Page 1

Installation Instructions for the

NC

NO

CO

MICRO SWITCH Z Series Basic Switches

(ZD, ZM, ZM1, ZW, ZX Series)

m WARNING

IMPROPER INSTALLATION

DO NOT USE these products as safety or emergency stop

devices or in any other application where failure of the

product could result in personal injury.

Failure to comply with these instructions could result in

death or serious injury.

, CAUTION

SWITCH DAMAGE

• Wiring must be rated to meet or exceed circuitry

requirements.

• Connecting circuitry must not exceed switch rating.

• Wiring connections must be properly secured.

• Do not exceed recommended soldering time or

temperature.

• Do not contact switch housing with soldering device.

• Do not exceed recommended mounting screw tightening

torques.

• Discontinue use if switch has been damaged or cover

removed.

• Do not apply side loads to actuator or exceed specified

travel limits.

• Do not operate or store in areas where corrosive gases

such as hydrogen sulfide are present.

Failure to comply with these instructions could result in

death or serious injury.

MOUNTING INFORMATION

Switch series Screw type*

ZX Pan head 2,0 mm 1,6 kg-cm [1.4 lb-in]

ZM, ZM1, ZW Pan head 2,0 mm 1,6 kg-cm [1.4 lb-in]

ZD Pan head 3,0 mm 4,8 kg-cm [4.2 lb-in]

*To prevent loosening of screws, use spring washers under

screw heads and thread lock adhesive.

• Position the operating device perpendicular to the

actuator/pushbutton to prevent side loading of the switch

actuator or pushbutton.

• Position the operating device so that no force is applied

to the pushbutton/actuator when the switch is in the free

(open) position.

• The operating device should be positioned so that when

the switch is in the operating position it should move the

actuator no less than 70 % of the total travel. Setting the

travel position so that less than 70 % of the total travel is

used may cause poor contact or welding conditions due to

an insufficient contact switching force.

• The operating device should never force the actuator/

pushbutton to exceed the total travel position.

• For switches with angled terminals, insert an insulator

separator between the switch body and the PC board

(insulator separator thickness 0,2 mm to 0,4 mm [0.008 in

to 0.016 in].

Screw

size

Issue 5

PK 80173

Tightening torque

max.

m DANGER

IMPROPER USE

DO NOT USE these products in hazardous environments

where flammable or explosive gases or liquids such as

gasoline or thinners, etc., are present.

Failure to comply with these instructions could result in

death or serious injury.

GENERAL INFORMATION

MICRO SWITCH Z Series switches are precision snap-action

contact mechanisms enclosed in molded plastic cases. Switch

actuation triggers the mechanical closure of the switch’s

contacts. A small amount of arcing between the contacts

during contact closure occurs during normal operation. In

order to obtain desired switch performance, the switch must be

chosen based on the mechanical, electrical and environmental

conditions of the application.

Z Series switches are designed for use in a wide range of

applications. Typical applications include:

• Computer mouse

• Tape systems

• Printers

• Copiers

Safety and Productivity Solutions

WIRING INFORMATION

• Connect wires firmly to terminals.

• Replace wires that have damaged insulation.

• Use properly sized spade terminals.

• Provide strain relief when a potential exists for forces to be

transferred from the lead wires to the switch terminals.

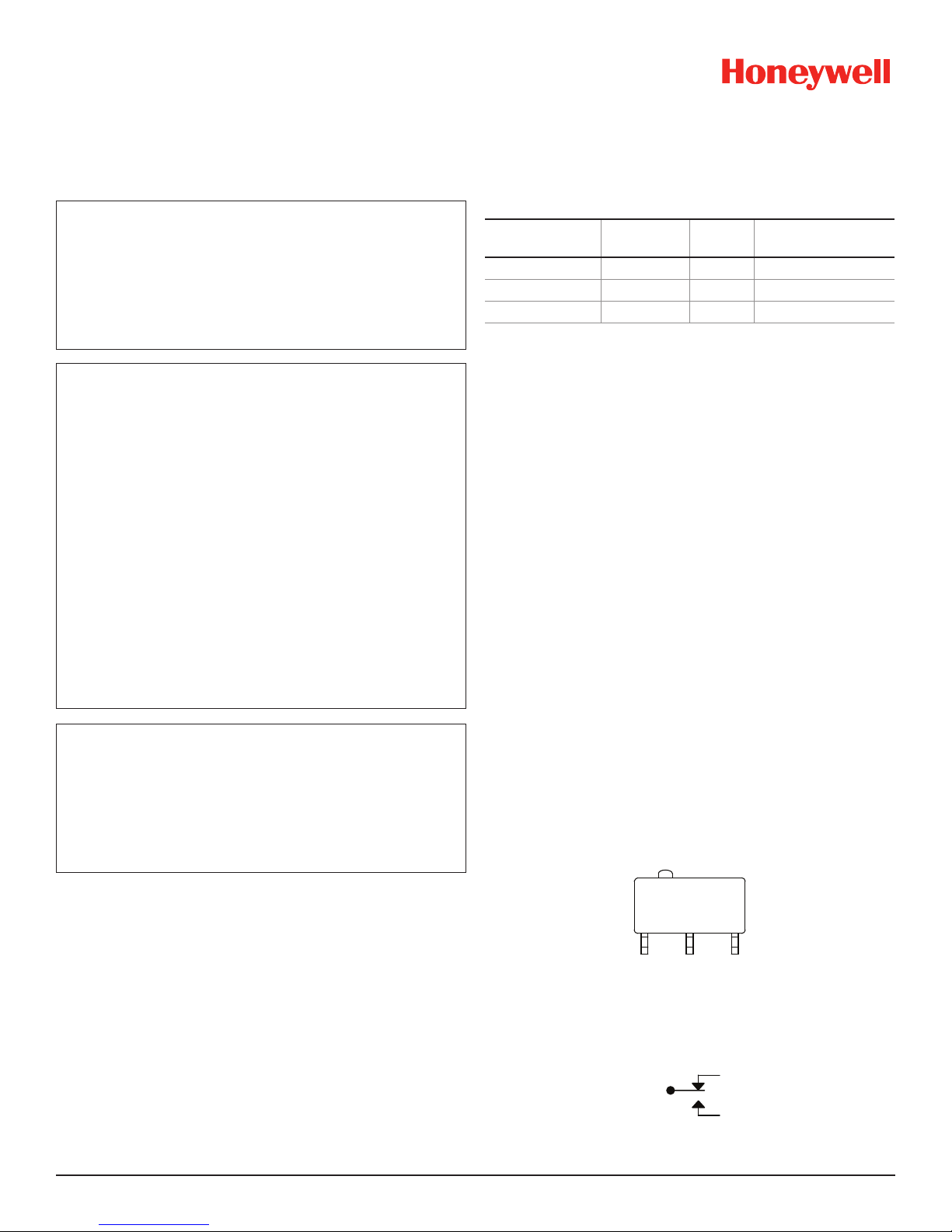

PIN LOCATION

(1)

(3)

COM

Note: The common pin is identifiable by its position on the end

of the switch closest to the actuator/pushbutton. The normally

open and normally closed contact positions are relative to the

common pin, as shown.

NO

NC

(2)

SPDT CIRCUITRY

M

Page 2

MICRO SWITCH Z Series Basic Switches

Issue 5 PK 80173

SOLDERING GUIDELINES

When hand soldering switch terminals, do not exceed five

seconds at 350 ºC [662 ºF] (exception for ZD Series switches:

Do not exceed five seconds at 300 °C [572 °F] or three seconds

at 350 °C [662 °F]). Contacting the switch housing with the

soldering device may damage the switch housing. Solder joints

must not be moved for at least one minute after soldering.

When wave soldering, do not exceed five seconds at 260 ºC

[500 ºF] or subject to aqueous wash. Use alcohol and swab to

clean terminals. Use of no-clean flux is recommended.

ENVIRONMENTAL OPERATING CHARACTERISTICS

Switch series Operating temperature range

ZX, ZD 40 °C to 85 °C [40 °F to 185 °F]

ZM, ZM1 0 °C to 120 °C [32 °F to 248 °F]

ZW

*Terminal types or pre-wired with high heat-resistant cables.

** Pre-wired with PVC cables.

40 °C to 120 °C [40 °F to 248 °F]*

40 °C to 70 °C [40 °F to 158 °F]**

WARRANTY/REMEDY

Honeywell warrants goods of its manufacture as being free

of defective materials and faulty workmanship. Honeywell’s

standard product warranty applies unless agreed to otherwise

by Honeywell in writing; please refer to your order acknowledgement or consult your local sales office for specific warranty

details. If warranted goods are returned to Honeywell during

the period of coverage, Honeywell will repair or replace, at its

option, without charge those items that Honeywell, in its sole

discretion, finds defective. The foregoing is buyer’s sole

remedy and is in lieu of all other warranties, expressed or

implied, including those of merchantability and fitness for a

particular purpose. In no event shall Honeywell be liable for

consequential, special, or indirect damages.

While Honeywell may provide application assistance personally, through our literature and the Honeywell web site, it is

customer’s sole responsibility to determine the suitability of the

product in the application.

Specifications may change without notice. The information we

supply is believed to be accurate and reliable as of this printing.

However, Honeywell assumes no responsibility for its use.

Honeywell serves its customers through a worldwide network of

sales offices, representatives and distributors. For application

assistance, current specifications, pricing or name of the nearest Authorized Distributor, contact your local sales office or:

E-mail: info.sc@honeywell.com

Internet: sensing.honeywell.com

Phone and Fax:

USA/Canada +18005376945

International +18152356847; +18152356545 Fax

Honeywell Safety and Productivity Solutions

9680 Old Bailes Road

Fort Mill, SC 29707

www.honeywell.com

801735EN IL50 GLOPrinted in USA

July 2016

© 2016 Honeywell International Inc. All rights reserved.

Loading...

Loading...