Put Bar Code Here

VU443A; VU444A; VU843A; VU844A

Fan Coil Valve Actuators

PRODUCT DATA

The VU443, VU444, VU843, and VU844 Fan Coil Valve

Actuators are used in conjunction with the VU52, VU53, and

VU54 fan coil valves for controlling the flow of hot or chilled

water. These valves are humidity resistant and are suitable for

use in condensing, non-corrosive environments.

SPECIFICATIONS

Actuator Electrical Rating & Connections: 10 VA maxi-

mum.

Model

VU443A

VU443E SPST

VU444A None 2-way, normally

VU843A

VU844A

Control

CIrcuit

120V,

60Hz

24V,

50-60Hz

Current

Draw (A)

0.07

0.32 None

End

Switch

None

Connection

/Leads Application

2-way, normally

open (use

6” motor

leads

standard.

18”, 36”, or

96”

Leadwires

optional.

VU444,

VU844);

closed (use

VU443,

VU843);

3-way, diverting

(use VU444,

VU844).

Note: Motors for all the above models are Class A, Plated.

End Switch Rating:

2.2 A inductive from 5 to 110 Vac.

1.0 A inductive above 110 Vac to 277 Vac.

Min. DC switching capability: 5 mA @ 24 Vdc.

Maximum Ambient @ Fluid Temperature Rating:

Standard models (with class A motor):

125° F (52° C) ambient @ 200° F (93° C) fluid.

Minimum Ambient Temperature: 34° F (1° C).

Shipping and Storage Temperature: -40° F to 150° F (-40°

C to 65° C).

Atmosphere: Non-corrosive, non-explosive, condensing.

Noise Rating: Low noise - non-obtrusive.

Materials:

Case: stainless steel.

Cover: aluminum.

Sector gear: reinforced with KEVLAR

KEVLAR

®

is a Dupont registered trademark.

®

brand fiber.

Approvals: CSA C/US Certified.

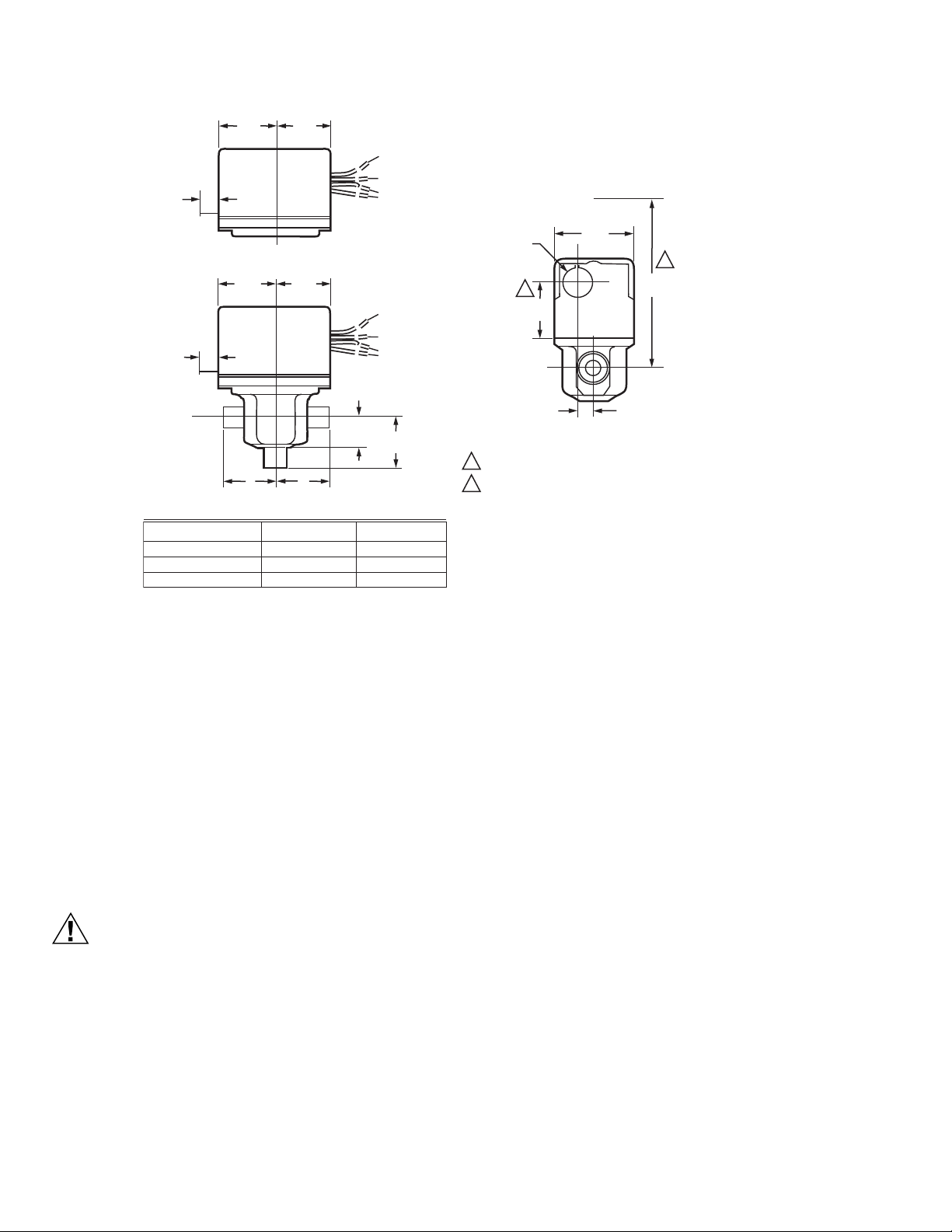

Dimensions: See Fig. 1.

95C-10883-03

VU443A; VU444A; VU843A; VU844A FAN COIL VALVE ACTUATORS

CAUTION

1-3/4

(44)

3/8

(10)

VU ACTUATOR

1-3/4

(44)

3/8

(10)

B

VU53 AND VU54 VALVE DIMENSIONS WITH ACTUATOR

VALVE BODY SIZE

1/2 IN. SWEAT

3/4 IN. SWEAT

1 IN. SWEAT

A

1-3/4

(44)

1-3/4

(44)

AB

A

A

1-5/6 (33)

1-3/8 (35)

1-11/16 (43)

A

7/8 (23)

2-WAY

B

3-WAY

B

1-5/6 (33)

1-11/16 (43)

1-11/16 (43)

M32203

7/8 DIA. (22)

2

1-1/2

(38)

15/32 (12)

VU52 OR VU53 VALVE WITH ACTUATOR

HEIGHT NEEDED TO REMOVE ACTUATOR OR COVER.

1

OPENING FOR 1/2 IN. CONDUIT ON OPPOSITE SITE OF

2

MANUAL LEVER FOR ALL MODELS.

2-3/8

(60)

3-3/4

(133)

1

M32204

Fig. 1. Mounting Dimensions in inches (mm).

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service technician.

4. After installation is complete, check out product operation as provided in these instructions.

1. Disconnect power supply before connecting wir-

ing to prevent electrical shock of equipment damage.

2. On 24V systems, never jumper the valve coil ter-

minals even temporarily. This can burn out the

heat anticipator in the thermostat.

To Install and Remove Actuator

INSTALLING ACTUATOR ON VU-SERIES VALVE BODY

ASSEMBLY

1. Orient slot in shaft of VU-series valve body toward

notch in side of body (i.e. 90° to water flow.) See

Fig.2. This lifts the ball off seat, prevents damage to the

ball seal while soldering, and makes actuator attachment easier.

2. Install valve body into pipe.

3. Wiring connections may be made either before or after

the actuator is installed on the valve body.

4. Place manual operating lever on the actuator in the

MAN. OPEN position.

5. Line up motor coupling to slot in shaft of body and fit the

head onto the valve body, ensuring that the shaft seats

correctly. (See Fig. 2).

6. Snap actuator onto body by pressing down.

7. Make wiring connections. Refer to wiring section for

proper instructions.

Inspect the actuator installation and the valve body to ensure

that all connections and adjustments have been correctly

made. Adjust the thermostat or controller connected to the

valve so that the valve runs through its cycle. Make sure the

valve runs smoothly and positively from closed to open to

closed again.

95C-10883—03 2

Loading...

Loading...