Page 1

Instruction

Book

Instructions for installation and use

Page 2

Page 3

Page 4

52 cm

8 kg

0.05 ÷ 0.8 MPa

85 cm

60 cm

Page 5

Page 6

Page 7

Page 8

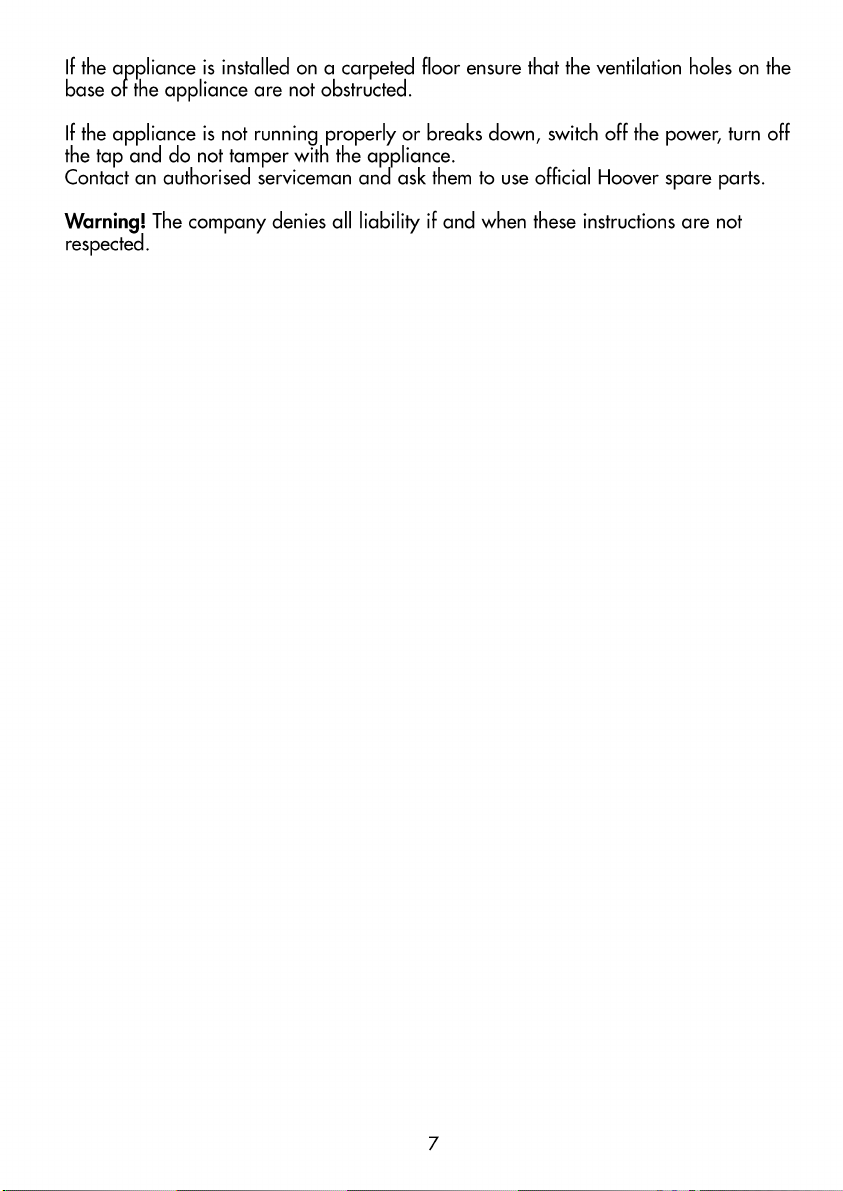

Unpacking the Product

Remove the machine from its packaging close to the final location of the machine.

Step 1. Remove all outer packaging from the

machine. Check there is no damage to the machine

before continuing the installation process.

Step 2. Carefully cut through the hose-retaining clip

at the rear of the machine, taking care not to cut

the hose itself.

Step 3. Remove the 4 retaining screws at the rear

of the machine, as indicated in the image on the

left. Use the blanking plugs provided in the

instruction booklet pack to cover the holes once the

screws have been removed.

Step 4. Tilt the machine forward and apply the

insulation base panel (corrugated plastic) to the

base of the machine using the self-adhesive strips.

All packaging materials used are environmentally friendly and recyclable. Please help

dispose of the packaging via environmentally friendly means. Your local council will be

able to give you details of current means of disposal.

8

Page 9

Installation

Before installing the machine, ensure that the mains plug and water supply valves are

easily accessible from your chosen machine location.

Make sure there is enough space for the machine. Select a space at least 600mm wide

and 850mm high. Also leave enough space to open the door fully so you can load

and unload it easily.

Keep the area underneath and around the machine free of combustible materials such

as lint, paper, rags, chemicals etc.

All machines are tested with water prior to leaving the factory, so a small amount of

water may be present in the drum and the drain hose.

Flooding may occur if any part of the installation process is not completed correctly.

Electricity Supply

Washing machines are supplied to operate at a voltage of 230-240V, 50 Hz single

phase. Please check that the supply circuit is rated to at least 13A.

The plug is already equipped with a 13A fuse, which is BS 1362 ASTA approved. Any

replacement must be the same rating and specification. If the fuse cover is lost, do not

use the plug until it is replaced.

Electricity can be extremely dangerous. Please take care when connecting your

machine to the electricity supply.

This washing machine must be earthed.

The socket outlet and the plug on the appliance must be of the same type.

Do not use multiple adapters and/or extension leads.

The wires in the mains lead are coloured in accordance with the following codes:

Blue NEUTRAL

Brown LIVE

Green and Yellow EARTH

Appliance complies with European Directive 73/23/EEC, 89/336/EEC

replaced by 2006/95/EC and 2004/108/EC and subsequent amendments.

9

Page 10

Water Supply

This machine should only be connected to a cold-water supply. The cold-water

pressure should be between 0.5 and 8 bar (0.05-0.8 Mpa).

Do not connect the machine to a single outlet instantaneous water heater.

Before connecting the fill hose, check that the water is running from the water supply

tap to be used. Let the water flow from the tap until the water runs clear before

connecting to the machine. The water supply tap should be accessible when the

machine is installed.

10

Page 11

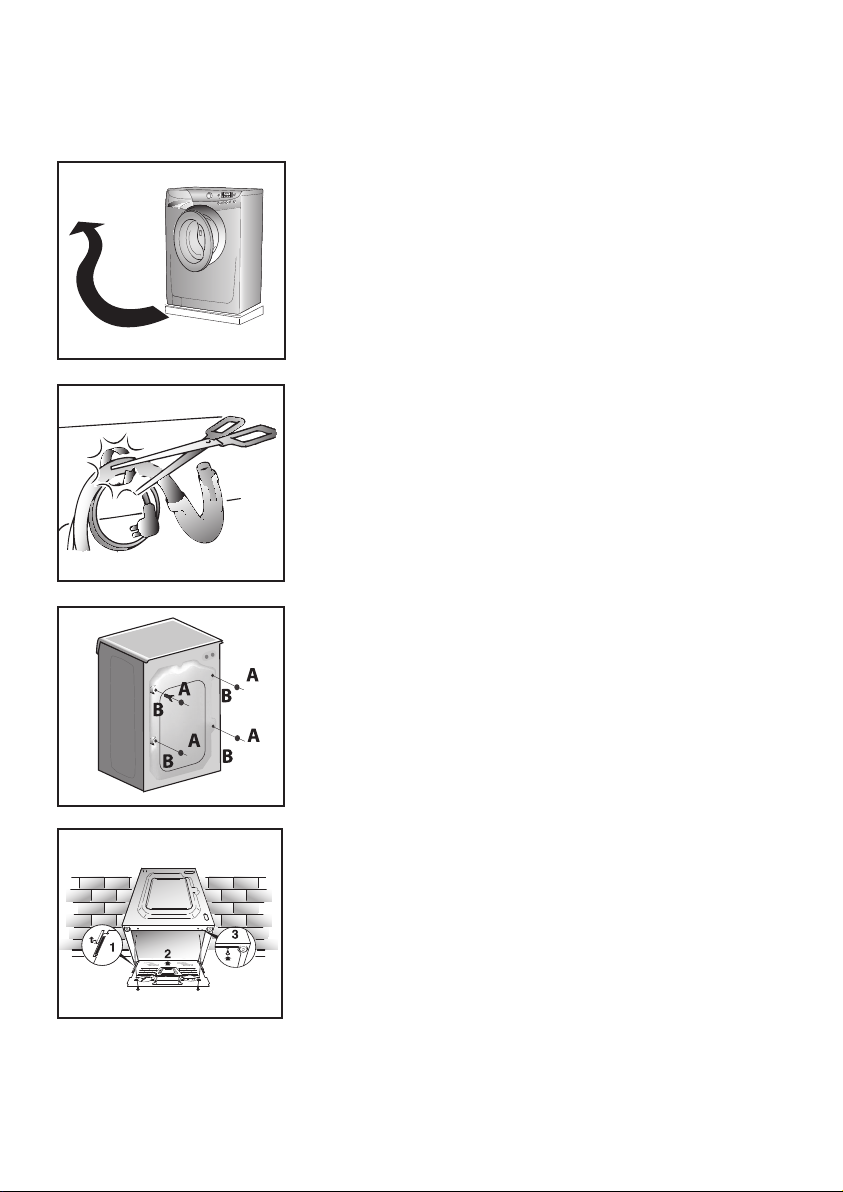

Connecting the Cold Water

Supply

Only one hose is required to install this machine to a cold water supply. Cold fill is an

energy efficient system. Only the water required to wash the laundry is heated. There

is no loss of heat in the pipeline from the hot water tank or the boiler.

If your previous machine installation was hot and cold fill ensure that the hot tap is

firmly closed to prevent leakage.

This machine has an inlet hose with a 19mm (3/4") threaded ferrule fitted to the end,

to attach between the threaded connector on the appliance and the water supply. Only

use the new hose supplied to connect the machine and ensure that the sealing washers

are in place inside the hose connectors.

Do not re-use old hoses that are attached to existing installations.

Do not over-tighten the connections. Hand tight is sufficient.

Do not trap or kink the hose.

Step 1. Connect the elbow end of the hose

provided to the threaded inlet on the back of the

machine.

The grey pipe needs to connect to the white

threaded inlet on the machine.

Step 2. Hand tighten the connector.

Step 3. Connect the straight ends of the pipes to

the water supply; ensure that there are no kinks.

Step 4. Turn on the water supply and check there

are no leaks. If there is a leak, turn off the water

supply, disconnect the hose and check the sealing

washers are in place. Refit the hose and turn on

the water supply.

11

Page 12

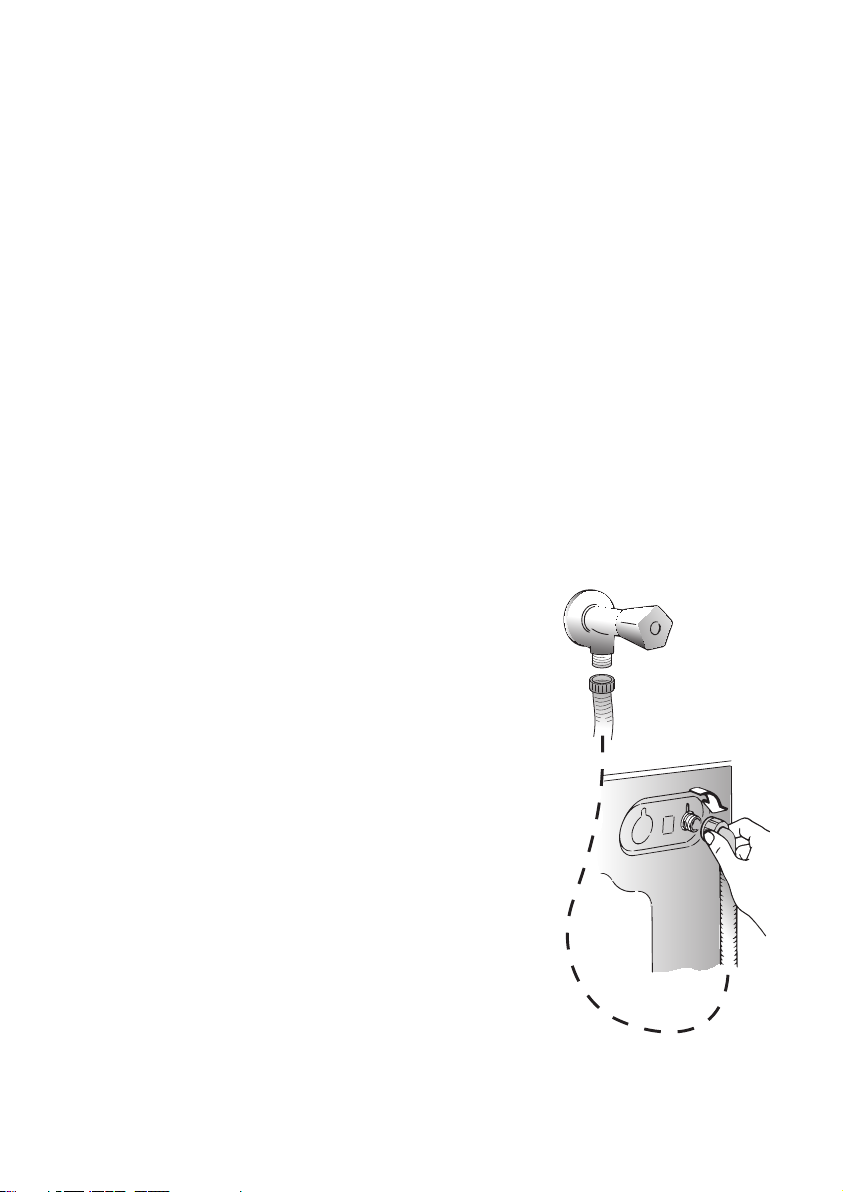

Connecting the drainage pipe

This machine must be connected in accordance with the water supply regulations.

Water bylaws prohibit connection to a surface water drain.

Decide which plumbing option suits you best then follow the instructions below:

Option 1 - Waste pipe connection (waste trap)

Fit the hooked end support to the outlet pipe and position it at least 800mm off the

floor.

After removing the blanking plug, or cutting the membrane from the waste system,

securely fix the outlet pipe to the drainage system, using a hose clip.

Secure the hooked end support up to at least 800mm to avoid water being drawn

back into the machine.

Option 2 - Into a standpipe

Ensure that the standpipe is not located near an electrical socket.

Fit the hooked end support to the outlet pipe. Install the hose into the standpipe

ensuring that the pipe is at least 500mm from the floor.

Insert the outlet pipe approximately 100mm into the standpipe.

12

Page 13

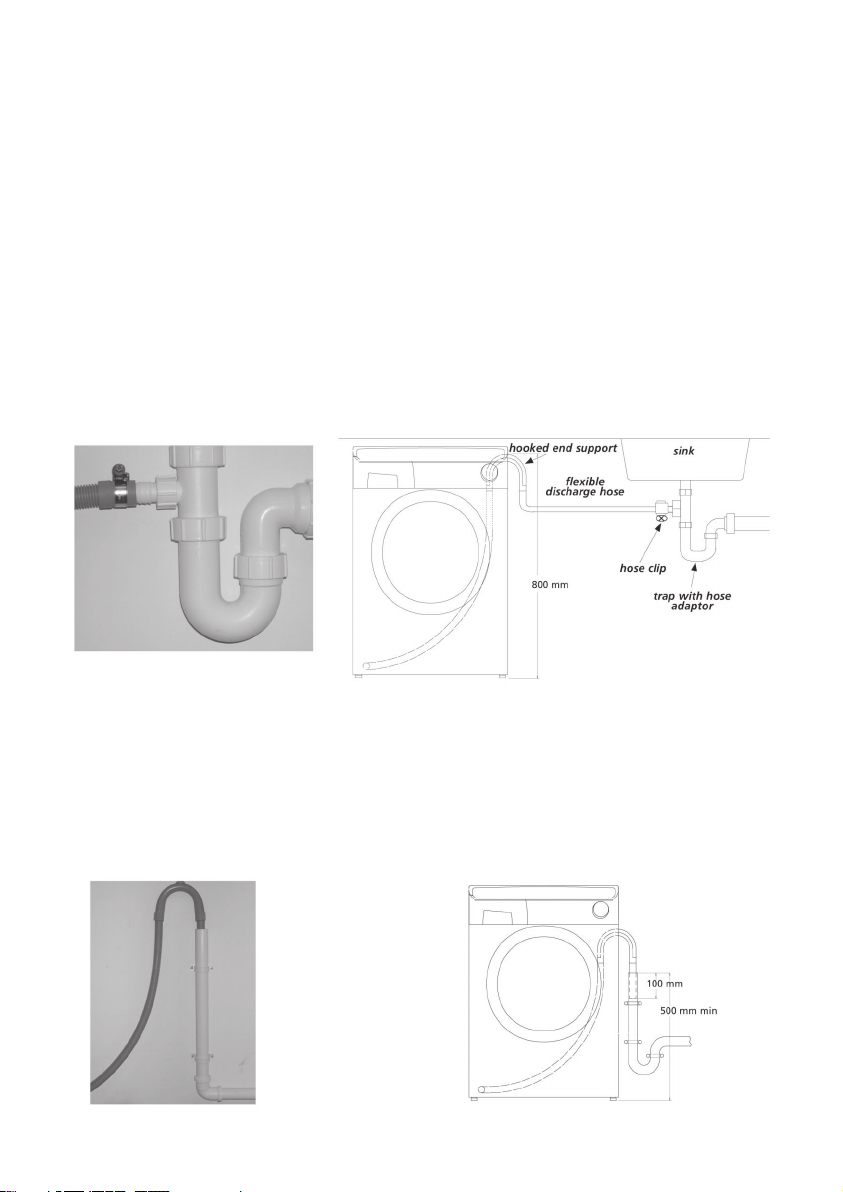

Levelling The Machine

Your machine is heavy so care must be taken when moving it.

We recommend that two people move the machine to avoid strain and possible injury.

Take care not to damage flooring when moving the machine and do not drag or lift

the machine by its door.

When moving the machine to its final position, take care not to kink or damage the

hose at the back of the machine.

Once the machine is in place the feet should be adjusted to ensure that the machine is

level. If the machine is not level it may become very noisy or move during the spin

cycle.

Step 1. Turn the locking nut clockwise to release the screw adjuster on the feet.

Step 2. Adjust the feet on the corners of the machine by rotating each foot to raise or

lower its position until it is firm and level on the ground.

Step 3. When the machine is firm and level, tighten the locking nuts on the feet in an

anti-clockwise direction until they reach the base of the machine.

Testing the Installation

Refer to “Selecting the wash programme” for details of how to select programmes.

Step 1. Turn on the water supply and check for leaks from the fill hose.

Step 2. Switch on the electricity supply.

Step 3. Select the spin programme and then press the Start Pause button to start the

machine. Allow the programme to continue for one minute and then cancel the

programme by returning the selector to the OFF position. This will remove any water

remaining in the machine from factory testing.

Step 4. To check for cold water filling to the machine:

Select the rinse programme and press the Start Pause button to start the machine.

Once the rinse has finished, allow the tumble action to continue until the water has

pumped out. Check that the drain outlet is not leaking or overflowing.

13

Page 14

Step 5. Switch off the machine at the end of the cycle by turning the Programme

Selector to the OFF position.

Step 6. Select the spin programme and press the Start Pause button to start the

machine. If the machine takes longer than one minute to empty check the drain hose

for kinks.

Installation testing is now complete.

Now you have successfully installed the machine we advise that you run the machine

to ensure the drum is thoroughly clean after testing and storage. Select Cottons 90°C

programme and run the machine for a complete cycle using only wash detergent and

water.

This programme will take approximately 2 hours to complete.

14

Page 15

Description of the Machine

The Hoover washing machine details are indicated below:

Detergent

Dispenser

Porthole

Door

Filter

Control

Panel

Door

Handle

Adjustable

Feet

15

Page 16

The Control Panel

Door Lock

Indicator

Programme

Selector

Spin Speed

Selector

Digital

Display

Wash Time

Selector

Stain

Blaster

Sensitive

Care

Temperature

Selector

Delay

Start

Start/Pause

Easy

Iron

Button

Turning the Machine On

Turning the Programme Selector to your chosen programme will turn the machine on.

The Programme Selector must be returned to the OFF position between each wash

cycle in order to reset the controls.

Start Pause Button

START

After selecting the programme and the required options press the Start Pause button

once to start the wash cycle. There will be a short time delay to the start of the

programme while the machine sets the wash parameters for the selected programme

and options. The Door Locked and KG Mode indicator lights will also illuminate a few

seconds after pressing the Start Pause button.

In some programs in the initial phase of the cycle there are planned spin sequences to

ensure optimal wash results.

PAUSE

The programme may be paused at any time during the wash cycle by holding down

the Start Pause button for about two seconds. The door locked indicator light will

remain illuminated for approximately 2 minutes. The door can be opened when this

indicator goes out. To restart the programme, press the Start Pause button once again.

Cancelling and Changing the Programme

To cancel the programme the Programme Selector should be rotated to the OFF

position. Select a new programme and start as detailed above.

16

Page 17

Digital Display

The easy-to-use Digital Display gives you total control of your wash cycle, whether it is

adjusting the wash length using our Wash Time Selector, delaying the start of your

wash, or adjusting the temperature and spin speed of your selected programme. The

simplicity of the Digital Display understates the advanced technology, which clearly

displays all the wash cycle information, putting you in control.

Wash Cycle Time/

Delay Start Indicator

Kg Mode

Spin Speed

Indicator

Door Locked

Indicator

Wash Temperature

Indicator

Wash Length

Indicator

Wash Temperature

When a programme is selected the relevant indicator will light up to show the

recommended wash temperature. You can select a different temperature by pressing

the Temperature button. For example: The Cottons programme will default to 40°C.

With this control the temperature can be reduced to 30°C to reduce energy

consumption or increased to 60°C for a more intensive wash.

Today, most detergents have been improved to wash efficiently at lower temperatures,

therefore we have set the default temperature settings of each programme to a lower

level, saving electricity and reducing the carbon footprint of your machine.

Please refer to the Programme Guide for the maximum temperature to which each

programme can be set.

Door Locked indicator

The Door Locked indicator light is illuminated when the door is fully closed and the machine

is ON.

When Start Pause is pressed on the machine with the door closed the indicator will flash

momentarily and then illuminate. If the door is not closed the indicator will continue to flash.

A special safety device prevents the door from being opened immediately after the end of

the cycle. Wait for 2 minutes after the wash cycle has finished and the door locked light has

gone out before opening the door. As a safety measure, check that there is no water evident

in the drum. At the end of the cycle turn the programme selector to OFF.

If the programme is paused, the door locked indicator will go out after 2 minutes and the

door can be opened. Check there is no water evident in the drum before opening the door.

17

Page 18

Spin Speed

When a programme is selected the maximum spin speed allowed for that programme

appears on the display. Pressing the Spin Speed button will reduce the speed by

100rpm each time the button is pressed. The minimum speed is 400rpm, or continuing

to press the button will eliminate the final spin completely.

Delay Start

This indicator shows the number of hours time delay, once the delay start has been set.

Wash Cycle Time

When a programme is selected the display automatically shows the maximum cycle

duration for a full load, which can vary, depending on the options selected. Once the

programme has started you will be kept informed constantly of the time remaining to

the end of the wash.

Wash Length Indicator

Once the programme has been selected the indicator light will automatically show

the wash time set for that programme. Selecting a different wash time the relevant

indicator will light up.

KG Mode Indicator

Available on Cotton and Synthetic cycles, during the first 4 minutes of the cycle the

indicator lights and wash time will flash. This means the intelligent sensor is weighing

the laundry and will adjust the cycle time, water and electricity consumption

accordingly.

Wash Options

The following options should be chosen once the required programme has been

selected and BEFORE pressing the Start Pause button. The indicator light on each

option button will illuminate if that option has been selected.

Stain Blaster

The Stain Blaster option, selectable on all Cotton cycles, tackles stubborn stains by

maintaining wash temperatures throughout the programme and adjusting the spin

speed of the drum during critical stages of the wash and rinse cycles. Using this

special programme will increase the wash efficiency without increasing the length of

your wash programme.

18

Page 19

Sensitive Care

The Sensitive Care option washes your clothes in a deeper than normal water level to

provide gentler washing for especially delicate fabrics, while detergent is removed

thoroughly with five extra rinses. Perfect for people with delicate skin, this option can

be selected on all Cotton and Synthetic cycles.

This option does not need to be selected on the Delicate, Woollen or Silk programmes,

as it is already an integrated part of the wash cycles.

Delay Start

This option allows you to delay the start of your wash cycle by up to 24 hours. By

pressing the Delay Start button, the time delay will be shown on the display (h00). This

will increase in one-hour intervals each time the Delay Start button is pressed.

Continue to press the button until the required time is reached, then press the Start

Pause button to activate the machine. The machine will start its cycle once the required

number of hours has passed.

To cancel the Delay Start option, press and hold the button for 5 seconds until the

display shows the settings for the selected programme. To start this programme, press

the Start Pause button. To cancel the process, turn the Programme Selector to the OFF

position and then select another programme.

Temperature

When a programme is selected the relevant indicator will light up to show the

recommended wash temperature. The Temperature button can be used to decrease or

increase the temperature of your chosen wash cycle. Each time the button is pressed,

the new temperature level is shown on the Wash Temperature Indicator.

Spin Speed

The spin cycle is used to remove as much water as possible from the laundry without

damaging your clothes. The recommended spin speed for each programme is already

set to the highest level for that chosen programme. By pressing the Spin Speed button

you can reduce the spin speed in 100rpm intervals.

To cancel the spin cycle altogether, set the spin speed to 0.

It is not possible to select a spin speed higher than that suitable for the programme

selected. This feature is designed to avoid damage to your clothes.

It is possible to modify the spin speed at any time without stopping or pausing the

machine.

19

Page 20

Easy Iron

This function is designed to reduce creasing of your clothes during your wash cycle,

and is tailored to specific fabric types. This option is only available on Synthetics,

Delicates, Woolmark and Silk programmes.

Programme

Mixed

& Synth’s

Delicate

Wool

& Silk

Easy Iron Function

The programme is completed by a

short spin of very low speed.

The machine stops in the final rinse

stage and the option indicators

blink.

The load is held in the water in the

drum, thus reducing creasing and

enabling easier ironing.

The machine stops in the final rinse

stage and the option indicators

blink. The load is held in the water

in the drum, thus reducing creasing

and enabling easier ironing.

Wash Time Selector

Action Required to Complete the

Cycle

_

Press the Easy Iron button to

continue with the programme.

The machine will then pump out

the water and the programme

will conclude with a short spin.

Finally, the programme carries

out a brief tumbling action to

loosen the items in the load.

Press the Easy Iron button and

the machine will pump out the

water and complete the cycle

with a short spin cycle.

Once the programme has been selected the indicator light will automatically show

the wash time set for that programme. Selecting a different wash time the relevant

indicator will light up. For example: Using this button on the Rapid Wash cycle will

enable you to select either a 14, 30 or 44 minute wash cycle.

This selection is only available on the Cotton, Synthetic and Rapid programmes.

20

Page 21

Automatic Features

KG Mode (Half Load)

Available on the Cottons and Synthetics cycles, the intelligent sensor adjusts the water

level and programme length throughout each phase of the cycle according to how

much laundry you load into the machine. The KG Mode indicator will light up when

the intelligent sensor is weighing the laundry.

The washing machine is fitted with a self-adjusting water level system. This system

enables the machine to use the optimum amount of water needed to wash and rinse

the laundry in relation to the particular load. This results in a reduction of the water

and electricity used without in any way compromising the washing and rinsing

performance. The amount of water and electricity used will always be appropriate for

the clothes load size.

The washing machine automatically ensures excellent washing results at minimum cost

whilst respecting the environment.

Out of Balance protection

This model is fitted with an electronic sensor device that checks if the load is balanced

correctly. If the load is slightly unbalanced the machine will re-balance it automatically

and then carry out the normal spin. If, after several attempts, balance is not restored a

reduced spin speed will be used. If loads are seriously unbalanced the spin stage will

be cancelled. This helps limit vibration, reduce noise and improve the washing

machine's reliability and life.

8 Pulse technology

This washing machine is equipped with an innovative system that by means of 8 high

pressure jets, sprays a mixture of water and detergent directly into the load.

When the cycle is started, in conjunction with the 8 high pressure jets spraying the

detergent mixture into the load, the cycle includes a set of spin actions that helps the

detergent solution to penetrate into the fibers, helping dirt removal and ensuring the

best available wash performance.

The spin cycle at the beginning of the wash is therefore a normal phase of the

program and should not be regarded as a malfunction of the machine.

The 8 pulse system is also used during the rinse phase where the high pressure jets aid

the complete removal of detergent residues trapped in the clothes.

21

Page 22

Programme Descriptions

For handling the various types of fabric and their level of dirtiness in your laundry the

washing machine has different programme groups according to type of wash,

temperature, spin speed and duration (see Programme Guide).

Once the programme is selected, the intelligent sensor will weigh the laundry using the

KG Mode and adjust the critical elements of the wash cycle depending on the weight

of the laundry to ensure perfect results (available on Cotton and Synthetic cycle). The

KG Mode is activated during the first 4 minutes of the cycle, which enables the machine to:

● adjust the amount of water required;

● determine the length of the wash cycle;

● control rinsing according to the fabric type selected;

● recognises if too much lather is present, adjusting the water level during rinsing if necessary;

● adjusts the spin speed according to the load, avoiding any imbalance

Cotton with Pre Wash

The Cotton programme is designed for maximum washing and rinsing efficiency. With

spin cycles in between, the programme guarantees the laundry is rinsed perfectly. The

final spin cycle ensures laundry is spun dry as much as possible up to the maximum speed.

The Cotton programme includes a Prewash cycle. This option is particularly useful for really

dirty loads and can be used independently of the main wash programme. Additional detergent for the Prewash part of the programme should be added to the first compartment of the

soap drawer labelled "1" (please refer to the section of this manual entitled “Detergent”). We

recommend you use only 20% of the quantity used for the main wash programme.

Coloureds

The Cottons programme is also designed for maximum washing and rinsing efficiency.

With spin cycles in between, the programme guarantees the laundry is rinsed

perfectly. The final spin cycle ensures laundry is spun dry as much as possible up to

the maximum speed. This cycle is set to 40°C, but the temperature may be altered

using the Temperature option button.

Synthetics

Washing and rinsing performance is optimised through using drum rotation speeds

and water levels suitable for synthetics and mixed fabrics. The programme will default

to 40°C, but the temperature may be altered using the Temperature option button. The

delicate spin action minimises creasing. The final spin speed for the synthetics

programme is 800rpm

Delicate

The cycle will consist of alternate periods of activity and pauses. This is particularly

suitable for washing very delicate fabrics, as it creates a hand-washing effect.

Washing and rinsing are carried out using a high water level to provide the best results.

Rinse

This programme carries out three rinses with an intermediate spin (which can be

reduced or excluded by using the Spin Speed option). It can be used for rinsing any

type of fabric e.g. use after hand washing.

22

Page 23

Spin

The Spin programme completes the spin at the maximum spin speed, this can be

reduced by using the Spin Speed option button.

Drain

This programme drains out the water from the machine.

Wool & Silk

This programme allows a complete washing cycle for garments specified as “MachineWashable” Wool fabrics and laundry items made from silk or specified “Wash as Silk”

on the fabric label. The programme has a maximum temperature of 40°C and

concludes with 3 rinses, one for fabric conditioner, and a slow spin.

Rapid

The Rapid programme allows a washing cycle to be completed in just 14 minutes! This

programme is particularly suited to slightly dirty cottons and mixed fabrics.

Using the Wash Time button on the Rapid cycle will enable you to select either a 14,

30 or 44 minute wash cycle.

When selecting the rapid programme, please note that we recommend you use only

20% of the recommended quantities shown on the detergent pack.

“A” Wash 59'

This specially designed programme maintains the high quality wash performance identified with the “A” rating whilst greatly reducing the wash time. The progrramme is

designed for a maximum load of 3 kg with a temperature of 60°C and concludes

with 2 rinses and a high speed spin sequence.

All in One

Thanks to 8 pulse technology, this innovative programme, allows you to wash fabrics

such as cottons, synthetics and mixed fabrics at 20°C with a performance which is

comparable to a 40°C wash.

The consumption of this program is about 50% of a conventional 40°C. Cottons wash.

Important Wash Performance Advice

● New, coloured garments should be washed separately for at least 5 or 6 washes

● Certain large dark items such as jeans and towels should always be washed separately

● Never mix NON COLOURFAST fabrics

For information about these programmes please refer to the programmes table.

23

Page 24

Programme Guide

Programme Guide

Water

Programme

Programme

**

**

Fabric Type

Fabric Type

Cottons,

Cottons,

Colourfast and

Colourfast and

linen

linen

Cottons, Non-

Cottons, Non-

fast Coloureds,

fast Coloureds,

mixed fabrics

mixed fabrics

Mixed fabrics

Mixed fabrics

and synthetics

and synthetics

Delicate fabrics

Delicate fabrics

-

-

-

-

Water

Temp

Temp

Recommended

Recommended

(C°)

60

40

40

40

(C°)

60

40

40

40

-

-

Water

Water

Temp

Temp

MAX

MAX

(C°)

(C°)

90

90

60

60

60

60

40

40

-

-

-

-

-

-

Spin

Spin

Speed

Speed

MAX

MAX

(RPM)

(RPM)

1600

1600

1600

1600

1000

1000

400

400

1000

1000

1600

1600

Max

Max

Load

Load

Size

Size

(kg)

(kg)

8

8

8

8

4

4

2,5

2,5

-

-

-

-

-

-

Silk and

Silk and

“Machine

“Machine

washable wool”

washable wool”

garments

garments

2)

2)

** Information for laboratories test (see page 26)

** Information for laboratories test (see page 26)

Lightly dirty

Lightly dirty

cottons and

cottons and

synthetics

synthetics

Cottons,

Cottons,

Colourfast and

Colourfast and

linen

linen

Cottons &

Cottons &

Mixed fabrics

Mixed fabrics

24

40

40

20

20

20

20

20

20

60

60

20

20

-

-

40

40

20

20

40

40

40

40

60

60

20

20

-

-

-

-

800

800

1000

1000

1000

1000

1000

1000

1600

1600

1000

1000

-

1.5

1.5

1.5

1.5

2.5

2.5

3.5

3.5

3

8

-

3

8

Page 25

Length of Programme Detergent

1)

Short

1:48

2:14

1:22

1:08

0:24

0:07

0:04

Med.

2:23

2:49

1:52

-

-

-

-

Long

3:01

3:27

2:02

-

-

-

-

2

✓

✓

✓

✓

1

✓

✓

✓

✓

-

-

-

✓

-

-

✓

-

-

-

-

-

-

1:06

0:14

-

-

0:59

1:39

1) For the programmes shown you can adjust the duration and

intensity of the wash using the Wash Time button.

2) Using the Wash Time button on the Rapid cycle will enable you to

select either a 14, 30 or 44 minute wash cycle.

-

-

0:30

-

-

2:04

-

-

-

0:44

-

2:30

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

25

-

-

-

-

-

-

Page 26

Refer to the programme guide (pag.24)

** STANDARD COTTON PROGRAMMES ACCORDING TO (EU) No 1015/2010 and

No 1061/2010

COTTON PROGRAMME with a temperature of 60°C

COTTON PROGRAMME with a temperature of 40°C

These programmes are suitable to clean normally soiled cotton laundry and they are

the most efficient programmes in terms of combined energy and water consumptions

for washing cotton laundry.

These programmes have been developed to be compliant with the temperature on the

wash label on the garments and the actual water temperature may slightly differ from

the declared temperature of the cycle.

Detergent

Recommendations on the use of detergent at various temperatures.

When washing heavily soiled whites, we recommend using cotton programs of 60°C

or above and a normal washing powder (heavy duty) that contains bleaching agents

that at medium/high temperatures provide excellent results.

For washes between 40°C and 60°C the type of detergent used needs to be appropriate

for the type of fabric and level of soiling.

Normal powders are suitable for “white” or colour fast fabrics with high soiling, while

liquid detergents or “colour protecting” powders are suitable for coloured fabrics with

light levels of soiling.

For washing at temperatures below 40°C we recommend the use of liquid detergents

or detergents specifically labeled as suitable for low temperature washing.

For washing wool or silk, only use detergents specifically formulated for these fabrics.

For dosage amounts please follow the instructions on the detergent package label.

Only use detergents that are suitable for use in a washing machine. You will obtain

the best results from your wash with the minimum use of chemical products, and the

best care for your laundry if you take into consideration the level of dirtiness as well as

the type of detergent to choose.

The amount of detergent to use depends on:

● Water hardness

Depending on the hardness of the water and the type of detergent used, it is

possible to reduce the amount of detergent.

The softer the water supply, the less detergent is required.

26

Page 27

● The level of dirtiness

It is possible to reduce the amount of detergent used depending on how dirty the

laundry is.

Use less detergent for items that are not very dirty.

● Amount of laundry

It is possible to reduce the amount of detergent when washing only a small amount

of laundry.

For smaller loads use less detergent.

The dosages shown on the packaging of detergents for washing delicates often already

refer to a reduced wash size.

Always follow the dosage instructions on the detergent packaging.

An over dosing of detergent can cause excessive foaming.

If the appliance detects the presence of excessive foam, it may exclude the spinning

phase or extend the duration of the program and increase water consumption.

Dispensing instructions

The detergent drawer is split into 3 compartments:

● The first, labelled "1", is for detergent

utilised during Prewash.

● The second, labelled "2", is for detergent

utilised during the main wash.

● The third, labelled is for special additives

such as fabric softeners, fragrances, starch,

brighteners etc.

Dispensing in the drum

Liquid detergents and some tablets are dispensed via the machine drum using the

recommended dispensing device which is placed upright on top of the wash load

towards the back of the drum. Some tablets are designed to be placed in the dispenser

drawer, check the detergent pack for details.

Do not put any items into the drawer other than detergents that are designed to be

dispensed from the drawer as they may cause blockage or damage.

27

Page 28

Laundry

Items to avoid

We recommend that you do not wash underwired bras in the machine. Should the wires

become detached they could cause damage to your clothes and the machine. If the wash

care label states that the bra is machine washable then we advise placing it in a wash bag.

Recommendations

Always follow the wash care labelling on the garments.

Fasten zips, tie strings and close press-studs to prevent tangling. Ensure that pockets

are emptied of loose change and other small items.

Unfold all items before placing them in the machine.

Check that there are no metal objects in the laundry as these may damage the laundry

and the machine.

Place small items in a wash bag.

Divide the laundry according to the type of material (the symbol on the garment label)

and colour, making sure that whites are separated from coloured garments

Do not exceed the values indicated in the “Programme Guide” which refers to the

weight of the laundry items when they are dry.

Washing Advice

The following tips are designed to assist in getting the best results from your machine

whilst using it in the most environmentally friendly and economical way. It is also

important to understand the items to avoid in your laundry, to ensure the continued

safe and reliable operation of your machine.

Loading your washing machine

To make further reductions of energy, water and detergent consumption, we

recommend that you put a full load into your machine. Energy savings of up to 50%

can be achieved by washing one full load compared to two half loads.

Do not overload the machine as this will reduce the quality of the wash and may

cause damage to the machine and your laundry.

When is prewashing really needed?

Only with particularly dirty loads! Energy savings of 5 to 15% are made by not

selecting the prewash option for less dirty laundry. Pre-treat awkward stains with a

washable stain remover.

Which wash temperature should you choose?

Using stain removers before machine washing reduces the need to wash at

temperatures over 60°C.

Using a 40°C wash temperature can make energy savings of up to 50%.

Very dirty laundry

To ensure the best performance when washing a particularly dirty load, we

recommend that you reduce the amount of items to be put into the machine. Allowing more

space in the drum means the items can circulate more freely and will wash better.

28

Page 29

Running a Wash Cycle

This section summarises the main points when completing a wash cycle. For detailed

explanations of features, options and details of the machine refer to the relevant

section in the instruction manual.

Preparing the laundry

Select and sort the laundry according to the wash care labels found on each garment.

Loading the laundry

Open the door. Put the laundry in the washing machine. Close the door by pushing it

until it clicks, ensuring that no items of laundry are obstructing the lock or door seal.

Putting detergent in machine

Open the drawer, choose the detergent and put in the recommended amount.

Do not exceed the dosage stated below:

Compartment

1

2

Close the drawer again.

Note: Liquid detergents and some concentrated powders and tablets that are to be

placed directly into the drum should be placed in the recommended dispensing device.

Wash

Prewash (option)

Main Wash

(all programmes)

Fabric Conditioner

Maximum quantity of

powder/liquid

100 ml

200 ml

200 ml

Selecting the wash programme

Refer to the Programme Guide or the programme descriptions on the front of the

machine to select the most suitable programme. Turning the programme selector and

aligning the programme name with the indicator selects the programme. Check that

the tap is turned on and that the discharge hose is positioned correctly. Select the

required wash options.

Starting the wash cycle

Press the Start Pause button. The Door Locked indicator and KG Mode lights will

illuminate.

After a few seconds the wash cycle will begin. During the first 4 minutes of

29

Page 30

the wash cycle, the KG Mode will weigh the clothes and update the wash time

remaining on the display every five seconds until the weight has been determined.

In some programs in the initial phase of the cycle there are planned spin sequences to

ensure optimal wash results.

Do not try to open the door when the door locked indicator is on, nor open the

dispenser drawer during the wash programme.

If you wish to pause the programme press the Start Pause button; after two minutes

you will be able to open the door. To cancel the programme the programme selector

should be turned to the OFF position. A new programme can be selected after

cancelling the previous programme.

When the programme has finished

Wait approximately two minutes for the door lock to be released. When the door

locked indicator light goes out it will then be safe to open the door.

Switch off the machine by turning the programme selector to the OFF position so that it

will be ready the next time you use the machine (this action resets the memory in the

machine). Open the door and remove the laundry. Disconnect the plug from the mains

power supply and turn off the water supply whenever you finish using it.

30

Page 31

Care and Maintenance

The washing machine needs very little maintenance, but regular attention to a few small

details will ensure the continued performance of your washing machine.

Do not use abrasive cleaners, scouring pads, solvent-based cleaners or polishes; wiping

the outside of the machine with a damp cloth will suffice.

Cleaning the soap dispenser

It is advisable to clean the compartments occasionally to remove detergents and

additives. To do this you need to do the following:

Step 1. Pull the drawer out firmly from the machine, but without forcing it.

Step 2. Clean the compartments and the siphon cover under warm running water.

Step 3. Clean the outlet of the soap dispenser to remove any residue of soap powder.

Step 4. Replace the drawer.

Cleaning the door glass

Regularly clean the door glass with a damp cloth. A build up of soiling and residues from

the water may result in water leaking from the door.

Do not use abrasive cleaners as they can scratch the surface.

Cleaning the filter

The washing machine is fitted with a special

filter to prevent items such as coins, buttons,

etc. blocking the discharge hose. These may be

retrieved by:

Step 1. Opening the filter cover.

Step 2. Pull out the corrugated hose (only

available on certain models), remove the

stopper and drain the water into a container.

Step 3. Before removing the filter, place an

absorbent towel below the filter cap to collect

the small amount of water that is likely to be

inside the pump.

31

Page 32

Step 4. Turn the filter anti-clockwise until it stops in the vertical position.

Remove the filter and clean.

Step 5. Replace the filter and turn in a clockwise direction until locked in position.

Replace the stopper in the hose and close the filter cover.

We recommend that the filter be cleaned frequently, at least once a month.

Maintenance wash

Using small quantities of detergent and low temperature wash programmes can cause

the gradual build up of grease, dirt and scale. Over time these deposits can damage

your laundry and your machine. They can also cause your machine to smell. We

recommend that you carry out a maintenance wash a couple of times per year to keep

your machine and pipe work clean and free of these deposits. Simply run the Cottons

90°C programme without a load and with the normal quantity of detergent.

32

Page 33

Problem Solving Guide

Defects you can remedy yourself

Before calling Hoover Service for technical advice please run through the following

checklist. A charge will be made if the machine is found to be working or has been

installed incorrectly or used incorrectly. If the problem persists after completing the

recommended checks, please call Hoover Service (tel: 08705 400 600); they may be

able to assist you over the telephone.

NOTE:

The initial spin at the beginning of the washing cycle is a normal

phase of the program and not a machine fault.

The machine will not start…

● Close the door. Check that there is power to the machine. Select a programme

and press Start Pause. Check if the door locked light is illuminated.

If it is not, check the following:

1. Is the machine connected to the electrical supply?

2. Is the electrical supply OK? Check another socket.

3. Has the fuse on the machine blown? If so, replace it.

● If the door locked light is illuminated and the machine does not start this means

that the machine cannot fill with water, check the following:

1. Check the programme dial is correctly aligned with the programme.

2. Is the water supply to the machine switched on?

3. Are the pipes kinked or restricted in any way?

Water does not drain away… (error 3 will be displayed)

● Ensure that there is not a blockage in the drain hose or the hose is not kinked.

● Is the drain hose installed correctly? If connected to the sink waste make sure you

have cut the membrane or removed the bung from the under sink drainage unit.

● Check for foreign bodies in the filter. If present, clean the filter.

● If you have found any of the above problems correct them and run the machine

through a spin cycle to drain the water.

33

Page 34

Water on the floor around the washing machine...

● Is the fill hose tightened? If so, replace the rubber washers and re-tighten.

● Is the standpipe or the household drain blocked? If so, clear the blockage yourself

or call a plumber.

● Is there clothing or dirt between the door gasket and the door glass? Ensure that

the door glass and gasket are kept clean and free of laundry when loading the

machine.

The machine does not spin…

● Water has not drained from the machine? Check the points highlighted above.

● Have you selected an option that changes the spin profile (change of spin speed

on the selector)? Check the feature in the description of the controls.

● Is the load unbalanced? To reduce noise and vibration and improve the machine’s

reliability and life, the machine is fitted with an electronic sensor that detects if the

load is unbalanced. To improve the spin performance the load can be re-distributed

by hand at the end of the cycle and then re-spun.

● The presence of excessive foam has aborted the spinning phase.

Do not use excessive amounts of detergent.

The machine is noisy or vibrates a lot during the cycle…

● Has the transit system been fully removed? (see Unpacking the Product).

● Are there any loose items in the pockets of clothing that can rattle in the drum

and cause damage?

● Is the load unbalanced? Stop the programme, redistribute the load and restart.

The programme takes a long time…

● Some programmes do take a long time (over 2.5 hours). Low water pressure can

increase the length of the programme.

34

Page 35

The door will not open…

● Has the programme finished? Is the END light illuminated? If not the programme

is not complete. Has the door locked light gone out? If not wait a further two

minutes and the light will go out and you will be able to open the door.

● Has the programme finished but the door remains locked? The display reads

Error 2. Turn the machine to OFF to reset the machine and this will allow the door

to open.

● If water remains in the drum refer to 'Water does not drain away…' above.

Problem with the dispenser…

● Not all the detergent has been flushed away.

1. Check the water supply tap is fully turned on.

2. Check the inlet hose is not kinked.

● The dispenser drawer will not close properly.

1. Check the drawer is aligned properly

2. Check the drawer is not clogged with detergent (see Care and

Maintenance)

● Steam is coming from the dispenser. The machine is designed to vent through the

drawer, this is nothing to worry about.

Remember, you may be charged for the service call if incorrect installation or misuse

causes a problem with your machine.

If the following error codes are displayed, switch OFF the machine and contact Hoover

Service: 0, 1, 4, 5, 7 and 8.

Note: The use of environmentally friendly, phosphate-free detergents (check detergent

information on pack) can have the following effects:

● Waste water from rinsing may be cloudier because of the presence of a white

powder (zeolites) held in suspension, without the rinse performance being adversely

affected.

● Presence of white powder on laundry after washing, which is not absorbed by

the fabric and does not alter the colour of the fabric.

● The presence of foam in the final rinsing water is not necessarily an indication of

poor rinsing. Carrying out more rinse cycles does not serve any purpose in such

cases.

35

Page 36

Power Failure

If there is a power failure the wash cycle will be interrupted, and the wash programme

and functions will be suspended. When the power is restored, the wash programme

and functions will re-start from the same point and complete the programme.

During a power failure the water can be drained and the load can be removed from

the machine as follows:

Step 1. Switch off the machine both via the programme dial and the mains power

supply. Remove the plug from the mains power supply socket.

Step 2. Carefully move the machine so the rear of the machine is accessible. Please

follow the safety precautions that we recommend under the Warning and Safety

Instructions section of this manual.

Step 3. Unclip the drain hose from the rear panel of the machine and lower the hose

into a bowl on the floor. When the bowl is full raise the end of the drainpipe to a

height higher than the top of the appliance to stop the flow of water. Empty and

replace the bowl and continue draining the machine until empty.

Step 4. Once the machine is fully drained of water, clip the hose to the rear of the

machine. Open the door and remove the load.

The door can be opened approximately 2 minutes after the power failure.

Do not force open the door.

Further Problem Solving advice can be found on the After Sales Service pages of

our website www.hoover.co.uk

36

Page 37

After Sales Service

Customer Service

At Hoover, we aim to make appliances that are reliable and long lasting. However,

should your appliance need to be serviced during its working life, no one is more

qualified to maintain your appliance than our own Hoover Service engineers. To book

a service call or to ask our customer service advisors for help on using your appliance,

please call:

08444 995599

or contact us online

www.hoover.co.uk

Please have your model and serial numbers at hand when calling our service

department, as they will require this information.

(Telephone lines open: Monday to Friday 8.30am to 5pm, Saturday 9am to 5pm,

Sunday 10am to 4pm). We may record your phone calls with our representatives to

monitor and improve the quality of service we provide.

Guarantee

Your new Hoover appliance automatically comes with a 12-month call out, parts and

labour guarantee.

Register your appliance now by calling

08444 810 157

or register online

www.hoover.co.uk

Providing that you register your purchase, Hoover guarantees all parts of this product

for 5 years from the date of purchase. During the first year Hoover approved

engineers will replace or repair all defective parts free of charge, except for parts

subject to fair wear and tear, such as interior lamps.

In years 2-5 replacement parts will be supplied free only if fitted in the UK or Republic

of Ireland by Hoover and the appropriate labour charges paid. An extended warranty

may be purchased to also cover the labour costs. Please ask our customer service

advisors for cost details or complete the enclosed form.

To qualify for benefits under the guarantee, you must be able to provide proof of date

of purchase and the appliance must have been supplied, maintained and used in

accordance with Hoover instructions.

37

Page 38

The guarantee excludes:

● Any faults which occur due to bad installation or misuse of the machine.

● Repair of, or interference with, the machine by any person not authorised by the

manufacturer.

● Any parts which are fitted to the machine that are not original manufacturer’s

parts.

● Non-domestic use of the machine.

● Operation at incorrect voltage.

● The result of using this machine for any purpose other than those described in the

instruction book.

Spares and Accessories

If any part of your appliances needs replacing during its lifetime, please make sure

that you replace them with genuine Hoover spare parts by calling:

01204 556 111

or online

www.hoover.co.uk

A number of accessories can also be purchased using the above contact details.

Brochures

At Hoover, we produce a range of home appliances including vacuum cleaners,

cooling appliances, washing machines, tumble dryers, dishwashers, cookers and

built-in appliances.

If you would like a brochure for any of our product ranges please call our head office

on:

01685 721222

or view our full range online

www.hoover.co.uk

Our customer service advisors will be able to advise you of any matching appliance,

or appropriate replacement product when it is time to replace your purchase.

38

Page 39

39

Page 40

13.02 - 41038569 - Canon Italia - Business Services Channel - Printed in Italy - Imprimé en Italie

Loading...

Loading...