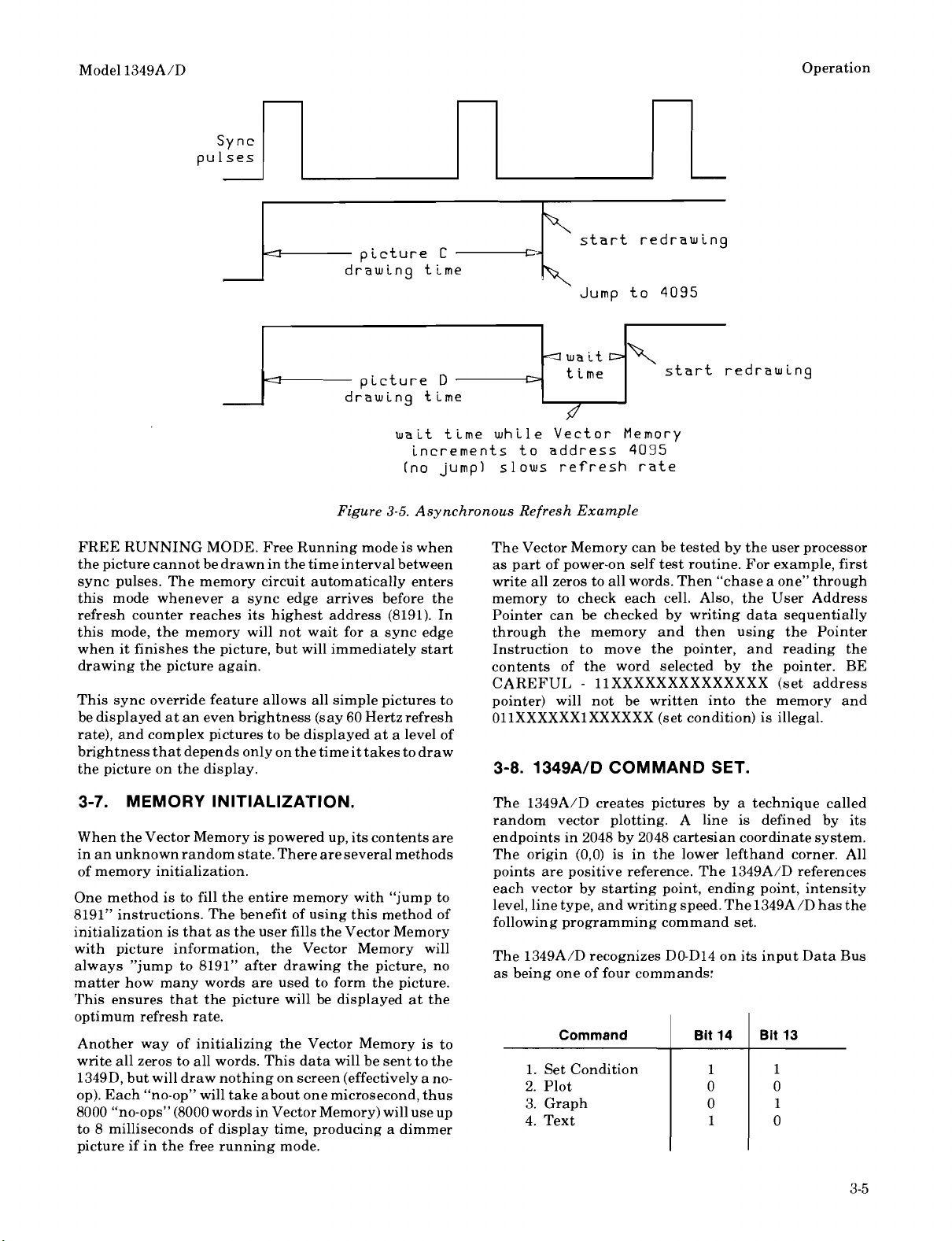

FREE RUNNING MODE. Free Running mode is when

the picture cannot be drawn in the time interval between

sync pulses. The memory circuit automatically enters

this mode whenever a sync edge arrives before the

refresh counter reaches its highest address (8191). In

this mode, the memory will not wait for a sync edge

when it finishes the picture, but will immediately start

drawing the picture again.

This sync override feature allows all simple pictures to

be displayed at an even brightness (say 60 Hertzrefresh

rate), and complex pictures to be displayed at a level of

brightness that depends only on the time it takes to draw

the picture on the display.

picture

drawing time

picture

drawing time

Figure

3-5.

C

D

uait time while Vector Memory

increments to address 4095

(no

jump1 slows refresh rate

Asynchronous Refresh Example

start redrawing

\

Jump to 4095

await

time

-\

start redrawing

P

The Vector Memory can be tested by the user processor

as part of power-on self test routine. For example, first

write all zeros to all words. Then "chase a one" through

memory to check each cell. Also, the User Address

Pointer can be checked by writing data sequentially

through the memory and then using the Pointer

Instruction to move the pointer, and reading the

contents of the word selected by the pointer. BE

CAREFUL

pointer) will not be written into the memory and

OllXXXXXXlXXXXXX (set condition) is illegal.

3-8. 1349AlD COMMAND SET.

-

1lXXXXXXXXXXXXXX (set address

3-7. MEMORY

When the Vector Memory is powered up, its contents are endpoints in 2048 by 2048 cartesian coordinate system.

in an unknown random state. There are several methods The origin

of memory initialization.

One method is to fill the entire memory with ''jump to

8191" instructions. The benefit of using this method of

initialization is that as the user fills the Vector Memorv

with picture information, the Vector Memory will

always "jump to 8191" after drawing the picture, no

matter how many words are used to form the picture.

This ensures that the picture will be displayed at the

optimum refresh rate.

Another way of initializing the Vector Memory is to

write all zeros to all words. This data will be sent to the

1349D, but will draw nothing on screen (effectively a noop). Each "no-op" will take about one microsecond, thus

8000 "no-ops" (8000 words in Vector Memory) will use up

to 8 milliseconds of display time, producing a dimmer

picture if in the free running mode.

INITIALIZA'rION.

The 1349A/D creates pictures by a technique called

random vector plotting. A line is defined by its

(0,O) is in the lower lefthand corner. All

points are positive reference. The

each vector by starting point, ending point, intensity

level,

line

type,

and

writing

following

The

as being one of four commands:

programming

1349A/D recognizes DO-Dl4 on its input Data Bus

Command

1. Set Condition

2. Plot

3. Graph

4. Text

speed,

command

4

1349A/D references

The

1349A/D

set.

Bit

14

Bit

13

has

the

Page 22

Operation

Scans by ArtekMedia © 2007

Model

1349A/D

SET CONDITION.

The Set Condition command controls theintensity level,

the line type, and the writing speed of vectors drawn on

the CRT.

B14 = 1, B13 - 1: SET CONDITION COMMAND.

With both MSBs (Most Significant Bits) set to one, the

1349A/D is commanded to draw all following vectors

according to the configuration commanded until

changed by subsequent condition command.

NOTE

A

one (1) = TTL high; a zero (0) = TTL low.

X=

DON'T CARE

B6 MUST be zero.

B14=1, B13-1 : Set display configuration according to choices

specified for intensity, line type, and writing speed.

1

11 1 10

1

intensity

I

When the line type "solid line with intensified endpoints"

is selected, the intensity of the endpoints may vary due

to optical illusion. As lines are linked together the

intensity of the point where one line ends and the next

line starts is a function of the angle separating the lines.

The closer the angle is to 180 degrees, the brighter the

point. The closer the angle is to zero degrees (absolute),

the dimmer the point.

PLOT COMMAND (B14

With both MSBs set to zero, the

to move the display beam to a specific X-Y location each

time that a Y coordinate is received. The beam position

may be moved with the beam either turned off or turned

on. The Plot command will draw all vectors according to

the display configuration established by the last Set

Condition command received by the

time that a Y coordinate is received, the pen status

(beam on or off) for the beam movement is established.

Also, the X-Y location to be moved to is formed from the

last X coordinate received and the current Y coordinate.

For example, to draw a vertical line send the

(1) Plot Command - X value; (2) Plot Command - Y1 value

(with beam off); (3) Plot Command

on).

=

0.

B13 = 0).

1349A/D is commanded

1349A/D. Each

1349A/D:

-

Y2 value (with beam

-

L2

0

0

0

0

1

W1

1

1

0

0

L1

0

0

1

1

0

Half Brightness

Full Brightness

Line Type

LO

Solid Line

0

Intensify Endpoints (solid line)

1

Long Dashes

0

1

Short Dashes

1

Dots on endpoints

WO

Writing Speed

0.19 cm per microsecond

1

0

0.34 cm per microsecond

0.52 cm per microsecond

1

0

0.69 cm per microsecond

DATA

MSB LSB

B14=0, B13=0 : Plot Command.

XY

0 = X coordinate (0-2047) as specified by DO - D10.

1

=

Y coordinate (0-2047) as specified by DO - D10.

PC (Pen Control Bit B11)

0 = Move (draw vector with pen up).

1

=,Draw (draw vector with pen down).

Page 23

Model 1349A/D

Scans by ArtekMedia © 2007

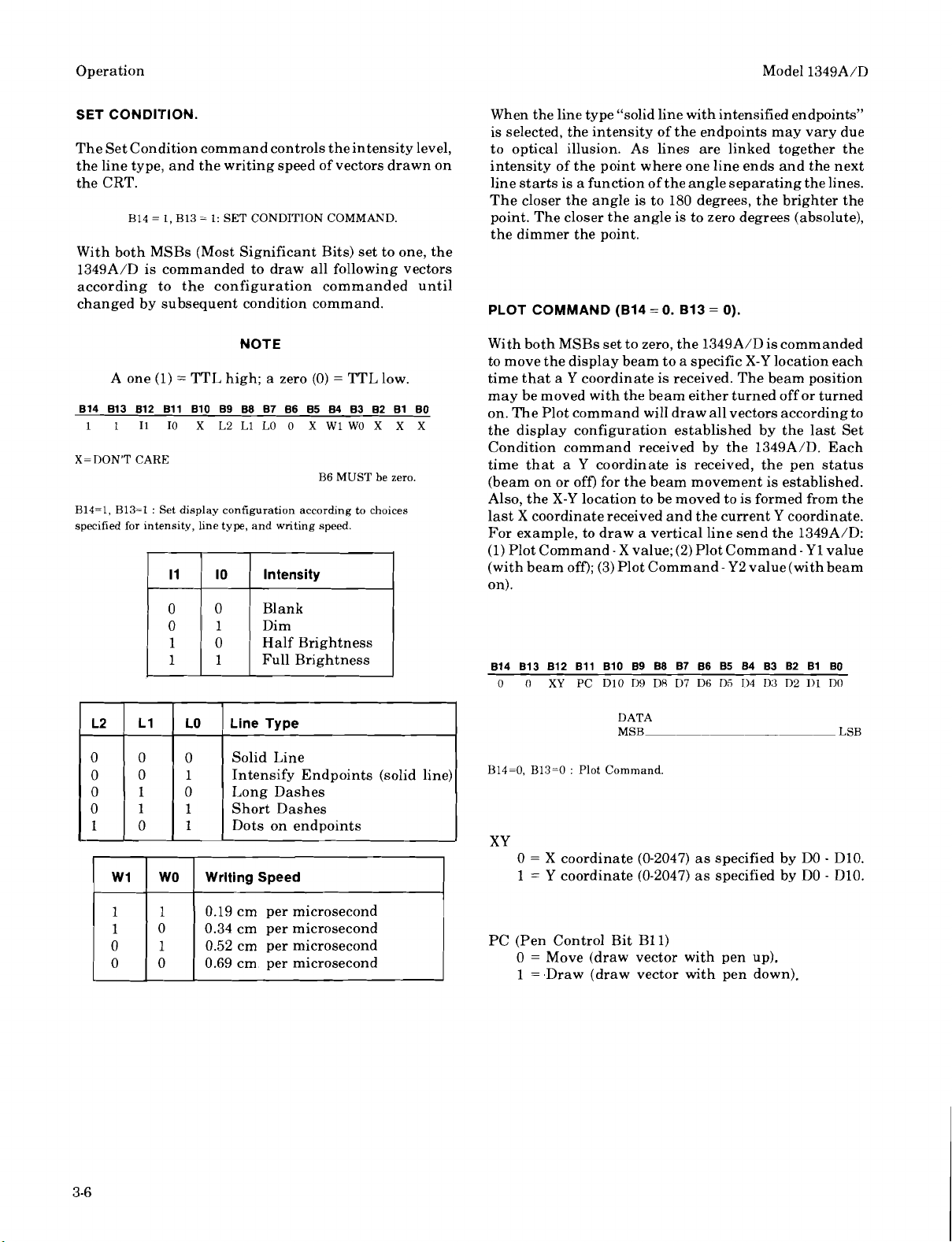

TOP

CRT

SCREEN

Operation

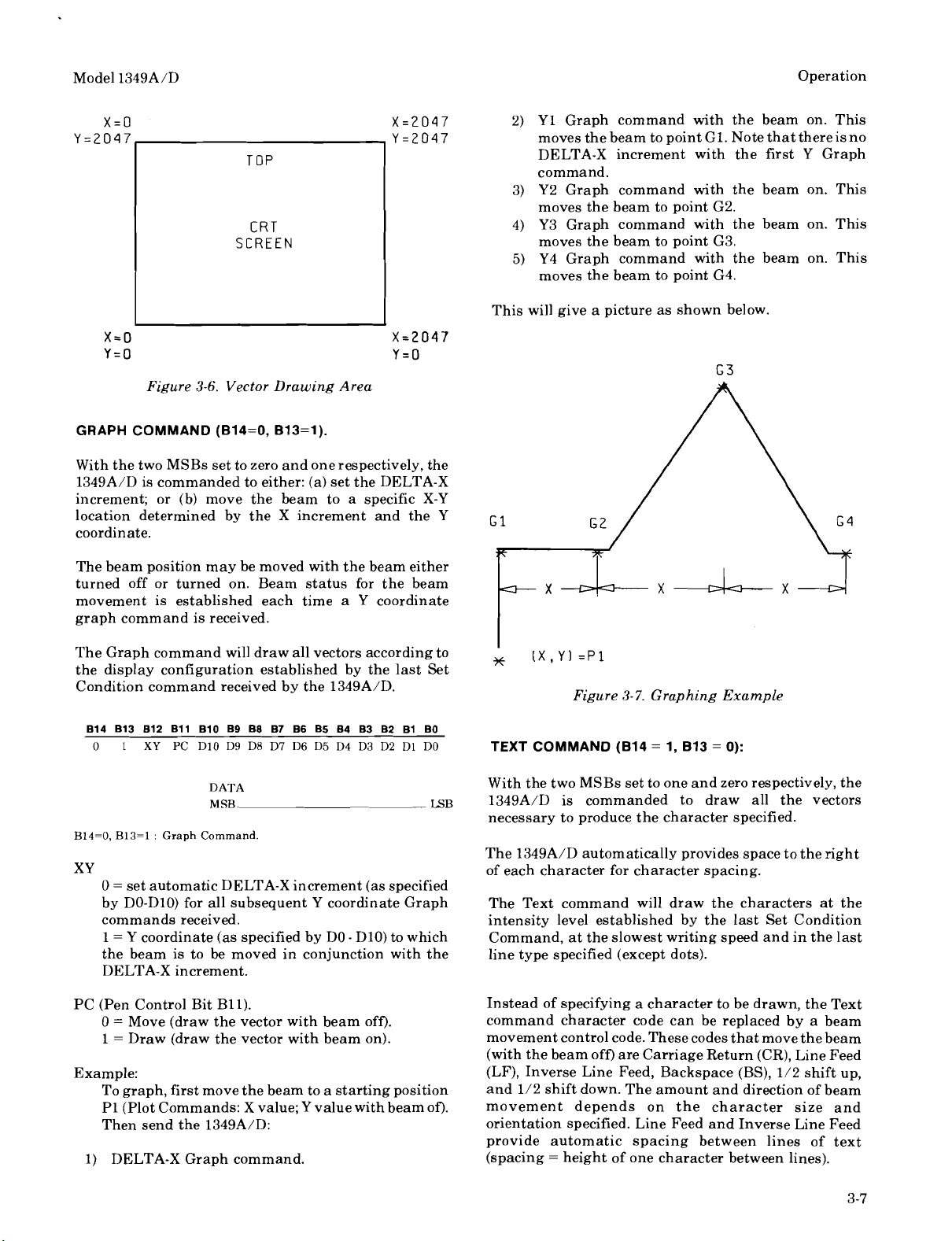

2) Y1 Graph command with the beam on. This

moves the beam to point

GI. Note that thereis no

DELTA-X increment with the first Y Graph

command.

Y2

3)

Graph command with the beam on. This

moves the beam to point G2.

Y3 Graph command with the beam on. This

4)

moves the beam to point G3.

5)

Y4 Graph command with the beam on. This

moves the beam to point G4.

This will give a picture as shown below.

Figure

GRAPH COMMAND (B14=0, B13=1).

3-6.

Vector Drawing Area

With the two MSBs set to zero and onerespectively, the

1349A/D is commanded to either: (a) set the DELTA-X

increment; or (b) move the beam to a specific X-Y

location determined by the X increment and the Y

coordinate.

The beam position may be moved with the beam either

turned off or turned on. Beam status for the beam

movement is established each time a

Y

coordinate

graph command is received.

The Graph command will draw all vectors according to

the display configuration established by the last Set

Condition command received by the

DATA

MSB

B14=0, B13=1

:

Graph Command

1349A/D.

LSB

XY

0 = set automatic DELTA-X increment (as specified

by DO-DIO) for all subsequent Y coordinate Graph

commands received.

1

=

Y

coordinate (as specified by DO - D10) to which

the beam is to be moved in conjunction with the

DELTA-X increment.

*

IX,Yl

=P1

Figure

TEXT

COMMAND (814 = 1, 813

3-7.

Graphing Example

=

0):

With the two MSBs set to one and zero respectively, the

1349A/D is commanded to draw all the vectors

necessary to produce the character specified.

The

1349A/D automatically provides space to the right

of each character for character spacing.

The Text command will draw the characters at the

intensity level established by the last Set Condition

Command, at the slowest writing speed and in the last

line type specified (except dots).

PC (Pen Control Bit

0 = Move (draw the vector with beam off).

1

=

Draw (draw the vector with beam on).

Example:

To graph, first move the beam to a starting position

P1 (Plot Commands: X value; Y value with beam of).

Then send the

1) DELTA-X Graph command.

Bll).

1349A/D:

Instead of specifying a character to be drawn, the Text

command character code can be replaced by a beam

movement control code. These codes that move the beam

(with the beam off) are Carriage Return (CR), Line Feed

(LF), Inverse Line Feed, Backspace (BS),

and

1/2 shift down. The amount and direction of beam

1/2 shift up,

movement depends on the character size and

orientation specified. Line Feed and Inverse Line Feed

provide automatic spacing between lines of text

(spacing

=

height of one character between lines).

Page 24

Operation Mode1 1349A/D

Scans by ArtekMedia © 2007

The starting point for non-rotated characters is the

lower left-hand corner of the character area. Forrotated

characters the entire character area is rotated the

specified number of degrees (90, 180, or 270) in a

counterclockwise direction around the starting point.

When the

1349A/D has finished drawing a character it

automatically advances the beam to the starting point

for the next character. In this way the

1349A/D

functions much like a typewriter when presenting text.

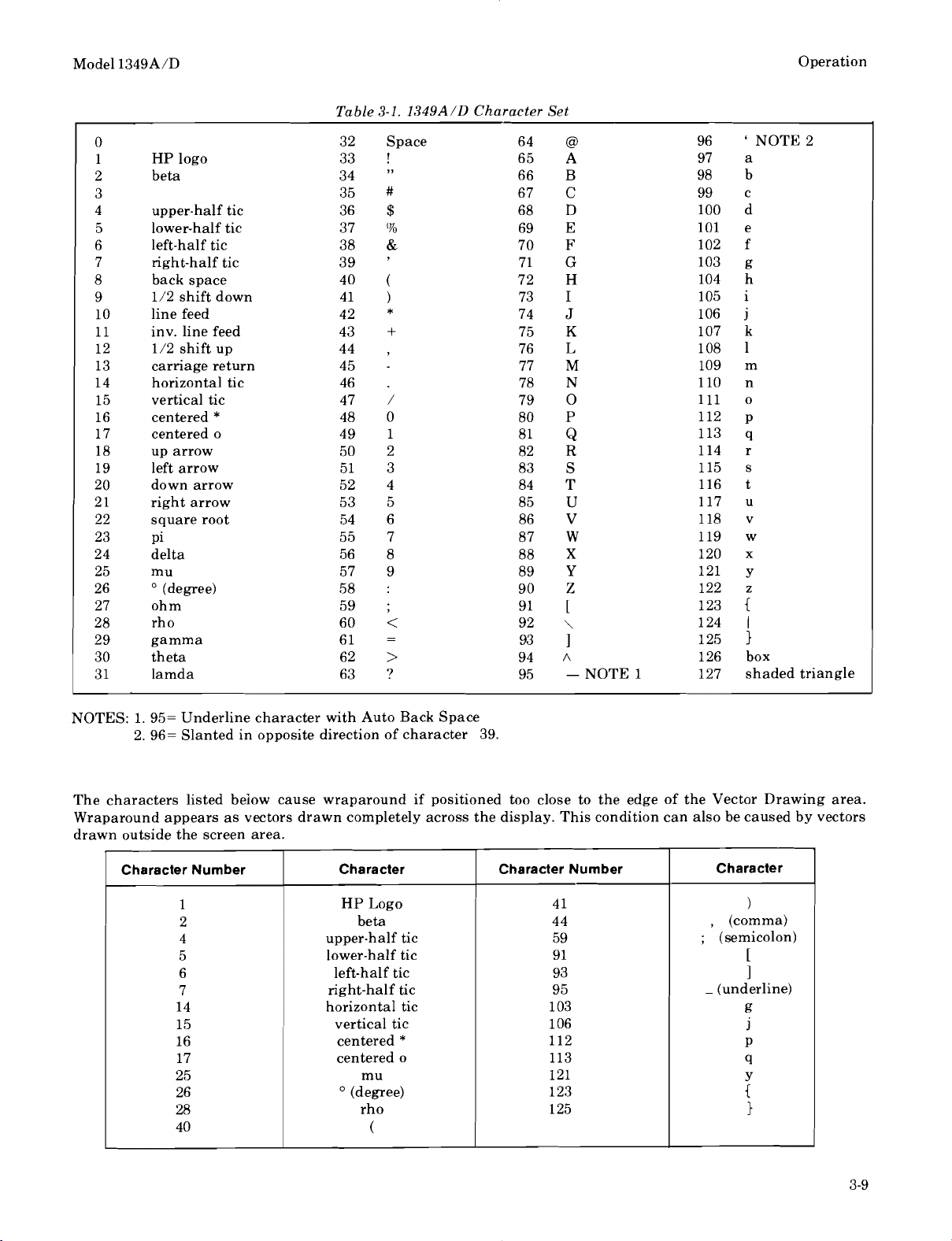

The modified ASCII character set for the

1349A/D is

shown in table 3-1.

814 813 812 Bll B10 B9 BE 87 B6 B5 84 83 82 B1 BO

1 0 S1 SO R1 RO ES D7

CHARACTER

MSB LSB

B14=1. B13=0

:

commands that the

(specified

by

DO - D7)

D6

D5 D4 D3 D2 Dl DO

1349A

display a text character

ES (Establish size of character Bit B8).

0 = use previous size and rotation.

1

=

establish new size and rotation according to

S1-SO and

R1-RO.

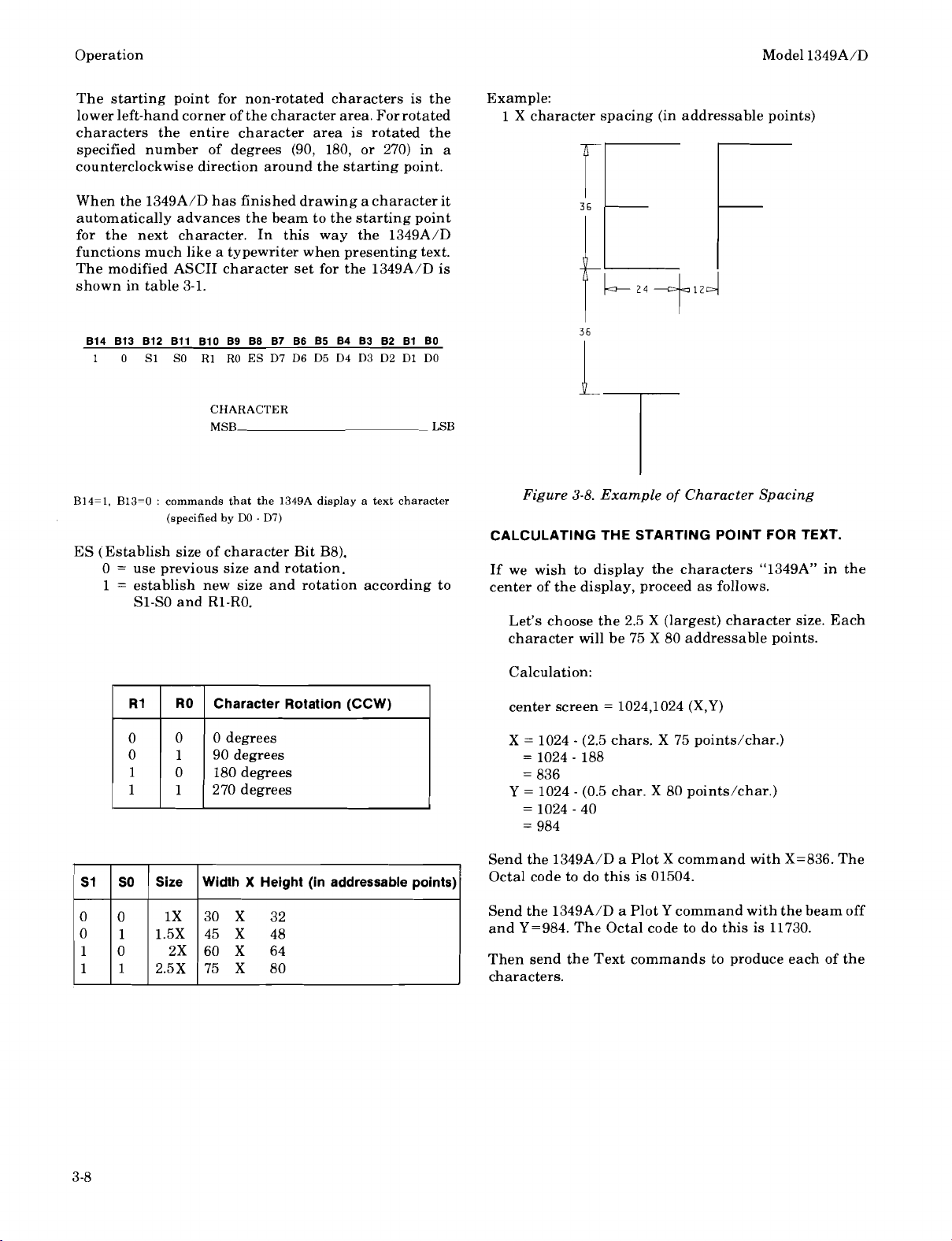

Example:

1

X character spacing (in addressable points)

Figure

CALCULATING THE STARTING POINT FOR TEXT.

If we wish to display the characters

center of

3-8.

Example

of

Character Spacing

"1349A" in the

the display, proceed as follows.

Let's choose the 2.5 X (largest) character size. Each

character will be 75 X 80 addressable points.

R1

0

0

1

1

1

S1

0

0

Size

SO

0

1.5X

1

10

1

2.5X

1

RO

Character Rotation (CCW)

0 degrees

0

90 degrees

1

180 degrees

0

270 degrees

1

Width X Height (in addressable points)

1X

30

X

32

45

X 48

2X

60

X

64

75 X 80

Calculation:

center screen

=

1024,1024 (X,Y)

X = 1024 - (2.5 chars. X 75 points/char.)

=

1024 - 188

=

836

Y

=

1024 - (0.5 char. X 80 points/char.)

=

1024 - 40

=

984

Send the 1349A/D a Plot X command with X=836. The

Octal code to do this is 01504.

Send the

and

1349A/D a Plot Y command with the beam off

Y=984. The Octal code to do this is 11730.

Then send the Text commands to produce each of the

characters.

Page 25

Model 1349A/D Operation

Scans by ArtekMedia © 2007

Table

HP logo

beta

upper-half tic

lower-half tic

left-half tic

right-half tic

back space

1/2 shift down

line feed

inv. line feed

1/2 shift up

carriage return

horizontal tic

vertical tic

centered

*

centered o

up arrow

left arrow

down arrow

right arrow

square root

pi

delta

mu

O (degree)

ohm

rho

gamma

theta

lamda

3-1. 1349A/D

32 Space

33

34

35 #

36

37

38

39

40

42

43

44

45

49

55 7

58

60

61

!

"

$

'%

&

'

(

41

*

+

,

-

46 .

47

48 0

50 2

51 3

52 4

53 5

54 6

56 8

57 9

:

59

;

<

=

62

>

63

?

/

1

Character Set

@

A

B

C

D

E

F

G

H

I

J

K

L

M

N

0

P

Q

R

S

T

u

v

W

X

Y

z

[

\

I

A

-

NOTE 1

'

NOTE 2

a

b

C

d

e

f

g

h

i

j

k

1

m

n

0

P

q

r

s

t

U

v

W

X

Y

z

E

box

shaded triangle

NOTES:

1. 95= Underline character with Auto Back Space

2. 96= Slanted in opposite direction of character

39.

The characters listed below cause wraparound if positioned too close to the edge of the Vector Drawing area.

Wraparound appears as vectors drawn completely across the display. This condition can also be caused by vectors

drawn

outside the screen area.

Character Number

1

2

4

5

6

7

14

15

16

17

25

26

28

40

Character

HP Logo

beta

upper-half tic

lower-half tic

left-half tic

right-half tic

horizontal tic

vertical tic

centered

*

centered o

mu

(degree)

rho

(

Character Number

41

4 4

59

91

93

95

103

106

112

113

121

123

125

Character

1

,

(comma)

;

(semicolon)

[

1

-

(underline)

g

j

P

q

f

I

Page 26

Operation Mode1 1349A/D

Scans by ArtekMedia © 2007

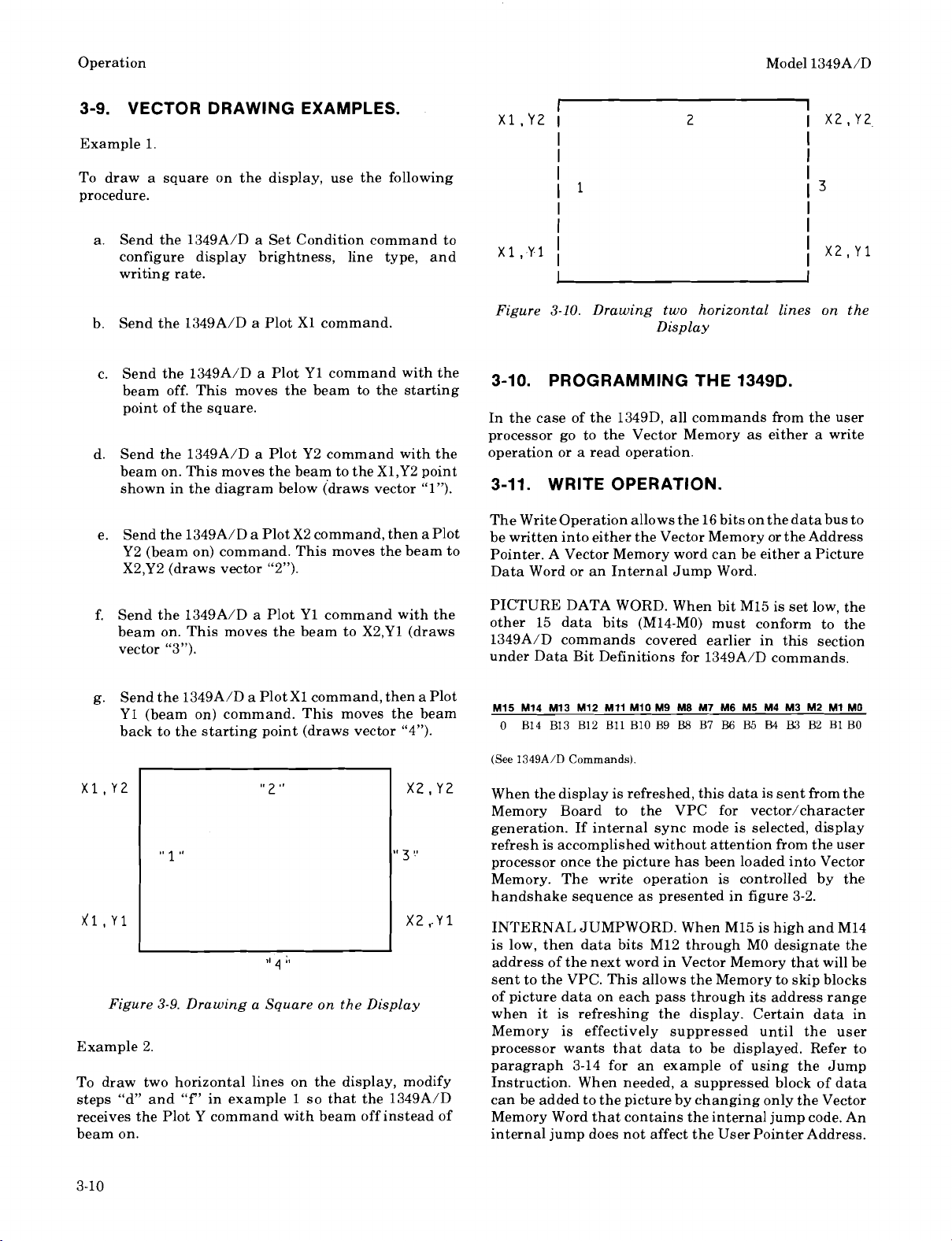

3-9. VECTOR DRAWING EXAMPLES.

Example 1.

To draw a square on the display, use the following

procedure.

a.

Send the

1349A/D a Set Condition command to

configure display brightness, line type, and

writing rate.

b. Send the

c. Send the

1349A/D a Plot X1 command. Display

1349A/D a Plot Y1 command with the

beam off. This moves the beam to the starting

point of the square.

Send the

d.

beam on. This moves the beam to the

shown in the diagram below (draws vector

Send the 1349A/D a PlotX2 command, then aplot

e.

1349A/D a Plot Y2 command with the

Xl,Y2 point

"1").

Y2 (beam on) command. This moves the beam to

X2,Y2 (draws vector "2").

f.

Send

the

beam

1349A/D a 'lot

On.

This

the

command

beam

to

X2'Y1

with

(draws

the

vector "3").

I

I

I

I

I

l'Y1

I

J

Figure

3-10.

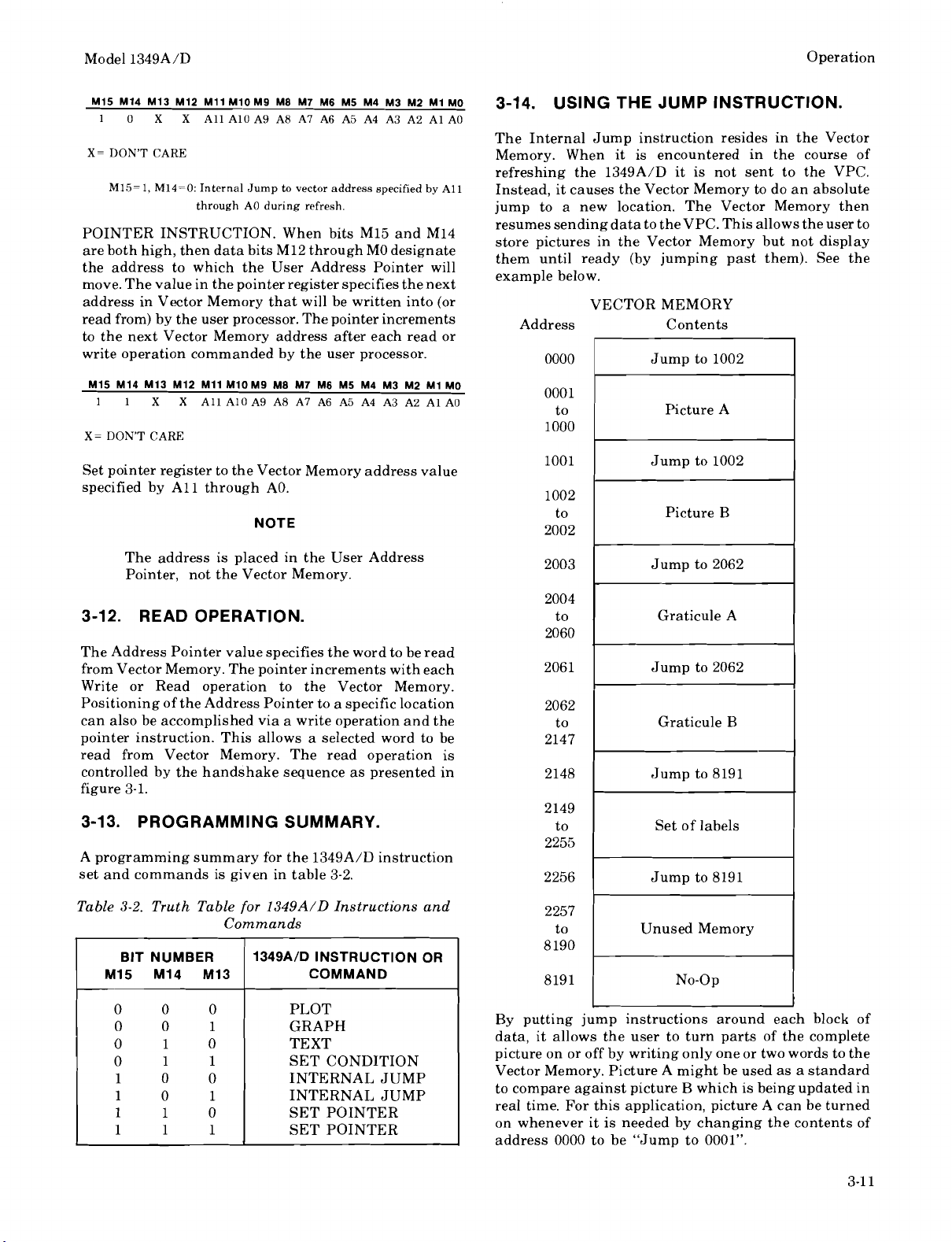

In the case of the

processor go to the Vector Memory as either a write

operation or a read operation.

3-1 1 WRITE OPERATION-

The Write Operation allows the 16 bits on thedata bus to

be written into either the Vector Memory or the Address

Pointer. A Vector Memory word can be either a Picture

Data Word or an Internal Jump Word.

PICTURE DATA WORD. When bit M15 is set low, the

other 15 data bits (M14-MO) must

1349A/D commands covered earlier in this section

under Data Bit Definitions for

3-10.

Drawing two horizontal lines on the

THE

1349D.

1349D, all commands from the user

conform

1349A/D commands.

I

I

X2,Yl

I

I

to the

g.

Send the

1349A/D a Plot X1 command, then a Plot

Y1 (beam on) command. This moves the beam

back to the starting point (draws vector "4").

Figure

3-9.

Drawing a Square on the Display

Example 2.

To draw two horizontal lines on the display, modify

"f'

steps "d" and

in example 1 so that the 1349A/D

receives the Plot Y command with beam off instead of

beam on.

MI5 M14 MI3 MI2 Mll Mi0 M9 M8 M7 M6 M5 M4 M3 M2 MI MO

0 B14 B13 B12 B11 BIO B9

(See

1349A/D

Commands)

I38

B7

B6

I35

B4

B3

B2 B1 BO

When the display is refreshed, this data is sent from the

Memory Board to the VPC for

vectodcharacter

generation. If internal sync mode is selected, display

refresh is accomplished without attention from the user

processor once the picture has been loaded into Vector

Memory. The write operation is controlled by the

handshake sequence as presented in figure 3-2.

INTERNAL JUMPWORD. When M15 is high and M14

is low, then data bits M12 through MO designate the

address of the next word in Vector Memory that will be

sent to the VPC. This allows the Memory to skip blocks

of picture data on each pass through its address range

when it is refreshing the display. Certain data in

Memory is effectively suppressed until the user

processor wants that data to be displayed. Refer to

paragraph 3-14 for an example of using the Jump

Instruction. When needed, a suppressed block of data

can be added to the picture by changing only the Vector

Memory Word that contains the internal jump code. An

internal jump does not affect the User Pointer Address.

Page 27

Model 1349A/D

Scans by ArtekMedia © 2007

Operation

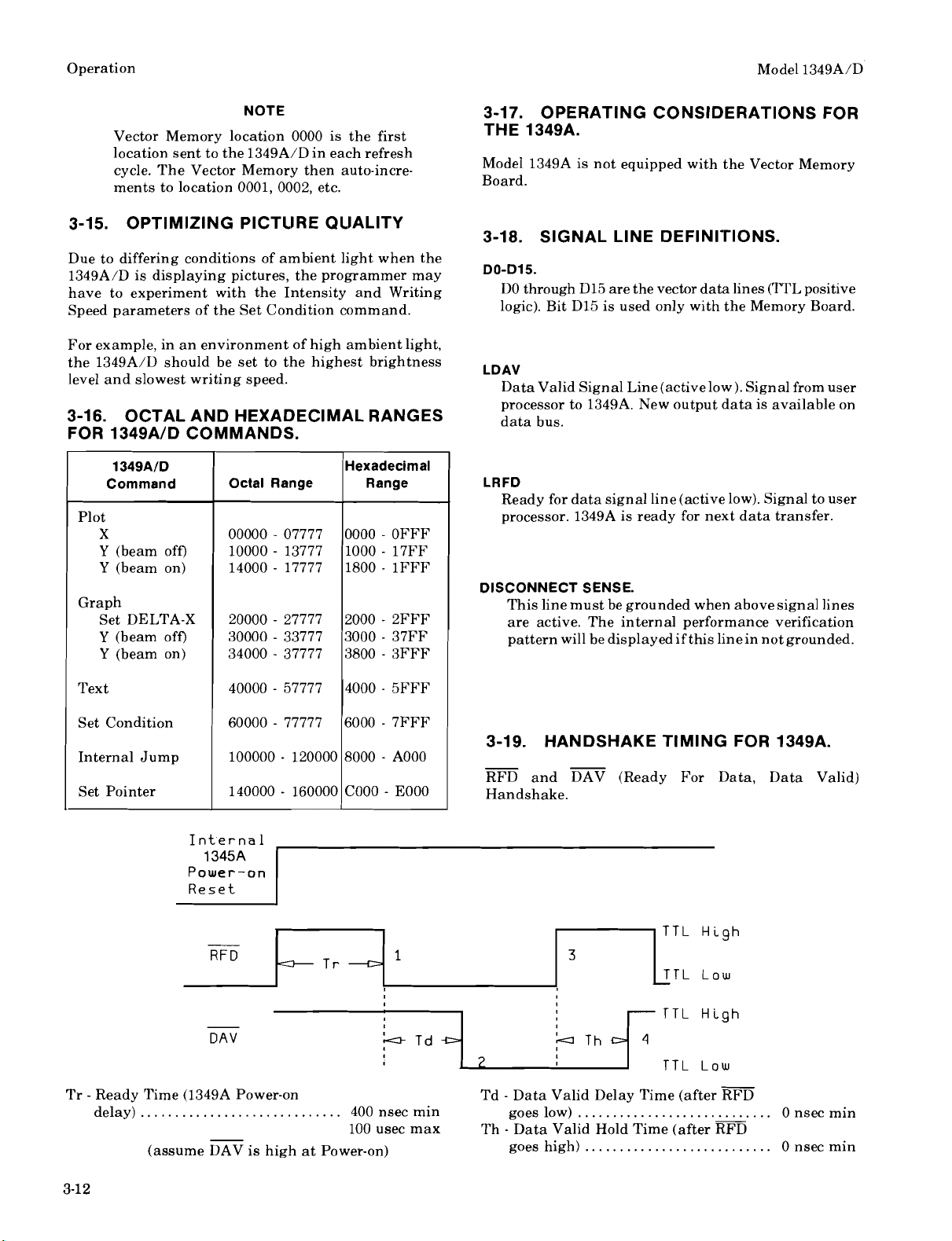

3-14. USING THE JUMP INS'TRUC'TION.

X=

DON'T

CARE

M15= 1, M14=0:

Internal Jump to vector address specified

through

A0

during refresh.

by

All

POINTER INSTRUCTION. When bits M15 and M14

are both high, then data bits M12 through MO designate

the address to which the User Address Pointer will

move. The value in the pointer register specifies the next

address in Vector Memory that will be written into (or

read from) by the user processor. The pointer increments

to the next Vector Memory address after each read or

write operation commanded by the user processor.

X=

DON'T

CARE

Set pointer register to the Vector Memory address value

specified by All through AO.

NOTE

The address is placed in the User Address

Pointer, not the Vector Memory.

The Internal Jump instruction resides in the Vector

Memory. When it is encountered in the course of

refreshing the

1349A/D it is not sent to the VPC.

Instead, it causes the Vector Memory to do an absolute

jump to a new location. The Vector Memory then

resumes sending data to the VPC. This allows the user to

store pictures in the Vector Memory but not display

them until ready (by jumping past them). See the

example below.

VECTOR MEMORY

Address Contents

Jump to 1002

Picture A

Jump to 1002

Picture B

Jump to 2062

3-12. READ OPERATION.

The Address Pointer value specifies the word to be read

from Vector Memory. The pointer increments with each

Write or Read operation to the Vector Memory.

Positioning of the Address Pointer to a specific location

can also be accomplished via a write operation and the

pointer instruction. This allows a selected word to be

read from Vector Memory. The read operation is

controlled by the handshake sequence as presented in

figure 3-1.

3-13. PROGRAMMING SUMMARY.

A programming summary for the 1349A/D instruction

set and commands is given in table 3-2.

Table

3-2.

Truth Table for

1349A/D

Instructions and

Commands

BIT NUMBER

MI5 MI4 MI3

0 0 0

0 0

0

0

1

1

1

0 0

1 0

1

1

1

1

1349AlD INSTRUCTION OR

COMMAND

PLOT

1

0

1

GRAPH

TEXT

SET CONDITION

INTERNAL JUMP

1

0

1

INTERNAL JUMP

SET POINTER

SET POINTER

Graticule A

Jump to 2062

Graticule B

Jump to 8191

Set of labels

Jump to 8191

Unused Memory

NO-Op

By putting jump instructions around each block of

data, it allows the user to turn parts of the complete

picture on or off by writing only one or two words to the

Vector Memory. Picture A might be used as a standard

to compare against picture B which is being updated in

real time. For this application, picture A can be turned

on whenever it is needed by changing the contents of

address 0000 to be "Jump to

0001".

Page 28

Operation Model 1349A/D

Scans by ArtekMedia © 2007

NOTE

Vector Memory location 0000 is the first

location sent to the

cycle. The Vector Memory then

ments to location 0001, 0002, etc.

1349A/D in each refresh

auto-incre-

3-15. OPTIMIZING PlCTLlRE QUALITY

Due to differing conditions of ambient light when the

1349A/D is displaying pictures, the programmer may

have to experiment with the Intensity and Writing

Speed parameters of the Set Condition command.

For example, in an environment of high ambient light,

the

1349A/D should be set to the highest brightness

level and slowest writing speed.

3-16. OCTAL AND HEXADECIMAL RANGES

1349AlD COMMANDS.

FOR

1349AlD

Command

Plot

X

(beam off)

Y

Y

(beam on)

Graph

Set DELTA-X

Y

(beam off)

Y

(beam on)

Octal Range

00000 - 07777

10000 - 13777

14000

-

17777

-

20000

30000

34000

27777

-

33777

-

37777

Hexadecimal

Range

0000 - OFFF

1000 - 17FF

1800

-

lFFF

2000 - 2FFF

3000 - 37FF

3800

-

3FFF

3-17. OPERATING CONSIDERATIONS FOR

THE

1349A.

Model 1349A is not equipped with the Vector Memory

Board.

3-18. SIGNAL LINE DEFINI'TIONS.

DO-D15.

DO through Dl5 are the vector data lines ('M'L positive

logic). Bit

LDAV

Data Valid Signal Line (active low

processor to

data bus.

LRFD

Ready for data signal line (active low). Signal to user

processor.

DISCONNECT SENSE.

This line must be grounded when above signal lines

are active. The internal performance verification

pattern will be displayed if this line in not grounded.

Dl5 is used only with the Memory Board.

).

Signal from user

1349A. New output data is available on

1349A is ready for next data transfer.

-

-

. .

. . . . . . . .

57777

77777

-

Text

Set Condition

Internal Jump

Set Pointer

Tr - Ready Time (1349A Power-on

delay)

. . . . . . . . . . . . . . .

40000

60000

100000 - 120000

140000

Internal

1345A

Power-on

Reset

-

DAV

-

(assume DAV is high at Power-on)

160000

. . . .

-

5FFF

4000

6000 - 7FFF

8000 - A000

COO0 - EOOO

k-

Td

400 nsec min

100 usec max

3-19. HANDSHAKE TIMING FOR 1349A.

-

RFD and DAV (Ready For Data, Data Valid)

Handshake.

-

7

Td

-

Data Valid Delay Time (after RFD

goes low)

-

Data Valid Hold Time (after FD

Th

goes high)

-

-

TTL High

. . .

4

. . . . . .

TTL Lou

.

. . .

hTh~

I

.

. . . . . . . . . . . . . . . . . . . . . . .

. . .

-

. . . . . . . .

. . .

.

.

0 nsec min

. .

0 nsec min

Page 29

Model 1349A/D

Scans by ArtekMedia © 2007

Operation

3-20. TRANSFER SEQUENCE.

1.

1349A sets RFD low to indicate that it is ready for a

word from the 16-bit Data Bus.

2. User processor sets DAV low to indicate that the

contents of the 16-bit Data Bus are valid.

1349A returns RFD high to indicate that it has

3.

accepted the word from the 16-bit Data Bus.

4. User processor returns DAV high so that the

1349A

can initiate the next transfer.

5.

1349A sets RFD low to indicate that it is ready for a

word from the 16-bit Data Bus.

3-21. RESTRICTIONS.

1.

User processor can set DAV low at the same time

or after