Hotpoint Ariston 7HPC 640 /HA, 7HPC 640 X/HA, 7HPC 640 GH/HA, 7HPC 631 /HA, 7HPC 631 X/HA User Manual

...Page 1

Operating Instructions

HOB

GB RS

Русский, 11English, 1

7HPC 640 /HA

7HPC 640 X/HA

7HPC 640 GH/HA

7HPC 631 /HA

7HPC 631 X/HA

7HPC 640N /HA

7HPC 640N GH/HA

7HPC 640N X /HA

PC 640N /HA

PC 640N X/HA

7HPC 640 T GH /HA

7HPC 640 T R /HA

7HPC 640 T X /HA

Contents

GB

Installation, 2-5

Positioning

Electrical connection

Gas connection

Data plate

Burner and nozzle specifications

Description of the appliance, 6

Overall view

Start-up and use, 7

Practical advice on using the burners

Precautions and tips, 8

General safety

Disposal

Maintenance and care, 9

Switching the appliance off

Cleaning the appliance

Gas tap maintenance

Troubleshooting, 10

1

Page 2

Installation

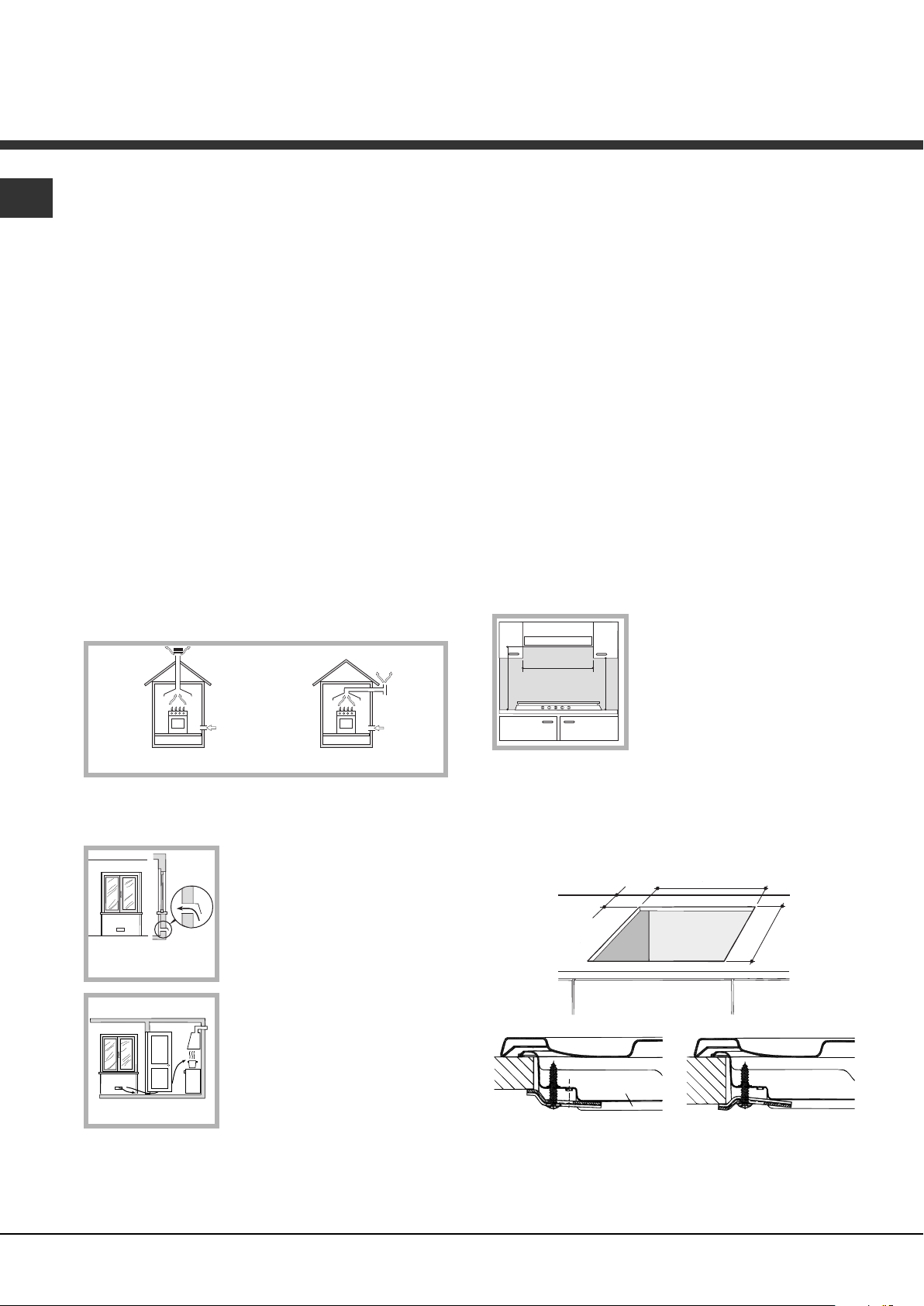

Enlarging the ventilation slot

between window and floor.

Adjacent

Room

Room to be

Vented

A

Examples of ventilation holes

for comburant air.

In a chimney stack or branched flue.

(exclusively for cooking appliances)

Directly to

the Outside

600mm min.

600mm min.

700mm min.

GB

! Before operating your new appliance please read this

instruction booklet carefully. It contains important information

for safe use, installation and care of the appliance.

! Please keep these operating instructions for future

reference. Pass them on to possible new owners of the

appliance.

Positioning

! Keep packaging material out of the reach of children. It

can become a choking or suffocation hazard (see

Precautions and tips).

! The appliance must be installed by a qualified professional

according to the instructions provided. Incorrect installation

may cause harm to people and animals or may damage

property.

! This unit may be installed and used only in permanently

ventilated rooms in accordance with British Standard Codes

Of Practice: B.S. 6172 / B.S. 5440, Par. 2 and B.S. 6891

Current Editions. The following requirements must be

observed:

• The room must be equipped with an air extraction system

that expels any combustion fumes. This may consist of a

hood or an electric fan that automatically starts each time

the appliance is switched on.

also be equipped with vents to allow gas to escape in the

event of a leak. As a result LPG cylinders, whether

partially or completely full, must not be installed or stored

in rooms or storage areas that are below ground level

(cellars, etc.). It is advisable to keep only the cylinder

being used in the room, positioned so that it is not

subject to heat produced by external sources (ovens,

fireplaces, stoves, etc. ) which could raise the

temperature of the cylinder above 50°C.

Fitting the appliance

Gas and mixed hobs are manufactured with type X degree

protection against overheating. The following precautions

must be taken when installing the hob:

• Kitchen cabinets adjacent to the appliance and taller

than the top of the hob must be at least 600 mm from the

edge of the hob.

• Hoods must be installed according to their relative

installation instruction manuals and at a minimum

distance of 650 mm from the hob.

• Place the wall cabinets adjacent to the hood at a

minimum height of 420 mm from the hob (see figure).

If the hob is installed beneath a

wall cabinet, the latter must be

situated at a minimum of 700 mm

above the hob (see figure).

• The room must also allow proper air circulation, as air is

needed for combustion to occur normally. The flow of air

3

must not be less than 2 m

/h per kW of installed power.

The air circulation system may

take air directly from the outside

by means of a pipe with an inner

cross section of at least 100 cm

the opening must not be

vulnerable to any type of

blockages.

The system can also provide the

air needed for combustion

indirectly, i.e. from adjacent rooms

fitted with air circulation tubes as

described above. However, these

rooms must not be communal

rooms, bedrooms or rooms that

may present a fire hazard.

• Liquid petroleum gas sinks to the floor as it is heavier

than air. Therefore, rooms containing LPG cylinders must

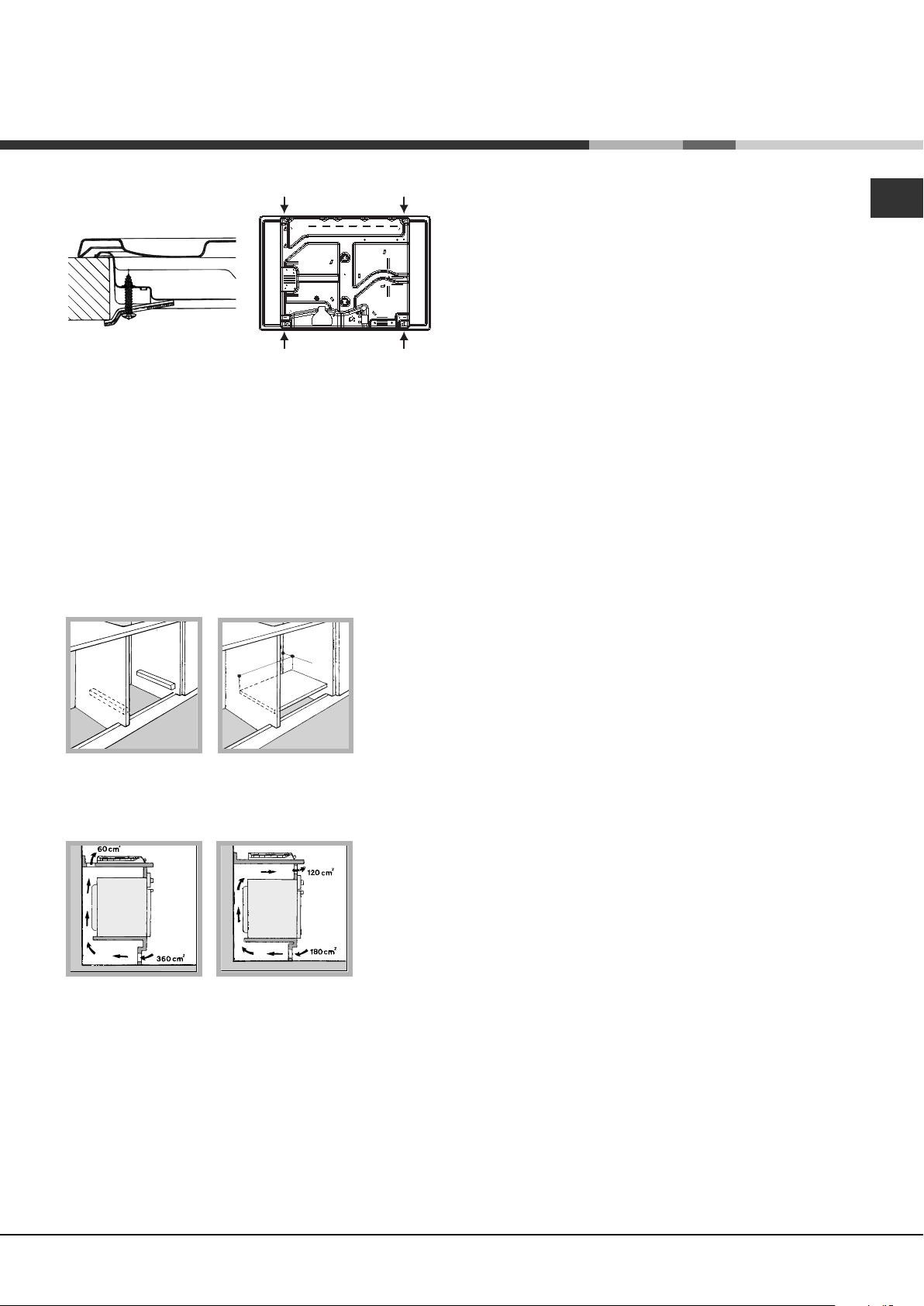

• The installation cavity should have the dimensions

indicated in the figure.

Fastening hooks are provided, allowing you to fasten the

hob to tops that are between 20 and 40 mm thick. To

ensure the hob is securely fastened to the top, we

recommend you use all the hooks provided.

555 mm

2

;

55 mm

475 mm

Hook fastening diagram

Hooking position Hooking position

for top H=20 mm for top H=30 mm

2

Page 3

Front

560 mm.

45 mm.

Hooking position Back

for top H=40 mm

! Use the hooks contained in the “accessory pack”

• Where the hob is not installed over a built-in oven, a

wooden panel must be installed as insulation. This

must be placed at a minimum distance of 20 mm from

the lower part of the hob.

Ventilation

To ensure adequate ventilation, the back panel of the

cabinet must be removed. It is advisable to install the

oven so that it rests on two strips of wood, or on a

completely flat surface with an opening of at least 45 x

560 mm (see diagrams).

When installing the cooktop above a built-in oven

without forced ventilation, ensure that there are air

inlets and outlets for ventilating the interior of the

cabinet adequately.

Electrical connection

Hobs equipped with a three-pole power supply cable are

designed to operate with alternating current at the voltage

and frequency indicated on the data plate (this is located

on the lower part of the appliance). The earth wire in the

cable has a green and yellow cover. If the appliance is to

be installed above a built-in electric oven, the electrical

connection of the hob and the oven must be carried out

separately, both for electrical safety purposes and to

make extracting the oven easier.

Connecting the supply cable to the mains

Install a standardised plug corresponding to the load

indicated on the data plate.

The appliance must be directly connected to the mains

using an omnipolar circuit-breaker with a minimum contact

opening of 3 mm installed between the appliance and the

mains. The circuit-breaker must be suitable for the charge

indicated and must comply with current electrical

regulations (the earthing wire must not be interrupted by the

circuit-breaker). The supply cable must not come into

contact with surfaces with temperatures higher than 50°C.

! The installer must ensure that the correct electrical

connection has been made and that it is compliant with

safety regulations.

Before connecting to the power supply, make sure that:

• The appliance is earthed and the plug is compliant with

the law.

• The socket can withstand the maximum power of the

appliance, which is indicated on the data plate.

• The voltage is in the range between the values indicated

on the data plate.

• The socket is compatible with the plug of the appliance. If

the socket is incompatible with the plug, ask an

authorised technician to replace it. Do not use extension

cords or multiple sockets.

! Once the appliance has been installed, the power supply

cable and the electrical socket must be easily accessible.

! The cable must not be bent or compressed.

! The cable must be checked regularly and replaced by

authorised technicians only (see Assistance).

! The manufacturer declines any liability should these safety

measures not be observed.

Gas connection

The appliance should be connected to the main gas supply

or to a gas cylinder in compliance with current national

regulations. Before carrying out the connection, make sure

the cooker is compatible with the gas supply you wish to

use. If this is not the case, follow the instructions indicated in

the paragraph “Adapting to different types of gas.”

When using liquid gas from a cylinder, install a pressure

regulator which complies with current national regulations.

! Check that the pressure of the gas supply is consistent

with the values indicated in Table 1 (“Burner and nozzle

specifications”). This will ensure the safe operation and

longevity of your appliance while maintaining efficient

energy consumption.

Connection with a rigid pipe (copper or steel)

! Connection to the gas system must be carried out in such

a way as not to place any strain of any kind on the

appliance.

GB

3

Page 4

GB

There is an adjustable L-shaped pipe fitting on the

appliance supply ramp and this is fitted with a seal in

order to prevent leaks. The seal must always be replaced

after rotating the pipe fitting (seal provided with

appliance). The gas supply pipe fitting is a threaded 1/2

gas cylindrical male attachment.

Connecting a flexible jointless stainless steel pipe to a

threaded attachment

The gas supply pipe fitting is a threaded 1/2 gas cylindrical

male attachment.

These pipes must be installed so that they are never

longer than 2000 mm when fully extended. Once

connection has been carried out, make sure that the

flexible metal pipe does not touch any moving parts and

is not compressed.

! Only use pipes and seals that comply with current

national regulations.

Checking the tightness of the connection

! When the installation process is complete, check the

pipe fittings for leaks using a soapy solution. Never use a

flame.

Adapting to different types of gas

To adapt the hob to a different type of gas other than

default type (indicated on the rating plate at the base of

the hob or on the packaging), the burner nozzles should

be replaced as follows:

1. Remove the hob grids and slide the burners off their

seats.

2. Unscrew the nozzles using a 7 mm socket spanner,

and replace them with nozzles for the new type of gas

(see table 1 “Burner and nozzle characteristics”).

3. Reassemble the parts following the above procedure in

the reverse order.

4. Once this procedure is finished, replace the old rating

sticker with one indicating the new type of gas used.

Sticker are available from any of our Service Centres.

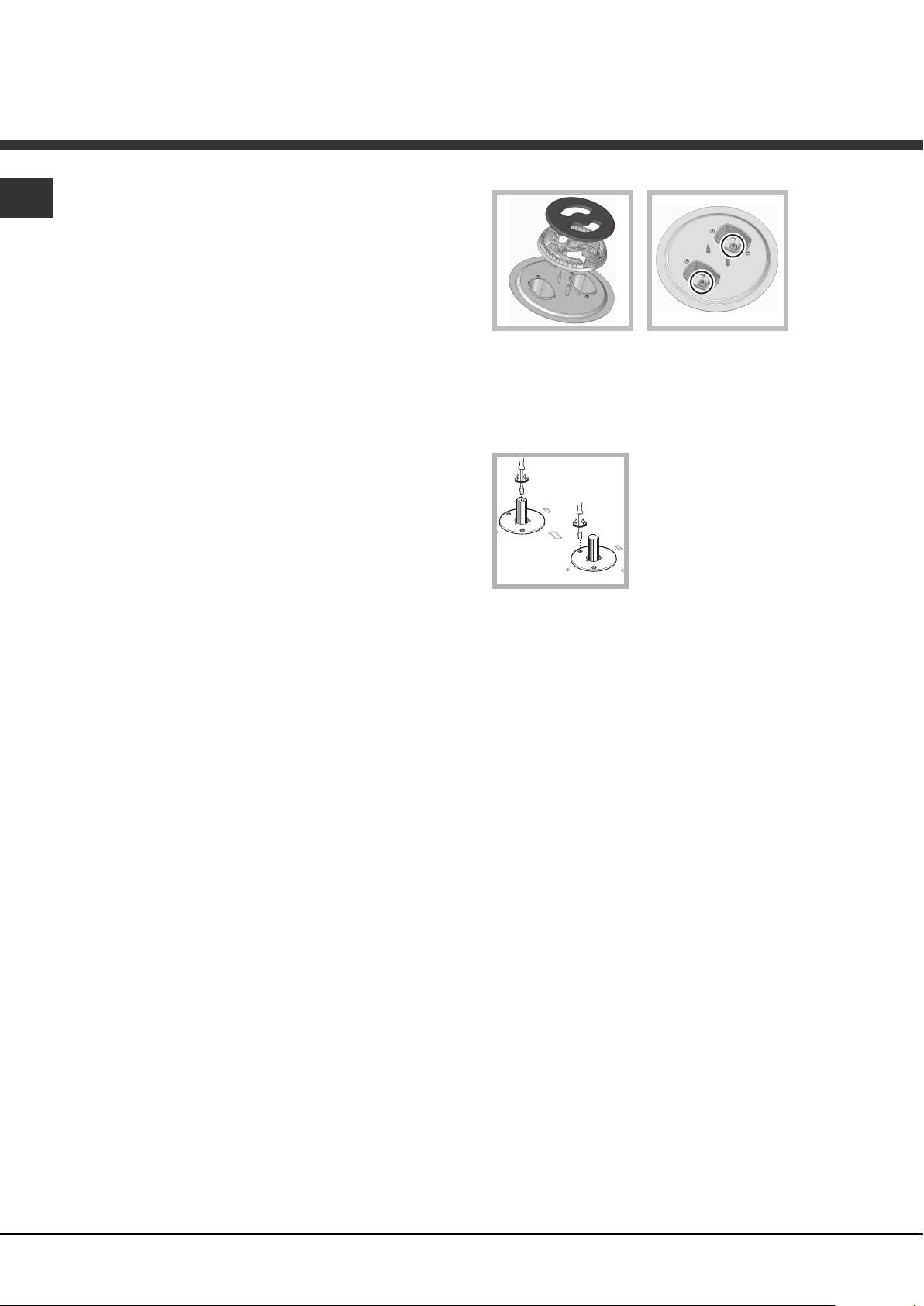

Replacing the Triple ring burner nozzles

1. Remove the pan supports and lift the burners out of

their housing. The burner consists of two separate parts

(see pictures).

2. Unscrew the nozzles using a 7 mm socket spanner.

Replace the nozzles with models that are configured

for use with the new type of gas (see Table 1). The two

nozzles have the same hole diameter.

3. Replace all the components by completing the above

operations in reverse order.

• Adjusting the burners’ primary air :

Does not require adjusting.

• Setting the burners to minimum:

1. Turn the tap to the low flame position.

2. Remove the knob and adjust

the adjustment screw, which is

positioned in or next to the tap

pin, until the flame is small but

steady.

3. Having adjusted the flame to the required low setting,

while the burner is alight, quickly change the position of

the knob from minimum to maximum and vice versa

several times, checking that the flame does not go out.

4. Some appliances have a safety device (thermocouple)

fitted. If the device fails to work when the burners are

set to the low flame setting, increase this low flame

setting using the adjusting screw.

5. Once the adjustment has been made, replace the seals

on the by-passes using sealing wax or a similar

substance.

! If the appliance is connected to liquid gas, the regulation

screw must be fastened as tightly as possible.

! Once this procedure is finished, replace the old rating

sticker with one indicating the new type of gas used.

Stickers are available from any of our Service Centres.

! Should the gas pressure used be different (or vary

slightly) from the recommended pressure, a suitable

pressure regulator must be fitted to the inlet pipe (in order

to comply with current national regulations).

4

Page 5

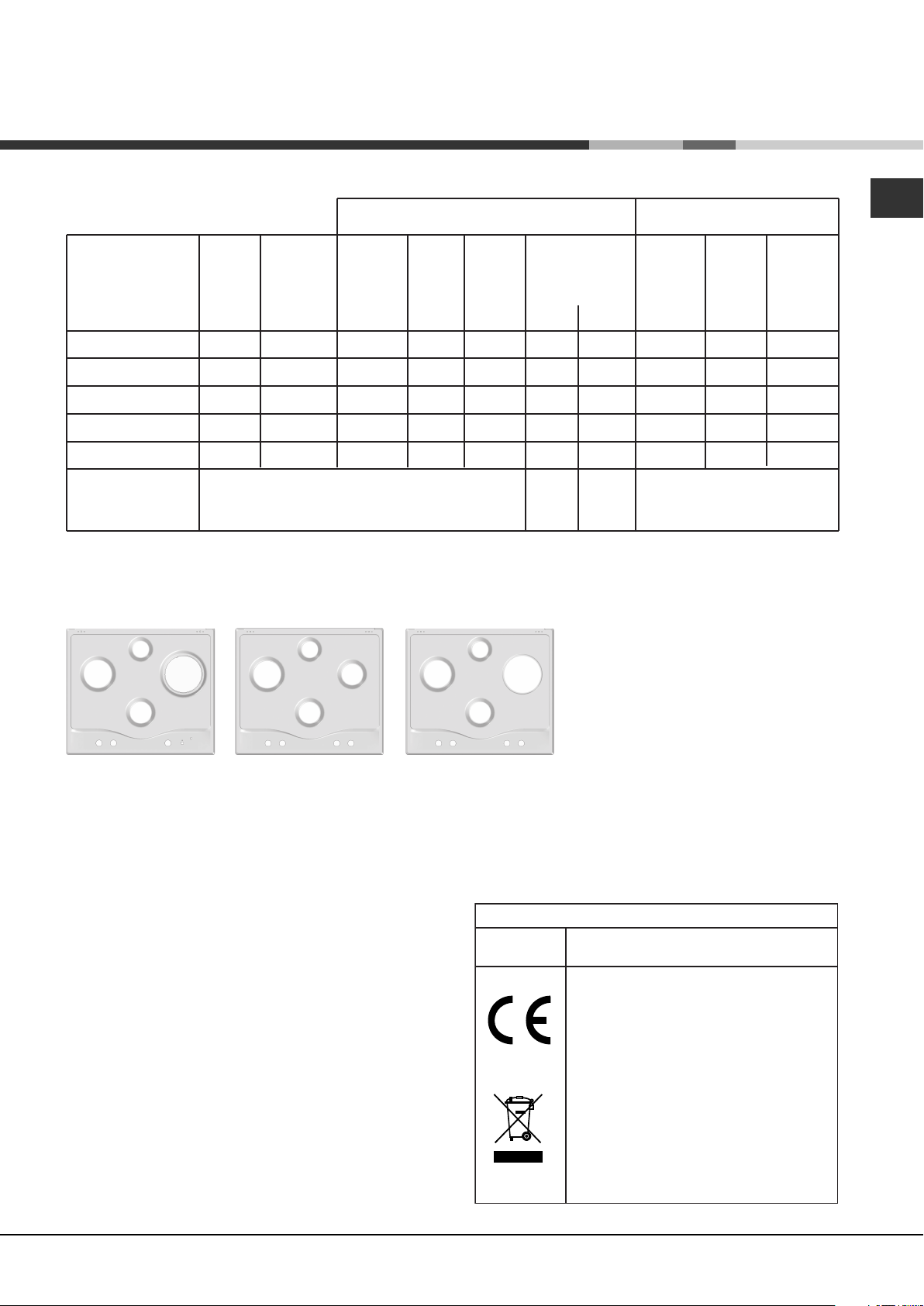

Burner and nozzle specifications

Table 1 Liquid Gas Natural Gas

Burner Diameter Thermal Thermal By-pass Nozzle Flow* Thermal Nozzle Flow*

power power 1/100 1/100 (g/h) power 1/100 (l/h)

kW kW kW

(p.c.s.*) (p.c.s.*) (p.c.s.*)

(mm) Reduced Nominal (mm) (mm) *** ** Nominal (mm)

GB

Fast (R)

Reduced Fast (RR)

Semi Fast (S)

Auxiliary (A)

Triple Crown (TC)

Supply pressures

* At 15°C and 1013 mbar - dry gas

** Propane P.C.S. = 50.37 MJ/Kg

*** Butane P.C.S. = 49.47 MJ/Kg

Natural P.C.S. = 37.78 MJ/m³

100

100

75

55

130

0.70

0.70

0.40

0.40

1.50

AA

R

7HPC 631 /HA

7HPC 631 X/HA

Ø145

S

R

S

7HPC 640 /HA

7HPC 640 X/HA

7HPC 640 GH/HA

7HPC 640N /HA

7HPC 640N GH/HA

7HPC 640N X /HA

PC 640N /HA

PC 640N X/HA

3.00

2.60

1.65

1.00

3.30

Nominal (mbar)

Minimum (mbar)

Maximum (mbar)

S

7HPC 640 T GH /HA

7HPC 640 T R /HA

7HPC 640 T X /HA

39

39

28

28

61

RR

86

80

64

50

65x2

28-30

A

TC

S

DATA PLATE

Electrical

connections

218

189

120

73

240

20

35

214

186

118

71

236

37

25

45

see data plate

This appliance conforms to the following

European Economic Community directives:

- 2006/95/EEC dated 12/12/06 (Low

Voltage) and subsequent amendments

- 2004/108/EEC dated 15/12/04

(Electromagnetic Compatibility) and

subsequent amendments

- 93/68/EEC dated 22/07/93 and

subsequent amendments.

- 2009/142/EEC dated 30/11/09 (Gas) and

subsequent amendments.

- 2002/96/EC and subsequent

amendments.

3.00

2.60

1.65

1.00

3.30

132 (H)

122 (H)

96

79 (6)

103x2

286

248

157

95

343

20

17

25

5

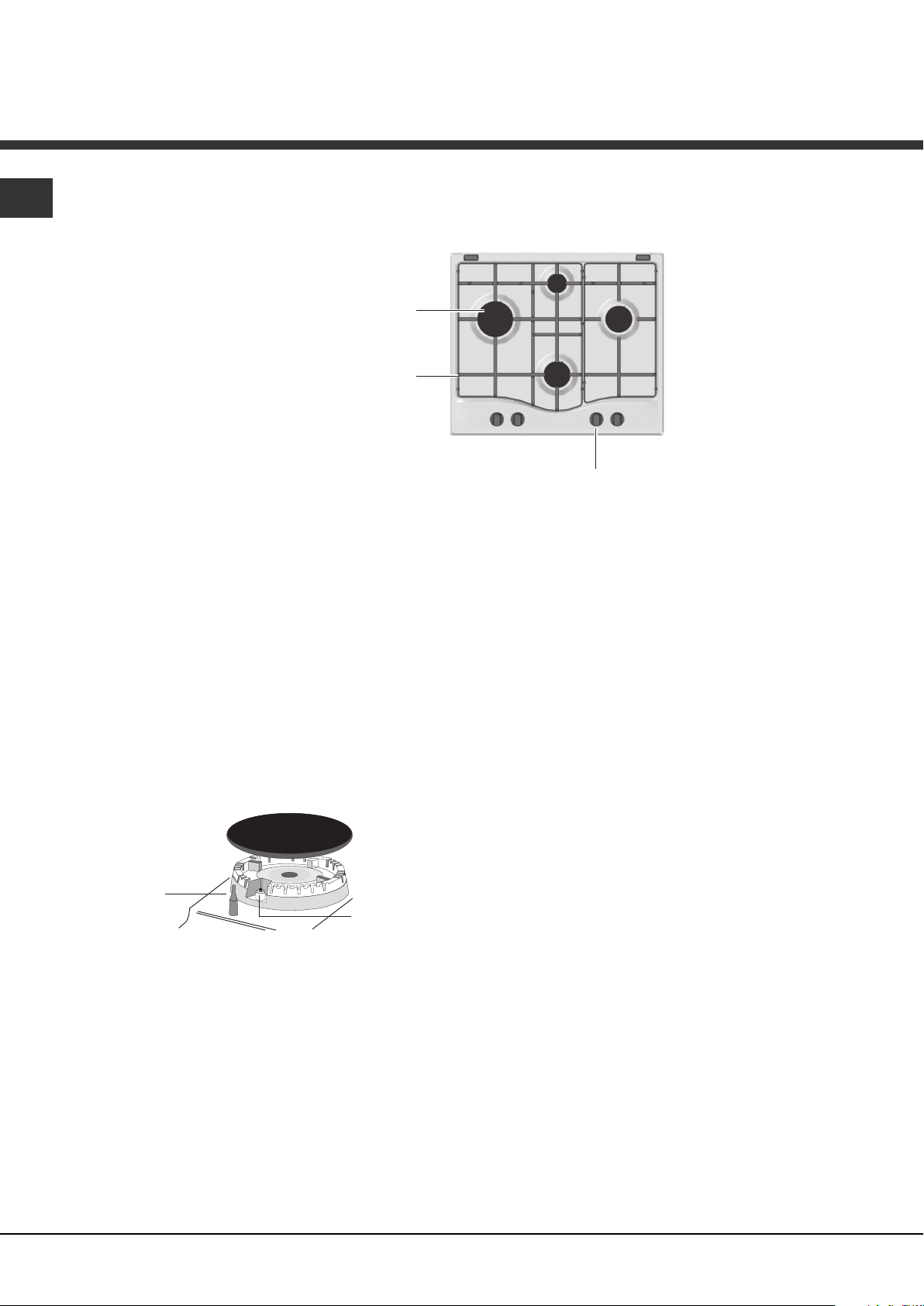

Page 6

Description of the

appliance

GB

Overall view

GAS BURNERS

Support Grid for

COOKWARE

Control Knobs for

GAS BURNERS

SAFETY

DEVICES *

• GAS BURNERS differ in size and power. Use the

diameter of the cookware to choose the most

appropriate burner to cook with.

• Control Knobs for GAS BURNERS adjust the size

of the flame.

6

Ignition for

GAS BURNERS *

• GAS BURNER ignition* enables a specific burner

to be lit automatically.

• SAFETY DEVICE* stops the gas flow if the flame

is accidentally extinguished.

Only available on certain models.

*

Page 7

Start-up and use

! The position of the corresponding gas burner or

electric hotplate* is shown on every knob.

Gas burners

Each burner can be adjusted to one of the following

settings using the corresponding control knob:

• Off

Maximum

Minimum

To light one of the burners, hold a lit match or lighter

near the burner and, at the same time, press down

and turn the corresponding knob anti-clockwise to

the maximum setting.

Since the burner is fitted with a safety device, the

knob should be pressed for approximately 2-3

seconds to allow the automatic device keeping the

flame alight to heat up.

When using models with an ignition button, light the

desired burner pressing down the corresponding

knob as far as possible and turning it anticlockwise

towards the maximum setting.

! If a flame is accidentally extinguished, turn off the

control knob and wait for at least 1 minute before

trying to relight it.

Practical advice on using the burners

To ensure the burners operate efficiently:

• Use appropriate cookware for each burner (see

table) so that the flames do not extend beyond

the bottom of the cookware.

• Always use cookware with a flat base and a cover.

• When the contents of the pan reach boiling point,

turn the knob to minimum.

Burner

Rapid (R)

Reduced Rapid (RR)

Semi-Rapid (S)

Auxiliary (A)

Triple Crown (TC)

To identify the type of burner, refer to the designs in

the section entitled, "Burner and Nozzle

Specifications".

Ø Cookware Diameter (cm)

24 - 26

24 - 26

16 - 20

10 - 14

24 - 26

GB

To switch off the burner, turn the knob in a clockwise

direction until it stops (when reaches the “•” position).

7

Page 8

Precautions and tips

GB

! This appliance has been designed and manufactured

in compliance with international safety standards. The

following warnings are provided for safety reasons and

must be read carefully.

General safety

• This is a class 3 built-in appliance.

• Gas appliances require regular air exchange to

maintain efficient operation. When installing the

hob, follow the instructions provided in the

paragraph on “Positioning” the appliance.

• These instructions are only valid for the countries

whose symbols appear in the manual and on the

serial number plate.

• The appliance was designed for domestic use inside

the home and is not intended for commercial or

industrial use.

• The appliance must not be installed outdoors, even in

covered areas. It is extremely dangerous to leave the

appliance exposed to rain and storms.

• Do not touch the appliance with bare feet or with wet

or damp hands and feet.

• The appliance must be used by adults only for the

preparation of food, in accordance with the

instructions outlined in this booklet. Any other

use of the appliance (e.g. for heating the room)

constitutes improper use and is dangerous. The

manufacturer may not be held liable for any

damage resulting from improper, incorrect and

unreasonable use of the appliance.

• Ensure that the power supply cables of other

electrical appliances do not come into contact with

the hot parts of the oven.

• The openings used for ventilation and dispersion of

heat must never be covered.

• Always make sure the knobs are in the “”/“

position when the appliance is not in use.

• When unplugging the appliance always pull the plug

from the mains socket, do not pull on the cable.

• Never carry out any cleaning or maintenance work

without having detached the plug from the mains.

• In case of malfunction, under no circumstances

should you attempt to repair the appliance yourself.

Repairs carried out by inexperienced persons may

cause injury or further malfunctioning of the

appliance. Contact a Service Centre (see

Assistance).

• Always make sure that pan handles are turned

towards the centre of the hob in order to avoid

accidental burns.

• Do not close the glass cover (if present) when the gas

burners or electric hotplates are still hot.

”

• Do not leave the electric hotplate switched on without

a pan placed on it.

• Do not use unstable or deformed pans.

• Remove any liquid from the lid before

opening it.

• Prevent children and the disabled from coming into

contact or having access at the ceramic glass

cooking surface (if present) immediately before and

after use, as the cooking surface will remain hot for at

least a half hour after being turned off;

• Contact service centers authorized by the

manufacturer in the event the ceramic glass cooking

surface breaks.

• It is recommended that you follow the guidelines

below:

• Disconnect the appliance from the electrical supply in

the event the ceramic glass cooking surface

breakds.

• The appliance should not be operated by people

(including children) with reduced physical, sensory or

mental capacities, by inexperienced individuals or by

anyone who is not familiar with the product. These

individuals should, at the very least, be supervised

by someone who assumes responsibility for their

safety or receive preliminary instructions relating to

the operation of the appliance.

• Do not let children play with the appliance.

• The appliance is not intended to be operated by

means of an external timer or separate remotecontrol system.

Disposal

• When disposing of packaging material: observe local

legislation so that the packaging may be reused.

• The European Directive 2002/96/EC on Waste

Electrical and Electronic Equipment (WEEE), requires

that old household electrical appliances must not be

disposed of in the normal unsorted municipal waste

stream. Old appliances must be collected separately

in order to optimise the recovery and recycling of the

materials they contain and reduce the impact on

human health and the environment. The crossed out

“wheeled bin” symbol on the product reminds you of

your obligation, that when you dispose of the

appliance it must be separately collected.

Consumers may take their old appliance to public

waste collection areas, other communal collection

areas, or if national legislation allows return it to a

retailer when purchasing a similar new product.

All major household appliance manufacturers are

active in the creation of systems to manage the

collection and disposal of old appliances.

8

Page 9

Maintenance and care

Switching the appliance off

Disconnect your appliance from the electricity

supply before carrying out any work on it.

Cleaning the appliance

! Do not use abrasive or corrosive detergents such

as stain removers, anti-rust products, powder

detergents or sponges with abrasive surfaces: these

may scratch the surface beyond repair.

! Never use steam cleaners or pressure cleaners on

the appliance.

• It is usually enough to wash the hob with a damp

sponge and dry it with absorbent kitchen roll.

• The removable parts of the burners should be

washed frequently with warm water and soap and

any burnt-on substances removed.

• For hobs which ligth automatically, the terminal

part of the electronic instant lighting devices

should be cleaned frequently and the gas outlet

holes should be checked for blockages.

Gas tap maintenance

GB

Over time, the taps may become jammed or difficult

to turn. If this happens, the tap must be replaced.

! This procedure must be performed by a

qualified technician authorised by the

manufacturer.

• Stainless steel can be marked by hard water that

has been left on the surface for a long time, or by

aggressive detergents containing phosphorus.

After cleaning, rinse and dry any remaining drops

of water.

9

Page 10

GB

Troubleshooting

It may happen that the appliance does not function properly or at all. Before calling the service centre for

assistance, check if anything can be done. First, check to see that there are no interruptions in the gas and

electrical supplies, and, in particular, that the gas valves for the mains are open.

Problem

The burner does not light or the flame is not

even around the burner.

The flame dies in models with a safety device.

The burner does not remain lit when set to

minimum.

The cookware is unstable.

If, despite all these checks, the hob does not function properly and the problem persists, call the nearest

Customer Service Centre. Please have the following information handy:

• The appliance model (Mod.).

• The serial number (S/N).

This information can be found on the data plate located on the appliance and/or on the packaging.

Possible causes/Solution

• The gas holes on the burner are clogged.

• All the movable parts that make up the burner are

mounted correctly.

• There are draughts near the appliance.

• You pressed the knob all the way in.

• You keep the knob pressed in long enough to activate the

safety device.

• The gas holes are not blocked in the area corresponding

to the safety device.

• The gas holes are not blocked.

• There are no draughts near the appliance.

• The minimum setting has been adjusted properly.

• The bottom of the cookware is perfectly flat.

• The cookware is positioned correctly at the centre of the

burner.

• The pan support grids have been positioned correctly.

! Never use unauthorised technicians and never accept replacement parts which are not original.

10

Page 11

Руководство по

эксплуатации

GB

English, 1

7HPC 640 /HA

7HPC 640 X/HA

7HPC 640 GH/HA

7HPC 631 /HA

7HPC 631 X/HA

7HPC 640N /HA

7HPC 640N GH/HA

7HPC 640N X /HA

PC 640N /HA

PC 640N X/HA

7HPC 640 T GH /HA

7HPC 640 T R /HA

7HPC 640 T X /HA

RS

Русскии,11

ВАРОЧНАЯ ПАНЕЛЬ

Содержание

RS

Монтаж, 12-15

Расположение

Электрическое подключение

Подсоединение к газопроводу

Характеристики конфорок и форсунок

Описание изделия, 16

Общии вид

Включение и эксплуатация, 17

Практические рекомендации по эксплуатации электрических

конфорок

Паспортная табличка

Предосторожности и рекомендации, 18

Общие требования к безопасности

Утилизация

Техническое обслуживание и уход, 19

Обесточивание изделия

Чистка изделия

Уход за рукоятками газовои варочнои панели

Неисправности и методы их устранения, 20

11

Page 12

Установка

У аа

С

В

A

Примеры вентиляционных

отверстий для притока

воздуха для горения

В камин или в дымоход с медным

покрытием (для кухонных устройств

для приготовления пищи)

Непосредственно

в атмосферу

600mm min.

600mm min.

700mm min.

RS

! Важно сохранить данное руководство для его

последующих консультации. В случае продажи, передачи

изделия или при переезде на новое место жительства

необходимо проверить, чтобы руководство оставалось

вместе с изделием, для того чтобы его новыи владелец мог

ознакомиться с правилами эксплуатации и с

соответствующими предупреждениями.

! Внимательно прочитаите инструкции: в них содержатся

важные сведения об установке, эксплуатации и

безопасности изделия.

Расположение

! Не разрешаите детям играть с упаковочными

материалами.

Упаковочные материалы должны быть уничтожены в

соответствии с правилами раздельного сбора мусора (см.

Предосторожности и рекомендации).

! Монтаж изделия производится в соответствии с данными

инструкциями квалифицированными специалистами.

Неправильныи монтаж изделия может стать причинои

повреждения имущества и причинить ущерб людям и

домашним животным.

! данное изделие может быть установлено и

использоваться только в помещениях с постояннои

вентиляциеи в соответствии с положениями деиствующих

Нормативов. Необходимо соблюдать следующие

требования:

• в помещении должна быть предусмотрена система

дымоудаления в атмосферу, выполненная в виде

вытяжного зонта или электровентилятора,

автоматически включающихся каждыи раз, когда

включается изделие.

тяжелее воздуха и следовательно застаивается

внизу. По этои причине помещения, в которых

установлены баллоны с СНГ (сжиженным

натуральным газом) должны иметь вентиляционные

отверстия внизу, сообщающиеся с улицеи, для

удаления возможных утечек газа. Поэтому баллоны

с СПГ должны быть опорожнены или оставаться

частично заполненными; они не должны

размещаться или храниться в подземных

помещениях и хранилищах (подвалах, и т.д.).

Следует держать в помещении только один рабочии

баллон, расположенныи таким образом, чтобы он не

подвергался прямому воздеиствию источников

тепла (печеи, каминов и т.д.), которые могут

привести к нагреву баллона свыше 50°C.

Встроенныи монтаж

Газовые и газо-электрические варочные панели

оснащены системои защиты от чрезмерного перегрева

класса Х, поэтому кухонная плита может быть

установлена рядом кухонными мебельными

элементами, высота которых не превышает уровень

варочнои панели. Для правильного монтажа варочнои

панели необходимо соблюдать следующие меры

предосторожности:

• Кухонные элементы, расположенные рядом с

кухоннои плитои, высота которых превышает

уровень варочнои панели, должны находиться на

расстояние не менее 600 мм от края варочнои

панели.

• Вытяжка должна быть установлена в соответствии с

руководством по эксплуатации вытяжки и в любом

случае на высоте не менее 650 мм.

• Расположите навесные шкафы, прилегающие к

вытяжке, на высоте не менее 420 мм от рабочеи

поверхности кухни (см. рисунок).

• В помещении должна быть предусмотрена система,

12

обеспечивающая достаточныи приток воздуха для

надлежащего горения. Расход воздуха, необходимого

для горения, должен быть не менее 2 м<+>3/час на кВт

установленнои мощности.

Приток воздуха может

обеспечиваться непосредственно

снаружи здания через воздуховод

полезным сечением не менее 100

2

см

и диаметром, исключающим

возможность случаиного

засорения.

Или же воздухозабор может

осуществляться из смежных

помещении, оснащенных

вентиляционным отверстием,

сообщающимся с улицеи, как

описано выше, при условии, что это

не общие зоны здания,

пожароопасные помещения и не

спальни.

• Сжиженныи газ пропан-бутан

Если варочная панель

устанавливается под навесным

шкафом, последнии должен

располагаться на высоте не

менее 700 мм от кухонного

топа (см. рисунок).

• Размеры ниши кухонного элемента должны

соответствовать рисунку. В крепежныи комплект входят

крепежные крюки для крепления варочнои панели на

кухоннои рабочеи поверхности толщинои от 20 до 40 мм.

Для надежного крепления варочнои панели

рекомендуется использовать все прилагающиеся крюки.

555 mm

55 mm

475 mm

Page 13

560 mm.

45 mm.

Схема крепления крюков

Монтаж крюка для опорных

брусков H=20 мм

Монтаж крюка для опорных

брусков H= 40 мм

! Используите крюки из комплекта «вспомогательные

принадлежности»

Монтаж крюка для

опорных брусков H=30 мм

Спереди

Сзади

• Если варочная панель не устанавливается сверху

встроенного духового шкафа, необходимо вставить

деревянную панель в качестве изоляции. Эта панель

должна быть установлена на расстоянии не менее 20

мм от нижнеи части варочнои панели.

Вентиляция

Для обеспечения надлежащеи вентиляции необходимо

снять заднюю панель ниши кухонного элемента.

Рекомендуется установить духовои шкаф на два деревянных

бруска или на сплошное основание с отверстием диаметром

не менее 45 х 560 мм (см чертежи).

Если варочная панель устанавливается сверху встроенного

духового шкафа, не оснащенного принудительнои

охладительнои вентиляциеи, для надлежащеи вентиляции

внутри кухонного элемента необходимо проделать

вентиляционные отверстия для циркуляции воздуха (см

чертежи).

Электрическое подключение

RS

Варочные панели, оснащенные трехполярным сетевым

кабелем, расчитаны на функционирование с переменным

током с напряжением и частотои электропитания,

указанными на паспортнои табличке (расположеннои

снизу варочнои панели). Провод заземления сетевого

кабеля имеет желто-зеленыи цвет. В случае установки

варочнои панели сверху духового шкафа, встроенного в

кухонныи элемент, электрическое подсоединение

варочнои панели и духового шкафа должно выполняться

раздельно по причинам безопасности, а так же для

легкого съема духового шкафа.

Подсоединение сетевого шнура изделия к

сети электропитания

Установите на сетевои кабель нормализованную

штепсельную вилку, расчитанную на нагрузку, указанную на

паспортнои табличке. В случае прямого подключения к сети

электропитания между изделием и сетью необходимо

установить многополюсныи выключатель с минимальным

расстоянием между контактами 3 мм, расчитанныи на

данную нагрузку и соответствующии деиствующим

нормативам (выключатель не должен размыкать провод

заземления). Сетевои кабель должен быть расположен

таким образом, чтобы ни в однои точке его температура не

превышала температуру помещения более чем на 50°C.

! Электромонтер несет ответственность за правильное

подключение изделия к электрическои сети и за

соблюдение правил безопасности.

Перед подключением изделия к сети электропитания

проверьте следующее:

• розетка должна быть соединена с заземлением и

соответствовать нормативам;

• сетевая розетка должна быть рассчитана на

максимальную потребляемую мощность изделия,

указанную в таблице технических характеристик;

• напряжение и частота тока сети должны

соответствовать электрическим данным изделия;

• сетевая розетка должна быть совместима со

штепсельнои вилкои изделия. В противном случае

замените розетку или вилку; не используите

удлинители или троиники.

! Изделие должно быть установлено таким образом,

чтобы электрическии провод и сетевая розетка были

легко доступны.

! Электрическии провод изделия не должен быть согнут

или сжат.

! Регулярно проверяите состояние кабеля электропитания и

в случае необходимости поручите его замену только

уполномоченным техникам (см. Техническое обслуживание).

! Производитель не несет ответственности за

последствия несоблюдения перечисленных выше

требовании.

Подсоединение к газопроводу

данное изделие может быть установлено и

использоваться только в помещениях с постояннои

вентиляциеи в соответствии с положениями деиствующих

Нормативов, только после проверки соответствия

изделия типу газа, к которому он подсоединяется. В

13

Page 14

RS

случае несоответствия выполнить операции, описанные в

параграфе «Настроика на различные типы газа». В случае

использования сжиженного газа из баллона использовать

регуляторы давления, соответствующие нормативами и их

последующим поправкам.

! Для надежного функционирования, рационального

использования энергии и более длительного срока службы

электрического изделия проверьте, чтобы давление

подачи газа соответствовало значениям, указанным в

таблице 1 «Характеристики газовых горелок и форсунок».

Подсоединение при помощи твердои трубки

(меднои или стальнои)

! Подсоединение к газопроводу не должно оказывать

каких-либо нагрузок на изделие.

На патрубке подачи газа в изделия имеется вращающееся

колено “L” с уплотнительнои прокладкои. При

необходимости повернуть колено обязательно замените

уплотнительную прокладку (прилагающется к изделию).

Патрубок подачи газа в изделие имеет цилиндрическую

наружную резьбу 1/2 газ.

Подсоединение при помощи гибкои трубки из

нержавеющеи стали со сплошными стенками с

резьбовыми соединениями.

Патрубок подачи газа в изделие имеет цилиндрическую

наружную резьбу 1/2 газ.

Подсоединение таких шлангов должно производиться

таким образом, чтобы их длина при максимальном

растяжении не превышала 2000 мм. По завершении

подсоединения проверьте, чтобы металлическии гибкии

шланг не касался подвижных частеи или не был сжат.

Использовать исключительно трубки, соответствующие

Нормативу, и уплотнительные прокладки, соответствующие

деиствующим государственным нормативам.

Проверка уплотнения

! По завершении подсоединения проверьте прочность

уплотнения всех патрубков при помощи мыльного

раствора, но никогда не пламенем.

Подготовка к различным типам газа

Для переоснащения варочнои панели для газа,

отличающемуся от газа, на которыи варочная панель

расчитана изначально (указан на этикетке на верхнеи

части варочнои панели или на упаковке), необходимо

заменить форсунки конфорок следующим образом:

1. снимите с варочнои панели опорные решетки и выньте

конфорки из своих гнезд.

2. отвинтите форсунки при помощи полои отвертки 7 мм и

замените их на форсунки, расчитанные на новыи тип

газа (смотрите таблицу 1 «Характеристики конфорок и

форсунок»).

3. восстановить детали на свои места, выполняя операции

в обратном порядке.

4. По завершении операции замените старую этикетку

тарирования на новую, соответствующую новому типу

используемого газа. Этикетку можно заказать в наших

Центрах Технического Обслуживания.

Замена форсунок тройной конфорки

1. снимите решетки и выньте конфорки из своих гнезд.

Конфорка состоит из двух отдельных частей (см. схемы);

2. отвинтите форсунки при помощи полой отвертки 7 мм.

Замените форсунки на новые, пригодные для нового типа

газа (см. таблицу 1). Обе форсунки имеют одинаковое

отверстие.

3. восстановите на место все комплектующие, выполняя

операции в обратном порядке по отношению к

описанным выше.

• Регуляция первичного воздуха конфорок

Конфорки не нуждаются в какои-либо регуляции

первичного воздуха.

• Регуляция минимального пламени

1. Поверните рукоятку-регулятор в положение

минимального пламени;

2. снимите рукоятку и поверните

регуляционныи винт,

расположенныи внутри или

рядом со стержнем крана,

вплоть до получения стабильного

малого пламени.

3. Проверьте, чтобы при резком

повороте рукоятки из положения

максимального пламени на

минимальное, конфорки не

гасли.

4. В изделиях, оснащенных защитным устроиством

(термопарои), в случае неисправности этого устроиства

при минимальном пламени конфорок увеличьте

расход газа минимального пламени при помощи

регуляционного винта.

5. По завершении регуляции восстановите сургучные или

подобные пломбы на обводном газопроводе.

! В случае использования сжиженного газа

регуляционныи винт должен быть завинчен до упора.

! По завершении операции замените старую этикетку

тарирования на новую, соответствующую новому типу

используемого газа. Этикетку можно заказать в наших

Центрах Технического Обслуживания.

! Если давление используемого газа отличается от

предусмотренного давления (или варьирует), необходимо

установить на питающем газопроводе соответствующии

регулятор давления (согласно нормативу «Регуляторы

для канализированных газов»).

14

Page 15

Характеристики конфорок и форсунок

RS

Таблица 1

Kонфорка Диаметр

Быстрая

(Большая)(R)

Быстрая

(сокращенная) (RR)

Полубыстрая

(Средняя)(S)

Вспомогательная

(Малая) (А)

Тройная

(ТС)

Давление

подачи

(мм)

100

100

75

55

130

Номинальное (мбар)

Минимальное (мбар)

Максимальное (мбар)

Теплотворная

способность

кВт (p.c.s.*)

Номин. Сокращ.

3.00

2.60

1.65

1.00

3.30

0.70

0.70

0.40

0.40

1.50

Сжиженный газ

Байпас

1/100

(mm)

39

39

28

28

61

Форсунка

1/100

(mm) ***

86

80

64

50

65x2

*

**

214

186

118

71

236

37

25

45

Форсунка

Расход

г/час

218

189

120

73

240

28-30

20

35

Природный газ

Расход

*

1/100

(mm) (mm)

132 (H)

122 (H)

96

79 (6)

103x2

20

17

25

л/час

286

248

157

95

343

Форсунка

1/100

143

135

105

119x2

80

Расход

13

6,5

18

*

л/час

286

248

157

95

303

* При температуре 15°C и давлении 1013 мбар – сухои газ

** Пропан Теплотворная способность = 50,37 МДж/кг

*** Бутан Теплотворная способность = 49,47 МДж/кг

Природныи газ Теплотворная способность = 37,78 МДж/м³

R

Ø145

S

7HPC 631 /HA

7HPC 631 X/HA

AA

R

S

S

7HPC 640 /HA

7HPC 640 X/HA

7HPC 640 GH/HA

RR

7HPC 640 T GH /HA

7HPC 640 T R /HA

7HPC 640 T X /HA

A

TC

S

7HPC 640N /HA

7HPC 640N GH/HA

7HPC 640N X /HA

PC 640N /HA

PC 640N X/HA

15

Page 16

Описание изделия

RS

Общии вид

g=?,2…%

3“2!%L“2"% *

• ГАЗОВЫЕ КОНФОРКИ имеют разную мощность и

размер. Выберите конфорку, наиболее

соответствующую диаметру используемой посуды.

• Регуляторы ГАЗОВЫХ КОНФОРОК для регуляции

пламени или мощности.

q"= ƒ=›,=…,

=ƒ%"/L *%…-%!%* *

• Свеча зажигания ГАЗОВЫХ КОНФОРОК* для

автоматического зажигания нужной конфорки.

• УСТРОЙСТВО БЕЗОПАСНОСТИ* при случайном

гашении пламени это устройство перекрывает подачу

газа.

* Имеется только в некоторых моделях.

16

Page 17

Включение и

эксплуатация

! На каждои рукоятке показано положение

соответствующеи конфорки на варочнои панели.

Газовые конфорки

При помощи соответствующего регулятор можно

выбрать один из следующих режимов конфорки:

• Выключено

Максимальная мощность

Минимальныи

Для зажигания однои из конфорок поднесите к неи

зажженную спичку или зажигалку, нажмите до упора и

поверните против часовои стрелки соответствующую

рукоятку в положение максимального пламени.

В моделях, оснащенных защитным устроиством,

необходимо держать рукоятку конфорки нажатои

примерно 6 секунды до тех пор, пока не нагреется

устроиство, автоматически поддерживающее горение

пламени.

Некоторые модели оснащены устроиством зажигания,

встроенным внутри рукоятки. В этом случае варочная

панель оснащена свечои зажигания, а не кнопкои. Для

включения нужнои конфорки достаточно нажать до упора

соответствующую рукоятку и повернуть ее против часовои

стрелки в положение максимального пламени,

удерживая ее нажатои вплоть до зажигания пламени.

Практические советы по

эксплуатации газовых горелок

Для максимальнои отдачи изделия следует помнить:

• для каждои конфорки используите подходящую посуду

(смотри таблицу) с тем, чтобы пламя конфорки не

выходило из-под дна посуды.

• всегда используите посуду с плоским дном и с крышкои.

• в момент закипания поверните рукоятку в положение

малого пламени.

КKонфорка

Быстрая (Большая)(R)

Быстрая сокращенная (RR)

Средняя (S)

Малая (А)

Тройная (ТС)

Для определения типа конфорки смотрите рисунки в

параграфе «Характеристики конфорок и форсунок».

ш Диаметр кастрюли (см)

24 - 26

24 - 26

16 - 20

10 - 14

24 - 26

RS

При случаином гашении пламени конфорки поверните

рукоятку управления в положение выключено и

попытаитесь вновь зажечь конфорку только по

прошествии 1 минуты.

Для выключения конфорки поверните рукоятку по

часовои стрелке вплоть до гашения пламени

(положение, обозначенное символом «•»).

ЗАВОДСКАЯ ТАБЛИЧКА

Электропитание

см. заводскую табличку

Данное изделие соответствует

следующим Директивам

Европейского Сообщества:

2006/95/CEE от 12/12/06 (Низкое

напряжение) с последующими

изменениями - 2004/108/СЕЕ от

15/12/04 (Электромагнитная

совместимость) с последующими

изменениями - 93/68/СЕЕ от

22/07/93 с последующими

изменениями. - 2009/142/СЕЕ от

30/11/09 (Газ) с последующими

изменениями; - 2002/96CEE с

последующими изменениями

17

Page 18

Предосторожности и

рекомендации

RS

! Изделие спроектировано и изготовлено в соответствии

с международными нормативами по безопасности.

Необходимо внимательно прочитать настоящие

предупреждения, составленные в целях вашеи

безопасности.

Общие требования к безопасности

• Данное устроиство является встраиваемым

бытовым электроприбором класса 3.

• Для исправного функционирования газовых

устроиств необходимо отрегулировать

воздухообмен. Проверьте, чтобы при

установке этих устроиств соблюдались

требования, описанные в параграфе

«Расположение».

• Инструкции относятся только к странам,

обозначения которых приведены в

руководстве и на паспортнои табличке

изделия.

• Данное изделие предназначается для

непрофессионального использования в домашних

условиях.

• Запрещается устанавливать изделие на улице, даже

под навесом, так как воздеиствие на него дождя и

грозы является чрезвычаино опасным.

• Не прикасаитесь к изделию влажными руками,

босиком или с мокрыми ногами.

• Изделие предназначено для приготовления пищевых

продуктов, может быть использовано только

взрослыми лицами в соответствии с инструкциями,

приведенными в данном техническом руководстве.

Любое другое его использование (например:

отопление помещения) считается ненадлежащим и

следовательно опасным. Производитель не несет

ответственности за возможный ущерб, вызванный

ненадлежащим, неправильным и неразумным

использованием изделия.

• Следите, чтобы сетевые шнуры других бытовых

электроприборов не прикасались к горячим частям

духового шкафа.

• Не закрываите вентиляционные решетки и отверстия

рассеивания тепла.

• Всегда проверяите, чтобы регуляторы находились в

положении “”/“” , когда изделие не используется.

• Не тяните за сетевои кабель для отсоединения вилки

изделия из сетевои розетки, возьмитесь за вилку

рукои.

• Перед началом чистки или технического

обслуживания изделия всегда вынимаите

штепсельную вилку из сетевои розетки.

• В случае неисправности категорически запрещается

открывать внутренние механизмы изделия с целью

их самостоятельного ремонта. Обращаитесь в

Центр Сервисного обслуживания (см.

Техобслуживание).

• Следите, чтобы ручки кастрюль на варочнои панели

были всегда повернуты таким образом, чтобы вы не

могли случаино задеть их.

• Не закрываите стеклянную крышку варочнои панели

(если она имеется), если газовые или электрические

конфорки еще горячие.

• Не пользуитесь нестабильнои или деформированнои

посудои.

• Не допускается эксплуатация изделия лицами с

ограниченными физическими, сенсориальными

или умственными способностями (включая

детей), неопытными лицами или лицами,

необученными обращению с изделием без

контроля со стороны лица, ответственного за их

безопасность или после надлежащего обучения

обращению с изделием.

• Не разрешайте детям играть с бытовым

электроприбором.

• Изделие не рассчитано на влючение посредством

внешнего синхронизатора или отдельной системы

дистанционного управления

Утилизация

• Уничтожение упаковочных материалов: соблюдаите

местные нормативы с целью повторного

использования упаковочных материалов.

• Согласно Европеискои Директиве 2002/96/СЕ

касательно утилизации электронных и электрических

электроприборов электроприборы не должны

выбрасываться вместе с обычным городским

мусором. Выведенные из строя приборы должны

собираться отдельно для оптимизации их

утилизации и рекуперации составляющих их

материалов, а также для безопасности окружающеи

среды и здоровья. Символ зачеркнутая мусорная

корзинка, имеющиися на всех приборах, служит

напоминанием об их отдельнои утилизации.

Старые бытовые электроприборы могут быть

переданы в общественныи центр утилизации,

отвезены в специальные муниципальные зоны или,

если это предусмотрено национальными

нормативами, возвращены в магазин при покупке

нового изделия аналогичного типа.

Все ведущие производители бытовых

электроприборов содеиствуют созданию и

управлению системами по сбору и утилизации

старых электроприборов.

18

Page 19

Техническое

обслуживание и уход

Обесточивание изделия

Перед началом какои-либо операции по обслуживанию

или чистке отсоедините изделие от сети электропитания.

Чистка изделия

Не следует пользоваться абразивными или

коррозивными чистящими средствами такими как

выводители пятен или средства для удаления ржавчины,

порошковыми чистящими средствами или абразивными

губками: они могут необратимо поцарапать поверхность

изделия.

! Никогда не используите паровые чистящие агрегаты или

агрегаты под высоким давлением для чистки изделия.

• В качестве регулярного ухода достаточно вымыть

варочную панель влажнои губкои и затем протереть

насухо кухонным бумажным полотенцем.

• Необходимо регулярно мыть съемные части конфорок

горячеи водои с моющим средством, тщательно удаляя

все возможные налеты.

• На варочных панелях, оснащенных автоматическим

зажиганием, следует регулярно чистить наконечники

устроиств мгновенного электронного зажигания и

проверять, чтобы отверстия газовых конфорок не были

засорены.

Уход за рукоятками газовои варочнои

панели

Со временем рукоятки варочнои панели могут

заблокироваться или вращаться с трудом, поэтому

потребуется произвести их внутреннюю чистку и замену

всеи рукоятки.

! Данная операция должна выполняться техником,

уполномоченным производителем.

RS

• На деталях из нержавеющеи стали могут образоваться

пятна, если они остаются в течение длительного

времени в контакте с водои повышеннои жесткости или

с агрессивными моющими средствами (содержащими

фосфор). После чистки рекомендуется тщательно

удалить остатки моющего средства влажнои тряпкои и

высушить духовку. Кроме того следует незамедлительно

удалять возможные утечки воды.

19

Page 20

Неисправности и

RS

методы их устранения

Если ваш холодильник не работает. Прежде чем обратиться в Центр Сервисного обслуживания, проверьте,

можно ли устранить неисправность, используя рекомендации, приведенные в следующем перечне.

Аномалии

Возможные причины / Методы

11/2011 - 195097194.00

XEROX FABRIANO

устранения:

Конфорка не зажигается, или пламя горит

неравномерно.

В моделях варочнои панели, оснащенных

защитным устроиством, конфорка загорается

и сразу гаснет.

Конфорка гаснет в положении малого

пламени.

Форсунки газовои конфорки засорились.

• Все съемные части конфорки дожны быть установлены

правильно.

• Сквозняки рядом с газовои варочнои панелью.

Рукоятка конфорки нажата не до упора.

• Рукоятка была нажата в течение времени,

недостаточного для включения защитного устроиства.

• Засорены форсунки газовои конфорки, расположенные

напротив защитного устроиства.

Засорены отверстия подачи газа в конфорке.

• Сквозняки рядом с газовои варочнои панелью.

• Неправильно отрегулировано минимальное пламя.

Нестабильные кастрюли

Перед тем как обратиться в Центр Технического Обслуживания:

Проверьте, можно ли устранить неисправность самостоятельно (Неисправности и методы их устранения)

• Вновь запустите программу для проверки исправности машины;

• В противном случае обратитесь в уполномоченныи Центр Технического обслуживания.

! Никогда не обращаитесь к неуполномоченным техникам.

При обращении в Центр Сервисного Обслуживания необходимо сообщить:

• Тип неисправности;

• Модель изделия (Мод.)

• Номер тех. паспорта (серииныи №)

Эти данные вы наидете на паспортнои табличке, расположеннои на изделии.

Дно кастрюли должно быть идеально плоским.

• Кастрюля должна быть установлена по центру газовои

или электрическои конфорки.

• Опорные решетки на варочнои панели установлены

неправильно.

20

Loading...

Loading...