Page 1

HP

LaserJet

1100A

Service

Manual

Page 2

Page 3

HP LaserJet 1100A

Service Manual ______________

Page 4

©

Copyright

Hewlett-Packard Company 1998

All Rights Reserved. Reproduction, adaptation, or translation without prior written permission is prohibited, except

as allowed under the copyright laws.

Publication number

C4224-90962

First edition, October 1998

Trademark Credits

Adobe and PostScript are trademarks of Adobe Systems Incorporated which may be registered in certain

jurisdictions.

Windows is a U.S. registered trademark of Microsoft Corporation.

Warranty

The information contained in this document is subject to change without notice.

Hewlett-Packard mak es no w arranty of an y kind with regard to this material, including, but not limited to, the implied

warranties or merchantability and fitness for a particular purpose.

Hewlett-Packard shall not be liable for errors contained herein or for incidental or consequential damages in

connection with the furnishing, performance, or use of this material.

WARNING

Electrical Shock Hazard

To avoid electrical shock, use only supplied power cords and connect only to properly grounded wall outlets.

2

C4224-90962

Page 5

Conventions

This manual uses the following conventions:

The names of major printer parts and assemblies are Capitalized.

Color is used to emphasize items which are important to the material under discussion.

NOTE:

CAUTION:

WARNING!

is used for emphasis, particularly in situations where

Bold

Italic type

Notes contain important information set off from the text.

Caution messages alert you to the possibility of damage to equipment or loss of data.

Warning messages alert you to the possibility of personal injury.

is used to indicate related documents or emphasis.

type would be confusing.

italic

C4224-90962

3

Page 6

Chapter Descriptions

1 Printer Specifications

Contains printer features and product overview, printer specifications, and required safety

and compliance statements.

2 Product Operation

Contains descriptions of the Control Panel, printer key functionality, scanner Control Panel,

paper handling, toner cartridge, and warranty statement.

3 Functional Overview

Contains details about basic functions, printer functions, Engine Control Unit (ECU) and

power system, formatter system, image formation system, printer paper feed system,

optional document scanner system, and basic sequence of operation.

4 Removal and Replacement

Contains step-by-step procedures for replacing field replaceable units (FRUs) in the printer.

5 Troubleshooting/Maintenance

Contains details basic troubleshooting steps, fatal errors and accessory errors, image

formation troubleshooting steps, solving image quality problems, cleaning procedures,

functional checks, ServiceMode functions, and troubleshooting tools.

6 Parts and diagrams

Contains exploded view drawings and part number listings for all replaceable parts in the

printer.

Contains two replaceable parts tables: one sorted alphabetically by part name and one

sorted numerically by part number. Both tables are cross referenced to the diagrams in the

chapter.

Index

Contains an alphabetical, cross referenced listing of information found in the main body of

the manual.

4

C4224-90962

Page 7

Contents

1 Printer Specifications

Printer description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Firmware description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

FCC compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Environmental Product Stewardship Program . . . . . . . . . . . . . . . . . . . . . . . . . .17

Protecting the Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Material safety data sheet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Additional product stewardship . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Environmental conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Regulatory statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Laser safety statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Canadian DOC regulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Korean EMI statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Laser statement for Finland . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

2 Product Operation

HP LaserJet 1100 Printer control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Printer key functionality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Scanner control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Printer paper handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Toner cartridge information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Warranty statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

3 Functional Overview

Basic functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Printer functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Engine Control Unit (ECU)/power system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Printer engine control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Power system on ECU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Formatter system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Draft mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Memory Enhancement technology (MEt) . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Enhanced I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Page Protect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

PJL Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Image formation system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Toner cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Printer paper feed system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Paper jam detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Solenoid, photosensors, and switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Document scanner system (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Basic sequence of operation (formatter to printer) . . . . . . . . . . . . . . . . . . . . . . .58

C4224-90962

5

Page 8

4 Removal and Replacement

Removal and replacement strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Required tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

External assemblies and covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Paper guides removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Document scanner removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Document scanner opening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Contact image sensor removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Printer door removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Pod removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Back cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Internal paper guide removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Front cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Stabilizer bars removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Printer laser/scanner cover removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Internal assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Scanner assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Output roller removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Delivery assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Paper exit sensor flag removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Fusing element removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Fusing element removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Gear train motor and solenoid removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Solenoid removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Pressure roller removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Transfer roller removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Pickup roller removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Paper pick-up assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Kick plate removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Separation pad removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Bottom assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Formatter pan removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Document scanner cable removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Hinge mechanism removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

ECU pan removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Paper feed assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

6

C4224-90962

Page 9

5 Troubleshooting/Maintenance

Basic troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Fatal errors/accessory errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Image formation troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Checking the toner cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Solving image quality problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Solving paper feed problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Cleaning procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Cleaning the toner cartridge area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Cleaning the printer paper path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Cleaning the pickup roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Cleaning the scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Functional checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Engine test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Self test page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Half-self test functional check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Drum rotation functional check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Heating element check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

High-voltage power supply check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Paper curl. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Paper path check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

ServiceMode functions (PJL Software Commands) . . . . . . . . . . . . . . . . . . . . . 149

Troubleshooting tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Printer paper path. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Document paper path. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Repetitive image defect ruler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Main wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

6 Parts and diagrams

How to use the parts lists and diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Parts and supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Consumables and accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Ordering consumables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Common hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

External covers and panels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Document scanner parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Internal components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Feeder assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Engine controller assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Formatter pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Parts list sorted by part number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Parts list sorted by part name. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

C4224-90962

7

Page 10

8

C4224-90962

Page 11

1

Printer Specifications

Chapter contents

Printer description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Firmware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

FCC compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Environmental Product Stewardship Program . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Material safety data sheet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Regulatory statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

C4224-90962

Chapter contents

9

Page 12

Printer description

The HP LaserJet 1100 Printer is the next generation low-cost HP LaserJet printer. It

provides 600 dots-per-inch (dpi) LaserJet features and add-on scanner capabilities at the

lowest possible price. The scanner is 300 dpi/8 bits per pixel (bpp) and contains an

automatic document feed (ADF) holding up to 20 pages.

The HP LaserJet 1100 Printer prints eight pages-per-minute (ppm). It provides an excellent

Windows printing solution, ease of use, and higher performance. With 600 dpi resolution, the

HP LaserJet 1100 Printer has exceptional text and graphics print quality. The simplified

Control Panel and improved paper handling make this product very simple to use. The

HP LaserJet 1100 Printer also provides modular scanner capability.

This product is sold in three configurations:

1. Printer Only:

• C4224AHP LaserJet 1100 Printer

• C4225AHP LaserJet 1100 xi Printer (U.S.)

• C4226AHP LaserJet 1100 si Printer (U.S.)

2. Printer and Scanner:

• C4218A HP LaserJet 1100A Printer-Copier-Scanner

• C4219A HP LaserJet 1100A xi Printer-Copier-Scanner (U.S.)

• C4220AHP LaserJet 1100A se Printer-Copier-Scanner (U.S.)

3. Scanner Only:

• C4221A Copier-Scanner for HP LaserJet 1100 Printer

10 Chapter Printer Specifications

C4224-90962

Page 13

Hardware description

The HP LaserJet 1100 Printer engine prints eight pages per minute. The HP LaserJet 1100

Printer has a compact design with vertical paper trays.

There is one main Paper Input Bin with a 125-sheet capacity for continuous, multiple-page

printing. Manual, single-sheet printing is possible through the Single Sheet Input Slot. Both

trays are center justified for all supported paper sizes. The output tray holds up to 100

sheets.

The HP LaserJet 1100 Printer has a very fast first-page-out, at less than twenty seconds. It

has a Control Panel containing two LEDs. A third LED is located on the Go Key. The

formatter board contains 4 MB of ROM, 2 MB of RAM, and a 32-bit MCF5202 chip. There is

one slot availab le f or DIMM Memory Expansion (supporting a 4 MB, 8 MB, or 16 MB DIMM).

The HP LaserJet 1100 Printer engine has a 7,000 pager-per-month duty cycle and has no

fan. The toner life for the HP LaserJet 1100 Printer is 2,500 pages. The attachable scanner

has two Control Panel buttons and up to 20-page ADF.

C4224-90962

Figure 1-1 Control panel

Hardware description

11

Page 14

Firmware description

The firmware in the HP LaserJet 1100 Printer includes:

• Enhanced PCL 5 with Status Readback

• 26 scalable Intellifont Fonts

• Full page 600 dpi bitmap

• 600 dpi

• Pixel Placement, Mosaic Characters

• Memory Enhancement technology (MEt) with Hardware Compression/Decompression

The HP LaserJet 1100 Printer firmware also has REt and EconoMode functionality. Scan

capability for the scanner attachment includes 300 dpi and 256 levels of gray (8 bpp).

12 Chapter Printer Specifications

C4224-90962

Page 15

Specifications

Table 1-1. Printer specifications

Environmental specifications

Operating

environment

Storage

environment

Acoustics

Noise level During printing:

Printer plugged into an AC outlet:

• Temperature: 10° C to 32.5° C (50° F to 90.5° F)

• Humidity: 20% to 80% (no condensation)

Printer unplugged from an AC outlet:

• Temperature: 0° C to 40° C (32° F to 104° F)

• Humidity: 10% to 90% (no condensation)

• 6.1 Bels sound power level (per ISO 9296)

(HP LaserJet 1100 Printer tested at 8 ppm)

• Sound pressure level (bystander position): 47 dB

• Sound pressure level (operator position): 55 dB

• Silent during standby and sleep mode

Electrical specifications

Power requirements • 100-120v (+/-10%), 50/60 Hz (+/-2); 127v, 60Hz NOM

or

• 220v (+/-10%), 50/60 Hz (+/-2 Hz)

• 220-240v (+/-10%), 50 Hz (+/-2 Hz)

Power consumption • During printing: 200 watts (average)

• During standby and power save: 6 watts

Minimum

recommended

circuit capacity

4.5A @ 115v; 2.5A @ 230v

C4224-90962

Specifications

13

Page 16

Table 1-1. Printer specifications (continued)

Physical specifications

Dimensions (1100) • Width: 367 mm (14.5 inches)

• Depth: 306 mm (12.8 inches)

• Height: 266 mm (14.9 inches)

Weight (cartridge

• 7.2 kg (16.1 lb)

installed)

1100A • Width: 367 mm (14.5 inches)

• Depth: 402 mm (15.8inches)

• Height: 378 mm (14.9 inches)

Weight • 8.7 kg (19.2 (lb)

Printer capacities and ratings

Print speed 8 pages per minute (Letter size paper)

Paper input bin

capacity

Paper output bin

125 sheets of regular weight 20 lb (75 g/m

10 envelopes

100 sheets of regular weight 20 lb (75 g/m

capacity

2

) paper or up to

2

) paper

Minimum paper size 76 x 127 mm (3 x 5 inches)

Maximum paper

size

Base memory 4 MB of ROM and 2 MB of RAM

Upgrade memory

expansion

Print resolution 600 dots per inch (dpi)

Duty cycle 7,000 single-sided pages per month

Scanning Capacities and Ratings

14 Chapter Printer Specifications

216 x 356 mm (8.5 x 14 inches)

One DIMM slot available for a 4 MB, 8 MB, or 16 MB RAM

DIMM

C4224-90962

Page 17

Table 1-1. Printer specifications (continued)

Scan Speed Up to 8 pages per minute (Letter size paper)

Input Capacity

Up to 20 pages of regular weight 20 lb (75 g/m

Minimum Paper Size 51 x 89 mm (2 x 3.5 inches)

Maximum Paper

216 x 762 mm (8.5 x 30 inches)

Size

Scan Resolution 300 dots per inch 256 levels of gray

Duty Cycle 2,500 pages per month

2

) paper

C4224-90962

Specifications

15

Page 18

FCC compliance

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio frequency energy. If it is not installed and

used in accordance with the instructions, it may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or tele vision

reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase separation between equipment and receiver.

• Connect equipment to an outlet on a circuit different from that to which the receiver is

located.

• Consult your dealer or an experienced radio/TV technician.

NOTE: Any changes or modifications to the printer that are not expressly approved b y HP could void

the user’s authority to operate this equipment.

Use of a shielded interface cable is required to comply with the Class B limits of Part 15 of

FCC rules.

16 Chapter Printer Specifications

C4224-90962

Page 19

Environmental Product Stewardship Program

Protecting the Environment

Hewlett-Packard Company is committed to providing quality products in an environmentally

sound manner. This HP LaserJet printer has been designed with several attributes to

minimize impacts on our environment.

This HP LaserJet printer eliminates:

Ozone production

The printer uses charging rollers in the electrophotographic process and therefore generates

no appreciable ozone gas (O

This HP LaserJet printer design reduces:

Energy consumption

Energy usage drops to as little as 6 W while in lo w-po wer (PowerSave) mode. Not only does

this save natural resources, but it also saves money without affecting the high performance

of this printer. This product qualifies for E

established to encourage the dev elopment of energ y-efficient office products. E

a U.S. registered service mark of the U.S. EPA.

).

3

NERGY STAR

. E

NERGY STAR

is a voluntary program

NERGY STAR

is

As an E

meets E

NERGY STAR

NERGY STAR

partner, Hewlett-Packard Company has determined that this product

Guidelines for energy efficiency.

Toner consumption

EconoMode uses significantly less toner, which may extend the life of the toner cartridge.

Paper use

Depending on the type of software program in use, y ou can request for a n umber of pages of

your document to be printed on one page of paper. This N-up printing practice and the

printer’s manual duplexing feature, which provides two-sided printing, can reduce paper

usage and the resulting demands on natural resources.

C4224-90962

Environmental Product Stewardship Program

17

Page 20

The design of this HP LaserJet printer facilitates the recycling of:

Plastics

Plastic housing parts have markings according to international standards that enhance the

ability to identify plastics for recycling purposes at the end of the printer’s life.

HP LaserJet printing supplies

In many countries, this product's printing supplies (e.g., toner cartridge, drum, fuser) can be

returned to HP through the HP Planet Partners Printing Supplies Environmental Program.

An easy-to-use takeback component of the program is available in over 20 countries. Multilingual program information and instructions are included in every new HP LaserJet Toner

Cartridge and Consumables box.

HP Planet Partners printing supplies environmental program information

Since 1990, the HP LaserJet Toner Cartridge Recycling Program has collected more than

12 million used HP LaserJet toner cartridges that otherwise may have been discarded in the

world's landfills. The HP LaserJet toner cartridges go to a collection center and are bulk

shipped to our recycling partners who disassemble the cartridge parts for recycling. After a

thorough quality inspection, minor parts such as nuts, screws, and clips are reclaimed for

use in new cartridges. Remaining materials are separated and converted into raw materials

for use by other industries to make a variety of useful products. For more information in the

U.S., call 1-800-340-2445 or visit the HP LaserJet Supplies website at:

Asia Pacific: http://www.hp.com/sg/asiapacific/planp1.htm

U.S.: http//www.ljsupplies.com/planetpartners/

Europe: http://www.hp.com/pays/eur_supplies/english/planetpartners

Non-U.S. customers should call the local HP Sales and Service Office for further information

regarding availability of the HP Planet P artners LaserJet Toner Cartridge and Consumables

Recycling Program.

Paper

This printer is suited for the use of recycled papers when the paper meets the guidelines

outlined in the

and Ordering Information” in the

ordering information. This printer is suitable for the use of recycled paper according to DIN

19 309.

HP LaserJet Printer Family Paper Specifications Guide

HP LaserJet Printer Family Paper Specifications Guide

. See “Accessories

for

18 Chapter Printer Specifications

C4224-90962

Page 21

Material safety data sheet

The Toner Cartridge/Drum MSDS can be obtained by contacting the HP LaserJet Supplies

website at http://www.ljsupplies.com/planetpartners/datasheets.html. If you do not have

access to the Internet, try calling the U.S. HP FIRST (fax-on-demand service) at 1-800231-9300. Use Index number 7 for a listing of the Toner Cartridge/Drum Material/Chemical

Safety Data Sheets. Non-US customers should refer to the front of this manual for

appropriate phone numbers and information.

C4224-90962

Material safety data sheet

19

Page 22

Additional product stewardship

Environmental conformity

The design of this HP LaserJet printer facilitates the recycling of:

Printer and parts

Design for recycling has been incorporated into this printer and its accessories. The number

of materials has been kept to a minimum while ensuring proper functionality and high

product reliability . Dissimilar materials hav e been designed to separate easily. Fasteners and

other connections are easy to locate, access, and remove with common tools. High priority

parts have been designed to be accessed quickly for efficient disassembly and repair.

Plastic parts have been primarily designed in two colors to enhance recycling options. A few

small parts are colored specifically to highlight customer access points. The plastics used in

the printer housing and chassis are technically recyclable.

HP provides a product return system for customers in Germany . Man y of the functional parts

are recovered, tested, and reused as fully warranted service parts. Used parts are not

placed into new products. Remaining product parts are recycled, if possible. For product

return information, contact the address below:

Hewlett-Packard GmbH

Wertstoffzentrum

Fronackerstr.30

71063 Sindelfingen

To ensure longevity of your HP LaserJet printer, HP provides the

following:

Extended warranty

HP SupportPack provides coverage for the HP hardware product and all HP-supplied

internal components. The hardware maintenance warranty covers a three-year period from

date of the HP product purchase. The customer must purchase HP SupportPack within 90

days of the HP product purchase. Inf ormation on HP SupportPack is availab le in a f ax format

by calling HP FIRST (Fax Inf ormation Retriev al Service Technology). The document number

is 9036. Customers can contact the nearest HP dealer about this service.

Spare parts and consumables availability

Spare parts and consumable supplies for this product will be made available for at least five

years after production has stopped.

20 Chapter Printer Specifications

C4224-90962

Page 23

Regulatory statements

Declaration of Conformity

according to ISO/IEC Guide 22 and EN45014

Manufacturer's Name:

Manufacturer's Address:

declares that the product

Product Name:

Model Number:

Product Options:

conforms to the following Product Specifications:

Safety: IEC 950:1991+A1+A2+A3+A4 / EN 60950:1992+A1+A2+A3+A4

EMC:

Supplementary Information:

The product herewith complies with the requirements of the following Directives and carries the CEmarking accordingly:

the EMC directive 89/336/EEC

the Low-Voltage Directive 73/23/EEC

The product was tested in a typical configuration with Hewlett-Packard Personal Computer Systems.

This Device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

For Compliance Information ONLY, contact:

Australia Contact: Product Regulations Manager, Hewlett-Packard

European Contact: Your Local Hewlett-Packard Sales and Service Office

USA Contact: Product Regulations Manager, Hewlett-Packard

Hewlett-Packard Company

11311 Chinden Boulevard

Boise, Idaho 83714-1021, USA

HP LaserJet 1100 Printer

C4224A

ALL

IEC 825-1:1993 / EN 60825-1:1994 Class 1 (Laser/LED)

CISPR 22:1993+A1 / EN 55022:1994 Class B

EN 50082-1:1992

IEC 801-2:1991 / prEN 55024-2:1992 - 4 kV CD, 8 kV AD

IEC 801-3:1984 / prEN 55024-3:1991 - 3 V/m

IEC 801-4:1988 / prEN 55024-4:1992 - 0.5 kV Signal Lines

IEC 1000-3-2:1995 / EN61000-3-2:1995

IEC 1000-3-3:1994 / EN61000-3.3:1995

FCC Title 47 CFR, Part 15 Class B2) / ICES-003, Issue 2 / VCCI-2

AS / NZS 3548:1992 / CISPR 22:1993 Class B

Australia Ltd., 31-41 Joseph Street, Blackburn,

Victoria 3130, Australia

or Hewlett-Packard GmbH, Department HQ-TRE /

Standards Europe, Herrenberger Straße 130, D71034 Böblingen (FAX: +49-7031-14-3143)

Company, PO Box 15 Mail Stop 160, Boise, ID

83707-0015 (Phone: 208-396-6000)

1

1.0 kV Power Lines

1)

1)

C4224-90962

Regulatory statements

21

Page 24

Laser safety statement

The Center for Devices and Radiological Health (CDRH) of the U.S. Food and Drug

Administration has implemented regulations for laser products manuf actured since August 1,

1976. Compliance is mandatory for products marketed in the United States. The printer is

certified as a “Class 1” laser product under the U.S. Department of Health and Human

Services (DHHS) Radiation Performance Standard according to the Radiation Control for

Health and Safety Act of 1968.

Since radiation emitted inside the printer is completely confined within protective housings

and external covers, the laser beam cannot escape during any phase of normal user

operation.

WARNING! Using controls, making adjustments, or performing procedures other than those specified in

this user’s guide may result in exposure to hazardous radiation.

22 Chapter Printer Specifications

C4224-90962

Page 25

Canadian DOC regulations

Complies with Canadian EMC Class B requirements.

«Conforme á la classe B des normes canadiennes de compatibilité électromagnétiques.

«CEM».»

Korean EMI statement

C4224-90962

Regulatory statements

23

Page 26

Laser statement for Finland

LASERTURVALLISUUS

LUOKAN 1 LASERLAITE

KLASS 1 LASER APPARAT

HP LaserJet 1100 Printer -laserkirjoitin on käyttäjän kannalta turvallinen luokan 1 laserlaite.

Normaalissa käytössä kirjoittimen suojakotelointi estää lasersäteen pääsyn laitteen

ulkopuolelle.

Laitteen turvallisuusluokka on määritetty standardin EN 60825-1 (1993) mukaisesti.

VAROITUS!

Laitteen käyttäminen muulla kuin käyttöohjeessa mainitulla tavalla saattaa altistaa käyttäjän

turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

VARNING!

Om apparaten används på annat sätt än i bruksanvisning specificerats, kan användaren

utsättas för osynlig laserstrålning, som överskrider gränsen för laserklass 1.

HUOLTO

HP LaserJet 1100 Printer -kirjoittimen sisällä ei ole käyttäjän huollettavissa olevia kohteita.

Laitteen saa avata ja huoltaa ainoastaan sen huoltamiseen koulutettu henkilö. Tällaiseksi

huoltotoimenpiteeksi ei katsota väriainekasetin vaihtamista, paperiradan puhdistusta tai

muita käyttäjän käsikirjassa lueteltuja, käyttäjän tehtäväksi tarkoitettuja ylläpitotoimia, jotka

voidaan suorittaa ilman erikoistyökaluja.

VARO!

Mikäli kirjoittimen suojakotelo avataan, olet alttiina näkymättömälle lasersäteilylle laitteen

ollessa toiminnassa. Älä katso säteeseen.

VARNING!

Om laserprinterns skyddshölje öppnas då apparaten är i funktion, utsättas användaren för

osynlig laserstrålning. Betrakta ej strålen.

Tiedot laitteessa käytettävän laserdiodin säteilyominaisuuksista:

Aallonpituus 770-795 nm

Teho 5 mW

Luokan 3B laser

24 Chapter Printer Specifications

C4224-90962

Page 27

2

Product Operation

Chapter contents

HP LaserJet 1100 Printer control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Printer key functionality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Scanner control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Printer paper handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Toner cartridge information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Warranty statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

C4224-90962

Chapter contents

25

Page 28

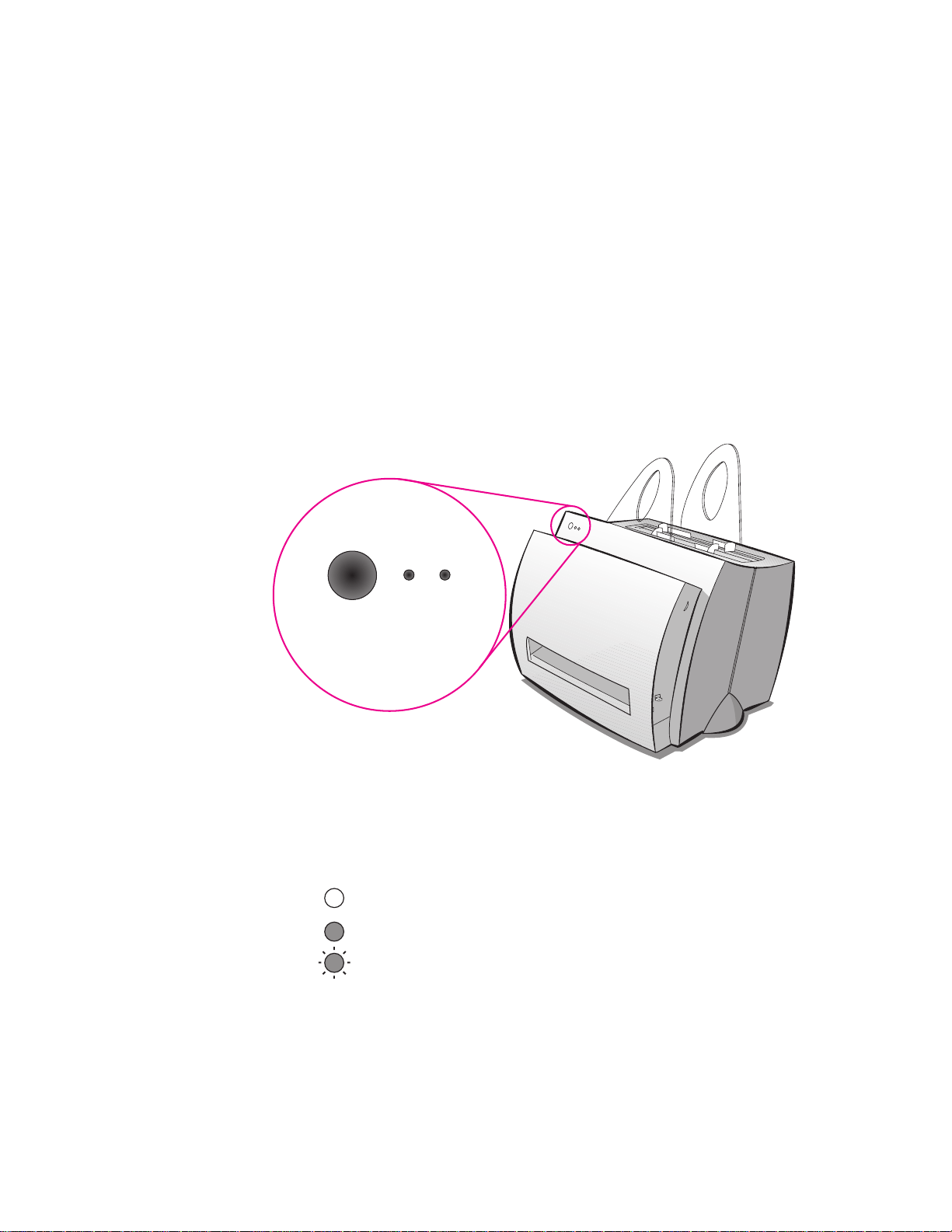

HP LaserJet 1100 Printer control panel

Hardware overview

The HP LaserJet 1100 Printer’s Control Panel consists of tw o LEDs and a Go ke y containing

a third LED. There is one amber LED (the Attention LED), and two green LEDs (the Ready

LED and the Go LED). The green LEDs are contained in the Go key. If the scanner is

attached, there are two additional buttons. Scanner modes are not shown on the printer

LEDs and scan keys have no effect on printer functionality.

Go key

The HP LaserJet 1100 Printer Control Panel’ s single Go k e y will be the only means the user

has of interacting with the printer, except through software. Therefore, the Go key must

perform all actions the user needs. The Go key performs ten functions. These functions are

explained in the table below. See “Scanner control panel” on page 31.

Figure 2-1 Printer light patterns

26 Chapter Product Operation

Light status legend

Symbol for “light off”

Symbol for “light on”

Symbol for “light blinking”

C4224-90962

Page 29

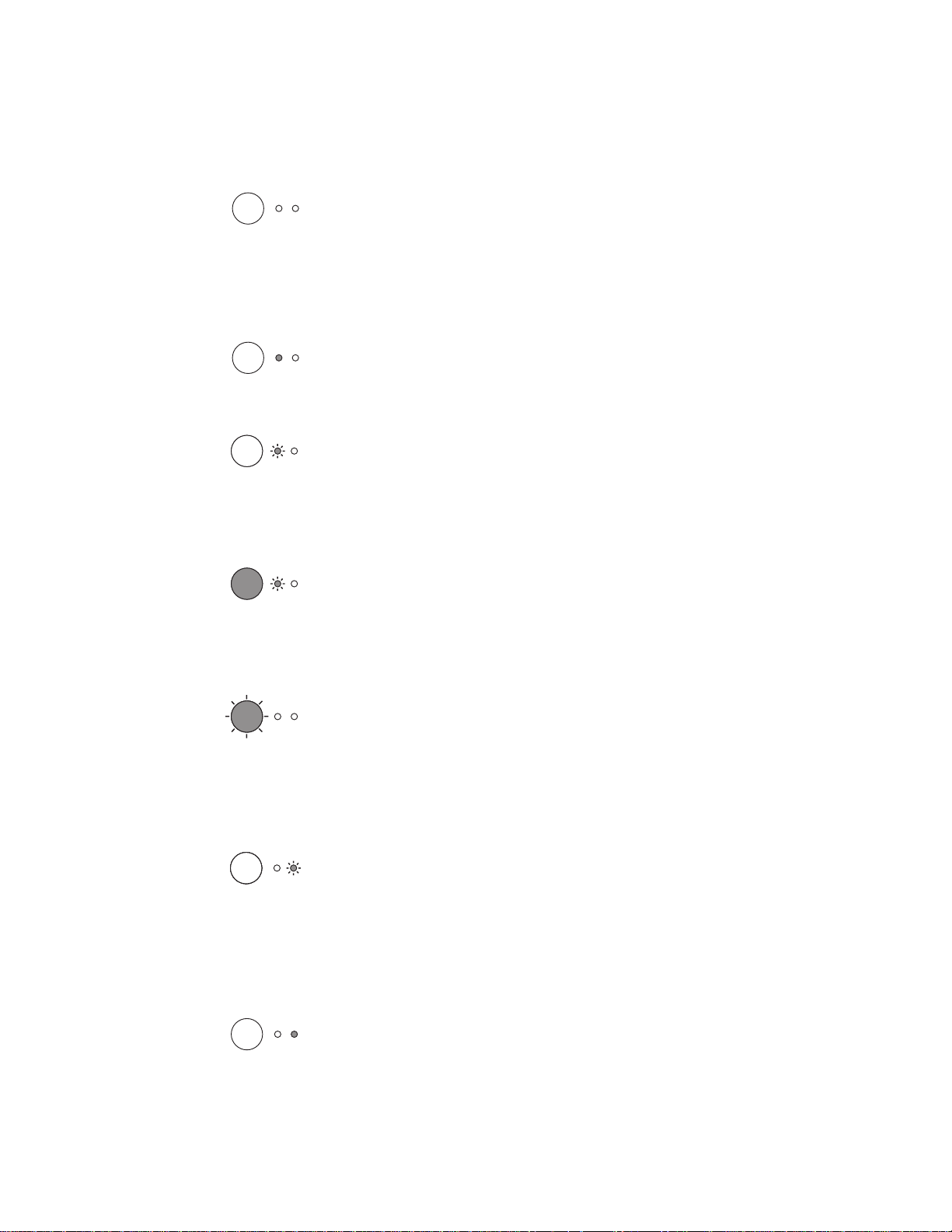

Table 2-1. Control panel light messages

Light status Condition of the printer Action

PowerSave mode

(or the printer is off)

The printer uses PowerSave

mode to conserve energy.

Ready

The printer is ready to print.

Processing

Self test page

Form Feed

The printer is receiving or

processing data.

Buffered data

The printer memory is retaining

unprinted data. A file has been

sent to the printer that does not

contain a from feed at the end.

Low power consumption mode. Pressing the

Go key

printing will awaken the printer from

PowerSave mode. Check the power cord if

the above actions do not generate a

response (and the power switch if your

printer is powered with 220-240 volts).

No action is necessary; however , if y ou press

and release the

panel, a self-test page will print.

Wait for the job to print.

Press and release the

control panel to print the remaining data.

on the printer control panel or

Go key

on the printer control

on the printer

Go key

Manual feed

The printer is in manual feed

mode. The printer is waiting for

a different size sheet of paper to

be placed in the Single Sheet

Input Slot or Paper Input Bin.

Door open, no Toner Cartridge,

or paper jam

The printer is in an error state.

Paper out

The printer is out of paper.

Check that you have loaded the correct

paper, then press and release the

the printer’s Control Panel to print. Manual

feed is controlled by the software. If you do

not want to be in manual feed mode, change

the setting in your printer properties.

Check the following:

The printer door is closed.

●

The Toner Cartridge is correctly installed

●

in the printer.

There are no paper jams.

●

Load paper into the printer.

Go key

on

C4224-90962

HP LaserJet 1100 Printer control panel

27

Page 30

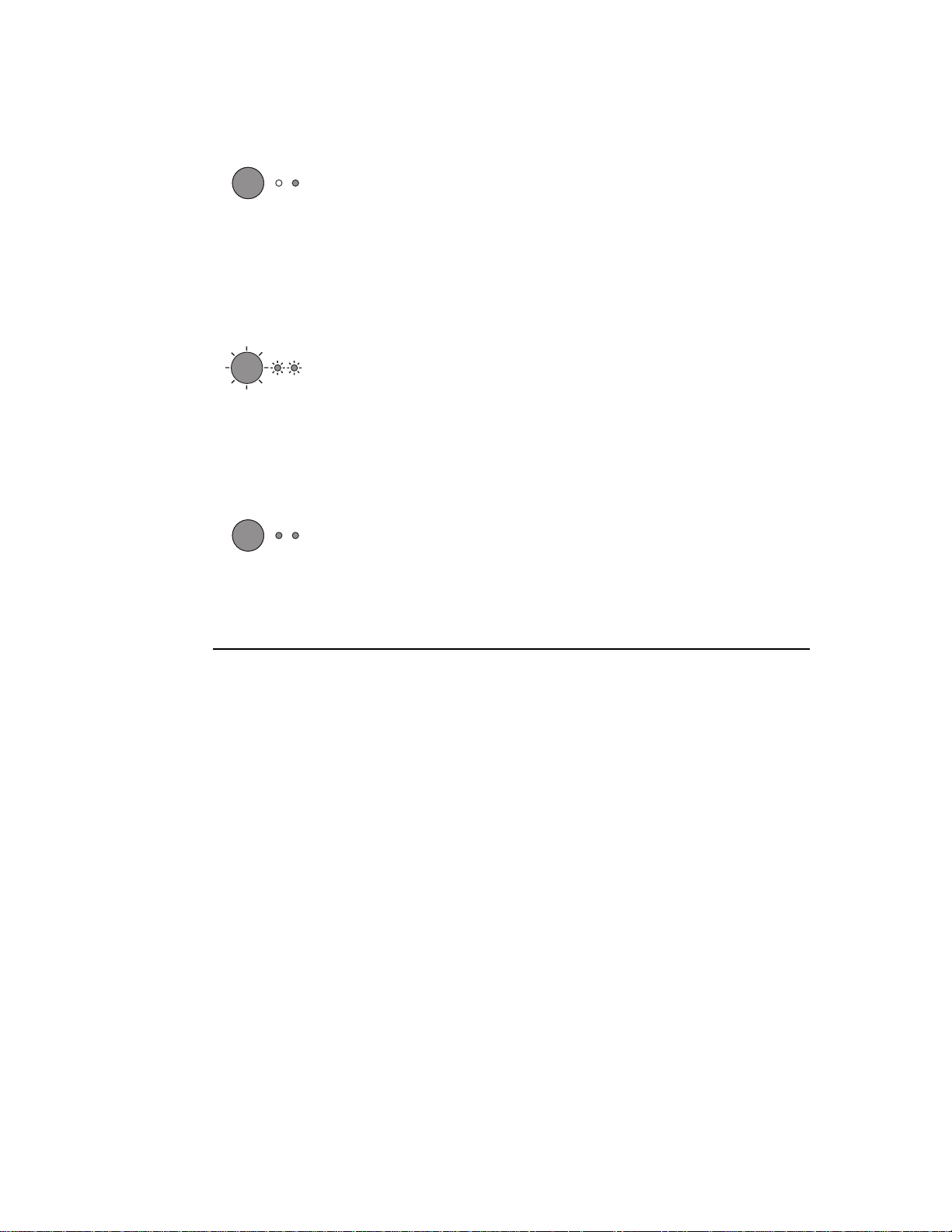

Table 2-1. Control panel light messages (continued)

Light status Condition of the printer Action

Memory out

The printer ran out of memory in

the middle of a print job.

Reset/Printer initialization

The printer memory is being

reset and all previously sent

print jobs are being purged. Or,

a printer initialization is taking

place. All lights blink for 1/2 of a

second or longer if initializing.

Fatal error

All lights are on.

The page being printed may have been too

complex for the memory capacity of the

printer.

●

See “Memory (DIMMs)” in the

HP LaserJet 1100 Printer User Guide to

add memory.

●

Press and release the Go key to print.

No action is necessary. However, you can

reset the printer if you press and hold the Go

key for five seconds.

●

Turn the printer off and then back on.

●

Press the Go key to see the secondary

light pattern.

●

See Chapter 5, “Troubleshooting/

Maintenance” for details onf fatal light

patterns.

28 Chapter Product Operation

C4224-90962

Page 31

Printer key functionality

The following table contains each printer mode and the result from a short press (when the

Go key

Go key

functionality other than the sharing of power resources, which may slow down either

function.

Table 2-2. Printer key functionality

is pressed for less than five seconds), and the results from a long press (when the

is pressed for five or more seconds). Scanner keys have no effect on printer

Short press (less than

Printer mode

Power on / Initialization No action Performs NVRAM Initialization if

Sleep mode Printer transitions to Ready

Ready Print the Self Test Page Printer Reset if held for five

Processing data No Action/Form Feed the

Self Test No action Printer Reset

Form Feeding No action Printer Reset

Buffered Data in printer Printer performs a form feed Printer Reset

Manual Feed request Printer prints the page Printer Reset

five seconds)

mode or Paper Out mode

current page

Long press (greater than

five seconds)

Go key is pressed during power

up and held for twenty seconds

Prints continuous Self Test if

pressed during RAM/ROM check

and held for 15 seconds

Printer transitions to Ready

mode or Paper Out mode

seconds

Cleaning Page if held for 20

seconds

C4224-90962

Door open / no toner No action Printer Reset

Paper Out No action Printer Reset

Paper Jam Attempts to reset jam

condition

Continuable error (Memory

Out/Page Punt)

Resetting No action No action

Fatal Error Shows LED error pattern as

Continuous Self Test Page Printer resets and transitions

Continue to print Printer Reset

long as the Go key is held

down

to Ready mode

Printer Reset

Shows LED error pattern as long

as the Go key is held down

Printer resets and transitions to

Ready mode

A form feed may occur when the LEDs on the Control Panel are showing a processing

mode. This could occur if the computer sends only part of the page to the printer because

the computer has not completed processing the entire page. When the Go key is pressed

Printer key functionality

29

Page 32

while data is in the printer, a form feed pending will occur. Once the data the printer has

received is completely formatted and no more data is in the I/O, the partial page will be

ejected due to the form feed pending.

Normal printer operation

When power is supplied to the printer, all LEDs go on and then off. The LEDs will sequence

on and off, one after the other, from the first LED (Go key/LED) to the last LED (Attention

LED). If an error is detected or if paper is out, the printer will enter that error mode.

When data is downloaded to the printer (during Ready mode), the Ready LED will blink.

When the printer stops receiving data, the Ready LED may continue to blink while the printer

formats the data.

If an error occurs, the printer will enter that error mode and display the error on the Control

Panel.

Error priority

The highest priority error will be displayed if multiple errors occur simultaneously. The

priority of errors, from highest priority (most important) to lowest, is:

1 Fatal Errors

2 Door Open/No Toner Cartridge

3 Paper Jam

4 Paper Out

5 Memory Error

While in any of the errors except Fatal Error, a reset may be performed by pressing and

holding the Go key for fiv e or more seconds, or unplug to reset. When the reset completes it

will return to the error condition. If the error was cleared by the reset (such as a Memory

Error), the printer will return to Ready mode.

30 Chapter Product Operation

C4224-90962

Page 33

Scanner control panel

Figure 2-2 Scanner control panel

The scanner Control Panel consists of two keys; a scan key and a copy key. These keys

have no effect on the printer other than contention for resources.

Scan

NOTE:

Pressing the scan key sends a message to the computer that opens the appropriate

software application to start the scan or starts a scan depending on how the computer

software is configured. If the scan is initiated with no paper in the ADF, an error message will

appear on the computer.

Quick copy

Pressing the copy button initiates a scan that is sent directly to the printer without using the

computer software. If there is no paper in the ADF, the scanner will still attempt to pick up a

sheet of paper. The Quick Copy function will work even if the unit is not attached to a

computer.

Scan Abort: Pressing both copy and scan keys within one half second of each other causes

the scanner to abort the current scan. If there is paper in the scanner, the scan engine will be

in a jam mode, and the paper will have to be removed manually. This decreases the chance

of documents being damaged by the scanner.

Scanner key functionality based on printer status

The following table contains scanner and printer modes and the result of pressing the scan

and/or copy keys. The scanner key has no effect on printer functionality other than some

print functionality will be held off due to contention for resources. The only print key press

that will affect a scan job, other than contention for resources, is a printer Control Panel

reset.

C4224-90962

Scanner control panel

31

Page 34

Table 2-3. Scanner key functionality based on printer status

Scan and copy

Scan key

Scanner mode

Power on /

Initialization

Sleep mode Starts scan No action Starts copy if paper

Ready Starts scan No action Starts copy Resets the printer

Processing data Starts scan if scan

Self Test Starts scan if scan

Form Feeding Starts scan if scan

Buffered Data in

printer

Manual Feed

request

Door open / no

toner

Paper Out Starts scan if scan

press

No action No action No action No action

manager can get

the required

resources

manager can get

the required

resources

manager can get

the required

resources

Starts scan if scan

manager can get

the required

resources

Starts scan if scan

manager can get

the required

resources

Starts scan if scan

manager can get

the required

resources

manager can get

the required

resources

key pressed

together

No action Starts copy if copy

No action Starts copy if copy

No action Starts copy if copy

No action Starts copy if copy

No action Starts scanning

No action Starts scanning

No action Starts scanning

Copy key

press Printer reset

is in the printer tray

manager can get

the required

resources

manager can get

the required

resources

manager can get

the required

resources

manager can get

the required

resources

copy, but will wait

until the printer is

ready

copy, but will wait

until the printer is

ready

copy, but will wait

until the printer is

ready

Resets the printer

Resets the printer

Resets the printer

Resets the printer

Resets the printer

Resets the printer

Resets the printer

Resets the printer

32 Chapter Product Operation

C4224-90962

Page 35

Table 2-3. Scanner key functionality based on printer status (continued)

Scan and copy

Scan key

Scanner mode

Printer Paper Jam Starts scan if scan

Continuable error

(Memory Out/Page

Punt)

Resetting No action No action No action No action

Fatal Error No action No action No action No action

Continuous Self

Test Page

Scanner jam No action No action No action Resets the printer,

Scanner door open No action No action No action Resets the printer

Scanning No action Scan Abort, if paper

Quick Copying After scan attempts

Scan Abort No action No action No action Resets the printer,

press

manager can get

the required

resources

Starts scan if scan

manager can get

the required

resources

Starts scan if scan

manager can get

the required

resources

to pick, but fails

because ADF is

empty

key pressed

together

No action Starts scanning

No action Starts scanning

No action Starts copy if copy

is in the scanner

results in a scanner

jam

If scan is still

processing, scan is

aborted. What was

scanned is still

printed. If paper is

still in the scanner,

results in a paper

jam.

Copy key

press Printer reset

copy, but will wait

until the printer is

ready

copy, but will wait

until the printer is

ready

manager can get

the required

resources

No action Resets the printer,

No action Resets the printer,

Resets the printer

Resets the printer

Resets the printer

scanner is still

jammed

scanner may be in a

jammed mode

scanner may be in a

jammed mode

scanner may be in a

jammed mode

C4224-90962

Scanner control panel

33

Page 36

Normal scanner operation

At power up or after a Control Panel reset, the scan motor rotates to verify it is ready for

operation. Scan functionality is only available through computer software. A scan can be

initiated two ways: from the computer or from the scanner Control Panel.

When the scan key is pressed on the scanner , it sends a signal to the computer to let it kno w

the firmware is ready to scan. The computer will either prompt the user to start the scan from

the computer, or automatically start it, depending on how the Document Assistant is

configured. When a scan job is initiated the scanner will pick up a page from the automatic

document feeder (ADF), and then wait for the necessary resources to be acquired.

The copy key functionality is always available, even when the printer is disconnected from

the computer. When the copy key is pressed it starts the scan of the document from the

ADF. If the scanner cannot get the resources it needs, it still picks the first page from the

ADF to give the user feedback. When the resources needed to continue are acquired, the

scan is started. This scan is passed directly to the printer as print data and printed. This is

called a Quick Copy. As much as .75 inches may be clipped (discarded) depending on

available memory. If memory resources are limited or the copy original exceeds the printer

media by more than .75 inches, the remaining copy data will be printed to a second page

with no data lost.

At any time during a scan or Quick Copy the user can press both the scan and copy keys to

abort the scan. If there is still a sheet of paper inside the scanner, it will enter the jam mode

and the sheet of paper will have to be removed manually. If a Quick Copy occurs, the printer

will still print any data it has received

34 Chapter Product Operation

C4224-90962

Page 37

Printer paper handling

There are two vertical input paper trays: the P aper Input Bin and the Single Sheet Input Slot.

With the vertical open trays, it is easier for the user to know exactly what paper is in the

printer and when the printer is out of paper. There are two paper output paths: the vertical

Paper Output Bin and the Front Output Slot in the front of the printer. The user may wish to

use the Front Output Slot occasionally since it provides a straighter path and reduces curl.

The Paper P ath Le ver is located on the side of the printer. When the le v er is pushed do wn, it

allows the paper to exit through the Front Output Slot. If the lever is pushed up, the paper

exits the printer to the Paper Output Bin.

Manual feed

Since the HP LaserJet 1100 Printer has only one paper input sensor, it cannot sense which

input tray/slot the paper is in. Therefore, when manual feed has been selected, the printer

pauses, waiting for the user to insert the correct paper into the printer (either in the Paper

Input Bin or the Single Sheet Input Slot) and press the

the paper is pulled from the Single Sheet Input Slot if paper is loaded there; otherwise, paper

is pulled from the Paper Input Bin.

Manual paper feed is normally set by a user’s software application. A user can create a

Manual Feed request by either sending the PCL Media Source escape sequence or setting

the PJL MANUALFEED command. The printer’s current PJL setting takes effect if the user

has not overridden it with a PCL escape sequence. Otherwise the setting by the PCL escape

sequence is used.

When Manual Feed is selected, there may not be any immediate indication on the Control

Panel. When the manual feed page has been processed and is ready to be printed, the Go

key/LED will begin blinking and the Ready LED will turn off, indicating that the printer is

requesting the user to place the correct paper in either the Single Sheet Input Slot or the

Paper Input Bin and press the

Go key

.

Go key

. When the Go key is pressed,

C4224-90962

If the HP LaserJet 1100 Printer has no paper it will show the Paper Out mode (Attention LED

on). When paper is loaded it will automatically pick the next page without the user having to

press the Go key. If the printer is in a manual feed mode and the user unloads and then

reloads paper, the HP LaserJet 1100 Printer will automatically pick the next page as well.

Printer paper handling

35

Page 38

Legal timing

Legal timing refers to the time between the first page picked and the second page picked.

Legal timing is the time it takes for a Legal page to go through the engine’s paper path.

The HP LaserJet 1100 Printer may run at legal timing if manual feed is selected. If the first

manual feed page is f ollo w ed b y a second man ual feed page, the first manual feed page will

run at legal timing. If a manual feed page is follow ed by a non-man ual feed page , the manual

feed page will run at engine speed.

Paper size change

The paper tray is merely a source f or paper; it cannot detect the size of the paper . Therefore ,

the user must inform the printer what size paper is being used. This is normally done

automatically by the user’s software application. However, this can be done on a job-by-job

basis by sending the PCL Page Size escape sequence or setting the PJL PAPER variable.

The PCL escape sequence for paper size takes precedence over the PJL PAPER setting.

The user may load a new size of paper and not modify the PJL or PCL variable. Therefore,

the paper size may be too large or too small for the formatted page. The image that has

been formatted will be placed on the sheet of paper and fed through the printer.

Scanner paper handling

The scanner can handle a slightly wider range of paper sizes than the print engine. It will

have a single automatic document feeder (ADF) that supplies a single straight paper path.

The ADF has no paper sensor, so the scanner will attempt a paper pic kup to determine if the

bin is empty or not. Therefore, when a job is started, it attempts to pick a page to make sure

a page is available in the ADF. Once a job is started, the scanner continues to pick pages

until the ADF is empty. The ADF has no ability to tell how wide the source page is, so page

scan width has to be set from the computer.

Main input tray (ADF)

A center justified, vertical Paper Input Bin with a 20-sheet capacity adjustable to all

supported paper and envelope sizes.

Output tray

None

Straight through paper path

Paper is output through the Front Output Slot in face-up, reverse order.

Priority feed

None

Supported paper and envelope sizes

Scan: Minimum 2 x 3.5 inches

Maximum 8.5 x 30 inches

36 Chapter Product Operation

C4224-90962

Page 39

Letter, Legal, A4, Executive

Copy:

Envelopes - Commercial 10, Monarch, C5, DL, B5, no custom

Paper Input Sensor(s)

None

Paper size change

As with the printer, the scanner has to receive paper size information on a job-by-job basis.

There is an unchangeable default, but the scan width can be adjusted by the job. The scan

length is determined by the media. Quick Copy paper sizes are set from the computer,

except in an NVRAM initialization or initial power up when paper size is set to a factory

default NVRAM value. This value is the same as the printer factory default paper size. If the

media is larger than the Quick Copy page size or the print page size, clipping might occur.

C4224-90962

Printer paper handling

37

Page 40

Toner cartridge information

The Toner Cartridge is designed to simplify replacement of the major “consumable” parts.

The Toner Cartridge contains the printing mechanism and a supply of toner.

At 5% page coverage, a Toner Cartridge will print approximately 10,000 pages. However, a

Toner Cartridge should print more pages if regularly printing pages with less coverage, such

as short memos. The cartridge may print fewer pages if heavy or bold print is used.

NOTE: For best results, alwa ys use a T oner Cartridge before the expiration date stamped on the T oner

Cartridge’s box.

Refilled toner cartridges

While Hewlett-Packard does not prohibit the use of refilled Toner Cartridges during the

warranty period or while the printer is under a maintenance contract, it is not recommended

for the following reasons:

• Repairs resulting from the use of refilled Toner Cartridges are not covered under

Hewlett-Packard warranty or maintenance contracts.

• Hewlett-Packard has no control or process to ensure that a refilled Toner Cartridge

functions at the high level of reliability of a new HP LaserJet Toner Cartridge. HewlettPackard also cannot predict what the long term reliability effect on the printer is from

using different toner formulations found in refilled cartridges.

• The print quality of HP LaserJet Toner Cartridges influences the customer’s perception

of the printer. Hewlett-Packard has no control over the actual print quality of a refilled

Toner Cartridge.

Recycling toner cartridges

In order to reduce waste, Hewlett-Packard offers a recycling program, called HP Planet

Partners, for used Toner Cartridges. Cartridge components that do not wear out are

recycled. Plastics and other materials are recycled. HP pays the shipping costs from the

user to the recycling plant. To join this recycling effort, follow the instructions inside the T oner

Cartridge’s box.

38 Chapter Product Operation

C4224-90962

Page 41

Warranty statement

This warranty gives specific legal rights. There may also be other rights which vary from

area to area. See the user guide for further warranty information or see the warranty card

included with the printer.

C4224-90962

Warranty statement

39

Page 42

40 Chapter Product Operation

C4224-90962

Page 43

3

Functional Overview

Chapter contents

Basic functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Printer functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Engine Control Unit (ECU)/power system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Formatter system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Image formation system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Printer paper feed system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Document scanner system (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Basic sequence of operation (formatter to printer) . . . . . . . . . . . . . . . . . . . . . . . 58

C4224-90962

Chapter contents

41

Page 44

Basic functions

This chapter presents a functional overview of the HP LaserJet 1100 Printer’s processes.

The following systems are discussed:

• engine controller unit (ECU) system/power system

• formatter system

• image formation system

• paper feed system (printer) and document feed system (optional document scanner)

• document scanner system (optional)

• optical system (located in the optional document scanner)

The HP LaserJet 1100 Printer consists of the printer and the document scanner

(HP LaserJet 1100A Printer-Copier-Scanner). Operation sequences of the printer are

controlled by the ECU. Oper ation sequences of the document scanner are controlled by the

video controller.

Figure 3-1 Basic configuration

42 Functional Overview

C4224-90962

Page 45

Printer functions

Printer functions are divided into six groups:

ECU/power system

1

formatter system

2

image formation system

3

printer paper feed system

4

document scanner system

5

basic sequence of operation (formatter to printer)

6

The following figure is a block diagram of the printer unit:

To external device (host computer, etc.)

via video controller

LASER/SCANNER SYSTEM

Scanning mirror

Laser

diode

Scanner

motor

Face-down delivery tray

IMAGE FORMATION

SYSTEM

Fixing

Face-up delivery slot

PICK-UP/FEED SYSTEM

BD

circuit

Cleaner

unit

Primary

charging

roller

Photo-

sensitive

drum

Transfer

charging

roller

Developing

unit

ENGINE CONTROL

SYSTEM

Engine controller PCB

Manual feed slot

Pick-up

control

Multi-purpose tray

C4224-90962

Figure 3-2 Printer unit functional block diagram

Printer functions

43

Page 46

Engine Control Unit (ECU)/power system

The Engine Control Unit (ECU) coordinates all print engine activities, drives the laser, and

coordinates print data from the formatter with the image formation process. The ECU also

includes power supply and distribution circuitry . The ECU controls the f ollo wing systems and

functions:

• Printer engine control

• printer laser/scanner drive

• paper motion monitoring and control

• motor

• Power system

• AC power distribution

• DC power distribution

• overvoltage/undervoltage protection

• high-voltage power distribution

Figure 3-3 ECU loads

44 Functional Overview

C4224-90962

Page 47

Printer engine control system

Printer laser/scanner drive

Based on information received from the formatter, the ECU sends signals to the laser/

scanner assembly to modulate the laser diode “on” and “off” and to drive the laser/scanner

motor. For more information, see “Image formation system” later in this chapter.

Paper motion monitoring and control

The ECU controls paper motion by continuously monitoring the various paper sensors and

coordinating the timing with the other print processes.

For a detailed explanation of paper movement, and the interaction of photosensors and

solenoid with the paper movement process, see “Printer paper feed system.”

Motor

The motor is controlled by the ECU. The motor provides all of the printer's paper

movement.

C4224-90962

Engine Control Unit (ECU)/power system

45

Page 48

Power system on ECU

The AC, DC, and high-voltage power supply circuits are all contained within the ECU.

AC power distribution

The AC power circuitry supplies AC v oltage whenev er the pow er cord is connected to the AC

power source. A C voltage is distrib uted to the DC power supply circuitry and to the A C driver

circuitry, which controls AC voltage to the fusing assembly's heating element.

DC power distribution

The DC power distribution circuitry , located on the ECU , distributes +3.3 V DC , +5 V DC and

+24 V DC as follows:

Table 3-1. DC power distribution

+3.3 V DC Formatter

Laser/Beam Detect Circuitry ECU

+5 V DC: Formatter

Photosensors

ECU

Laser/Beam Detect Circuitry

+24 V DC: Motor

Laser Scanner Motor

Document Scanner Motor

Solenoid

Formatter

+24VA DC: High Voltage Power Supply

Overcurrent/overvoltage

There are two overvoltage devices in this printer:

• Fuse F101 provides overcurrent protection for the fusing system circuitry. To check or

replace the fuse requires the removal of the ECU . Fuse F102 (f ound only on 110V units)

provides overcurrent protection to the printer DC power supply circuitry.

• In addition, the +24V DC, +3.3 V DC, and +5V DC power circuitry contains an

overcurrent protection circuit which automatically shuts off the output voltage when an

overcurrent condition occurs due to a short or abnormal voltage on the load side.

High-voltage power distribution

The high-voltage power supply PCA applies an overlap of DC and AC voltage to the primary

charging roller and the developing roller. This circuit also applies a positive or negative DC

voltage to the transfer roller according to the instructions from the ECU.

46 Functional Overview

C4224-90962

Page 49

This circuit also controls the image density by changing the primary AC voltage and the

developing AC bias according to the print density setting.

High voltage is disabled when the printer door is open.

Figure 3-4 High-voltage power supply circuit

C4224-90962

Engine Control Unit (ECU)/power system

47

Page 50

Formatter system

The formatter is responsible for the following:

• controlling the optional document scanner

• formatting and controlling copies

• receiving and processing print data from the printer interface

• monitoring the control panel and relaying printer status information

• developing and coordinating data placement and timing with the print engine

• communicating with the host computer through the bidirectional interface

The formatter receives print data from the bidirectional Extended Capabilities Port (ECP)

mode interface and conv erts it into a dot image. The ECU synchronizes the image f ormation

system with the paper feed system and signals the formatter to send the print image data.

The formatter sends the print image data (dots) in the form of a video signal and the printing

process begins.

Central processing unit

The formatter incorporates an MCF5202 custom microprocessor operating at 35 megahertz

(MHz).

Random-access memory (RAM)

• One bank of Non-Volatile RAM (NVRAM) stores parameters

• DRAM (Dynamic RAM) provides temporary storage of copy, scan, and print data

Parallel interface

The formatter receives incoming data through its ECP interface . This interf ace pro vides high

speed and two-way communication between the printer and the host, allowing the user to

change printer settings and monitor printer status from the host computer.

48 Functional Overview

C4224-90962

Page 51

Control panel

• Three front panel status lights (one contained in the Go key)

•

Go

key

Draft mode

Depending on which printer driver is used, selecting “draft” or EconoMode from the printer

driver allows the HP LaserJet 1100 Printer to use approximately 50% less toner, extending

the life of the toner cartridge.

Memory Enhancement technology (MEt)

The Hewlett-Packard Memory Enhancement technology (MEt) effectively doubles the

standard memory through a variety of font and data compression methods.

Enhanced I/O

The Enhanced I/O feature allows printer memory to be used for storing data received from

the host computer. When Enhanced I/O is enab led, y ou can send more data to the printer in

shorter amounts of time, which allows you to return to your application sooner. Enhanced I/O

has the following options:

•

- Allows the printer to use Enhanced I/O memory allocating to increase the speed

Auto

of data transfer from the host computer to the printer, if necessary.

•

- Uses the minimum amount of printer memory for storing data sent from the host

Off

computer.

Page Protect

Page complexity (rules, complex graphics, or dense text) may exceed the printer’s ability to

create the page image fast enough to keep pace with the Image Formation process. If Page

Protect is disabled and a page is too complex, the page may print in parts (for example, the

top half on one page and the bottom half on the next page). Some print data loss is likely in

these instances, and the printer will display an error message.

Page Protect allows the Formatter to create the entire page image in page buffer memory

before physically moving the paper through the printer. This process ensures that the entire

page will be printed. The default setting is Auto.

C4224-90962

Formatter system

49

Page 52

PJL Overview

Printer Job Language (PJL) is an integral part of configuration, in addition to the standard

Printer Command Language (PCL). With standard ECP cabling, PJL allows the printer to

perform functions such as:

• Two-way communication with the host computer through a bidirectional Parallel

connection. The printer can tell the host such things as the control panel status.

• Isolation of print environment settings from one print job to the next. F or e xample, if a

print job is sent to the printer in landscape mode, the subsequent print jobs print in

landscape only if they are formatted for landscape printing.

50 Functional Overview

C4224-90962

Page 53

Image formation system

Laser printing requires the interaction of several different technologies including electronics,

optics, and electrophotographics to provide a printed page. Each process functions

independently and must be coordinated with the other printer processes. Image formation

consists of six processes:

CAUTION:

Figure 3-5 Image formation block diagram

Toner cartridge

As the heart of the image formation system, the Toner Cartridge houses the cleaning,

conditioning, and developing steps of the process. The Toner Cartridge contains the

photosensitive primary charging roller, developing station, toner cavity, and cleaning station.

Including these components (which wear, degrade, or are consumed) in the replaceable

Toner Cartridge eliminates the need for a service call when replacement is required. The

special photosensitive properties of the drum allow an image to be formed on the drum

surface and then transferred to paper.

The printer's Toner Cartridge does not include a light-blocking shutter. Be careful to avoid

exposing the drum to light, which can permanently damage the drum. Protect the Toner

Cartridge whenever removing it from the printer.

Step 1

Cleaning stage. The cleaning blade is in contact with the surface of the drum at all

times. As the drum rotates during printing, excess toner is wiped off and stored in

the waste toner receptacle.

C4224-90962

Image formation system

51

Page 54

Step 2 Conditioning stage. This process consists of applying a uniform negative charge to

the surface of the drum with the primary charging roller located in the Toner

Cartridge. The primary charging roller is coated with conductive rubber . An AC bias

is applied to the roller to erase any residual charges from any previous image. In

addition, a negative DC bias is applied by the charging roller to create a uniform

negative potential on the drum surface. The amount of DC v oltage is modified by the

print density setting.

Step 3 Writing stage. During this process, a modulated laser diode projects the beam onto

a rotating scanning mirror. As the mirror rotates, the beam reflects off the mirror, first

through a set of focusing lenses, then off a mirror, and finally through a slot in the

top of the Toner Cartridge, and onto the photosensitive drum. The beam sweeps the

drum from left to right, discharging the negative potential wherever the beam strikes

the surface. This creates a latent electrostatic image, which later is de veloped into a

visible image.

Because the beam is sweeping the entire length of the drum and the drum is

rotating, the entire surface area of the drum can be covered. At the end of each

sweep, the beam strikes the beam detect lens, generating the beam detect signal

(BD signal). The BD signal is sent to the ECU where it is converted to an electrical

signal used to synchronize the output of the next scan line of data.

Step 4 Developing stage. At this stage of the process, the latent electrostatic image is

present on the drum. The toner particles obtain a negative surface charge by

rubbing against the developing cylinder which is connected to a negativ e DC supply.

The negatively charged toner is attracted to the discharged (exposed, grounded)

areas of the drum, and repelled from the negatively charged (unexposed) areas.

Step 5 Transferring stage. During the transferring process, the toner image on the drum

surface is transferred to the paper. A positive charge applied to the back of the

paper by the transfer roller causes the negativ ely charged toner on the drum surface

to be attracted to the paper. After separation, the drum is cleaned and conditioned

for the next image.

During the separating process, the paper separates from the drum. To stabilize the

feed system and prevent dropouts on the printed image at low temperature and