Page 1

Hoshizaki

“A Superior Degree

of Reliability”

www.hoshizaki.com

Model

F-300BAF

Self-Contained Flaker

Hoshizaki America, Inc.

Number: 73072

Issued: 3-2-1999

Revised: 01-25-2007

SERVICE MANUAL

Page 2

IMPORTANT

Only qualified service technicians should attempt to service or maintain this

unit. No such service or maintenance should be undertaken until the technician

has thoroughly read this Service Manual.

HOSHIZAKI provides this manual primarily to assist qualified service technicians in the

service and maintenance of the unit.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call, write or send an e-mail message to the HOSHIZAKI Technical

Support Department for assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City, GA 30269

Attn: HOSHIZAKI Technical Support Department

Phone: 1-800-233-1940 Technical Service

(770) 487-2331

Fax: 1-800-843-1056

(770) 487-3360

E-mail: techsupport@hoshizaki.com

Web Site: www.hoshizaki.com

NOTE: To expedite assistance, all correspondence/communication MUST include the

following information:

• Model Number

• Serial Number

• Complete and detailed explanation of the problem

2

Page 3

Please review this manual. It should be read carefully before the unit is serviced or

maintenance operations are performed. Only qualified service technicians should service

and maintain the unit. This manual should be made available to the technician prior to

service or maintenance.

CONTENTS

I. Specifications ...................................................................................................................... 5

A. Icemaker ....................................................................................................................... 5

II. General Information ........................................................................................................... 6

A. Construction .................................................................................................................. 6

B. Ice Making Unit ............................................................................................................. 7

C. Control Box Layout ........................................................................................................ 8

a) Auxiliary Code K-1 and Earlier ............................................................................. 8

b) Auxiliary Code K-2 and L-0 .................................................................................. 8

c) Auxiliary Code L-1 and M-0 .................................................................................. 9

d) Auxiliary Code M-1 and Later ............................................................................... 9

D. Timer Board ................................................................................................................. 10

1. Solid-State Timer Board Control ............................................................................ 10

E. Sequence of Operation ............................................................................................... 11

1. Startup ................................................................................................................... 11

2. Fill Cycle ................................................................................................................ 11

3. Ice Purge Cycle (60 seconds) ............................................................................... 11

4. Freeze Cycle (Ice Making Process) ....................................................................... 11

5. Shutdown: ............................................................................................................. 11

F. Ice Production Check ................................................................................................... 11

III. Technical Information ...................................................................................................... 13

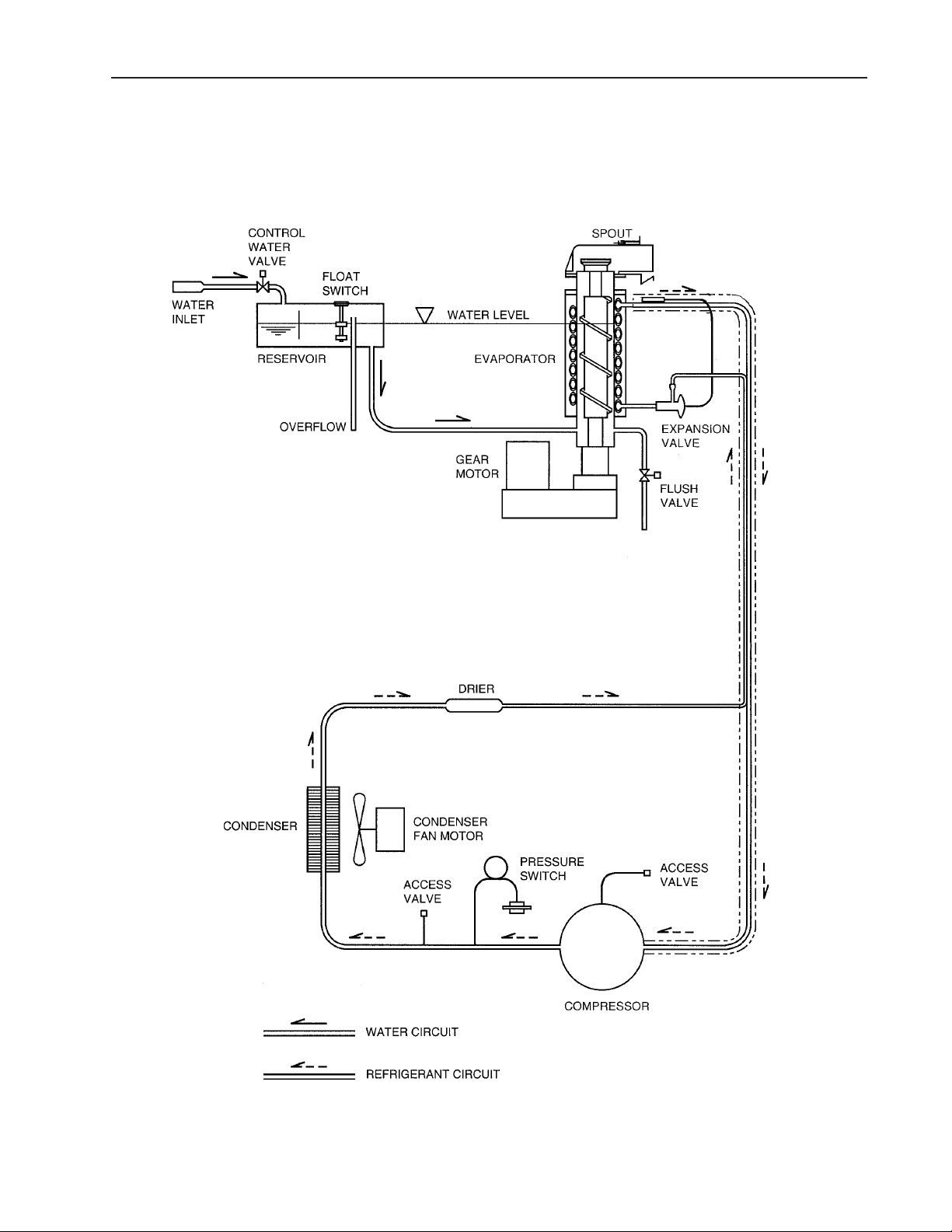

A. Water Circuit and Refrigeration Circuit ........................................................................ 13

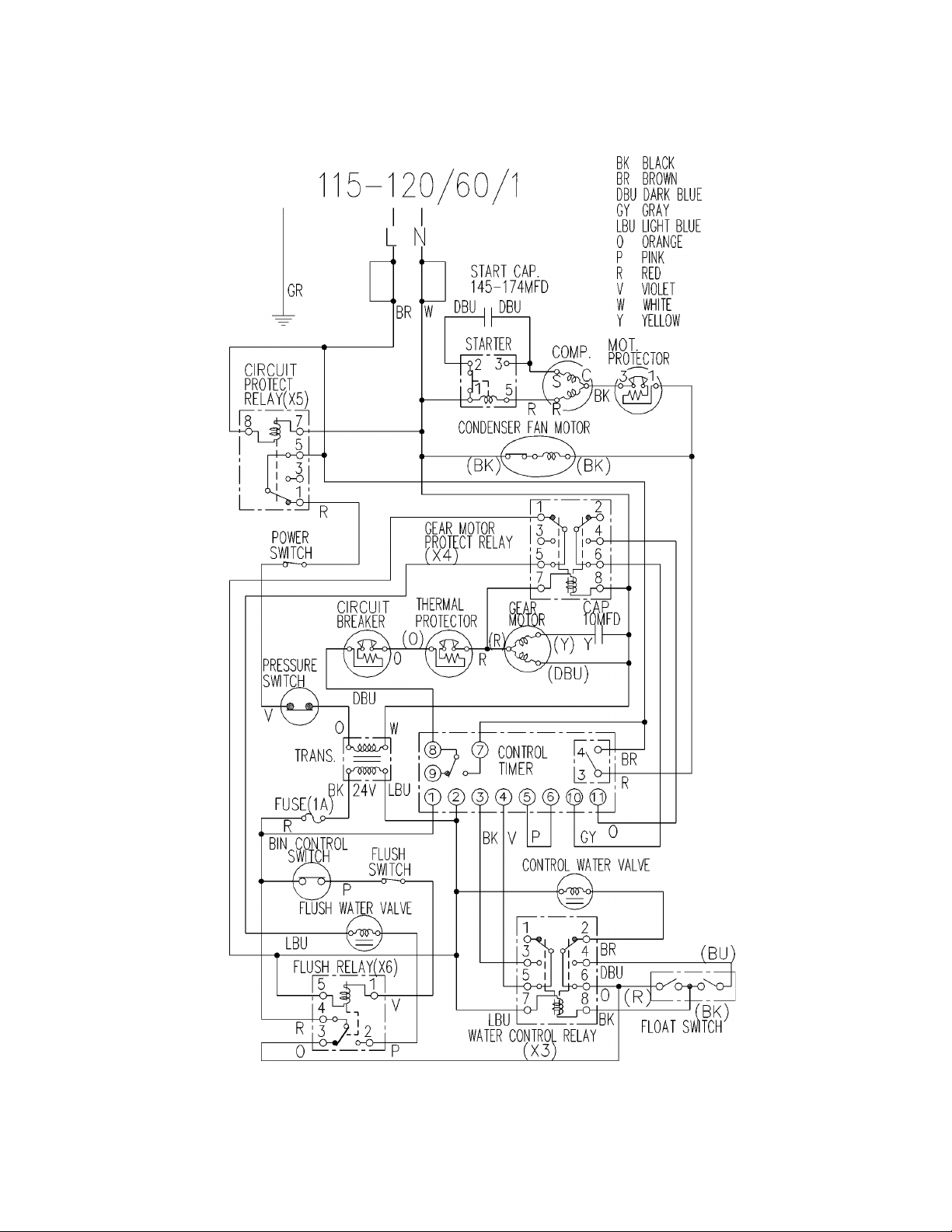

B. Wiring Diagram ............................................................................................................ 14

1. Auxiliary Code K-1 and Earlier .............................................................................. 14

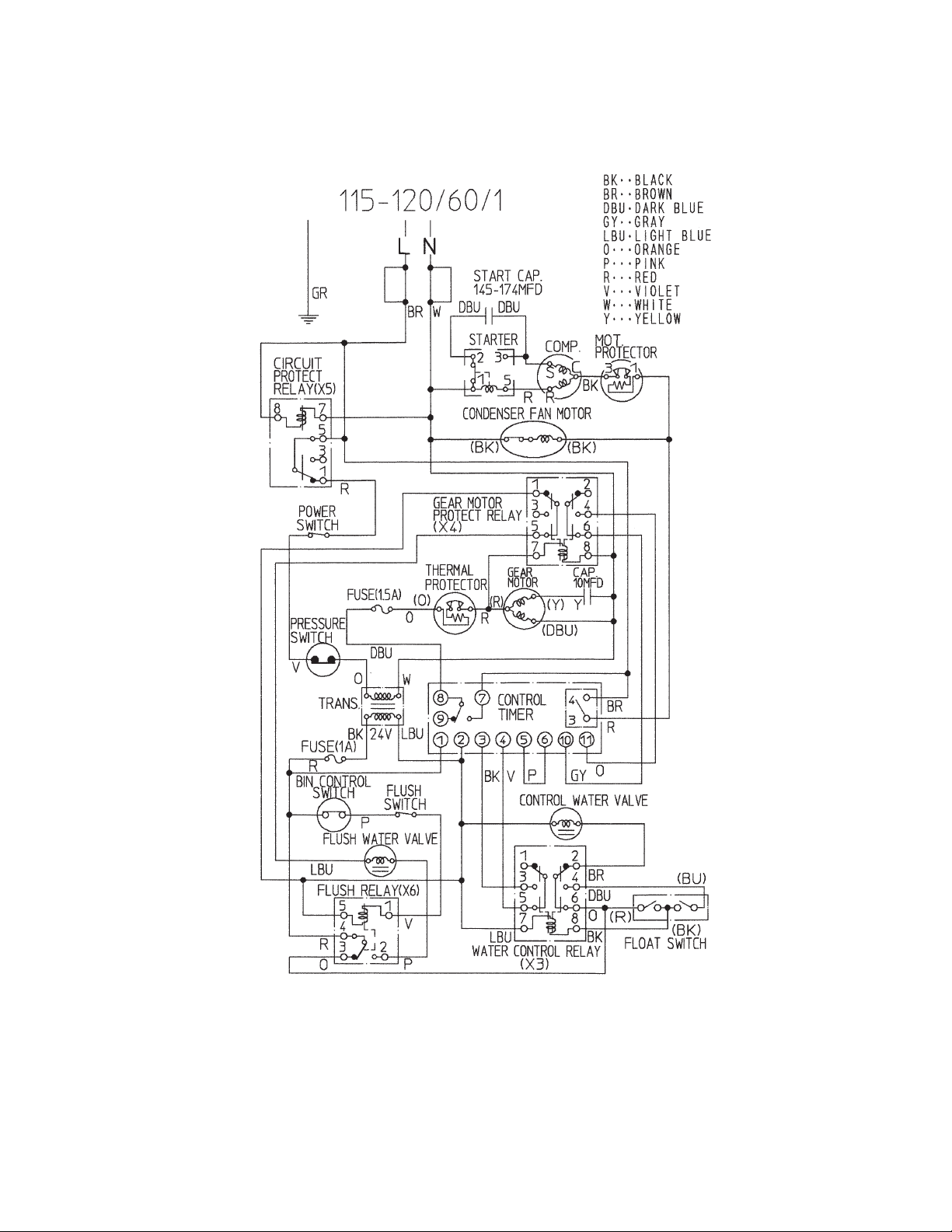

2. Auxiliary Code K-2 and L-0 ....................................................................................

3. Auxiliary Code L-1 and M-0 ................................................................................... 16

4. Auxiliary Code M-1 and Later ................................................................................ 17

C. Sequence of Electrical Circuit ..................................................................................... 18

1. Fill Cycle ............................................................................................................... 18

2. Ice Purge Cycle ....................................................................................................

3. Freeze Cycle ......................................................................................................... 20

4. Shutdown .............................................................................................................. 21

5. Cleaning - Flush Switch ........................................................................................ 22

6. Low Water Safety ................................................................................................... 23

7. Spout Safety Switch .............................................................................................. 24

8. High Pressure Switch ............................................................................................ 25

D. Performance Data ....................................................................................................... 26

IV. Service Diagnosis ........................................................................................................... 27

A. Diagnostic Procedure .................................................................................................. 27

B. Diagnostic Charts ........................................................................................................ 29

1. No Ice Production .................................................................................................. 29

2. Low Ice Production ................................................................................................

3. Other ...................................................................................................................... 32

15

19

31

3

Page 4

V. Removal and Replacement of Components .................................................................... 33

A. Service for Refrigerant Lines ...................................................................................... 33

1. Refrigerant Recovery ............................................................................................ 33

2. Evacuation and Recharge [R-404A] ...................................................................... 33

B. Brazing ........................................................................................................................ 34

C. Removal and Replacement of Compressor ................................................................ 35

D. Removal and Replacement of Drier ............................................................................ 36

E. Removal and Replacement of Expansion Valve .......................................................... 36

F. Removal and Replacement of Evaporator Assembly Components ............................. 38

1. Upper Bearing Wear Check ..................................................................... 39

2. Removal and Replacement of Cutter..................................................................... 39

3. Removal and Replacement of Extruding Head ..................................................... 40

4. Removal and Replacement of Auger ..................................................................... 40

5. Removal and Replacement of Evaporator ............................................................. 40

6. Removal and Replacement of Mechanical Seal and Lower Housing ................... 41

7. Removal and Replacement of Gear Motor ............................................................ 42

G. Removal and Replacement of Fan Motor ................................................................... 43

H. Removal and Replacement of Inlet Water Valve ......................................................... 43

I. Removal and Replacement of Flush Water Valve ......................................................... 43

VI. Cleaning and Maintenance ............................................................................................. 45

A. Cleaning and Sanitizing Instructions ........................................................................... 45

1. Cleaning Solution .................................................................................................. 45

2. Cleaning Procedure ............................................................................................... 45

3. Sanitizing Solution ................................................................................................. 46

4. Sanitizing Procedure - Initial .................................................................................. 47

5. Sanitizing Procedure - Final .................................................................................. 47

B. Maintenance ................................................................................................................ 49

C. Preparing the Icemaker for Long Storage ................................................................... 50

4

Page 5

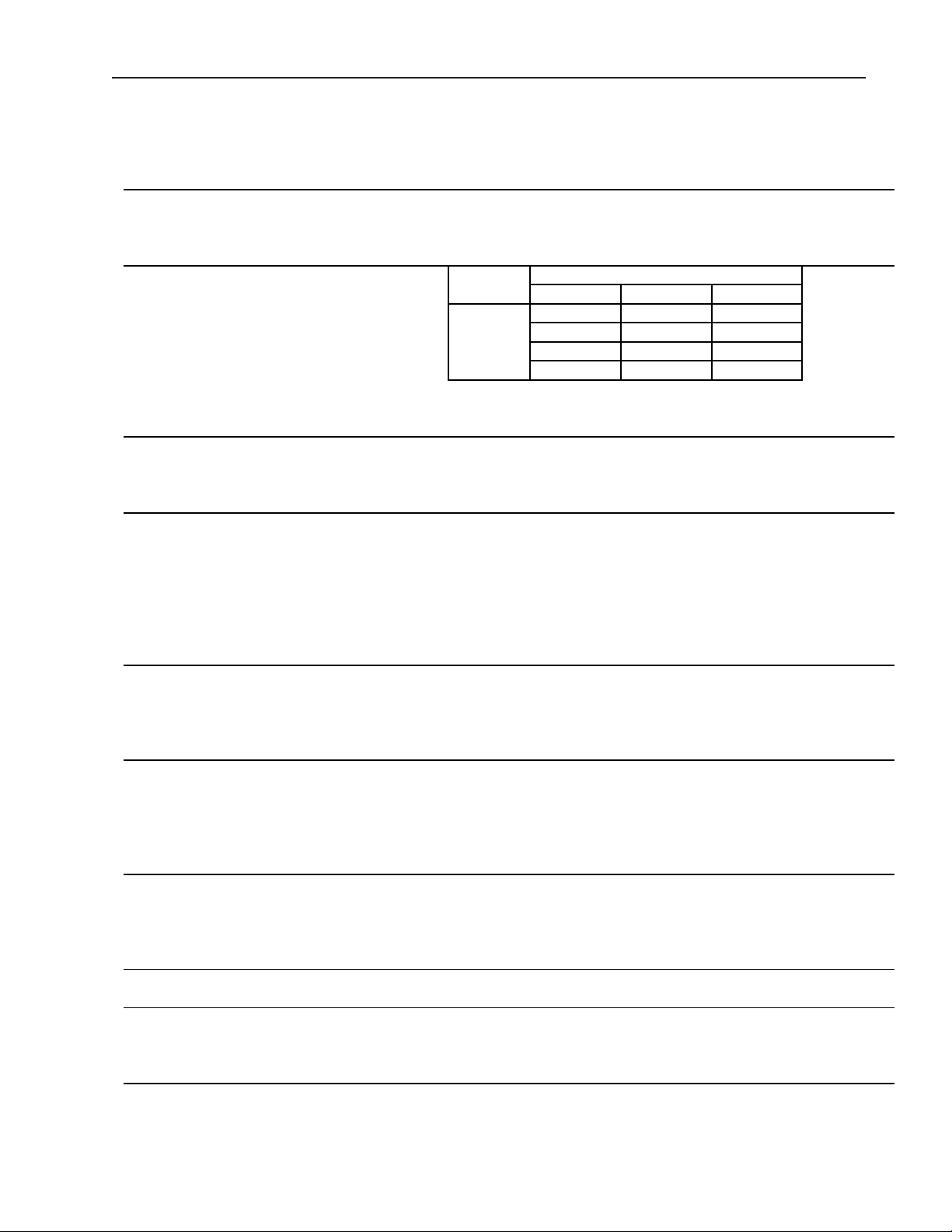

I. Specifications

AC SUPPLY VOLTAGE 115/60/1

AMPERAGE 9.0 A ( AT 104°F/ WT 80°F )

MINIMUM CIRCUIT AMPACITY N/A

MAXIMUM FUSE SIZE N/A

APPROXIMATE ICE PRODUCTION Ambient WATER TEMP. (°F)

PER 24 HR. Temp.(°F) 50 70 90

lbs./day ( kg/day ) 70 * 303 (137) 290 (131) 278 (126)

Reference without *marks 80 267 (121) 256 (116) 246 (112)

90 236 (107) * 232 (105) 218 (99)

100 209 (95) 201 (91) * 188 (85)

SHAPE OF ICE Flake

ICE QUALITY Approx. 70%, Ice (90/70°F, Conductivity 200 µs/cm)

APPROXIMATE STORAGE CAPACITY 110 lbs.

ELECTRIC & WATER CONSUMPTION 90/70°F 70/50°F

ELECTRIC W (kWH/100 lbs.) 674 (7.0) 667 (5.3)

POTABLE WATER 28 (12) 36 (12)

gal./24HR (gal./100 lbs.)

EXTERIOR DIMENSIONS (WxDxH) 36" x 24" x 33" (914 x 610 x 838 mm)

EXTERIOR FINISH PVC Coated Galvanized Steel; Galvanized Steel (Rear);

Stainless Steel (Top)

WEIGHT Net 182 lbs. ( 83 kg ), Shipping 221 lbs. ( 100 kg )

CONNECTIONS - ELECTRIC Cord Connection

- WATER SUPPLY Inlet 1/2" FPT

- DRAIN Drain Pan 3/4" FPT

Bin Drain 3/4" FPT

ICE MAKING SYSTEM Auger type

HARVESTING SYSTEM Direct Driven Auger ( 1/6 HP Gear Motor )

ICE MAKING WATER CONTROL Float Switch

COOLING WATER CONTROL N/A

BIN CONTROL SYSTEM Mechanical Bin Control ( Proximity Sw. )

COMPRESSOR Hermetic, Model JS25C1E-IAA-252

CONDENSER Air-cooled, Fin and tube type

EVAPORATOR Copper Tube on Cylinder

REFRIGERANT CONTROL Thermostatic Expansion Valve

REFRIGERANT CHARGE R-404A, 10.5 oz. (300 g)

DESIGN PRESSURE High 460 PSIG, Low 290 PSIG

P.C. BOARD CIRCUIT PROTECTION High Voltage Cut-off Relay

COMPRESSOR PROTECTION Auto-reset Overload Protector

GEAR MOTOR PROTECTION Manual reset Circuit Breaker

REFRIGERANT CIRCUIT PROTECTION Auto-reset High Pressure Control Switch

LOW WATER PROTECTION Float Switch and Timer

ACCESSORIES - SUPPLIED Ice Scoop, Spare Fuse

- REQUIRED Legs

OPERATING CONDITIONS VOLTAGE RANGE 104 - 127 V

AMBIENT TEMP. 45 - 100° F

WATER SUPPLY TEMP. 45 - 90° F

WATER SUPPLY PRESSURE 10 - 113 PSIG

A. Icemaker

1. F-300BAF

Note: We reserve the right to make changes in specifications and design without prior

notice.

5

Page 6

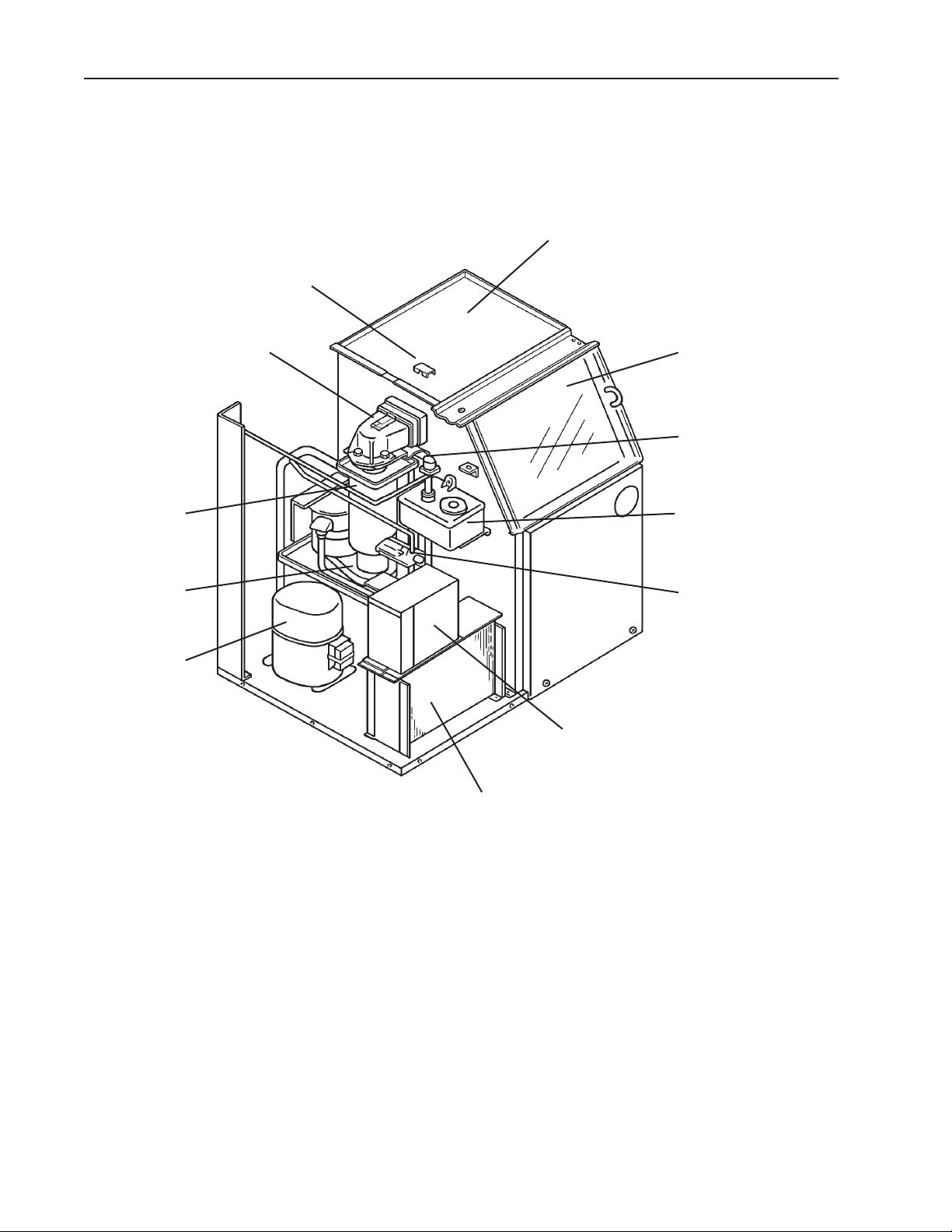

II. General Information

A. Construction

1. F-300BAF

Bin Control *

Ice Storage Bin

Evaporator

Gear Motor

Compressor

Spout

Sliding Door

Control Water Valve

Reservoir

Expansion Valve

Control Box

Air-cooled Condenser

*The switch actuator is located in the ice storage bin.

6

Page 7

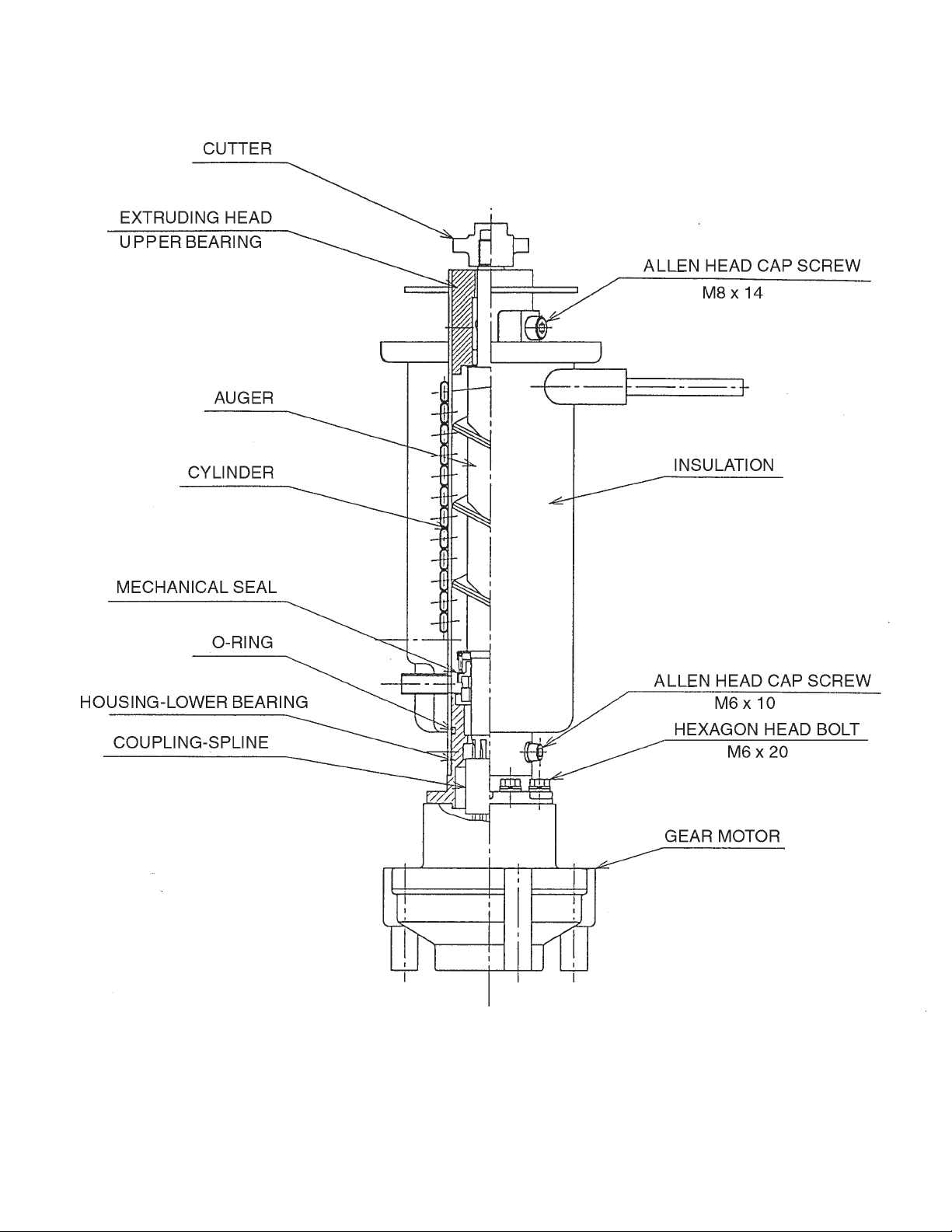

B. Ice Making Unit

7

Page 8

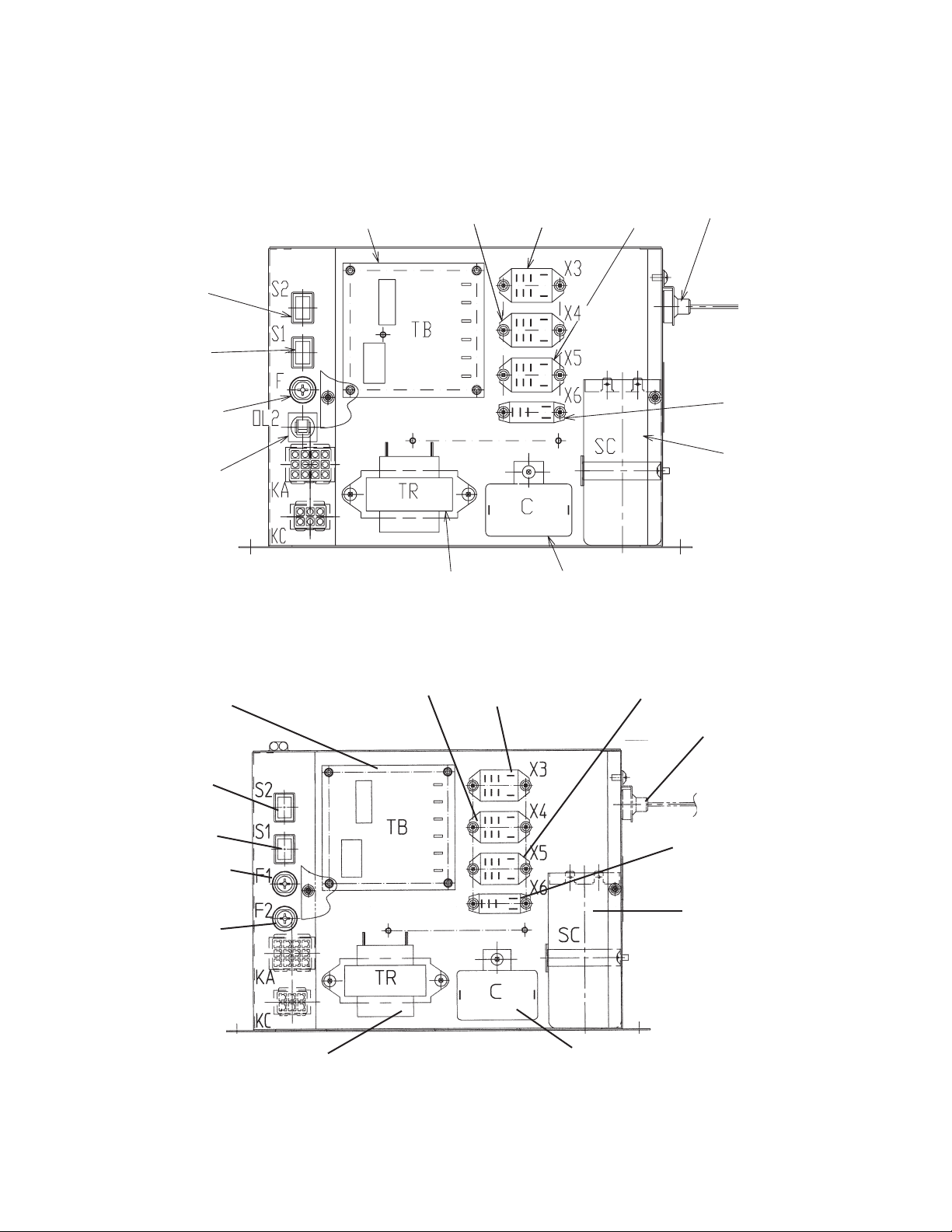

C. Control Box Layout

TRANSFORMER

CAPACITOR

GEAR MOTOR

START

CAPACITOR

FLUSH

RELAY

PRESSURE

SWITCH

CIRCUIT

PROTECT

RELAY

WATER

CONTROL

RELAY

GEAR MOTOR

PROTECT

RELAY

CONTROL

TIMER

FLUSH

SWITCH

POWER

SWITCH

CONTROL BOARD

FUSE (1A)

CIRCUIT

BREAKER

GEAR MOTOR

1. F-300BAF

a) Auxiliary Code K-1 and Earlier

b) Auxiliary Code K-2 and L-0

CONTROL TIMER

FLUSH SWITCH

POWER SWITCH

CONTROL BOARD

FUSE (1A)

GEAR MOTOR

FUSE (1.5A)

Note: The above component names are identical with the wiring label, but not with

TRANSFORMER

the parts list.

GEAR MOTOR

PROTECT RELAY

WATER CONTROL

RELAY

CAPACITOR - GEAR

MOTOR

CIRCUIT PROTECT

RELAY

PRESSURE SWITCH

FLUSH RELAY

START CAPACITOR

8

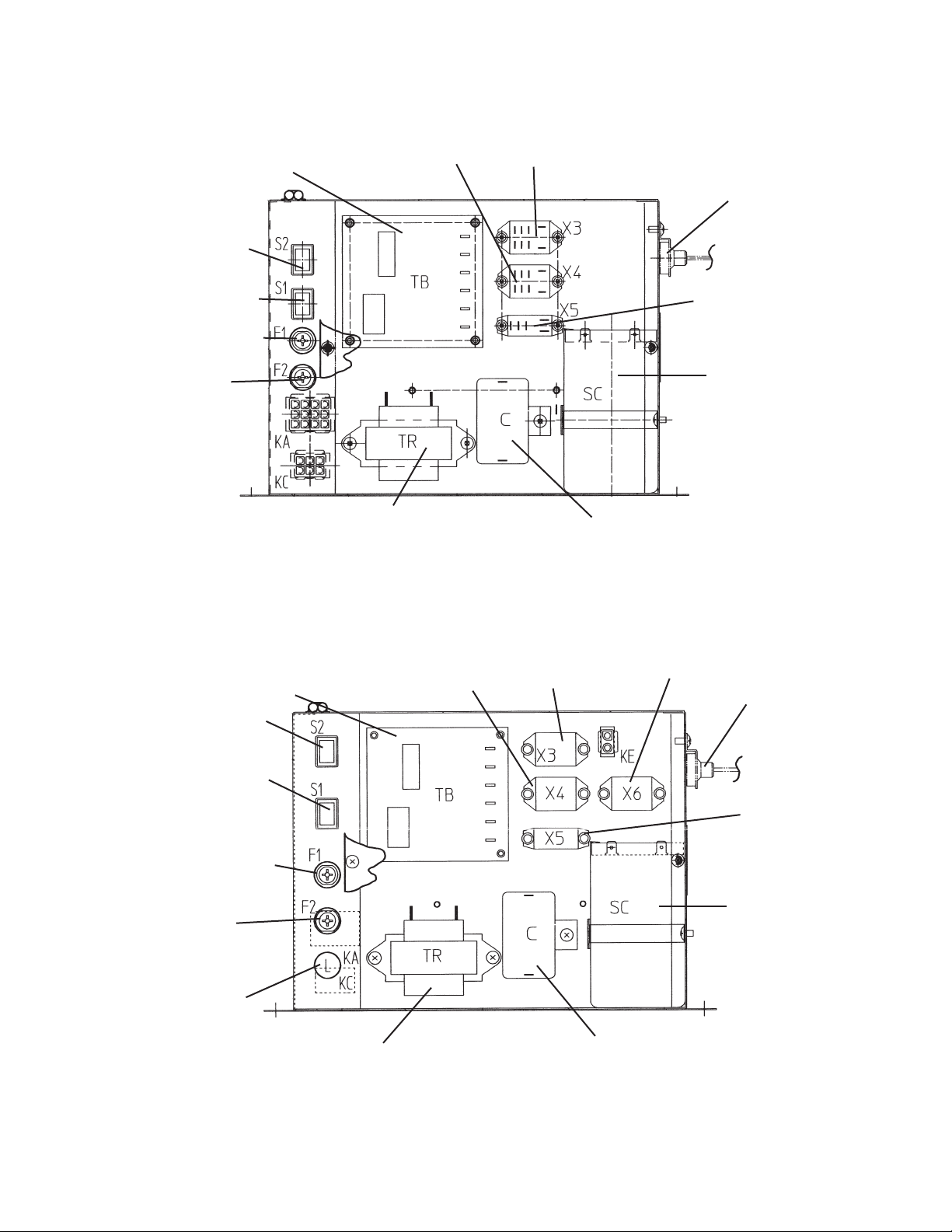

Page 9

c) Auxiliary Code L-1 and M-0

CONTROL TIMER

FLUSH SWITCH

POWER SWITCH

CONTROL BOARD

FUSE (1A)

GEAR MOTOR

FUSE (1.5A)

GEAR MOTOR

PROTECT RELAY

TRANSFORMER

WATER CONTROL

RELAY

PRESSURE SWITCH

FLUSH RELAY

START CAPACITOR

CAPACITOR - GEAR

MOTOR

d) Auxiliary Code M-1 and Later

GEAR MOTOR

CONTROL TIMER

FLUSH SWITCH

POWER SWITCH

CONTROL BOARD

FUSE (1A)

GEAR MOTOR

FUSE (1.5A)

BIN CONTROL

SAFETY SWITCH

LAMP

TRANSFORMER

PROTECT RELAY

WATER CONTROL

RELAY

CAPACITOR - GEAR

MOTOR

SAFETY RELAY

PRESSURE SWITCH

FLUSH RELAY

START CAPACITOR

Note: The above component names are identical with the wiring label, but not with

the parts list.

9

Page 10

D. Timer Board

1. Solid-State Timer Board Control

• A HOSHIZAKI exclusive solid-state sequence timer board is employed in Hoshizaki selfcontained flaker icemakers.

• All models are pre-tested and factory-adjusted.

CAUTION

1. Fragile, handle very carefully.

2. The timer board contains CMOS (Complementary Metal-Oxide

Semiconductor) integrated circuits, which are susceptible to failure due to

static discharge. It is especially important to use an anti-static wrist strap

when handling or replacing the board.

3. Do not touch the electronic devices on the board or the back of the board to

prevent damage to the board.

4. Do not change wiring and connections. Especially, never misconnect

terminals.

5. Do not fix the electronic devices or parts on the board in the field. Always

replace the whole board assembly if it goes bad.

The timer board provides the following safeguards:

• Provides component protection during low water supply.

• Purges remaining ice in the evaporator.

• Provides short cycle protection for the compressor.

10

Page 11

E. Sequence of Operation

Hoshizaki utilizes a solid state timer board to switch the components on and off as

needed. The sequence is as follows:

1. Startup

Flush switch in "ICE" position, power switch in "ON" position. FR energizes.

2. Fill Cycle

WV opens and the reservoir fills with water until UF/S closes. Note: GM will not start

unless UF/S is closed. For details, see "IV. Service Diagnosis".

3. Ice Purge Cycle (60 seconds)

WCR energizes, closing the low water safety circuit and de-energizing WV. GMR

energizes (clear relay located on TB). GM starts and GMPR energizes. GM runs for 60

seconds to clear any ice from the evaporator.

Note: Low water safety circuit is terminals 3 and 4 on TB.

4. Freeze Cycle (Ice Making Process)

CR energizes (black relay located on TB). Comp and FMS energize. As the water in the

evaporator cools, ice starts forming within 4 to 6 minutes. This time frame depends on

the inlet water and ambient temperature conditions.

UF/S and LF/S operate WV as needed to continue the ice making process. This

continues until BC shuts the ice maker down or power is turned off to the unit.

5. Shutdown:

BC activates (opens). FR de-energizes, FWV energizes. Approximately 90 seconds after

BC activates, Comp and FMS de-energize, one minute later GMPR de-energizes and

GM stops.

Legend: BC–bin control; Comp–compressor; CR–compressor relay; FMS–self-

contained fan motor; FR–flush relay; FWV–flush water valve; GM–gear motor;

GMPR–gear motor protect relay; GMR–gear motor relay; LF/S–lower float

switch; TB–timer board; UF/S–upper float switch; WCR–water control relay;

WV–inlet water valve.

F. Ice Production Check

To check production, prepare a bucket or pan to catch the ice and a set of scales to

weigh the ice. After the unit has operated for 10 to 20 minutes, catch the ice production

for 10 minutes. Weigh the ice to establish the batch weight. Multiply the batch weight by

144 for the total production in 24 hours.

11

Page 12

If refill achieved, icemaking

cycle starts and timers

are reset.

4. Low Water Safety

Refill Cycle

UF/S closes terminating

90 sec TC.

60 sec. timer

90 sec. timer

If refill > 90 sec. TC

GM de-energized

GMPR de-energized

UF/S open

90 sec. TC exceeded

LF/S closed

UF/S closed

90 sec. TC ended

Comp de-energized

WCR de-energized

WV continues

FMS de-energized

WCR energized

FR continues

WV continues

WV continues

WV de-energized

Comp continues

GM continues

GM continues

Comp continues

GMPR continues

FMS continues

GM continues

FR continues

FMS continues

GMPR continues

FR continues

GMPR continues

FR continues

5. Compressor and fan

motor energize. Ice

production begins in 4

to 6 minutes.

60 seconds

4. Bin control proximity switch

closes. Reservoir fills. LF/S

and UF/S close. Gear motor

starts 6.7 seconds later.

6.7 sec.

Comp energized

FMS energized

LF/S and UF/S close

WCR energized

BC closed

FR energized

GM continues

WV de-energized

WV energized

GMPR continues

GM energized

FWV de-energized

WCR continues

GMPR energized

FR continues

FR continues

UF/S open

LF/S open

90 sec. TC started

WCR de-energized

WV energized

Comp continues

LF/S opens

initiating refill

60 sec. timer

and 90 sec. TC

Comp energized

FMS energized

WCR continues

GM continues

GMPR continues

3. Icemaking Cycle

2. Ice Purge Cycle

F-300BAF, F-500BAF Sequence Flow Chart and Component Operation

LF/S closed

UF/S closed

WCR energized

WV de-energized

GM continues

FR continues

GM energized

FMS continues

GMPR energized

GMPR continues

FR continues

FR continues

3. Gear motor de-energizes

and unit is "OFF"

GM de-energized

GMPR de-energized

FWV continues

60 seconds

2. Compressor and fan motor

de-energize, gear motor

continues running.

Comp de-energized

FMS de-energized

GM continues

90 seconds

BC open

FR de-energized

1. Bin control proximity switch

opens to stop ice production.

WCR de-energized

GMPR continues

FWV energized

FWV continues

Comp continues

FMS continues

GM continues

GMPR continues

Components Energized when the Flush Switch is in the FLUSH Position

The FLUSH position is used when cleaning and sanitizing the machine. When in the FLUSH position, power is

supplied to the flush valve. This allows cleaner and sanitizer to drain from the evaporator assembly.

1. Startup

1. Fill Cycle

Flush switch in "ICE"

Power switch "ON"

FR energized

WCR de-energized

WV energized

Low water safety ciruit

closed. (Terminals 3

and 4 on timer board)

Bin control operation

12

2. Shutdown & Restart

Legend:

BC - bin control

Comp - compressor

FMS - self-contained fan motor

FR - flush relay

FWV - flush water valve

GM - gear motor

GMPR - gear motor protect relay

LF/S - lower float switch

TC - timer control

UF/S - upper float switch

WCR - water control relay

WV - inlet water valve

Page 13

III. Technical Information

A. Water Circuit and Refrigeration Circuit

F-300BAF

13

Page 14

B. Wiring Diagram

1. Auxiliary Code K-1 and Earlier

14

F-300BAF

Page 15

2. Auxiliary Code K-2 and L-0

15

F-300BAF

Page 16

3. Auxiliary Code L-1 and M-0

16

F-300BAF

Page 17

4. Auxiliary Code M-1 and Later

17

F-300BAF

Page 18

C. Sequence of Electrical Circuit

1. Fill Cycle

When power switch is moved to "ON" position, water is supplied to reservoir.

18

F-300BAF

Page 19

2. Ice Purge Cycle

When reservoir has filled, gear motor starts.

19

F-300BAF

Page 20

3. Freeze Cycle

Compressor and condenser fan motor start about 60 sec. after gear motor starts.

20

F-300BAF

Page 21

4. Shutdown

Compressor and condenser fan motor stop about 90 sec. after bin control operates, gear

motor stops about 60 sec. later. Flush water valve then operates.

21

F-300BAF

Page 22

5. Cleaning - Flush Switch

Compressor and condenser fan motor stop about 90 sec. after manually moving flush

switch to FLUSH position. Gear motor stops about 60 sec. later. Flush water valve then

operates.

22

F-300BAF

Page 23

6. Low Water Safety

If upper float switch fails to close, water valve remains open until upper float switch

closes and water control relay energizes.

23

F-300BAF

Page 24

7. Spout Safety Switch

When saftey switch is activated, the safety switch relay operates, and the icemaker does

not run.

24

F-300BAF

Page 25

8. High Pressure Switch

In case of high pressure, pressure switch shuts down unit.

25

F-300BAF

Page 26

D. Performance Data

APPROXIMATE Ambient Water Temp. (°F)

ICE PRODUCTION Temp. (°F)

PER 24 HR. 70 *303 *(137) 290 (131) 278 (126)

80 267 (121) 256 (116) 246 (112)

90 236 (107) *232 *(105) 218 (99)

lbs./day (kg/day) 100 209 (95) 201 (91) *188 *(85)

APPROXIMATE ELECTRIC 70 *667 -- 668 -- 669 -CONSUMPTION 80 670 -- 671 -- 672 --

90 673 -- *674 -- 681 -watts 100 688 -- 695 -- *702 -APPROXIMATE WATER 70 *36 *(137) 35 (131) 33 (126)

CONSUMPTION PER 24 HR. 80 32 (121) 31 (116) 30 (112)

90 28 (107) *28 *(105) 26 (99)

gal./day (l/day)

100 25 (95) 24 (91) *23 *(85)

EVAPORATOR OUTLET TEMP. 70 *19 *(-7) 19 (-7) 19 (-7)

80 19 (-7) 22 (-6) 22 (-6)

90 22 (-6) *22 *(-6) 26 (-4)

°F (°C) 100 26 (-4) 26 (-4) *26 *(-4)

HEAD PRESSURE 70 *250 *(17.5) 250 (17.5) 250 (17.5)

80 280 (19.7) 280 (19.7) 280 (19.7)

90 311 (21.9) *311 *(21.9) 311 (21.9)

PSIG (kg/cm²G)

100 351 (24.7) 351 (24.7) *351 *(24.7)

SUCTION PRESSURE 70 *35 *(2.5) 35 (2.5) 35 (2.5)

80 37 (2.6) 37 (2.6) 37 (2.6)

90 39 (2.7) *39 *(2.7) 39 (2.7)

PSIG ( kg/cm²G )

100 43 (3.0) 43 (3.0) *43 *(3.0)

TOTAL HEAT OF REJECTION 3178 BTU/h (AT 90°F /WT 70°F)

Note: The data without *marks should be used for reference.

507090

1. F-300BAF

We reserve the right to make changes to specifications and design without prior notice.

26

Page 27

IV. Service Diagnosis

A. Diagnostic Procedure

This diagnostic procedure is a sequence check that allows you to diagnose the electrical

system and components under normal operating conditions of 70°F or warmer air and

50°F or warmer water temperatures. Before proceeding, check for correct installation,

proper voltage per unit nameplate and adequate water supply.

1) Unplug the unit from the electrical outlet and access the control panel.

2) Plug the unit back in. Make sure the flush switch is in the ICE position, then place the

power switch in the ON position.

3) Fill Cycle – The water valve energizes. The reservoir begins to fill and the lower float

switch closes. Nothing occurs at this time. The reservoir continues to fill and the upper

float switch closes, energizng the water control relay. When the water control relay

energizes, the inlet water valve de-energizes and the low water safety circuit closes to

the timer board. Diagnosis: Check that the water valve fills the reservoir. If not, check

for clogged water filters, clogged water valve screen, power supply to the unit, power

circuit to the water valve (power switch, high pressure switch, transformer, safety switch,

safety relay contacts, fuse, bin control, flush switch, flush relay, flush relay contacts,

float switch, water control relay contacts), and the coil on the water valve.

3) Ice Purge Cycle – (short cycle protection) The gear motor and the gear motor protect

relay energize, and the 60 second compressor short cycle protection timer starts.

Diagnosis: Check that the gear motor starts. If not, check the low water safety circuit

on terminals 3 and 4 on the timer board, check for 120 volts on the gear motor relay

terminal 8 on the timer board, check the gear motor fuse, thermal protector, and gear

motor windings. If the gear motor starts but the auger does not turn: check the gear

motor coupling between the auger and the gear motor. If the compressor starts the

same time the gear motor starts: Check the compressor relay on the timer board (the

black relay on the timer board is the compressor relay).

4) Freeze Cycle – The compressor and fan motor energize, the gear motor, gear motor

protect relay, flush switch relay, and the water control relay remain energized. Ice

production begins 4 to 6 minutes after the compressor and fan motor start depending

on ambient and water conditions. Diagnosis: Check that the compressor and fan

motor are running. If not, check for 120 volts on the compressor relay terminal 4 on the

timer board (the black relay on the timer board is the compressor relay), check for 120

volts on the gear motor protect relay, check gear motor relay contacts 4 and 6, check

voltage on the compressor terminals, check the internal overload (motor protector), the

compressor capacitors, and voltage to the fan motor and fan capacitor.

27

Page 28

5) Refill/Low Water Safety Cycle – As ice is produced, the water level in the reservoir

drops. As it drops, the upper float switch and lower float switch open. The upper float

switch opens first. Nothing occurs at this time. When the lower float switch opens, the

refill begins. The water control relay de-energizes, the low water safety circuit opens

(terminals 4 and 6 on the water control relay, 3 and 4 on the timer board), a 90 second

countdown timer begins on the timer board, and the inlet water valve energizes. The

compressor, fan motor and gear motor continue to run. The upper float switch now

has 90 seconds to close before the low water safety timer terminates and shuts down

the unit. Once the upper float switch closes, the water control relay energizes, the

inlet water valve de-energizes and the low water safety 90 second countdown timer

terminates. Diagnosis – Check that the water fill begins. If not, check the lower float

switch, voltage to the inlet water valve, the water control relay, water supply, filters, and

inlet water valve screen.

7) Shutdown – The bin fills and activates the bin control proximity switch. 90 seconds

later the compressor and fan motor de-energize, then 60 seconds later the gear motor

de-energizes. Diagnosis: Check that the bin control paddle is activated and that

the proximity switch opens. If the compressor and gear motor fail to stop, check the

proximity switch and timer board relays.

28

Page 29

B. Diagnostic Charts

1. No Ice Production

Problem Possible Cause Remedy

[1] The icemaker will not

start. (fill cycle, water

valve)

a) Power Supply 1. Off. 1. Turn on.

Power cord

2.

unplugged.

3. Loose connection. 3. Tighten.

4. Bad contacts. 4. Check for contintinuity and

5. Blown fuse. 5. Replace.

b) Power Switch

(Control Box)

c) High Pressure Switch 1. Dirty air filter or

d) Transformer 1. Coil winding opened. 1. Replace.

e) Spout Safety Switch

and Relay

f) Fuse (Control Box) 1. Blown. 1. Check for short circuit and

g) Bin Control 1. Actuator sticking. 1. Adjust or replace.

h) Flush Switch 1. FLUSH position. 1.Move to ICE position.

i) Flush Switch Relay 1. Coil open. 1. Replace.

1. OFF position. 1. Move to ON position.

Bad contacts. 2. Check for continuity and

2.

condenser.

Ambient or condenser

2.

water temperature too

warm.

3. Condenser water

pressure too low or off.

(water-cooled model

only)

4. Water regulating valve

set too high. (watercooled model only)

5. Fan not rotating. 5.See "3. [1] a) Fan Motor.”

6. Refrigerant

overcharged.

7. Refrigerant line or

components plugged.

8. Bad contacts. 8. Check for continuity and

9. Loose connections. 9. Tighten.

1. Bin control not

activating.

2. Proximity switch open. 2. Replace.

2. Bad contacts. 2. Check for continuity and

2. Plug into receptacle.

replace.

replace.

1. Clean.

2. Reduce temperature.

3. Check and get

recommended pressure.

4. Adjust it lower.

6. Recharge.

7. Clean and replace drier.

replace.

1. Check bin control actuator

and proximity switch.

replace.

replace.

29

Page 30

Problem Possible Cause Remedy

j) Water Control Relay 1. Bad contacts. 1. Replace.

Open coil. 2. Replace.

2.

k) Water Valve 1. Coil winding opened. 1. Replace.

l) Shut-off Valve 1. Closed. 1. Open.

Water failure. 2. Wait until water is

2.

supplied.

Water does not stop,

[2]

and the gear motor

will not start.

Water has been

[3]

supplied, but the gear

motor will not start.

Gear motor starts,

[4]

but compressor will

not start or operates

intermittently.

m)Plug and Receptacle

(Control Box)

a) Float Switch 1. Bad contacts. 1. Check for continuity and

b) Water Control Relay 1. Contact fused. 1. Replace.

c) Flush Water Valve 1. Valve seat clogged

d) Hoses 1. Disconnected. 1. Connect.

a) Bin Control 1. Open 1.Bin full, check for

b) Water Control Relay 1. Low water safety

c) Control Timer

(Printed Circuit Board)

d) Gear Motor Fuse 1. Blown. 1. Check gear motor

e) Gear Motor Thermal

Protector

f) Gear Motor 1. Open windings. 1. Replace gear motor.

a) Gear Motor Protect

Relay

b) Timer Board Relay 1. Bad contacts. 1. Check for continuity and

c) Starter 1. Bad contacts. 1. Check for continuity and

d) Start Capacitor or Run

Capacitor

1. Disconnected. 1.Connect.

Loose terminal. 2. Repair terminal

2.

connection.

replace.

2. Float does not move

freely.

2. Coil winding opened. 2. Replace.

and water leaking.

circuit open

(bad conacts ).

1. Fails to operate gear

motor relay.

1. Open. 1. Check gear motor

Locked bearings 1. Replace gear motor.

2.

1. Open coil. 1. Replace.

Open contacts. 2. Replace.

2.

2. Coil winding opened. 2. Replace timer.

Coil winding opened. 2. Replace.

2.

3. Loose connections. 3. Tighten.

1. Defective. 1. Replace.

2. Clean or replace.

1. Clean or replace.

continuity on proximity

switch.

1. Replace relay.

1. Check water control relay

circuit.

amperage, bearing

wear (see "V. F. 1. Upper

Bearing Wear Check"),

supply voltage.

bearings, voltage supply.

replace.

replace.

30

Page 31

Problem Possible Cause Remedy

e) Compressor 1. Loose connections. 1. Tighten.

[5] Gear motor and

compressor start, but

no ice is produced.

Motor winding opened

2.

or grounded.

3. Compressor locked

and motor protector

tripped.

f) Power Supply 1. Circuit ampacity too

low.

a) Refrigerant Line 1. Gas leaks. 1. Check for leaks with a

2. Refrigerant line

clogged.

2. Replace.

3. Replace compressor.

1. Install a larger-sized

circuit.

leak detector. Replace

drier and charge with

refrigerant. Refrigerant

charge is marked on

nameplate or rating label.

2. Replace the clogged

component.

2. Low Ice Production

Problem Possible Cause Remedy

[1] Low ice production. a)Refrigerant Line 1. Gas leaks. 1.See "2. [5] a) Refrigerant

Line."

b)High-Side Pressure Too

High

c) Expansion Valve (not

adjustable)

2. Refrigerant line

clogged.

3. Overcharged. 3. Recharge.

1. Dirty air filter or

condenser.

Ambient or condenser

2.

water temperature too

warm.

3. Condenser water

pressure too low or off.

[water-cooled model

only]

4. Fan, slow rpm. 4.See "3. [1] a) Fan Motor".

5. Water regulating valve

clogged. [water-cooled

model only]

1. Low-side pressure too

low.

2. Low-side pressure too

high.

2. Replace the clogged

component.

1. Clean.

2. Reduce temperature.

3. Check and get recommended pressure.

5. Clean.

1. Replace.

2. See if expansion valve

bulb is mounted properly,

and replace the valve if

necessary.

31

Page 32

3. Other

Problem Possible Cause Remedy

[1] Abnormal noise a)Fan Motor 1. Bearing worn out. 1. Replace.

Fan blade deformed. 2. Replace fan blade.

2.

Overflow from

[2]

reservoir (water does

not stop).

[3] Gear motor protector

operates frequently or

fuse blows frequently.

3. Fan blade does not

move freely.

b)Compressor 1. Bearings worn out, or

cylinder valve broken.

2. Mounting pad out of

position.

c) Refrigerant Lines 1. Rub or touch lines or

other surfaces.

d)Gear Motor 1. Bearing or gear worn

out / damaged.

e)Evaporator 1. Low refrigerant

pressures.

Expansion valve bad. 2.Replace.

2.

3. Evaporator bad. 3.Replace.

4. Scale on inside wall of

freezing cylinder.

a)Water Supply 1. Water pressure too

high.

b)Water Valve 1. Diaphragm does not

close.

c) Float Switch 1.Bad contacts. 1. Check for continuity and

d)Water Control Relay 1. Bad contacts. 1. Replace

a)Power Supply Voltage 1. Too high or too low. 1. Connect the unit to a

b)Evaporator Assembly 1. Bearings or auger

worn out.

c) Bin Control 1. Bad contacts. 1. Check for continuity and

Actuator does not

2.

move freely.

3. Replace.

1. Replace.

2. Reinstall.

1. Replace or separate.

1. Replace.

1. Check charge, check for

possible leak, repair,

re-charge.

4. Use "SCALE AWAY" or

"LIME-A-WAY" solution to

clean periodically. If the

water is found hard by

testing, install a softener.

1. Install a pressure reducing

valve.

1. Clean or replace.

replace.

power supply of proper

voltage.

1. Replace bearings or

auger.

replace.

2. Clean shaft and its

corresponding holes or

replace bin control.

32

Page 33

V. Removal and Replacement of Components

IMPORTANT

Ensure all components, fasteners and thumbscrews are securely in place after

the equipment is serviced.

IMPORTANT

1. The Polyol Ester (POE) oils used in R-404A units can absorb moisture

quickly. Therefore it is important to prevent moisture from entering the system

when replacing or servicing parts.

2. Always install a new drier every time the sealed refrigeration system is

opened.

3. Do not leave the system open for longer than 15 minutes when replacing or

servicing parts.

A. Service for Refrigerant Lines

1. Refrigerant Recovery

The icemaker unit is provided with refrigerant access valves. Using proper refrigerant

practices recover the refrigerant from the access valves and store it in an approved

container. Do not discharge the refrigerant into the atmosphere.

2. Evacuation and Recharge [R-404A]

1) Attach service manifold hoses and a vacuum pump to the system. Be sure to connect

charging hoses to both high-side and low-side access valves.

IMPORTANT

The vacuum level and vacuum pump may be the same as those for current

refrigerants. However, the rubber hose and gauge manifold to be used for

evacuation and refrigerant charge should be exclusively for POE oils.

2) Turn on the vacuum pump. Never allow the oil in the vacuum pump to flow backward.

3) Allow the vacuum pump to pull down to a 29.9" Hg vacuum. Evacuating period

depends on pump capacity.

4) Close the low-side valve and high-side valve on the service manifold.

5) Disconnect the vacuum pump, and attach a refrigerant service cylinder to the highside line. Remember to loosen the connection, and purge the air from the hose. See

the nameplate for the required refrigerant charge. Hoshizaki recommends only virgin

refrigerant or reclaimed refrigerant which meets ARI Standard No. 700-88 be used.

6) A liquid charge is recommended for charging an R-404A system. Invert the service

cylinder and place it on scales. Open the high-side, service manifold valve.

7) Allow the system to charge with liquid until the proper charge weight is met.

33

Page 34

8) If necessary, add any remaining charge to the system through the low-side. Use a

throttling valve or liquid dispensing device to add the remaining liquid charge through

the low-side access port with the unit running.

9) Close the two refrigerant access valves, and disconnect the service manifold hoses.

10) Cap the access valves to prevent a possible leak.

B. Brazing

WARNING

1. Refrigerant R-404A itself is not flammable at atmospheric pressure and

temperatures up to 176°F.

2. Refrigerant R-404A itself is not explosive or poisonous. However, when

exposed to high temperatures (open flames) R-404A can be decomposed to

form hydrofluoric acid and carbonyl fluoride both of which are hazardous.

3. Always recover the refrigerant and store it in an approved container. Do not

discharge the refrigerant into the atmosphere.

4. Do not use silver alloy or copper alloy containing arsenic.

5. Do not use R-404A as a mixture with pressurized air for leak testing.

Refrigerant leaks can be detected by charging the unit with a little refrigerant,

raising the pressure with nitrogen and using an electronic leak detector.

Note: All brazing connections are clear-paint coated. Use sandpaper to remove the

coating from the brazing connections before unbrazing the components.

34

Page 35

C. Removal and Replacement of Compressor

IMPORTANT

Always install a new drier every time the sealed refrigeration system is opened.

Do not replace the drier until after all other repair or replacement has been

made.

Note: When replacing a compressor with a defective winding, be sure to install the

new start capacitor and start relay supplied with the replacement compressor.

Due to the ability of the POE oil in the compressor to absorb moisture quickly,

the compressor must not be opened more than 15 minutes for replacement or

service. Do not mix lubricants of different compressors even if both are charged

with R-404A, except when they use the same lubricant.

1) Unplug the unit from the electrical outlet.

2) Remove the panels.

3) Recover the refrigerant and store it in an approved container.

4) Remove the terminal cover on the compressor and disconnect the compressor wiring.

5) Remove the hold-down bolts, washers and rubber grommets .

6) Remove the discharge and suction pipes

7) Remove the compressor. Unpack the new compressor package.

8) Attach the rubber grommets of the prior compressor.

9) Place the compressor in position and secure it using the bolts and washers.

10) Remove the drier, then place the new drier in position.

11) Remove plugs from the suction, discharge and process pipes.

12) Braze all fittings while purging with nitrogen gas flowing at a pressure of 3 to 4 PSIG.

13) Check for leaks using nitrogen gas (140 PSIG) and soap bubbles.

14) Evacuate the system, and charge it with refrigerant. See the nameplate for the required

refrigerant charge.

15) Connect the terminals and replace the terminal cover in its correct position.

16) Replace the panels in their correct positions.

17) Plug the unit back in.

35

Page 36

D. Removal and Replacement of Drier

IMPORTANT

Always install a new drier every time the sealed refrigeration system is opened.

Do not replace the drier until after all other repair or replacement has been

made.

1) Unplug the unit from the electrical outlet.

2) Remove the panels.

3) Recover the refrigerant and store it in an approved container.

4) Remove the drier, then place the new drier in position. Install the new drier with the

arrow on the drier in the direction of the refrigerant flow.

5) Braze all fittings while purging with nitrogen gas flowing at a pressure of 3 to 4 PSIG.

6) Check for leaks using nitrogen gas (140 PSIG) and soap bubbles.

7) Evacuate the system, and charge it with refrigerant. See the nameplate for the required

refrigerant charge.

8) Replace the panels in their correct positions.

9) Plug the unit back in.

E. Removal and Replacement of Expansion Valve

IMPORTANT

Sometimes moisture in the refrigeration circuit exceeds the drier capacity and

freezes up at the expansion valve. Always install a new drier every time the

sealed refrigeration system is opened. Do not replace the drier until after all

other repair or replacement has been made.

1) Unplug the unit from the electrical outlet.

2) Remove the panels.

3) Recover the refrigerant and store it in an approved container.

4) Remove the insulation and the expansion valve bulb on the suction line.

5) Remove the expansion valve cover and disconnect the expansion valve. Place the new

expansion valve in position.

6) Remove the drier, then place the new drier in position.

7) Braze all fittings while purging with nitrogen gas flowing at a pressure of 3 to 4 PSIG.

WARNING

Always protect the valve body by using a damp cloth to prevent the valve from

overheating. Do not braze with the valve body exceeding 250°F (121°C).

36

Page 37

8) Check for leaks using nitrogen gas (140 PSIG) and soap bubbles.

9) Evacuate the system, and charge it with refrigerant. See the nameplate for the required

refrigerant charge.

10) Attach the expansion valve bulb to the suction line in the same location as the previous

bulb. The bulb should be at the 12 o'clock position on the tube. Be sure to secure the

bulb with the clamp and holder and to insulate it.

11) Place the expansion valve cover in position.

12) Replace the panels in their correct positions.

13) Plug the unit back in.

37

Page 38

F. Removal and Replacement of Evaporator Assembly Components

CAUTION

Make sure that the saftey switch and spout are properly installed after making

repairs in the evaporator assembly. Failure to install the safety switch and spout

correctly could result in serious damage to the unit.

Safety Bracket A

Safety Switch

Drip Bracket

Channel

Drip Bracket

Safety Bracket B

Channel

Auger

Safety Switch Assembly

Safety Bracket A

Spout

Safety Bracket B

Spout

Drip Bracket

Cutter

Extruding Head

Upper Bearing

Spring Retainer

Mechanical Seal

O-Ring

Barrier

Gear Motor

Evaporator

Allen Head Cap Screw

Allen Head Cap Screw

with Washer

Housing-Lower Bearing

Coupling-Spline

Fig. 1

38

Page 39

1. Upper Bearing Wear Check

To ensure that the bearing inside the extruding head does not exceed the wear tolerance

of .02", follow the instructions below.

1) Unplug the unit from the electrical outlet.

2) Remove the panels.

3) Remove the thumbscrews and take off the

spout from the evaporator.

.02" Round Stock

or Pin Gauge

4) Loosen the cutter with a wrench and

remove it.

5) Grasp the top of the auger and move the

auger towards you and then try to insert a

.02" round stock or pin gauge in between

the back side of the auger shaft and the

bearing surface. Check several locations

around the auger shaft. If the gauge goes

between the shaft and the bearing at

any point or if the bearing is scratched

or cracked, both the top bearing in the

extruding head and the lower bearing in the

housing should be replaced. Instructions

for removing the extruding head and

housing are located later in this procedure.

Note: Replacing the bearing requires a bearing press adaptor. If one is not available,

replace the whole extruding head and housing.

6) Replace the cutter.

7) Replace the spout. Make sure that the drip bracket is in the channel and that safety

bracket B is behind safety bracket A. See Fig. 1.

Fig. 2

Auger

Extruding

Head

8) Replace the panels in their correct positions.

9) Plug the unit back in.

2. Removal and Replacement of Cutter

1) Unplug the unit from the electrical outlet.

2) Remove the panels.

3) Remove the thumbscrews and take off the spout from the evaporator.

4) Loosen the cutter with a wrench and remove it.

5) Install the new cutter.

6) Replace the spout. Make sure that the drip bracket is in the channel and that safety

bracket B is behind safety bracket A. See Fig.1.

7) Replace the panels in their correct positions.

8) Plug the unit back in.

39

Page 40

3. Removal and Replacement of Extruding Head

1) Unplug the unit from the electrical outlet.

2) Remove the panels.

3) Remove the thumbscrews and take off the spout from the evaporator.

4) Loosen the cutter with a wrench and remove it.

5) Remove the allen head cap screws and lift off the extruding head.

6) Place new extruding head in place and tighten down allen head cap screws. If the seals

on the allen head cap screws are RED, they must be replaced. If the seals are BLUE,

they may be re-used.

7) Replace the cutter and spout. Make sure that the drip bracket is in the channel and that

safety bracket B is behind safety bracket A. See Fig. 1.

8) Replace the panels in their correct positions.

9) Plug the unit back in.

4. Removal and Replacement of Auger

1) Drain water from the evaporator by using the flush switch.

2) Unplug the unit from the electrical outlet.

3) Remove the panels.

4) Remove the thumbscrews and take off the spout from the evaporator.

5) Loosen the cutter with a wrench.

6) Remove the allen head cap screws securing the extruding head. Using the cutter, lift out

the auger assembly.

7) Remove the cutter and extruding head from the auger and place on the new auger.

8) Install the new auger.

9) Replace the removed parts in the reverse order of which they were removed. When

replacing the spout, make sure that the drip bracket is in the channel and that safety

bracket B is behind safety bracket A. See Fig. 1.

10) Replace the panels in their correct positions.

11) Plug the unit back in.

5. Removal and Replacement of Evaporator

IMPORTANT

Always install a new drier every time the sealed refrigeration system is opened.

Do not replace the drier until after all other repair or replacement has been

made.

1) Remove the panels.

2) Drain water from the evaporator by using the flush switch.

3) Unplug the unit from the electrical outlet.

40

Page 41

4) Recover the refrigerant and store it in an approved container.

5) Remove the thumbscrews and take off the spout from the evaporator.

6) Disconnect the water hoses.

7) Remove the allen head cap screws securing the extruding head. Using the cutter, lift

out the auger assembly.

8) Remove the insulation and the expansion valve bulb on the suction line.

9) Disconnect the inlet and outlet tubing.

10) Remove the allen head cap screws securing the evaporator to the lower housing.

11) Lift off the evaporator.

12) Inspect the mechanical seal and O-ring prior to installing the new evaporator. The

mechanical seal consists of two parts. One moves along with the auger, and the other

is fixed on the lower housing. If the contact surfaces of these two parts are worn,

cracked or scratched, the mechanical seal may cause water leaks and should be

replaced. Instructions for removing the mechanical seal and lower housing are located

later in this procedure.

13) Make sure the lower mechanical seal is in place, then place the evaporator in position.

Secure the evaporator to the lower housing using the allen head cap screws.

14) Remove the drier, then place the new drier in position.

15) Braze all fittings while purging with nitrogen gas flowing at a pressure of 3 to 4 PSIG.

16) Check for leaks using nitrogen gas (140 PSIG) and soap bubbles.

17) Evacuate the system, and charge it with refrigerant. See the nameplate for the required

refrigerant charge.

18) Replace the removed parts in the reverse order of which they were removed. When

replacing the spout, make sure that the drip bracket is in the channel and that safety

bracket B is behind safety bracket A. See Fig. 1.

19) Replace the panels in their correct positions.

20) Plug the unit back in.

6. Removal and Replacement of Mechanical Seal and Lower Housing

6a. Mechanical Seal

1) Drain water from the evaporator by using the flush switch.

2) Unplug the unit from the electrical outlet.

3) Remove the panels.

4) Remove the thumbscrews and take off the spout from the evaporator.

5) Remove the allen head cap screws securing the extruding head. Using the cutter, lift

out the auger assembly.

6) The mechanical seal consists of two parts. One moves along with the auger, and the

other is fixed on the lower housing. If the contact surfaces of these two parts are worn,

cracked or scratched, the mechanical seal may cause water leaks and should be

replaced.

41

Page 42

7) Remove the allen head cap screws securing the evaporator to the lower bearing

housing.

8) Raise the evaporator up to access the lower housing.

9) Remove the O-ring and mechanical seal from the housing. If only replacing mechanical

seal, proceed to step 12).

WARNING

To help prevent water leaks, be careful not to damage the surfaces of the

O-ring or mechanical seal.

6b. Lower Housing

10) Remove the bolts securing the housing to the gear motor and remove the housing from

the gear motor. If inspection of the upper bearing inside the extruding head (see "F. 1.

Upper Bearing Wear Check") indicates that it is out of tolerance, replace both it and the

bearing inside the lower housing.

Note: Replacing the bearing requires a bearing press adaptor. If one is not available,

replace the whole extruding head and housing.

11) Mount the lower housing on the gear motor.

12) Install the O-ring and lower part of mechanical seal on the lower housing.

13 ) Lower the evaporator down and secure it to the lower housing.

14) Install the auger assembly with the upper part of the mechanical seal attached.

15) Replace the removed parts in the reverse order of which they were removed. When

replacing the spout, make sure that the drip bracket is in the channel and that safety

bracket B is behind safety bracket A. See Fig. 1.

16) Replace the panels in their correct positions.

17) Plug the unit back in.

7. Removal and Replacement of Gear Motor

1) Drain the water from the evaporator by using the flush switch.

2) Unplug the unit from the electrical outlet.

3) Remove the panels.

4) Remove the thumbscrews and take off the spout assembly from the evaporator.

5) Remove the bolts securing the lower housing to the gear motor. Lift the evaporator up

slightly.

6) Remove the bolts securing the gear motor.

7) Remove the wiring from the gear motor, then remove the gear motor.

8) Remove the barrier, gear motor bracket and coupling-spline from the old gear motor

and place on the new gear motor. Apply silicone over barrier screws.

9) Replace the removed parts in the reverse order of which they were removed. When

replacing the spout, make sure that the drip bracket is in the channel and that safety

bracket B is behind safety bracket A. See Fig. 1.

42

Page 43

10) Replace the panels in their correct positions.

11) Plug the unit back in.

G. Removal and Replacement of Fan Motor

1) Unplug the unit from the electrical outlet.

2) Remove the panels.

3) Remove the wire connectors from the fan motor leads.

4) Remove the fan motor bracket and fan motor.

5) Install the new fan motor.

6) Replace the fan motor bracket and the wire connectors.

7) Replace the panels in their correct positions.

8) Plug the unit back in.

H. Removal and Replacement of Inlet Water Valve

1) Unplug the unit from the electrical outlet.

2) Remove the panels.

3) Close the water supply line shut-off valve.

4) Disconnect the terminals from the water valve.

5) Loosen the fitting nut on the water valve inlet, and remove the water valve. Do not lose

the packings inside the fitting nut.

6) Remove the water supply hose from the water valve.

7) Install the new water valve.

8) Assemble the removed parts in the reverse order of the above procedure.

9) Open the water supply line shut-off valve.

10) Check for water leaks.

11) Replace the panels in their correct positions.

12) Plug the unit back in.

I. Removal and Replacement of Flush Water Valve

1) Unplug the unit from the electrical outlet.

2) Remove the panels and close the water supply line shut-off valve.

3) Remove the clamp and disconnect the water valve.

Note: Water may still remain inside the evaporator. Be sure to drain the water into the

drain pan.

4) Disconnect the terminals from the water valve.

5) Remove the water valve from the bracket.

6) Remove the drain pipe from the water valve.

7) Connect the drain pipe to the new water valve, and place the valve in position.

43

Page 44

8) Connect the hose to the water valve and secure it with the clamp.

9) Pour water into the reservoir, and check for water leaks.

10) Open the water supply line shut-off valve.

11) Plug the unit back in.

12) Move the flush switch to the "ICE" position.

13) Check for water leaks.

14) Move the flush switch to the "FLUSH" position, and make sure water is flushing.

15) Move the flush switch to the "ICE" position.

16) Replace the panels in their correct positions.

17) Plug the unit back in.

44

Page 45

VI. Cleaning and Maintenance

IMPORTANT

Ensure all components, fasteners and thumbscrews are securely in place after

any maintenance or cleaning is done to the equipment.

A. Cleaning and Sanitizing Instructions

WARNING

1. HOSHIZAKI recommends cleaning this unit at least once a year. More

frequent cleaning, however, may be required in some existing water

conditions.

2. To prevent injury to individuals and damage to the icemaker, do not use

ammonia type cleaners.

3. Always wear liquid-proof gloves to prevent the cleaning and sanitizing

solutions from coming into contact with skin.

1. Cleaning Solution

Dilute 4.8 fl. oz. (142 ml) of recommended cleaner Hoshizaki "Scale Away" or

"LIME-A-WAY" (Economics Laboratory, Inc.) with 0.8 gallons (3 l) of warm water. This is

a minimum amount. Make more solution if necessary.

IMPORTANT

For safety and maximum effectiveness, use the solution immediately after

dilution.

2. Cleaning Procedure

1) Unplug the unit from the electrical outlet then remove the front panel and the top panel.

2) Close the water supply line shut-off valve.

3) Remove all ice from the storage bin.

4) Move the flush switch to the "FLUSH" position.

5) Plug the unit back in and turn on the power

supply and drain out all water from the

water line.

6) Turn off the power supply.

Note: This unit is designed to start operating when the

reservoir is filled with water.

7) In the storage bin, remove the thumbscrews attaching spout (B), then remove spout (B)

and spout packing (B). See Fig. 3.

Thumbscrews

Spout Packing (B)

Fig. 3

Spout (B)

45

Page 46

8) Remove the thumbscrews attaching spout

(A) to the evaporator assembly and lift off

spout (A) and spout packing (A). See Fig 4.

Thumbscrews

Spout (A)

9) Pour the cleaning solution over the

extruding head until the evaporator

Evaporator Assembly

Spout (A) Packing

assembly and the reservoir are filled and

the solution starts to overflow into the drain

pan.

Fig. 4

Note: If there is excess scale on the extruding head, fill the evaporator assembly and

reservoir as described above, then use a clamp on the reservoir hose between

the reservoir and evaporator assembly to block flow. Pour additional cleaning fluid

over the extruding head until the evaporator assembly is completely full.

10) Using the thumbscrews, replace spouts (A) and (B) and spout packings (A) and (B) in

their correct positions.

11) Allow the icemaker to sit for about 10 minutes before operation. If you placed a clamp

on the reservoir hose in step 9, remove it before operation.

12) Move the flush switch to the "ICE" position, then turn on the power supply. Replace the

top panel and the front panel in their correct positions. Make ice using the solution until

the icemaker stops making ice.

13) Remove the front panel.

14) Move the flush switch to the "FLUSH" position to drain the remainder of the solution.

15) After the solution is drained, move the flush switch to the "ICE" position.

16) Replace the front panel in its correct position.

17) Open the water supply line shut-off valve, and supply water to the reservoir.

18) When the gear motor starts, remove the top panel and front panel. Turn off the power

supply.

19) Drain out all water from the water line. See 4) through 6).

3. Sanitizing Solution

Dilute 2.5 fl. oz. (74 ml or 5 tbs) of a 5.25% sodium hypochlorite solution (chlorine

bleach) with 5 gallons (19 l) of warm water.

IMPORTANT

For safety and maximum effectiveness, use the solution immediately after

dilution.

46

Page 47

4. Sanitizing Procedure - Initial

1) Close the water supply line shut-off valve.

2) In the storage bin, remove the thumbscrews attaching spout (B), then remove spout (B)

and spout packing (B).

3) Remove the thumbscrews attaching spout (A) to the evaporator assembly and

lift off spout (A) and spout packing (A), and the cylinder packing.

4) Pour the sanitizing solution over the extruding head until the evaporator assembly and

the reservoir are filled and the solution starts to overflow into the drain pan.

5) Remove the thumbscrews attaching the bin

control assembly to the inside of the bin

Bracket

Thumbscrews

top panel. See Fig. 5.

6) Remove the snap pin, shaft and actuator.

7) Remove the sliding door.

Snap Pin

8) Soak the removed parts in .25 gallons (1 l)

Shaft

Actuator

of sanitizing solution for 10 minutes then

wipe them down.

Fig. 5

9) Rinse the parts thoroughly.

IMPORTANT

If the solution is left on these parts, they will rust.

10) Replace all parts in their correct positions.

11) Move the flush switch to the "ICE" position, then turn on the power supply. Replace the

top panel and the front panel in their correct positions. Make ice using the solution until

the icemaker stops making ice.

5. Sanitizing Procedure - Final

1) Remove the front panel and the top panel, then turn off the power supply.

2) Move the flush switch to the "FLUSH" position.

3) Turn on the power supply and drain out all water from the water line.

4) Turn off the power supply.

Note: This unit is designed to start operating when the reservoir is filled with water.

5) In the storage bin, remove the thumbscrews attaching spout (B), then remove spout (B)

and spout packing (B).

6) Remove the thumbscrews attaching spout (A) to the evaporator assembly and lift off

spout (A) and spout packing (A).

7) Pour the sanitizing solution over the extruding head until the evaporator assembly and

the reservoir are filled and the solution starts to overflow into the drain pan.

47

Page 48

8) Using the thumbscrews, replace spouts (A) and (B) and spout packings (A) and (B) in

their correct positions.

9) Allow the icemaker to sit for about 10 minutes before operation.

10) Move the flush switch to the "ICE" position, then turn on the power supply. Replace the

top panel and the front panel in their correct positions. Make ice using the solution until

the icemaker stops making ice.

11) Remove the front panel.

12) Move the flush switch to the"FLUSH" position to drain the remainder of the solution.

13) After the solution is drained, move the flush switch to the "ICE" position.

14) Replace the front panel in its correct position.

15) Open the water supply line shut-off valve and supply water to the reservoir.

16) When the gear motor starts, remove the front panel and turn off the power supply.

17) Drain out all water from the water line. See 2) and 3).

18) Move the flush switch to the "ICE" position and run the icemaker.

19) Turn off the power supply after 30 minutes.

20) Pour warm water into the storage bin to melt all ice, then clean the bin liner with the

solution.

21) Flush out any solution from the storage bin.

22) Turn on the power supply and start the automatic icemaking process.

IMPORTANT

1. After cleaning, do not use ice made from the sanitizing solution. Be careful

not to leave any solution in the storage bin.

2. Follow carefully any instructions provided with the bottles of cleaning or

sanitizing solution.

3. Never run the icemaker when the reservoir is empty.

48

Page 49

B. Maintenance

1. This icemaker must be maintained individually, referring to the instruction

manual and labels provided with the icemaker.

2. To have the optimum unit performance, the following parts need periodic

inspection and maintenance:

These parts should be inspected at least once a year or every 10,000 hours

of operation. Their service life, however, depends on water quality and

environment. More frequent inspection and maintenance are recommended in

bad or severe water conditions.

Replacement of the following consumable parts is recommended if wear

exceeds factory recommendations:

Upper Bearing

Lower Bearing

Mechanical Seal

Consult with your local distributor about inspection and maintenance service.

To obtain the name and phone number of your local distributor, call Hoshizaki

Technical Support at 1-800-233-1940.

IMPORTANT

Extruding Head and Upper Bearing

Housing and Lower Bearing

Mechanical Seal

Auger

Evaporator Cylinder

Gear Motor

1) Stainless Steel Exterior

To prevent corrosion, wipe the exterior occasionally with a clean and soft cloth. Use a

damp cloth containing a neutral cleaner to wipe off oil or dirt build up.

2) Storage Bin and Scoop

• Wash your hands before removing ice. Use the plastic scoop provided (bin accessory).

• The storage bin is for ice use only. Do not store anything else in the bin.

• Keep the scoop clean. Clean using a neutral cleaner and rinse thoroughly.

• Clean the bin liner using a neutral cleaner. Rinse thoroughly after cleaning.

3) Air Filter

A plastic mesh air filter removes dirt or dust from the air, and keeps the condenser from

getting clogged. As the filter gets clogged, the icemaker’s performance will be reduced.

Check the filter at least twice a month. When clogged, use warm water and a neutral

cleaner to wash the filter.

4) Condenser

Check the condenser once a year, and clean if required by using a brush or vacuum

cleaner. More frequent cleaning may be required depending on the location of the

icemaker.

49

Page 50

C. Preparing the Icemaker for Long Storage

WARNING

When shutting off the icemaker for an extended time, drain out all water from

the water line and remove the ice from the storage bin. The storage bin should

be cleaned and dried. Drain the icemaker to prevent damage to the water

supply line at sub-freezing temperatures, using air or carbon dioxide. Shut off

the icemaker until the proper ambient temperature is resumed.

1) Run the icemaker with the water supply line shut-off valve closed.

2) Open the drain valve and blow out the water inlet line by using air pressure.

3) Unplug the unit from the electrical outlet.

4) Remove the front panel.

5) Move the flush switch on the control box to the “FLUSH” position.

6) Plug the unit back in, drain all water from the water line.

7) Unplug the unit from the electrical outlet.

8) Turn off the power switch on the control box.

9) Replace the front panel in its correct position.

10) Close the drain valve.

11) Remove all ice from the storage bin, and

clean the bin.

Fig. 6

50

Loading...

Loading...