Page 1

Page 2

Page 3

Table of Contents

TABLE OF CONTENTS

Section Page Section Page

I

GENERAL INFORMATION

1- 1

.

Introduction

1.4

.

Description

1.14 . Cathode Ray Tube Warranty

1.16

.

Options

11

INSTALLATION 2-1

.

2.1 Incoming Inspection 2-

2.7

.

Power Requirements 2-1

2.10 . Installation 2-2

2.13 . Repackaging for Shipment 2-2

.

3.1

3.3

3.5

IV

PRINCIPLES OF OPERATION

4.1

4.9

4- 10

4.16

4.30

4.34

4.41

Introduction

.

Controls and Indicators

.

General Operating Suggestions

.

Overall Block-Diagram Description . 4-1

Circuit Analysis

.

Vertical Amplifier

.

Sweep Generator

:

Horizontal Amplifier

.

Low-Voltage Power Supply

.

.

High-Voltage Power Supply 4-6

.................

.................

...................

...................

.................

.................

............

......

...........

...........

.......

.........

....

.........

..............

..........

...........

.........

.....

....

1-1

1-

1-1

1-2

1-2

3-1

3-1

3-1

4.1

4-2

4-2

4-3

4-4

4-5

V MAINTENANCE

1

1

5.24

5.27 Low-Voltage Power Supply 5-6

5.33 High-Voltage Power Supply 5-6

5.35

5.42 Horizontal Amplifier 5-10

5.48 Sweep Generator 5-11

5.52 Performance Check 5-11

5.67 Diagrams 5-14

VI

REPLACEABLE PARTS

6.1 Introduction 6-1

6.3 Ordering Information 6-1

Introduction 5-1

Test Equipment 5-1

Troubleshooting 5-1

Repair 5-5

Adjustments 5-6

.

.

.

.

.

.

.

.

.

.

...................

.................

...............

...............

System Troubleshooting 5-1

Sectional Troubleshooting

High-Voltage Power Supply

....................

Replacement of Semiconductors

Servicing Etched Circuit Boards

Crt Replacement

...........

................

Adjustments Following Repair

Vertical Amplifier

..........

...........

...........

..................

............

................

..........

Model 120B

......

.....

....

.

.

. .

.....

....

........

-6-1

5-1

5-2

5-2

5-5

5-5

5-5

5-6

5-9

Page 4

Model 120B

LlST OF ILLUSTRATIONS

Number Title Page Number Title Page

List of Illustrations and Tables

Model 120B Oscilloscope

Primary-Power Connections

Rack Mounting.

Model

Operation Using Internal Horizontal

Operation Using External Horizontal

Operation Using Balanced Vertical

Vertical Deflection Calibration and

Overall Block Diagram 4Sweep Generator, Block Diagram 4-2

Sweep Generator Waveforms 4-3

Typical Schmitt Trigger 4-3

Low-Voltage Power Supply, Block

High-Voltage Power Supply, Block

120B Oscilloscope, Front View

Sweep or Single Sweep 3-3

......................

Input .3-4

......................

Input .3-5

Balance Adjustment 3-6

Diagram.

Diagram. .4-6

...............

...................

...................

...........

........

;

.

.

.

...........

.............

............

.....

........

...........

.4-5

LlST OF TABLES

1-1

22-2

3-2

Top View, Location of Parts and

1

1

Adjustments 5-3

High-Voltage Power Supply, Location

of Parts. 5-4

Vertical Sensitivity

Source

Parts and Adjustments

Right-Side View, Side Panel Removed,

Location of Parts and Adjustments 5-6

Servicing Etched Circuit Boards.

Vertical Amplifier, Schematic

Diagram 5 - 15

Horizontal Amplifier, Schematic

Diagram 5- 17

Sweep Generator, Schematic Diagram

Low-Voltage Power Supply, Schematic

Diagram 5 - 2

High-Voltage Power Supply, Schematic

Diagram 5- 23

Horizontal Display Switch, Schematic

Diagram. 5-25

..................

....................

(A21 and Trigger

(A201) Switches, Location of

...........

...

.....

.....................

.....................

.....................

.....................

....................

5-5

5-7

.

.

5-19

1

Number Title Page

1-1.

Specifications 1-0

Recommended Test Equipment

System Troubleshooting. 5-4

Adjustments Following Tube,

Transistor, and Diode Replacement.

Low-Voltage Power Supply Voltages

Horizontal Sweep-Time Adjustment.

Horizontal Sweep Time 5-14

Reference Designation Index

Replaceable Parts 6- 14

Code List of Manufacturers

..................

.......

...........

..

...

...

............

........

...............

.........

5-

1

5-8

5-9

5-12

6-

2

6-17

Page 5

Section I

1-

Table

Model 120B

1

Table

1- 1.

Specifications

SWEEP

Sweep Range:

One

p3ec/cm to

calibrated sweeps accurate to within

1,2,5,10.. . sequence, from 5 psec/cm to 200

millisec/cm. Vernier control permits continuous adjustment of sweep time between calibrated steps, and extends the 200

least 0.5 sec/cm.

Sweep Expand:

X5 sweep expansion may be used on all ranges

and expands fastest sweep to

panded sweep accuracy

Automatic Synchronization:

Internal: from signals 50 cps to 450 kc with

approximately 0.5-cm or more vertical deflection; and from line voltage.

External: from signal 50 cps to 450 kc, 1.5

peak-to-peak.

Trigger Point:

Zero-crossing negative slope of external sync

signals; or zero-crossing positive or negative

slope of vertical deflection signals. Front-panel

control overrides automatic and permits the

trigger point to be set between

Turning control fully counterclockwise restores

automatic operation.

at

least 0.5 sec/cm.

millisec/cm to at

1

is

*lo%.

psec/cm. Ex-

-7 to +7 volts.

Fifteen

*5%, in a

v

VERTICAL AMPLIFIER

Bandwidth: ating potential. Face plate eliminates glare and

DC coupled: dc to 450 kc. AC coupled: 2 cps reduces hazard of implosion. P2, P7, and

to 450 kc. Bandwidth

less of sensitivity setting.

Sensitivity:

10 millivolts/cm to 100 volts/cm. Four cali- divisions. Eliminates parallax error.

brated steps with attenuator accuracy of

10 mv/cm, 100 mv/cm, 1 v/cm, and 10 v/cm.

Vernier permits continuous adjustment of

tivity between steps, and extends 10

to at least 100

Internal Calibrator: 16-3/4

Calibrating signal automatically connected to deep, overall; hardware furnished for quick convertical amplifier for standardizing of gain, accuracy

Input Impedance

1

Balanced Input:

On 10 mv/cm range only; input impedance

megohms shunted by approximately 25 pf.

Common-Mode Rejection: 06. Rear terminals in parallel with front.

Rejection at least 40 db. Common mode signal 10. Provision for single sweep operation.

must not exceed

+2%.

megohm, shunted by approximately 50 pf.

v/cm.

:

is

at least 450 kc regard-

+3 volts peak.

*3%,

sensi-

v/cm step

is

2

Phase Shift:

Vertical and horizontal amplifiers have same

phase characteristics within

verniers are in CAL.

+ZO

to 100 kc when

HORIZONTAL AMPLIFIER

Bandwidth:

DC coupled: dc to 300 kc. AC coupled: 2 cps

to 300 kc. Bandwidth

less of attenuator setting.

Sensitivity:

0.1 volt/cm to 100 volts/cm. Three calibrated

steps, accurate within

and 10 v/cm. Vernier permits continuous adjustment of sensitivity between steps and

tends 10

Input Impedance

1

megohm nominal, shunted by approximately

100 pf.

Phase Shift:

Horizontal and vertical amplifiers have same

phase characteristics within

verniers are in CAL.

v/cm step to at least 100 v/cm.

:

is

at

least 300 kc regard-

&5%,

0.1 v/cm, 1 v/cm,

k2O to 100 kc when

GENERAL

Cathode Ray Tube:

P31 phosphor, mono-accelerator with internal

graticule normally supplied; 2700-volt acceler-

phosphors also available.

Internal Graticule:

10 cm x 10 cm marked in cm squares. Major

horizontal and vertical axes have 2-mm

Intensity Modulation:

Terminals on front panel. Plus 20 volt pulse

required to blank trace of normal intensity.

Dimensions:

in.

wide, 7-1/2 in. high, 18-3/8

version to 7 in. x 19 in. rack mount.

Weight:

Net: 32 lbs; shipping 45 lbs.

Power:

115 or 230 volts

mately 95 watts.

Options

:

05. External graticule crt with P31 phosphor.

13. Special front panel for rack mounting only.

*lo%,

50 to 1000 cps, approlci-

ex-

PI1

sub-

in.

Page 6

Model 120B

Paragraphs

Section

1-1

to 1-8

I

SECTION

GENERAL INFORMATION

1-1. INTRODUCTION.

1-2. This manual provides complete instructions on

the installation, operation, theory of operation, and

maintenance of the Hewlett-Packard Model 120B Os-

cilloscope.

1-3. The Hewlett-Packard Company uses a

section, eight-digit serial number (e. g. 000-00000).

If

the serial prefix (first three digits) on your instru-

ment does not agree with the prefix shown on the title

page of this manual, refer to either the separate

I,

change sheet included or Appendix

changes required to adapt this manual

prefixes. The separate change sheet also contains

corrections required for all known errata (errors).

Contact your Hewlett-Packard

if

additionalinformation or clarification is required.

Sales/Service Office

which contain

to

1-4. DESCRIPTION.

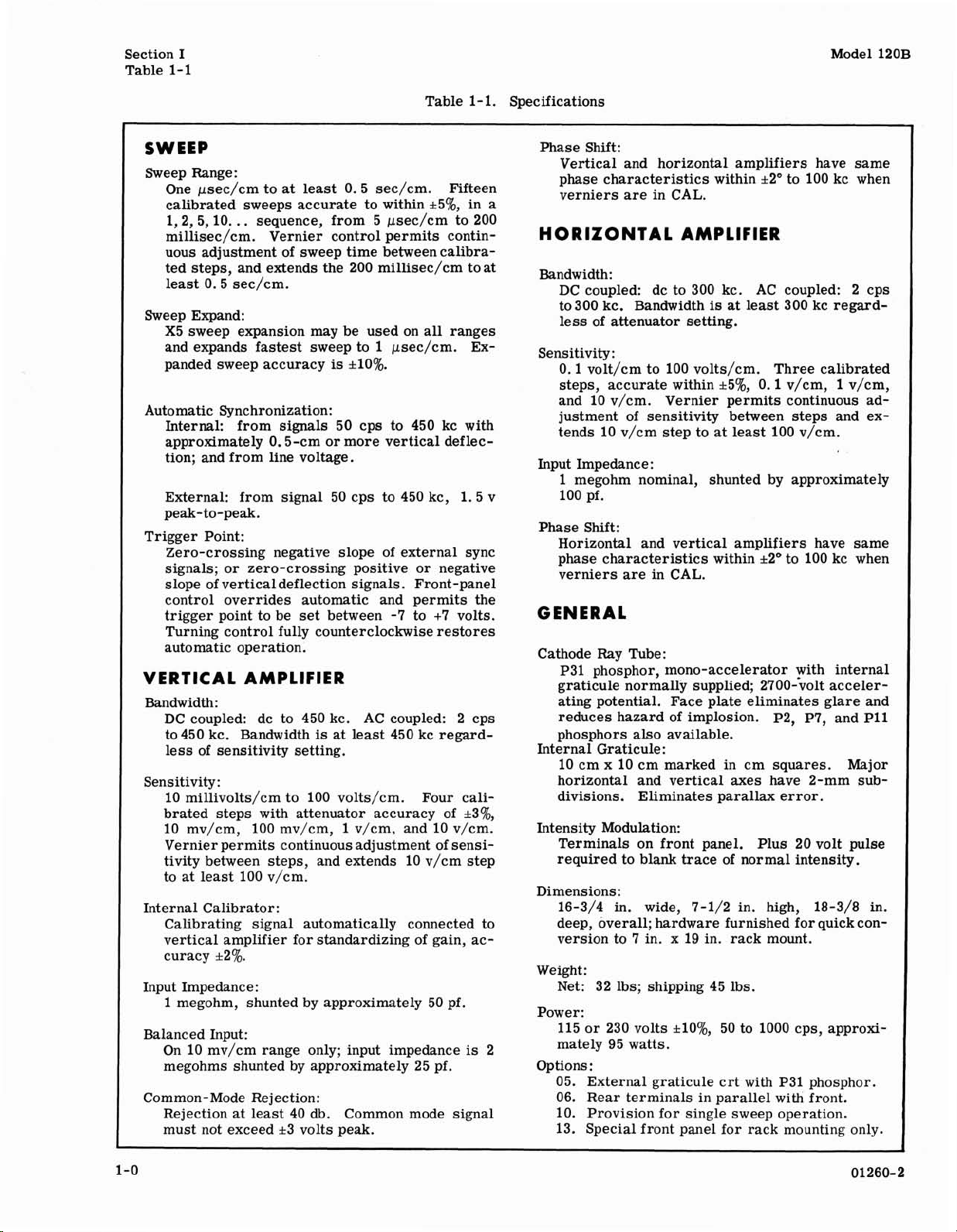

1-5. The Model 120B

scope whose bandwidth extends from dc to 450 kc. It

combines the precision characteristics of calibrated

is

a general-purpose oscillo-

two-

the listed

I

horizontal sweeps, calibrated vertical sensitivity,

a

crt that eliminates parallax error; in addition,

and

its construction provides easy circuit accessibility

and quick convertibility from a rack-mounting to a

bench-model configuration. Specifications are listed

in table

1-6. The internal graticule of the Model 120B

the same plane as the phosphor and crt trace; consequently, crt parallax error

quicker, and more accurate measurements.

1-7. The Model 120B can be used with either internal

or external sweeps, which can be either internally or

externally synchronized. Because of

tivity and balanced input, the Model 120B can be used

to view complex waveforms and monitor transducer

outputs.

1-8. Computations are avoided and possibilities of

error are reduced by direct-reading calibrated sweeps.

A

between the ranges

1-1.

is

in

is

avoided, allowing easier,

its

high sensi-

single control selects 1 of 15 calibrated sweeps

microseconds/cm and 200

of 5

Figure

1-

1.

Model 120B Oscilloscope

1-1

Page 7

Section I

Paragraphs 1

-

9 to 1 - 18

Model 120B

milliseconds/cm or determines the calibrated sensitivity of the horizontal amplifier. Continuous control

of sweep time and horizontal sensitivity between cali-

brated steps is provided

vernier control extends the 200

sweep time to at least 0.5 seconds/cm, and reduces

the horizontal amplifier sensitivity to at least 100

volts/cm.

1-9. Accurate direct-reading sweeps are obtained

from a feedback type (Miller) integrator, which en-

sures high linearity and stability of the horizontal

sweep. This type of sweep generator is reliable and

relatively independent of vacuum-tube characteristics.

1-

10. Observation and analysis of transients are simplifiedby the expanded-sweep control. This X5 sweep

expander may be used on all sweep time settings, and

expands the fastest sweep time to

1-

11.

An automatic trigger capability facilitates establishinga base line on the crt when a synchronizing

signal is not present. The automatic baseline provision can be easily locked-out and an adjustable trigger level established.

1-

12. Accurate voltage measurements of waveforms

are quickly made with the Model

calibrator that

mits rapid verification and standardization of vertical

amplifier sensitivity.

1-13. Phase-shift measurements can be made accurately over a wide range of input frequencies. Relative phase shift between the vertical and horizontal

amplifiers is less than 2 degrees up to 100 kc.

is

accurate to within *2 percent per-

by

a vernier control; the

milliseconds/cm

1

microsecond/cm.

120B. A built-in

1-14. CATHODE RAY TUBE WARRANTY.

1-15. The cathode ray tube supplied with the Model

120B and replacement crt's purchased from HewlettPackard Company are guaranteed against electrical

failurefor one year from the date of sale by HewlettPackard. The Cathode Ray Tube Warranty and Claim

sheet is included at the rear of this manual.

1-19. OPTION 06.

connectors in parallel with the front panel input connectors.

VERTICAL input terminals on the front panel, and

one connector is

TAL input terminals as shown in figures 5-6 and

Mating connectors and cable clamps are also supplied.

The additional circuitry changes the vertical input

capacitance to approximately

input capacitance to approximately 135 pf.

1-20. OPTION 10.

single sweep operation.

contained in figure 3-2 and a schematic for the added

circuit is shown in figure 5-8.

1-21. OPTION 13. This option provides a plain

7 x 9 x 3/16 inch front panel for rack mounting only.

The panel is suitablefor installing special handles to

match existing equipment in system or console

configuration.

1-22. AMBER FILTER.

supplied with oscilloscopes having an internal graticule

crt with

for improved visual observation of displays such as

single-shot phenomena or very low frequency applica-

tions.

characteristics desired for visualobservations of this

type display.

a. Remove front panel crt bezel.

b. Set filter into bezel, aligning larger rectangular

slots in the edge of filter with metal guide posts of the

bezel casting.

c. Remove oscilloscope top cover for access to

rear of crt.

d. Carefully move crt towardrear of instrument

enough to provide clearance for thickness of installed

filter (about 1/8 inch).

One connector is wired in parallel with the

P7 phosphor.

The filter will improve the long persistency

To install the filter proceed as follows:

This option provides rear panel

wiredin parallel with the HORIZON-

5-

75pf, and the horizontal

Thisoptionprovides circuitry for

Operation procedures are

A special amber filter is

This filter may be installed

7.

1-16. OPTIONS.

1-

17. The Model 120B is available with four options,

as

listed in table

are listedunder MISCELLANEOUS at the end of table

6-1.

1-18. OPTION 05. This optionprovides a crt without

internal graticule.

able illumination

Refer to figure 5- 9 for

CRT's without internal graticule are available with

types P7,

plied with each crt; amber for

type, and green for P31 type.

1-

1.

Replaceable parts for alloptions

An

external graticule with adjust-

is

installed over the face of the crt.

a

schematic of the added circuit.

P11, andP3l phosphor. Afilter

P7 type, blue for PI1

is

also sup-

e. Loosen clamp at socket of crt.

f.

Replace bezel with filter and tighten bezel

screws.

g. Slide crt forward until light mask on front of crt

just lightly touches filter.

h. Tighten clamp just enough to keep crt from turn-

ing.

Do not over-tighten the clamp or tube damage

may result.

i. Check alignment of trace with graticule accord-

ing to theprocedure given in Section V of this manual.

Page 8

Model 120B

Paragraphs 2-1 to 2-9

Section

I1

SECTION

INSTALLATION

2-1.

INCOMING INSPECTION.

2-2. MECHANICAL INSPECTION. Unpack and inspect the Model 120B in the presence of the carrier.

Be careful when unpacking the instrument, for all

electron tubes including the cathode ray tube remain

installed during shipment. Save all packing materials

until inspection

be required for reshipment in the event shipping dam-

is

age

age in shipment such as scratched panel, broken

knobs, etc.

check it operationally (see paragraph

claim with the carrier. Refer to the Hewlett-Packard

Warranty sheet at the front of this manual.

2-5. PERFORMANCE CHECK. Paragraph 5-52 contains performance check procedures for verifying

operation within listed specifications. The performance check is recommended for inclusion in receiving quality-control inspection. The following proce-

dure

operation.

2-6. INITIAL TURN ON. Energize the 120B as

follows:

power cable.

LISECONDS/CM position.

POSITION controls.

If

adjust position controls as necessary.

adjust HORIZONTAL POSITION to place left end of

sweep on left-end graticule line.

discovered.

2-3. Inspect the instrument for signs of possible dam-

If

2-4.

a. Turn INTENSITY control to OFF and plug in

b.

c. Set HORIZONTAL DISPLAY switch to 0.5

d. Center HORIZONTAL POSITION and VERTICAL

e. Turn 120B on and allow

f

g. Rotate INTENSITY clockwise until trace appears.

h. Adjust FOCUS for thin, -well-defined trace, and

there are any indications of damage, file a

is

offered, however, as a means to check basic

Set SWEEP MAGNIFIER switch to X1 position.

.

Set TRIGGER LEVEL to AUTO.

crt remains blank, press BEAM FINDER and re-

is

complete. These materials may

If

possible, energize the equipment and

2-

5).

two

minutes warmup.

MIL-

II

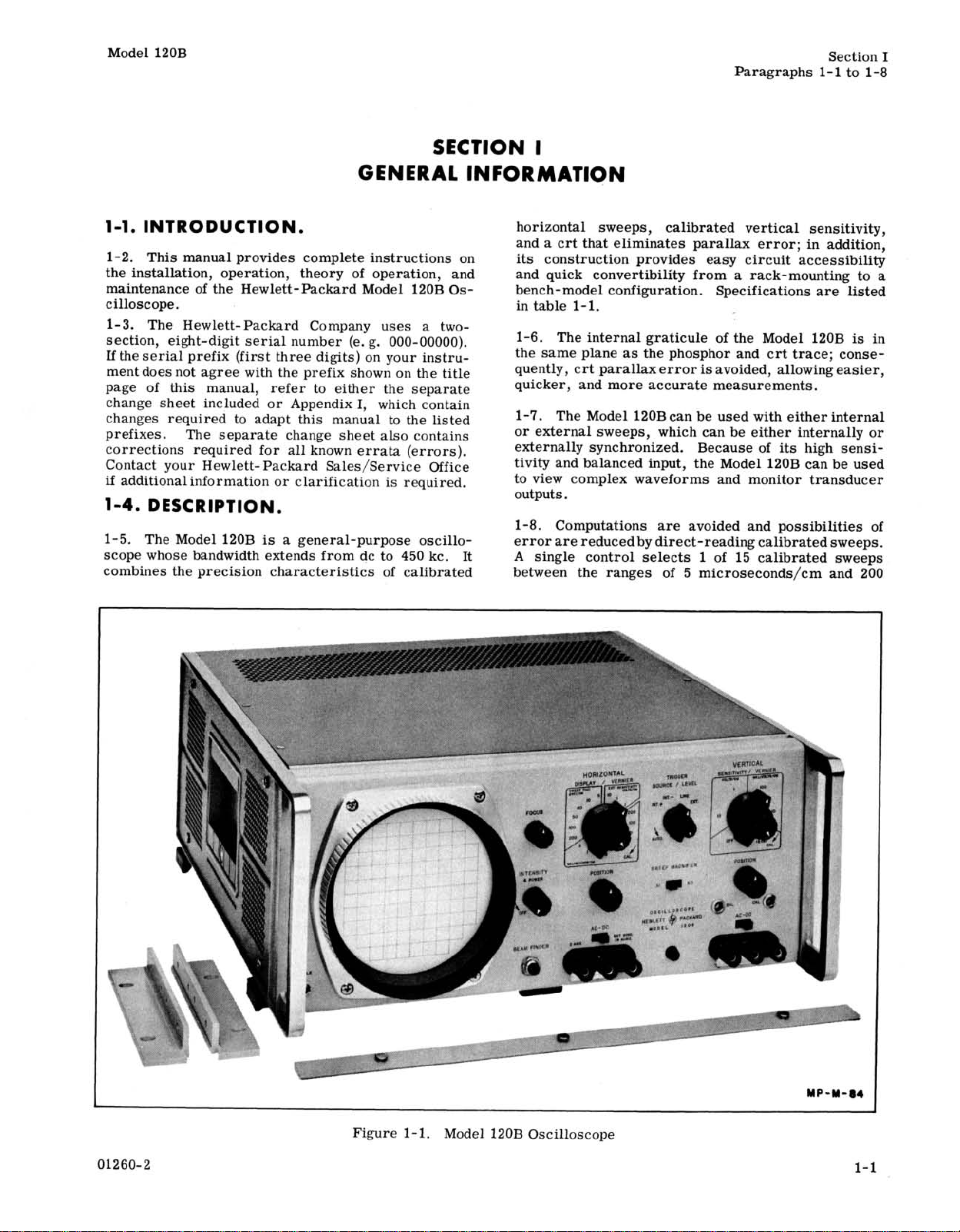

230

VOLTS AC

115

VOLTS AC

:41

Figure 2-

I

2

3

4

1L

230 VOLT CONNECTION

I

2

3

4

115

VOLT CONNECTION

1.

Primary-Power Connections

T302

T 302

LO-S-529

2-7.

2-8. The Model 120B requires a power source of 115

or 230 volts

can deliver approximately 95 watts. The oscilloscope

is

with a 115-volts power source. To convert the in-

strument for use with a 230-volt source, change the

dual primary windings of transformer T302 from a

parallel combination to a series combination. Figure

2-1 illustrates the connection for 115- and 230-volt

operation. At the time of the change, replace the

1.5-ampere slow-blow line fuse with 1-ampere

blow fuse.

POWER REQUIREMENTS.

?lo%,

single phase, 50 to 1000 cps, which

normally shipped from the factory wired for use

slow-

2-9.

For the protection of operating personnel, the

National Electrical Manufacturers' Assn (NEMA)

recommends that the instrument panel and cabinet

be grounded. This instrument is equipped with a

three-conductor power cable which, when plugged into

an appropriate receptacle, grounds the instrument.

The offset pin on the power cable three-prong connector is the ground pin. To preserve the protection

feature when operating the instrument from a

contact outlet, use a three-prong to two-prong adapter and connect the green pigtail on the adapter to

ground.

two-

Page 9

Section

II

Paragraphs 2-10 to 2-14

INSTRUCTIONS

I. REMOVE TILT STAND, FEET, AND

TRIM STRIP.

2.ATTACH FILLER STRIP AND FLANGES

KEEPING LARGENOTCHONFLANGES

TO INSTRUMENT BOTTOM.

Model 120B

FILLER STRIP

RACK MOUNTING

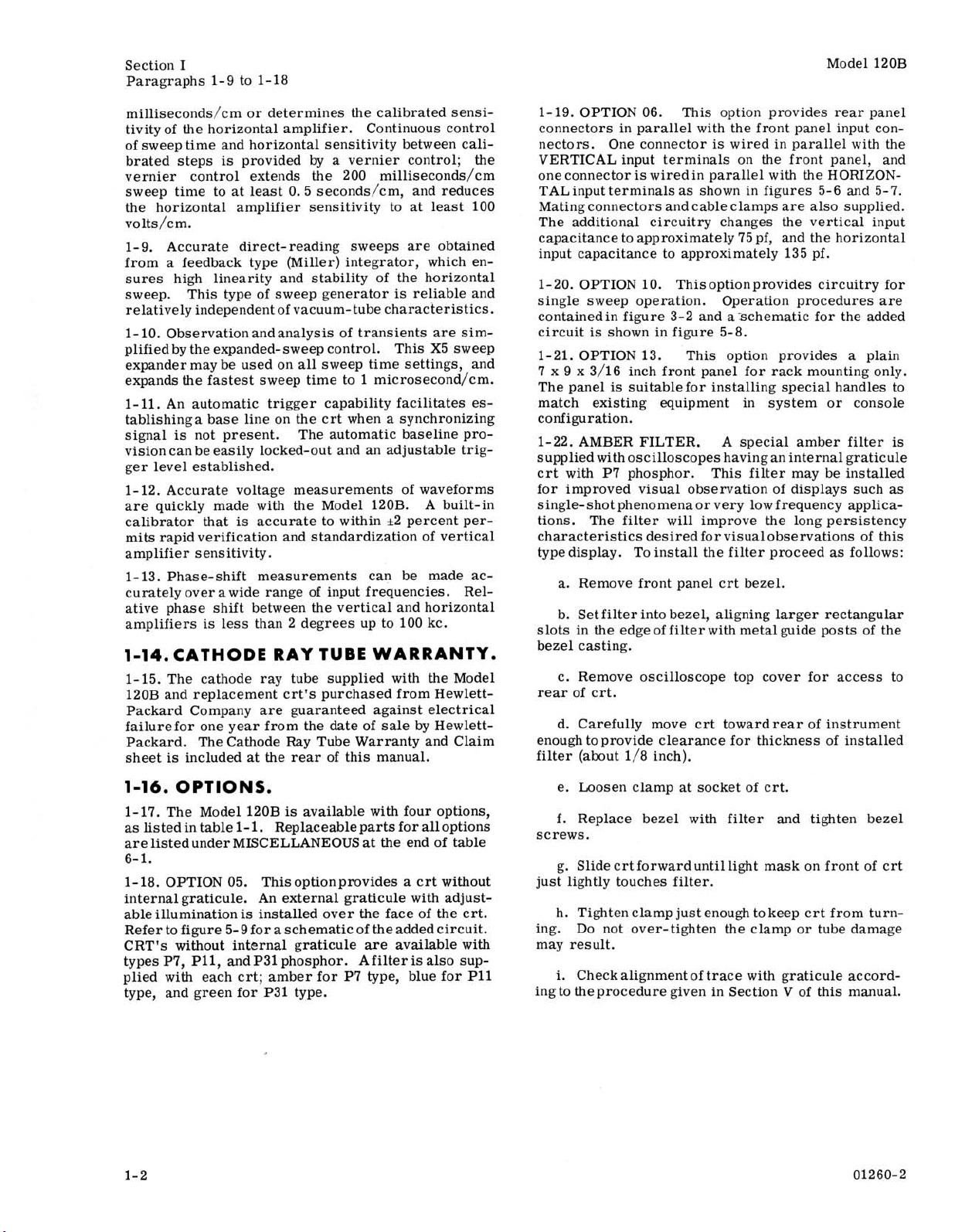

Figure 2-2. Rack Mounting

2-10. INSTALLATION.

2-11. MODULAR CABINET. The Model l2OB Oscil-

is

loscope

ment with the tilt stand, feet andplastic trim

shipped fromthe factory as a bench instru-

inplace.

The top and bottom cabinet covers may be removed,

giving complete accessibility to all components and

adjustments. When used on the bench, other instru-

be

ments may

stacked on the louver-free top surface;

however, sufficient space should be allowed around

the cabinet for adequate circulation of air.

2-12.

RACK

MOUNTING. Prepare the cabinet for

rack mounting as illustrated in figure 2-2. The trim

strip and rack-mounting flanges are in the shipping

container with the instrument. After preparation, lift

instrument into place and secure mounting flanges to

rack with appropriate screws. Allow adequate ventilation for the instrument in the rack.

2-13. REPACKAGING FOR SHIPMENT.

2-14. The following

packagingan instrument for shipment; however,

have any questions, contact your authorized

Packard sales representative.

list

is

a general guide for re-

Hewlett-

if

you

LO-M-489

a.

If

possible, use original container designed for

the instrument.

b. Wrap instrument

in

heavy paper or plastic before

placing it in shipping container.

c. Use sufficient quantities of packing material

around all sides of the instrument and protect panel

with cardboard strips.

d. Use heavy cardboard carton or wooden box to

house the instrument and use heavy tape or metal

bands to seal the container.

e. Mark packing box with "Fragile", "Delicate Instrument", etc.

Note

If

the instrument

is

to be shipped to

Hewlett-Packard Company for ser-

vice or repair, attach to the instru-

ment atag identifyingthe owner, the

instrument's complete serial number, and the service or repair to be

accomplished; in addition, notify

Hewlett-Packard Company or a representative before shipping the instrument. In any correspondence,

reference the instrument by model

number and complete serial number.

Page 10

Model 120B

Section

Paragraphs 3- 1 to 3-16

III

SECTION

OPERATION

3-2. This section contains operating instructions for

the Model 120B Oscilloscope. Included are descriptions of the Model 120B controls and indicators, and

operation of the Model

oscilloscope.

3-3.

CONTROLS AND INDICATORS.

Figure 3-1 illustrates the controls and indica-

3-4.

tors along with a short description of the particular

function of each.

3-5, GENERAL OPERATING

SUGGESTIONS.

3-6. The following paragraphs, 3-7 through 3-16,

provide suggestions for expediting and simplifying

operation of the Model

3-7. SYNCHRONIZING THE SWEEP. The horizontal

sweep can be synchronized with the vertical input

signal (INT positions of TRIGGER SOURCE switch),

the ac line frequency (LINE position), or an external

sync signal (EXT position).

3-8. When the TRIGGER LEVEL control

position, a sweep appears on the crt without application of any type of synchronizing signal; however,

when a synchronizing signal above approximately 50

cps is applied, the sweep automatically synchronizes

with this signal and the sweep

point where the signal crosses the zero axis (average

dc level of synchronization signal).

ing signal below approximately 50 cps

the TRIGGER LEVEL control should be out of AUTO

position.

3-9. Rotating the TRIGGER LEVEL control in a

clockwise direction permits the trigger point to be

set between

going portion of a vertical input signal, depending on

whether the TRIGGER SOURCE switch is in

INT- position, respectively. When the TRIGGER

SOURCE switch

GER LEVEL control in a clockwise direction permits

the trigger point to be set between

negative-going portion of the synchronizing signal.

3-10. The particular type of synchronization best

suited depends on the type of measurement being made

and the type of crt display desired.

3-11.

switch in AC position) removes any dc level present

in the vertical or horizontal input signals. This prevents excessive dc levels from deflecting the crt trace

off the face of the crt, often to the point where the

POSITION controls cannot bring the crt trace within

view.

rt2 cm along the positive or negative-

is

in EXT position, rotating the TRIG-

AC/DC COUPLING. Ac coupling (AC - DC

120B as a general-purpose

120B.

is

in AUTO

is

triggered at the

If

a synchroniz-

is

being used,

INT+ or

rt7 volts along the

Ill

CAUTION

When using ac coupling, do not

ceed a dc level input of 600 volts.

3-12. When pulse or square waves having a

cy less than 200 cps are being measured, dc coupling

is recommended (AC-DC switch-in DC position).

3-13. BEAM FINDER OPERATION. The crt trace

may frequently be deflected off the crt face by excessive dc input levels or by misadjustment of the vertical POSITION and horizontal POSITION controls.

The BEAM FINDER pushbutton is extremely useful

under these conditions. When the BEAM FINDER

depressed, the beam is confined to the face of the

crt, brightened, and defocused to prevent burning of

the crt phosphor.

POSITION controls when the BEAM FINDER

pressed, the trace will remain on the crt face when

the BEAM FINDER

3-14. VERTICAL SENSITIVITY SELECTION. When

the vertical VERNIER control

VERTICAL SENSITIVITY switch provides attenuation

of the vertical input signal in four calibrated steps,

10

mv/cm, 100 mv/cm, 1 v/cm, and 10 v/cm.

tating the vertical VERNIER control in a counter-

clockwise direction permits continuous adjustment of

sensitivity between steps, and extends 10

at

least 100 v/cm. When the VERTICAL SENSITI-

to

VITY switch

is automatically connected to the vertical amplifier.

3

-

15. COMMON-MODE REJECTION. Balanced input to the vertical amplifier

the ground jumper across two of the vertical input

terminals and applying a balanced signal input. Balanced input

sired to simultaneously amplify the out-of-phase (differential) signal and attenuate the in-phase (common

mode) signals, such as hum, noise, etc.

3-16. A change in the relative position of the Model

120B Oscilloscope with respect to the earth's magnetic field could result in the trace becoming misaligned. To re-align the trace with the graticule,

adjust SCALE, screwdriver adjustment ,on the front

panel (Figure 3-1).

Figures 3-2 through 3-5 assume

that the FOCUS, POSITION, and INTENSITY controls are preset by the

operator for the desired display.

If

in doubt as to the exact function

of a switch listed in figures 3-2

through 3-5, refer to figure 3-1

for a functional description.

If

the crt trace

is

released.

is

in CAL position, a calibrating signal

is

useful in applications where it

Notes

is

is

in CAL position, the

is

obtained by removing

ex-

frequen-

is

centered with the

is

de-

Ro-

v/cm step

is

de-

Page 11

Section

III

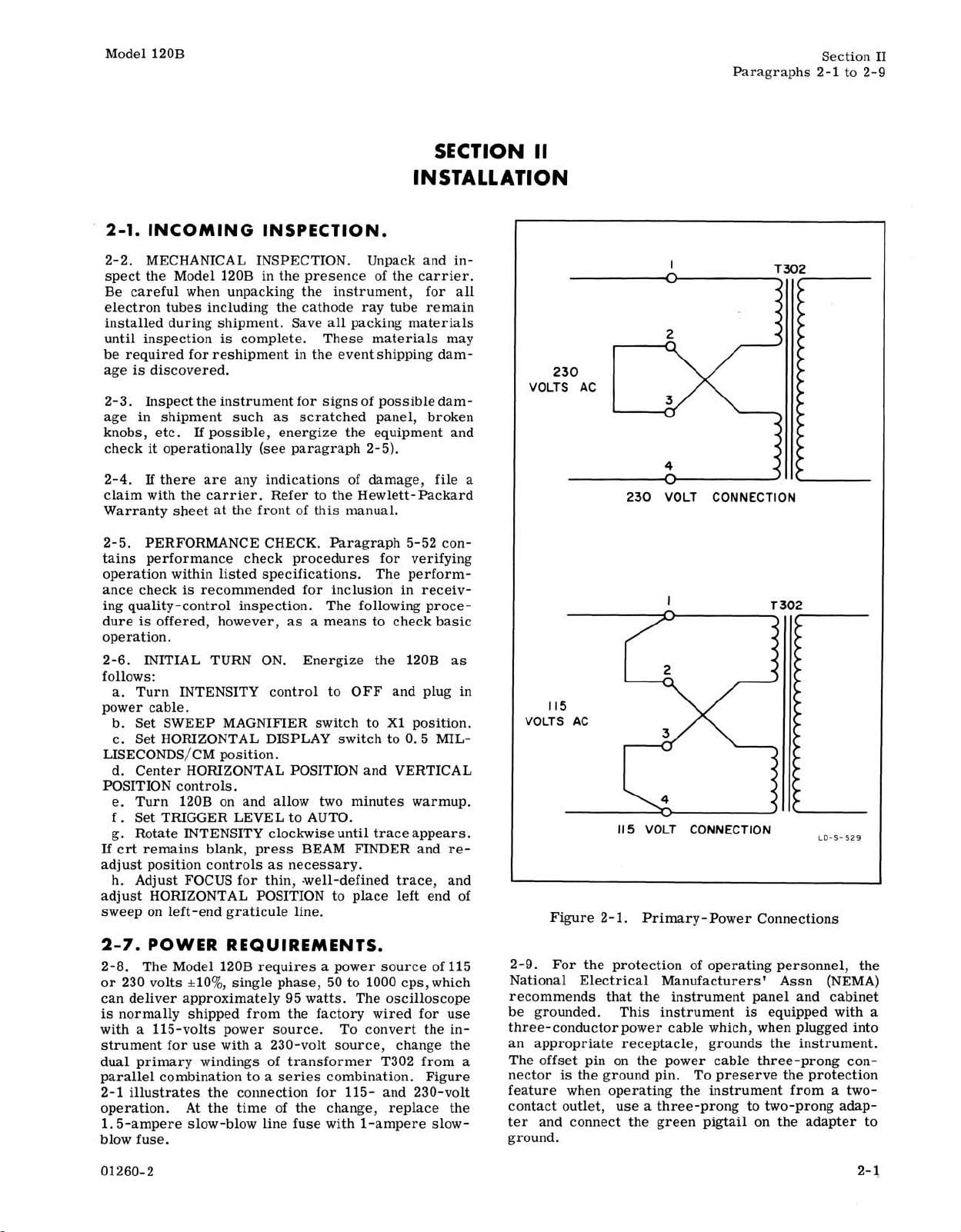

Figure 3-

Model 120B

1

7

-4

0.c

HEWLC

20 19

1.

FOCUS: Controls crt focus.

18

I7 16 15

11.

14

13 12

11

10 9 8

MP-M-

Vertical POSITION: Controls verticalposition of crt display.

2. Horizontal VERNIER: Adjusts sensitivity

between ranges; in CAL position, deflec-

tion

as

indicated

by

selected

VOLTS/CM

position of HORIZONTAL DISPLAY switch.

3. HORIZONTAL DISPLAY: 15 positions se- 13. SWEEP MAGNIFIER:

3

lect sweep speed,

positions select hori-

zontal deflection sensitivity.

4. TRIGGER LEVEL: Determines level of

trigger point on sync signal.

12. BAL: Adjust for no vertical shift with rotation of vertical VERNIER.

In

Xl position sweep

time selected by HORIZONTAL DISPLAY.

In

X5position sweep speed

is

5

times faster.

14. EXT. SYNC OR HORIZ: External sync or

horizontal amplifier input.

5. TRIGGER SOURCE: Four positions select

sweep synchronization. 15. Horizontal AC-DC: AC position input

itively coupled into horizontal amplifier.

6.

Vertical VERNIER: Adjusts sensitivity be-

DC position input directly coupled into hor-

tween ranges; in CAL position, deflection izontal amplifier.

as selected by VERTICAL SENSITMTY

switch. 16. Z AXIS: Input for crt intensity modulation

signal.

7. VERTICAL SENSITIVITY: Four positions

select deflection sensitivity. CAL position 17. Horizontal POSITION: Controls horizontal

displays internal calibrator signal.

position of crt display.

85

capac-

8.

CAL: Adjusts calibration of vertical input.

18.

BEAM FINDER: Returns beam to crt face

regardless of horizontal and vertical POSI-

9.

Vertical input terminals. TION settings.

10. Vertical AC-DC: AC position input capaci- 19. INTENSITY

tively coupled into vertical amplifier. DC

power and controls crt intensity.

&

POWER: Applies ac line

position input directly coupled into vertical

amplifier. 20. SCALE: Aligns trace with graticule.

Figure 3-1.

Model 120B Oscilloscope, Front View

01260-1

Page 12

Model

120B

Section

Figure

Ill

3-2

INTERNAL HORIZONTAL SWEEP:

1.

Set vertical AC-DC to desired type of input A. Set SWEEP switch to normal (N), TRIGGER

coupling.

2.

Set VERTICAL SENSITIVITY to desired vertical

sensitivity.

3.

Set vertical VERNIER to CAL for calibrated Minimum trigger sensitivity

SINGLE SWEEP (OPTION

SOURCE switch to EXT, and remove any external

trigger source.

B.

Adjust TRIGGER LEVEL control fully clockwise.

is

10):

obtained with the

sensitivity. control in this position.

4.

Set HORIZONTAL DISPLAY to desired horizontal

C. To increase trigger sensitivity, rotate TRIGGER

sweep time. Set VERNIER to CAL for calibrated LEVEL control counterclockwise. Maximum

sweep time.

X1

5. Set SWEEP MAGNIFIER to

6.

Set TRIGGERSOURCE to desired type of horizontal sweep synchronization.

or X5, as desired.

If

external sync

selected, connect sync signal to EXT. SYNC.

7.

Apply vertical input signal to vertical input

terminals.

8.

Adjust TRIGGER LEVEL for desired synchroni-

zation.

I

Figure

3-2.

Operation Using Internal'Horizontal Sweep or Single Sweep

is

sensitivity will be obtained just prior to the point

where the oscilloscope sweeps intermittently.

D. Set SWEEP switch to single (S). The instrument

is

now in the "armed" state and will sweep once

when triggered.

E. To rearm the sweep circuit, set SWEEP switch

from S to N and then back to S. External triggering

should not be applied during this operation to

vent the single sweep from occurring immediately

is

when the switch

returned to the S position.

pre-

Page 13

Section

III

Figure 3-3

SWEEP

MAGNIFIER

Model

120B

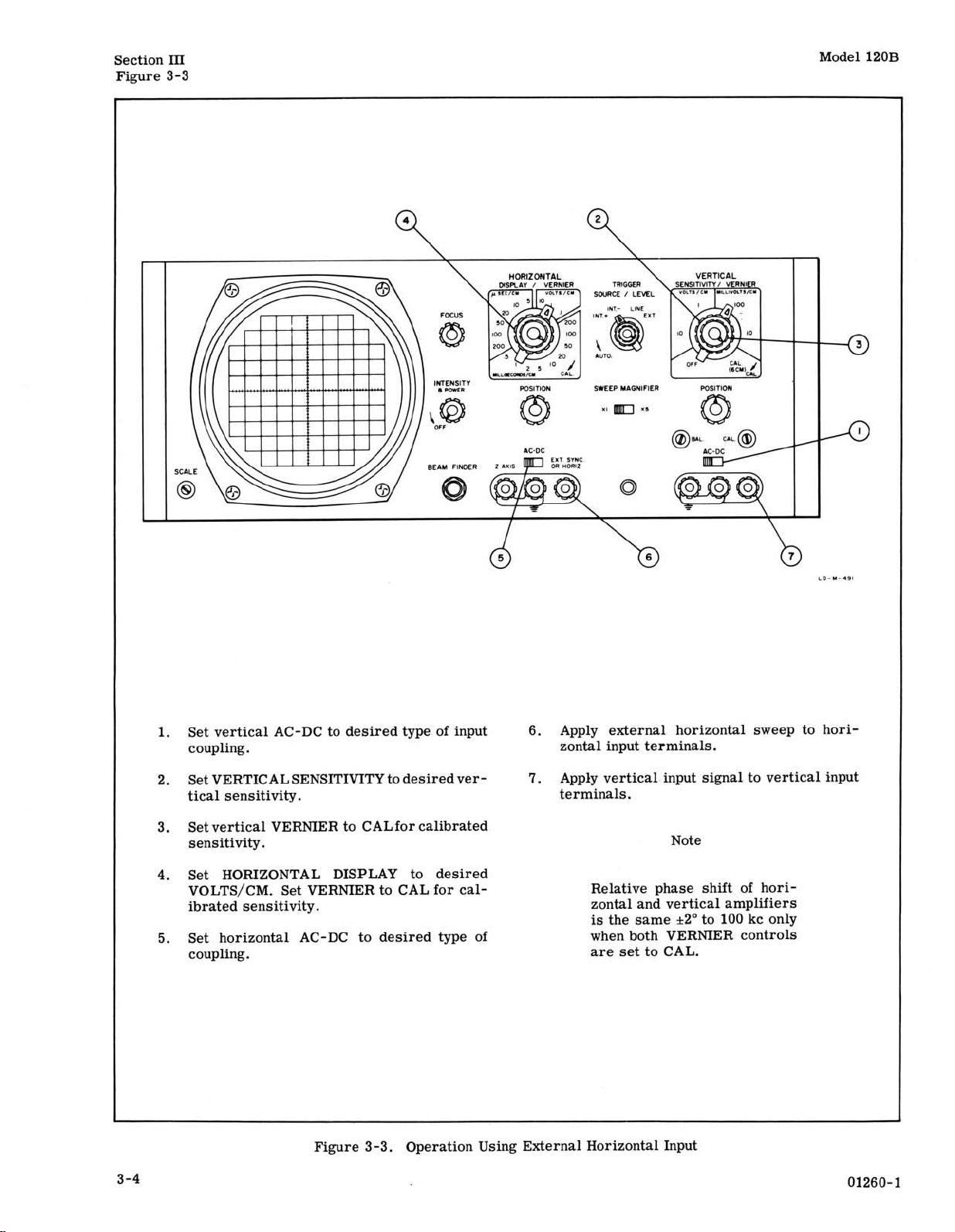

1.

Set vertical AC-DC to desired type of input

6.

Apply external horizontal sweep to hori-

coupling. zontal input terminals.

2.

Set VERTICAL SENSITIVITY to desired ver-

7.

Apply vertical input signal to vertical input

tical sensitivity. terminals.

Set vertical VERNIER to

3.

CALfor calibrated

sensitivity. Note

4.

Set HORIZONTAL DISPLAY to desired

VOLTS/CM. Set VERNIER to CAL for calibrated sensitivity.

5.

Set horizontal AC-DC to desired type of

Relative phase shift of horizontal and vertical amplifiers

is

the same

+2"

to

100

kc only

when both VERNIER controls

coupling. are set to CAL.

Figure 3-3. Operation Using External Horizontal Input

3

-4

Page 14

Model 120B

SWEEP

MAGNIFIER

Section

111

Figure 3-4

Remove grounding strap from vertical in-

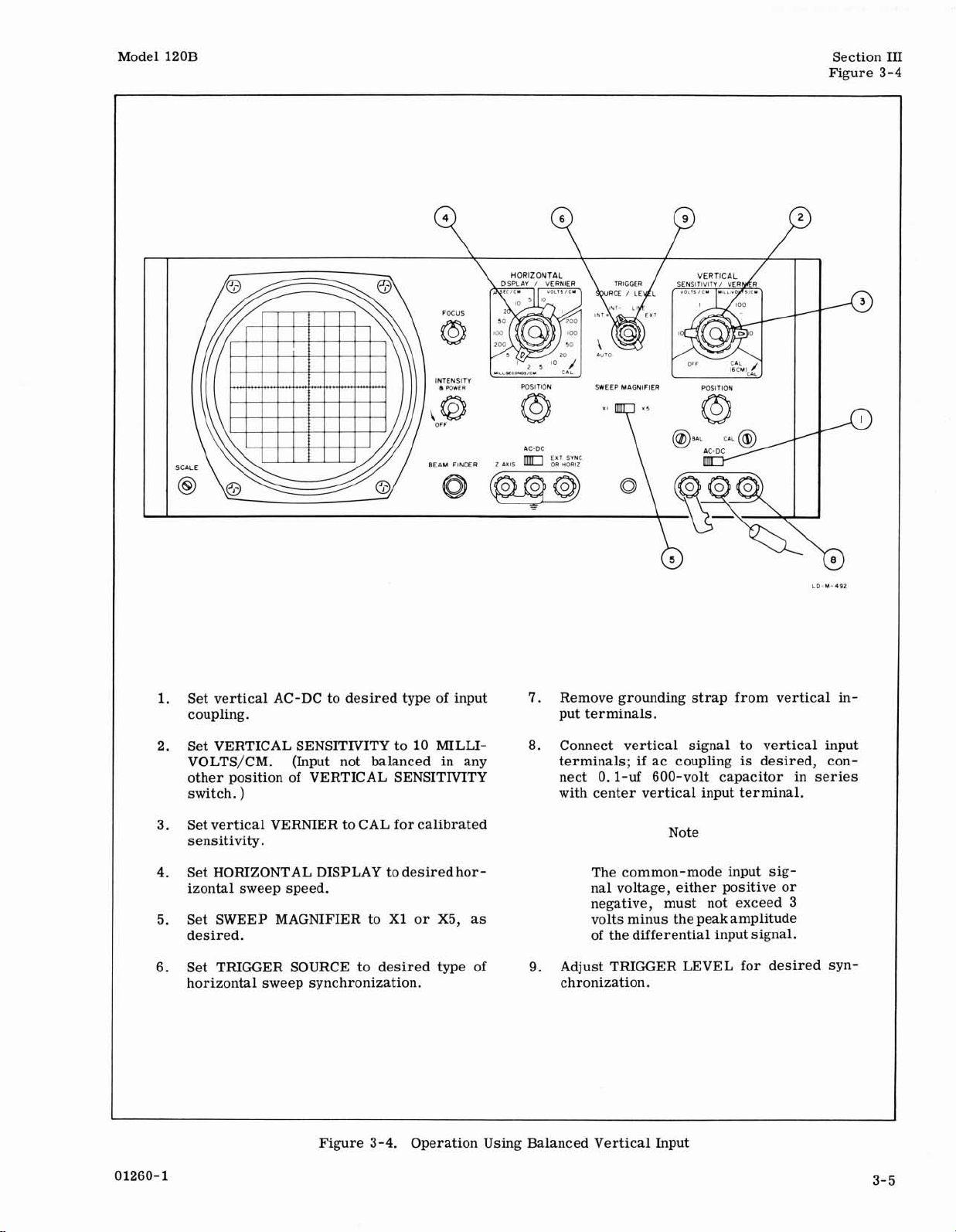

Set vertical AC-DC to desired type of input

1.

7.

coupling. put terminals.

2. Set VERTICAL

VOLTS/CM. (Input not balanced in any terminals;

other position of VERTICAL SENSITMTY nect

switch.

Set vertical VERNIER to CAL for calibrated

3.

)

sensitivity.

Set HORIZONTAL DISPLAY to desired hor- The common-mode input sig-

4.

izontal sweep speed.

SENSITIVITY to 10 MILLI-

8.

Connect vertical signal to vertical input

if

ac coupling

0. 1-uf 600-volt capacitor in series

with center vertical input terminal.

Note

nal voltage, either positive or

negative, must not exceed 3

5. Set SWEEP MAGNIFIER to

desired.

6. Set TRIGGER SOURCE to desired type of

X1 or X5, as volts minus the peak amplitude

of the differential input signal.

9.

Adjust TRIGGER LEVEL for desired syn-

horizontal sweep synchronization. chronization.

is

desired, con-

LO-U-.92

Figure 3-4. Operation Using Balanced Vertical Input

3-5

Page 15

Section

Figure 3-5

III

Model 120B

SWEEP MAGNIFIER

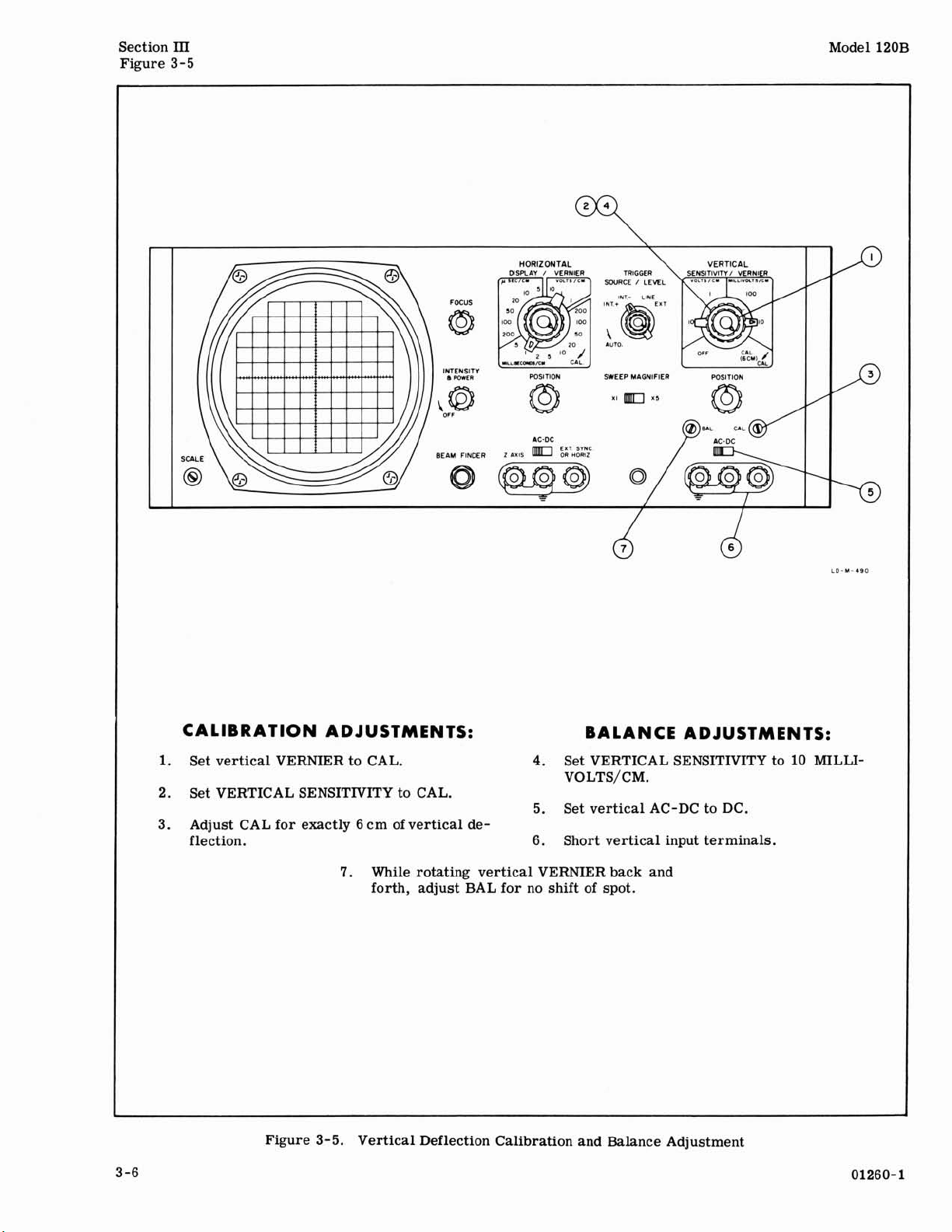

CALIBRATION ADJUSTMENTS:

1.

Set vertical VERNIER to CAL.

2. Set VERTICAL SENSITIVITY to CAL.

Adjust CAL for exactly

3.

flection.

6

cm of vertical de-

While rotating vertical VERNIER back and

7.

forth, adjust BAL for no shift of spot.

BALANCE ADJUSTMENTS:

4.

Set VERTICAL SENSITIVITY to 10

VOLTS/CM.

Set vertical AC-DC to DC.

5.

6.

Short vertical input terminals.

LD-Y-490

MILLI-

Figure 3

-

5.

Vertical Deflection Calibration and Balance Adjustment

01260-1

Page 16

Model 120B

Section

IV

Paragraphs 4-1 to 4-8

SECTION

PRINCIPLES OF OPERATION

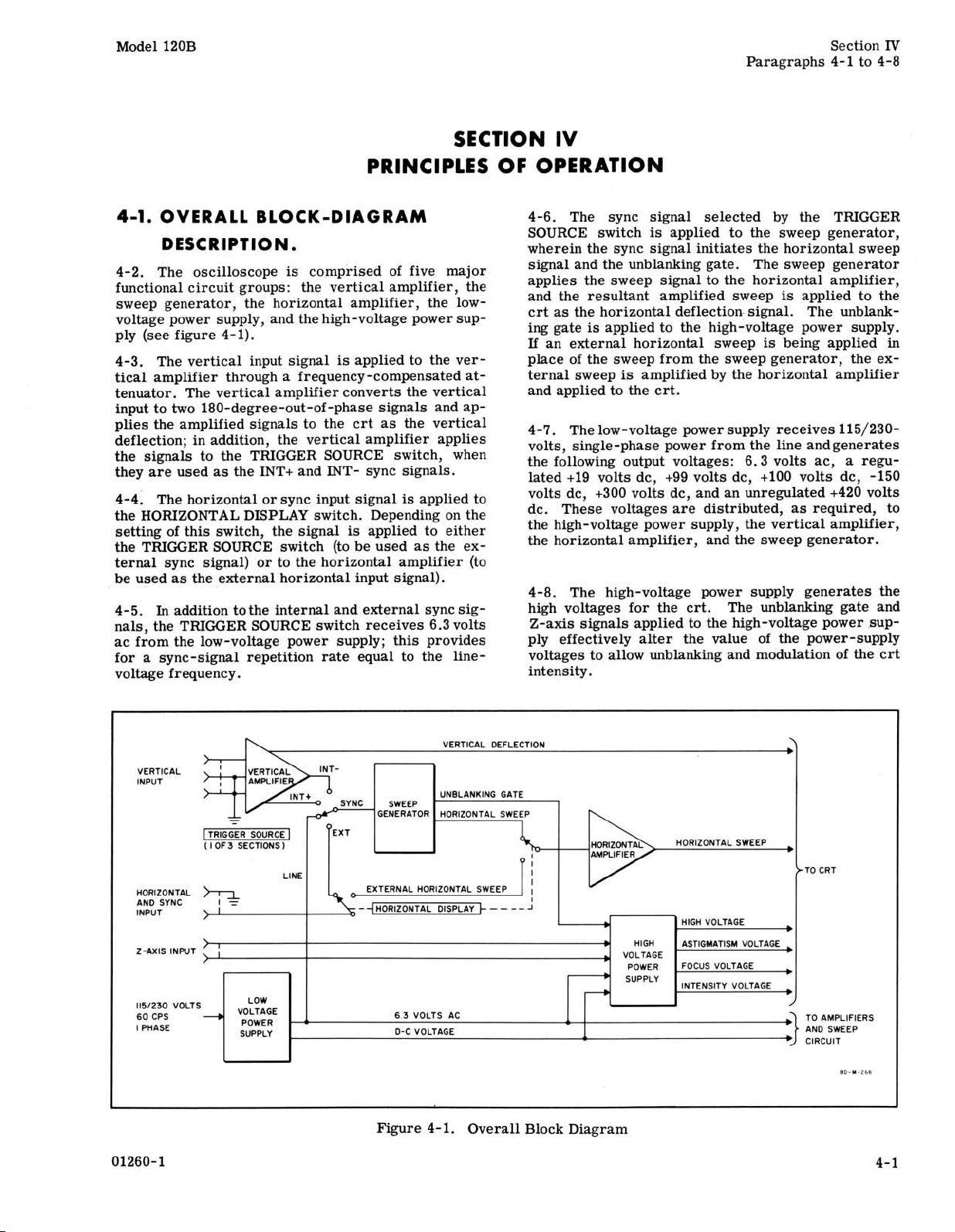

4-1.

OVERALL BLOCK-DIAGRAM

DESCRIPTION.

is

4-2. The oscilloscope

functional circuit groups:

sweep generator, the horizontal amplifier, the lowvoltage power supply, and the high-voltage power

ply (see figure 4-1).

4-3. The vertical input signal is applied to the vertical amplifier through a frequency -compensated

tenuator. The vertical amplifier converts the vertical

input to two 180-degree-out-of -phase signals and applies the amplified signals to the crt as the vertical

deflection; in addition, the vertical amplifier applies

the signals to the TRIGGER SOURCE switch, when

they are used

as

the INT+ and INT- sync signals.

4-41 The horizontal or sync input signal

the HORIZONTAL DISPLAY switch. Depending on the

setting of this switch, the signal is applied to either

the TRIGGER SOURCE switch (to be used as the external sync signal) or to the horizontal amplifier (to

be used as the external horizontal input signal).

In

4-5.

addition tothe internal and external sync sig-

nals, the TRIGGER SOURCE switch receives 6.3 volts

ac from the low-voltage power supply; this provides

a

sync-signal repetition rate equal to the line-

for

voltage frequency.

comprised of five major

the vertical

amplifier,

sup-

is

applied to

the

at-

IV

4-6. The sync signal selected by the TRIGGER

SOURCE switch is-applied to the sweep generator,

wherein the sync signal initiates the horizontal sweep

signal and the unblanking gate. The sweep generator

applies the sweep signal to the horizontal amplifier,

and the resultant amplified sweep

crt as the horizontal deflection signal. The unblank-

is

ing gate

If

an external horizontal sweep is being applied

applied to the high-voltage power supply.

place of the sweep from the sweep generator, the ex-

ternal sweep

is

amplified by the horizontal amplifier

and applied to the crt.

4-7. The low-voltage power supply receives

volts, single-phase power from the line andgenerates

the following output voltages: 6.3 volts ac, a regu-

lated +19 volts dc, +99 volts dc,

volts dc,

+300 volts dc, and an unregulated +420 volts

dc. These voltages are distributed, as required, to

the high-voltage power supply, the vertical amplifier,

the horizontal amplifier, and the sweep generator.

4-8. The high-voltage power supply generates the

high voltages for the

crt. The unblanking gate and

Z-axis signals applied to the high-voltage power .supply effectively alter the value of the power-supply

voltages to allow unblanking and modulation of the crt

intensity.

is

applied to the

in

115/230-

+I00 volts dc, -150

VERTICAL DEFLECTION

VERTICAL

GENERATOR HORIZONTAL SWEEP

(

I OF 3 SECTIONS

115/230 VOLTS

60 CPS 6 3 VOLTS AC

l PHASE

)

LOW

POWER

SUPPLY D-C VOLTAGE AND SWEEP

Figure 4-1. Overall Block Diagram

-

-+

HIGH VOLTAGE

POWER FOCUS VOLTAGE

SUPPLY

INTENSITY VOLTAGE

\

*

>TO CRT

b

+

1

CIRCUIT

80-"-266

4-1

Page 17

Section IV

Paragraphs 4-9 to 4-15

Model

120B

4-9.

CIRCUIT ANALYSIS.

4-10.

VERTICAL AMPLIFIER.

4-11. For ac coupling, capacitor C1

is

placed in

series with the signal path by means of the AC-DC

switch. (See figure 5-6.

applied to VERTICAL SENSITIVITY switch

the switch

is

in the CAL position, the input of the am-

)

The input signal

is

then

S2. When

plifier is directly connected to the output of the calibrator (V4, V5, and associated circuit parts). When

is

the VERTICAL SENSITIVITY switch

in other positions, precision frequency-adjusted attenuators are

inserted. These attenuators give a ten-to-one attenuation between adjacent positions. The input signal

is

then applied to the control grid of amplifier VIA.

4-12. Balanced input to differential amplifier V1B

is

obtained by removing the ground jumper across resistor

R1 (ground strap on front panel) and applying a

balanced signal input. Balanced input is useful in applications where it

is

desired to simultaneously amplify the out-of-phase (differential) signal and attenuate the in-phase (common mode) signals, such as

hum, noise, etc. This rejection

is

an inherent property of differential amplifiers. The common-mode

signals are attenuated by 40 db

differential input

is

amplified.

(100:1), whereas any

4-13. The vertical amplifier consists of three sets

of balanced differential amplifiers

(Vl, V2, and V3)

in cascade. The three stages are neutralized by

plate-to-grid cross neutralization. The first stage,

V1, has balance and gain adjustments. The balance

adjustment (BAL)

is

potentiometer R16 in the cathode

circuit, which adjusts the current distribution be-

tween the two triodes. Potentiometers

control) and

R20 (CAL) adjust the resistance between

R21 (VERNIER

the plates and therefore determine the gain of the amplifier. The VERTICAL VERNIER control provides

a

ten-to-one variation in gain between ranges of the

VERTICAL SENSITIVITY switch. The second differential amplifier,

V2, has potentiometer R32 (vertical

POSITION control) between its cathodes. This potentiometer controls the current distribution between

the two triodes and thus determines the vertical position of the crt display. The third differential

fler, V3,

is

the output stage. Synchronization signals

ampli-

are taken from the plates of V3 for application to the

TRIGGER SOURCE switch. Since the horizontal

sweep circuits trigger only on the negative slope of

the signal, provision is made to take the proper synchronizing signal from either plate of V3.

4-14. One section of the BEAM FINDER switch is in

the cathode circuit of V3.

When pressed, the switch

increases the common cathode resistance and so re-

duces the gain of the stage that no amount of unbalance

ahead of V3 can deflect the sweep off the crt.

4-15. The calibrator circuit consists of neon lamps

V4,

V5, and associated circuit parts. When VERT-

ICAL SENSITIVITY switch

S2 is placed in the CAL

position, V4 ionizes and capacitor C14 begins charg-

ing. As the voltage across capacitor C14 rises, the

voltage at the junction of V4 and R52 rises proportionally. When the voltage at this junction reaches

the firing potential of

ducting potential of V5

V5, V5 ionizes. Since the con-

is

less the firing potential, the

voltage at the junction of V4 and V5 drops, and V4 deionizes. C14 discharges through

R53, and the poten-

tial across V4 increases. When the potential across

FROM

ITRIGGER

SOURCE

SW

SYNC

I

-+

9

[TRIGGER LEVEL

I

I

I

TRIGGER

GENERATOR

v201

-

Figure

I

-

NETWORK

4-2.

TRIGGER

v202

STOP

A

HOLD-

OFF

CATHODE

FOLLOWER

V203B

Sweep Generator,

i

Block

SWITCH DIODE

CLAMP

V203A

A

-

Diagram

GATE-OUT

CATHODE

FOLLOWER

V204

-v

n

'

I V205A

I

I

I

I

:--

ISWEEP

MAGNIFIER]

*

-

UNBLANKING

GATE TO

HIGH-VOLTAGE

POWER SUPPLY

SAWTOOTH

*

INTEGRATOR

+

SAWTOOTH

CATHODE

FOLLOWER

V205B

-

A

TO

HORIZONTAL

AMPLIFIER

83-U-267

01260-1

Page 18

Model 120B

Section

IV

Paragraphs 4-16 to 4-22

GRlD OF

V201A

PLATE OF

V201B

JUNCTION

OF C207

C208

AND

PLATE OF

V202B

GRID OF

V203B

(SEE NOTE)

GRlD

OF

V202A

-1

'

-

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

1

I

I

I

I

I

I

I

I

I

LENGTH

OF

SAWTOOTH

TIME CONSTANT

ON RC

SELECTEDBY

HORIZONTAL

SWITCH

DISPLAY^

DEPENDS

LD-S-

530

the negative-going output

is

applied to switch diode

CR201.

4-19. Switch diode CR201 normally clamps the input

to sawtooth integrator

age, preventing sawtooth integrator

erating a sawtooth waveform. When the

going step signal from the start-stop trigger

to the switch diode, however, the diode

V205A to a low negative volt-

V205A from gen-

negative-

is

applied

is

reverse

biased and allows the sawtooth integrator to generate

a sawtooth waveform.

4-20. The sawtooth output of

V205B

applied to the horizontal amplifier to serve

is

simultaneously

as

the

horizontal sweep signal and the hold-off cathode fol-

V203B. The output of the hold-off cathode fol-

lower

lower

is

applied to the input of the start-stop trigger

terininate the sweep. The values of R and C selected

to

by the HORIZONTAL DISPLAY switch determines the

slope of the

Clamp V204 ensures that the sawtooth always

sweepand therefore the time of the sweep.

starts

at the same level. Figure 4-3 shows the relative

timing of the sweep generator waveforms.

4-21. TRIGGER GENERATOR V201. (See figure

5-8.)

SOURCE switch

resistor

is

control

form of bi-stable multivibrator, and

The sync signal selected by the TRIGGER

is

applied through capacitor C202 and

R201 to the input control grid of V201, which

a Schmitt trigger circuit when the TRIGGER LEVEL

is

not in AUTO. The Schmitt trigger

is

used to obtain

is

pulses with rapid rise and fall times.

4-22. Figure 4-4 illustrates a simplified Schmitt

If

trigger and typical input and output waveforms.

is

itially the input voltage (figure 4-4)

+

DC

such that V1

in-

is

a

Figure 4-3. Sweep Generator Waveforms

V4 reaches the firing potential, V4 fires and the volt-

4

b

(w

OUTWT

age at the junction of V4 and V5 drops, deionizing V5.

C14 starts charging again, and the cycle repeats. A

is

60-mv square wave

this signal

is

applied through the SENSITIVITY switch

developed across R54, and

I

INPUT

v2

v

to the vertical amplifier.

4-16.

SWEEP GENERATOR.

4-17. BLOCK-DIAGRAM DESCRIPTION. (See figure

4-2.) The sync signal from the TRIGGER SOURCE

is

switch

applied to trigger generator V201. The trig-

-

-

-

-

-

ger generator produces a rectangular wave with a

repetition frequency equal to that of the input sync

signal. This rectangular wave is applied to a differ-

it

entiating network which converts

to positive and

negative spikes that are coincident with the leading

and trailing edges of the rectangular wave. These

spikes are then applied to the input of start-stop trigger V202.

4-18. The negative spike switches the start-stop

trigger, which produces two step outputs. The posi-

is

tive-going output

applied through V204 to the high-

-

ob

-

-

a

I

b

LO 5-53!

voltage power supply as the crt unblanking gate, and Figure 4-4. Typical Schmitt Trigger

Page 19

Section IV

Paragraphs 4-23 to 4-32

Model 120B

cutoff, V2 conducts. As the input voltage becomes

more positive, it eventually reaches a predetermined

level (a) at which the circuit changes state; that

V1 conducts and V2

goes negative, the common cathode potential decreases

and the grid of V2 becomes positive. When the input

reaches a second predetermined level

and the circuit switches back to

output of the circuit

or negative depending upon the slope of the input

signal.

4-23. The input voltage levels at which a Schmitt

trigger circuit switches are called the hysteresis

limits. Note that the circuit (figure 4-4) does not

switch unless the input crosses both limits.

4-24. Trigger generator V201 has some additional

features: the TRIGGER LEVEL control adjusts the

bias on

input trigger must reach to change state; in addition,

when the TRIGGER LEVEL control

limit, switch S202

shunt across resistor R207 and capacitors C205 and

C206, and the trigger generator becomes an astable

multivibrator. This provides triggers to the

start trigger even though no sync is applied to the

trigger generator. When a sync signal above approxi-

mately 50 cps

erator then synchronizes with the sync signal. The

step output of the trigger generator

plate of

4-25. DIFFERENTIATING NETWORK. (See figure

5-8.) The differentiating network

series combination of capacitor

and resistor R210. The r-c time constant of this network

the trigger generator output pulses; consequently, the

signal developed across inductor L201 and resistor

R210 consists of short negative and positive spikes

that are coincident with the leading and trailing edges

of the trigger generator output pulses. These spikes

are coupled through capacitor C208 to the control grid

of

4-26. START-STOPTRIGGER

AND SWITCH DIODE CR201. -(See figure 5-8. ) The

start-stop trigger is a Schmitt trigger circuit. A

typical Schmitt trigger

V202 is triggered by a negative spike pulse from the

differentiating network. One output step waveform is

taken from the plate of

plies to switch diode

V203A. The waveform applied to V203A cuts off

V203A, and thus disables the clamping action of this

tube. The waveform applied to switch diode

reverse-biases the diode, and thus it ceases conduction. Another step output

V202A and applied through cathode follower V204 to

the high-voltage power supply; this serves as the crt

unblanking gate.

4-27. SAWTOOTH GENERATOR

TOOTH CATHODE FOLLOWER

V2OlA and thus determines the level which the

V201B andapplied to a differentiating network.

is

extremely small compared with the width of

V202A, one half of the start-stop trigger.

is

cutoff.

is

a voltage step, either positive

is

placed in AUTO. This opens the

is

applied, however, the trigger gen-

is

V202B and simultaneously ap-

CR201 and the grid of clamp

If

the input voltage then

(b),

V2 conducts

its

initial state. The

is

at its extreme

is

taken from the

is

composed of the

C207, inductor L201,

V202, CLAMP V203A,

described in paragraph 4-22.

is

taken from the plate of

V205A AND SAW-

V205B. (See figure

is,

stop-

CR201

5-8.) Sawtooth generator

tegrator which produces a linear sawtooth waveform.

When switch diode

tegrating capacitor charges through the integrating

resistance, producing a negative-going potential at

the control-grid of

the plate of

cathode follower

completing the negative feedback required by this

Miller type integrator.

4-28. The sawtooth signal at the cathode of

also applied to SWEEP MAGNIFIER switch S102.

When ,9102

to the horizontal amplifier has

times greater than that applied when S102

position; hence, the angle of slope is increased five

times and the sweep time

by the HORIZONTAL DISPLAY switch.

4-29. The sawtooth signal at the cathode of

applied to the control grid of V202A. When the slope

of the signalreaches the upper hysteresis limit of the

start-stop trigger, the trigger changes state; hence,

the unblanking gate output of

The switch diode

respectively, halting the charging of the integrating

capacitor and terminating the sawtooth waveform.

The hold-off capacitor in the cathode of

during the rising slope of the signal output of the

off cathode follower but does not immediately discharge when the sawtooth input to the hold-off cathode

follower terminates. This prevents the start-stop

trigger from again being triggered by a negative spike

until the sweep circuits have fully recovered. A different value of hold-off capacity

setting of the HORIZONTAL DISPLAY switch.

4-30.

4-31. The grid of VlOlA (figure 5-7) receives either

the sweep output from the horizontal sweep circuits

or from an external sweep source, depending on the

setting of the HORIZONTAL DISPLAY switch. When

external sweep is being used (EXT SENSITIVITY positions), any one of three horizontal sweep sensitivities

can be selected:

VOLTS/CM. The AC-DC switch allows selection of

direct coupling, or ac coupling through capacitor

C101.

4-32. The horizontal amplifier consists of two differential amplifiers

the HORIZONTAL DISPLAY switch

EXT SENSITIVITY positions, the resistance between

the cathodes of amplifier VlOl consists of the horizontal VERNIER control

horizontal gain control

R107 is between the cathodes. The horizontal POSITION control (potentiometer

of VlOl controls the horizontal position of the crt

trace. The second stage

plate-to-grid cross neutralization. The output of the

horizontal amplifier

and applied directly to the horizontal deflection plates

of the crt.

V205A

is

HORIZONTAL AMPLIFIER.

CR201 ceases conduction, the in-

V205A. The amplified signal at

is

V205B to the integrating capacitor,

in the X5 position, the sawtooth applied

CR20l and clamp V204 again conduct,

.1

VOLTS/CM, 1 VOLTS/CM, or 10

(V101 and V102) in cascade. When

is

V205A is a Miller in-

coupled back through sawtooth

V205B

a

peak amplitude five

is

in the X1

is

one-fifth of that selected

V203B

V203A is terminated.

V203B charges

is

selected for each

is

set to one of the

(R275B) in series with the

(R104); otherwise, resistor

R109) between the plates

(V102)

taken from the plates of V102

is

neutralized by

is

is

hold-

Page 20

Model 120B

Section

Paragraphs 4-33 to 4-40

IV

+I9 VOLT DC

AC

b

REGULATED

POWER SUPPLY

-

115/230 VOLTS

60

CPS

IPHASE

4-33.

the cathode circuit of

increases the common cathode resistance and so reduces the gain of the stage that no amount of unbalance

ahead of V102 can deflect the sweep off the crt.

4-34.

4-3 5. BLOCK-DIAGRAM DESCRIPTION. (See figure

4-5.) The

plied through switch S301 to transformer

transformer applies 6.3 volts ac to the vertical amplifier, horizontal amplifier, sweep generator, and

high-voltage power supply for use as filament voltage;

the transformer also applies appropriate ac voltages

to the following: the

supply; the

power supply; and the -150-volt dc regulated power

supply.

4-36. The regulated power supplies deliver their dc

outputs to the following circuits:

applied

'I9, + loo,

vertical amplifier, the horizontal amplifier, the hor-

izontal sweep circuits, and the high-voltage power

supply; in addition, the -150-volt supply applies

ative

supplies for use as a control voltage.

One section of the BEAM FINDER switch

LOW-VOLTAGE POWER SUPPLY.

to

voltage to the +19-. +99-. +loo-. and +300-volt

S301

--

I

I

I

115/230-volt, single-phase power is ap-

+300-, +loo-, and +99-volt dc regulated

the horizontal and vertical amplifiers; and

+300,

TRANSFORMER

T302

Yigure 4-5. Low-Voltage Power Supply, Block Diagram

V102. When pressed, the switch

+19-volt d-c regulated power

and

-

-

-

b

T302. The

+

19 volts dc is

are

'

to

aneg-

+420,*300,+

AND199 VOLTS

OC REGULATED

POWER SUPPLY

-150-VOLT DC

POWER SUPPLY

is

the

T

100

t

REGULATED

in

tor C325A. The resulting dc voltage

further by tubes

4-38. The circuit functions as follows: when power

is

justed properly) the cathode of V310 becomes fixed at

-65 volts and the grid assumes a slightly more negative value.

change were to occur, tending to lower the supply

voltage, V310 grid potential would tend to change by

half the amount, since the grid

divider between -150 volts and ground. The result

is

raising

bias on

resistance, decreasing the voltage drop across this

element which tends to return the supply voltage

its original value.

4-39.

POWER

operates in almost exactly the same manner as the

-

150-volt supply except that it uses the - 150-volt sup-

ply

CR302, V307, and V308

ulator, and amplifier, respectively. The

+99-volt supply is further regulated by V308B, referenced to the +300-volt supply.

+

19

VOLTS DC

TO AMPLIFIERS

VI,V2 AND VlOl

2)

+99VOLTS DC

+300 VOLTS DC

+I00 VOLTS DC

+420VOLTS DC UNREG

TO AMPLIFIERS,

6.3 VOLTS AC AND HIGH-VOLTAGE

-150 VOLTS DC

V309, V310, and V311.

applied (assuming the - 150-volt supply has been ad-

If

a line voltage surge or load current

increased bias for V310, lowering its current,

its

plate voltage, which, in turn, lowers the

V309. This bias change in V309 lowers its

+300-. +loo- AND +99-VOLT DC REGULATED

as

SUPPLY.

its

voltage

The +300-volt supply (figure 5-9)

reference.

are

the rectifier,

SWEEP CIRCUITS,

POWER SUPPLY

is

is

tied to a voltage

In

this

supply,

BD-M-268

regulated and

,to

CR301,

series

reg-

+loo- and

4-37. -150-VOLT DC REGULATED POWER SUP- (See figure 5-9.

PLY. The -150-volt supply (figure 5-91 in the 120B

is

used as a reference supply for the +300-, +loo-, CR304 and capacitor C328 for rectifier and filter.

and

+99-volt supplies; therefore, any change in the

-150 volt supply is reflected as a change inthese supply voltages. The ac voltage from T302

and partially filtered by rectifier

CR303 and capaci-

is

rectified

4-40.

ments of vertical amplifiersvland V2) uses rectifier

Transistor

tial across Zener diode CR302 for its voltage reference. The current in transistor

value of the dc voltage across the filaments.

+19-VOLT DC REGULATED POWER SUPPLY.

)

The +19-volt supply (for the

Q301

is

a

series regulator using the poten-

Q301 determines the

fila-

Page 21

Section IV

Paragraphs 4-41 to 4-48

-

Model 120B

-

REGULATOR

V301

CONTROL

VOLTAGE

OSC~LLATOR

V302

FROM SWEEP

GENERATOR

4-41.

HIGH-VOLTAGE POWER SUPPLY.

4-42. BLOCK-DIAGRAM DESCRIPTION. (See figure 4-6.) Oscillator V302 generates an ac voltage and

applies it to step-up transformer

up ac voltage

The negative high-voltage output of V303

the cathode of the crt, and the negative high-voltage

output of V304 is applied to the control grid of the crt.

The difference between the two voltages is the crt bias

and thus controls the crt intensity.

4-43. When the INTENSITY control setting

a

change occurs in the cathode high voltage, causing

a change in the voltage level at the wiper of the

volt adjust potentiometer. This results in regulator

V30l altering the control voltage in a direction necessary to return the cathode high voltage to

value; however, this now results in the control-grid

high voltage being higher or lower than previously

and thus the crt intensity

4-44. HIGH-VOLTAGE RECTIFIER

ure 5-10.) The ac high voltage present in one secondary winding of T301

by capacitor

taken from the wiper of INTENSITY potentiometer

R321

is

effectively in series with and opposing the

high-voltage output of

ER pushbutton is depressed, the opposing voltage

from the wiper of potentiometer R321

removed and the intensity of the crt trace

4-45.

the signal is applied through capacitor C307 to the

cathode of the crt and thus modulates the crt intensity.

When a signal

-

,TRANSFORMER

c

is

applied to rectifiers V303 and V304.

is

is

rectified by V303 and filtered

C308. A portion of the +I00 volts dc

V303. When the BEAM FIND-

is

applied to the Z AXIS input,

HlGH

VOLTAGE

ADJUST

+300VDC

HIGH A-C

STEP-UP

T301

Figure 4-6. High-Voltage Power Supply, Block Diagram

T301. The stepped-

altered.

V303. (See fig-

VOLTAGE

HIGH A-C

VOLTAG E

UNBLANKING GATE

is

applied to

is

changed,

-2500-

its

original

is

effectively

is

increased.

HIGH-VOLTAGE

RECTIFIER

b

V303

I

/

A

[BEAM

bml

HIGH-VOLTAGE

RECTIFIER

V304

4-46. A voltage-divider network, consisting of resistors

eters R312 (FOCUS control) and R308 (-2500 adjust),

is tied between

crt. The voltage present at the wiper of R312 is ap-

plied to the crt focusing grid as focusing voltage, and

the voltage present at the wiper of R308

amplifier V301B as the high-voltage control voltage.

4-47. AMPLIFIER V301. (See figure 5-10. ) When a

change in the value of the high voltage occurs, a corresponding change occurs at the wiper of potentiometer

and the resultant change in the plate voltage is dc

coupled through R305 to the control grid of

This, in turn, results in a change in the plate voltage

of

oscillator

high voltage decreases, the screen grid voltage of

V302 increases to a point where the increasedac out-

put of V302 restores the high voltage to its original

value.

4-48. HIGH-VOLTAGE RECTIFIER V304. (See figure 5-10.

ondary of transformer T301 is rectified by V304 and

filtered by capacitor

high voltage is applied through resistor

control grid of the crt. The positive side of the high

voltage is applied through resistor R326 to the horizontal sweep circuits, wherein the unblanking gate is

generated. When the positive-going unblanking gate is

generated, the crt control grid bias becomes less negative and the crt is unblanked.

R313, R311, R310, R309, R307, potentiom-

+300 volts dc and the cathode of the

R308. This alters the bias at the grid of V301B,

V301A, which is connected to the screen grid of

V302. The overall effect is that when the

)

The ac high voltage across the other sec-

&2500VDC + CATHODE

FINDER^

.

=

C310. The negative side of the

TO

OF CRT

TO CONTROL

+GRID OF

CRT

ED-M-269

is

applied to

R327 to the

V301A.

Page 22

Model 120B

Section V

Paragraphs 5-1 to 5-8

SECTION

MAINTENANCE

5-1.

INTRODUCTION.

5-2. This section provides maintenance and service

instructions for the Model 120B Oscilloscope.

cluded are troubleshooting, repair, adjustment, performance checks, and diagrams.

5-3.

TEST

5-4'

maintain

characteristics can be substituted.

EQUIPMENT.

5-1

lists

the

the

120B'

test

equipment

Equipment

required

with

5-5. TROUBLESHOOTING.

5-6. The troubleshooting procedures are divided into

two categories: system troubleshooting, which

5-

Table

In-

to

is

used

1.

Recommended Test Equipment

V

to isolate a malfunction to aparticular functional section of the Model 120B; and sectional troubleshooting,

which

is

used to locate the faulty detail part. Figures

5-1 through 5-4 show the location of parts whose designations are not directly imprinted on

or chassis.

5-7.

SYSTEM TROUBLESHOOTING.

5-8. Most troubles occurring in the Model 120B will

directly affect the display on the crt; consequently, the

system-troubleshooting procedures are based on the

most common types of faults detectable by crt observations.

that occur in oscilloscope displays, together with the

circuits most likely to be at fault. After finding the

faulty section, refer to the sectional troubleshooting

procedures.

able-5-2

lists

the common types of defects

a

circuit board

Item

No.

1

2

3

4

5

Test

Oscilloscope

Precision

DC Voltmeter

High-Voltage

DC Voltmeter

Audio

Oscillator

AC Voltmeter

Characteristics

Bandwidth: dc to at least

600 kc. Sensitivity:

10

mv/cm to 100 v/cm,

Voltage range: 10-300 volts.

Accuracy:

Input impedance: 1 megohm.

Voltage range: 3000 volts.

Accuracy: 8%.

Input impedance: 100

ohms.

Frequency range: 50 cps

to 450 kc.

Voltage range:

300 v.

Accuracy:

on scale used.

Frequency Range: 50 cps

to

450 kc.

*I%.

meg-

1

mv

to

3% depending

Use

Observation of waveforms.

Voltage measurements.

Voltage measurements.

Source of sine-wave

signal.

I

Voltage measurements.

Model No.

Hewlett-Packard

140A.

Hewlett- Packard

Model

412A.

Hewlett- Packard

Model 410C with

Model

Voltage Divider

Hewlett- Packard

Model

Hewlett- Packard

Models

11045A

Probe

200CD.

400~/~/L.

Page 23

Section V

Paragraphs 5-9 to 5-14

Table 5-

1.

Recommended Test Equipment (Cont'd)

Model 120B

Item

No.

6

7

8

9

Type

Square Wave

Generator

Voltmeter

Calibrator

Time Mark

Generator

Power

Transformer

Auto-

Characteristics

Frequency range: 1 kc to

100 kc.

Rise time: Less than

0.2

pet.

Amplitude: To 50 volts

peak- to-peak.

Accuracy:

Marker intervals: decade

steps from 10

100 msec.

Accuracy:

Output voltage: 103-127

volts ac (for 115-volt

input to

254 volts ac (for 230volt input to 120B).

0.5%.

wec to

1%.

120B); 206-

Use

Source of square wave.

Accurate source of ac

and dc voltages.

Set sweep times.

Vary line voltage.

Model No.

Hewlett- Packard

Model

211A.

Hewlett-Packard

Models

Tektronix 180.

General Radio

Type

738A/~.

WlOHM.

10

5-9.

5-10. GENERAL.

tional section, a visual inspection should be performed. Check for open fuse, broken wires, discolored parts, leaky capacitors, etc. The best method for checking tubes is by substitution.

5-11. HORIZONTAL AND VERTICAL AMPLIFIERS.

In the event of vertical or horizontal troubles such as

unbalance or no deflection, check plate voltages,

starting at the input stage and working toward the crt.

Be sure the position controls are centered, no signals

are applied, and the HORIZONTAL DISPLAY switch

is

set to an external horizontal input position. Make

detailed voltage checks (see paragraph 5-67) in the

first stage with incorrect plate voltages.

of frequency response troubles, check tubes first (by

substitution) then frequency-compensating devices

such as trimmer capacitors, neutralizing and bypass

capacitors.

5- 12. SWEEP GENERATOR. With the exception of

trigger generator

form a feedback loop; consequently,

functional stage in the loop results in abnormal waveforms appearing in all stages of the loop. For this

reason, voltage readings are the best means for locating troubles in the sweep generator circuit. Voltage

measurements for both the start-of-sweepand end-of-

sweep circuit conditions are listed on figure 5-8. In

Attenuator

SECTIONAL TROUBLESHOOTING.

Prior to troubleshooting any func-

V201, the sweep generator circuits

Attenuation: 110 db in 1-db

steps.

Power capacity: 5 watts.

In

the event

a

failure in any

Attenuation

the event of sweep failure, it

voltage measurements be employed to isolate the trou-

ble. A10 to

be expected, a larger deviation indicates a source of

trouble.

5-13. LOW

checking the power supplies, check the

plyfirst, for it affects all supplies. Check the other

supplies in any order. Check all vacuum tubes and

transistor

paragraph 5- 67). Voltage and ripple tolerances are

given in table 5-4.

5-14.

HIGH-VOLTAGE POWER SUPPLY.

15% deviation from the values given can

-

VOLTAGE POWER SUPPLY. When

Q301;

if

normal, make voltage checks (see

CAUTION

Do not operate the Model 120B with

incorrect power supply voltages for

prolonged periods of time. Where

the procedure calls for a measurement, turn the instrument on just

long enough to make the measurement; then turn the instrument off

again.

WARNING

Use caution when measuring high

voltages. Use equipment suited for

high-voltage measurements.

Hewlett-Packard

Model

is

350D.

recommended that both

-

150-volt sup-

Page 24

Model 120B

Section V

Paragraph 5- 15

Figure 5-1.

5-15. Measure the voltages supplied to the crt.

they are normal, replace the crt.

are-not present, check that oscillator V302

lating. Note that a fault in the crt cathode supply affects the crt grid supply, whereas a fault in the crt

grid supply has no effect on the cathode supply.

both crt supplies are excessively high, or both exces-

sively low, make voltage checks on V301 (see para-

graph 5-67).

Top View, Location of Parts and Adjustments

Zf

If

the high voltages

is

oscil-

If

Note

Do not reset high voltage adjustment

R308 unless the need for

ment

is

clearly indicated. The ad-

justment of high voltages affects the

sensitivity of the crt and makes necessary the readjustment of vertical

and horizontal gain and time scales.

suchadjust-

Page 25

Section V

Figure 5-2

Model 120B

Figure 5-2. High-Voltage Power Supply, Location of Parts

Symptom

Nothing visible on crt with

BEAM FINDER pressed.

Vertical sensitivity out of

specifications on

tivity ranges; horizontal

sweep normal.

Vertical sensitivity out of

specifications on one range.

External horizontal

tivity out of specifications;

vertical sensitivity normal.

Faulty sweep; external

zontal deflection normal.

all

sensi-

sensi-

hori-

Table 5-2. System Troubleshooting

Probable Trouble

1.

Low-voltage power supply.

2. Vertical amplifier.

3. Horizontal amplifier.

4. High-voltage power supply.

5. Crt.

1.

Vertical amplifier.

2. VERTICAL SENSITIVITY

switch S2.

1.

Horizontal amplifier.

1.

Sweep generator circuits.

Paragraph Reference

1.

Paragraphs 4-34 and 5-13

2. Paragraphs 4-10 and 5-11

3. Paragraphs 4-30 and 5-11

4. Paragraphs 4-41 and 5-14

5. Paragraph 5-21

1.

Paragraphs 4-10 and 5-11

1.

Paragraphs 4-30 and 5-11

1.

Paragraphs 4-16 and 5-12

Poor focusing; intensity

normal.

Poor intensity.

1.

High-voltage power supply.

2. Crt

1.

Low-voltage power supply.

2. High-voltage power supply.

3.

Crt

1.

Paragraphs 4-41 and 5-14

2. Paragraph 5-21

1.

Paragraphs 4-34 and 5-13

2. Paragraphs 4-41 and 5-14

3. Paragraph 5-21

1

Page 26

Model 120B

Section

Paragraphs 5-16 to 5-22

V

Figure 5-3.

5-16.

5-17. REPLACEMENT OF SEMICONDUCTORS.

5-18. Excessive heat can destroy semiconductors.

When solderingor unsoldering transistors or diodes,

place a heat-sink (such as long-nose pliers) on the

lead of the part; in addition, isolate the Model 120B

from ground, or ground the body of the soldering iron

to prevent leakage current

5-20. Figure 5-5 illustrates the recommended

od of servicing etched circuit boards.

REPAIR.

When replacing

of silicone grease (hp Stock No.

0059) on each side of the insulator to

improve heat transfer from transistor

to deck.

SERVICING ETCHED CIRCUIT BOARDS.

VerticalSensitivity (A2) and Trigger Source (A201)Switches, Locationof Parts and Adjustments

f

rom damaging the part.

Note

Q301, use a thin coat

8500-

meth-

Removal of

components, such as tube sockets, that are attached

to the board at more than two points is difficult when

trying to remove the part intact. Simplify the removal

by first cutting the pins or other connections between

the body of the part and the circuit board, and then

remove the pins individually.

5-21. CRT REPLACEMENT.

WARNING

When replacing the crt, handle crt

with care; wear gloves and plastic

face mask or goggles.

5-22. Replace the crt as follows:

a. Remove four mounting screws from bezel, and

remove bezel.

b. Loosen clamp screw (figure 5-1) on crt base; do

not remove screw or clamp.

Page 27

Section V

Paragraphs 5-23 to 5-34

Model 120B

5-26. The following paragraphs, 5-27 through 5-51,

describe the adjustments necessary to align the Model

120B.

5-27. LOW-VOLTAGE POWER SUPPLY

5-28. Table 5-4

age outputs of the low-voltage power supply.

voltage is not within tolerance it is probable that the

line voltage

or the replacement of a tube or part has caused the

misadjustment.

ply and line voltage are normal and the voltages are

not within tolerance, adjustment

5-29. -150-VOLT ADJUSTMENT. Using a dc VTVM,

adjust potentiometer R352 (figure 5-1) for -150 volts

dc.

5-30.

justment for the

faulty transistor or part

in the -150-volt power supply.

5-31.

justment for the

a faulty tube or part is indicated, or a fault exists in

the -150-volt power supply.

5-32.

is