Honeywell VMC-03WENN1, VMC-01WENN1, VMC-04WENN1, VMC-00WENN1, VMC-02WENN1 Installation Manual

Page 1

Installation Manual

Tema-Voyager™ Multi

VMC-xx

1

Page 2

Document Release Issue Date

800-20652

1.0

H December 2017

Notice

This document contains Honeywell proprietary information. Information contained herein is to be

used solely for the purpose submitted, and no part of this document or its contents shall be

reproduced, published, or disclosed to a third par ty without the express permission of Honeywell

Europe.

This document and the data in it shall not be duplicated, used or disclosed to others for

procurement or manufacturing, except as authorized by and with the written permission of

Temaline, Inc. The information contained in this document or in the product itself is the exclusive

property and trade secrets of Temaline, Inc.

Copyright laws of the United States protect all information in this document or in the software

product itself.

While this information is presented in good faith and believed to be accurate, Honeyw ell disclaims

the implied warranties of merchantability and fitness for a purpose and makes no express

warranties except as may be stated in its written agreement with and for its customer.

In no event is Honeywell liable to anyone for any direct, special, or consequential damages.

The information and specifications in this document are subject to change without notice.

Trademarks

Tema-VoyagerTM is a trademark of Honeywell International Inc.

MIFARE® is a registered trademark of Philips Electronics N.V.

HID is a trademark or registered trademark of HID Global Corporation.

Any other trademarks that appear in this document are used only to the benefit of the trademark

owner, with no intention of trademark infringement.

Compliance

To obtain applicable EU compliance Declaration of Conformities for this product, please refer to

our website, https://extranet.honeywell.com

compliance of this product to any EU-specific requirements, please send email to

temaline.orders@honeywell.com

. For any additional information regarding the

Single contact point and Support

Manufacturer’s single point of contact:

Honeywell S.r.l.

Via Philips, 12

20052 Monza

ITALY

For technical assistance, call your nearest Honeywell office.

2

Page 3

TABLE OF CONTENTS

INTRODUCTION .......................................................................................................................................................... 9

Purpose of this manual ......................................................................................................................................... 9

Device overview .................................................................................................................................................... 9

System Architecture ............................................................................................................................................ 10

Device components ............................................................................................................................................. 11

Related documentation ....................................................................................................................................... 11

PREPARING FOR INSTALLATION .......................................................................................................................... 12

Contents of the box ............................................................................................................................................. 12

Multi device .................................................................................................................................................... 12

Device support kit .......................................................................................................................................... 12

Optional Boards (included into a separate box) ............................................................................................. 12

Spare Parts ......................................................................................................................................................... 13

Mounting tools ..................................................................................................................................................... 13

Calculation of the current provided by Multi ........................................................................................................ 13

Wires Characteristics .......................................................................................................................................... 15

Power supply wire .......................................................................................................................................... 15

Network wire .................................................................................................................................................. 15

Readers wires ................................................................................................................................................ 15

RS485 Data Cables (for OSDP reader connection) ................................................................................ 15

Wiegand reader cables ........................................................................................................................... 16

Input wires ..................................................................................................................................................... 16

Output cable .................................................................................................................................................. 16

MOUNTING THE DEVICE ......................................................................................................................................... 17

Wall mount .......................................................................................................................................................... 17

DIN rail mount ..................................................................................................................................................... 18

IP32 protection mount ......................................................................................................................................... 18

CONNECTING THE CABLES ................................................................................................................................... 20

Connecting the DC Power Supply ....................................................................................................................... 21

Connecting the network cable ............................................................................................................................. 22

Connecting the readers ....................................................................................................................................... 24

Reader in position 1 ....................................................................................................................................... 26

Reader in position 2 ....................................................................................................................................... 26

Reader in position 3 ....................................................................................................................................... 27

Reader in position 4 ....................................................................................................................................... 27

RS485 line length setting ............................................................................................................................... 28

Connecting Inputs ............................................................................................................................................... 29

Connecting Fixed Inputs ................................................................................................................................ 30

Fixed Input 1 ........................................................................................................................................... 30

Fixed Input 2 ........................................................................................................................................... 30

Fixed Input 3 ........................................................................................................................................... 31

Fixed Input 4 ........................................................................................................................................... 31

Connecting configurable Inpu t s ..................................................................................................................... 32

Configurable Input 1 ............................................................................................................................... 32

Configurable Input 2 ............................................................................................................................... 32

Configurable Input 3 ............................................................................................................................... 33

3

Page 4

Configurable Input 4 ............................................................................................................................... 33

Configurable Input 5 ............................................................................................................................... 34

Configurable Input 6 ............................................................................................................................... 34

Configurable Input 7 ............................................................................................................................... 35

Configurable Input 8 ............................................................................................................................... 35

Connecting Outputs ............................................................................................................................................ 36

Connecting Fixed Outputs ............................................................................................................................. 37

Fixed Output 1 ........................................................................................................................................ 37

Fixed Output 2 ........................................................................................................................................ 37

Fixed Output 3 ........................................................................................................................................ 38

Fixed Output 4 ........................................................................................................................................ 38

Connecting Configurable Outputs .................................................................................................................. 39

Configurable Output 1 ............................................................................................................................. 39

Configurable Output 2 ............................................................................................................................. 39

Configurable Output 3 ............................................................................................................................. 40

Configurable Output 4 ............................................................................................................................. 40

Configurable Output 5 ............................................................................................................................. 41

Configurable Output 6 ............................................................................................................................. 41

Configurable Output 7 ............................................................................................................................. 42

Configurable Output 8 ............................................................................................................................. 42

USING RELAYS PLUGS-IN (VMA-06, VMA-07) ....................................................................................................... 44

Mounting the plugs-in .......................................................................................................................................... 45

Setting up Plug-in jumper .................................................................................................................................... 47

Configuration of Multi to use VMA-06 and VMA-07 plugs-in ............................................................................... 48

Connecting Fixed Outputs (Plug-in in slot of position 1) ................................................................................ 49

Fixed Output 1 ........................................................................................................................................ 49

Fixed Output 2 ........................................................................................................................................ 49

Fixed Output 3 ........................................................................................................................................ 50

Fixed Output 4 ........................................................................................................................................ 50

Connecting Configurable Outputs (Plug-in in slot of position 2) ..................................................................... 51

Configurable Output 3 ............................................................................................................................. 51

Configurable Output 4 ............................................................................................................................. 51

Configurable Output 5 ............................................................................................................................. 52

Configurable Output 6 ............................................................................................................................. 52

Connecting Configurable Outputs (Plug-in in slot of position 3) ..................................................................... 53

Configurable Output 1 ............................................................................................................................. 53

Configurable Output 2 ............................................................................................................................. 53

Configurable Output 7 ............................................................................................................................. 54

Configurable Output 8 ............................................................................................................................. 54

Connection of the emergency input to VMA-07 ............................................................................................. 55

FINAL OPERATIONS ................................................................................................................................................ 56

Closing the device ............................................................................................................................................... 56

Commissioning tips ............................................................................................................................................. 56

Configuring the Voyager Multi ........................................................................................................................ 57

Factory default IP Address ..................................................................................................................... 57

Factory FW version ................................................................................................................................. 57

MULTI DEVICE ANATOMY ....................................................................................................................................... 58

Terminal Blocks and Jumpers ............................................................................................................................. 59

Terminal Blocks ............................................................................................................................................. 59

Jumpers ......................................................................................................................................................... 60

Switches and LEDs ............................................................................................................................................. 61

Switches ........................................................................................................................................................ 61

LED ................................................................................................................................................................ 62

Device Tampers .................................................................................................................................................. 63

Anti open tamper ........................................................................................................................................... 63

4

Page 5

External tampers connection ......................................................................................................................... 64

OPERATING INSTRUCTIONS & MAINTENANCE ................................................................................................... 65

Reset Multi device ............................................................................................................................................... 65

Switch off Multi device ......................................................................................................................................... 65

Multi application quick health chec k .................................................................................................................... 66

CONDITIONS RESULTING IN IMPAIRED OPERATION .......................................................................................... 67

PROTECTIVE FEATURES (WARNING OF BYPASSING) ....................................................................................... 68

TECHNICAL SPECIFICATIONS ................................................................................................................................ 69

REGULATIONS ......................................................................................................................................................... 71

CE Compliance ................................................................................................................................................... 71

“Access Control System for use in Security Applications” Compliance ............................................................... 71

FCC Notice.......................................................................................................................................................... 72

Canadian and United States UL Listed ............................................................................................................... 72

Australian CTick Conformity ................................................................................................................................ 73

RoHS compliance ............................................................................................................................................... 73

WEEE compliance .............................................................................................................................................. 73

China RoHS declaration ...................................................................................................................................... 73

Appendix 1 - Application switches ......................................................................................................................... 74

Appendix 2 – Meaning of graphical symbols used ............................................................................................... 75

5

Page 6

Warnings and Cautions

Before installat ion

Warning: Before installation, TURN OFF the external circuit breaker which supplies

power to the device.

Before connecting the device to the power supply, verify that the output voltage is within

specifications of the power supply. (See “Technical specifications” on page 37.)

Do not apply power to the device until after the installation has been completed.

The equipment can be damaged if this precaution is not observed.

Fire Safety and Liability Notice

Warning: Never connect card readers to any critical entry, exit door, barrier, elevator or

gate without providing an alternative exit in accordance with all the fire and life safety

codes pertinent to the installation.

These fire and safety codes vary from city to city and you must get approval from local

fire officials whenever using an electronic product to control a door or other barrier. Use

of egress buttons, for example, may be illegal in some cities. In most applications, single

action exit without prior knowledge of what to do is a life safety requirement. Always

make certain that any required approvals are obtained in writing.

DO NOT ACCEPT VERBAL APPROVALS SINCE THEY ARE NOT VALID.

Damage during shipment

Caution: IF ANY DAMAGE TO THE SHIPMENT IS NOTICED, A CLAIM MUST BE

FILED WITH THE COMMERCIAL CARRIER RESPONSIBLE FOR THE DAMAGE.

Electrostatic discharge

Caution: Electrostatic discharge (ESD) can damage integrated circuits and modules. To

prevent damage always follow these procedures.

Use static shield packaging and containers to transport all electronic components,

including completed reader assemblies.

Handle all ESD sensitive components at an approved static controlled workstation. These

workstations consist of a desk mat, floor mat and an ESD wrist strap. Workstations are

available from various vendors.

Note: This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the installation and user guides, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Disclaimer – Product Liability; Mut ual Indemnification

If a Customer receives a claim that a Product or any component thereof has caused

personal injury or damage to the property of others, Customer shall immediately notify

Honeywell S.r.l. Italy in writing of all such claims. Honeywell S.r.l. Italy shall defend or

settle such claims and shall indemnify and hold Customer harmless for any costs or

damages including reasonable attorneys’ fees which Customer may be required to pay as a

result of the defective Product or the negligence of Honeywell S.r.l. Italy, its agents, or its

employees.

6

Page 7

Customer shall hold harmless and indemnify Honeywell S.r.l. Italy from and against all

claims, demands, losses and liability arising out of damage to property or injury to persons

occasioned by or in connection with the acts or omissions of Customer and its agents and

employees, and from and against all claims, demands, losses and liability for costs of fees,

including reasonable attorneys’ fees, in connection therewith.

Compliance

For any additional information regarding the compliance of this product to any EUspecific requirements, please send an e-mail to temaline.orders@honeywell.com.

Unpacking

Caution: If any damage to the shipment is noticed before unpacking, a claim must be filed

with the commercial carrier.

All containers should be opened and unpacked carefully in order to prevent damage to the

contents.

Follow these steps to unpack equipment in preparation for installation:

Open the container and remove the unit(s) and all packing material. Retain the container

and all the packing materials. They may be used again for reshipment of the equipment, if

needed.

Inspect the contents to see if anything is missing. If you notice any missing items, send an

e-mail to temaline.orders@honeywell.com.

Visually check the contents. If you see any damage, do the following:

If shipping has caused damage to the unit, file a claim with the commercial carrier.

If any other defect is apparent, call for a return authorization.

Shipping instructions

To ship equipment back to Temaline, contact the customer service department at

temaline.orders@honeywell.com before returning the equipment. When you call, please have

available:

A description of the problem or the reason you are returning the equipment.

Your original purchase order number, invoice number and if the unit is still under

warranty.

A new purchase order number if the unit is not under warranty.

From the customer service department, obtain the Return Merchandise Authorization

(RMA).

Show the RMA number on all packages shipped. Packages which are not marked with an

RMA number will be refused at the factory and returned to you COD.

Carefully pack the equipment for shipment. Use the original packing material whenever

possible

Limited warranty

All warranty work shall be handled through Customer who shall notify Temaline and

apply for a Return Merchandise Authorization (RMA) number prior to returning any

Product for service, repair, credit or exchange. Temaline warrants that its Products shall be

free from defects in materials and workmanship for a period of 18 months from the date of

shipment from the Temaline warehouse. Satisfaction of this warranty shall be limited to

repair or replacement of Products which are defective or defective under normal use.

7

Page 8

Temaline’s warranty shall not extend to any Product which, upon examination, is

determined to be defective as a result of misuse, improper storage, incorrect installation,

operation or maintenance, alteration, modification, accident or unusual deterioration of the

Product due to physical environments in excess of the limits set forth in Product manuals.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THIS PROVISION.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES WHETHER

EXPRESS, IMPLIED OR STATUTORY, INCLUDING IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE. NO

REPRESENTATION OR WARRANTY OF THE DISTRIBUTOR SHALL EXTEND

THE LIABILITY OR RESPONSIBILITY OF THE MANUFACTURER BEYOND THE

TERMS OF THIS PROVISION. IN NO EVENT SHALL TEMALINE BE LIABLE FOR

ANY RE-PROCUREMENT COSTS, LOSS OF PROFITS, LOSS OF USE,

INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES TO ANY PERSON

RESULTING FROM THE USE OF TEMALINE’S PRODUCTS.

Confidentiality

All software, drawings, diagrams, specifications, catalogs, literature, manuals and other

materials furnished by Honeywell HSG –Temaline relating to the design, use and service

of the Products shall remain confidential and shall constitute the proprietary rights of

Honeywell HSG -Temaline and Customer agrees to treat such information as confidential.

Customer shall acquire no rights in the design of the Products or the related materials

except to use such information solely for the purpose of and only during the time it sells

the Products. Customer shall not copy the design of any of the Products or use or cause to

be used any Product design or related materials for its own benefit or for the benefit of any

other party. The covenants contained in this section shall remain effective throughout the

term of this Agreement and thereafter unless specifically waived by Honeywell HSG Temaline in writing.

8

Page 9

INTRODUCTION

Purpose of this manual

This manual details how to install the Tema-Voyager™ Multi (from

now on it will be simply called: Multi).

Details on operating instruction, plant maintenance and

troubleshooting are also provided.

Device overview

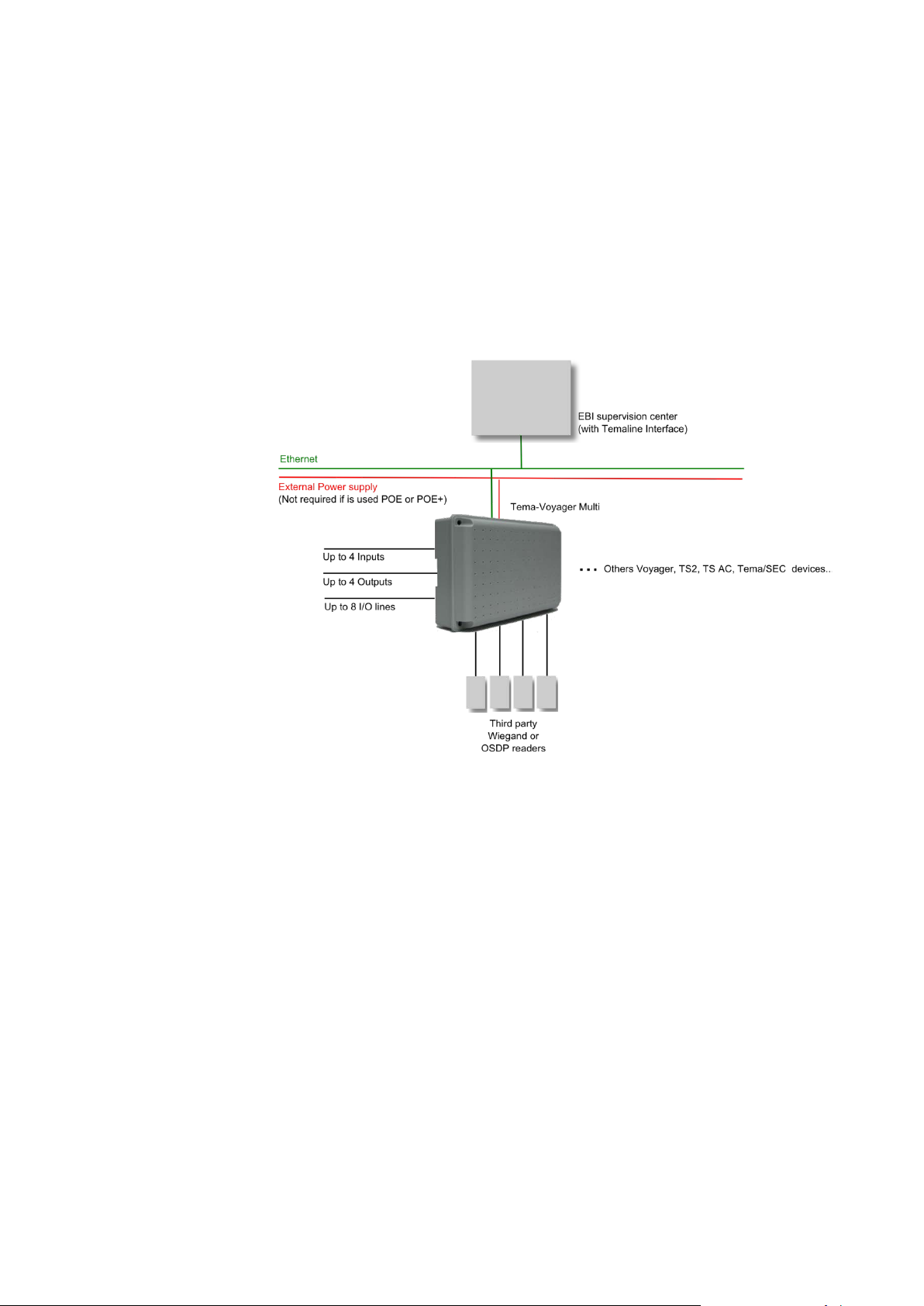

Multi acts as a controller in Temaline architecture.

Multi manages applications included: Access Contr ol ,

Time&Attendance, Canteen and light Intrusion detection.

It has the capability to manage up to 4 third party readers.

The readers can be connected to the device through standard

Wiegand lines or RS485 lines and OSDP protocol.

The usage of OSDP protocol with secure channel makes the solution

more secure in respect to the one using Wiegand connection.

Doors can be managed with reader on one side and REX button on

the other, or with readers on both sides of the door.

The actual number of the readers managed by your dev ic e is based

on the product you purchased (see: Contents of the box - Multi device).

Multi has on board dig i tal I/O use d for the m a nag em ent of the

Wiegand reader (buzzer, green/red led, reader tamper) and also 4

inputs (that can be set to be supervised or digital), 4 open drain

outputs and 8 I/O lines can be freel y configured as inputs or outputs.

These I/O can be used both for the manage m ent o f the doors and for

light Intrusion detection purpose.

Two different types of relays boards are available, as options, for the

Multi device. Each relay board can manage up to 4 outputs 24V @3A.

Up to 3 relay output boards can be connected to the Multi (See:

USING RELAYS PLUGS-IN (VMA -06, VMA-07))

9

Page 10

It is connected to the supervisor centre and with other peer devices via

Ethernet line (10Mb/100Mb/1Gb).

It can be supplied with an external 10-30 V DC power supply or using

POE or POE+

System Architecture

Figure 1 shows a typical system architecture in which Multi is inserted.

Figure 1 – Multi system architecture

The connections shown are:

• The Ethernet connection: it connects Honeywell Enterprise

Buildings Integrator™ (EBI) supervision center and in peer to

peer other Temaline peripheral devices.

• The external Power supply connection; not required if the Multi

device is supplied using POE or POE+.

• The Reader connections: to connect Multi with third party

readers (Wiegand connection and RS485/OSDP connection).

• Inputs/outputs connections

As part of the overall Temaline solution, Multi is fully compatible to

peer to peer communication with other Temaline peripheral devices

(TS-AC01, TS2, Tema/SEC, Tema ID, Tema-Voyager™ Compact).

10

Page 11

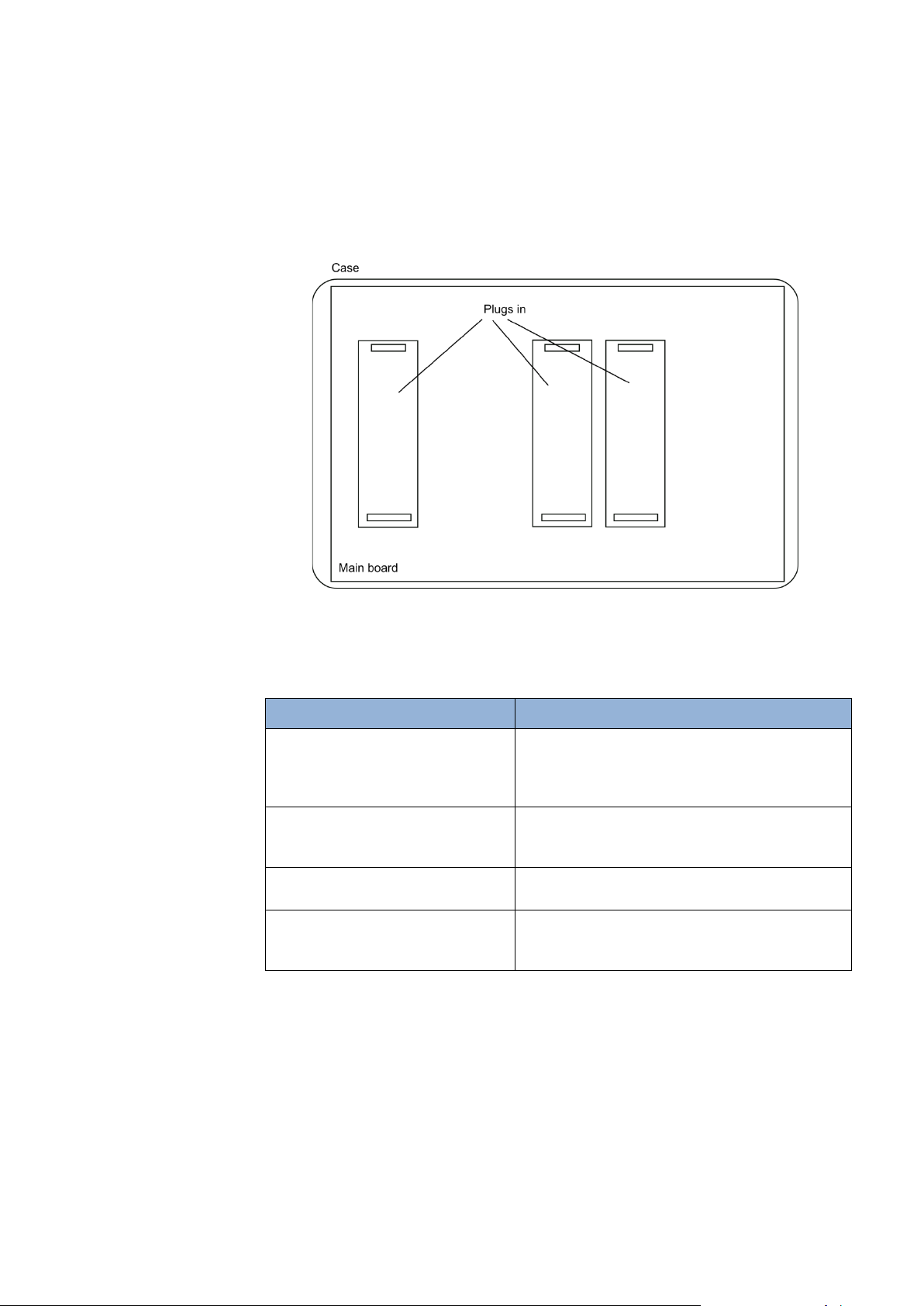

Device components

This chapter gives an overview of the components of MULTI device;

the intent is to provide the main terms used into the installation phase.

For a more deep understanding of the device please refer to the

chapter Multi Device Anatomy.

Related documentation

Document Content

EBI - Temaline Access Control

Configuration Guide

Tema-Voyager Multi - Web

interface Guide

Tema-Voyager Multi - Quick

Installation Guide

Voyager Multi - VMA06 VMA07 Quick installation Guide

Figure 2 - Multi components overview

Further information on the EBI T ema system ,

complete commissioning steps and system

configuration are inc luded in the CD which is

provided with EBI documentation package.

User manual of the MULTI Web Interface

used for commissioning and maintenance

operations.

It’s the quick guide f or the Mult i installation; it

is included into the device box.

It’s the quick guide for the VMA-06, VMA-07

plugs in installation; it is shipped together

with the devices box.

11

Page 12

PREPARING FOR INSTALLATION

Contents of the box

Before you begin, unpack the shipment and check the parts list

against the components in the shipment.

Your shipment contains:

Multi device

One of the following Multi devices:

Code Item

VMC-00WENN1 Tema-Voyager Multi-0, it is used for managem ent of onl y I/O,

no reader connection available..

VMC-01WENN1 Tema-Voyager Multi-1, it manages 1 reader and I/O

VMC-02WENN1 Tema-Voyager Multi-2, it manages up to 2 readers and I/O

VMC-03WENN1 Tema-Voyager Multi-3, it manages up to 3 readers and I/O

VMC-04WENN1 Tema-Voyager Multi-4, it manages up to 4 readers and I/O

Device support kit

Code Qty Item

P8160-5 4 Shunt Jumper, 2PINS, FEM, 2.54mm, 3.0A, -55C to

+105C

300-04883 12 Resistor: CARB. 392R 1/4W 1% THT LF (White)

300-04884 12 Resistor: METAL. 1K21, 1/4W 1% THT LF (Yellow)

300-07677 4 Resistor: CARB. 270R, 1%, 1/4W THT LF (Blue)

P460 12 Diodes 1N4004 or equivalent

700-04116 1 Lower seal rubber (to be u sed only when IP32 protection

is required)

700-04114 1 Upper seal rubber (t o be used only when IP32 protection

is required)

800-19900 1 Tema-Voyager Multi - Quick Installation Guide

Optional Boards (included into a separate box)

Code Item

VMA-06 Tema-Voyager Multi Relay Output board: provides 4 R elay Output,

dry contact NO/NC 24V-3A.

Up to 3 can be added to a Multi device.

12

Page 13

Spare Parts

VMA-07 Tema-Voyager Multi Emergency Relay Output board, provides:

4 Relay Output, dry contact NO/NC 24V-3A;

1 Input, dry contact, for emergency alarm, with separate power

supply.

Up to 1 can be added to a Multi device.

800-20479 Tema-Voyager Multi - VMA06, VMA07 - Quick Installation Guide

(only when optional boards are presen t)

It is possible to order the following spare parts for this device:

Spare part

code

VMS-RUB 700-04114

VMS-KIT 100-05961 Resistors and diodes kit. 1

Code Item Q.ty

Upper Seal Rubber

700-04116

Lowest Seal Rubber

Mounting tools

The following screwdrivers are required for the installation:

• 3mm slotted screwdriver

• T10 Torx screwdriv er

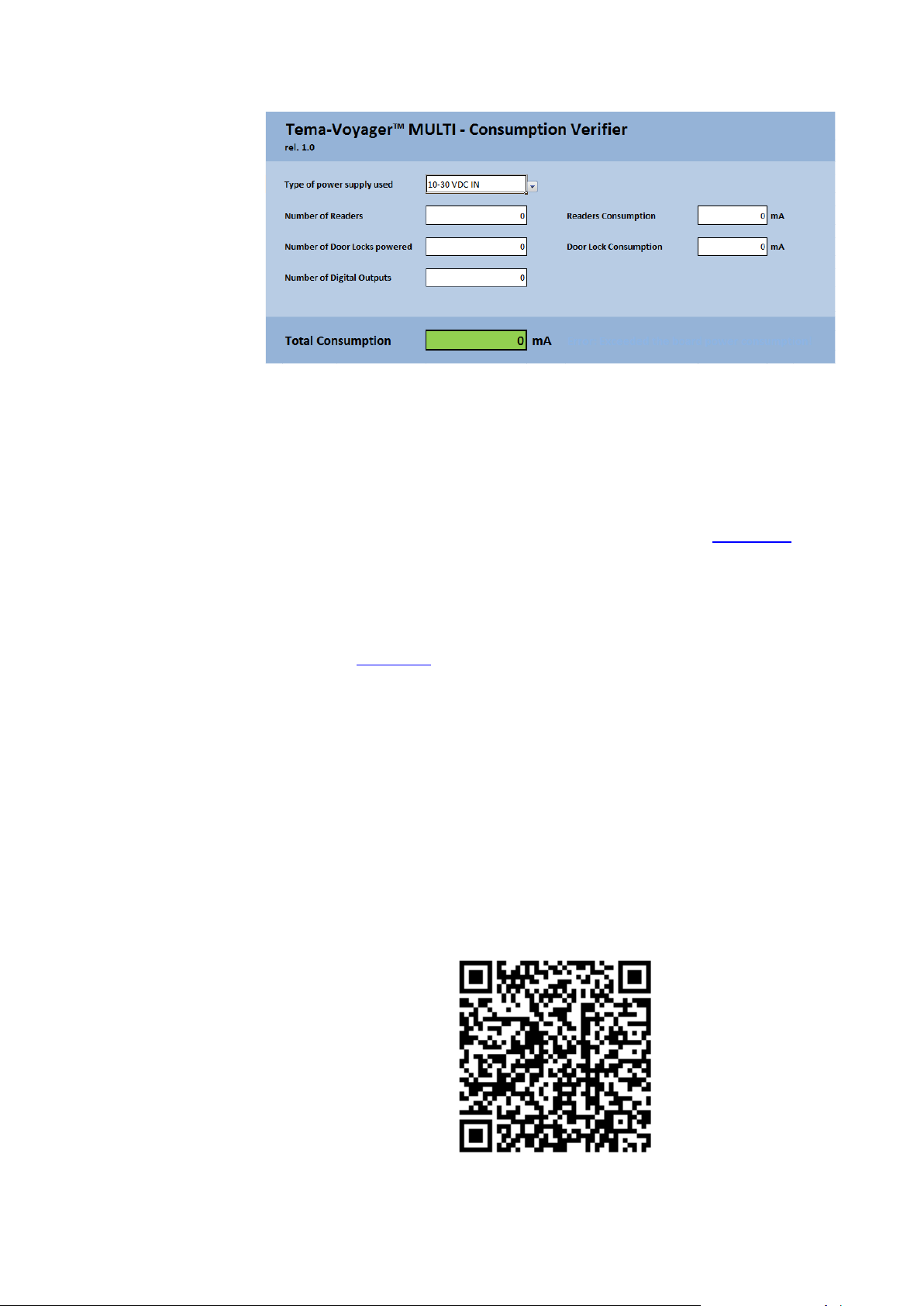

Calculation of the current provided by Multi

Multi device can be powered either with a 10V-30V DC

power supply, PoE or PoE+; each of these power sources can provide

a different amount of current used to power the Multi device itself,

outputs, readers and door locks directly supplied by the device.

Tema-Voyager Multi - Consumption Veri fier s pr eadsheet is been

available into EBI Global Support repository to help in calculate the

max number of outputs, readers and door lock s can be directly

connected to the device and to verify that their consumption is inside

what provided by the selected power supply source.

5

13

Page 14

Figure 3 - Tema-Voyager Multi - Consumption verifier spreadsheet

To get the s preadsheet follow one of the below options.

If you are reading this document in Acrobat pdf format click here to get

the spreadsheet attached to this document.

Or

Follow this hyperlink to retrieve the last version of the document from

the EBI Global Support repository:

If you are reading this document in paper format go to EBI Gl obal

Support repository then into the Tech Tips sectio n and download the

Tema-Voyager Multi - Consumption Veri fier s pr eadsheet.xlsx

Or

Using your phone or tablet QR scanner follow the QR code of the

spreadsheet:

14

Page 15

Wires Characteristics

Use this chapter to understand the types of wire you need to use for

your plant.

Power supply wire

Multi device can be powered either with a 10V-30V DC third party

power supply, with PoE or with PoE+.

To determine the correct size for power cables need to be used for

third party power supply, refer to the below table (T he fol l owing table

lists examples of wire gauge and distance for a 12V):

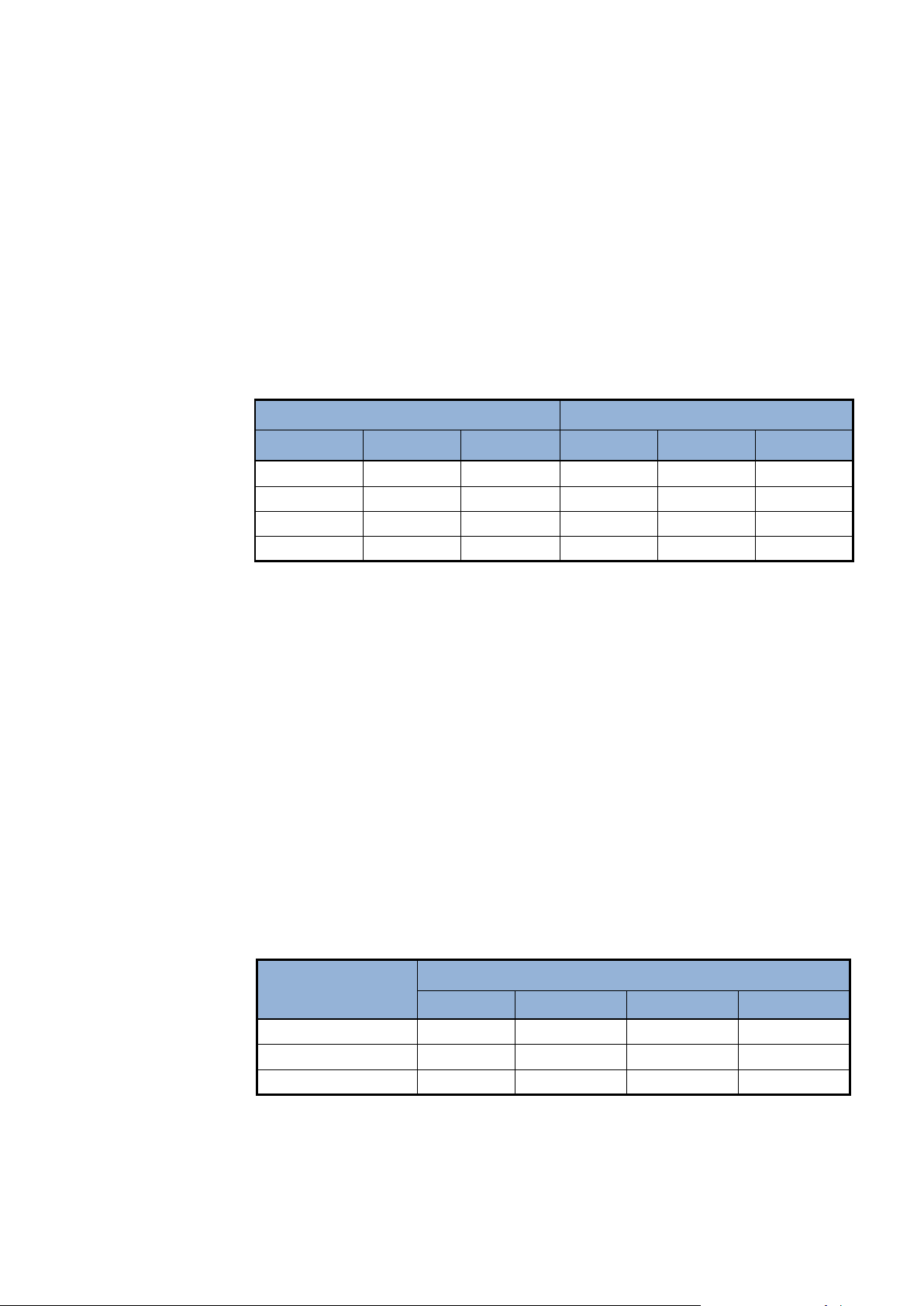

Type of cable Length (m) at different currents

Network wire

Readers wires

AWG mm2 Ohm/Km

16 1.3 14 119 60 30

18 0.9 21 79 40 20

20 0.6 34 49 25 12

22 0.35 52 32 16 8

Table 1 - Length of Power Supply cables [m]

600 mA 1200 mA 2400 mA

Warning: The above table shows the values for a single Multi device;

if more than one Multi needs to be connected to the same line, divide

the length by the number of the devices.

For POE+ and POE: Cat5 or Cat6 Ethernet cable has to be used.

RS485 Data Cables (for OSDP reader connection)

Data cables used with RS485 must be twisted-pair and with 120 ohm

impedance.

Refer to Table 2 for the size of data cables to be used for this

connection with cable with AWG from 24 to 16 not shielded.

Communication

speed (bit/sec)

9600 1000 500 250 100

19200 500 250 125 50

38400 240 120 60 24

Table 2 - Length/Capacity of RS485 Data Cables not shi e lded (m)

Length in meters in relation to the cable capacity

50nF/Km 100nF/Km 200nF/Km 500nF/Km

Refer to Table 2 for sizing data cabl es to be used for RS485

connection with cable with AWG from 24 to 16 shielded.

15

Page 16

Input wires

Communication speed

(bit/sec)

9600 1200

19200 900

38400 700

Table 3 - Length of RS485 Data Cables shielded (m)

Length in meters

50nF/Km

Caution:

If the distance betw een the reader and the Multi

device is more that 15 m you need to change the

RS485 switch position to insert the 120 ohm

termination resistor. Refer to the Multi Device

Anatomy chapter

Wiegand reader cables

The wires used to connect Multi device with third party Wiegand

readers are those specified into the reader technical specification.

Use a twisted pair cable for the contacts connections.

For outdoor wiring is mandatory to use shielded cables.

For internal wiring without shielded cables is recommended an

electrical environment where the cables are well separated, even at

short runs, especially to whom can be essentially subjected to

interference.

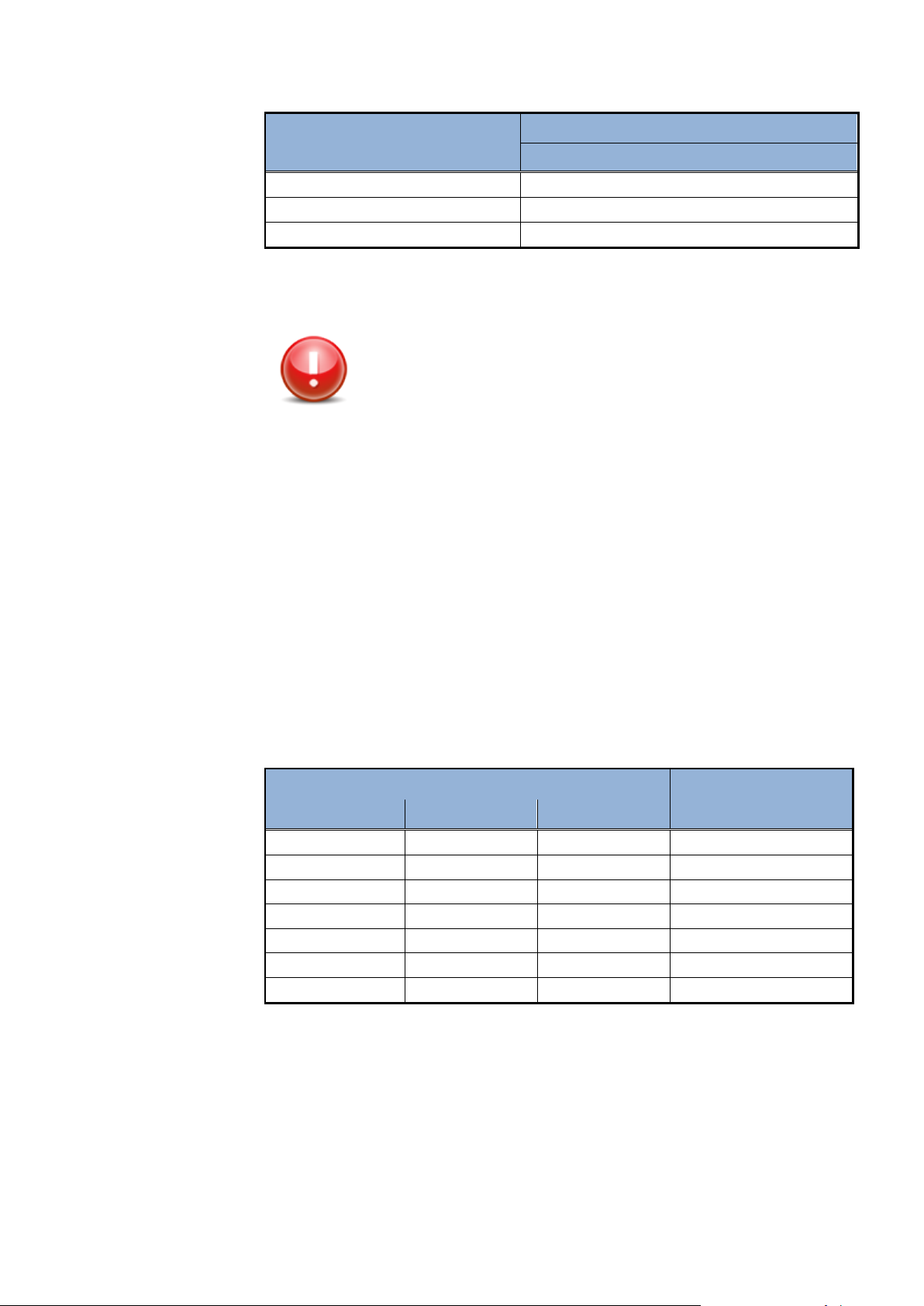

The following table lists wire gauges and distances for Inputs.

Cable type Max distance (m)*

AWG mm2 Ohm/km

14 2 8.8 1420

16 1.3 14 893

18 0.9 21 595

20 0.52 34 368

22 0.35 52 240

24 0.2 85 147

26 0.13 137 93

Table 3 Length of Input cables

Output cable

16

*One-volt voltage drop is considered typical.

Cable used for connecting output should have a MAX size of 2 mm

that it is AWG14.

Page 17

MOUNTING THE DEVICE

Wall mount

These are the steps needed to be followed to mount the device on the

wall:

1. Determine an appropriate mounting position for the device;

keep into consideration that the wires shall be connected on the

top and bottom side of the box. To establish a common

reference the Ethernet connector should be on the right bottom

corner.

2. Use the back case to mark the position of the 4 mounting holes

Figure 4 - Multi back case and holes positions

3. Drill the holes

4. Introduce M6 (6 mm) plastic dowels (not included).

5. Attach the back case to the wall. No need to remove the board.

6. Setup jumpers for the desired configuratio n

7. Connect the readers

17

Page 18

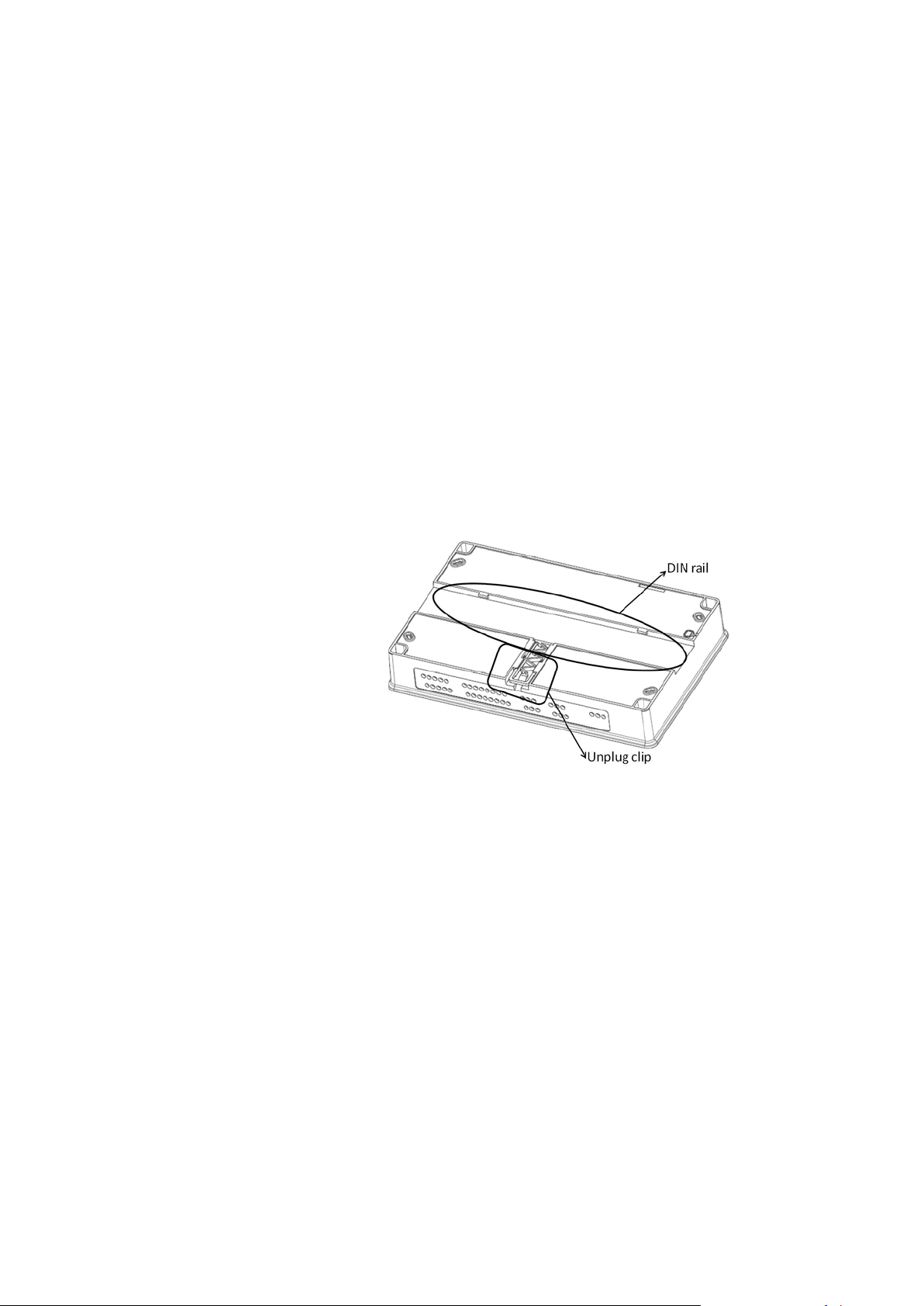

DIN rail mount

These are the steps needed to be followed to mount the device on a

DIN rail:

8. Connect the inputs/outputs

9. Connect the power supply of the device.

10. Use screws to lock the cover of the device

1. Determine an appropriate mounting position for the device;

keep into consideration that the wires shall be connected on the

top and bottom side of the box. To establish a common

reference the Ethernet connector should be on the right bottom

corner.

2. Plug the device back case on the DIN Rail (use screw driver if

you need to unplug it).

3. Setup jumpers for the desired configuration

4. Connect the readers

5. Connect the inputs/outputs

6. Connect the power supply of the device.

7. Use screws to lock the cover of the device

IP32 protection mount

The Voyager Multi device can be mounted to ensure IP32 protection

and so be in compliance with CEI EN-50133-1 group III - Outdoor but

sheltered from direct rain and sunshine or Indoor with extreme

environmental condition.

To achieve IP32 protection it is required to:

Figure 5 – Multi DIN rail and unplug clip

18

Page 19

1. Have the device mounted with Ethernet connector on the right

bottom corner.

2. Apply the adhesive seals rubber provided in the Device support

kit. The two seals are different in shape; the longer one is for

the top of the device where the shorter is for the bottom.

To wire the device when adhesive seals rubber are in place follow

these steps:

1. Using a screwdriver gently enlarge only the sealed holes need

to be used.

2. If the cable has stranded wires (flexible core) strongly twist the

stripped portion of the wire, in order to have a rigid tip, before

inserting it in the hole.

19

Page 20

CONNECTING THE CABLES

Caution:

To ensure IP32 protection to the device you must follow

what specified into “IP32 protection mount” chapter.

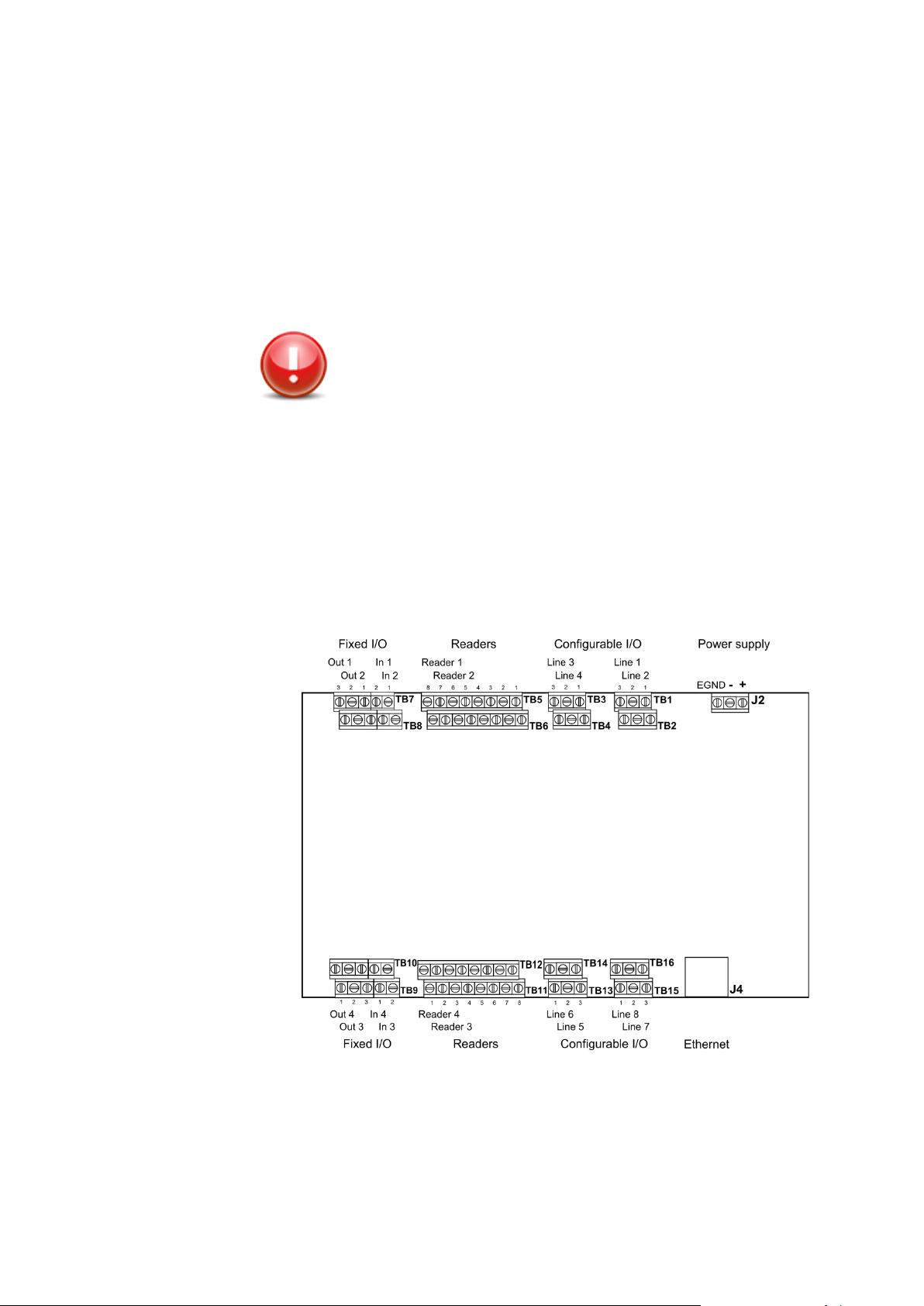

Cables to be connected are (see Figure 6 - Multi Wiring Diagram):

• DC power supply (only if the device is not supplied using

POE/POE+)

• Readers lines

• Ethernet (10/100/1G BaseT)

• Input/Outputs (both Fixed and Configurable)

20

Figure 6 - Multi Wiring Diagram

Page 21

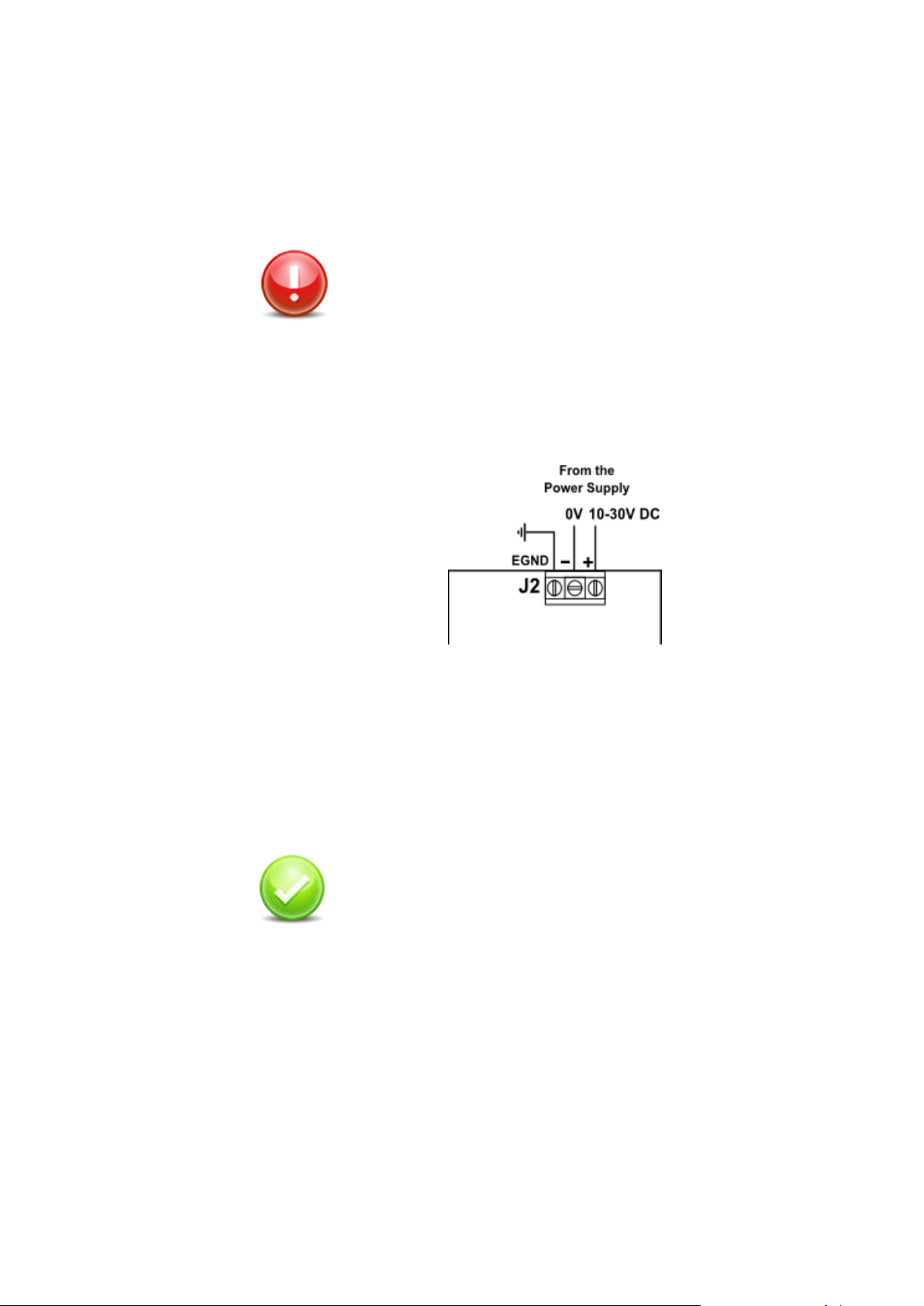

Connecting the DC Power Supply

The connection of an external power supply is required only if the

device is not supplied using POE or POE+.

Warning:

To be in compliance with UL60950 the Tema-Voyager Multi

device must be supplied by a separately certified NEC Class

2 (LPS) power unit.

1. Connect the DC Power supply cable heads onto the J2 terminal

blocks (use a ∅ 3mm slotted screwdriver).

2. Connect the ground wire (EGND).

Figure 7 - Multi - Power supply connections

The J2 connector is provided of a polarized direct screw connector

with the following connection characteristics:

• Conductor section AWG min = AWG24 max = AWG16

• Conductor rigid or flexible min = 0.2 mm2 max = 1.5 mm2

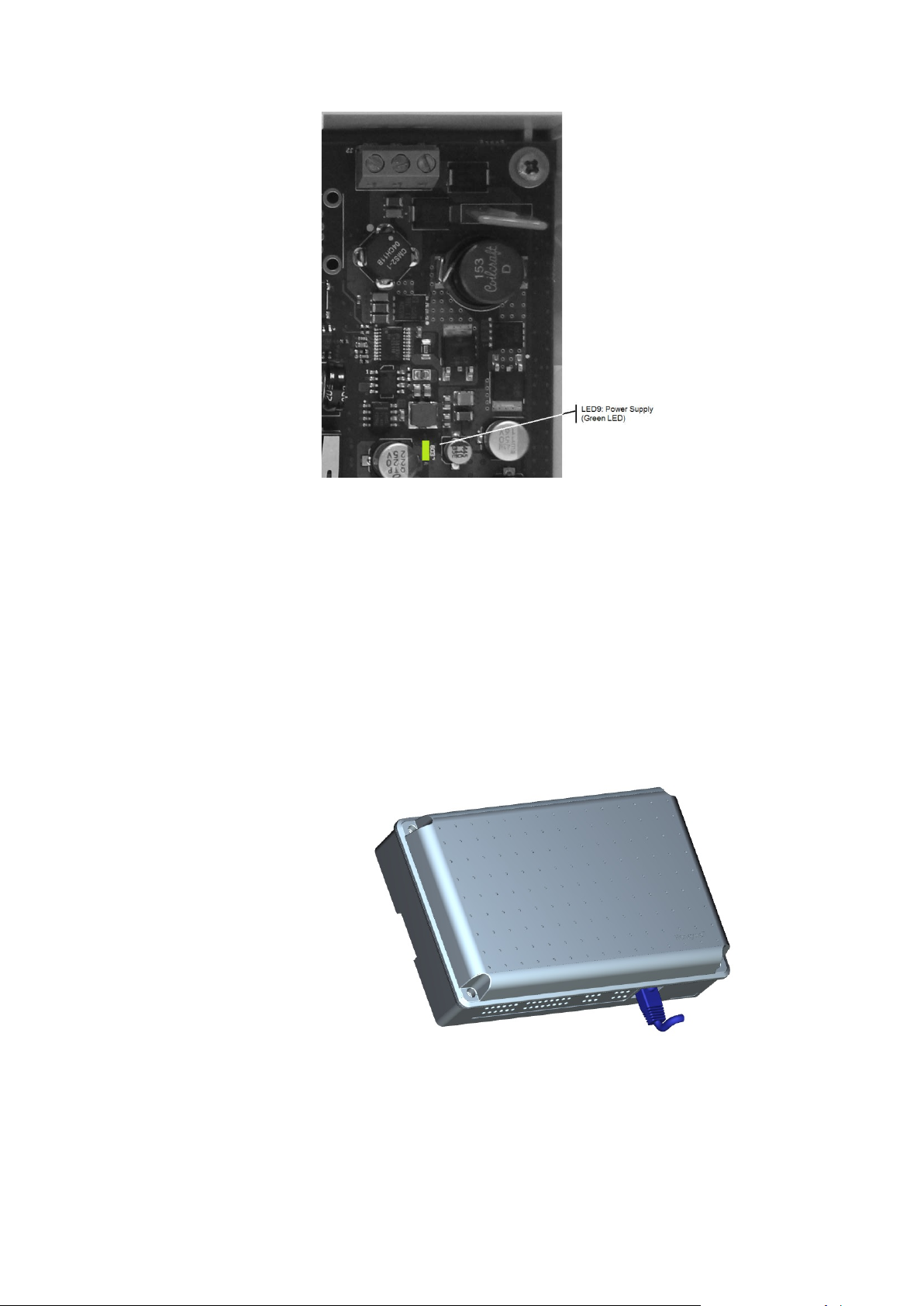

Check: Once the DC Power Supply is properly

connected and switched on, the LED9 Green Led (Power

Supply) must be in ON status.

21

Page 22

Figure 8 - Power supply LED

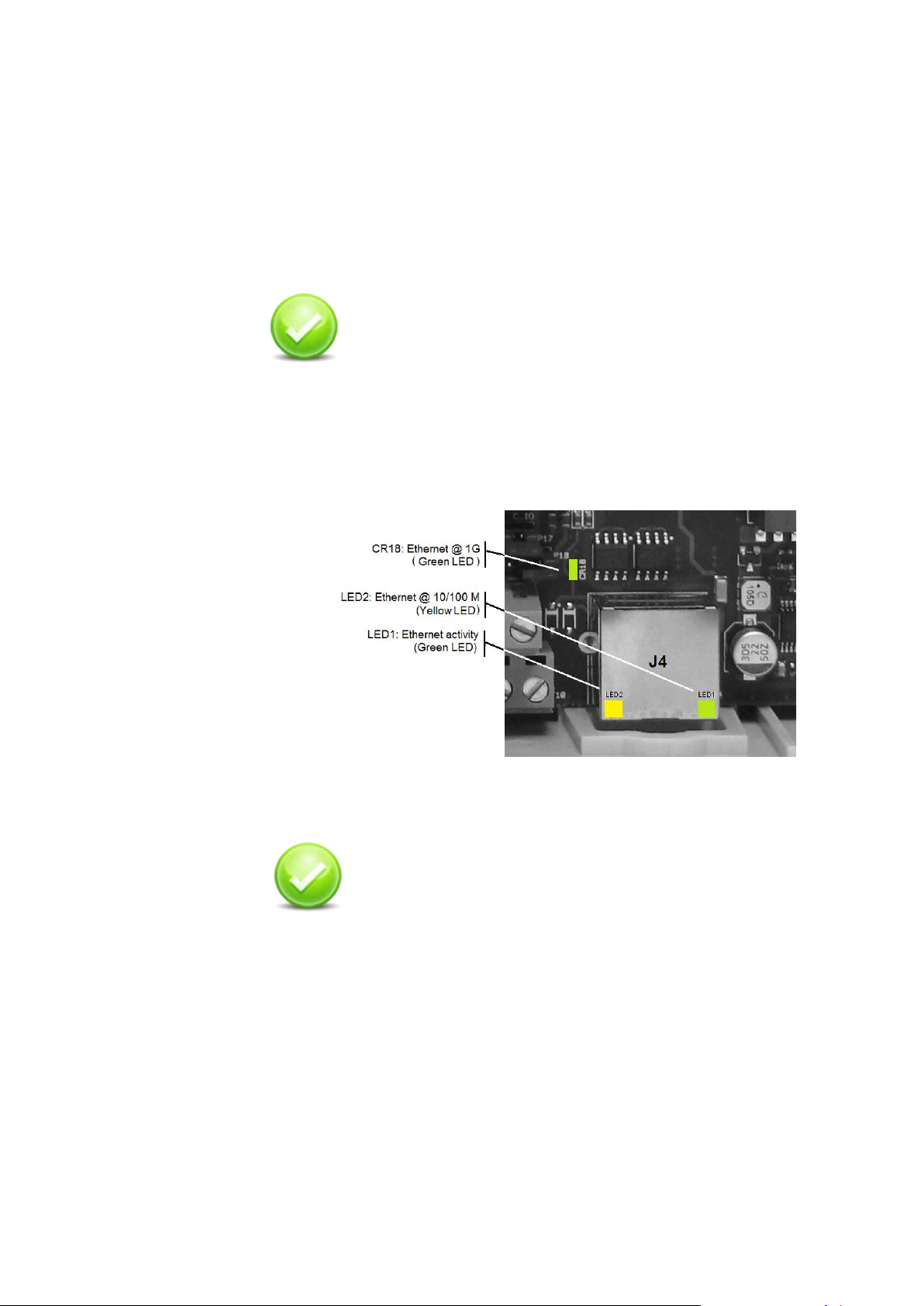

Connecting the netw or k cable

The Multi device is equipped with an RJ45 female connector J4.

The network cable must be a BaseT standard unshielded CAT5 or

CAT6 cable terminated with an RJ45 male connector.

Select the network cable in compliance to what specified into the

“Networ k wire” chapter on page 15.

Plug the cable into the J4 connector.

22

Figure 9 - Plug network connector

Characteristics of the network connection are:

Page 23

• Auto-MDIX: automatically detects and corrects for straight or

Check: once the Ethernet wire is properly connected and

• LED2 (green) - Ethernet @ 10/100 Mbit/s

• CR18 (green) - Ethernet @ 1 Gbit/s

blink regularly.

Check: in case of use of POE or POE+ as power supply

cross-over cables

• Error free operation up to 150mt: dependable network

performance over long distance

• > 8.0 KV ESD protection: robust operation in Harsh

environments

the Multi device switched on, one of the two led LED2 or

CR18 (Ethernet physical link) must be on. Which led is

switched on depends from the speed of the network:

The yellow LED1 (Ethernet Communication activity) must

Figure 10 - Ethernet LED positions

source once connected to Ethernet the device shall power

on and the green LED9 (Power supply) must be in on

status.

23

Page 24

Connecting the readers

Multi can connect up to 4 third party readers; connection can be

established using RS485 lines (for OSDP readers) or using Wiegand

line (for Wiegand readers).

The actual number of readers it is possible to connect depends from

the product code has been purchased (see: Multi device on page 12).

The connection position of the readers depends, as well, from product

code purchased:

Figure 11 - Power supply LED for POE/POE+

24

Code Reader

number

VMC-01WENN1 1 reader Reader1 (TB5)

VMC-02WENN1 2 readers Reader1 (TB5) and Reader2 (TB6)

VMC-03WENN1 3 readers Reader1 (TB5) and Reader2 (TB6) and

VMC-04WENN1 4 readers Reader1 (TB5) and Reader2 (TB6) and

Reader Connectors to be used

Reader3 (TB11)

Reader3 (TB11) and Reader4 (TB12)

Page 25

OSDP and Wiegand readers can be connected to the same terminal

blocks; to inform the device of the type of connection need to be used

it is required to set specific jumpers present on the board.

Multi is set in factory for the management of Wiegand

readers; this means that, on a brand new device, you

need to change the reader configuration jumpers only

if you need to connect OSDP readers.

The following pictures show for every reader position how to connect

the reader device and how to set the reader configuration jumpers in

case of Wiegand or OSDP reader.

Please note that to detect the tamper alarm of Wiegand reader it is

required to insert, closer to the reader device, the blue resistor

provided in the Devic e supp or t kit.

25

Page 26

Reader in position 1

The below pictures show the connections schematics and jumpers

setting for reader in position 1:

Wiegand reader

Reader in position 2

The below pictures show the connections schematics and jumpers

setting for reader in position 2:

OSDP reader

Wiegand reader

OSDP reader

26

Page 27

Reader in position 3

The below pictures show the connections schematics and jumpers

setting for reader in position 3:

Wiegand reader

Reader in position 4

The below pictures show the connections schematics and jumpers

setting for reader in position 4:

OSDP reader

Wiegand reader

OSDP reader

27

Page 28

OSDP reader check: once the connection with the

reader is properly established and configured, the Multi

and the reader are switched on; the bi-color LED (Red

and Green) must blink regularly. Red color indicates

transmission where green color receiving.

RS485 line length setti ng

On Multi device there is a series of switches used, when OSDP

readers are connected, to select RS-485 matched di stance mode.

Multi supports biasing and end-of-line termination for the RS-485

network. Please refer chapter “Switches and LEDs” on page 61 for the

position of the switches.

For every reader there are two switches, one for Data A and one for

Data B that need to be set both in the same way:

• When switch is OFF (terminator resistor is not inserted) RS-485

allows the wiring of single-drop communication network of up to

15 m in length.

• When switch is ON (terminator resistor is inserted) RS-485

allows the wiring of single-drop communication network of up to

1200 m in length.

Figure 12 - OSDP readers, communication LED positions

28

Page 29

OSDP

reader

Switch Meaning Default

Reader1 SW3.1 RS485 termination resistor, Data A.

ON = termination resistor inserted

OFF = termination resistor not inserted

SW3.2 RS485 termination resistor, Data B.

ON = termination resistor inserted

OFF = termination resistor not inserted

Reader2 SW4.1 RS485 termination resistor, Data A.

ON = termination resistor inserted

OFF = termination resistor not inserted

SW4.2 RS485 termination resistor, Data B.

ON = termination resistor inserted

OFF = termination resistor not inserted

Reader3 SW5.1 RS485 termination resistor, Data A.

ON = termination resistor inserted

OFF = termination resistor not inserted

SW5.2 RS485 termination resistor, Data B.

ON = termination resistor inserted

OFF = termination resistor not inserted

Reader4 SW6.1 RS485 termination resistor, Data A.

ON = termination resistor inserted

OFF = termination resistor not inserted

SW6.2 RS485 termination resistor, Data B.

ON = termination resistor inserted

OFF = termination resistor not inserted

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Connecting Inputs

Multi provides four fixed inputs and other eight lines can be freely

configured as Inputs or Outputs; when lines are configured as input

these are called: Configurable inputs.

All the inputs can be either work as digital or supervised; this type of

configuration is done at the EBI level, so there are no jumpers on the

board for this type of setting.

The typical connection for supervised inputs requires using the couple

of yellow and white resistors distributed into the device support kit.

Yellow resistor: 1210 Ohm 1%

White resi stor: 392 Ohm 1%

Close contact resistance: 296 Ohm

Open contact resistance: 1210 Ohm

Table 4 - RS485 Terminator resistor switches

29

Page 30

Characteristics and connections are the same for fixed and

configurable inputs.

Connecting Fixed Inputs

Fixed Input 1

The below pictures show the connections schematics for dry contact

and supervised contact for fixed input 1:

Dry contact connection

Supervised connection

Fixed Input 2

The below pictures show the connections schematics for dry contact

and supervised contact for fix ed inp ut 2:

Dry contact connection

Supervised connection

30

Page 31

Fixed Input 3

The below pictures show the connections schematics for dry contact

and supervised contact for fix ed inp ut 3:

Dry contact connection

Supervised connection

Fixed Input 4

The below pictures show the connections schematics for dry contact

and supervised contact for fix ed inp ut 4:

Dry contact connection

Supervised connection

31

Page 32

Connecting configurable Inputs

Configurable Input 1

The below pictures show the connections schematics for dry contact

and supervised contact for configurable input 1:

Dry contact connection

Supervised connection

Configurable Input 2

The below pictures show the connections schematics for dry contact

and supervised contact for configurable input 2:

Dry contact connection

Supervised connection

32

Page 33

Configurable Input 3

The below pictures show the connections schematics for dry contact

and supervised contact for configurable input 3:

Dry contact connection

Supervised connection

Configurable Input 4

The below pictures show the connections schematics for dry contact

and supervised contact for configurable input 4:

Dry contact connection

Supervised connection

33

Page 34

Configurable Input 5

The below pictures show the connections schematics for dry contact

and supervised contact for configurable input 5:

Dry contact connection

Supervised connection

Configurable Input 6

The below pictures show the connections schematics for dry contact

and supervised contact for configurable input 6:

Dry contact connection

Supervised connection

34

Page 35

Configurable Input 7

The below pictures show the connections schematics for dry contact

and supervised contact for configurable input 7:

Dry contact connection

Supervised connection

Configurable Input 8

The below pictures show the connections schematics for dry contact

and supervised contact for configurable input 8:

Dry contact connection

Supervised connection

Caution: Temaline recommends that you establish

an electrical environment where the cables are well

separated, even at short runs, especially for the

power cables or external cables which can be

essentially subjected to interference or lightning.

Use a twisted-pair cable for the contact cables.

Make sure that the cables correspond in size to the

norms indicated in section Input wires.

Max contact resistance = 25 Ohm

35

Page 36

Connecting Outputs

Multi provides four fixed outputs and other eight lines can be freely

configured as Inputs or Outputs; when such lines are configured as

Outputs these are called: Configurable outputs.

Multi outputs are provided with open collector transistors.

Using the open collector directly (i.e. to connect an external relay), the

current must not exceed 50mA; when the load exceeds such value

is mandatory to use an external power supply.

In the following section we give the connection schematics in the case

of external relay powered directly from Multi and with relay powered

from an external power supply for both fixed output and for

configurable ones.

Note: Use 12VDC relay - max coil current = 50mA each. In this case

it’s mandatory to connect a 1N4004 diode as shown into schematics.

Multi can also be equipped with optional VMA-06 or VMA-07 relay

plugs-in (see chapter USING RELAYS PLUGS-IN (VMA-06, VMA-07)

on page 44 for these approach); to inform the board about the use of

external relays or Multi relay plugs-in on the board are present several

jumpers. Every schematic reports the relating setting of the jumpers.

The default jumpers’ configuration of Multi board (factory setting) is the

one used for external relay s.

36

Page 37

Connecting Fixed Outputs

Fixed Output 1

The below pictures show the connections schematics for an external

relay powered directly from Multi or from an external power supply

using fixed output 1:

External Relay Powered by Multi

External relay powered by

external power supply

Fixed Output 2

The below pictures show the connections schematics for an external

relay powered directly from Multi or from an external power supply

using fixed output 2:

External Relay Powered by Multi

External relay powered by

external power supply

37

Page 38

Fixed Output 3

The below pictures show the connections schematics for an external

relay powered directly from Multi or from an external power supply

using fixed output 3:

External Relay Powered by Multi

External relay powered by

external power supply

Fixed Output 4

The below pictures show the connections schematics for an external

relay powered directly from Multi or from an external power supply

using fixed output 4:

External Relay Powered by Multi

External relay powered by

external power supply

38

Page 39

Connecting Configurable Outputs

Configurable Output 1

The below pictures show the connections schematics for an external

relay powered directly from Multi or from an external power supply

using configurable out put 1:

External Relay Powered by Multi

External relay powered by

external power supply

Configurable Output 2

The below pictures show the connections schematics for an external

relay powered directly from Multi or from an external power supply

using configurable out put 2:

External Relay Powered by Multi

External relay powered by

external power supply

39

Page 40

Configurable Output 3

The below pictures show the connections schematics for an external

relay powered directly from Multi or from an external power supply

using configurable out put 3:

External Relay Powered by Multi

External relay powered by

external power supply

Configurable Output 4

The below pictures show the connections schematics for an external

relay powered directly from Multi or from an external power supply

using configurable out put 4:

External Relay Powered by Multi

External relay powered by

external power supply

40

Page 41

Configurable Output 5

The below pictures show the connections schematics for an external

relay powered directly from Multi or from an external power supply

using configurable out put 5:

External Relay Powered by Multi

External relay powered by

external power supply

Configurable Output 6

The below pictures show the connections schematics for an external

relay powered directly from Multi or from an external power supply

using configurable out put 6:

External Relay Powered by Multi

External relay powered by

external power supply

41

Page 42

Configurable Output 7

The below pictures show the connections schematics for an external

relay powered directly from Multi or from an external power supply

using configurable out put 7:

External Relay Powered by Multi

External relay powered by

external power supply

Configurable Output 8

The below pictures show the connections schematics for an external

relay powered directly from Multi or from an external power supply

using configurable out put 8:

External Relay Powered by Multi

External relay powered by

external power supply

42

Page 43

Outputs check: On Multi board are present 8 green LED

to monitor the Outputs state. To be able to use this

check the outputs must be properly configured and the

Multi switched on; Green color indicates output active

where LED switched o ff means output not configured or

inactive.

Figure 13 - Outputs monitor LED

43

Page 44

USING RELAYS PLUGS-IN (VMA-06, VMA-07)

Tema-Voyager™ Multi Relay Output board: provides 4

Relay Output, dry contact NO/NC 24V-3A.

Tema-Voyager™ Multi Emergenc y Relay Output board:

separate power supply.

VMA-06 and VMA-07 are optional plugs-in used together with Multi

devices. When these are plugged on the Multi board and properly

configured using the related jumpers they turn the open collector

digital outputs of the board in relay outputs.

VMA-07 includes the connection for an input that drives the cut of the

power supply of the device in case of emergency.

Up to 3 relay output plugs-in can be connected to Multi.

These are the product codes and the characteristics of the plugs-in:

Code Item

VMA-06

VMA-07

provides:

• 4 Relay Output, dry contact NO/NC 24V-3A;

• 1 Input, dry contact, for emergency alarm, with

44

Page 45

Figure 14 - VMA-06 relays Plug-in

Figure 15 - VMA-07 Relay Plug-in

Mounting the plugs-in

To mount the plugs-in on the Multi device follows the below steps:

1. Determine an appropriate mounting position for the plugs in. If you

have a VMA-07 you have to plug it only on the position 1, where

VMA-06 can be plugged in any of the 3 sockets' positions (in

relation to the outputs to be managed).

a. Position 1 drives fixed outputs 1, 2, 3, 4

b. Position 2 drives flexible outputs 3, 4, 5, 6

c. Position 3 drives flexi bl e outpu ts 1, 2, 7, 8

45

Page 46

Figure 16 - Plugs-in position

2. Switch off the Multi device.

3. Unscrew the cover of the Voyager Multi case and remove it.

4. Plug the VMA-0x devices on the Multi board.

46

Figure 17 - Plugging the VMA-06 on position 1

Caution:

The plugin has two connectors, one with 8 pins and

another with 6 pins, this has to be matched with the

socket on the main board

5. Set the jumpers required to configure the use of the plug-in

(see for details: Configurati on o f Multi t o use VM A-06 and VMA07 plugs-in on page 48)

6. Wire the outputs as specified in the following of the chapter.

Page 47

7. If you are using VMA-07 wire the input used to cut the

1

2

3

POE/POE+ internal power supply (see for det ai l s: Connection

of the emergency input to VMA-07 on page 55).

Setting up Plug-in jumper

On VMA-06 and VMA-07 each jumpers block is relating to a single

output; the below picture and table give the match between ju mper s

block and outputs based on the position of the plug-in on the board.

Figure 18 - Jumpers blocks on plugs-in

Plug-in position Outputs match

P5 – Fixed output1

P3 – Fixed output2

Table 5 - Matches between jumpers blocks and outputs

P4 – Fixed output3

P6 – Fixed output4

P5 – Line3

P3 – Line4

P4 – Line5

P6 – Line6

P5 – Line1

P3 – Line2

P4 – Line7

P6 – Line8

Specific position of jumpers on the jumper block is used to specify one

of the four modes in which the relay outputs can work:

• Dry contact normally open (default jumper setup)

47

Page 48

• Dry contact normally closed

• Power output normally open

• Power output normally closed

The below picture shows the way to set the jumpers to have the

desired mode:

Figure 19 - Relay output mode

Configuration of Multi to use VMA-06 and VMA-07 plugs-in

To use relay outputs on VMA-06 and VMA-07 plugs-in it is required to

properly configure the jumpers on Multi board.

In the following pictures we show all the possible configuration of Multi

to use plugs-in relay outputs. For every configuration is shown also the

related Jumper settings.

Caution:

After inserting VMA-06 and VMA-07 plugs-in it is

required to configure some jumpers on Multi board

to drive the outputs through relays.

48

Page 49

Connecting Fixed Outputs (Plug-in in slot of position 1)

Door Lock Powered by Multi relay

Door lock powered by external

NC

Door Lock Powered by Multi relay

Door lock powered by external

NC

The below pictures show the connections schematics for Multi using

VMA-06 or VMA-07 plugs-in and fixed output s: a door lock powered by

Multi relay and a door lock power from an external power supply and

driven by an internal relay used as dry contact. Wiring of outputs and

jumper configuration are done in the same way for VMA-06 and VMA-

07. VMA-06 or VMA-07 plug-in must be inserted in slot 1.

Fixed Output 1

Relay output mode:

Power Output NO (as in above picture) or NC

Fixed Output 2

power supply and driven by Multi

relay

Relay output mode:

Dry Contact NO (as in above picture) or

power supply and driven by Multi

relay

49

Relay output mode:

Power Output NO (as in above picture) or NC

Relay output mode:

Dry Contact NO (as in above picture) or

Page 50

Fixed Output 3

Door Lock Powered by Multi relay

Door lock powered by external

NC

Door Lock Powered by Multi relay

Door lock powered by external

NC

Relay output mode:

Power Output NO (as in above picture) or NC

Fixed Output 4

power supply and driven by Multi

relay

Relay output mode:

Dry Contact NO (as in above picture) or

Relay output mode:

Power Output NO (as in above picture) or NC

power supply and driven by Multi

relay

Relay output mode:

Dry Contact NO (as in above picture) or

50

Page 51

Connecting Configurable Outputs (Plug-in in slot of position 2)

Door Lock Powered by Multi relay

Door lock powered by external power

NC

Door Lock Powered by Multi relay

Door lock powered by external power

NC

The below pictures show the connections schematics for Multi using

VMA-06 plugs-in and configurable out put s : a door lock powered by

Multi relay and a door lock power from an external power supply and

driven by an internal relay used as dry contact. VMA-06 plug -in must

be inserted in slot of position 2.

Configurable Output 3

Relay output mode:

Power Output NO (as in above picture) or NC

Configurable Output 4

supply and driven by Multi relay

Relay output mode:

Dry Contact NO (as in above picture) or

Relay output mode:

Power Output NO (as in above picture) or NC

supply and driven by Multi relay

Relay output mode:

Dry Contact NO (as in above picture) or

51

Page 52

Configurable Output 5

Door Lock Powered by Multi relay

Door lock powered by external power

NC

Door Lock Powered by Multi relay

Door lock powered by external power

NC

Relay output mode:

Power Output NO (as in above picture) or NC

supply and driven by Multi relay

Relay output mode:

Dry Contact NO (as in above picture) or

Configurable Output 6

Relay output mode:

Power Output NO (as in above picture) or NC

supply and driven by Multi relay

Relay output mode:

Dry Contact NO (as in above picture) or

52

Page 53

Connecting Configurable Outputs (Plug-in in slot of position 3)

Door Lock Powered by Multi relay

Door lock powered by external power

NC

Door Lock Powered by Multi relay

Door lock powered by external power

NC

The below pictures show the connections schematics for Multi using

VMA-06 plugs-in and configurable out put s : a door lock powered by

Multi relay and a door lock power from an external power supply and

driven by an internal relay used as dry contact. VMA-06 plug -in must

be inserted in slot of position 3.

Configurable Output 1

Relay output mode:

Power Output NO (as in above picture) or NC

Configurable Output 2

supply and driven by Multi relay

Relay output mode:

Dry Contact NO (as in above picture) or

Relay output mode:

Power Output NO (as in above picture) or NC

supply and driven by Multi relay

Relay output mode:

Dry Contact NO (as in above picture) or

53

Page 54

Configurable Output 7

Door Lock Powered by Multi relay

Door lock powered by external power

NC

Door Lock Powered by Multi relay

Door lock powered by external power

NC

Relay output mode:

Power Output NO (as in above picture) or NC

supply and driven by Multi relay

Relay output mode:

Dry Contact NO (as in above picture) or

Configurable Output 8

Relay output mode:

Power Output NO (as in above picture) or NC

supply and driven by Multi relay

Relay output mode:

Dry Contact NO (as in above picture) or

54

Page 55

Connection of the emergency input to VMA-07

When the door lock is powered by the Multi (POE/POE+ or

+12V) using the VMA-07 relay plug-in, it’s possibl e to con nect an

external dry contact signal (normally closed) used to cut the

power of the door lock. This can be used in case of emergency

like a fire alarm.

The J1 terminal block is opto-isolated; this allows connecting

simultaneously several emergency Inputs.

Figure 26 – VMA-07 Emergency input

The two wires must enter in the Multi case from the two holes

located on the right of the first group of holes on the bottom of the

device (see picture)

Figure 27 – Emergency input holes

55

Page 56

FINAL OPERATIONS

Closing the device

To close the terminal, follow these steps:

1. Position the cover with the corner with “Honeywell label” in the

lower right (this is important to properly close the anti-tamper

switch).

2. Close the device cover.

3. Secure the cover by mean of the 4 torx screws (see Figure 20);

this operation requi res a TORX anti-tamper T10 screwdriver.

Commissioning tips

Commissioning of the device is outside the scope of this manual,

never the less we will include here some tips on this activity

addressing you to the EBI documentation f or the ful l detai ls :

EBI - Temaline Access Control Configuration Guide

56

Figure 20 Multi cover

Page 57

Configuring the Voyager Multi

Factory default IP Address

A device from factory is configured with this default IP address:

After the first connection, the IP address must be changed because, to

avoid conflicts, every device in the network must have a different

address.

To change the IP address please refers to:

EBI - Temaline Access Control Configuration Guide

Configuring the Voyager Device

Factory FW version

A device is shipped from factory with a running version of the FW

application corresponding to the most recent version, available at the

manufacturing time, of the released FW.

The installed version may not be suitable for your plant or a more

recent version of the FW could be available.

You should verify the FW version installed on your device and check

the Temaline compatibi l i ty tables distributed on the EBI Global

Support site.

To verify the FW application version running on the device and to

update the FW version please refers to:

Tema-Voyager Multi - Web Interface Guide

160.221.230.127

57

Page 58

MULTI DEVICE ANATOMY

VMA-06VMA-06VMA

-06/VMA-07

MULTI

Enclosure

Figure 22 is a picture of the Multi device board in it case.

Figure 21 – Photo of Multi device board

Figure 22 provides a graphical representation of the MULTI device

and of the boards (Main board and VMA-0x plugs-in).

Figure 22 Graphical representation of Multi device and VMA-0x plugs-in

58

Page 59

Terminal Blocks and Jumpers

Terminal Blocks

Figure 23 - Position of terminal blocks and jumpers (factory configuration)

The above picture shows the position of Terminal Blocks and Jumpers

on the Voyager Multi board.

The below table lists the terminal blocks and explain their meaning.

Terminal Block Meaning

TB1 Configurable I/O line 1

TB2 Configurable I/O line 2

TB3 Configurable I/O line 3

TB4 Configurable I/O line 4

TB5 Reader1

TB6 Reader2

TB7 Fixed Input 1 and Fixed Output 1

TB8 Fixed Input 2 and Fixed Output 2

TB9 Fixed Input 3 and Fixed Output 3

TB10 Fixed Input 4 and Fixed Output 4

TB11 Reader3

59

Page 60

Jumpers

TB12 Reader4

TB13 Configurable I/O line 5

TB14 Configurable I/O line 6

TB15 Configurable I/O line 7

TB16 Configurable I/O line 8

Table 6 Terminal blocks

The below table lists the Jumpers and explain their meaning.

Jumper Meaning

P01 External tamper

P02 Console serial line

P03 Configurable Output 4 relay selector

P04 Fixed Output 4 relay selector

P05 Fixed Output 4 relay selector

P07 Fixed Output 3 relay selector

P08 Fixed Output 3 relay selector

P09 Fixed Output 2 relay selector

P10 Fixed Output 2 relay selector

P11 Fixed Output 1 relay selector

P12 Fixed Output 1 relay selector

P13 Configurable Output 3 relay selector

P14 Configurable Output 3 relay selector

P15 Configurable Output 8 relay selector

P16 Configurable Output 8 relay selector

P17 Configurable Output 7 relay selector

P18 Configurable Output 7 relay selector

P19 Configurable Output 2 relay selector

P20 Configurable Output 2 relay selector

P21 Configurable Output 6 relay selector

P22 Configurable Output 6 relay selector

P23 Configurable Output 5 relay selector

P24 Configurable Output 5 relay selector

P25 Configurable Output 1 relay selector

P26 Configurable Output 4 relay selector

P27 Configurable Output 1 relay selector

P29 Reader 1 Wiegand/OSDP selector

P30 Reader 2 Wiegand/OSDP selector

P31 Reader 1 Wiegand/OSDP selector

P32 Reader 1 Wiegand/OSDP selector

60

Page 61

Switches and LEDs

P33 Reader 2 Wiegand/OSDP selector

P34 Reader 2 Wiegand/OSDP selector

P35 Reader 3 Wiegand/OSDP selector

P36 Reader 4 Wiegand/OSDP selector

P37 Reader 3 Wiegand/OSDP selector

P38 Reader 3 Wiegand/OSDP selector

P39 Reader 4 Wiegand/OSDP selector

P40 Reader 4 Wiegand/OSDP selector

Table 7 Jumpers

Switches

Figure 33 – Switches and LEDs

The below table lists the switches and explain their meani ng .

Switch Function Default

SW1.1 Application Switches: Spare. SW1.2 Application Switches: FW application roll back.

See Appendix 1 for details.

SW1.3 Application Switches: Restore Factory

See Appendix 1 for details.

SW1.4 Application Switches: Linux Console activation Open

Open

Open

61

Page 62

See Appendix 1 for details.

SW1.5 Application Switches: Spare SW1.6 Application Switches: Manufacturing test.

DO NOT USE: This feature is used for factory test.

See Appendix 1 for details.

SW3.1 RS485 (Reader 1) termination resistor, Data A.

ON = termination resistor inserted

OFF = termination resistor not inserted

SW3.2 RS485 (Reader 1) termination resistor, Data B.

ON = termination resistor inserted

OFF = termination resistor not inserted

SW4.1 RS485 (Reader 2) termination resistor, Data A.

ON = termination resistor inserted

OFF = termination resistor not inserted

SW4.2 RS485 (Reader 2) termination resistor, D ata B.

ON = termination resistor inserted

OFF = termination resistor not inserted

SW5.1 RS485 (Reader 3) termination resistor, Data A.

ON = termination resistor inserted

OFF = termination resistor not inserted

SW5.2 RS485 (Reader 3) termination resistor, D ata B.

ON = termination resistor inserted

OFF = termination resistor not inserted

SW6.1 RS485 (Reader 4) termination resistor, Data A.

ON = termination resistor inserted

OFF = termination resistor not inserted

SW6.2 RS485 (Reader 4) termination resistor, D ata B.

ON = termination resistor inserted

OFF = termination resistor not inserted

SW7 System reset Open

Open

Open

Open

Open

Open

Open

Open

Open

Open

LED

62

Table 8 - Switches

The below table lists the led and explain their meaning.

LED Function Values

CR18 Ethernet 10/100M bit/s Green

CR25 Database status, Red ON=Database not present

ON= Ethernet working at

10/100M bit/s

OFF=Ethernet not working at

10/100M bit/s

OFF= Database present

Page 63

CR68 RS485 2 TX/RX activity, Bi-color

LED, Red and Green

CR69 RS485 3 TX/RX activity, Bi-color

LED, Red and Green

CR70 RS485 4 TX/RX activity, Bi-color

LED, Red and Green

CR78 Application status, Green ON=Application running

CR96 EBI communication, Red ON=Communication with EBI

RJ45.1 Ethernet TX/RX activity

Green

RJ45.2 Ethernet physical link, 1G bit/s

Yellow

LED1 Configurable I/O 1

Green LED

LED2 Configurable I/O 2

Green LED

LED3 Configurable I/O 3

Green LED

LED4 Configurable I/O 4

Green LED

LED5 Configurable I/O 5

Green LED

LED6 Configurable I/O 6

Green LED

LED7 Configurable I/O 7

Green LED

LED8 Configurable I/O 8

Green LED

LED9 DC or POE Power in LED,

Green,