Page 1

VMM

ROTARY VALVE ACTUATORS

PRODUCT DATA

Features

Application

The Honeywell VMM actuator is designed to provide floating

control in heating and air conditioning systems. High control

performance and a robust design are standard. In combination with the valves DR/ZR/DRU, it is possible to control

very exact heating and cooling water temperatures. The

mechanical interface between actuator and valve is designed

for reliable operation. Actuators with torques from 20 Nm up

to 40 Nm are available for a wide range of rotary mixing

valves (DN 15…200).

Specification per Actuator

torque

(Nm)

20 VMM20-24 VMM20 1.6

30 VMM30-24 VMM30 2.3

40 VMM40-24 VMM40 3.5

40 VMM40-24F VMM40F 1.2

order no. actuator

24Vac floating 230Vac floating

run-time

(min./90°)

Attention (VMM40-24F)

Higher temperatures (>50 °C) combined with the min. voltage

(19.2 Vac) could reduce the output torque by approx. 10%.

Higher temperatures (>60 °C) combined with the max. voltage

(28.8 Vac) allow only three full strokes to be carried out

without interruption.

® U.S. Registered Trademark EN0B-0621GE51 R0916

Copyright © 2016 Honeywell Inc.

All Rights Reserved

Protected against overload and blocking

Maintenance-free electrical actuator for rotary valves

Clear position indicator

Direct mounting on rotary valves

Manual operation

High torque

Large wiring cabinet

Long lifetime

Specifications

Power supply

Power consumption

Control signal

Run-time depending on type (see table)

Nominal torque

Angle of rotation 90°

Protection standard IP 54 per EN 60529

Insulation class l per EN 60730

Ambient operating temp. 0 to 60 °C

Water temp. in valve 2 to 130 °C

Relative humidity non-condensing

Weight 1.5 kg

230 Vac / 24 Vac; 50 Hz

depending on type (see table)

VMMxx-24: 3.5 VA

VMM40-24F: 9.0 VA

VMMxx: 3.5 VA

VMM40F: 6.0 VA

230 Vac / 24 Vac, floating.

depending on type (see table)

20 Nm / 30 Nm / 40 Nm.

depending on type (see table)

Suitable Valves

DRxxxGMLA; DRxxxGFLA; ZRxxxMA; ZRxxxFA, DRU.

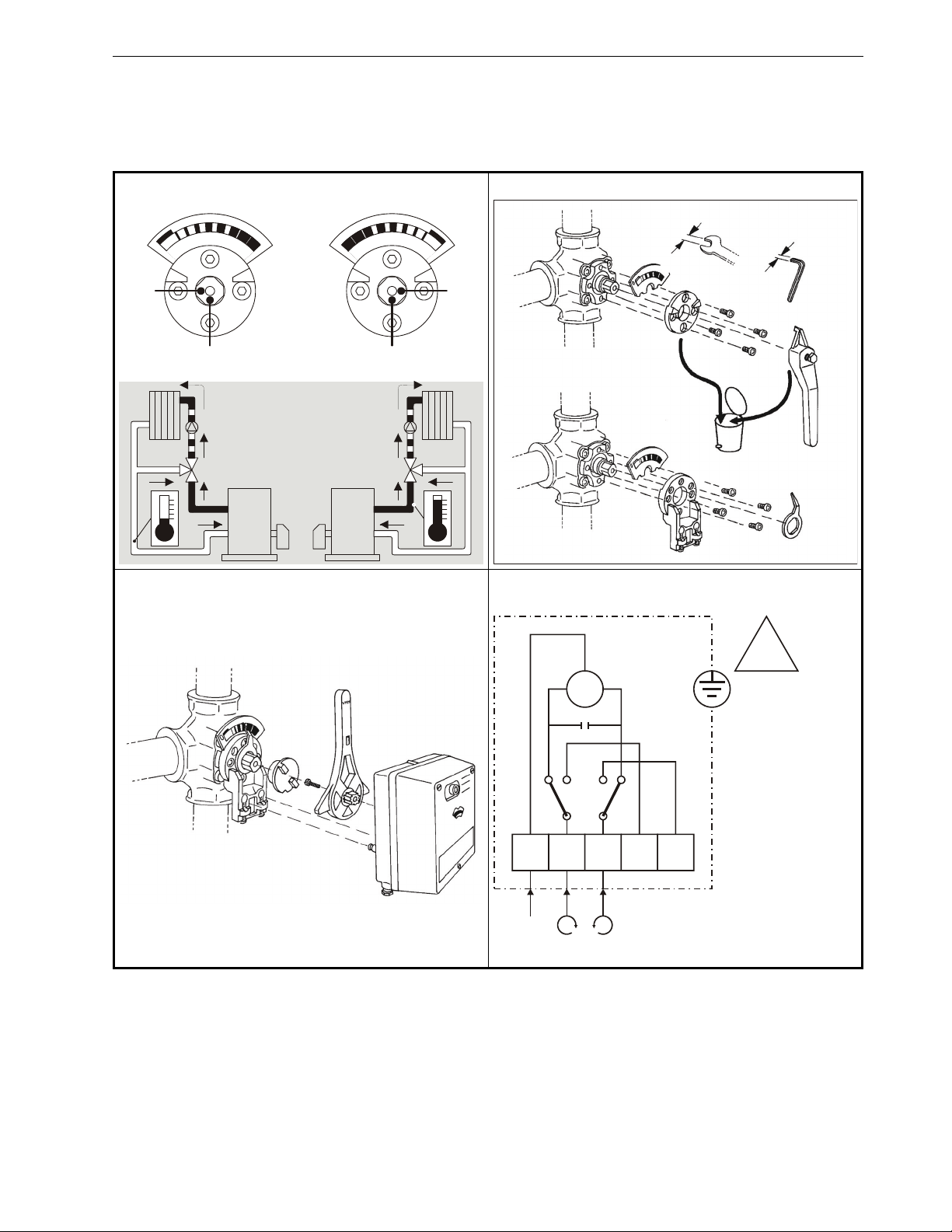

Mounting on the Valve

Before mounting the actuator, position the rotary valve

according to its installation instruction. In the case of boiler

applications, it is recommended that the actuator be mounted

in a vertical position. If mounted in the horizontal position, one

should position an isolation shield between the top of the

valve and the actuator; this is to protect it against radiant heat

and to ensure ambient temperatures of below 60 °C.

Operation

The actuator is powered by a synchronous motor. The spindle

of the actuator rotates 90°. In the end positions, the motor is

switched off by end switches.

Manual operation declutches the gear from the valve. As soon

as the actuator is powered, the valve is driven by the actuator

again.

No adjustment necessary. The actuator is maintenance-free.

Page 2

VMM – PRODUCT DATA

1 2

10 mm (3/8”)

0

0

4 mm (5/32”)

R

L

3 4

R

L

!

M

Disconnect the

power from the

controller before

opening the

actuator!

EN0B-0621GE51 R0916

A B

1 2

2

3

M MN

+ °C - °C

Page 3

VMM – PRODUCT DATA

Dimensions (mm)

Table 1. DRxxxGMLA, dimensions (in mm)

type DN a c SW h i

DR15GMLA 15 110 179 41 55 R1/2“

DR20GMLA 20 110 179 46 55 R3/4“

DR25GMLA 25 115 179 50 58 R1“

DR32GMLA 32 140 188 60 70 R1 1/4“

DR40GMLA 40 150 188 65 75 R1 1/2“

h

a

146

i

133

Fig. 1. VMM and DRxxxGMLA, dimensions (in mm)

Table 2. DRxxxGFLA, dimensions (in mm)

type DN a b c d e f g h

DR20GFLA 20 140 15 179 65 90 50 4x11 70

DR25GFLA 25 150 15 179 75 100 60 4x11 75

DR32GFLA 32 160 17 188 90 120 70 4x14 80

DR40GFLA 40 170 16 188 100 130 80 4x14 85

DR50GFLA 50 190 16 202 110 140 90 4x14 95

DR65GFLA 65 210 16 219 130 160 110 4x14 105

DR80GFLA 80 250 18 219 150 190 128 4x18 125

DR100GFLA 100 270 18 240 170 210 148 4x18 135

DR125GFLA 125 310 20 267 200 240 178 8x18 155

DR150GFLA 150 330 20 274 225 265 202 8x18 165

DR200GFLA/ DR200GFLA1 200 390 22 314 280 320 258 8x18 195

c

h

b

d

a e

146

f

g

133

EN0B-0621GE51 R0916

Fig. 2. VMM and DRxxxGFLA, dimensions (in mm)

3

c

Page 4

VMM – PRODUCT DATA

type DN a c SW h i net wt. (kg)

ZR15MA 15 110 179 41 55 R1/2“ 2.4

ZR20MA 20 110 179 46 55 R3/4“ 2.5

ZR25MA 25 115 179 50 58 R1“ 2.6

ZR32MA 32 140 188 60 70 R1 1/4“ 4.3

ZR40MA 40 150 188 65 75 R1 1/2“ 4.5

146

Table 3. ZR...MA, dimensions (in mm)

h

a

a

i

133

Fig. 3. VMM and ZRxxxMA, dimensions (in mm)

Table 4. ZRxxxFA, dimensions (in mm)

type DN a b c d e f g net wt. (kg)

ZR25FA 25 150 15 179 75 100 60 4x11 4.8

ZR32FA 32 160 16 188 90 120 70 4x14 7.6

ZR40FA 40 170 16 188 100 130 80 4x14 8.5

ZR50FA 50 190 16 202 110 140 90 4x14 11.0

ZR65FA 65 210 16 219 130 160 110 4x14 14.4

ZR80FA 80 250 18 219 150 190 128 4x18 24.3

ZR100FA 100 270 18 240 170 210 148 4x18 32.9

ZR125FA 125 310 18 267 200 240 178 8x18 49.0

ZR150FA 150 330 20 274 225 265 202 8x18 57.0

ZR200FA 200 390 22 314 280 320 258 8x18 84.0

c

a

b

d

146

a

e

f

133

EN0B-0621GE51 R0916

g

Fig. 4. VMM and ZRxxxFA, dimensions (in mm)

4

c

Page 5

VMM – PRODUCT DATA

Table 5. DRU, dimensions (in mm)

type DN a b c d e g h R net wt. (kg)

DRU25-2.5 25 55 32 110 89 55 51 182 1 ½ 2.2

DRU25-4.0 25 55 32 110 89 55 51 182 1 ½ 2.2

DRU25-6.3 25 55 32 110 89 55 51 182 1 ½ 2.2

DRU25-10 25 55 32 110 89 55 51 182 1 ½ 2.2

DRU25-16 25 55 32 110 89 55 51 182 1 ½ 2.2

DRU32-10 32 70 44 140 99 70 59 200 2 4.1

DRU32-16 32 70 44 140 99 70 59 200 2 4.1

DRU32-25 32 70 44 140 99 70 59 200 2 4.1

a

b d

146

R

c

e

gg

133

Fig. 5. VMM and DRU, dimensions (in mm)

h

EN0B-0621GE51 R0916

5

Page 6

VMM – PRODUCT DATA

ACCESSORIES

The VMM is suitable for use in conjunction with the following accessories.

Table 6. Accessories

accessory description remarks

VMP10-90 Feedback potentiometer 10 kOhm

VMS2 Auxiliary switch package

Suitable only for VMM30, VMM40F, and

VMM-40-24F

Ready-to-mount assembly consisting of

two switches (3A / 250 V~) and two

switching cams; max. one VMS2 per

actuator.

Manufactured for and on behalf of the Environmental & Energy Solutions Division of Honeywell Technologies Sàrl, Rolle, Z.A. La Pièce 16, Switzerland by its Authorized Representative:

Automation and Control Solutions

Honeywell GmbH

Böblinger Strasse 17

71101 Schönaich, Germany

Phone +49 (0) 7031 637 01

Fax +49 (0) 7031 637 740

http://ecc.emea.honeywell.com

EN0B-0621GE51 R0916 Subject to change without notice

Loading...

Loading...