Page 1

Hoshizaki America, Inc.

Hoshizaki

Modular Flaker

“A Superior Degree

of Reliability”

www.hoshizaki.com

Models

F-450MAH(-C)

SERVICE MANUAL

Issued: 8-25-2009

Page 2

IMPORTANT

Only qualified service technicians should install, service, and maintain the

icemaker. No service or maintenance should be undertaken until the technician

has thoroughly read this Service Manual. Failure to service and maintain the

equipment in accordance with this manual may adversely affect safety,

performance, component life, and warranty coverage.

Hoshizaki provides this manual primarily to assist qualified service technicians in the

service and maintenance of the icemaker.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call, write, or send an e-mail message to the Hoshizaki Technical

Support Department for assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City, GA 30269

Attn: Hoshizaki Technical Support Department

Phone: 1-800-233-1940 Technical Support

(770) 487-2331

Fax: 1-800-843-1056

(770) 487-3360

E-mail: techsupport@hoshizaki.com

Web Site: www.hoshizaki.com

NOTE: To expedite assistance, all correspondence/communication MUST include the

following information:

• Model Number

• Serial Number

• Complete and detailed explanation of the problem.

2

Page 3

Please review this manual. It should be read carefully before the icemaker is serviced or

maintenance operations are performed. Only qualified service technicians should service and

maintain the icemaker. This manual should be made available to the technician prior to service

or maintenance.

CONTENTS

I. Specifications .................................................................................................................... 4

1. F-450MAH .................................................................................................................... 4

2. F-450MAH-C ................................................................................................................ 5

II. General Information .......................................................................................................... 6

1. Construction .................................................................................................................6

2. Control Box Layout ....................................................................................................... 7

3. Timer Board ..................................................................................................................8

[a] Solid-State Control ................................................................................................ 8

[b] Timer Board ........................................................................................................... 8

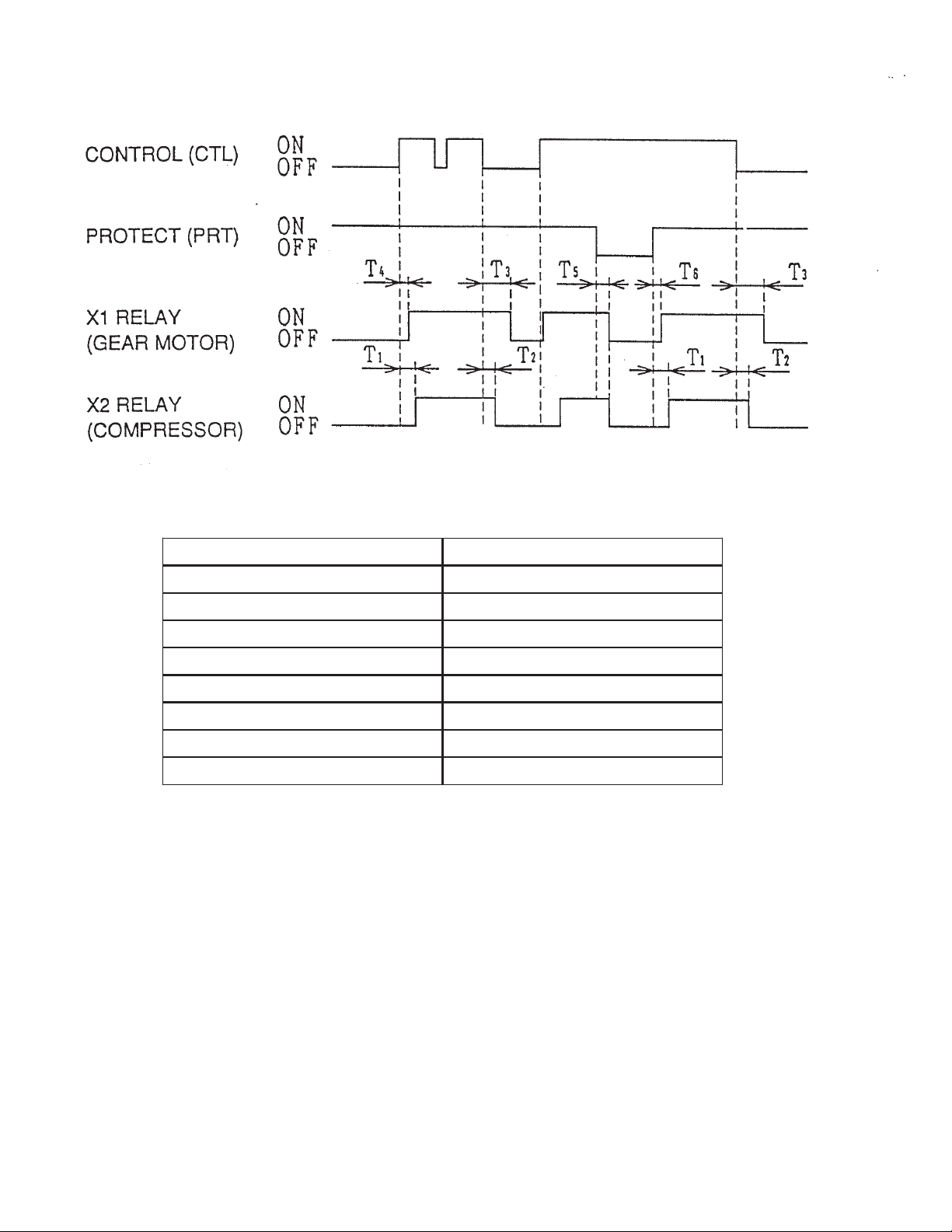

[c] Sequence .............................................................................................................. 9

III. Technical Information ..................................................................................................... 12

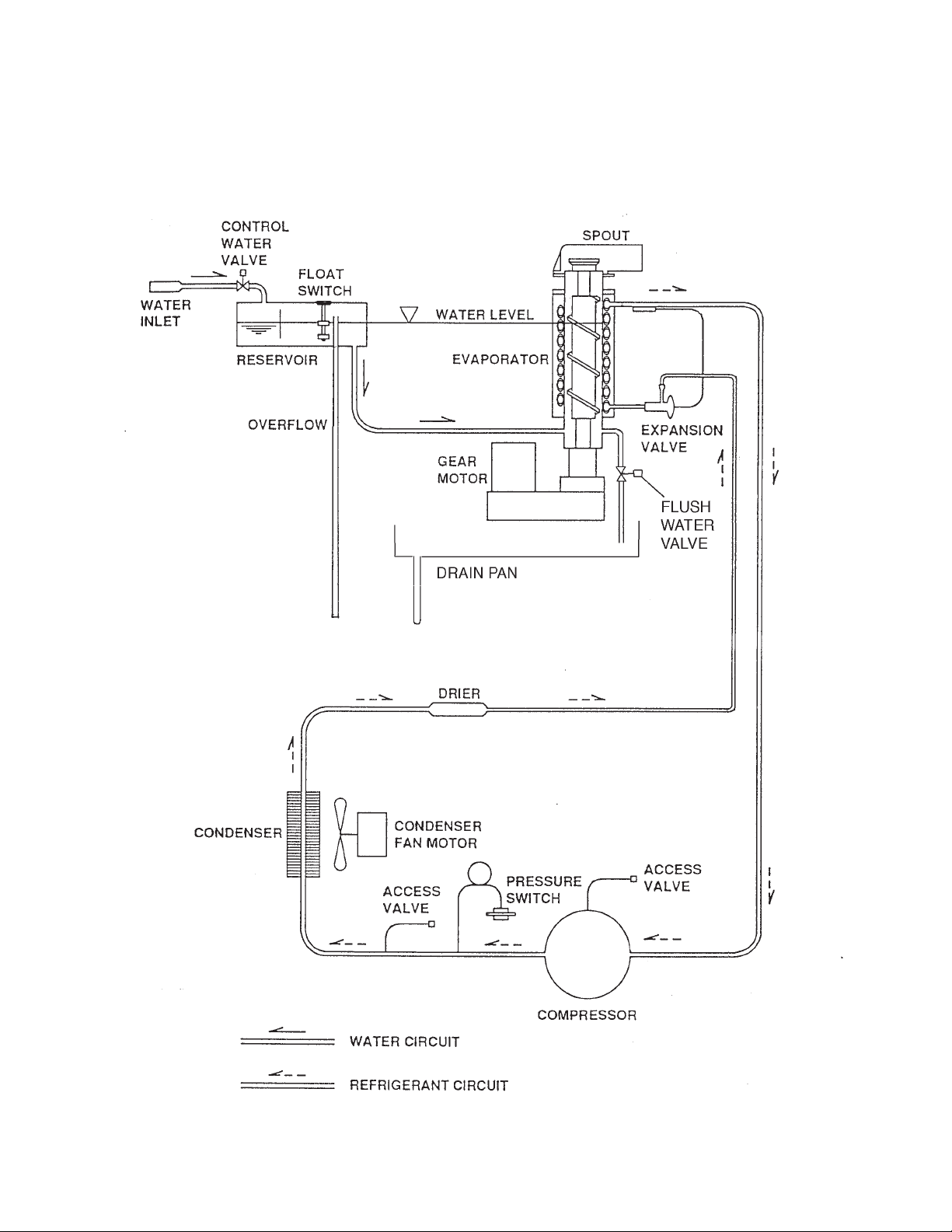

1. Water Circuit and Refrigeration Circuit........................................................................ 12

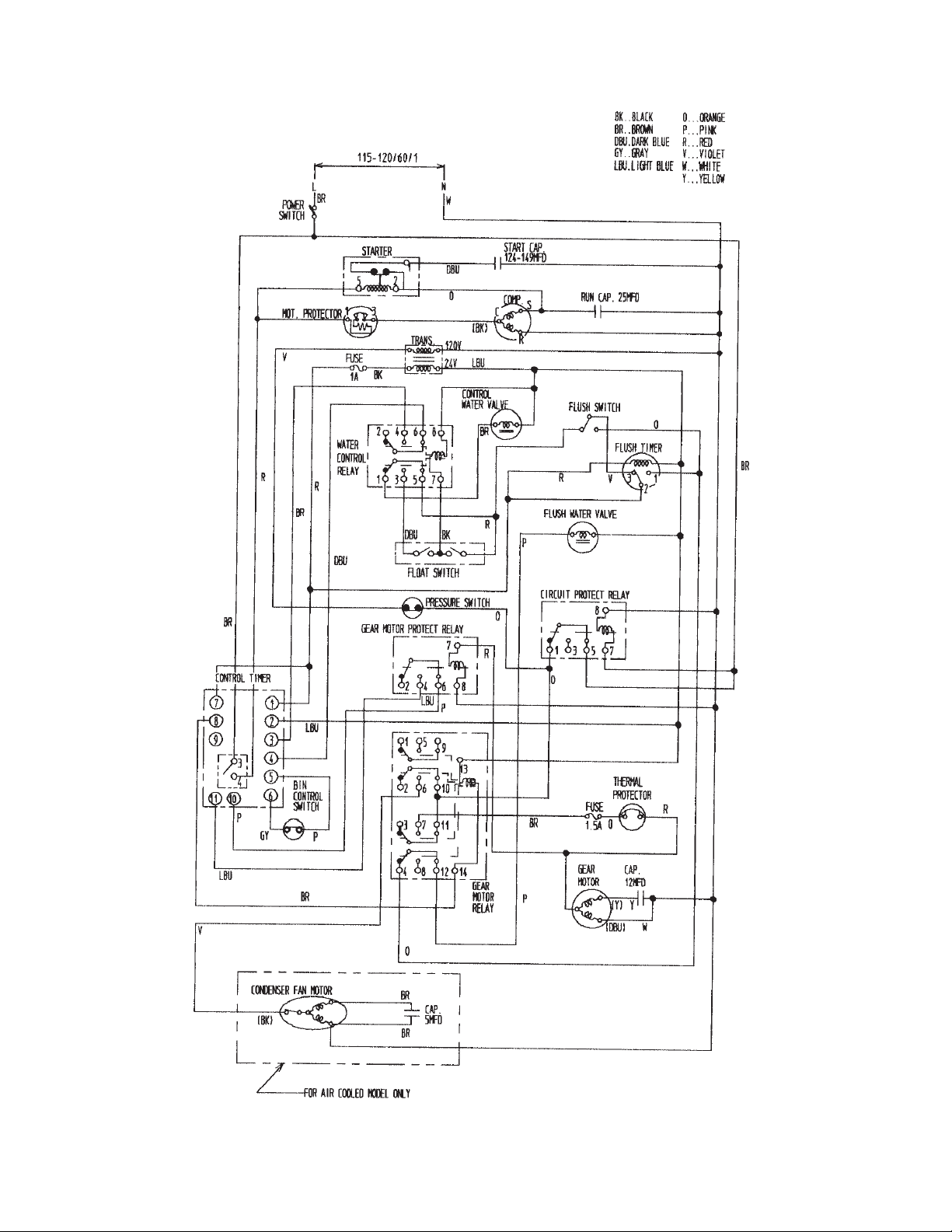

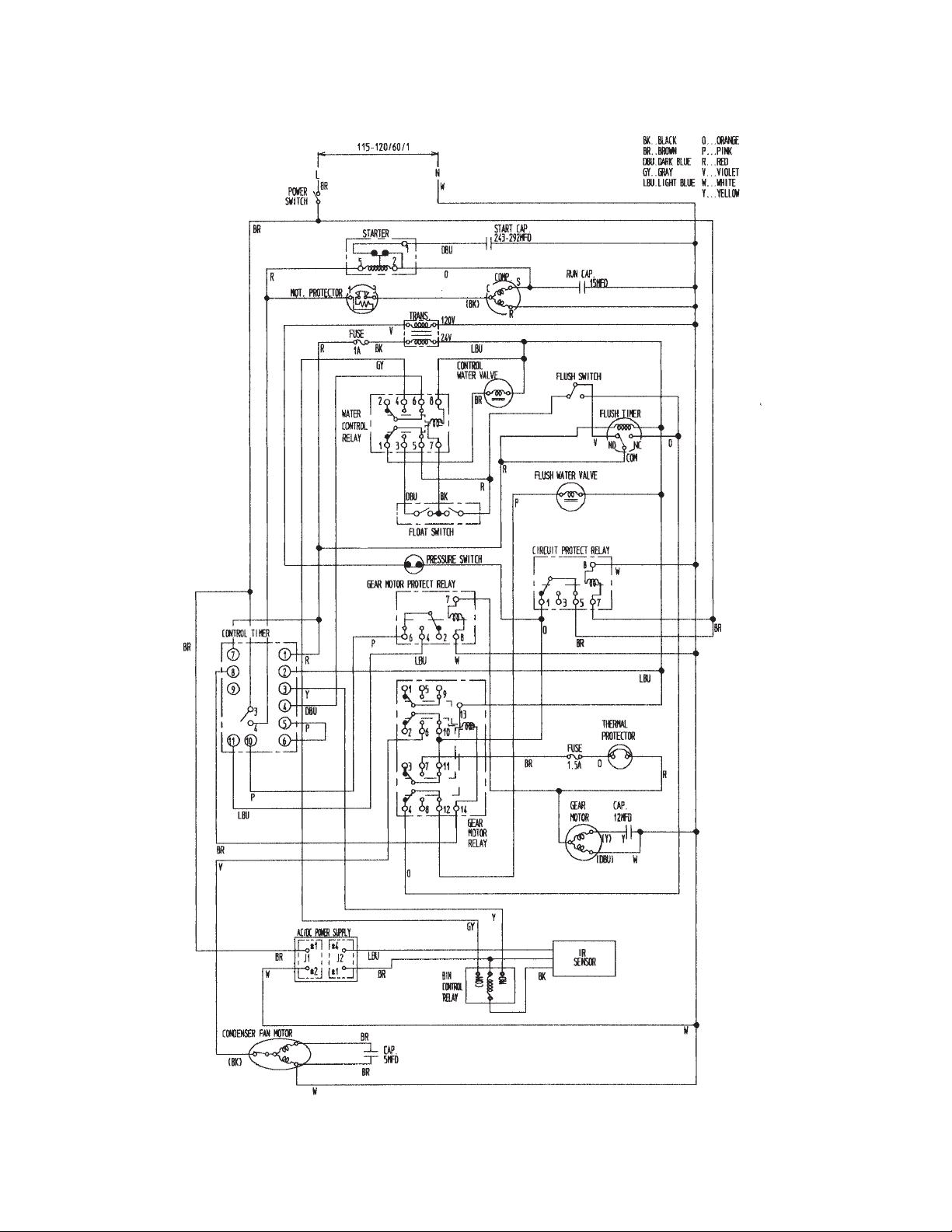

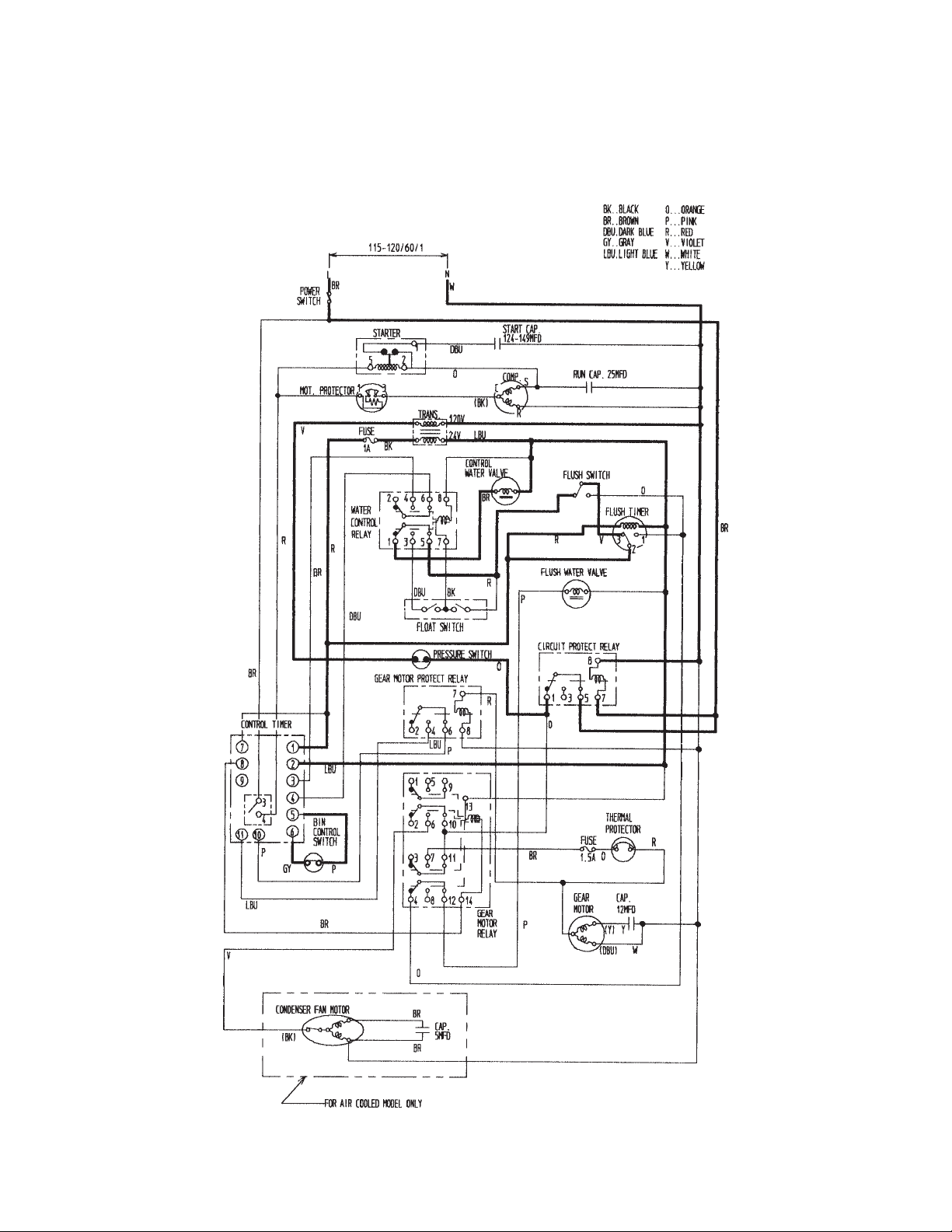

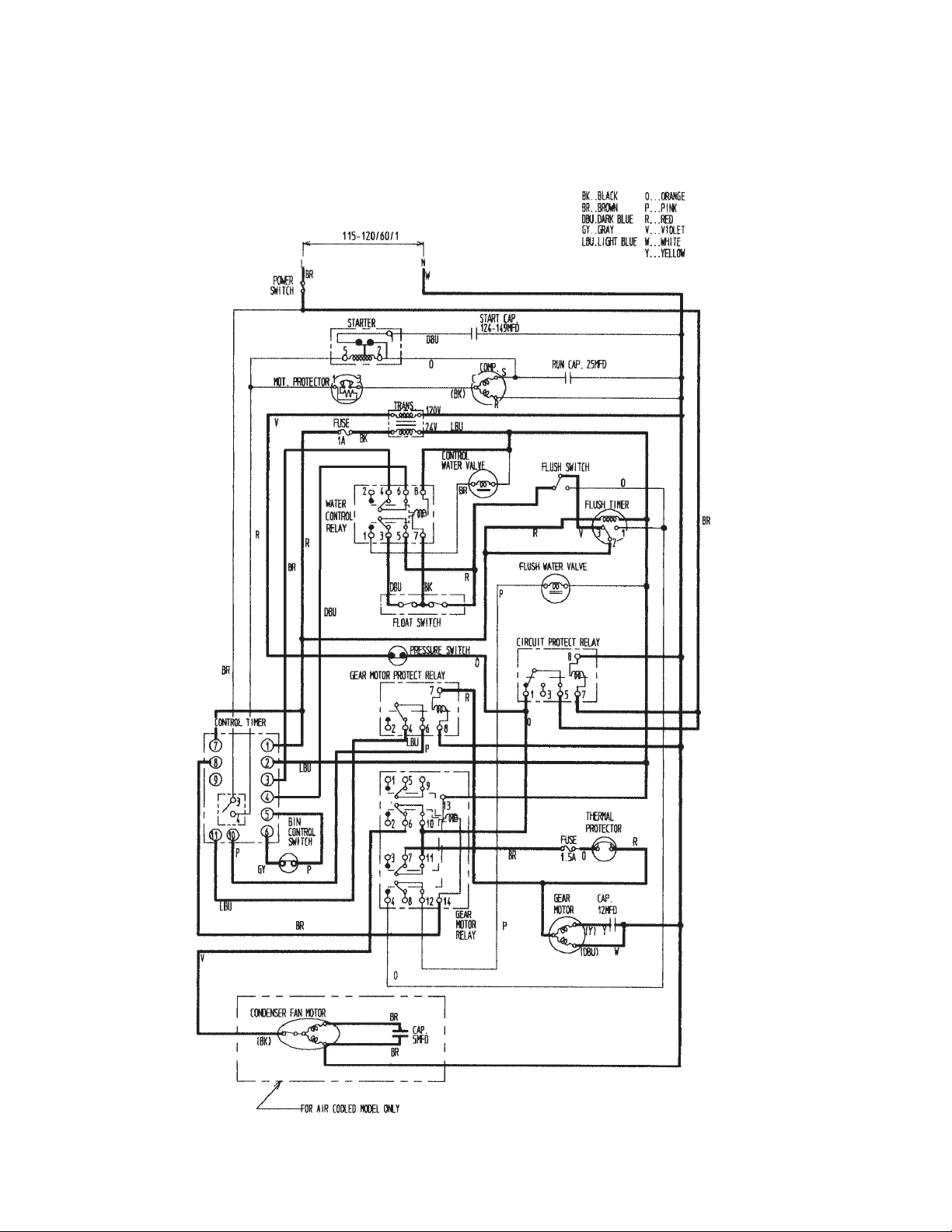

2. Wiring Diagram ........................................................................................................... 13

[a] F-450MAH ........................................................................................................... 13

[b] F-450MAH-C ....................................................................................................... 14

3. Sequence of Electrical Circuit .................................................................................... 15

4. Timing Chart ............................................................................................................... 25

5. Performance Data ....................................................................................................... 28

[a] F-450MAH ........................................................................................................... 28

[b] F-450MAH-C ....................................................................................................... 29

IV. Service Diagnosis.......................................................................................................... 30

1. No Ice Production ....................................................................................................... 30

2. Low Ice Production ..................................................................................................... 33

3. Other ........................................................................................................................... 34

V. Removal and Replacement of Components ................................................................... 35

1. Service for Refrigerant Lines ...................................................................................... 35

[a] Refrigerant Recovery........................................................................................... 35

[b] Evacuation and Recharge [R-404A] .................................................................... 35

2. Brazing ....................................................................................................................... 36

3. Removal and Replacement of Compressor ................................................................ 37

4. Removal and Replacement of Drier ........................................................................... 38

5. Removal and Replacement of Expansion Valve......................................................... 39

6. Removal and Replacement of Evaporator Assembly ................................................ 40

7. Removal and Replacement of Fan Motor ................................................................... 42

8. Removal and Replacement of Control Water Valve .................................................... 42

9. Removal and Replacement of Flush Water Valve ....................................................... 43

VI. Cleaning and Maintenance ........................................................................................... 44

1. Preparing the Icemaker for Long Storage ................................................................... 44

2. Cleaning and Sanitizing Instructions .......................................................................... 45

[a] Cleaning Solution ................................................................................................ 45

[b] Cleaning Procedure ............................................................................................ 46

[c] Sanitizing Solution............................................................................................... 47

[d] Sanitizing Procedure - Initial................................................................................ 47

[e] Sanitizing Procedure - Final ................................................................................ 48

3. Maintenance Instructions ............................................................................................ 50

3

Page 4

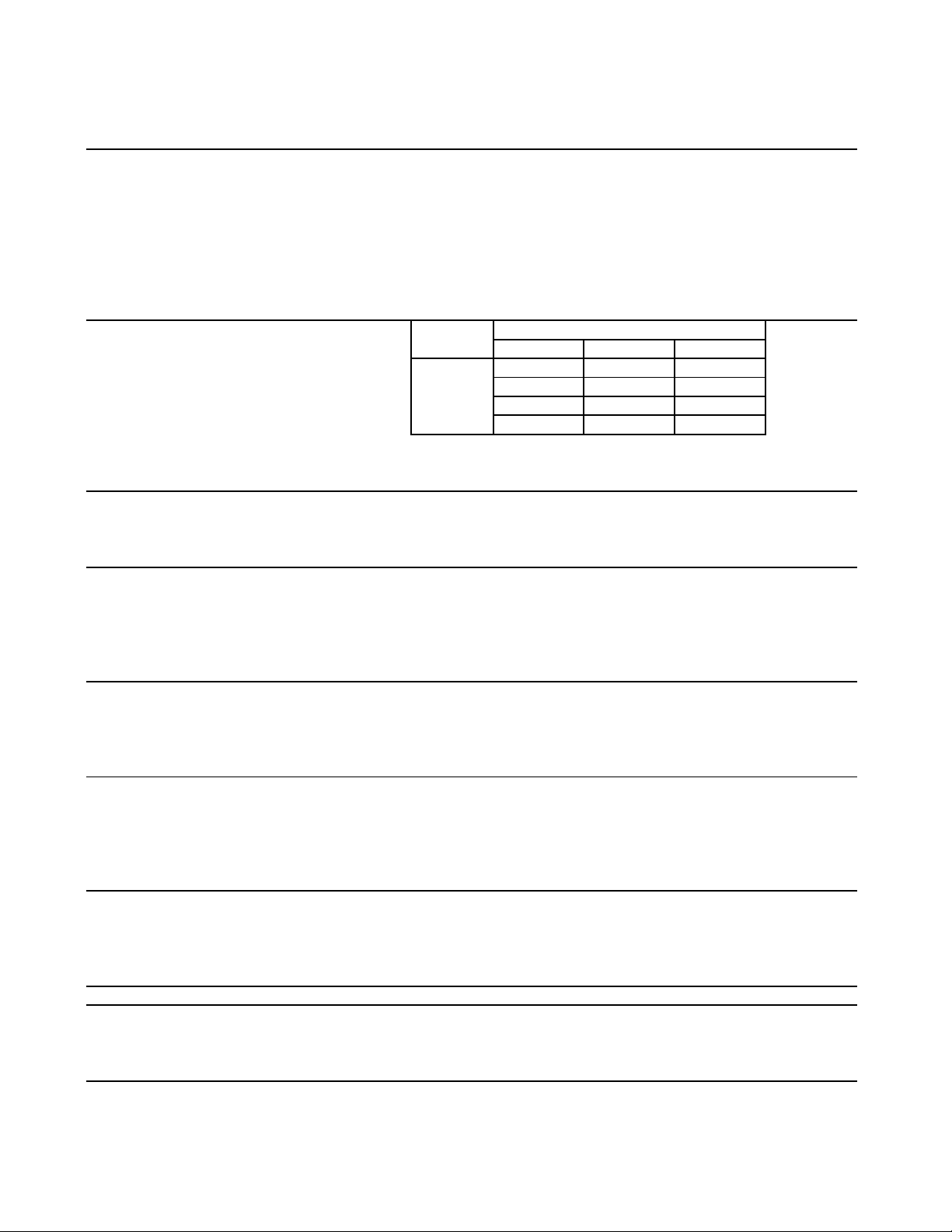

I. Specifications

1. F-450MAH

AC SUPPLY VOLTAGE 115/60/1

COMPRESSOR 120 V 8.5 RLA 51 LRA

GEAR MOTOR 120 V 1.6 FLA 1/6 HP

FAN MOTOR 115 V 0.85FLA 50W

OTHER 120 V 0.03A

MAXIMUM FUSE SIZE 20 A

MAX. HACR BREAKER (USA ONLY) 20 A

MAX. CIRC. BREAKER (CANADA ONLY) 20 A

MINIMUM CIRCUIT AMPACITY 20 A

APPROXIMATE ICE PRODUCTION Ambient WATER TEMP. (°F)

PER 24 HR. Temp.(°F) 50 70 90

lbs./day ( kg/day ) 70 *476 (216) 456 (207) 435 (197)

Reference without *marks 80 416 (189) 397 (180) 379 (172)

90 362 (164) *355 (161) 330 (150)

100 315 (143) 301 (137) *282 (128)

SHAPE OF ICE Flake

ICE QUALITY Approx. 70%, Ice (90/70°F, Conductivity 200 µs/cm)

APPROXIMATE STORAGE CAPACITY N/A

ELECTRIC & WATER CONSUMPTION 90/70°F 70/50°F

ELECTRIC W (kWH/100 lbs.) 915 (6.2) 858 (4.3)

POTABLE WATER 43 (12) 57 (12)

gal./24HR (gal./100 lbs.)

EXTERIOR DIMENSIONS (WxDxH) 21"-7/8" x 27-3/8" x 21-61/64" (556 x 696 x 557.7mm)

EXTERIOR FINISH Stainless Steel, Galvanized Steel (Rear)

WEIGHT Net 150 lbs. ( 68 kg ), Shipping 175 lbs. ( 80 kg )

CONNECTIONS - ELECTRIC Permanent - Connection

- WATER SUPPLY Inlet 1/2" FPT

- DRAIN Outlet 3/4" FPT

ICE MAKING SYSTEM Auger type

HARVESTING SYSTEM Direct Driven Auger ( 1/6 HP Gear Motor )

ICE MAKING WATER CONTROL Float Switch

COOLING WATER CONTROL N/A

BIN CONTROL SYSTEM Mechanical Bin Control ( Proximity Sw. )

COMPRESSOR Hermetic, Model RS43C1E-CAA-219

CONDENSER Air-cooled, Fin and tube type

EVAPORATOR Copper Tube on Cylinder

REFRIGERANT CONTROL Thermostatic Expansion Valve

REFRIGERANT CHARGE R-404A, 1 lb. (455 g)

DESIGN PRESSURE High 427 PSIG, Low 230 PSIG

P.C. BOARD CIRCUIT PROTECTION High Voltage Cut-off Relay

COMPRESSOR PROTECTION Internal Protector

GEAR MOTOR PROTECTION Manual reset Circuit Breaker or Fuse

REFRIGERANT CIRCUIT PROTECTION Auto-reset High Pressure Control Switch

LOW WATER PROTECTION Float Switch and Timer

ACCESSORIES - REQUIRED Ice Storage Bin

OPERATING CONDITIONS VOLTAGE RANGE 104 - 127 V

AMBIENT TEMP. 45 - 100° F

WATER SUPPLY TEMP. 45 - 90° F

WATER SUPPLY PRESSURE 10 - 113 PSIG

We reserve the right to make changes in specifications and design without prior notice.

4

Page 5

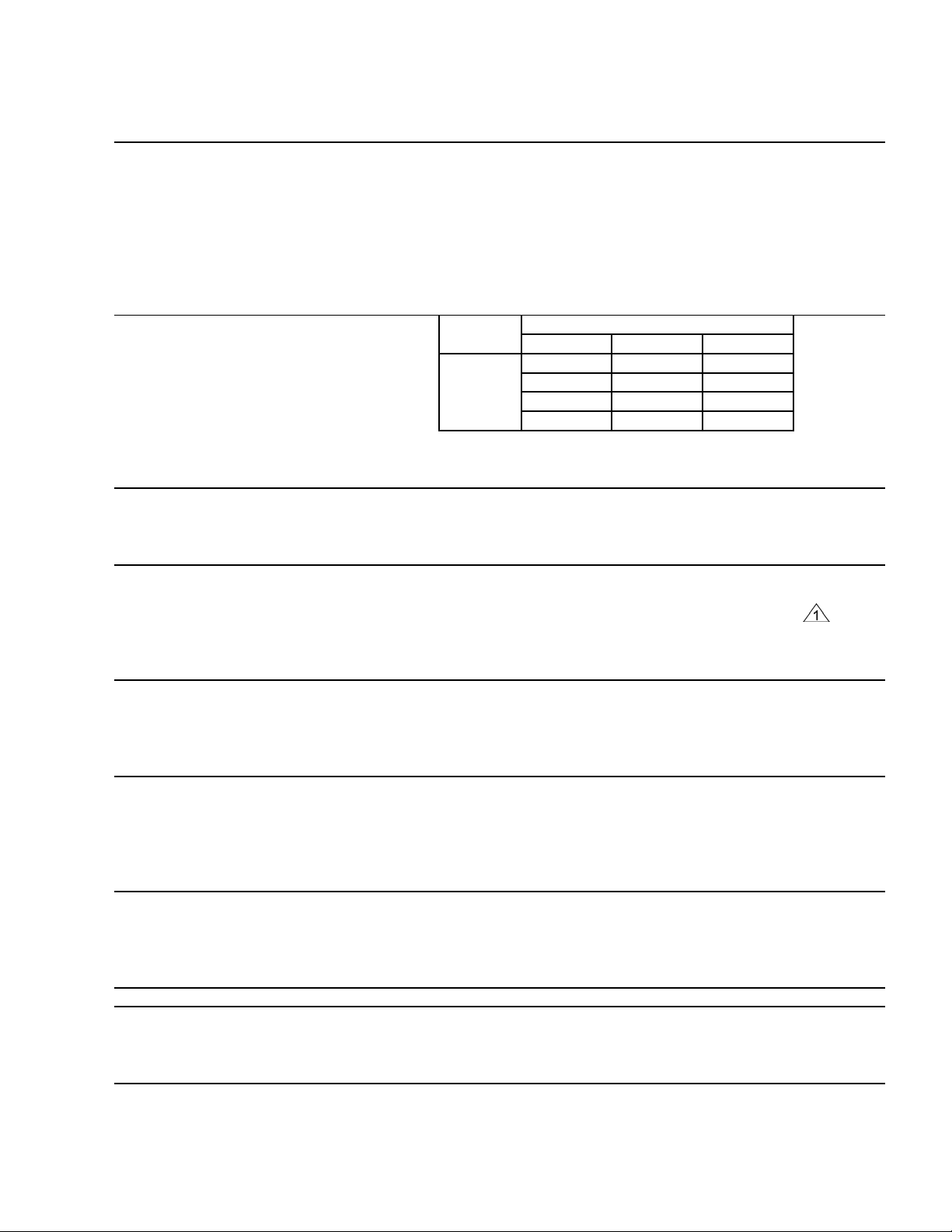

2. F-450MAH-C

AC SUPPLY VOLTAGE 115/60/1

COMPRESSOR 120 V 8.5 RLA 51 LRA

GEAR MOTOR 120 V 1.6 FLA 1/6 HP

FAN MOTOR 115 V 0.85FLA 50W

OTHER 120 V 0.03A

MAXIMUM FUSE SIZE 20 A

MAX. HACR BREAKER (USA ONLY) 20 A

MAX. CIRC. BREAKER (CANADA ONLY) 20 A

MINIMUM CIRCUIT AMPACITY 20 A

APPROXIMATE ICE PRODUCTION Ambient WATER TEMP. (°F)

PER 24 HR. Temp.(°F) 50 70 90

lbs./day ( kg/day ) 70 *426 (193) 407 (185) 387 (176)

Reference without *marks 80 368 (167) 350 (159) 333 (151)

90 317 (144) *310 (141) 287 (130)

100 273 (124) 260 (118) *244 (111)

SHAPE OF ICE Cubelet

ICE QUALITY Approx. 80%, Ice (90/70°F, Conductivity 200 µs/cm)

APPROXIMATE STORAGE CAPACITY N/A

ELECTRIC & WATER CONSUMPTION 90/70°F 70/50°F

ELECTRIC W (kWH/100 lbs.) 956 (7.4) 880 (5.0)

POTABLE WATER 37 (12) 51 (12)

gal./24HR (gal./100 lbs.)

EXTERIOR DIMENSIONS (WxDxH) 21"-7/8" x 27-3/8" x 21-61/64" (556 x 696 x 557.7mm)

EXTERIOR FINISH Stainless Steel, Galvanized Steel (Rear)

WEIGHT Net 150 lbs. ( 68 kg ), Shipping 175 lbs. ( 80 kg )

CONNECTIONS - ELECTRIC Permanent - Connection

- WATER SUPPLY Inlet 1/2" FPT

- DRAIN Outlet 3/4" FPT

ICE MAKING SYSTEM Auger type

HARVESTING SYSTEM Direct Driven Auger ( 1/6 HP Gear Motor )

ICE MAKING WATER CONTROL Float Switch

COOLING WATER CONTROL N/A

BIN CONTROL SYSTEM Infrared Sensor

COMPRESSOR Hermetic, Model RS43C1E-CAA-219

CONDENSER Air-cooled, Fin and tube type

EVAPORATOR Copper Tube on Cylinder

REFRIGERANT CONTROL Thermostatic Expansion Valve

REFRIGERANT CHARGE R-404A, 1 lb. (455 g)

DESIGN PRESSURE High 427 PSIG, Low 230 PSIG

P.C. BOARD CIRCUIT PROTECTION High Voltage Cut-off Relay

COMPRESSOR PROTECTION Internal Protector

GEAR MOTOR PROTECTION Manual reset Circuit Breaker or Fuse

REFRIGERANT CIRCUIT PROTECTION Auto-reset High Pressure Control Switch

LOW WATER PROTECTION Float Switch and Timer

ACCESSORIES - REQUIRED Ice Storage Bin

OPERATING CONDITIONS VOLTAGE RANGE 104 - 127 V

AMBIENT TEMP. 45 - 100° F

WATER SUPPLY TEMP. 45 - 90° F

WATER SUPPLY PRESSURE 10 - 113 PSIG

We reserve the right to make changes in specifications and design without prior notice.

5

Page 6

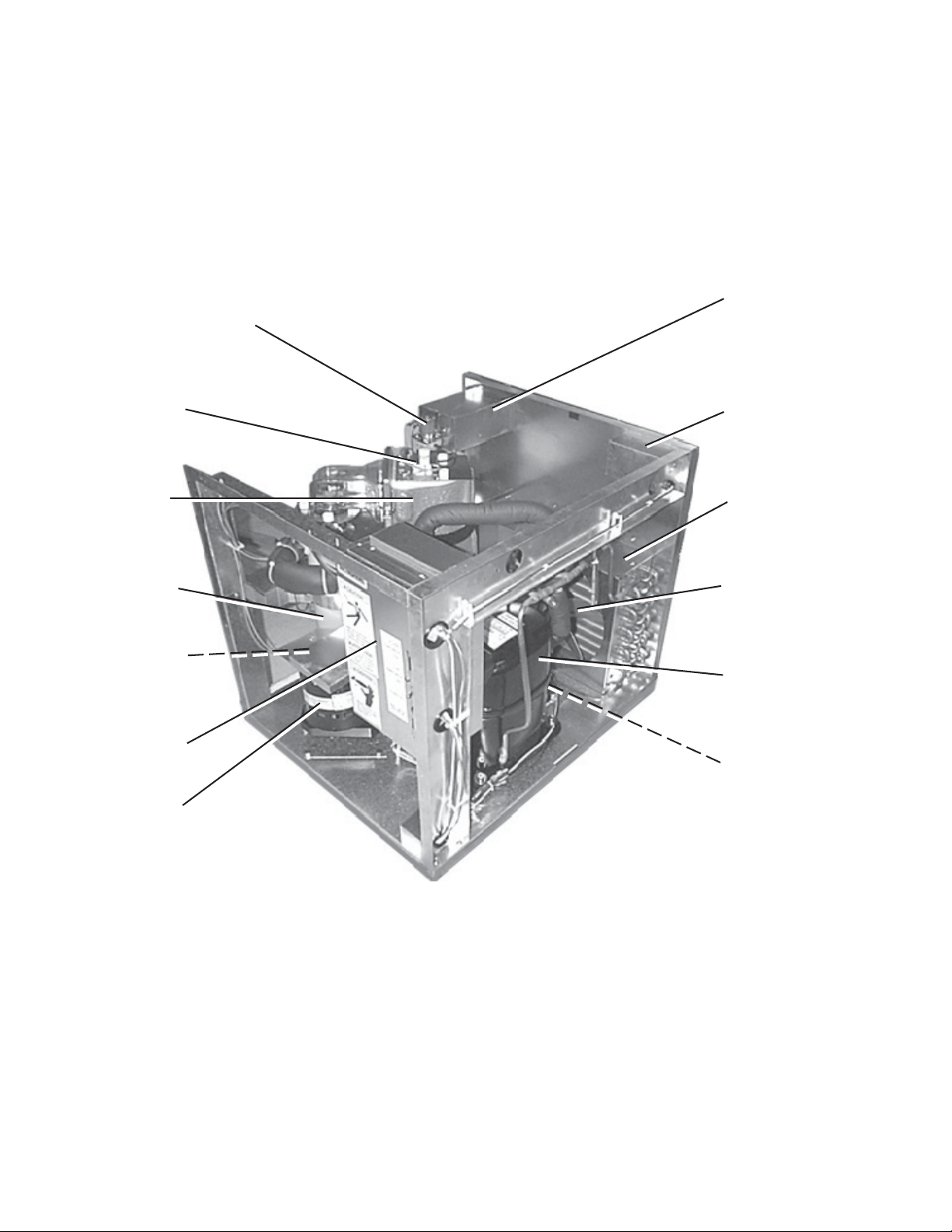

II. General Information

1. Construction

Control Water Valve

Water Supply

Inlet

Bin Control

Ice Chute

Evaporator

Flush Water

Valve

Control Box

Gear Motor

Junction Box

Condenser

Fan Motor

Compressor

Drier

6

Page 7

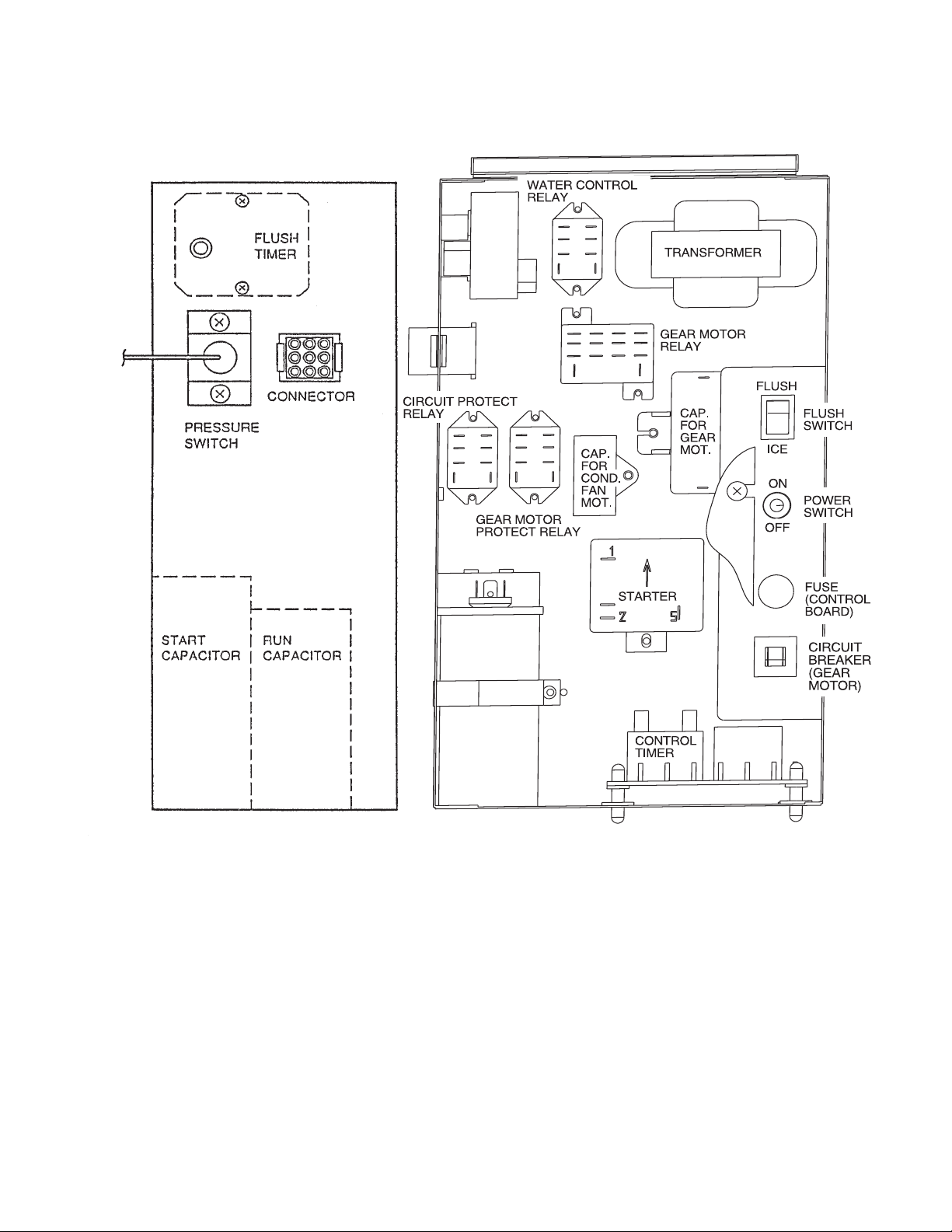

2. Control Box Layout

Note: The above component names are identical with the wiring label, but not with

the parts list.

7

Page 8

3. Timer Board

[a] Solid-State Control

1) A HOSHIZAKI exclusive solid-state control is employed in the self-contained flaker

icemakers.

2) A printed circuit board (hereafter called “timer board”) includes a stable and high

quality control system.

3) All models are pre-tested and factory-adjusted.

[b] Timer Board

CAUTION

1. Fragile, handle very carefully.

2. A timer board contains CMOS (Complementary Metal-Oxide Semiconductor) integrated circuits, which are susceptible to failure due to static

discharge. It is especially important to use an anti-static wrist strap when

handling or replacing the board.

3. Do not touch the electronic devices on the board or the back of the

board to prevent damage to the board.

4. Do not change wiring and connections. Especially, never misconnect

terminals.

5. Do not fix the electronic devices or parts on the board in the field. Always

replace the whole board assembly when it goes bad.

The icemaker is controlled by the timer board for the following purposes:

1) To prevent the gear motor and the compressor from starting or stopping

simultaneously.

2) To reduce remaining ice in the refrigeration casing.

3) To protect the unit in case of low water and low water pressure.

4) To protect the unit in case the bin control causes chattering.

8

Page 9

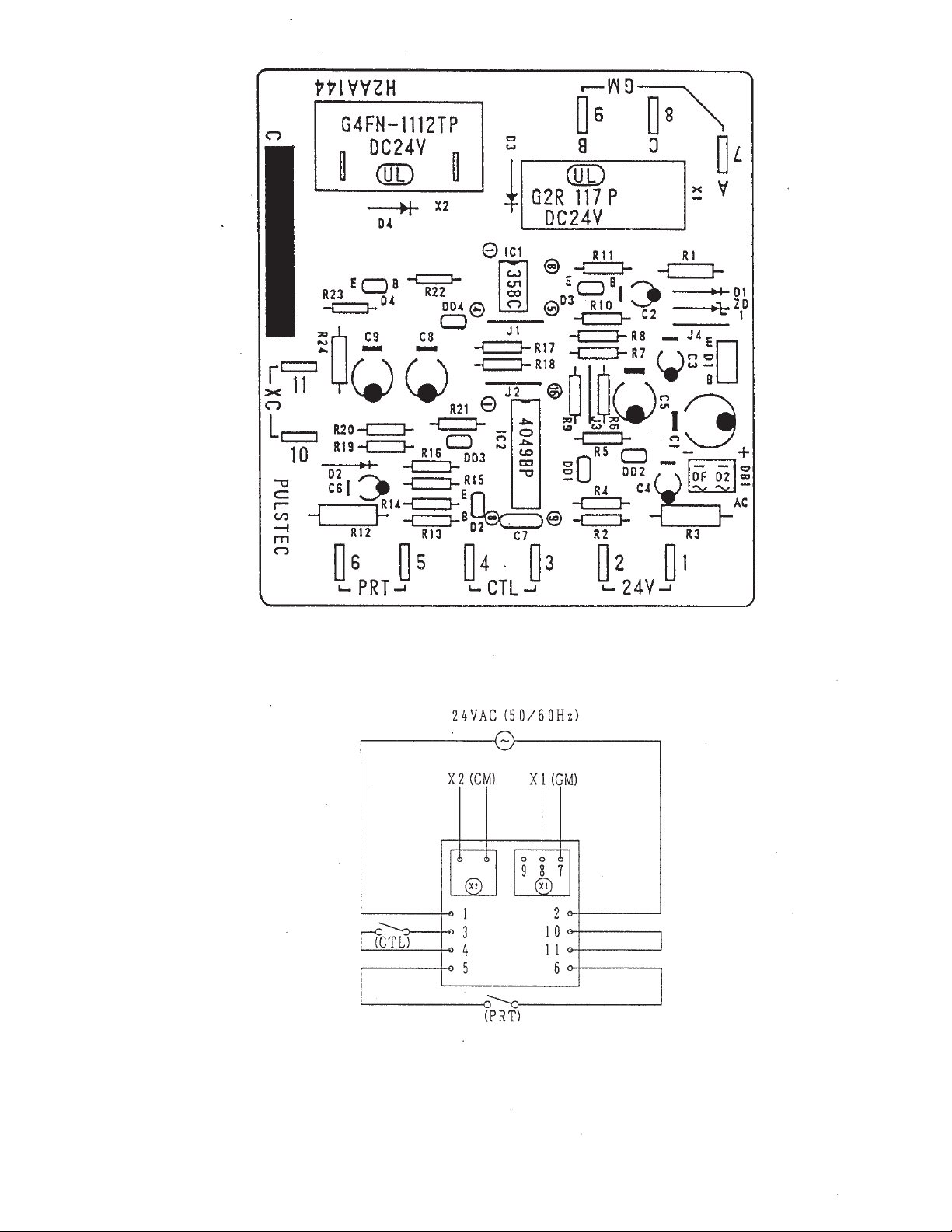

[c] Sequence

Fig. 1

Fig. 2

9

Page 10

EDOCTRAP10-503734

LEDOM10C441AA2H

GNITARzH06/05CAV42

1T.ces51±06

2T.ces22±09

3T.ces54±051

4Tsselro.ces1

5T%07±.ces7.6

6T%07±.ces7.6

Fig. 3

10

Page 11

Functions of Terminals

1) Terminals 1, 2

Power supply AC 24V.

2) Terminals 3, 4

Control X1 (GM) and X2 (CM) Relays.

When closed, energize X1 (GM) in 1 sec. and X2 (CM) in 60 sec.

When opened, de-energize X

1 (GM) in 150 sec. and X2 (CM) in 90 sec.

3) Terminals 5, 6

Control X

1 (GM) and X2 (CM) Relays.

When opened, de-energize X1 (GM) and X2 (CM) immediately.

When closed again, energize X1 (GM) in 1 sec. and X2 (CM) in 60 sec.

4) Terminals 7, 8, 9

X1 (GM) contacts.

8 is a movable contact, 7 is a make contact, and 9 is a break contact.

5) Terminals 10, 11

Control X2 (CM) Relays.

When opened, de-energize X2 (CM) immediately.

When closed, energize X2 (CM) immediately.

Note: 1. X2 Relay is a single pole, normally open relay, and its terminals are mounted

on the relay itself.

2. The above operation times are median. See Fig. 3 for details.

11

Page 12

III. Technical Information

1. Water Circuit and Refrigeration Circuit

12

Page 13

2. Wiring Diagram

[a] F-450MAH

13

Page 14

[b] F-450MAH-C

14

Page 15

3. Sequence of Electrical Circuit

[a] When power switch is moved to “ON” position and flush switch to “ICE” position,

water starts to be supplied to reservoir.

15

Page 16

[b] When reservoir has been filled, gear motor starts immediately.

16

Page 17

[c] Compressor starts about 60 sec. after gear motor starts.

17

Page 18

[d] Bin control operates, and about 6 sec. later, compressor and gear motor stop

simultaneously.

18

Page 19

[e] Low water (except water-cooled model).

19

Page 20

[f] When flush switch is moved to “FLUSH” position, flush water valve opens and

flushes reservoir and evaporator.

20

Page 21

[g] When flush timer operates (for 21 min. every 12 hours), flush water valve opens

and flushes reservoir and evaporator.

21

Page 22

[h] When 208-230V are supplied to circuit protect relay, it protects the circuit from being

miswired. If the power supply is properly connected, the contact of circuit protect

relay does not move even when the coil is energized.

22

Page 23

[i] When pressure switch opens, power supply to the control board is cut off causing the

compressor and gear motor to turn off immediately.

23

Page 24

[j] When input voltage is too low (less than 70%) gear motor fuse (1.5A) is blown

causing compressor and gear motor to turn off immediately.

24

Page 25

4. Timing Chart

1. CIRCUIT PROTECT

RELAY

2. WATER LEVEL

ON

OFF

UPPER

LOWER

BOTTOM

Miswiring. Circuit Protect Relay operates.

Proper wiring. The unit starts.

BIN CONTROL

OFF ON

UPPER

3. FLOAT

SWITCH

LOWER

4. WATER CONTROL

RELAY

5. CONTROL WATER

VALV E

6. FLUSH TIMER

7. FLUSH SWITCH

8. FLUSH WATER

VALV E

ON

OFF

ON

OFF

ON

OFF

ON

OFF

1 - 2

2 - 3

FLUSH

ICE

ON

OFF

9. BIN CONTROL

10. GEAR MOTOR

RELAY

11. GEAR MOTOR

12. FAN MOTOR

13. COMPRESSOR

14. PRESSURE

SWITCH

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

1 sec

60 sec

6 sec 1 sec

60 sec

25

Page 26

LOW WATER

FLUSH TIMER

1. CIRCUIT PROTECT

RELAY

2. WATER LEVEL

UPPER

3. FLOAT

SWITCH

LOWER

4. WATER CONTROL

RELAY

5. CONTROL WATER

VALV E

6. FLUSH TIMER

7. FLUSH SWITCH

ON

OFF

UPPER

LOWER

BOTTOM

ON

OFF

ON

OFF

ON

OFF

ON

OFF

1 - 2

2 - 3

FLUSH

ICE

21 min every 12 hr

8. FLUSH WATER

VALV E

9. BIN CONTROL

10. GEAR MOTOR

RELAY

11. GEAR MOTOR

12. FAN MOTOR

13. COMPRESSOR

14. PRESSURE

SWITCH

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

150 sec

90 sec 60 sec 90 sec 60 sec

1 sec

150 sec

1 sec

26

Page 27

FLUSH

FLUSH SWITCH PRESSURE SWITCH

ICE

OFF ON

1. CIRCUIT PROTECT

RELAY

2. WATER LEVEL

UPPER

3. FLOAT

SWITCH

LOWER

4. WATER CONTROL

RELAY

5. CONTROL WATER

VALV E

6. FLUSH TIMER

ON

OFF

UPPER

LOWER

BOTTOM

ON

OFF

ON

OFF

ON

OFF

ON

OFF

1 - 2

2 - 3

7. FLUSH SWITCH

8. FLUSH WATER

VALV E

9. BIN CONTROL

10. GEAR MOTOR

RELAY

11. GEAR MOTOR

12. FAN MOTOR

13. COMPRESSOR

FLUSH

ICE

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

150 sec

90 sec 60 sec

1 sec

1 sec

60 sec

14. PRESSURE

SWITCH

ON

OFF

27

Page 28

5. Performance Data

[a] F-450MAH

APPROXIMATE Ambient

ICE PRODUCTION Temp. (°F)

PER 24 HR. 70 484 220

80 424 192 406 184 389 176

90 372 169 362 164 341 155

lbs./day kg/day

APPROXIMATE ELECTRIC 70 879 -- 885 -- 890 -CONSUMPTION 80 896 -- 901 -- 907 --

watts 100 937 -- 947 -- 956 -APPROXIMATE WATER 70 0 0

CONSUMPTION PER 24 HR. 80 53 201 51 192 49 184

gal./day l/day

EVAPORATOR OUTLET TEMP 70 3 -16 3 -16 3 -16

°F °C

HEAD PRESSURE 70 225 15.8 225 15.8 225 15.8

PSIG kg/cm²G

SUCTION PRESSURE 70 28 2.0 28 2.0 28 2.0

PSIG kg/cm²G

TOTAL HEAT OF REJECTION 4724 BTU/h (AT 90°F /WT 70°F)

100 327 148 313 142 294 133

90 912 -- 918 -- 928 --

90 47 176 45 169 43 164

100 41 155 39 148 38 142

80 3 -16 7 -14 7 -14

90 7 -14 7 -14 9 -13

100 9 -13 9 -13 9 -13

80 256 18.0 256 18.0 256 18.0

90 286 20.1 286 20.1 286 20.1

100 324 22.8 324 22.8 324 22.8

80 31 2.1 31 2.1 31 2.1

90 33 2.3 33 2.3 33 2.3

100 37 2.6 37 2.6 37 2.6

50 70 90

Water Temp. (°F)

462 209 442 201

58 220 55 209

We reserve the right to make changes in specifications and design without prior notice.

28

Page 29

[b] F-450MAH-C

APPROXIMATE Ambient

ICE PRODUCTION Temp. (°F)

PER 24 HR. 70 430 195

80 380 170 365 165 350 160

90 135 150 325 150 310 140

lbs./day kg/day

APPROXIMATE ELECTRIC 70 883 -- 891 -- 898 -CONSUMPTION 80 906 -- 913 -- 921 --

watts 100 953 -- 961 -- 964 -APPROXIMATE WATER 70 52 195

CONSUMPTION PER 24 HR. 80 46 170 44 165 42 160

gal./day l/day

EVAPORATOR OUTLET TEMP 70 3 -16 3 -16 3 -16

°F °C

HEAD PRESSURE 70 225 15.8 225 15.8 225 15.8

PSIG kg/cm²G

SUCTION PRESSURE 70 28 2 28 2 28 2

PSIG kg/cm²G

TOTAL HEAT OF REJECTION 5150 BTU/h (AT 90°F /WT 70°F)

100 300 135 290 130 270 120

90 928 -- 936 -- 944 --

90 16 150 39 150 37 140

100 36 135 35 130 32 120

80 3 -16 9 -13 9 -13

90 9 -13 9 -13 12 -11

100 12 -11 12 -11 123 -11

80 257 18.1 257 18.1 257 18.1

90 289 20.3 289 20.3 289 20.3

100 325 22.8 325 22.8 325 22.8

80 31 2.2 2 2.2 31 2.2

90 34 2.4 2.2 2.4 34 2.4

100 37 2.6 37 2.6 37 2.6

50 70 90

Water Temp. (°F)

410 185 395 180

49 185 47 180

We reserve the right to make changes in specifications and design without prior notice.

29

Page 30

IV. Service Diagnosis

1. No Ice Production

PROBLEM POSSIBLE CAUSE REMEDY

[1] The icemaker will

not start.

[2] Water does not

stop, and the

icemaker will not

start

[3] Water has been

supplied, but the

icemaker will not

start.

a) Power Supply 1. OFF position. 1. Move to ON position.

2. Loose connection. 2. Tighten.

3. Bad contacts. 3. Check for continuity

and replace.

4. Blown fuse. 4. Replace.

b) Power Switch

(Control Box)

c) Fuse (Control Box) 1. Blown out. 1. Check for short circuit

d) Circuit Protect Relay 1. Miswiring. 1. Check power supply

e) Flush Timer 1. Flushing out. 1. Wait for 21 minutes.

f) Flush Switch 1. FLUSH position. 1. Move to ICE position.

g) Transformer 1. Coil winding opened. 1. Replace.

h) Control Water Valve 1. Coil winding opened. 1. Replace.

i) Shut-off Valve 1. Closed. 1. Open.

j) Plug and Receptacle

(Control Box)

a) Water Control Relay 1. Contacts fused. 1. Replace.

b) Float Switch 1. Bad contacts. 1. Check for continuity

c) Flush Water Valve 1. Valve seat clogged

d) Hoses 1. Disconnected. 1. Connect.

a) Water Control Relay 1. Bad contacts. 1. Check for continuity

b) Bin Control 1. Bad contacts. 1. Check for continuity

1. Off position. 1. Move to ON position.

2. Bad contacts. 2. Check for continuity

and replace.

and replace.

voltage and wire

properly.

2. Bad contacts. 2. Check for continuity

and replace.

2. Bad contacts. 2. Check for continuity

and replace.

2. Water failure. 2. Wait till water is

supplied.

1. Disconnected. 1. Connect.

2. Terminal out of Plug

or Receptacle.

2. Coil winding opened. 2. Replace.

2. Float does not move

freely.

and water leaking.

2. Activator does not

move freely.

2. Insert Terminal back in

position

and replace.

2. Clean or replace.

1. Clean or replace

and replace.

and replace.

2. Clean Axle and its

corresponding holes

or replace Bin Control.

30

Page 31

PROBLEM POSSIBLE CAUSE REMEDY

c) Gear Motor Relay 1. Coil winding opened. 1. Replace.

2. Bad contacts. 2. Check for continuity

and replace.

[4] Water has been

supplied. Fan Motor

starts, but

Compressor and

Gear Motor will not

start.

[5] Gear Motor starts,

but Compressor will

not start or operates

intermittently

[6] Gear Motor and

Compressor start,

but operate

intermittently

d) Control Timer

(Printed Circuit

Board)

e) Gear Motor Protect

Relay

a) Gear Motor Fuse

(Bussman GMD

1.5A)

b) Thermal Protector

(Gear Motor)

a)

X2 Relay on Control

Timer

b) Starter 1. Bad contacts. 1. Check for continuity

c) Start Capacitor or

Run Capacitor

d) Compressor 1. Loose connections. 1. Tighten.

e) Power Supply 1. Circuit Ampacity too

a) Pressure Switch 1. Dirty Air Filter or

1. Broken. 1. Replace.

1. Coil winding opened. 1. Replace.

2. Bad contacts. 2. Check for continuity

and replace.

1. Blown Fuse. 1. See 3. [3]. Find out the

cause and replace the

Fuse.

2. Bad contacts. 2. Check for continuity

and replace.

1. Bad contacts. 1. Check for continuity

and replace.

2. Coil winding opened. 2. Replace Timer.

and replace.

2. Coil winding opened. 2. Replace.

3. Loose connections. 3. Tighten.

1. Defective. 1. Replace.

2. Motor winding

opened or grounded.

3. Motor Protector

tripped.

low.

Condenser.

2. Ambient temperature

too warm.

3. Fan not rotating. 3. See "3. [1] a) Fan

4. Refrigerant

overcharged.

5. Refrigerant line or

components plugged.

2. Replace.

3. Find out the cause of

overheat or

overcurrent.

1. Install a larger-sized

conductor.

1. Clean.

2. Get cooler.

Motor."

4. Recharge.

5. Clean and replace

drier.

6. Bad contacts. 6. Check for continuity

and replace.

7. Loose connections. 7. Tighten.

31

Page 32

PROBLEM POSSIBLE CAUSE REMEDY

[7] Gear Motor and

Compressor start

but no ice is

produced.

a) Refrigerant Line 1. Gas leaks. 1. Check for leaks with a

leak detector. Reweld

leak, replace drier and

charge with

refrigerant. The

amount of refrigerant

is marked on

Nameplate or Label.

b) Shut-off Valves on

Condensing Unit

2. Refrigerant line

clogged.

1. Closed. 1. Open.

2. Replace the clogged

component.

32

Page 33

2. Low Ice Production

PROBLEM POSSIBLE CAUSE REMEDY

[1] Low ice production a) Refrigerant Line 1. Gas leaks. 1. See "1. [5] a)

Refrigerant Line."

b) High-side Pressure

Too High

2. Refrigerant line

clogged.

3. Overcharged. 3. Recharge.

1. Dirty Air Filter or

Condenser.

2. Ambient temperature

too warm.

2. Replace the clogged

component.

1. Clean.

2. Get cooler.

c) Expansion Valve

(not adjustable)

3. Fan rotating too

slow.

4. Condensing unit out

of order.

1. Low-side pressure

too low.

2. Low-side pressure

too high.

3. See "3 [1] a) Fan

Motor."

4. Check condensing

unit.

1. Replace.

2. See if Expansion

Valve Bulb is mounted

properly, and replace

the valve if necessary.

33

Page 34

3. Other

PROBLEM POSSIBLE CAUSE REMEDY

[1] Abnormal noise a) Fan Motor 1. Bearing worn out. 1. Replace.

2. Fan blade deformed. 2. Replace fan blade.

[2] Overflow from

Reservoir (Water

does not stop.)

[3] Gear Motor Fuse

blows or circuit

breaker trips

frequently

3. Fan blade does not

move freely.

b) Compressor 1. Bearings worn out,

or cylinder valve

broken.

2. Mounting pad out of

position.

c) Refrigerant Lines 1. Rub or touch lines or

other surfaces.

d) Gear Motor (Ice

Making)

e) Evaporator 1. Low-side pressure

a) Water Supply 1. Water pressure too

b) Control Water Valve 1. Diaphragm does not

c) Float Switch 1. Bad contacts. 1. Check for continuity

a) Power Supply

Voltage

b) Evaporator Assy 1. Bearings or Auger

c) Bin Control 1. Bad contacts. 1. Check for continuity

1. Bearing or Gear

worn out / damaged.

too low.

2. Scale on inside wall

of Freezing Cylinder.

high.

close.

1. Too high or too low. 1. Connect the unit to a

worn out.

2. Activator does not

move freely.

3. Replace.

1. Replace.

2. Reinstall.

1. Replace.

1. Replace.

1. See if Expansion

Valve Bulb is mounted

properly, and replace

the valve if necessary.

2. Remove Auger. Use

"SCALE AWAY" or

"LIME-A-WAY"

solution to clean

periodically. If the

water is found hard by

testing, install a

softener.

1. Install a pressure

Reducing Valve

1. Clean or replace.

and replace.

power supply of

proper voltage.

1. Replace Bearing or

Auger.

and replace.

2. Clean Axle and its

corresponding holes

or replace Bin Control.

34

Page 35

V. Removal and Replacement of Components

IMPORTANT

1. The Polyol Ester (POE) oils used in R-404A units can absorb moisture

quickly. Therefore it is important to prevent moisture from entering the

system when replacing or servicing parts.

2. Always install a new filter drier every time the sealed refrigeration system

is opened.

3. Do not leave the system open for longer than 15 minutes when replacing

or servicing parts.

1. Service for Refrigerant Lines

[a] Refrigerant Recovery

The icemaker unit is provided with two refrigerant access valves - one on the low-side and

one on the high-side line. Using proper refrigerant practices recover the refrigerant from the

access valves and store it in an approved container. Do not discharge the refrigerant into

the atmosphere.

[b] Evacuation and Recharge [R-404A]

1) Attach charging hoses, a service manifold and a vacuum pump to the system. Be sure

to connect charging hoses to both high-side and low-side access valves.

IMPORTANT

The vacuum level and vacuum pump may be the same as those for current

refrigerants. However, the rubber hose and gauge manifold to be used for

evacuation and refrigerant charge should be exclusively for POE oils.

2) Turn on the vacuum pump. Never allow the oil in the vacuum pump to flow backward.

3) Allow the vacuum pump to pull down to a 29.9" Hg vacuum. Evacuating period

depends on pump capacity.

4) Close the low-side valve and high-side valve on the service manifold.

5) Disconnect the vacuum pump, and attach a refrigerant service cylinder to the high-side

line. Remember to loosen the connection, and purge the air from the hose. See the

nameplate for the required refrigerant charge. Hoshizaki recommends only virgin

refrigerant or reclaimed refrigerant which meets ARI Standard No. 700-88 be used.

35

Page 36

6) A liquid charge is recommended for charging an R-404A system. Invert the service

cylinder. Open the high-side, service manifold valve.

7) Allow the system to charge with liquid until the pressures balance.

8) If necessary, add any remaining charge to the system through the low-side. Use a

throttling valve or liquid dispensing device to add the remaining liquid charge

through the low-side access port with the unit running.

9) Close the two refrigerant access valves, and disconnect the hoses and service

manifold.

10) Cap the access valves to prevent a possible leak.

2. Brazing

WARNING

1. Refrigerant R-404A itself is not flammable at atmospheric pressure and

temperatures up to 176°F.

2. Refrigerant R-404A itself is not explosive or poisonous. However, when

exposed to high temperatures (open flames) R-404A can be

decomposed to form hydrofluoric acid and carbonyl fluoride both of

which are hazardous.

3. Always recover the refrigerant and store it in an approved container. Do

not discharge the refrigerant into the atmosphere.

4. Do not use silver alloy or copper alloy containing arsenic.

5. Do not use R-404A as a mixture with pressurized air for leak testing.

Refrigerant leaks can be detected by charging the unit with a little

refrigerant, raising the pressure with nitrogen and using an electronic

leak detector.

Note: All brazing-connections are clear-paint coated. Sandpaper the brazing-connec

tions before unbrazing the components. Use a good abrasive cloth to remove

coating.

36

Page 37

3. Removal and Replacement of Compressor

IMPORTANT

Always install a new drier every time the sealed refrigeration system is

opened. Do not replace the drier until after all other repair or replacement

has been made.

1) Unplug the icemaker.

2) Remove the panels.

2) Remove the terminal cover on the compressor, and disconnect the compressor

wiring.

3) Recover the refrigerant and store it in an approved container, if required by an

applicable law.

4) Remove the discharge, suction, and access pipes from the compressor using

brazing equipment.

WARNING

When repairing a refrigerant system, be careful not to let the burner flame

contact any electrical wires or insulation.

5) Remove the bolts and rubber grommets.

6) Slide and remove the compressor. Unpack the new compressor package. Install

the new compressor.

7) Attach the rubber grommets of the prior compressor.

8) Sandpaper the discharge, suction and access pipes.

9) Place the compressor in position, and secure it using the bolts.

10) Remove plugs from the discharge, suction and access pipes.

11) Braze the access, suction and discharge lines (Do not change this order),

while purging with nitrogen gas flowing at the pressure of 3-4 PSIG.

12) Install the new drier.

37

Page 38

13) Check for leaks using nitrogen gas (140 PSIG) and soap bubbles.

14) Evacuate the system, and charge it with refrigerant. See the nameplate for the

required refrigerant charge and type.

15) Connect the terminals to the compressor, and replace the terminal cover in its

correct position.

16) Replace the panels in their correct position.

17) Plug in the icemaker.

4. Removal and Replacement of Drier

IMPORTANT

Always install a new drier every time the sealed refrigeration system is

opened. Do not replace the drier until after all other repair or replacement

has been made.

1) Unplug the icemaker.

2) Remove the panels.

3) Recover the refrigerant and store it in an approved container, if required by an

applicable law.

4) Remove the drier using brazing equipment.

5) Install the new drier with the arrow on the drier in the direction of the refrigerant flow.

Use nitrogen gas at the pressure of 3-4 PSIG when brazing the tubings.

6) Check for leaks using nitrogen gas (140 PSIG) and soap bubbles.

7) Evacuate the system, and charge it with refrigerant. See the nameplate for the

required refrigerant charge and type.

8) Replace the panels in their correct position.

9) Plug in the icemaker.

38

Page 39

5. Removal and Replacement of Expansion Valve

IMPORTANT

Sometimes moisture in the refrigerant circuit exceeds the drier capacity

and freezes up at the expansion valve. Always install a new drier every

time the sealed refrigeration system is opened. Do not replace the drier

until after all other repairs or replacement have been made.

1) Unplug the icemaker.

2) Remove the panels.

3) Recover the refrigerant and store it in an approved container, if required by an

applicable law.

4) Remove the expansion valve bulb at the evaporator outlet.

5) Remove the expansion valve cover, and remove the expansion valve using

brazing equipment.

6) Braze the new expansion valve with nitrogen gas flowing at the pressure of 3-4

PSIG.

WARNING

Always protect the valve body by using a damp cloth to prevent the valve

from overheating. Do not braze with the valve body exceeding 250°F.

7) Install the new drier.

8) Check for leaks using nitrogen gas (140 PSIG) and soap bubbles.

9) Evacuate the system. Charge it with refrigerant. See the nameplate for the required

refrigerant charge and type.

10) Attach the bulb to the suction line. Be sure to secure the bulb using a band and

to insulate it.

11) Place the expansion valve cover in position.

12) Replace the panels in their correct position.

13) Plug in the icemaker.

39

Page 40

6. Removal and Replacement of Evaporator Assembly

1) Drain the water from the evaporator by switching the flush switch to “FLUSH” on the

control box.

2) Unplug the icemaker.

3) Remove the panels.

4) Remove the three thumbscrews and take off the spout from the evaporator.

Cutter

5) Loosen the cutter by a wrench and remove it.

6) Remove the cylinder gasket at the top of the evaporator.

Extruding Head

7) Remove the three socket head cap screws and lift off the extruding head.

8) Replace the bearing inside the extruding head if it exceeds the wear tolerance of

0.02” or is scratched.

Note: Replacing the bearing requires a bearing press adaptor. If it is not available,

replace the whole extruding head.

Auger

9) Lift out the auger. If the area in contact with the bearing is worn or the blade is

scratched, replace the auger.

Evaporator

Note: Skip the following steps 10) through 12) when the evaporator does not need

replacement.

10) Recover the refrigerant and store it in an approved container, if required by an

applicable law.

IMPORTANT

Always install a new drier every time the sealed refrigeration system is

opened. Do not replace the drier until after all other repair or replacement

has been made.

40

Page 41

11) Remove the bulb of the expansion valve.

12) Disconnect the brazing-connections of the expansion valve and the copper tube-

low side from the evaporator, using brazing equipment.

13) Remove the two truss head machine screws and the bracket securing the

evaporator.

14) Disconnect the three hoses from the evaporator.

15) Remove the four socket head cap screws securing the evaporator with the

bearing-lower.

16) Lift off the evaporator.

Bearing-Lower and Mechanical Seal

17) The mechanical seal consists of two parts. One moves along with the auger, and the

other is fixed on the bearing-lower. If the contact surfaces of these two parts are worn

or scratched, the mechanical seal may cause water leaks and should be

replaced.

18) Remove the O-ring on the bearing-lower.

19) Remove the four bolts and the bearing-lower from the gear motor. Replace the

bearing inside the bearing-lower, if it exceeds the wear tolerance of 0.02" or is

scratched.

Note: Replacing the bearing requires a bearing press adaptor. If it is not available,

replace the whole bearing-lower.

Gear Motor

20) Remove the coupling-spline on the gear motor shaft.

21) Remove the three bolts securing the gear motor.

22) Assemble the removed parts in the reverse order of the above procedure.

WARNING

Be careful not to scratch the surface of the O-ring, or it may cause water

leaks. Handle the mechanical seal with care not to scratch nor to

contaminate its contact surface.

41

Page 42

23) When replacing the evaporator:

(a) Braze the new evaporator with nitrogen gas flowing at the pressure of 3-4 PSIG.

(b) Replace the drier.

(c) Check for leaks using nitrogen gas (140 PSIG) and soap bubbles.

(d) Evacuate the system. Charge it with refrigerant. See the nameplate for required

refrigerant charge and type.

24) Replace the panels in their correct position.

25) Plug in the icemaker.

7. Removal and Replacement of Fan Motor

1) Unplug the icemaker.

2) Remove the panels.

3) Remove the wire connectors from the fan motor leads.

4) Remove the fan motor bracket and fan motor.

5) Install the new fan motor.

6) Replace the fan motor bracket and the wire connectors.

7) Replace the panels in their correct position

8) Plug in the icemaker.

8. Removal and Replacement of Control Water Valve

1) Unplug the icemaker.

2) Remove the panels.

3) Close the water supply line shut-off valve.

4) Disconnect the terminal from the control water valve.

5) Loosen the fitting nut on the control water valve Inlets, and remove the control water

valve. Do not lose the packings inside the fitting nut.

42

Page 43

6) Remove the water supply hose from the control water valve.

7) Install the new control water valve.

8) Assemble the removed parts in the reverse order of the above procedure.

9) Open the water supply line shut-off valve.

10) Check for water leaks.

11) Replace the panels in their correct position.

12) Plug in the icemaker.

9. Removal and Replacement of Flush Water Valve

1) Turn off the power supply.

2) Remove the panels.

3) Close the water supply line shut-off valve.

4) Remove the clamp and disconnect the hose from the flush water valve that attaches to

the evaporator.

Note: Water may still remain inside the evaporator. Be sure to drain the water into the

drain pan.

5) Disconnect the flush water valve from the tube connected to the plastic tee leading to

the drain hose.

6) Disconnect the terminals from the flush water valve.

7) Remove the flush water valve from the frame or bracket.

8) Connect the new flush water valve back onto the frame or bracket.

9) Connect the tube from the plastic tee to the new flush water valve.

10) Connect the hose to the flush water valve and secure it with the clamp.

11) Pour water into the reservoir, and check for water leaks on the flush water valve.

12) Open the water supply line shut-off valve.

13) Turn on the power supply.

43

Page 44

14) Move the flush switch to the “ICE” position.

15) Check for water leaks.

16) Move the flush switch to the “FLUSH” position, and make sure water is flushing.

17) Move the flush switch to the “ICE” position.

18) Replace the panels in their correct position.

VI. Cleaning and Maintenance

IMPORTANT

Ensure all components, fasteners and thumbscrews are securely in place after

any maintenance or cleaning is done to the equipment.

1. Preparing the Icemaker for Long Storage

WARNING

When shutting off the icemaker for an extended time, drain out all water from

the water line and remove the ice from the storage bin. The storage bin should

be cleaned and dried. Drain the icemaker to prevent damage to the water

supply line at sub-freezing temperatures, using air or carbon dioxide. Shut off

the icemaker until the proper ambient temperature is resumed.

1) Run the icemaker with the water supply line shut-off valve closed.

2) Open the drain valve and blow out the water inlet line by using air pressure.

3) Turn off the power supply.

4) Remove the front panel.

5) Move the flush switch on the control box to

the “FLUSH” position.

6) Turn on the power supply, and then drain out all

water from the water line.

7) Turn off the power supply.

8) Turn off the power switch on the control box.

44

Page 45

9) Replace the front panel in its correct position.

10) Close the drain valve.

11) Remove all ice from the storage bin, and

clean the bin.

2. Cleaning and Sanitizing Instructions

WARNING

1. HOSHIZAKI recommends cleaning this unit at least twice a year. More

frequent cleaning, however, may be required in some existing water

conditions.

2. To prevent injury to individuals and damage to the icemaker, do not use

ammonia type cleaners.

3. Always wear liquid-proof gloves to prevent the cleaning and sanitizing

solutions from coming into contact with skin.

[a] Cleaning Solution

Dilute 4.8 fl. oz. (142 ml) of recommended cleaner Hoshizaki “Scale Away” or

“LIME-A-WAY” (Economics Laboratory, Inc.) with 0.8 gallons (3 l) of warm water. This is a

minimum amount. Make more solution if necessary.

IMPORTANT

For safety and maximum effectiveness, use the solution immediately after

dilution.

45

Page 46

[b] Cleaning Procedure

The cleaning process will remove lime deposits from the water system.

1) Remove the front panel and top panel, then turn off the power supply.

2) Close the water supply line shut-off valve.

3) Remove all ice from the storage bin.

4) Move the flush switch to the “FLUSH” position.

5) Turn on the power supply and drain out all water from the water line.

6) Turn off the power supply.

7) Remove the strap connecting the spout to the chute assembly.

8) Remove the thumbscrews securing the spout and lift it off.

9) Pour the cleaning solution over the extruding head until the evaporator assembly and the

reservoir are filled and the solution starts to overflow into the drain pan.

Note: If there is excess scale on the extruding head, fill the evaporator assembly and

reservoir as described above, then use a clamp on the reservoir hose between the

reservoir and evaporator assembly to block flow. Pour additional cleaning fluid

over the extruding head until the evaporator assembly is completely full.

10) Replace the spout and strap in their correct positions.

11) Allow the icemaker to sit for about 10 minutes before operation. If you placed a clamp on

the reservoir hose in step 9, remove it before operation.

12) Move the flush switch to the “ICE” position, then turn on the power supply. Replace the

top panel and front panel in their correct positions. Make ice using the solution until the

icemaker stops making ice.

13) Remove the front panel.

14) Move the flush switch to the “FLUSH” position to drain the remainder of the solution.

15) After the solution is drained, move the flush switch to the “ICE” position.

16) Replace the front panel in its correct position.

17) Open the water supply line shut-off valve and supply water to the reservoir.

18) When the gear motor starts, remove the front panel and turn off the power supply.

19) Drain out all water from the water line. See 4) through 6).

46

Page 47

[c] Sanitizing Solution

Dilute 2.5 fl. oz. (74 ml or 5 tbs) of IMS-II Sanitizer or a 5.25% sodium hypochlorite solution

(chlorine bleach) with 5 gallons (19 l) of warm water.

IMPORTANT

For safety and maximum effectiveness, use the solution immediately after

dilution.

[d] Sanitizing Procedure - Initial

The sanitizing process will sanitize the icemaker.

1) Close the water supply line shut-off valve.

2) Remove the strap connecting the spout to the chute assembly.

3) Remove the thumbscrews securing the spout and lift it off. Remove the rubber O-ring and

nylon O-ring at the top of the cylinder and also remove the packing between the spout

and the chute.

4) Pour the sanitizing solution over the extruding head until the evaporator assembly and

the reservoir are filled and the solution starts to overflow into the drain pan.

5) Remove the two thumbscrews securing the proximity switch to the chute assembly.

6) Remove the chute assembly from the icemaker.

7) Remove the packing at the bottom of the ice chute.

8) Remove the three ties and the chute insulation.

9) Remove the six wing nuts and two baffles.

10) Remove the two thumbscrews, the plate and the packing from the top of the ice chute,

then remove the bin control assembly by sliding it slightly toward the chute opening and

lifting it off.

11) Disassemble the bin control assembly by removing the two snap pins, shaft and

actuator.

12) Soak the removed parts in .25 gallons (1 l) of sanitizing solution for 10 minutes then

wipe them down.

13) Rinse the parts thoroughly.

If the solution is left on these parts, they will rust.

IMPORTANT

47

Page 48

14) Replace all parts in their correct positions.

IMPORTANT

When installing the baffles, make sure that the bent surface (the one without the

studs) faces the actuator so that the bent surface can guide the ice to the center

of the actuator.

15) Move the flush switch to the “ICE” position, then turn on the power supply. Replace the

top panel and front panel in their correct positions. Make ice using the solution until the

icemaker stops making ice.

[e] Sanitizing Procedure - Final

1) Remove the front panel and top panel, then turn off the power supply.

2) Move the flush switch to the “FLUSH” position.

3) Turn on the power supply and drain out all water from the water line.

4) Turn off the power supply.

5) Remove the strap connecting the spout to the chute assembly.

6) Remove the thumbscrews securing the spout and lift it off.

7) Pour the sanitizing solution over the extruding head until the evaporator assembly and

the reservoir are filled and the solution starts to overflow into the drain pan.

8) Replace the spout and strap in their correct positions.

9) Allow the icemaker to sit for about 10 minutes before operation.

10) Move the flush switch to the “ICE” position, then turn on the power supply. Replace the

top panel and front panel in their correct positions. Make ice using the solution until the

icemaker stops making ice.

11) Remove the front panel.

12) Move the flush switch to the “FLUSH” position to drain the remainder of the solution.

13) After the solution is drained, move the flush switch to the “ICE” position.

14) Replace the front panel in its correct position.

15) Open the water supply line shut-off valve and supply water to the reservoir.

48

Page 49

16) When the gear motor starts, remove the front panel and turn off the power supply.

17) Drain out all water from the water line. See 2) and 3).

18) Move the flush switch to the “ICE” position and run the icemaker.

19) Turn off the power supply after 30 minutes.

20) Pour warm water into the storage bin to melt all ice, and then clean the bin liner with the

solution.

21) Flush out any solution from the storage bin.

22) Turn on the power supply and start the automatic icemaking process.

IMPORTANT

1. After cleaning, do not use ice made from the sanitizing solution. Be careful

not to leave any solution in the storage bin.

2. Follow carefully any instructions provided with the bottles of cleaning or

sanitizing solution.

3. Never run the icemaker when the reservoir is empty.

49

Page 50

3. Maintenance Instructions

1. This icemaker must be maintained individually, referring to the instruction

manual and labels provided with the icemaker.

2. To have the optimum performance of this icemaker, the following

consumable parts need periodic inspection, maintenance and

replacement:

Extruding Head

Housing

Gear Motor

Auger

Mechanical Seal

These parts should be inspected at least once a year or every 10,000 hours of

operation. Their service life, however, depends on water quality and

environment. More frequent inspection and maintenance are recommended.

IMPORTANT

Consult with your local distributor about inspection and maintenance service.

To obtain the name and phone number of your local distributor, call Hoshizaki

Technical Support at 1-800-233-1940 in the USA.

1) Stainless Steel Exterior

To prevent corrosion, wipe the exterior occasionally with a clean and soft cloth. Use a

damp cloth containing a neutral cleaner to wipe off oil or dirt build up.

2) Storage Bin and Scoop

• Wash your hands before removing ice. Use the plastic scoop provided (bin accessory).

• The storage bin is for ice use only. Do not store anything else in the bin.

• Keep the scoop clean. Clean using a neutral cleaner and rinse thoroughly.

• Clean the bin liner using a neutral cleaner. Rinse thoroughly after cleaning.

50

Page 51

3) Air Filter

A plastic mesh air filter removes dirt or dust from the air, and keeps the condenser

from getting clogged. As the filter gets clogged, the icemaker’s performance will be

reduced. Check the filter at least twice a month. When clogged, use warm water and

a neutral cleaner to wash the filter.

4) Condenser

Check the condenser once a year, and clean if required by using a brush or vacuum

cleaner. More frequent cleaning may be required depending on the location of the

icemaker.

5) Infrared Sensor ( -C model only )

The infrared sensor inside the ice chute can be accessed by opening the bin door

and reaching into the chute from below the ice machine. Clean the sensor using a

neutral cleaner on a clean soft cloth at least twice a month.

51

Loading...

Loading...