Hoshizaki FM-120EE-50 Service Manual

NO. E2EB-679

ISSUED: JUN. 3, 2005

REVISED: JAN. 20, 20 06

HOSHIZAKI

SELF-CONTAINED ICE MAKER

MODEL

CUBELET

FLAKE

CM-110EE

FM-80EE

FM-120EE(-N)

FM-120EE-50(-N)

SERVICE MANUAL

CONTENTS

I. SPECIFICA TIONS ---------------------------------------------------------------------------------------1

1. DI MENSIONS /CONNEC TIONS ------------------------------------------------------------------1

[a] CM-110EE, FM-120EE, FM-120EE-N, FM-80EE --------------------------------------1

[b] FM-120EE-50, FM-120EE-50-N ------------------------------------------------------------2

2. SPECIF ICA TIONS-----------------------------------------------------------------------------------3

[a] CM-110EE ----------------------------------------------------------------------------------------3

[b] FM-120EE ----------------------------------------------------------------------------------------4

[c] FM-120EE-N -------------------------------------------------------------------------------------5

[d] FM-120EE-50 ------------------------------------------------------------------------------------6

[e] FM-120EE-50-N---------------------------------------------------------------------------------7

[f] FM-80EE ------------------------------------------------------------------------------------------8

II. G ENERAL INFO RMA TION----------------------------------------------------------------------------9

1. CO NSTRUCT ION------------------------------------------------------------------------------------9

2. OPERA TION - How i t works---------------------------------------------------------------------12

3. TIMER BOARD-------------------------------------------------------------------------------------13

[a] SOLID- ST A TE CONTROL------------------------------------------------------------------- 13

[b] TIMER BOARD --------------------------------------------------------------------------------13

[c] SEQUENCE ------------------------------------------------------------------------------------14

PAGE

III. INSTALLATION INSTRUCTIONS ----------------------------------------------------------------- 17

1. UNP ACKING----------------------------------------------------------------------------------------17

2. LOCA TI ON ------------------------------------------------------------------------------------------18

3. IN STA LLA TION ------------------------------------------------------------------------------------- 19

4. ELECTRICAL CONNECTION S ---------------------------------------------------------------- 19

5. WA TER SUPPLY AN D DRAIN CONNEC TIONS ------------------------------------------- 20

IV . OP ERA TING I NSTRUC TIONS-------------------------------------------------------------------- 22

1. ST ART UP------------------------------------------------------------------------------------------- 22

2. PREP ARING THE ICEMAKER FOR LONG STORAGE --------------------------------- 23

V . MAIN TENANCE --------------------------------------------------------------------------------------24

1. PERIOD ICAL CLEAN ING -----------------------------------------------------------------------24

2. CLEANI NG OF WA TER SYSTEM -------------------------------------------------------------26

VI. TECHNICAL INFORMA TION---------------------------------------------------------------------- 30

1. WA TER CIRCUI T AND REF RIGERAN T CIR CUIT ----------------------------------------- 30

2. WIRI NG DIA GRAM -------------------------------------------------------------------------------- 31

[a] CM-1 10EE, FM-120EE(-N), FM-120EE-50(-N)----------------------------------------31

[b] FM-80EE ----------------------------------------------------------------------------------------32

3. TI MING C HART ------------------------------------------------------------------------------------33

[a] PRINCIPL E OF OPERATION--------------------------------------------------------------- 33

[b] PROTECTO RS --------------------------------------------------------------------------------33

4. PERFORMANCE DA TA ------------------------------------------------------------------------- 35

[a] CM-110EE --------------------------------------------------------------------------------------35

i

[b] FM-120EE, FM-120EE-50 ------------------------------------------------------------------ 36

[c] FM-120EE-N, FM-120EE-50-N ------------------------------------------------------------37

[d] FM-80EE ----------------------------------------------------------------------------------------38

VII. S ERVICE D IAGNOSI S ---------------------------------------------------------------------------- 39

1. NO IC E PRODU CTION---------------------------------------------------------------------------39

2. LOW ICE PROD UCTION ------------------------------------------------------------------------ 41

3. OTHERS--------------------------------------------------------------------------------------------- 41

VIII. REMOV AL AND REPLACEMENT OF COMPONENTS ----------------------------------43

1. SERVICE FOR REFRIGERAN T LINES------------------------------------------------------43

[a] SER VICE INF ORMA TION------------------------------------------------------------------- 43

[b] REFRIGER ANT RECOVERY -------------------------------------------------------------- 44

[c] EV ACUATION AND REC HARGE ---------------------------------------------------------44

2. BR AZING -------------------------------------------------------------------------------------------- 45

3. COMPRESSOR -----------------------------------------------------------------------------------45

4. DRIER ------------------------------------------------------------------------------------------------47

5. EXP ANSION VALVE------------------------------------------------------------------------------48

6. EV APORATOR ASSEMBL Y -------------------------------------------------------------------- 49

7. F AN MO TOR----------------------------------------------------------------------------------------53

8. FLOAT SWITCH -----------------------------------------------------------------------------------53

9. CONTROL WA TER VAL VE --------------------------------------------------------------------- 54

ii

I. SPECIFICATIONS

1. DIMENSI ONS/CONNE CTIONS

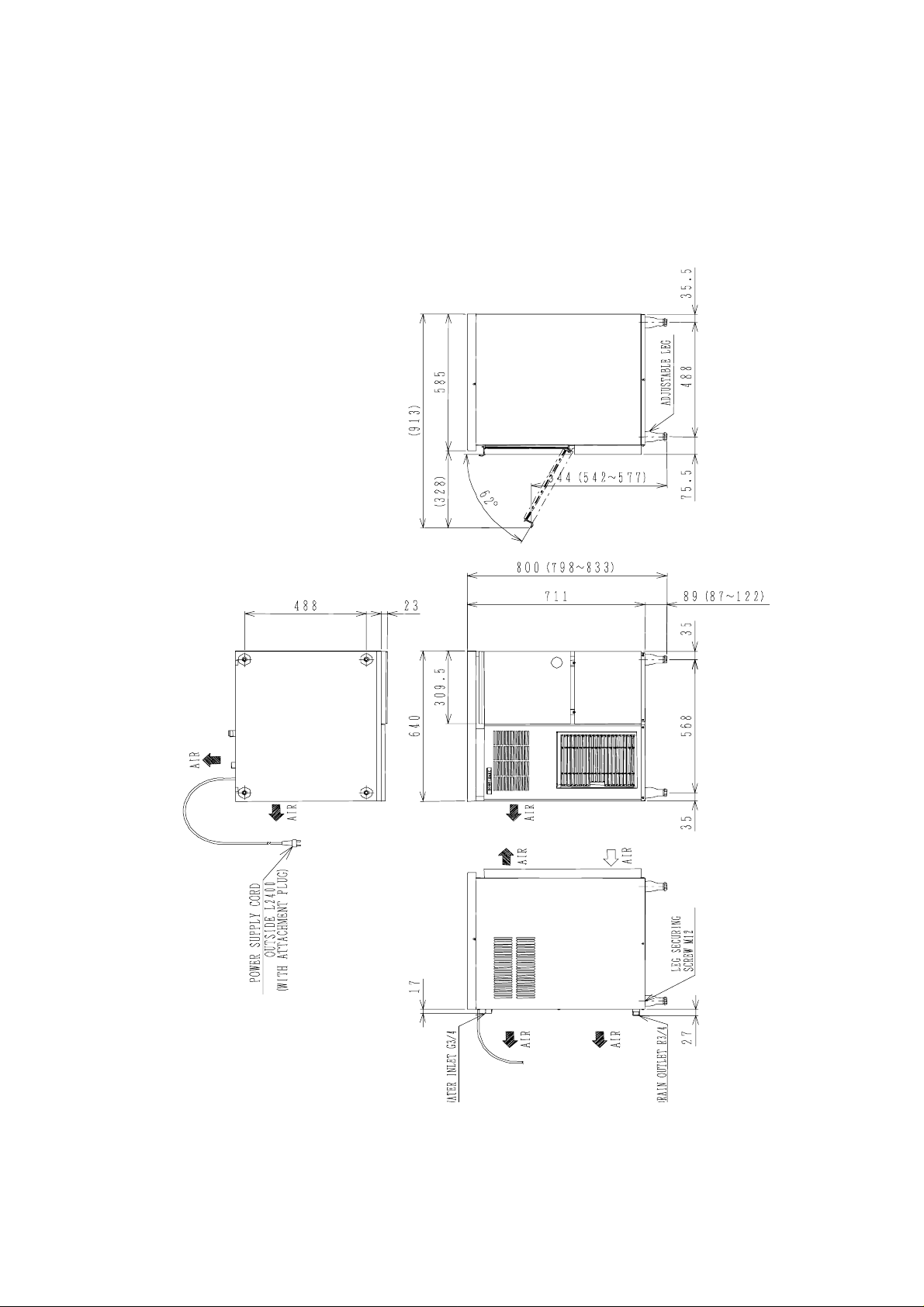

[a] CM-110EE, FM-120EE, FM-120EE-N , FM - 8 0EE

1

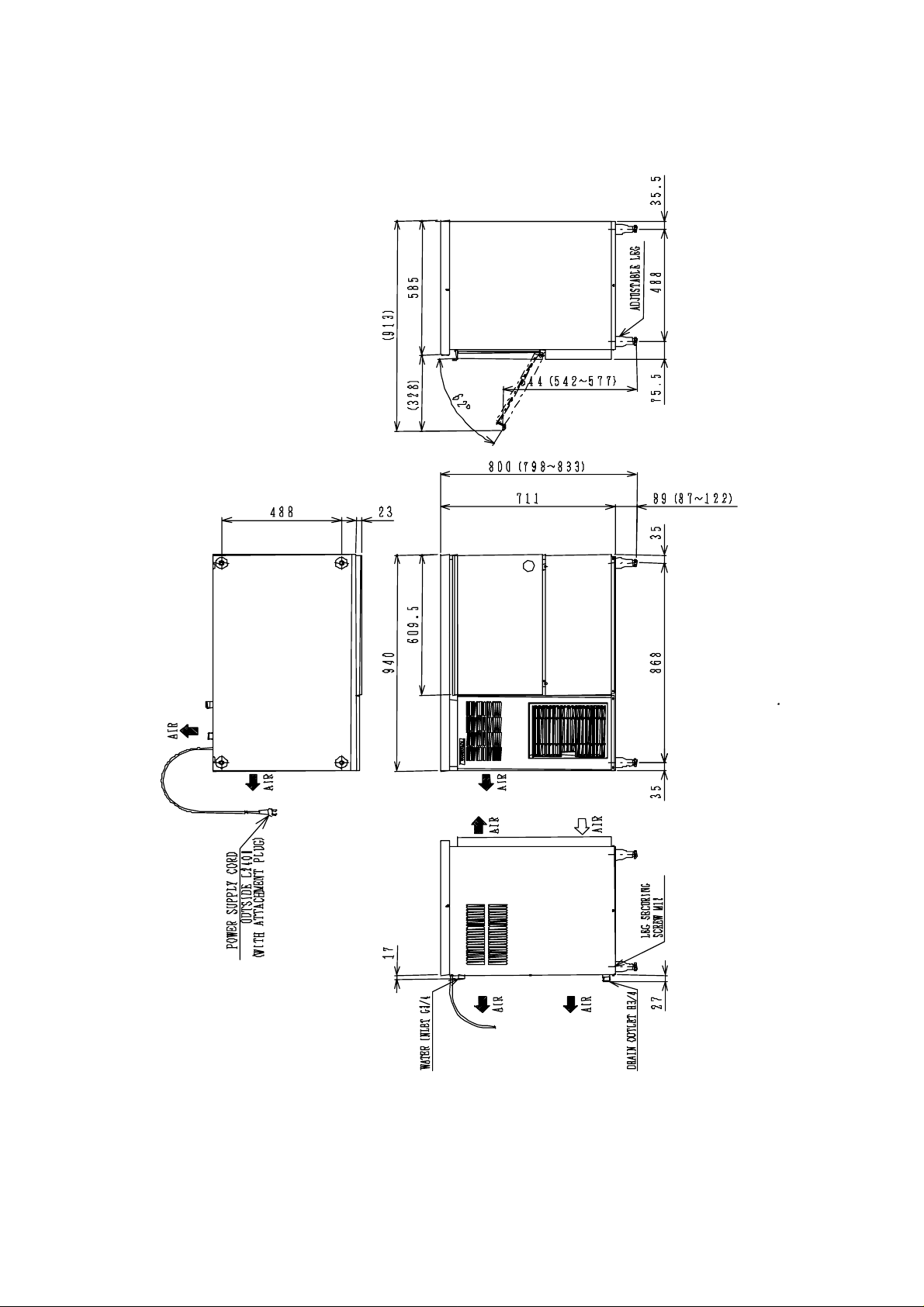

[b] FM-120EE-50, FM-120EE-50-N

2

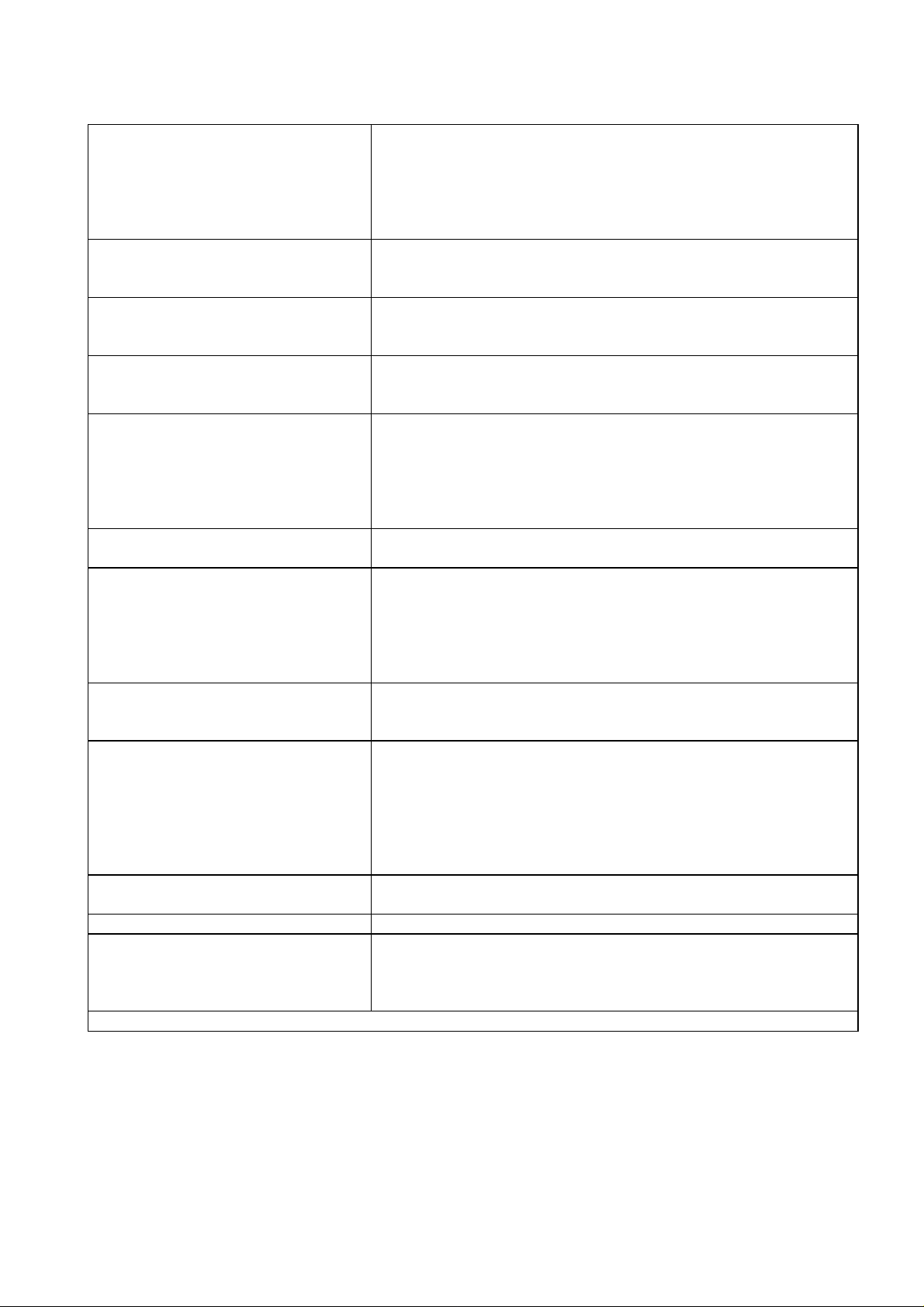

2. SPECIFICATIONS

[a] CM-110EE

AC SUPPLY VOLTAGE

AMPERAGE

STARTING AMPERAGE

ELECTRIC CONSUMPTION

POWER FACTOR

POWER SUPPLY CAPACITY

ICE PRODUCTION PER 24h

WATER CONSUMPTION PER 24h Approx. 0.110 m3 (Ambient temp. 10°C, Water temp. 10°C)

SHAPE OF ICE

MAX STORAGE CAPACITY

DIMENSIONS (DRAWING No.)

EXTERIOR

INSULATION

CONNECTION - ELECTRIC

- WATER SUPPLY

- DRAIN

ICE MAKING SYSTEM

HARVESTING SYSTEM

COMPRESSOR

CONDENSER

HEAT REJECTION

EVAPORATOR

REFRIGERANT CONTROL

REFRIGERANT CHARGE

BIN CONTROL SYSTEM

ICE MAKING WATER CONTROL

ELECTRICAL PROTECTION

COMPRESSOR PROTECTION

GEAR MOTOR PROTECTIO N

LOW WATER PROTECTION

WEIGHT

PACKAGE

ACCESSORIES Scoop, Installation Kit

OPERATION CONDITIONS

AMBIENT TEMP.

WATER SUPPLY TEMP

WATER SUPPLY PRESSURE

We reserve the right to make changes in specifications and design without prior notice.

1 phase 220-240V 50Hz

3.5A (Ambient temp. 32°C, Water temp. 21°C)

13A

525W (Ambient temp. 32°C, Water temp. 21°C)

65%

Min 1.08kVA (4.5A)

Approx. 110 kg (Ambient temp. 10°C, Water temp. 10°C)

Approx. 98 kg (Ambient temp. 21°C, Water temp. 15°C)

Approx. 75 kg (Ambient temp. 32°C, Water temp. 21°C)

Approx. 0.098 m

Approx. 0.075 m

Cubelet

Approx. 32kg - Leveled

(Bin Control Setting Approx. 27kg)

640(W) x 600(D) x 800(H) (mm) (359551)

Stainless Steel, Galvanized Steel (Rear)

Polyurethane Foam

Y-type Con. (with EU Plug)

Inlet G 3/4” (Connected at rear side)

Outlet R 3/4” (Connected at rear side)

Auger type

Direct driven Auger (80W Gear Motor)

Hermetic Compressor 315W Model SC12G

Fin and Tube type forced air cooling

1030W

Copper Tube on Cylinder

Capillary Tube

R134a 150g

Mechanical Bin Control (or Actuator and Reed Switch)

(Time Delay Controlled)

Float Switch and Water Valve

Class I Appliance

6A Circuit Breaker

Auto-reset Overload Protector

Auto-reset Pressure Switch

Manual-reset Circuit Breaker

Auto-reset Thermal Protector

Float Switch and Timer

Net weight 71kg / Gross weight 82 kg

Carton 746mm(W) x 706mm(D) x 922mm(H)

5 - 40°C

5 - 35°C

0.5 - 8 bar (0.05 - 0.8MPa)

3

(Ambient temp. 21°C, Water temp. 15°C)

3

(Ambient temp. 32°C, Water temp. 21°C)

3

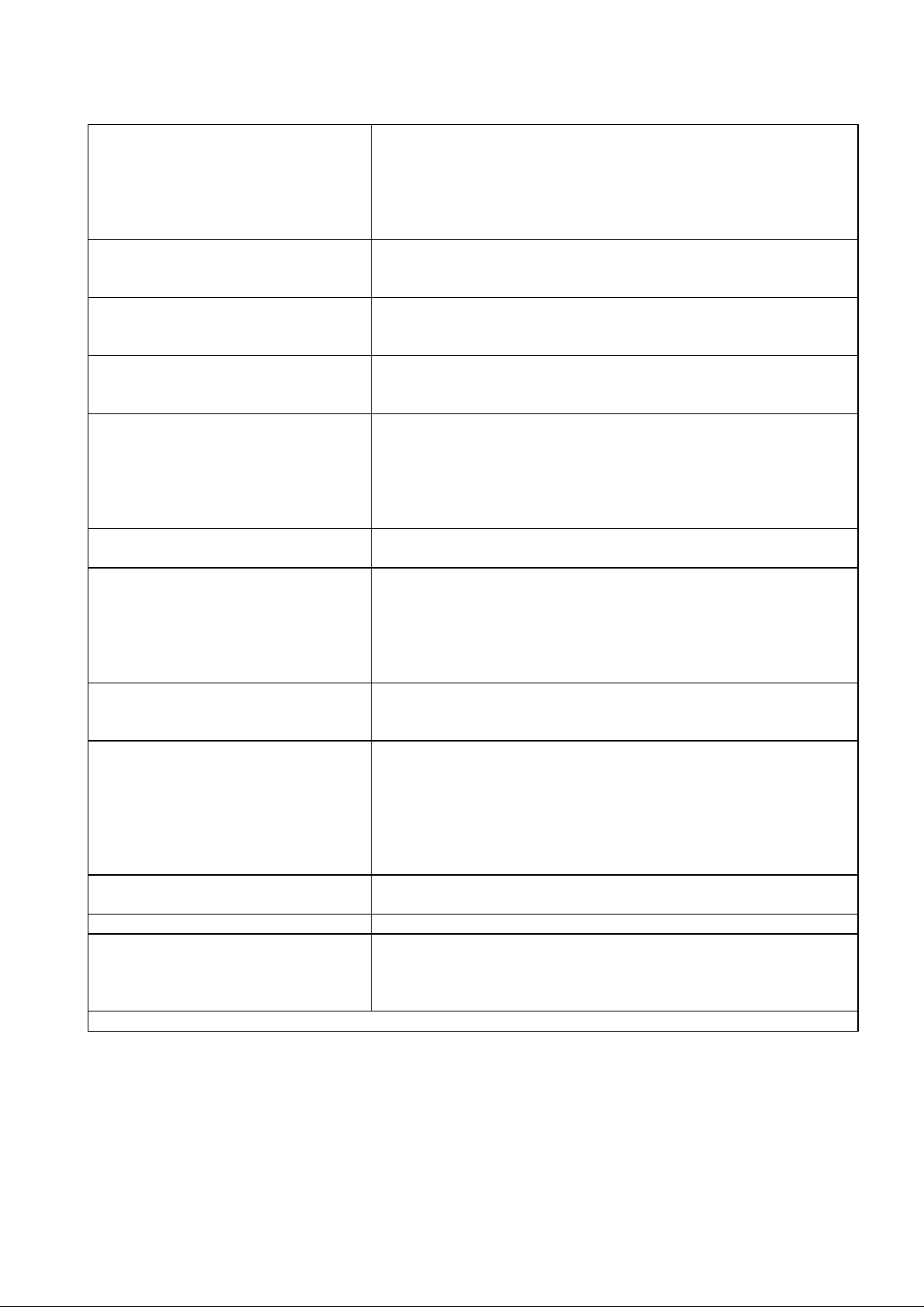

[b] FM-120EE

AC SUPPLY VOLTAGE

AMPERAGE

STARTING AMPERAGE

ELECTRIC CONSUMPTION

POWER FACTOR

POWER SUPPLY CAPACITY

ICE PRODUCTION PER 24h

WATER CONSUMPTION PER 24h Approx. 0.125 m3 (Ambient temp. 10°C, Water temp. 10°C)

SHAPE OF ICE

MAX STORAGE CAPACITY

DIMENSIONS (DRAWING No.)

EXTERIOR

INSULATION

CONNECTION - ELECTRIC

- WATER SUPPLY

- DRAIN

ICE MAKING SYSTEM

HARVESTING SYSTEM

COMPRESSOR

CONDENSER

HEAT REJECTION

EVAPORATOR

REFRIGERANT CONTROL

REFRIGERANT CHARGE

BIN CONTROL SYSTEM

ICE MAKING WATER CONTROL

ELECTRICAL PROTECTION

COMPRESSOR PROTECTION

GEAR MOTOR PROTECTIO N

LOW WATER PROTECTION

WEIGHT

PACKAGE

ACCESSORIES Scoop, Installation Kit

OPERATION CONDITIONS

AMBIENT TEMP.

WATER SUPPLY TEMP

WATER SUPPLY PRESSURE

We reserve the right to make changes in specifications and design without prior notice.

1 phase 220-240V 50Hz

3.5A (Ambient temp. 32°C, Water temp. 21°C)

13A

520W (Ambient temp. 32°C, Water temp. 21°C)

65%

Min 1.08kVA (4.5A)

Approx. 125 kg (Ambient temp. 10°C, Water temp. 10°C)

Approx. 115 kg (Ambient temp. 21°C, Water temp. 15°C)

Approx. 85 kg (Ambient temp. 32°C, Water temp. 21°C)

Approx. 0.115 m

Approx. 0.085 m

3

(Ambient temp. 21°C, Water temp. 15°C)

3

(Ambient temp. 32°C, Water temp. 21°C)

Flake

Approx. 26kg - Leveled

(Bin Control Setting Approx. 21kg)

640(W) x 600(D) x 800(H) (mm) (359549)

Stainless Steel, Galvanized Steel (Rear)

Polyurethane Foam

Y-type Con. (with EU Plug)

Inlet G 3/4” (Connected at rear side)

Outlet R 3/4” (Connected at rear side)

Auger type

Direct driven Auger (80W Gear Motor)

Hermetic Compressor 315W Model SC12G

Fin and Tube type forced air cooling

1030W

Copper Tube on Cylinder

Capillary Tube

R134a 150g

Mechanical Bin Control (or Actuator and Reed Switch)

(Time Delay Controlled)

Float Switch and Water Valve

Class I Appliance

6A Circuit Breaker

Auto-reset Overload Protector

Auto-reset Pressure Switch

Manual-reset Circuit Breaker

Auto-reset Thermal Protector

Float Switch and Timer

Net weight 71kg / Gross weight 82 kg

Carton 746mm(W) x 706mm(D) x 922mm(H)

5 - 40°C

5 - 35°C

0.5 - 8 bar (0.05 - 0.8MPa)

4

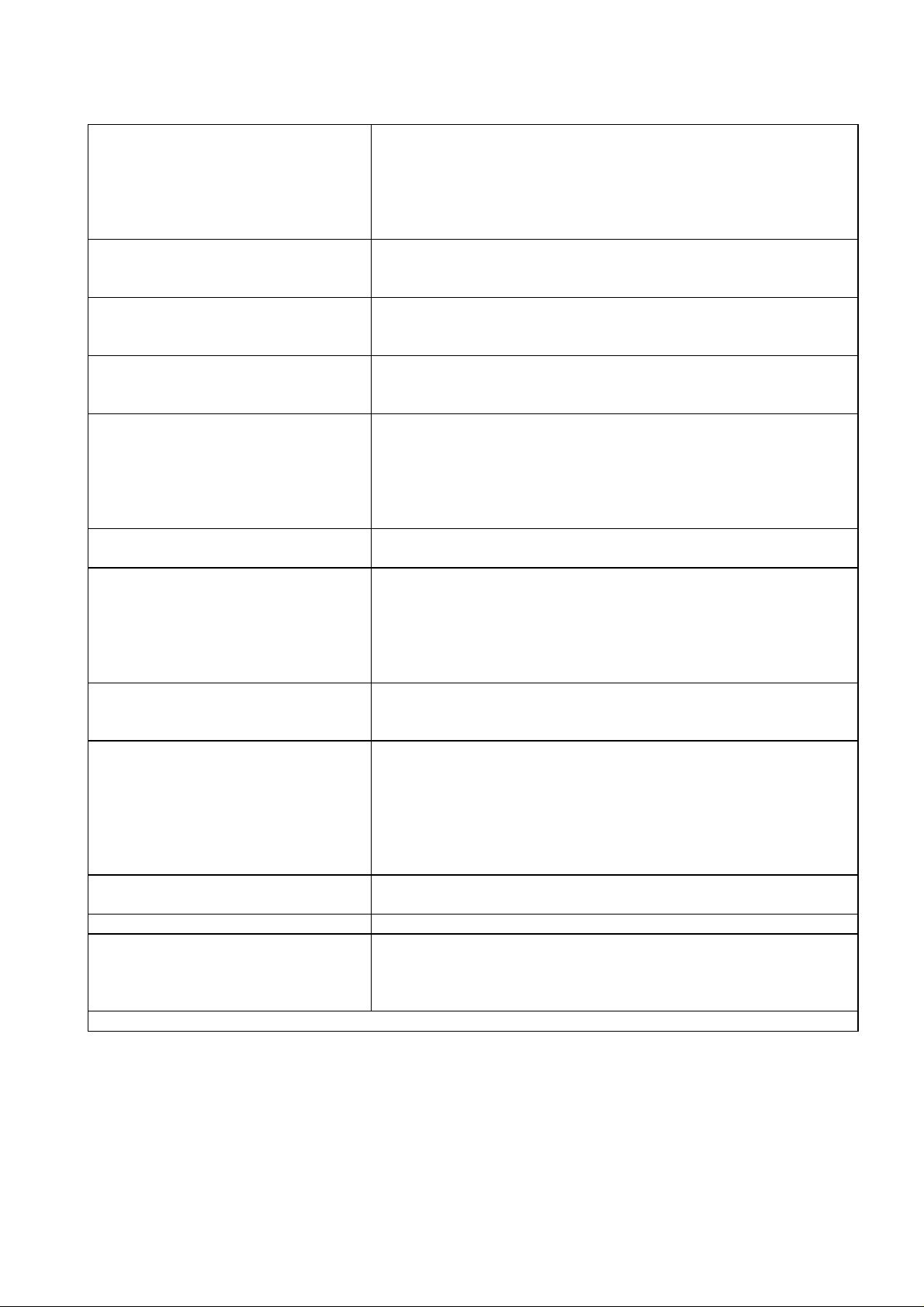

[c] FM-120EE-N

AC SUPPLY VOLTAGE

AMPERAGE

STARTING AMPERAGE

ELECTRIC CONSUMPTION

POWER FACTOR

POWER SUPPLY CAPACITY

ICE PRODUCTION PER 24h

WATER CONSUMPTION PER 24h Approx. 0.110 m3 (Ambient temp. 10°C, Water temp. 10°C)

SHAPE OF ICE

MAX STORAGE CAPACITY

DIMENSIONS (DRAWING No.)

EXTERIOR

INSULATION

CONNECTION - ELECTRIC

- WATER SUPPLY

- DRAIN

ICE MAKING SYSTEM

HARVESTING SYSTEM

COMPRESSOR

CONDENSER

HEAT REJECTION

EVAPORATOR

REFRIGERANT CONTROL

REFRIGERANT CHARGE

BIN CONTROL SYSTEM

ICE MAKING WATER CONTROL

ELECTRICAL PROTECTION

COMPRESSOR PROTECTION

GEAR MOTOR PROTECTIO N

LOW WATER PROTECTION

WEIGHT

PACKAGE

ACCESSORIES Scoop, Installation Kit

OPERATION CONDITIONS

AMBIENT TEMP.

WATER SUPPLY TEMP

WATER SUPPLY PRESSURE

We reserve the right to make changes in specifications and design without prior notice.

1 phase 220-240V 50Hz

3.5A (Ambient temp. 32°C, Water temp. 21°C)

13A

525W (Ambient temp. 32°C, Water temp. 21°C)

65%

Min 1.08kVA (4.5A)

Approx. 110 kg (Ambient temp. 10°C, Water temp. 10°C)

Approx. 98 kg (Ambient temp. 21°C, Water temp. 15°C)

Approx. 75 kg (Ambient temp. 32°C, Water temp. 21°C)

Approx. 0.098 m

Approx. 0.075 m

3

(Ambient temp. 21°C, Water temp. 15°C)

3

(Ambient temp. 32°C, Water temp. 21°C)

Nugget

Approx. 32kg - Leveled

(Bin Control Setting Approx. 27kg)

640(W) x 600(D) x 800(H) (mm) (359550)

Stainless Steel, Galvanized Steel (Rear)

Polyurethane Foam

Y-type Con. (with EU Plug)

Inlet G 3/4” (Connected at rear side)

Outlet R 3/4” (Connected at rear side)

Auger type

Direct driven Auger (80W Gear Motor)

Hermetic Compressor 315W Model SC12G

Fin and Tube type forced air cooling

1030W

Copper Tube on Cylinder

Capillary Tube

R134a 150g

Mechanical Bin Control (or Actuator and Reed Switch)

(Time Delay Controlled)

Float Switch and Water Valve

Class I Appliance

6A Circuit Breaker

Auto-reset Overload Protector

Auto-reset Pressure Switch

Manual-reset Circuit Breaker

Auto-reset Thermal Protector

Float Switch and Timer

Net weight 71kg / Gross weight 82 kg

Carton 746mm(W) x 706mm(D) x 922mm(H)

5 - 40°C

5 - 35°C

0.5 - 8 bar (0.05 - 0.8MPa)

5

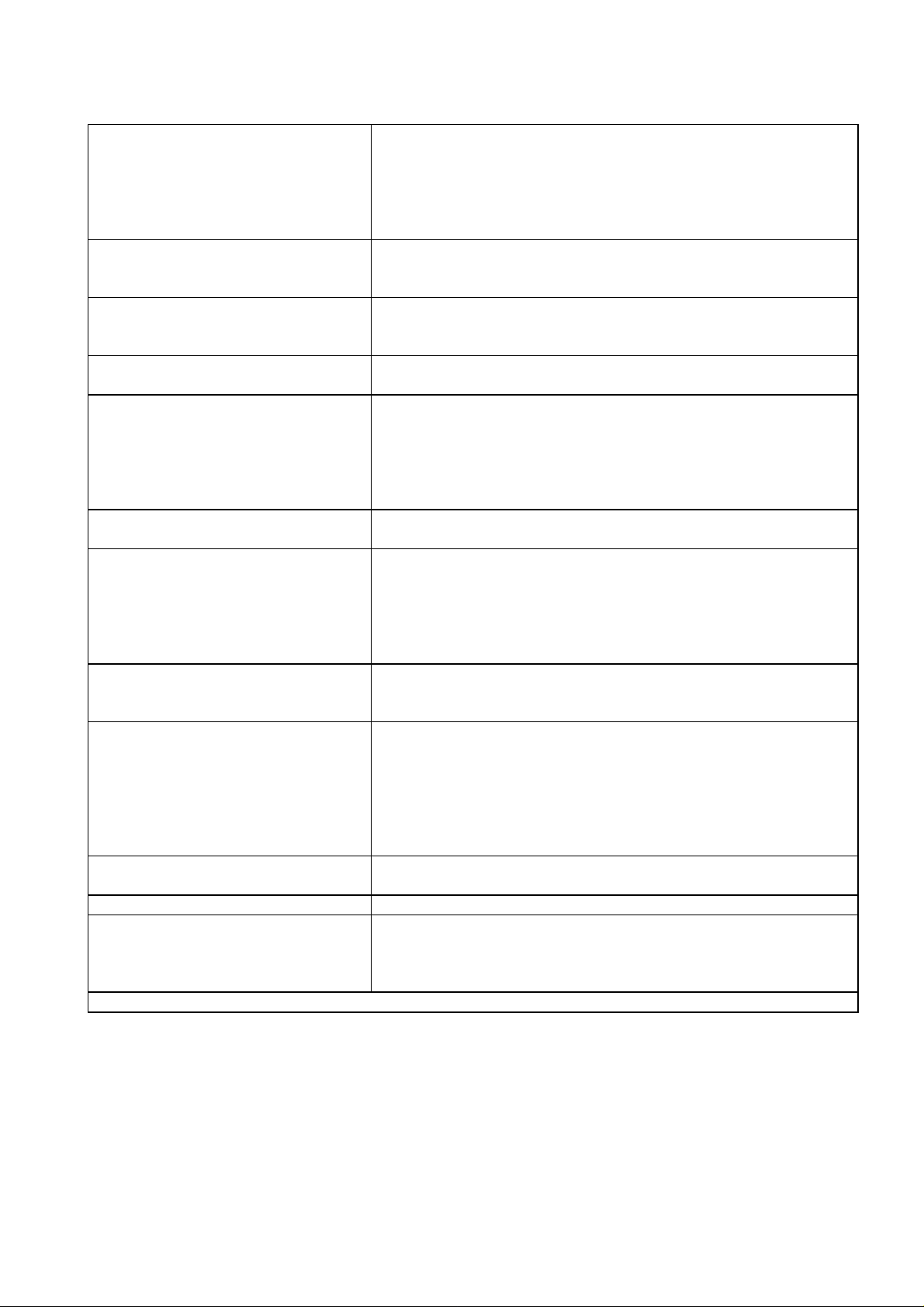

[d] FM-120EE-50

AC SUPPLY VOLTAGE

AMPERAGE

STARTING AMPERAGE

ELECTRIC CONSUMPTION

POWER FACTOR

POWER SUPPLY CAPACITY

ICE PRODUCTION PER 24h

WATER CONSUMPTION PER 24h Approx. 0.125 m3 (Ambient temp. 10°C, Water temp. 10°C)

SHAPE OF ICE

MAX STORAGE CAPACITY

DIMENSIONS (DRAWING No.)

EXTERIOR

INSULATION

CONNECTION - ELECTRIC

- WATER SUPPLY

- DRAIN

ICE MAKING SYSTEM

HARVESTING SYSTEM

COMPRESSOR

CONDENSER

HEAT REJECTION

EVAPORATOR

REFRIGERANT CONTROL

REFRIGERANT CHARGE

BIN CONTROL SYSTEM

ICE MAKING WATER CONTROL

ELECTRICAL PROTECTION

COMPRESSOR PROTECTION

GEAR MOTOR PROTECTIO N

LOW WATER PROTECTION

WEIGHT

PACKAGE

ACCESSORIES Scoop, Installation Kit

OPERATION CONDITIONS

AMBIENT TEMP.

WATER SUPPLY TEMP

WATER SUPPLY PRESSURE

We reserve the right to make changes in specifications and design without prior notice.

1 phase 220-240V 50Hz

3.5A (Ambient temp. 32°C, Water temp. 21°C)

13A

520W (Ambient temp. 32°C, Water temp. 21°C)

65%

Min 1.08kVA (4.5A)

Approx. 125 kg (Ambient temp. 10°C, Water temp. 10°C)

Approx. 115 kg (Ambient temp. 21°C, Water temp. 15°C)

Approx. 85 kg (Ambient temp. 32°C, Water temp. 21°C)

Approx. 0.115 m

Approx. 0.085 m

3

(Ambient temp. 21°C, Water temp. 15°C)

3

(Ambient temp. 32°C, Water temp. 21°C)

Flake

Approx. 57kg - Leveled

(Bin Control Setting Approx. 41kg)

940(W) x 600(D) x 800(H) (mm) (359552)

Stainless Steel, Galvanized Steel (Rear)

Polyurethane Foam

Y-type Con. (with EU Plug)

Inlet G 3/4” (Connected at rear side)

Outlet R 3/4” (Connected at rear side)

Auger type

Direct driven Auger (80W Gear Motor)

Hermetic Compressor 315W Model SC12G

Fin and Tube type forced air cooling

1030W

Copper Tube on Cylinder

Capillary Tube

R134a 150g

Mechanical Bin Control (or Actuator and Reed Switch)

(Time Delay Controlled)

Float Switch and Water Valve

Class I Appliance

6A Circuit Breaker

Auto-reset Overload Protector

Auto-reset Pressure Switch

Manual-reset Circuit Breaker

Auto-reset Thermal Protector

Float Switch and Timer

Net weight 81kg / Gross weight 94 kg

Carton 1046mm(W) x 706mm(D) x 922mm(H)

5 - 40°C

5 - 35°C

0.5 - 8 bar (0.05 - 0.8MPa)

6

[e] FM-120EE-50-N

AC SUPPLY VOLTAGE

AMPERAGE

STARTING AMPERAGE

ELECTRIC CONSUMPTION

POWER FACTOR

POWER SUPPLY CAPACITY

ICE PRODUCTION PER 24h

WATER CONSUMPTION PER 24h Approx. 0.110 m3 (Ambient temp. 10°C, Water temp. 10°C)

SHAPE OF ICE

MAX STORAGE CAPACITY

DIMENSIONS (DRAWING No.)

EXTERIOR

INSULATION

CONNECTION - ELECTRIC

- WATER SUPPLY

- DRAIN

ICE MAKING SYSTEM

HARVESTING SYSTEM

COMPRESSOR

CONDENSER

HEAT REJECTION

EVAPORATOR

REFRIGERANT CONTROL

REFRIGERANT CHARGE

BIN CONTROL SYSTEM

ICE MAKING WATER CONTROL

ELECTRICAL PROTECTION

COMPRESSOR PROTECTION

GEAR MOTOR PROTECTIO N

LOW WATER PROTECTION

WEIGHT

PACKAGE

ACCESSORIES Scoop, Installation Kit

OPERATION CONDITIONS

AMBIENT TEMP.

WATER SUPPLY TEMP

WATER SUPPLY PRESSURE

We reserve the right to make changes in specifications and design without prior notice.

1 phase 220-240V 50Hz

3.5A (Ambient temp. 32°C, Water temp. 21°C)

13A

525W (Ambient temp. 32°C, Water temp. 21°C)

65%

Min 1.08kVA (4.5A)

Approx. 110 kg (Ambient temp. 10°C, Water temp. 10°C)

Approx. 98 kg (Ambient temp. 21°C, Water temp. 15°C)

Approx. 75 kg (Ambient temp. 32°C, Water temp. 21°C)

Approx. 0.098 m

Approx. 0.075 m

3

(Ambient temp. 21°C, Water temp. 15°C)

3

(Ambient temp. 32°C, Water temp. 21°C)

Nugget

Approx. 65kg - Leveled

(Bin Control Setting Approx. 47kg)

940(W) x 600(D) x 800(H) (mm) (359554)

Stainless Steel, Galvanized Steel (Rear)

Polyurethane Foam

Y-type Con. (with EU Plug)

Inlet G 3/4” (Connected at rear side)

Outlet R 3/4” (Connected at rear side)

Auger type

Direct driven Auger (80W Gear Motor)

Hermetic Compressor 315W Model SC12G

Fin and Tube type forced air cooling

1030W

Copper Tube on Cylinder

Capillary Tube

R134a 150g

Mechanical Bin Control (or Actuator and Reed Switch)

(Time Delay Controlled)

Float Switch and Water Valve

Class I Appliance

6A Circuit Breaker

Auto-reset Overload Protector

Auto-reset Pressure Switch

Manual-reset Circuit Breaker

Auto-reset Thermal Protector

Float Switch and Timer

Net weight 81kg / Gross weight 94 kg

Carton 1046mm(W) x 706mm(D) x 922mm(H)

5 - 40°C

5 - 35°C

0.5 - 8 bar (0.05 - 0.8MPa)

7

[f] FM-80EE

AC SUPPLY VOLTAGE

AMPERAGE

STARTING AMPERAGE

ELECTRIC CONSUMPTION

POWER FACTOR

POWER SUPPLY CAPACITY

ICE PRODUCTION PER 24h

WATER CONSUMPTION PER 24h Approx. 0.850 m3 (Ambient temp. 10°C, Water temp. 10°C)

SHAPE OF ICE

MAX STORAGE CAPACITY

DIMENSIONS (DRAWING No.)

EXTERIOR

INSULATION

CONNECTION - ELECTRIC

- WATER SUPPLY

- DRAIN

ICE MAKING SYSTEM

HARVESTING SYSTEM

COMPRESSOR

CONDENSER

HEAT REJECTION

EVAPORATOR

REFRIGERANT CONTROL

REFRIGERANT CHARGE

BIN CONTROL SYSTEM

ICE MAKING WATER CONTROL

ELECTRICAL PROTECTION

COMPRESSOR PROTECTION

GEAR MOTOR PROTECTIO N

LOW WATER PROTECTION

WEIGHT

PACKAGE

ACCESSORIES Scoop, Installation Kit

OPERATION CONDITIONS

AMBIENT TEMP.

WATER SUPPLY TEMP

WATER SUPPLY PRESSURE

We reserve the right to make changes in specifications and design without prior notice.

1 phase 230V 50Hz

1.78A (Ambient temp. 32°C, Water temp. 21°C)

5.41A

0.3kW (Ambient temp. 32°C, Water temp. 21°C)

67%

Min 0.52kVA (2.0A)

Approx. 85 kg (Ambient temp. 10°C, Water temp. 10°C)

Approx. 75 kg (Ambient temp. 21°C, Water temp. 15°C)

Approx. 60 kg (Ambient temp. 32°C, Water temp. 21°C)

Approx. 0.750 m

Approx. 0.600 m

3

(Ambient temp. 21°C, Water temp. 15°C)

3

(Ambient temp. 32°C, Water temp. 21°C)

Flake

26kg - Leveled

640(W) x 600(D) x 800(H) (mm)

Stainless Steel, Galvanized Steel (Rear)

Polyurethane Foam

Y-type Con. (with EU Plug)

Inlet G 3/4” (Connected at rear side)

Outlet R 3/4” (Connected at rear side)

Auger type

Direct driven Auger (40W Gear Motor)

Hermetic Compressor Model TLS6F

Fin and Tube type forced air cooling

470W (Ambient temp. 32°C, Water temp. 21°C)

Copper Tube on Cylinder

Capillary Tube

R134a 140g

Mechanical Bin Control (or Actuator and Reed Switch)

(Time Delay Controlled)

Float Switch and Water Valve

5A Circuit Breaker, Earthing Wire

6A Circuit Breaker

Auto-reset Overload Protector

Auto-reset Pressure Switch

Manual-reset Circuit Breaker

Auto-reset Thermal Protector

Float Switch and Timer

Net weight 65kg / Gross weight 75 kg

Carton 746mm(W) x 706mm(D) x 922mm(H)

5 - 40°C

5 - 35°C

0.5 - 8 bar (0.05 - 0.8MPa)

8

II. GENERAL INFORMATION

1. CONSTRUCTION

Self-containe d cub el et icemaker model C M - 110EE and self-contai ned flaker models FM120EE, FM-120EE- N, FM- 120EE-50 , FM-120E E-50- N and FM-80 EE include Wat er Supply , Ev aporator , Condensing and Control Assemblies.

Top Panel

Door

Front Panel (Left)

Power Supply Cord

Air Filter

Spout

Evaporator

Reservoir

Compressor

Front Cover

Louver

Bin Control Switch

Drainboard

Circuit Breaker

Control Box

Gear Motor

Fan Motor

Condenser

9

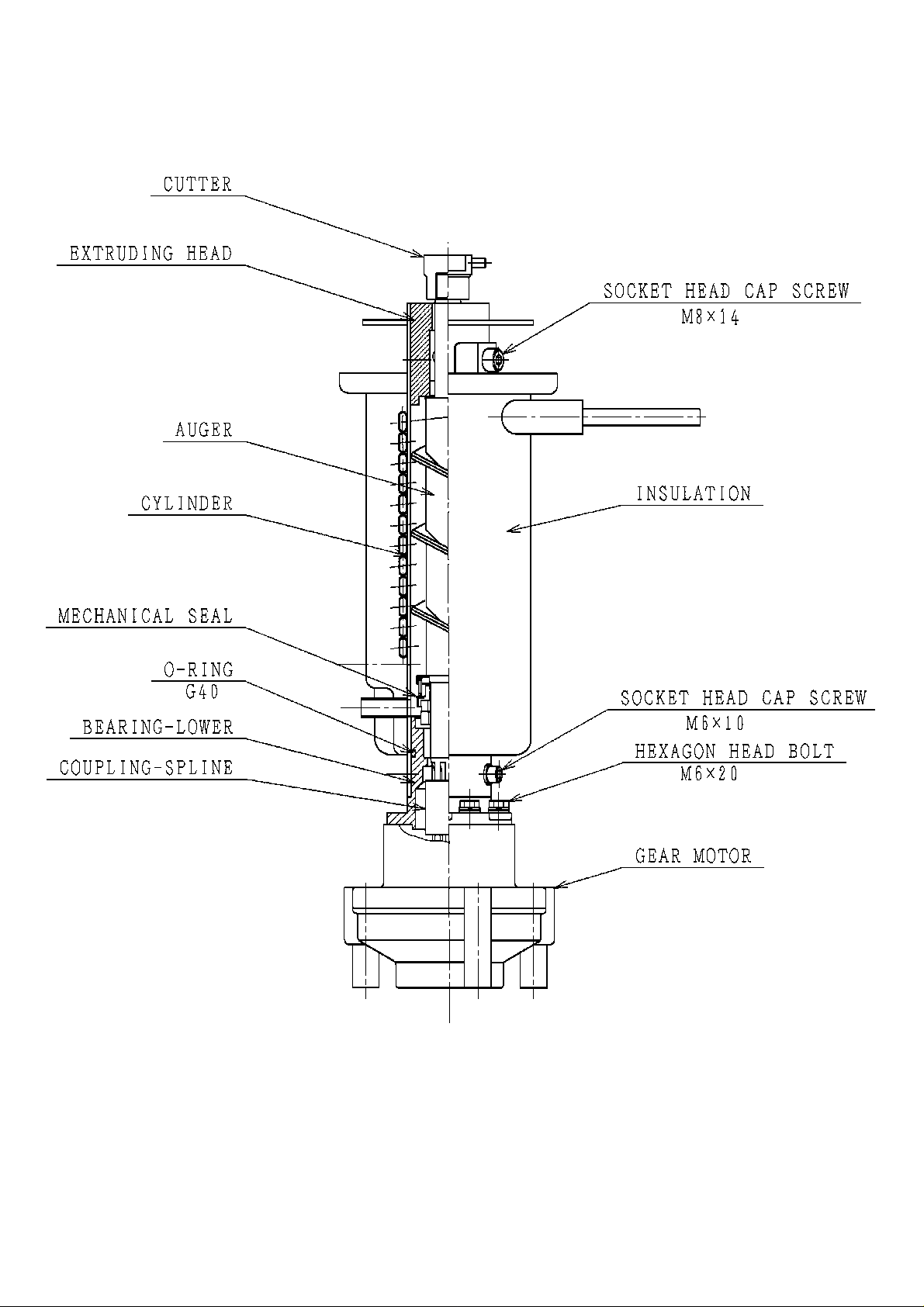

ICE MAK IN G U N IT [CM-110EE, FM-120EE-N, FM-120EE-50-N]

10

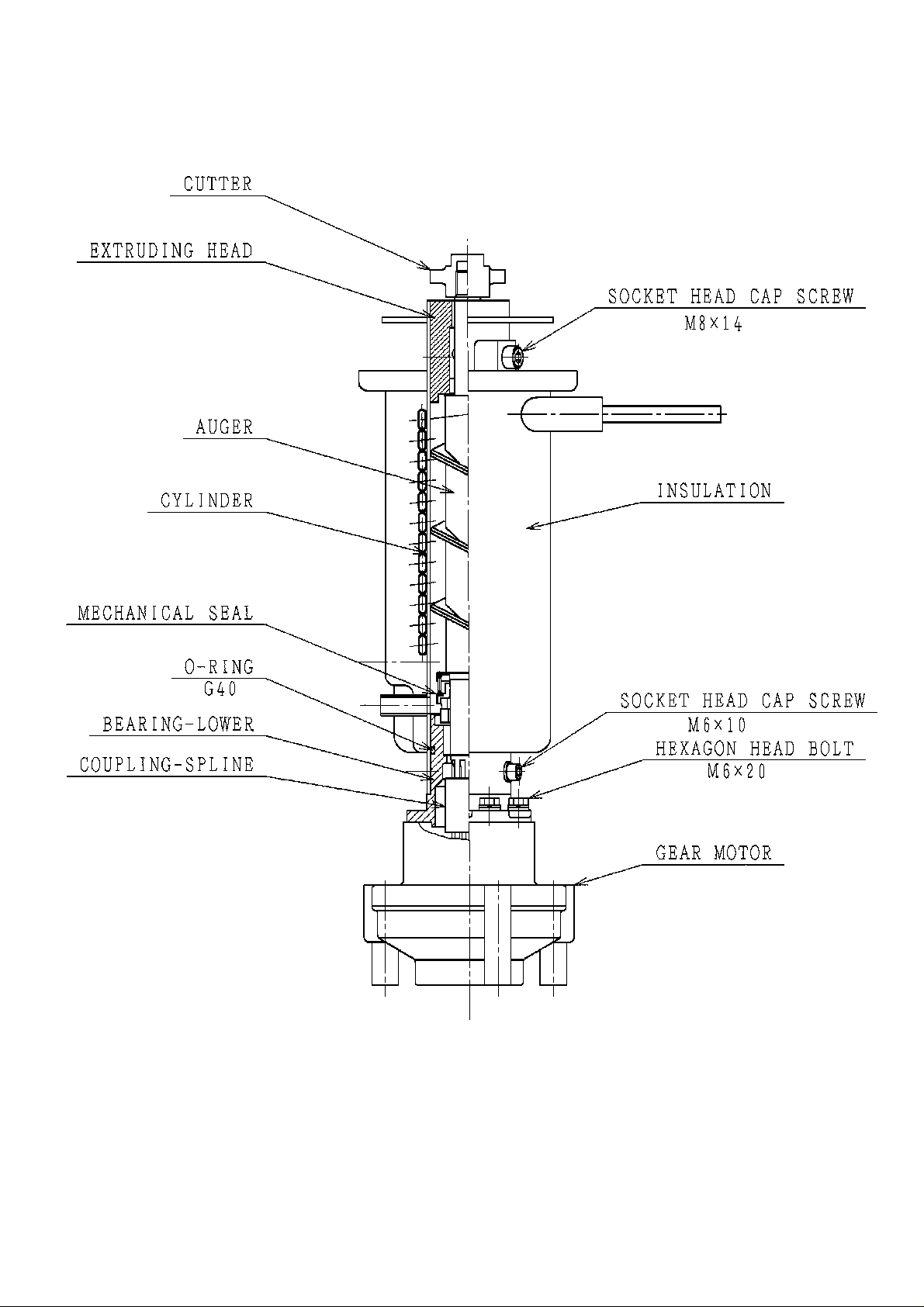

ICE MAK I NG UNIT [FM-120EE, FM-120EE-50, FM-80EE]

11

2. OPERATION - How it works

Potable water flows from the ex ternal supply tap and enters the water inlet on the machine,

passes through an electr ically operated Water Valve before flowing i nto the Reservoir Tank.

From the Tank, water flows by gravity into the bottom of the Evaporato r to completely surround

the Auger and fil l the Evapor ator wit h water to the same level as in the Reservoi r Tank.

Water leak age at the bo ttom of the Evapo rator is pr evente d by the us e of a mechanical seal.

The Evaporator serves to change the water i nto ice by using a heat exchange process in

conjunction wi th the Compr essor/Condenser assembly.

As water is used and turned into ice, the level in the Ev aporator and the Reservoir Tank will

fall. At a pre-determined level , a dual action Float Switch fitt ed to the Reservoir T ank electrically

commands the Water Valve to open and refill the Tank. This system functions therefore to

maintain a constant w ater level i nside the Evaporator ass embly.

The Auger, which is located inside the Evaporator is driven by an external Gear Motor

assembly . The rotating Auger carries the ice upwards wh ere it is pressed ag ainst the Extruding

Head at the top o f the Evapor ator to remove excess w ater, before finally being e xtrude d and

broken into irregular shapes and siz es of ice by the Flake/Nugg et Cutter or into cubelet ic e.

The continuous flow of ice is then pushed into the Ice S pout and falls by gravity into the S torage

Bin below .

Moving the Operation Switch, located on t he Control Box, to the “ON” po sition starts an

automatic and continuous icemaki ng process. When the S torage Bin has fill ed with ice, the

Bin Control Switch, located at the top of the Storage Bin, stops the icemaking process. When

ice is removed from the Storage Bin, the Bin Control Switch will automatically reset and

restar t the i cema king pro cess .

12

3. TIME R BOARD

[a] SOLID-STATE CONTROL

1) An exclusive H OSHIZAKI solid-state control is employed in C M-110EE, FM-120EE, FM120EE-N, FM-120EE-50, FM-120EE-50-N and FM-80EE self-contained icemakers.

2) A Pr inted Circ uit Board (her eafter cal led “T imer Board” ) incl udes a stable and high- quality

control sy stem.

3) No adjustment is requir ed.

[b] TIMER BOARD

CAUTION

1. Fragi le, hand le ver y care fully .

2. A ti mer board contains CMOS (Complementary Metal-Oxide Semiconductor)

integrated circuits, which are susceptible to failure due to static discharge. It

is especially important to either wear an anti-static wrist strap or touch a

metal part of the machine before servicin g to be static free.

3. Do not touch the electronic devices on either side of the board to prevent

damage.

4. Do not change wiring and connections. Especially, never misconnect

terminals.

5. Do not repair the electronic devices or parts on the board in the field. Always

replace the whole board assembly w hen it fails.

The icemaker is controlled by the T imer Board for the follow ing purposes:

1) To prevent the Gear Motor and the Compr essor from st arting or s topping simul taneously.

2) To reduce ice remaining in the Evaporator.

3) To protect the unit in case of low w ater and l ow water pr essure.

4) To protect the unit from short cyclin g if the Bin Contro l resets q uickly.

13

[c] SEQUENCE

Fig. 1

Fig. 2

14

CONTROL (CTL)

PROTECT (PRT)

X1 RELAY

(GEAR MOTOR)

X2 RELAY

(COMPRESSOR)

PART CODE 437305-02

MODEL H2AA144C02

RATI NG 24 V AC 50/60Hz

T

1

T

2

T

3

T

4

T

5

T

6

60±15 sec.

90±22 sec.

150±45 sec.

Max. 1 sec.

Max. 0.25 sec.

Max. 1 sec.

Fig. 3

Note: “T” (ti me) functions of the T imer Boar d are non-adjust able.

15

Loading...

Loading...