Page 1

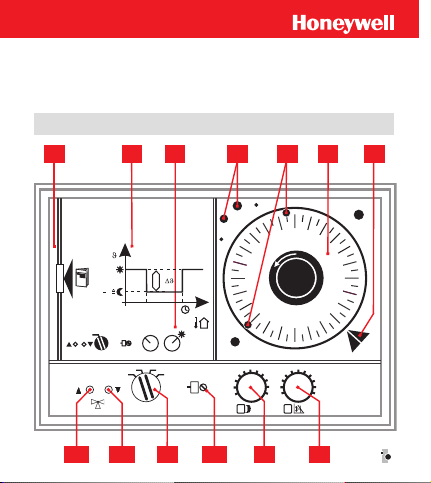

Comfort Compact Controller ZG 215VN

OPERATION AND PUTTING INTO SERVICE

142 376

5

B

BC

ZG215 VN

auto1

P1 CB

L1 L2 P1

///

C( )

0

-8

P1

S

8311.7151

CB

C

CB50268

B

A

Page 2

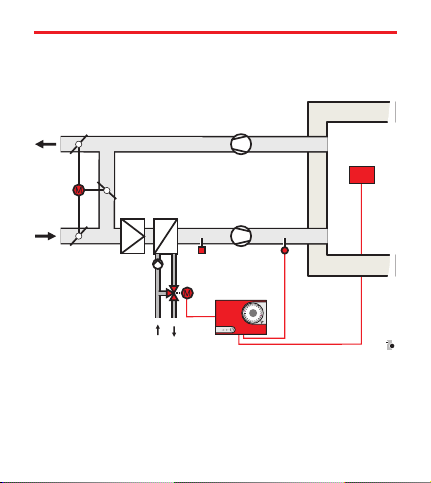

Constant discharge temperature control

TW

V

FT

LF

VM

DR

ZG 215VN

/////

//

///

CB2282

ZG Control Unit

VM Servomotor

DR Heating mixing valve

LF Air flow sensor

TW Temperature selector (opt.)

FT Frost protection thermostat

V Air heater

Page 3

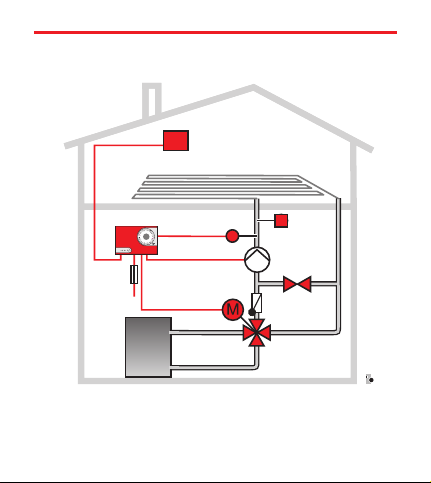

Constant flow temperature control for a

floor heating system

TW

ZG215VN

////

ZG Control Unit

VM Servo motor

ZR Heating mixing valve

VF Flow sensor

VF

//

////

VM

////

P

ZR

TW Temperature selector

T Temperature limiter

P Heating circuit pump

T

CBZG107.cdr

Page 4

Operating the Control

The ZG 215VN can be used at choice for the control of an

air-handling system’s constant discharge temperature (left-

hand system diagram) or a floor heating’s constant flow tempe

rature (right-hand system diagram).

TheVF/LF temperature sensors monitor constantly the actual va

lues and transmitthese values to theZG control unit. Should the “

temperature or the supply temperature deviate from the target va

lue, the controller commands the VM servo motor to adjust the

ZR/DR mixing valve.

The mixing valve performs the necessarychange tothe mixing ra

tio betweenthe heated supplywater and theheating circuit’s retur

ning cooled water.

TheTW temperature selector is used as remotecontrol. By means

of theP2 selector knobthe flow or supplytemperature can be mo

dified. The temperature selector is not absolutely necessary in

functional terms, but it makes the operation easier.

The FT frost protection thermostat (air-handling system only)

works independentlyfrom the controlunit and protects theair hea

ter against freezing.

-

-

-

-

-

-

-

Page 5

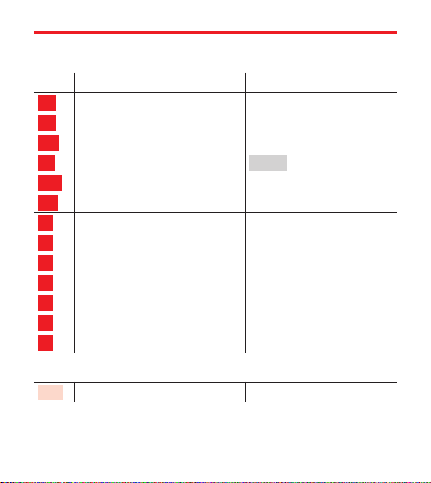

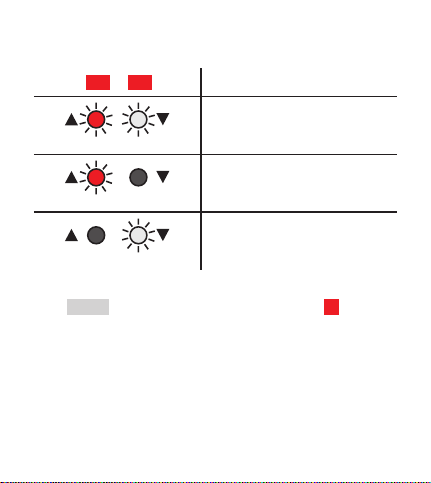

Operating and Display Components

Pos. Function Basic Setting

B Day mode

C Reduced mode

P1 Sensitivity 5

S Operating mode selector auto

L1 ”Hotter“ LED (red)

L2 ”Colder“ LED (green)

1 Instructions compartment

2 Heating curve diagram

3 Basic Settings

4 Reserve trip pins

5 Inserted trip pins

6 Timer (optional)

7 Pointer for the current time

Settings on the Temperature Selector

P2 Selector knob

Page 6

Operating Mode Selector

manu The control unit is deactivated (the timer runs).

The mixing valve can be set manually (by hand).

The pump is switched on.

auto Recommended setting for higher energy saving:

automatic change between day and reduced mode

according to the timer with night switch-off.

Only night mode, timer not active.

Constant reduced mode according to the settings on

the setting knobs B minus C , the timer remains

inactive.

Page 7

LED’s

L1 L2

Both LED’s light up:

”neutral“

– mixing valve stops

only red LED lights up:

”hotter“

– mixing valve opens

only green LED lights up:

”colder“

– mixing valve closes

In themanu settings ofthe operating modeselector S there isno

LED display.

Page 8

Putting into service

Set the timer 6 with the current time

n

Set the operating mode selector S to auto

n

The remaining basic factory settings are printed under 3 on the

control unit.

Timer for reduced mode 6

With theaid of thetimer, the roomtemperature during idleperiods

can be reduced automatically to save on operating costs.

The timer has a built-in power reserve of approx. 60 hours thanks

to a rechargeable battery.

Page 9

Changing the program

Factory settings: red pin 6:00, bluepin 22:00.

Pull out the trip pin and insert it again at the desired

n

switch-on time. Push in the trip pins until they reach the

stop!

Owing to the different lengths, the trip pins must always be inser

ted in a red/blue alternate ordere. Thered trip pinswitches on day

mode, while the blue pin activates reduced mode.

In order tomake sure that the rooms areheated well in the morning,

the heating system’sday mode should be activatedbetween a half

an hour and an hour before using the rooms.

Energy saving tip: Reduced mode can be activated

up to an hour before the room is left. The storage

capacity of the heating system and building is

enough to keep the rooms warm for some time.

Timer with day program

The day program is repeated every 24

hours. Ifa (second) decrease intempera

ture is desired in thecourse of the day to

save energy,the program needs tobe ex

tended. Take the extra trip pins 4 and

insert them at the desired time.

-

-

-

CB5044.7.cdr

Page 10

Example:

Desired time program

Normal temperature: 6:00 h to 8:00 h and 16:00 h to 22:00 h

Night decrease: 22 :00 h to 6:00 h

Day decrease: 8:00 h to 16:00 h

Position of the trip pins

red pin 6:00 h – Start day mode (normal temperature)

blue pin 8:00 h – Start day decrease

red pin 16:00 h – Start day mode (normal temperature)

blue pin 22:00 h – Start night decrease

Timer with week program

The timer has a changeable dial.

With the week program, dialling a different heating program for

each weekday is possible.

The dial isprepared ex factory for theday programand, if required,

it can bechanged toweek program (see installationinstructions).

Setting the right time

To set the time, the time dial is to be placed on the trip pins and

turned clockwise until the indication on the setting marker 7

matches with the current time.

Page 11

Optimization of the Settings

The ZG 215VN control unit is a constant temperature controller.

The desired temperature, e. g. the supply temperature of an

air-handling system or the flow temperature of a heating system

can be set on the setting knobs B and C of the controller.

Day mode (setting knob B )

The selectingrange onthe setting knob B varies from0 to 100°C.

Normally the setting knob B sets the desired target value for day

mode.

If a temperature selector is used as a

remote control, the setting knob B is to be

set on 20.

Reduced mode (setting knob C )

By meansof setting knob C , the intensity ofthe decrease tobe ac

tivated withthe timercan be set. The settingrange varies from 0 to

-100 K (°C). The decrease set with setting knob C refers to the

temperature either on setting knobBor on the TW.

Example (without TW)

n

Setting on the setting knob B è 50

Setting on the setting knob C è

i. e. for normal mode (day mode): constant target value of 50 °C,

for reduced mode (night) a target value of 30 °C.

-20

-

Page 12

Example (with TW 23)

n

Setting on the setting knob B è 20

Setting on the TW 23’s selector knob P2 è 50

Setting on the setting knob C è -20

Both settings give target values of 50 °C in the day and of 30 °C at

night.

Setting the target value

Temperature selector TW 21 to 23

When using a temperatureselector the setting knob B on thecon

troller is always to be set on 20. The setting of the selector knob

P2 on the TW is relevant for the target value.

There are temperature selectors for various temperature ranges:

TW 21 – settable temperature range -15... + 15° C

TW 22 – settable temperature range 0… 30 °C

TW 23 – settable temperature range 20… 70 °C

If notemperature selector isavailable, the desiredtarget value isto

be set on the setting knob B of the control unit

Energy saving tip:

Set the operating mode selectorSon .

The controller hence works constantly in reduced

mode.

-

Page 13

Troubleshooting Checklist

Is the heat generator at the required temperature?

n

è Read the heat generator’s thermometer.

Is the burner ready?

n

Is the burner failure lamp on?

è If necessary, press the reset button.

Was the temperature selector set by mistake?

n

Setting of the selector knob P2

Check the setting of the control unit.

n

Setting knobs BCand operating mode selector S .

Is the timer running? Is the displayed time correct?

n

è Check the time and switch-on point.

If the problem still has not been solved after checking the settings,

position the setting knob B on +7

The servomotor should now open the mixing valve and the red

LED L2 should light up. Ifthis is not the case, the control system

has failed. Contact your heating technician.

Page 14

Manual mode

CB5043.7.cdr

Page 15

Manual mode (fig. on the left)

In case of the breakdown of the heating mode regulation, you can

proceed temporarily as follows:

1. Set the operating mode selector S on manu .

n

2. Open the mixing valve by hand until the desired flow and

n

room temperatures are reached.

– The coupling incorporated in the mixing valve drive unit

provides for the release of the connection between the

motor and the mixing valve.

– Press firmly on the unlock key on the cover of the drive

unit and keep the key pressed (firmly!).

– Use the setting lever to set the mixing valve in the

desired position.

After eliminating the problem, the mixing valve is

set again to the right position by the control unit in

automatic mode.

Page 16

Behavior of the target values

during day and reduced mode

B

BC

Day mode setpoint

C ()

///

Reduced mode

setpoint

Page 17

Instructions for the Technician (only!)

Removing the Timer

(see also the installation instructions)

Operating steps:

1. Pull out the instructions case.

n

2. Hold the timer by the two white stems and turn to the left

n

until the connector is released.

3. Remove the timer.

n

(To install the timer proceed in the opposite order.)

Regulation Stability (Sensitivity)

The stability of the regulation can be modified with the setting

potentiometer P1 .

For the regulation technician:

By means of P1, set the proportionalrange ofthe PD control unit.

Recommended basic setting: P1 è 10.

In case of unstable regulation set higher values.

Page 18

Flow- and airflow-sensors

LF20

VF 20AVF20

Page 19

Reference

Installation instructions

Compact Control Units ZG 215N / 215 VN / 252 N

EN 1H-0181 GE51

Operating Instructions

ZG 252N:EN-2H0215 GE51

ZG 215N:EN-2H0216 GE51

ZG 215V:EN-2H0217 GE51

“Informationsschrift”(Planning broschure in German)

L3 – Komfort Compact Regler

GE-0H 0327 GE51

Page 20

Page 21

Page 22

Page 23

Page 24

Centra Regelungstechnik http://www.honeywell.de/hga

Honeywell AG

Böblinger Straße 17

D 71101 Schönaich

Telefon +49 (70 31) 637-01

Telefax +49 (70 31) 637-493

Technical data may be changed without prior notice.

EN 2H-0217 GE51 R1001 7157 560

Loading...

Loading...