Honeywell V8043A1312/U, V8043A1313/U, V8043A1311/U, V8043E1412/U, V8043E1411/U Installation Instructions Manual

...

33-00402EF-01

V8043 Zone Valves

CAUTION

with Press Connection

INSTALLATION INSTRUCTIONS

Model Pipe Size Description

V8043A1311/U DN15 1/2" Zone Valve Pro Press with 18" lead wires

V8043A1312/U DN20 3/4" Zone Valve Pro Press with 18" lead wire

V8043A1313/U DN25 1" Zone Valve Pro Press with 18" lead wires

V8043E1411/U DN15 1/2" Zone Valve Pro Press with 18" lead wires and End Switch

V8043E1412/U DN20 3/4" Zone Valve Pro Press with 18" lead wires and End Switch

V8043E1413/U DN25 1" Zone Valve Pro Press with 18" lead wires and End Switch

V8043F1511/U DN15 1/2" Zone Valve Pro Press with Terminal Block Connections and End Switch

V8043F1512/U DN20 3/4" Zone Valve Pro Press with Terminal Block Connections and End Switch

V8043F1513/U DN25 1" Zone Valve Pro Press with Terminal Block Connections and End Switch

APPLICATION

These valves consist of an actuator motor and valve

assembly for controlling the flow of hot and/or cold

water. The V8043A provides two-position, straightthrough control of supply water. The valves are

designed for use with fan coil and other units

requiring quiet, compact water valves. The V8043E

and V8043F also control supply water for baseboard

radiators and convectors.

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to

follow them could damage the product or cause

a hazardous condition.

2. Check the ratings given in the instructions and

on the product to make sure the product is

suitable for your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

1. Disconnect power supply before connecting

wiring to prevent electrical shock of

equipment damage.

2. Normally it is not necessary to remove the

powerhead from the valve body during

installation. If the valve must be disassembled,

be certain that it is reassembled with the water

flow in the direction of the arrow. Reversal of

the powerhead will result in damage to the

gear train.

3. On 24V systems, never jumper the valve coil

terminals even temporarily. This may burn

out the heat anticipator in the thermostat.

IMPORTANT

Use this valve in hydronic heating systems

which do not contain dissolved oxygen in the

system water. The dissolved oxygen, which is

found in systems that have a frequent source

of m akeu p wa ter, c ause s the rubb er pl ug i nsid e

the valve to deteriorate and eventually fail.

LOCATION

Install the valve in an area with adequate clearance to:

— move the manual opening lever on the side of

the powerhead;

— remove the powerhead cover;

— wire the powerhead;

— replace the powerhead motor.

The valve location should be in an area where the

temperature does not exceed the maximum valve

operating temperature as shown in Specifications.

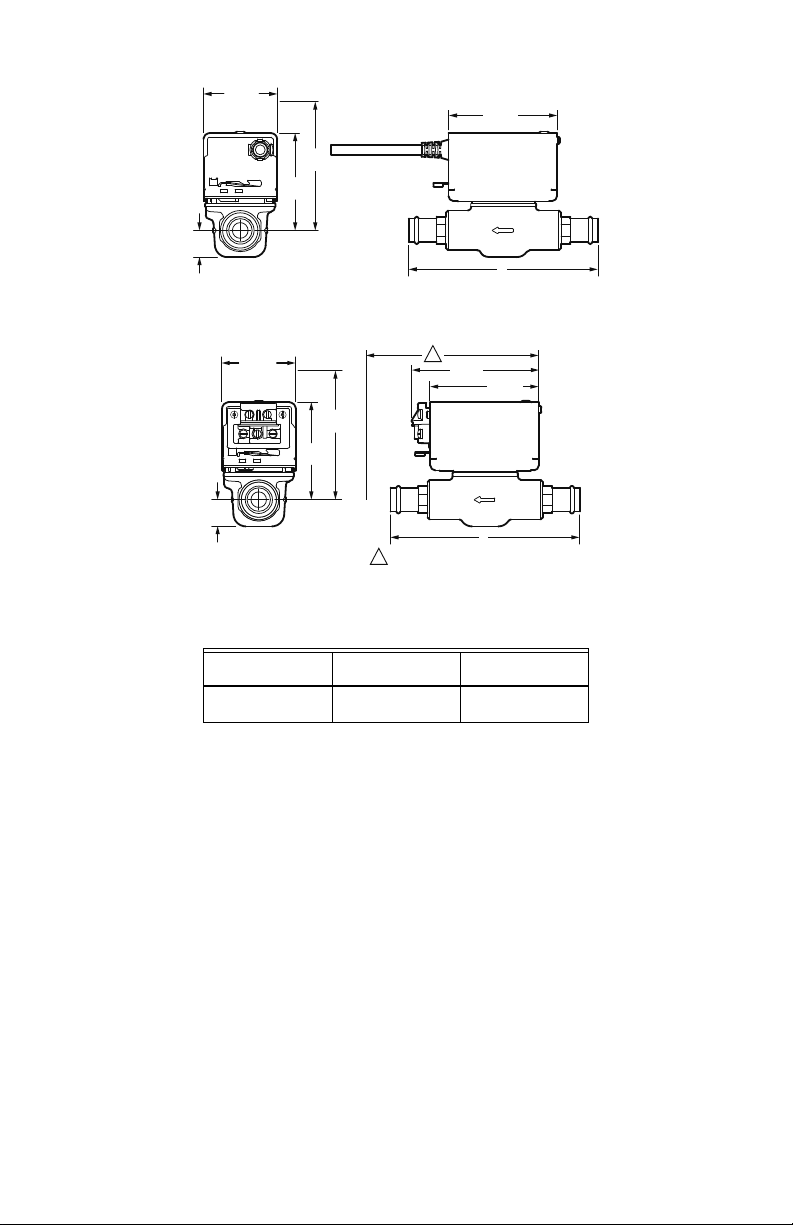

V8043 ZONE VALVES WITH PRESS CONNECTION

M37333

3–7/16

(88)

X

7/8

(23)

2–11/32

(59)

3–3/32

(79)

5–1/4

(133)

Fig. 1. Dimensions (V8043A, V8043E). Measurements in inches (mm). See Table 1.

2–11/32

(59)

END SWITCH

TH TR

TH TR

7/8

(23)

3–3/32

(79)

5–1/4

(133)

Fig. 2. Dimensions (V8043F). Measurements in inches (mm). See Table 1.

Table 1. X dimension. See Fig. 1 or Fig. 2.

1/2 in. Valves

DN15

6–13/32 in.

163 mm

SPECIFICATIONS

Static Pressure Rating:120 psi

Maximum Differential Pressure

and Capacity Ratings (C

1/2 in. valves at 20 psi: C

3/4 in. valves at 20 psi: C

1in. valves at 6.5psi: C

Temperature Rating:

Liquid: 4 to 93 °C (40 to 200 °F).

Ambient: 4 to 52 °C (40 to 125 °F).

Steam: Consult your local Honeywell representative.

Humidity Rating: 5-95% RH (non-condensing)

Atmosphere: non-corrosive, non-explosive

):

v

v

v

v

= 3

= 3

= 8.5

1

4–1/16

(103)

3–7/16

(88)

X

1

ALLOW ADEQUATE CLEARANCE TO

ACCESS WIRING TERMINALS.

3/4 in. Valves

DN20

6–25/32 in.

173 mm

Power Requirements and Timing:

All models: 24 V, 50/60 Hz (cycles) 6 W nominal,

15 seconds to open, and 4-5 seconds to close.

Order transformer separately.

Tran sform er:

All models: AT72 or AT20B (maximum of 4 valves per

AT72 or 2 valves per AT20B).

Order transformers separately.

Auxiliary Switch Ratings:

‘E’, ‘F’ Models: 4.4 Amps running at 120 Vac.

Recommended Wall Thermostats:

Heating Only - T86A, T822D:

(T822C for normally open [N.O.] valves).

Cooling Only, or Heating-Cooling - T87F with Q539.

Thermostat Heater Setting:

For heat anticipation: 0.32 Amps.

1in. Valves

DN25

6–7/8 in.

175 mm

M37334

33-00402EF—01 2

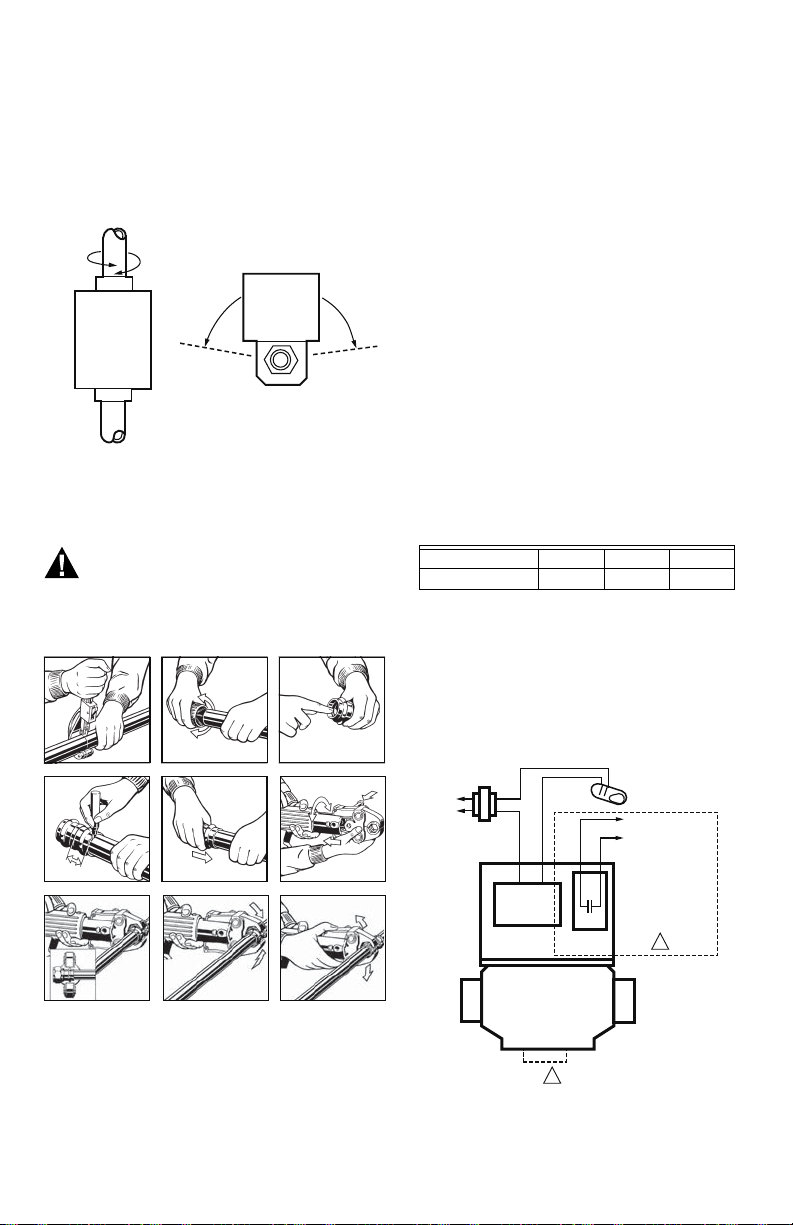

V8043 ZONE VALVES WITH PRESS CONNECTION

WARNING

M10162A

VERTICAL

PIPING

HORIZONTAL

PIPING

MOUNTING

The valve can be mounted in any position on a vertical

line. If the valve is mounted horizontally; the

powerhead must be even with or above the center line

of the piping. Make sure that enough room is provided

above the powerhead to remove the cover for

servicing.

Fig. 3. Mounting positions.

Mount the valve directly in the tube or pipe. Make sure

that the flow through the valve is in the direction

indicated by the arrow stamped on the valve body.

Read and understand all instructions for

installing the press connection. Failure to

follow all instructions may result in extensive

property damage, serious injury or death.

123

3. Check seal for correct fit. Do not use oils or

lubricants.

4. Mark proper insertion depth as shown in Table 2.

Improper insertion depth may result in improper

seal.

5. While turning slightly, slide press fitting onto

tubing to the marked depth.

NOTE: End of tubing must contact stop.

6. Insert appropriate jaw into the pressing tool and

push in, holding pin until it locks in place.

7. Open the jaw and place at right angles on the

fitting. Visually check insertion depth using

mark on tubing.

8. Start the pressing process and hold the trigger

until the jaw has engaged the fitting.

9. After pressing, the jaw can be opened again.

10. Leak Testing with Smart Connect®:

Unpressed connections are located by

pressurizing the system with air or water. When

testing with water the proper pressure range is

15 psi to 85 psi maximum. Leak testing with air

can be dangerous at high pressures. When

testing with compressed air the proper pressure

range is ½ psi to 45 psi maximum. Following a

successful leak test, the system may be pressure

tested up to 200 psi with air, or up to 600 psi with

water, if required by local code requirements or

project specifications.

Table 2. Insertion depth.

Tube Size 1/2 in. 3/4 in. 1 in.

Insertion Depth 3/4in. 7/8in. 7/8in.

WIRING

Disconnect the power supply before connecting wiring

to prevent electrical shock or equipment damage.

All wiring must comply with local codes and

ordinances. Connections to the individual valves are

shown in Fig. 5-6.

45 6

78

Reproduced with permission from Viega LLC (2018).

1. Cut copper tubing at right angles using

2. Remove burr from inside and outside of tubing

Fig. 4. Mounting procedure.

displacement-type cutter or fine-toothed steel

saw.

to prevent cutting sealing element.

M37346

9

TO

LINE

YELLOW

LEADS

MOTOR

AUXILIARY

SWITCH

1 NOT APPLICABLE FOR V8043A.

THERMOSTAT

(TYPICALLY T87F)

TO CIRCULATOR

OR ANOTHER VALVE

RED LEADS

1

M37335

Fig. 5. Typical wiring for V8043A, V8043E.

3 33-00402EF—01

Loading...

Loading...