Page 1

Please phone us on

08448 24 24 24

to activate your

guarantee

CH 10450 GF S

CH 10456 GF S

English

Operating Instructions

COOKER

Contents

Operating Instructions,1

Warnings,2

Description of the appliance,3

Introduction,4

Installation,4

For your safety,7

Oven timer operation,8

Hotplate,11

Griddle,12

Some recipe ideas for your griddle,12

Top grill,12

Fan oven (1st Oven),13

Conventional oven (2nd Oven),14

The ‘slow cook’ setting,16

Care and cleaning,17

Something wrong with your cooker,18

After Sales Service,19

Guarantee,20

Page 2

PLEASE PHONE US TO REGISTER YOUR APPLIANCE AND ACTIVATE YOUR PARTS GUARANTEE ON 08448 24 24 24

Warnings

GB

WARNING: The appliance and its accessible parts

become hot during use. Care should be taken to

avoid touching heating elements. Children less than 8

years of age shall be kept away unless continuously

supervised. This appliance can be used by children

aged from 8 years and above and persons with

reduced physical, sensory or mental capabilities or

lack of experience and knowledge if they have been

given supervision or instruction concerning use of the

appliance in a safe way and understand the hazards

involved. Children shall not play with the appliance.

Cleaning and user maintenance shall not be made

by children without supervision.

WARNING: Unattended cooking on a hob with fat or

oil can be dangerous and may result in re.

NEVER try to extinguish a re with water, but switch

off the appliance and then cover ame e.g. with a lid

or a re blanket.

Do not use harsh abrasive cleaners or sharp metal

scrapers to clean the oven door glass since they can

scratch the surface, which may result in shattering

of the glass.

The internal surfaces of the compartment (where

present) may become hot.

Never use steam cleaners or pressure cleaners on

the appliance.

“Remove any liquid from the lid before opening it.

Do not close the glass cover (if present) when the

gas burners or electric hotplates are still hot.”

WARNING: Ensure that the appliance is switched

off before replacing the lamp to avoid the possibility

of electric shock.

CAUTION: the use of inappropriate hob guards can

cause accidents.

! When you place the rack inside, make sure that the

stop is directed upwards and in the back of the cavity.

2

Page 3

PLEASE PHONE US TO REGISTER YOUR APPLIANCE AND ACTIVATE YOUR PARTS GUARANTEE ON 08448 24 24 24

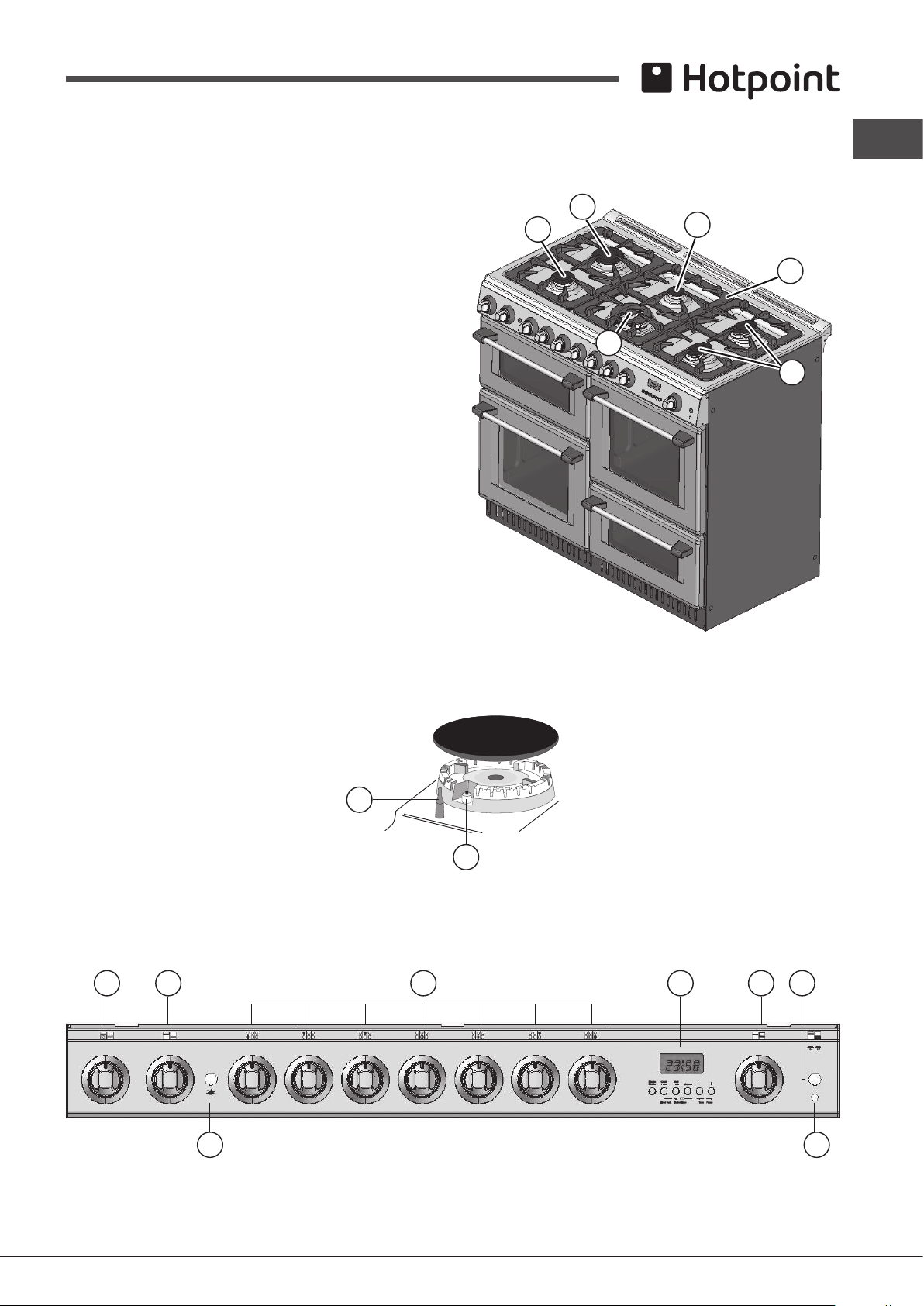

Description of the appliance

Overall view

GB

1 AUXLIARY gas burner

2 SEMI-RAPID gas burner

3 RAPID gas burner

4 DCDR gas burner

5 DOUBLE FACE gas burner

6 PAN SUPPORT FOR COOKWARE

7 SAFETY DEVICE - Activates if the ame accidentally goes out (spills,

drafts, etc.), interrupting the supply of gas to the burner.

8 IGNITOR for Gas BURNERS

Control panel

9 THERMOSTAT AND CONTROL KNOB

(Main Ventilated Oven)

10 TOP GRILL Energy Regulator

11 GAS BURNERS Control knobs

12 TIMER

13 THERMOSTAT AND CONTROL KNOB

(Main Convectional Oven)

14 FOOD WARMER switch

15 FOOD WARMER indicator

16 HOB GAS BURNER ignition button

3

2

4

1

6

5

7

8

9 10 11 1413

16

12

15

3

Page 4

PLEASE PHONE US TO REGISTER YOUR APPLIANCE AND ACTIVATE YOUR PARTS GUARANTEE ON 08448 24 24 24

Introduction

GB

from our Service and Genuine Parts and Accessories department (see

back cover).

! Before placing your new appliance into operation please read these operating

instructions carefully. It contains important information concerning the safe

installation and operation of the appliance.

! Please keep these operating instructions for future reference. Make sure that

the instructions are kept with the appliance if it is sold, given away or moved.

! The appliance must be installed by a qualied professional in accordance

with the instructions provided.

! Any necessary adjustment or maintenance must be performed after the

cooker has been disconnected from the electricity supply.

The cookers have the following technical specications:

Category: II 2H3+

This appliance must be installed in accordance with the regulations in force

and only used in a well ventilated space.

The data badge is tted on the rear panel. The model/serial number can also be

found on a badge located below the left-hand oven door beneath the door seal.

Read these instructions before installing or using the appliance and

retain them for future reference.

These instructions are only valid for the countries whose symbols

appear in the manual and on the serial number plate.

To help you make the best use of your cooker, PLEASE READ THIS

BOOKLET CAREFULLY.

Your new cooker is guaranteed and will give lasting service. The guarantee

is only applicable if the cooker has been installed in accordance with the

Installation Instructions. The cooker is designed specically for domestic

use and responsibility will not be accepted for use in any other installation.

When rst using the cooker ensure that the room is well ventilated (e.g. open

a window or use an extractor fan) and that persons who may be sensitive to

the odour avoid any fumes. It is suggested that any pets be removed from

the room until the smell has ceased. This odour is due to any temporary nish

and also any moisture absorbed by the insulation.

Our policy is one of continual improvement in design and development,

therefore strict accuracy of illustrations and descriptions cannot be guaranteed.

GAS SAFETY (INSTALLATION & USE) REGULATIONS

It is the law that all gas appliances are installed by competent persons in

accordance with the current edition of the above regulations. It is in your

interest and that of safety to ensure compliance with the law.

In the UK, CORGI registered installers work to safe standards of practice.

The cooker must also be installed in accordance with Current national

legislation.

Failure to install the cooker correctly could invalidate the warranty liability

claims and could lead to prosecution.

LOCATION

The cooker may be located in a kitchen, kitchen/diner or a bed-sitting room, but

not in a room containing a bath or shower. The cooker must not be installed

in a bed-sitting room of less than 20m

When adjusted for use on BUTANE (G30) or PROPANE (G31) the cooker

must not be installed in a room or internal space below ground level, eg. in

a basement.

PROVISION FOR VENTILATION

The room containing the cooker should have an air supply in accordance with

Current national legislation.

The room must have an opening window or equivalent; some rooms may also

require a permanent vent. If the room has a volume between 5 and 10m

it will require an air vent of 50cm2 effective area unless it has a door which

opens directly to outside. If the room has a volume of less than 5m

require an air vent of 100cm

appliances in the same room, in accordance with Current national legislation

should be consulted to determine air vent requirements.

DIMENSIONS

Height: 900 - 915 mm

Widht: 1000 mm

Depth: 600 mm (excluding door handles)

GENERAL

Gas connection Rp ½ (½” BSP female)

Pressure test point Hotplate burner injector

Gas rate adjustment None

Aeration adjustment None

3

.

3

2

effective area. If there are other fuel burning

, it will

3

,

Installation

Prior to installation, ensure that the local distribution conditions (nature of the

gas and gas pressure) and the adjustment conditions are compatible. The

adjustment conditions for this appliance are stated on the data badge which

is tted on the back panel.

This appliance is not designed to be connected to a combustion products

evacuation device. It must be installed and connected in accordance with

current installation regulations. particular attention should be given to the

relevant requirements regarding ventilation.

MODEL NUMBERS

CH10450GF S, CH10455GF S, CH10456GF S

Category II2H3+ (GB. IE)

This model is set to burn NATURAL GAS (G20) at 20 mbar but can be

converted for use on BUTANE (G30) at 28-30mbar or PROPANE (G31) at

37mbar with the use of a service kit supplied with the appliance or available

4

Page 5

PLEASE PHONE US TO REGISTER YOUR APPLIANCE AND ACTIVATE YOUR PARTS GUARANTEE ON 08448 24 24 24

TECHNICAL DATA (1st Oven)

Liquid GasNatural Gas

Burner Diameter

(mm)

Thermal power

kW (p.c.s.*)

By-Pass

1/100

Nozzle

1/100

Flow*

g/h

Nozzle

1/100

Flow*

l/h

Nomin. Ridot. (mm) (mm) ***** (mm)

HOTPLATE - Semi Rapid - Front Left

HOTPLATE - Rapid - Rear Left

HOTPLATE - Work Outer - Centre Front

HOTPLATE - Work Inner - Centre Front

HOTPLATE - Auxiliary - Centre Rear

HOTPLATE - Double Face - Front Right

HOTPLATE - Double Face - Rear Right

75

100

130

35

50

-

-

1,90

3,00

4,10

1,00

1,00

1,50

1,50

0,40

0,70

1,50

0,40

0,40

0,40

0,40

35

44

63

24

24

35

35

65

86

70 x 2

44

50

60

60

138

218

298

73

73

109

109

136

214

293

71

71

107

107

102 Z

116 Y

110 x 2

74

71 X

88 X

88 X

181

286

390

95

95

143

143

Supply

Pressures

Nominal (mbar)

Minimum (mbar)

Maximum (mbar)

28-30

20

35

37

25

45

20

17

25

* At 15°C and 1013 mbar - dry gas

Propane P.C.S. = 50.37 MJ/kg

Butane P. C.S. = 49.47 MJ/kg

Methane P. C.S. = 37.78 MJ/kg

Element

Heat Input

230-240V ~

TWIN GRILL

L/H OVEN

R/H OVEN

WARMING DRAWER

Max Input

2.50 kW

1.60 kW

1.80 kW

0.15 kW

6.00-6.80 kW

Oven dimensions

HxLxP

Volume

Voltage and

frequency

Burners

36,6 x 40,6 x 40,9 cm

lt. 61

230-240V~ 50Hz

(Total electrical heat input: 6,0 - 6,8 kW)

may be adapted for use with any type

of gas shown on the data plate.

EU Directive no 65/2014

supplementing Directive 2010/30/EU.

EU Regulation no 66/2014

Energy

Label e

Ecodesign

implementing Directive 2009/125/EC.

Standard EN 60350-1,

Standard EN 30-2-1,

Standard EN 50564

Declared energy consumption for

Forced convection Class –

heating mode: Fan assisted.

This appliance conforms to the

following European Economic

Community directives:

- 2006/95/EC dated 12/12/06 (Low

Voltage) and subsequent amendments.

- 2004/108/EC dated 03/05/89

(Electromagnetic Compatibility) and

subsequent amendments.

- 93/68/EEC dated 22/07/93 and

subsequent amendments.

- 2009/142/EC dated 30/11/09 (Gas)

and subsequent amendments.

- 2012/19/EU and subsequent

amendments.

- 1275/2008 standby/off mode.

TECHNICAL DATA (2nd Oven)

Oven dimensions

HxLxP

Volume

Voltage and

frequency

Burners

34,0 x 40,8 x 44,8 cm

lt. 63

230-240V~ 50Hz

(Total electrical heat input: 6,0 - 6,8 kW)

may be adapted for use with any type

of gas shown on the data plate.

EU Directive no 65/2014

supplementing Directive 2010/30/EU.

EU Regulation no 66/2014

Energy

Label e

Ecodesign

implementing Directive 2009/125/EC.

Standard EN 60350-1,

Standard EN 30-2-1,

Standard EN 50564

Energy consumption for Natural

convection – heating mode:

Convection mode

This appliance conforms to the

following European Economic

Community directives:

- 2006/95/EC dated 12/12/06 (Low

Voltage) and subsequent amendments.

- 2004/108/EC dated 03/05/89

(Electromagnetic Compatibility) and

subsequent amendments.

- 93/68/EEC dated 22/07/93 and

subsequent amendments.

- 2009/142/EC dated 30/11/09 (Gas)

and subsequent amendments.

- 2012/19/EU and subsequent

amendments.

- 1275/2008 standby/off mode.

GB

5

Page 6

PLEASE PHONE US TO REGISTER YOUR APPLIANCE AND ACTIVATE YOUR PARTS GUARANTEE ON 08448 24 24 24

Conversion for use on Butane or Propane

750

mm min.

400

mm min.

1005

mm min.

65

mm min.

GB

Each hob burner requires the injector to be replaced and each burner gas

tap to have the by-pass screw adjusted according to the following procedure:

1. Lift off the burner cap and the burner body and place it to one side.

2. Remove the injector from the burner base with a suitable box spanner

and discard.

3. Replace the injector with the appropriate replacement (see Table).

4. Repeat for each burner.

5. Replace the burner bodies and caps, taking care that they are positioned

correctly.

6. Remove the tap knob from the left hand hotplate tap. Insert a narrow at

screwdriver centre of the tap spindle and turn fully clockwise. Replace the

tap knob. Repeat this procedure with the other six hotplate taps.

7. Position and x the self-adhesive LPG conversion label over the gas details

on the rating plate label.

Aluminium burner bodies (6) Griddle

Wok Stand Literature pack

After unpacking your cooker, make sure that you remove all the packing from

the oven and grill, and any stickers from the oven door and the hob.

Levelling

Your cooker is heavy, so it would be advisable for two people to move it. The

cooker is tted with rear wheels and will slide into position easily. Movement

of your cooker is most easily achieved as follows. Open the grill/oven door

sufciently to allow a comfortable grip on the underside front edge of the

oven roof, avoiding any grill or oven interior furniture, and then lift and slide

back at the same time.

Your cooker must stand on a at surface so that the hob is perfectly level, and

the cooker is stable and cannot be rocked, this is easily achieved by adjusting

the three feet which are under the front of the cooker and the 3 castors under

the rear of the cooker, if necessary.

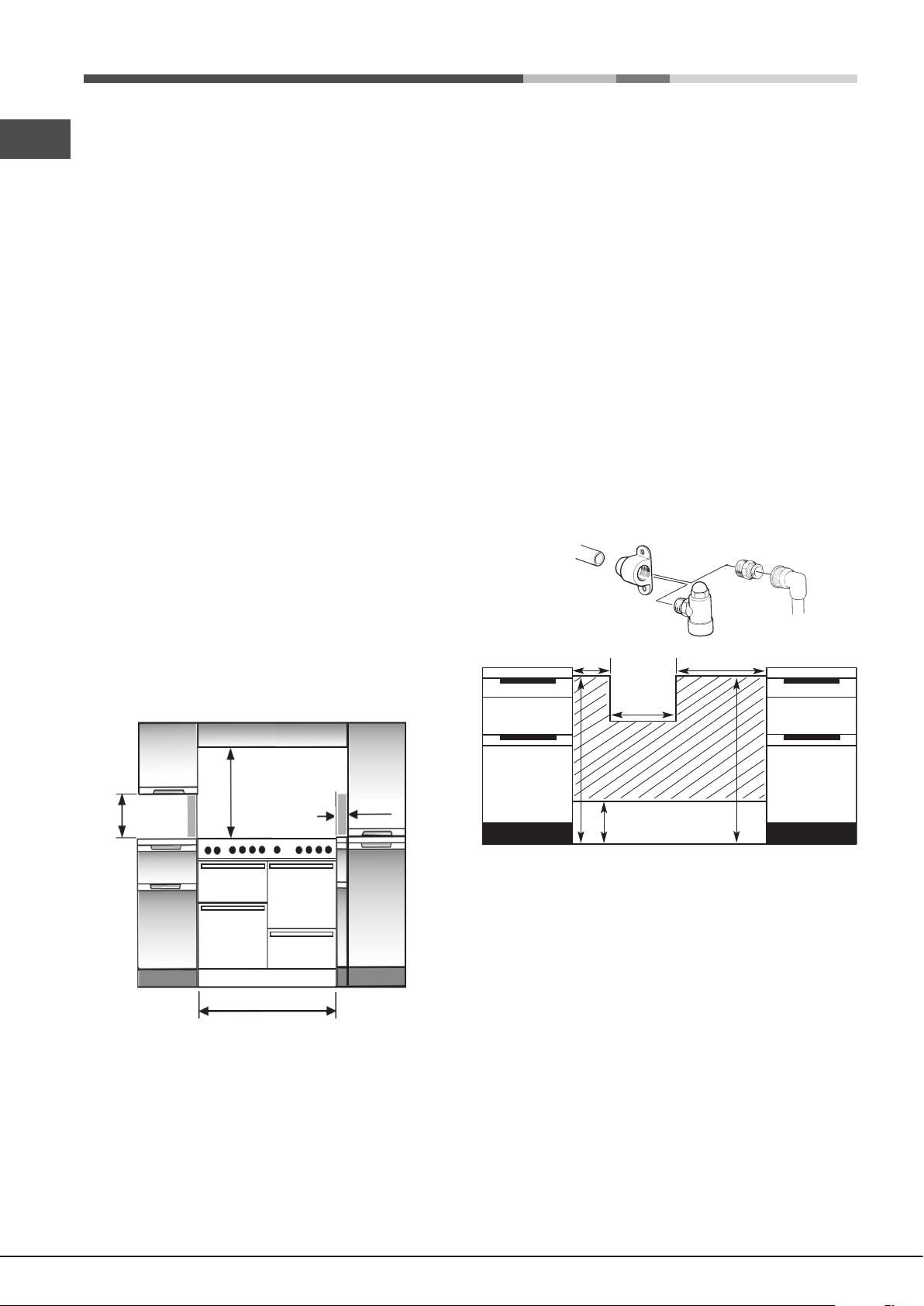

Space for xing

The cooker can be close tted below hotplate level. This requires a minimum

distance of 600mm between cupboard units of hotplate height.

NOTE: If the cooker is to be placed on a base, precautions must be taken to

prevent it from slipping off the base.

The cooker is designed to match the depth of standard 600mm worktops. An

adaptor backplate should, therefore, be tted within the shaded area shown

When installing next to a tall cupboard, partition or wall, for a minimum distance

of 400mm above hotplate level, allow a side clearance of at least 65mm.

to allow the cooker to be pushed fully to the wall. If a forward facing backplate

is used, it must be chased into the wall.

The diagram below illustrates the minimum clearance between the cooker

and adjacent walls, cupboards etc.

The wall behind the cooker, 50mm below and 450mm above, and the width

of the cooker, must be a non-combustible material such as ceramic wall tiles.

If the cooker is to be tted close to a corner on the left hand side, ensure that

there is a clearance of at least 50mm to allow the main oven door to open

fully for when removing oven shelves.

Connection to the cooker should be made with an approved appliance exible

connection in according to current National legislation. A length of 0.9 to 1.25m

is recommended. The length of hose chosen should be such that when the

cooker is in situ, the hose does not touch the oor.

180

750

450

370

750

250

The temperature rise of areas at the rear of the cooker that are likely to come

in contact with the exible hose do not exceed 70°C.

LPG cookers should be connected with a hose suitable for LPG and capable

of withstanding 50mbar pressure.

Cooker hoods

WARNING - THIS APPLIANCE MUST BE EARTHED

Your cooker should have been checked to ensure that the voltage corresponds

with your supply voltage, which is stated on the data badge tted on the rear

panel.

The cooker must be connected by a contractor/engineer who is registered with

the National Inspection Council for Electrical Installation Contracting (NICEIC),

to a suitable double - pole control unit with a minimum rating of 30A and a

minimum contact clearance of 3mm, which should be tted adjacent to (but

not above) the cooker, in accordance with IEE regulations.

If a cooker hood is to be installed, refer to the cooker hood manufacturers’

instructions regarding xing height.

UNPACKING THE COOKER

Unpack the components from inside the grill and oven. Check that the following

parts are present:

Meat pan Pan supports (3)

Grill pan, grid and handle LPG conversion kit

Loose burner parts (14) Oven shelves (4)

6

Page 7

PLEASE PHONE US TO REGISTER YOUR APPLIANCE AND ACTIVATE YOUR PARTS GUARANTEE ON 08448 24 24 24

The power supply cable should conform to Current national legislation with

a conductor size of 4mm2.

The power supply cable must be type H05RR-F 3x4mm².

The control unit should be easily accessible in the event of an emergency.

This appliance conforms to EN55014 regarding suppression of radio and

television interference.

• If the event of malfunctions under no circumstances should you attempt to

perform the repairs yourself. Contact an authorized Service Centre (see

Assistance).

• Do not rest object on the open door

• If the cooker is placed on a pedestal, take the necessary precautions to

prevent the cooker from sliding off the pedestal itself.

• The appliance is not intended to be operated by means of an external

timer or separate remote-control system.

GB

Access to the mains terminals is gained by removing the rear access cover.

The mains cable must pass through the cable clamp adjacent to the terminal

block.

Sufcient cable should be used to allow the cooker to be pulled out for

servicing.

Installation & Operational Checks

After installation, check for gas soundness.

Fit the hotplate burner bodies, burner port rings, enamelled discs and pan

supports referring to the instructions for use where necessary.

1. Check that the hotplate burners ignite correctly and burn with a steady

ame.

Check for a steady ame on the low setting.

2. Check that with the left hand oven set at 230°C, the oven fan operates

and the oven heats up.

3. Check that with the right hand oven set at 230°C, the oven heats up.

4. Check that the twin grill heats up.

5. Check that the warming drawer heats up.

6. Check operation of clock.

Instruct the user on the operation of the cooker.

ALWAYS . . .

ALWAYS

make sure you understand the controls before using the cooker.

ALWAYS

check that all controls on the cooker are turned off after use.

ALWAYS

stand back when opening an oven door to allow heat to disperse.

ALWAYS

use dry, good quality oven gloves when removing items from the ovens.

ALWAYS

take care when removing items from the top oven/grill when the main oven

is on, as the contents may be hot.

ALWAYS

keep the oven and grill doors closed when the cooker is not in use.

ALWAYS

place pans centrally over the hotplate burners and position them so that the

handles cannot accidentally be caught or knocked or become heated by

other burners.

For your safety

Please read the precautions below before using your cooker.

• The appliance was designed for domestic use inside the home and is not

intended for commercial or industrial use

• The appliance must not be installed outdoors, even in covered areas. It is

extremely dangerous to leave the appliance exposed to rain and storms.

• When moving or positioning the appliance, always use the handles

provided on the sides of the oven

• Do not touch the appliance while barefoot or with wet or damp hands and

feet

• The appliance must be used by adults only for the preparation of food, in

accordance with the instructions provided in this booklet. Any other use

of the appliance (e.g. for heating the room) constitutes improper use and

is dangerous. The manufacturer may be hot be held responsible for any

damage caused as a result of improper, incorrect and unreasonable use

of the appliance.

• Make sure that the power supply cables of other electrical appliances do

not come into contact with the hot parts of the oven

• Always grip the oven door handle in the centre: the ends may be hot.

• Always use oven gloves when placing cookware in the oven or when

removing it.

• Do not place ammable materials in the oven: if the appliance is switched

on accidentally, the materials could catch re.

• When unplugging the appliance, always pull the plug from the mains

socket; do not pull on the cable.

ALWAYS

keep the cooker clean, as a build up of grease or fat from cooking can cause

a re.

ALWAYS

allow the cooker to cool before cleaning.

ALWAYS

follow the basic principles of food handling and hygiene to prevent the

possibility of bacterial growth.

ALWAYS

keep ventilation slots clear of obstructions.

ALWAYS

turn off the electricity supply before cleaning or replacing an oven lamp.

ALWAYS

refer servicing to CORGI registered appliance service engineers.

ALWAYS

ACCESSIBLE PARTS MAY BECOME HOT WHEN THE GRILL IS USED.

YOUNG CHILDREN SHOULD BE KEPT AWAY.

ALWAYS

Children should be supervised to ensure that they do not play with the

appliance

7

Page 8

PLEASE PHONE US TO REGISTER YOUR APPLIANCE AND ACTIVATE YOUR PARTS GUARANTEE ON 08448 24 24 24

ALWAYS

.

.

GB

During use the appliance becomes hot. Care should be taken to avoid touching

heating elements inside the oven

NEVER . . .

NEVER

leave children unsupervised where the cooker is installed as all surfaces will

get hot during and after use.

or more than one hotplate burner, open a window if a mechanical ventilation

device is not operating.

! The appliance should not be operated by people (including children) with

reduced physical, sensory or mental capacities, by inexperienced individuals

or by anyone who is not familiar with the product. These individuals should,

at the very least, be supervised by someone who assumes responsibility

for their safety or receive preliminary instructions relating to the operation

of the appliance.

NEVER

allow anyone to sit or stand on any part of the cooker.

NEVER

store items that children may attempt to reach above the cooker.

NEVER

heat up unopened food containers as pressure can build up causing the

container to burst.

NEVER

store chemicals, food stuffs, pressurised containers in or on the cooker, or in

cabinets immediately above or next to the cooker.

NEVER

ll a deep fat frying pan more than 1/3 full of oil, and NEVER use a lid. DO

NOT LEAVE UNATTENDED WHILE COOKING.

NEVER

place ammable or plastic items on or near the hotplate.

NEVER

use proprietary spillage collectors on the hotplate.

NEVER

use the cooker as a room heater.

NEVER

dry clothes or place other times over or near to the hotplate or oven/gril doors.

NEVER

wear garments with long owing sleeves whilst cooking.

NEVER

operate the grill with the grill doors closed. This may cause overheating of

your cooker.

NEVER

line the shelves, oor or sides of the oven or grill with aluminium foil as over

heating and damage can result.

NEVER

use steam cleaners.

Oven timer operation

The oven timer (only ventilated

1. Time of Day

2. Automatic Cooking

3. Minute Minder

Automatic cooking

The main oven can be controlled automatically.

Guidance on automatic cooking

1. Select foods which will take the same time to cook.

2. Set the oven timer so that the food has just nished or is just about to

nish cooking on your return to the oven. This will ensure the food has

not cooled down and does not require reheating before serving.

3. Food should be as cold as possible when it goes into the oven, ideally

straight from the refrigerator. Frozen meat and poultry should be thawed

thoroughly before it is put in the oven.

4. Warm food should never be placed in the oven if there is to be a delay

period. Stews prepared by frying the meat and vegetables should be

cooked as soon as possible.

5. Dishes containing left-over cooked poultry or meat, for example

Shepherds Pie, should not be cooked automatically if there is to be a

delay period.

6. Stews and joints should be cooked by the long slow method, so that the

delay period is kept to a minimum.

7. On warm days, to prevent harmful bacterial growth in certain foods (ie

poultry, joints, etc) the delayed start should be kept to a minimum.

8. Wine or beer may ferment and cream may curdle during the delay period,

so it is best to add these ingredients just before serving.

9. Foods which discolour should be protected by coating in fat or tossing in

water to which lemon juice has been added, prior to placing food in the

oven.

10. Dishes containing liquid should not be lled too full to prevent boiling over.

11. Food should be well sealed (but not airtight) in a container to prevent the

loss of liquid during cooking. Aluminium foil gives a good seal.

12. Ensure food is cooked thoroughly before serving.

CLOCKFACE

A

U

T

000

O

1st

Oven) offers you the following features:

The timer incorporates a 24 hour clock.

Ensure the correct time of day is always set,

before using your cooker.

NEVER

touch the heating elements inside the oven or grill even when off.

NOTE: The use of a gas cooking appliance results in the production of heat

and moisture in the room in which it is installed. Always ensure that the kitchen

is well ventilated; keep natural ventilation holes open or install a mechanical

ventilation device (mechanical extractor hood). In particular when using the grill

8

SYMBOLS

000

A ‘bell’ symbol will light up when you select a

Minute Minder Period and will remain lit for the

period set.

Page 9

PLEASE PHONE US TO REGISTER YOUR APPLIANCE AND ACTIVATE YOUR PARTS GUARANTEE ON 08448 24 24 24

At the end of the Minute Minder Period, the timer will emit an audible tone

.

.

.

.

.

000

.

.

and the ‘bell’ symbol will disappear.

The ‘cookpot’ symbol will light up either:-

000

- When the timer is in manual mode, or

- During the actual Cook Period.

A

U

T

000

O

Step 4 Press & hold in both the Cook Period &

End Time buttons together.

Step 5 With the Cook Period & End Time

buttons still held in, press either the “+” or “-”

buttons to set the correct time of day.

Step 6 Release all the buttons simultaneously.

THE TIME OF DAY IS NOW SET.

GB

A

U

T

000

O

The ‘AUTO’ symbol will ash at the end of an Auto Cooking programme to

indicate that the programme has nished.

(When the ‘AUTO’ symbol is ashing, to return the oven to Manual

operation, turn the oven controls off, ensure that the correct time of day

is set, and press the “Manual” button - The ‘AUTO’ symbol will go out).

‘AUTO’ will light up:-

- When the timer is rst turned on it will ash.

It will go out when a time of day is set or when

the timer is set to manual.

To change the time of day repeat Steps 4, 5 & 6 above.

Note: You cannot adjust the time of day if the timer has been set for

an Auto Cooking Programme.

Setting the minute minder

Step 1 Ensure the time of day is set correctly.

Timer function buttons

Minute Minder Button

Here you can set a time period of up to 23 hours 59 minutes, that will count down.

When it reaches zero, the timer will emit an audible tone.

For Example: If you set 20 minutes, the audible tone will occur 20 minutes

later.

Auto cooking programme

Cook Period Button

Cook Period is the actual length of time for which, the timer will switch the

oven(s) on as part of an “Auto Cooking” programme. (e.g. If you set 2 hours,

the food will be cooked for 2 hours).

End Time Button

The time of day at which you want an “Auto Cooking” programme to end.

For Example: If you set a “Cook Period” for 2 hours, and “End Time” of 11:00.

The timer will switch the oven(s) on at 9:00 and turn the oven(s) off at 11:00. You

will hear a audible tone at 11:00, to indicate that the Auto Cooking Programme

has nished.

Notes:

- When setting an Auto Cooking programme you will need to set the oven

control(s) to the required temperature(s) when you set the timer.

- If an Auto Cooking programme has been set the oven(s) will only operate

during the pre-programmed time.

will remain lit to signify that a Minute Minder period has been set.

At the end of the set time an audible tone will be heard, and the ‘bell’ symbol

will disappear.

A

U

T

000

O

Note 1: When the Minute Minder has been set, the time remaining can

be checked at any time by simply pressing the Minute Minder button.

Note 2: If necessary the Minute Minder can be cancelled before the

tone sounds by pressing and holding the Minute Minder button and

then at the same time pressing the “-” button until 0.00 appears in the

display window.

Auto cooking programmes

There are two Auto Cooking programmes that can be selected using your

timer:-

(a) To set the timer to switch the oven(s) On and Off Automatically

(b) To set timer to switch on immediately and OFF automatically after

a set cook period.

Step 2 Press and hold the Minute Minder button.

Step 3 With the Minute Minder button held in,

set the required Minute Minder period using the

“+” and “-” buttons. A ‘bell’ symbol will light up.

Release all buttons and the timer display will

revert back to the time of day. The ‘bell’ symbol

Step 4 To cancel the audible tone press the

Minute Minder button.

a) To set the timer to switch the oven(s) on and off

Manual Button

Needs to be pressed to cancel an Auto Cooking programme and return the

oven(s) to Manual operation.

“+” and “-” Buttons

Used to adjust the various timer function settings.

Setting the time of day

A

U

T

000

O

Step 1 Make sure all oven controls are turned

Off.

Step 2 Check the electricity supply to the

cooker is turned on.

Step 3 When switched on the display will

show 0.00 and the Auto symbol, ashing

intermittently.

automatically

This allows you to cook at a specied time for a chosen period before

the oven switches off Automatically.

Step 1 Check that the correct time of day is set, if not follow instructions for

setting the time of day.

Step 2 Place food onto the correct shelf position in the oven and close the

oven door(s).

9

Page 10

GB

PLEASE PHONE US TO REGISTER YOUR APPLIANCE AND ACTIVATE YOUR PARTS GUARANTEE ON 08448 24 24 24

.

.

.

.

.

.

.

NOTE: The Cookpot symbol disappears

.

.

000

A

U

T

4120

O

Step 3 Press and hold in the Cook Period button.

The display will read 0.00 with the ‘cookpot’

symbol lit.

Step 4 With the Cook Period button still held

in, set the required Cook Period using the “+”

and “-” buttons.

Release the buttons and the timer display will

revert to the time of day with the ‘Auto’ symbol

and ‘cookpot’ symbol lit.

Step 3 Turn the oven control(s) to the required temperature, and if necessary

select the appropriate oven function.

Step 4 Press & hold in the Cook Period button,

the display will read 0.00 and the ‘cookpot’

symbol will light up.

With the Cook Period button still held in set

the required Cook Period using the “+” and

“-” buttons.

Example: 1hr 30 minutes (as shown).

Step 5 Release all buttons.

A

U

T

6120

O

A

U

T

4120

O

Step 7 Turn the oven control(s) to the required temperature, and if necessary

select the appropriate oven function.

A

U

T

6120

O

The audible tone will continue unless cancelled.

The ‘Auto’ symbol will continue to ash until the timer is returned to Manual

operation (see below).

Step 5 Press and hold in the End Time button.

The display will read the earliest possible end

time for the Cook Period that you have set

above. The ‘Auto’ symbol and ‘cookpot’ symbol

will be lit.

Step 6 With the End Time button still held in, use

the “+” and “-” buttons to set the ‘End Time’ (i.e.

The time you require the oven to switch off ).

Release all the buttons and the timer will revert

back to the time of day.

The ‘Auto’ symbol will remain lit to signify that

an Auto Cooking Programme has been set. The

‘cookpot’ symbol will go out.

At the end of the Automatic Cook Period the Auto

Symbol will ash and an intermittent bleeping

sound will be heard.

A

U

T

4120

O

A

U

T

.

6120

O

6120

Step 7 Turn the oven control(s) to the OFF position.

The timer display will revert to the time of day

with the ‘Auto’ symbol lit & ‘cookpot’ symbol

remaining lit.

At the end of the Cook Period the ‘Auto’ symbol

will ash and an intermittent audible tone will be

heard. The audible tone will continue until

cancelled. The ‘Auto’ symbol will continue to ash

until the timer is returned to Manual operation (see

below).

Step 6 Press the Manual button. The audible

tone will be cancelled and the oven(s) will be

returned to Manual.

To cancel an auto cooking programme before the cook

period has nished.

Step 1 Turn the oven control to the OFF position.

Step 2 Press the Manual button to return the

5100

oven to “Manual” operation. The ‘Auto’ symbol

will go out.

6120

Step 8 Press the Manual button, the audible

tone will be cancelled and the oven(s) will be

returned to Manual.

Note 1: When cooking automatically the Cook Period can be checked

at any time by simply pressing the Cook Period button.

Other notes on timer operation

Step 9 Turn the oven control(s) to the OFF position.

1. When cooking Automatically the Cook Period can be checked at any time

Note 1: When cooking automatically the Cook Period can be checked

at any time by simply pressing the Cook Period button.

Note 2: When cooking automatically the End Time can be checked at

any time by simply pressing the End Time button.

b) To set timer to switch on immediately and off

automatically after a set cook period

Step 1 Check that the correct time of day is set, if not follow instructions for

setting the time of day.

Step 2 Place food onto the correct shelf position in the oven and close the

oven door(s).

10

simply by pressing the Cook Period button.

2. When cooking Automatically the End Time can be checked at any time

by simply pressing the End Time button.

3. Having set a Cook Period and End Time an electronic device stores the

information. The device within the timer will switch the oven(s) on and off

at the required times.

4. When setting an Auto Cooking Programme and a mistake is made, to

clear:

(a) Press & release the Manual button.

(b) Start the sequence again.

5. If at any time the display shows three ashing zero’s 0.00 and ‘Auto’, it is

likely that the electricity supply to the oven has been interrupted. Reset

Page 11

PLEASE PHONE US TO REGISTER YOUR APPLIANCE AND ACTIVATE YOUR PARTS GUARANTEE ON 08448 24 24 24

the timer to the correct time of day. Food in the oven may, therefore, not

have been cooked, before serving check food is thoroughly heated

and completely cooked.

6. To set each function always press and hold the required function button

and at the same time press “+” or “-” buttons.

Hotplate

edge of the pan support ngers. See ‘Care and Cleaning’ section for cleaning

information.

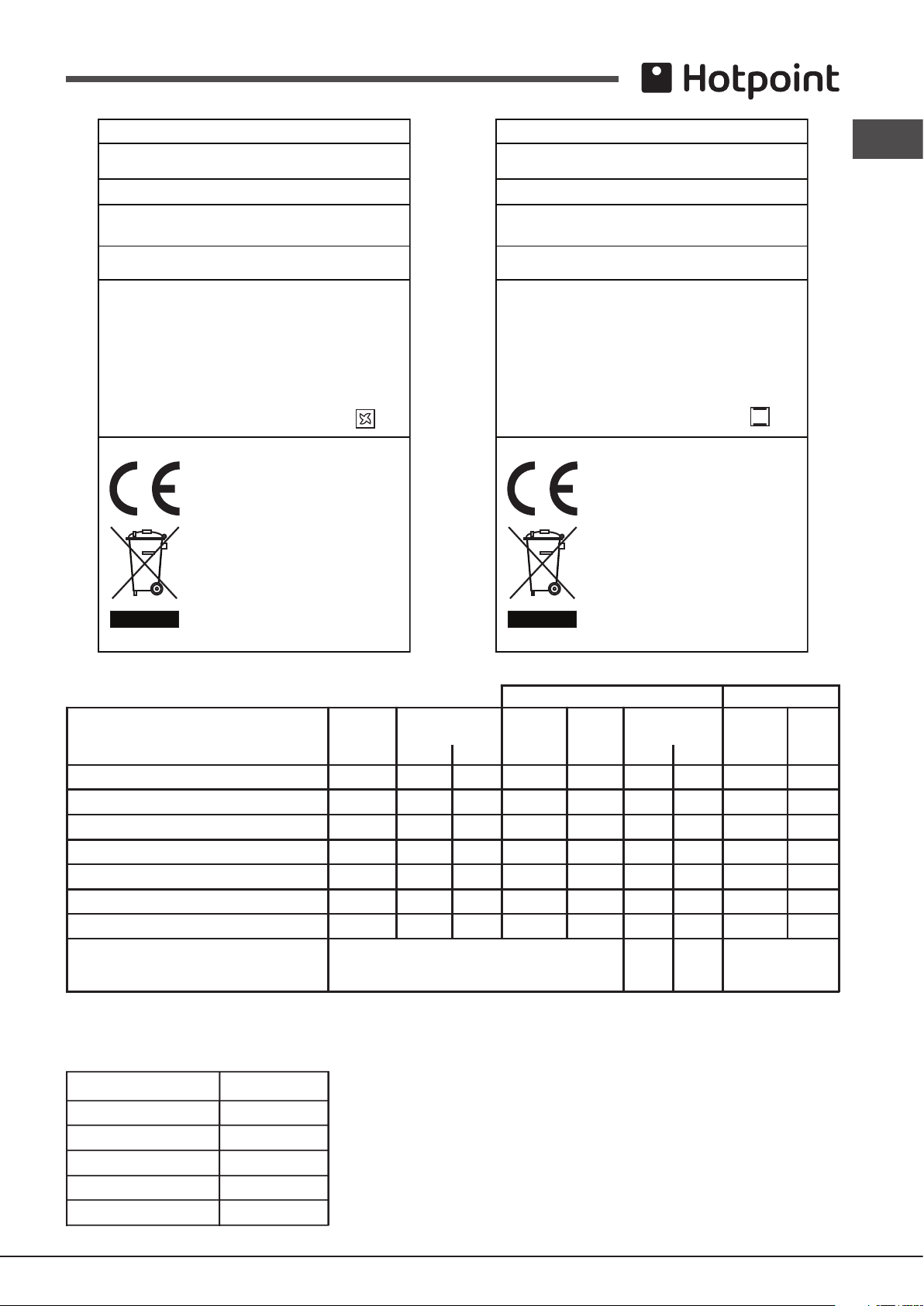

Models with Hob Gas Burner Safety Devices to Prevent Leaks *

These models can be identied by the presence of the device itself.

! Since the hob burners are equipped with a safety device, you must hold the

control knob in for about 3 seconds after the burner has been lighted to allow

the gas to pass until the safety thermocouple has heated.

GB

The hotplate has one dual control wok burner, one large high speed burner,

three normal simmering burners and one small simmering burner. The dual

control wok burner consists of a smaller inner and a larger outer burner that

can operate either together or separately. Use of the two burners together

with large pans on maximum setting gives a very high input and reduces

cooking times with respect to conventional burners. Use of the two burners

together provides a more uniform distribution of heat on the bottom of the

pan. Cookware of all sizes can be used above the dual control wok burner.

For small pans it is recommended that only the inner burner is used.

For the hotplate to work in the most efcient way possible and in order to

save on the amount of gas consumed, it is recommended that only pans

which have a lid and a at base are used. They should also be suited to the

size of the hotplate.

Rear left 24 - 26

Front left 16 - 22

The knob situated below the symbol on the fascia panel

operates the outer burner.

Centre rear 10 - 14

Front right 16 - 22

The knob situated below the symbol on the fascia panel

operates the inner burner.

Rear right 16 - 22

Centre front (DCDR

The two normal simmering burners on the right hand side of the hotplate are

oval in form and can be turned through 90°. This makes the hotplate more

exible in how it can be used.

For cooking sh or heating oval cookware use the two burners with their

longest sides at 90° to the front of the hotplate.

When using the griddle or for heating rectangular, square or large cookware

use the two burners with their longest sides parallel to the front of the hotplate.

For medium size cookware use any of the two burners in any orientation.

All pans should be placed centrally over the burners.

TO USE THE HOTPLATE

1. Press the ignition button and then push in and turn the control knob of

the chosen burner anti-clockwise to the large ame symbol. Continue to

press the ignition button until the spark lights the gas. When operating

the dual control burner there is a separate control knob for the inner and

outer burners.

2. Turn the control knob anti-clockwise to the desired setting. Only turn

the control knob between the large ame symbol and the small ame

symbol for adjusting the setting.

3. To turn off, turn the control knob fully clockwise to the O position.

DO NOT use mis-shapen pans which may be unstable.

DO NOT use round base woks directly on the pan supports.

Each burner is tted with a spark ignitor for lighting the gas. To ensure

rapid lighting of the burners every time they are used, the ignitors must be

kept clean and dry. Remove any food spillage or cleaning materials from

the ignitor using a small nylon brush such as a tooth brush. Access to the

ignitor can be achieved by lifting off the loose burner parts carefully when

the burners are cool.

internal)

Centre front (DCDR

external)

! Make sure the pans do not overlap the edges of the hob while it is being used.

Safety requirements for deep fat frying

1. Never ll chip pans more than one third full with oil or fat.

2. Never leave oil or fat unattended during the heating or cooling period.

3. Never heat fat or fry with a lid on the pan.

4. Always dry food thoroughly before frying, and lower it slowly into the hot

oil or fat. Frozen foods in particular will cause frothing and spitting if added

too quickly.

5. Always keep the outside of the pan clean and free from streaks of oil or

fat.

How to deal with a fat re

1. Do not move the pan.

2. Turn off the hotplate burners.

3. Smother the ames with a re blanket or damp cloth to extinguish the re.

Do not use water or a re extinguisher as the force of it may spread the

burning fat or oil over the edge of the pan.

4. Leave the pan for at least 60 minutes before moving it.

Hotplate ø Cookware diameter (cm)

10 -14

26 - 28

In the event of the burner ames being accidentally extinguished, turn off the

burner controls and do not attempt to re-ignite the burners for at least 1 minute.

If aluminium based pans are used, a silvery deposit may appear on the top

11

Page 12

PLEASE PHONE US TO REGISTER YOUR APPLIANCE AND ACTIVATE YOUR PARTS GUARANTEE ON 08448 24 24 24

Griddle

GB

WARNING ! The oven is provided with

a stop system to extract the racks and

prevent them from coming out of the

oven (1).

As shown in the drawing, to extract them

completely, simply lift the racks, holding

them on the front part, and pull (2).

A non-stick griddle is supplied for use

over the two burners on the right hand

side of the hob. The griddle is made of cast iron and the surface is covered

with a special nonstick nish. To protect the non-stick coating never use metal

cooking utensils as they may scratch the surface. Wooden or heat resistant

plastic utensils may be used. Do not use saucepans on the griddle plate.

UNDER NO CIRCUMSTANCES MUST THE GRIDDLE PLATE BE USED

OVER ANY OTHER HOTPLATE BURNERS.

Use of the griddle

The griddle may be used with either or both of the burners on, depending on

the food being cooked. The griddle can be positioned with the ridged portion

at the front or at the rear.

METHOD

1. Rub the fat into the our.

2. Beat in the remaining ingredients.

3. When a smooth batter has been obtained, drop spoonfuls on to the pre-

heated griddle plate.

4. Turn each scone when bubbles start to burst on the upper side.

5. Cook on the reverse side until light brown and the scone, when split, is

dried through.

6. Allow approx. 3 minutes for the rst side and 2 minutes for the second.

7. Place inside a clean folded towel laid over a cooling rack.

8. When cool, butter and serve.

WELSH CAKES

6oz (175g) plain our

1/2 level tsp (2.5ml) salt

1/4oz (5g) baking powder

2oz (50g) margarine

2oz (50g) sugar

2oz (50g) currant or sultanas

1/4 tsp grated nutmeg

1 egg

a little milk

1. Secure the griddle above the two simmer burners, on the right hand side

of the hob, making sure that the support feet are located correctly on the

pan support ngers.

2. Press the ignition button and then push in and turn the control knob(s) of

the burners anticlockwise to the large ame symbol. Continue to press

the ignition button until the spark lights the gas. Preheat the griddle plate

for approximately four minutes.

3. Place the food directly on the griddle plate. However when cooking drier

foods eg. drop scones the griddle plate can be lightly greased.

4. The controls can be left at high for the sealing of foods or turned down to

a lower heat setting depending on what food is being cooked.

NB. A gentle heat is all that is required for the majority of griddling. Once

the griddle plate is up to temperature it maintains the cooking temperature

on a medium/low setting.

5. Cook the food for the required time, which will depend on the type of food

being cooked.

6. To turn off, push in and turn the control knob(s) fully clockwise to the O

position.

7. Allow the griddle plate to cool before cleaning.

In the event of the burner ames being accidentally extinguished, turn off the

burner controls and do not attempt to re-ignite the burners for at least 1 minute.

METHOD

1. Sieve the our and salt into a bowl.

2. Rub in the fat.

3. Add the dry ingredients.

4. Beat the egg and mix to a soft dough adding a little milk to obtain a soft

consistency.

5. Roll out 1/4” (5mm) thickness.

6. Cut out with a 2” (50mm) plain cutter.

7. Cook on the pre-heated griddle for about 6 minutes each side.

8. They may be eaten hot or cold and should be split and buttered.

POTATO CAKES

8oz (225g) warm creamed potatoes

2oz (50g) plain our

1/2 (2.5ml) salt

pepper to taste

2 tsp (10ml) milk

METHOD

1. Mix all the ingredients together.

2. Knead lightly.

3. Roll out thinly and cut with a pastry cutter to suit requirements.

4. Cook on a pre-heated griddle for 3-4 minutes on each side.

Some recipe ideas for your griddle

DROPPED SCONES

4oz (100g) plain our

1/4 tsp salt

1 level tsp (5ml) cream of tartar

1/2 level tsp (2.5ml) bicarbonate of soda

1 egg

1oz (25g) caster sugar

1/4 pint (150ml) milk

1/2oz (10g) margarine

Top grill

! Before operating the product, remove all plastic lm from the sides of the

appliance.

! The rst time you use your appliance, heat the empty oven with its door closed

at its maximum temperature for at least half an hour. Ensure that the room is

well ventilated before switching the oven off and opening the oven door. The

appliance may emit a slightly unpleasant odour caused by protective substances

used during the manufacturing process burning away.

* Only available on certain models

12

Page 13

PLEASE PHONE US TO REGISTER YOUR APPLIANCE AND ACTIVATE YOUR PARTS GUARANTEE ON 08448 24 24 24

CAUTION - ACCESSIBLE PARTS MAY BECOME HOT WHEN THE

1

2

GRILL IS USED.

YOUNG CHILDREN SHOULD BE KEPT AWAY.

GRILLING SHOULD NEVER BE UNDERTAKEN WITH THE GRILL

DOOR CLOSED.

The grill control is designed to provide variable heat control of either the full width

of the grill or just the grill half. Turning the control knob clockwise will switch on

the full width and turning anticlockwise will switch on just the grill half. A gentle

ow of air will be blown from underneath the control panel when the grill is in use.

If the fan fails to blow air beneath the control panel when the grill is in

use, you should contact your service engineer immediately (see back

page).

momentary puff of steam when the oven door is opened, this will disperse

in a few seconds and is a perfectly normal characteristic of an oven with a

good seal.

Since a fan oven heats up more quickly and generally cooks food at a

lower temperature than a conventional oven, pre-heating the oven is often

unnecessary. However, foods such as bread, scones, Yorkshire pudding do

often benet from being placed in a preheated oven.

The charts on pages 20 and 21 are a guide only, giving approximate cooking

temperatures and times. To suit personal taste and requirements, it may be

necessary to increase or decrease temperatures by 10°C.

Unless otherwise indicated in the charts, food is placed in a cold oven ie.

without preheating. If food is placed in an already hot oven, the suggested

cooking time should be reduced, depending on the type and quantity of

food being cooked.

GB

Using the grill pan kit

The grill pan handle is detachable from the pan to facilitate cleaning and

storage. Fix the pan handle securely before use:

1. Fit the handle to the grill pan so the external ‘hooks’ embrace the that edge

of the pan (g. 1)

2. Make sure that the middle part of the handle ts exactly the protruding

support of the pan (g .2) and holds the pan from the bottom.

The food must be placed on the rack in the grill pan.

Position the grill pan on top of the oven rack. The best results are achieved

by placing the oven rack on the uppermost shelves. Pouring a little water into

the grill pan will make the collection of grease particles more efcient and

prevent the formation of smoke.

TO USE THE GRILL

2. Open the top grill door

2. Turn the grill control knob clockwise to 4 for full width grilling or

anticlockwise for half width grilling.

3. Slide the grill pan toward the back of the grill compartment until it stops.

4. Leave the control at 4 for toast and for sealing and for fast cooking of

foods. For thicker foods requiring longer cooking, turn the control to a

lower setting after sealing on both sides at 4.

Grilling can be started from cold but for best results preheat for approximately

2 minutes.

DO NOT

cover the grill pan or grid with aluminium foil as this can hold fat, intensify the

heat and create a re hazard.

Fan oven (1st Oven)

The heating of the oven is achieved by turning the control knob clockwise

to the required temperature as recommended in the temperature charts.

The pilot light will immediately come on and will automatically go off and on

during cooking as the oven thermostat maintains the correct temperature.

It should be noted that at the end of a cooking period there may be a

OVEN POSITIONS

Since the distribution of heat in the fan oven is very even, most foods will cook

satisfactorily on any shelf position, but the shelves should be evenly spaced.

To ensure even circulation do not use meat pans larger than 390 x 300mm

(15ins x 12ins) and baking trays no larger than 330 x 255mm (13ins x 10ins),

these should be positioned centrally on the oven shelf.

- Do not t shelves upside down.

- Never use more than 3 shelves in the oven as air circulation will be

restricted.

- Food or cooking utensils should not be placed on the oor of the oven.

To avoid unnecessary cleaning, rod shelves which are not in use should be

removed from the oven.

TEMPERATURE AND TIME

When all three shelves are used to cook large quantities of food for home

freezing or parties, it may be necessary to increase the cooking times given

in the charts by a few minutes to allow for the loss of heat due to the extra

time taken to load the oven, and the larger mass of food. Baking trays should

allow an equal gap on all sides of the oven.

NB. Recipes in cookery books give times and temperatures for cooking in

ordinary ovens. The fan oven makes it possible in most cases to:

- Reduce the recommended temperatures 25°C (45°F).

- Reduce the recommended time by approximately 10 minutes per hour.

- Make pre-heating the oven unnecessary for certain foods.

TO PREPARE MEAT AND POULTRY FOR ROASTING IN YOUR FAN

OVEN

a. Wipe the meat or poultry, dry well and weigh it. Meat which has been stored

in a refrigerator should be allowed to come to room temperature before

cooking and frozen meat or poultry must be completely defrosted before

placing in the oven.

b. The weight of any stufng used should be added before calculating the

cooking time.

c. Place meat / poultry in the main oven meat pan supplied with your cooker.

Small joints weighing less than 1.75kg (31/2lb) should be roasted in a smaller

meat pan / tin - or they may be ‘pot roasted’ - a small joint in a large meat

pan causes unnecessary oven splashing and evaporation of meat juices.

d. Additional fat should not be added, except for veal, very lean meat or

poultry which can be ‘larded’ with bacon fat or brushed very sparingly with

cooking oil or melted fat.

e. Beef, lamb, mutton and poultry may be dusted lightly with seasoned our

to give a crisp outer surface. The skin of duck and goose should be pricked

to release excess fat during cooking and the rind of pork should be scored,

brushed lightly with oil and rubbed with salt to give crisp crackling.

f. Meat and poultry wrapped in, or covered with a tent of aluminium foil will

be juicy and tender. Roasting bags offer the same advantage. Always

follow the manufacturer’s packing instructions and remember to reduce

the temperatures given for conventional ovens by approximately 25°C

13

Page 14

GB

PLEASE PHONE US TO REGISTER YOUR APPLIANCE AND ACTIVATE YOUR PARTS GUARANTEE ON 08448 24 24 24

Conventional Oven Cooking

Food

Pre-heat Temperature and Time Position in Oven

Scones Yes220/230°C approx. 10 - 15 mins.Runner 3

Small CakesYes 180/190°C approx. 20 - 25 mins.Runner 3

Victoria SandwichYes 170/180°C 6½" - 7" tins approx. 20 - 25 mins.Runner3

Sponge Sandwich (fatless) Yes190/200°C 7" tins 15 - 20 mins.Runner 3

Swiss Roll Yes190/200°C approx. 10 - 15 mins.Runner 3

Rich Fruit cakesYes 130/140°C dependent on useRunner 2

Semi-Rich CakesYes 160/170°C 7" - 8" tins 1¼ - 1½ hoursRunner 3

Shortcrust Pastry Yes190/200°C depending on useRunner 2

Puff Pastry Yes220°C approx. dependent on useRunner 2 & 5

Yorkshire PuddingYes 200/210°C 30 - 45 mins.Runner 3

Individual Yorkshire PuddingYes 210/220°C approx. 20 - 25 mi ns.Runner 3

Milk Pudding Yes150/160°C approx. 2 - 2½ hoursRunner 2

Baked CustardYes 150/160°C approx. 45 - 55 mins.Runner 2

BreadYes

220/230°C 50 - 60 mins. reducing to 210/220°C

230°C 45-50 mins after fi rst 10 minutes

Runner 2

Meringues Yes

100/110°C Large 3½ - 4½ hours

Small 2½ - 3 hours

Runner 1

g. Potatoes for roasting only require to be brushed with cooking oil or melted

fat.

h. It is not necessary to baste when roasting in an electric oven and stock

or liquid should not be added to the meat pan since this only causes

unnecessary soiling, steam and condensation.

FROZEN MEAT AND POULTRY

Joints of meat and whole birds should be defrosted slowly, preferably in a

domestic refrigerator (allowing 5-6 hours per 450g, 1lb), or at room temperature

(allowing 2-3 hours per 450g, 1lb). Frozen meat or poultry must be completely

defrosted before placing in the oven. It is essential to wash thoroughly and cook

meat and poultry immediately after defrosting.

and the time by approxi mately 10 minutes per hour.

Conventional oven (2

nd

Oven)

OVEN CONTROL

Heating of the oven is achieved by turning the control clockwise to the

required oven temperature scale on the control panel, as recommended

in the temperature charts. The pilot light will immediately come on and off

during cooking as the thermostat maintains the correct temperature.

The charts on pages 14, 15 and 16 are a guide only, giving approximate

cooking temperatures and times. To suit personal taste and requirements, it

may be necessary to increase and decrease temperatures by 10°C.

The oven is tted with ‘heat clean’ liners and two rod shelves. The heating

of the oven is achieved by turning the control knob clockwise to the required

temperature as recommended in the temperature charts. The pilot light will

immediately come on and will automatically go off and on during cooking

as the oven thermostat maintains the correct temperature.

It should be noted that at the end of a cooking period there may be a

momentary puff of steam when the oven door is opened. This will disperse

in a few seconds and is a perfectly normal characteristic of an oven with a

good seal.

The correct positioning of food is indicated on the temperature charts.

TO PREPARE MEAT FOR ROASTING IN YOUR CONVENTIONAL

OVEN

Wipe the joint, dry well with a clean cloth, kitchen tissue etc. and weigh it.

Meat which has been stored in a refrigerator should be allowed to come to

room temperature for approximately 30 minutes before cooking and frozen

meat or poultry must be completely defrosted beforehand.

Beef, lamb, mutton and poultry may be lightly oured, but pork should be

scored, brushed lightly with oil and rubbed with salt to give crisp crackling.

Place joint in the main oven meat pan supplied with your cooker. (Small joints

weighing less than 1.75kg (31/2lb) should be roasted in a smaller meat pan

/ tin - or they may be ‘pot roasted’ - a small joint in a large meat pan causes

unnecessary oven splashing and evaporation of meat juices). Additional fat

should not be added, except for veal, very lean meat or poultry which can be

‘larded’ with bacon fat or brushed very sparingly with cooking oil or melted

fat. It is not necessary to baste, when roasting in an electric oven and liquid

/ stock should not be added to the pan.

For optimum cooking performance, there must be clearance between meat

pan and oven sides.

The meat pan must be placed lengthways in the oven to allow for air circulation.

TIMES AND TEMPERATURES FOR ROASTING

The secret of succulent, tender meat, is not to roast it too quickly at too high

a temperature.

Best results are obtained when roasting is carried out at a low temperature.

When a lower temperature is used, the joint loses less weight, is more tender

(too high a temperature causes meat to be tough and dry) and the splashing

of fat onto oven interior is reduced to a minimum.

When a complete meal is being cooked in the oven, cooking time may need

to be increased and temperature may need to be raised for approximately the

last 30 minutes of the cooking period (for instance when cooking Yorkshire

pudding to serve with roast beef ). The suggested times and temperatures

given below should be used as a guide, but may vary according to:-

1. Whether you prefer meat rare, medium or well done.

2. The size and shape of your joint.

(a) A short thick joint requires a longer cooking period than a long thin joint.

(b) A small joint under 1.5kg (3lbs) takes longer per 450g (1lb) cook in the

time given for ‘minutes’ per 450g (1lb) without the ‘minutes’ over added.

14

Page 15

PLEASE PHONE US TO REGISTER YOUR APPLIANCE AND ACTIVATE YOUR PARTS GUARANTEE ON 08448 24 24 24

Conventional Oven

sR

sR

GB

Meat Pre-heat Temperature °C Time (approx.)

Beef Yes 190/20025-30 mins per 450g (1lb) +25 mins over.

Lamb Yes 190/20025-30 mins per 450g (1lb) +25 mins over.

Pork Yes 190/200 30-35 mins per 450g (1lb) +30 mins over.

Veal Yes 190/20025-35 mins per 450g (1lb) +30 mins over

Poultry/Game

up to 4kg (8lb)

Turkey up to

5.5 kg (12lb)

Turkey over

5.5 kg (12lb)

Casserole

Cooking

Yes180/190 20-25 mins per 450g (1lb) +30 mins over

Yes

Yes

Yes 140/160 2-2½ hr

1.Allow foil to touch sides of oven. 2.Cover oven interior with foil. 3.Cover shelves with foil.

190

180

If using aluminium foil, never:

22 mins per 450g (1lb) eg.

5.5kg (11lb) = 242mins

18 mins per 450g (1lb) eg.

10kg (22lb) = 352mins

Fan Oven

Meat Pre-heat Temperature °C Time (approx.)

Position in Oven

from bottom

In meat pan on

runner 2

Runner 2

unner 3

Position in Oven

from bottom

Beef No 160/18020-25 mins per 450g (1lb) +20 mins over.

Lamb No 160/18025 mins per 450g (1lb) +25 mins over.

Pork No 160/18025 mins per 450g (1lb) +25 mins over.

Veal No 160/17025-30 mins per 450g (1lb) + 25 mins over

Chicken/Turkey

up to 4kg (8lb)

Turkey up to

5.5 kg (12lb)

Turkey over

5.5 kg (12lb)

Casserole

Cooking

No 160/18018-20 mins per 450g (1lb) + 20 mins over

No

No

No 140 - 1501½ - 2 hr

1.Allow foil to touch sides of oven. 2.Cover oven interior with foil. 3.Cover shelves with foil.

150 - 160

150

If using aluminium foil, never:

13-15 mins per 450g (1lb) eg.

5.5kg (11lb) = 143-165 mins

12 mins per 450g (1lb) eg.

10kg (22lb) = 264 mins

In meat pan on

runner 2

Runner 2

unner 3

15

Page 16

PLEASE PHONE US TO REGISTER YOUR APPLIANCE AND ACTIVATE YOUR PARTS GUARANTEE ON 08448 24 24 24

Fan Oven Cooking

Food

Pre-heat Temperature and Time Position in Oven

Scones Yes210/220°C approx. 8 - 10 mins.Runner 3

Small CakesYes 160/170°C approx. 15 - 20 mins.Runner 3

Victoria Sandwich No 160/170°C approx. 20 - 25 mins.Runner3

Sponge Sandwich (fatless) Yes 160/170°C approx. 15 - 20 mins.Runner 3

Swiss Roll Yes170/180°C approx. 12 - 15 mins.Runner 3

Rich Fruit cakesNo120/130°C dependent on useRunner 2

Semi-Rich CakesNo 140/150°C approx. 1¼ - 2¼ hrs. Runner 3

Shortcrust Pastry No 180/190°C approx. 45 - 50 mins.Runner 2

Puff Pastry No 190/200°C dependent on useRunner 2 & 5

Yorkshire PuddingYes 170/180°C approx. 40 - 45 mins.Runner 3

Individual Yorkshire Pudding Yes180/190°C approx. 20 - 25 mins.Runner 3

Milk PuddingNo 130/140°C approx. 1¼ - 2¼ hrs. Runner 2

Baked CustardNo 140/150°C approx. 40 - 50 mins.Runner 2

BreadYes 200/210°C approx. 40 - 45 mins.Runner 2

MeringuesNo70/80°C approx. 3 - 4 hrs. Runner 1

(c) Boned/rolled and stuffed joints take longer to cook through than those

GB

with a bone. The weight of stufng should be added to the oven ready

weight of the meat / poultry to calculate roasting times.

NOTE: Remember to switch off the oven control after cooking is nished. If

the door of the oven is left open for long periods of time with the control switch

ON, then the grill element will become hot. The correct positioning of food is

indicated in the temperature charts.

It is not necessary to pre-heat the fan oven before roasting.

Note: Where times are stated, they are approximate only.

The most accurate method of testing the readiness of joints of meat or whole

poultry is to insert a meat thermometer into the thickest part of a joint, or the

thickest part of poultry thighs, during the cooking period.

The meat thermometer will indicate when the required internal temp has

been reached.

Beef

Rare: 60°C

Medium: 70°C

Well Done: 75°C

Lamb: 80°C

Pork: 90°C

Veal: 75°C

Poultry: 90°C

Note: If soft margarine is used for cake making, temperatures recommended

by the manufacturers should be followed.Temperatures recommended in this

chart refer to cakes made with block margarines or butter only.

The ‘slow cook’ setting

With the fanned oven thermostat set to 90° the oven can be used for slow

cooking - The ‘Slow Cook’ setting.

PREPARING FOOD FOR SLOW COOKING

1. All dishes cooked by the ‘Slow Cook’ setting should be cooked for a

minimum 6 hours. They will ‘hold’ at this setting for a further hour but

marked deterioration in appearance will be noticed in some cases.

2. Joints of meat and poultry should be cooked at 170° for 30 minutes before

turning to the ‘Slow Cook’ setting and never be cooked lower than the

middle shelf position.

3. Joints of meat over 6 lbs (2.7kg) and poultry over 4 lbs 8oz (2 kg) should

not be cooked using the ‘Slow Cook’ setting.

4. Always stand covered joints on a rack over the meat tin to allow good air

circulation.

5. A meat thermometer should be used when cooking pork joints and poultry.

The internal temperature of the food should reach at least 88°C.

6. This method is unsuitable for stuffed meat and stuffed poultry.

7. Always bring soups, casseroles and liquids to the boil before putting in

the oven.

8. Cover casseroles with foil and then the lid to prevent loss of moisture.

9. Always thaw frozen food completely before cooking.

10. Root vegetables will cook better if cut into small pieces.

11. Adjust seasonings and thickenings at the end of the cooking time.

12. Use the zones of heat in the oven, e.g. meringues and milk puddings can

be cooked lower in the oven whilst other dishes requiring greater heat

can be cooked above them.

13. Egg and sh dishes need only 1-5 hours cooking and should be included

in day cooking sessions, when they can be observed from time to time.

14. Dried red kidney beans must be boiled for a minimum of ten minutes after

soaking, before inclusion in any dish.

Warming compartment

The warming compartment is situated at the bottom right hand side of the

cooker. It can be used for keeping plates or food warm. It is not designed as

a ‘Slow Cook’ oven.

16

Page 17

PLEASE PHONE US TO REGISTER YOUR APPLIANCE AND ACTIVATE YOUR PARTS GUARANTEE ON 08448 24 24 24

‘Heat clean’ liners

Care and cleaning

! Never use steam cleaners or pressure cleaners on the appliance.

! Clean the glass part of the oven door using a sponge and a non-abrasive

cleaning product, then dry thoroughly with a soft cloth. Do not use rough abrasive

material or sharp metal scrapers as these could scratch the surface and cause

the glass to crack.

! The accessories can be washed like averyday crockery (even in your

dishwasher).

The oven linings are coated with a special enamel which has a continuous

cleaning action. The higher the oven temperature the more effective the action.

In most cases this cleaning operation will proceed during normal cooking.

However, if high temperatures are not used regularly it may be necessary to

run the oven empty at maximum setting for one hour. If desired, they can be

wiped over with a soapy cloth followed by a wipe with a clean, damp cloth.

Cleaning the griddle plate

After cooking, leave the griddle plate on the hob and allow to cool before

cleaning. It can then be taken to the sink and washed using warm soapy

water, gently wipe the cooking surface with a dishcloth. DO NOT use abrasive

cleaning materials.

GB

! Switch off the electricity supply and allow to cool before cleaning the

cooker.

! Clean the cooker regularly and wipe up spills soon after they occur to

prevent them from becoming burnt on. Never use biological washing

powder, caustic cleaners, harsh abrasives, scouring pads, steam

cleaners, aerosol cleaners or oven chemical cleaners of any kind.

! Before moving your cooker ensure that it is cool and note that it is

heavy so you may require assistance. The cooker is tted with rear wheels

and will slide in and out of position easily.

Movement of your cooker is most easily achieved as follows:

Open the grill/oven door sufciently to allow a comfortable grip on the

underside front edge of the oven roof, avoiding contact with any grill or oven

furniture and then lift and slide at the same time.

When repositioning the cooker, ensure that it is level. Take care to ensure that

any oor covering is not damaged.

! If the cooker is placed on a pedestal, take the necessary precautions to

prevent the cooker from sliding off the pedestal itself.

Replacement of oven light bulb

CAUTION: DISCONNECT THE APPLIANCE FROM THE ELECTRICITY

SUPPLY BEFORE

REPLACING THE LAMP TO AVOID THE POSSIBILITY OF AN

ELECTRIC SHOCK.

Light bulbs are not covered by the manufacturer’s guarantee.

A new 15W, 300°C rated SES bulb can be obtained from your cooker supplier

or any major electrical retailer.

1. Remove the shelves from the oven.

2. Unscrew the lens using a thick cloth to protect your ngers in the unlikely

event of a lens fracture.

3. Unscrew bulb.

4. Fit new bulb and ret lens.

! Do not use the oven lamp as/for ambient lighting.

Disposal of your product

To minimise the risk of injury to children please dispose of your product

carefully and safely. Remove all doors and lids. Remove the mains cable

COOKER FINISH CLEANING METHOD

Vitreous Enamel

Hotplate (Traditional), pan supports, burner caps,

roasting dish, grill pan, oven base, rear and roof,

door inner panels, grill and warming

compartments.

Cloth wrung out in warm soapy water. Stubborn stains can be

removed with a cream paste, liquid cleaner or by rubbing with

fine steel wool soap pads e.g. Brillo, Ajax.

Check that the cleaning agent is approved by the Vitreous

Enamel Association.

Aluminium

Burner bodies, door handles.

Glass

Chromium Plating

Oven shelves, grill pan grid, grill pan handle

support.

Plastic

Grill pan handle, control knobs, door handle

supports.

Stainless Steel (Professional)

Door trims, control panel, hotplate

Paint

Control panel and doors (Traditional), side

panels

Similar to paint cleaning above. Use a nylon brush to remove any

cleaning materials, water or dirt from the hotplate burner ports.

Care should be taken when refitting the bodies over the electrodes.

As for enamel cleaning. Polish with a clean dry cloth or kitchen roll.

Wipe with a cloth wrung out in warm soapy water. A fine steel

wool soap pad e.g. Brillo, Ajax, or a chro

cleaner may be used.

Wipe with a cloth wrung out in warm soapy water.

Wipe with a cloth wrung out in warm soapy water. Polish with a

clean dry cloth or kitchen towel. For stubborn stains, use a

proprietary stainless steel cleaner and follow the instructions on

the container.

Wipe with a cloth wrung out in warm soapy water only. DO NOT

USE ABRASIVES.

me or stainless steel

17

Page 18

PLEASE PHONE US TO REGISTER YOUR APPLIANCE AND ACTIVATE YOUR PARTS GUARANTEE ON 08448 24 24 24

(where tted) by cutting off ush with the appliance and always ensure that no

PROBLEM CHECK

Slight odour or small amount of smoke

when grill/oven used for first time.

This is normal and should cease after a short period.

Oven cooks too fast or too slow.

Check that the oven setting and shelf positi ons are as recommended in

the Cooking Charts. However, it may be necessary to increase or

decrease the recommended setting slightly to suit your taste.

Ignition does not work:

If all burners fail to ignite

:

Check that sparks appear at the burners; a clicking noise should be heard.

If not;

(i) Check that the electricity supply is turned on.

(ii) Check other appliances to see if you have had a power cut.

If only one burner fails to ignite

:

(i) Check the burner cap is seated correctly.

(ii) Check the slots in the burner bodies are not blocked with any soap

residue or cooking soil (see care and cleaning).

(iii) Check, if the burners have recently been cleaned using a wire wool

pad eg. "Brillo Pad', ensure that no stray strands are caught on the

ignitor or burner body.

NOTE. Satisfactory ignition will only be achieved if all the hotplate burners are

fitted. In the event of an electricity failure, all burners can be lit with a match.

Cannot set an "Auto Cook" programme

or cannot get the timer to turn the oven

on or off at the required times.

Read the Timer instructions in this book carefully remembering that the

Cook period is the length of ti me that the timer will switch the oven(s) on

as part of an Auto Cooking Programme.

Timer Display shows "0:00" with

"AUTO" Flashing.

The electricity supply to the cooker may have been been interrupted, but

has now come back on again. Set the correct ti me of day by following

the instructions given in the timer section of this book.

Fanned oven does not work, but th

e

grill, top oven and hotplate burners

work.

The Timer may be set for an Auto Cooking programme. Check the Timer

to see if "AUTO" is illuminated. If it is, follow the instructions given in the

Timer section of this book to cancel the Auto Cooking programme.

Oven lamp does not work.

The oven lamp is not covered by the guarantee. The part is easily

changed (see the section on oven lamp replacement). A new lamp may be

obtained from our Parts department, (see back page).

GB

plug is left in a condition where it could be connected to the electricity supply.

To help the environment, Local Authority instructions should be followed for

the disposal of your product.

Disposal of old electrical appliances

The European Directive 2012/19/EEC on Waste Electrical and Electronic

Equipment (WEEE), requires that old household electrical appliances must

not be disposed of in the normal unsorted municipal waste stream. Old

appliances must be collected separately in order to optimise the recovery

and recycling of the materials they contain and reduce the impact on human

health and the environment.

The crossed out “wheeled bin” symbol on the product reminds you of your

obligation, that when you dispose of the appliance it must be separately

collected.

Consumers should contact their local authority or retailer for information

concerning the correct disposal of their old appliance.

• If you have a timed tariff electricity contract, the “delay cooking” option

will make it easier to save money by moving operation to cheaper time

periods.

• Make the most of your hot plate’s residual heat by switching off cast iron hot

plates 10 minutes before the end of your cooking time and glass ceramic

hot plates 5 minutes before the end of cooking time.

• The base of your pot or pan should cover the hot plate. If it is smaller,

precious energy will be wasted and pots that boil over leave encrusted

remains that can be difcult to remove.

• Cook your food in closed pots or pans with well-tting lids and use as little

water as possible. Cooking with the lid off will greatly increase energy

consumption

• Use purely at pots and pans

• If you are cooking something that takes a long time, it’s worth using a

pressure cooker, which is twice as fast and saves a third of the energy.

! This product complies with the requirements of the latest European Directive

on the limitation of power consumption of the standby mode.

Respecting and conserving the environment

Something wrong with your cooker

• Whenever possible, avoid pre-heating the oven and always try to ll it.

Open the oven door as little as possible because heat is lost every time it

is opened. To save a substantial amount of energy, simply switch off the

Before contacting your nearest Service Centre/Installer, check the

problem guide below; there may be nothing wrong with your cooker.

oven 5 to 10 minutes before the end of your planned cooking time and

use the heat the oven continues to generate.