Page 1

Thor™ VM1 Vehicle-Mount Computer

with Microsoft® Windows® Embedded Standard 2009

User’s Guide

Page 2

Disclaimer

Honeywell International Inc. (“HII”) reserves the right to make changes in specifications and other information contained in this

document without prior notice, and the reader should in all cases consult HII to determine whether any such changes have been

made. The information in this publication does not represent a commitment on the part of HII.

HII shall not be liable for technical or editorial errors or omissions contained herein; nor for incidental or consequential damages

resulting from the furnishing, performance, or use of this material.

This document contains proprietary information that is protected by copyright. All rights are reserved. No part of this document

may be photocopied, reproduced, or translated into another language without the prior written consent of HII.

© 2011-2014 Honeywell International Inc. All rights reserved.

Web Address: www.honeywellaidc.com

Trademarks

RFTerm is a trademark or registered trademark of EMS Technologies, Inc. in the United States and/or other countries.

Microsoft

trademarks or trademarks of Microsoft Corporation.

Intel® and Atom™ are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United States and other

countries.

Summit Data Communications, the Laird Technologies Logo, the Summit logo, and “Connected. No Matter What” are trademarks of Laird Technologies, Inc.

Wi-Fi

marks or registered trademarks of Wi-Fi Alliance.

The Bluetooth

®

Windows, ActiveSync®, MSN, Outlook®, Windows Mobile®, the Windows logo, and Windows Media are registered

®

, WMM®, Wi-Fi Mutlimedia™, Wi-Fi Protected Access®, WPA™, WPA2™ and the Wi-Fi CERTIFIED™ logo are trade-

®

word mark and logos are owned by the Bluetooth SIG, Inc.

Symbol® is a registered trademark of Symbol Technologies. MOTOROLA, MOTO, MOTOROLA SOLUTIONS and the Stylized

M Logo are trademarks or registered trademarks of Motorola Trademark Holdings, LLC and are used under license.

Freefloat, Link*One and Access*One are trademarks of Freefloat, Mölndalsvägen 30B, SE-412 63Gothenburg, Sweden.

RAM® and RAM Mount™ are both trademarks of National Products Inc., 1205 S. Orr Street, Seattle, WA 98108.

Qualcomm

®

is a registered trademark of Qualcomm Incorporated. Gobi is a trademark of Qualcomm Incorporated.

Verizon® is a registered trademark of Verizon Trademark Services LLC.

®

T-MOBILE

AT &T

is a registered trademark of Deutsche Telekom AG.

®

is a registered trademark of AT&T Intellectual Property.

SD and SDHC are trademarks or registered trademarks of SD-3C, LLC in the United States, other countries or both.

®

SanDisk

Transcend

and CompactFlash® are trademarks of SanDisk Corporation, registered in the United States and other countries.

®

is a registered trademark of Transcend Information, Inc.

ATP is a trademark of ATP Electronics, Inc.

Acrobat

®

Reader © 2014 with express permission from Adobe Systems Incorporated.

Other product names or marks mentioned in this document may be trademarks or registered trademarks of other companies

and are the property of their respective owners.

Patents

For patent information, please refer to www.hsmpats.com.

Page 3

Table of Contents

Chapter 1 - Thor VM1 Agency Information

FCC Part 15 Statement........................................................................................................1-1

FCC 5GHz Statement ..........................................................................................................1-1

EMC Directive Requirements...............................................................................................1-1

Canada, Industry Canada (IC) Notices ................................................................................1-1

COFETEL ............................................................................................................................1-2

ANATEL (Brazil)...................................................................................................................1-2

Vehicle Power Supply Connection Safety Statement ..........................................................1-2

Li-Ion Battery........................................................................................................................1-2

RF Safety Notice..................................................................................................................1-3

Bluetooth..............................................................................................................................1-3

Honeywell Scanning & Mobility Product Environmental Information....................................1-3

CE Mark ...............................................................................................................................1-3

Dealer License - Republic of Singapore ..............................................................................1-3

Chapter 2 - Getting Started

Overview ..............................................................................................................................2-1

About this Guide ..................................................................................................................2-1

Out of the Box ......................................................................................................................2-1

Initial Setup for Thor VM1 ....................................................................................................2-2

Hardware Setup .............................................................................................................2-2

Software .........................................................................................................................2-2

Languages ...............................................................................................................2-2

First Boot..................................................................................................................2-2

Software Setup.........................................................................................................2-2

Quick Mount Smart Dock .....................................................................................................2-2

Components.........................................................................................................................2-3

Front View ......................................................................................................................2-3

Back View with Quick Mount Smart Dock ......................................................................2-4

Access Panels...............................................................................................................2-4

Backlights and Indicators .....................................................................................................2-5

Display Backlight............................................................................................................2-5

Power Management .................................................................................................2-5

Backlight Brightness.................................................................................................2-5

Screen Blanking .......................................................................................................2-5

Keypad Backlight ...........................................................................................................2-5

Speaker Volume.............................................................................................................2-5

Power Up .............................................................................................................................2-6

Rebooting the Thor VM1 ................................................................................................2-7

Restart......................................................................................................................2-7

Tapping the Touch Screen with a Stylus .............................................................................2-7

Setup Terminal Emulation Parameters ................................................................................2-7

Cleaning the Touch Screen .................................................................................................2-8

Startup Help .........................................................................................................................2-8

i

Page 4

Chapter 3 - Hardware Overview

System Hardware ................................................................................................................ 3-1

802.11a/b/g/n Wireless Client........................................................................................3-1

Central Processing Unit................................................................................................. 3-1

Input/Output Components..............................................................................................3-1

System Memory.............................................................................................................3-1

Video Subsystem........................................................................................................... 3-1

Audio Interface...............................................................................................................3-1

Card Slots......................................................................................................................3-2

CompactFlash (CF) Slot .......................................................................................... 3-2

Secure Digital (SD) Slot........................................................................................... 3-2

Bluetooth EZPair............................................................................................................3-2

WWAN........................................................................................................................... 3-2

GPS ...............................................................................................................................3-2

Power ..................................................................................................................................3-2

Vehicle DC Power Supply..............................................................................................3-2

External AC Power Supply ............................................................................................ 3-3

Uninterruptible Power Supply ........................................................................................3-3

Safe Charging Temperature Range......................................................................... 3-3

Charging Timeout .................................................................................................... 3-3

Charging and Power Management .......................................................................... 3-3

Backup Battery ..............................................................................................................3-3

Fuse............................................................................................................................... 3-4

Power Management Modes...........................................................................................3-4

Full On Mode ........................................................................................................... 3-4

StandbyMode...........................................................................................................3-4

Hibernate Mode ....................................................................................................... 3-4

Off Mode .................................................................................................................. 3-4

Power Controls ..............................................................................................................3-5

Power Switch ........................................................................................................... 3-5

Power Button ........................................................................................................... 3-5

Auto On Behavior .................................................................................................... 3-5

External Connectors ............................................................................................................ 3-6

Serial Connector (COM1 and COM2)............................................................................3-6

Screen Blanking...................................................................................................... 3-6

USB Connector.............................................................................................................. 3-6

CANbus / Audio Connector............................................................................................3-7

Power Supply Connector............................................................................................... 3-7

Antenna Connections .................................................................................................... 3-8

External Antenna Connector.................................................................................... 3-8

Internal 802.11 Antenna .......................................................................................... 3-8

Vehicle Remote Antenna .........................................................................................3-8

Keyboard Options................................................................................................................3-9

64-Key QWERTY Keyboard ..........................................................................................3-9

IBM 3270 Overlay .................................................................................................... 3-9

IBM 5250 Overlay .................................................................................................. 3-10

Keypad LEDs............................................................................................................... 3-10

USB Keyboard / Mouse ...............................................................................................3-10

ii

Page 5

LED Functions ...................................................................................................................3-10

System LEDs............................................................................................................... 3-10

SYS (System Status) LED ..................................................................................... 3-11

UPS Status LED .................................................................................................... 3-11

SSD (Solid State Drive) LED ................................................................................. 3-11

Connection LEDs.........................................................................................................3-12

WWAN LED ........................................................................................................... 3-12

Wi-Fi LED .............................................................................................................. 3-12

Bluetooth LED........................................................................................................3-12

Keyboard LEDs............................................................................................................3-13

2nd LED.................................................................................................................3-13

Shift LEDs..............................................................................................................3-13

Ctrl LED ................................................................................................................. 3-13

Alt LED...................................................................................................................3-13

Display...............................................................................................................................3-13

Touch Screen ..............................................................................................................3-13

Touch Screen Defroster...............................................................................................3-14

Screen Blanking...........................................................................................................3-14

Display Backlight Control.............................................................................................3-14

Chapter 4 - Vehicle Mounting and Accessory Installation

Introduction........................................................................................................................4-15

Prepare for Vehicle Mounting ............................................................................................ 4-15

Quick Start................................................................................................................... 4-15

Maintenance - Vehicle Mounted Devices .......................................................................... 4-15

Cleaning ............................................................................................................................ 4-16

Place Thor VM1 in the Dock..............................................................................................4-16

Dock I/O Pin Cover...................................................................................................... 4-17

Padlock........................................................................................................................ 4-17

Laptop Security Cable ................................................................................................. 4-17

Install RAM Mount ............................................................................................................. 4-18

Components - RAM Mounting Kits .............................................................................. 4-18

Procedure - RAM Mount Assembly ............................................................................. 4-19

Torque Measurement ............................................................................................ 4-19

Step 1a – Attach RAM Ball to Vehicle ................................................................... 4-19

Step 1b – Mount RAM Clamp to Vehicle ............................................................... 4-20

Step 1c – Attach RAM Plate to Vehicle and Attach RAM Ball ............................... 4-21

Step 2 – Attach RAM Mount Ball to the Thor VM1 Quick Mount Smart Dock .......4-22

Step 3 – Attach Thor VM1 Assembly to RAM Mount............................................. 4-23

Step 4 – Place the Thor VM1 into the Dock........................................................... 4-23

Install U Bracket Mount ..................................................................................................... 4-24

Components - U Bracket Mounting Assembly............................................................. 4-24

Procedure - U Bracket Assembly.................................................................................4-24

Torque Measurement ............................................................................................ 4-24

Mounting Positions ................................................................................................ 4-25

Step 1 - Install U Bracket to Vehicle ...................................................................... 4-25

Step 2 - Remove RAM Ball.................................................................................... 4-26

Step 3 - Attach Adapter Bracket ............................................................................ 4-26

iii

Page 6

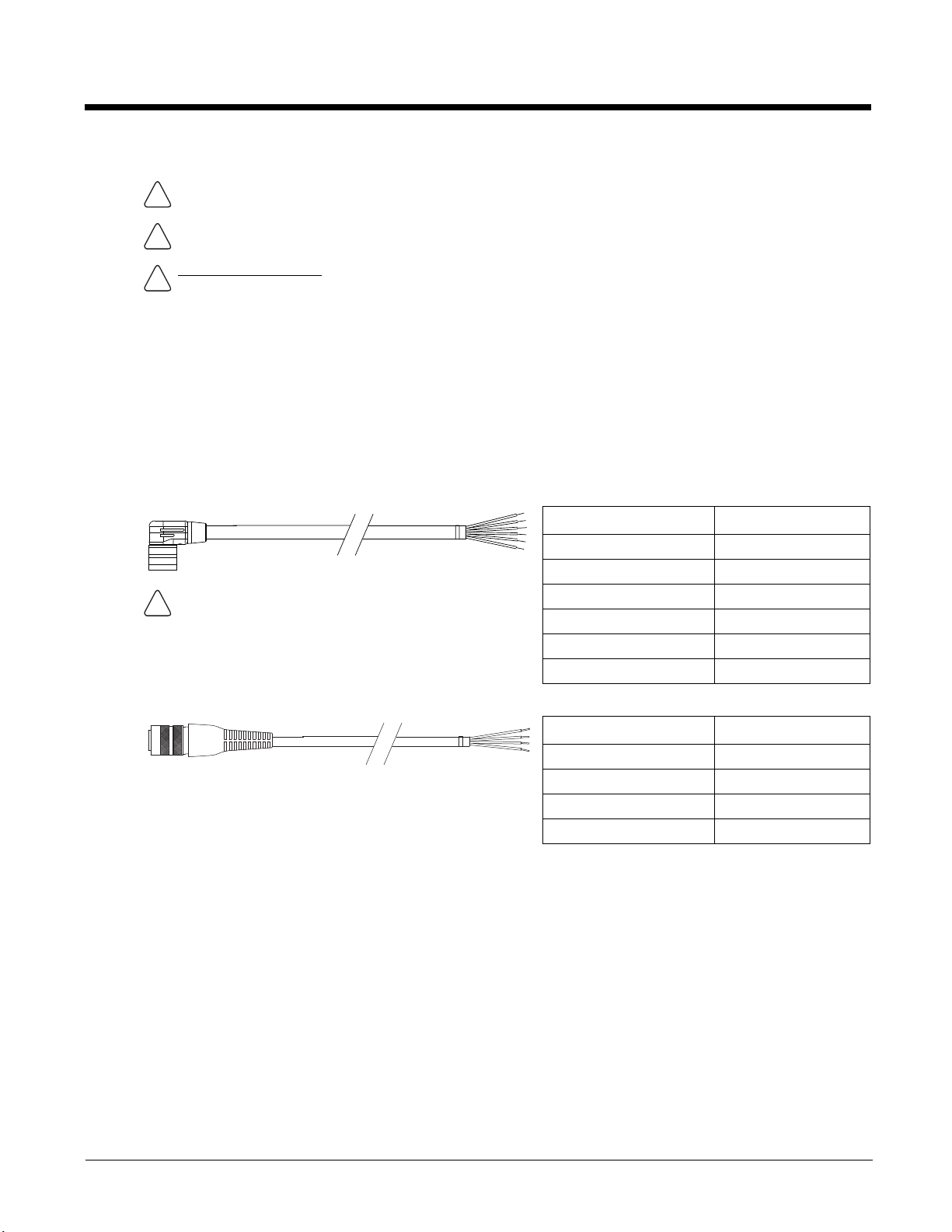

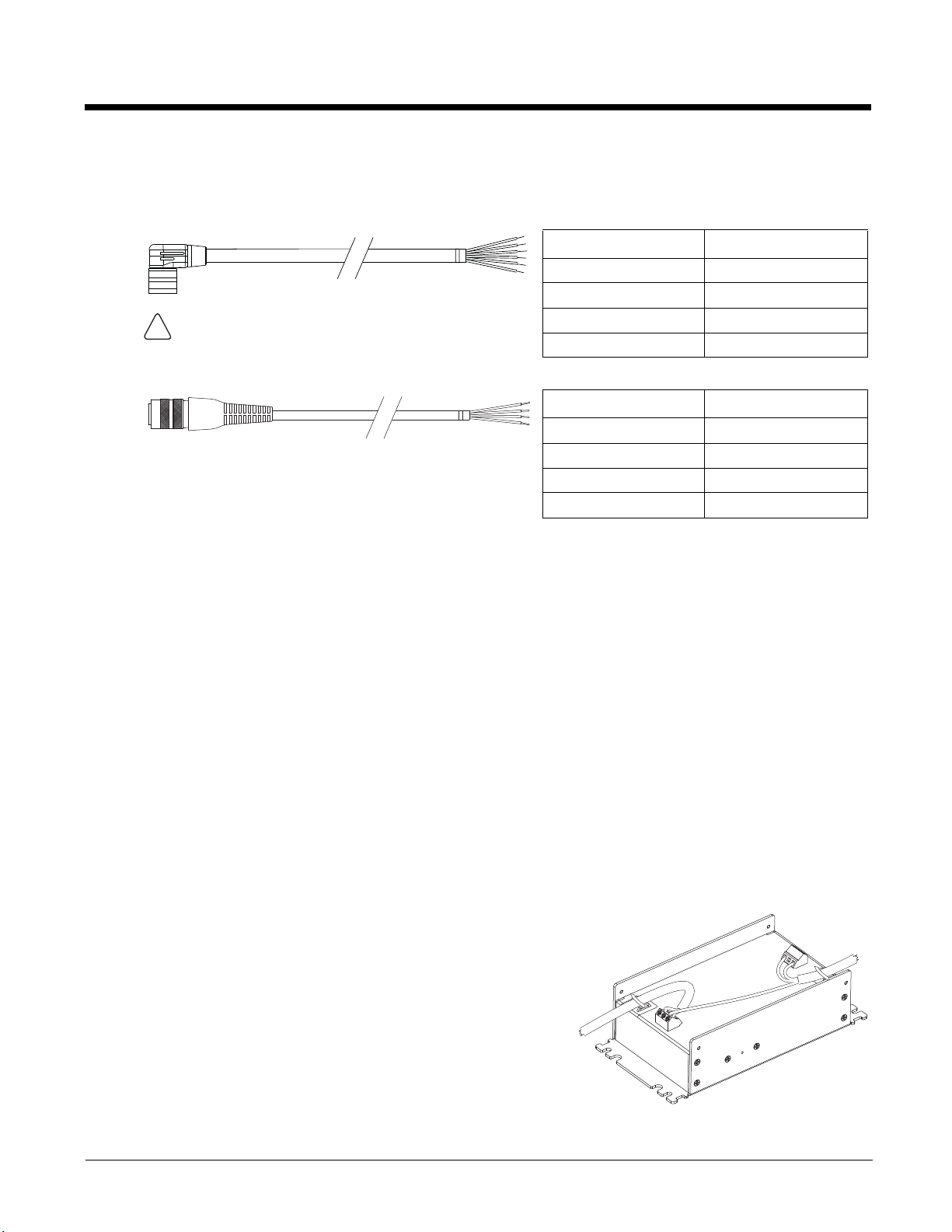

Connect Cables ................................................................................................................. 4-27

Strain Relief Cable Clamps..........................................................................................4-27

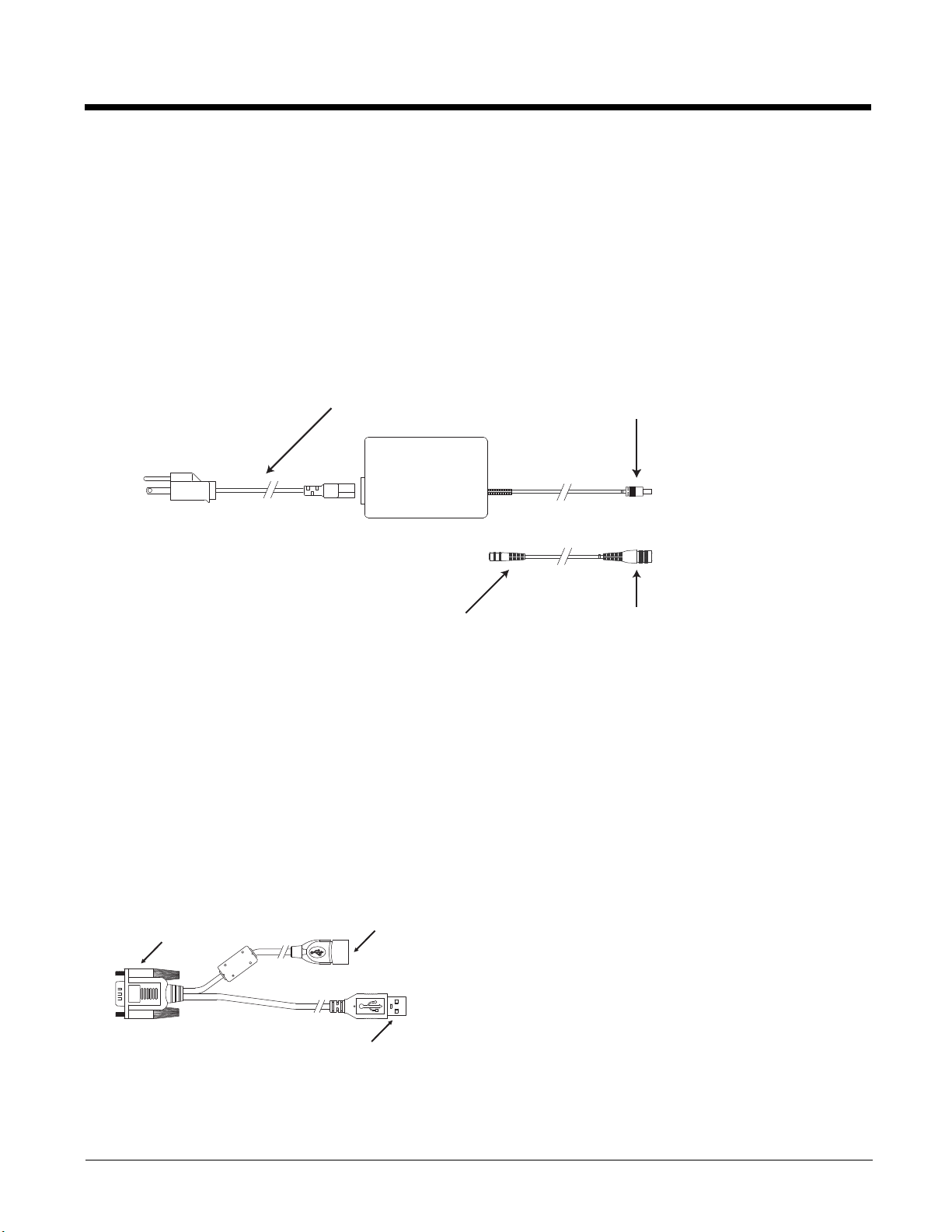

Connect Power ............................................................................................................4-28

Power Cable Cautions................................................................................................. 4-28

12-48 VDC Vehicles (10-60 VDC Direct Connection)............................................ 4-29

60-144 VDC Vehicles (50-150 VDC Power Supply, Screws on Side of Lid) ......... 4-34

60-144 VDC Vehicles (50-150 VDC Power Supply, Screws on Top of Lid) .......... 4-38

VX6 / VX7 Adapter Cable ......................................................................................4-42

Thor VX8 / Thor VX9 Adapter Cable ..................................................................... 4-43

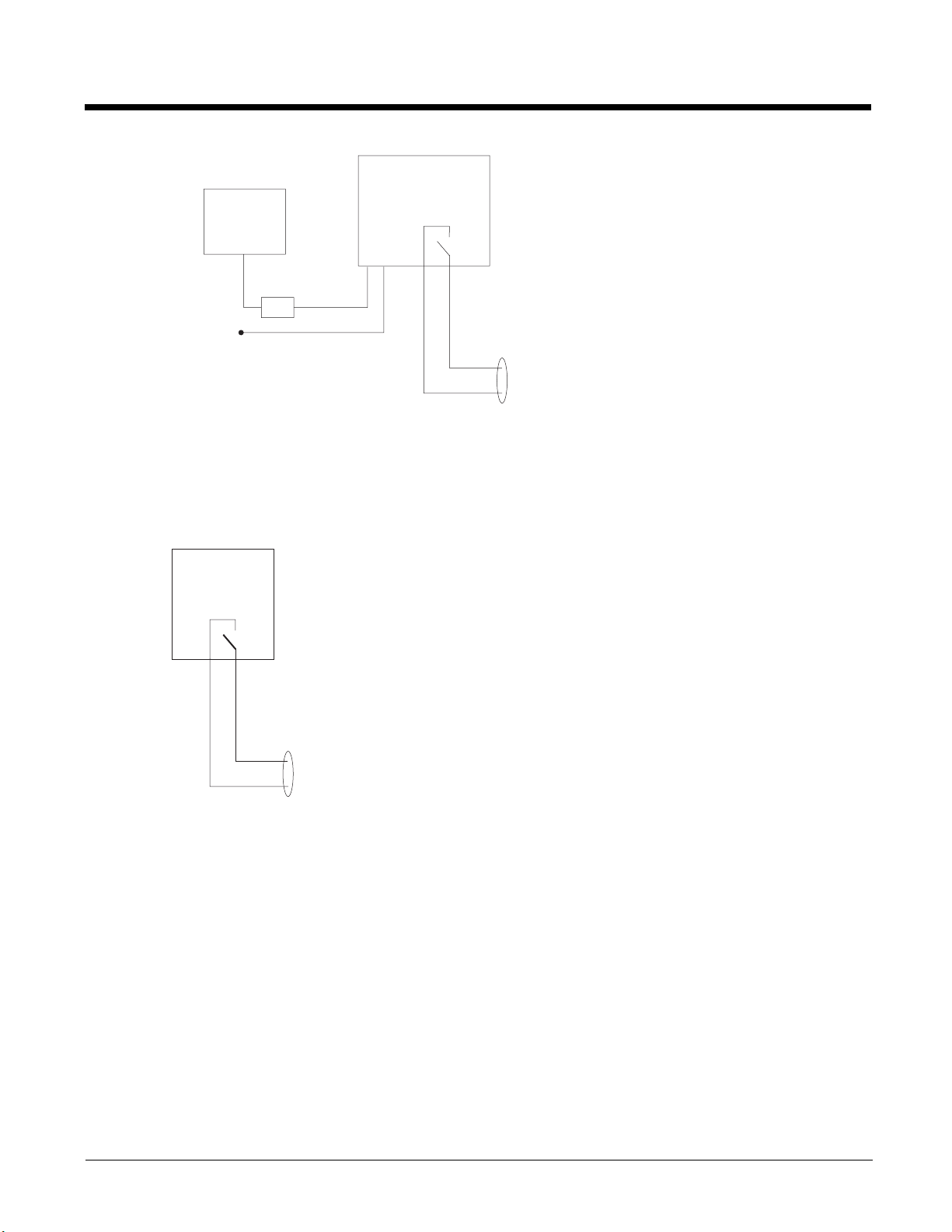

Screen Blanking..................................................................................................... 4-44

External AC/DC Power Supply .............................................................................. 4-47

Connect USB Host.......................................................................................................4-47

Connect USB Client.....................................................................................................4-48

Connect Serial Device .................................................................................................4-48

Connect a Tethered Scanner.................................................................................4-48

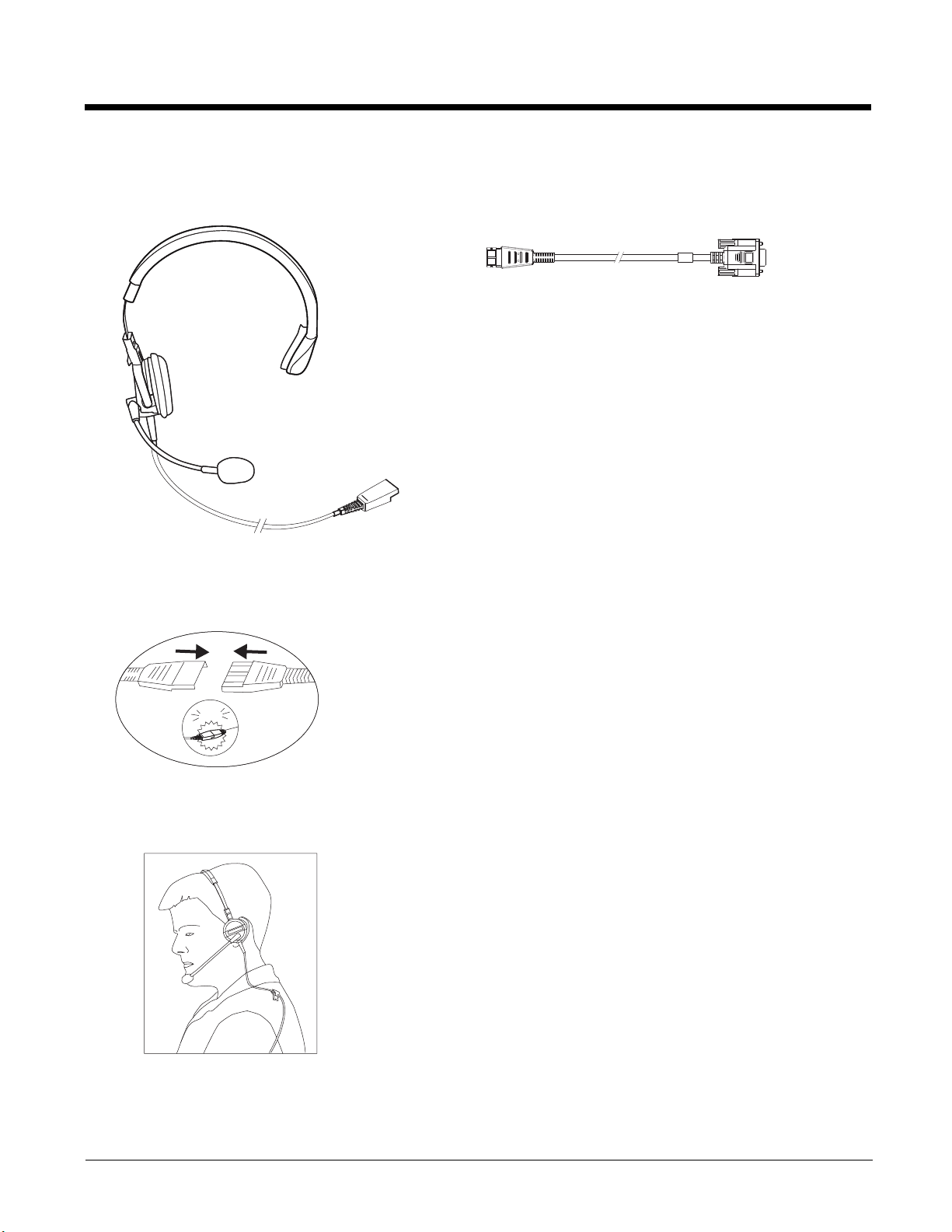

Connect Headset Cable...............................................................................................4-49

Adjust Headset / Microphone and Secure Cable................................................... 4-49

Connect CANbus Cable...............................................................................................4-50

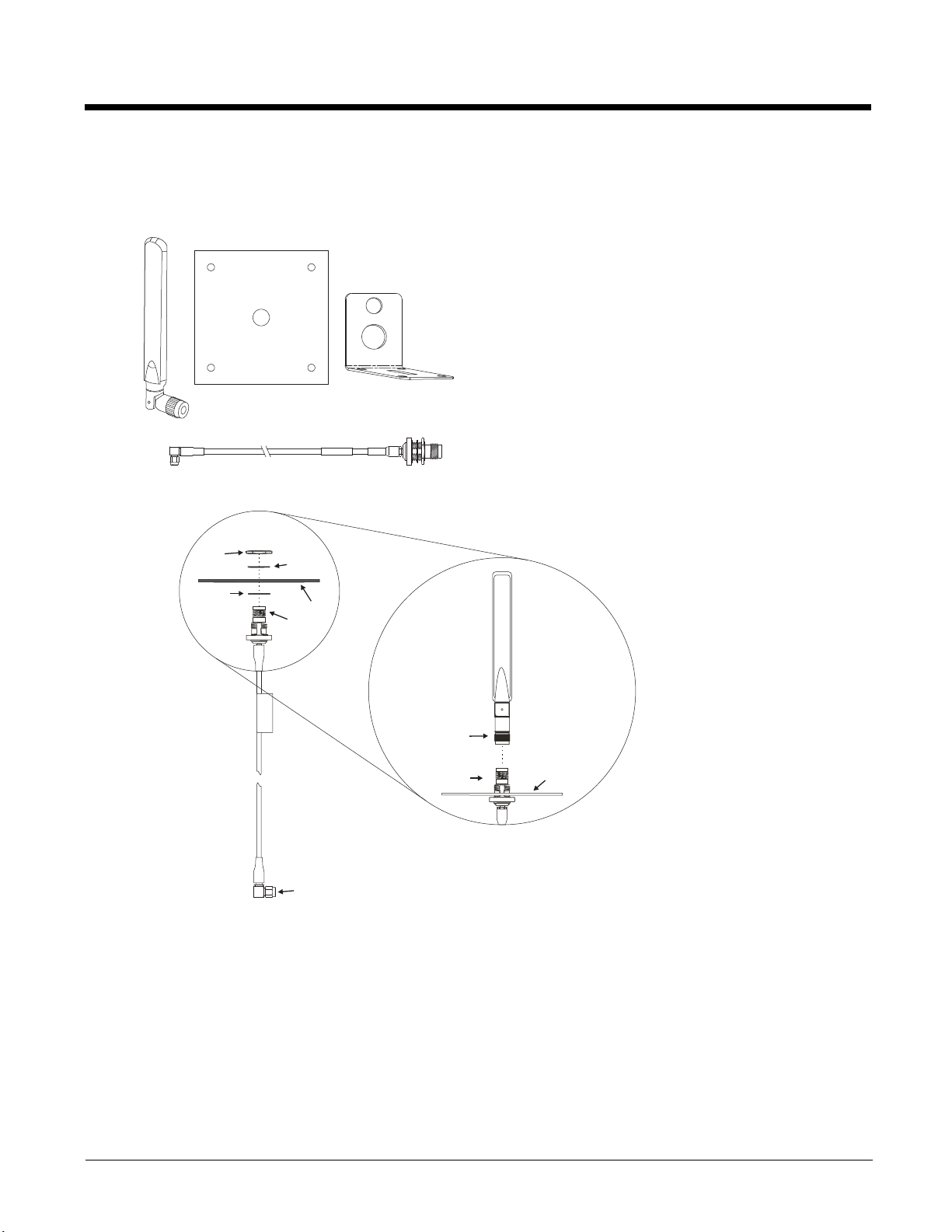

Install Remote Antenna ...............................................................................................4-51

802.11 Remote Mount Antenna............................................................................. 4-51

WAN Remote Mount Antenna ............................................................................... 4-53

GPS Remote Mount Antenna ................................................................................ 4-53

Apply Touch Screen Protective Film ................................................................................. 4-54

Installation....................................................................................................................4-54

Removal.......................................................................................................................4-54

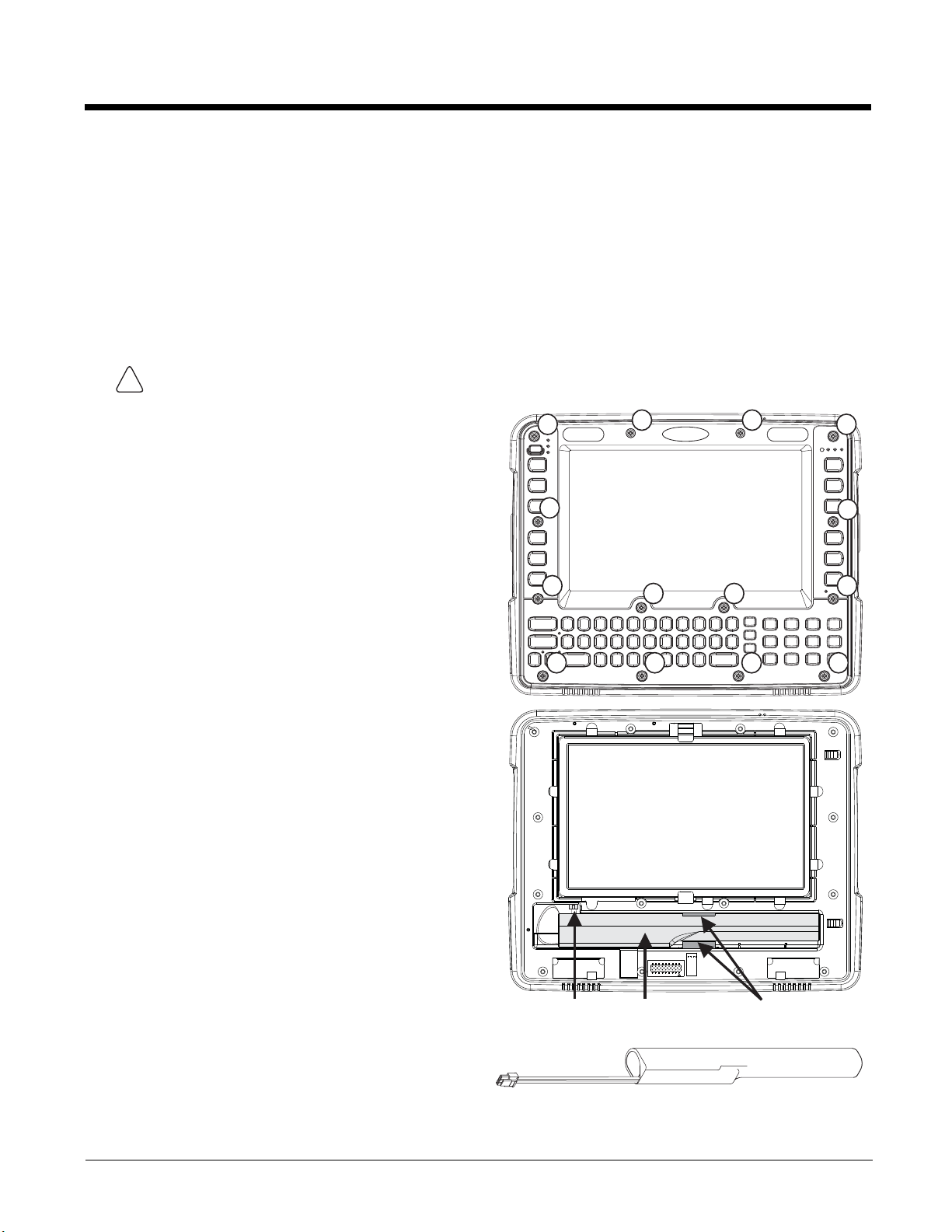

Disconnect UPS Battery .................................................................................................... 4-55

Install SD Card .................................................................................................................. 4-56

Install SIM Card ................................................................................................................. 4-57

Replace Front Panel..........................................................................................................4-58

Replace UPS Battery......................................................................................................... 4-60

Chapter 5 - Software

Microsoft Windows Setup and Configuration.......................................................................5-1

Drive C Folder Structure................................................................................................ 5-1

Software Loaded on Drive C....................................................................................5-1

Control Panel.......................................................................................................................5-3

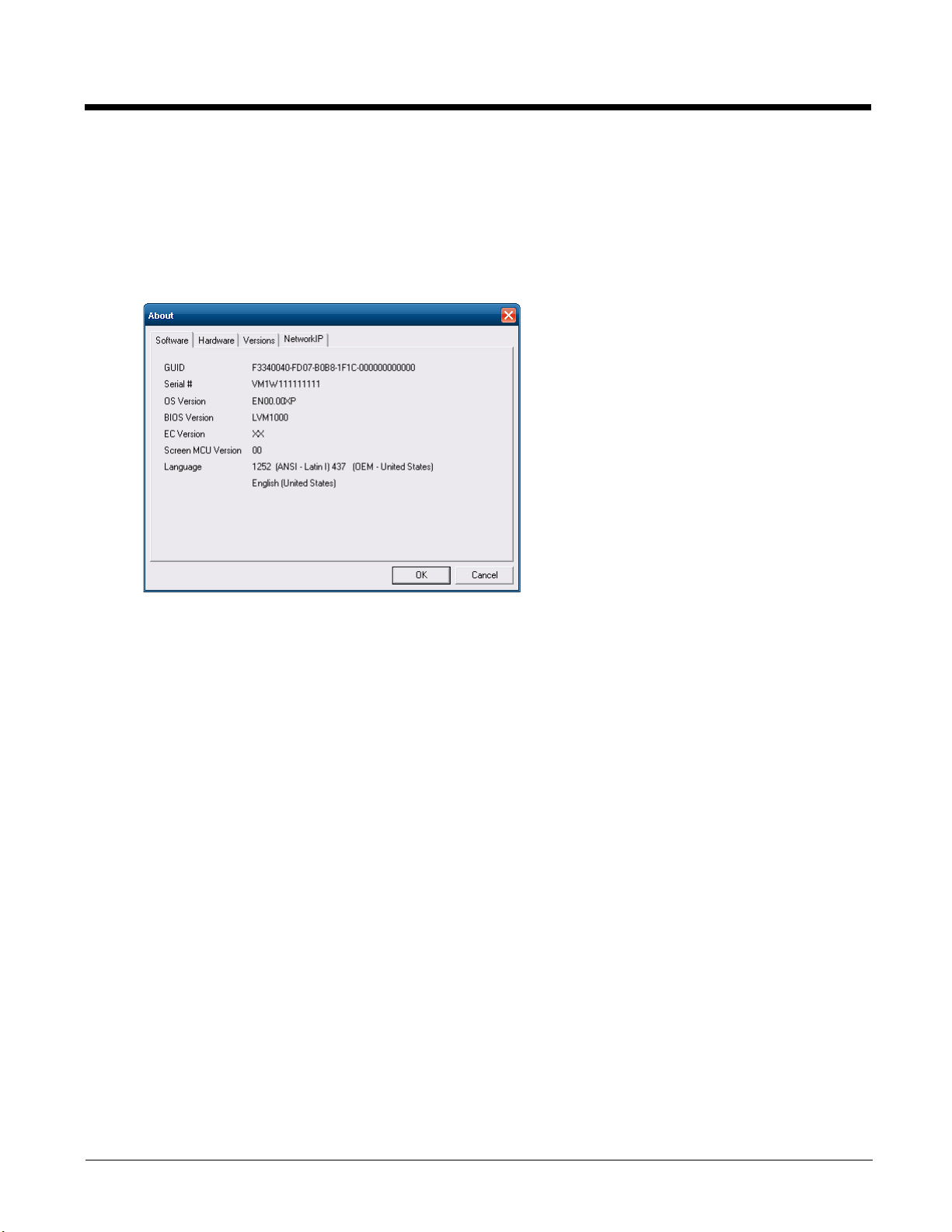

About .............................................................................................................................5-3

Software...................................................................................................................5-3

Versions...................................................................................................................5-3

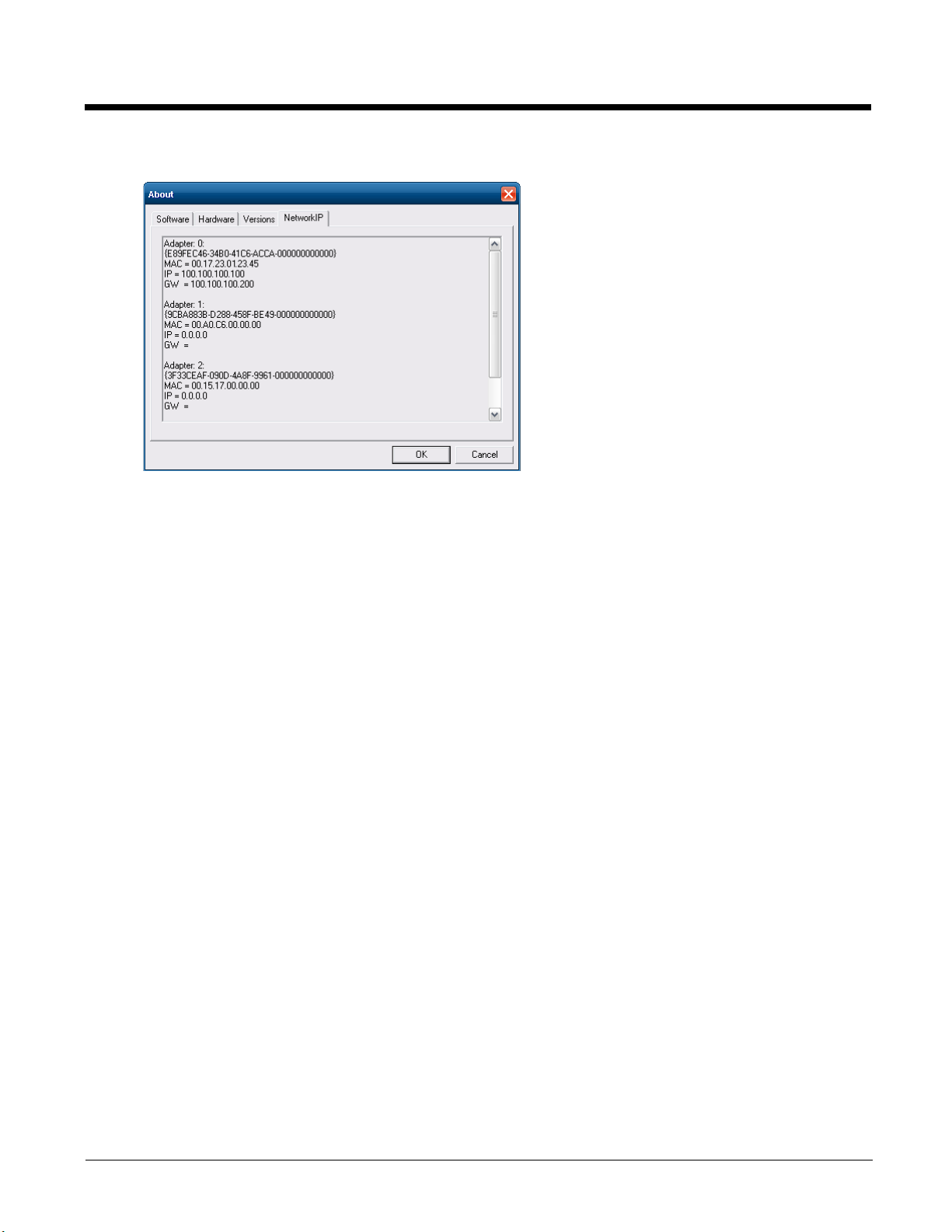

Network IP ............................................................................................................... 5-4

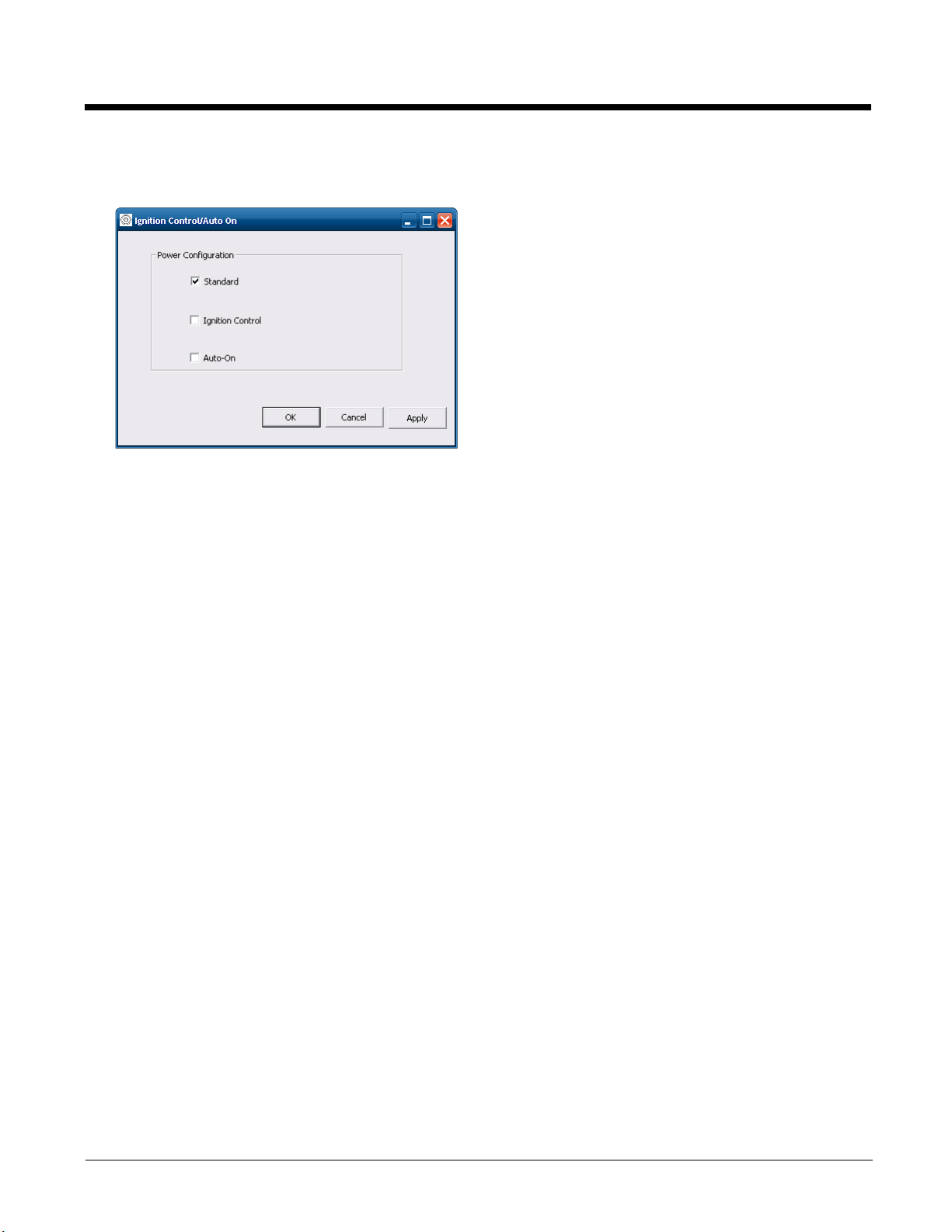

AutoOn........................................................................................................................... 5-5

Standard ..................................................................................................................5-5

Ignition Control......................................................................................................... 5-5

Auto-On ................................................................................................................... 5-5

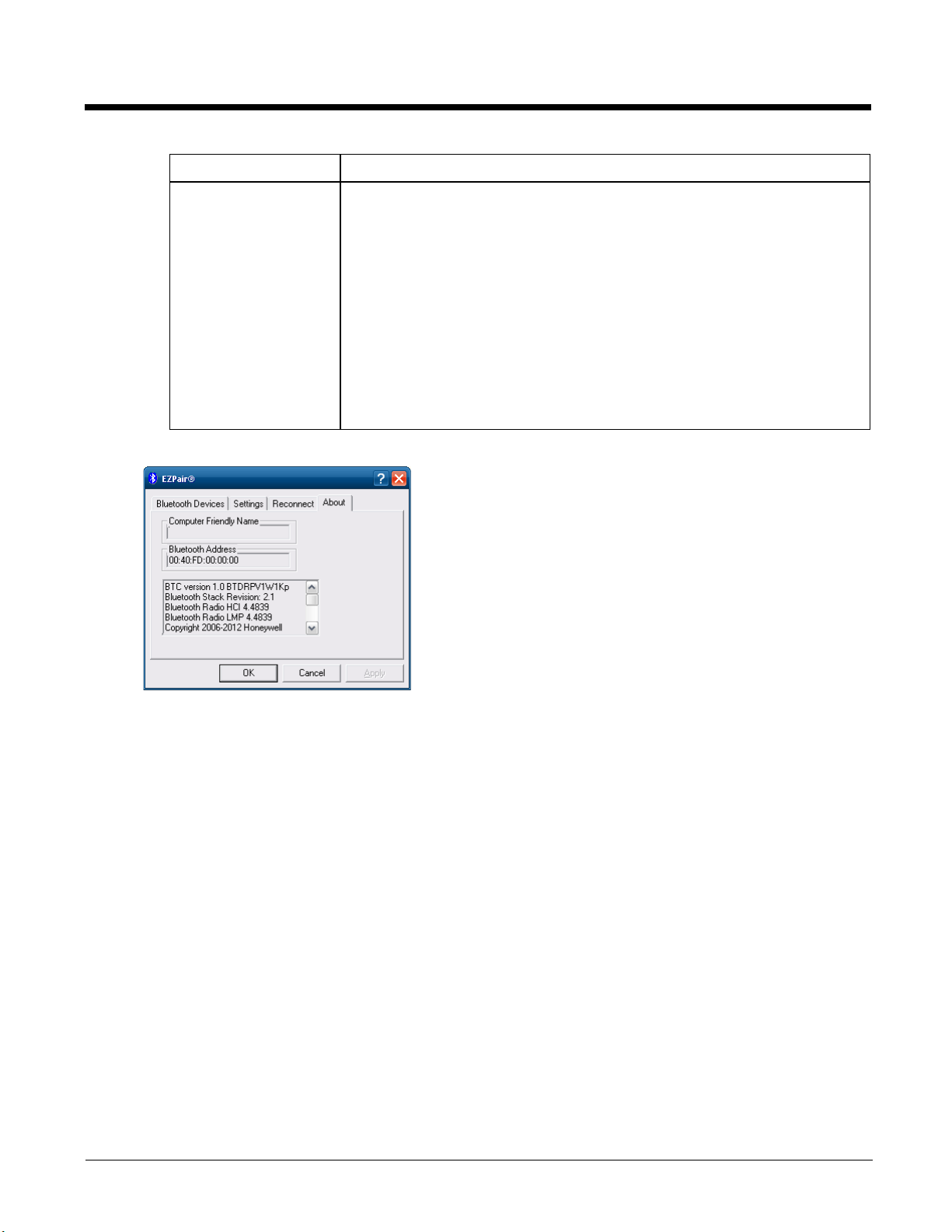

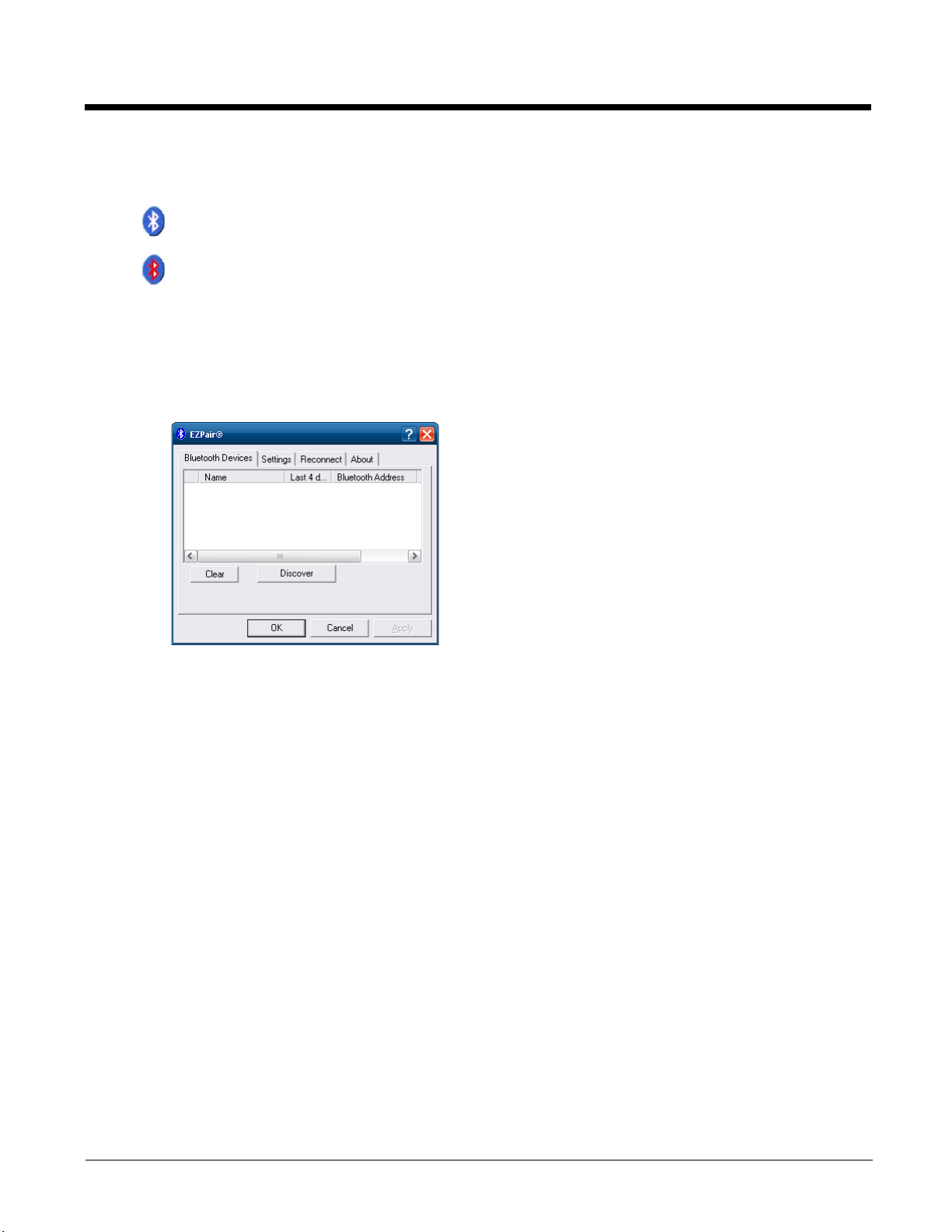

Bluetooth........................................................................................................................ 5-6

Bluetooth Devices....................................................................................................5-8

Discover...................................................................................................................5-8

Settings..................................................................................................................5-10

iv

Page 7

Reconnect..............................................................................................................5-12

About ..................................................................................................................... 5-13

Using Bluetooth ..................................................................................................... 5-14

Display.........................................................................................................................5-18

Power Options .............................................................................................................5-19

Select a Power Scheme ........................................................................................ 5-19

View UPS Battery Status ....................................................................................... 5-20

Hibernate ............................................................................................................... 5-22

Screen Control............................................................................................................. 5-23

Screen Blanking..................................................................................................... 5-24

Automatic Brightness Control ................................................................................ 5-24

Current Level ......................................................................................................... 5-24

Defroster Control ................................................................................................... 5-24

Screen Rotation........................................................................................................... 5-25

Sounds.........................................................................................................................5-25

System Rating (Windows Experience Index)...............................................................5-26

Tablet PC Settings (Touch Screen Calibration)........................................................... 5-26

User Accounts .............................................................................................................5-26

Wi-Fi ............................................................................................................................5-26

Bar Code Readers.............................................................................................................5-27

Scanner Wedge........................................................................................................... 5-27

Touch Screen Calibration .................................................................................................. 5-27

BIOS .................................................................................................................................. 5-28

Accessing the BIOS Setup ..........................................................................................5-28

Boot Order ...................................................................................................................5-28

Exiting BIOS Setup...................................................................................................... 5-28

Thor VM1 Recovery DVD .................................................................................................. 5-28

Upgrading the Thor VM1 ................................................................................................... 5-28

Automatic Firmware Update Utility .................................................................................... 5-29

Requirements ..............................................................................................................5-29

Firmware Distribution Files ..........................................................................................5-29

Update Process ...........................................................................................................5-29

Configuration Cloning Utility (CCU) ................................................................................... 5-30

Configuration Cloning Utility GUI................................................................................. 5-31

Menu Options ........................................................................................................ 5-32

Shortcuts................................................................................................................5-34

Modifying Settings ................................................................................................. 5-35

Using the CCU.......................................................................................................5-36

Configuration Cloning Utility Command Line Interface................................................ 5-37

Chapter 6 - Wireless Network Connections

Network Connections Control Panel....................................................................................6-1

Summit Wireless Network Configuration .............................................................................6-1

Important Notes ................................................................................................................... 6-1

Summit Client Utility ............................................................................................................ 6-1

Summit Tray Icon...........................................................................................................6-1

Wireless Zero Config Utility ........................................................................................... 6-2

To Switch Control to the Wireless Zero Config Utility ..............................................6-2

v

Page 8

To Switch Control to SCU........................................................................................ 6-2

Main............................................................................................................................... 6-3

Admin Login.............................................................................................................6-3

Profile............................................................................................................................. 6-5

Buttons.....................................................................................................................6-5

Profile Parameters ................................................................................................... 6-6

Status............................................................................................................................. 6-8

Diags..............................................................................................................................6-9

Global ..........................................................................................................................6-10

Custom Parameter Option .....................................................................................6-11

Global Parameters.................................................................................................6-11

Logon Options ....................................................................................................... 6-13

Sign-On vs. Stored Credentials ......................................................................................... 6-15

To Use Stored Credentials ..........................................................................................6-15

To Use Sign On Screen...............................................................................................6-16

To Use Windows Username and Password ................................................................6-16

Windows Certificate Store vs. Certs Path.......................................................................... 6-17

User Certificates ..........................................................................................................6-17

Root CA Certificates ....................................................................................................6-17

Certs Path..............................................................................................................6-17

Windows Certificate Store ..................................................................................... 6-17

Configuring the Profile ....................................................................................................... 6-18

No Security ..................................................................................................................6-19

WEP.............................................................................................................................6-20

LEAP............................................................................................................................6-21

PEAP/MSCHAP........................................................................................................... 6-22

PEAP/GTC................................................................................................................... 6-24

WPA/LEAP ..................................................................................................................6-26

EAP-FAST ................................................................................................................... 6-27

EAP-TLS...................................................................................................................... 6-29

WPA PSK ....................................................................................................................6-31

Certificates.........................................................................................................................6-31

Generate a Root CA Certificate................................................................................... 6-32

Install a Root CA Certificate.........................................................................................6-33

Generate a User Certificate......................................................................................... 6-34

Exporting a User Certificate................................................................................... 6-35

Install a User Certificate...............................................................................................6-36

Manually Initiate Certificate Installation ................................................................. 6-37

OneClick Internet...............................................................................................................6-38

Preparing for Initial Use on the Thor VM1 ................................................................... 6-38

Install SIM Card ..................................................................................................... 6-38

Load Firmware.......................................................................................................6-38

Activation ............................................................................................................... 6-38

Using OneClick Internet...............................................................................................6-40

Connection Management....................................................................................... 6-40

Menu Buttons............................................................................................................... 6-41

Radio Button .......................................................................................................... 6-41

Statistics Button ..................................................................................................... 6-41

vi

Page 9

Update Button........................................................................................................6-41

Help Button ............................................................................................................ 6-41

Settings Button ...................................................................................................... 6-42

Application Buttons...................................................................................................... 6-49

SMS ....................................................................................................................... 6-49

Web Browser ......................................................................................................... 6-52

Email......................................................................................................................6-52

GPS .......................................................................................................................6-52

About ...........................................................................................................................6-53

System Requirements ........................................................................................... 6-53

OneClick Internet Connection Manager.......................................................................6-55

Connection Management....................................................................................... 6-56

Information Buttons................................................................................................ 6-57

Chapter 7 - Key Maps

64-Key QWERTY Keypad Key Map .................................................................................... 7-1

IBM Terminal Emulation ...................................................................................................... 7-5

IBM 3270 .......................................................................................................................7-5

IBM 5250 .......................................................................................................................7-6

Chapter 8 - Specifications and Reference Material

Technical Specifications ...................................................................................................... 8-1

Thor VM1....................................................................................................................... 8-1

Quick Mount Smart Dock...............................................................................................8-1

Dimensions..........................................................................................................................8-2

Thor VM1....................................................................................................................... 8-2

Quick Mount Smart Dock...............................................................................................8-2

Environmental Specifications .............................................................................................. 8-2

Thor VM1 and Quick Mount Smart Dock....................................................................... 8-2

Network Card Specifications ............................................................................................... 8-3

Summit 802.11 a/b/g/n...................................................................................................8-3

Bluetooth........................................................................................................................ 8-3

WWAN........................................................................................................................... 8-3

Port and Connector Pinouts ................................................................................................ 8-4

Power Supply Connector............................................................................................... 8-4

COM1 and COM2 Connector ........................................................................................ 8-4

USB Connector.............................................................................................................. 8-5

USB Y Cable............................................................................................................ 8-5

CANbus / Audio Connector............................................................................................8-6

Headset Adapter Cable ...........................................................................................8-6

CANbus Y Cable...................................................................................................... 8-7

Hat Encoding ....................................................................................................................... 8-8

Chapter 9 - Customer Support

Product Service and Repair.................................................................................................9-1

Technical Assistance...........................................................................................................9-1

Limited Warranty ................................................................................................................. 9-1

vii

Page 10

viii

Page 11

1

!

!

Thor VM1 Agency Information

Thor VM1 mobile computers meet or exceed the requirements of all applicable standards organizations for safe operation.

However as with any electrical equipment, the best way to ensure safe operation is to operate them according to the agency

guidelines that follow. Read these guidelines before using your Thor VM1.

This documentation is relevant for the following Thor models: VM1W.

RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE. The battery should be disposed of by

a qualified recycler or hazardous materials handler. Do not incinerate the battery or dispose of the battery with general

waste materials.

FCC Part 15 Statement

This device complies with FCC Rules, part 15. Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause undesired operation.

NOTE - This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense.

Caution - Changes or modifications made to this equipment not expressly approved by Honeywell may void the FCC authorization to operate this equipment.

FCC 5GHz Statement

LAN devices are restricted to indoor use only in the band 5150-5250 MHz.

For the band 5600-5650 MHz, no operation is permitted.

When using IEEE 802.11a wireless LAN, this product is restricted to indoor use, due to its operation in the 5.15- to 5.25GHz Frequency range. The FCC requires this product to be used indoors for the frequency range of 5.15 GHz to 5.25

GHz to reduce the potential for harmful interference to co-channel mobile satellite systems. High-power radar is allocated

as the primary user of the 5.25- to 5.35-GHz and 5.65- to 5.85-GHz bands. These radar stations can cause interference

with and/or damage to this device.

EMC Directive Requirements

This is a Class A product. In a domestic environment this product may cause radio interference in which case the user may be

required to take adequate measures.

Canada, Industry Canada (IC) Notices

This Class A digital apparatus complies with Canadian RSS-GEN issue 3:2010 and RSS-210 issue 8:2010.

Operation is subject to the following two conditions: (1) this device may not cause interference, and (2) this device must accept

any interference, including interference that may cause undesired operation of the device.

Radio Frequency (RF) Exposure Information

The radiated output power of the Honeywell Thor VM1 is below the Industry Canada (IC) radio frequency exposure limits. The

Honeywell Thor VM1 should be used in such a manner such that the potential for human contact during normal operation is

minimized.

This device has been certified for use in Canada. Status of the listing in the Industry Canada’s REL (Radio Equipment List) can

be found at the following web address: Additional Canadian information on RF exposure also can be found at the following web

address: Canada, avis d'Industry Canada (IC)

1 - 1

Page 12

Cet appareil numérique de classe A est conforme aux normes canadiennes RSS-GEN numéro 3:2010 et RSS-210 numéro

8:2010.

Son fonctionnement est soumis aux deux conditions suivantes : (1) cet appareil ne doit pas causer d'interférence et (2) cet

appareil doit accepter toute interférence, notamment les interférences qui peuvent affecter son fonctionnement.

Informations concernant l'exposition aux fréquences radio (RF)

La puissance de sortie émise par de le Honeywell Thor VM1 est inférieure à la limite d'exposition aux fréquences radio d'Industry Canada (IC). Utilisez le Honeywell Thor VM1 de façon à minimiser les contacts humains lors du fonctionnement normal.

Ce périphérique est homologué pour l'utilisation au Canada. Pour consulter l'entrée correspondant à l’appareil dans la liste

d'équipement radio (REL - Radio Equipment List) d'Industry Canada rendez-vous sur: Pour des informations supplémentaires

concernant l'exposition aux RF au Canada rendez-vous sur : ANATEL (Brazil)

Este equipamento opera em caráter secundário, isto é, não tem direito a proteção contra interferência prejudicial, mesmo de

estações do mesmo tipo, e não causar interferência a sistema operando em caráter primário.

COFETEL

ANEXO CUMPLIMIENTO REGULATORIO NOM-121-SCT1-2009

EQUIPO: Terminal montada en vehículo

MARCA: Honeywell

MODELO: VM1 W

Para su uso en México, la operación de este equipo está sujeta a las siguientes dos condiciones: (1) es posible que este equipo

o dispositivo no cause interferencia perjudicial y (2) este equipo o dispositivo debe aceptar cualquier interferencia, incluyendo la

que pueda causar su operación no deseada.

Este equipo ha sido diseñado para operar con las antenas que enseguida se enlistan y para una ganancia máxima de antena

de 2.0 y 1.0 dBi @ 2.4 GHz WLAN; 4.0 y 5.0 dBi @ 5 GHz WLAN; -1.5 dBi @ 2.4 GHz para Bluetooth. Siendo únicas las antenas con que cuenta la terminal. El uso con este equipo de antenas no incluidas en esta lista o que tengan una ganancia mayor

que lo especificado quedan prohibidas. La impedancia requerida de la antena es de 50 ohms.1

Marca Modelo Tipo Ganancia

LARSEN R380500314 Dipolo, Banda Dual 2.0 y1.0 dBi @ 2.4 GHz WLAN

LARSEN R380500314 Dipolo, Banda Dual 4.0 y 5.0 dBi @ 5 GHz WLAN

ANATEL (Brazil)

Este equipamento opera em caráter secundário, isto é, não tem direito a proteção contra interferência prejudicial, mesmo de

estações do mesmo tipo, e não causar interferência a sistema operando em caráter primário.

Vehicle Power Supply Connection Safety Statement

WARNING - For proper and safe installation, the input power cable must be connected to a fused circuit on the vehicle. If the

supply connection is made directly to the battery, the fuse should be installed in the positive lead within 5 inches of the battery’s

positive (+) terminal. The fused circuit requires a maximum time delay (slow blow) fuse with a current rating as noted below.

•For 12VDC input, use a 10A slow blow fuse that has a DC voltage rating greater than 12VDC.

•For 24VDC input, use a 6A slow blow fuse that has a DC voltage rating greater than 24VDC.

•For 36VDC input, use a 4A slow blow fuse that has a DC voltage rating greater than 36VDC.

•For 48VDC input, use a 3A slow blow fuse that has a DC voltage rating greater than 48VDC.

Note: For North America, a UL Listed fuse is to be used

Li-Ion Battery

When disposing of the Thor VM1 UPS battery, the following precautions should be observed: The battery should be disposed of

properly. The battery should not be disassembled or crushed. The battery should not be heated above 212°F (100°C) or incinerated.

1 - 2

Page 13

Safety requirements restrict the temperature at which the Li-Ion UPS battery can be charged. Charging is disabled if the ambi-

1177

Complies with

IDA Standards

DA104647

ent temperature is outside of the 0ºC to 35ºC safe charging range. In order to maintain UPS charge the Thor VM1 should have

power applied while the unit is within the safe charging range for at least an hour each day.

RF Safety Notice

This device is intended to transmit RF energy. For protection against RF exposure to humans and in accordance with

FCC rules and Industry Canada rules, this transmitter should be installed such that a minimum separation distance of at

least 20 cm (7.8 in.) is maintained between the antenna and the general population. This device can only be co-located

with FCC ID:TWG-SDCPE15N.

Bluetooth

Class II

Honeywell Scanning & Mobility Product Environmental Information

Refer to www.honeywellaidc.com/environmental for the RoHS / REACH / WEEE information.

CE Mark

The CE marking on the product indicates that this device is in conformity with the following directives:

• 1995/5/EC R&TTE

• 2011/65/EU RoHS (Recast)

In addition, complies to 2006/95/EC Low Voltage Directive, when shipped with recommended power supply.

European contact:

Hand Held Products Europe BV

Nijverheidsweg 9-13

5627 BT Eindhoven

The Netherlands

Honeywell shall not be liable for use of our product with equipment (i.e., power supplies, personal computers, etc.) that is not CE

marked and does not comply with the Low Voltage Directive.

Dealer License - Republic of Singapore

WWAN is not available in Singapore.

Part

Number

Republic of Singapore - Dealer License Number DA104647 complies with IDA Standards.

1 - 3

Page 14

1 - 4

Page 15

2

UPS

SYS

SSD

Wi Fi

THOR

VM1

Getting Started

Overview

The Thor VM1 Vehicle Mount Computer (VMC) is a rugged, vehicle mounted computer running a Microsoft® Windows® Embedded Standard 2009 operating system and capable of wireless data communications from a fork-lift truck or any properly configured vehicle. Wireless communications are supported over a 802.11 WLAN network and, optionally, over a WWAN network.

The Bluetooth® module supports Bluetooth printers and scanners.

CAUTION - Before shipping the Thor VM1, be sure to Disconnect UPS Battery (page 4-55) .

!

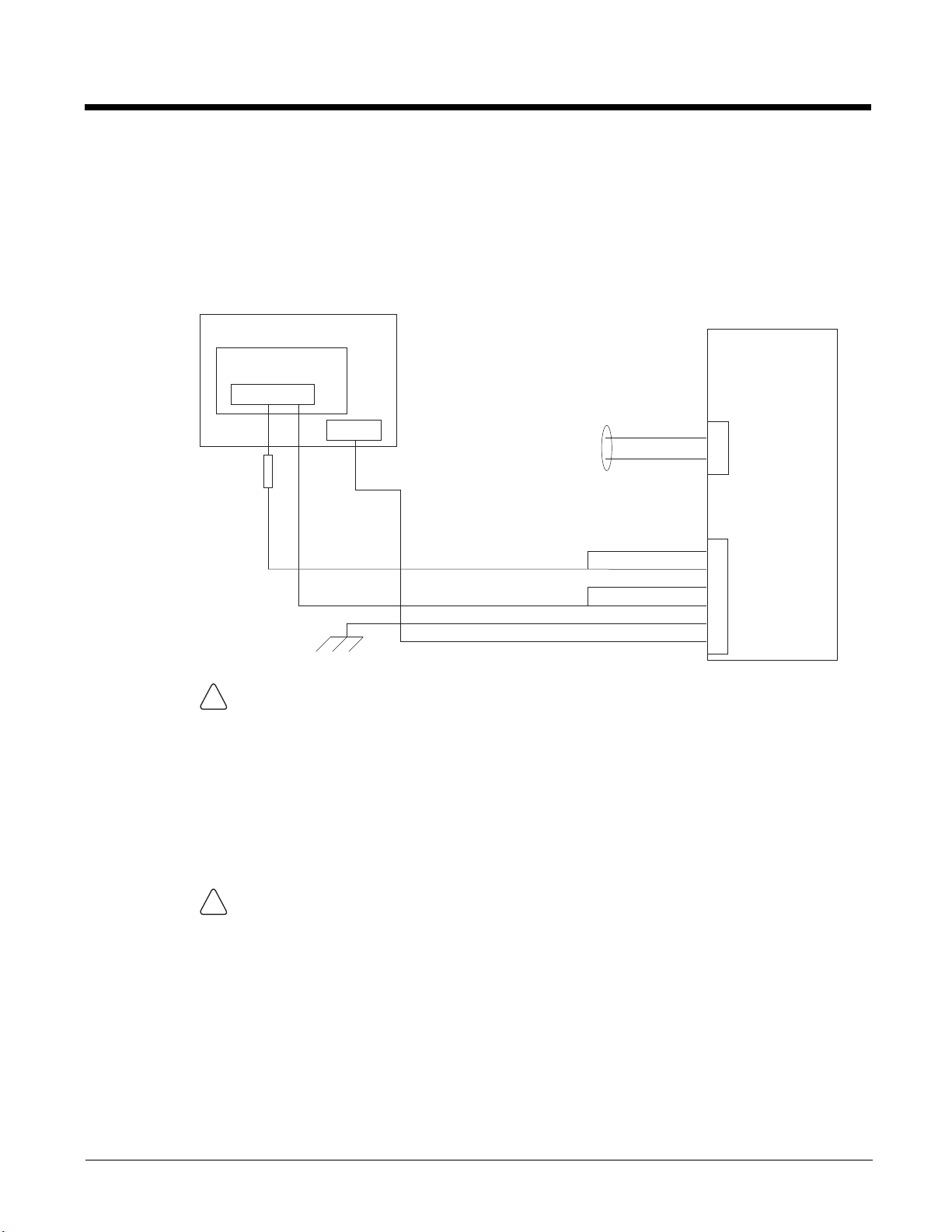

The Thor VM1 is designed for use with a vehicle Quick Mount Smart Dock. The dock installs in the vehicle and connects to

vehicle power. The dock provides conditioned input power for the Thor VM1. Peripheral connections are on the dock. The Thor

VM1 is designed to easily be removed from the dock with a latch on the lower rear of the Thor VM1 housing. Since the dock

remains attached to the vehicle, the Thor VM1 computer can easily be moved from one vehicle equipped with a dock to another

vehicle equipped with a dock.

The Thor VM1 contains a UPS battery which, when fully charged, can power the Thor VM1 for a minimum of 30 minutes. This

can be when the Thor VM1 is not attached to a Quick Mount Smart Dock or when the Thor VM1 is attached to a dock but the

vehicle power is interrupted, such as when the vehicle battery is being changed.

Contact Technical Assistance (page 9-1) for information on the latest upgrades for your Thor VM1.

About this Guide

This user’s guide has been developed for a Thor VM1 with a Microsoft® Windows® Embedded Standard 2009 operating system.

Out of the Box

The following items may be packaged separately:

• Thor VM1

• Quick Mount Smart Dock (includes 10-60VDC power cable)

• RAM or U-Bracket vehicle mount kit

2 - 1

Page 16

If you ordered additional accessories for the Thor VM1, verify they are also included with the order. Keep the original packaging

material in the event the Thor VM1 should need to be returned for service. For details, see Product Service and Repair (page 9-

1).

Initial Setup for Thor VM1

This page lists a quick outline of the steps you might take when setting up a new Thor VM1. More instruction for each step is

listed later in this guide.

Contact Technical Assistance (page 9-1) if you need additional help.

Hardware Setup

1. Install RAM Mount (page 4-18) or Install U Bracket Mount (page 4-24) to the vehicle.

2. Place Thor VM1 in the Dock (page 4-16).

3. Connect Cables (page 4-27) for any peripherals.

4. Connect Power (page 4-28).

5. Secure all cables in Strain Relief Cable Clamps (page 4-27).

6. Press the Power Switch (page 3-5) on the dock to the on position.

7. Press the Power Button (page 3-5) on the Thor VM1.

Software

Languages

The Thor VM1 may be shipped with an English only operating system. Contact Technical Assistance (page 9-1) to

order a Thor VM1 Recovery DVD (page 5-27) in a different language. The language installed is identified on the Soft-

ware tab of the About (see page 5-3) control panel.

First Boot

When a new Thor VM1 starts up a EULA (End User License Agreement) may be displayed on the touch screen. It

remains on the screen until the Accept or Decline button is tapped with a stylus.

Tap the Accept button to accept the EULA terms and the Thor VM1 continues the startup process. The EULA is not

presented to the user again.

Tap the Decline button to decline the EULA and the Thor VM1 reboots. It will continue to reboot until the Accept but-

ton is tapped with the stylus.

Software Setup

Hardware setup should be completed before starting software setup.

1. If prompted, perform Touch Screen Calibration (page 5-26).

2. Select a Power Scheme (page 5-18) and set timers.

3. Adjust Speaker Volume (page 2-5).

4. Pair Bluetooth (page 5-6) devices

5. Set Wireless client parameters using the Summit Client Utility (page 6-1).

6. Set terminal emulation parameters.

Quick Mount Smart Dock

The Thor VM1 assembly consists of two parts, the Thor VM1 computer and the Quick Mount Smart Dock.

The Thor VM1 contains an internal UPS battery that, once fully charged, powers the Thor VM1 for a minimum of 30 minutes

when the unit is not mounted in the dock.

The dock provides:

2 - 2

Page 17

• A mount for the Thor VM1 computer. The dock attaches to a vehicle via a RAM or U-bracket mount or to a RAM table stand

UPS

SYS

SSD

WiFi

Power Button

Speakers

Microphone

Ambient

Light

Sensor

for use in an office environment.

• Conditioned power for the Thor VM1. The dock accepts 10-60VDC power input directly or 50-150VDC power input with a DC/

DC converter.

• COM1 and COM2 serial connections for a tethered scanner, printer, PC connection, etc.

• USB host connection via an adapter cable.

• CANbus connection via an adapter cable.

• Headset connection via an adapter cable. When a headset is not attached, the microphone and speakers on the Thor VM1

are active.

• Strain relief cable mounts.

• Mobility of the Thor VM1, since the dock remains attached to the vehicle the Thor VM1 computer can easily be moved from

one vehicle equipped with a dock to another.

External antenna connectors may be present on the back of the Thor VM1. The connectors may include:

• 802.11 antenna connectors, used when the Thor VM1 is not equipped with internal antennas.

• External GPS antenna connector, when the Thor VM1 is equipped with GPS.

• External WWAN antenna connectors, when the Thor VM1 is equipped with WWAN. Optional WWAN radio (available in North

America, Europe, New Zealand, and Australia only).

Components

Front View

2 - 3

Page 18

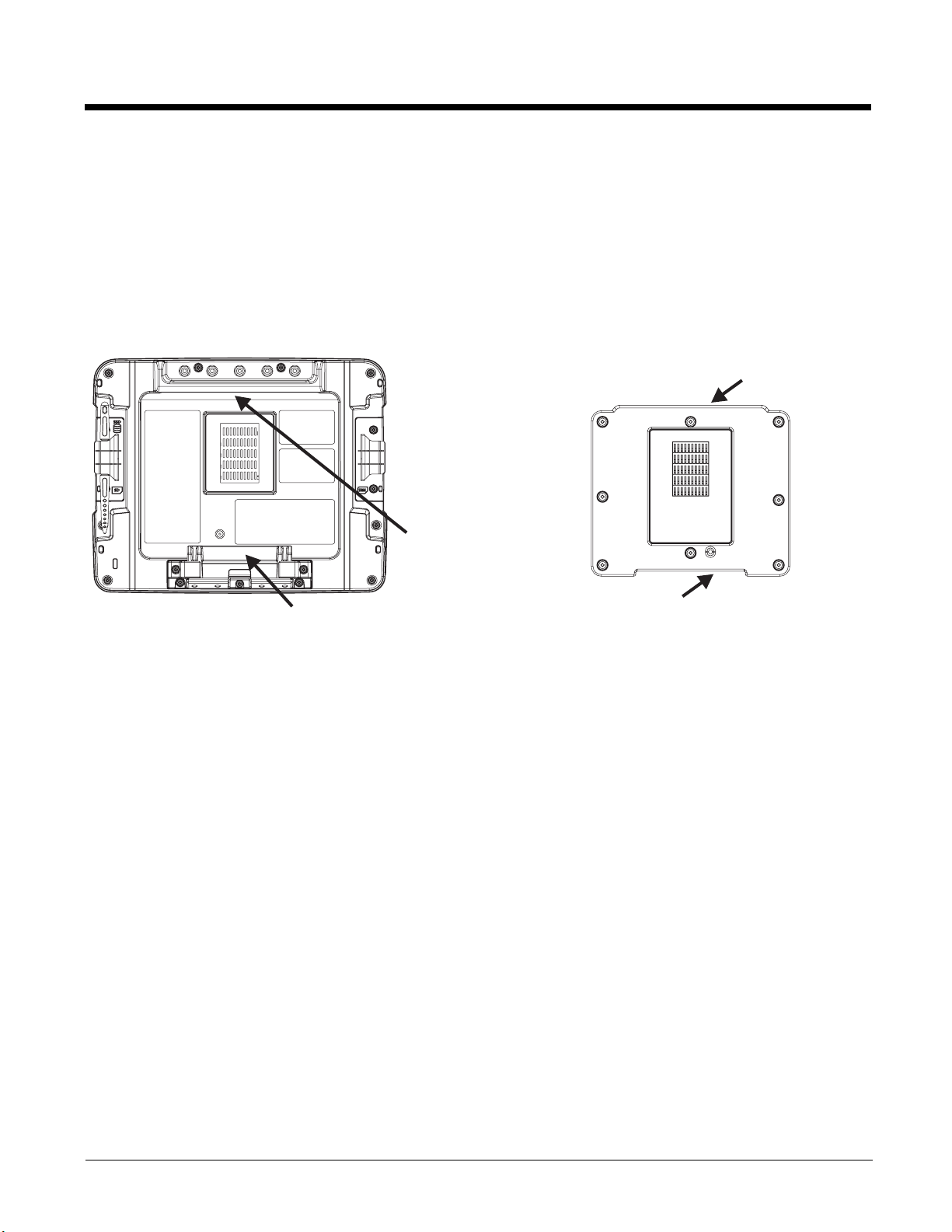

Back View with Quick Mount Smart Dock

Antenna Connectors

SIM Card

Access Panel

COM1 Connector

COM2 Connector

USB Connector

CANbus/Audio

Connector

Quick Release HandleProvision for Padlock

Provision for

Laptop Security

Cable

Power

Switch

Power

Connector

Fuse

SD Card

Access

Panel

RAM Ball

Strain Relief

Clamps

CompactFlash

Hard Drive

SD (Secure Digital)

Memory Card Slot

SIM Card Slot

for WWAN Radio

UPS Battery

Disconnect

SD

SIM

Access Panels

SD Card Access Panel with door removed SIM Card Access Panel with door removed

2 - 4

SSD

Access Panel Door is labeled with and .

Access Panel Door is labeled with .

Page 19

Backlights and Indicators

Display Backlight

There are several configuration options for the Thor VM1 display backlight:

Power Management

The display backlight is controlled by power management. When the user activity timer expires, the display backlight is

turned off. Timeouts can be set for the available power management schemes.

See Power Options (page 5-18) for configuration options.

Backlight Brightness

The intensity of the display backlight can be manually configured:

• Use the 2nd + F7 keppress to increase backlight brightness or the 2nd + F8 keypress to decrease backlight

brightness.

Refer to the Screen Control (page 5-22) panel for the current display brightness level.

Screen Blanking

The Thor VM1 can be configured to blank (blackout) the display while the vehicle is in motion.

Refer to the Screen Control (page 5-22) panel for information.

Keypad Backlight

The integrated keypad backlight follows the display backlight. If the display backlight is on, the keypad backlight is on.

Speaker Volume

The speaker volume can be adjusted via the Thor VM1 keypad:

•Use the 2nd + F9 keppress to increase speaker volume or the 2nd + F10 keypress to decrease speaker volume.

The current volume level can be viewed on the Sounds (page 5-24) control panel or via the system tray speaker icon.

These items can also be used to adjust speaker volume

2 - 5

Page 20

Power Up

!

If a USB drive, such as a thumb drive is attached to the Thor VM1, the device attempts to boot from the USB drive and

cannot. Please remove the USB drive and power up the Thor VM1 again.

The Quick Mount Smart Dock has a power switch on the back.

The “On” side of this rocker switch has a raised bump to allow the state of the switch to be determined when the switch may not

be easily viewed, for example, after the dock is mounted in a vehicle.

After external power has been connected and the Thor VM1 has been mounted in the dock, press the side of the power switch

with the raised bump to pass power from the dock to the Thor VM1.

Next locate the power button on the front of the Thor VM1.

Press the power button to turn the Thor VM1 on. When the Windows desktop is displayed or an application begins, the power up

sequence is complete.

See Power Controls (see page 3-5) for more information.

2 - 6

Page 21

Rebooting the Thor VM1

!

If a USB drive, such as a thumb drive is attached to the Thor VM1, the device attempts to boot from the USB drive:

• If the USB drive contains a bootable sector, the Thor VM1 boots from the USB drive.

• If the USB drive does not contain a bootable sector, the Thor VM1 does not boot. Remove the USB drive and boot

the Thor VM1 again.

Restart

Restart performs a controlled shutdown of the Thor VM1 and then restarts the device.

• Use the Ctrl + Alt + Del keypress sequence to start the task manager. Tap the Shut Down button and select

Restart from the pull-down list. Tap the OK button to restart the Thor VM1..

•Select Start > Shut Down > Restart and tap OK to restart the Thor VM1

Tapping the Touch Screen with a Stylus

Note: Always use the point of the stylus for tapping or making strokes on the touch screen.

Never use an actual pen, pencil, or sharp/abrasive object to write on the touch screen.

Hold the stylus as if it were a pen or pencil. Touch an element on the screen with the tip of the stylus then remove the stylus from

the screen.

Firmly press the stylus into the stylus holder when the stylus is not in use.

Using a stylus is similar to moving the mouse pointer then left-clicking icons on a desktop computer screen.

Using the stylus to tap icons on the touch screen is the basic action that can:

• Open applications

• Choose menu commands

• Select options in dialog boxes or drop-down boxes

• Drag the slider in a scroll bar

• Select text by dragging the stylus across the text

• Place the cursor in a text box prior to typing in data

• Place the cursor in a text box prior to retrieving data using a scanner/imager.

A right click is generated by tapping the mouse icon , usually located in the upper right hand corner of the screen. After

tapping, the mouse icon highlights the right button. The next touch screen tap is treated as a right click. The mouse icon

returns to the left button highlighted so subsequent taps are treated as left clicks.

Note: If the mouse icon is not displayed, this feature can be enabled by tapping the PenMount icon in the System Tray. From

the menu that pops up, tap the Right Button to enable the mouse icon. When this option is enabled, a checkmark is

displayed in the menu.

A stylus replacement kit is available.

When a dialog box is too large for the display, tap and drag the dialog box up or down or from side to side to view the remainder

of the dialog box.

Setup Terminal Emulation Parameters

Note: The instructions below are for Honeywell RFTerm. If a different terminal emulation software is installed on your Thor VM1

refer to the documentation for that software.

Before you make a host connection, you will, at a minimum, need to know:

• the alias name or IP address (Host Address) and

• the port number (Telnet Port) of the host system to properly set up your host session.

1. Make sure the mobile client network settings are configured and functional. If you are connecting over wireless LAN

(802.11x), make sure your mobile client is communicating with the Access Point.

2. From Start > Program, run RFTerm or tap the RFTerm icon on the desktop.

3. Select Session > Configure from the application menu and select the “host type” that you require. This will depend on the

type of host system that you are going to connect to; i.e., 3270 mainframe, AS/400 5250 server or VT host.

2 - 7

Page 22

4. Enter the “Host Address” of the host system that you wish to connect to. This may either be a DNS name or an IP address

of the host system.

5. Update the telnet port number, if your host application is configured to listen on a specific port. If not, just use the default

telnet port.

6. Select OK.

7. Select Session > Connect from the application menu or tap the “Connect” button on the Tool Bar. Upon a successful

connection, you should see the host application screen displayed.

To change options such as Display, Colors, Cursor, Bar Code, etc., refer to these sections in the RFTerm Reference Guide for

complete descriptions of these and other features.

Cleaning the Touch Screen

Note: These instructions are for components made of glass. If there is a removable protective film sheet on the display, remove

the film sheet before cleaning the screen.

Keep fingers and rough or sharp objects away from the bar code reader scanning aperture and the mobile device touch screen.

®

If the glass becomes soiled or smudged, clean only with a standard household cleaner such as Windex

isopropyl alcohol. Dampen the cloth with the cleaner and then wipe the surface.

Do not use paper towels or harsh-chemical-based cleaning fluids since they may result in damage to the glass surface. Use a

clean, damp, lint-free cloth.

Do not scrub optical surfaces. If possible, clean only those areas which are soiled. Lint and particulates can be removed with

clean, filtered canned air.

without vinegar or use

Startup Help

Contact Technical Assistance (page 9-1) if you need more help.

Touch screen is not accepting stylus

taps or needs recalibration.

Thor VM1 seems to lockup as soon

as it is rebooted.

Press Ctrl+Esc to force the Start Menu to appear. Use the tab, backtab and arrow keys

to move the cursor from element to element.

See Touch Screen Calibration (page 5-26).

There may be slight delays while the wireless client connects to the network, authorization for voice-enabled applications complete, and Bluetooth relationships establish or reestablish.

When an application begins, the Thor VM1 is ready for use.

2 - 8

Page 23

3

CF Slot

SD Slot

Antenna Connectors

CompactFlash

Hard Drive

Secure

Digital

Memory

Card

Power

Connector

SIM

Card

USB

Connector

CANbus/

Audio

Connector

Serial

Connector

COM2

Serial

Connector

COM2

Serial

Connector

COM1

SIM Slot

Hardware Overview

System Hardware

802.11a/b/g/n Wireless Client

The Thor VM1 has an 802.11a/b/g/n network card that supports diversity with two internal or external antennas. Power

management for the network card is configured with the Summit Client Utility (page 6-1).

Central Processing Unit

The CPU is a 1.6 GHz Intel Atom processor. The operating system is Microsoft Windows Embedded Standard 2009. The

OS image is stored on an internal CompactFlash memory card and is loaded into DRAM for execution.

Input/Output Components

The Thor VM1 supports the following I/O components of the core logic:

• Two 9-pin RS-232 serial ports, COM1 and COM2.

• One slot for SD memory card.

• CompactFlash (CF) memory card drive.

• Integrated keyboard.

• Ports available via adapter cables: USB host port, CANbus, Audio. USB client port is not supported with Windows

Embedded Standard 2009.

System Memory

Main system memory is 2 GB SDRAM.

Video Subsystem

The Thor VM1 video subsystem consists of a color TFT display. The video subsystem complies with the VESA VL bus

standard. The resolution of this display is pixels. This resolution complies with the VGA graphics industry standard.

The display supports screen blanking to eliminate driver distraction when the vehicle is in motion.

Audio Interface

Speakers are located on the bottom front of the Thor VM1. A headset adapter cable provides a connection for headset

operation. When a headset is plugged into the adapter cable, the main speakers are disabled.

3 - 1

Page 24

A microphone is located at the upper right of the Thor VM1 display, near the Thor VM1 emblem. When a headset is

plugged into the adapter cable, the internal microphone is disabled.

Card Slots

CompactFlash (CF) Slot

The CF ATA slot is not hot swappable. The Thor VM1 must be powered down to insert or remove an ATA card. Since

the operating system is stored on the CF ATA card, the Thor VM1 cannot operate without the ATA card.

Secure Digital (SD) Slot

The SD slot accepts an SD memory card. The SD card is hot swappable.

Bluetooth EZPair

The Thor VM1 contains Bluetooth version 2.0 with Enhanced Data Rate (EDR) up to 3.0 Mbit/s over the air. Bluetooth

device connection (or pairing) can occur at distances up to 32.8 ft (10 meters) Line of Sight. The wireless client retains

wireless connectivity while Bluetooth is active.

The user cannot select PIN authentication or encryption on connections from the Thor VM1. However, the Thor VM1 supports authentication requests from pairing devices. If a pairing device requests authentication or encryption, the Thor VM1

displays a prompt for the PIN or passcode. Maximum encryption is 128 bit. Encryption is based on the length of the user’s

passcode.

Bluetooth simultaneously supports one printer as a slave Bluetooth device and one scanner, either as a slave or as a master Bluetooth device.

• The LED on the Bluetooth scanner illuminates during a scanning operation.

• Bar code data captured by the Bluetooth scanner can be manipulated by the settings in the optional Freefloat Link*One

application.

• Multiple beeps may be heard during a bar code scan using a mobile Bluetooth scanner; beeps from the mobile Bluetooth

scanner as the bar code data is accepted/rejected, and other beeps from the Thor VM1 during final bar code data

manipulation.

WWAN

WWAN (Wireless Wide Area Networking) is available on the Thor VM1. A slot is provided for a SIM card.

GPS

GPS (Global Positioning System) is available on the Thor VM1.

Power

Vehicle DC Power Supply

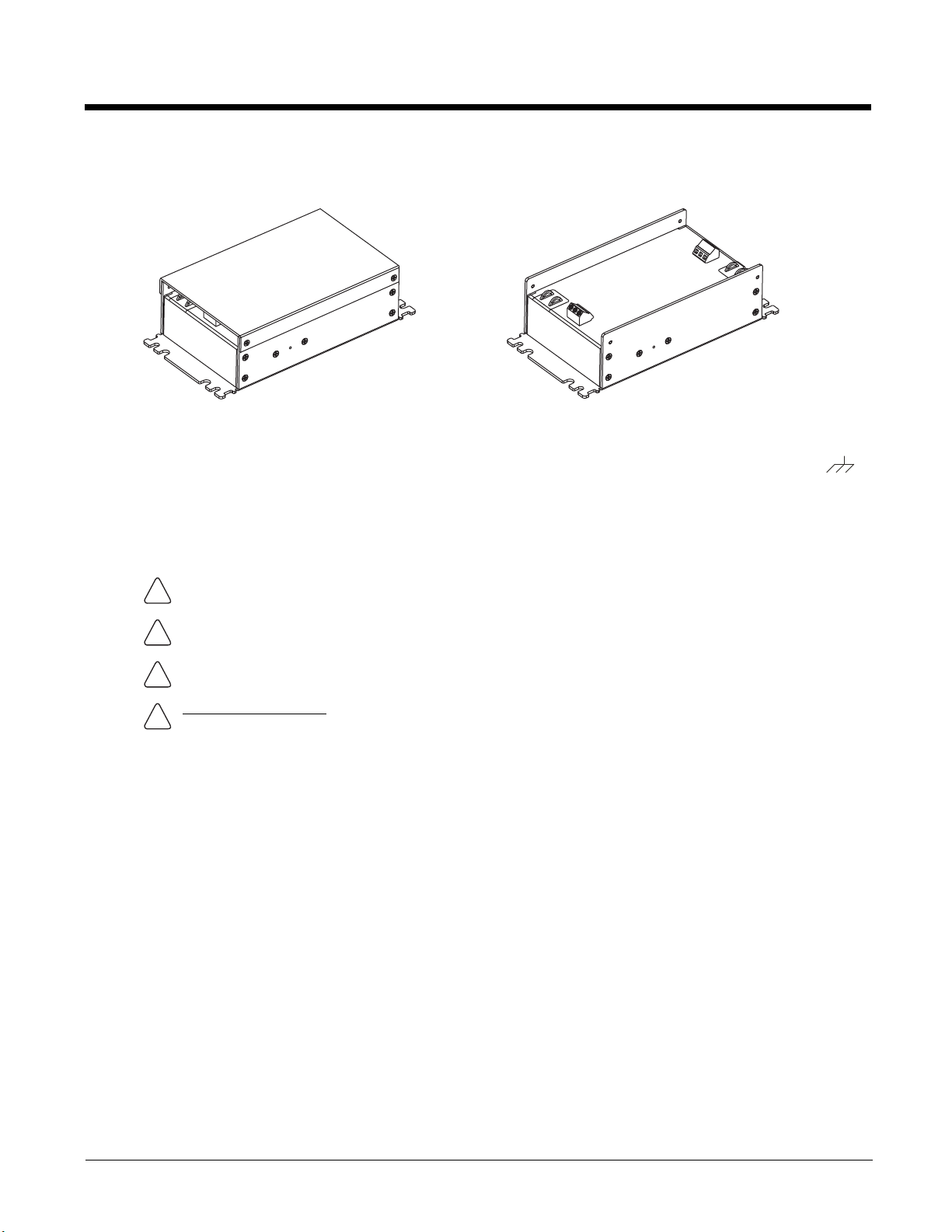

Vehicle power input for the Thor VM1 dock is 10V to 60V DC and is accepted without the need to perform any manual operation within the Thor VM1 dock, see 12-48 VDC Vehicles (10-60 VDC Direct Connection) (page 4-29). The dock provides

a conditioned power output for the Thor VM1. By using a specified DC/DC power supply, input voltage of 50-150V DC can

be accepted, see 60-144 VDC Vehicles (50-150 VDC Power Supply, Screws on Top of Lid) (page 4-38) or 60-144 VDC

Vehicles (50-150 VDC Power Supply, Screws on Top of Lid) (page 4-38).

Power input is fused for protection and the fuse is externally accessible, see Fuse (page 3-4).

External AC Power Supply

If DC power is not available – for example, in an office environment – an optional external Universal Input Power Supply can

be used to convert AC wall power to an appropriate DC level. AC to DC power input for the Thor VM1 is delivered to the

Quick Mount Smart Dock via an optional external power supply and adapter cable. See External AC/DC Power Supply

3 - 2

Page 25

(page 4-47).

Uninterruptible Power Supply

The Thor VM1 contains an internal UPS battery. The user can Replace UPS Battery (page 4-60).

The UPS battery is automatically charged when the Thor VM1 is placed in a powered dock, provided the safe charging temperature conditions below are met.

When external power is removed, the UPS automatically powers the Thor VM1 with no user intervention. When running on

UPS power, the power management timeouts may be different than when vehicle power is applied.

The UPS allows the Thor VM1 to continue operation when not mounted in a dock or when the vehicle battery is being

swapped. When fully charged the UPS battery is designed to power the Thor VM1 for a minimum of 30 minutes at temperatures of -20ºC (-4ºF) or greater. For the extended temperature version of the Thor VM1, the UPS provides a minimum

of 10 minutes of operation between -20ºC (-4ºF) and -30ºC (-22ºF).

If operating on UPS power and the UPS battery becomes critically low, the Thor VM1 performs a controlled shutdown.

If there is no external power available, there must be 10% or greater power in the UPS battery or the Thor VM1 does not

power on.

The UPS status LED and the Battery Control Panel can be used to monitor the state of the UPS battery.

Safe Charging Temperature Range

The internal temperature of the Thor VM1 is the trigger for UPS battery charging.

• The UPS battery is not charged when the internal Thor VM1 temperature is below 0°C (32°F). This corresponds to

an ambient (room) temperature of approximately -10°C (-14°F).

• The UPS battery is not charged when the internal Thor VM1 temperature is above 45°C (113°F). This corresponds

to an ambient (room) temperature of approximately 35°C (95°F).

• If the UPS battery cannot be charged due to a temperature extreme, the UPS Status LED (page 3-11) is amber.

Move the Thor VM1 to a different location to charge the UPS battery.

When the Thor VM1 is operated in an environment where the UPS battery is not able to charge due to temperature

extremes, the Thor VM1 should be removed to a location within the safe charging temperature range during off hours.

A discharged UPS battery cannot protect against data loss in the event vehicle power is interrupted.

Charging Timeout

• A fully discharged UPS battery normally recharges in less than 4 hours when the Thor VM1 is in a powered dock and

within the safe charging temperature range.

• If the UPS battery is not charged before an 8 hour (or 4 hours for some earlier software revisions) timeout period

expires, the UPS Status LED (page 3-11) is amber.

• The charge timeout is reset if charging resumes upon application of external power.

• The charge timeout is reset if charging resumes when the Thor VM1 enters the permissible temperature range for

charging.

Charging and Power Management

• Charging of the UPS battery continues when the Thor VM1 is in power management (display off, suspend or

hibernate modes).

Backup Battery

The Thor VM1 has a permanent Lithium battery installed to maintain time, date and CMOS setup information for a minimum

of 90 days. The lithium battery is not user serviceable and should last five years with normal use before it requires replacement.

Note: The backup battery should only be changed by authorized service personnel.

3 - 3

Page 26

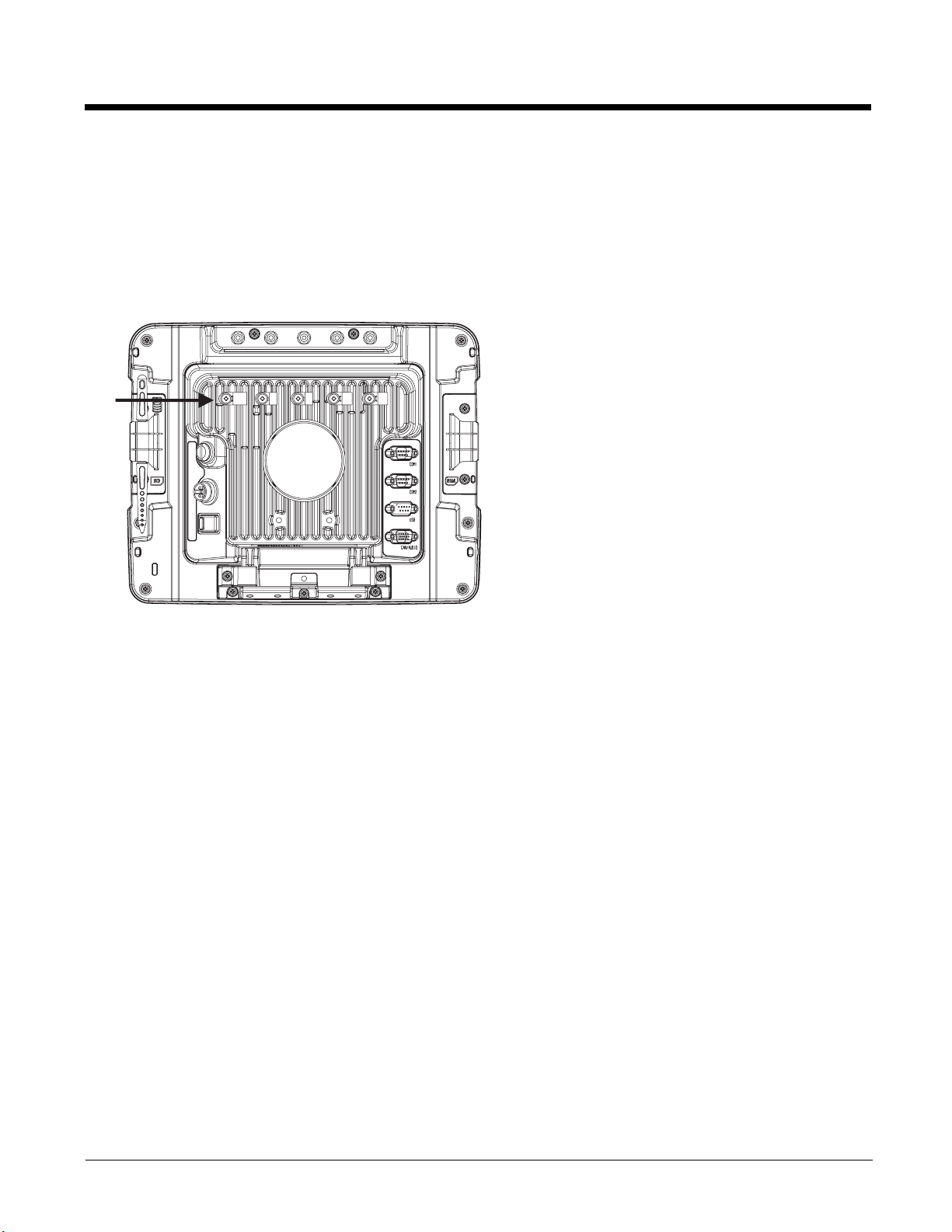

Fuse

The Thor VM1 uses an 8A time delay (slow blow), fuse that is externally accessible and user

replaceable. The fuse is located on the back of the Quick Mount Smart Dock. The fuse is accessed

by unscrewing the cap as indicated.

Should it need replacement, replace with same size, rating and type of fuse:

• Littelfuse 0215008.MXP

• Cooper Bussmann BK1/S506-8-R

• Bel Fuse 5HT 8-R

or equivalent.

Fuse has voltage on it even when power is off. Always disconnect input power before changing the

fuse.

Power Management Modes

The Thor VM1 has four power modes: Full On, Standby, Hibernate and Off.

Full On Mode