Page 1

r/i~

.:~

HEWLETT

PACKARD

HP

20-Slot

Installation

1000 A990

System/Computer

and

Service

Manual

Page 2

rl"-'

.:~

HEWLETT

PACKARD

H P 1

000

A990

20-Slot

System/Computer

Installation and Service Manual

Manual Part No. 02959-90002

E0292

Measurement & Control Systems Dlvison

11000 Wolfe Road

Cupertino, CA 95014

Printed in U.S.A. February 1992

First Edition

Page 3

NOTICE

The information contained

HEWLETT-PACKARD

INCLUDING, BUT NOT

FITNESS

FOR A PARTICULAR

contained herein or for

MAKES

LIMITED

incidental or consequential damages in connection with the furnishing,

performance, or use of this

Hewlett-Packard

ment that is not furnished

assumes no responsibility for the use or reliability of its software on equip-

by

This document contains proprietary information which is protected

in

this document is subject to change without notice.

NO

WARRANTY

TO,

THE

OF

ANY

IMPLIED

KIND

WITH

WARRANTIES

REGARD

OF

PURPOSE. Hewlett-Packard shall not be liable for errors

material.

Hewlett-Packard.

by

copyright. All rights are

reserved. No part of this document may be photocopied, reproduced, or

language without the prior written consent of Hewlett-Packard Company.

RESTRICTED

Use,

duplication, or disclosure

subparagraph

DFARs

RIGHTS

(c)

(1)

252.227.7013

LEGEND

by

(ii) of the Rights

the Government is subject to restrictions as set forth

in

Copyright © 1992

Technical Data and Computer Software clause at

by

HEWLETT-PACKARD

2

COMPANY

TO

THE

MATERIAL,

MERCHANTABILITY AND

translated to another

in

Page 4

Safety and Regulatory Information

For your protection, this product has been tested to various national and international

regulations and standards. The scope of this regulatory testing includes electrical/mechanical

safety, radio frequency interference, ergonomics, acoustics, and hazardous materials. Where

required, approvals obtained from third-party test agencies are shown on the product label.

In addition, various regulatory bodies require some of the information under the following

headings.

USA (Radio Frequency Interference)

The United States Federal Communications Commission (in 47CFR Subpart J, of Part

15)

has specified that the following notice be brought to the attention of the users of this product:

Warning

o

This equipment generates, uses, and can radiate radio frequency

if

energy, and

tions

manual, may cause interference to radio communications. It

not installed and used in accordance with the instruc-

has been tested for compliance with the limits for Class A computing

devices pursuant to Subpart J

designed

ence. Operation

to

provide reasonable protection against such interfer-

of

this equipment in a residential area is likely

of

Part

15

of

FCC

Rules, which are

to

cause interference, in which case the user, at his own expense, will

be required to take whatever measures may be required

to

correct

the interference.

Japan (Radio Frequency Interference)

The following notice

is

for users of this product in Japan:

c::.

0)~11l

~~I~~~~~~

~

11.

~

Vf

~

:r

/

~Fa.~

1&

t&

(V

1:",

m

DJ)

'i,

m

-fitn

•••

eel)

it'={;

m

~ ~

itt!

~ i

Ie

~1~·1tr.tr;y

Ie

VE

"?

-r

Japanese Radio Frequency Interference

fa

~

in (ttli

I~!tI.!~

W~~§~~L~m~M~~

Ie

~

~

L L

jo

J)

i T u

t.:

,;t

-'C

~

~

tf

L

t.:

It!l

~

~4~

1f.

L

-5

c.

~'1&

~

t&

C

tJ~ ~ ~

~

,~

L L F

3

Ie

io~'

~

(i

,Efj

i:

j-o

~

-C

fl!ffl

T

7.>

~'o

~ n ~ ~ ~

•••

~,

~.~m~m~

7::.i

*,

Uf

fi~

T v

t:"

iI)

~

Page 5

United Kingdom (Telecom Declaration)

This product is approved under approval number

public telecommunication systems within the United Kingdom.

NS/G/1234/J/1()()()()3

for indirect connection to

Europe (Data Communications)

The remote support interface conforms to

connection to a public telecommunications network, use only a modem complying with local

regulations.

CCITI

Recommendations

V.24

and

V.28.

For

Germany (Acoustics)

Laermangabe (Schalldruckpegel

nach

DIN

45635,

Acoustic Noise (A-weighted Sound Pressure Level

normal operation to

Teil

19:

ISO

LpA

7779:

LpA)

<

70

LpA

gemessen am fiktiver Arbeitsplatz bei normalem Betrieb

dB

LpA)

measured at the bystander position,

<

70

dB

4

Page 6

Safety Considerations

GENERAL - This product and related documentation must be reviewed for familiarization with

safety markings and instructions before operation.

SAFETY SYMBOLS

Instruction manual symbol: the product will be marked with this symbol when it is

necessary for the user to refer to the instruction manual in order to protect the

product against damage.

Indicates hazardous voltages.

Indicates earth (ground) terminal (sometimes used

common connected to grounded chassis).

Caution

I

Warning

G

in

manual

Explanation

The CAUTION sign denotes a hazard.

procedure, practice, or the like, which, if not correctly performed or

hered to, could result in damage to or destruction of part or all of the

product. Do not proceed beyond a

fully

conditions are

understood and met.

Explanation

The WARNING sign denotes a hazard. It calls attention

dure, practice,

hered to, could result in injury.

sign until the indicated conditions are fully understood and met.

or

the like, which,

of

Caution

It

calls attention to an operating

CAUTION sign until the indicated

of

Warning

if

not correctly performed

Do

not proceed beyond a WARNING

to

indicate circuit

to

a proce-

or

ad-

ad-

5/6

Page 7

Page 8

Printing History

The Printing History

cally, update packages are distributed which contain replacement pages to

cluding an updated

Each reprinting

Thus, the reprinted

update information. New editions

To

determine what manual edition and update is compatible with your current software revision code, refer to

the Manual Numbering File or the Computer User's Documentation Index. (The Manual Numbering File is

included with your software.

First Edition

below

of

this manual will incorporate all past updates; however, no

copy

identifies the edition

copy

of

this printing history page. Also, the update

will

be

identical

It

consists of an "M" followed

..................

of

this manual and any updates that are included. Periodi-

in

content to prior printings of the same edition with its user-inserted

of

this manual will contain new information, as well as all updates.

by

a five digit product number.)

Feb 1992

..................................

be

merged into the manual, in-

may

contain write-in instructions.

new

information will

be

.

added.

7/8

Page 9

Page 10

Preface

The

HP

1000

A990

20-S10t System/Computer Installation and Service Manual, part number

02959-90002,

A990 Computer and the

service engineers.

Chapter 1 - Introduction

Includes environmental and electrical specifications plus site preparation, unpacking, and loss or

damage claims procedure information.

Chapter 2 - Installation

Gives configuration information and describes the procedures for installing the A990 computer.

Chapter 3 - Service

Describes maintenance and troubleshooting requirements and procedures, power supply checks,

power-on self-tests, and definitions of LED indicators. Also describes procedures for removing

and replacing assemblies and reconfiguring the power supply.

describes the procedures for configuring, installing, and servicing, the

HP

2999A A990 System. This manual is written for systems and field

HP

2959A

Chapter 4 - Replaceable Parts

Lists and illustrates replaceable parts for the A990 computer.

9/10

Page 11

Page 12

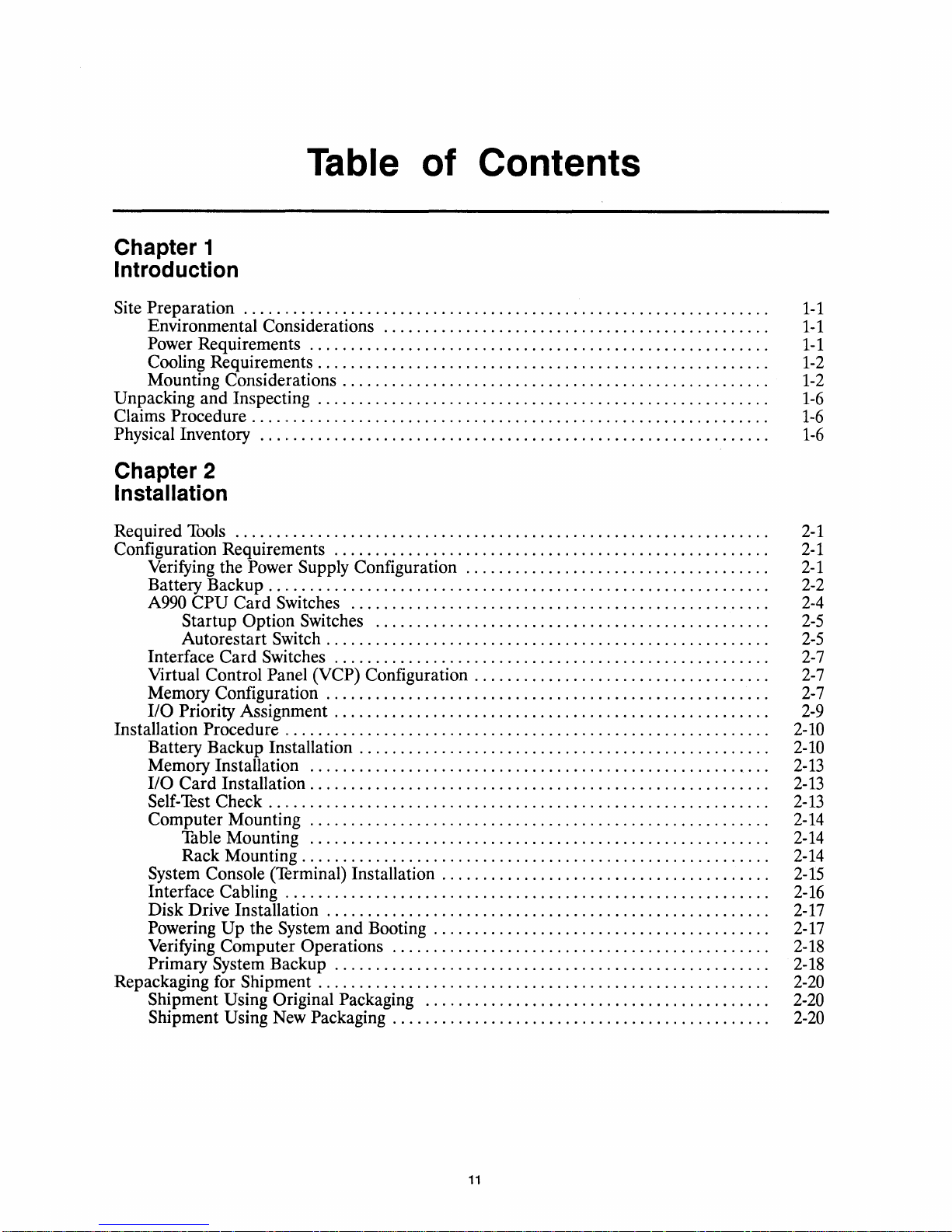

Chapter 1

Introduction

Table of Contents

Site Preparation

Environmental Considerations

Power

Cooling Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking and Inspecting

Claims Procedure

Physical Inventory

.....

"..........................................................

Requirements.

....

" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...

"..........................................................

...............................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

Installation

Required Tools

Configuration Requirements

Verifying the Power Supply Configuration

Battery

A990

Startup Option Switches

Autorestart Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interface

Virtual Control Panel (VCP) Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Configuration

I/O

Priority Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Procedure

Battery Backup Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Installation

I/O

Card

Self-Test Check . .

Computer

Table Mounting

Rack Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Console (Terminal) Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interface Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disk Drive Installation

Powering

Verifying Computer Operations

Primary System Backup

Repackaging for

Shipment Using Original Packaging

Shipment Using New Packaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..................................................................

.....................................................

.....................................

Backup. . ..

CPU

Card

Card

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting.

Up

Shipment.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switches

Switches

..

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the System and

...................................................

................................................

.....................................................

............................

........................................................

. .

..

. . . . .

..

. . . . . . . .

........................................................

.................

Booting.

..............................................

.....................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..........................................

.. ..

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

1-1

1-1

1-2

1-2

1-6

1-6

1-6

2-1

2-1

2-1

2-2

2-4

2-5

2-5

2-7

22-7

2-9

2-10

2-10

2-13

2-13

2-13

2-14

2-14

2-14

2-15

2-16

2-17

2-17

2-18

2-18

2-20

2-20

2-20

7

11

Page 13

Chapter 3

Service

Electrical Safety

Periodic Maintenance

Troubleshooting

Power Supply

A990 Self-Test

Test 1

Test 2

Diagnostics

Memory Card LEDs

Assembly Removal and Replacement

Fan Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fans

......................................................................

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement. .

Power Supply

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Pack

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plug-in Cards

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EPROM

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement. . . . . . . . . . . . . . . .

Backplane.

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Filter

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

115/230

Power Distribution Diagram

Vac

..............................................................

...........................................................

................................................................

Check....

Programs.

.................................................................

.................................................................

................................................................

..............................................................

...............................................................

..............................................................

and Time-of-Day Clock

. . . . . .

.................................................................

Reconfiguration

..

..

... . .. . ...

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.....................................

..

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

.....................................................

...............................................

.... . ... ... ... ...

.............................................

Chips.......................................

..

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.. .. . .. .. .. .. .. ..

. . . . . . . . . . . . . . . . . . .

...

. . . . . . . . . . . . . . . . . . . . . . . . .

. .

. . .

..

. . . . . .

3-1

3-1

3-2

. 3-2

3-4

3-4

3-5

3-9

3-9

3-9

3-10

3-10

3-10

3-10

3-10

3-10

3-11

3-11

3-11

3-12

3-12

3-12

3-12

3-12

3-13

3-13

3-13

3-13

3-14

3-14

3-15

3-15

3-15

3-15

3-16

3-16

Chapter 4

Replaceable Parts

Replaceable Parts Table

Ordering Information

Parts Exchange Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.........................................................

...........................................................

4-1

4-1

4-1

12

Page 14

List of Illustrations

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure 3-1.

Figure

Figure

Figure

Figure

Figure

Table

Table

Table

Table

Table

Table 3-2.

Table

Table 3-4.

Table

1-1.

1-2.

2-1.

2-2.

2-3.

2-4.

2-5.

2-6.

2-7.

2-8.

2-9.

2-10.

2-11.

2-12.

3-2.

3-3.

4-1.

4-2.

4-3.

1-1.

2-1.

2-2.

2-3.

3-1.

3-3.

4-1.

AC

Power Cord Sets (USA)

AC

Power Cord Sets (Non-USA)

of

Front View

Power Supply Connector Diagram

Computer Back

A990

CPU

Switch

A990 Memory Configurations

HP

Backup Battery and Battery Bracket

Backup Battery Installed in Battery Bracket

Battery Assembly in Initial Position

Battery Assembly in Final Position

System Cabling Diagram

Sample Display

A990

Power Distribution Diagram

2O-Slot

2O-Slot

Front

SW2 in Default Configuration

2959/2999

CPU

:Box

Box Exploded View (Rear)

Panel Assembly

Chassis with Bezel and Fan Panel Removed

Panel and Power Panel

Card

Switches SW1 and SW2

Cards and

of

Self-Test Test 2

Card

Chip Location Diagram

Exploded View (Front)

.......................................

..................................

.................................

.............................

...........................

..............................

.....................................

I/O

Priority Assignments

...............................

.........................

................................

.................................

..........................................

Error

......................................

............................................

Code

...........................

.................................

.................................

..................

.......................

............

Tables

Electrical and Environmental Specifications. . . . . . . . . . . . . . . . . . . . . . . . . .

SW2 Start-Up Switch Settings

Memory Array Cards and Frontplanes

A-Series

Power Supply Test Voltages

LED

Self-Test

LED

List

1/0

Interface

Indicators and

Pass Indications

Indicators and

of

Replaceable

Card

Error

Error

Parts.

......................................

..............................

ID

Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . .

........................................•

Codes for Test 1 and Phase 1

..........................................

Codes for Test 2 . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

of

Test 2

......

1-5

.

1-5

.

2-2

.

2-3

.

2-3

.

2-4

.

2-5

.

2-8

.

2-9

.

2-11

.

2-11

.

2-12

.

2-12

.

2-16

.

3-7

.

3-14

.

3-17

.

4-5

.

4-7

.

4-9

.

1-2

2-6

2-8

2-19

"

3-3

3-6

3-7

3-8

13

Page 15

Page 16

1

Introduction

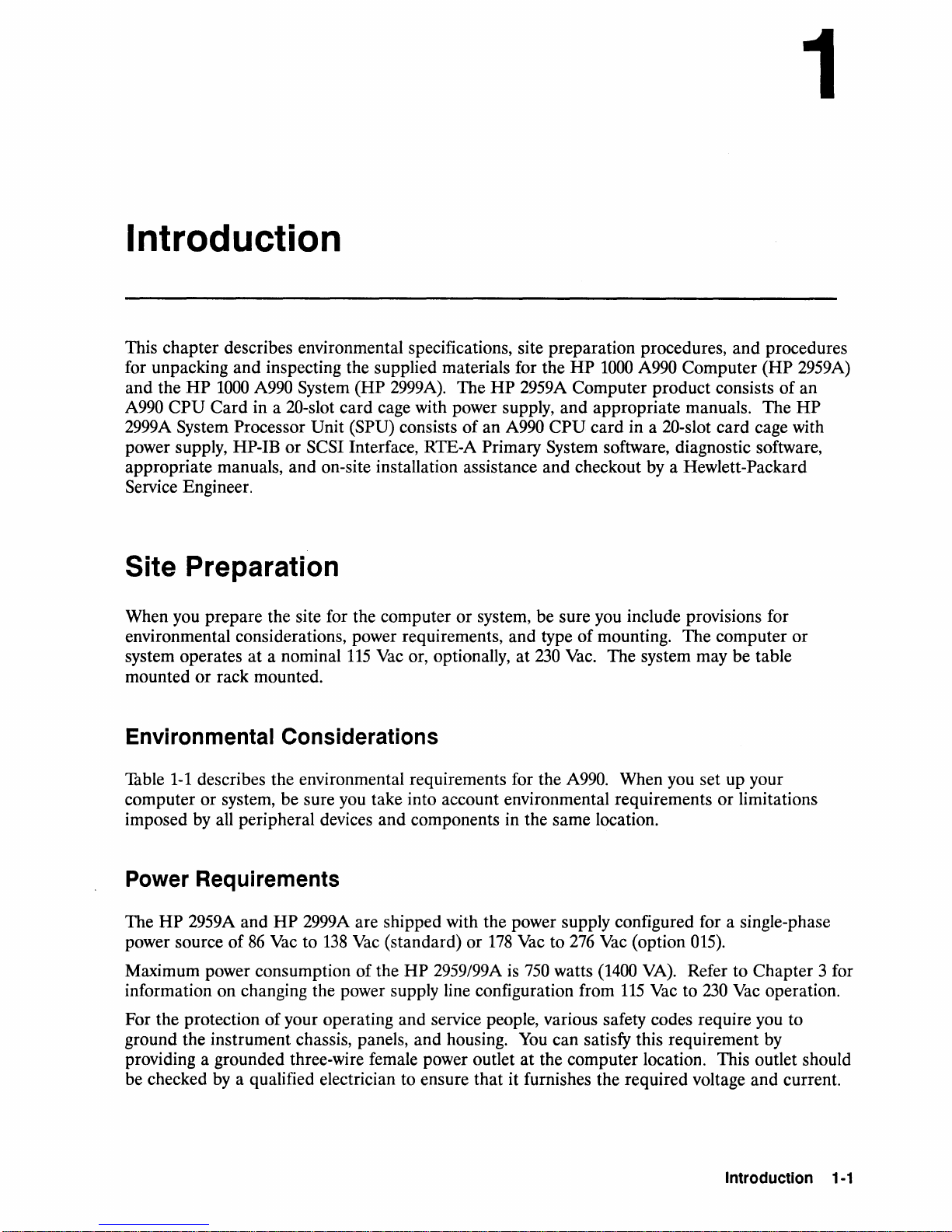

This chapter describes environmental specifications, site preparation procedures, and procedures

HP

1000

for unpacking and inspecting the supplied materials for the

HP

1000

and the

A990 CPU Card in a

2999A System Processor Unit (SPU) consists of an A990 CPU card in a

power supply,

appropriate manuals, and on-site installation assistance and checkout by a Hewlett-Packard

Service Engineer.

A990 System (HP 2999A). The

20-s10t

HP-IB or SCSI Interface, RTE-A Primary System software, diagnostic software,

card cage with power supply, and appropriate manuals. The

HP

2959A Computer product consists

A990 Computer (HP 2959A)

of

an

HP

20-s10t

card cage with

Site Preparation

When you prepare the site for the computer

environmental considerations, power requirements, and type

115

Vac

system operates at a nominal

or

mounted

rack mounted.

or, optionally, at

Environmental Considerations

Table

1-1

describes the environmental requirements for the A990. When you set up your

computer or system, be sure you take into account environmental requirements or limitations

imposed by all peripheral devices and components in the same location.

Power Requirements

The

HP

2959A and

power source of

Maximum power consumption

information on changing the power supply line configuration from

For the protection

ground the instrument chassis, panels, and housing.

providing a grounded three-wire female power outlet at the computer location. This outlet should

be checked by a qualified electrician to ensure that it furnishes the required voltage and current.

HP

2999A are shipped with the power supply configured for a single-phase

86

Vac

to

138

Vac

(standard) or

of

the

HP

of

your operating and service people, various safety codes require you to

or

system, be sure you include provisions for

of

mounting. The computer or

230

Vac.

The system may be table

178

Vac

to

276

Vac

2959/99A

(option

is

750

watts

(1400

VA).

115

You

can satisfy this requirement by

015).

Refer to Chapter 3 for

Vac

to

230

Vac

operation.

Introduction

1-1

Page 17

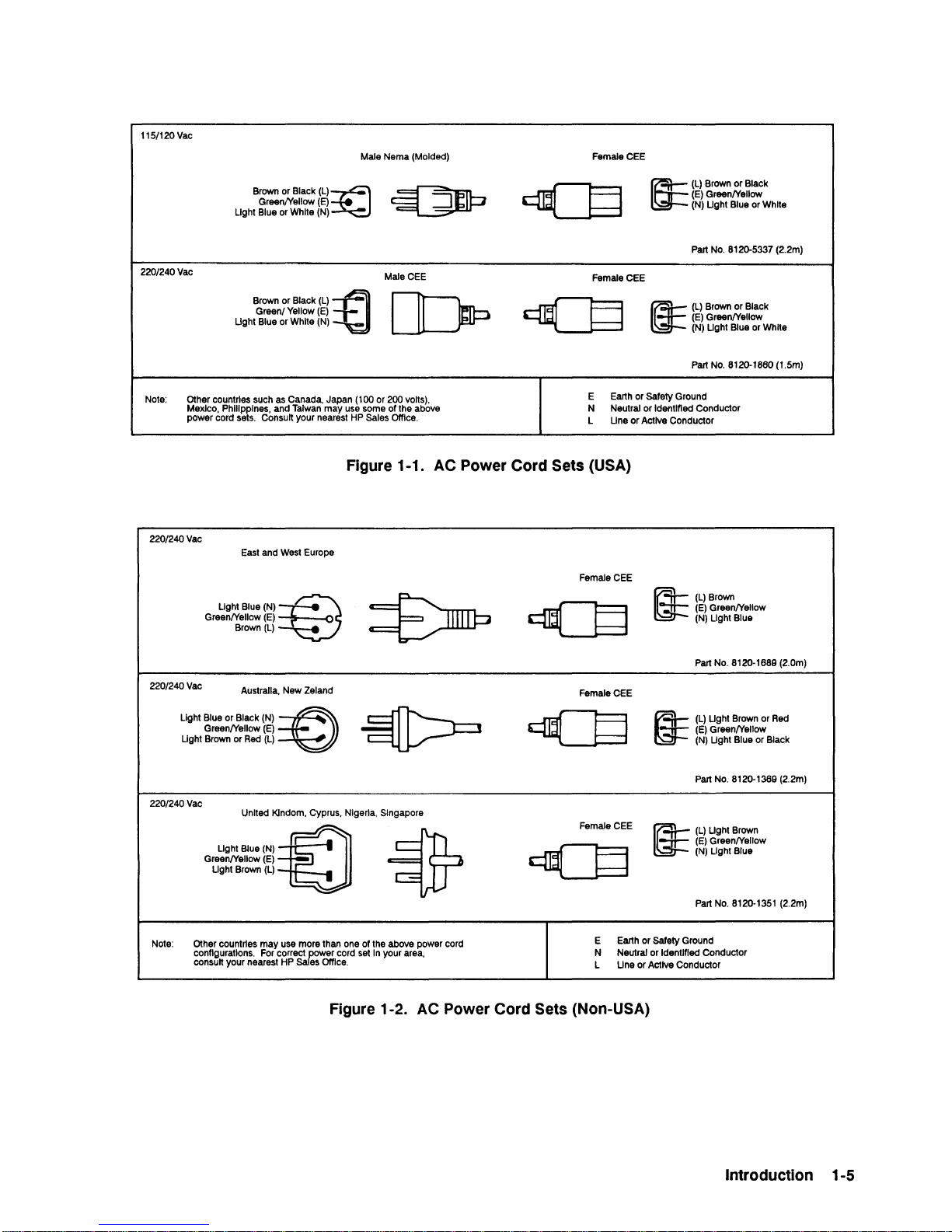

The computer or system also must be properly protected by fuses or circuit breakers of sufficient

capacity to carry the current load specified for the computer or system. Refer to Figures

1-2

for descriptions of the various types of ac power cord configurations.

1-1

and

Cooling Requirements

No external cooling

airflow as long as the computer or system

1-1

in Table

and the front and rear grills are not obstructed.

Four fans provide approximately

Half of the airflow is used to cool the power supply, and half the airflow

is

required for the computer or system. The internal fans provide enough

is

operated within the temperature limitations specified

10.1

cubic meters per minute

(360

CFM) front-to-rear airflow.

is

card cage.

Mounting Considerations

You

can use the computer either free-standing on a table, or mounted in a standard

If

(19-inch) equipment rack.

mounted equipment rack. Refer to Table

mounting the

A990 on a table, provide enough clear space at the front and back of the computer

to permit an unimpeded intake and exhaust of airflow.

Table 1-1. Electrical and Environmental Specifications

ELECTRICAL SPECIFICATIONS

AC Power Requirements

used in a mobile environment, install the computer in a shock-

1-1

for physical dimensions of the computer. When

directed through the

483

mm

Line

Line

Inrush

Maximum

Power Supply

Output

and

tolerances:

Available Backplane

1-2 Introduction

voltage:

frequency:

Current

Power

DC

voltages

86

to

172

47.5

(cold power-up): 20.0

40.0

Required:

750

+5.1

+ 12.0 V

-12.0

Power:

380

power may be used if

voltages between 104-138

(option 015).

138

to

276

to

66

Amps

Amps

Watts

V

V

Watts,

Vac

(115

Vac

(230

Hz

maximum

maximum

(1400

VA)

±2%

+6/-3%

±6%

maximum.

Vac

Vac

(at

(at

An

the

-25%/

+ 20%) standard;

-23

%/

+ 20%) option 015.

115

Vac)

230

Vac)

additional

input voltage

Vac

60

(standard)

Watts

range

or

of backplane

is limited

178-276

to

Vac

Page 18

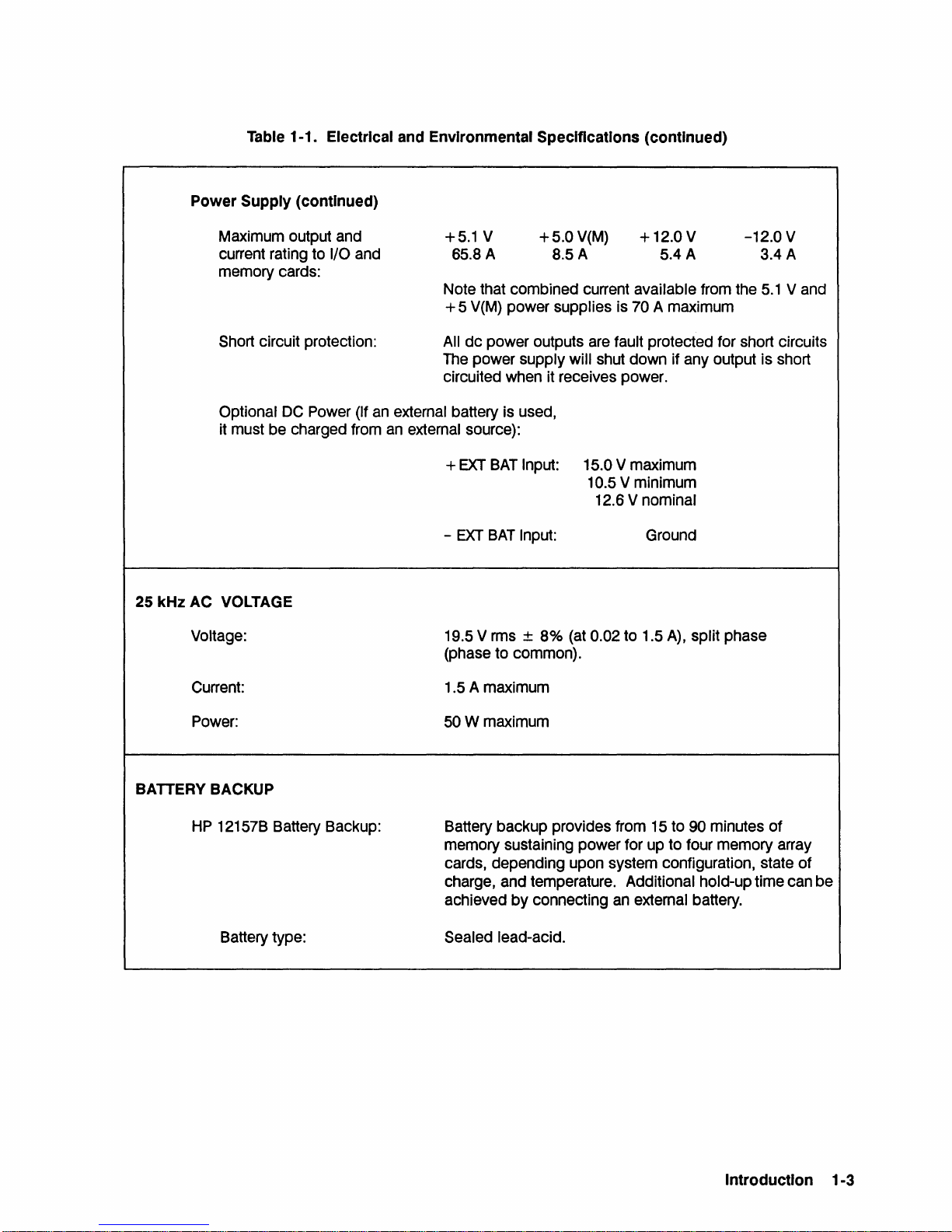

Table

1-1. Electrical and Environmental Specifications (continued)

Power

Supply (continued)

Maximum output and

current rating to

memory cards:

Short circuit protection:

Optional

it must be charged from

DC

25 kHz AC VOLTAGE

Voltage:

I/O and

Power (If

+5.1 V

65.8 A

Note that combined current available from the

+5

V(M) power supplies is 70 A maximum

All

dc

power outputs are fault protected for short circuits

The power supply will shut down if any output is short

circuited when it receives power.

an

external battery is used,

an

external source):

EXT

BAT

+

-

EXT

BAT

19.5 V rms ±

(phase to common).

+5.0

V(M)

8.5A

Input: 15.0 V maximum

10.5 V minimum

Input: Ground

8%

(at

0.02 to 1.5

+ 12.0 V

5.4 A

12.6 V nominal

A),

-12.0 V

split phase

3.4 A

5.1

V and

Current:

Power:

BATTERY BACKUP

HP

12157B Battery Backup:

Battery type:

1.5 A maximum

50Wmaximum

Battery backup provides from 15 to 90 minutes

memory sustaining power for up to four memory array

cards, depending upon system configuration, state

charge, and temperature. Additional hold-up time can be

achieved

Sealed lead-acid.

by

connecting

an

external battery.

of

of

Introduction 1-3

Page 19

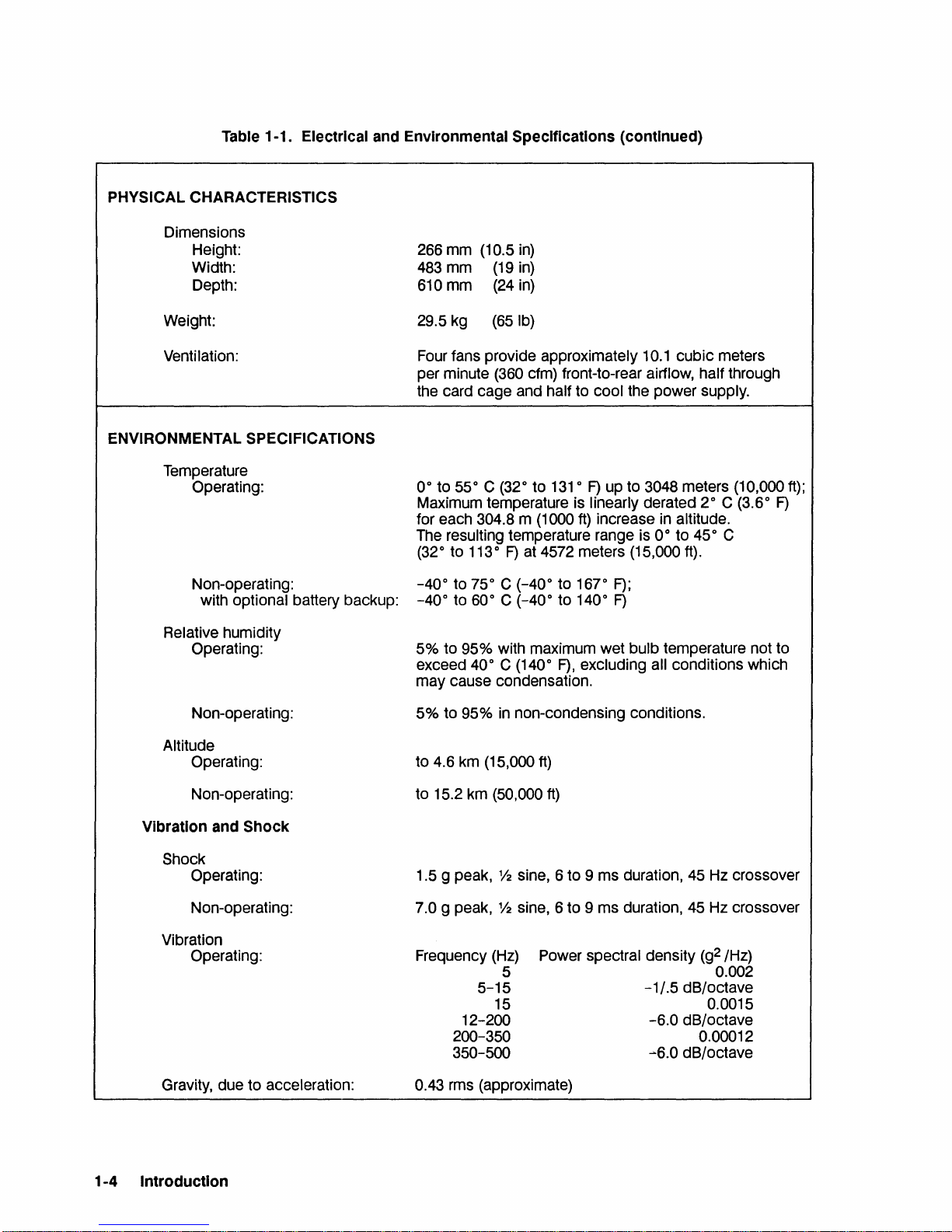

Table 1-1. Electrical and Environmental Specifications (continued)

PHYSICAL CHARACTERISTICS

Dimensions

Height:

Width:

Depth:

266 mm (10.5

483

mm

(19

610 mm

(24

in)

in)

in)

Weight:

Venti lation:

ENVIRONMENTAL SPECIFICATIONS

Temperature

Operating:

Non-operating:

with optional battery backup:

Relative humidity

Operating:

Non-operating:

Altitude

Operating:

29.5 kg

Four fans provide approximately

per minute

the card cage and half to cool the power supply.

0° to 55° C (32° to

Maximum temperature is linearly derated 2° C (3.6°

for each 304.8 m (1000

The resulting temperature range is

(32° to

-40°

-40°

(65

Ib)

10.1

cubic meters

(360 cfm) front-to-rear airflow, half through

131

°

F)

up to 3048 meters (10,000

ft)

increase in altitude.

0° to 45° C

113

°

F)

at 4572 meters (15,000

to 75° C (-40° to 167°

to 60° C (-40° to 140°

F);

F)

ft).

F)

5% to 95% with maximum wet bulb temperature not to

exceed

may cause condensation.

40° C (140°

F),

excluding all conditions which

5% to 95% in non-condensing conditions.

4.6 km (15,000

to

ft)

ft);

Non-operating:

Vibration and

Shock

Operating:

Non-operating:

Vibration

Operating:

Gravity, due to acceleration:

1-4

Introduction

Shock

to 15.2 km (50,000

1.5 g peak,

Y2

ft)

sine, 6 to 9 ms duration,

45

Hz crossover

7.0 g peak, % sine, 6 to 9 ms duration, 45 Hz crossover

Frequency

(Hz)

5

5-15

15

12-200

200-350

350-500

Power spectral density

-1/.5

dB/octave

-6.0

dB/octave

~6.0

dB/octave

(g2

/Hz)

0.002

0.0015

0.00012

0.43 rms (approximate)

Page 20

115/120 Vac

220/240Vac

Brown or Black

Green/Yellow

Light Blue or White (N)

Brown

Green/ Yellow

Light Blue

'"

Blad<

or

White (N) r

(E)

(E)

Male Nema (Molded) Female CEE

(l)~

crn{-§

~

MaleCEE

II.)

:(J

~

~

Female CEE

a::

(l) Brown

(E) Green/Yellow

(N) Light Blue or White

Part No.

~

(l)

Brown or Black

(E)

Green/Yellow

(N) Light

Part No.

or

Black

8120-5337 (2.2m)

Blue or White

8120-1860 (1.5m)

Note:

Other countries such as Canada, Japan

Mexico, Philippines, and Taiwan

power cord sets.

220/240Vac

Green/Yellow

220/240Vac

Ugh!

Blue

Green/Yellow

Light Brown or Red

220/240 Vac

Green/Yellow

Light Brown (l)

Note: Other countrtes

configurations. For correct

consult your nearest HP Sa es Office.

Consult your nearest HP Sales Office.

East and West Europe

Ugh!

BI,.

Brown (l)

Australia, New Zeland

0'

BlaOk

United Klndom, Cyprus, Nigeria,

Ugh!

BI,.

may

(100 or 200 volts),

may

use some of the above N

Figure 1-1. AC Power Cord Sets (USA)

IN)

~

(E)

~

IN)

=©

(E)

(l)

IN)

~

(E)

~

Singapore

•

use more than one of the above power cord

Fe0wer

cord set In your area,

E Earth or Safety Ground

l

FemaieCEE

~

FemaieCEE

~

FemaieCEE

~

--

Neutral or Identified Conductor

Line

or

Active Conductor

(l) Brown

(E)

~

(N) Light Blue

Part No. 8120-1689 (2.0m)

(l) Light Brown or Red

(E)

(N) Light Blue or Black

~

Part No. 8120-1369 (2.2m)

~

(l) Light Brown

~

(E)

(N) Light Blue

Part No. 8120-1351 (2.2m)

or

Safety Ground

Earth

E

N

l

Identified Conductor

Neutral or

Line or Active Conductor

Green/Yellow

Green/Yellow

Green/Yellow

Figure 1-2.

AC

Power Cord Sets (Non-USA)

Introduction 1-5

Page 21

Unpacking and Inspecting

Your A990 computer or system may be shipped in several containers. Verify the number of

containers received against the carrier's paperwork. Inspect each container for damage that may

If

have occurred during transit.

carrier be present when you open the container.

Open the shipping container marked "MANUALS AND ACCESSORIES" and locate the

materials list. Compare it with your purchase order. Make sure it includes everything you have

ordered. Unpack the shipping container(s) and inspect each item for external damage, such as

broken controls and connectors, dented corners, bent panels, scratches, and loose components.

Also check the rigid foam-plastic packing material (if used) for signs of deformation or cracking.

Such signs may indicate rough handling in transit.

If

you find damage to the computer or accessories,

below. Be sure you keep

settling a claim, or to repackage the computer or system.

all

you find damage or water stains, request that an agent of the

follow

shipping containers and packing materials.

the damage claim procedure described

You

may need them for

Claims Procedure

If

you need to make a claim, contact your nearest Hewlett-Packard Sales and Service Office.

the loss occurred in transit, notify the carrier as

retain all shipping and packaging materials for inspection. Hewlett-Packard

or replace damaged or lost items even though claims against the carrier may not yet be settled.

well

as Hewlett-Packard, and also be sure you

will

arrange to repair

If

Physical Inventory

Make sure all manuals listed in the bill of materials are included. Your computer's model and

serial number

serial numbers should match those on the packing list.

Hewlett-Packard

computer or system, verify that the cards have been supplied as specified on your purchase order.

is

located on the identification label on the back of the chassis. The model and

If

they do not, immediately contact your

Sales and Service Office.

If

you have ordered I/O or memory cards with your

1-6 Introduction

Page 22

Installation

2

This chapter describes procedures for configuring and installing the A990

and system.

Required Tools

Slot and Phillips head screwdrivers are the only tools you

system.

cards.

We

strongly recommend the use of a wrist strap and ground cord when handling plug-in

will

need to install the computer or

Configuration Requirements

Verifying the Power Supply Configuration

Warning

G

To

avoid damage

adjustments,

only by qualified maintenance people.

or

to

equipment

repair

or

injury

to

the power supply must be performed

to

people, any service,

20-s10t

box computer

The computer's ac line voltage configuration

configuration power connector. The power connector must be plugged into one of two connectors

(P7 or P8) located at the left side of the power supply when viewing the computer from the front.

See Figure

connectors P7 and P8. For

P8. For

To

check the position of the ac line configuration/fan power plug connector, remove the computer

front panel and fan panel and inspect the position of the power line connector relative to sockets

P7 and P8. The ac power cord

configuration connector

panel, refer to Chapter 3 of this manual.

230

2-1

for a

view

of the power supply from the front, and Figure

Vac

operation, the connector must be plugged into socket P7.

is

is

determined by the position

115

Vac

operation, the power connector must be plugged into socket

is

always connected to plug P9 regardless of how the line

set. For step-by-step information on removing the front panel and fan

of

the line

2-2

for the location

Installation 2-1

of

Page 23

B. B.

ON

Terminal

Positive

Battery

Terminal

Figure 2-1. Front View of Chassis with Bezel and

Battery

Backup Terminal

Assembly

B. B.

OFF

Fan

Negative

Battery

Terminal

Panel Removed

Battery Backup

The

HP

12157B

system configuration, state of charge, and temperature. Additional memory hold-up time can be

achieved by connecting an external battery.

If

Battery Backup

ENABLE. The switch

position if the power is turned off and if memory backup

be set to DISABLE if cards are to be connected or disconnected from the backplane.

Refer to the

battery backup. Note that if batteries are not installed, the strapping connector from the terminal

on the lower board of the power supply must be connected to B.B.

batteries are installed, the strapping connector must be connected to B.B. ON.

Battery Backup

is

installed, set the Battery Enable switch on the back panel of the computer to

is

shown in Figure

will

sustain memory for

2-3.

15

to

90

minutes, depending on the

This switch should be set to the DISABLE

is

not required. The switch should also

Battery Backup Installation section later in this chapter for instructions on installing

OFF. (See Figure 2-1.)

If

2-2 Installation

Page 24

B

P9

pSL-1

P7L-1

___

___

....J

....J

(Toward

Front

of

Power Supply

Fan

Panel and Front Panel)

P2

P1

P5

[!!l

Connector

P1

P2

P5

P6

P7

PS

P9

P14

-

Figure

Description

DC

Output Connectors

DC

Output Connectors

Battery Switch Connector

Test Points and External Battery Connector

230 Vac Line Configuration Connector

115 Vac Line Configuration Connector

AC

Line Input Connector

Battery Backup

2-2.

Power

OFF Connector

Supply

Connector

Diagram

-

Figure

2-3.

Computer

Back

Panel

and

Power

Panel

Installation

2-3

Page 25

A990

CPU

Card Switches

The A990 CPU card contains two switches, SWI and

action (push and release) reset switch that resets the A990

DIP switch (see Figure

1.

BOOT

2.

Autorestart override (Memory Lost), which sets the conditions under which autorestart

occurs.

SELECT, which selects computer operations at power-up.

2-5)

that controls the following functions:

· .

· .

· .

..

· .

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

· .

0

~

2

m

Cti

C

..

· .

. .

..

. .

. .

· .

. .

..

. .

. .

. .

..

. .

. .

. .

..

. .

.

.

. .

· .

. .

. .

..

. .

.

.

. .

. .

. .

. .

. .

..

. .

. .

. .

..

. .

..

..

SW2

(s,ee

Figure

CPU card. SW2 is an eight-section

SW1

2-4).

SWI is a momentary

2-4 Installation

Firmware

EPROM

Figure 2-4. A990

A bank

board,

CPU

Card Switches

of 4 LEOs

directly below the upper bank

is located on the lower side

SW1

and SW2

of

8 LEOs.

of

the

Page 26

Startup Option Switches

There are eight switches,

SW2-1

through

SW2-8,

that control the startup options. Table

specifies the available startup options and corresponding switch settings.

Autorestart Switch

Autorestart

1.

DOWN

autorestart or if battery backup is not installed. When using the

be sure you set the Battery Enable switch to DISABLE.

When

that was running prior to the powerfail condition. Instead, the boot loader (or

routine)

2.

UP (oft) - Autorestart

is

restart the program that was running prior to the powerfail condition. With no battery

backup installed, you

is

controlled by switch

(on) - Autorestart

SW2-8 is ON, if power

will

execute.

set to ENABLE.

SW2-8

is

not enabled. Use this setting if you do not wish to use

is

is

enabled if battery backup is installed and the Battery Enable switch

If

power

will

is

get a self-test error when you switch the computer on.

(see Figure

lost, the autorestart feature

2-5).

The settings for switch SW2-8 are:

ON

position for

will

not restart the program

lost and memory was sustained, autorestart

will

2-1

SW2-8,

VCP

automatically

Figure 2-5. Switch SW2 In Default Configuration

Installation 2-5

Page 27

Table 2-1. SW2 Start-Up Switch Settings

Computer Action

S1

Loop on self-test Test 2 regardless of error. D D

Loop on

Run

For the

is restarted (JMP 4B).

VCP will execute. When a loader finishes an autoboot, it starts execution

self-test Test 2 and stop on error.

Virtual Control Panel

following switch settings, the computer action indicated will occur if memory is lost, otherwise, the program

VCP.

Run

Speed sense and run

Execute program from

must have

Load and execute the program via the HDLC

the

to loader command %BDS. **

Load and execute program from the first file of the disk (via HP-IB

To

autoboot via HP-IB

and, for

dress

select code 22. This is equivalent to the loader command %BRM. **

HDLC

or

LAN card, the card must have select code 24. This is equivalent

HP-IB, the disk drive must have HP-IB address 2

6.

This is equivalent to the loader command %BDC. **

(VCP)

routine on completion of self-test.

If the autorestart feature is disabled (switch SW2-8 down), the program cannot restart and

VCP.

See Notes 2 and

PROM card. In order to autoboot from PROM, the card

or

SCSI, the interface card must have select code 27;

3.

or

LAN card.

To

autoboot via U

or,

for SCSI, ad-

of

the loaded program at location 02.

or

SCSI). U U U

D D

D

U

U U

U

Swlt~h~~*

S2 S3 S4 S5 S6 S7 S8

D D

U

U U

D D D

D

D

U

D D z

U

D z

D z

U

D z

D

Y

Y

Y

Y

Y

Y

Y

Y

D M

D M

D M

M

D

D M

M

D

M

D

D M

z

z

z

z

Execute bootstring from the time-of-day clock

the A990

*

**

Notes:

CPU card.

D = Down (On); U =

Refer to the

=

D,

y

=

U,

y

=

D,

z

z =

U,

M =

M =

1.

2.

3.

HP

normal mode, system console uses ENQ-ACK handshaking.

system console does not use ENQ-ACK handshaking.

normal mode, break enabled.

break disabled (but not halts).

D,

disable autorestart (battery backup not installed).

U,

enable autorestart (battery backup installed).

Do not use any switch combination that is not specified above.

Use this switch configuration for normal computer operation.

Speed sense allows VCP to execute at any baud rate supported

Up

(Off)

1000 A990 Computer Reference Manual, part number 02959-90001.

RAM

(non-volatile

RAM)

on

D D

D

by

the 8-channel MUX.

U z

Y

D M

2-6 Installation

Page 28

Interface Card Switches

Assign each I/O interface card to be installed in the computer a unique select code by setting the

select code switches on the interface cards. Refer to the appropriate interface card reference

manuals for select code switch information and for information on any other card switches that

must be set.

Virtual Control Panel (VCP) Configuration

If

you are installing a Virtual Control Panel (VCP), assign one of your

(HP

12005B),

cards as the VCP interface card.

LAN (HP

12076A),

or HDLC (HP

12007B

Modem or

MUX

HP

(HP 12040D), ASIC

12044A Direct Connect)

Set switch U1S1 on that card to

ON

(closed) to designate it as the VCP interface card.

Memory Configuration

Several memory configurations, using

can be installed in the

memory configurations. All three array sizes may be used together in the same system provided

that the largest memory card

can be installed in the

and frontplane connectors. Refer to the

instructions on installing memory.

A990.

A990 computer. Refer to Table

Refer to Figure

is

768

Kbyte, 3 Mbyte and/or 8 Mbyte memory array cards,

2-6

for an illustration of minimum and maximum

closest to the A990 CPU card.

2-2

for the available memory array cards

Memory Installation section in this chapter for

Up

to four memory array cards

Installation 2-7

Page 29

Minimum A990 Memory Configuration

slot #

11

Available for I/O Card 1

12

Available for

13

Available for I/O Card

14 Available for

15

Available for

16 Available for

17 Available for

18

Available for I/O Card

19

Available for I/O Card

20 Available for I/O Card

§!Q1it

11

Available for I/O Card 1

12 Available for

13

Available for I/O Card

14 Available for

15 Available for

16

Available for I/O Card

17 Available for

18 Available for

19

Available for I/O Card 9

Available for I/O Card

20

I/O Card 2 12220A 768

I/O Card 4 Available for I/O Card

I/O Card

I/O Card

I/O Card

I/O Card

I/O Card 4

I/O Card

I/O Card 7 Available for I/O Card

I/O Card

§!Q1it

A990 CPU Card

12oo9A HP-IB Interface Card

3

Available for I/O Card

5

Available for I/O Card

6

7 Available for

Available for I/O Card

8

Available for

9

Available for I/O Card

10

Maximum A990 Memory Configuration

slot #

A990 CPU Card

12221

2

3

5

6

8

10

B 8 MB Memory Array Card

12221

B 8 MB Memory Array Card

12221

B 8 MB Memory Array Card

12221

B 8 MB Memory Array Card

12009A

Available for I/O Card

Available for

Available for I/O Card

HP-IB Interface Card

Figure 2-6. A990 Memory Configurations

KB

Memory Array Card

I/O Card

I/O Card

I/O Card

12220A 768 KByte Memory Array Card

12221A 3 MByte Memory Array Card 12221-60001

12221

Connector for 1 Memory Card

Connector for 2 Memory Cards

Connector for 3 Memory Cards 12230-60003

Connector for 4 Memory Cards

2-8 Installation

Table 2-2. Memory Array Cards and Frontplanes

Description Part Number

12220-60001

B 8 MByte Memory Array Card 12221-66001

12230-60001

12230-60002

12230-60004

Page 30

I/O Priority Assignment

Each peripheral device in the system must be connected to the computer system through an

interface card installed in the card cage. A priority chain connects all interface cards in series to

prioritize simultaneous

priority of an interface card

after the last memory card having the highest priority and slot

Figure

installing interface cards in the desired order

I/O requests from a higher priority device inhibit lower priority requests by breaking the priority

chain.

peripherals. Consult the system manager to establish

cards accordingly.

2-7

for an illustration of the I/O priority assignments. Configuring I/O priority consists of

To

maximize system response time and efficiency, assign the higher priorities to high-speed

DMA

requests and interrupt requests from two or more peripherals. The

is

determined by the slot the card occupies, with the slot directly

20

having the lowest priority. See

of

priority.

I/O device priority and install the interface

Note

"

Correct computer operation requires that there be NO vacant slots

between plug-in cards.

Memory Array

Card

Memory

Frontplane

Connector

Cable to I/O Device

with Lowest Priority

Figure 2-7.

Cable

to I/O Device with

Highest Priority

(System Disk Drive)

HP

2959/2999 Cards and I/O Priority Assignments

A990 CPU

Card

Installation 2-9

Page 31

Installation Procedure

Battery Backup Installation

The A990 Computer or System accommodates an optional battery backup, which you can install

To

in the power supply compartment.

1.

Make sure that the ac power cord is not connected to the computer chassis and that the ac

LINE switch is set to the

Enable switch on the back of the chassis to DISABLE.

2.

Remove the front panel, the fan panel, and the ac line configuration/fan power connector

from the chassis. Note whether the connector is attached to

Refer to Chapter 3 of this manual for instructions on removing these assemblies.

3.

If

the strapping connector

supply marked "B.B.

ON".

4.

Place the battery bracket over the battery. Align the negative (-) terminal of the battery with

the label on the battery bracket that reads

See Figure

2-1.

OFF

is

OFF", connect it to the terminal on the upper board marked "B.B.

install the battery backup:

position.

connected to the terminal on the lower board

If

you have not already done so, set the Battery

P7

(230

Vac)

"Black Wire (-)". See Figures

or

to P8

of

the power

2-8

and

(115

2-9.

Vac).

5.

On the right side of the chassis, locate a pair of wires (a white covered wire and a black

covered wire) in a gray sheath. Connect the terminal lug on the white wire to the positive

( + ) battery terminal and connect the terminal lug on the black wire to the negative (-)

battery terminal. See Figure

6.

Place the battery, bracket, and attached wires in an upright position in the battery tray

beneath the power supply.

not upward. See Figure

bracket assembly under the power supply as you set it into place. Rotate the battery and

bracket assembly so the battery terminals face upward. See Figure

screws on the battery bracket.

7.

Reinstall the fan panel and front panel. Remember to reconnect the line configuration

connector to

complete instructions.

P7 or P8, as appropriate for your line power voltage. Refer to Chapter 3 for

2-9.

Place the assembly so the battery terminals are facing outward,

2-10.

The fit

is

close, so you may have to maneuver the battery and

2-11.

Fasten the captive

2-10 Installation

Page 32

Place bracket

over

battery

Figure 2-8. Backup Battery and Battery Bracket

Allach battery cable

terminal lugs onto

battery terminals.

I

I

I

White wire

l

Black wire

Figure 2-9. Backup Battery Installed

In

Battery Bracket

Installation

2-11

Page 33

Battery

Assembly

Battery

Terminal

(Negative)

Figure 2-10. Battery Assembly

Positive

Battery

Terminal

Battery

Backup

Assembly

In

Initial Position

B. B.

Terminal

B.

B.

Terminal

OFF

ON

Negative

Battery

Terminal

Figure 2-11. Battery Assembly

2-12 Installation

In

Final Position

Page 34

Memory Installation

Caution

I

You

can install from one to four memory array cards in the A990 card cage. With available

memory cards, you can install up to

ECC memory array cards. The memory frontplane connectors, however, are unique to the

A900 memory frontplane connectors cannot be used with the

types of memory array cards and frontplanes.

Install the first memory array card in the slot immediately to the left of the

immediately to the left of the first, and so on.

CPU card and a memory array card or between any memory array cards.

array cards of different capacities, place the largest capacity card(s) nearest the

Install the appropriate frontplane connector using one of the four supplied with your computer.

Attach the small connector of the frontplane to the

memory array card(s). Be sure you use a frontplane that matches the number of memory array

cards you have installed. For example, if you have installed four memory array cards, the

frontplane must have

STATIC SENSITIVE DEVICES you install or remove memory cards, you

switch to DISABLE. Also, make sure the LINE switch is set to

the ac power cord

antistatic wrist strap connected to a ground wire.

five

connectors.

is

not connected to the ac power mains. Wear an

32

Mbytes of memory. The A990 supports only the A900

To

avoid damage to equipment, before

must set the Battery Enable

A990.

Do

not leave an empty backplane slot between the

CPU card and the other connector( s) to the

Table

2-2

lists the available

CPU card, the second

If

you have memory

OFF

and

A990.

A990 CPU card.

I/O Card Installation

Install I/O cards the same way you installed the CPU and memory cards.

priorities for

CPU card, the higher the priority. Install

I/O cards are related to their placement relative to the CPU card. The closer to the

all

cards contiguously (no empty slots between cards).

DMA

and interrupt

Self-Test Check

The self-test for the processor automatically executes every time the computer is powered on.

recommended that you run the self-test to ensure that the CPU

must be made with all plug-in cards installed in the computer.

proceed as follows:

1.

Set the LINE switch to the

battery backup is installed, set the Battery Enable switch to DISABLE.

2.

Remove the rear cover for observation of the processor LEDs.

OFF

position and connect the power cord to a power outlet.

is

operating correctly. This check

To

verify the self-test operation,

It

If

is

Installation 2-13

Page 35

3.

Set the power switch to ON. Observe the eight LEDs on the top of the A990 CPU card.

the computer passes the self-test, the LEDs

will

display one of the following values within

seconds. Any other LED display indicates a self-test failure. Refer to Chapter 3 for

troubleshooting information.

If

20

000001*1- VCP program

000000*0 - VCP program

VCP console to respond to the first Enq/ Ack handshake.

is

00000001

00000000

10000000

- Loader

- User software

- Loader error. Probably a checksum error; change media on loading device.

where: 1

for the

= LED lit; 0 = LED unlit; * = LED blinking

is

running; VCP console is connected.

is

running; VCP console

running.

is

running.

is

not connected, that

is,

VCP

is

waiting

Computer Mounting

Table Mounting

The computer may be used as a freestanding instrument in a land-based environment. The only

considerations are that adequate space should be allowed at the front and rear to ensure

intake and exhaust of ventilating air, and that all covers are installed. Also, a minimum of

centimeters

(15

inches) of clearance behind the computer

is

required when removing and

installing plug-in cards.

full

38

Rack Mounting

You

can mount the A990 Computer in any standard 19-inch cabinet, such as the

HP

29431G.

The usual location for the computer

is

at the bottom of the cabinet. Refer to the

HP

29429A or

manuals supplied with your cabinet for specific information on installing mounting rails, installing

the computer chassis, and grounding requirements.

When installing the

power cord to the ac power socket in the chassis and the other end to the

(PDU) mounted on the back door of the cabinet.

switch

is

set to OFF, then remove the four screws that secure the

HP 2959A CPU or the

HP

2999A SPU in a cabinet, connect one end of the ac

Power Distribution Unit

To

access the PDU, make sure the Main Power

PDU

access panel.

2-14

Installation

Page 36

System Console (Terminal) Installation

Except for the cabling information given in this section and in Figure

2-12,

refer to the

documentation supplied with your terminal for all other installation information. For information

on configuring the console interface as the Virtual Control

Virtual Control Panel Configuration section

in

this chapter.

Panel (VCP) interface, refer to the

Use one of the following interfaces for your system console:

HP

12005B

HP

12040C/D Multiplexer Interface (MUX) Card

Asynchronous Serial Interface (ASIC) Card

Use the following procedure to connect your terminal to the interface card:

1.

Set the system power switch to

OFF

and, if battery backup is installed, set the Battery

Enable switch to DISABLE.

2.

Remove the computer card cage rear cover.

3.

If

you connect the terminal with an electrical cable (instead of a fiber optic cable), connect

the cable's hooded connector to the interface card, with the cable extending down. Connect

the ground lug from the hooded connector to the computer chassis.

4.

If

you connect the terminal with a fiber optic cable (to the

HP

12005B

ASIC card only),

connect the gray connector on the cable to the gray transmitter on the interface card and the

blue connector on the cable to the blue receiver on the interface card.

If

an

HP

12040

MUX

is

used as the VCP interface, the VCP terminal must be connected to

Port 0 of the MUX.

If

your terminal is connected to an ASIC card or to revision C of the

must configure the terminal for

If

you are using revision D of the

to operate at the baud rate of your

9600

HP

HP

baud rate.

12040

MUX card, the computer

terminal.

You

must have your terminal configured for the

ENQ/ACK protocol and 8 data bits with no parity or 7 data bits with

1200,2400,4800,9600, and

You

may also use one

19.2k

are supported for terminals connected to an

of

the following I/O interfaces as your VCP interface for remote VCP

HP

12040

MUX

is

automatically configured

O's

parity. Baud rates

HP

card, you

12040

MUX.

download and boot capabilities:

HP 12076A

:HP

12007B

If

you want to use the LAN card as your VCP interface, refer to the

and Installation Manual,

If

you want to use an HDLC card as your VCP interface, your remote system must be running

either

NS-ARPAl1000 or DS/1000-IV software.

refer to the NS-ARPA/lOOO Generation and Initialization Manual,

information on remote

DS/1000-WTheory

information on remote

LAN/IODO

or

HP

12044A

part number

VCP.

o/Operation

VCP.

Link Interface Card

HDLC Interface Card

92077-90034,

If

your remote system

and

Troubleshooting Manual, part number

RTE-A

for information on remote

If

your remote system is running NS-ARPAl1000,

part

is

running DS/1000-IV software, refer to the

System Generation

VCP.

number

91790-90030,

91750-90014,

for

300,

for

Installation 2-15

Page 37

Interface Cabling

Refer to the manuals supplied with your interface cards and peripherals for information on

connecting devices to

procedure to install the interface cables:

1.

Set the power switch to

switch to DISABLE. Remove the rear panel.

2.

Connect the hooded connector of each cable to the edge connector of the appropriate

interface card, with the cable extending to the bottom of the card cage. Connect the cable

ground wire, if present, to the grounding strip.

3.

Connect the other end of each cable to the appropriate peripheral device. Reinstall the rear

panel.

I/O cards. After all interface cables have been assembled, use the following

OFF

and, if battery backup is installed, set the Battery Enable

Memory Frontplane

ill

I A990

C

d C

ar age

CPU

Card

V Connector

~-

v

I Memory Array

l HP-IB or SCSI

I

ASICorMUX

ill

As additional memory array cards are added, the appropriate frontplane connector must

array frontplane part numbers

respectively.

~

When installing the optional

cabling information. Note that revision

terminal.

~

Connect gray connectors to gray transmitters; connect blue connectors to blue receivers.

* Portions

or

all

of

this product line are discontinued; shown for reference only.

HP

~

_ CS/80 or SCSI

r-

Disk Drive

Jt---+----------I'------~

~

E-~------

,,/

..-------.

239x*

Terminal

......

Alternate System Console Configurations

12230-60001 through -60004 connect one through four memory array cards,

12040 MUX card, refer to the card manual, part number 12040-90123, for

0 of the MUX senses and sets the baud rate

5061-5798 (Fiber Optic) ~

--;------,

/ I I

5061-6634

I

r::::::=-1

I

~~OO_1~*

I

~~~:~~

~I~

J.

Is061J

r

l.§.8QQ

I I 262x* I

I I

Terminal

L..

____

Fi~r

OptiC

Adapter

1 ,

I

J

be

used. Memory

to

match that of the

2-16

Installation

Figure 2-12. System Cabling Diagram

Page 38

Disk Drive Installation

A variety of disk drives are available for use with A990 computers and systems. Except for

installing the

for installation information. Use the following instructions to install your disk drive cabling:

HP-IB or SCSI cable, refer to the installation manual supplied with your disk drive

Note

"

1.

Set the system power switch to

2.

Connect the HP-IB or SCSI connector on the disk drive cable to the HP-IB or SCSI

connector on the back of the disk drive.

3.

Connect the hooded connector on the disk drive cable to the

Card or

cage.

4.

Install the rear panel.

Where both standard and high-speed disk drives are used in a multiple

drive installation, assign one

OFF

HP

12016A

SCSI Interface Card, with the cable extending to the bottom of the card

HP-IB Interface Card to each class of drive.

and remove the rear panel of the computer.

HP

12009A HP-IB Interface

Powering Up the System and Booting

Use the following procedure to complete the installation and power up the system:

1.

Set the terminal Power switch to ON; then set the system Power switch to ON.

backup

appear on the terminal screen after approximately

the

is

installed, set the Battery Enable switch to ENABLE. A blinking cursor

15

seconds. Press carriage return to get

VCP power-up message which displays the following:

If

battery

will

• 110 table with the select code, ID number, and revision of each installed 110 card

• Pretest errors, if present

• CPU identification

• Amount

• Contents of selected registers

Table

of

memory installed

2-3

gives the ID number for each A-Series interface card.

Installation 2-17

Page 39

The following is an example YCP power-up message for a system with an

card at select code

27

and an

HP

12005B

ASIC card at select code

20

and designated as the

YCP interface:

HP

12009A HP-IB

Installed

ID Rev

004

000

(Pretest

HP

1000

A-Series

A990

CPU

P

00000

A

000002

VCP>

Note that the A-Register contains the number

contains the revision

the

A990 firmware EPROM.

2.

Boot up the RTE-A Primary System using the instructions given in the

System Software Installation Manual,

I/O

Cards

SC

0 27

1 20

Error

M

Message)

8192KB

00000

B

004022

of

<-

VCP

(this message appears only if an error was detected;

3,

Y

000000

cards found by YCP; the B-Register

?

for

MEMORY

T

Help

000000

X

refer to Chapter

RW

000000

000003

of

I/O

the YCP code; and the X-Register contains the revision number of

part number

92077-90038.

Verifying Computer Operations

A990

Self-Test Programs)

E 0 o 0

RTE-A

Primary

You

can use the diagnostic programs supplied with the

5270

or later) to verify the installation and operation of your A990 CPU. Complete

HP

24612A Diagnostic Package (Revision

documentation is supplied with the package.

Primary System Backup

Use the appropriate backup utility to back up the Primary System. Refer to the

Manual,

part number

92077-90004.

RTE-A

Utilities

2-18 Installation

Page 40

Table 2-3. A-Series I/O Interface Card

10

Number Rev. Number Interface Card

10

Numbers

000 0

000

001

002

002

003

003 0

004 0

005

006

022

023

025

040

** **

044

060

061

102

102

102

102

102

102

102

106

115

126

141

143

177 7

HP 12005A*

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

HP

12005B

HP

12oo6A Parallel Interface Card

HP

12043A Multi-Use Programmable Serial Interface

HP

12092A Data Link Master Interface Card

HP12008A PROM I/O Card

HP

12155A A700 PROM Control Store Card

HP12009A HP-IB Interface Card

HP

12010A Breadboard Card

HP

12041B Multi-Use 8-Channel MUX Interface Card

HP

37222A Integral MODEM Interface Card

HP

12022A

HP

12065A

HP

12060A*/B

HP

12061A

HP

12062A

HP

12153A A700 Writable Control Store Card

HP

12205A A900 Writable Control Store Card

HP

12007B HDLC (Modem) Card

HP

12044A HDLC (Direct Connect) Card

HP

12042A

HP

12042B Programmable

HP

12073A

HP

12075A

HP

12082A DS/1000-IV Direct Connect Interface to

HP

12040B* /C/D 8-Channel Multiplexer Interface Card

HP

12016A

HP 12076A

HP

12063A

HP

12072A

HP

12100A

Asynchronous

Asynchronous

Integrated Disk Interface Card

Color Video Interface Card

High

Level Analog Input Card

Analog Multiplexer Expansion Card

Digital-to-Analog Card

Programmable Serial Interface

DS/1000-IV Modem Interface to

LAP-B Network

SCSI Interface Card

LAN

Interface Card

161N/160UT Isolated Digital Card

Data Link

A400 Processor Card On-Board

Interface Card

Interface Card

S~rial

Interface (Direct Connect) Card

Interface Card

Slave Interface Card

(Modem) Card

HP

3000

HP

3000

I/O (not an I/O card)

Discontinued product; shown for reference

*

**

Has no I/O master or

ID

number.

only.

Installation 2-19

Page 41

Repackaging for Shipment

If

you need to return any part or all of your computer or system to the factory, you can use the

same shipping materials originally used

from Hewlett-Packard

available materials.

Sales and Service Offices. Alternatively, you can use commercially

Shipment Using Original Packaging

When returning an item in its original or factory supplied packaging, use the following procedure:

1.

Attach a tag to the item clearly describing the type of service needed or

returning the item; include the item's model number and serial number on the tag.

2.

Mark the container "Fragile" to assure special handling (although this

proper packaging).

3.

In correspondence dealing with an item, please refer to it by both model and serial numbers.

Shipment Using New Packaging

by

the factory or you can obtain new shipping packages

why

you are

is

no substitute for

The following instructions should be used

commercially available materials:

1.

Wrap the computer in Aircap film or foam.

Hewlett-Packard, first attach a tag to the computer with your return address and indicate the

type of service required. Include the computer model number and full serial number.

2.

Use a strong shipping container large enough to hold the item and enough shock absorbing

material to cushion the item and prevent movement inside the container. A double-wall

carton made of

3.

Seal the shipping container securely and mark it "Fragile".

4.

In any correspondence dealing with the computer, be sure you refer to it by its model

number and serial number.

2.41

MPa (350-psi) test material

as

a guide when packaging the computer with

If

shipping the computer back to

is

adequate.

2-20

Installation

Page 42

3

Service

This chapter describes periodic maintenance procedures, troubleshooting information for

level,

isolating malfunctions to the assembly

computer assemblies.

Electrical Safety

Before proceeding with any maintenance or service on the computer which requires physical

contact with electrical or electronic

safety precautions are followed to protect against shock. Heed all

equipment and in this manual. All service work must be done by qualified personnel.

components, be sure that either power

and procedures for removing and replacing various

is

removed or that

"WARNING" signs on

Periodic Maintenance

Warning

G

Maintenance schedules should be set up according to the quality of the environment in which the

computer

periodic maintenance than one that

or other particulate matter. Consult the service manuals for any peripherals for the procedures

required for a preventive maintenance schedule.

Perform the following steps as often as necessary:

1.

2.

3.

is

Clean the cabinet exterior and interior.

Check the ventilating fans for proper operation. The fans have sealed bearings and need no

lubrication.

Clean the computer air filter by washing it in a solution of warm water and mild soap. Dry

the filter thoroughly before you re-install it.

High voltages are present

nect power before performing any maintenance. Failure to do this

in

could result

operating. A computer in a clean and air-conditioned atmosphere requires less

serious injury.

is

located in an atmosphere laden with dust, smoke, moisture,

in