Hotpoint Ariston AQCF851BUEU, AQCF851BUFR, AQCF851BUIT, AQCF852BIEU, AQCF852BUEU Service Information

...Page 1

Indesit Company UK Ltd

© 2008 Reg. Office: Peterborough PE2 9JB Registered in London: 106725

Service

Information

Aqualtis

8 Kg

"B Energy"

CONDENSER

ELECTRONIC

TUMBLE DRYER

Models Covered

AQCF851BUEU 61513

AQCF851BUFR 61408

AQCF851BUIT 61375

AQCF852BIEU 61523

AQCF852BUEU 61526

AQCF852BUSK 61527

5407471 Issue 1 Nov. 2008

Page 2

2 of 33

Service Manual UK

Indesit Company

English

SAFETY NOTES & GENERAL SERVICING ADVICE

1. This manual is NOT intended as a comprehensive repair/maintenance guide to the appliance.

2. It should ONLY be used by suitably qualified persons having technical competence applicable

product knowledge and suitable tools and test equipment.

3. Servicing of electrical appliances must be undertaken with the appliance disconnected (unplugged)

from the electrical supply.

4. Servicing must be preceded by Earth Continuity and Insulation Resistance checks.

5. Personal safety precautions must be taken to protect against accidents caused by sharp edges on

metal and plastic parts.

6. After Servicing the appliance must be rechecked for Electrical Safety. In the case of appliances which

are connected to a water supply (i.e.: Washing Machines, Dishwashers & Food Centres etc.) checks

must be made for leaks from seals gaskets and pipe work and rectification carried out where

necessary.

7. It can be dangerous to attempt ‘DIY’ repairs / maintenance on complex equipment and the Company

recommends that any problem with the appliance is referred to its own Service Organisation.

8. Whilst the Company has endeavoured to ensure the accuracy of the data within this publication they

cannot hold themselves responsible for any inconvenience or loss occasioned by any error within.

INDEX

Safety Notes & General Servicing Advice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Dryer Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 5

Console Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 9

Component Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 - 11

‘B’ Energy Rating - Additional Components . . . . . . . . . . . . . . . . . . . . . . . . . . .12 - 13

Programme Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 - 16

Control Board Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 - 18

Dismantling Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19 - 23

Fault Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24 - 26

Auto Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

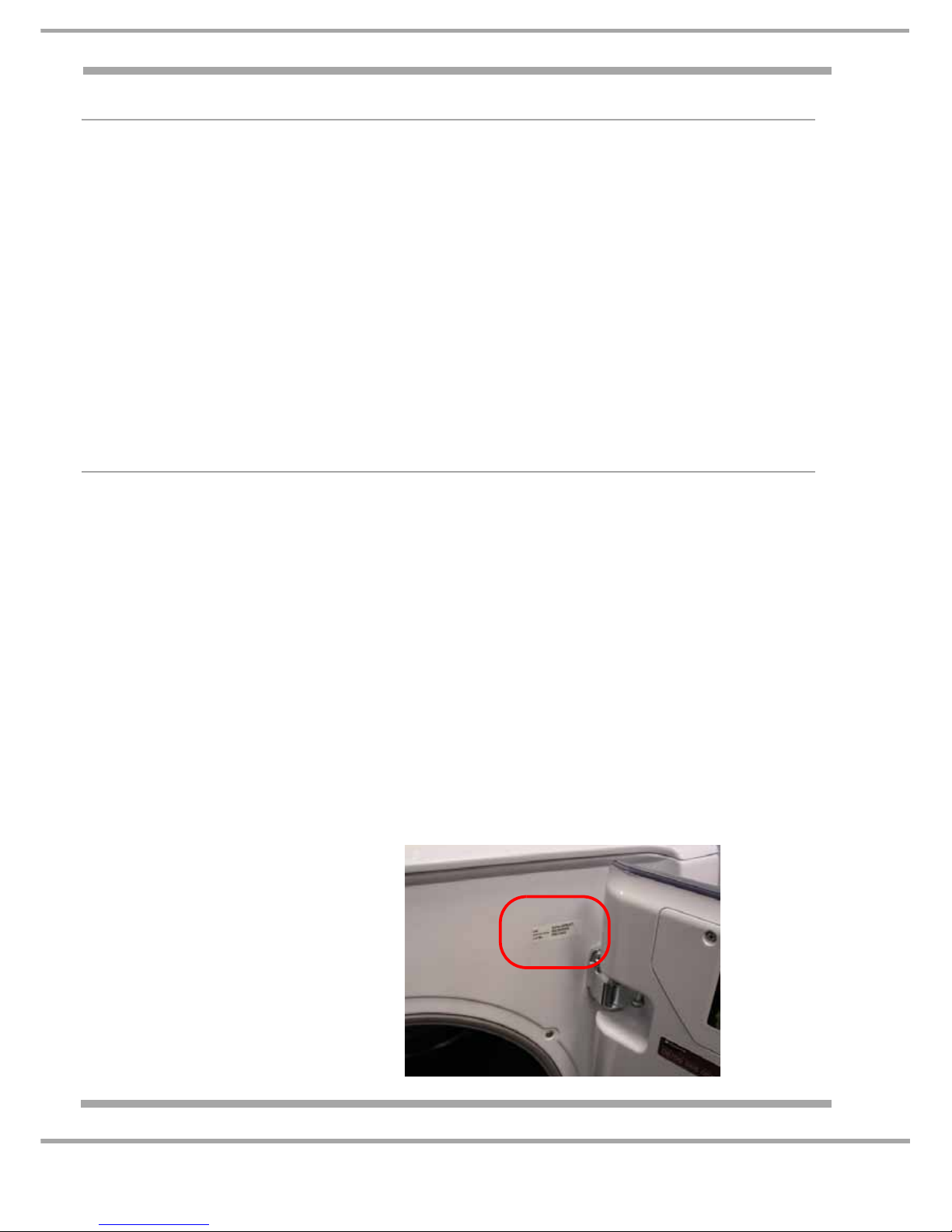

Serial Number Location

The serial number is located on the front

panel behind the door - open the door to

see it.

Page 3

3 of 33

Indesit Company

Service Manual UK English

TECHNICAL SPECIFICATIONS

First Production October 2008

General Model Colour Commercial Code

AQCF851BUEU Silver 61513

AQCF851BUFR Silver 61408

AQCF851BUIT Silver 61375

AQCF852BIEU White 61523

AQCF852BUEU Silver 61526

AQCF852BUSK Silver 61527

Features Electronically controlled tumble dryer comprising of an interface module

fitted into the door and a control module mounted on the plinth,

connected by a serial link.

Country of Origin Great Britain

Dimensions

Height 850 mm

Width 595 mm

Depth 584 mm

Weight 41 kg (Packed)

Energy Class B

Noise Level 65 dBA approximately

Drum Volume 112 litres

Drying Load Dry weight maximum 8 kg

Programmes 16

Drying Sensing Levels Up to 5 depending on programme selected.

Door Operation Lever operated door catch

Heater 2050W @ 230V

Electronic Platform EVO2

Heater Controls Variable using electronic control and thermistors

Safety Thermostats Cycling Thermostat: 106°C

One Shot Thermostat: 143°C (White Spot)

Rear Thermistor) 25°C = 400 KΩ to 540 KΩ

100°C = 15 KΩ to 17 KΩ

Front Thermistor 25°C = 400 KΩ to 540 KΩ

100°C = 15 KΩ to 17 KΩ

Motor Type 350 Single phase capacitor run 2 pole induction motor - 2800 rpm

Capacitor 8.5 uF

Page 4

4 of 33

Service Manual UK

Indesit Company

English

DRYER FUNCTION

Drying Overview

These models are freestanding tumble dryers with a full width metal door.

The drum is capable of accepting a maximum 8 kg lo ad of damp clothi ng. The drum is su pported a t

the front by 2 wheels mounted on the front air duct and a single bearing at the rear located in the

rear panel. A shaft fixed to the rear of the drum runs in the rear bearing. The drum is driven by a belt

which passes around its periphery and onto the shaft of a motor secured to the base of the dryer.

The belt is tensioned by a pulley mounted to the motor.

The motor also drives two impellers (rotors), fixed to each end of its shaft. The front impeller draws

cold air into the machine, while the rear impeller recirculates drying air.

The addition of heat to the recirculating air is provided by a heating unit attached to the rear panel,

enabling the air to hold moisture when in contact with the wet load , thus causing it to dry. As the warm

recirculating air passes through the drum, it collects lint as well as moisture. To prevent the lint from

blocking the heat exchanger (condenser), the air is passed through a filter located in the front air

duct.

The filter unit is positioned so as to be easily removable for cleaning by the user. After passing

through the filter, the circulating air is ducted through passageways in a heat exchanger (condenser)

located in a housing on the base of the dryer.

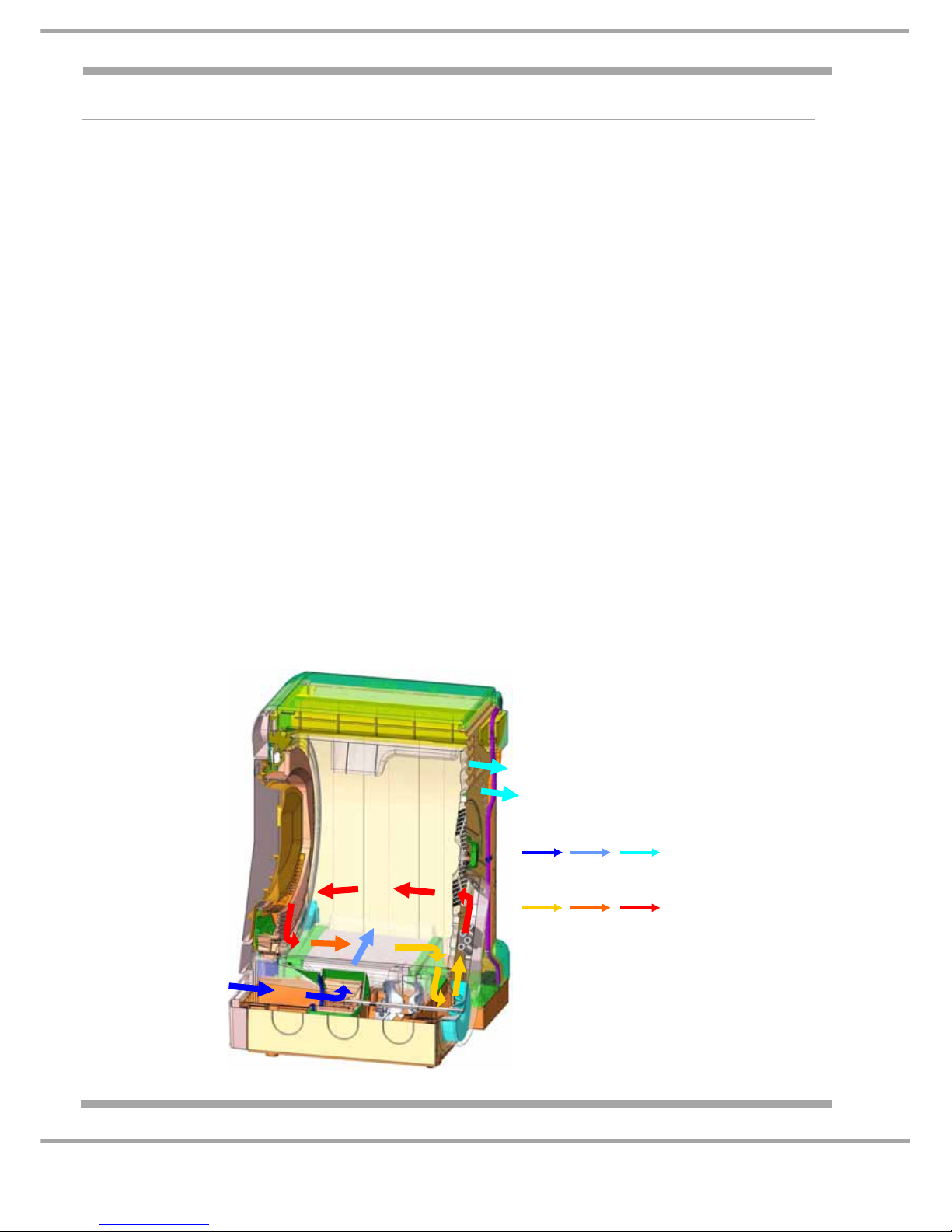

Cold air is drawn into the machine and flows across the heat exchanger passageways. This cold air

is not mixed with the warm, damp recirculating air. See the condenser airflow picture below.

This has the effect of reducing the circulating air temperature, causing it to give up its moisture.

(Cold air holds less moisture than hot air.) The now warm cooling air is exhausted through slots in

the rear of the dryer.

The moisture removed from the recircul ating air is pumped to a r emovable container moun ted in the

left hand side of the console. The user c an easily withdraw the co ntainer to d ispose of the co llected

condensed water. There is no requirement for venting to atmosphere on this dryer.

Cooling Air Circuit (open to atmosphere)

Recirculating Air Circuit (sealed)

CONDENSER DRYER

AIR FLOW

Page 5

5 of 33

Indesit Company

Service Manual UK English

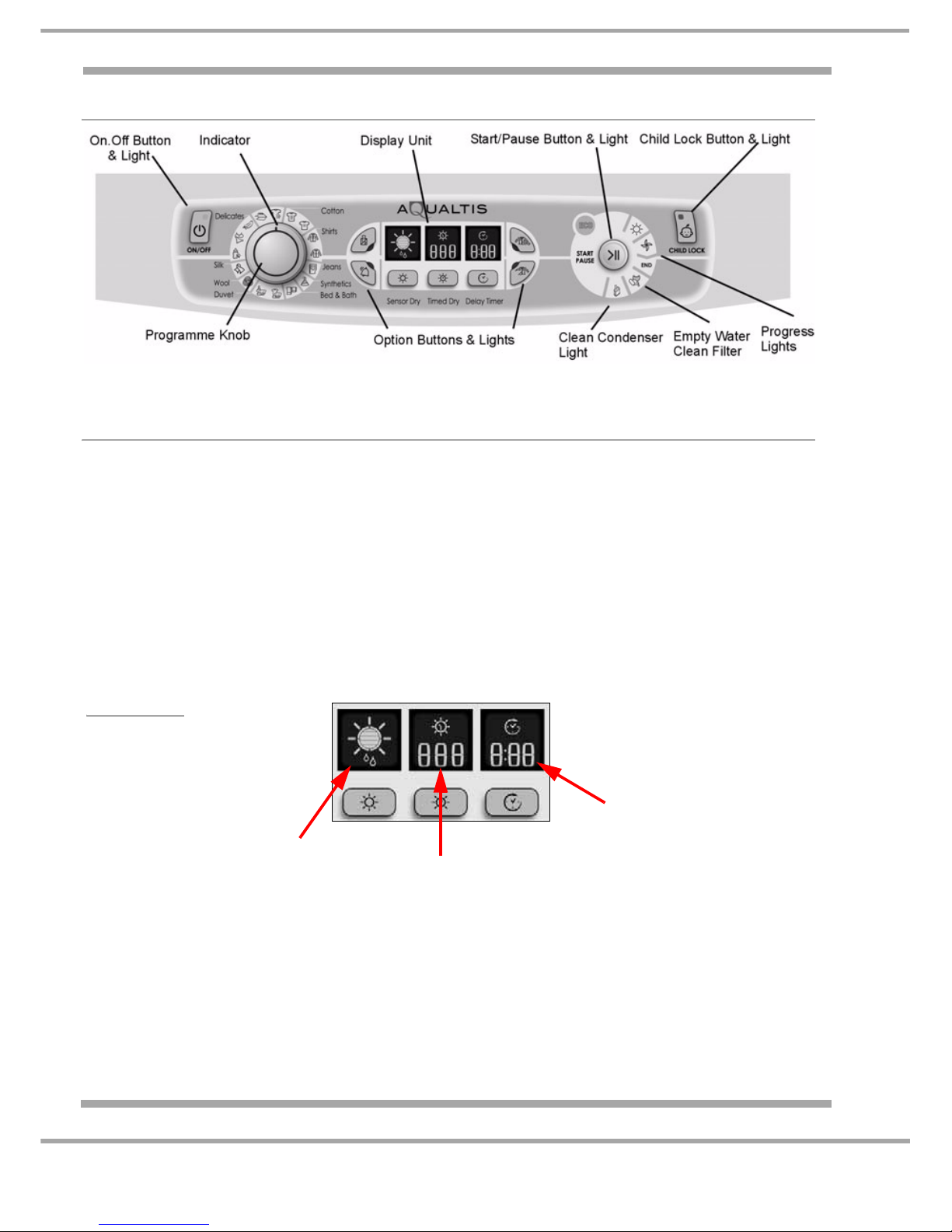

Controls Overview

The user controls consist of an Digit display, programme selection buttons, option buttons;

Start/Pause button and an On/Off button.

The control system consists of a control module, 2 thermistors and a conductivity sensor.

The conductivity sensor is mounted in the front air duct. A single wire connects the sensor to the

control module. The thermistors and conductivity sensor sends values back to the control module.

The control module then determines the programme duration and dryness of the load to set values

for a particular programme held within the control module software.

The control module is located behind the right hand side panel and there is a service port behind the

plinth cover that allows attachment of a computer, Smart Card Reader or Handheld Device to

programme the Control Module.

The control module can be programmed with the relevant settings file if the module is replaced, the

eeprom file becomes corrupted or if an updated file becomes available.

Each of the sensing programmes has a maximum time of 240 minutes.

Once the Automatic cycle has started, the machine’s sensors, (front and rear thermistors and the

conductivity sensor) continually monitor the dampness of the drying clothes. Once a final dry time

has been determined, the display will update.

If the display counts down to 10 minutes and the clothes are not at the required dryness level, the

display will hold at 10 minutes, depending on the programme in progress and the material being

dried, the dryer will either wait until the correct dryness level is reached and move to the cool down

period, or wait until the machines sensors are able to recalculate the dryness time and the display

will update accordingly.

If, after the maximum programme time of 240 minutes, the clothes are still not dry, the programme

advances to cool tumble and completes the programme. No fault is indicated if this occurs.

The module also controls the heater. This has an upper and lower element. The lower (static)

element is permanently energised (except in cool tumble) and the upper element (dynamic) is cycled

on and off by the control module during a programme to maintain the correct temperature within the

drum for the programme selected.

If the user turns off the power or disconnects the mains cable or there is a power cut, the dryer will

remember its last settings and resume the programme when the start button is pressed.

The start of a programme can be delayed up to a maximum of 18 hours programmed in 1 hour steps.

Pre-crease care (see page 8) can only be selected if a timed delay has been selected; this option

tumbles the clothes for 3 seconds every 30 minutes for the duration of the time delay.

If selected, the Post crease care option (see page 8) tumbles the clothes after the programme has

finished for 3 seconds every 4 minutes up to a maximum duration of 10 hours.

In the event of a controls or thermistor failur e, a one-shot cut-out thermostat is fitted as safety device.

Page 6

6 of 33

Service Manual UK

Indesit Company

English

CONSOLE FUNCTIONS

Option Buttons

ON OFF BUTTON and LIGHT

Push to switch the dryer On and Off.

If the button glows the dryer is turned on and either running or waiting to be started.

PROGRAMME KNOB AND INDICATOR.

Used to select the required programme option.

16 timed auto and special programmes are available.

Consult the programme chart on pages 14 and 15, to see Programme descriptions.

Display

Indicates Current

Dryness Level

Sensor cycles only

(See Sensing Levels)

Active. Auto Cycles

only

Indicates Time Set

Active. Manual Time

Cycles Only

Countdown Timer

Gives Estimated time to

end of delay or cycle

Displays during delay

start, auto, special and

manual programmes.

Page 7

7 of 33

Indesit Company

Service Manual UK English

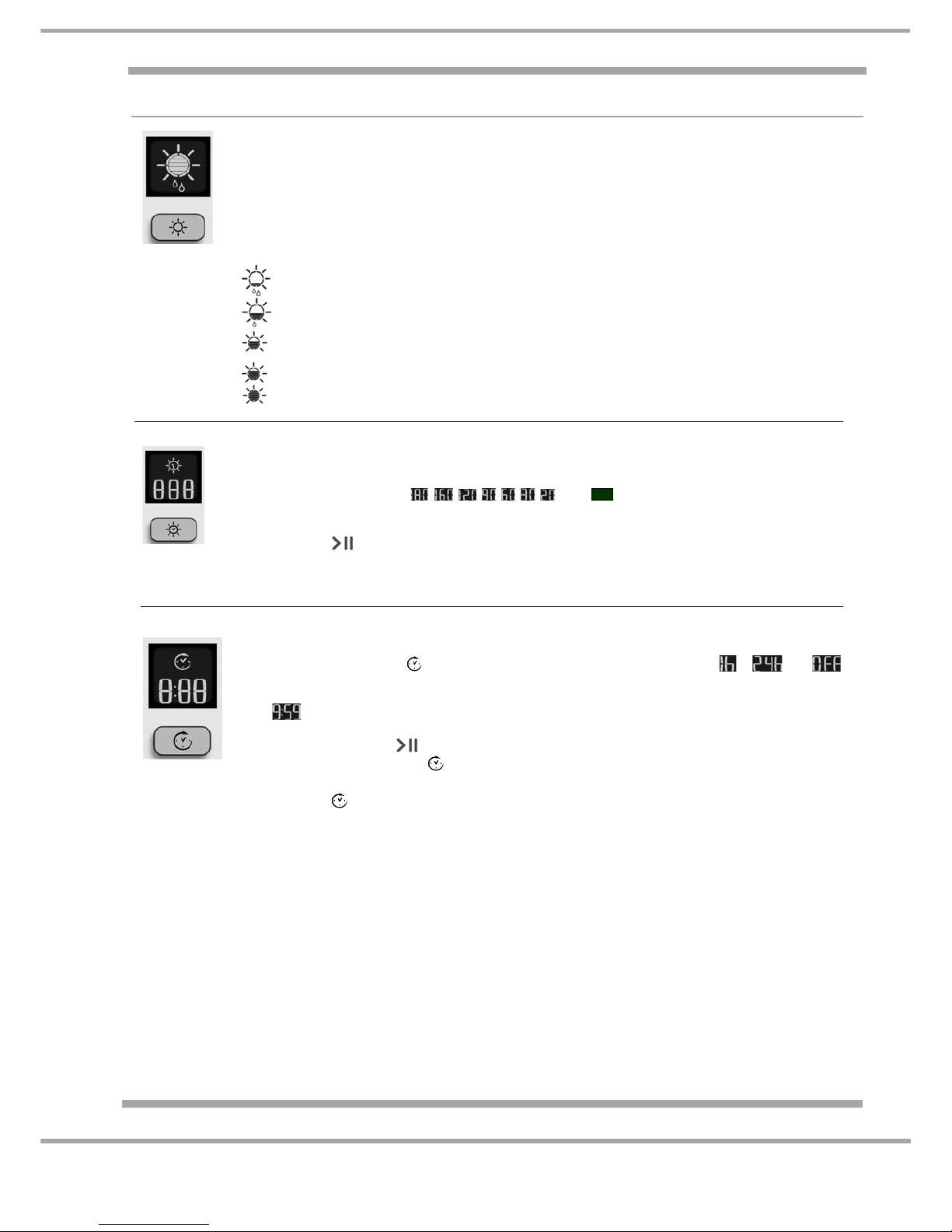

Display Information

Note:

During Sensor Cycles the Centre Timed display screen is blank

During Timed Cycles the left Sensor screen is blank

During Special cycles only the left Countdown screen is on and illuminated.

Sensing Levels

After selecting a programme that has a Sensing Dry Option, press and release the button until the

required dryness sensing level is displayed. If the sensing option is not available the display will ash

and the buzzer beeps three times.

Note: ‘Cottons - High Heat’ and ‘Jeans’ programmes are the only programmes which have all ve

dryness level options - all other programmes have only 4 options.

Dryness levels available

Damp Dry

: Dries your items ready to be ironed using a machine or rotary ironer.

Iron Dry

: Dries you items ready to be ironed with a hand iron.

Hanger Dry: Dries you clothes ready to be hanged for nal drying; Use this program if

you do not need the items to be fully dry as it uses less Energy.

Cupboard Dry

: Dries your items ready to be put away.

Ready to Wear / Extra Dry

: Dries your clothes ready to be worn.

Timed Dry

After selecting a Programme that has aTimed Dry Option, press the Timed Button and the displaywill

Note: Timed Dry is only available on the following programmes:

Cottons - High Heat, Cottons - Low Heat, Shirts - High Heat, Shirts - Low Heat, Synthetics, Delicates.

reduce the selected time each time you press and release this button (see Start and Programmes).

Each press decreases the set time

, , , , , , , then and then repeats.

If the Timer Dry option is not available the display will ash and the buzzer beeps three times.

The selected time remainsdisplayed after the programme starts and cannot be changed after the after the

Start/Pause Button

is Pressed.

Delay Timer

After selecting a Programme that has a Delay Timer Option a delay start time can be selected.

Each press of the Delay button

advances the delay setting in 1 hour Increments from to then

and then after ve seconds cancels the delay.

For delays of 10 hours or more the display counts down the time in hours for rst ten hours, then the display

shows

and then counts down in minutes. For delays less then 9 hours or less the display shows hours

and minutes and then count down in minutes for all of the delay.

After the Start/Pause Button

is pressed the time cannot be changed.

When the delay period nished the

symbol is o and the Time to End is displayed

Time to End

If the delay icon

is o the time displayed is the Time to End of the programme running.

When timed programmes are selected the time displayed throughout the cycle is the actual time

remaining.

When an Automatic programme is selected the time displayed is an estimate of the time remaining.

When the programme is selected the display shows the time required to dry a full load, after around 10

minutes the controller calculates a better estimate of the cycle time

Thetimetoendisdisplayedinhoursand minutes and counts down each minute.

The colons between the hours and minutes display ashes to show that the time is counting down.

The Display also shows if there is a problem with your dryer, if this occurs the display will show F

followed by a fault code number, the four option lights and the pause light will also ash Orange.

Page 8

8 of 33

Service Manual UK

Indesit Company

English

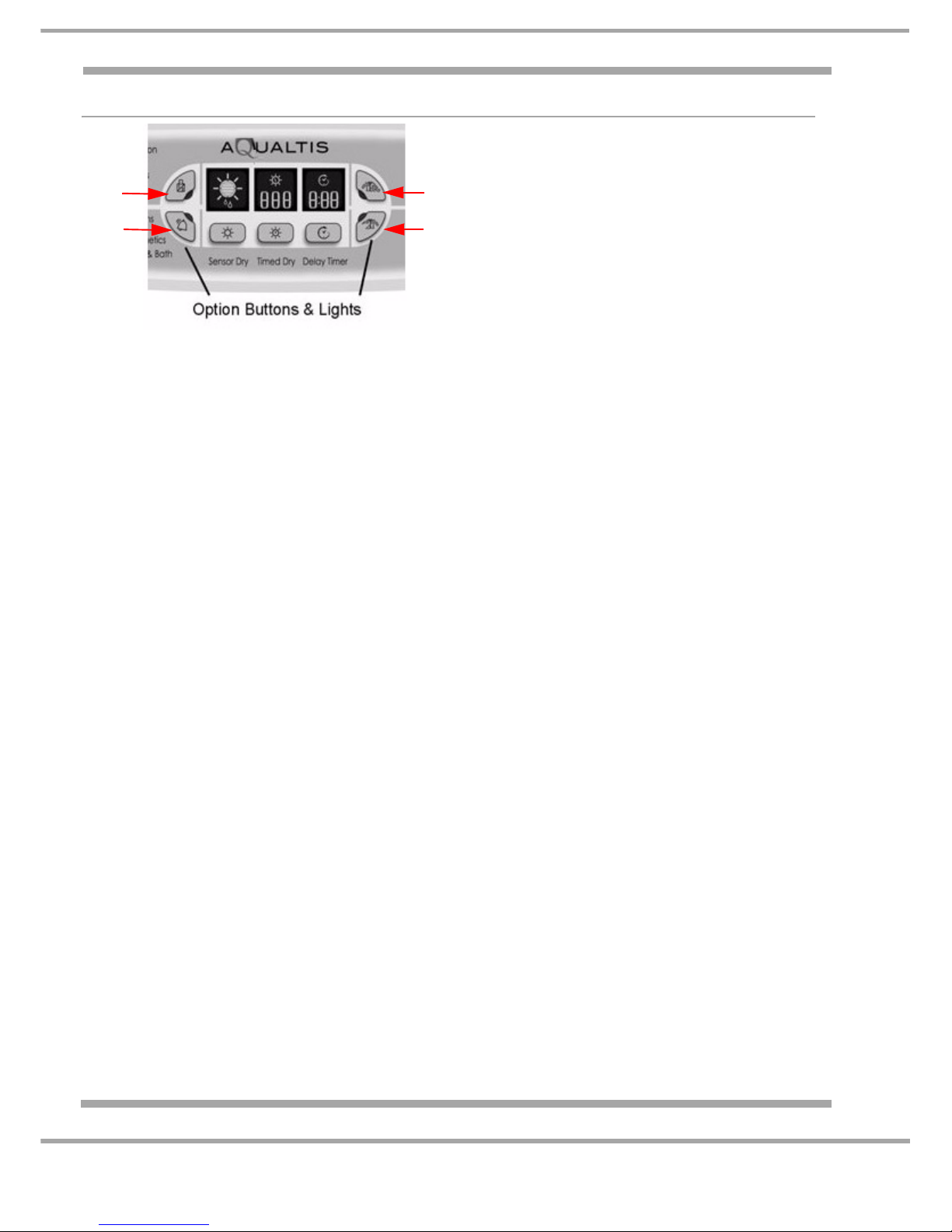

OPTION BUTTONS

1. Mini Load

Should be selected if between 1 & 2 kg of clothes are to be dried. The Time to END display is

adjusted to give a more accurate Cycle Time to end estimation time.

2. Alarm

If selected, the buzzer will sound at the end of the cycle. Beeps 3 times when the cycle finishes.

3. Pre-Crease Care

Option can be selected if the Delay Start Option has been selected; the clothes are tumbled

occasionally during the Delay period to help prevent creases developing.

- 3 secs Clockwise

- 30 min Pause

- 3 secs Anti -Clockwise

- 30 Pause--- continuously until programme starts.

4. Post Crease Care

Can be selected, if the clothes will not be removed as soon as the cycle is finished.

This option occasionally tumbles the clothes to prevent creases developing, while the clothes are in

the drum when the cycle is finished.

- 3 secs clockwise

- 237 secs Pause

- 3 secs anti clockwise

- 237secs pause ……continuously until the clothes are removed.

This option will run for a maximum of 10 hours.

1.

2.

3.

4.

Page 9

9 of 33

Indesit Company

Service Manual UK English

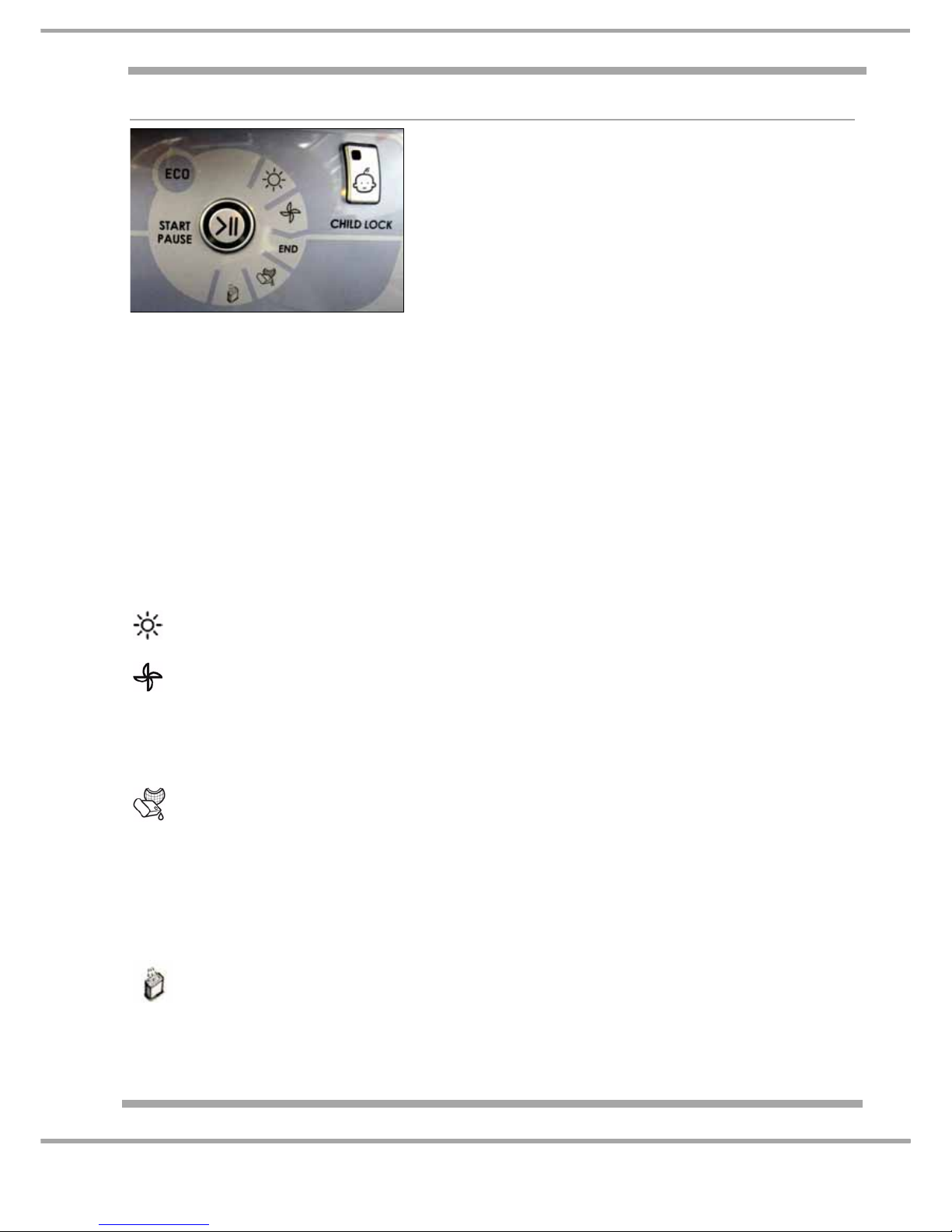

Progress and Warning Lamps

ECO Led

The Eco LED will illuminate when the user adjusts the knob/option settings, which involve an

energy reduction, from the default settings.

Auto Cycles - If the sensing level is reduced. (Hanger, iron or damp dry)

Timed Cycles - If the time is adjusted to 120 minutes or lower.

Child Lock (Button)

To enable the Child Lock function, press and hold the "Child Lock" button until the Button Led

illuminates. All the controls on the dryer are now disabled.

If the selector is turned or an Option is pressed the Child Lock button will flash and the machine will

bleep, to remind the customer that the Child Lock is active.

To remove the controls child lock, press and hold the child lock button and until the button lamp

goes out.

Drying Led

Is illuminated when the machine is drying.

Cool Tumble

Is illuminated, when the dryer is on a cycle, and the heater element is off, this would be the

cool down period at the end of the cycle.

End

Is illuminated when the programme has finished its cycle.

Empty Water/ Clean Filter

Is illuminated (permanently "on"), at the end of every cycle as a reminder to the customer to

empty the water container and to clean the filter after every use.

If the Empty Water / Clean Filter Led illuminates during a cycle, (H2) woul d also be shown in

the display. The machine has sensed the water container is full, after approximately

1 minute the heater is turned off and continues for 10 minutes with cool air only, before

displaying the fault (H2) and LED. To continue the cycle, empty the container, push the

Start/Pause button and the machine will continue.

Clean Condenser

Is illuminated every 25 cycles to remind the customer the condenser should be regularly

removed and cleaned. The Clean Condenser Warning is only a reminder and is not

connected to any sensing device-It does not indicate the condition of the condenser.

Page 10

10 of 33

Service Manual UK

Indesit Company

English

COMPONENT DESCRIPTION

Door

The Aqualtis Tumble Dryer door, holds the customer interface controls and the water container

handle is only visible when the door is opened.

Filter

Comprises of a plastic mesh moulded into its housing, which slides into the front air duct.

Control Module

This is an electronic device that monitors and controls all devices within the appliance. It is located

behind the right-hand Side Panel.

A production Control Module is pre-programmed at the factory.

Drum

The drum comprises of a zinc coated front and rear body and two removable plas tic lifters. The rear

of the drum is perforated to allow the passage of air. Fixed to the rear pressing is a support shaft

which runs in a bearing located in the rear panel of the dryer.

A drive pin and collar on the drum shaft prevents forward thrust during use. The front lock seam of

the drum rotates on bearing pads.

Note: Galvanised and Stainless steel drums are used in production, depending on the model of the

dryer.

Door Switch

A single unit comprising two single microswitches, fitted to th e front panel of the

dryer.

- One microswitch signals to the module whether the door is opened or clos ed.

- One microswitch disconnects supply to the motor whenev er the d oor is op en.

Door Handle - Pull to Open

Condenser

location

Page 11

11 of 33

Indesit Company

Service Manual UK English

One-Shot (Safety) Thermostat (White Spot)

This device is a disc type thermostat set to operate

at 143°C. It is used as a safety device.

It is positioned above the element. If this device fails

it cannot be reset.

Note: The one-shot (safety) thermostat is wired

in the control module Neutral circuit.

If the one-shot fails open-circuit, the dryer will be

DEAD. No fault code will display.

Cycling Thermostat

The cycling thermostat is mounted adjacent to the one-shot (safety) and is designed to open at

106°C. It limits the temperature of the heat entering the drum.

Heater Unit

Consists of four coils wound on mica supports, which are supported by mica end insulators. These end

insulators fit into a steel pressing that also locates the rear thermal controls. This is fixed by screws to the

rear cover. This pressing also forms air guides. The heater elements, thermal controls, thermistors and

rear cover are supplied as an assembly and has a five-way connector provided to interface with the

electronic module. The heater has an upper and lower heater. The lower (static) heater is permanently

energised and the upper heater (dynamic) is cycled on and off by the control module during a programme

to maintain the correct temperature for the programme selected.

Pump & Float Switch

Mounted on the bottom right hand side of the rear panel, condensate water from the condenser

chamber is pumped via an external hose to the water container situated behind the console.

The pump runs continually throughout the programme.

Motor

A two pole P.S.C running at 2800 rpm with the impeller fitted to the rear end of the shaft and the drive

belt running directly in grooves in the front end of the shaft. It is protected from overload by a

self-resetting internal cut-out that interrupts the electrical supply to the windings.

It is used together with a capacitor that is mounted on the base of the dryer.

Drum Rear Seal

This unit comprises of a ring of foam with a webbing bearing face. Lubrication is applied to the drum

where the webbing surface runs, to reduce noise and wear. The seal reduces air losses at the rear

of the drum. The joints in the foam are sealed with glue and the joints in the webbing are stitched to

further reduce air leakage.

Operation of the Float Switch:

After continuing to tumble and dry for a further

one minute, the dryer will turn off the heater and

cool tumble for a further

10 minutes - before displaying the Fault Code

H20, with the Start/Pause button flashing orange

and the Empty Water light flashing.

One-shot

Thermostat

Cycling

Thermostat

Rear (NTC)

Thermistor

Thermostat Location as seen inside heater cover

Page 12

12 of 33

Service Manual UK

Indesit Company

English

‘B’ Energy Rating - Additional Components Information

BASE Assembly

Aqualtis ‘B’ Energy Condenser Dryers have additional components to improve airflow efficiency.

continued on following page...

A) Base Cover

B) Motor Top Cover

C) Motor Cover Inner

D) Motor Cover Outer

E) Base Duct Lower

These covers are used to retain the heat

within the Drying System to increase the

Condenser efficiency.

E

B

C

D

A

Page 13

13 of 33

Indesit Company

Service Manual UK English

HEATER COVER ASSEMBLY

A hole in the bottom of the Heater Cover diverts condensate onto the wick (sponge).

Any condensate will be absorbed into the wick and evaporated away by the heat of the cover.

Back Panel

Wick (sponge)

Inside view of

Drain

Wick

Absorbent

rear cover:

Hole

Page 14

14 of 33

Service Manual UK

Indesit Company

English

PROGRAMME GUIDE

Programmes Table

! If the On/Off light is not lit; Press the On/Off Button

and then select programme.

Post Dry Programmes

Pro

gramme What it does How to set it Notes / Options available

Easy Iron

Brief programme

(approximately 10 minutes)

that softens fibres of clothing

that is ready for ironing.

1. Position the PROGRAMME knob on

.

2. Select Alarm Option if required

3. Press the Start Button.

! This is not a drying programme

(see previous page)

Options available

Alarm

AIRING

20-minute programme that

airs: your clothes with cool

air. Use also to cool warm

clothes.

1. Position the PROGRAMME knob on

.

2. Select Alarm Option if required

3. Press the Start Button

Alarm

Cottons

Programme What it does How to set it Notes / Options available

Cottons - High

Heat

Dries: your Cotton

clothes on High heat

1. Position the PROGRAMME knob on.

2. Choose Timed

or Automatic. option

If Timed Drying

see next page - Or

To change from default dryness setting

press and release Dryness Levels

button

until required level is displayed.

3. Select any Options if required.

4. Press the Start Button.

Alarm

, Delay Timer ,

Pre care

, Post care

Mini Load

Dryness options, Automatic

Damp Dry, Iron Dry

,

Hanger Dry,

Cupboard Dry, Extra Dry

Cottons - Low

Heat

Dries: your Cotton

clothes on Low heat

1. Position the PROGRAMME knob on.

2. Select a drying time, see Timed

next page

See Timed

next page

Shirts

Programme What it does How to set it Notes / Options available

Shirts - High

Heat

Dries: your Cotton

Shirts on High heat

1. Position the PROGRAMME knob on.

2. Choose Timed

or Automatic. option

If Timed Drying

see next page - Or

To change from default dryness setting

press and release Dryness Levels

button

until required level is displayed.

3. Select any Options if required.

4. Press the Start Button.

Alarm

, Delay Timer ,

Pre care

, Post care

Mini Load

Dryness options, Automatic

Iron Dry,Hanger Dry,

Cupboard Dry.

Shirts - Low

Heat

Dries: your Synthetic

Shirts on Low heat

1. Position the PROGRAMME knob on.

2. Choose Timed

or Automatic. option

If Timed Drying

see next page - Or

To change from default dryness setting

press and release Dryness Levels

button

until required level is displayed.

3. Select any Options if required.

4. Press the Start Button.

Alarm

, Delay Timer ,

Pre care

, Post care

Mini Load

Dryness options, Automatic

Iron Dry,Hanger Dry,

Cupboard Dry.

Programme What it does How to set it Notes / Options available

Jeans

Dries: your Cotton

clothes on High heat

1. Position the PROGRAMME knob on.

2. Select any Options if required.

3. Press the Start Button.

Alarm , Delay Timer ,

Pre care

, Post care

An Automatic Programme

Page 15

15 of 33

Indesit Company

Service Manual UK English

PROGRAMME GUIDE - continued

Programmes Table

Pro

g

ramme What it does How to set it Notes / Options available

Synthetics

Dries: your synthetics

clothes on High heat

1. Position the PROGRAMME knob on.

2. Choose Timed

or Automatic. option

If Timed Drying

see below - Or

To change from default dryness setting

press and release Dryness Levels

button

until required level is displayed..

3. Select any Options if required.

4. Press the Start Button.

Alarm

, Delay Timer ,

Pre care

, Post care

Mini Load

Dryness options,

Automatic

Damp Dry, Iron Dry

,

Hanger Dry, Cupboard Dry.

Bed & Bath

Dries your Towels and

bedding on High Heat

1. Position the PROGRAMME knob on

2. Select any Options if required.

3. Press the Start Button.

Alarm

, Delay Timer ,

Pre care

, Post care

x

An Automatic Programme

Duvet

Cotton

Dries your Duvet on

High Heat

1. Position the PROGRAMME knob on

2. Select any Options if required.

3. Press the Start Button.

Alarm

, Delay Timer ,

Pre care

, Post care

An Automatic Programme

Duvet

Synthetic

Dries your Duvet

bedding on Low Heat

1. Position the PROGRAMME knob on

2. Select any Options if required.

3. Press the Start Button.

Alarm

, Delay Timer ,

Pre care

, Post care

An Automatic Programme

Wool

Dries: your Woollen

clothes,

(see previous page)

1. Position the PROGRAMME knob on

.

2. Select Alarm Option if required.

3. Press the Start Button.

Alarm

x

An Automatic Programme

Silk

Dries your Silk items

on Low Heat

1. Position the PROGRAMME knob on

2. Select any Options if required.

3. Press the Start Button.

Alarm

, Delay Timer ,

Pre care

, Post care

An Automatic Programme

Baby Cycle

Dries your Baby

clothes on Low Heat

1. Position the PROGRAMME knob on

2. Select any Options if required.

3. Press the Start Button.

Alarm , Delay Timer ,

Pre care

, Post care

An Automatic Programme

Lingerie

Dries your Lingerie on

Low Heat

1. Position the PROGRAMME knob on

2. Select any Options if required.

3. Press the Start Button.

Alarm , Delay Timer ,

Pre care

, Post care

An Automatic Programme

Delicates

(e.g. Acrylics)

Dries: your clothes on

Low heat setting,

ready to be worn.

1. Position the PROGRAMME knob on

2. If Timed

Programme required (see Timed below)

Otherwise default is Automatic

3. Select any Options if required

4. Press the Start Button

Alarm

, Delay Timer ,

Pre care

, Post care

x

The default is Automatic

Timed

First select a programme

(see programmes table)

Programme What it does How to set it Notes / Options available

Timed Drying

(180, 160, 120,

90, 60, 30 or 20

minutes)

Always use timed drying for

loads less than 1kg or if you

prefer a different dryness

result.

The heat setting depends on

the Programme (material

option) selected;

1. Press and release the Timed Button until the display

shows the required selection. Each press decreases

time

, , , , , , then and

then repeats.

x

Delicates have maximum time of

x

After is displayed, Automatic option is

available if you change your mind.

2. Select any Options if required

3. Press the Start Button.

Options available

Alarm

, Delay Timer ,

Pre care

, Post care

Consult suggested drying times (see

Laundry)

The last 10 minutes of these

programmes is the cool tumble

phase.

Page 16

16 of 33

Service Manual UK

Indesit Company

English

SPECIAL PROGRAMMES

Notes

• Times shown above are for the dryest setting available for the programme concerned.

• All 5 Sensing Levels are not available on all Programmes.

• The Cool down period varies between 15 and 4 minutes depending on the cycle selected.

• Times are estimated for an average load. The actual duration will vary, depending on the size

and type of the load being dried.

• The display may show 10 minutes for an extended period if the clothes are not dry when the

cool down period is reached.

• The display may update its time to end during the cycle., if its sensors calculate either more or

less time is required to dry the clothes to the required dryness level.

• Loads using these programmes will usually be ready to use or wear, in some situations the

edges or seams may be slightly damp.

Symbol Programme Approx.Time/Heat Max. Weight Notes

Wool

Programme

60 minutes

High Heat

1 kg

(approx

3 sweaters

For Tumble dryer safe garments, with

symbol.

It is recommended garments re turned inside

out before drying.

Jeans 85 minutes

High Heat

3 kg

(approx.

4 pairs)

For garments made of Denim Cotton, turn

front pockets inside out. Garments with

embroidery or elasticated waistbands should

not be dried.

Shirts

High Heat

80 minutes

High Heat

3 kg

(approx.

10 shirts)

For Shirts made from cotton

Shirts

Low Heat

65 minutes

Low Heat

3 kg

(approx

14 shirts)

For Shirts made from synthetic materials, or

a mixture of natural and synthetic materials

such as Polyester and cotton

Silk 110 minutes

Low Heat

0.5kg For Delicate Silk.

Duvet Cotton 120 minutes

Low Heat

Single Duvet

Duvet

Synthetic

115 minutes

Low Heat

Single Duvet Loads using this programme will usually be

ready to use, the edges or seams may be

slightly damp.

Baby Cycle 120 minutes

Low Heat

2 kg For baby’s small items of clothing and

bedding made from Cotton and Chenille.

Lingerie 90 minutes

Low Heat

1 kg For very delicate lingerie including silk.

Buttons and hooks should be fastened

before drying.

Note: Low Heat. Heater Cycles to maintain

delicate temperature during cycle.

Page 17

17 of 33

Indesit Company

Service Manual UK English

CONTROLS BOARD PROGRAMMING for Modules with fixed EEProm

NOTE: This board does NOT have a physically replaceable EEProm.

Programming a Main Board

There are a number of ways the board can be programmed - some of which are not applicable to

certain markets.

Types of programming:

1. Handheld Terminal (Not UK)

2. Smart Reader & Smart Card - see photo below and following page.

Programming (using Handheld):

This machine can be programmed via Handheld, using:

1) a serial cable (photo 1), adapters connector (photo 2) and one of the 2 HW keys (see photo 3)

2) a Bluetooth HW key (photo 4)

Photo 1 Photo 2

Photo 3 Photo 4

Page 18

Indesit Company

18 of 33

Service Manual UK English

Programming using Smart Card Reader - Flowchart:

Page 19

19 of 33

Indesit Company

Service Manual UK English

DISMANTLING INSTRUCTIONS

SAFETY NOTES

1. ENSURE THAT THE MACHINE IS UNPLUGGED BEFORE DISMANTLING.

2. BEWARE OF SHARP EDGES ON METAL PANELS AND PRESSED PARTS.

A. Top Cover

1. Remove the 2 screws securing the top cover to the back panel.

2. Slide the top cover back and lift clear of the retainers.

B. Side Panels

1. Remove the top cover.

2. Remove the 4 screws securing the side panel to the rear panel and 1 screw securing the side

panel to the water container at the front of the dryer.

3. Pull the side panel backward to disenga ge from the lugs on the base panel.

C. Door Assembly

1. Remove the Top Cover (A)

2. Disconnect the lead to the Control Card. The connector is situated along the top front edge of

the right hand side panel. (Fig.1)

3. While holding the Door, remove 4 Torx T20 screws (2 per hinge) securing the Door hinges to

the cabinet. (Fig.2)

4. Carefully feed the loom from the Control Card through the Top Hinge access hole, while lifting

the door clear. (Fig.3).

5. It is important the hinge gasket is correctly located and fitted.

The cable tie must be tight and located exactly as shown below. Do NOT cut off the tail.

Fig.1

Fig.2

Fig.3

Gasket

Connector

Cable Tie

The cable tie MUST be located in

front of this raised edge

Page 20

20 of 33

Service Manual UK

Indesit Company

English

D. Control / Display Module Assembly

E. Door Seal

1. Remove the front Panel as in (G)

2. The seal can now be removed from the front panel.

Note: The seal is held in place by being compressed between the front air duct and front panel.

When re-fitting, fit the door seal to the front panel first, and then carefully locate the front panel in position

without disturbing the seal.

F. Belt

1. Remove Door assembly (C)

2. Place the door assembly on a

protected flat surface.

3. Remove the control module

cover 5 Torx T8 screws.

4. Disconnect the edge connector.

5. Release the 4 retaining lugs and

ease the control module away

from the door.

(The knobs, buttons etc. remain

fitted to the module.

Note: When refitting the control module you are advised to fit the

edge connector before clipping into position.

1. Remove the side panels as in (B).

2. Remove the cooling impeller cover using a small

blade screwdriver to lift the cover locking tabs.

3. Unclip & lift away the Motor Cover Top (see Fig 1)

4. Unclip & lift away the Outer Motor Cover (see Fig 2)

5. Remove the cooling impeller.

6. Remove the rear bearing as in (K).

7. Remove the heater unit as in (M).

8. Remove the recirculating impeller.

9. Remove the 3 hex head screws behind the

recirculating impeller securing the motor to rear of

the base moulding. This will release the belt

tension.

10. Rotate the motor towards the centre of the dryer to

disengage the belt from the jockey pulley.

11. Remove the 2 screws securing the rear panel to the

side strut.

12. Remove the 2 screws securing the water container

housing to the rear panel.

13. Remove the hose spigot from the container housing

by rotating 90°.

14. Pull the rear panel backward to disengage the drum

shaft from the drum rear panel and slide the belt

back to remove from the drum.

15. Replace in reverse order. When refitting the belt

first position the belt over the jockey wheel, refit as

in (O).

Fig 1

Unclip

and lift

clear

Fig 2

Release

clip and

lift away

Page 21

21 of 33

Indesit Company

Service Manual UK English

G. Front Panel

1. Remove the top cover

2. Remove the Door Assembly. (C)

3. Slide out the water container and lay to one side, then remove the 3 screws from the water

container front surround. Remove the surround

4. Remove the 5 screws around the door opening.

5. Remove the 3 screws along the bottom edge of the front panel.

Note that the bottom edge of the front panel is positioned behind the base.

6. Remove the 2 screws securing the front panel to the side strut at the top of the dryer.

7. Remove the door switch fixing screw and remove the door switch, noting the positions of the

connections.

Note: When refitting, fit the door switch before finally locating the front panel in position and be

careful not to trap any wiring between the front panel and air duct.

H) Front Air Duct, Dryer Sensor and Front Thermistor

1. Remove the front panel (G)

2. Ease the air duct forward, to remove the wiring from the guide clips, disconnect the dryer

sensor and front thermistor.

3. Lift the front air duct and ease past the front support wheels.

Note: When refitting, be careful to ease the air duct past the wheels and locate correctly into the

air duct.

J. Door Switch

1. Remove the top cover as in (A).

2. Remove front panel as in (G). It is not necessary to completely remove the front panel.

The front panel should just be leaned forward to access to the door switch.

3. Slide the switch to remove from the front panel.

4. Transfer wiring, noting connections.

Note. Be careful not to trap any wiring between the front panel and air duct.

K. Rear Bearing (Tear Drop shaped)

1. Remove the rear bearing cover.

2. Remove the drive pin and collar.

- Continued on following page.

I) Front Drum Support Wheels

1. Remove the Drum (O)

2. Unscrew the Bearing Support

Wheel fixing bolt.

Note: When first started, it is

normal for the drum to make a

noise for approx.

2 minutes, while the drum

support wheels centralise to the

load conditions.

Support

wheel

fixing bolt

Page 22

22 of 33

Indesit Company

Service Manual UK English

3. Remove the tear drop bearing fixing screw.

4. Slide the bearing off the drum shaft.

Note: Place the insulation pad before refitting the rear bearing cover.

L. Pump & Float Switch

1. Release the two pump/float assembly cover clips. See Photos 1 and 2.

2. Release the two clips at either end of the pump/float assembly and lift the unit clear.

Teardrop Bearing

fixing Screw

Bearing

Cover

Insulation Pad

Heater

Cover

Foam

Pad

Photo 1 Photo 2

Released Clips

Photo 3

Shown with

Cover removed

Page 23

23 of 33

Indesit Company

Service Manual UK English

M. Heating Assembly, Thermostats & Thermistor

1. Remove the right hand side panel.

2. Disconnect the wiring to the heater multi-pin connector.

3. Remove the 8 screws securing the heater unit to the rear panel.

4. Remove the 2 screws securing the heater to the rear cover.

Notes:

1. If replacing the thermostats both the cycling and one-shot thermostat MUST

be replaced should

either fail.

2. When refitting the heater cover, ensure the heater wiring is not trapped between the inner and

outer rear panels.

N. Motor

1. Follow steps 1 to 8 as in (F).

2. Remove motor covers as necessary.

3. Lift the motor clear from the base moulding.

4. Replace in reverse order first positioning the belt over the jockey wheel. It will be necessary to

use a pair of water pump pliers as a lever on the motor casing (as illustrated) to enable it to be

rotated under tension to line up the holes in rear moulding with the fixing holes on the motor

casing, refit the 4 hex. head screws.

O. Drum Assembly

1. Remove the top cover as in (A).

2. Remove the side panels as in (B).

3. Remove the console as in (C).

4. Slacken the belt as in (F) 1 to 8.

5. Remove the rear bearing as in (K).

6. Remove the front panel as in (G) leaving the air duct attached to the front panel if required.

7. The drum can now be removed from the rear panel.

8. Replace in reverse order. Note: When reassembling, a new drive pin must be fitted.

P. Rear Seal

1. Remove the drum as in (O).

2. Remove the rear seal and clean any remnants of the seal and adhesive from the inner face of

rear panel.

Rotate motor with water

pump pliers using

downward pressure to

tension belt and line up

motor fixings in rear

moulding

NOTE:

Ensure pliers do not

cause damage to

motor windings.

Page 24

24 of 33

Indesit Company

Service Manual UK English

FAULT CODES

In the event of a fault being detected by the

electronics, a code will appear in the LCD

display.

These codes are listed in the following table.

Please Note:

• Components with a low resistance to

Earth may cause erroneous faults or

loss of the display.

• Always check relevant wiring and

connector blocks security before considering replacing the modules.

• On ALL automatic programmes; there is no heat during the first 3 minutes.

The first 10 minutes of all automatic cycles is used to calculate the drying time.

• ONE-SHOT STAT OPERATION

The one-shot thermostat is wired into the Neutral supply of the module.

If the One-Shot Thermostat operates and opens the machine will be 'dead' and the display will

be blank. A fault code will NOT be displayed.

FAULT Cause Control Action

F01 The motor is running when

it should be off.

• Check if module connector J3 has shorted due to moisture.

• Replace module.

F02 Open circuit between

module & motor Common.

• Check security of module connector J3;

•

Test motor Common (TOC);

•

Check wiring between J3 and motor.

F03 Front thermistor open or

short circuit.

• Check security of module connector J12;

•

Test from connector pins (approximately 500 Kohms);

•

If open or short circuit, test thermistor and wiring between

thermistor and J12 to locate fault.

F04 Pump working when should

be off.

• Check security of module connector J5;

• Check connector for signs of shorting due to moisture;

• Replace module (F04 would normally be caused by a

faulty module).

F05 Pump is not working when

it should be on.

• Check security of module connector J5;

• Check connector for signs of shorting due to moisture;

• Replace module (F05 would normally be caused by a

faulty module).

F06 Not used.

----

Example of a Fault Code

All 4 options button lights and the Start/Pause

light will flash when a Fault Code is displayed.

Page 25

25 of 33

Indesit Company

Service Manual UK English

F07 Lower element failure

(or Heater Plug not

connected to module.)

• Check security of module connector J4;

• Test between pins 4 and 3 on J4 (approximately 48

Ohms);

• If open circuit, test lower element and wiring between J4

and the heater.

F08 Lower element is energised

when it should be off.

• Check security of module connector J4;

• Check connector for signs of shorting due to moisture;

• Test heater elements and wiring;

• Replace module (F08 would normally be caused by a

faulty module).

F09 Error Set Up File. Eeprom

is either not programmed

or is not functioning.

• If the module is a production board, replace the module;

• If the module has an Eeprom socket, check the eeprom is

correctly inserted and programmed.

F10

Open circuit in the heater

Common wiring.

• Check the wiring between the cycling stat and the

module;

•

Check wiring between module connector J4 and the

heater;

•

Test heater elements.

Note:- Frequent cycling stat operation can cause F10,

check filter and condenser for blockages. The module

checks and waits 3 times before displaying F10.

F11

Open circuit pump circuit.

• Test continuity of pump;

•

Check connector J5;

•

Check wiring between pump and module J5.

Note:- F11 is usually caused by a fault in the pump circu it

not the module. Auto cycle being used fault displays

within 1 minute Time and Wool cycles being used

fault displays at the end of the cycle.

F12

No communication

between display module

and control module.

• Check connector J9 on module;

•

Check wiring between module connector J9 and display;

•

Check display connector;

•

Replace module, display or wiring as required.

F13

Rear thermistor open or

short circuit.

• Check security of module connector J4;

•

Test from J4 connector pins 1 and 2 (approximately 500

Kohms);

•

If open circuit, test thermistor and wiring between

thermistor and J4 to locate fault.

F14

Upper element failure

• Check security of module connector J4;

•

Test between pins 4 and 5 on J4 (approximately 48

ohms);

•

If open circuit, test upper element and the wiring between

J4 and the heater.

Page 26

26 of 33

Indesit Company

Service Manual UK English

Servicing Notes

Drum Thumping Noise

When first started, it is normal for the drum to make a thumping noise for approximately 2 minutes,

while the drum support wheels centralise to the load conditions.

No Motor Action

When diagnosing the cause of no motor action, it should be remembered that one of the door

switches is in the motor supply.

F15

Upper element is on when

it should be off.

• Check security of module connector J4;

•

Check connector for signs of shorting due to moisture;

•

Check heater elements and wiring;

•

Replace module (F15 would normally be caused by a

faulty module).

F16

Not used.

F17

Master Relay contacts

welded closed.

• Replace module.

Operation of the float switch:

After continuing to tumble and dry for a further

one minute, the dryer will turn off the heater

and cool tumble for a further 10 minutes before displaying the Fault Code H20, the

Empty Water light flashing the Start/Pause

button flashing Orange.

Page 27

27 of 33

Indesit Company

Service Manual UK English

Auto Test

Required

• Hardware Key with a Test Switch (see photo.)

•

Test Lead approximately 1.5 metres long with a 270 KΩ resistor in series

with a conductive magnet at one end, and a ring connector at the other.

•

Amp meter

With the machine disconnected from the Electricity supply.

1. Attach the magnet end of the test lead on to the conductivity sensor.

2. Attach the other end of the test lead to an earth point. One of the rear

panel fixing screws is recommended.

3. Connect the Hardware key to the module. (access behind the plinth)

3a Select Cotton High Heat programme on selector.

4. START TEST

4a Plug the machine into the electricity supply, but do not switch on.

4b Switch the Test button on the Hardware key, To Test Position

The Display Shows Start Led green, Extra Dry bar, and 2:50

Drum Rotates anti clockwise. No Heat (approx. 1 amp)

4c Press the Post Crease care Button

The Display shows Start Led, Extra Dry bar, 2:50 and Post Care Led.

The Drum Stops

The Drum restarts rotating clockwise. Half heat. (approx. 5 or 6 amps)

4d Press the Alarm Button

The Display shows Start Led, Extra Dry bar, 2:50 Post Care and Alarm Led’s.

Drum continues to revolve clockwise. Full Heat. (approx 10 to 11amps)

5. Conductivity Sensor Test

Press the Post Crease Care button again

The Heater Switches Off

The Drum Stops.

The Display shows Extra Dry bar, 2:50 and Alarm Led.

> If the Conductivity Sensor is working correctly.

The Drum Starts to rotate anti clockwise.

The Display shows Start Led green, Extra Dry Bar, 2:50. in the display.

> If the Conductivity Sensor is Faulty.

The Display briefly flashes END and Start Led flashes green, plus Drying, Cool Tumble and Empty

Water/Clean filter Led’s come on.

The drum does not rotate.

Note: If a fault is detected the fault code will display in the display on the console and in the Test Plu g

screen.

Hardware Key

with Test switch

Page 28

Indesit Company

28 of 33

Service Manual UK English

WIRING DIAGRAM

MAIN MODULE

GREEN/YELLOW

ONE SHOT

CUT OUT

UPPER

HEATER

LOWER

ORANGE

54 3 2 1

BROWN

BROWN

ORANGE

BLACK

RED

FRONT NTC

J4

PB

PB

M

MOTOR WITH

PROTECTOR

RED

BLACK

CAPAC

-ITOR

J3

1

2

3

BLACK

RED

WHITE

WHITE

WHITE

J9

USER

INTERFACE

PCB

PUMP

FLOAT

SWITCH

2

1

NTC

HEATER & COVER ASSEMBLY

DOOR

SWITCH (1)

MAINS CONNECTION

WITH SUPPRES SION

L

N

E

J10

43

WHITE

J11

1

4.8

2

SENSING

STRIP

DRUM

ASSY

BLACK

F = FLAG RECEPTACLE

PB = PIGGY BACK

M = MALE TAB

= INSULATOR

= LOCKING RECEPTACLE

CYCLING

THERMOSTAT

B

R

O

W

N

M

M

BLUE

BLUE

BLUE

1

2

DOOR SWITCH (2)

R

E

D

R

E

D

R

E

D

R

E

D

W

H

I

T

E

B

L

U

E

B

L

U

E

B

L

U

E

B

L

U

E

B

L

U

E

GREY

GREY

WHITE

wd-160024345.ai

Page 29

29 of 33

Service Manual UK

Indesit Company

English

Page 30

30 of 33

Service Manual UK

Indesit Company

English

Loading...

Loading...