Hoshizaki IM-240DNE, IM-240DWNE, IM-240DWNEC, IM-240DSNE, IM-240XNE SERVICE MANUAL

...

NO. E1CK-810

ISSUED: JUN. 28, 2010

REVISED: JUN. 27, 2014

HOSHIZAKI

MODULAR CUBER

MODEL

IM-240DNE/DWNE(-C)

IM-240DSNE

IM-240XNE/XWNE(-C)

IM-240XSNE

IM-240ANE/AWNE

SERVICE MANUAL

CONTENTS

PAGE

I. SPECIFICATIONS -------------------------------------------------------------------------------------1

1. DIMENSIONS/SPECIFICATIONS --------------------------------------------------------------1

[a] IM-240DNE [Copeland compressor: auxiliary code B0 and earlier] ---------------1

[b] IM-240DNE [Danfoss compressor: auxiliary code B1 and later] -------------------2

[c] IM-240DNE-C -----------------------------------------------------------------------------------3

[d] IM-240DWNE [Copeland compressor: auxiliary code B0 and earlier] ------------4

[e] IM-240DWNE [Danfoss compressor: auxiliary code B1 and later] ----------------5

[f] IM-240DWNE-C ---------------------------------------------------------------------------------6

[g] IM-240ANE [Copeland compressor: auxiliary code B0 and earlier] ---------------7

[h] IM-240ANE [Danfoss compressor: auxiliary code B1 and later] -------------------8

[i] IM-240AWNE [Copeland compressor: auxiliary code B0 and earlier] -------------9

[j] IM-240AWNE [Danfoss compressor: auxiliary code B1 and later] ---------------- 10

[k] IM-240DSNE [Danfoss Compressor] ---------------------------------------------------- 11

[l] URC-240C-E-4 (Condenser Unit) --------------------------------------------------------- 12

II. GENERAL INFORMATION ----------------------------------------------------------------------- 13

1. CONSTRUCTION -------------------------------------------------------------------------------- 13

[a] IM-240DNE/XNE, IM-240DNE-C/XNE-C ----------------------------------------------- 13

[b] IM-240DWNE/XWNE, IM-240DWNE-C/XWNE-C ----------------------------------- 14

[c] IM-240ANE ------------------------------------------------------------------------------------- 15

[d] IM-240AWNE ---------------------------------------------------------------------------------- 16

[e] IM-240DSNE ---------------------------------------------------------------------------------- 17

[f] URC-240C-E-4 -------------------------------------------------------------------------------- 18

2. CONTROLLER BOARD ------------------------------------------------------------------------ 19

[a] CONTROLLER BOARD LAYOUT ------------------------------------------------------- 20

[b] INPUT/OUTPUT LAYOUT ----------------------------------------------------------------- 21

[c] BEFORE CHECKING CONTROLLER BOARD -------------------------------------- 22

III. OPERATING INSTRUCTIONS ------------------------------------------------------------------ 23

1. START UP ------------------------------------------------------------------------------------------ 23

2. PREPARING THE ICEMAKER FOR LONG STORAGE -------------------------------- 24

3. BIN CONTROL ------------------------------------------------------------------------------------ 25

[a] BIN CONTROL SWITCH ASSEMBLY -------------------------------------------------- 25

[b] REMOVAL -------------------------------------------------------------------------------------- 26

IV. MAINTENANCE INSTRUCTIONS ------------------------------------------------------------- 27

1. PERIODICAL CLEANING ---------------------------------------------------------------------- 27

2. WATER VALVE ------------------------------------------------------------------------------------ 29

3. WATER-COOLED CONDENSER ------------------------------------------------------------ 30

4. ICEMAKING WATER SYSTEM --------------------------------------------------------------- 31

V. TECHNICAL INFORMATION --------------------------------------------------------------------- 34

1. WATER CIRCUIT AND REFRIGERANT CIRCUIT --------------------------------------- 34

[a] IM-240DNE/XNE, IM-240DNE-C/XNE-C, IM-240ANE ----------------------------- 34

[b] IM-240DWNE/XWNE, IM-240DWNE-C/XWNE-C, IM-240AWNE --------------- 35

i

[c] IM-240DSNE/XSNE+URC-240C-E-4 --------------------------------------------------- 36

2. WIRING DIAGRAM ------------------------------------------------------------------------------ 37

[a] IM-240DNE(-C)/XNE(-C), IM-240DWNE(-C)/XWNE(-C),

IM-240ANE/AWNE --------------------------------------------------------------------------- 37

[b] IM-240DSNE/XSNE+URC-240C-E-4 --------------------------------------------------- 38

3. PERFORMANCE DATA ------------------------------------------------------------------------- 39

[a] COPELAND COMPRESSOR ------------------------------------------------------------- 39

[b] SECOP (DANFOSS) COMPRESSOR -------------------------------------------------- 42

VI. SERVICE DIAGNOSIS --------------------------------------------------------------------------- 46

1. ERROR CODE INDICATION ------------------------------------------------------------------ 46

2. NO ERROR CODE INDICATION ------------------------------------------------------------- 47

VII. ADJUSTMENT ------------------------------------------------------------------------------------- 49

1. EXPANSION VALVE ----------------------------------------------------------------------------- 49

2. WATER REGULATING VALVE - WATER-COOLED MODEL ONLY ----------------- 50

3. FULL DRAIN FLUSH ---------------------------------------------------------------------------- 50

4. DIMPLE DIAMETER ----------------------------------------------------------------------------- 50

VIII. REMOVAL AND REPLACEMENT ------------------------------------------------------------ 52

1. SERVICE FOR REFRIGERANT LINES ---------------------------------------------------- 52

[a] SERVICE INFORMATION ----------------------------------------------------------------- 52

[b] REFRIGERANT RECOVERY ------------------------------------------------------------- 53

[c] EVACUATION AND RECHARGE -------------------------------------------------------- 53

2. COMPRESSOR ----------------------------------------------------------------------------------- 54

3. DRIER ----------------------------------------------------------------------------------------------- 55

4. EXPANSION VALVE ----------------------------------------------------------------------------- 56

5. EVAPORATOR ------------------------------------------------------------------------------------ 57

6. HOT GAS VALVE --------------------------------------------------------------------------------- 58

7. WATER REGULATING VALVE - WATER-COOLED MODEL ONLY ----------------- 59

[a] VALVE BODY --------------------------------------------------------------------------------- 59

[b] WHOLE VALVE ------------------------------------------------------------------------------- 59

8. WATER PAN ASSEMBLY ---------------------------------------------------------------------- 61

9. PUMP MOTOR ------------------------------------------------------------------------------------ 63

10. WATER VALVE------------------------------------------------------------------------------------ 63

11. ACTUATOR MOTOR ---------------------------------------------------------------------------- 64

12. CAM ARM ------------------------------------------------------------------------------------------ 64

[a] CAM ARM (A) - ACTUATOR MOTOR SIDE ------------------------------------------- 64

[b] CAM ARM (B) - REAR SIDE -------------------------------------------------------------- 64

13. CONTROLLER BOARD ------------------------------------------------------------------------ 67

14. THERMISTOR FOR CUBE CONTROL ----------------------------------------------------- 69

15. FAN MOTOR - AIR-COOLED MODEL ONLY --------------------------------------------- 70

IX. MULTI-STACK APPLICATIONS ---------------------------------------------------------------- 71

ii

I. SPECIFICATIONS

1. DIMENSIONS/SPECIFICATIONS

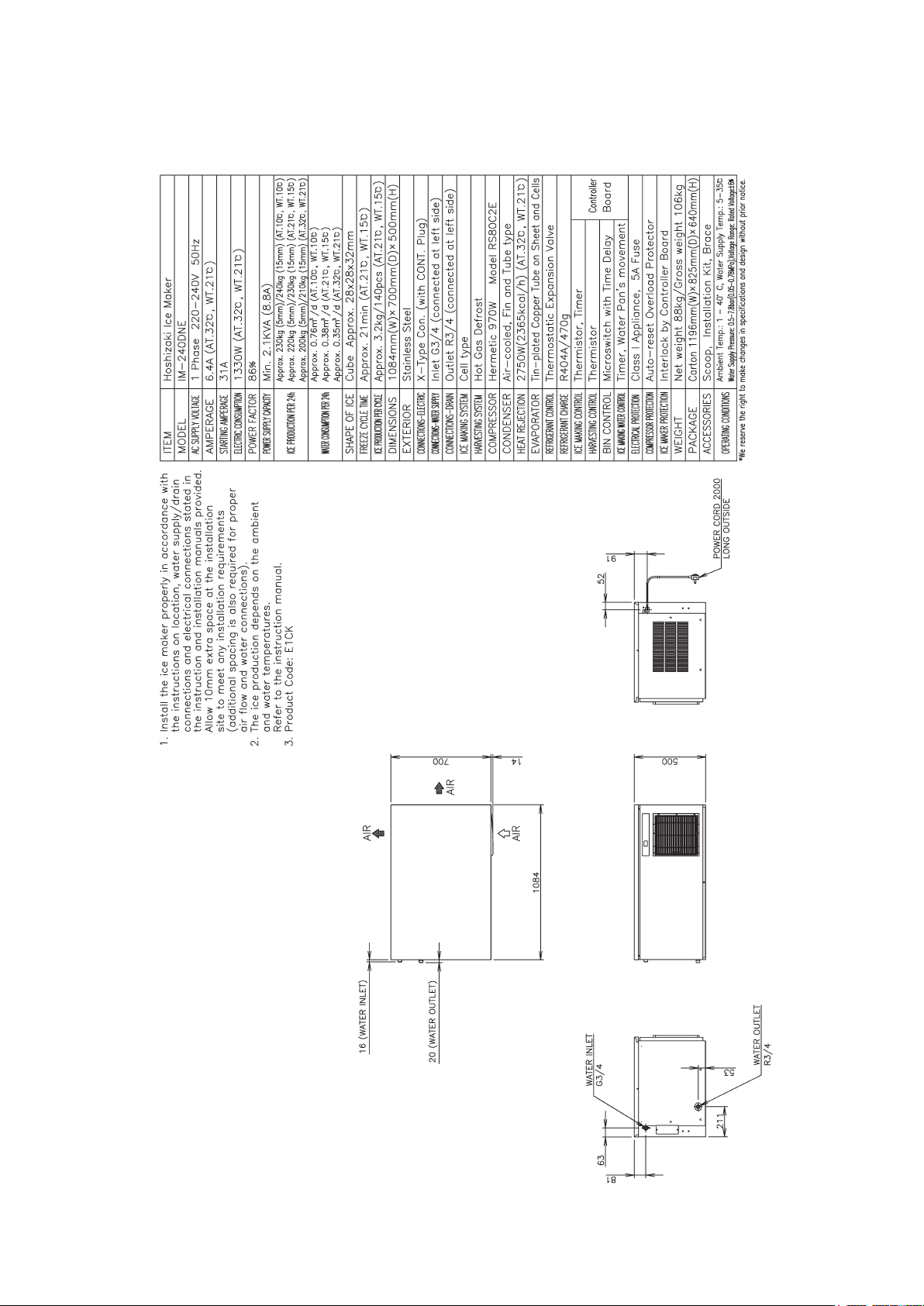

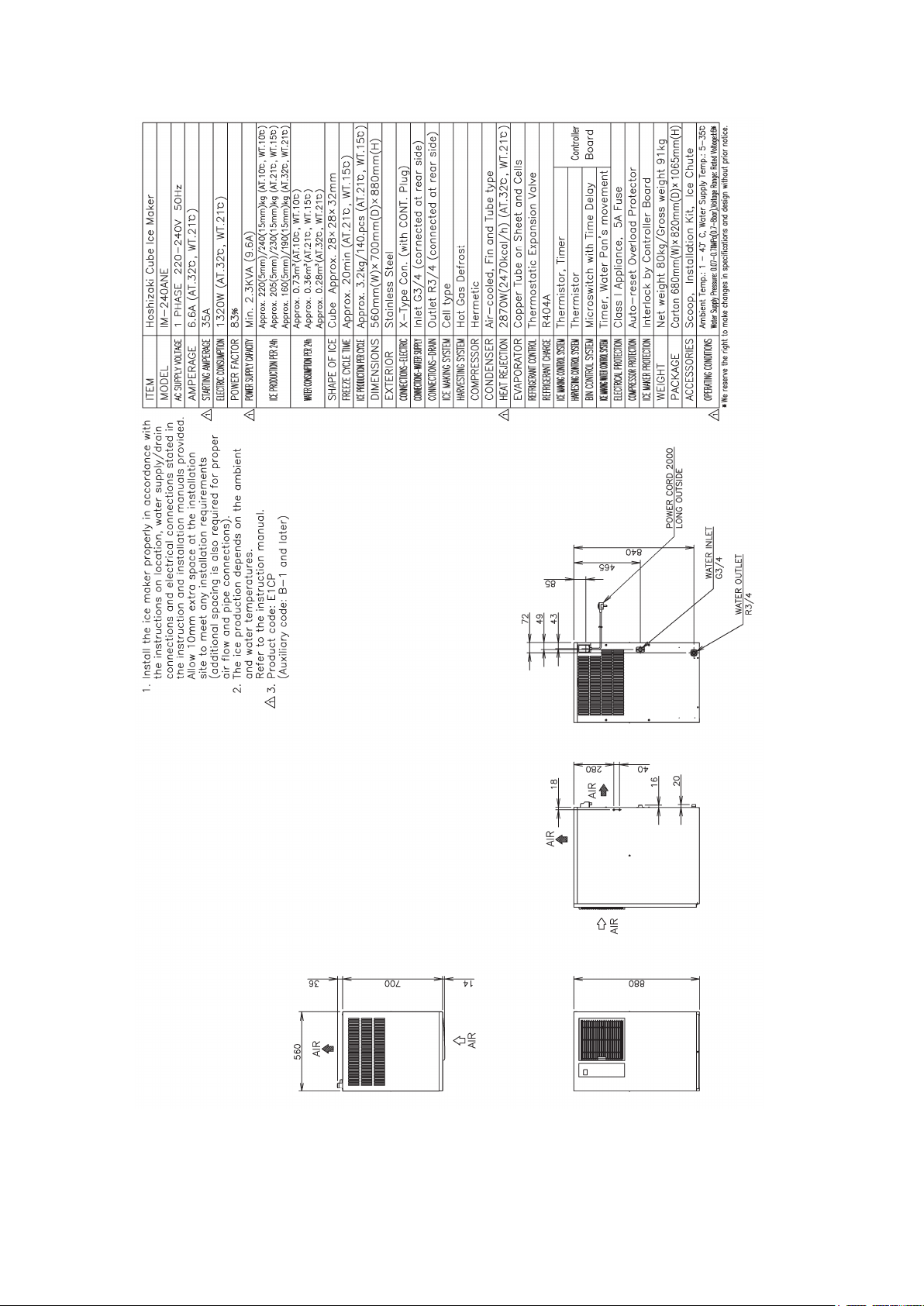

[a] IM-240DNE (Air-cooled) [Copeland compressor: auxiliary code B0 and earlier]

1

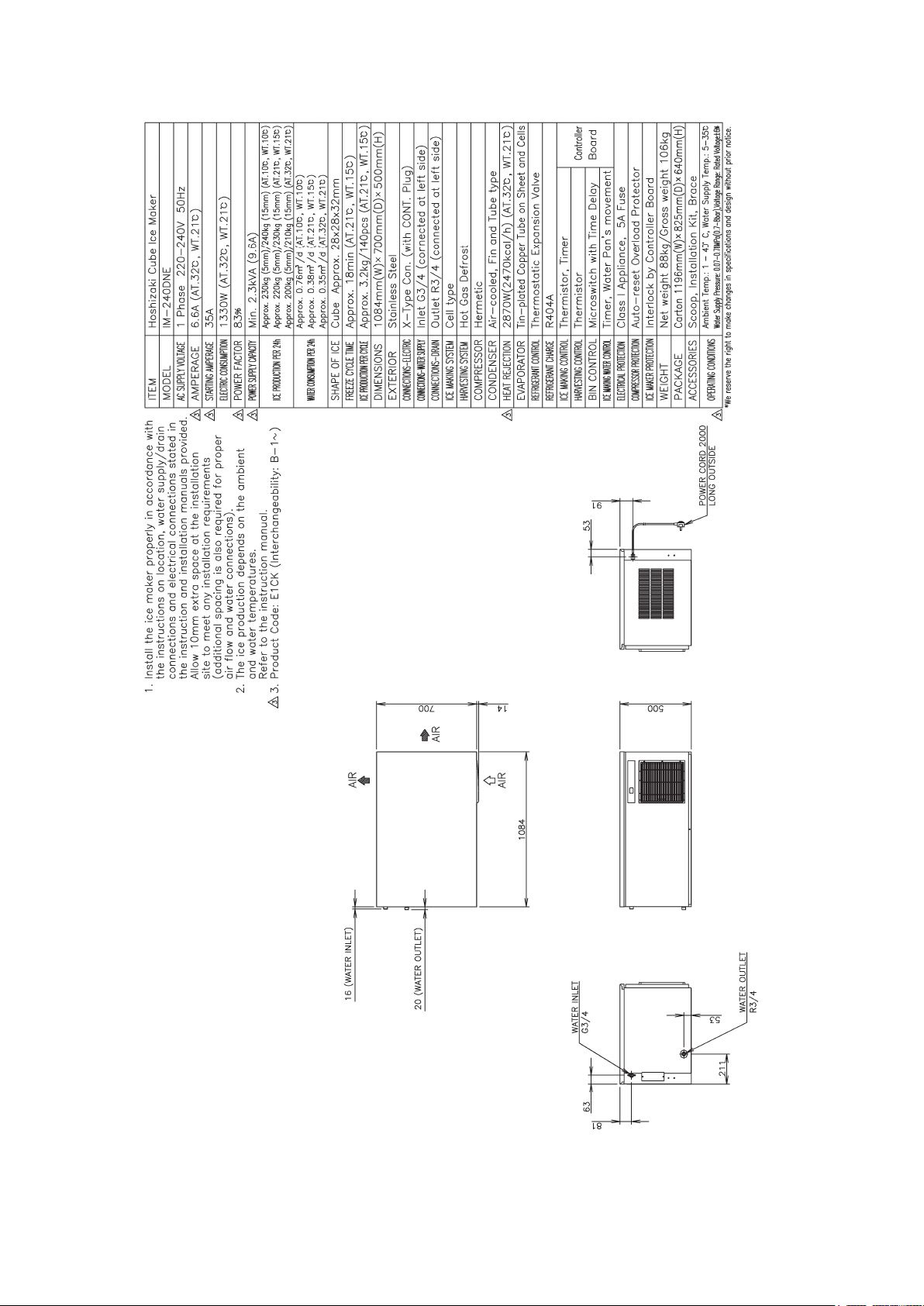

[b] IM-240DNE (Air-cooled) [Danfoss compressor: auxiliary code B1 and later]

2

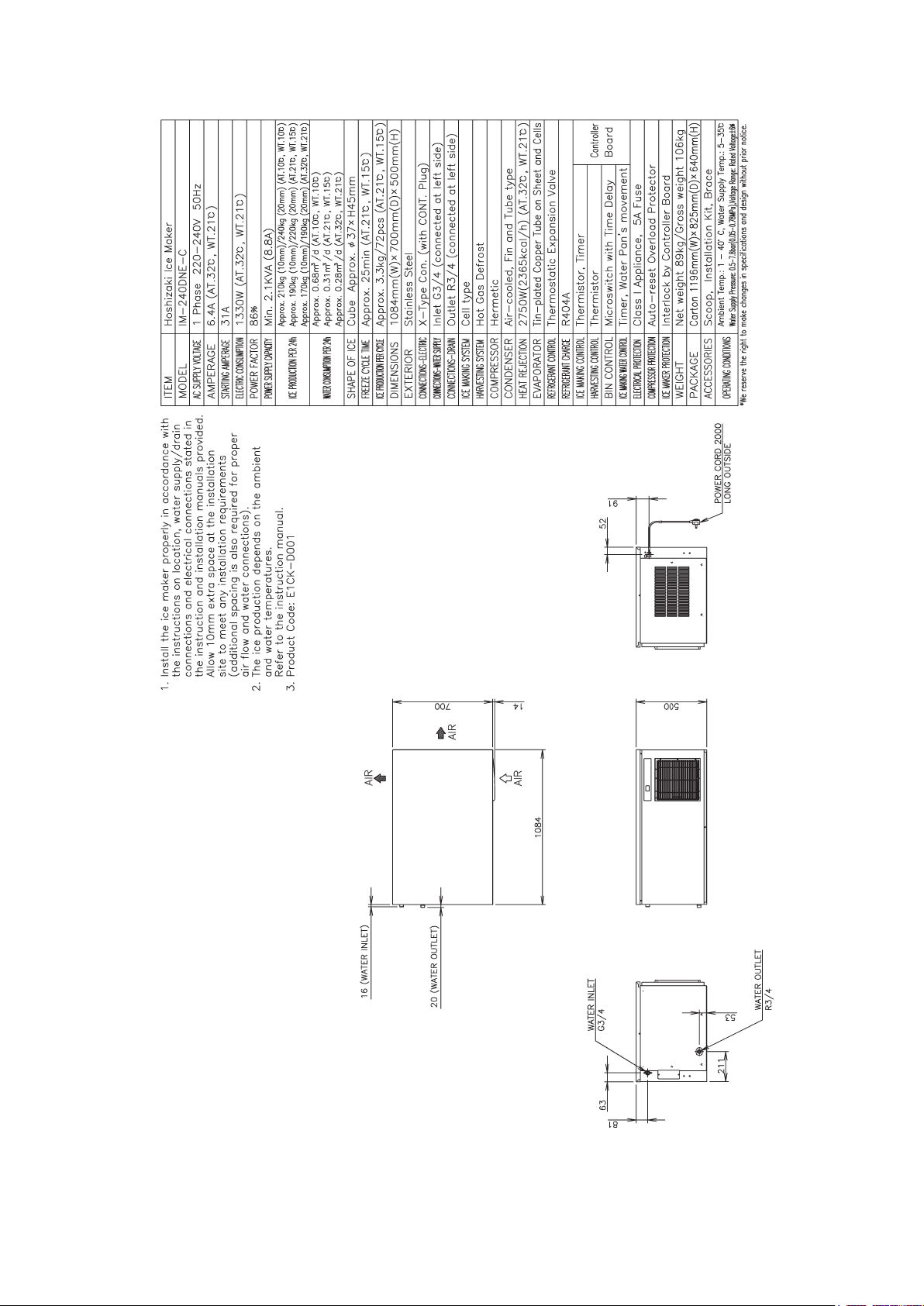

[c] IM-240DNE-C (Air-cooled)

3

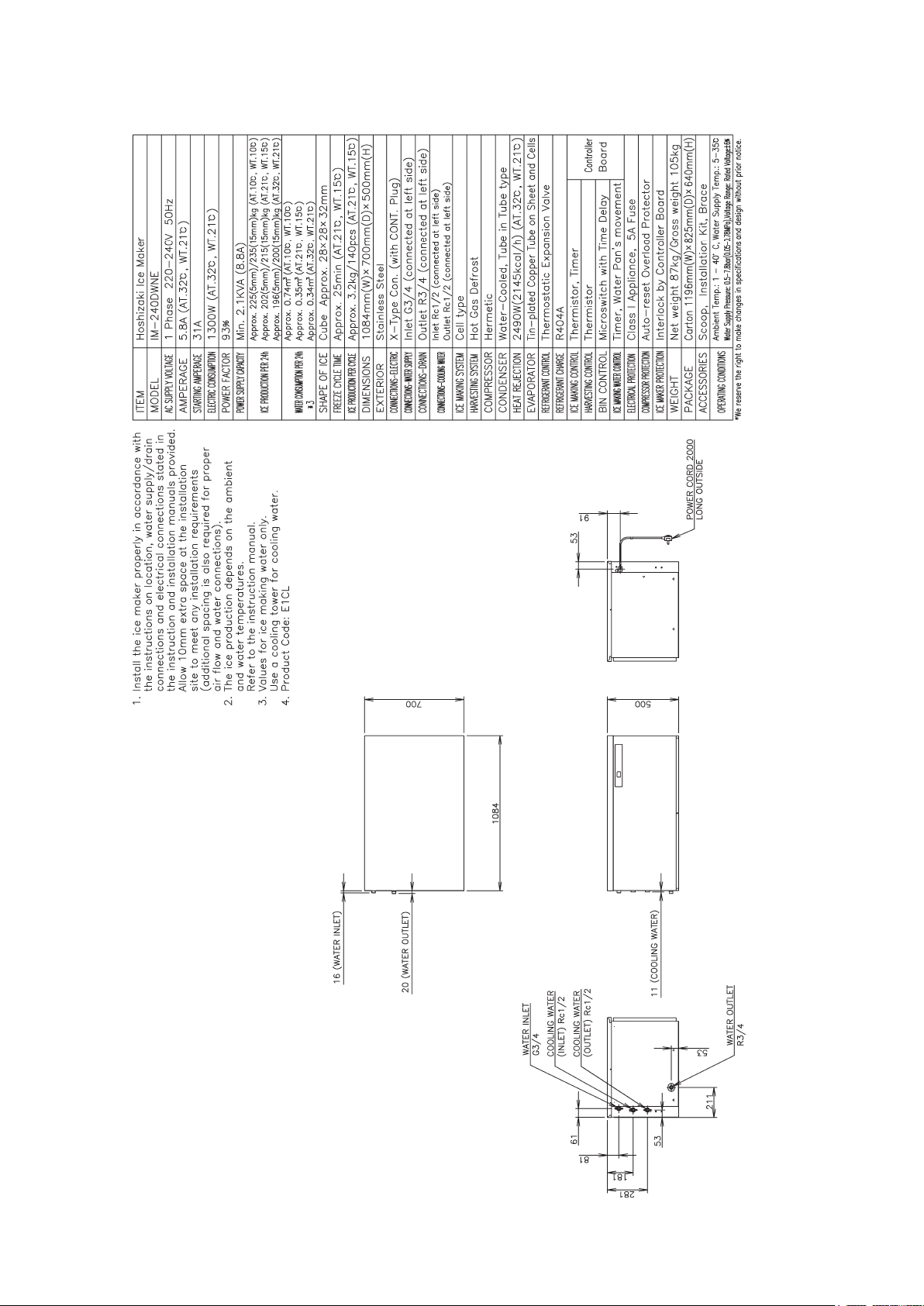

[d] IM-240DWNE (Water-cooled) [Copeland compressor: auxiliary code B0 and

earlier]

4

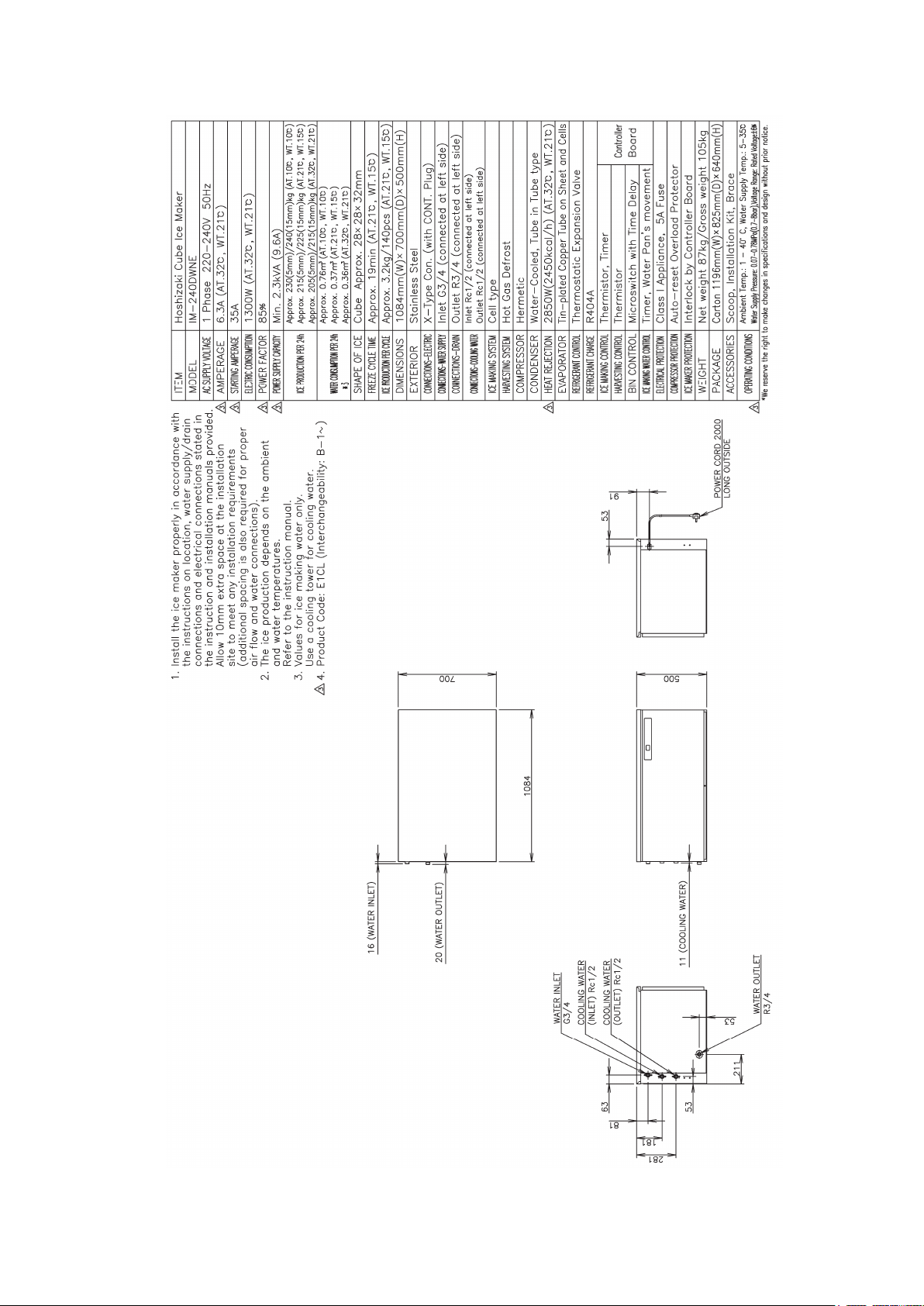

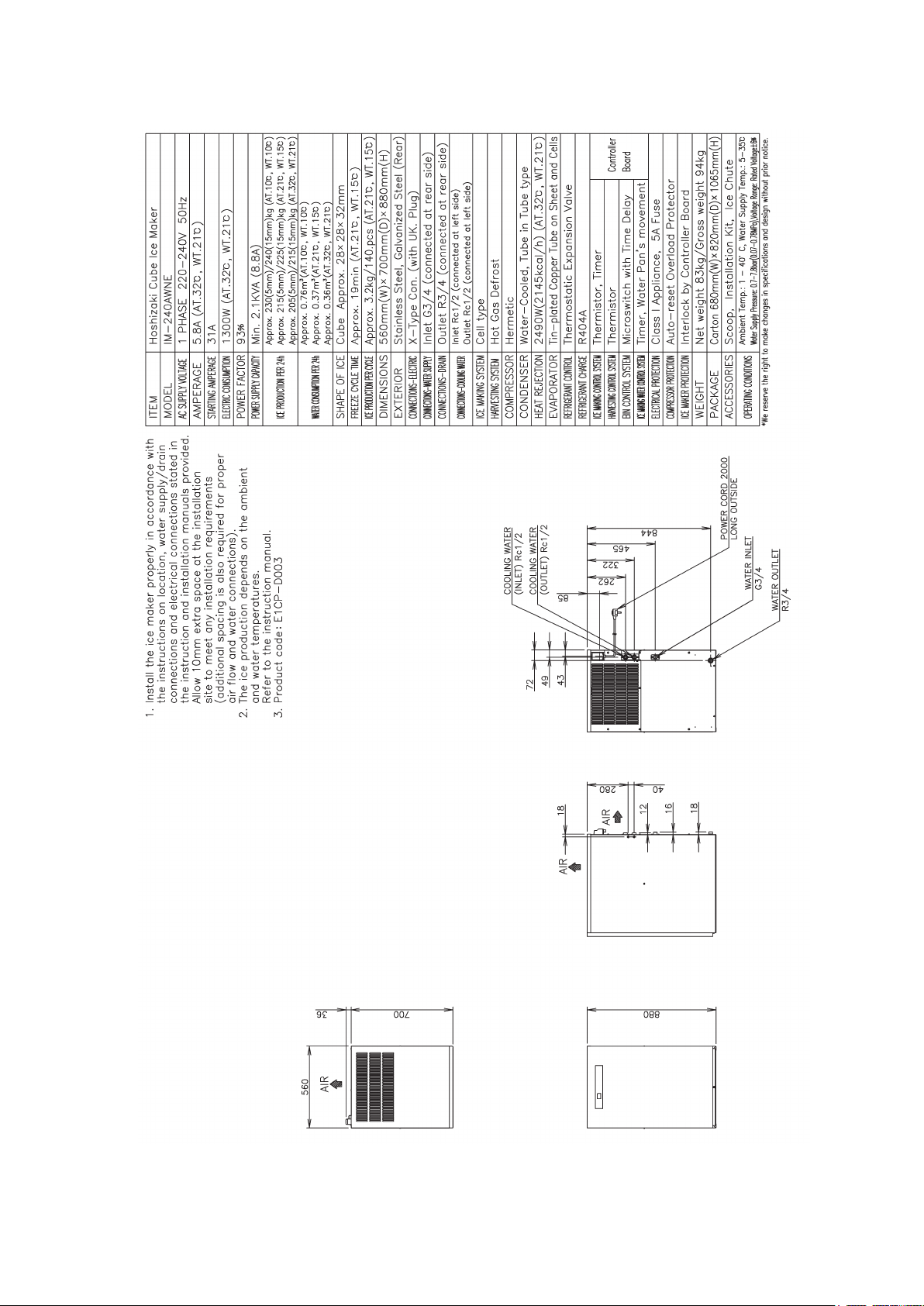

[e] IM-240DWNE (Water-cooled) [Danfoss compressor: auxiliary code B1 and later]

5

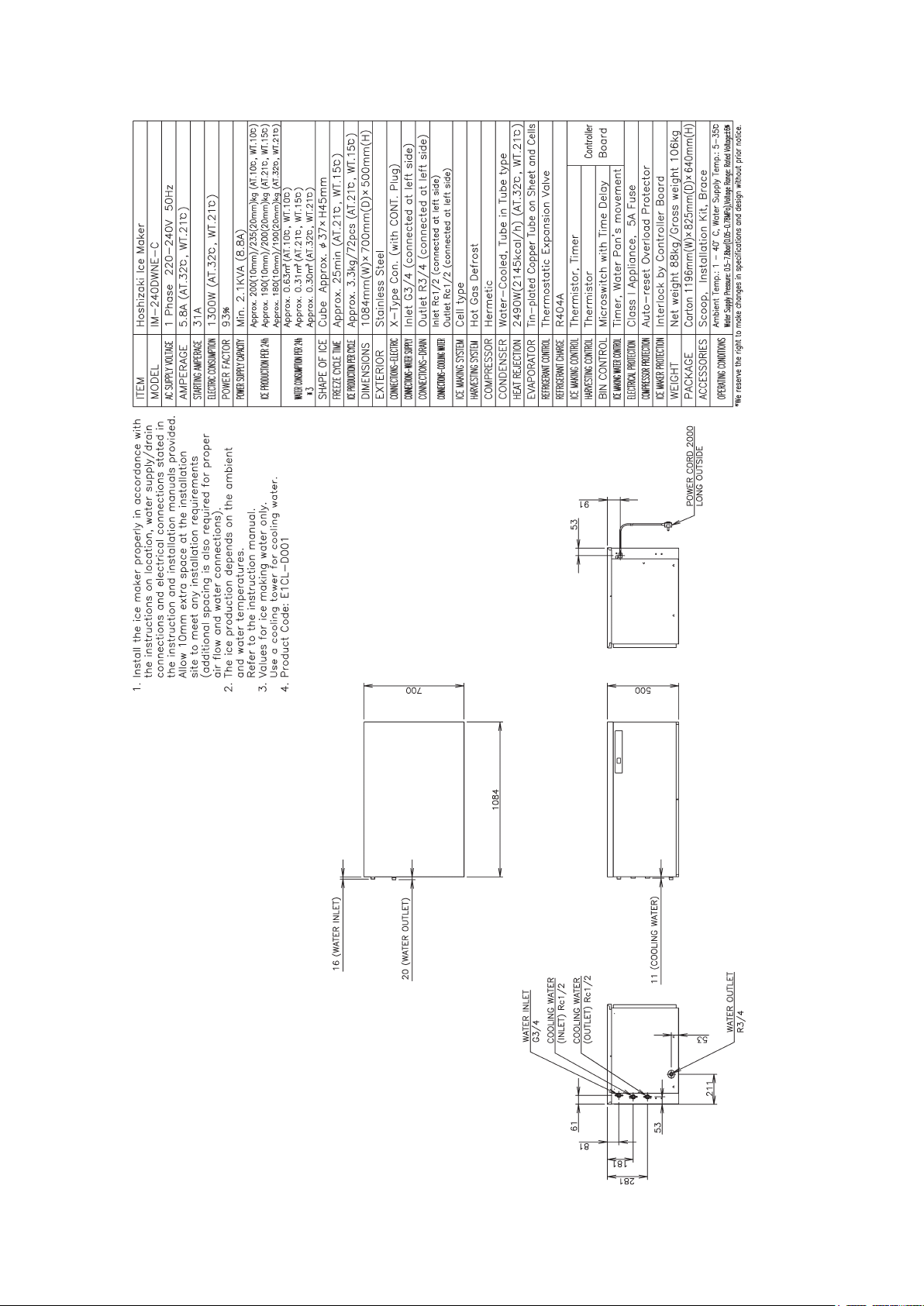

[f] IM-240DWNE-C (Water-cooled)

6

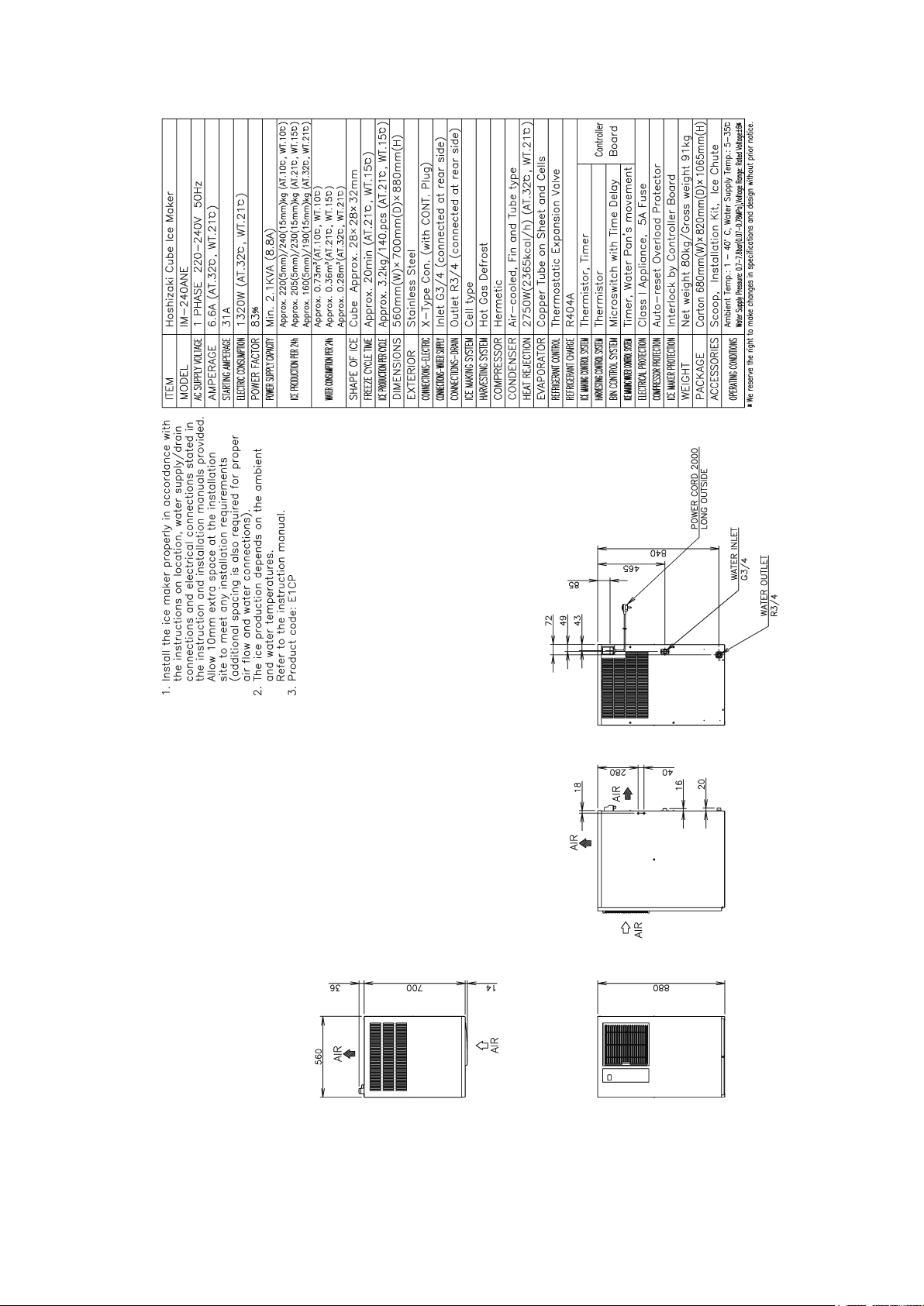

[g] IM-240ANE (Air-cooled) [Copeland compressor: auxiliary code B0 and earlier]

7

[h] IM-240ANE (Air-cooled) [Danfoss compressor: auxiliary code B1 and later]

8

[i] IM-240AWNE (Water-cooled) [Copeland compressor: auxiliary code B0 and

earlier]

9

[j] IM-240AWNE (Water-cooled) [Danfoss compressor: auxiliary code B1 and later]

10

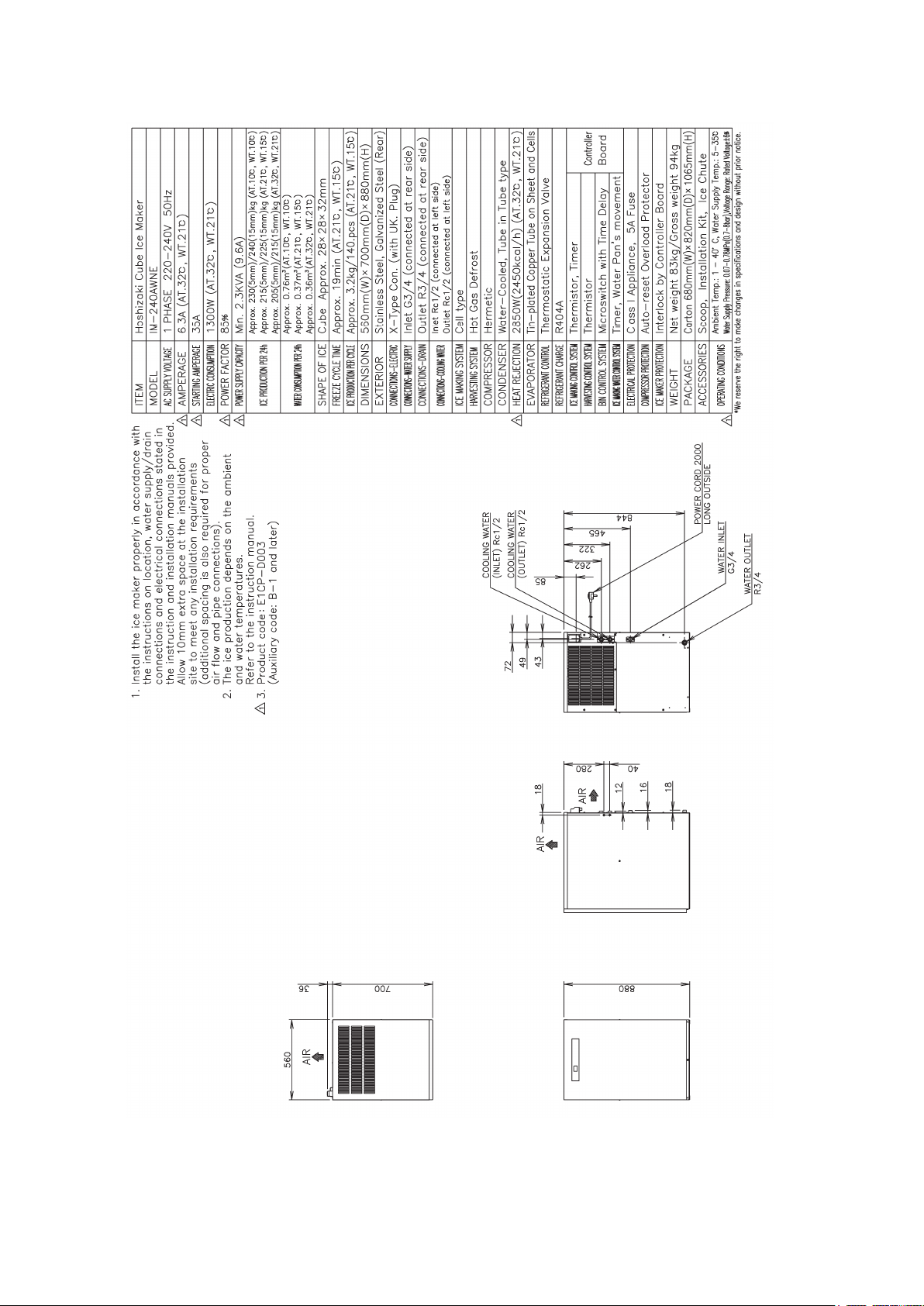

[k] IM-240DSNE (Remote Air-cooled) [Danfoss Compressor]

11

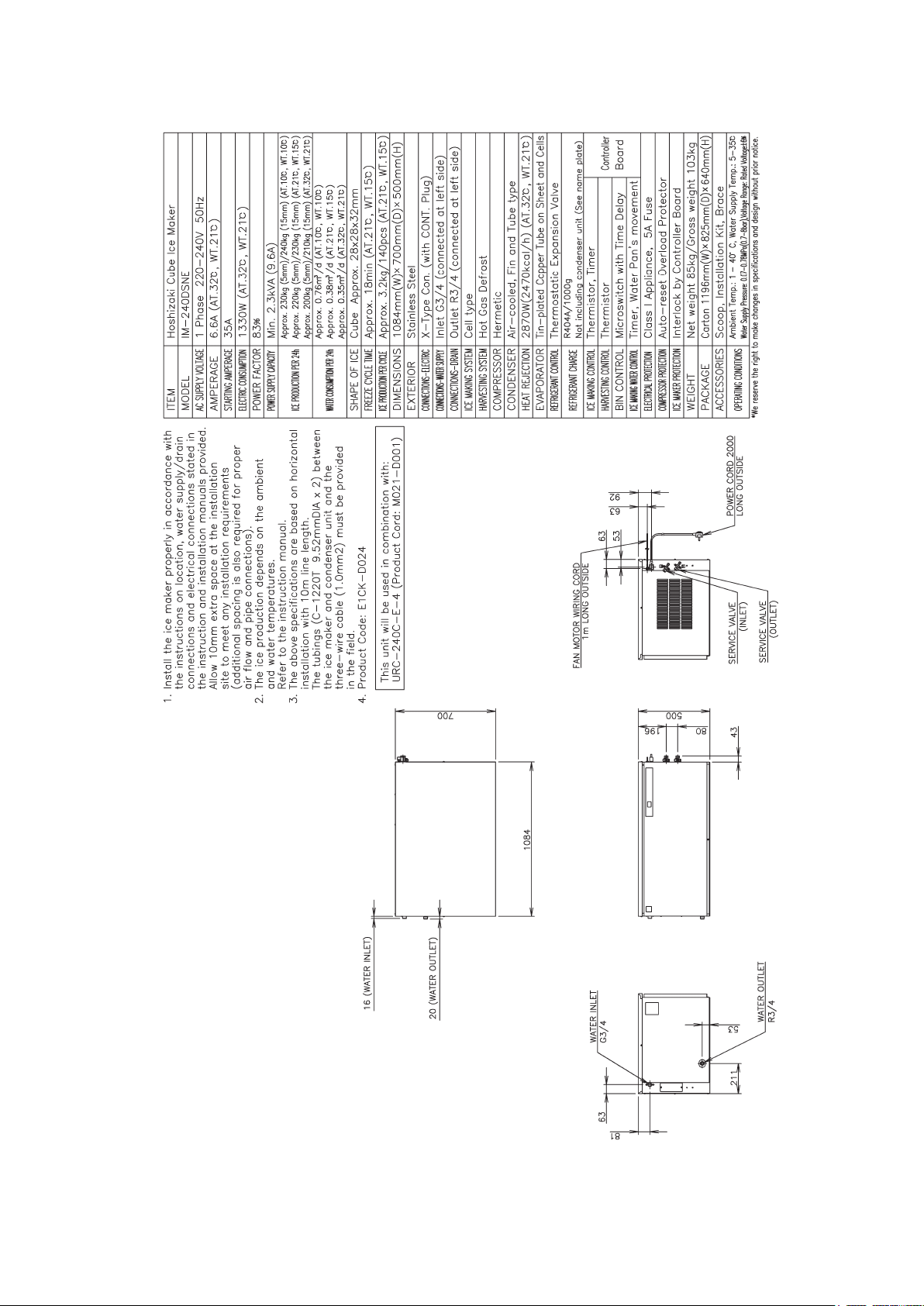

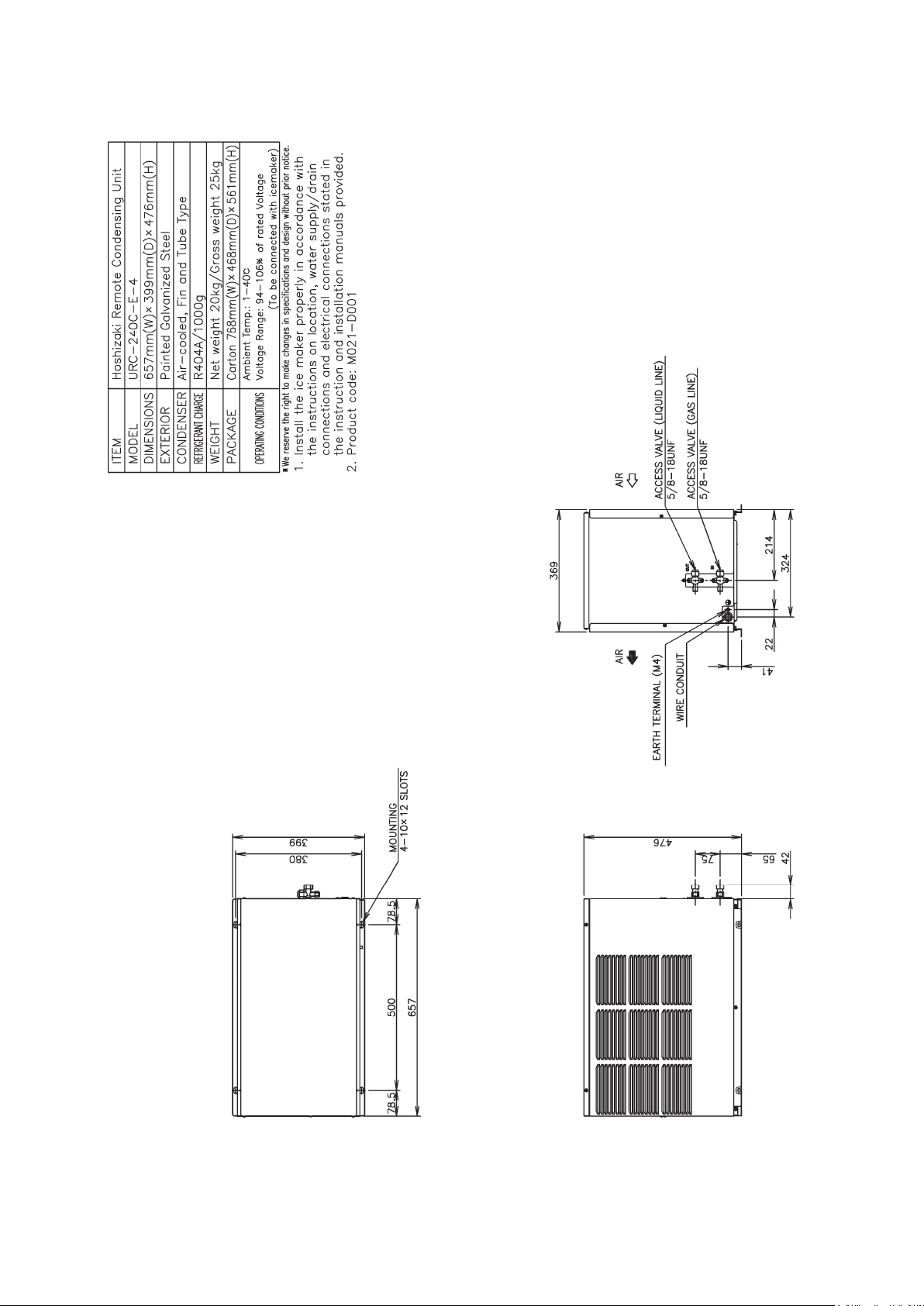

[l] URC-240C-E-4 (Condenser Unit)

12

II. GENERAL INFORMATION

1. CONSTRUCTION

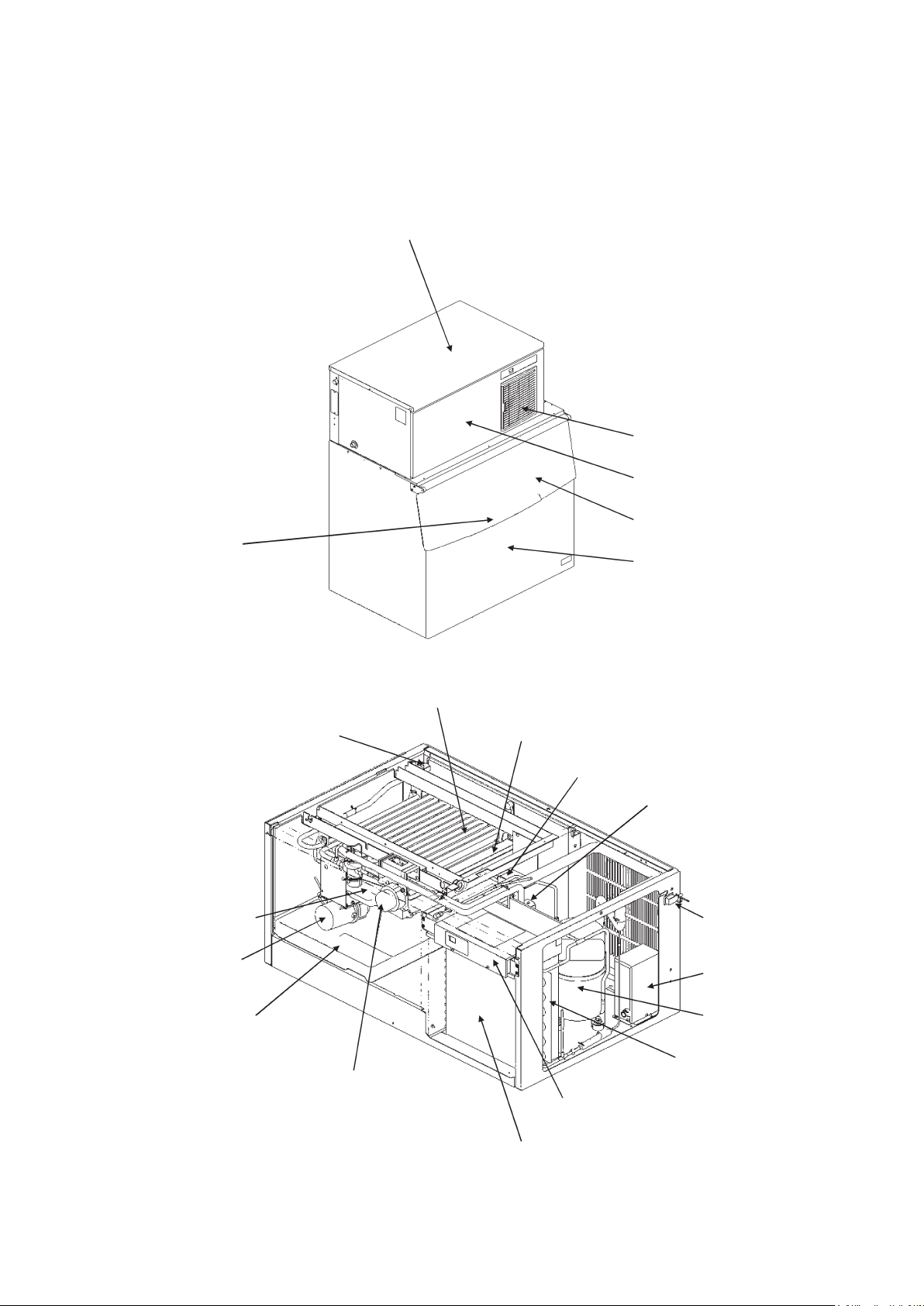

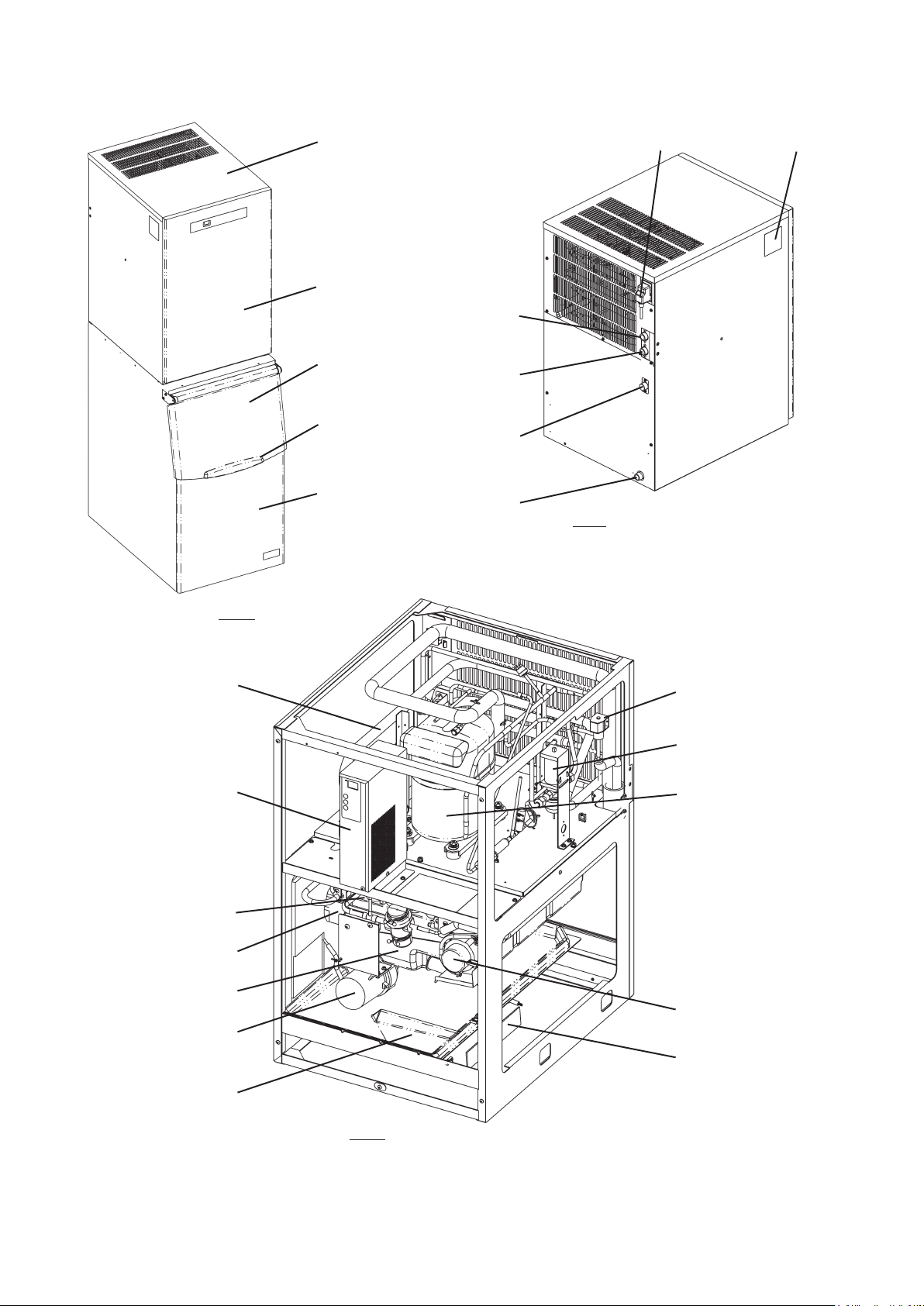

[a] IM-240DNE/XNE, IM-240DNE-C/XNE-C (Air-cooled)

Top Panel

Handle

Louver, Air Filter

Front Panel

Bin Door

Bin

Water Tank

Pump Motor

Drain Pan

Water Valve

Actuator Motor

Evaporator

Water Plate

Bin Control Switch

Hot Gas Valve

Power Cord

Control Box (B)

Compressor

Fan Motor

Control Box (A)

Air-Cooled Condenser

13

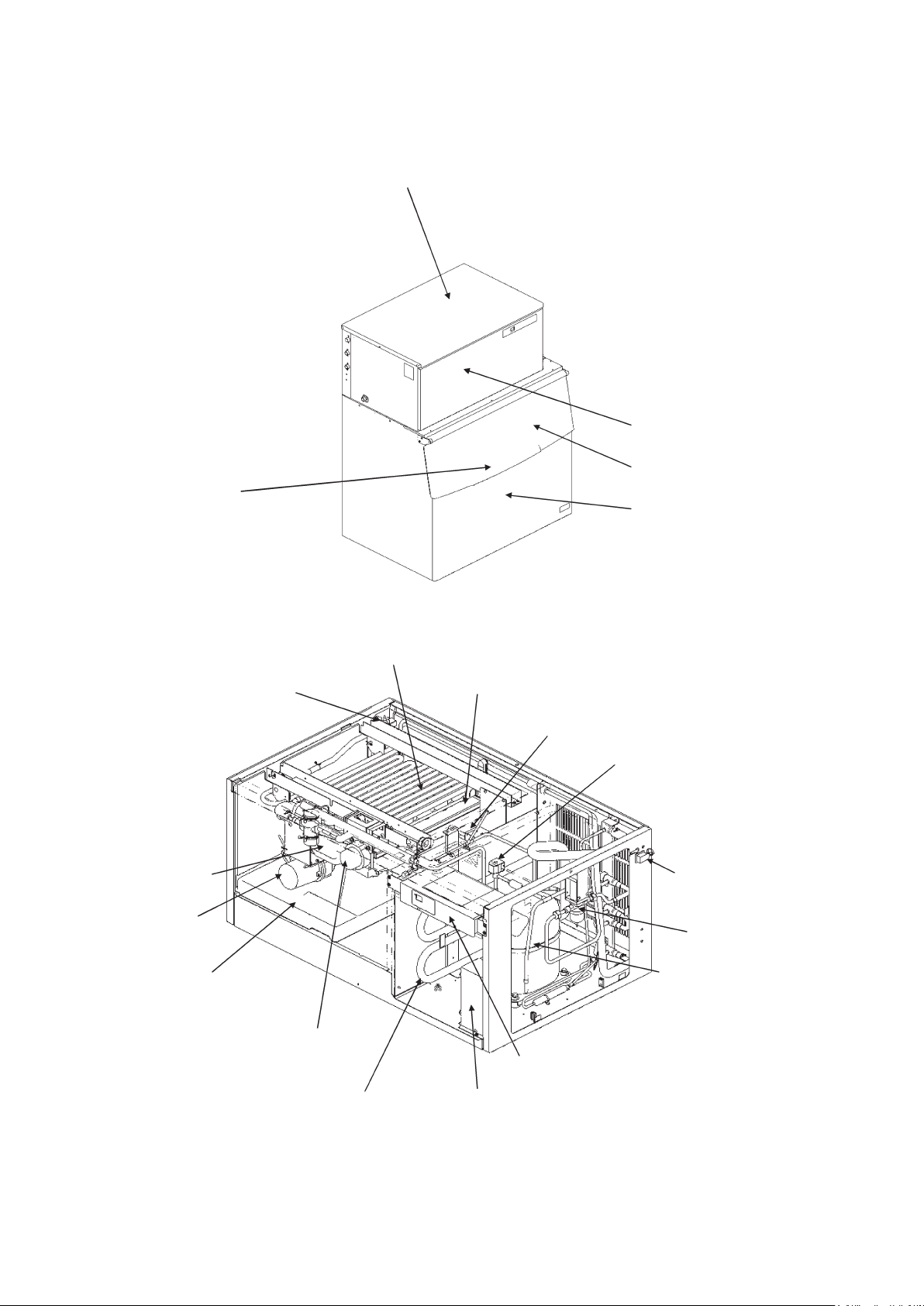

[b] IM-240DWNE/XWNE, IM-240DWNE-C/XWNE-C (Water-cooled)

Top Panel

Front Panel

Bin Door

Handle

Bin

Water Tank

Pump Motor

Drain Pan

Evaporator

Water Valve

Actuator Motor

Water-Cooled Condensor

Water Plate

Bin Control Switch

Hot Gas Valve

Power Cord

Water Regulator

Compressor

Control Box (A)

Control Box (B)

14

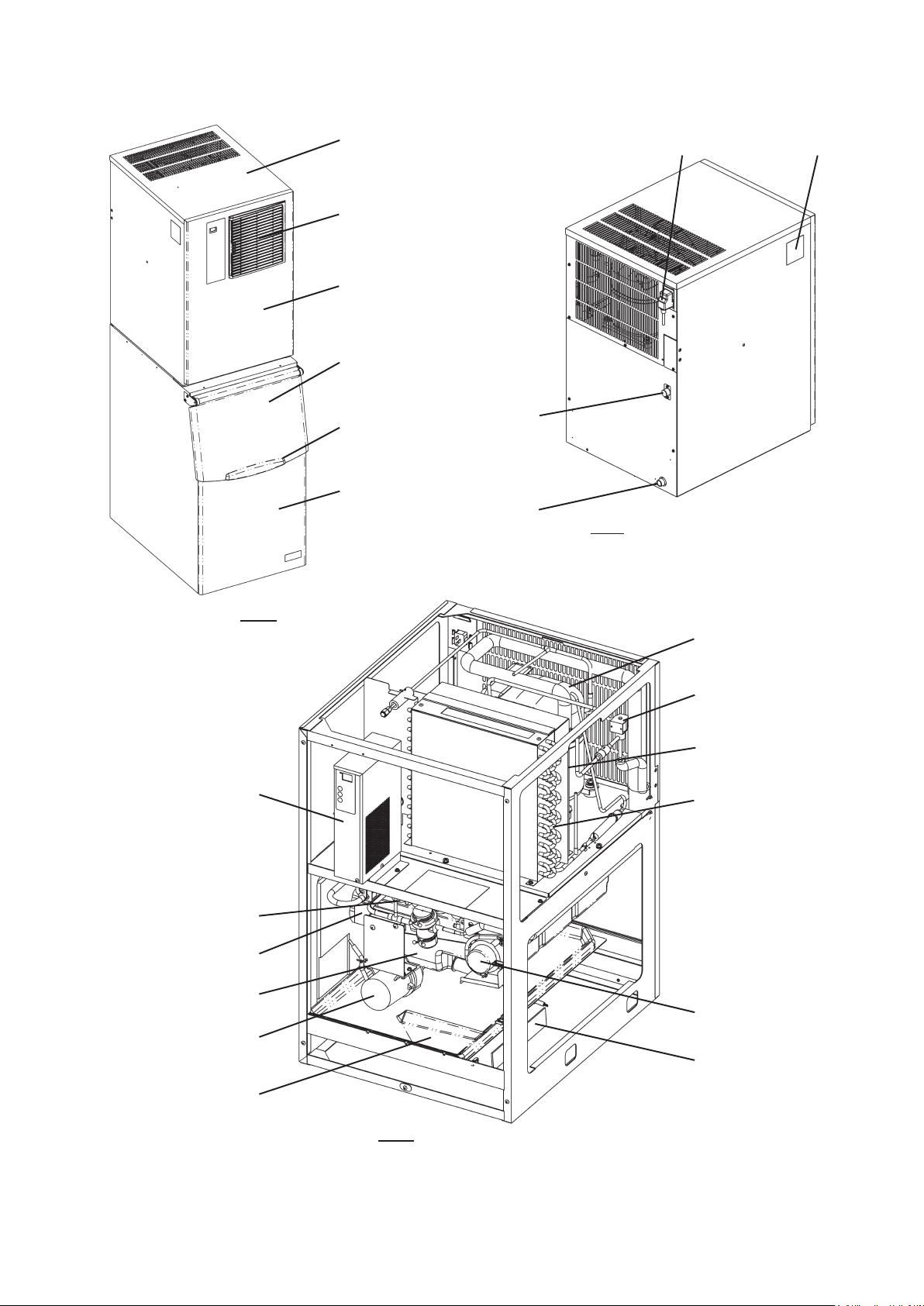

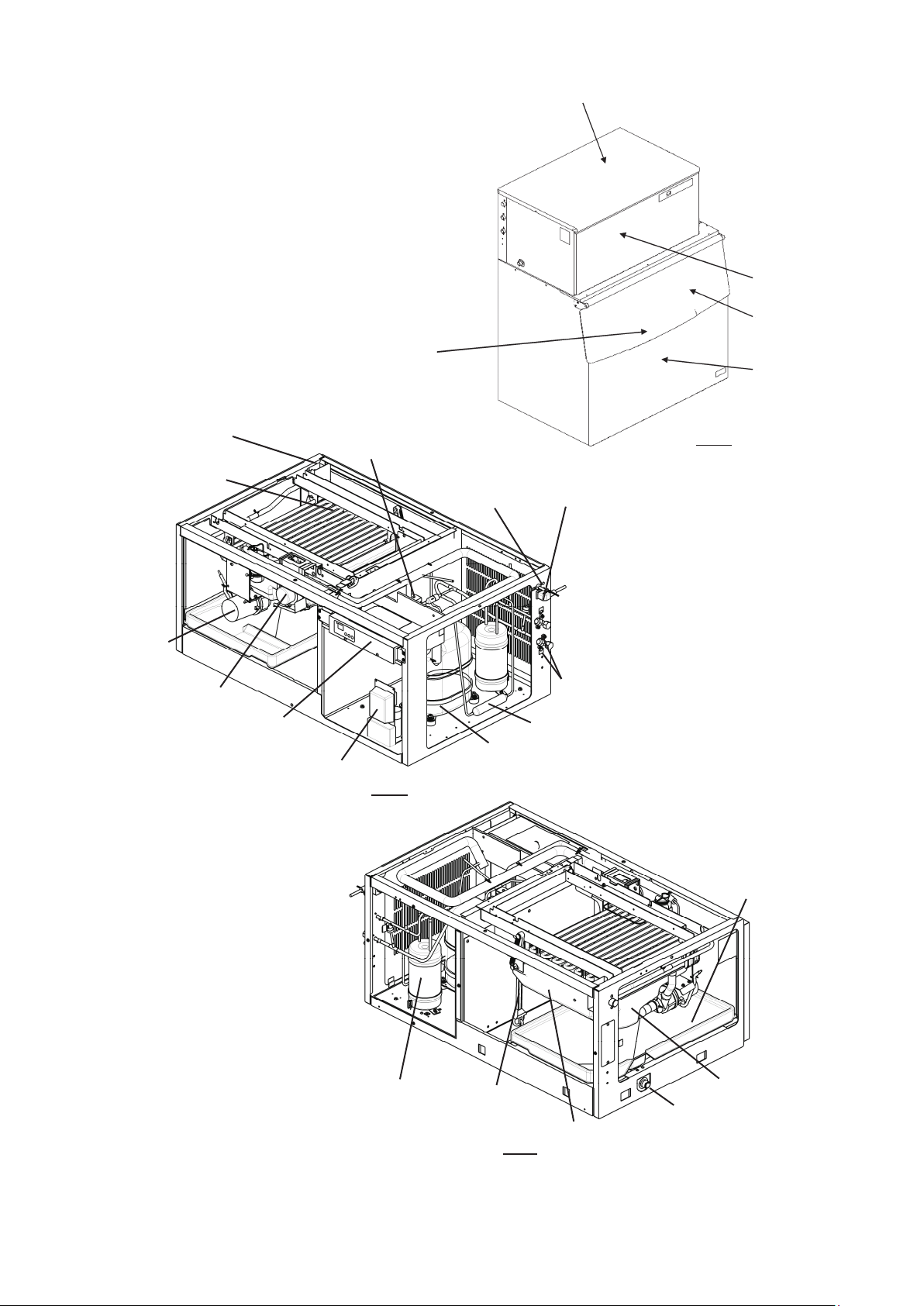

[c] IM-240ANE (Air-cooled)

Top Panel

Louver, Air Filter

Front Panel

Bin Door

Handle

Bin

Water Valve

Drain Pipe

Rear

Power Cord

Nameplate

Front

Control Box

Evaporator

Water Plate

Water Tank

Pump Motor

Compressor

Hot Gas Valve

Fan Motor

Air-Cooled Condenser

Actuator Motor

Bin Control Switch

Drain Pan

Front

15

[d] IM-240AWNE (Water-cooled)

Top Panel

Front Panel

Bin Door

Handle

Bin

Cooling Water

Inlet

Cooling Water

Outlet

Water Valve

Drain Pipe

Rear

Power Cord

Nameplate

Front

Water-Cooled Condenser

Control Box

Evaporator

Water Plate

Water Tank

Pump Motor

Hot Gas Valve

Water Regulator

Compressor

Actuator Motor

Bin Control Switch

Drain Pan

Front

16

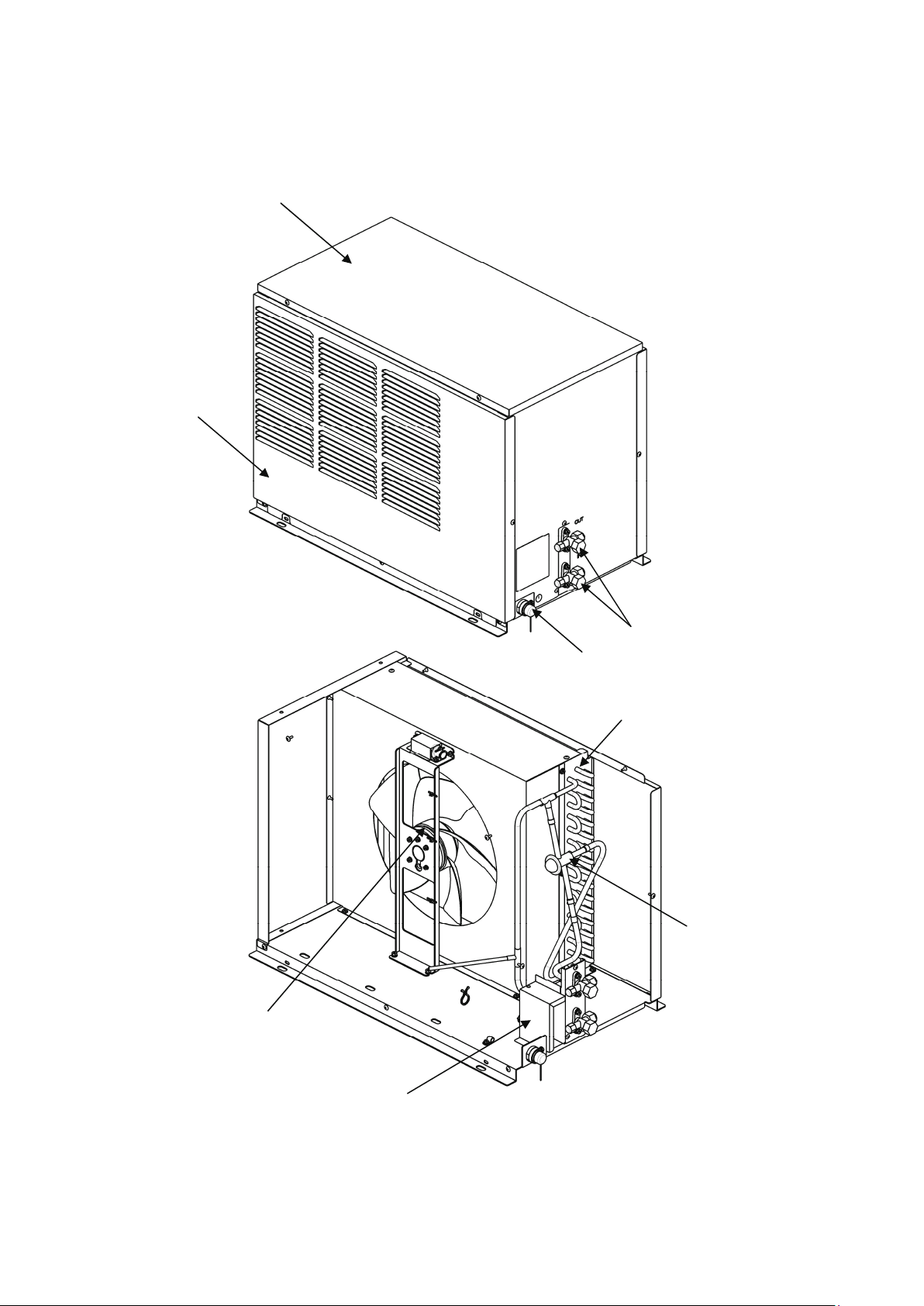

[e] IM-240DSNE (Remote Air-cooled)

Handle

Top Panel

Front Panel

Bin Door

Bin

Water Valve

Evaporator

Pump

Motor

Actuator

Motor

Control Box

Starting Device

Hot Gas Valve

Front

Fan Motor

Wiring Cord

Compressor

Front

Power

Cord

Access Valve

Dryer

Drain Pan

Receiver Tank

Bin Control

Switch

Water Plate

Water Tank

Drain Pipe

Rear

17

[f] URC-240C-E-4 (Condenser Unit)

Top Panel

Unit Cover

Fan Motor

Service Valve

Cable Clamp

Condenser

CP Regulator

Control Box

18

2. CONTROLLER BOARD

Note: Refer to the controller board service manual.

IMPORTANT

If receiving a service call, ask the user to turn off the power to the icemaker

and turn it on again, while watching the icemaker. This will reset the

controller, and in some cases normal operation will resume.

CAUTION

1. Check that the icemaker has been earthed properly. If not, the controller

board will not work properly.

2. Do not change wiring and connections, or the controller board will not

work properly.

3. Do not touch the reverse side of the controller board and tiny electronic

devices on it.

4. Do not repair the electronic devices and parts on the controller board

in the field (except for fuse replacement). Replace the whole board

assembly when it fails.

5. To get static free, always touch the metal part of the icemaker before

servicing. Electrostatic discharge will cause severe damage to the

controller board.

6. The signal ground wire must be connected to the control box when

replacing the controller board after service.

7. The controller board is fragile. Handle with care.

* Do not drop the board on the oor.

* Make sure that the board is placed correctly into the guides in the

control box. Mis-alignment could cause breakage when replacing the

control box cover.

* Handle the board by the edges only. Do not touch the electric parts and

devices.

19

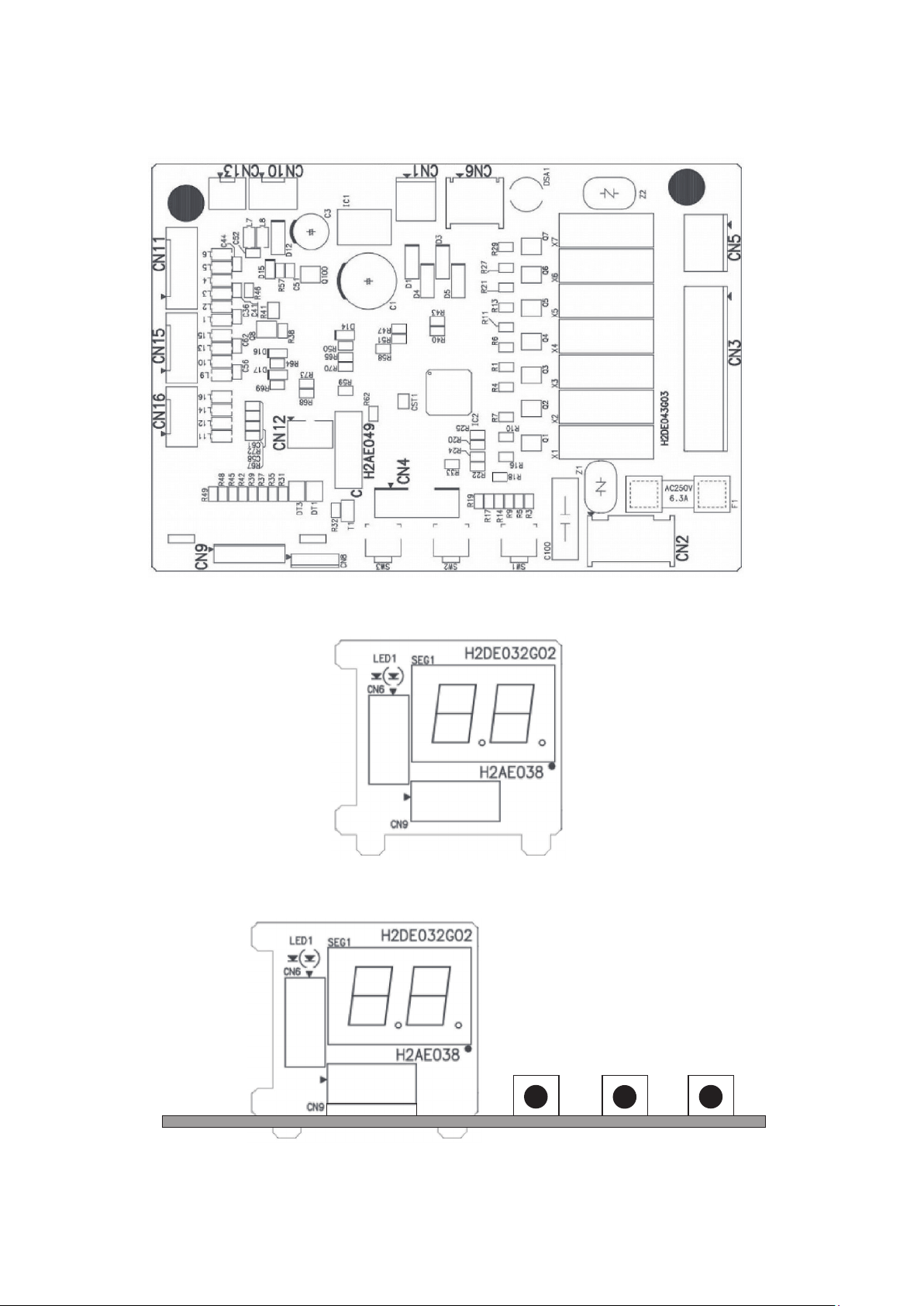

[a] CONTROLLER BOARD LAYOUT

Main Board

Sub Board

Combination

20

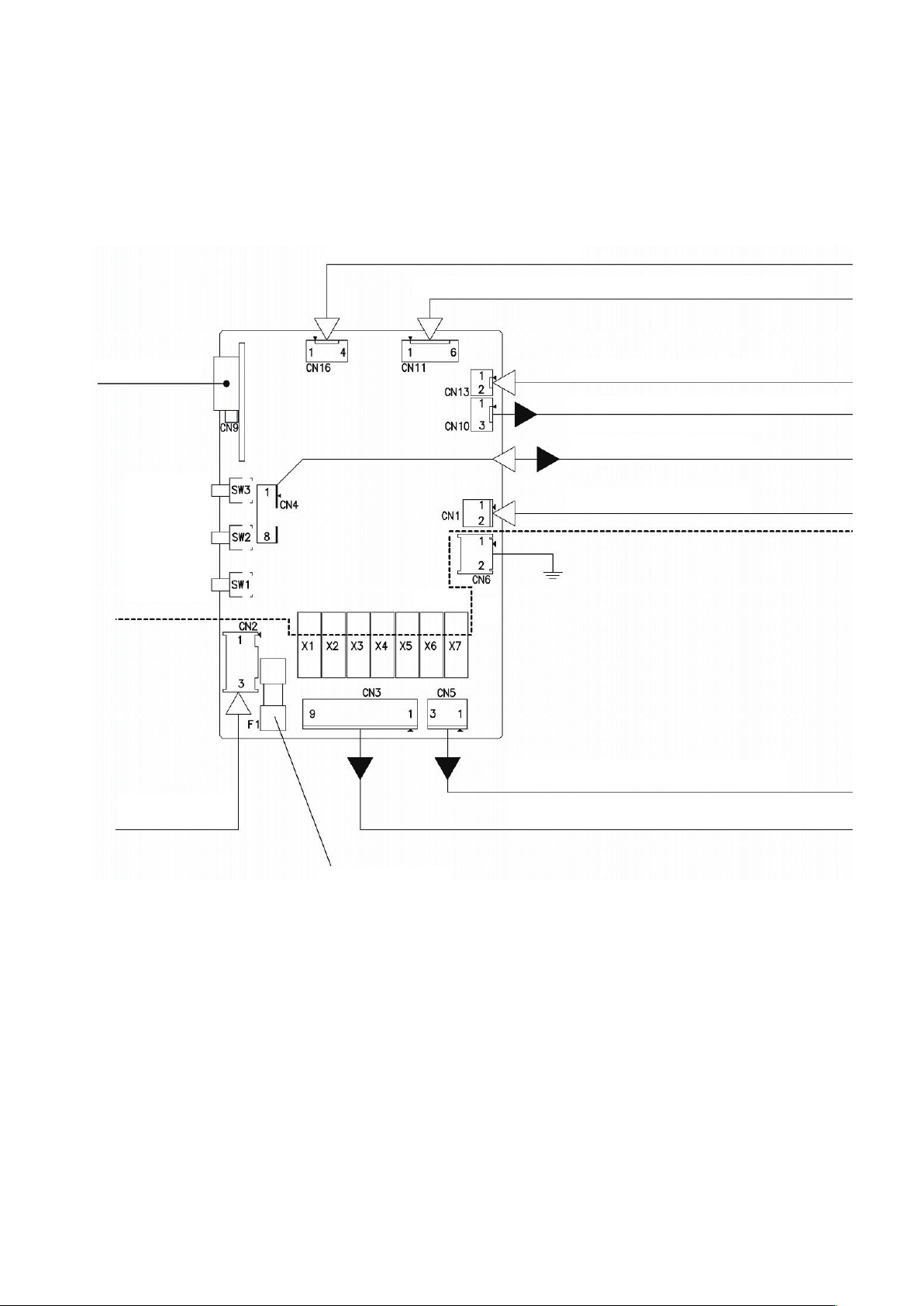

[b] INPUT/OUTPUT LAYOUT

Hall IC Input XA Connector (4P)

Bin Control Switch / Pressure Switch /

Condenser Thermistor Input XA Connector (6P)

7-Segment DoubleDigit Display

Reset Button

Close Button

Open Button

220-240V AC Input

VYH Connector (3P)

AC Low Voltage,

DC Circuit

Pump Motor / Hot Gas Valve / Fan Motor / Water Valve /

Compressor AC Relay Drive Output VH Connector (9P)

Cube Control Thermistor Input XA Connector (2P)

Data Input/Output PA Connector (8P)

10.5V AC Input VH Connector (2P)

AC High

Voltage Circuit

Actuator Drive Output VH Connector (3P)

Fuse

P01992-01

6.3A

21

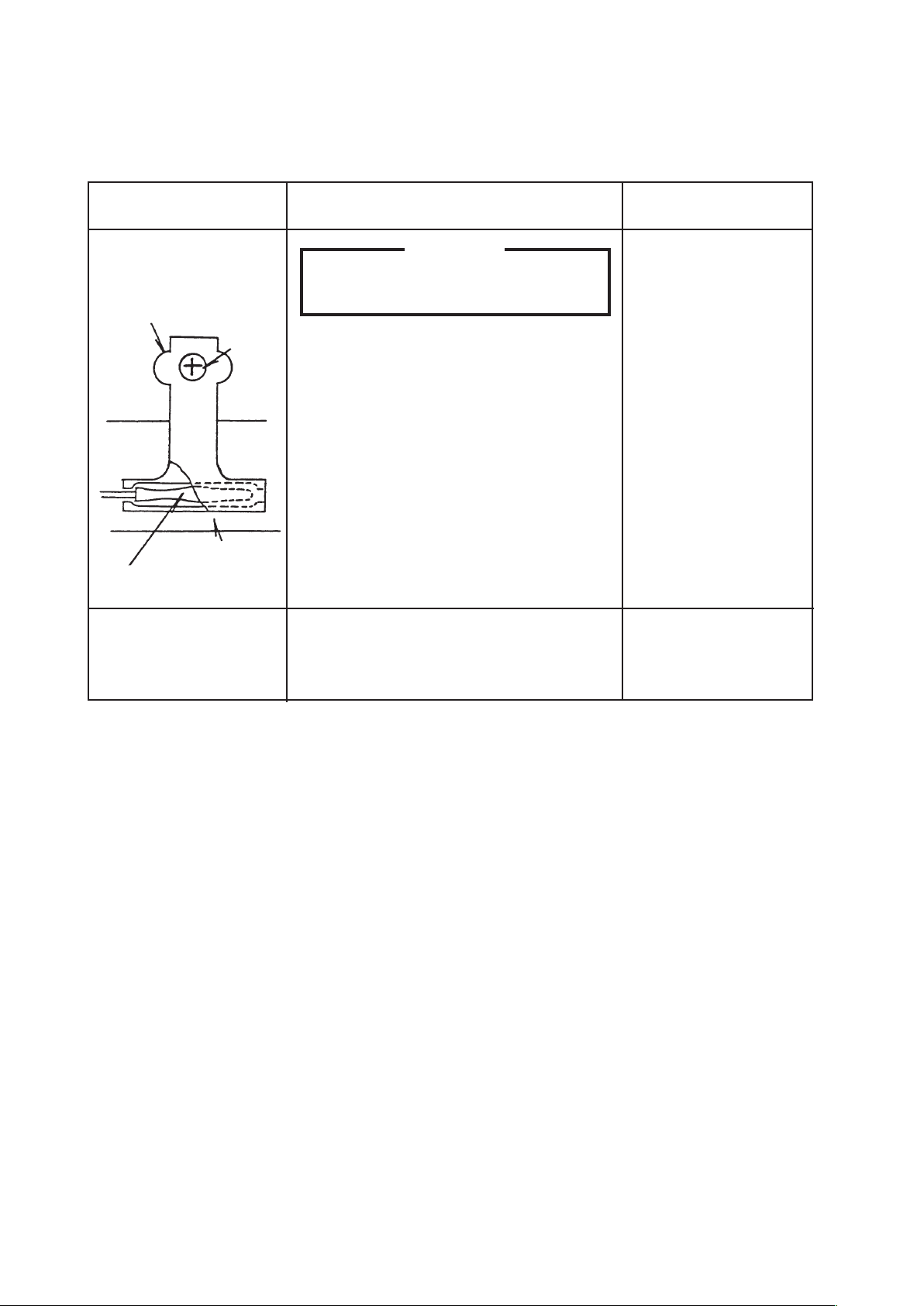

[c] BEFORE CHECKING CONTROLLER BOARD

Check the power source voltage and the components as shown in the table below.

Component

1. Thermistor

(on evaporator)

Holder

Screw

Evaporator

Thermistor

2. Bin Control Switch

Procedure

CAUTION

Thermistor sensor part is fragile,

glass sealed. Handle with care.

* Disconnect the connector CN13 on

the board.

* R e m o v e t h e s c r e w a n d t h e

thermistor holder on the evaporator.

* Immerse the sensor part in a glass

co nt a i n i n g i c e a n d wat e r for 5

minutes.

* Check the resistance between CN13

connector pins.

* Replace the thermistor in its correct

position.

* Connect CN13.

Manually set the micro switch in the

TRI P and RE S ET p os i tio n s, and

check the period.

Normal

5 -7 kilohms

Approx.

TRIP(Closed) 10 sec.

RESET(Open) 80 sec.

22

Loading...

Loading...