Page 1

Service Manual

Modular Flaker with

F-A and F-C Control Boards

Models

H and J Series

hoshizakiamerica.com

Number: 73204

Issued: 7-23-2014

Revised: 3-6-2019

Page 2

WARNING

Only qualied service technicians should install and service the appliance. To

obtain the name and phone number of your local Hoshizaki Certied Service

Representative, visit www.hoshizaki.com. No service should be undertaken until

the technician has thoroughly read this Service Manual. Failure to service and

maintain the appliance in accordance with this manual will adversely affect safety,

performance, component life, and warranty coverage and may result in costly water

damage. Proper installation is the responsibility of the installer. Product failure or

property damage due to improper installation is not covered under warranty.

Hoshizaki provides this manual primarily to assist qualied service technicians in the

service of the appliance.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call, send an e-mail message, or write to the Hoshizaki Technical

Support Department for assistance.

Phone: 1-800-233-1940; (770) 487-2331

Fax: 1-800-843-1056; (770) 487-3360

E-mail: techsupport@hoshizaki.com

618 Highway 74 South

Peachtree City, GA 30269

Attn: Hoshizaki Technical Support Department

Web Site: www.hoshizaki.com

NOTE: To expedite assistance, all correspondence/communication MUST include the

following information:

• Model Number

• Serial Number

• Complete and detailed explanation of the problem.

2

Page 3

IMPORTANT

This manual should be read carefully before the appliance is serviced. Read

the warnings and guidelines contained in this manual carefully as they provide

essential information for the continued safe use, service, and maintenance of the

appliance. Retain this manual for any further reference that may be necessary.

CONTENTS

Important Safety Information ................................................................................................. 6

I. Construction and Water/Refrigeration Circuit Diagram ....................................................... 8

A. Construction .................................................................................................................. 8

1. Air-Cooled Models .................................................................................................... 8

2. Water-Cooled Models ............................................................................................. 9

3. Remote Air-Cooled Models .................................................................................... 10

4. Low-Side, Parallel Rack System Models ................................................................11

B. Icemaking Unit ............................................................................................................ 12

C. Water/Refrigeration Circuit Diagram ............................................................................ 13

1. Air-Cooled Models .................................................................................................. 13

2. Water-Cooled Models ............................................................................................ 14

3. Remote Air-Cooled Models .................................................................................... 15

4. Low-Side, Parallel Rack System Models ............................................................... 16

II. Sequence of Operation and Service Diagnosis ............................................................... 17

A. Sequence of Operation Flow Chart ............................................................................. 17

1. Icemaking and Drain Cycle .................................................................................... 17

2. Shutdown .............................................................................................................. 18

B. Service Diagnosis ....................................................................................................... 19

C. Control Board Check ................................................................................................... 25

D. Bin Control Check ....................................................................................................... 30

E. Float Switch Check and Cleaning ............................................................................... 34

F. Diagnostic Tables ......................................................................................................... 36

III. Controls and Adjustments ............................................................................................... 39

A. Control Board .............................................................................................................. 39

1. Control Board Layout ............................................................................................. 40

2. LED Lights and Audible Alarm Safeties ................................................................. 41

3. Ice Purge Cycle Bypass ......................................................................................... 41

B. Controls and Adjustments ........................................................................................... 42

1. Default Dip Switch Settings .................................................................................... 42

2. BC1 (Infrared Sensor) Shutdown Delay (S1 dip switch 1, 2, 3) ............................. 43

3. Drain Frequency Control (S1 dip switch 4) ............................................................ 43

4. Continuous Dispensing Timer (S1 dip switch 5 & 6) .............................................. 43

5. Bin Control Selector (S1 dip switch 7) ................................................................... 44

6. BC2 (Mech. Stand-Alone) Shutdown Initiation Delay (S1 dip switch 8) ................. 44

7. BC2 (Mech. Stand-Alone) Shutdown Time (S1 Dip Switch 9) ................................ 44

8. Factory Use (S1 Dip Switch 10) ............................................................................. 44

C. Power Switch and Control Switch ................................................................................ 45

IV. Refrigeration Circuit and Component Service Information.............................................. 46

A. Refrigeration Circuit Service Information .................................................................... 46

B. Component Service Information .................................................................................. 49

3

Page 4

V. Maintenance .................................................................................................................... 56

VI. Disposal .......................................................................................................................... 58

VII. Technical Information ..................................................................................................... 59

A. Specication & Performance Data Sheets .................................................................. 59

1a. F-1001MAH .......................................................................................................... 59

1b. F-1001MAH-C ...................................................................................................... 60

2a. F-1001MWH ......................................................................................................... 61

2b. F-1001MWH-C ..................................................................................................... 62

3a. F-1001MRH .......................................................................................................... 63

3b. F-1001MRH-C ...................................................................................................... 64

4a. F-1501MAH .......................................................................................................... 65

4b. F-1501MAH-C ..................................................................................................... 66

5a. F-1501MWH ......................................................................................................... 67

5b. F-1501MWH-C ..................................................................................................... 68

6a. F-1501MRH.......................................................................................................... 69

6b. F-1501MRH-C ...................................................................................................... 70

7. F-2001MWH ........................................................................................................... 71

8a. F-2001MRH ......................................................................................................... 72

8b. F-2001MRH-C ...................................................................................................... 73

8c. F-2001MRH3 .........................................................................................................74

9. F-2001MLH ............................................................................................................ 75

10. FD-650MAH-C ..................................................................................................... 76

11. FD-650MWH-C ..................................................................................................... 77

12. FD-650MRH-C ..................................................................................................... 78

13. FD-1001MAH-C ................................................................................................... 79

14. FD-1001MRH-C ................................................................................................... 80

15a. F-450MAJ .......................................................................................................... 81

15b. F-450MAJ-C ....................................................................................................... 82

16a. F-801MAJ........................................................................................................... 83

16b. F-801MAJ-C ....................................................................................................... 84

17a. F-801MWJ.......................................................................................................... 85

17b. F-801MWJ-C ...................................................................................................... 86

18a. F-1001MAJ ......................................................................................................... 87

18b. F-1001MAJ-C ..................................................................................................... 88

19a. F-1001MWJ ........................................................................................................ 89

19b. F-1001MWJ-C .................................................................................................... 90

20a. F-1001MRJ ........................................................................................................ 91

20b. F-1001MRJ-C ..................................................................................................... 92

21a. F-1001MLJ ......................................................................................................... 93

21b. F-1002MLJ ......................................................................................................... 94

22a. F-1002MAJ ........................................................................................................ 95

22b. F-1002MAJ-C ..................................................................................................... 96

23a. F-1002MWJ ....................................................................................................... 97

23b. F-1002MWJ-C .................................................................................................... 98

24a. F-1002MRJ ........................................................................................................ 99

24b. F-1002MRJ-C .................................................................................................. 100

4

Page 5

25a. F-1501MAJ........................................................................................................101

25b. F-1501MAJ-C ................................................................................................... 102

26a. F-1501MWJ...................................................................................................... 103

26b. F-1501MWJ-C .................................................................................................. 104

27a. F-1501MRJ ...................................................................................................... 105

27b. F-1501MRJ-C ................................................................................................... 106

28a. F-2001MLJ ....................................................................................................... 107

28b. F-2001MWJ...................................................................................................... 108

28c. F-2001MRJ ...................................................................................................... 109

28d. F-2001MRJ-C ...................................................................................................110

28e. F-2001MRJ3 ..................................................................................................... 111

29. FD-650MAJ-C .....................................................................................................11 2

30. FD-650MWJ-C ....................................................................................................11 3

31. FD-650MRJ-C .....................................................................................................114

32. FD-1001MAJ-C ...................................................................................................115

33. FD-1001MRJ-C ................................................................................................... 116

34. FD-1002MAJ-C ...................................................................................................11 7

35. FD-1002MRJ-C ...................................................................................................11 8

B. Wiring Diagrams ......................................................................................................... 119

1. F-1001MAH(-C), F-1001MWH(-C), F-1001MRH(-C), FD-1001M_H-C ...................119

2. F-1501M_H(-C) .................................................................................................... 120

3. F-2001MWH(-C), F-2001MRH(-C)(3), F-2001MWJ, F-2001MRJ(-C)(3) ............... 121

4. F-1001MLJ, F-1002MLJ, F-2001MLH, F-2001MLJ ............................................... 122

5. FD-650M_H-C ..................................................................................................... 123

6. F-450MAJ(-C) ...................................................................................................... 124

7. F-801M_J(-C) ....................................................................................................... 125

8. F-1001MAJ(-C), F-1001MWJ(-C), F-1001MRJ(-C) ............................................... 126

9. F-1002MAJ(-C), F-1002MWJ(-C), F-1002MRJ(-C), FD-1002M_J-C .................... 127

10. F-1501M_J(-C) ................................................................................................... 128

11. FD-650M_J(-C)................................................................................................... 129

12. FD-1001M_J-C ................................................................................................... 130

5

Page 6

Important Safety Information

Throughout this manual, notices appear to bring your attention to situations which could

result in death, serious injury, damage to the appliance, or damage to property.

WARNING Indicates a hazardous situation which could result in death or

serious injury.

NOTICE Indicates a situation which could result in damage to the

appliance or property.

IMPORTANT Indicates important information about the installation, use, and

care of the appliance.

WARNING

The appliance should be destined only to the use for which it has been expressly

conceived. Any other use should be considered improper and therefore dangerous.

The manufacturer cannot be held responsible for injury or damage resulting

from improper, incorrect, and unreasonable use. Failure to install, operate, and

maintain the appliance in accordance with this manual will adversely affect safety,

performance, component life, and warranty coverage and may result in costly water

damage.

To reduce the risk of death, electric shock, serious injury, or re, follow basic

precautions including the following:

• Only qualied service technicians should install and service the appliance.

• The appliance must be installed in accordance with applicable national, state, and

local codes and regulations.

• Electrical connection must be hard-wired and must meet national, state, and local

electrical code requirements. Failure to meet these code requirements could result

in death, electric shock, serious injury, re, or damage.

• The icemaker requires an independent power supply of proper capacity. See the

nameplate for electrical specications. Failure to use an independent power supply

of proper capacity can result in a tripped breaker, blown fuse, damage to existing

wiring, or component failure. This could lead to heat generation or re.

• THE ICEMAKER MUST BE GROUNDED. Failure to properly ground the icemaker

could result in death or serious injury.

• To reduce the risk of electric shock, do not touch the power switch or control switch

with damp hands.

• Move the power switch to the "OFF" position and turn off the power supply before

servicing. Lockout/Tagout to prevent the power supply from being turned back on

inadvertently.

• Do not place ngers or any other objects into the ice discharge opening.

• Do not make any alterations to the appliance. Alterations could result in electric

shock, injury, re, or damage.

6

Page 7

WARNING, continued

• The appliance is not intended for use by persons (including children) with reduced

physical, sensory, or mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction concerning use of the

appliance by a person responsible for their safety.

• Children should be properly supervised around the appliance.

• Do not climb, stand, or hang on the appliance or allow children or animals to do so.

Serious injury could occur or the appliance could be damaged.

• Do not use combustible spray or place volatile or ammable substances near the

appliance. They might catch re.

• Keep the area around the appliance clean. Dirt, dust, or insects in the appliance

could cause harm to individuals or damage to the appliance.

Additional Warning for Remote Models

• THE REMOTE CONDENSER UNIT MUST BE GROUNDED. The power supply and

ground connection to the remote condenser unit are supplied from the icemaker.

Failure to properly ground the remote condenser unit could result in death or

serious injury.

• Wire routing (conduit) and disconnect (if required) must meet national, state, and

local electrical code requirements. Failure to meet these code requirements could

result in death, electric shock, serious injury, re, or damage.

NOTICE

• Follow the instructions in this manual carefully to reduce the risk of costly water

damage.

• In areas where water damage is a concern, install in a contained area with a oor

drain.

• Install the appliance in a location that stays above freezing. Normal operating

ambient temperature must be within 45°F to 100°F (7°C to 38°C).

• Do not leave the icemaker on during extended periods of non-use, extended

absences, or in sub-freezing temperatures. To properly prepare the icemaker for

these occasions, follow the instructions provided in the instruction manual.

• Do not place objects on top of the appliance.

• The dispenser unit/ice storage bin is for ice use only. Do not store anything else in

the dispenser unit/ice storage bin.

7

Page 8

I. Construction and Water/Refrigeration Circuit Diagram

A. Construction

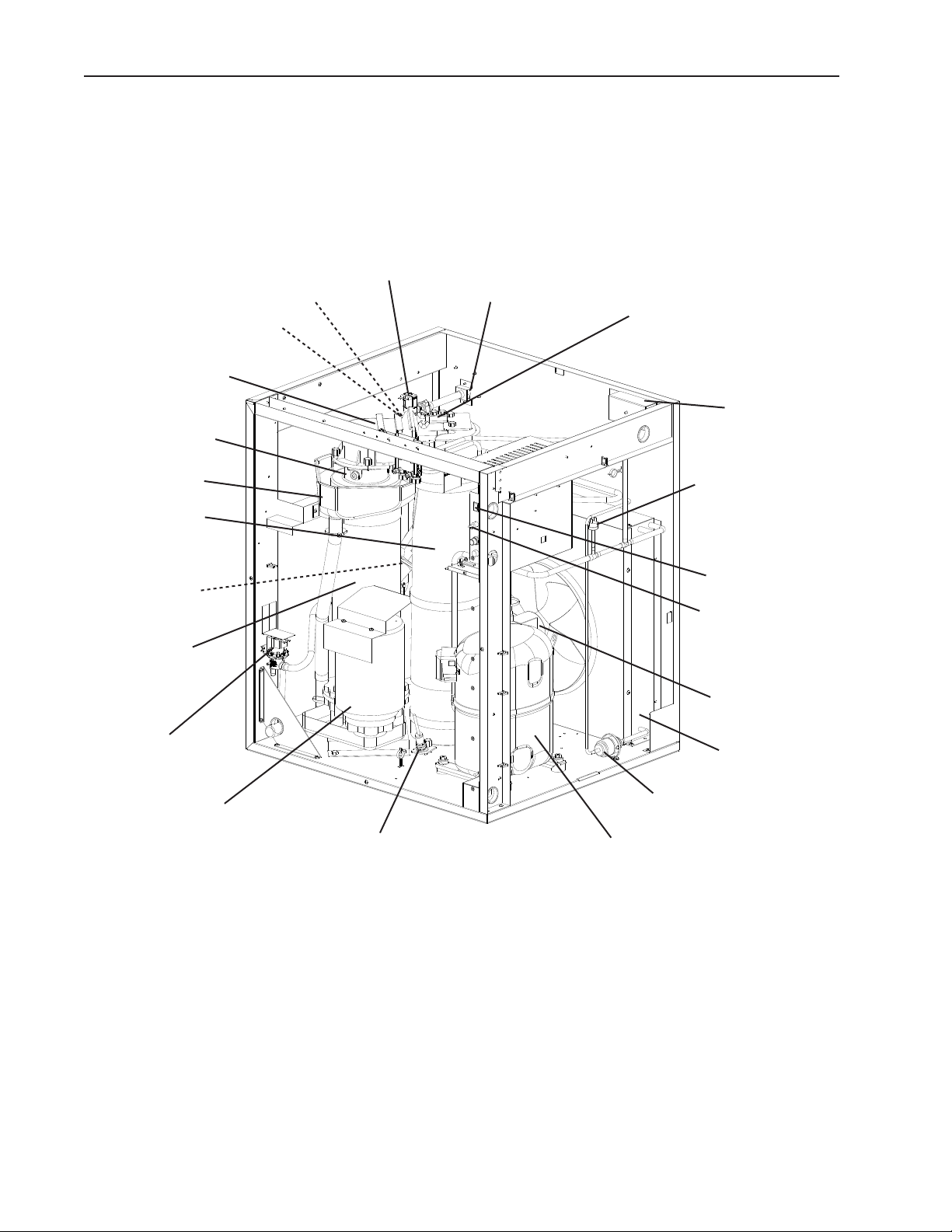

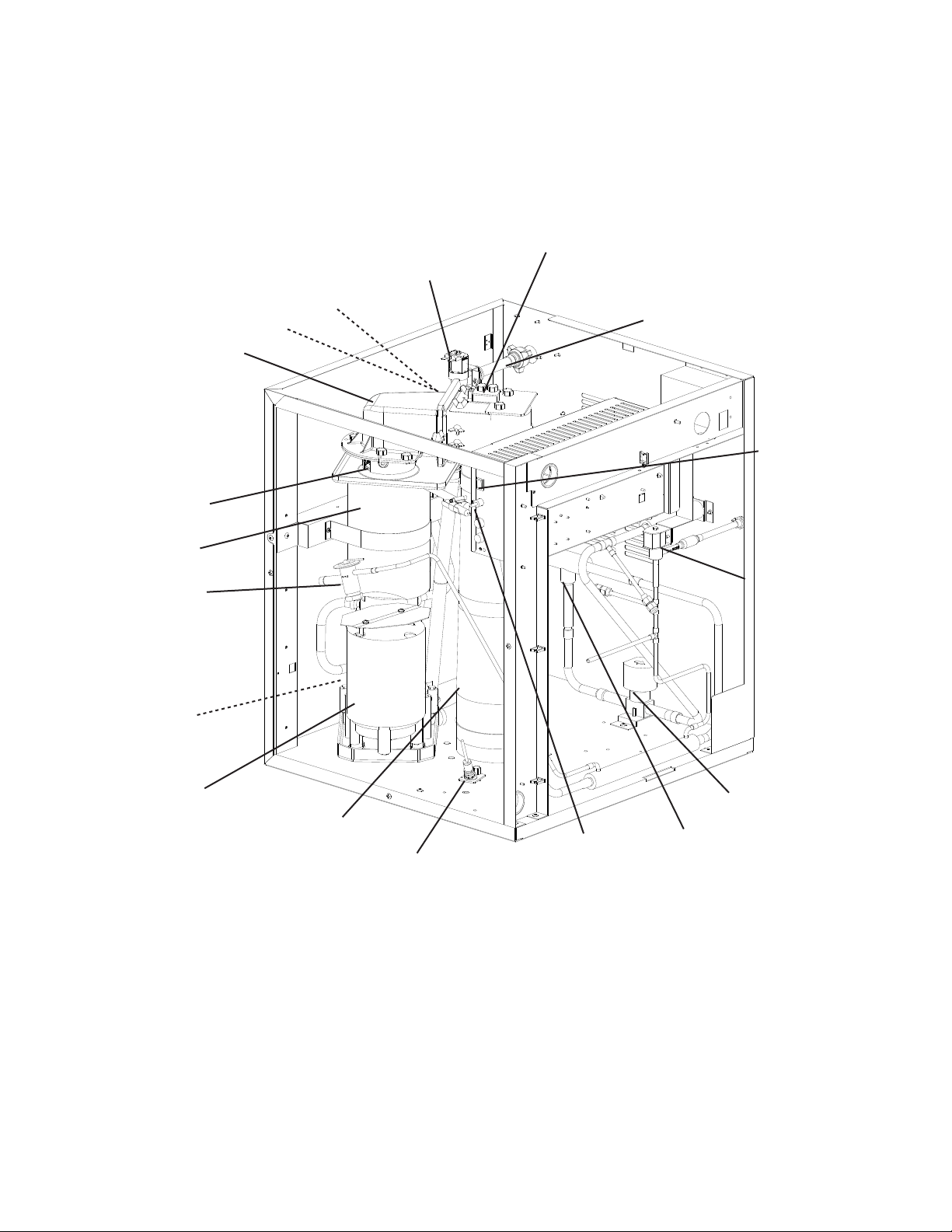

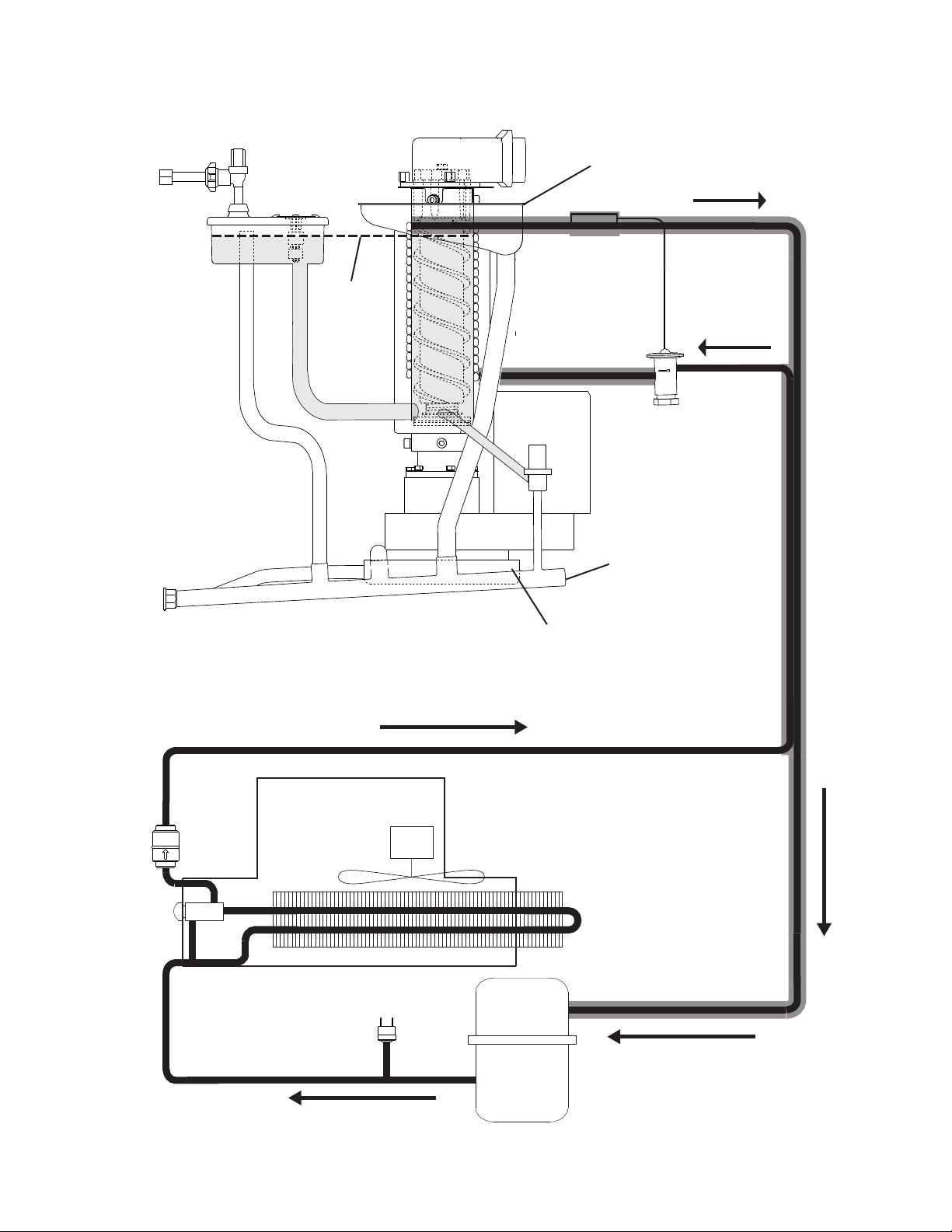

1. Air-Cooled Models

Inlet Water Valve

Float Switch

Reservoir

Spout

Evaporator

Heater (-C)

Drip Pan

Ice Chute

Water Supply Inlet

Bin Control 2

(Mechanical)

(If Applicable)

Junction Box

High-Pressure Switch

Thermostatic

Expansion Valve

Evaporator

Drain Valve

Gear Motor

Bin Control 1

(Infrared Sensor)

Model Shown: F-1501MAH

Control Switch

Power Switch

Fan Motor

Condenser

Drier

Compressor

8

Page 9

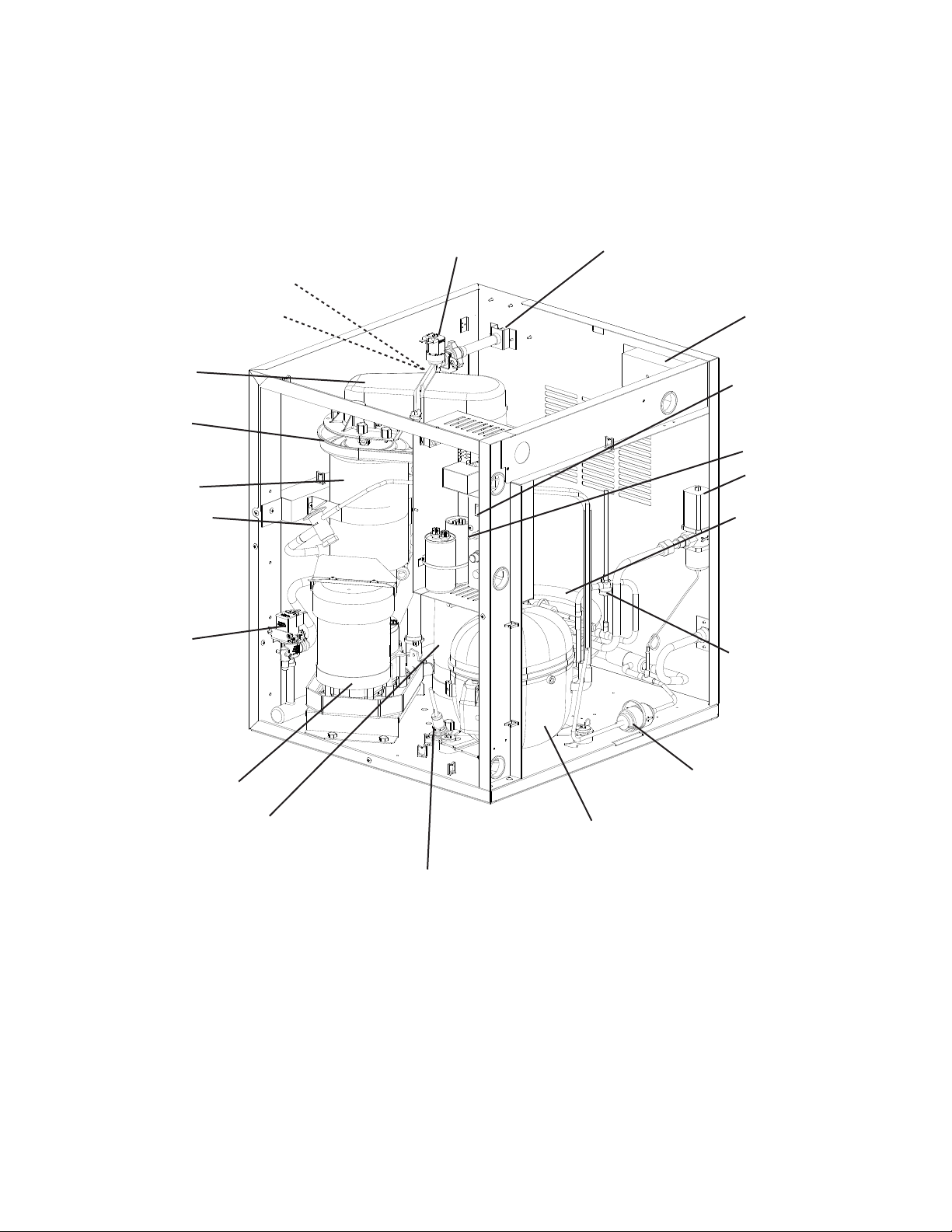

2. Water-Cooled Models

Spout

Drip Pan

Evaporator

Thermostatic

Expansion Valve

Drain Valve

Float Switch

Reservoir

Inlet Water Valve

Water Supply Inlet

Junction Box

Control Switch

Power Switch

Water Regulating

Valve

Water-Cooled

Condenser

High-Pressure Switch

Gear Motor

Ice Chute

Drier

Compressor

Bin Control 1

(Infrared Sensor)

Model Shown: FD-650MWH-C

9

Page 10

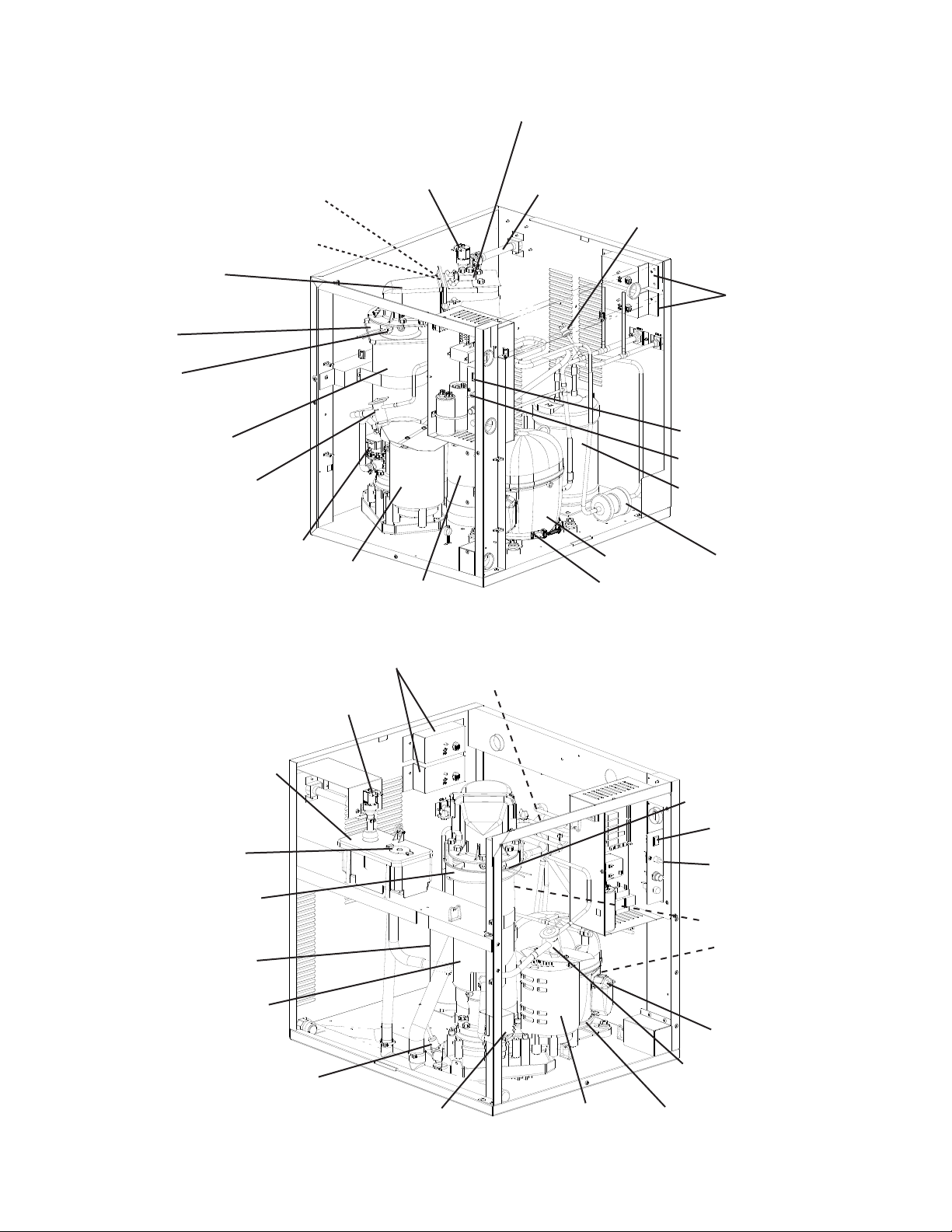

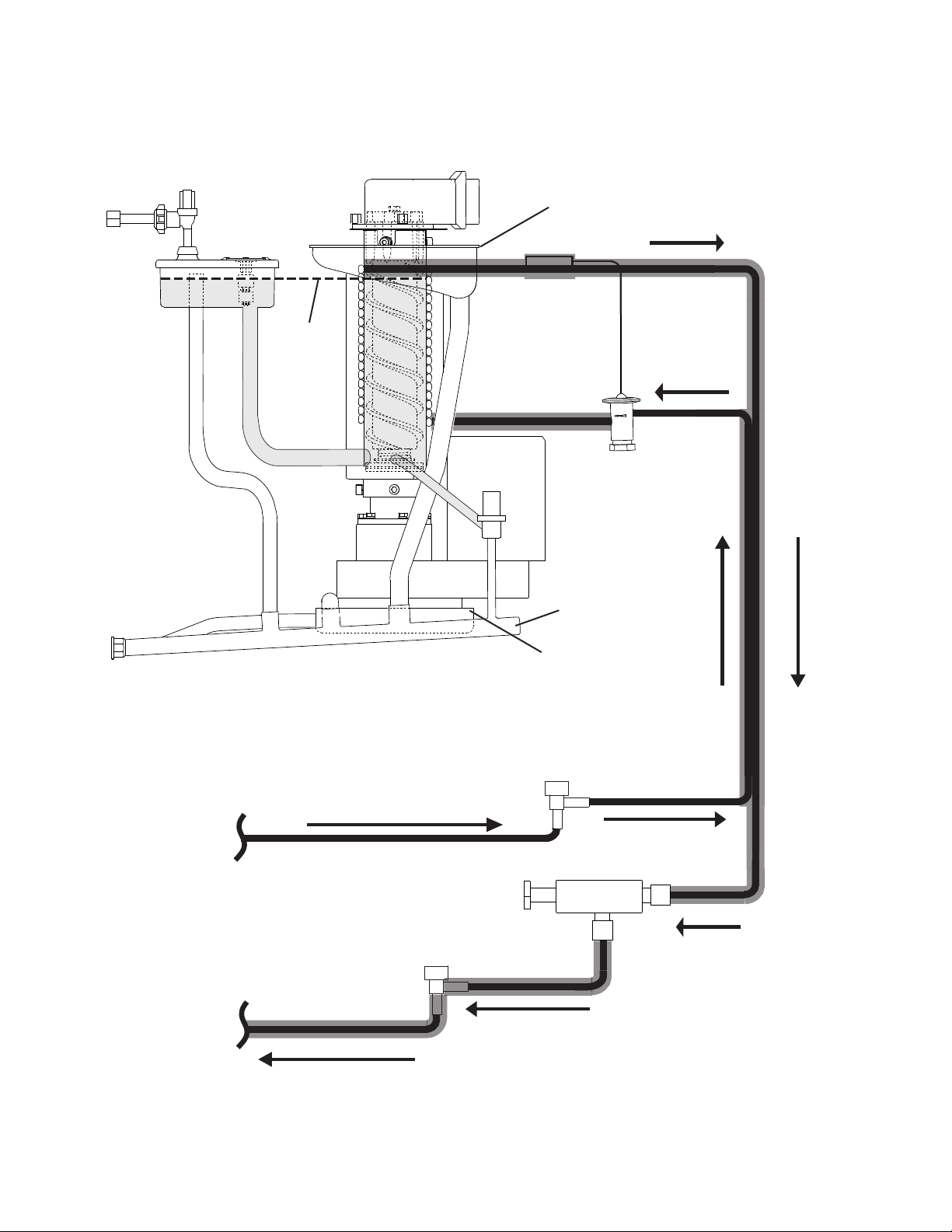

3. Remote Air-Cooled Models

Float Switch

Reservoir

Spout

Drip Pan

Evaporator

Heater (-C)

Inlet Water Valve

Bin Control (2)

(Mechanical)

(If Applicable)

Water Supply Inlet

High-Pressure Switch

Junction Box

Evaporator

Thermostatic

Expansion Valve

Drain Valve

Inlet Water Valve

Reservoir

Spout

Water Supply Inlet

Float Switch

Gear Motor

Junction Box

Ice Chute

Model Shown: F-1001MRH-C

High-Pressure Switch

Compressor

Crankcase

Heater

Control Switch

Power Switch

Reciever

Drier

Evaporator

Heater (-C)

Control Switch

Power Switch

Drip Pan

Reciever

Evaporator

Bin Control

(Infrared Sensor)

Drain Valve

Model Shown: F-1001MRJ-C

10

Gear Motor

Ice Chute

Drier

Compressor

Thermostatic

Expansion Valve

Crankcase

Heater

Page 11

4. Low-Side, Parallel Rack System Models

Inlet Water Valve

Float Switch

Reservoir

Spout

Evaporator

Heater (-C)

Evaporator

Bin Control 2

(Mechanical)

(If Applicable)

Water Supply Inlet

Control Switch

Thermostatic

Expansion Valve

Drain Valve

Gear Motor

Ice Chute

Bin Control 1

(infrared sensor)

Model Shown: F-2001MLH

Power Switch

Liquid Line Valve

Suction Line Valve

Evaporator Pressure

Regulator Valve (EPR)

11

Page 12

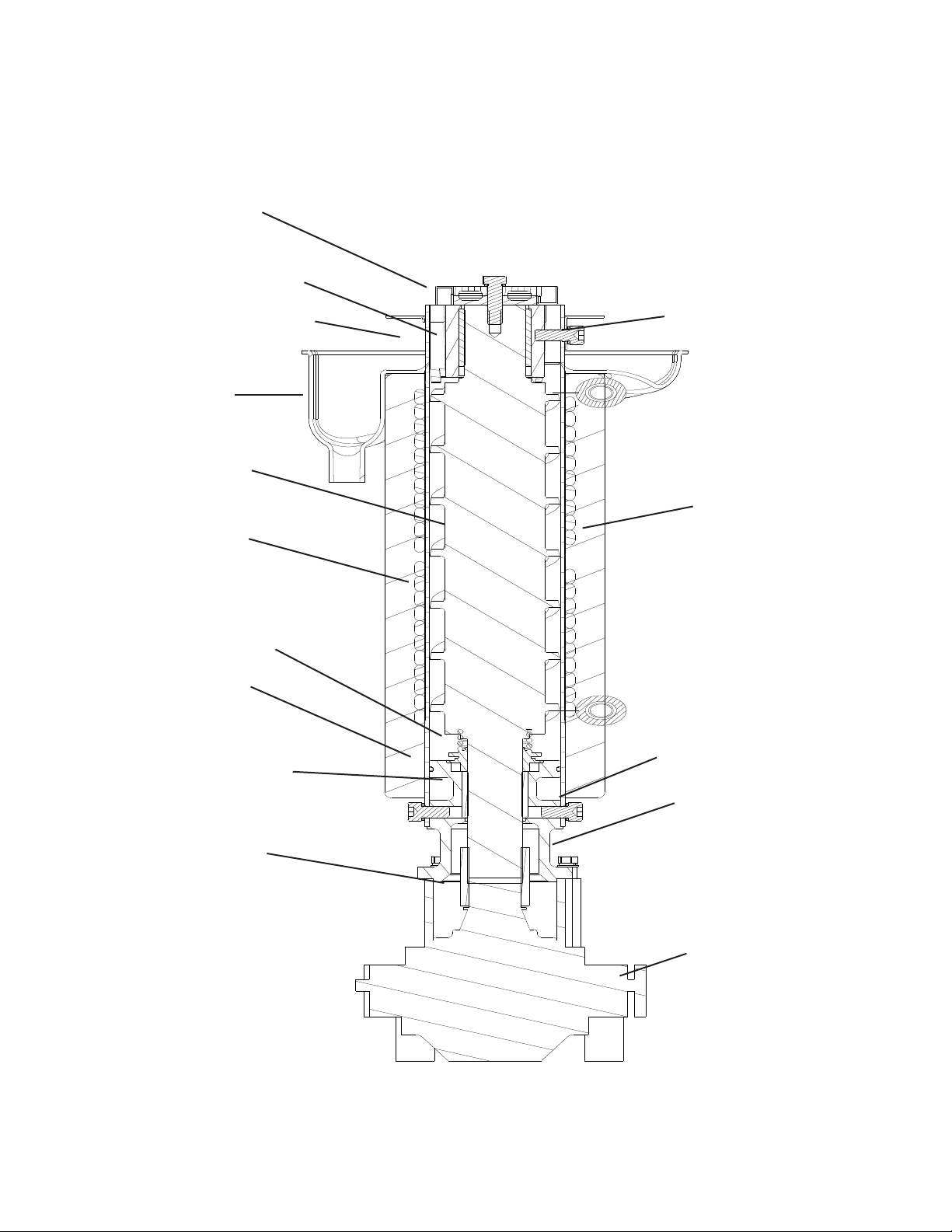

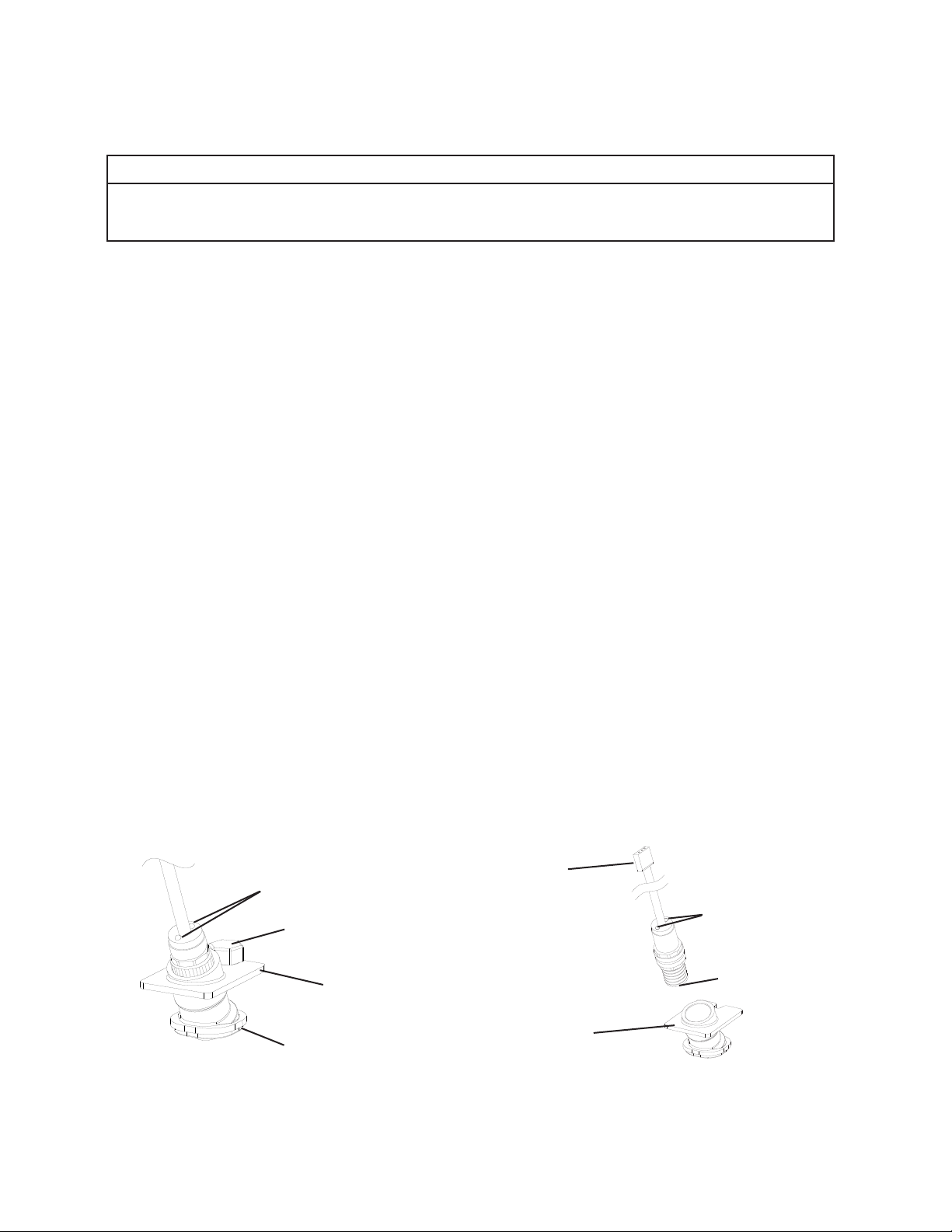

B. Icemaking Unit

Cutter

Extruding Head-Upper Bearing

Evaporator Heater (-C Models)

Drip Pan

Auger

Cylinder

Mechanical-Seal

O-Ring

Lower Housing

Seal Bolt

Insulation

Socket Head Cap Screw

with Split Lock Washer

Hex Bolt and Washer

Spline Coupling

Gear Motor

Model Shown: F-1501MAH

12

Page 13

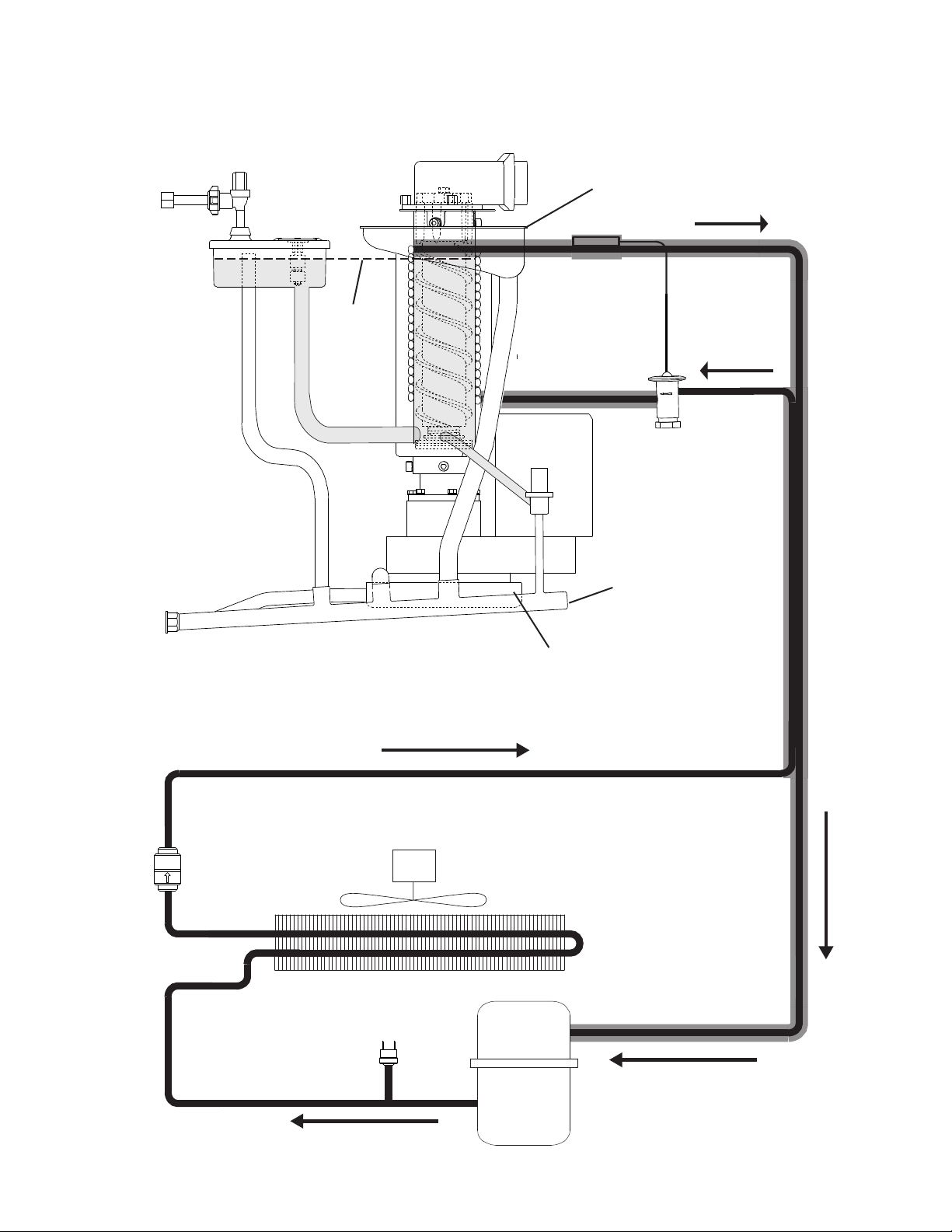

C. Water/Refrigeration Circuit Diagram

1. Air-Cooled Models

Inlet Water Valve

Float

Water Supply

Line

Reservoir

Overow

Switch

Water Level

Evaporator

Spout

Evaporator Condensate

Drain Pan (Drip Pan)

Insulation

Drain Outlet

Drier

Condenser

Fan Motor

Drain

Valve

Gear Motor Drain Pan

Thermostatic

Expansion Valve

Gear Motor

Drain Hose

Condenser

High Pressure

Switch

Compressor

13

Page 14

2. Water-Cooled Models

Water Supply

Line

Reservoir

Inlet Water Valve

Float

Switch

Overow

Water Level

Evaporator

Spout

Evaporator Condensate

Drain Pan (Drip Pan)

Drain

Valve

Thermostatic

Expansion Valve

Gear Motor

Drain Hose

Insulation

Drain Outlet

Water Supply Line

Condenser

Drain Outlet

Water Regulating Valve

Gear Motor Drain Pan

Drier

High-Pressure

Switch

Compressor

14

Page 15

3. Remote Air-Cooled Models

Inlet Water Valve

Float

Water Supply

Line

Reservoir

Overow

Switch

Water Level

Evaporator

Spout

Evaporator Condensate

Drain Pan (Drip Pan)

Insulation

Drain Outlet

Drier

Condenser Fan Motor

Drain

Valve

Gear Motor Drain Pan

Thermostatic

Expansion Valve

Gear Motor

Drain Hose

Remote Condenser

High-Pressure

Switch

Compressor

15

Page 16

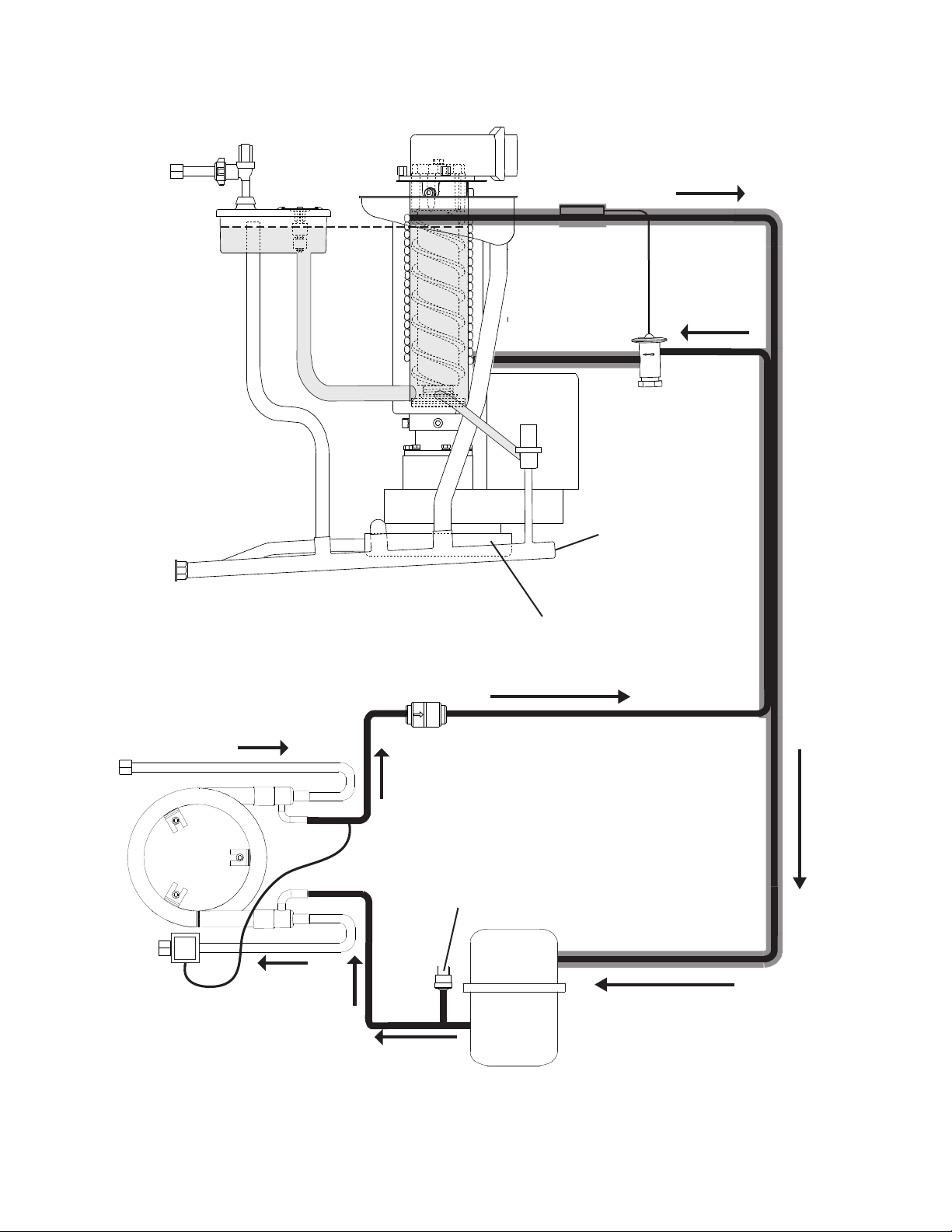

4. Low-Side, Parallel Rack System Models

Inlet Water Valve

Water Supply

Line

Reservoir

Overow

Float

Switch

Water Level

Evaporator

Spout

Evaporator Condensate

Drain Pan (Drip Pan)

Insulation

Drain

Valve

Drain Outlet

NOTICE! F-1001MLH Use only with R-404A

F-1002MLJ Use only with R-404A, R-407A, or R-407F

EPR Settings:

F-1001MLH: R-404A EPR Setting: 31 PSIG

F-1002MLJ: R-404A EPR Setting: 31 PSIG

R-407A EPR Setting: 22 PSIG

R-407F EPR Setting: 23 PSIG

From Rack System

Evaporator Pressure Regulator (EPR Valve)

Thermostatic

Expansion Valve

Gear Motor

Drain Hose

Gear Motor Drain Pan

Liquid Line Valve

To Rack System

Suction Line Valve

16

Page 17

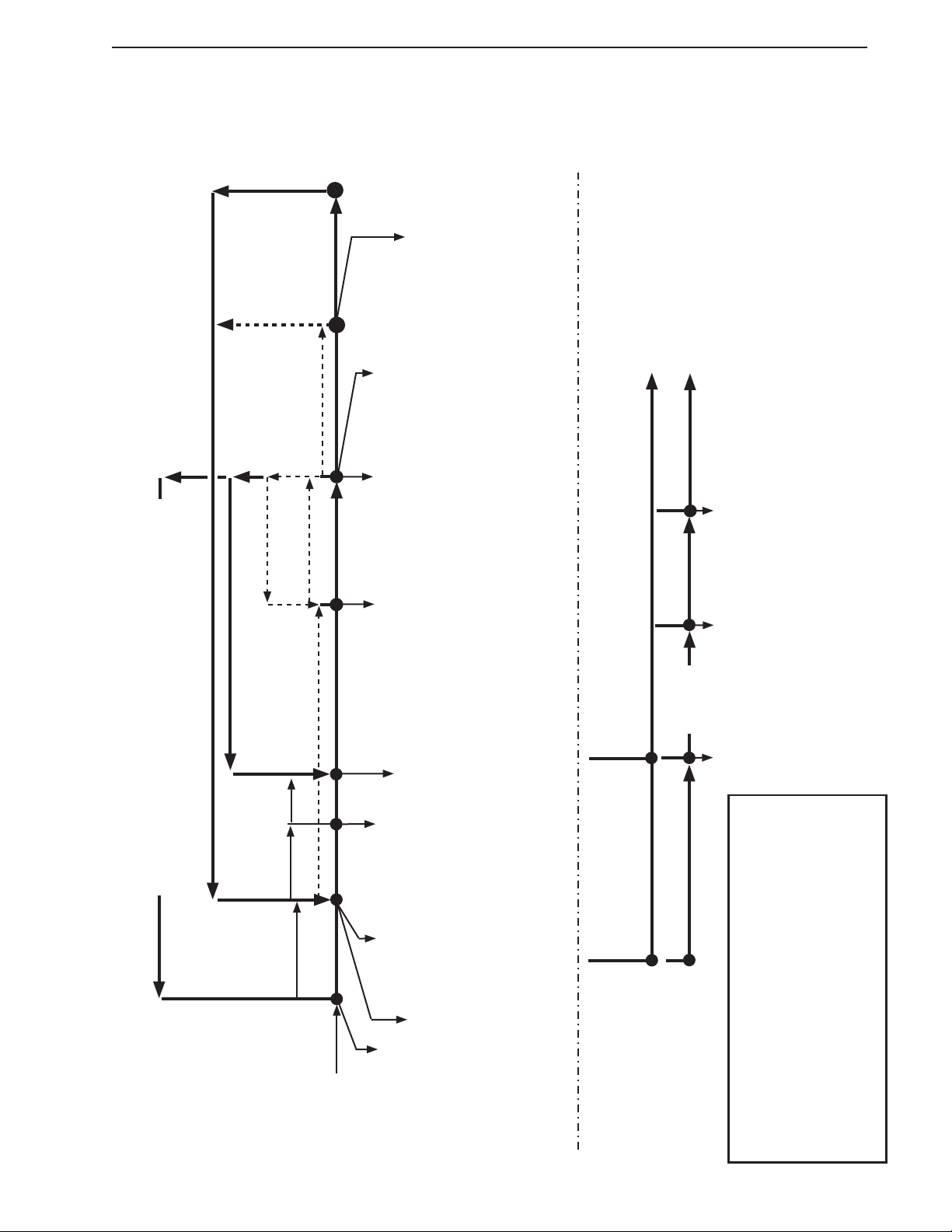

II. Sequence of Operation and Service Diagnosis

A. Sequence of Operation Flow Chart

1. Icemaking and Drain Cycle

WV continues

GM de-energized

FM de-energized

FMR de-energized

Low Water Safety

Shutdown

90. sec. PT terminates

unit shuts down and

1-beep alarm continues.

When UFS closes, alarm

resets and 2. Ice Purge

Cycle starts.

GM continues

FM continues

WV de-energized

Comp continues

FMR continues

GM continues

FM continues

FMR continues

LLV continues

SLV continues

Low Water Safety

Purge Timer

90 sec. FT exceeded,

90 sec. PT starts and

1-beep alarm sounds

90 sec.

UFS open

WV energized

LFS closed

UFS closed

Comp de-energized

LLV de-energized

min.)

FZT starts (30

SLV de-energized

FT terminated

Normal Operation

to "1. Fill Cycle" above

4. Icemaker Restart

10-min. DT terminated

DV de-energized

1-in-12 DT reset

Control Board Sequence of Operation Flow Chart - Icemaking and Drain Cycle

4. 1-in-12 Drain Cycle - Although the factory default 1-in-1 drain cycle

is recommended, a 1-in-12 drain cycle is available. For 1-in-12 drain

3. Freeze Cycle

cycle sequence, see "3. 1-in-12 Hour Drain Cycle & Restart (optional)."

2. Ice Purge Cycle

1. Fill Cycle

Rell

1-in-1 drain cycle. DV opens for 2 sec. every hour

(CB S1 Dip Switch 4).

To bypass, press the

"SERVICE" button after

FT Maximum

90 sec.

Icemaker status does not change.

5 min.

GM starts.

5 or 30 sec.

FT off (90 sec.)

30-min. FZT

FZT exceeded (LFS does not

open): CB shuts down icemaker

(S1 Dip Switch 7)

FT Maximum

90 sec.

UFS open

LFS open (WV on)

and sounds a 5-beep alarm.

Comp energized

EH energized

GM energized

LFS closed

UFS closed

FT starts (90 sec.)

FZT terminated

WV energized

LLV energized

SLV energized

GM continues

FM energized

FMR energized

FZT starts

FT terminated

WV de-energized

Comp continues

FM continues

GM continues

FMR continues

FM continues

FMR continues

LLV continues

SLV continues

DV de-energizes, no

2. Continued Operation

1. DT Initiates DC

Continued uninterrupted

interruption in ice production

DV energizes for 2 sec.

operation

3. 10-Min. Drain

5 min.

2. Ice Purge Cycle

1. DT Initiates DC

DV energized

Comp de-energized

GM de-energized

LLV de-energized

FM de-energized

SLV de-energized

FT-ll timer (low water safety)

FMR de-energized

GM continues

FM continues

FZT-freeze timer

GM-gear motor

FMR continues

LFS-lower oat switch

LLV-liquid line valve (MLH)

PT-purge timer

SLV-suction line valve (MLH)

UFS-upper oat switch

WV-inlet water valve

Power Switch "ON"

Control Switch in "ICE"

1. Startup

POWER OK LED on

BC1 Green LED on

Startup

BC1 Yellow LED off

BC(2) Closed

WV energized

If Fill > 90 sec. FT

1-beep alarm sounds

WV continues

When UFS closes

alarm resets and

2. Ice Purge Cycle starts.

17

(CB S1 dip switch 4 "OFF")

2. 1-in-1 Drain Cycle

& Restart (optional)

(CB S1 dip switch 4 "ON")

3. 1-in-12 Drain Cycle

Legend:

BC-bin control (mechanical stand-alone)

BC1-bin control 1 (infrared sensor)

BC(2)-bin control (2) (mechanical)

CB-control board

Comp-compressor

DC-drain cycle

DT-drain timer

DV-drain valve

EH-evaporator heater

FM-fan motor

FMR-fan motor-remote

Page 18

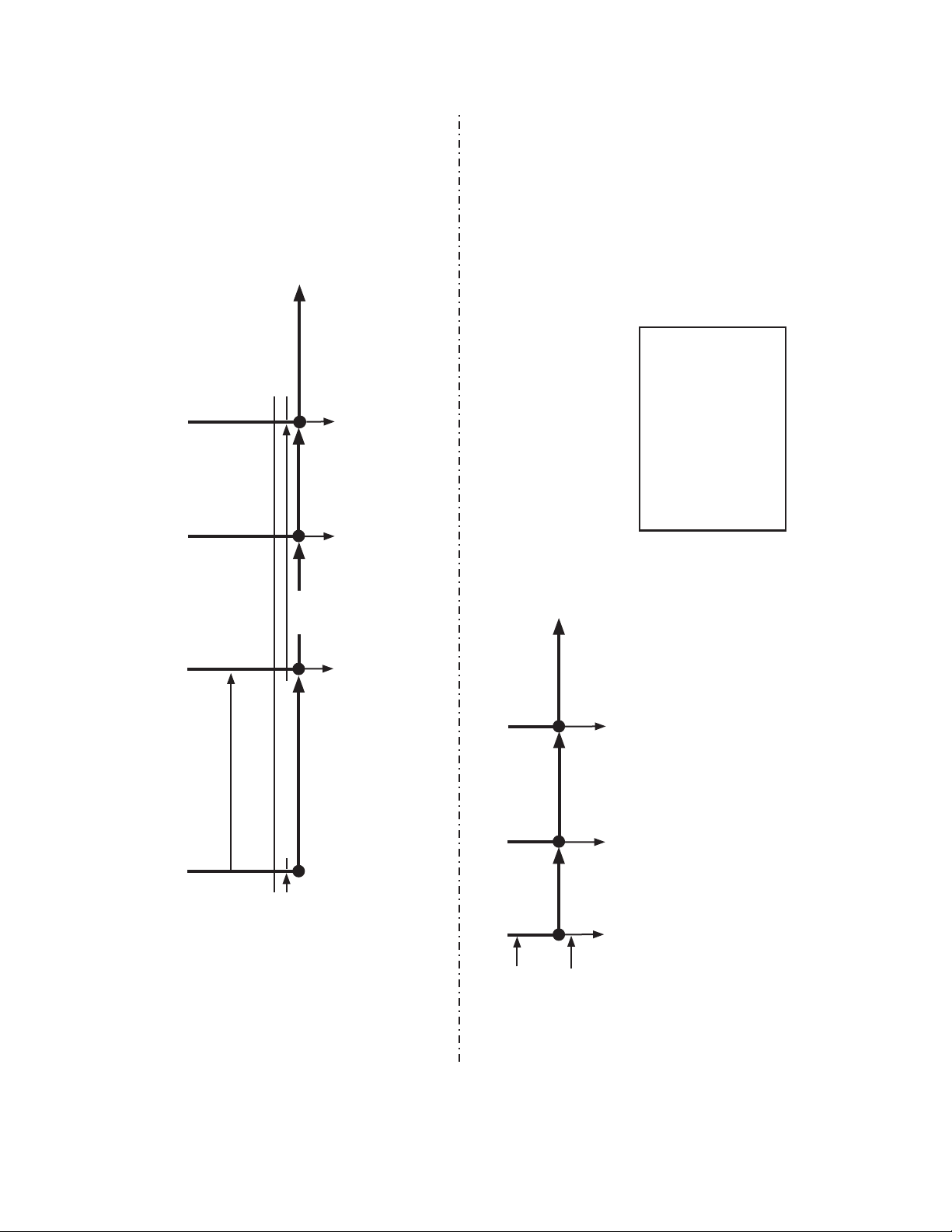

2. Shutdown

4. Icemaker Restart

Note for models with BC1 and BC2:

If BC1 fails to shutdown the icemaker, BC2

opens and a 9-beep alarm sounds. See

"II.D. Bin Control Check."

to "2. Ice Purge Cycle"

in Icemaking and Drain

BC1 Green LED on

BC1 Yellow LED off

Cycle Chart

BC1 de-activated

Control Board Sequence of Operation Flow Chart - Shutdown

3. Icemaker Off

2. Ice Purge Cycle

1. Bin Full

BC1 delay determined by CB S1 dip

switch 1, 2, 3

5 min.

BC1 Yellow LED (ashing or steady)

BC1 Green LED on

BC1 Yellow LED off

GM de-energized

BC1 activated

FM de-energized

Comp de-energized

FMR de-energized

LLV de-energized

SLV de-energized

GM continues

FM continues

FMR continues

to "2. Ice Purge Cycle" in Icemaking

Ice level lowered

2. Icemaker Off 3. Icemaker Restart

1 to 10 sec.

1. Bin Full

BC

and Drain Cycle Chart

BC(2) closed

All Components

Immediate

BC(2) open

BC2

Legend:

BC-bin control (mechanical stand-alone)

BC1-bin control 1 (infrared sensor)

(BC paddle and proximity

switch disengaged)

de-energized

BC paddle and

proximity switch

engaged

Note for models with BC1 and BC2:

When BC2 is activated, a 9-beep alarm

BC(2)-bin control 2 (mechanical)

CB-control board

Comp-compressor

FM-fan motor

FMR-fan motor-remote

GM-gear motor

sounds. See "II.D. Bin Control Check."

LLV-liquid line valve (MLH)

SLV-suction line valve (MLH)

1. BC1 Shutdown (infrared sensor)

2. BC(2) Shutdown (mechanical)

18

Page 19

B. Service Diagnosis

WARNING

• The appliance should be diagnosed and repaired only by qualied service

personnel to reduce the risk of death, electric shock, serious injury, or re.

• Risk of electric shock. Use extreme caution and exercise safe electrical practices.

• Moving parts (e.g., fan blade or auger) can crush and cut. Keep hands clear.

• CHOKING HAZARD: Ensure all components, fasteners, and thumbscrews are

securely in place after the appliance is serviced. Make sure that none have fallen

into the dispenser unit/ice storage bin.

• Make sure all food zones in the icemaker and dispenser unit/ice storage bin are

clean after service.

1. Ice Production Check

To check production, prepare a bucket or pan to catch the ice and a set of scales to

weigh the ice. After the appliance has operated for 10 to 20 min., catch the ice production

for 10 min.. Weigh the ice to establish the batch weight. Multiply the batch weight by

144 for the total production in 24 hours. When conrming production or diagnosing

low production, reference production information found in "VII.A. Specication and

Performance Data."

19

Page 20

2. Diagnostic Procedure

This diagnostic procedure is a sequence check that allows you to diagnose the electrical

system and components. Before proceeding, check for correct installation, proper voltage

per appliance nameplate, and adequate water pressure (10 PSIG to 113 PSIG).

Note: • When checking high voltage (115VAC), always choose a neutral (W) wire to

establish a good neutral connection.

• When checking low voltage (24VAC), always choose a neutral (LBU) wire to

establish a good neutral connection.

• When checking control board DC voltage (5VDC), always place the red positive

test lead from the multimeter to CB K5 pin closest to CB K4 connector.

See "II.C. Control Board Check."

• When checking BC1 (infrared sensor) (20VDC), check that the infrared sensor

green LED is on. This green LED conrms 20VDC power from CB K6to the

infrared sensor and remains on constantly. If green LED is not on, check for

20VDC from CB K6 #1 (DBU) to CB K6 #3 (BR). See "II.D. Bin Control Check."

• To speed up the diagnostic process, the 5-min. ice purge cycle may be bypassed

by pressing the "SERVICE" button on the control board after the gear motor

starts. WARNING! Risk of electric shock. Care should be taken not to touch

live terminals.

• If the icemaker is in alarm, see "III.A.2. LED Lights and Audible Alarm Safeties."

• FM/FMR and EH (-C model except FD-650) energize when "GM" LED turns on.

• MLH Model: CB X1 relay energizes LLV and SLV.

• CB monitors the following switches with 5VDC during the icemaking process:

Control Switch (CS), High-Pressure Switch (HPS), Float Switch (FS),

Compressor Control Relay/Gear Motor Protect Relay (CCR/GMPR), and Bin

Control (2) (mechanical stand-alone or backup). When 5VDC is present across

any of these switches, the switch is open.

1) Remove the front panel, then move the power switch to the "OFF" position. Move the

control switch to the "DRAIN" position, then move the power switch back to the "ON"

position. Replace the front panel in its correct position.

2) Allow the water system to drain for 5 min.

3) Remove the front panel. Move the power switch to the "OFF" position, then turn off the

power supply.

4) Remove the control box cover and access CB.

5) Check the CB S1 dip switch settings, see "III.B.1. Default Dip Switch Settings" to assure

that they are in the correct positions. For proper operation of BC1 (infrared sensor),

conrm that S1 dip switch 7 is in the "ON" position.

20

Page 21

6) Startup–CB "POWER OK" LED is on. Turn on the power supply, then move the power

switch to the "ON" position. Make sure the control switch is in the "ICE" position.

CB "POWER OK" LED and IS (BC1 if applicable) green LED turn on.

Diagnosis CB "POWER OK" LED: Check that CB "POWER OK" LED is on. Ifnot,

check for 115VAC at control transformer brown (BK on 115VAC models (except

FD-650M_H-C) and BR on 208/230VAC models and 115VAC FD-650M_H-C) wire to

neutral (W). If 115VAC is not present, check the power switch and breaker. If 115VAC

is present, check control transformer continuity. Replace as needed. Next, check for

24VAC at control transformer red (R) wire to neutral (LBU). If 24VAC is not present,

check control transformer continuity. Replace as needed. If24VAC is present, check

24VAC 1A fuse. If fuse is good, check for 24VAC at CB K8 #1 (W/R) to CB K8 #2 (LBU).

If 24VAC is present and "POWER OK" LED is off, replace CB.

Diagnosis BC(2) (mechanical stand-alone or backup): Check that the actuator

paddle is properly positioned. Check continuity across BC(2). If open, replace BC(2).

Next, check VDC at CB K8#3(GY) to CB K8 #4 (GY). When BC(2)is closed 0VDC is

read. Move the actuator paddle to open BC(2). When open, 5VDCis present between

CB K8 #3 (GY) and CB K8#4(GY). If 5VDC is not present when BC(2) is open, replace

CB. Return actuator to its normal position.

Diagnosis BC1 (infrared sensor): If "POWER OK" LED is on and BC1 green LED

is off, check 20VDC at CB K6 #1 (DBU) to CB K6 #3 (BR). If 20VDC is not present,

conrm dip switch 7 is in the "ON" position. If dip switch 7 is in the "ON" position and

20VDC is not present, replace CB. If BC1 yellow LED is on or ashing, move ice away

from lens. If no ice is present, clean the lens with a warm, clean damp cloth. If cleaning

the lens does not work, replace BC1.

7) Fill Cycle – "WTRIN" LED is on. Reservoir is empty and LFS and UFS are open.

90-sec. FT starts. WV energizes and ll cycle starts. LFS closes. Nothing occurs at this

time. Reservoir continues to ll until UFS closes. When UFS closes, WV de-energizes,

90-sec. FT is terminated, and CB "WTRIN" LED turns off. 30-min. FZTand 30-sec.

GM delay timer start. IfUFS remains open longer than 90 sec. after LFS opens,

FTexceeded and CB sounds a 1-beep alarm. WVremains energized until UFS closes.

Alarm resets automatically when UFS closes. Diagnosis: If reservoir is empty and

"WTRIN" LED is off, conrm LFS status. See "II.E.1. Float Switch Check." IfLFS is open

and "WTRIN" LED is off, replace CB. If "WTRIN" LED is on, check that the reservoir lls.

If not, check water supply line shut-off valve, water lters, and WVscreen. If "WTRIN"

LED is on and WV is off, check CB K2 #8(O) to a neutral (LBU) for 24VAC. If24VAC is

not present, check CB K2 #9(W/R) to a neutral (LBU) for 24VAC. If 24VAC is present

on CB K2 #9(W/R)and not on CB K2 #8 (O), replace CB. If 24VAC is present on

CB K2 #8(O), check continuity through WV solenoid. If open, replace WV. If WV is

energized and rell exceeds FT with no water in the reservoir, check for DV leaking.

Ifreservoir is full and overowing check for open UFS. See "II.E.1. Float Switch Check."

If UFS is closed, check that WV de-energizes. If not, check CB K2 #8 (O) to a neutral

(LBU) for 24VAC. If 24VAC is present, replace CB. IfWV de-energizes and water

continues to ll the reservoir, replace WV.

21

Page 22

8) Ice Purge Cycle – "GM" LED is on. 30-sec. GM delay timer terminates. GM,

CCR/GMPR, FM/FMR, and EH (-C model except FD-650) energize. Once CCR/GMPR

energizes, 5VDC circuit closes through CCR/GMPR terminal #3 (W/O) and terminal

#5 (W/O) and CB K9 #5 (W/O) and K9 #6 (W/O). After 5VDC circuit closes, 5-min.

ice purge timer starts. Tobypass the 5-min. Ice Purge Cycle, press the "SERVICE"

button on CB after the "GM" LED turns on. WARNING! Risk of electric shock. Care

should be taken not to touch live terminals. Diagnosis: If "GM" LED is off, check

that UFS closes and WV de-energizes. IfUFS is closed, 30 sec. has passed, and "GM"

LED remains off, replace CB. If"GM" LED is on and GM is off, check CB K1 #2 (BK

or BR) to a neutral (W) for 115VAC. If115VAC is not present, check 115VAC power

supply. If115VAC is present, check CB K1 #3(BK, P, or R) to a neutral (W). If 115VAC

is present on CB K1 #2 (BK or BR) and not on CB K1 #3 (BK, P, or R), replace CB.

If115VAC is present on CB K1#3 (BK, P, or R), check GM fuse, GM internal protector,

GM windings and capacitor, and GM coupling between auger and GM. When GM

energizes,

CCR/GMPR energizes starting 5-min. ice purge timer. If FM/FMR does not start, check

FM/FMR capacitor, FM/FMR windings, and FM/FMR bearings.

9) Freeze Cycle – "COMP" and "GM" LEDs are on. The 5-min. ice purge timer

terminates. GM, EH, CCR, and FM/FMR continue. Comp or LLV/SLV (MLH model)

energize. Ice production starts 4to 6 min. after Comp or LLV/SLV (MLH model) energize

depending on ambient and water conditions. As ice is produced, the water level in

the reservoir drops. UFS opens. Nothing happens at this time. When LFS opens, WV

energizes and rell cycle begins, FZT terminates, and FTstarts.

FZT: 30-Min. Freeze Safety Timer – FZT starts when UFS closes and terminates

when LFS opens. If LFS does not open within 30 min. of UFS closing, CB shuts down

the icemaker and sounds a 5-beep alarm. See "III.A.2.LED Lights and Audible Alarm

Safeties." To reset, turn the power supply off and on again. See "II.F. Diagnostic Tables"

for troubleshooting details.

Icemaker Diagnosis (CCR/GMPR): 5-min. ice purge timer terminates, CB "COMP"

LED is on and COMP or LLV/SLV (MLH model) energizes. If not, check for 5VDC

between CB K5 connector pin closest to CB K4 connector and CB K9connector

#5(W/O). If 5VDC is not present, replace CB. If 5VDC is present, check for 5VDC

between CB K5 connector pin closest to CB K4 connector and CB K9connector

#6(W/O). If 5VDC is present and CB "Comp" LED is off (CR, COMP, or LLV/SLV (MLH

model) not energized), replace CB. If 5VDC is not present, check for 115VAC between

CCR/GMPR terminal #7(O) to CCR/GMPR terminal #8(W) for 115VAC. If115VAC

is not present (GM not energized), see step 8 above. If 115VAC is present and CCR/

GMPR contacts are open (5VDCpresent between terminals #3(W/O) and #5(W/O)),

check CCR/GMPR solenoid voltage and solenoid continuity. Replace CCR/GMPR if

necessary.

Icemaker Diagnosis (COMP or LLV/SLV (MLH model)): If"COMP" LED is on and

COMP or LLV/SLV (MLH model) is not energized, check CB X1 relay BK or BR wire to

a neutral (W) and CB X1 relay V, BR, or R wire to a neutral (W) for 115VAC. If115VAC

is present on CB X1BK or BR wire and not on CBX1 V, BR, or R wire, replace CB.

If115VAC is present on CBX1V, BR, or R wire and COMP or LLV/SLV (MLH model) is

not energized, check for 115VAC at CB X1 Comp relay, Comp or LLV/SLV (MLH model).

Check Comp internal overload (motor protector), start relay, and capacitors.

Check LLV/SLV (MLH model) solenoid continuity.

22

Page 23

10) Rell Cycle – "GM", "COMP", and "WTRIN" LEDs are on.

LFS opens. WVenergizes and 90-sec. FT starts. Comp or LLV/SLV (MLH model), GM,

CCR/GMPR, and FM/FMR continue. LFS closes. Nothing occurs at this time. Reservoir

continues to ll until UFS closes. When UFS closes, WV de-energizes, 90-sec. FT

terminates, and 30-min. FZT starts. If UFS remains open longer than 90 sec. after LFS

opens, FT exceeded and CB sounds a 1-beep alarm. WVremains energized until UFS

closes. Alarm resets automatically when UFS closes.

Diagnosis – Conrm that the water level has dropped and the UFS and LFS are open.

See "II.E.1. Float Switch Check." Check that "WTRIN" LED is on. IfLFS is open and

"WTRIN" LED is off, replace CB. If "WTRIN" LED is on, check that the reservoir lls.

Ifnot, check water supply line shut-off valve, water lters, and WVscreen. If"WTRIN"

LED is on and WV is off, check CB K2 #8(O) to a neutral (LBU) for 24VAC. If 24VAC

is not present, check CB K2 #9(W/R) to a neutral (LBU) for 24VAC. If 24VAC is

present on CB K2 #9 (W/R)and not on CB K2#8 (O), replace CB. If 24VAC is

present on CB K2#8(O),check continuity through WV solenoid. If open, replace WV.

IfWV is energized and rell exceeds FT with no water in the reservoir, check for DV

leaking. Ifreservoir is full and overowing check for open UFS. See "II.E. Float Switch

Check and Cleaning." If UFS is closed, check that WVdeenergizes. If not, check

CB K2 #8(O) to a neutral (LBU) for 24VAC. If 24VAC is present, replace CB. If WV

de-energizes and water continues to ll the reservoir, replace WV.

Note: Each time UFS closes, 30-min. freeze timer starts. The 30-min. freeze timer

resets when UFS closes again. If UFS does not close again within 30 min., CB

shuts down the unit and sounds a 5-beep alarm every 5 sec.

See "III.A.2 LED Lights and Audible Alarm Safeties."

FT: 90-Sec. Low Water Safety Timer – When LFS opens, 90-sec. low water safety

timer starts. If UFS does not close within 90 sec. after LFS opens (FTexceeded),

CBsounds a 1-beep alarm and a 90-sec. shutdown cycle starts

See "III.A.2.LED Lights and Audible Alarm Safeties." Comp or LLV/SLV (MLH model)

de-energizes. GM, CCR/GMPR, and EH continue. 90-sec. purge timer terminates, GM,

EH, and CCR/GMPR de-energize. WV and 1-beep alarm continue until UFS closes.

11) Drain Cycle

a) 1-in-1 Drain Cycle: DV energizes once every hour when the 1-in-1 drain cycle is

activated (S1 dip switch 4 in the "OFF" position (factory default position)). GM,

FM/FMR, Comp, LLV/SLV (MLH model), continue. DV energizes for 2 sec. every

hour. This setting is recommended for optimum icemaker performance. The 1-in-1

drain cycle allows any sediment to drain from the evaporator without interrupting the

icemaking process.

b) 1-in-12 Drain Cycle (optional): DV energizes once every 12 hours when the 1-in-12

drain cycle is activated (S1 dip switch 4 in the on position (optional)). 12-hour drain

cycle timer terminates, Comp or LLV/SLV (MLH model) de-energize. GM, and

FM/FMR continue. The 5-min. ice purge timer starts. When the 5-min. ice purge

timer terminates, GM and FM/FMR de-energize. 10-min. DT starts, DV energizes.

After 10-min. DT terminates, DV de-energizes icemaking process restarts and

12-hour drain cycle timer starts.

23

Page 24

c) Manual Drain: Manual drain is used when servicing evaporator components and

cleaning and sanitizing the unit. When the unit is making ice and the control switch

is moved to the "DRAIN" position, there is a 3-sec. delay, then Comp or LLV/SLV

(MLH models) de-energize and the 5-min. ice purge timer begins. When the 5-min.

ice purge timer terminates, GM, and FM/FMR de-energize. DV energizes to drain

the evaporator and reservoir. To avoid the 5-min. shutdown delay, turn off the power

supply, then move the control switch to the "DRAIN" position. Turn on the power

supply. DV energizes to drain the evaporator and reservoir. DV de-energizes when

the control switch is moved to the "ICE" position.

10) Shutdown

a) BC1 (infrared sensor): When power is supplied to the icemaker, the green LED on

BC1 turns on. The green LED remains on constantly. As ice lls the storage bin to

the level of activating BC1, BC1 yellow LED turns on (ashing or steady). The yellow

LED ashes when ice is at the outer limit of its range and turns steady as ice nears.

After the yellow LED turns on (ashing or steady), BC1 shutdown delay timer (S1 dip

switch 1, 2, 3) starts. For a typical dispenser unit application, a 100-sec. shutdown

delay is recommended. When used with a standard Hoshizaki storage bin, any

shutdown delay setting is acceptable. See "III.B.2. BC1 (Infrared Sensor) Shutdown

Delay (S1 dip switch 1, 2, 3)." Once BC1 shutdown delay timer terminates, Comp or

LLV/SLV (MLH models) de-energize and the 5-min. ice purge timer starts. When

the 5-min. ice purge timer terminates, GM, CCR/GMPR, and FM/FMR de-energize.

Diagnosis: See "II.D.1. Bin Control 1 (infrared sensor) Check."

Note: When BC1 and BC2 are applied–If BC1 fails to shut down the icemaker, BC2

opens, CB shuts down the icemaker and sounds a 9-beep alarm.

b) BC(2) (mechanical stand-alone or backup):

BC (stand-alone): BC opens (actuator paddle engaged). CB shuts down the

icemaker within 10 sec.

BC2 (backup): BC2 opens (actuator paddle engaged). CB shuts down the icemaker

immediately and sounds a 9-beep alarm.

Diagnosis: See "II.D.2. Bin Control(2) (mechanical stand-alone or backup) Check."

Legend: BC1–bin control 1 (infrared sensor); BC(2)–bin control (2) (mechanical stand-alone

or backup); CB–control board; CCR–compressor control relay (formerly GMPR

gear motor protect relay); Comp–compressor; DV–drain valve; EH–evaporator

heater (-C model except FD-650); FM–fan motor; FMR–fan motor-remote;

GM–gear motor; LFS–lower oat switch; L LV –liquid line valve (MLH model); SLV –

suction line valve (MLH model); UFS–upper oat switch; WV–inlet water valve

24

Page 25

C. Control Board Check

Before replacing a control board that does not show a visible defect and that you suspect

is bad, always conduct the following check procedure. This procedure will help you verify

your diagnosis.

1) Check CB S1 dip switch settings to assure that they are in the factory default position.

For factory default settings, see "III.B.1. Default Dip Switch Settings."

Note: S1 dip switch 7determines bin control application:

BC (mechanical stand-alone) or BC2 (mechanical backup only): S1 dip switch 7 in

the "OFF" position. WARNING! On CB 2A8054-01, do not put S1 dip switch 9 in the

"OFF" position when S1 dip switch 7 is in the "OFF" position.

BC1 (infrared sensor stand-alone) or with BC2 (mechanical backup): S1 dip switch

7in the "ON" position.

2) Move the power switch to the "ON" position and move the control switch to the "ICE"

position. The "POWER OK" LED turns on. Diagnosis "POWER OK" LED: Check that

the CB "POWER OK" LED is on. If not, check for proper supply voltage (115VAC) input

to the control transformer (power switch, breaker, and fuse). Next, check for proper

low-voltage (24VAC) output from the control transformer and that the 1A fuse is good.

Check for 24VAC at CB K8 #1 (W/R) to CB K8 #2 (LBU). If 24VAC is present and the

"POWER OK" LED is off, replace CB.

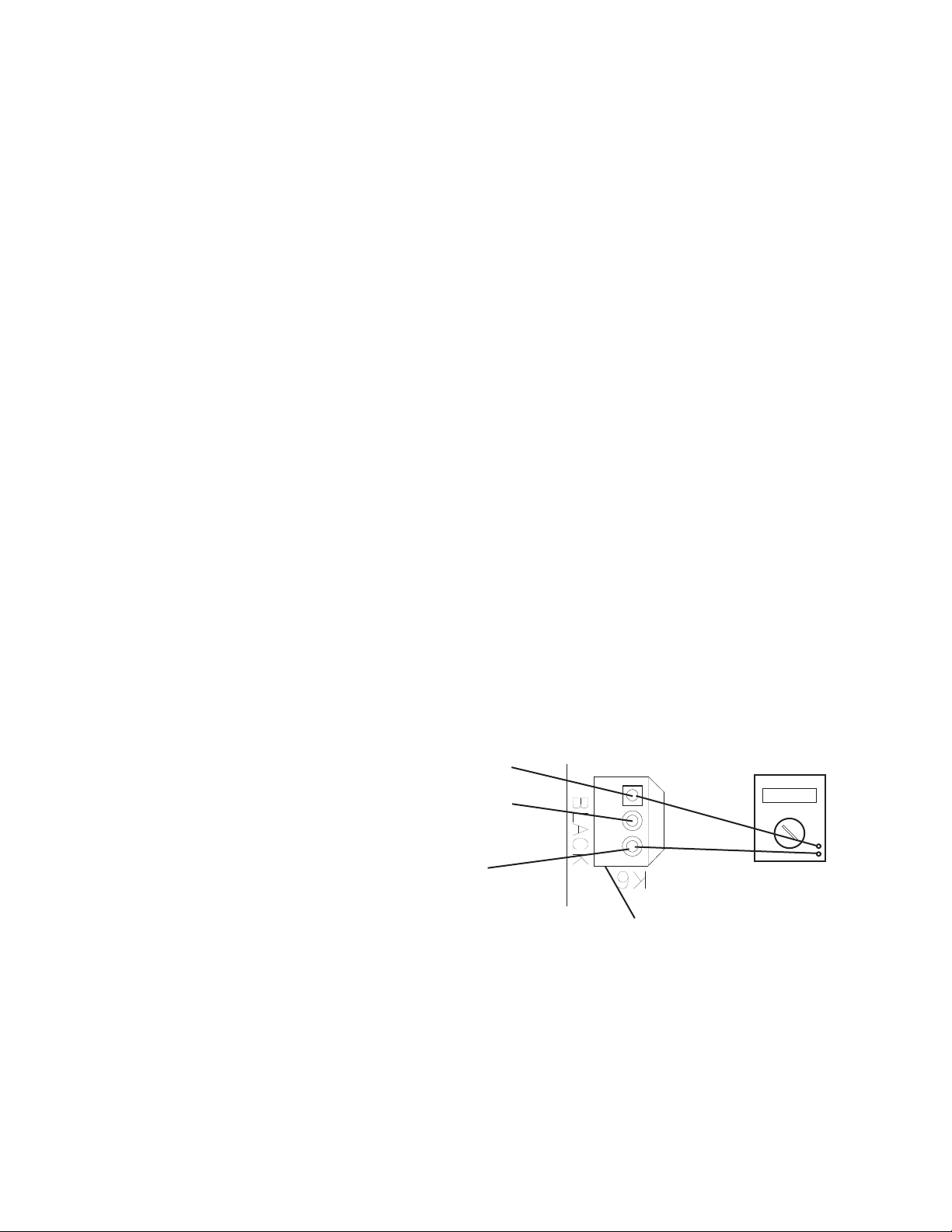

3) BC1 (infrared sensor) Power Supply (K6 connector): CB supplies 20VDC to BC1

and BC1 green LED is on. Diagnosis: Check that BC1 green LED is on. If not, check

for 20VDC between CB K6 #1 (DBU) and CB K6 #3(BR). See Fig. 1. If 20VDC is not

present, replace CB. If 20VDC is present, conrm that the yellow LED is not ashing

or steady. If BC1 yellow LED is on or ashing, move ice away from lens. If no ice is

present, clean the lens with a warm, clean damp cloth. If cleaning the lens does not

work, replace BC1 (infrared sensor).

BC1 (infrared sensor) (20VDC) Closed

20VDC K6 #1 (DBU) to K6 #3 (BR)

20VDC K6 #1 (DBU) to K6 #2 (W)

0VDC K6 #2 (W) to K6 #3 (BR)

BC1 (infrared sensor) (20VDC)

Open (yellow LED ashing or steady)

20VDC K6 #1 (DBU) to K6 #3 (BR)

0VDC K6 #1 (DBU) to K6 #2 (W)

20VDC K6 #2 (W) to K6 #3 (BR)

K6 #3

Brown (BR)

K6 #2

White (W)

K6 #1

Dark Blue (DBU)

Fig. 1

25

Red Positive

Test Lead

3

20VDC

2

1

Black Negative

Test Lead

Multimeter

• K6 Connector

BC1 (Infrared Sensor)

Page 26

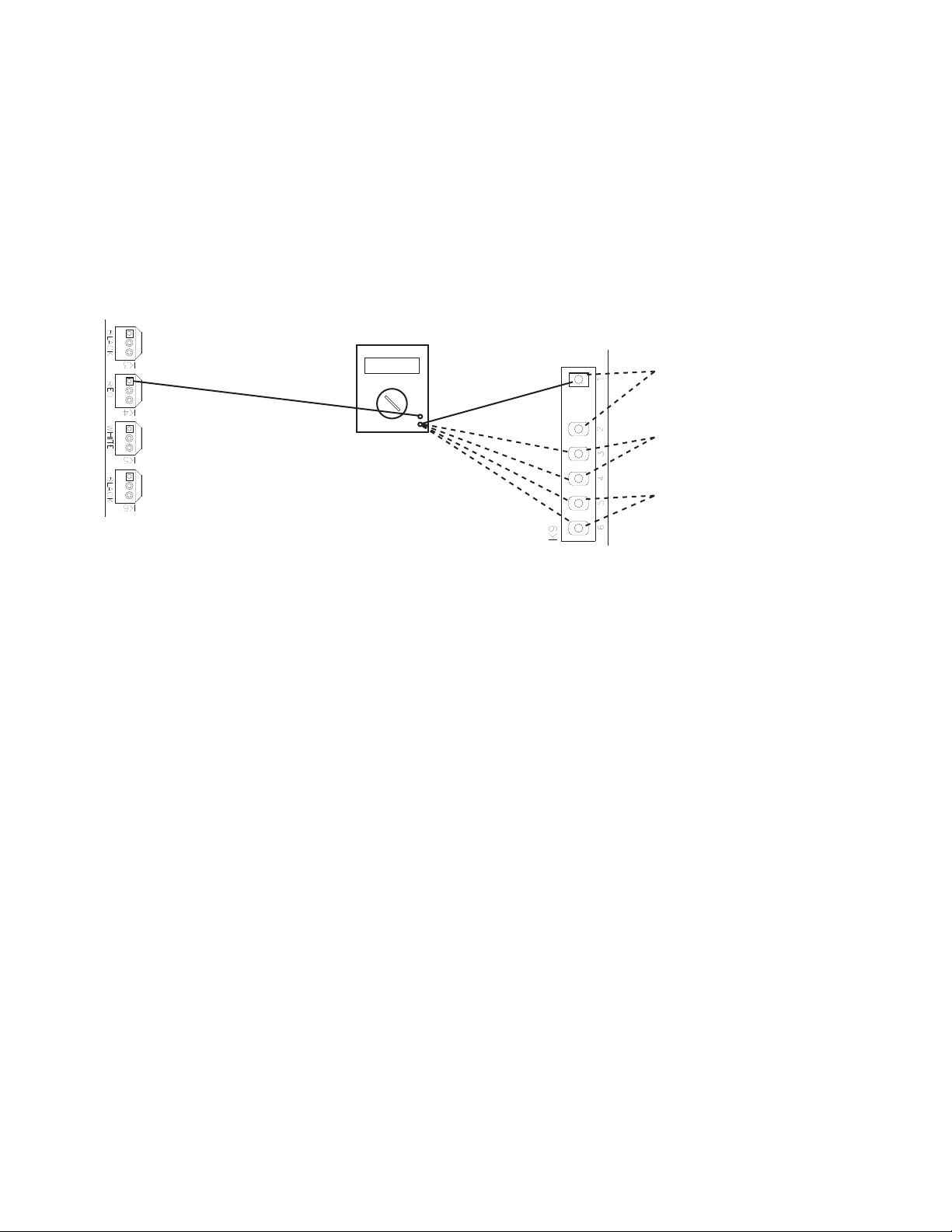

4) 5VDC Output Checks:

CB K9 Connector: Control Switch (CB K9 #1 and #2) (open contacts for icemaking,

closed contacts for drain), High-Pressure Switch (CB K9 #3 and #4), Compressor

Control Relay/Gear Motor Protect Relay (K9 #5 and #6).

CB K8 Connector: Bin Control (2) (K8 #3 and #4) and Float Switch (K8 #5 (common),

#6 (lower), and #7 (upper)).

When checking 5VDC control voltage, always place the red positive test lead from

the multimeter to the CB white K5 pin closest to the CB red K4 connector. See Fig. 2.

Then place the black negative test lead from the multimeter to the corresponding pin to

complete the 5VDC check.

Red positive test lead

to K5 pin closest to K4

connector

Red Positive

Test Lead

5VDC

Multimeter

Black Negative

Test Lead

Control Board K9 Connector

Control Switch

white/black (W/BK)

High-Pressure Switch

yellow (Y) wires

Compressor Control Relay/

Gear Motor Protect Relay

(terminals #3 and #5)

white/orange (W/O)

Fig. 2

a) Control Switch – CB K9 #1 (W/BK) and CB K9 #2 (W/BK):

5VDC is present between CB white K5 connector, pin closest to CB red

K4 connector and CB K9 #1 (W/BK) at all times. If 5VDC is not present, replace

CB. When the control switch is in the "ICE" position, the control switch contacts

are open. 0VDC is present between CB white K5 connector, pin closest to CB red

K4 connector and CB K9 #2 (W/BK). When in the "ICE" position, 5VDC is present

between CB K9 #1 (W/BK) to CB K9 #2 (W/BK). When the control switch is in the

"DRAIN" position, the control switch contacts are closed. 5VDC is present between

CB white K5 connector, pin closest to CB red K4 connector, to CB K9 #1 (W/BK)

or#2(W/BK). If 5VDC is not present, replace CB. 0VDC is present from CB K9

#1(W/BK) to CB K9 #2 (W/BK).

b) High-Pressure Switch – CB K9 #3 (Y) and CB K9 #4 (Y):

5VDC is present between CB K5 connector, pin closest to CB red K4 connector and

CB K9 #3 (Y) at all times. When the high-pressure switch is closed, 5VDC is present

between CB K5 pin closest to CB K4 connector to CB K9 #3 (Y) and CB K9 #4 (Y).

If 5VDC is not present, replace CB. When the high-pressure switch is closed, 0VDC

is present at CB K9 #3 (Y) to CB K9 #4 (Y). When the high-pressure switch is open,

5VDC is present at CB K9 #3 (Y) to CB K9 #4 (Y). If the high-pressure switch is open

and CB is not in alarm, replace CB. If5VDC is present at CB K9 #3 (Y) and not at

CB K9 #4 (Y), the high-pressure switch is open and CB sounds a 3-beep alarm.

Check continuity across the high-pressure switch (CB K9 #3 (Y) and CB K9 #4 (Y)).

26

Page 27

c) Compressor Control Relay/Gear Motor Protect Relay (CCR/GMPR) –

CB K9 #5(W/O) and CB K9 #6 (W/O): 5VDC is present from CB white K5 connector,

pin closest to CB red K4 connector to CB K9 #5 (W/O) at all times. If 5VDC is not

present, replace CB. When CCR/GMPR terminals #3 (W/O) and #5 (W/O) are open

(CCR/GMPR de-energized), 5VDC is present between CB K9 #5 (W/O) and CB K9

#6 (W/O). When CCR/GMPR terminals #3(W/O) and #5 (W/O) are closed (CCR/

GMPR energized), 5VDC is present between CB K9 #5 (W/O) and CB K9 #6 (W/O).

When CCR/GMPR terminals #3 (W/O) & #5 (W/O) are open CB may be in an

8-beep alarm. See "III.A.2. LED Lights and Audible Alarm Safeties."

d) Bin Control (2) (mechanical stand-alone or backup) –

CB K8 #3 (GY) and CB K8 #4(GY): 5VDC is present from CB white K5 connector,

pin closest to CB red K4 connector to CB K8 #3 (GY) at all times. If 5VDC is not

present, replace CB. When BC(2) is closed (calling for ice), 5VDC is present from

CB white K5 connector, pin closest to CB red K4 connector, to CB K8 #3 (GY) and

CB K8 #4(GY). If 5VDC is not present to either CB K8 #3 (GY) or CB K8 #4(GY),

replace CB. If 5VDC is present at CB K8 #3 (GY) and not to CB K8 #4 (GY), BC(2) is

open. See "II.D.2. Bin Control (2) (mechanical stand-alone or backup) Check."

e) Float Switch (LFS and UFS) – CB K8 #5 (BK) (common), CB K8 #6(R) (upper),

and CB K8 #7 (BU) (lower): 5VDC is present from CB white K5 connector pin closest

to CB red K4 connector to CB K8 #5(BK) (common) at all times. If not, replace CB.

5VDC is present from CB white K5 connector pin closest to CB red K4connector

to CB K8 #6 (R) (upper) and CB K8 #7 (BU) (lower) when FS is open. If 5VDC

is present between CB K8 #5 (BK) and CB K8 #6 (R) (upper) or CB K8 #7 (BU)

(lower), FS is open. Forfurther FS diagnostics, see "II.E. Float Switch Check and

Cleaning."

5) Fill "WTRIN" LED is on: 24VAC is present at CB K2 #9 (W/R) at all times. If not,

conrm 24VAC from CB K2 #9(W/R) to a neutral (LBU). When LFS open at startup

or opens during normal operation, "WTRIN" LED turns on, ll timer (FT) starts, freeze

timer (FZT) terminates (only during normal operation), and WV energizes. If LFS is

open and "WTRIN" LED is off, conrm LFS status. See "II.E. Float Switch Check and

Cleaning." If LFS is open and "WTRIN" LED is off, replace CB. If "WTRIN" LED is on

and WV is not energized, check for 24VAC at CB K2 #8(O) to a neutral (LBU). If24VAC

is not present at CB K2 #8(O), replace CB. "WTRIN" LED turns off once UFS closes.

Ifnot, conrm UFS status. See "II.E. Float Switch Check and Cleaning." IfUFS is

closed and "WTRIN" LED is on, replace CB. If "WTRIN" LED is off and WV is open,

check for 24VAC at CB K2 #8 (O). If 24VAC is present at CB K2 #8 (O), replace CB.

If24VAC is not present, check WV diaphragm.

6) Ice Purge Cycle "GM" LED is on: When UFS closes, GM delay timer starts (5 or

30sec. depending on CB S1 dip switch #7). Once GM delay timer terminates, "GM"

LED turns on, GM and EH (-C model except FD-650) energize and 5-min. ice purge

timer starts. If GM does not energize 30 sec. after UFS closes, conrm UFS status.

See "II.E. Float Switch Check and Cleaning." If UFS is closed and GM LED does not

turn, replace CB. If "GM" LED is on and GM and EH are off, check for 115VAC from

CBK1#2to a neutral (W). If 115VAC is not present, check 115VAC power supply

connections from power switch. If 115VAC is present, check for 115VAC from CB K1

#3to a neutral (W). If115VAC is present on CB K1 #2and not on CB K1 #3, replace

CB.

27

Page 28

7) Freeze Cycle "GM" and "COMP" LED are on: The 5-min. ice purge timer terminates

or the ice purge cycle bypass button ("SERVICE") is pressed, "COMP" LED turns on.

Tobypass the 5-min. Ice Purge Cycle, press the "SERVICE" button on CB after the

"GM" LED turns on. WARNING! Risk of electric shock. Care should be taken not

to touch live terminals. 115VAC is present between CB X1 relay power supply brown

(BR) or black (BK) wire and neutral (W) at all times. If not, check 115VAC power supply

wire connections from power switch. If"COMP" LED is not on after 5-min. ice purge

timer terminates, replace CB.

When "COMP" LED turns on, CR (if applicable) and compressor energize. If "COMP"

LED is on and compressor relay (CR) (if applicable) and compressor are not, check for

115VAC from CB X1 relay power supply brown (BR) or black (BK) wire to neutral (W).

If 115VAC is present, check X1 relay red (R), violet (V), or brown (BR) to neutral (W).

If 115VAC is present on X1 relay brown (BR) or black (BK) and not on X1 relay red (R),

violet (V), or brown (BR), replace CB.

8) Rell "WTRIN" LED is on: See "5) Fill "WTRIN" LED is on:" above.

Legend: BC1–bin control 1 (infrared sensor); BC(2)–bin control (2) (mechanical stand-alone

or backup); CB–control board; CR–compressor relay; CCR/GMPR–compressor

control relay/gear motor protect relay; EH–evaporator heater (-C model except

FD-650); FS–oat switch; GM–gear motor; LFS–lower oat switch; UFS–upper

oat switch; WV–inlet water valve

28

Page 29

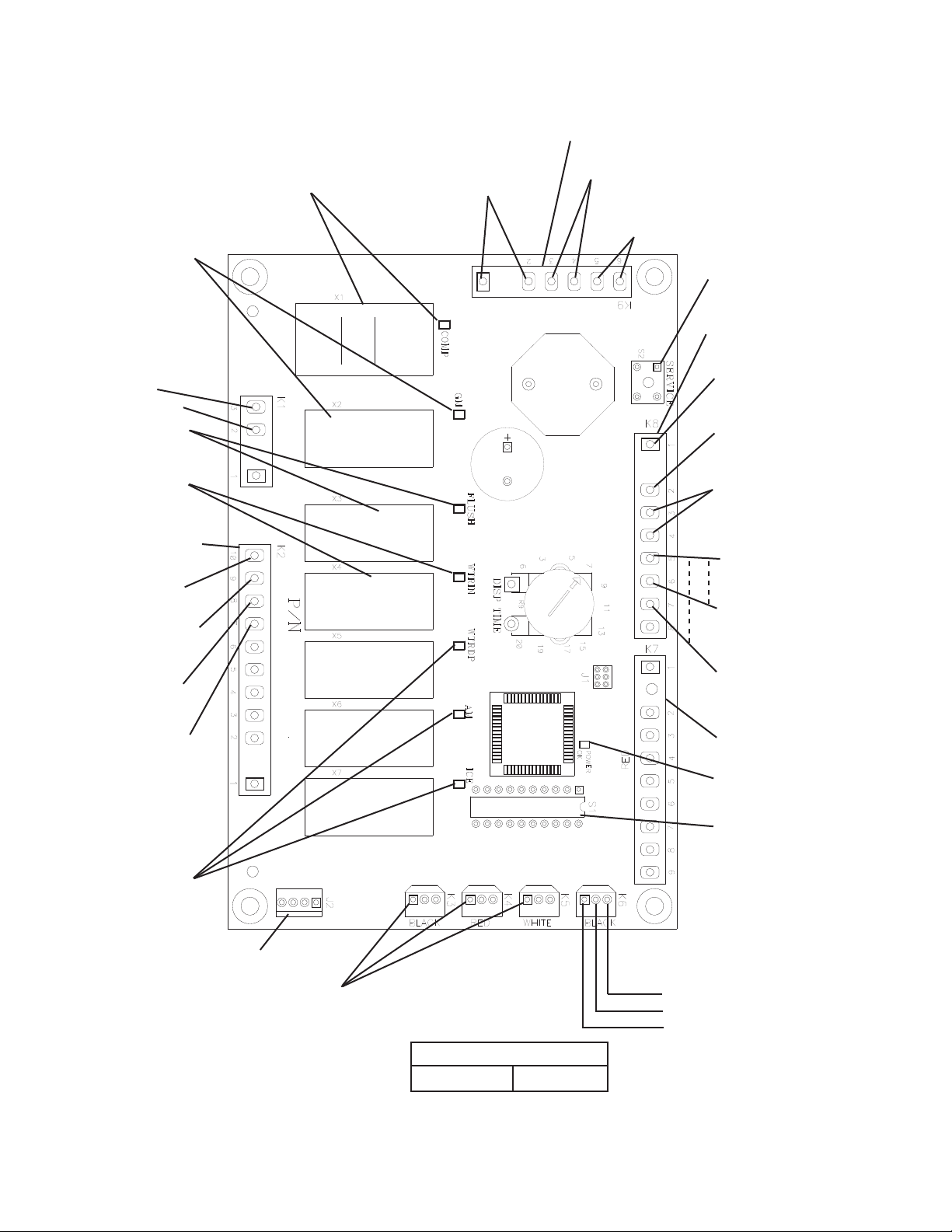

Control Board

• K9 Connector (5VDC)

• "COMP" LED

(X1 Relay)

• "GM" LED

(X2 Relay)

GM

• K1 Connector

(115VAC)

GM, CCR/GMPR, EH,

FM, FMR #3

115VAC Input #2

• "FLUSH" LED

(X3 Relay) (drain)

DV

• "WTRIN" LED

(X4 Relay)

WV

Comp, LLV, SLV

• K2 Connector

(24VAC)

Drain Valve

#10 (W/BU)

Control Transformer

24VAC Input

#9 (white/red)

Inlet Water Valve

#8 (O)

Control Switch

#1 to #2 (white/black)

High-Pressure Switch

#3 to #4 (yellow)

Compressor Control Relay Circuit/Gear

Motor Protect Relay Circuit

#5 to #6 (white/orange)

• S2 "SERVICE" Button

(Ice Purge Cycle Bypass)

• K8 Connector

(24VAC and 5VDC)

Control Transformer

24VAC Input

#1 (white/red)

Control Transformer

24VAC Neutral

#2 (light blue)

(DRAIN)

Bin Control (2) (mechanical)

#3 & #4 (gray) (5VDC)

Float Switch-Common

#5 (black) (5VDC)

Upper Float Switch

#6 (red) (5VDC)

2A8054-01

Lower Float Switch

#7 (blue) (5VDC)

Control Transformer

24VAC Input

#7 (white/red)

Water Dispensing

Valve, Agitation

Motor, and Ice

Dispensing LEDs

(not used on

these models)

5VDC common terminals

• K3 Connector-Open

• K4 Connector-Open

• K5 Connector-Open

• J2 Connector-Open

Control Board

Part Number

Fig. 3

29

• K7 Connector-Open

• "POWER OK" LED

• S1 Dip Switch

3 2 1

• K6 Connector (20VDC)

Bin Control 1 (infrared sensor)

(dark blue)

(white)

(brown)

2A8054-01

Page 30

D. Bin Control Check

1. Bin Control 1 (infrared sensor) Check

IMPORTANT

Make sure CB S1 dip switch 7 is in the "ON" position. This allows the control board

to monitor BC1 (infrared sensor) along with BC2 (mechanical) backup bin control.

1) Turn off the power supply.

2) Remove the front panel, top panel, and control box cover.

3) Conrm that CB S1 dip switch 1, 2, 3 are in the proper position for your application.

See "III.B.2. BC1 (Infrared Sensor) Shutdown Delay (S1 dip switch 1, 2, 3)."

4) Conrm that BC1 is connected to CB K6 connector. Wipe down BC1 lens with a warm,

clean, damp cloth. If the bottom of the icemaker is not accessible in your application,

remove the thumbscrew securing the BC1 housing, then remove the housing from the

base. See Fig. 4.

5) Move the control switch to the "ICE" position, then move the power switch to the "ON"

position.

6) Turn on the power supply to start the automatic icemaking process. Check that BC1

green LED is on. The BC1 green LED conrms 20VDC power from CB to BC1 and

remains on constantly. Diagnosis: If the BC1 green LED is not on, conrm 20VDC

at CB K6 #1 (DBU) to CB K6 #3 (BR). If 20VDC is present and the BC1 green LED is

off, replace BC1. If not, see step "3) BC1 (infrared sensor) Power Supply," under "II.C.

Control Board Check.

7) Make sure CB "GM" LED is on. There is a delay of at least 30 sec. before the "GM" LED

turns on after power-up. After CB "GM" LED turns on, press CB "SERVICE" button to

bypass the 5-min. ice purge cycle. WARNING! Risk of electric shock. Care should be

taken not to touch live terminals.

BC1 (infrared sensor)

Connector

LEDs

Thumbscrew

Housing

Lens

(20VDC from

K6 connector on

control board)

Housing

LEDs

Lens

Fig. 4

30

Page 31

8) CB "GM" and "COMP" LEDs are on. Use an object to cover BC1 lens at the bottom of

the icemaker. If the bottom of the icemaker is not accessible in your application, remove

the thumbscrew securing BC1 housing, remove the housing from the base, then cover

BC1 lens. See Fig. 4. The yellow LED on BC1 turns on (ashing or steady). The yellow

LED ashes when ice is at the outer limit of its range and turns steady as ice nears.

After the yellow LED turns on (ashing or steady), BC1 shutdown delay timer starts.

See "III.B.2. BC1 (Infrared Sensor) Shutdown Delay (S1 dip switch 1, 2, 3)." Comp

(LLV/SLV on MLH model) should de-energize immediately after the shutdown delay

timer terminates. 5 min. later, GM and FM/FMR should de-energize.

Diagnosis: If BC1 yellow LED is not on after covering the lens, replace BC1. If the

appliance remains on after BC1 shutdown delay timer terminates and the 5-min. ice

purge timer terminates, replace CB. If BC1 fails to shut down the icemaker and the level

of ice activates BC2, the icemaker shuts down and a 9-beep alarm sounds. To reset,

move the power switch to the "OFF" position, and then back to the "ON" position.

9) Remove the object covering the lens. If you removed BC1 housing from the base,

replace it in its correct position, and secure it with the thumbscrew.

10) Move the power switch to the "OFF" position. Turn off the power supply, then proceed

to "II.D.2. Bin Control 2 (mechanical stand-alone or backup) Check."

Legend: BC1–bin control 1 (infrared sensor); BC2–bin control 2 (mechanical stand-alone

or backup); CB–control board; Comp–compressor; FM–fan motor; FMR–fan

motor-remote; GM–gear motor; LLV –liquid line valve;

SLV –suction line valve

31

Page 32

2. Bin Control (2) (mechanical stand-alone or backup) Check

When the actuator paddle is not engaged BC(2) is closed and the icemaker produces

ice.

a) Bin Control (Mechanical Stand-Alone)(F-1001M_H and F-1001M_J only):

With CB S1 dip switch 7 placed in the "OFF" position, BC is used as a stand-alone

bin control. The stand-alone application should only be used in standard ice storage

bin applications. WARNING! Do not place CB S1 dip switch 7 in the "ON"

position. On CB 2A8054-01, do not place dip switch 9 in the "OFF" position

when S1 dip switch 7 is in the "OFF" position. When ice lls the chute and

engages the actuator paddle, BC opens and dip switch 8 timer starts. Once dip

switch 8 timer terminates, CB shuts down the icemaker within 10 sec.

WARNING! On CB 2A8054-01, If dip switch 9 is in the "OFF" position, the shut

down delay is too long. This could lead to icemaker movement or ice overow.

b) Bin Control 2 (Mechanical Backup): With CB S1 dip switch 7 placed in the

"ON" position, BC2 is used as a backup bin control safety. When ice lls the chute

and engages the actuator paddle, BC2 opens and CB shuts down the icemaker

immediately and sounds a 9-beep alarm.

1) Make sure the power supply is off. Remove the front panel, top panel, and control box

cover.

2) Remove the spout-to-chute strap connecting the spout to the chute assembly.

See Fig. 5. Pull up the chute assembly slightly so that you can access the actuator

paddle located in the top of the chute.

Strap

Chute Assembly

Strap

Model Shown: F-1501MRH-C

Proximity Switch

Actuator Paddle

Spout

Fig. 5

3) Move the power switch to the "ON" position.

4) Turn on the power supply to start the automatic icemaking process.

5) Make sure CB "GM" LED is on. There is a delay of at least 30 sec. before "GM" LED

turns on after power-up. After "GM" LED turns on, press CB "SERVICE" button to

bypass the 5-min. compressor delay. WARNING! Risk of electric shock. Care should

be taken not to touch live terminals. The "COMP" LED turns on.

32

Page 33

6) Press the actuator paddle located in the top of the chute. Comp (LLV and SLV on MLH

model) and GM de-energize within 10 sec.

Diagnosis: If BC(2) does not open and the icemaker continues to make ice

(mechanical stand-alone or backup), CB fails to shutdown icemaker within 10 sec. or

go into alarm, check that the actuator paddle is engaged. Check for continuity across

BC(2) wires. If BC(2) contacts are found open and the icemaker continues to make

ice or CB fails to go into alarm (BC2), replace CB. If BC(2) is closed with the actuator

paddle engaged, replace BC(2).

WARNING! On CB 2A8054-01, If dip switch 9 is in the "OFF" position, the shut

down delay is too long. This could lead to icemaker movement or ice overow.

7) Move the power switch to the "OFF" position and turn off the power supply.

8) Replace the chute assembly and strap in their correct positions.

9) Move the power switch to the "ON" position.

10) Replace the control box cover, top panel, and front panel in their correct positions.

11) Turn on the power supply to start the automatic icemaking process.

Legend: BC1–bin control 1 (infrared sensor); BC(2)–bin control (2) (mechanical stand-alone

or backup); CB–control board; Comp–compressor; FM–fan motor; FMR–fan

motor-remote; GM–gear motor; LLV –liquid line valve; SLV –suction line valve

33

Page 34

E. Float Switch Check and Cleaning

1. Float Switch Check

A dual oat switch is used to determine that there is sufficient water in the reservoir

during ll and rell. CB monitors UFS to de-energize WV when UFS closes during ll and

rell. CB monitors LFS to energize WV when LFS opens during the freeze cycle (rell).

CB monitors the time between LFS opening and UFS closing (90-sec. low water safety).

CB also monitors the time between UFS closing and LFS opening (30-min. freeze timer).

No adjustment is required.

1) Remove the front panel and move the power switch to the "OFF" position. Move the

control switch to the "DRAIN" position.

2) Move the power switch to the "ON" position.

3) Allow the water to drain from the reservoir, then move the power switch to the "OFF"

position and the control switch to the "ICE" position.

4) Disconnect the molex plug from the control box and check continuity across FS wires.

(BK) to (R) for UFS and (BK) to (BU) for LFS. See Fig.6. With the water reservoir

empty, FS switches are open. If open, continue to step 5. If closed, follow the steps in

"II.E.2. Float Switch Cleaning." After cleaning the oats, check them again. Replace if

necessary.

5) Reconnect the molex plug on the control box.

6) Move the power switch to the "ON" position and let the water reservoir ll.

7) Once the reservoir is full and GM starts, move the power switch to the "OFF" position.

8) Disconnect the molex plug from the control box and check continuity across FS wires.

(BK) to (R) for UFS and (BK) to (BU) for LFS. They should be closed. Clean or replace if

necessary.

Red (R)

(upper oat switch)

Black (BK)

(common)

Blue (BU) (lower

oat switch)

Fig. 6

Magnet (towards top)

Upper Float (blue)

Spring Retainer Clip

Magnet (towards top)

Lower Float (white)

Plastic Retainer Clip

34

Page 35

2. Float Switch Cleaning

Depending on local water conditions, scale may build up on FS. Scale on FS can cause

the oats to stick. In this case, FS should be cleaned and checked.

1) Turn off the power supply.

2) Remove the oat switch assembly from the reservoir cover. See Fig. 7.

3) Wipe down FS assembly with a mixture of 1 part Hoshizaki "Scale Away" and 25 parts

warm water.

4) While not necessary, the oats can be removed from the shaft during cleaning. If you

remove them, note that the blue oat is on top. The oats must be installed with the

magnets inside them towards the top of the switch. See Fig. 6. Installing the oats

upside down will affect the timing of FS operation.

5) Rinse FS assembly thoroughly with clean water and replace in its original position.

Legend: CB–control board; FS–oat switch; GM–gear motor; LFS–lower oat switch;

UFS–upper oat switch; WV–inlet water valve

Fig. 7

Float Switch Assembly

Reservoir Cover

Reservoir

35

Page 36

F. Diagnostic Tables

Before consulting the diagnostic charts, check for correct installation, proper voltage per

appliance nameplate, and adequate water supply. Check control board using the steps in

"II.C. Control Board Check."

1. No Ice Production

No Ice Production - Possible Cause

Startup

1. Power Supply a) Off, blown fuse, or tripped breaker.

b) Loose connection.

c) Bad contacts.

d) Not within specications.

2. Water Supply a) Water supply off or pressure too low.

3. Power Switch

(Control Box)

4. Control Transformer a) Coil winding opened.

5. Fuse (Control Box) a)Blown.

6. BC1 (Infrared Sensor) a) No power or defective.

7. BC(2) (Mechanical

Stand-Alone or

Backup)

8. High-Pressure Switch a) Bad Contacts.

9. Control Switch a) "DRAIN" position. 2-beep alarm if in "DRAIN" position for more than 15 min.

1. Control Board a)No Power to inlet water valve.

2. Inlet Water Valve a) Screen or orice clogged.

3. Float Switch a) Float does not move freely.

4. Drain Water Valve a) Valve seat clogged and water leaking.

5. Hoses a) Disconnected.

a) "OFF" position.

b) Bad contacts.

a) Tripped with bin lled with ice.

(9-beep alarm when used in conjunction with BC1 (infrared sensor)

b) Switch stuck open.

c) Actuator paddle does not move freely.

b) Dirty air lter or condenser.

c) Ambient or condenser water temperature too warm.

d) Refrigerant overcharged.

e) Fan not operating (except water-cooled model).

f) Refrigerant line or component restricted.

g) Condenser water pressure too low or off (water-cooled model).

h) Water regulating valve set too high (water-cooled model).

b) Bad contacts.

Fill Cycle

b) No power to oat switch or not reading oat switch condition.

b) Coil winding opened.

b) Defective.

36

Page 37

Ice Purge Cycle

1. Control Board a)No power to gear motor.

b) No power to compressor control relay.

2. Gear Motor a) Blown fuse.

b) Internal protector open.

c) Defective.

Freeze Cycle

1. Compressor Control

Relay

2. Control Board a) Defective.

3. Start Relay a) Bad contacts.

4. Capacitor (start or run) a) Defective, weak.

5. Power Supply a) Not within specications.

6. Refrigerant Line a) Gas leaks.

7. Thermostatic

Expansion Valve

(TXV) (not adjustable)

8. Compressor a) Defective.

9. Liquid Line Valve

(MLH models)

10. Suction Line Valve

(MLH models)

11. Fan Motor

(if applicable)

12. Evaporator a) Dirty.

13. Headmaster (C.P.R.)

(remote air-cooled

model)

14. Water Supply Line

(water-cooled model)

15. Water Regulating

Valve

(water-cooled model)

16. Magnetic Contactor

(if applicable)

1 7. Drain Valve a)Dirty, leaking by.

18. Water System a) Water leaks.

a) No voltage from gear motor.

b) Defective.

b) Coil winding opened.

c) Loose connections.

b) Refrigerant line or component restricted.

a) Defective.

a) Defective.

a) Defective.

a) Compressor Control Relay/Magnetic Contactor defective.

b) Defective capacitor.

c) Defective.

d) Control board defective.

b) Damaged or defective.

a) Not operating properly and liquid line temperature too warm.

a) Condenser water pressure too low or off and high pressure control opens and

closes frequently.

a) Set too high.

a) Defective.

b) Defective.

37

Page 38

Rell

1. Float Switch a) Dirty/sticking.

b) Defective.

2. Inlet Water Valve a) Clogged or defective.

3. Water Supply a) Off.

4. Control Board a) No power to oat switch or not reading oat switch condition.

b) No power to inlet water valve.

Shutdown

1. BC1 (Infrared Sensor)

See "II.D. Bin Control

Check."

2. BC(2) (Mechanical

Stand-Alone or

Backup)

See "II.D. Bin Control

Check."

3. Control Board a) Control board dip switches set incorrectly.

1. Drain Valve a) Screen or orice clogged.

2. Control Board a) Defective.

a) Dirty lens.

b) Defective.

a) Actuator paddle does not move freely.

b) Defective.

b) In alarm.

c) Defective.

Drain Cycle

b) Defective.

38

Page 39

III. Controls and Adjustments

A. Control Board

• A Hoshizaki exclusive control board is employed.

• All models are pretested and factory adjusted.

• For a control board check procedure, see "II.C. Control Board Check."

NOTICE

• Fragile, handle very carefully.