Page 1

MODEL

11180A

DATA

STORAGE

Page 2

"J

OPERATING

-hp- Part No. 11180-90000

AND

SERVICE

MANUAL

MODEL

DATA

STORAGE

11180A

Copyright Hewlett-Packard Company 1971

P.O. Box 301, Loveland, Colorado, 80537 U.S.A.

Printed: SEPTEMBER

1971

Page 3

HP Archive

This vintage Hewlett Packard document was

preserved and distributed by

www.hparchive.com

Please visit us on the web !

Prepared by on-line curator: Tony Gerbic

For FREE Distribution Only ***

Page 4

• • ...:.....,,·

... _ .. , ••• • •.•

~'

'•••·

•• :

•••

·•.:.,: .

!~·

·•~·

•

-····

···•'""--

'"'

••

:.h.'~O·:

.....

~~·.

·.:...1.:....:.r!"-'--

.,.

,;.~

.>~

---------HEWLETT.PACKARD---------

~

CE

RTI

Fl

The

Hewlett-Packard

thoroughly

tested

specifications

Packard

ments

the

Company

are

extent

traceable

allowed

when

Company

and

inspected

it

was

certifies that

shipped

further certifies that its

to

the

U.S.

by

the

Bureau's

CATI

and

National

0 N

found

from

the

Bureau

calibration

this

instrument

to

meet its

factory.

The

calibration

of Standards

fatility.

~ .··~·

••

,~~.,...,..-;..~

..:..:....~

was

published

Hewlett-

measure-

to

.a.

.:.-i..-""-"'~·-

~-~

;]

~

r1

WARRANTY

All

Hewlett-Packard products are warranted against defects

materials and workmanship. This warranty applies for

from the date of delivery, or,

nents listed

will

repair or replace products which prove to

the

warranty

Packard.

in

the operating manual, for the specified period.

period provided

No

other warranty

AND

in

is

ASSISTANCE

the case of certain major

be

defective during

they

expressed or implied.

are

returned

in

one

year

compo-

We

to Hewlett-

We

are not

liable for consequential damages.

Service contracts or customer assistance agreements are available

for Hewlett-Packard products that require maintenance and repair on-site.

For any assistance, contact your nearest Hewlett-Packard

Service Office. Addresses are provided

at

the back of this manual.

Sales and

!] .

;J

1 J

LJ.

IJ

;j

:J.

u·

Page 5

Model 1 l 180A

Table

of

Contents

··

]

..

.

]

]

.J

~fun

I. GENERAL INFORMATION .

1-1

. Introduction

1-

7. Accessories Furnished

(with Data

1-8. Accessories Available

(with Data Storage Only) . ....

~fun

II. INSTALLATION

2-1. Introduction ...

2-3

. Initial Inspection ... . .

2-5. Installation

2-

7. Storage Connector . . ........

2-9

. Repackaging for Shipment . ....

~fun

III. OPERATING INSTRUCTIONS ... . ....

3-1

. Introduction . .

3-3.

Basic

Operation . . .

3-13. Operation with Single Channel Plug-Ins .

3-18. Operation with Scanning Unit .

3-25. Sample-and-Hold Improves Digitizing .

3-29. Data Storage Used in the 2070A

3-32. How to Clear Data Storage ............

3-36. Applications .

Section

IV. THEORY OF OPERATION . .

4-1. Data Output

4-2. Present Mode (Isolated

44.

Storage Mode (Memory) . .

4-6. Panel Transfer

4-8.

IBCD

.......

4-13. Inhibit and Printer Hold

4-15. Encode (External Trigger)

4-1

7.

Basic

Storage .....

......

Storage Only) . .

...

. ............

......

of

1l180A

......... . . ........

.. ..

.......

........

...

........

.. ..

. . . .... . . .

.. .. ......

. . . . .

.....

. .

.........

into 3480A/B . . . . .

. . ....

...

...

.............

......

...

...

.......

.......

..... .. ..........

BCD) ....... ... 4-1

...........

.. ............. 4-1

. .

..........

. . . .

...

. . .

...... ........

.........

.............. 4-

TABLE

......

....

...

. .

....

........

...

.. ..

......

......

...

...

.....

.. ..

......

....

. . . . . . .

OF

CONTENTS

&~

. 1-1

1-1

1-1

..

1-1

&~

2-1

2-1

2-1

2-1

...

2-1

. .

2-1

~

3-1

...

3-1

3-2 5-8. Storage Check . .....

..

3-5 5-14. Troubleshooting

. 3-6

. 3-8

. 3-9

3-10

3-10

Page

. .

4-1

4-1

..

4-1

4-1

4-1

4-1

Section IV (Cont'd) Page

4-22. Turn-On

4-24. Printer and Dump Hold Cycling . .

4-

26. Panel Transfer . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-30.

Basic

4-3

7. Preset Triggers

4-39. Jump . .

441.

Limits ......

443.

Measurement Hold ...

446.

Scanner Control

4-51. Computer Control ......

~fun

V.

MAINTENANCE . . . . ..........

5-1

. Introduction ...... .

5-3. Equipment Required .

5-5. Performance Checks

5-7. IBCD Check ..........

~fun

VI.

REPLACEABLE PARTS

6-1

. Introduction

64

. Ordering Information .... ..........

6-6. Non-Listed Parts .

Section Page

VII. CIRCUIT DIAGRAMS .

7-1. Introduction .

7-3

. Notes .........

Appendix

l

A.

CODE LIST OF MANUFACTURERS

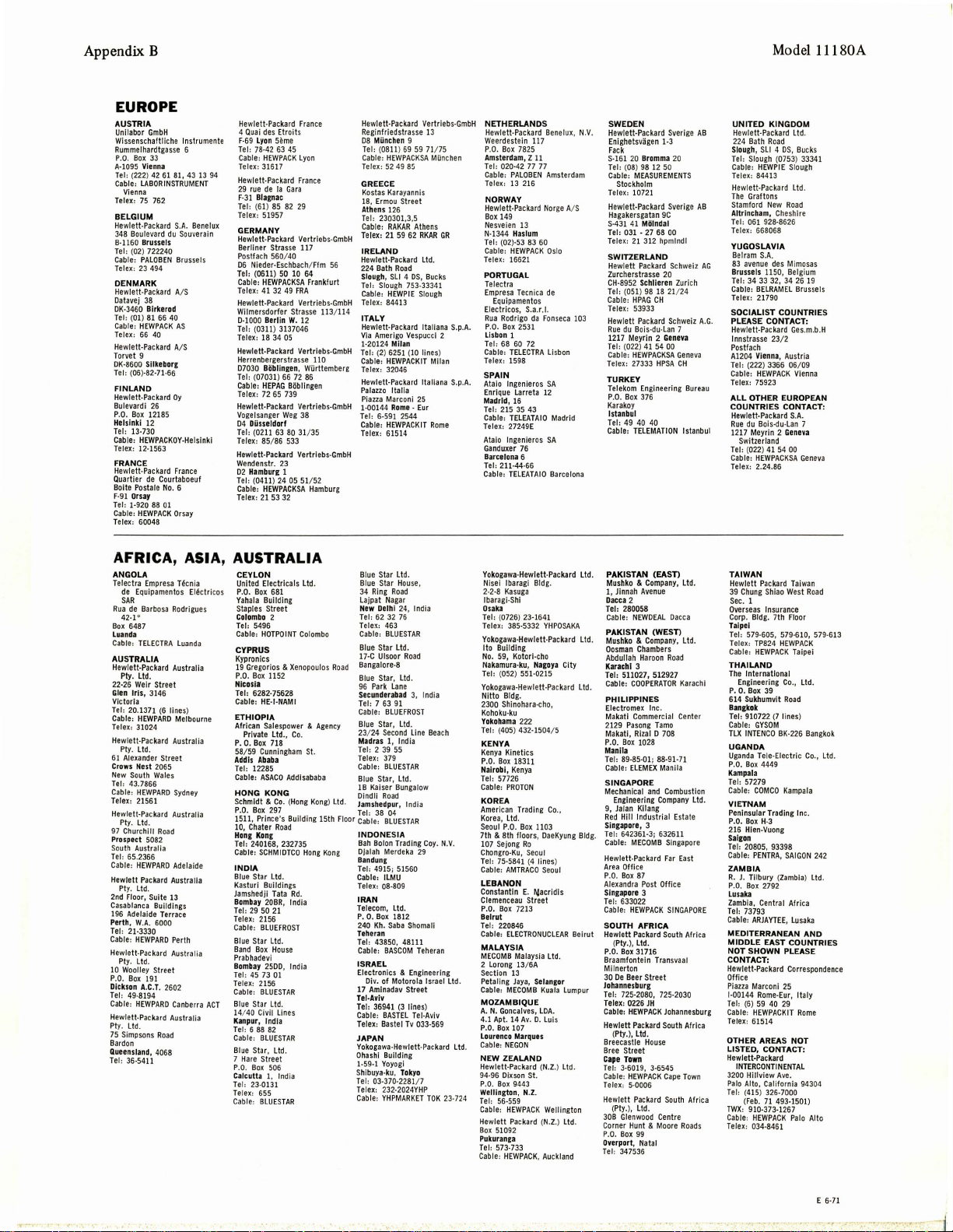

B. SALES

AND

........

Counter ....

...............

SERVICE OFFICES

................

....

. . .

.. ..

....

. . .

........

. .

........... 4-3

......

.. .. ..

............

...

....

.....

... ............ . 4-3

......... ............

....

. . ....... .

. ..........

...

. . ............

...

. . .... .

.....

....

. .

...

...

....

. . . . ....... .

........

...

.........

....... .

........

............. 5-1

...

. .

.......

.............

.....

.....

. ....

. .... . . . . .

...

....... 4-2

...

. .

...

.

...

. . . . 4-2

....

. 4-3

&~

.......

...

....

.. ..

...

&~

.. ..

...

. .

. . .

......

..

. .... 7-l

......

..

4-1

4-2

4-3

44

5-1

5-1

5-1

5-1

5-1

5-1

6-1

6-1

6-1

6-1

7-1

7-1

J

J

' t

.,

~~m

l-1. Specifications ... .....

3-1. Storage Connector ... ...................

3-2. Storage Controls

3-3

. Methods

34.

Minimum Triggering Rates

3-5. Decoding Output Information for Single

Channel Plug-Ins

3-6. Decoding Output Information for the

3485A Scanning Unit ........ .

3-7. 3485A/Data Storage Operation for Bursts

of

of

Readings . . . . . .

...... ...... ....

Outputting Data

. .... .

......

....

(3481A3482A

................

.. ..

. . .... . 1-2/1-3

........

........

. . .

...........

, or 3484A)

....

. .

LIST

...

......

......

&~

..

..

. .

3-7

3-8

OF

3-1

3-2

3-5

3-6

3-6

TABLES

Number Page

3-8. Improvement in A/D

Using Sample-and-Hold (3482A or 3484A

10 V Range Only) . .......

3-9 Sample-and-Hold Accuracy (Digitization

is

Limited

Rate

3-10. 2070A Rear Panel Connector for

Data Storage ...

5-1. Troubleshooting

6-1. Replaceable Parts

Conversion Accuracy

........

to

1 kHz)

...

. .

...

. . . ......

.. .....

..........

. . . . . .

...

. .... . . 3-9

....

. .....

. . . . . . . . .... 3-l 0

....... . . . 5-1/5-3

.........

...

6-2/6-6

3-9

iii

Page 6

Table

of

Contents

LIST

OF

ILLUSTRATIONS

Model l l l 80A

;l

I.

'

Number

1-1. Data Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3-1. Storage Operations

3-2.

Basic

Operation

3-3. A Jump

3-4. Printer Output . .

3-5. Preset Trigger

3-6. Measurement Hold

3-7.

Computer Control Enable

3-8. Data Storage Timing

3-9. Printer Format for

3-10. The Printer Format

3-11. Data Storage

3-12. Jump Printout .

3-13. Burst Operation . . .

3-14. Burst Printout . .

3-15. Sample-and-Hold

3-16. Sample-and-Hold Technique

3-17. Rear

3-18. Trigger Source for Single Channel

Plug-Ins

Command

Scanning

Panel

Unit

of

......... ...

..................

of

Data Storage

...........

..

. . .

......

......

Used with the 3485A

the 2070A Data Logger

. ........

..........

.................

2070A Data Logger .... . .

................

.......

..

.

.................

................

..............

Circuit Position

.............

. . .

. .

. . .

.

.............

...............

..............

.............

.........

.......

..........

............

..........

...

....

. . . .

...........

..

........

.

..........

Page

......

. 3-4

.

..

. .....

..

.... 3-7

. .

... 3-7

... 3-7

...

. . .... 3-9

3-10

3-10

-1

3-3

3-4

3-4

3-4

3-5

3-5

3-5

3-6

3-8

3-8

3-9

Number Page

3-19. Clearing Data Storage

3-20.

Response Time Measurement

3-21.

Preset Trigger Measurement ......

3-22.

Peak Reading

3-23. Single Input System .

3-24. Multiple Input System . .

3-

25. Random Sample .........

Schematics and Diagrams

7-1. Isolated

7-2.

Basic

Storage ...

7-3

. Address Counter, Limits

7-4. Preset Trigger, Printer Hold,

Control

7-5. Scanner

7-6.

Panel Transfer, Printer and Dump Hold

Cycling

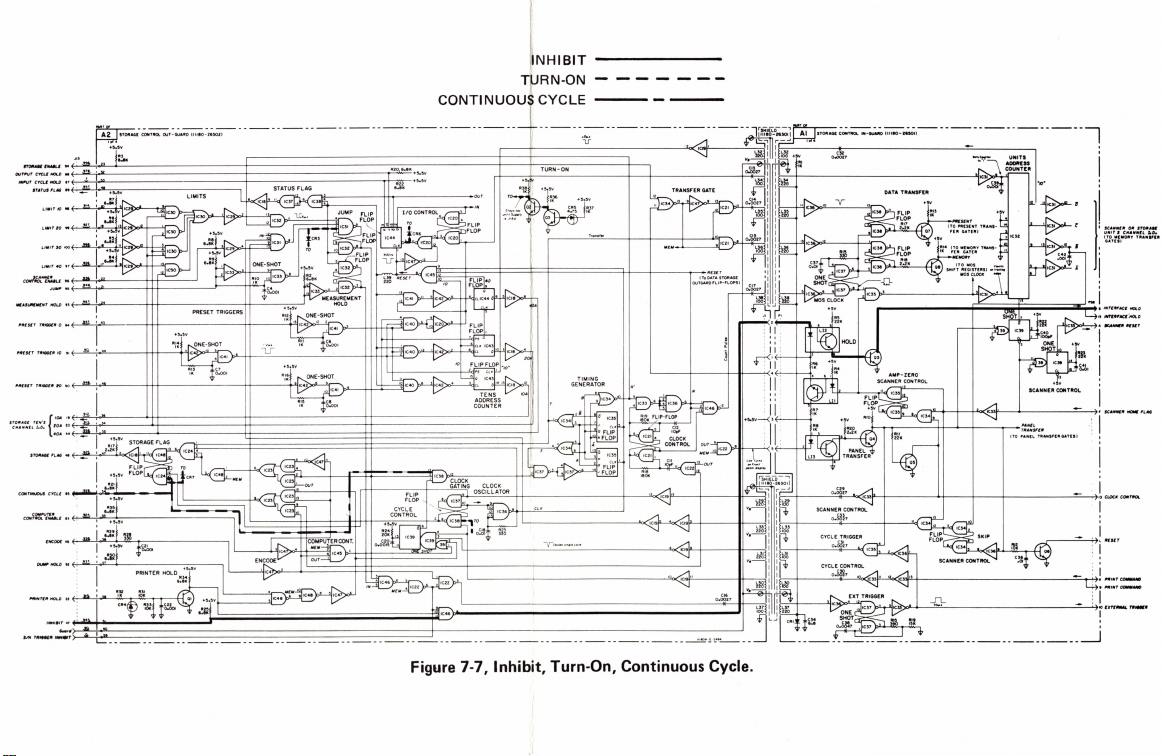

7-7

. Inhibit, Turn-On, Continuous Cycle ....

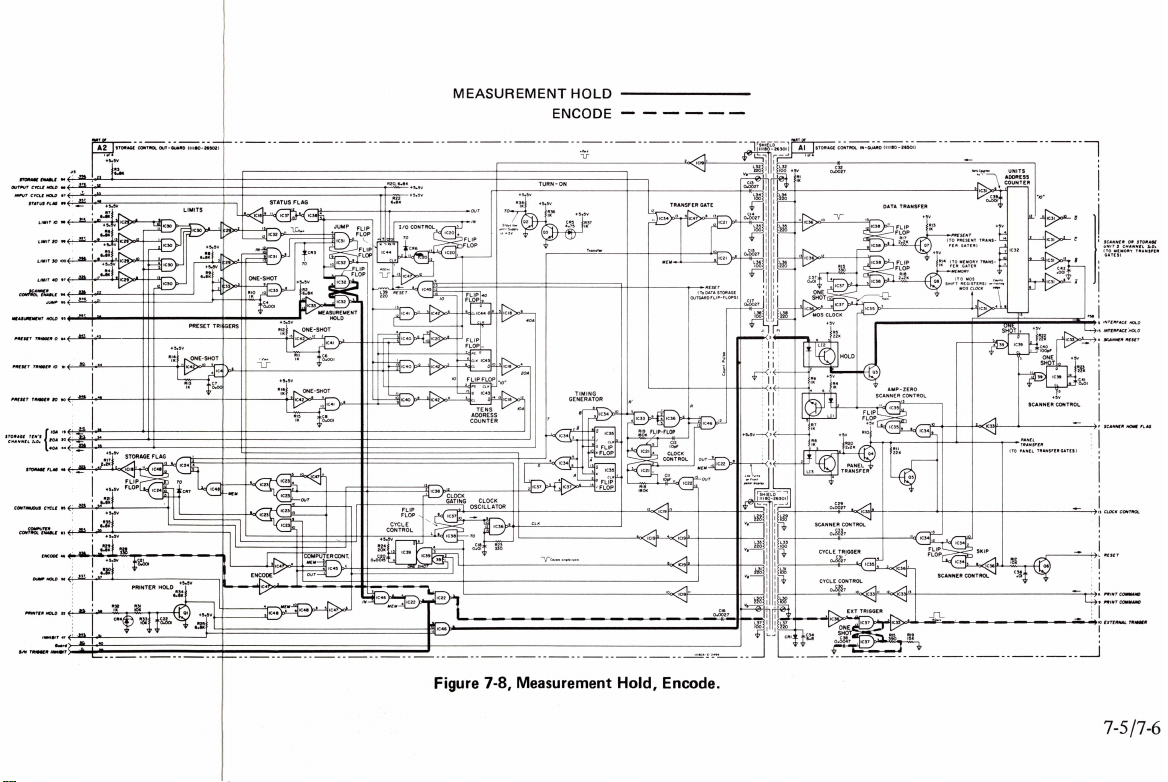

7-8

. Measurement Add, Encode .

Control and Timing ........ . . .

7-9.

7-10. Data Output .

....................

BCD

..........

Enable

Control, Jump

.......................

........................

....

..

......

.........

..

...................

.................

.......

.

.. ..

.......

.......................

.

.......

.................

Computer

..................

...

. .

..........

.

. . . .

. . .

...

.....

.........

....

...... . 3-12

........

......

..

.

.....

....

....

...

..

...

3-10

3-11

3-11

3-12

. 3-12

3-12

7-3/7-4

7-3/7-4

7-3/7-4

7-3/7-4

7-5/7-6

7-5/7-6 I

. 7-5/7-6

. 7-5/7-6

7-7/7-8

.

...

7-9

:1

. '

]

,.

'

iv

L l

,'·J

!;'

..

Page 7

••

.!.'...~

-·~

.:-·.

_,

;..

'·'.

Model

l l 180A

r.

l,

"

Section I

SECTION

GENERAL

1-1.

INTRODUCTION.

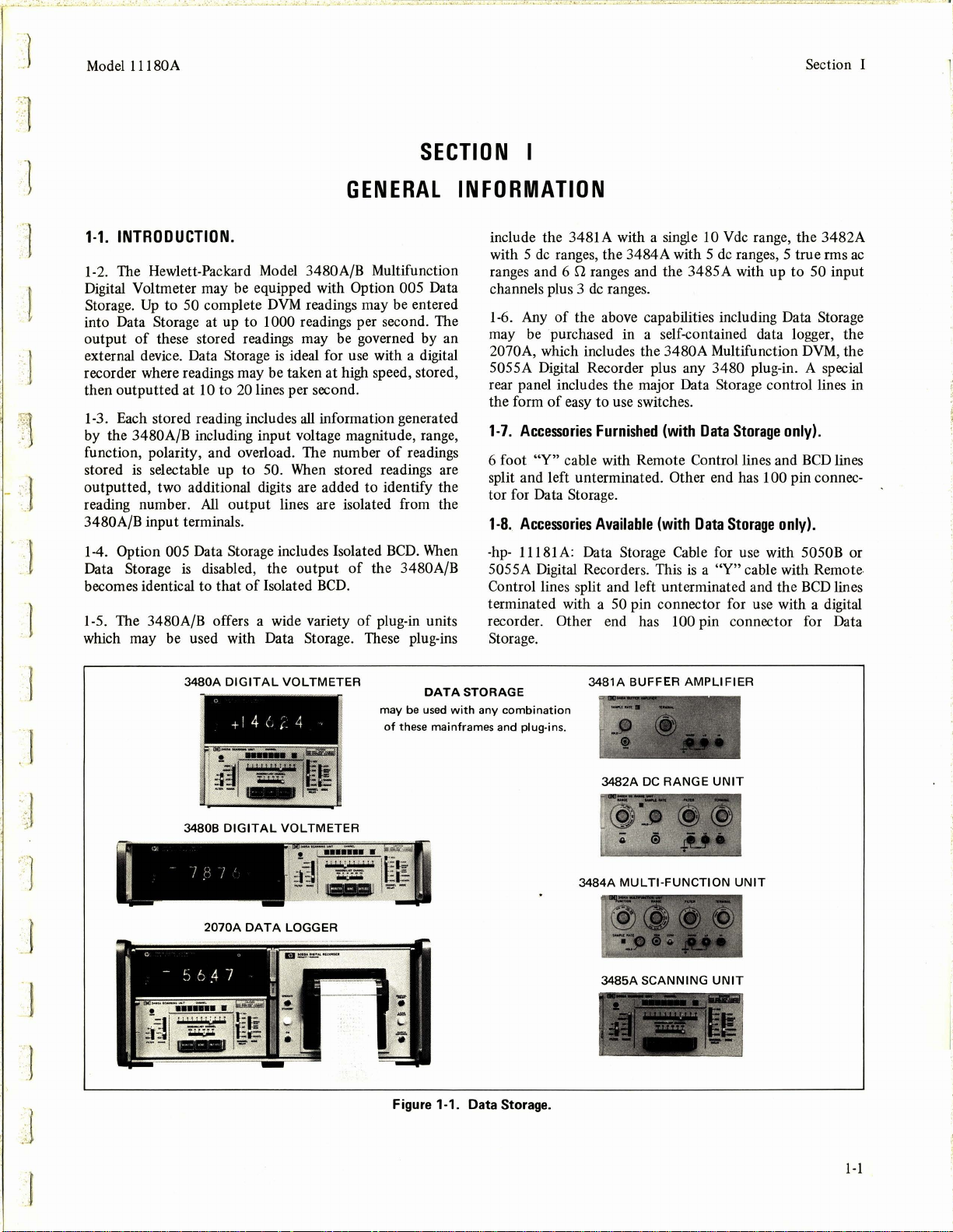

1-2.

The Hewlett-Packard

Digital Voltmeter may be equipped with

t

'r.'.

1

•.

.

:.·,;.

~.

.

..

' l

-

·~

·

,··

i

Storage.

into Data

output

external device. Data

recorder where readings may be taken at high speed, stored,

then outputted at

1-3. Each stored reading includes

by the 3480A/B including input voltage magnitude, range,

function, polarity, and overload. The number

stored

outputted, two additional digits are added

reading number.

3480A/B input terminals.

Up

to 50 complete

Storage at up to 1000 readings per second. The

of

these stored readings may be governed by an

10 to

is

selectable up to 50.

All

Model

Storage

20

lines per second.

output lines are isolated from the

3480A/B Multifunction

Option 005 Data

DVM

readings may be entered

is

ideal for use with a digital

all

information generated

of

When

stored readings are

to

identify the

readings

INFORMATION

include the 3481 A with a single

de

with 5

ranges and 6

channels plus 3

1-6.

may

2070A, which includes the 3480A Multifunction

5055A Digital Recorder plus any 3480 plug-in. A special

rear panel includes the major Data

the form

1-7.

6 foot

split and left unterminated.

tor for Data Storage.

1-8.

ranges, the 3484A with 5

S1

ranges and the 3485A with up

de

ranges.

Any

of

the above capabilities including Data Storage

be

purchased in a self-contained data logger, the

of

easy

to

use switches.

Accessories

"Y"

Accessories

Furnished

cable with Remote Control lines and

Available

(with

10 V

de

range, the 3482A

de

ranges, 5 true rms

Storage control lines in

(with

Data

Storage

Other end has 100 pin connec-

Data

Storage

only).

only).

to

50 input

DVM,

BCD

ac

the

lines

·1

..

''

J .

..

··

1

Option 005 Data Storage includes Isolated

1-4.

Data Storage

becomes identical to that

1-5. The 3480A/B offers a wide variety

which may be used with Data

·

l("

I "

is

disabled, the output

of

Isolated

3480A

DIGITAL

+I 4

1

~1-

.....

-

34808

DIGITAL

Ir'

' . I

2070A

VOLTMETER

(,

r 4

,

·

7 1'

VOLTMETER

DATA

LOGGER

BCD.

Storage. These plug-ins

(e:

..

-

BCD.

of

the 3480A/B

of

plug-in units

may

of

these mainframes

be

When

DATA

used

-hp-

11181 A: Data Storage Cable for use with 5050B or

is

5055A Digital Recorders. This

Control lines split and left unterminated and the

terminated with a

recorder.

Storage.

STORAGE

with

any

combination

and

Other end has 100 pin connector for Data

plug-ins.

50

pin connector for use with a digital

3481A

BUFFER

3482A

3484A

MULTI-FUNCTION

3485A

DC

SCANNING

a

AMPLIFIER

RANGE

"Y"

cable with Remote

UNIT

UNIT

UNIT

BCD

lines

J

J

~

J

.

..

..

Figure 1-1. Data Storage.

1-1

Page 8

·

.....

__

,.

:...

••

-.:.

......... • -.-·

t.

...

~·

•

.r

•· ·-..

Section I

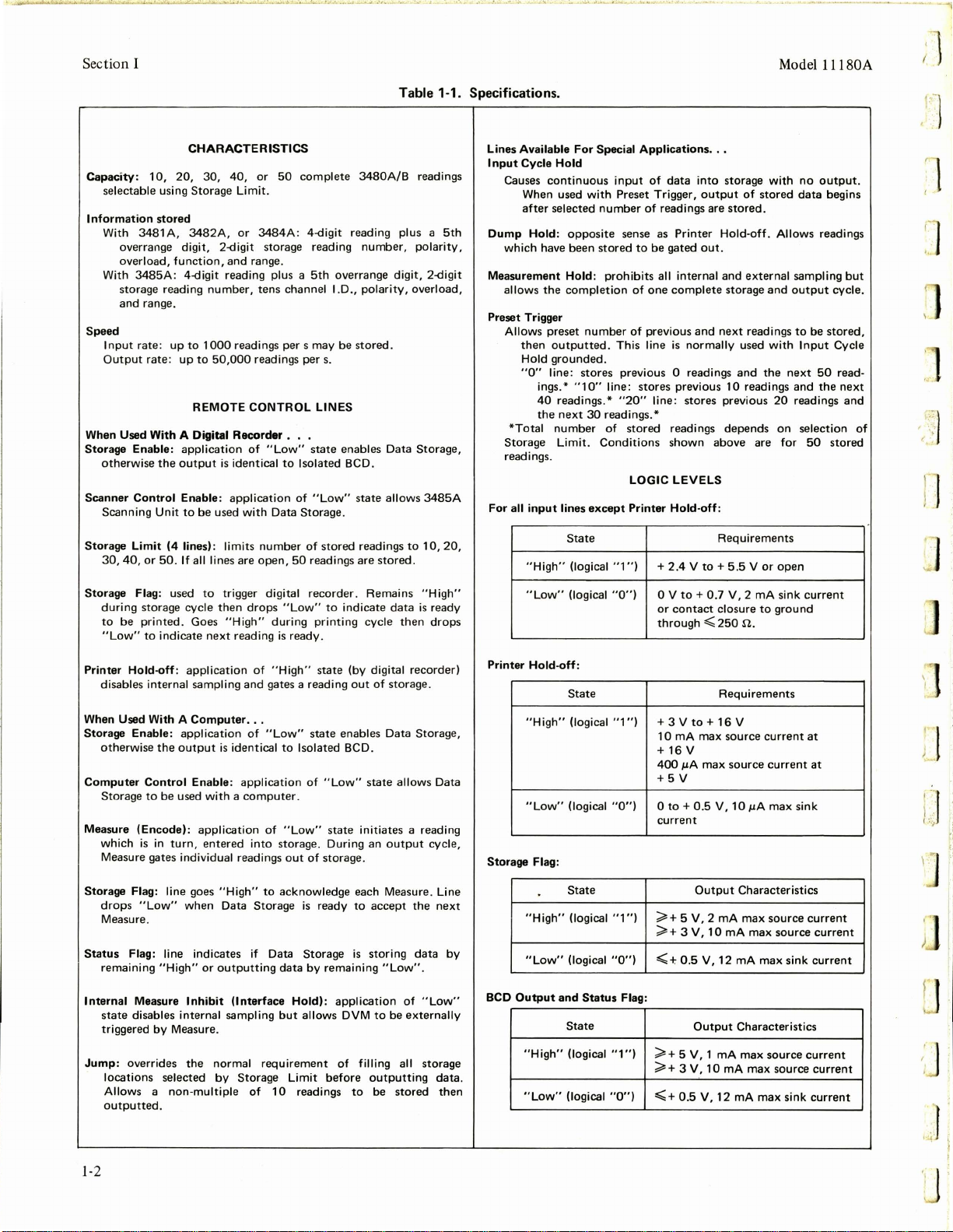

CHARACTERISTICS

Capacity:

Information

Speed

When Used With A Digital

Storage

otherwise

Scanner

Scanning

Storage

30,

10,

20,

30,

40,

selectable using Storage Limit.

With 3481 A,

With

Input

Output

stored

overrange digit, 2-digit storage reading

overload,

3485A

storage reading

and

rate: up

Enable:

Control

Limit

40,

3482A, or

function,

: 4-digit reading plus a

range.

rate: up

the

Unit

or

50.

number,

to

1000

to

REMOTE

application

output

Enable:

to

be

(4

lines): limits

If all lines

or

3484A

and

range.

tens

readings per s may

50,000

readings

CONTROL

Recorder

of

"Low"

is

identical

application

used

with

number

are

open,

50

complete

: 4-digit reading plus a

5th

channel l.D.,

per

. . .

state

to

Isolated BCD.

of

Data

Storage

of

50

readings

3480A/B

number,

overrange digit, 2-digit

polarity,

be

stored.

s.

LINES

enables

"Low"

state

.

stored

readings

are

Table 1-1. Specifications.

Lines Available

5th

20,

Input

Causes

Dump

which

Measurement

allows

Preset Trigger

Allows preset

*Total

Storage

readings.

For

all

Data

allows

stored

readings

polarity,

overload,

Storage,

3485A

to

10,

.

Cycle Hold

continuous

When used

after

selected

Hold:

opposite

have been

Hold:

the

completion

then

outputted.

Hold

grounded.

"O"

line:

ings.*

40

readings .*

the

next

number

Limit.

input

lines

State

"High"

(logical "1

For

Special

input

with

Preset Trigger,

number

sense as

stored

prohibits

number

of

This line

stores

previous 0 readings

"1

O"

line:

"20"

30

readings.*

of

stored

Conditions

LOGIC

except

Printer

") + 2.4 V to+

Applications

of

data

of

readings

Printer

to

be

gated

all internal

of

one

complete

previous

is

normally

stores

previous

line:

stores

readings

shown

LEVELS

Hold-off:

Model l l l

...

into

storage

with

output

of

are

stored

Hold-off. Allows readings

out

.

and

external

storage

and

next

readings

used

and

10

readings

previous

depends

above

Requirements

5.5 V or

stored

.

and

with

the

are

output

next

20

on

for

open

no

data

sampling

to

Input

and

readings

selection

output.

be

50

the

50

80A

begins

but

cycle.

stored,

Cycle

read-

next

and

stored

of

;l

1

'

rJ

"

'

:~

1

'

Storage

Printer

When

Storage

Computer

Measure

Storage

Status

Internal

Jump:

Flag: used

during

storage cycle

to

be

printed.

"Low"

to

Hold-off:

disables internal sampling

Used With A

Enable:

otherwise

Control

Storage

to

(Encode):

is

which

Measure gates individual readings

drops

Measure.

remaining

state

triggered

locations

Allows a

outputted

in

Flag: line goes

"Low"

Flag: line indicates if Data

Measure

disables internal sampling

by

overrides

to

Goes

indicate

application

Computer

application

the

output

Enable:

be

used

application

turn,

entered

when

"High"

or

Inhibit

Measure.

the

selected

non-multiple

.

trigger digital

then

"High"

next

reading

is

identical

with a computer.

"High"

Data

outputting

(Interface

normal

by

Storage

drops

"Low"

during

is

ready.

of

"High"

and

gates a reading

...

of

"Low"

to

application

of

"Low"

into

storage. During

out

to

acknowledge

Storage

data

but

requirement

Limit

of

10

recorder. Remains

to

indicate

printing

state

state

Isolated BCD.

of

of

is

ready

Storage

by

Hold):

allows DVM

readings

cycle

(by digital recorder)

out

enables

"Low"

state

state

initiates a reading

an

storage.

each Measure. Line

to

is

storing

remaining

application

of

filling all storage

before

outputting

to

data

of

storage.

Data

allows Data

output

accept

"Low"

to

be

be

stored

"High"

is

ready

then

drops

Storage,

cycle,

the

next

data

.

of

"Low"

externally

data.

by

then

Printer

Storage

BCD

Output

"Low"

Hold-off:

"High"

"Low"

Flag:

"High"

"Low"

and

"High"

"Low"

(logical

State

(logical "1

(logical

State

(logical "1

(logical

Status

State

(logical

(logical

"O")

0 V

or

through

")

+ 3 V

10

+

16

400

+5V

"0") 0 to+

current

")

;;;,,

+ 5 V, 2 mA max

;;;,,

+ 3 V,

"0")

<+

Flag:

"1")

;;;;.+

;;;,,

+ 3 V,

"0")

<+

to+

0.7 V, 2

contact

.:;;;

to+

mA

max

v

µA

max

0.5

V,

Output

10

0.5

V,

Output

5 V, 1 mA

10

0.5

V,

mA

closure

to

250

Requirements

16

source

source

mA

12

mA

12

ground

n.

V

current

current

10

µA

max

Characteristics

source

max

source

mA

max

Characteristics

max

source

max

source

mA

max

sink

sink

sink

current

at

at

sink

current

current

current

current

current

current

;J

r

1-2

Page 9

Model l l l 80A

•.

J •

••

•

:..

''

~·

•.

>'.•-

I.

,.

.•

·•

'Ill•

.i.,. { •

_.,

•• '

•

..._·,

~,.

•.

..

......

""•

....... 1

... , ..

1 ....

..

:r

Se

ction I

Table 1-1. Specifications (cont'd).

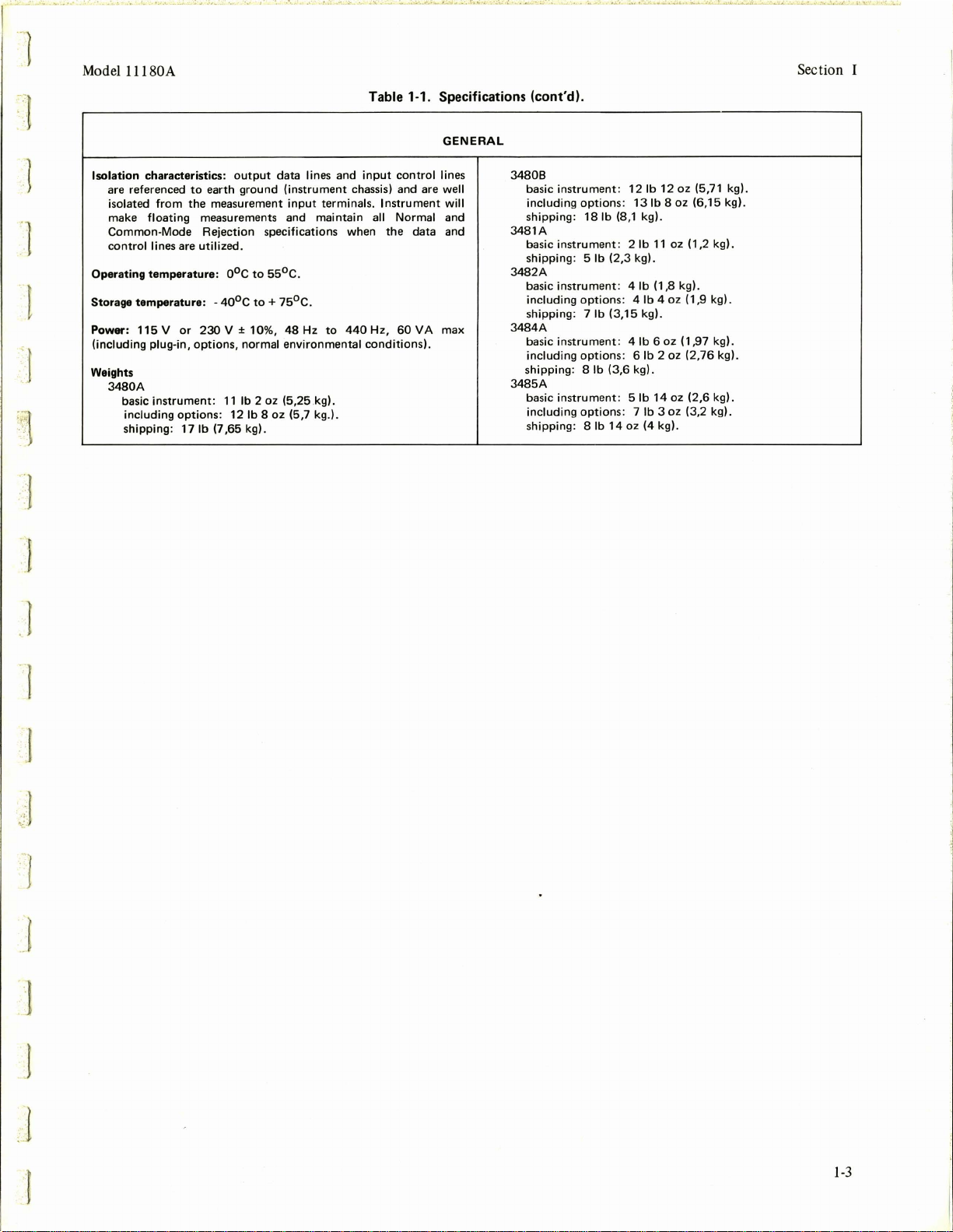

GENERAL

1

1

. ·1

I

Isolation

characteristics:

are referenced

isolated

make

floating

Common-Mode

control

Operating

Storage

temperature: -40°c

Power:

115 V or

(i

ncluding

Weights

3480A

basic

including

shipping:

to

from

earth

the

measurements and

Rejection

lines are

utilized

temperature:

230

plug-in,

options,

instrument:

options:

17

lb

output

ground

measurement

specifications when

.

0

o

c

to

55°C

to + 75°c

V ± 10%,

normal

11

lb

2 oz (5,25 kg).

12

lb

(7,65

8 oz (5 ,7 kg.).

kg) .

data lines and

(instrument

input

terminals.

maintain

.

.

48

Hz

to

envi

440

ronmental

input

control

lines

chassis) and are well

Instrument

all

Normal

the

Hz,

60

conditions)

will

and

data and

VA

max

.

34808

basic

instrument: 12

including

shipping:

3481A

basic

instrument

shipping

3482A

basic

instrument: 4 lb

i

ncluding

shipping

3484A

basic

instrument

including

shipping: 8 lb

3485A

basic

instrument: 5 lb

including

hipping

s

options: 13

18

lb

(8,1 kg) .

: 2

: 5

lb

(2,3

options

: 7

: 4

lb (3,

: 4

options

: 6

(3,6

options

lb

: 7

14

: 8

lb

lb

lb

11

kg).

(1,8 kg).

lb

15

kg).

lb 6 oz (1,

lb

kg) .

14

lb 3 oz

oz

(4

12

oz

(5,71 kg).

8 oz (6,

15

oz (1,2 kg).

4 oz (1,9 kg) .

97

(2,76

kg).

kg).

2 oz

oz (2,6 kg).

(3,2 kg).

kg).

kg).

.1

1-3

Page 10

"

••

!.

·•''·.,;

'Jo, • ;'

''-

~&•

•(·'·

....:..

··•

·•'-'·

~..,_

o.

..,

.o.."k.:

r.:. ~ -

......

, •

..,.,1.

. :.0

o"J.o."o'&•--'-',11.J.~·;

.,,....__

4

_.,.

..

--.._.

l 1

; ·

..

J '

r;'

,·

'

r

I

I

Page 11

"I

-l

~.

:· I

Model

l l l 80A

Section

II

,/·

1·

::-

..

·:

"

( r

·~-

i

]

·1

SECTION

IN

STALLATI

2-1.

INTRODUCTION.

2-

2.

This section contains installation and shipping infor-

mation for the

2-3.

INITIAL

2-4.

Each l l l 80A has been carefully inspected prior to

shipment and should

of

mars or scratches.

should

have occurred in transit or for deficiencies otherwise.

there

is

carrier;

attributable to shipping, refer to the statement

on the cover page

Section V to check the instrument performance. Refer to

Section I for the list

instrument.

2-5.

INSTALLATION

2-6. Contact

Office

regarding installation

3480A/B. (See Appendix B for office locations.)

2-7.

STORAGE

2-8.

See

Model

l l l 80A.

INSPECTION.

be

in perfect electrical order and free

To

confirm this, the instrument

be

inspected upon receipt for damage that might

damage due to shipping, file a claim with the

if

there are electrical or mechanical deficiencies not

of

warranty

of

your

CONNECTOR.

Table

3-1

this manual.

of

equipment supplied with the

OF

11180A

IMPORTANT

local Hewlett-Packard Sales and Service

of

for the

Use

the procedures

INTO

3480A/B.

the

11l80A

signal

arrangement at the

into

an

existing

If

of

II

0 N

Storage Connector.

2-9.

REPACKAGING

2-10.

If

the instrument

for service or repair, attach a tag to the instrument

describing the work to be accomplished and identifying the

owner and instrument. Identify the instrument by serial

number, model number and name in any correspondence.

you have any questions, contact your local Hewlett-Packard

Sales

and Service Office.

locations.

2-11.

If

the original shipping container

the instrument in the container with appropriate packing

meterial and

metal bands. A

nearest

2-12.

If

heavy carton or wooden box with an inner container.

the instrument with heavy paper or plastic and place

cardboard strips across the face for protection before

placing the instrument in the inner container.

material around

outer container

the container with "DELICATE INSTRUMENT," or

"FRAGILE".

-hp-

an

seal

Sales

-hp-

FOR

SHIPMENT.

is

to be shipped to Hewlett-Packard

See

Appendix B for office

is

to be used, place

the container

new

container may be purchased from your

and

Service

container

all

sides

of

well

with strong tape or metal bands.

well

with strong tape or

Office.

is

not to

the inner container, and

be

used, then use a

Use

If

Wrap

packing

seal

the

Mark

J

J

·1

2-1

Page 12

:1

~

l

]

,]

'

"'.

)

'J

' -

.:.J

JJ

Page 13

Model l l l 80A

Section III

r

J

<

"'·

1

..

. 'I

r

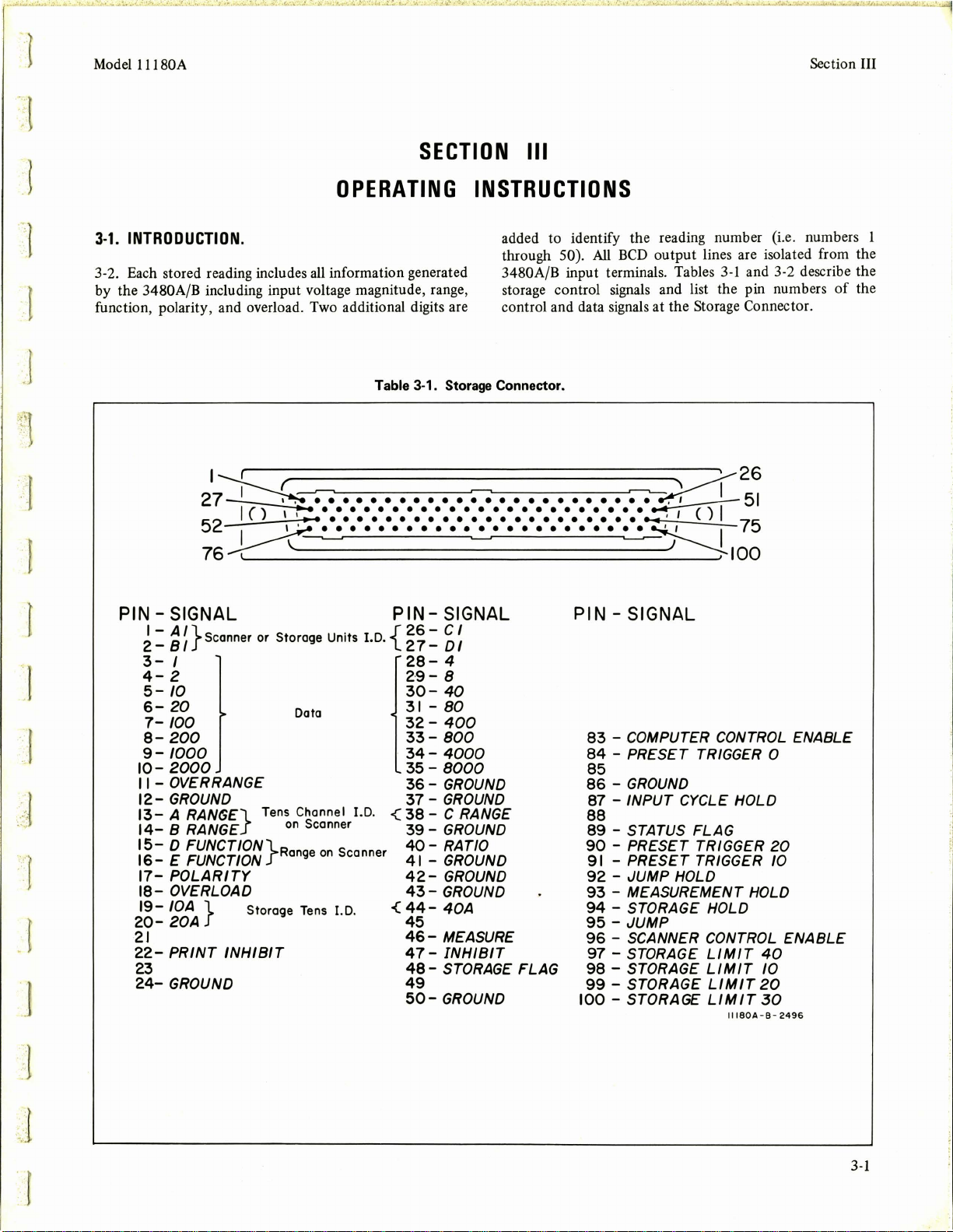

SECTION

OPERATING

3-1.

INTRODUCTION.

3-2. Each stored reading includes all information generated

by the

function, polarity, and overload. Two additional digits are

3480A/B including input voltage magnitude, range,

Table 3-1. Storage Connector.

d1~

I()

52

76~

........................

...........................

I I - • • • • • • • • • • • • • • • • • • • • • • - ' I

•••••••••••••••••••••••

Ill

INSTRUCTIONS

added to identify the reading number (i.e. numbers 1

through 50).

3480A/B input terminals. Tables

storage control signals and list the pin numbers

control and data signals at

All

BCD

output lines are isolated from the

3-1

and 3-2 describe the

the

Storage Connector.

~~~

~rc')'I

~100

75

of

the

r

I

.f

r

J

PIN - SIGNAL

I - A

I}

BI

_

2

3-

4-2

5-

6-

7-

8-

9 -

10-

11

- OVER RANGE

121314-

1516-

17-

1819-

20-

21

22-

23

24-

Scanner or Storage Units

I

10

20

100

200

1000

2000

GROUND

A

RAN(;E}

B RANGE

D

FUNCTION}

E FUNCTION

POLARITY

OVERLOAD

IOA

} Storage

20A

PRINT

GROUND

INHIBIT

PIN-

{

I.D.

Data

Tens Channel I.D. c(

on

Scanner

Range

on

Scanner

Tens

I.D. <

SIGNAL PIN - SIGNAL

26

- C I

_

DI

2 7

28-

4

2·

9-8

30-

40

31

-

80

32

-

400

33-

800

34

-

4000

35 -

8000

36

-

GROUND

37-

GROUND

38

- C RANGE

39

- GROUND

40-

RATIO

41

- GROUND

42-

GROUND

43-

GROUND

44-

40A

45

46

- MEASURE

47-

INHIBIT

48

- STORAGE FLAG

49

50-

GROUND

83

- COMPUTER CONTROL ENABLE

84

- PRESET TRIGGER 0

85

86

-

87 - INPUT CYCLE HOLD

88

89

- STATUS FLAG

90

- PRESET TRIGGER

91

- PRESET TRIGGER

92

- JUMP HOLD

93

- MEASUREMENT HOLD

94

- STORAGE HOLD

95

- JUMP

96

- SCANNER CONTROL

97

- STORAGE

98

- STORAGE

99

- STORAGE

100 - STORAGE

GROUND

LIMIT

LIMIT

LIMIT

LIMIT

II

180A-8-

20

10

ENABLE

40

10

20

30

2496

3-1

Page 14

Section III

Table 3-2. Storage Controls.

Model

l l l 80A

':

l

'·

ENABLES

Storage Enable - Activates Data Storage; otherwise

like

the

Option

004

Isolated

Computer

Scanner

Storage Limit

FLAGS

Status

Storage Flag_ Line goes

HOLDS

Inhibit

Measurement

Control Enable - Application

Storage

to

be used

with a computer.

Control

Command.

All

four

locations

readings are

mand may

up

with

or

50

may be reached

Flag - Line

and

"low"

command;

- Disables

3481,

3482,

3485A

. Ground this line when external triggering

but

allows manual sampling. When released

Enable - Allows

10,

20,

30,

lines

open

up

to

the

outputted.

be

used

the

last reading so

is

"high"

while

data

goes

"low"

the

and

Hold - Prevents

front,panel SAMPLE RATE

3484,

BCD

.

of

the

Scanner

40

- Limits

the

allows

Storage Limit

Scanner Control Enable

to

cause

the

that

and

the

while

is

being

outputted

"high"

when

the

and

both

number

50

stored

must

unused storage positions

a Storage Limit

data

outputted.

data

is

being

to

acknowledge each Measure

next

Measure may be accepted. reading so

the

free running ability

internal

"low"

readings.

be filled

entered

.

and

the

11180A

acts

state

allows Data

to

give a

Jump

of

stored

readings.

All

storage

before

Jump

20,

to

be used.

any

Com-

to

fill

30,

40,

storage,

of

the

of

the

or

of

10,

into

control

is

external sampling,

momentarily,

allows

one

be

used with

Printer Hold -

by

the

Dump

Input

doesn't

set

COMMANDS

Measure·

used

line may

Jump

· Causes

reached

Preset Trigger - Allows a preset

prior

"O"

line -

"10"

line - Stores

"20"

line·

*Total

lines;

it

50

complete

the

3485A.

The

3485A.

Hold · Inverted Printer Hold.

Cycle Hold -

Trigger.

When

to

to

Stores

number

readings per trigger

printer

go

and

and

Stores

The

into

the

Output

Computer

input

and

be

that

output

used

to

trigger

the

unused storage positions

a Storage Limit

the

data

after

the

Zero readings prior

10

readings prior

20

readings prior

of

stored

input

and

output

storage cycle. It

disables internal triggering, including

Storage Unit

Control Enable

the

outputed.

trigger.

readings

is

continuously

Cycle. It may be overridden

storage

data.

3480.

of

10,

20,

number

illustrated here.

to

trigger

to

trigger

to

trigger

depends

of

inputs

is

held low, this line

When CCE

to

fill

up

30,

readings

and

and

and

on

with

40,

or

to

50

after.*

40

after.*

30

after.*

the

Storage Limit

is

is

not

data

by

high, this

the

50

may be

be

stored

to

that

and

Pre,

last

is

I.

··

1.

'

f

l

3-3.

BASIC

3-4. The following rules apply to operation

OPERATION.

of

Data

Storage:

a. The number

outputs from Data Storage

will

of

always equal the Storage Limit setting (10, 20, 30, 40, or

50).

b.

The number

Storage Limit unless Jump

of

readings stored must always equal the

is

used to artificially begin an

output cycle.

c.

The Storage Limit must equal or exceed the number

of

readings to be stored.

d.

The maximum input rate (into storage)

The maximum output

3-5. Readings may

a.

Printer Hold-Off (for

b.

Dump Hold (opposite sense

rate..;;;

be

gated out

50,000/s.

of

use

with printers).

as

Data Storage by:

Printer Hold-Off).

..;;;

1000/s.

c. Measure (special case with Computer Control Enable

grounded).

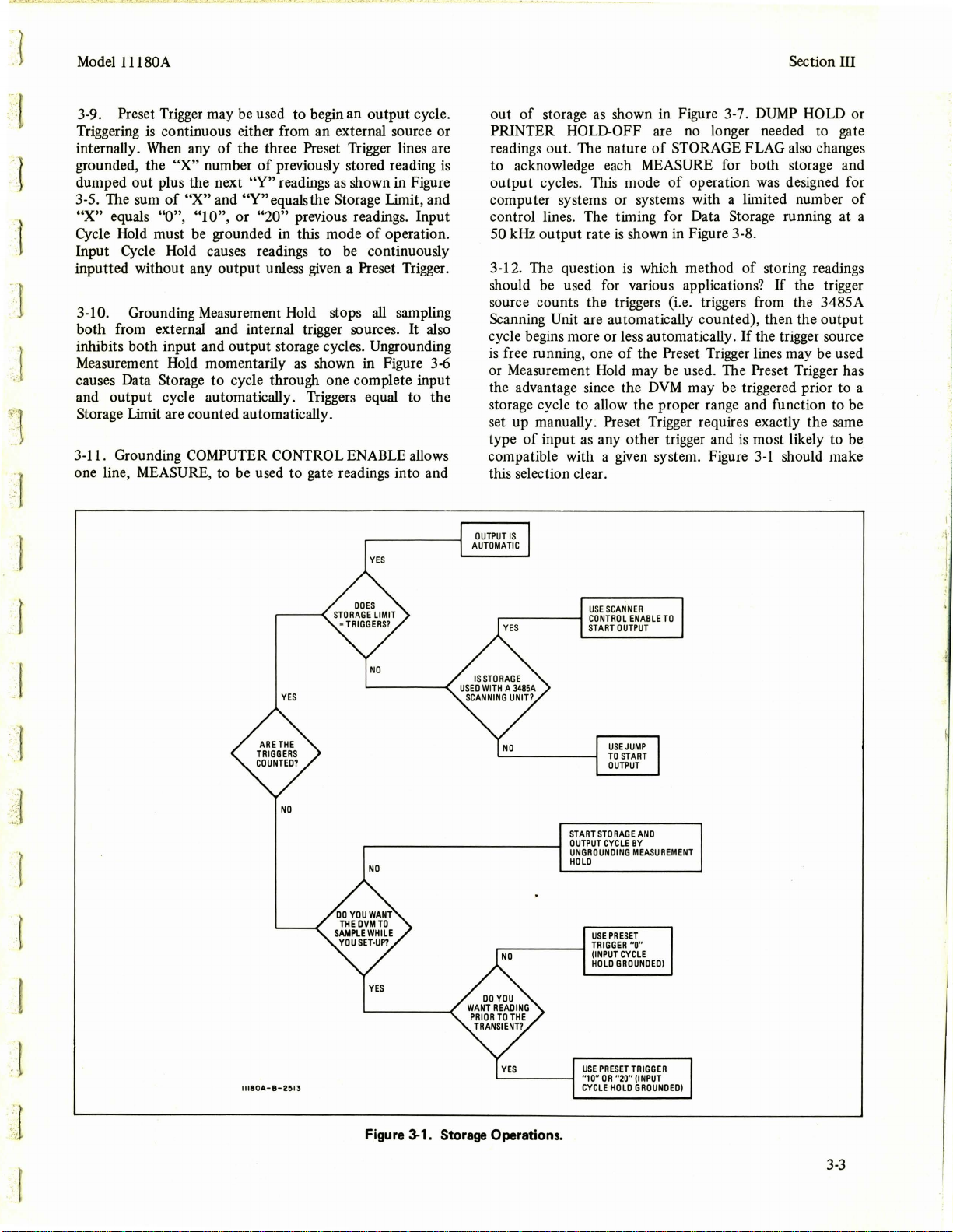

3-6

. Figure 3-2 illustrates the fundamental operation

of

Data Storage with a printer. Storage Flag falls low to

indicate that the first stored reading

recorded. Printer Hold-Off

the printer (or other device)

Hold-Off drops low, Storage Flag

is

transmitted back to signal that

is

taking data.

will

later to signal that the next reading

(not shown)

is

identical to Printer Hold-Off but

opposite sense. Status Flag indicates

is

ready to

When

be

Printer

drop low 16 to 20 µ s

is

ready. Dump Hold

of

the

if

Data Storage

storing (high) or outputting (low). The output cycle

continues until the Storage Limit

3-

7.

A non-multiple

gated out using Jump

the desired number

storage, a Jump

The last reading

of

10 readings may be stored then

as

shown in Figures

of

readings have been entered into

is

issued which begins the output cycle.

is

repeated to fill the number

is

reached.

3-3

and 3-4. Once

of

outputs to

equal the Storage Limit.

If

3-8.

Data Storage

and the number

is

used with a 3485A Scanning Unit

of

channels scanned

is

less than the Storage

Limit, grounding Scanner Control Enable causes an auto-

matic Jump once the

Last

Channel

is

reached.

More

details

on use with the scanner follows the next section.

ll

is

3-2

Page 15

.l

..

"•

'•

:1

r

Model 11180A

3-9. Preset Trigger may be used

Triggering

internally. When any

grounded, the

dumped

3-5. The sum

"X"

is

continuous either from an external source or

"X"

out

plus the next

of

equals ''O",

of

the three Preset Trigger lines are

number

"X"

and "Y" equals

"1

O"

, or

Cycle Hold must be grounded in this mode

Input Cycle Hold causes readings

to

begin an

of

previously stored reading

"Y"

readings

the

"20"

previous readings. Input

output

as

shown in Figure

Storage Limit, and

of

to

be continuously

cycle.

operation.

inputted without any output unless given a Preset Trigger.

3-10. Grounding Measurement Hold stops

both

from external and internal trigger sources.

inhibits

Measurement Hold momentarily

causes Data Storage

both

input and output storage cycles. Ungrounding

as

shown in Figure 3-6

to

cycle through one complete input

and output cycle automatically. Triggers equal

all

sampling

It

also

to

the

Storage Limit are counted automatically.

3-11. Grounding

COMPUTER CONTROL ENABLE allows

one line, MEASURE, to be used to gate readings into and

Section III

out

of

storage

PRINTER

readings out. The nature

to

is

acknowledge each MEASURE for both storage and

output

cycles. This mode

computer systems or systems with a limited number

as

shown in Figure 3-7.

DUMP

HOLD or

HOLD-OFF are no longer needed to gate

of

STORAGE FLAG also changes

of

operation

was

designed for

of

control lines. The timing for Data Storage running at a

50 kHz

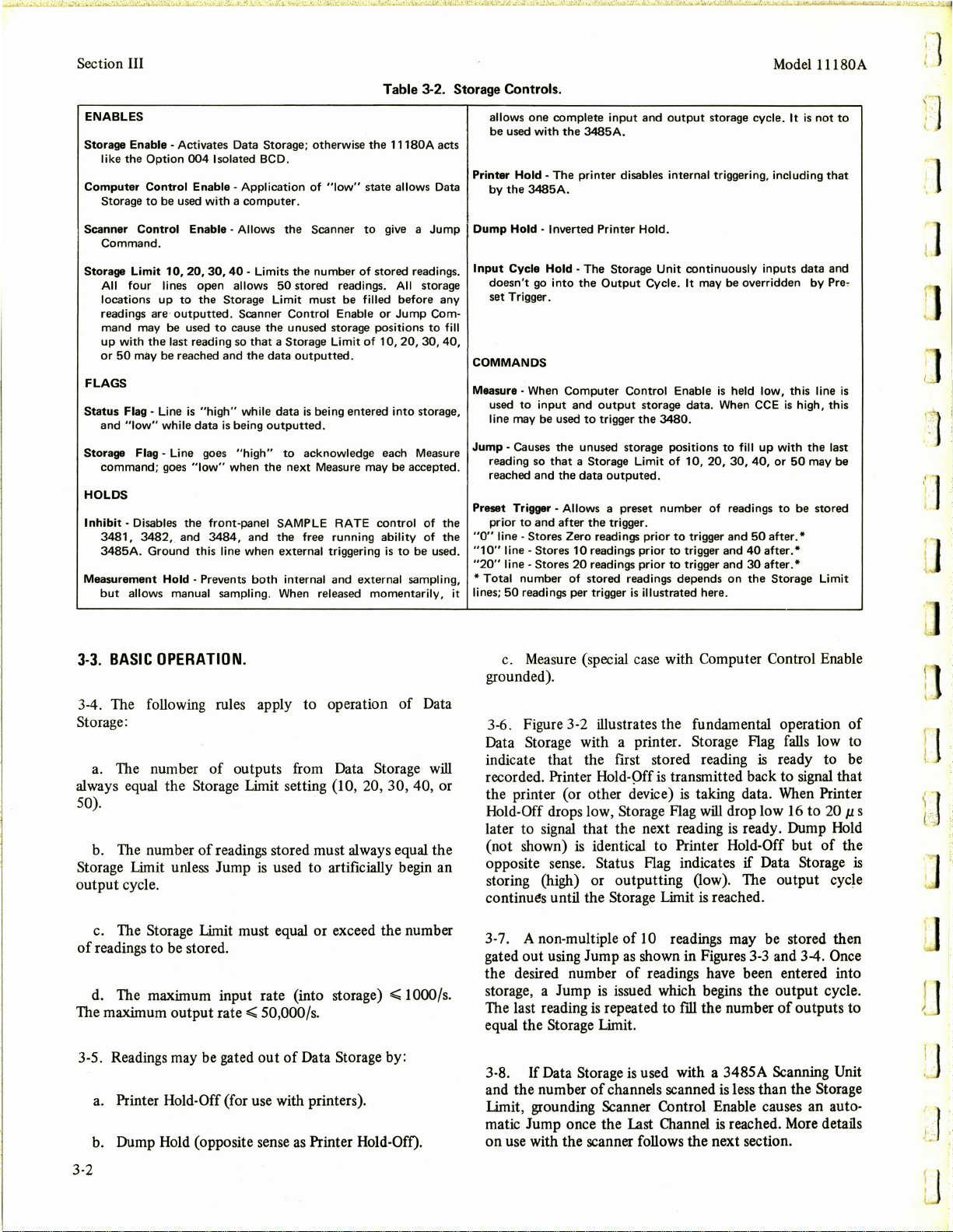

3-12. The question is which method

should be used for various applications?

source counts the triggers (i.

Scanni

cycle begins more or less automatically.

is

output

rate

is

shown in Figure 3-8.

of

e.

triggers from the 3485A

ng

Unit are automatically counted), then the output

If

the trigger source

free running, one

of

the Preset Trigger lines may be used

storing readings

If

the trigger

or Measurement Hold may be used. The Preset Trigger has

DVM

the advantage since the

may be triggered prior to a

storage cycle to allow the proper range and function to be

set up manually. Preset Trigger requires exactly the same

type

of

input as any other trigger and

compatible with a given system. Figure

is

most likely

3-1

should make

to

be

this selection clear.

1

J

. 1

'.

'f

.·:

l

"'""'•

r

YES

NO

OUTPUT

IS

AUTOMATIC

~-----1

.---------f

USE

SCANNER

CONTROL

START

OUTPUT

USE

JUMP

TO

START

OUTPUT

START

STORAGE

OUTPUT

CYCLE

UNGROUNDING

HOLD

USE

PRESET

TRIGGER

(INPUT

CYCLE

HOLD

GROUNDED)

ENABLE

TO

ANO

BY

MEASUREMENT

"O"

llllOA-l-2Sl3

~----I

Figure 3-1. Storage Operations.

USE

PRESET

"10"

CYCLE

OR

HOLD

TRIGGER

"20"

(INPUT

GROUNDED)

3-3

Page 16

Section III

INTERNAL

OR

EXTERNAL

TRIGGERS

Model l 1180A

I'

J

(UP

TO

1000/S)

l'.

STORAGE

FLAG

(FROM

~~~~~-

PRINTER

DVM)

-~~~--1·r--~~--"'-"1~~~~~

HOLD-OFF

(TO

~:-.--iU

STATUS

FLAG

(FROM

OVMI

STORAGE

10, 20,

DEPENDING

l

lll!IOA-8-251

..

Figure 3-2. Basic Operation

Basic

operation

readings are ready . Printer

automatically

but

of

opposite

or

outputting

CYCLE

30,40,or

50

READINGS

ON STORAGE

of

Data Storage uses Storage Flag

outputting

sense.

Status

data.

16TO

20,..s

DVM)

UNIT

Hold-Off

data.

Dump

I

I

TIME

TO PRINT

(50TO 100ms)

OUTPUT

10.20.30,40,

OR

DEPENDING

ON

of

Data Storage.

is

used with digital recorders for

Hold

(not

Flag indicates if Data Storage

CYCLE

50

READINGS

STORAGE

shown)

to

0

00

UNIT

indicate when

is

identical

is

storing

STORAGE

LIMIT=

11110&-1-2011

Printer

made

on

number

issued

repeated

10

output

the

of

to

begin

three

1050014679

0950014679

0850014679

0750014679

0650012437

0550001956

0450002458

0350011400

0250010499

0150009567

POLARITY/OVERLOAD

Figure 3-4. Printer Output.

on a 2070A

100

readings

the

times.

mV range,

is

output

Data Logger when 7

stored,

less

than

the

cycle. Note

7th

READING

3

}

and

TIMES

JUMP

printed

Storage Limit, a

that

the

REPEATED

WHEN

IS

ISSUED

de

readings are

out.

Since

Jump

7th

reading

the

must be

.]

is

J

INTERNAL

OR

EXTERNAL

TRIGGERS

-i

llJIOA-

n I

~

JUMP

STORAGE

PRINTER HOLO·OFF (

1

STATUS

8-2515

---uu----

0 :

NUMBER

OF

READINGS

LESS

THAN

STORAGE

!FROM

(FROM

STORAGE

DVM)

TO

OV~I-

DVMl

UMIT DELAY

CYCLE

(TO

DVM)

FLAG

FLAG

Figure 3-3. A

A

Jump

readings. In this case,

command

Limit.

After

output

cycle; otherwise, storage will wait

required

to

fulfill

to

the

fill

may

the

all triggers have been issued, a

up

to

set

the

by

number

(UP

TO

1000/s)

1

_

___r--u--

Jump

be

used

number

Storage Limit.

;;.

50

µs

DEPENDING

Command.

to

output

of

readings

Jump

for

The

I

I

OUTPUT

CYCLE

10

. 20,30.40.

OR

50

READINGS

ON

STORAGE

a non-multiple

is

less

than

is

given

the

remaining triggers

last reading

LIMIT

to

is

Storage Limit.

of

10

Storage

begin an

repeated

EXTERNAL

TRIGGERS

WP

1IULJ

I

INTERNAL

1IUlf

STORAGE

PRINTER

INPUT

PRESET

l

lllOA·B-2!117

ooo

TRIGGERS

ooo

FLAG

HOLO·OFF

INPUT

ICON

TINUOUSL Y INPUTS

INTO

CYCLE

HOLD

TRIGGER

"O"

1JlJ1J1Jliljo

(UP

lILilJu---

CYCLE

STORAG

(GROUNOEOJ

Figure 3-5. Preset Trigger.

Preset Trigger "O" may

storage

and

output

Cycle Hold

equal

the

at

the

rate

manual

adjustments

Storage Limit.

cycle. Triggers may

must

be grounded.

of

the

trigger source. This allows

on

TO

1000/sl

TO 40/

s)

READINGS

E!

be

used

The

DVM samples prior

his

system.

to

automatically

be

The

number

(OUTPUTS 10,

external

of

oo

OUTPUT

CYCLE

20. 30.40.

OR

READINGS!

start

one

complete

or

internal.

readings

the

taken

to

a Preset Trigger

user

to

50

Input

will

make

'.

l]

:J

I

I

(.

'·

1

h

(J

I·

'.

J

3-4

u

Page 17

J

.

.(

---.

_·":

~

1

r

\

Model l l l 80A

1

1JiJCF:•::

I

'

tnJ[f:·:

STORAGE

PRINTER

110,20,30,40,

AUTOMATICALLY

>

5~1

MEASUREMENT

ONE

INPUT

llllOA-1-2'

11

1JiJulJLrlrooo

OR

·

~lil_r----

FLAG (FROM

OVM)

HOLD·OFF

ITO

OVM

)

INPUT

CYCLE

0R

50TRIGGERS

ACCEPTED

I

HOLD

UNHIBITS

OUTPUT

CYCLE

SAMPLING

TO

TAKE

AND

TIME

TO

BUT ALL

PLACE)

PRIN

T

OWS

OUTPUT

CYCLE

MEASURE

I I I

IOA-8-2527

17T022µs

I

I

16

TO

•

20µs

Section III

v

1

TO

2µs

J

r

.j

J

J

l

.. :·I

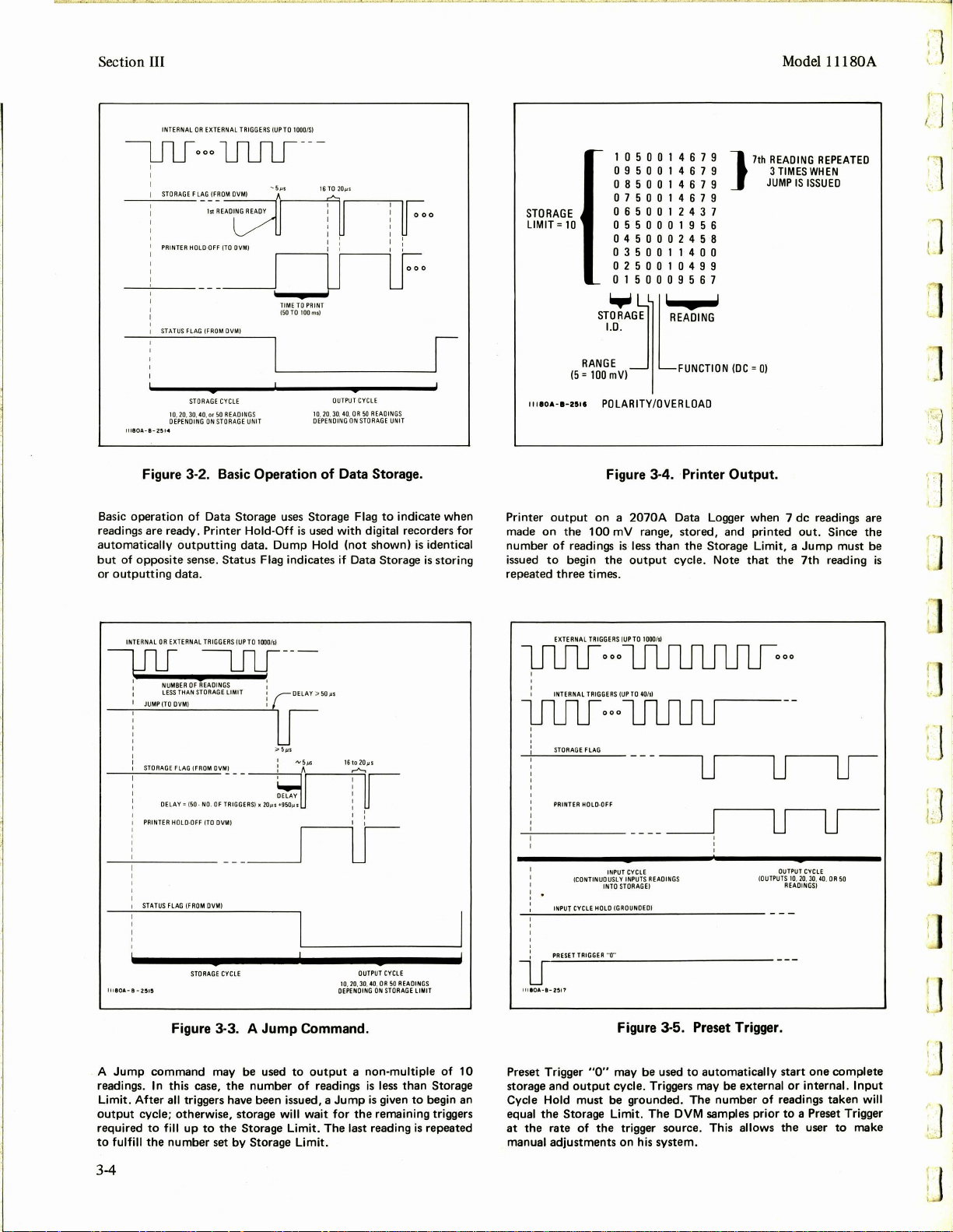

Figure 3-6. Measurement Hold.

Measurement

storage and

Sampling does

proper number

automatically

Hold

output

not

of

.

MEASURE

~~~~~~~~~~~~,--------"----.

flfiJ

I I

1

STATUS

FLAG

STORAGE

COMPUTER

INTERNAL

STORAGE

Figure 3-7. Computer Control Enable.

COMPUTER

readings

line

(MEASURE). PRINTER

STORAGE

and

output

to

be

FLAG

cycles .

CONTROL

gated

may be

used

1000

to

by

prior

/s

;>

1

ms

cycle

take place

triggers equal

UP

TO

UuulJ

INPUT

CYCLE

ENABLE

CONTROL

ENABLE

MEASURE

INHIBIT

LIMIT ("10" "20"

into

acknowledges each

OR

"40"1

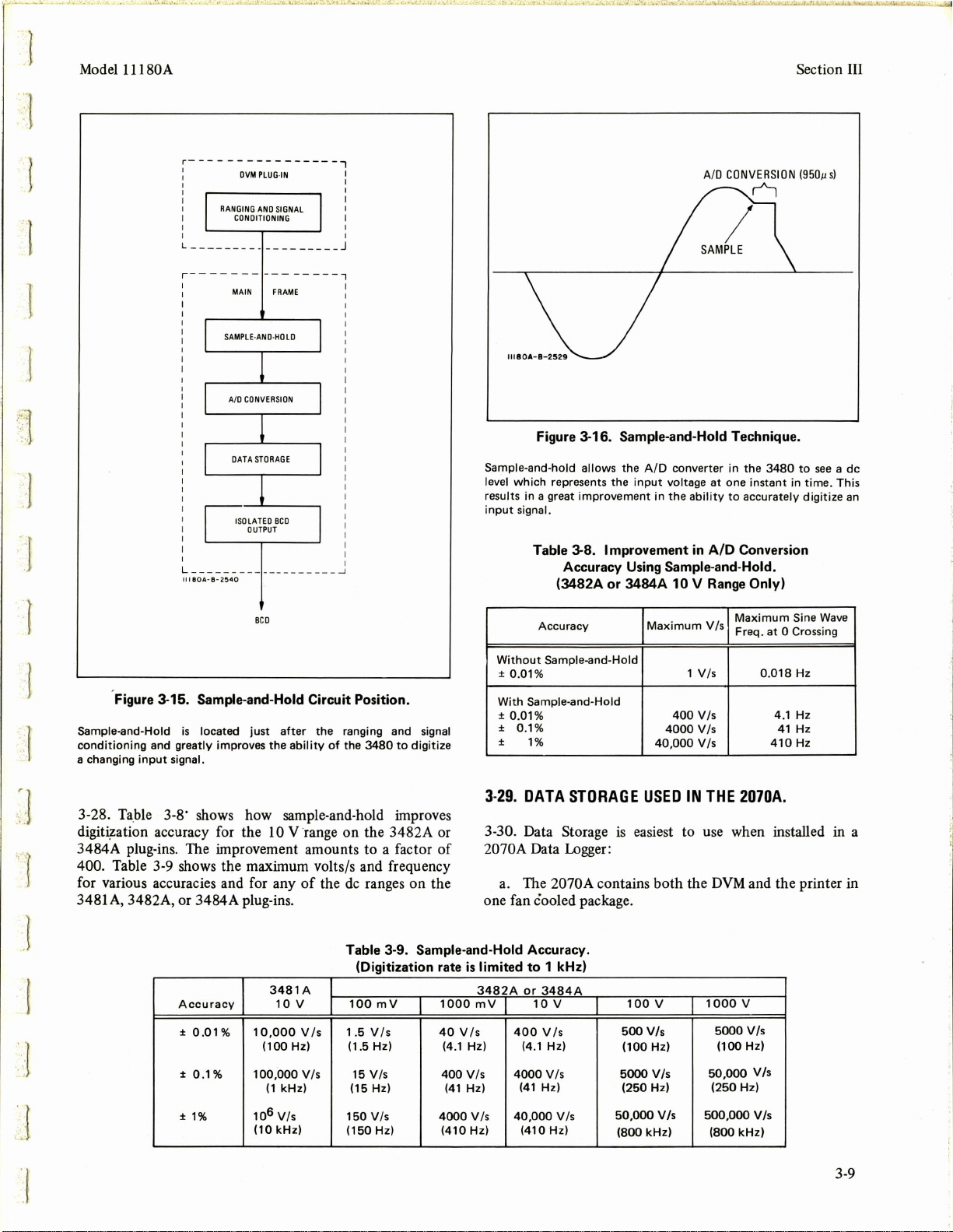

ENABLE

storage and

HOLD-OFF

automatically

breaking this line

to

or

to

the Storage

start one complete

after a storage cycle. The

UP

TO 50,

..

20µs

momentarily.

Limit

000

/s

are counted

I

~____.I

OUTPUT

CYCLE

}

'"""""'"

may be grounded

out-of

storage using the

is

MEASURE

no longer needed .

in

both

to

storage

allow

same

Figure 3-8. Data Storage Timing.

Data Storage running

Measure is

Storage Flag remains high

grounded

acknowledged

to

achieve this speed.

Table 3-3. Methods

Lines Used

Jump

Preset Trigger

"O",

"1

O",

Input

Grounded

Measurement

Released

Ground

3-13.

or "20"

Cycle

Hold

from

OPERATION

Hold

at a 50

with

WITH

kHz

output

a high going Storage Flag. The

16

to

of

Outputting Data.

Triggers

10,20,30,40,orSO

Triggers < Storage

Last reading repeated

Storage

Trigger source may free run

Triggers counted

DVM

storage

Trigger source may free run

Triggers counted

DVM

SINGLE

rate. Each

20 ms. Continuous Cycle

Trigger Requirement

= Storage

Limit

samples before and

but

not

samples

only

CHANNEL

low

Limit

Limit

to

fill

automatically

during

while

printing

automatically

when storing

PLUG-INS.

going

3-14. There are 3 single channel plug-ins available for use

with the

3480:

3481A Single 10 V de range

3482A 5

3484A 5

de

ranges from 100 m V

ac

or de ranges from I 00 m V

6 ohms ranges from I 00

to

1000 V

il

to

to

I 000 V

I 0 Mil.

is

3-5

Page 18

Section

III

Model

l l l 80A

3-15.

In

either

de

or ohms, these plug-ins are able to make

1000 correct readings/s. Within 1 ms, the 3480

is

able to

respond to a full-scale change and digitize. These single

channel plug-ins combined with the

3480 main frame are

able to act like a low cost, 1 kHz A-to-D converter. Data

Storage allows up to 50 readings taken at up to 1000/s to

be

stored and printed.

3-16.

As

shown in Table 3-4, these plug-ins contain their

own sample-rate oscillator able to take from 1 reading/s up

to approximately

40 readings/s. These plug-ins must

be

externally triggered (throup,h the main frame) to achieve

higher sampling rates.

Table 3-4. Maximum Triggering Rates.

Internal External

3481A

3482A

3484A

*Variable

front

panel sample-rate

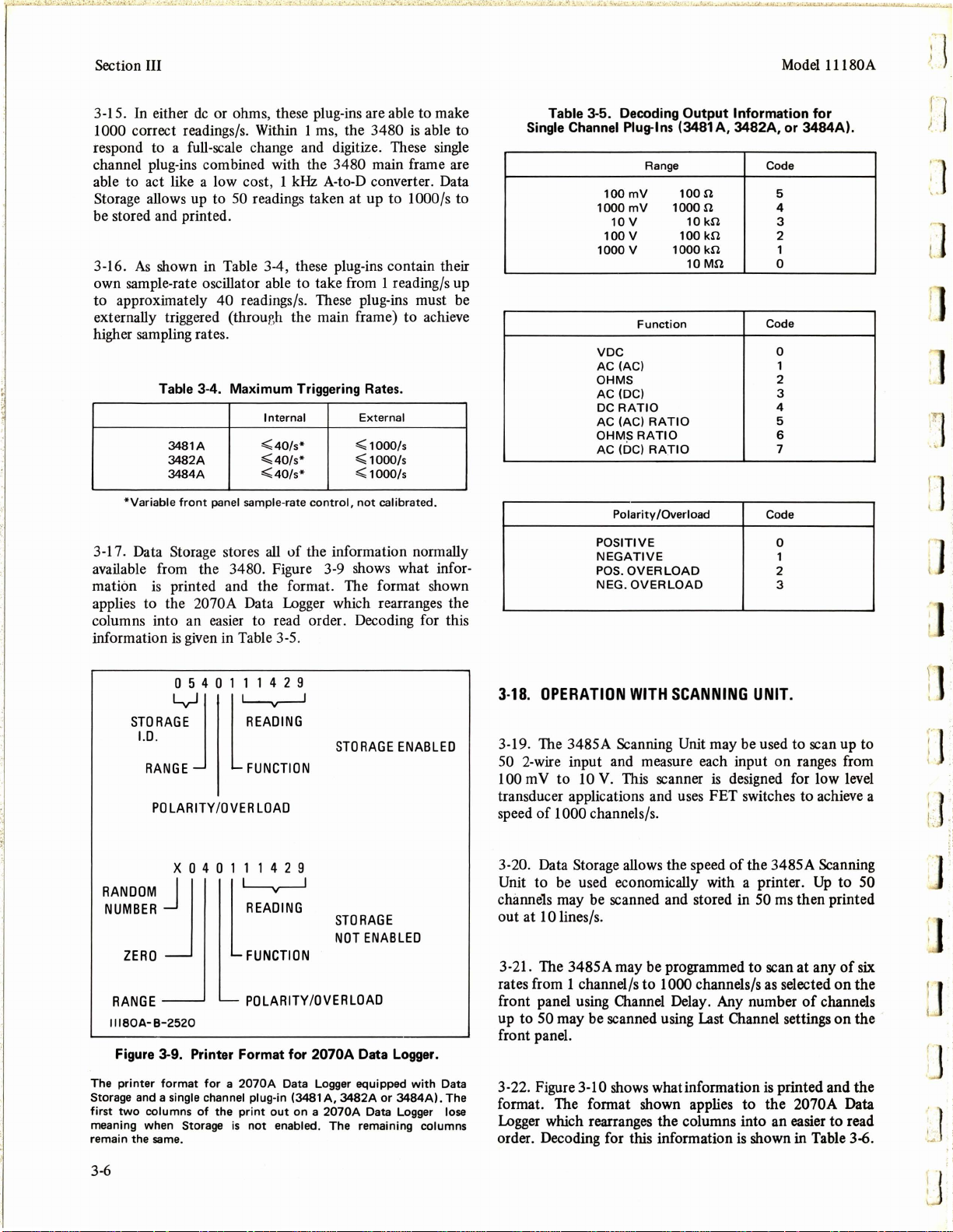

3-17. Data Storage stores

available from the

mation

is

printed and the format. The format shown

applies to the

3480. Figure 3-9 shows what infor-

2070A Data

<(40/s*

<(40/s*

<(40/s*

all

of

the information normally

Logger

<( 1000/s

<( 1000/s

<( 1000/s

control,

not

calibrated.

which rearranges the

columns into an easier to read order. Decoding for this

information

is

given

in Table 3-5.

Table 3-5. Decoding

Single Channel Plug-Ins (3481

100mV

1000

mV

10V

100

v

1000

v

VDC

AC (AC) 1

OHMS

AC (DC)

DC

RATIO

AC (AC)

OHMS

AC (DC)

Polarity /Overload

POSITIVE

NEGATIVE

POS.

OVER

NEG.

OVERLOAD

Output

Range Code

1oon

1ooon

10

100

1000

10Mn

Function

RATIO

RATIO

RATIO

LOAD

Information

A,

3482A,

kn

kn

kn

5

4

3

2

1

0

Code

0

2

3

4

5

6

7

Code

0

1

2

3

or

3484A).

for

ri·.

I .

I .

Tl:

' .

"

1".

J

. .

I .

0 5 4 0 1 1 1 4 2 9

1

STORA~J

l.D.

RANGE

POLARITY/OVER

l1REA~ING

STORAGE

FUNCTION

LOAD

x 0 4 0 1 1 1 4 2 9

RANDOM]

NUMBER

ZERO

RANGE

lllSOA-B-2520

Figure 3-9. Printer Format

The

printer

two

format

single channel plug-in (3481

columns

same

.

Storage and a

first

meaning when Storage

remain the

l~

READING

FUNCTION

POLARITY

for a 2070A

of

the

print

is

not

STORAGE

NOT

/OVERLOAD

for

2070A Data Logger.

Data Logger equipped

A,

out

on a

enabled. The remaining columns

3482A

2070A

ENABLED

ENABLED

with

3484Al.

Data

The

or

Data Logger lose

3-18.

OPERATION

WITH

SCANNING

UNIT.

3-19. The 3485A Scanning Unit may be used to scan up to

50 2-wire input and measure each input on ranges from

100 m V to 10 V. This scanner is designed for low level

transducer applications and uses FET switches to achieve a

speed

of

1000 channels/s.

3-20. Data Storage allows the speed

Unit to

be

used economically with a printer.

of

the 3485A Scanning

Up

to 50

channels may be scanned and stored in 50 ms then printed

out at

10 lines/s.

3-21. The 3485A may be programmed to scan at any

rates from 1 channel/s to 1000 channels/s as selected

front panel using Channel Delay. Any number

up to

50 may be scanned using

Last

Channel settings

of

channels

of

on

on

six

the

the

front panel.

3-22. Figure

format. The format shown applies to the

Logger

order. Decoding for this information

3-10 shows whatinformation

is

printed and the

2070A Data

which rearranges the columns into an easier to read

is

shown in Table 3-6.

:1

I .

' }

/.:

J.

3-6

Page 19

Model l l l 80A

STD

1 5 1

RAGE

ENABLED

204068

PROGR

AM INITIA

TE (TO SCAN

NER

Section III

)

. I

J

TENS

POLARITY

OVERLOAD

STORAGE

CHANNEL

l.D.

L.,JJ

1.0

.

AND

STORAGE

~

l

RANGE

NOT

ENABLED

x 5 1 1 2 0 4 0 6 8

RANDOM

NUMBER

JI

CHANNEL

BACKWARDS

II

llOA-1-2521

1.0

.

POLARITY

OVERLOAD

Figure 3-10. The Printer Format.

~

l

RANGE

AND

17

TRIGGER

AST CHANNEL"'

AG (FROM

OFF

(TO OVM)

BLE (GROUNDED

LIMIT "20"

LINE (GROUNDED

S

OVM)

17

)

)

)

Used

L

ST

______;_.,;..__;___~u

11180A-B-25

ORAGE FL

PRINTE

R HOLD-

STORA

GE ENA

SCANNER ENABLE (GROUNDED

S

TORAGE

22

Figure 3-11. Data Storage

Scanning Unit.

Data

Storage

non-multiple

Scanner

storage

Outputting

of

20

readings.

Enable

jumps

begins

used

of

ahead

10

must

with

with

channels

be

grounded.

to

the

the

the

is·

Storage

17th

3485A

scanned,

When Chan:iel

Limit

reading

JUMP FROM

SCA

I

c::

ST

~CYC

5µs 16TO 20µs

/\

·

..-----~u-0

ORA

GE STAR

LE

r"'i

NNER

TS

OUTPUT

LJooo

20 REA

DING GATED OUT

STORAGE

LIMIT" 20

with

the

3485A

Scanning

in

setting

repeated 3 times

this

case,

, in

Unit

17

17

this

channels

is

for a total

TO

0 0

where

reached,

case 20.

a

.

..

·r

.·

.r

1

]

3-23. When

equal

cause Data Storage

the

number

the

Storage Limit, grounding Storage Enable will

to

of

jump

channels

to

an

output

to

be scanned does

cycle after

the

not

last

channel has been scanned as shown in Figure 3-11. The

reading

Limit

on

the last channel

is

reached as shown in

is

repeated until the Storage

the

printout in Figure 3-12.

Table 3-6.

Decoding

Output

Information for

Range

100

1000

lOV

Polarity/Overload

POSITIVE

NEGATIVE

POSITIVE

NEGATIVE

OVERLOAD

the

mV

mV

OVERLOAD

3485A Scanning Unit.

Code

0

1

2

Code

0

1

2

3

The

3485A

Logger

Channel =

scanner

Note

that

reverts

l.D.

for

17).

may

the

to

17th

READING

REPEATED

3

TIMES

LAST

CHANNEL/

TENSCHANNELl

lllSOA-B-2523

Figure 3-12.

Scann

ing

scanning

Scanner

issue a

Jump

17th reading

zero

during

2

000112

l 9 0 0 1 1 2 3 4 1

{

1 8 0 0 1 1 2 3 4 1

1710112

1 6 1 0 1 0 9 7 7 4

1510100167

1410111245

1310009467

1210201140

1 l 1 0 1 0 1 4 2 l

1010210456

090101

0801001875

0700200509

0600111121

0501110025

0401101125

0301201489

0200001232

0100101379

STOR::J

l.D.

.D.

POLARITY /OVER

Jump

Unit

used

17

Enable

the

with

channels

must

when

17

is

repeated 3 times. The

repeated

3

41

3

41

1

992

L

READING

RANGE

LOAD

Printout.

Storage

(Storage

be

grounded

channels

readings.

in a

Limit=

have

2070A

so

been

Tens

Data

20;

that

scanned.

Channel

Last

the

3-7

Page 20

Section III

3-24. The 3485A may

programmed to take bursts

of

be

readings across the same channels, store each burst then

all

output

be divisible into the

readings. The number

Storage Limit an integral number

times. For example, 2 bursts

Limit = 20. Table

A timing example

3-

7 illustrates the different combinations.

is

shown in Figure 3-13 with a printout

of

channels scanned must

of

10 channels with Storage

of

in Figure 3-14.

Table 3-7.

3485A/Data

Last Channel Storage

Storage Operation for Bursts of Readings.

3485A

Setting Setting

5

5

5

5

5

10

10

10

10

25

2

2

2

2

2

3

4

Limit

10

20

30

40

50

20

30

40

50

50

10

20

30

40

50

30

40

Number

of

Bursts

2

4

6

8

10

2

3

4

5

2

5

10

15

20

25

10

10

PROGRAM

PROGRAM

llllOA-1-1525

2ND

25

CHANNELS

INITIATE

IST

25

CHANNELS

INITIATE

BURST

--

BURST

--

OF

Of

5020604328

4 9 2 0 6 0 4 5 0 9

4820604292

4 7 2 0 6 0 4 0 5 8

4 6 2 0 3 0 5 6 4 9

4 5 2 0 2 0 4

4410204519

4310204353

4210604132

4110701062

4010701753

3910701713

3810301673

3710301741

3610301658

3 5 1 0 7 0 1 7 7 1

3400701679

3300700679

3200300319

3100305199

3000704653

2900701459

2800704120

2 1 0 0 1 0 1 5 0 0

2600301010

2520601

2420601512

2320601621

2220601482

2120201440

2020205572

1910205032

1810205160

1 7 1 0 6 0 4 1 7 1

1 6 1 0 6 0 5 1 7 0

1510605060

1410605681

I 3 1 0 2 0 5 4 9 0

12

1110204409

1 0 1 0 6 0 I 0 4 0

0900601190

0800604070

0700601180

0600201072

0500201632

0400201392

0300601271

0200600033

0100601423

5.

510

10204180

8

Model

1 l l 80A

IJ

]

IHURNALTlllGGUlfWITHINSCAfOIE;:.Rl-------------

l.J1•IURST

I

OCHA

NNEL

S

INO. JTHROUGHN0.10)

"'"1

~-------~

STORAGEflAG

(fROMDVM)

PlllliTEAHOLO·OHITOOVMI

_____

INl'UT

CYCLE,21

-~"'~"':GE~l~'"'-'-'

Data Storage may be used

the

3485A

stored. Separate Program

to

start

may be given its

"20"

··

"-20

·

__

}GROUNDED

Figure 3-13. Burst Operation.

to

Scanning

the

input

Unit.

scanning sequence. Ready indicates when

next

Program

and

output

LJ

2ndBURST

!OCHANNHS

(

NQ.lTHAOUG

HN0.101

n I

~------~·

URSTSOF10CHANNEl$

to

store bursts

In

this

case,

Initiate

commands are given

Initiate.

20

readings.

two

The

of

bursts

Storage

f--OUT

PUT

-

lflrl0···

___,11.flf-··

O

UTl'UTCYClE

2011f

AOI

NGS

scanned readings

of

10

to

Limit

from

channels are

the scanner

the

scanner

is

set

to

Figure 3-14. Burst Printout.

The

print-out

channels then

Channel=

burst.

3-25.

on a

2070A

is

shown

all

50

the

10's Channel

25).

outputting

Note

how

SAMPLE-ANO-HOLD

for

scanning

readings (Storage

IMPROVES

l.D.

DIGITIZING.

two

Limit = 50;

helps

identify

bursts

of

Last

each

25

3-26. The successive approximation technique used for

A/D conversion in the 3480

is

limited in its ability to

accurately digitize a changing input voltage. This limit

equal to

range, 1 V /s. This translates to a 0.018

10%

of

the full-scale voltage range/s or on the 10 V

Hz

sine

wave

digitized to ± 0.01 % accuracy.

3-27. Sample-and-hold may

frame

as

shown in Figure 3-15. Sample-and-hold takes the

changing input

signal

conditioned by the plug-in and holds

be

added to the 3480 main

it just prior to A/D conversion. The A/D converter,

therefore , looks at a

level at the time

de

of

the sample

level which represents the

as

shown in Figure 3-16.

signal

J

:J

is

3-8

Page 21

1

·1

Model l l l 80A

r----------------1

:

I I

I I

I I

I

I

I I

I I

L

_____

DVM

RANGING

CONDITIONING

____

PLUG-IN

AND

SIGNAL

_________

r---------------,

:

I

I I

L------

111BOA·8-2

MAIN

FRAME

SAMPLE·AND·HDLD

A/0

CONVERSION

DATA

STORAGE

ISO

LA

TEO

BCD

OUTPUT

---

------

540

----

I

J

I

~

Figure 3-16. Sample-and-Hold Technique.

Sample-and-hold allows the

level

which

represents the

results in a great

input

signal.

improvement

Table 3-8. Improvement

Accuracy

(3482A

or

Using

3484A

A/D

converter in the

input

voltage at one instant in

in

the

ability

in

A/D

Sample-and-Hold.

10 V Range

3480

to

accurately

Conversion

Only)

Section III

to

see

a de

time.

This

digitize

an

l

..

'·1

·'·

: .-1

BCD

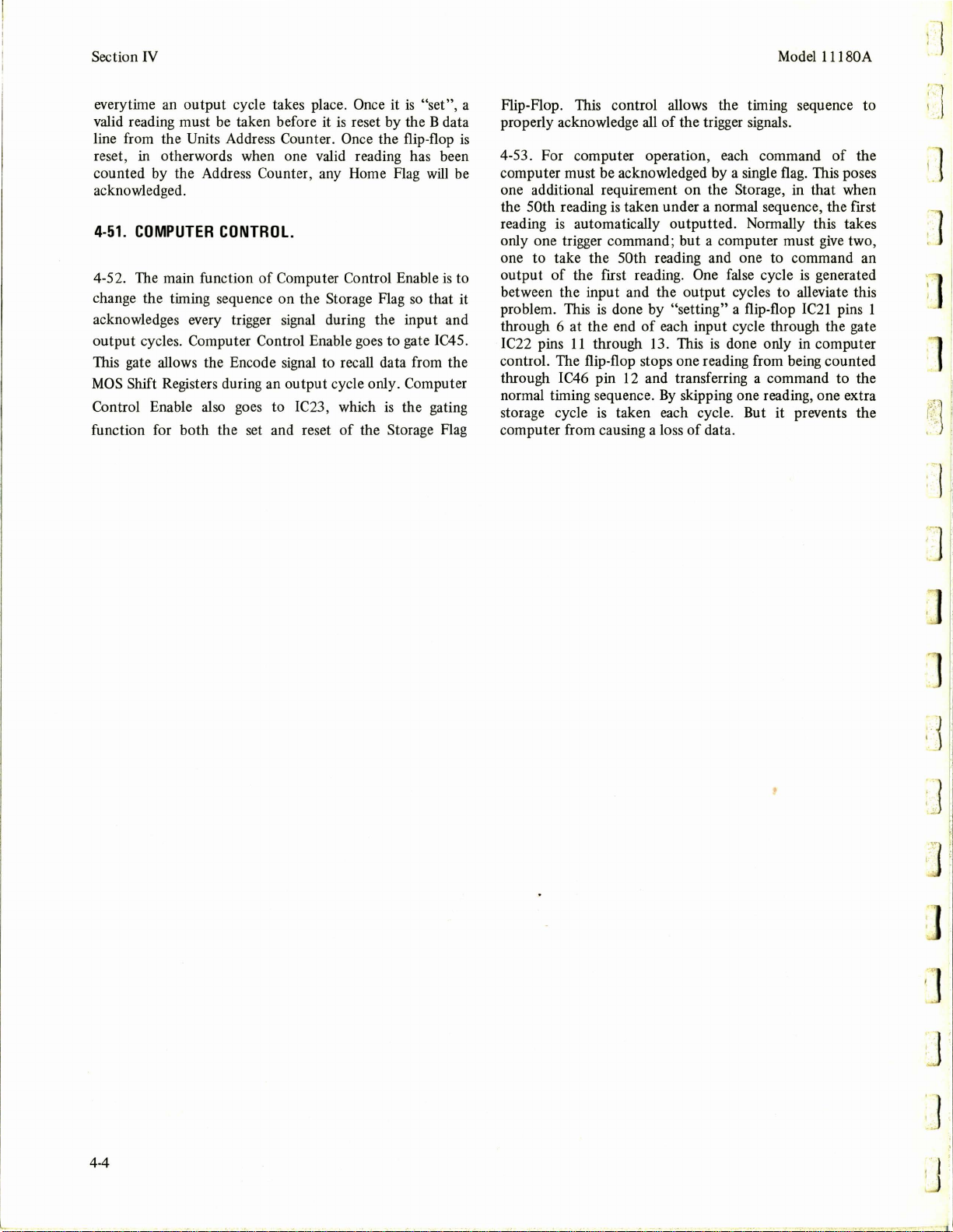

Figure 3-15. Sample-and-Hold Circuit Position.

Sample-and-Hold

conditioning

a changing

is

and greatly improves the

input

located

signal.

just

after

the ranging and signal

ability

of

the

3480

to

digitize

3-28. Table 3-8· shows how sample-and-hold improves

digit~ation

3484A plug-ins. The improvement amounts to a factor

accuracy for the 10 V range on the 3482A or

of

400. Table 3-9 shows the maximum volts/s and frequency

of

the

de

for various accuracies and for any

3481

A,

3482A, or 3484A plug-ins.

Accuracy

±

0.01

%

± 0.1 % 100,000 Vis

3481A

10

10,000

(100 Hz)

(1

kHz) (15 Hz)

v

Vis

ranges on the

Table 3-9. Sample-and-Hold Accuracy.

(Digitization rate

100

mV

1 .5

Vis

(1

.5 Hz) (4.1 Hz)

15 Vis

1000

40

400

Accuracy

Without

With Sample-and-Hold

± 0.Q1%

± 0.

±

3-29.

Sample-and-Hold

± 0.01%

1%

1%

DATA

3-30. Data Storage

2070A Data Logger:

a. The

one fan cooled package.

is

limited to 1 kHz)

or

400

(4

4000

(41

3484A

10

V

.1 Hz)

Vis

Hz)

(41

3482A

mV

Vis

Vis

Hz)

Maximum

1

V/s

400

Vis

4000

V/s

40,000

V/s

STORAGE

USED

IN

is

easiest to use when installed in a

2070A contains both the

v

Is

100

500

(100

5000

(250

v

V/s

Hz)

V/s

Hz)

Maximum

V/s

Freq .

0.018

THE

2070A.

DVM

and the printer in

1000

v

5000

V/s

(100 Hz)

50,000

V/s

(250

Hz)

Sine

at

0 Crossing

Hz

4.1 Hz

41

Hz

410

Hz

Wave

50,000

V/s

106

±

1%

(10

Vis

kHz)

150

Vis

(150 Hz)

4000

Vis

(410Hz)

40,000

(410Hz)

Vis

(800

kHz) (800

500,000

V/s

kHz)

3-9

Page 22

Section III

Model 11180A

All interconnections are make within

b.

system comes ready

to

use.

the

2070A;

the

c. The major Data Storage controls are available as

switches

include Storage Limit, Storage Enable, Scanner

on

the

rear panel

of

the 2070A. These controls

Control

Enable, Measure (External Trigger) and Internal Measure

Inhibit (See Figure 3-17).

EXTERNAL

TRIGGER

SWITCH

ALLOWS

SELECTION

OF

STORAGE

LIM

IT

ENABLE

SCANNER

CONTROL

ENABLE

\

JUMP

COMMAND

FROM

SCANNER

)

SYS

TEM LINE

SWI

TCH ITUR

NSON

FAN PLUS DVM

AND

PRINTE

R)

Figure 3-17. Rear Panel

The rear panel

Storage

available on the rear panel. This makes operation

easier.

(Option

of

005).

the

2070A

INPUT

ENABLES

STORAGE

of

the

Data Logger equipped

Many

of

the

2070A Data Logger.

major

d. A convenient 14 pin connector

INTERNAL SAM

14PIN CONNE

CT

WITH MAJOR DATA

STORAGE

CONTROL

LI

NES

storage

on

DISABLES

PLING

with

Data

controls

of

Data Storage

the rear panel

are

provides additional Data Storage control lines including

Preset Trigger (See Table

e. The printer columns have been rearranged

an easier

Table

to

read format (see Figures 3-10 and 3-11 ).

3-10. 2070A Rear Panel Connector for Data Storage.

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

3-10).

Function

GROUND

MEASUREMENT

JUMP

STORAGE

STORAGE

STORAGE

STORAGE

MEASURE

SCANNER

STORAGE

INPUT

PRESET

PRESET

PRESET

LIMIT

LIMIT

LIMIT

LIMIT "40"

ENABLE

ENABLE

CYCLE

TRIGGER

TRIGGER

TRIGGER

HOLD

"10"

"20"

"30"

HOLD

" O"

"10"

"20"

to

provide

50

K

-=-5.4V

111ao•-1-zs••

14 13 12

HP1820·0207

OR

OR

MOTOROLA

2 3 5 6

11

10

FAIRCHILD

MC8601P·7025

EXT.

9 8

9601

TRIG

Uv

OUTPUT

1000

/s

.

+5

RANGE

Figure 3-18. Trigger Source for Single Channel Plug-ins.

Variable Trigger source

source may be

Storage. The short

applications. Internal triggering in the 3481

plug-in

is

on

the

limited

5055A

calibrated

to

MANUAL PRINT may have

times

but

will eventually cause Data Storage

output

cycle.

3-35. An example

MANUAL PRINT causes a partial reading

Full readings are printing during an

output

cycle

Direction

of

tape

is

complete, Data Storage

paper

for

use

with

Data Storage. This trigger

a counter, then applied

is

good enough

A,

3482A,

term

40

readings/s.

with

stability

Digital Recorder in the OPERATE mode.

to

be pushed a number

to

is

shown in Figure 3-19. Note

to

be printed .

1041100023

0941100023

0841500023

0741500023

0641100023

0541500023

0441100023

0341500023

0241100023

0141100023

1043515

0943515

0843315

0743315

0643515

0543315

0443515

output

Data

cleared

Automatic

'>

output/

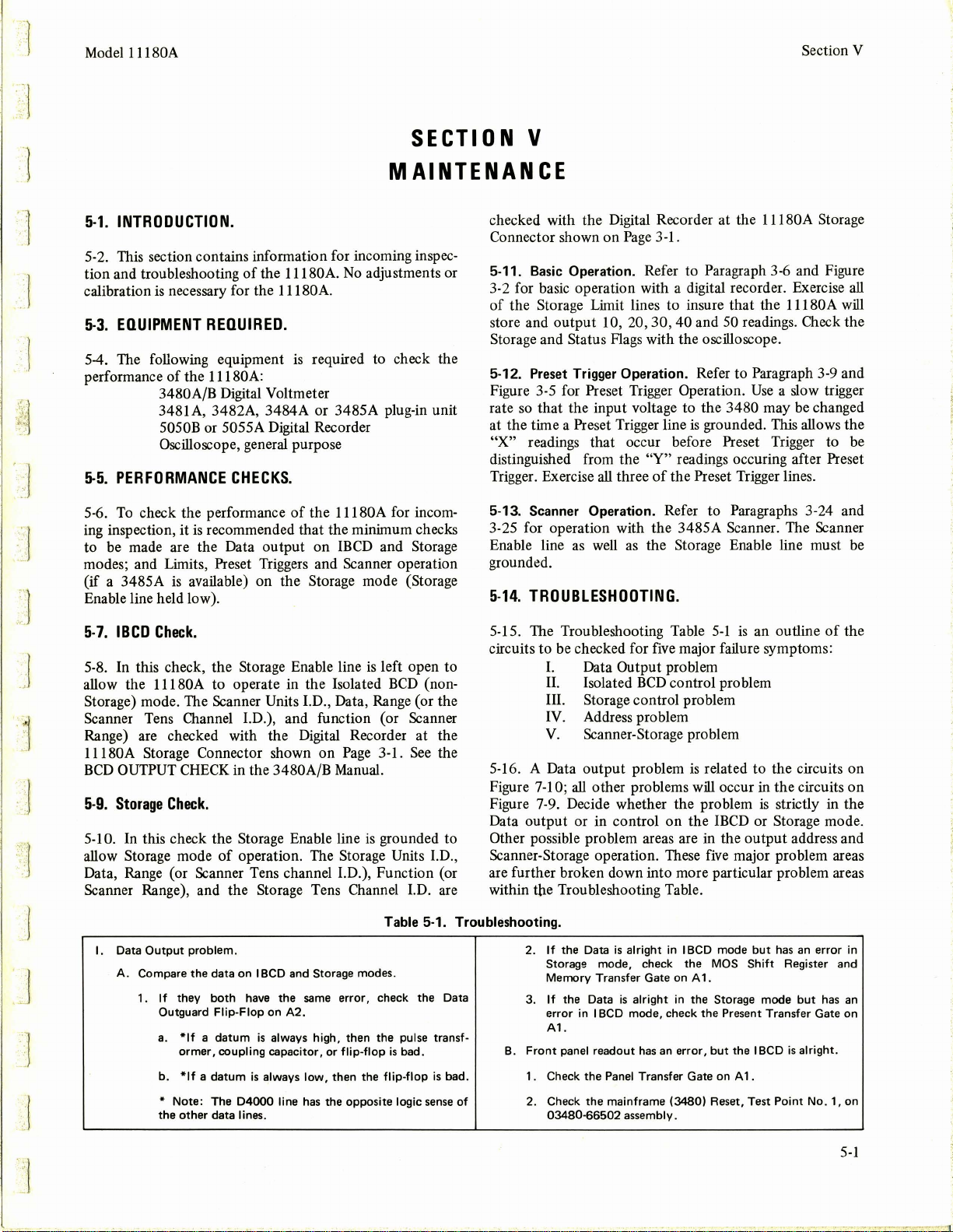

MANUAL