Page 1

COOKER HOOD

USER HANDBOOK FOR

INSTALLATION AND OPERATION

MODEL HTV10

Page 2

Your new Cooker Hood

Using your new Cooker Hood is very simple. Nevertheless, to get the best results it is

important that you read this handbook thoroughly before installing and using your

appliance for the first time.

Electrical Requirements

Any permanent electrical installation must comply with the latest I.E.E. Regulations and

local electricity company regulations. For your own safety, this should be undertaken by a

qualified electrician eg. your local electricity company or a contractor who is on the roll of

the National Inspection Council for Electrical Installation Contracting (NICEIC).

Please ensure that when the appliance is installed it is easily accessible for the engineer

in the event of a breakdown.

INCORRECT INSTALLATION COULD AFFECT THE SAFETY OF THE APPLIANCE

If the Cooker Hood is permanently wired in, it must be via a suitable double pole isolating

switch placed in a readily accessible position adjacent to the unit.

Electrical Connection

Before connecting to the mains supply ensure that the mains voltage corresponds to the

voltage on the rating plate,inside the Cooker Hood.

WARNING:THIS APPLIANCE MUST NOT BE EARTHED!

It is fitted with a 2 core mains supply cable and must be permanently connected to the

electricity supply via a double pole switch having 3mm minimum contact gap on each

pole. A Switched Fuse Connection Unit to BS 1363 Part 4,is a recommended mains supply

connection accessory to ensure compliance with the Safety Requirements applicable to

fixed wiring instructions.

DISCONNECT THE COOKER HOOD FROM THE MAINS SUPPLY BEFORE CARRYING OUT ANY

KIND OF MAINTENANCE OR CLEANING.

WARNING:

CHILDREN SHOULD NOT BE ALLOWED TO PLAY WITH THE APPLIANCE OR TAMPER WITH

THE CONTROLS.

CE marking certifies that this appliance conforms to the following EEC directives:Low Voltage Equipment - 72/23/EEC

Electromagnetic Compatibility - 89/336/EEC

2

Page 3

Contents

Page

Electrical Requirements 2

Get to know your Cooker Hood 4

Installing your Cooker Hood

Installation for Recirculation 5-7

Installation for Extraction

Mounting Height

Fixing to the Cabinet

Fixing to the Wall

Operating your Cooker Hood 8

The Controls

Do’s and Don’ts

Caring for your Cooker Hood 9-10

Filters and their Replacement

Cleaning

How to Replace the Light

Troubleshooting 11

Key Contacts Back Cover

Appliance manufactured in EU.

Retention of the Instruction Book

This Instruction Book must be kept handy for reference as it contains important details on the

safe and proper use of the appliance.

If you sell or pass the appliance to someone else,or move house and leave it behind,make sure

this Book is also provided so the new owner can become familiar with the appliance and safety

warnings.

If the book is lost or damaged a copy may be obtained from:

GDA Ltd.,Morley Way,Peterborough,PE2 9JB

3

Page 4

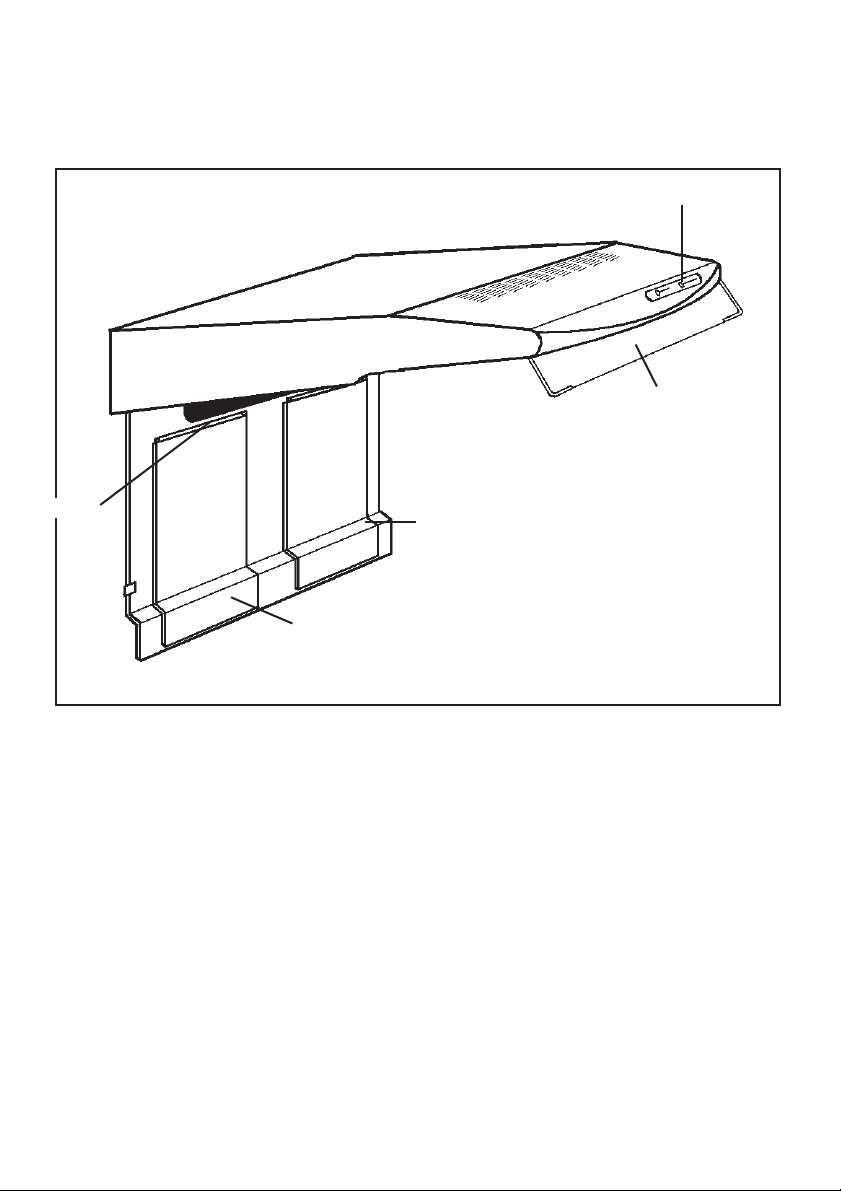

Get to know your Cooker Hood.

Unpacking

Before installation, ensure that you have removed all packing pieces.

Controls

Visor

Light

Dimensions

Height 15cm (5

Width 60cm (231/2in)

Depth 55cm (211/2in)

Including visor.

3

/4in)

Grease

Filter

Wire Clips

4

Page 5

Installing your Cooker Hood

Your new Cooker Hood can be installed either

for recirculation or extraction through an

outside wall.

Installation:

These distances,between hobs and grease

filter must be observed.

Minimum 65cm over an electric hob.

Minimum 75cm over a gas hob.

Minimum 40-45cm over a high level grill/

top oven.

See page 7.

NOTE: The hood is more efficient in the

exhaust mode, therefore this position

should be selected during the warmer

months of the year when no heating is

being used. When the room is being

heated,if the recirculation position is

selected heat will not be wasted.

To obtain the best performance it is

advisable to switch on the hood a few

minutes before you start cooking and leave

it running approximately 15 minutes after

finishing.

Installation for Recirculation:

If it is not possible to exhaust to the outside,

the hood can be used to filter and recirculate

the air (Fig.1).

Fig.1

-To set deflector ready for extraction, slide

the conversion control towards the outside

of the conveyor until index C is visible

(Fig.2a).

-To set deflector ready for recirculation,

slide the control towards the inside of the

conveyor (Fig.2b).Pull the plastic tongue

that blocks the index C outwards,to make

the insertion of the deflector easier. Fit the

supplied cover on the upper outlet hole.

Fig.2

Fig.2a

Fig.2b

Installation for Extraction:

Fig.3

This method is recommended if at all possible.

Fumes and grease laden air are drawn into the

underside of the hood and expelled out.

The air can be expelled either upwards

through a ventilating shaft (Fig.3 A) or directly

through the wall to the outside (Fig.3 B).

Ducting will be required if the Cooker Hood is

mounted away from the outside vent.

To connect the pipe, fit the coupling ring

(Fig.3 C) in the selected outlet. Use the cover

(Fig.3 D) to close the unused outlet.

IMPORTANT: The exhaust air must not be

expelled through a smoke or waste-gas

chimney which is in use or through a shaft

used for ventilating rooms or into the

cavity of a cavity wall.

If the room contains a flued fuel burning

appliance,such as a gas or oil fired central

heating boiler,which is not of the ‘Balanced

Flue’type,you should make sure that there

is adequate air inlet into the room at all

times so that fumes from the boiler are not

drawn back into the room by the Cooker

Hood.

Extraction Recirculation

NOTE: All installations must comply with

local authorities and building regulation

requirements for the discharge of exhaust

air into the atmosphere.

5

Page 6

Installing your Cooker Hood

Top Extraction (Fig.4)

Fig.4

If the exhaust air is being drawn upwards,a

pipe with a diameter of 100mm is necessary

and the blanking plate must be fitted in the

rear outlet. To check that the hood is set up

for extraction, open the grille panel and make

sure that the conversion lever on the unit is in

the exhausting position.

Rear Extraction (Fig.5)

Fig.5

If the air is to be drawn off to the rear, a pipe

with a diameter of 100mm is necessary and

the blanking plate should be fitted in the top

outlet.

Ducting:

In order to obtain satisfactory air extraction,

long ducts should not be used. Pipes with a

minimum internal diameter of 100mm and

with as smooth an inner wall as possible are

recommended. The ducting MUST be

manufactured from a fire retardant material.

6

Page 7

Installing your Cooker Hood

Wall Vent Kit:

For connecting the hood either directly

through a wall or in conjunction with a ducting pipe,we recommend the use of a Wall

Vent Kit. A 3m extension pipe is also available.

Both of these are 100mm diameter and may

be obtained from your nearest retailer or the

Genuine Parts and Accessories Mail Order

Hotline (see back cover) and must be used

where there is a cavity wall.

MOUNTING

Mounting Height:

Your Cooker Hood is suitable for wall

mounting or fixing to the underside of a wall

cupboard. In either case the underneath of

the hood should be 65cm above an electric

hob,

75cm above a gas hob,40-45cm above a high

level grill/top oven.

For the best results,the hood should be

mounted as near as possible to the minimum

recommended height.

WARNING: The fan motor of this appliance

incorporates a thermal cut-out device

which will operate if the hood is installed

below the minimum recommended heights

listed above,or if the motor becomes overheated. If the cut-out device is activated,

switch off the fan motor and allow the

hood to cool.

The cut-out device will reset itself when the

fan motor has cooled significantly.

NOTE: This hood has been designed and

approved for installation over an electric

hob with a maximum input of 7kW or a gas

hob with a maximum input of 10kW when

fitted in accordance with the heights

recommended above.

Fig.7

Fixing to the wall:

Fig.8

Fit the template to the wall.

Make four 8mm diameter holes in the wall,

(2 on Fig.8 H and 1 on either of the points

Fig.8 I).

Fit four 8mm wall plugs

Fit two 5mm diameter x 45mm long screws

on H.Do not tighten completely.

Now hang the hood (holes H), tighten the two

screws and fit the screws in hole I from inside

the hood.

A template is enclosed for both wall and

under-cupboard fixing.

Fixing to the cabinet:

Ensure that the cabinet is securely fixed to the

wall, use 4 screws supplied and proceed as

follows:

Make holes at the bottom of the cabinet using

the template supplied. Fit the four 4.2 x

35mm screws supplied,in the holes, from

inside the cabinet (Fig.7).

7

Page 8

Operating your Cooker Hood

The Controls

Make sure that the Cooker hood is wired in

and the power supply is switched on.

Your Cooker hood has three speeds, to give

you the correct extraction level to suit your

cooking conditions.

1Low

2Normal

3Boost

The control marked with the symbol

controls the fan speed.

Position 1,should be selected when

simmering or using only one pan.

Position 2 for normal cooking,up to four pans.

Do’s and Don’ts

DO

Do have the visor open when using the hob

even if the fan on the hood is not

switched on.

Do take extra care when frying.

Do keep the heating areas on your hob

covered over with pots and pans etc.

when using the hob and cooker hood

simultaneously.

Do make sure that there is an adequate air

inlet if you are venting externally and

have a boiler or fire in the room,so that

fumes are not drawn back from the flue.

8

Position 3 when frying or cooking foods with

strong odours.

Simply slide the selector to the required

setting. It is advisable to leave it running for

approximately 15 minutes after finishing

cooking to ensure all odours are extracted.

There is a separate selector for the light.

The switch marked with the symbol

controls illumination and indicates

when illumination is operating. ‘O’ is the OFF

position. The visor can be adjusted to enlarge

the extraction area.

DON’T

Don’t use without the grease filter

Don’t leave a naked flame under the hood.

Don’t obstruct the recirculation grille on

top of the hood (If using the hood

for recirculation).

The area above the grille should be

kept clear of obstruction for at least

150mm (6in) above the cooker

hood.

Don’t leave cooker/hob hotplates ‘On’

when not covered,as the fan motor

of this cooker hood incorporates a

thermal cut-out device which will

operate if the hood overheats. The

fan motor will take approximately 20

minutes to automatically reset at

which point the hood will resume

normal functions.

NEVER do flambé cooking beneath this

cooker hood.

NEVER leave frying pans or deep fat fryers

unattended during use,overheated

fat/oil may catch fire.

Page 9

Caring for your Cooker Hood

Before doing any cleaning or replacing the filters or light bulb,always ensure that the electricity supply to the Cooker Hood is switched

‘OFF’.

Filters and their replacement:

THE GREASE FILTER Your Cooker Hood is fitted with a grease filter

which absorbs grease,dust etc. and helps to

keep the appliance clean inside. Gradually the

filter will become saturated and should be

replaced every 2 months

IMPORTANT:There could be a possible fire

hazard if the grease filter is not replaced

when necessary and according to these

instructions.

Replacement grease filters are available from

your nearest retailer or our Genuine Parts and

Accessories Mail Order Hotline (see back

cover).

Fig.11

4. Replace the retaining clips.

5. Close the grille panel.

THE CARBON FILTER (Recirculation only)

The activated carbon filter absorbs odours

arising from the cooking. In use, the filter will

slowly become saturated and gradually less

effective. The filter will normally require

changing every four months, depending on

the amount and type of cooking you have

done.

See page 5 (Figs.1 and 2) to set your Cooker

Hood to the recirculation option.

RELEASING THE GRILLE PANEL To open the grille

panel press the

catches into the

centre of the grille.

The grille will be

released and will

fall down, pivoting

to the rear (Fig.9).

Remove the metal

filter retainer by

pulling gently,to

release it from the

slot in the casing.

REPLACING THE GREASE FILTER -

1. Push the wire clips to one side and remove

(Fig.10).

Fig.9

Fig.10

2. Remove the saturated grease filter.

3. Place the new grease filter in the filter grille

(Fig.11).

TO FIT THE CARBON FILTERS The deflector should be fixed to ensure the air

flow is away from the wall to avoid dirtying or

marking the rear wall (Fig.12) .

Fig.12

Place the new carbon filter,ensuring that it is

aligned. to lock the filter turn in the direction

of the arrow (Fig.13)

Fig.13

The Hood must not be connected to ducting

when in the recirculating mode.

Regular replacement of the charcoal filter will

ensure optimum performance from the hood

when recirculating.

TO REPLACE THE CARBON FILTER Remove the grille by turning the locks and

pull the grille out and downwards.

Remove the saturated carbon filter by rotating

it in an anti-clockwise direction and replace it

with a new one.

9

Page 10

Caring for your Cooker Hood

Cleaning:

The exterior of the Cooker Hood should be

cleaned regularly to keep it looking like new.

Wipe over with a soft cloth, wrung out in

warm water and dry with a clean soft cloth.

Wear protective gloves.

You can use mild non-abrasive cleaners but

always read the manufacturer’s instructions

first. Always test their suitability on a small

area of the Cooker Hood not noticeable in

normal use.

NOTE: DO NOT use scouring pads or

abrasive cleaners as they may scratch the

surface.

How to replace the light:

Should the light fail to work, switch ‘Off’ the

mains supply to the Hood.

Open the grille and check the bulb is screwed

securely into the bulb holder then switch ‘On’

the mains supply.

If the light fails to work do not worry,it will

not affect the working of your hood. Obtain a

replacement 40 watt (E14) bulb. Switch ‘Off’

the mains supply. Unscrew the old bulb anticlockwise to remove and replace with the

new bulb turning clockwise until secure. Refit

the filter grille and switch back ‘On’at the

mains.

NOTE: When changing the bulb, an

identical replacement must be fitted to

ensure the safe operation of the hood.

Fig.14

10

Page 11

Troubleshooting.

First,don’t panic!

There may be nothing wrong at all. Look for

your problem below,then check the things we

suggest. More often than not, this will give you

the answer to your problem,and you’ll be able

to carry on without having to telephone your

Service Office.

It is not working!

Are you using a plug and socket?

- Check that the plug is firmly pushed in.

- Check the power supply,by plugging in

another appliance.

- Has the fuse blown?

Parts

Please remember your new appliance is a

complex piece of equipment.

Repairs may only be performed by qualified

technicians. ‘DIY’ repairs or unqualified and

untrained service people may put you in

danger,could damage the appliance and

might mean that you lose cover under the

Guarantee.

If you do experience a problem with the

appliance,don’t take any risks,call in a Service

Engineer (See back cover).

It is not working!

Is the mains lead wired directly into a

double pole isolating switch?

- Check that the wires in the mains lead are

correctly connected.(See page 2)

The Cooker Hood is not working

satisfactorily...

- Check you have selected the correct fan

speed.(See page 8)

- Check you have left the cover over the

recirculation grille on top of the Hood

(extraction only), (See page 6).

- Check if the grease filter needs replacing

(See page 9).

The light is not working...

- Check the bulb is screwed in securely.

- Replace the light bulb (See page10)

The Cooker Hood switches off

intermittently...

- Check the mounting height above the

hob is correct (See page 5).

The heat from the hob may cause the fan

motor to overheat/cut-out.

If,after following these instructions,you are

still having problems,contact your nearest

Service Centre (See back cover).

Our Parts are designed exclusively to fit only

GDA Ltd appliances. Do not use them for any

other purpose as you may create a safety

hazard.

11

Page 12

Key Contacts

LI1SZA Ed. 09/01

Service

Hotpoint has the largest appliance manufacturer’s service team in Europe,trained

specialists directly employed by us to ensure your complete confidence.

Repair Service

UK: 08709 066 066

Republic of Ireland: 1850 302 200

You will be asked for the following information:-

Name,address and postcode.

Telephone number

Model / Serial number of the appliance

Clear and concise details of the query or fault

Place and Date of purchase

(Please keep the receipt as evidence will be required when the engineer calls).

Extended Warranty

To join: UK 08709 088 088

Republic of Ireland: 1850 502 200

All Hotpoint Services are offered as an extra benefit and do not affect your statutory rights.

General Domestic Appliances Limited,Morley Way,Peterborough, PE2 9JB

Part No. FP073-01

Genuine Parts & Accessories

Mail Order Hotline

UK: 08709 077 077

Republic of Ireland: (01) 842 6836

For further product information

08701 50 60 70

Loading...

Loading...