Honeywell VISTA-128BPEN Installation And Setup Manual

V

V

VV

V

V

VV

IIII

IIII

S

S

SS

S

S

SS

T

T

TT

T

T

TT

A

A

AA

A

A

AA

----

----

1111

1111

2222

2222

8888

8888

B

B

BB

B

B

BB

P

P

PP

P

P

PP

E

E

EE

E

E

EE

N

N

NN

N

N

NN

Commercial Burglary

Partitioned Security System

With Scheduling

Installation and Setup Guide

800-05855 2/10 Rev B

Table of Contents

•••••••••••••••••••••••••••••••••••••••••••••••••

List of Figures..........................................................................................................................................................vi

Conventions Used in This Manual........................................................................................................................ vii

SECTION 1 ...........................................................................................................................................................1-1

General Description ..............................................................................................................................................1-1

About the VISTA-128BPEN................................................................................................................................................1-1

Features.............................................................................................................................................................................1-1

SECTION 2 ...........................................................................................................................................................2-1

Partitioning and Panel Linking.............................................................................................................................2-1

Theory of Partitioning.........................................................................................................................................................2-1

Setting-Up a Partitioned System ........................................................................................................................................2-1

Common Lobby Logic ........................................................................................................................................................2-1

Master Keypad Setup and Operation .................................................................................................................................2-3

Panel Linking......................................................................................................................................................................2-3

SECTION 3 ...........................................................................................................................................................3-1

Installing the Control ............................................................................................................................................3-1

Mounting the Control Cabinet.............................................................................................................................................3-1

Installing the Cabinet Lock.................................................................................................................................................3-1

Mercantile Premises Listing Guidelines..............................................................................................................................3-1

Mercantile Safe and Vault Listing Guidelines.....................................................................................................................3-2

Installing the Control's Circuit Board ..................................................................................................................................3-2

Installing the Keypads........................................................................................................................................................3-3

Installing External Sounders...............................................................................................................................................3-4

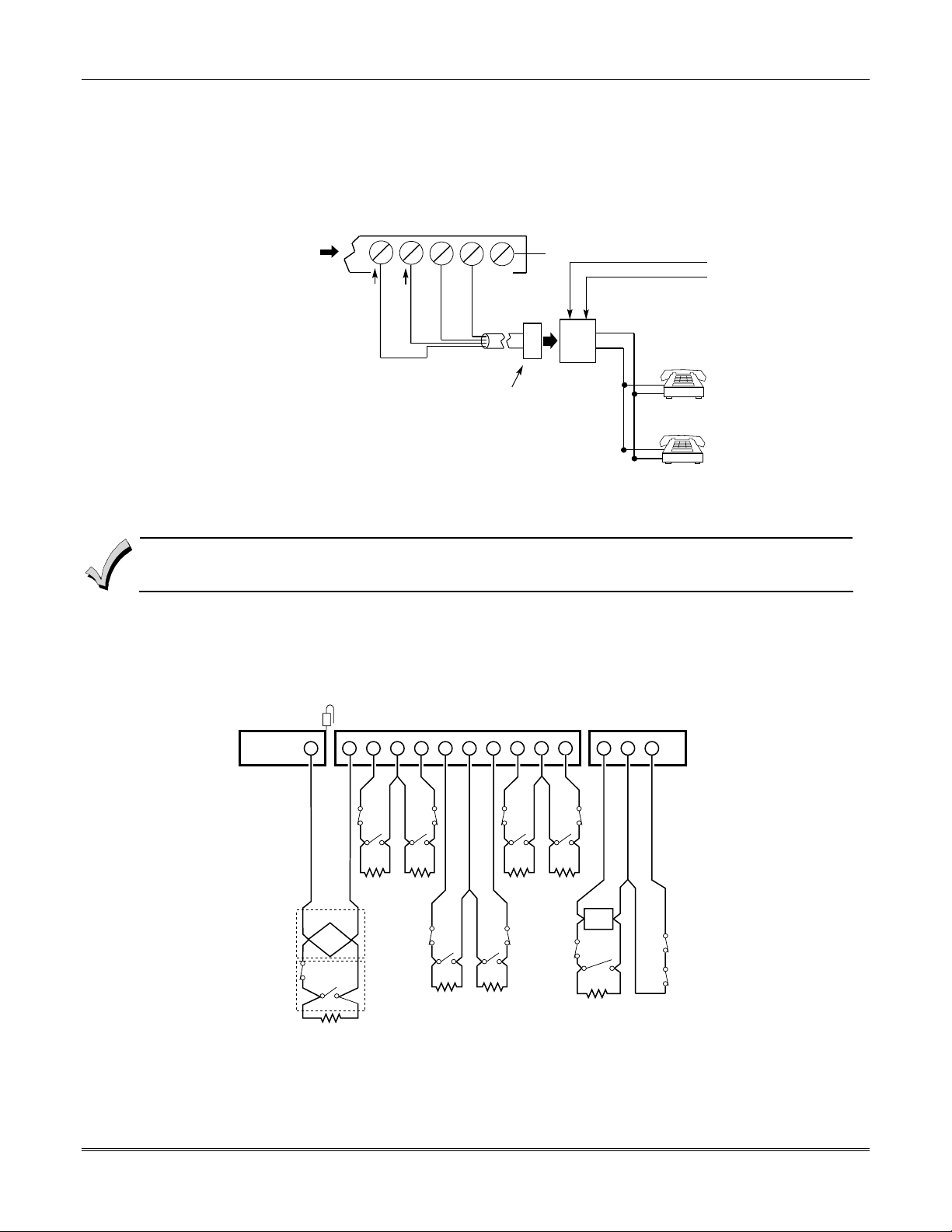

Telephone Line Connections..............................................................................................................................................3-6

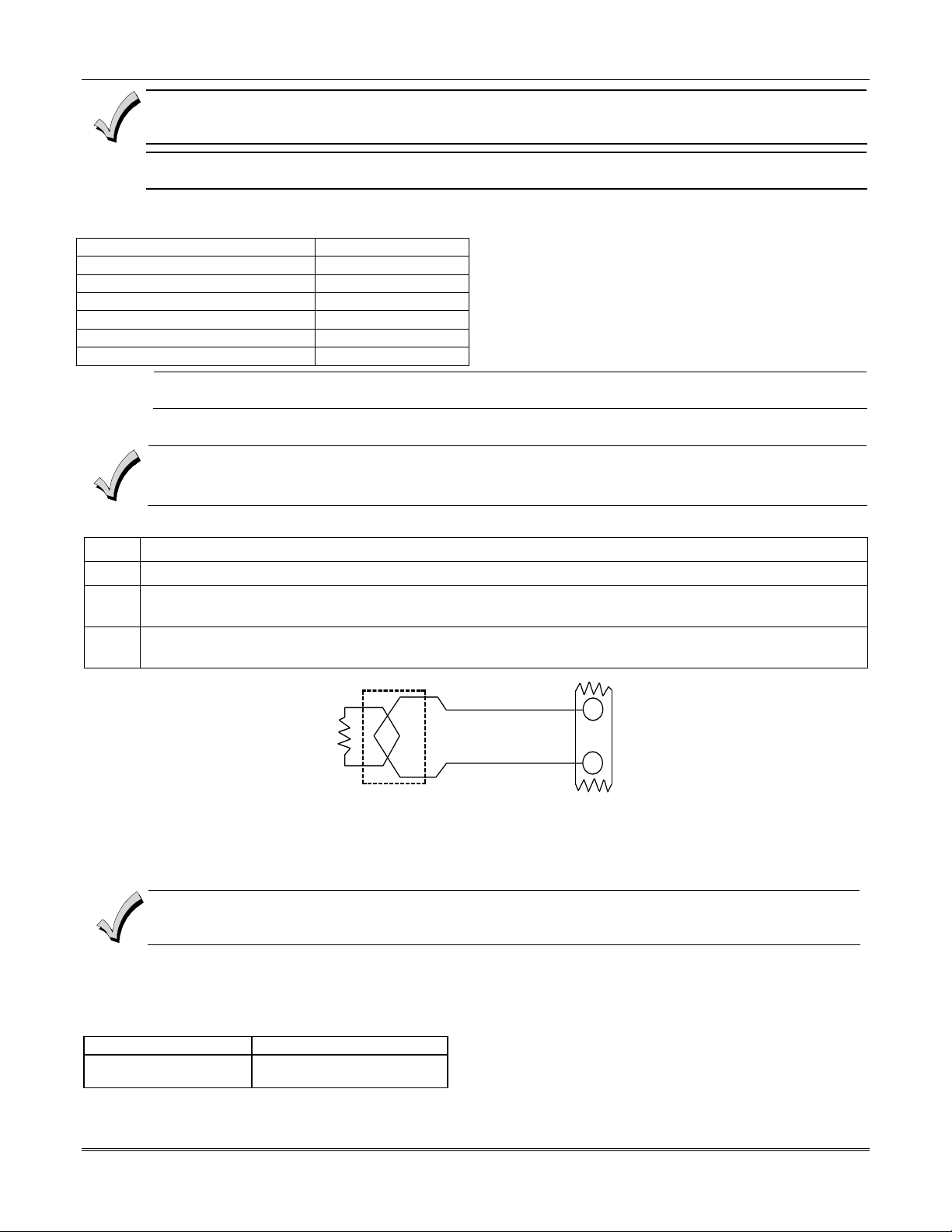

Wiring Burglary, Panic and Smoke Detector Devices to Zones 1-9 ...................................................................................3-7

Installing V-PLEX Devices................................................................................................................................................3-11

Wireless Zone Expansion.................................................................................................................................................3-13

Installing Output Devices..................................................................................................................................................3-18

Installing the Ground Start Module...................................................................................................................................3-19

Installing a Remote Keyswitch .........................................................................................................................................3-20

Smoke Detector Reset .....................................................................................................................................................3-21

Remote Keypad Sounder.................................................................................................................................................3-21

Installing the VA8200 Panel Link Module.........................................................................................................................3-22

Communicator Connected to the J7 Triggers...................................................................................................................3-23

Communicator Connected to the ECP .............................................................................................................................3-23

Access Control Using VistaKey........................................................................................................................................3-25

Access Control Using the PassPoint Access Control System..........................................................................................3-27

Installing a 4100SM..........................................................................................................................................................3-27

Installing the 4286 VIP Module.........................................................................................................................................3-28

Installing the Audio Alarm Verification Module .................................................................................................................3-30

Connecting the Transformer.............................................................................................................................................3-32

Panel Earth Ground Connections.....................................................................................................................................3-33

Determining the Control’s Power Supply Load.................................................................................................................3-33

Determining the Size of the Standby Battery....................................................................................................................3-35

SECTION 4 ...........................................................................................................................................................4-1

Programming .........................................................................................................................................................4-1

Program Modes..................................................................................................................................................................4-1

Entering and Exiting Programming Mode...........................................................................................................................4-1

Data Field Programming Mode ..........................................................................................................................................4-1

#93 Menu Mode Programming...........................................................................................................................................4-2

Zone Number Designations................................................................................................................................................4-4

Zone Response Type Definitions .......................................................................................................................................4-5

Zone Input Type Definitions ...............................................................................................................................................4-7

Programming for Panel Linking ..........................................................................................................................................4-8

Programming for 4100SM ..................................................................................................................................................4-8

Programming for Access Control........................................................................................................................................4-8

Programming for ECP Communicator..............................................................................................................................4-10

iii

Table of Contents

SECTION 5 ...........................................................................................................................................................5-1

Data Field Descriptions ........................................................................................................................................5-1

About Data Field Programming..........................................................................................................................................5-1

Programming Data Fields...................................................................................................................................................5-1

SECTION 6 ...........................................................................................................................................................6-1

Scheduling Options ..............................................................................................................................................6-1

Time Window Definitions....................................................................................................................................................6-2

Open/Close Schedules Definitions.....................................................................................................................................6-3

Scheduling Menu Mode......................................................................................................................................................6-4

Time Windows....................................................................................................................................................................6-5

Daily Open/Close Schedules..............................................................................................................................................6-6

Holiday Schedules..............................................................................................................................................................6-6

Time-Driven Events............................................................................................................................................................6-7

Limitation of Access Schedules........................................................................................................................................6-11

Temporary Schedules ......................................................................................................................................................6-12

User Scheduling Menu Mode ...........................................................................................................................................6-14

SECTION 7 ...........................................................................................................................................................7-1

Downloading Primer .............................................................................................................................................7-1

General Information............................................................................................................................................................7-1

Unattended Download........................................................................................................................................................7-1

Getting On-Line with a Control Panel.................................................................................................................................7-3

Scheduled Download .........................................................................................................................................................7-4

Direct-Wire Downloading....................................................................................................................................................7-4

Telco Handoff.....................................................................................................................................................................7-4

SECTION 8 ...........................................................................................................................................................8-1

Setting the Real-Time Clock ................................................................................................................................. 8-1

General Information............................................................................................................................................................8-1

Setting the Time and Date..................................................................................................................................................8-1

SECTION 9 ...........................................................................................................................................................9-1

User Access Codes...............................................................................................................................................9-1

General Information............................................................................................................................................................9-1

User Codes & Levels of Authority ......................................................................................................................................9-1

Multiple Partition Access....................................................................................................................................................9-2

Adding a Master, Manager, or Operator Code ...................................................................................................................9-3

Changing a Master, Manager, or Operator Code...............................................................................................................9-4

Adding an RF Key to an Existing User ...............................................................................................................................9-4

Deleting a Master, Manager, or Operator Code .................................................................................................................9-4

Exiting the User Edit Mode.................................................................................................................................................9-4

SECTION 10 .......................................................................................................................................................10-1

Testing the System .............................................................................................................................................10-1

Battery Test......................................................................................................................................................................10-1

Dialer Test........................................................................................................................................................................10-1

Burglary Walk-Test (Code + [5] TEST).............................................................................................................................10-1

Armed Burglary System Test ...........................................................................................................................................10-1

Testing Wireless Transmitters..........................................................................................................................................10-2

Smoke Detector Test........................................................................................................................................................10-3

Trouble Conditions...........................................................................................................................................................10-3

To the Installer .................................................................................................................................................................10-3

APPENDIX A....................................................................................................................................................... A-1

Regulatory Agency Statements .......................................................................................................................... A-1

UL Installation Requirements ............................................................................................................................................ A-1

UL609 Local Mercantile Premises/Local Mercantile Safe & Vault..................................................................................... A-1

UL365 Police Station Connected Burglar Alarm................................................................................................................ A-1

UL611/UL1610 Central Station Burglary Alarm................................................................................................................. A-2

California State Fire Marshal (CSFM) and UL Residential Fire Battery Backup Requirements......................................... A-2

APPENDIX B....................................................................................................................................................... B-1

Summary of System Commands ........................................................................................................................ B-1

APPENDIX C....................................................................................................................................................... C-1

iv

Table of Contents

Specifications ....................................................................................................................................................... C-1

APPENDIX D ...................................................................................................................................................... D-1

Contact ID Event Codes....................................................................................................................................... D-1

TABLE OF CONTACT ID EVENT CODES .......................................................................................................................D-1

Event Log Alpha Descriptors............................................................................................................................................. D-1

Index ............................................................................................................................................................... Index-1

THE LIMITATIONS OF THIS ALARM SYSTEM

HONEYWELL LIMITED WARRANTY

v

List of Figures

•••••••••••••••••••••••••••••••••••••••••••••••••

Figure 3-1: Installing the Lock ...............................................................................................................................................3-1

Figure 3-2: Cabinet Attack Resistance Considerations..........................................................................................................3-2

Figure 3-3: Mounting the PC Board.......................................................................................................................................3-2

Figure 3-4: Keypad Connections to Control Panel .................................................................................................................3-3

Figure 3-5: Using A Supplementary Power Supply...............................................................................................................3-4

Figure 3-6: Wiring Polarized Fire Devices .............................................................................................................................3-5

Figure 3-7: Wiring Nonpolarized Burglary Devices...............................................................................................................3-5

Figure 3-8: Telephone Line Connections ................................................................................................................................3-7

Figure 3-9: Wiring Connections for Zones 1-9........................................................................................................................3-7

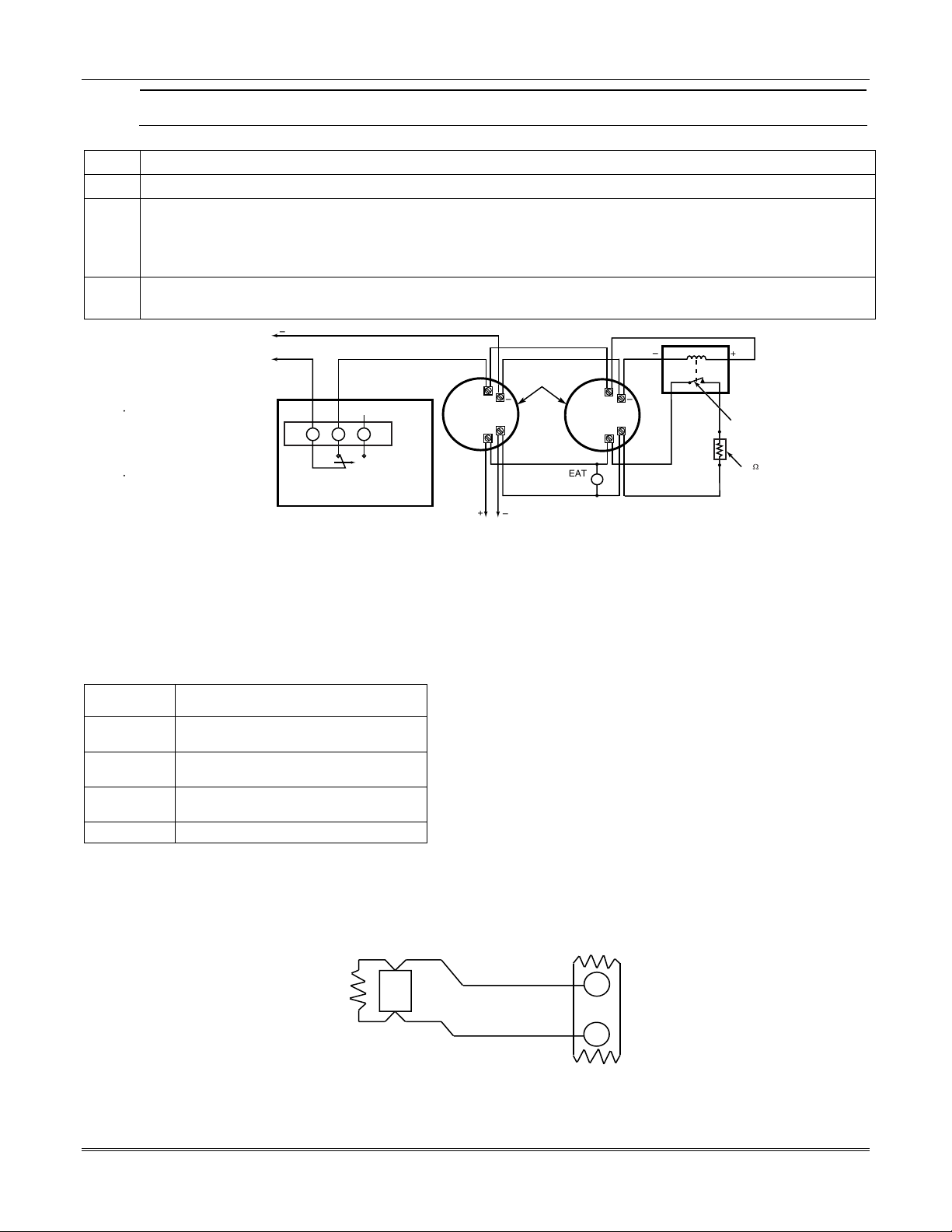

Figure 3-10: 2-Wire Smoke Detector on Zone 1 ......................................................................................................................3-8

Figure 3-11: 4-Wire Smoke Detectors......................................................................................................................................3-9

Figure 3-12: Wiring Latching Glassbreaks to Zone 8 .............................................................................................................3-9

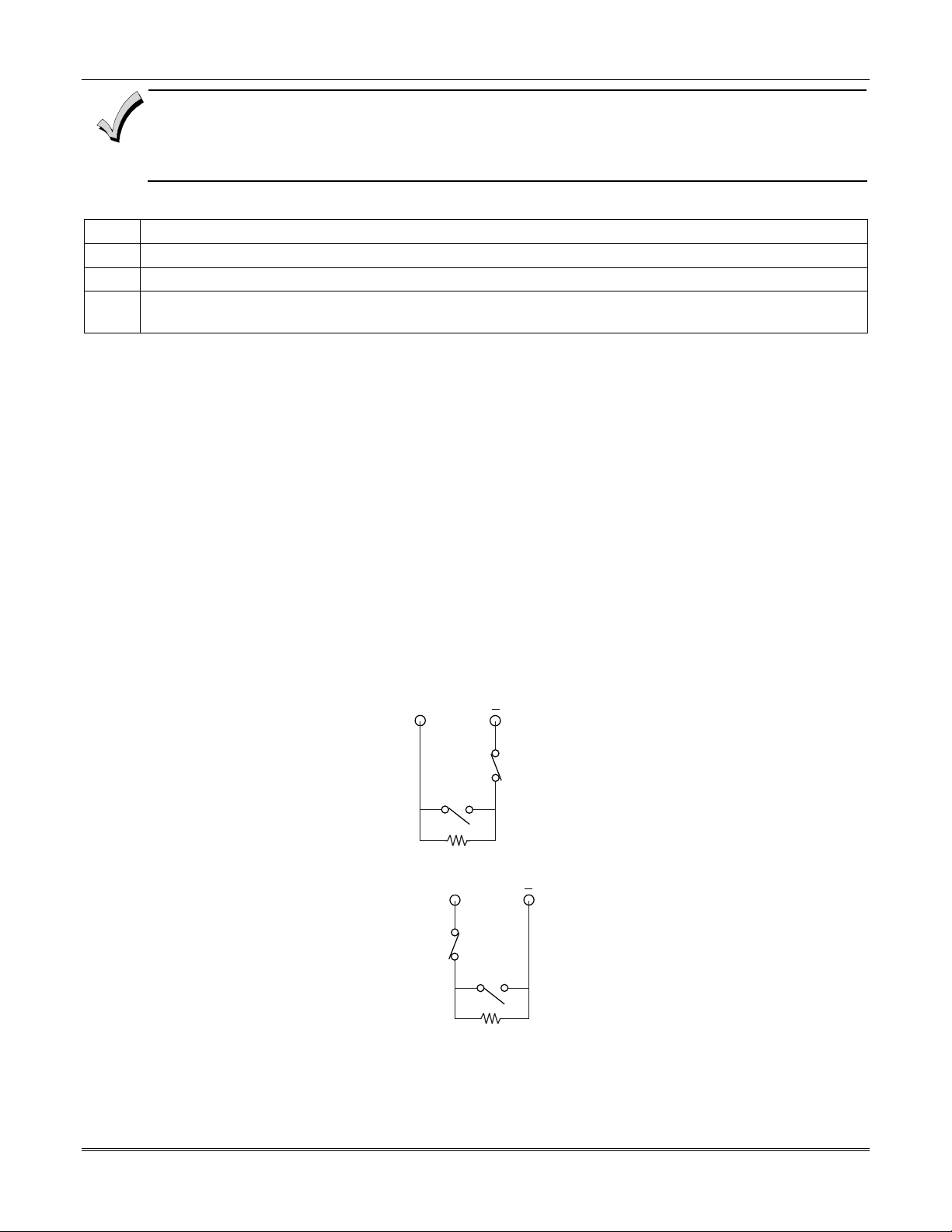

Figure 3-13: Wiring a Normally Closed Loop for Tamper Supervision ..............................................................................3-10

Figure 3-14: Wiring a Normally Open Loop for Tamper Supervision.................................................................................3-10

Figure 3-15: Polling Loop Connections to the VISTA-128BPEN.........................................................................................3-12

Figure 3-16: Polling Loop Connections Using One 4297 Extender Module ........................................................................3-13

Figure 3-17: Polling Loop Connections Using Multiple Extender Modules ........................................................................3-13

Figure 3-18: Installing the 5881ENHC with Tamper Protection .........................................................................................3-14

Figure 3-19: 5881 RF Receiver (cover removed) ...................................................................................................................3-15

Figure 3-20: 4204 Relay Module...........................................................................................................................................3-18

Figure 3-21: 4204CF Relay Module......................................................................................................................................3-18

Figure 3-22: Wiring the FSA Module ...................................................................................................................................3-19

Figure 3-23: Ground Start Module Connections..................................................................................................................3-20

Figure 3-24: Remote Keyswitch Wiring ................................................................................................................................3-21

Figure 3-25: Remote Keypad Sounder Wiring......................................................................................................................3-22

Figure 3-26: Panel Linking Block Diagram.........................................................................................................................3-22

Figure 3-27: VA8200 Panel Link Module Wiring.................................................................................................................3-23

Figure 3-28: Wiring Communicator to Keypad Terminals ..................................................................................................3-24

Figure 3-29: Wiring the VistaKey ..........................................................................................................................................3-26

Figure 3-30: Wiring the VISTA Gateway Module................................................................................................................3-27

Figure 3-31: 4100SM Using a Serial Printer ........................................................................................................................3-28

Figure 3-32: 4100SM Using Home Automation...................................................................................................................3-28

Figure 3-33: VIP Module Connections..................................................................................................................................3-30

Figure 3-34: UVS Connections to the Control Panel............................................................................................................3-31

Figure 3-35: 1361 Transformer and Battery Connections ...................................................................................................3-32

Figure 3-36: 1361X10 Transformer Connections .................................................................................................................3-33

Figure 7-1: Direct-Wire Downloading Connections................................................................................................................7-4

vi

g

Conventions Used in This Manual

•••••••••••••••••••••••••••••••••••••••••••••••••

Before you begin using this manual, it is important that you understand the meaning of the following

symbols (icons).

U

L

ZONE PROG?

1 = YES 0 = NO 0

✴

00 Additional system options are programmed via data fields, which are indicated by a “star” (

These notes include specific information that must be followed if you are installin

a UL Listed application.

These notes include information that you should be aware of before continuing with the

installation, and that, if not observed, could result in operational difficulties.

This symbol indicates a critical note that could seriously affect the operation of the system, or

could cause damage to the system. Please read each warning carefully. This symbol also

.

denotes warnings about physical harm to the user

Many system options are programmed in an interactive mode by responding to

alpha keypad display prompts. These prompts are shown in a single-line box.

followed by the data field number.

this system for

✴

)

PRODUCT MODEL NUMBERS:

Unless noted otherwise, references to specific model numbers represent ADEMCO products.

vii

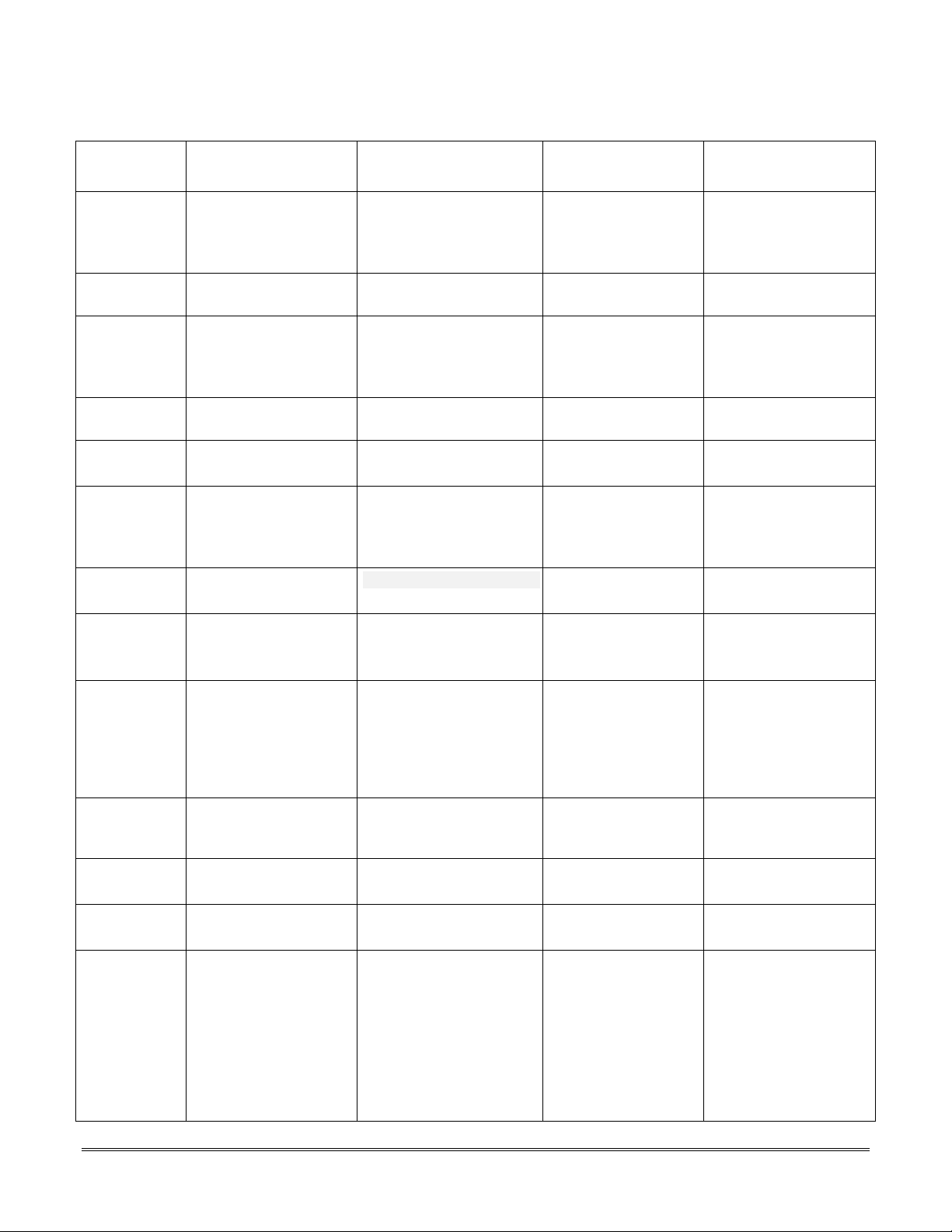

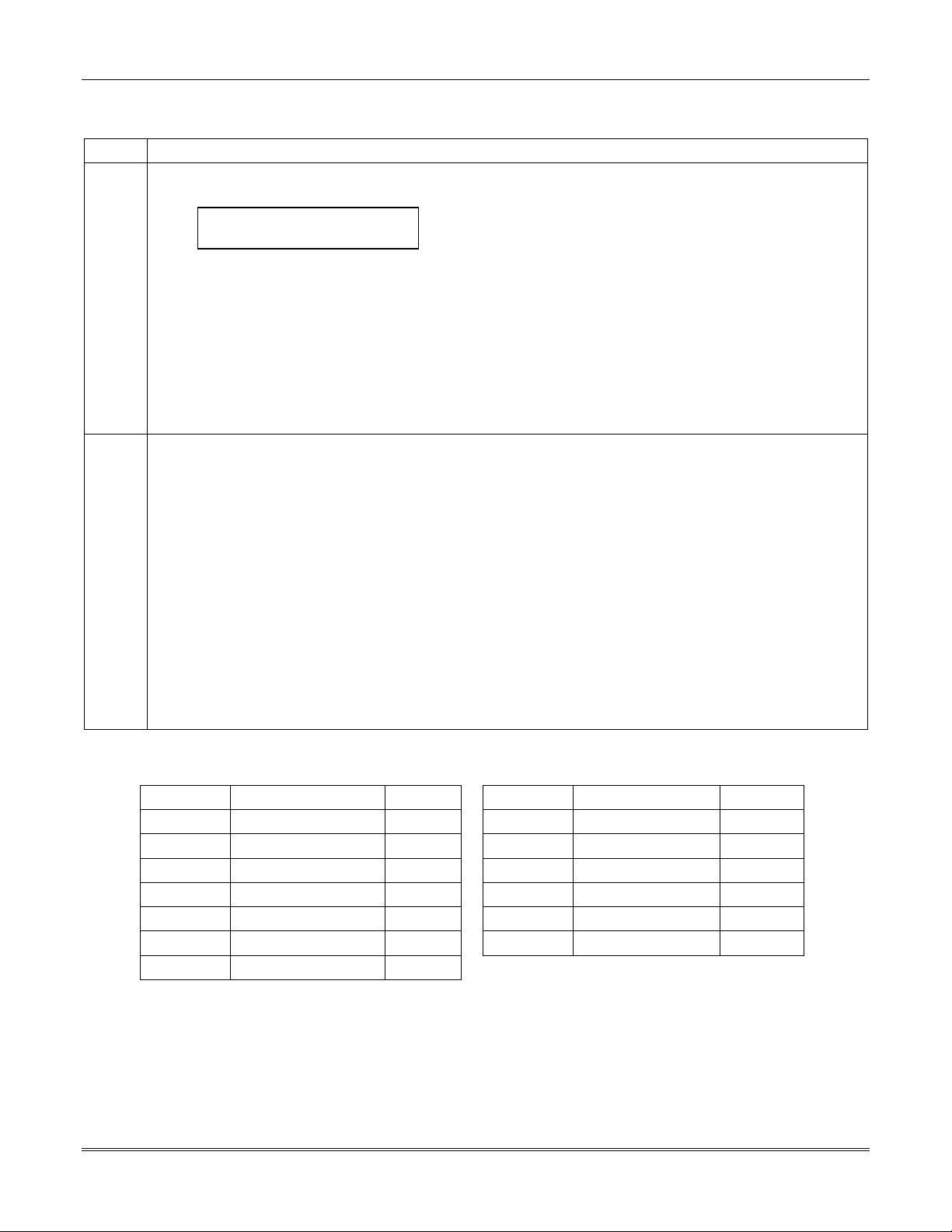

SIA CP-01 Quick Reference Chart

The minimum required system for SIA CP-01 is a UL Listed Control, Keypad and Bell.

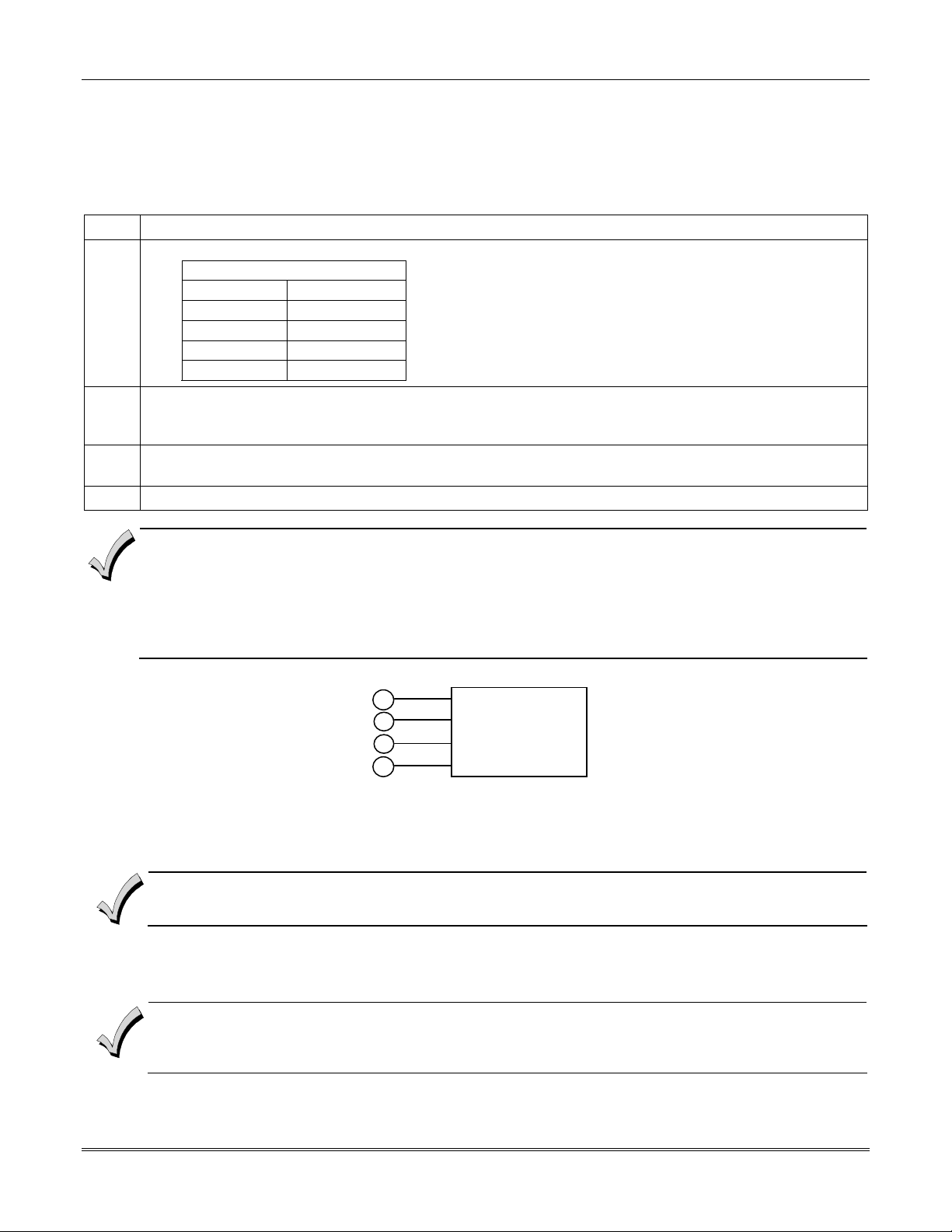

Item Feature Range Shipping

Default

*09 Entry Delay # 1 02 – 15 multiplied by 15

seconds

00 = 240 sec (4

minutes)

*10 Exit Delay #1 03 – 15 multiplied by 15

seconds

*11 Entry Delay # 2 02 – 15 multiplied by 15

seconds

00 = 240 sec (4

minutes)

*12 Exit Delay #2 03 – 15 multiplied by 15

seconds

*28 Power Up in Previous

State

*57 Dynamic Signaling

Priority

*84 Swinger Suppression 01= 1 alarm

*88 Abort Window Time

(for non-fire zones)

1*21 Exit Time Reset 0=no

1*22 – 1*25 Cross Zoning Zone 001 – 128

1*42 Call Waiting Defeat 0 = no

1*61 Abort Verify 0 = Disable

Zone

Programming

Auto Stay

Zone, Zone

type 04 has

this feature

enabled by

default

Auto Stay Arm or

Occupied Premises

0 = no

1 = yes

0 = primary dialer

1 = Communicator as

first reporting

destination

02= 2 alarms

1 = 15 seconds

2 = 30 seconds

3 = 45 seconds

1=Resets Exit Delay to

programmed value after

zone is closed and then

faulted prior to end of

exit delay.

000, 000 = Disabled

1 = yes

1 = Enable

0 = Disable

1 = Enable

30 Seconds` At least 30 Seconds **

60 Seconds 60 Seconds

30 Seconds At least 30 Seconds **

60 Seconds 60 Seconds

Yes Yes

0 (primary dialer) 0 (primary dialer)

1 alarm 1 alarm

30 Seconds At least 15 Seconds **

1 (Enabled) 1 (Enabled)

Disabled Enabled and two (or

Disabled (0) Enabled if user has

Enabled Enabled

1 (Enabled) Enabled

SIA

Requirement*

more) zones

programmed

call waiting

viii

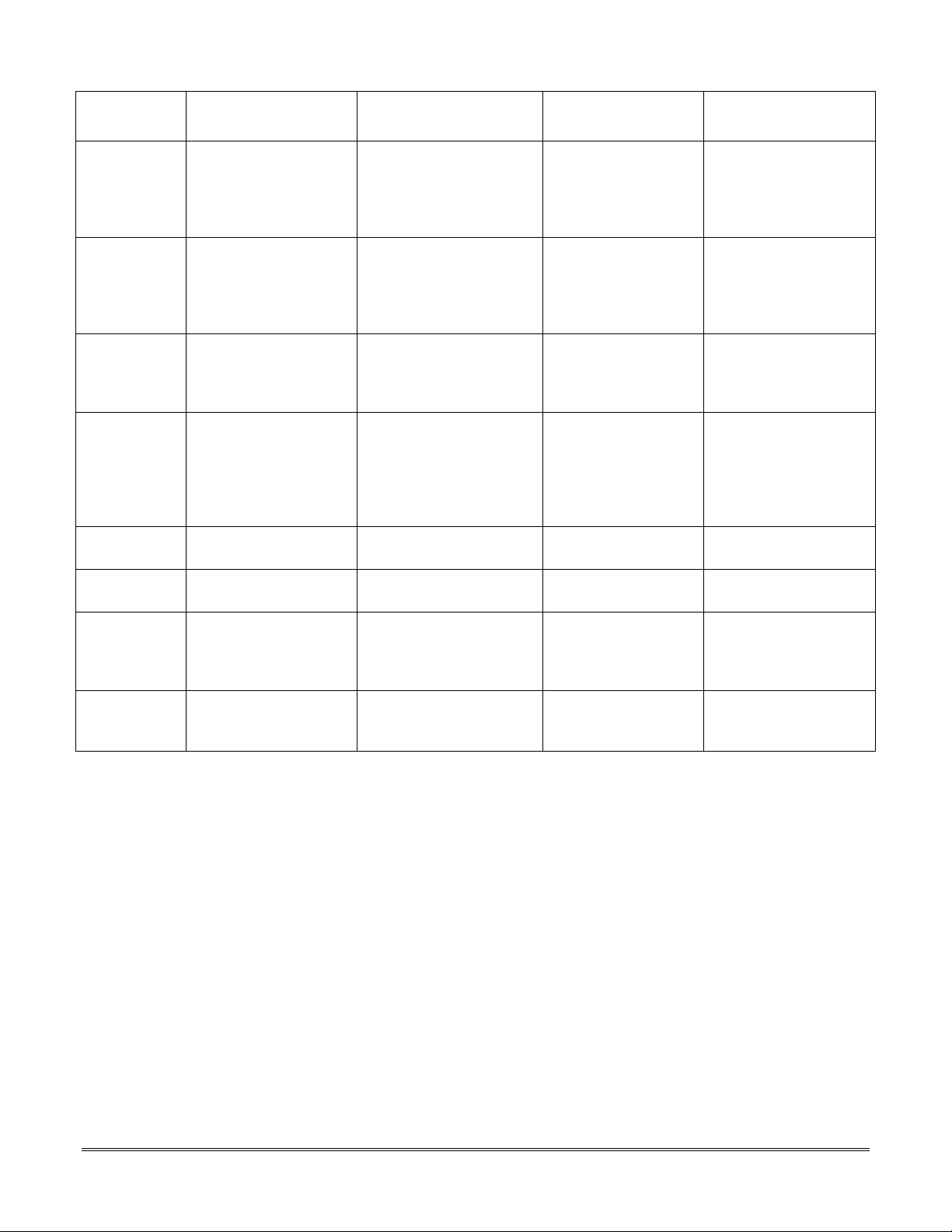

Item Feature Range Shipping

Default

Zone

Programming

(Abort

Window

Enable)

Zone

Programming

(Swinger

Suppression

Enable)

Zone

Programming

Tamper

Option

- Exit Time and

- Programmable Cross

- Cancel Window 5 minutes Enabled Not required to be

- Cancel Annunciation -

User

Authority

Level 6

* Programming at installation may be subordinate to other UL requirements for the intended application.

** Combined Entry Delay and Abort Window should not exceed 1 minute.

Abort Window (for

non-fire zones)

Swinger Suppression

Enable

Fire Alarm Verification For Zone Response

Progress

Annunciation/Disable

for Remote Arm (Not

Evaluated for SIA CP-

01)

Zoning Time

Keypad displays

“Alarm Cancel” when

report is received

Duress Feature NA Disabled Disabled

0 = no abort window

1 = yes, use abort

window according to *88

selection

0 = no suppression

1 = yes, suppress

alarms according to *84

selection

Type 16 (Fire) tamper

selection must be set to

“0”

Always Enabled Enabled Enabled

Both zones must be

faulted within 5 minutes

NA Enabled Enabled

1 = yes Yes (all non-fire

zones)

Yes (enabled) Yes (enabled (all

zones))

Disabled Enabled unless

sensors can self verify

Per Manufacturer Per walk path in

protected premises

programmable

SIA

Requirement*

ix

SECTION 1

General Description

•••••••••••••••••••••••••••••••••••••••••••••••••

About the VISTA-128BPEN

The VISTA-128BPEN is an 8-partition, UL Listed control panel with the following features:

• Supports hardwired, polling loop, and wireless zones

• Supervision of bells, keypads, RF receivers, and output devices

• Scheduling capabilities (allows certain operations to be automated

Scheduling is currently not approved for ULC applications.

ULC

• The capability to link up to eight control panels using Panel Linking Modules

The VISTA-128BPEN can interface with the following devices:

• An alpha numeric paging device (VA8201)

• SYMPHONY (AUI)

• Panel Link Module (VA8200)

• Voice Keypad (6160V)

• An ECP Communicator that can send Contact ID messages

• An access control system by using either the ADEMCO PassPoint system (via the VISTA Gateway Module) or a

VistaKey module (via the polling loop)

UL

The access control function is not Listed for use with the VISTA-128BPEN Control Panel in a UL installation.

The system supports either the VistaKey or the VISTA Gateway Module, not both.

Features

Hardwire and Optional Expansion Zones

• Provides nine hardwire zones.

• Supports up to 16 2-wire smoke detectors on zone 1.

• Automatically resets 4-wire smoke detectors using the J7 output when a code + off is entered.

• Triggers the built-in sounders on other hardwired smoke detectors if one smoke detector annunciates an alarm. This

feature requires a 4204 Relay Module.

• Provides tamper supervision on the hardwire zones.

• Supports up to 50 2-wire latching glassbreak detectors on zone 8.

• Supports up to 119 additional expansion zones using a built-in polling (multiplex) loop.

• Supports up to 127 wireless zones (fewer if using hardwire and/or polling loop zones).

The 5881ENHC RF Receiver, 5869 Holdup Switch Transmitter and 5817CB Wireless Commercial Household

U

• Can program burglary zones as silent in the alarm condition (alarm output is silent and the keypad does not display

• Provides three keypad panic keys: 1 + ✴ (A), ✴ + # (B), and 3 + # (C).

Transmitter are listed for UL Commercial Burglary applications. All other RF receivers and transmitters are not listed

L

for UL Commercial Burglary applications.

or sound the alarm).

1-1

Vista-128BPEN Installation and Setup Guide

• Full Status (Remote Interactive Service)

Peripherals Devices

• Supports up to 31 addressable devices, (keypads, RF receivers, relay modules, etc.).

• Supervises devices (keypads, RF receivers, and relay modules) and individual relays (up to 32), as well as system

zones (RF receivers and keypad panics).

• Provides 96 outputs using 4204 and 4204CF Relay Modules, Fire System Annunciators (FSA-8, FSA-24), V-Plex

Relay Modules and X-10 devices can activate outputs in response to system events (alarm condition), at a specific

time of day, at random times, and manually using the #70 Relay Command Mode.

• Supports the Honeywell 4286 VIP Module, which allows access to the system from either a remote location or on the

premises

U

• Supports the ADEMCO 4146 Keyswitch on any one of the system's eight partitions.

The VIP Module is not Listed for use with the VISTA-128BPEN Control Panel in a UL installation.

L

Arming/Disarming and Bypassing

• Can arm the system with zones faulted (Vent Zone). These zones are automatically bypassed and can be

programmed to automatically unbypass when the zone restores.

• Can arm with entry/exit and interior type zones faulted (Arm w/Fault). These zones must be restored before the exit

delay expires, otherwise an alarm is generated.

U

• Provides global arming capability (ability to arm all partitions the user code has access to in one command).

• Can Quick Exit an armed premises without having to disarm and then rearm the system.

U

• Can be armed in one of three STAY modes or Instant modes, automatically bypassing specific burglary zones

• Can automatically bypass specific zones if no one exits the premises after arming (Auto-STAY). Auto-STAY will not

• Can bypass a group of zones with one set of keystrokes.

• Supports Exit Error Logic, whereby the system can tell the difference between a regular alarm and an alarm caused

• Supports Recent Close report, which is designed to notify the central station that an alarm has occurred within 2

• Vent zones cannot be used in UL installations.

L

• You must disable the Force Arm option (used in conjunction with the Arm w/Fault option), in UL installations.

Quick Exit is not permitted for use with the VISTA-128BPEN Control Panel in a UL installation.

L

regardless of the zone response type.

occur if the system is armed via an RF transmitter, VIP module, scheduling, access control, keyswitch, RS232

automation or downloading.

by leaving an entry/exit door open. If the system is not subsequently disarmed, faulted E/E zone(s) and/or interior

zones are bypassed and the system arms.

minutes after the exit delay has expired.

Partitioning and Panel Linking

• Can control eight separate areas independently, each functioning as if it had its own separate control.

• Provides a Common Lobby partition, which can be programmed to arm automatically when the last partition is

armed, and to disarm when the first partition is disarmed.

• Provides a Master partition (9), used for the purpose of viewing the status of all partitions at the same time.

• Can display fire, burglary, panic and trouble conditions at all other partitions’ keypads (selectable option).

• Can “link” together up to eight control panels. This allows users to access and control from a keypad another control

panel.

Scheduling

• Can automate system functions, such as arming, disarming, and activation of outputs (e.g., lights).

1-2

Section 1 - General Description

• Provides access schedules (for limiting system access to users by time).

• Provides an End User Output Programming Mode, allowing the user to control outputs.

Access Control

• Supports up to 8 VistaKey modules (8 access points) which are used for access control. It is a single-door access

control module.

• Support up to 250 access cards.

• Supports ADEMCO PassPoint system via one VISTA Gateway Module (VGM), for a fully integrated access control

system.

• Can store access control events in the event log.

System Communication

• Supports ADEMCO Contact ID; ADEMCO High Speed; ADEMCO Express; and 3+1, 4+1, and 4+2 ADEMCO and

Sescoa/Radionics Low-Speed formats.

The system is shipped defaulted for Contact ID communication. It is the only format capable of uniquely reporting all

128 zones, as well as openings and closings for all 150 users. This requires central stations to be equipped with the

MX8000 receiver to fully support all new VISTA-128BPEN report codes. If you need to update your MX8000

receiver, contact your distributor.

• Supports Dynamic Signaling feature, which prevents redundant signals being sent to the central station when both

the built-in dialer and Communicators are used.

• Provides an Audio Alarm Verification (AAV) option that permits voice dialog between an operator at the central

station and a person at the premises. An AAV unit, such as Honeywell UVS, is required.

• Provides the Dialer Queue Report in the event of a loss of communications between the dialer and the central

station, i.e. telco loss. The total events that will be queued up are 128 (91 Burg + 37 Life Safety). A Dialer Queue

Overflow report (E354) will be sent if the report queue goes beyond its limits. Note that: Life Safety includes

Fire, CO, 24 HR Silent/Audible/Auxiliary, and Duress. Life Safety events may go beyond 37 (up to 128) if

there are no Burg events in the queue.

Downloading

• Supports upload and download capability.

• Can perform unattended downloading (no one at the downloading computer).

• Provides an Installer Unattended Program Mode. This allows the installer to program the download phone number,

subscriber number, and primary central station receiver phone number without entering the normal program mode.

• Can periodically and automatically perform a scheduled download.

• Panels can be downloaded via the following 7845GSM, 7845i-GSM or 7847i using Compass revision 1.5.8 or above.

U

• Can download access control cardholder information.

Unattended and Scheduled Downloading are not UL Listed features.

L

Event Log

• Provides an event log (history log) that can store up to 512 events.

Can print the event log on a serial printer via the RS232 (J8) header and a 4100SM.

•

• Can view the event log on an alpha keypad or AUI.

Additional Features

• Provides up to 60 installer-defined, custom words that can be used for zone descriptors.

• Provides 32 keypad macro commands (each macro is a series of keypad commands of up to 32 keystrokes) using the

A, B, C, and D keys by partition.

• Provides cross-zone capability, which helps prevent false alarms by preventing a zone from going into alarm unless

its cross-zone is also faulted within a 5-minute period.

• Contains a built-in User’s Manual, which provides the end user with a brief explanation of the function of a key

when the user presses any of the function keys on the keypad for 5 seconds.

1-3

Vista-128BPEN Installation and Setup Guide

• Provides trigger outputs, which may interface with Communicator equipment or other devices such as keyswitch

LEDs, or printer.

• Provides an RS232 input for serial data. This is useful for interfacing the system with Automation software.

Automation software cannot be used if a serial printer is used on the system.

At least one 2-line alpha keypad (6160) must be connected to the system for programming (if you are using keypad

programming), and must remain connected to the system in order to allow the primary user to program additional

user codes into the system at a later time.

1-4

SECTION 2

Partitioning and Panel Linking

•••••••••••••••••••••••••••••••••••••••••••••••••

Theory of Partitioning

This system provides the ability to arm and disarm up

to eight different areas, as if each had its own control.

These areas are called partitions. A Partitioned system

allows the user to disarm certain areas while leaving

other areas armed, or to limit access to certain areas to

specific individuals. Each system user can be assigned

to operate any or all partitions, and can be given a

different authority level in each.

Before anything can be assigned to those partitions, you

must first determine how many partitions (1-8) are

required. Following are some facts you need to know

about partitioning.

Keypads

Each keypad must be given a unique "address" and be

assigned to one partition. It can also be assigned to

Partition 9 if Master keypad operation is desired. (See

“Master Keypad Setup and Operation” later in this

section.)

Setting-Up a Partitioned System

The basic steps to setting up a partitioned system are

described below. If you need more information on how

to program the options, see SECTION 4: Programming.

1. Determine how many partitions the system will

consist of (programmed in field 2*00).

2. Assign keypads to partitions (Device Programming

in the #93 Menu Mode).

3. Assign zones to partitions (Zone Programming in

the #93 Menu Mode).

Zones

Each zone must be assigned to one partition. The zones

assigned to a partition will be displayed on that

partition's keypad(s).

Users

Each user may be given access to one or more

partitions. If a user is to operate more than one

partition and would like to arm/disarm all or some of

those partitions with a single command, the user must

be enabled for Global Arming for those partitions (when

entering user codes).

A user with access to more than one partition (multiple

access) can "log on" to one partition from another

partition's keypad, provided that program field 2*18:

Enable GOTO is enabled for each partition he/she

wants to log on to from another.

A partition can be selected as a "common lobby"

partition, and other partitions can affect this partition

by causing arming/disarming of this partition to be

automated (see “Common Lobby Logic” later in this

section).

4. Confirm zones are displayed at the keypad(s)

assigned to those partitions.

5. Assign users to partitions.

6. Enable the GOTO feature (program field 2*18) for

each partition a multiple-access user can log on to

(alpha keypad only).

7. Program partition-specific fields (see the Data Field

Descriptions section).

Common Lobby Logic

When an installation consists of a partition shared by

users of other partitions in a building, that shared

partition may be assigned as the "common lobby"

partition for the system (program field 1*17). An

example of this might be in a medical building where

there are two doctors’ offices and a common entrance

area (see example that follows explanation).

The Common Lobby feature employs logic for automatic

arming and disarming of the common lobby. Two

programming fields determine the way the common

lobby will react relative to the status of other partitions.

They are: 1*18 Affects Lobby and 1*19 Arms Lobby.

1*18 Affects Lobby (must be programmed by

partition)

Setting this field to 1 for a specific partition causes that

partition to affect the operation of the common lobby as

follows:

a. When the first partition that affects the lobby is

disarmed, the lobby is automatically disarmed.

2-1

Vista-128BPEN Installation and Setup Guide

b. The common lobby cannot be armed unless every

partition selected to affect the lobby is armed.

1*19 Arms Lobby (must be programmed by

partition)

Setting this field to 1 for a specific partition causes that

partition to affect the operation of the common lobby as

follows:

a. The common lobby cannot be armed unless every

partition selected to affect the lobby is armed.

b. Arming a partition that is programmed to arm the

lobby causes the system to automatically attempt

to arm the lobby. If any faults exist in the lobby

partition, or if another partition that affects the

lobby is disarmed, the lobby cannot be armed, and

the message "UNABLE TO ARM LOBBY

PARTITION" is displayed.

You cannot select a partition to "arm" the lobby

unless it has first been selected to "affect" the

lobby. Do not enable field 1*19 without enabling

field 1*18.

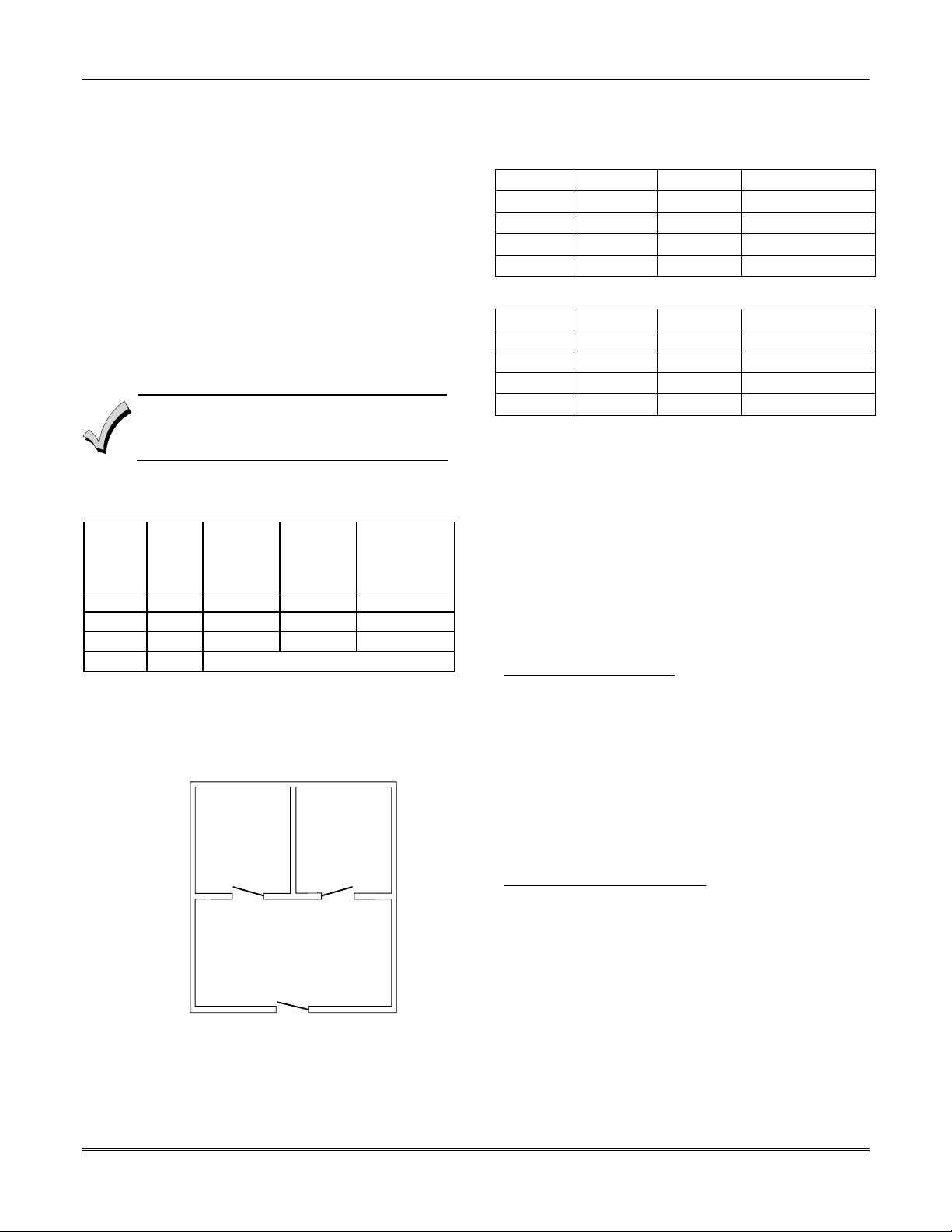

The following chart sums up how the common lobby

partition will operate.

1*18

Affects

Lobby

1*19

Arms

Lobby

0 0 NO NO YES

1 0 YES NO NO

1 1 YES YES NO

0 1 ---ENTRY NOT ALLOWED---

Disarms

when

partition

disarms?

Attempts

to arm

when

partition

arms?

Can be armed

if other

partitions

disarmed?

Example

Here is an example of how the lobby would react in a

typical setup.

OFFICE 1 OFFICE 2

COMMON LOBBY

MAIN ENTRANCE

V128BP-001-V0

User #1 has access to Office #1 and the Common Lobby.

User #2 has access to Office #2 and the Common Lobby.

Office #1 is set up to affect the Common Lobby, but not

arm it.

Office #2 is set up to affect and arm the Common Lobby.

NOTE: In the tables below, the notations in

parentheses ( ) indicate the current status of the other

partition when the user takes action.

Sequence #1:

Office 1 Office 2 Lobby Action

User #1:

User #2:

User #1:

User #2:

Disarms (Armed) Disarms

(Disarmed) Disarms No Change

Arms (Disarmed) No change

(Armed) Arms Arms

Sequence #2:

User #2:

User #1:

User #2:

User #1:

Office 1 Office 2 Lobby Action

(Armed) Disarms Disarms

Disarms (Disarmed) (No change)

(Disarmed) Arms No Change

Arms (Armed) No Change

Notice that in sequence #1, because Office #2 was the

last to arm, the lobby also armed (Office #2 is

programmed to affect and arm the lobby). In sequence

#2, the lobby could not arm when Office #2 armed,

because Office #1, which affects the lobby, was still

disarmed.

When Office #1 armed, the lobby still did not arm

because Office #1 was not programmed to arm the

lobby. User #1 would have to arm the lobby manually.

Therefore, you would want to program a partition to

affect and arm the lobby if the users of that partition

are expected to be the last to leave the building.

How User Access Codes Affect the Common Lobby

Codes with Global Arming

If a code is given "global arming" when it is defined (see

SECTION 9: User Access Codes), the keypad prompts

the user to select the partitions they want to arm. Only

the partitions the user has access to are displayed. This

allows the user to choose the partitions to be armed or

disarmed, and so eliminates the "automatic" operation

of the lobby. Keep in mind, however, that if a user

attempts to arm all, and another "affecting" partition is

disarmed, the user cannot arm the lobby, and the

message "UNABLE TO ARM LOBBY PARTITION" is

displayed.

Codes with Non-Global Arming

If a user arms with a non-global code, the lobby

partition operation is automatic, as described by fields

1*18 and 1*19.

Other Methods of Arming/Disarming

Common Lobby logic remains active when arming or

disarming a partition that affects and/or arms the

common lobby in one of the following manners:

• Quick-Arm

• Keyswitch

• Wireless Button

• Wireless Keypad

2-2

Section 2 – Partitioning and Panel Linking

Arming/Disarming Remotely

If a user arms or disarms remotely (through Compass

downloading software), the lobby does not automatically

follow another partition that is programmed to arm or

disarm the lobby. The lobby must be armed separately,

after arming all affecting partitions first.

Auto-Arming/Disarming

If scheduling is used to automatically arm and/or

disarm partitions, the common lobby partition does not

automatically follow another partition that is

programmed to arm or disarm the lobby.

Master Keypad Setup and Operation

Although this system has eight actual partitions, it

provides an extra partition strictly for the purpose of

assigning keypads as Master keypads for the system.

Assigning any keypad to Partition 9 in Device

Programming in the #93 Menu Mode makes that

keypad a Master keypad. A Master keypad reflects the

status of the entire system (Partitions 1-8) on its

display at one time. This is useful because it eliminates

the need for a building security officer to have to log on

to various partitions from one partition's keypad to find

out where an alarm has occurred.

The following is a typical display:

S Y S T E M 1 2 3 4 5 6 7 8

S T A T U S R R N N A ✴ B

Possible status indications include:

A = Armed Away S = Armed Stay M = Armed Maximum

C = Comm Fail I = Armed Instant R = Ready

N = Not Ready B = Bypassed/Ready

T = Trouble F = Fire Alarm P = AC Power Failure

L = Low System Battery

To obtain more information regarding a particular

partition, enter [✴] + Partition No. (e.g., [✴] + [4]). This

allows viewing only of that partition. In order to affect

that partition, the user must use a code that has access

to that partition.

Also, in order for a user of any partition to log on to

Partition 9 to view the status of all partitions, that user

must have access to all partitions. Otherwise, access is

denied.

The following is displayed for a fault condition on Zone

2 (Loading Dock Window) on Partition 1 (Warehouse)

when a user logs on from a keypad on Partition 9:

WHSE DISARMED

HIT ✴ FOR FAULTS

✴ = Alarm

The lobby must be included as a partition to be

armed/disarmed and must be scheduled as the last

partition armed.

If you are using auto-arming, make sure that

the Auto-Arm Delay and Auto-Arm Warning

periods, for the lobby partition, (fields 2*05 and

2*06) combined are longer than that of any

other partition that affects the lobby. This

causes the lobby to arm last.

Pressing [✴] causes the following display to appear at

Partition 1's keypad(s):

FAULT 002 LOADING

DOCK WINDOW

Additional zone faults are displayed one at a time. To

display a new partition's status, press [✴] + Partition

No.

The Armed LED on a Master keypad is lit only if all

partitions have been armed successfully. The Ready

LED is lit only if all partitions are "ready to arm."

Neither LED is lit if only some partitions are armed

and/or only some partitions are ready.

Press [✴] + [0] or [✴] + [9] to return to the master

partition. Otherwise, if no keys are pressed for 2

minutes, the system automatically returns to the

master partition

The sounder on a Master keypad reflects the sound of

the most critical condition on all of the partitions. The

priority of the sounds, from most to least critical, is as

follows:

1. Pulsing fire alarm sounds

2. Steady burglar alarm sounds

3. Trouble sounds (rapid beeping)

Silence the sounder by pressing any key on the Master

keypad or a keypad on the partition where the condition

exists.

A Master keypad uses the same panics as

Partition 1. Master keypad panics are sent to

Partition 1, and will activate on Partition 1.

Therefore, panics must be programmed for

Partition 1.

Panel Linking

Up to eight VISTA-128BPEN control panels may be

networked, enabling a user to control the features of all

control panels from a single location. The panel linking

bus supports an end-to-end network length of up to

4,000 feet. This makes it ideal for multi-building

environments (e.g., shopping mall, college campus, etc.).

U

Panel Linking is not permitted in UL

L

installations.

Panel linking requires a VA8200 Panel Link Module

(PLM) on each VISTA-128BPEN. Users can link (access

2-3

Vista-128BPEN Installation and Setup Guide

other control panels) in any of three different modes:

Single-Partition, Single-Panel Mode; Multi-Partition,

Multi-Panel Mode; Multi-Panel View Mode. These

modes are described later in this section.

Each PLM connects to the ECP bus on the control panel

and communicates to each PLM via an RS-485 bus (3wire twisted cable run) with a maximum wire-run of

4000 feet end-to-end.

• Users 001-050 are the only users that can

perform panel linking and are automatically

assigned panel linking access when added

to the system.

• An alpha keypad must be used for panel

linking.

• The system may take up to 7 seconds to

respond to a command when in a panel

linking mode

NOTE: A user cannot access partitions or panels that

they have not been assigned to.

Panel Link Module Supervision

The Panel Link Module can be supervised for its

connection to the control panel. The module’s

supervisory zone is zone 8xx, where “xx” = the ECP

address of the PLM. You must program that zone with

response type 05 (Day/Night) in Zone Programming in

the #93 Menu Mode (refer to the Programming Guide

for detailed programming instructions). If you want to

report the supervisory failure to the central station

and/or to a paging service, the appropriate reporting

parameters for that zone must be programmed.

If you want the supervisory failure of PLM(s) on other

linked control panels to display on this control panel,

they must be programmed into Zone Programming in

the #93 Menu Mode with response type 12 in this

control panel (refer to the Programming Guide for

detailed programming instructions). The panel ID

number for each module must match the panel ID

number programmed in Device Programming of its

“host” VISTA-128BPEN.

How to Use Panel Linking

Panel Linking can be used in any of three different

modes:

• Single-Partition, Single-Panel − displays status of a

partition on a remote control panel and allows

control of that remote control panel.

• Multi-Partition, Multi-Panel Mode − displays

status and allows arming/disarming of multiple

partitions at once on a remote control panel.

• Multi-Panel View Mode − displays status and

allows arming/disarming of multiple remote control

panels at a time.

NOTE: A user will not be able to access or view

partitions or panels that they have not been assigned

to.

2-4

Section 2 – Partitioning and Panel Linking

Single-Partition Single-Panel Mode

To access the Single-Partition, Single Panel mode, perform the following steps:

Step Action

1

2

3 Enter the partition number of the panel. The keypad displays “AWAITING PANEL LINK.” After a few

4

Multi-Partition Multi-Panel Mode

To perform a function in the Multi-Partition, Multi Panel mode, follow the steps below:

Step Action

1

2 The following functions can be performed:

Enter User Code (for users 001-050) + [#] + [86].

Enter the panel ID number (01-08) of the panel you want to link to.

seconds, the keypad displays the status of the partition along with the panel ID number and partition

number flashing in the upper right-hand corner. The user now has full control of the remote control panel.

All functions can be performed except the following:

• Those limited by the user’s authority level.

• The user cannot enter Installer Program mode.

• The user cannot execute another panel linking mode.

NOTE: To execute another panel linking mode or to access a different remote panel, the user must first exit

this mode (return to the original control panel).

To exit, enter the User Code (for users 001-050) + [#] + [85]. After a few seconds, the keypad displays the

status of the original partition for the keypad.

Enter User Code (for users 001-050) + [#] + [88].

The keypad displays the following:

PANELnn 1 2 3 4 5 6 7 8

STATUS x x x x x x x x

where “nn” = panel ID number (01-08), “12345678” are the partition numbers and “xxxxxxxx” is the status of

each partition of that panel. Status indications include:

A = Armed Away S = Armed Stay M = Armed Maximum

I = Armed Instant R = Ready N = Not Ready

B = Bypassed/Ready ✴ = Alarm T = Trouble

F = Fire Alarm P = AC Power Failure L = Low System Battery

C = Comm Fail

NOTES: See table later in this section for priority of displays.

A “•” under a partition number indicates the user does NOT have access to that partition.

Press [1] to attempt to disarm all partitions.

Press [2] to attempt to arm AWAY all partitions.

Press [3] to attempt to arm STAY all partitions.

Press [4] to attempt to arm MAXIMUM all partitions.

Press [7] to attempt to arm INSTANT all partitions.

Press [✴] to read the status of the next panel.

Press [#] key to read the status of the previous panel.

Press [0] to exit mode. After a few seconds, the keypad displays the status of the original partition of the

original panel for the keypad. Also, this mode will end in approximately 2 minutes if no keys are pressed.

NOTES: When performing any of the arming commands, if there are faults in any of the partitions, none

of the partitions will arm. These faults must be corrected or bypassed before attempting to arm.

When performing either a STAY or INSTANT arm command the system always arms in mode 1.

The user cannot execute another panel linking mode. To execute another panel linking mode or

to access a different remote panel, the user must first exit this mode (return to the original

control panel).

2-5

Vista-128BPEN Installation and Setup Guide

Multi-Panel View Mode

To perform a function in the Multi-Panel View mode, follow the steps below:

Step Action

1

2 The following functions can be performed::

Enter User Code (for users 001-050) + [#] + [87].

The keypad displays the following typical display:

ALLPANEL 1 2 3 4 5 6 7 8

STATUS x x x x x x x x

where “12345678” are the panel ID numbers and “xxxxxxxx” is the overall status of each panel. Status

indications include:

A = Armed Away S = Armed Stay M = Armed Maximum

I = Armed Instant R = Ready N = Not Ready

B = Bypassed/Ready ✴ = Alarm T = Trouble

F = Fire Alarm P = AC Power Failure L = Low System Battery

C = Comm Fail

NOTE: See table later in this section for priority of displays.

Press [1] to attempt to disarm all partitions on all panels.

Press [2] to attempt to arm AWAY all partitions on all panels.

Press [3] to attempt to arm STAY all partitions on all panels.

Press [4] to attempt to arm MAXIMUM all partitions.

Press [7] to attempt to arm INSTANT all partitions.

Press [0] to exit mode. After a few seconds, the keypad displays the status of the original partition of the

original panel for the keypad. Also, this mode will end in approximately 2 minutes if no keys are pressed.

NOTES:

When performing any of the arming commands, if there are faults in any of the partitions of a panel, the

system will not arm that panel, but will arm all the other partitions of the other panels.

When performing either a STAY or INSTANT arm command, the system always arms in mode 1 (see the

VISTA-128BPEN User Guide for a detailed explanation of the STAY and INSTANT arming modes).

The user cannot execute another panel linking mode. In order to perform another panel linking mode or to

access a different remote panel, the user must first exit this mode (return to the original control panel).

Priority of Displays for Multi-Partition and Multi-Panel Modes

This table shows the priority of displays if more than one of these conditions exists at the same time.

Priority Description Display Priority Description Display

1 Fire Alarm

2 All Other Alarms

3 AC Loss

4 Comm Fail

5 System Low Battery

6 Trouble

7 Bypass

F

✴

P

C

L

T

B

8 Not Ready

9 Ready

10 Armed STAY

11 Armed AWAY

12 Armed INSTANT

13 Armed MAXIMUM

2-6

N

R

S

A

I

M

SECTION 3

Installing the Control

•••••••••••••••••••••••••••••••••••••••••••••••••

This section describes the procedures for mounting and wiring the control panel and all the peripheral devices.

Mounting the Control Cabinet

To mount the control cabinet, perform the following steps:

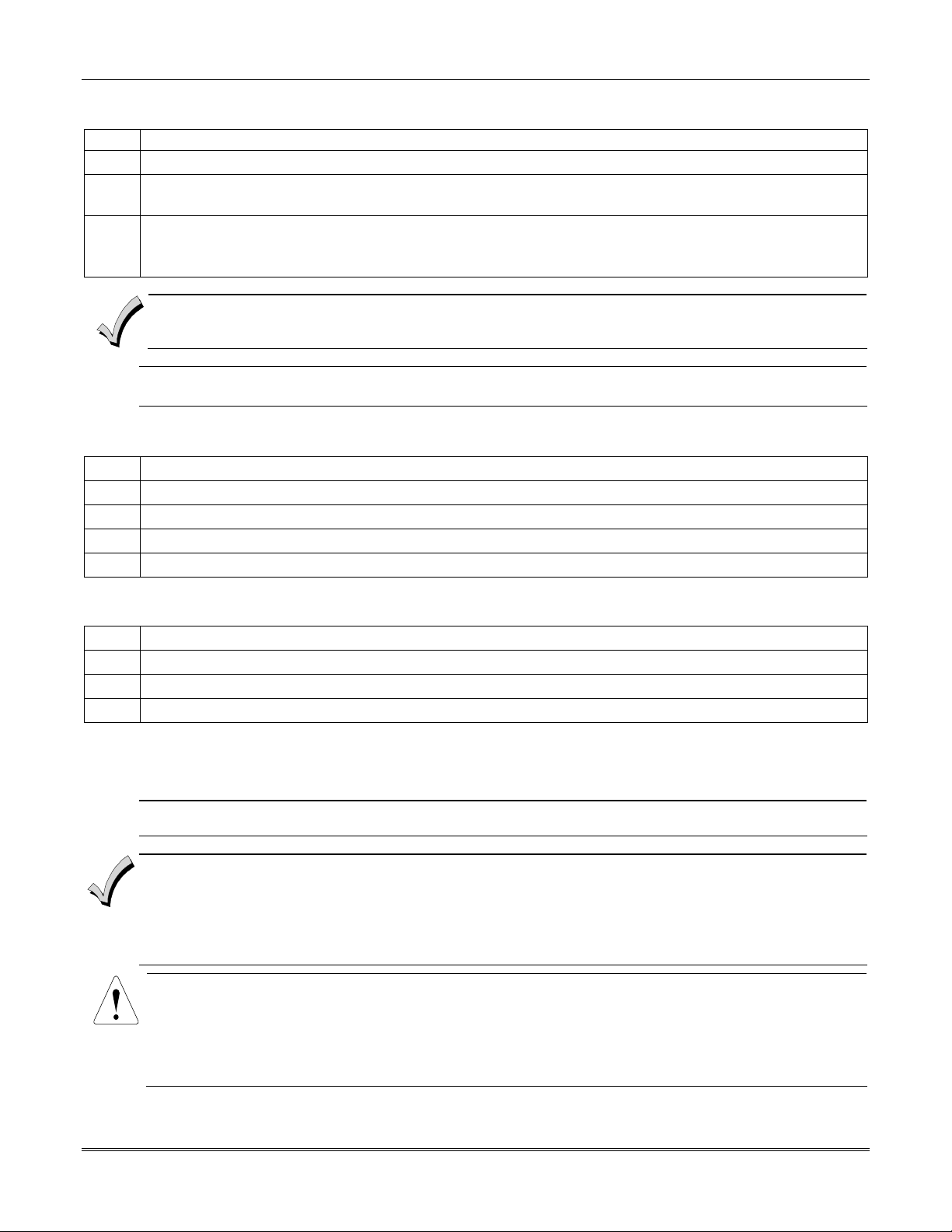

Step Action

1 Before mounting the circuit board, remove the metal knockouts for the wiring entry that you will be using.

DO NOT ATTEMPT TO REMOVE THE KNOCKOUTS AFTER THE CIRCUIT BOARD HAS BEEN

INSTALLED.

2 Using fasteners or anchors (not supplied), mount the control cabinet to a sturdy wall in a clean, dry area

that is not readily accessible to the general public. The back of the cabinet has 4 holes for this purpose.

U

To provide certificated burglary service for UL installations, refer to the special requirements and

Cabinet Attack Resistance Considerations

L

ATTACK RESISTANCE, use the cabinet included in the VISTA-ULKT kit.

to follow. For UL Commercial Burglary installations that require

Figure 3-2

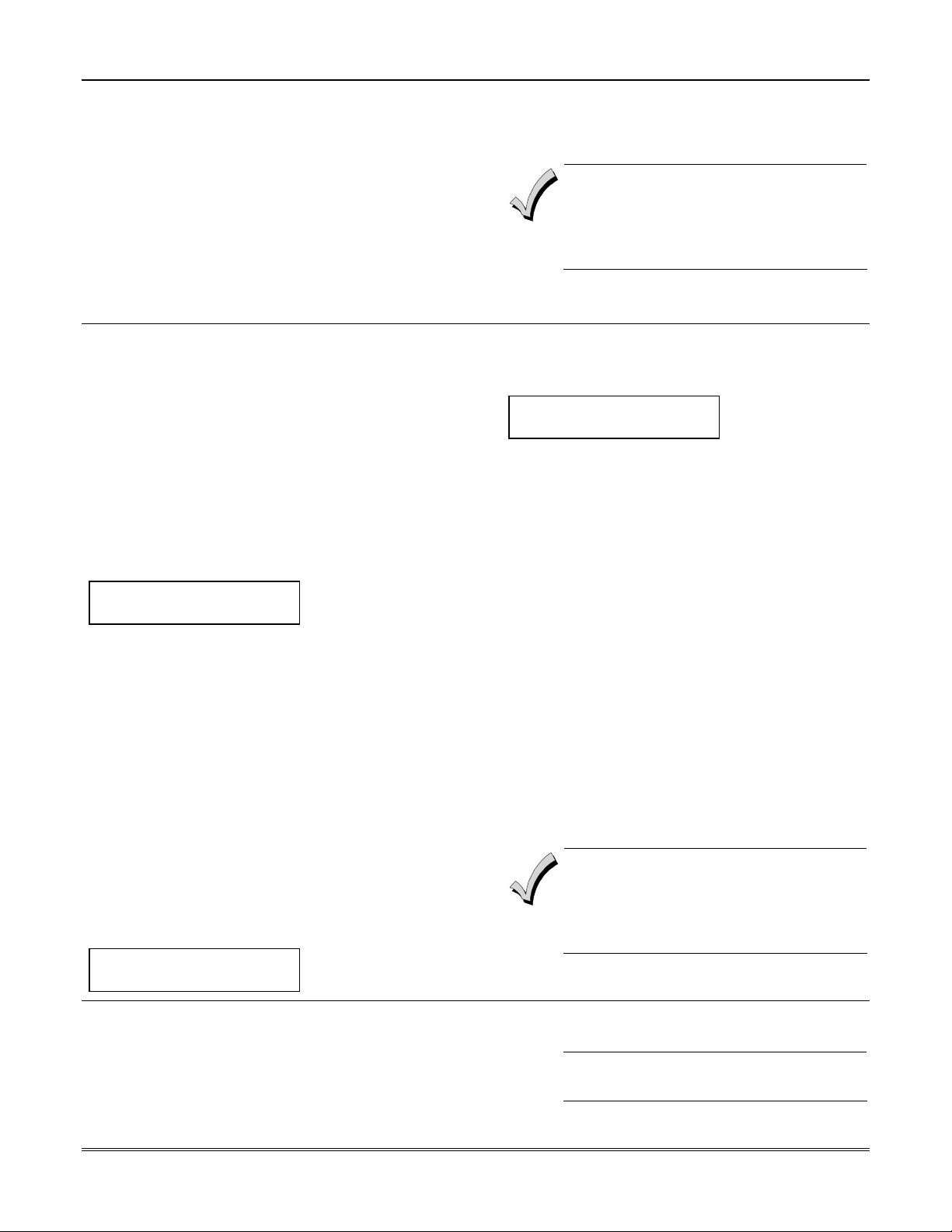

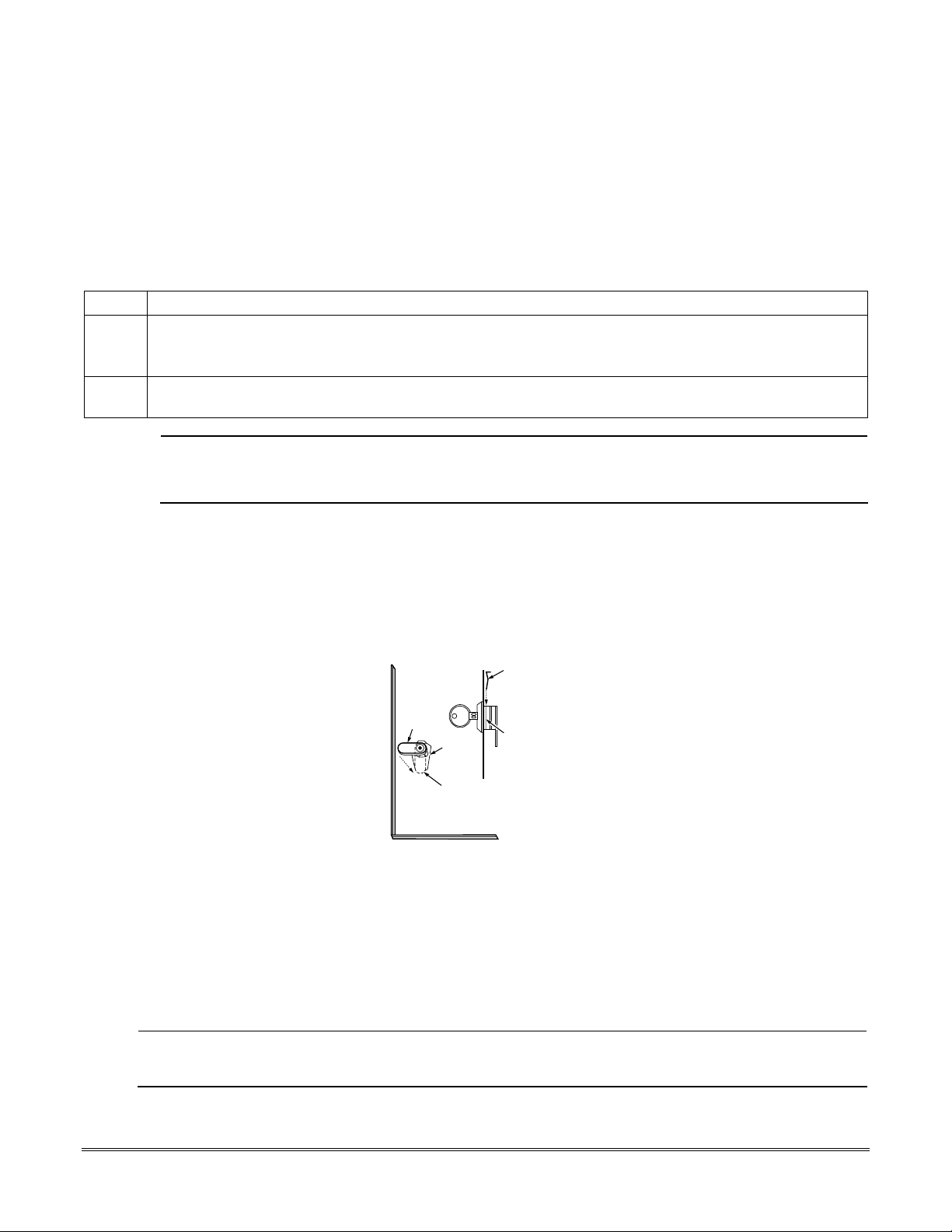

Installing the Cabinet Lock

1. Remove cabinet door, then remove the lock knockout from the door. Insert the key into the lock.

2. Position the lock in the hole (Figure 3-1), making certain that the latch will make contact with the latch bracket

when the door is closed.

3.

When correctly positioned, insert supplied lock clip on the inside of the cabinet into the slots on the

lock cylinder. Use ADEMCO Lock # N6277V1 and Lock Clip # P3422-2 (supplied).

LOCKED

RETAINER

CLIP

UNLOCKED

CABINET DOOR BOTTOM

Figure 3-1: Installing the Lock

RETAINER CLIP

(NOTE POSITION)

RETAINER

SLOTS

cab_lock_clip-001-V0

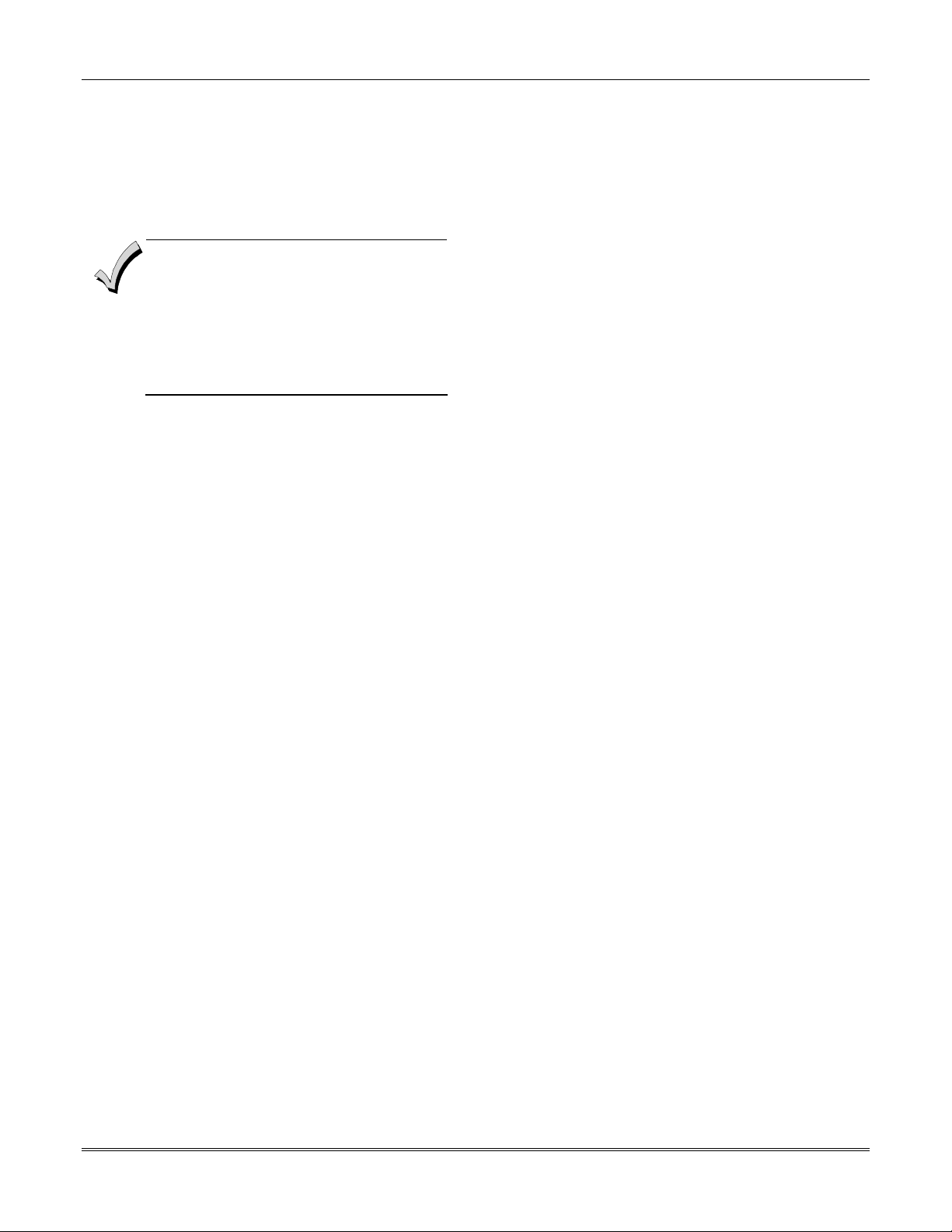

Mercantile Premises Listing Guidelines

• The panel door must be supervised. Mount the clip-on tamper switch (supplied) to the cabinet's right side wall as

shown in the diagram below, and wire it to one of the hardwire zones.

• Use a bell with a tamper-protected housing such as the ADEMCO AB12M. The bell housing's tamper switch and

inner tamper linings must also be wired to the hardwire zone.

• Assign the tampers’ hardwire zone to a burglary partition. Program the hardwire zone for day trouble/night alarm

(zone type 5) when only one burglary partition is used. Program it for 24-hr. audible alarm (zone type 7) when more

than one burglary partition is used.

24-Hour audible alarm (zone types 6 and 7) is not approved for ULC applications.

ULC

• All wiring between the bell and panel must be run in conduit. Remaining wires do not need to be run in conduit.

• All wiring that is not run in conduit must exit from the knockout openings on the bottom or back of the cabinet.

3-1

Vista-128BPEN Installation and Setup Guide

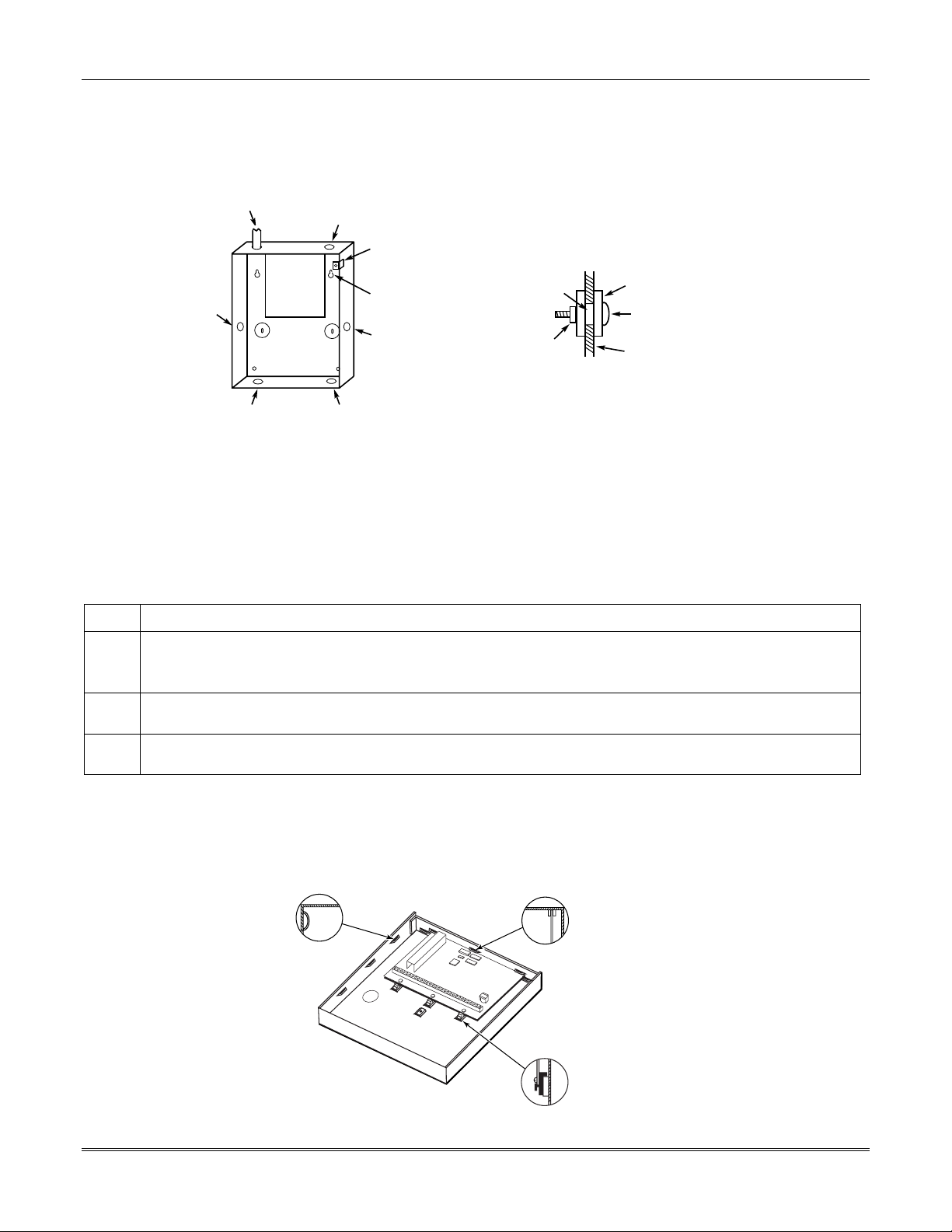

• All unused knockouts must be plugged using the disc plugs and carriage bolts (supplied), as indicated in the

diagram below.

• Fasten the cabinet door to the cabinet backbox using the 18 one-inch-long Phillips-head screws (supplied) after all

wiring, programming, and checkout procedures have been completed.

(Shows typical local Grade A listing installation)

RUN BELL WIRES

PLUG THIS

KNOCKOUT

IN CONDUIT

PC

BOARD

PLUG THIS

KNOCKOUT

CLIP-ON DOOR

TAMPER SWITCH

CABINET

MOUNTING

HOLE

(4 PLACES)

PLUG THIS

KNOCKOUT

TO PLUG AN UNUSED KNOCKOUT OPENING,

REMOVE KNOCKOUT AND INSTALL A PAIR OF

DISC PLUGS AND A CARRIAGE BOLT AS SHOWN.

DISC PLUGS (DIMPLES IN DISC

KNOCKOUT

OPENING

HEX NUT AND

WASHER

PLUG SHOULD REGISTER INSIDE

KNOCKOUT OPENING)

CARRIAGE BOLT

CABINET SIDE WALL

(OUTSIDE)

PLUG THIS

KNOCKOUT

RUN ALL REMAINING

WIRE THROUGH HERE

cabattack-001-V0

Figure 3-2: Cabinet Attack Resistance Considerations

• Mercantile Safe and Vault Listing GuidelinesFollow the guidelines given above for Mercantile Premises listing.

• Mount a shock sensor such as Sentrol No. 5402 to the control's backbox. Follow the manufacturer's instructions for

proper sensor mounting. This sensor also must be wired to a hardwire zone.

• For safe and vault applications, a UL Listed contact must be used inside the cabinet through one of the knockouts

for pry-off tamper purposes. This sensor also must be wired to a hardwire zone.

Installing the Control's Circuit Board

To install the circuit board in the cabinet, perform the following steps:

Step Action

1

2

3

NOTES:

• Make certain that the mounting screws are tight. This ensures that there is a good ground connection between the

• Dress field wiring away from the microprocessor (center) section of the PC board. Use the loops on the left and right

Hang the three mounting clips on the raised cabinet tabs. Refer to Figure 3-3 (Detail B).

Make sure the clip orientation is exactly as shown in the diagram to avoid damage. This will also avoid

problems with insertion and removal of the PC board.

Insert the top of the circuit board into the slots at the top of the cabinet. Make certain that the board rests in

the slots as indicated (Detail A).

Swing the base of the board into the mounting clips and secure the board to the cabinet with the

accompanying screws.

PC board and the cabinet.

sidewalls of the cabinet for anchoring field wiring using tie wraps (Detail C). These steps are important to minimize

the risk of panel RF interference with television reception.

DETAIL A

SIDE VIEW OF

BOARD INSERTED

INTO SLOTS

DETAIL C

SIDE VIEW

OF SLOTS

+

+

+

3-2

DETAIL B

SIDE VIEW OF SHORT

MOUNTING CLIPS

(TYP.)

Figure 3-3: Mounting the PC Board

hi_end_mnt-PCB

Installing the Control

g

Installing the Keypads

Up to 31 addressable keypads (addresses 00-30) may be used (you may need to use an auxiliary power supply if the

750mA aux. output is exceeded).

NOTE: Refer to the Alpha Vocabulary list found in the #93 Menu Mode in the Programming Guide for list of the words

annunciated by the 6160V.

To wire the keypads, perform the following steps:

Step Action

1

2 Wire keypads to a single wire run or connect individual keypads to separate wire runs. The maximum wire

3 Run field wiring from the control to the keypads (using standard 4-conductor cable of the wire gauge

4 Connect the keypad(s) to terminals 6, 7, 8, and 9 on the control board, as shown in Figure 3-4.

Determine wire gauge by referring to the Wire Run Length/Gauge table below.

Wire Run Length/Gauge Table

Wire Gauge Length

#22 gauge 450 feet

#20 gauge 700 feet

#18 gauge 1100 feet

#16 gauge 1750 feet

run length from the control to a keypad, which is homerun back to the control must not exceed the lengths

listed in the table.

determined in step 1).

• The length of all wire runs combined, regardless of the wire gauge, must not exceed 2000 feet when unshielded

quad conductor cable is used (1000 feet if unshielded cable is run in conduit, which acts a shield, or if shielded

cable is used).

• If more than one keypad is wired to one run, then the above maximum lengths must be divided by the number of

keypads on the run (e.g., the maximum length is 225 feet if two keypads are wired on a #22 gauge run).

RED

6

BLACK

7

GREEN

8

YELLOW

9

CONTROL

TERMINALS

KEYPADS

Figure 3-4: Keypad Connections to Control Panel

Addressing the Keypads

Set each keypad for an individual address (00-30) according to the keypad's instructions. Set an alpha keypad for

address 00 and other keypads for higher addresses (00 and 01 are enabled in the system's default program). Any

keypads set for address 02 and above will appear blank until they are enabled in the system's program. Each keypad

must be set for a different address.

• Do not set any keypads to address 31 (nonaddressable mode). They will interfere with other keypads (as well as

• If an “OC” or “OPEN CIRCUIT” message is present on a keypad, data from the control is not reaching the

The keypads will not operate until they are physically addressed and enabled in the system's

in the

#93 Menu Mode

.

other devices) connected to the keypad terminals.

keypad. Check your wiring.

Device Programmin

3-3

Vista-128BPEN Installation and Setup Guide

Supplementary Power Supply for Additional Keypads

When the control’s auxiliary power load for all devices exceeds 750mA, you can power additional keypads from a

regulated 12VDC power supply (e.g., ADEMCO AD12612 (1.2A)). Use a UL Listed, battery-backed supply for UL

installations.

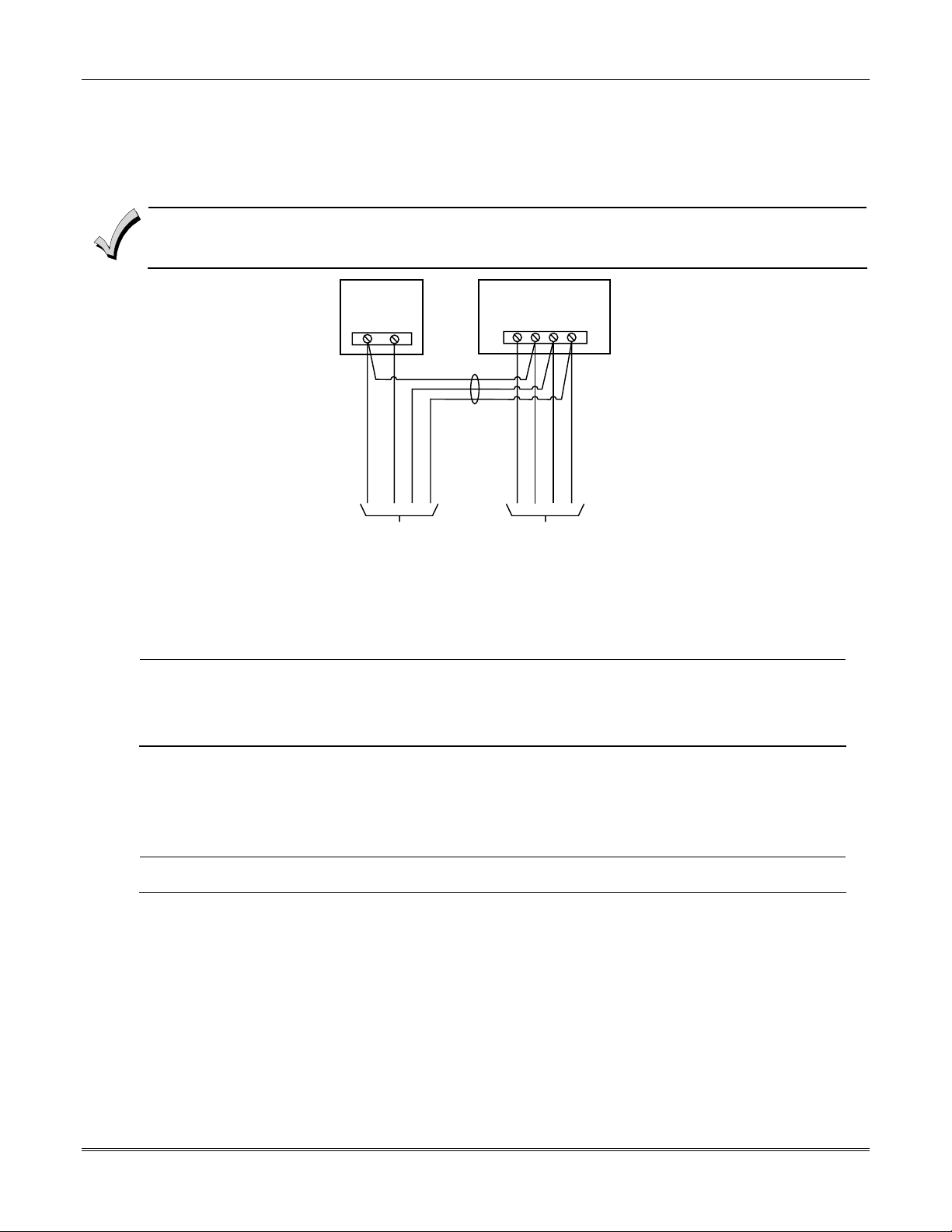

Connect the additional keypads as shown in Figure 3-5, using the keypad wire colors shown. Be sure to observe the

current ratings for the power supply used.

• Make connections directly to the screw terminals as shown in

• Be sure to connect the negative (–) terminal on the power supply unit to terminal 7 (–) on the control.

present).

SUPPLEMENTARY

POWER SUPPLY

+

–

RED WIRE

BLACK WIRE

CONNECTIONS

TERMINALS AS

YELLOW WIRE

GREEN WIRE

CONTROL TERMINAL STRIP

IMPORTANT:

MAKE THESE

DIRECTLY TO

SCREW

SHOWN.

Figure 3-5

AUX. DATA

AUX.

IN

+

–

678 9

BLACK WIRE

RED WIRE

GREEN WIRE

DATA

OUT

YELLOW WIRE

. Make no connection to the blue wire (if

TO

SECONDARY

KEYPAD

TO

MAIN

KEYPAD

pwr_supply-002-V0

Figure 3-5: Using A Supplementary Power Supply

Installing External Sounders

The VISTA-128BPEN provides a bell circuit output for operating fire and burglary alarm notification appliances. The

alarm output is rated as follows: 10VDC – 14VDC, 1.7A max., power-limited.

• For Household Fire and combination Household Fire/Burglary installations, the total current drawn from the

U

L

auxiliary power, polling loop, and alarm output combined must not exceed 750mA.

• For Household Burglary installations, the total current drawn from the alarm output must not exceed 1.7A. A

battery must be installed, as it supplies the current for the combined auxiliary power, polling loop, and alarm

output in excess of 750mA.

The output has the following options:

• Selectable for supervision.

• Selectable for confirmation of arming ding.

• Selectable to chime when entry/exit or perimeter zones are faulted.

• Selectable for timeout of 2-30 minutes.

UL

Burglary bell circuits must be programmed for a timeout of 16 minutes or longer.

UL985 Household Fire or Combination Household Fire/Burglary Installations

For installations that must provide UL Listed protection, the total combined current drawn from the alarm output,

auxiliary power output, and polling loop must not exceed 750mA in order to comply with the battery independence

requirements. If, for example, two System Sensor MH piezo alarm sounders, wired in parallel, are used (24mA total),

then 726mA (750mA – 24mA) is available for auxiliary output and polling loop use.

UL1023 Household Burglary Installations

For Household Burglary installations, the total current drawn from the alarm output must not exceed 1.7A. A battery

must be installed, as the battery supplies current from the combined auxiliary power, polling loop, and alarm output in

excess of 750mA.

Non-UL Installations

For non-UL installations, the total current drawn from this output can be up to 1.7A. A battery must be installed, as the

battery supplies current in excess of 750mA. Up to two 719 sirens can be used wired in parallel.

3-4

Installing the Control

U

This control complies with National Fire Protection Association (NFPA) requirements for temporal pulse sounding

L

of fire notification appliances.

Alarm Output Supervision

When supervision is enabled, the VISTA-128BPEN monitors the alarm output wiring for open and short circuit faults

while the output is inactive. The system provides a trouble indication (Zone 970) when an open occurs; or when a short

occurs between the Bell (+) and Bell (-) terminal wiring, or between the Bell (+) terminal wiring and earth ground.

U

NOTE: When supervising the bell output (zone 970), only one device can be connected to the alarm output

L

(terminals 4 and 5) for UL and Fire installations.

The VISTA-128BPEN indicates the trouble condition regardless of whether the system is armed or disarmed. The zone

displays on the keypads, reports to the event log, and transmits to the central station (if programmed) on Partition 1.

The Contact ID event code is 321, Bell Trouble. The trouble is cleared from the display by entering the user code + OFF.

Wiring the Alarm Output

The wiring of the alarm output depends upon whether you are going to supervise the output or not. Use the appropriate

procedure below for your application.

U

Use only UL Listed sounding devices for UL installations.

L

Compatible Alarm Indicating Devices

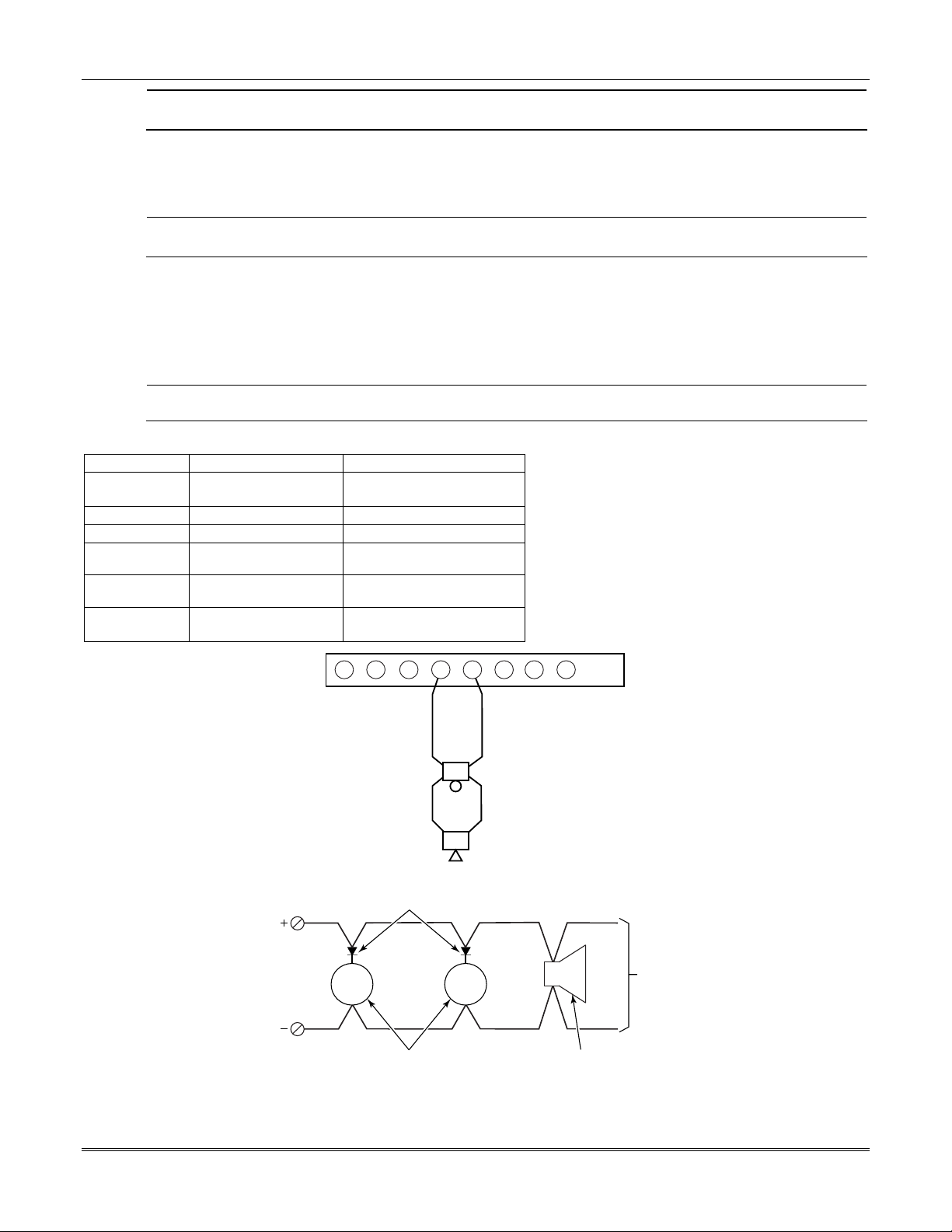

Model Number Device Type Polarizing Diode

719 Compact Outdoor Siren

(not UL Listed)

747 Indoor Siren Yes