Page 1

V8043A,E,F 5000 Series

APPLICATION

These valves consist of a motorized

actuator and valve assembly for controlling

the flow of hot water to a heat exchanger

such as a radiator, convector, finned

baseboard radiator, or infloor radiant coil

for space temperature control. The V8043

5000 series valves provide two-position,

straight through control of supply water at

up to 300 psi operating pressure.

Quick Fit actuator provides easy snap on and

off connection to the valve assembly.

SPECIFICATION

ZONE V ALVES

Patent Pending

Actuator Electrical Rating:

24Vac 60 Hz, 0.30 A Current Draw,

5 W, 7.2 VA maximum

Electrical Connection:

18” leads or screw terminal board

Auxiliary Switch Rating:

120V, 4.4A running, 26.4A Inrush (60 Hz);

50 VA Pilot duty at 24 V.

Fluid Temperature:

Standard models (class F motor):

200° F (93° C) Max.

Ambient Temperature:

125° F (52° C) Max.

Humidity Limits:

95% Relative Humidity, Non-condensing

Shipping and Storage Temperature:

-40° F to 150° F (-40° C to 65° C).

Atmosphere:

Non-corrosive, non explosive.

Maximum Soldering Temperature:

500° F (260° C). Rubber ball plug must be

moved away from the seat for soldering.

Maximum System Pressure Rating:

300 psi (2000 kPa), PN20.

Flow Characteristics:

Quick opening for on-off application.

Slow return for water hammer resist.

Maximum Close-off Rating (@ Flow

Capacity Rating) :

20 psi (@ 3.5 Cv)

8 psi (@ 8 Cv)

Actuator Materials:

Case:galvanized steel.

Cover : zinc plated steel.

Sector gear: Brass

Valve Material:

Body of forged brass; drive shaft stem of

stainless steel; ball plug of Buna-N rubber;

o-ring seals of EPDM rubber.

Service Medium:

Suitable for glycol/water mix up to 50:50

use in closed hydronic systems. Not for

use with oxygenated water, potable water

or steam.

Use this valve in hydronic systems which

do not contain dissolved oxygen in the

system water. The dissolved oxygen,

which is found in systems that have a

frequent source of make-up water, causes

the rubber plug inside the valve to

deteriorate and eventually fail.

Approvals:

CSA C/US Certified to Canadian Standards

Association and Underwriter's Laboratories

Standards.

MODELS

V8043 (Straight through, Normally Closed)

V8043A: Leadwires

V8043E: Leadwires and End Switch

V8043F: Terminal Board and End Switch

2004.09 Printed in Canada

1

Form No. 95C-10932

Page 2

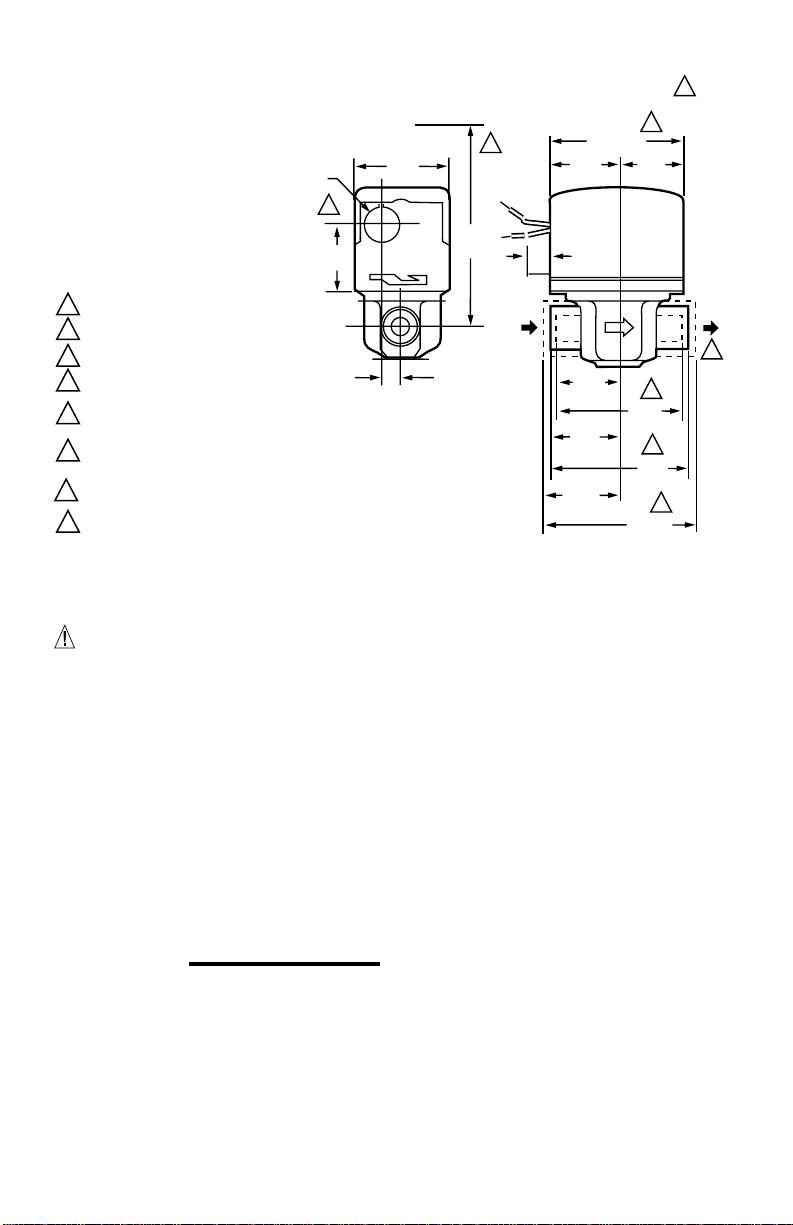

1

HEIGHT NEEDED TO REMOVE COVER.

2

DIMENSIONS FOR 1/2 IN. COPPER TUBING.

DIMENSIONS FOR 3/4 IN COPPER TUBING.

3

DIMENSIONS FOR 1 IN. COPPER TUBING.

4

4-7/8 IN. (124) MAX ON V8034F WITH TERMINAL

5

BOARD ENCLOSURE.

V4034B AND V8043B VAL VES THAT ARE

6

NORMALLY OPEN IN THE DE-ENERGIZED

POSITION HAVE NO MANUAL LEVER.

REFER TO MOUNTING INSTRUCTIONS.

7

OPENING FOR 1/2 IN. CONDUIT ON MANUAL

8

LEVER SIDE FOR V4043, V8043.

Fig. 1 - Mounting Dimensions in in. (mm in Brackets)

M10175.A4

V4043, V8043 SWEAT COPPER CONNECTION MODELS

3-1/2 (89)

1-3/4

(44)

A B

1-5/16

(33)

1-3/8

(35)

1-11/16

(43)

7/8 DIA.

(22)

8

1-1/2

(38)

15/32

(12)

AUTO

2-3/8

(60)

MAN OPEN

5-1/4

(133)

1

3/8

(10)

IN

1-3/4

(44)

2-5/8

(66)

2-3/4

(70)

3-3/8

(86)

6

5

OUT

7

2

3

4

CAUTION

1. Disconnect power supply before

connecting wiring to prevent electrical

shock or equipment damage.

2. Normally it is not necessary to remove

the actuator from the valve body during

installation. If the valve must be

disassembled, be certain that it is

reassembled with the water flow in the

direction of the arrow. Reversal of the

actuator results in damage to the gear

train.

3.

On 24V systems, never jumper the

valve coil terminals even tempor arily.

This can burn out the heat anticipator in

the thermostat.

INSTALLATION

When Installing this Product…

1. Read these instructions carefully. Failure

to follow them could damage the product

or cause a hazardous condition.

2. Check the ratings given in the

instructions and on the product to make

sure the product is suitable for your

application.

3. Installer must be a trained, experienced

service technician.

4. After installation is complete, check out

product operation as provided in these

instructions.

Location

Install the valve in an area with adequate

clearance to:

- Move the manual opening lever on the

side of the actuator

- Remove the actuator cover

- Wire the actuator

Replace the actuator motor

-

The valve location should be in an area

where the temperature does not exceed the

maximum valve operating ambient

temperature and fluid temperatuare.

Manual Lever

The V8043 normally closed valves can be

opened manually by moving the manual lever

slowly and firmly to the MAN. OPEN position

and pushing up to the stop. The stop permits

the valve to be locked in the open position.

The valve returns to automatic position when

it is energized.

2

Page 3

R

L1

(HOT)

L2

1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

END SWITCH

TO CIRCULATOR

OR ANOTHER

VALVE

TH

TR

24V

TRANSFORMER

THERMOSTAT

(TYPICALLY T87F)

TH TR

M5952

MOUNTING

The valve can be mounted in any position

on a vertical line. See Fig. 2. If the valve is

mounted horizontally; the actuator must be

even with or above the center line of the

piping. Make sure to leave enough room

above the actuator to remove the cover for

servicing.

thermostat or controller connected to the

valve so that the valve runs through its

cycle. Make sure the valve runs

smoothly and positively from closed to

open to closed again. (See Operation

and Checkout Sections.)

Mount the valve directly in the tube or pipe

after the coil.

Make sure that the flow

through the valve is in the direction

indicated by the arrow stamped on the

valve body.

HORIZONTIAL

PIPING

VERTICAL

PIPING

Fig. 2 - Mounting Positions

M10162

Sweat Copper Models

1. Use new, properly reamed pipe, free

from dents or corrosion.

2. Place the valve on the pipe. Set the

manual opening lever to MAN. OPEN

position before applying heat. This

protects the plug inside the valve by

removing it from the seat.

3. Sweat the joints, keeping the outer

surface free from solder. DO NOT use

silver solder because of the high

melting temperature required.

TO INSTALL A COMPLETE VALVE (V8043):

1. Disconnect power supply before

connecting wiring to prevent electrical

shock or equipment damage.

2. Install valve into pipe on the return side

of the coil. (See Mounting Section.)

3. Make wiring connections to valve. (Refer

to Wiring section for proper instructions.)

4. Inspect the valve installation to ensure

that all connections and adjustments

have been correctly made.

Adjust the

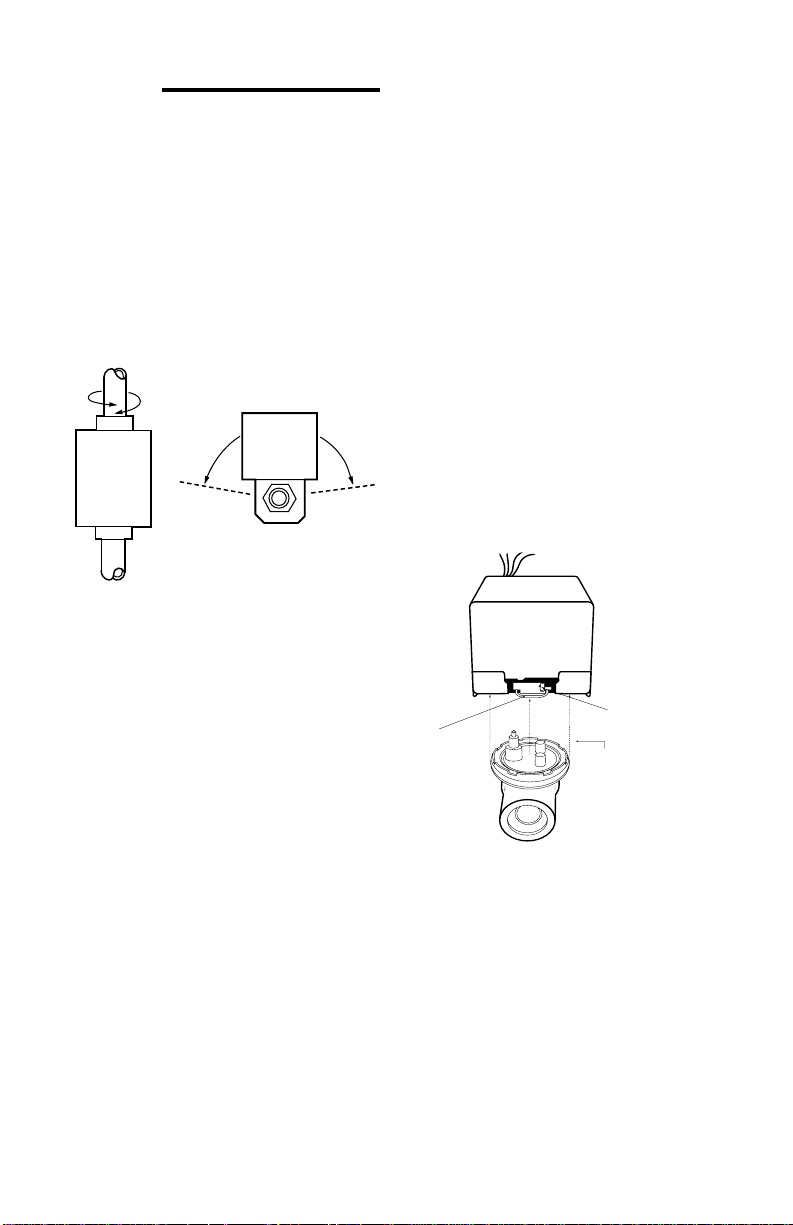

TO REMOVE THE ACTUATOR FROM THE

VALVE BODY (See Fig. 3)

NOTE!

It is not necessary to drain the hydronic

system if the valve body assembly remains in

the pipe line.

1. Switch power supply OFF. Disconnect

electrical leads carefully, noting the

position and colour of each lead.

2. Place the manual lever in the MAN.

OPEN position.

3. Remove actuator by fully depressing

spring release button and lift it straight

off of the body .

1. PLACE MANUAL

AUTO OPEN

2. DEPRESS

LOCKING

BUTTON

Fig. 3 - Removing Actuator from Valve Body

LEVER IN OPEN

POSITION

3. LIFT ACTUATOR

STRAIGHT UP

TO INSTALL REPLACEMENT ACTUATOR

ON THE VAL VE BODY

1.

Align the parallel flat surfaces in

double-D shaft of valve body with

notch in side of body (i.e. 90

flow.) See Fig. 4.

This makes actuator

to water

°

attachment easier.

2. Wiring connections may be made either

before or after actuator installed on

valve body.

3.

Place the manual lever on the

actuator in the MAN. OPEN position.

3

Page 4

4. Line up motor coupling to the parallel flat

R

L1

(HOT)

L2

1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

END SWITCH

TO CIRCULATOR

OR ANOTHER

VALVE

TH

TR

24V

TRANSFORMER

THERMOSTAT

(TYPICALLY T87F)

TH TR

M5952

surfaces in double-D shaft of body and fit

the actuator onto the valve body,

ensuring that the shaft seats correctly .

(See Fig. 5)

5. Snap actuator onto body by pressing

down.

6.The manual lever may be released

manually, but it is also automatically

released when the valve is operated

electrically.

Double-D

Shaft

Notch

Actuator

Coupling

Fig. 4 - Shaft Position

Parallel flat surfaces

align with Notch on

side of valve body

Notch Tab

TO (TYPICALLY T87F)

LINE

YELLOW

LEADS

MOTOR

AUXILIARY

SWITCH

Fig. 6 - Typical wiring for V8043E, V8044E.

THERMOSTAT

TO CIRCULATOR

OR ANOTHER VALVE

RED LEADS

M5953

Fig. 5 - Installing Actuator

WIRING

Disconnect the power supply before

connecting wiring to prevent electrical shock

or equipment damage.

All wiring must comply with local codes and

ordinances. Connections to the individual

valves are shown in Fig. 6 and 7. See Fig. 8

through 14 for typical hookups.

If replacing a Taco, Dole, Flair or White

Rodgers 3-wire valve with a 2-wire V8043E or

F, see Fig. 15 through 27. Check that the

pressure rating of the new valve is

appropriate for the application.

Notch

Fig. 7 - Typical wiring for V8043F.

T822 T822 T822

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

CONNECT V8043A BLACK LEADWIRE TO THERMOSTAT.

2 2 2

V8043A V8043A V8043A

M10168

Fig. 8 - T822 Thermostat, V8043A valve hookup.

4

Page 5

T822 T822 T822

T822 T822 T822

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

CONNECT V8043E YELLOW LEADWIRE TO THERMOSTAT.

CONNECT V8043E RED LEADWIRES TO L1 (HOT) LINE AND

3

PRIMARY CONTROL.

Fig. 9 - T822, V8043E zone hookup for gas or oil. No domestic hot

2 2 2

V8043E V8043E V8043E

3 3 3

L4006A

TO OIL PRIMARY

CONTROL OR TO

TRANSFORMER

AND LOW VOLTAGE

GAS VALVE

CIRCULATOR

water.

HIGH

LIMIT

M10169

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

CONNECT V8043E YELLOW LEADWIRE TO THERMOSTAT.

CONNECT V8043E RED LEADWIRES TO AQUASTAT®.

3

Fig. 10 - T822, V8043E zone hookup for gas or oil with or ithout

domestic hot water. Without domestic hot water, use L8148J for

gas, and L8148A for oil. With domestic hot water, use L8124E for

gas, and L8124A or C for oil.

2 2 2

V8043E V8043E V8043E

3 3 3

T T

1

2 C1

CIRCULATOR

B1

TO BURNER

CONTROL

CIRCUIT

B2

C2

M10170

V4044, V8044

VALVE OPERATOR

1

MOTOR

AQUASTAT® CHANGEOVER CONTROL SWITCHES TO HEATING (RED)

1

AT FLUID TEMPERATURE OF 85°F (29°C) MAX TO COOLING (BLUE) AT

FLUID TEMPERATURE OF 60°F (18°C) MIN.

Fig. 11 - Wiring diagram for V4244 and V8244 with Aquastat®

changeover control.

RED

BLUE

YELLOW

HEATING

COOLING

THERMOSTAT

TO

POWER

M10171

ZONE 1

ZONE 2 ZONE 3

T87F

V8043F

END SWITCH

TH-TR

TH

TR

TV

C1

TO

CIRCULATOR

Fig. 12 - Typical 3-zone system. Use an AT87A Transformer

to power up to five more zone valves.

V8043F V8043F

END SWITCH END SWITCH

TH-TR

TH

TR

2

1

B1

B2

TO BURNER

CIRCUIT

L1

(HOT)

L2

T Z

L8124G

C2

5

T87F

TH-TR

TH

120 V

POWER

SUPPLY

T87F

ADD

JUMPER

TO EACH

VALVE

TR

M5954

Page 6

ZONE 1

ZONE V8043E

RED

RED

RED

RED

YELLOW

YELLOW

W775A PANEL

T87F

CONNECTIONS FOR V8043E

(LEADWIRE MODEL)

ZONE 3

END SWITCH

V8043F

TH-TR TH

ZONE 3

YELLOW

POWER

SUPPLY

YELLOW

B

B

R

W

BR

L1

(HOT)

L2

TO

CIRCULATOR

CONTROL

CIRCUIT

ZONE 1

END SWITCH

V8043F

TH-TR TH

ZONE 1

INTEGRAL

TRANSFORMER

W775A PANEL

T87F

ZONE 2

END SWITCH

V8043F

TH-TR TH

TR

B

B

R

W

BR

TR

ZONE 2

B

B

R

W

BR

T87F

Fig. 13 - Typical 4-zone system. Use an additional W775A to power up to four more zone valves.

ZONE 2

T87F T87F T87F T87F

ZONE 3

ZONE 4

T87F

ZONE 4

END SWITCH

V8043F

TH-TR TH

TR

B

B

R

W

BR

ZONE 5

ZONE 4

TR

B

B

R

W

BR

T87F

M5980

TO BURNER

AND / OR

CIRCULATOR

CIRCUIT

V8043F

END SWITCH

TH-TR

TH

TR

NOTE: IF CODE PERMITS, V8043E AND V8043F CAN BE USED INTERCHANGEABLY WHEN WIRED AS SHOWN.

V8043F

END SWITCH

TH-TR

TH

TR

AT87A

TRANSFORMER

V8043F

END SWITCH

TH-TR

L1

(HOT)

L2

1

TH

TR

Fig. 14 - Typical 5-zone system. Use an AT87A Transformer to power up to five more zone valves.

1

L1

(HOT)

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

THERMOSTAT

A

TO AUXILIARY

CIRCUITS

B

C

Fig. 15 - Existing Taco system. (Wires are identified with

letters to correspond with wires in Fig. 16 and 17.)

D

E

TACO VALVE

1

2

3

M5958

L1

(HOT)

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

Fig. 16 - Wiring Honeywell V8043E to Taco System (Wires are

identified with letters to correspond with wires in Fig. 15.)

6

V8043E V8043E

YELLOW

YELLOW

RED

RED

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

1

C

A

THERMOSTAT

TO

AUXILIARY

CIRCUITS

B

D

E

YELLOW

YELLOW

RED

RED

M10164

V8043E

YELLOW

YELLOW

RED

RED

M10163

Page 7

L1

(HOT)

L2

V8043F

END SWITCH

1

C

TH-TR

TH

A

D

TO

AUXILIARY

E

CIRCUITS

L1

(HOT)

L2

1

TR

B

A

B

C

V8043F

END SWITCH

TH-TR

TH

F

TO TERMINALS

E

T, T ON

BURNER RELAY

TR

D

THERMOSTAT

V8043F

L1

(HOT)

L2

END SWITCH

1

C

TH-TR

A

TH

D

TO

AUXILIARY

E

CIRCUITS

TR

B

THERMOSTAT

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

Fig. 17 - Wiring Honeywell V8043F to Taco System (two options).

(Wires are identified with letters to correspond with wires in Fig. 15.)

DOLE VALVE

B

A

C

THERMOSTAT

1

L1

(HOT)

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

3

D

1

M5960

2

4

E

F

TO TERMINALS

T, T ON

BURNER RELAY

M5977

Fig. 18 - Existing Dole System. (Wires are identified with letters to

correspond with wires in Fig. 19 and 20.)

V8043E

YELLOW

YELLOW

RED

RED

M5965

C

B

THERMOSTAT

A

E

F

1

L1

(HOT)

L2

TO TERMINALS

T, T ON

BURNER RELAY

POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

D

Fig. 19 - Wiring Honeywell V8043E to Dole System. (Wires are

identified with letters to correspond with wires in Fig. 18.)

THERMOSTAT

V8043F

END SWITCH

1

L1

(HOT)

L2

1

Fig.20 -. Wiring Honeywell V8043F to Dole System (two options).

(Wires are identified with letters to correspond with wires in Fig. 18.)

A

B

TH-TR

C

THERMOSTAT

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

F

TO TERMINALS

E

T, T ON

BURNER RELAY

TH

TR

D

M5966

FLAIR VALVE

E

L1

(HOT)

L2

1

3

A

2

1

B

4

5

C

F

D

TO TERMINALS

T, T ON

BURNER RELAY

THERMOSTAT

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

Fig. 21 - Existing Flair System. (Wires are identified with

letters to correspond with wires in Fig. 22 and 23.)

C

B

THERMOSTAT

A

D

E

F

1

L1

(HOT)

L2

TO TERMINALS

T, T ON

BURNER RELAY

POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

Fig. 22 - Wiring Honeywell V8043F to Flair System. (Wires are

identified with letters to correspond with wires in Fig. 21.)

M5978

V8043E

YELLOW

YELLOW

RED

RED

M5965

7

Page 8

V8043F

L1

(HOT)

L2

END SWITCH

1

A

B

TH-TR

C

F

TO TERMINALS

E

T, T ON

BURNER RELAY

TH

TR

D

THERMOSTAT

V8043F

L1

(HOT)

L2

END SWITCH

1

A

B

TH-TR

C

F

TO TERMINALS

E

T, T ON

BURNER RELAY

TH

TR

D

THERMOSTAT

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

Fig. 23 - Wiring Honeywell V8043F to Flair System (two options).

(Wires are identified with lettersto correspond with wires in Fig. 21.)

WHITE-RODGERS

WATER VALVE

THERMOSTAT

5 6

4

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

1311 OR 1321

VALVE

5

TO AUXILIARY

CIRCUIT

3 4 6

2

1

Fig. 24 - Existing White-Rodgers System.

1

L1

(HOT)

L2

5

6

3

TO

AUXILIARY

CIRCUIT

1

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

2

IF TRANSFORMER SUPPLIES POWER TO AUXILIARY CIRCUIT,

WIRE AUXILIARY CIRCUIT AS SHOWN IN LOWER DIAGRAM.

3

TAPE UNUSED END AND TUCK INTO HOLE.

4

THERMOSTAT

TO 6 ON

THERMOSTAT

TO AUXILIARY

CIRCUIT

Fig. 25 - Wiring Honeywell V8243E to White-Rodgers System.

YELLOW

YELLOW

RED

RED

YELLOW

RED

RED

M5966

1

L1

(HOT)

L2

M5711

2

M5712

V8043F

END SWITCH

TH

TH-TR

6

5

4

3

1

2

L1

(HOT)

L2

TO AUXILIARY

CIRCUITS

THERMOSTAT

TO

AUXILIARY

CIRCUIT

END SWITCH

TH-TR

TH-TR

3

THERMOSTAT

TH

END SWITCH

5

TO AUXILIARY

2

CIRCUITS

L1

(HOT)

1

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

2

IF TRANSFORMER SUPPLIES POWER TO AUXILIARY CIRCUIT,

WIRE AUXILIARY CIRCUIT AS SHOWN IN LOWER DIAGRAM.

3

TAPE UNUSED END AND TUCK INTO HOLE.

Fig. 26 - Wiring Honeywell V8043F to White-Rodgers System

(one option).

2

L1

(HOT)

1

L2

TO

AUXILIARY

2

CIRCUIT

L1

(HOT)

1

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

IF TRANSFORMER SUPPLIES POWER TO AUXILIARY CIRCUIT,

2

WIRE AUXILIARY CIRCUIT AS SHOWN IN LOWER DIAGRAM.

TAPE UNUSED END AND TUCK INTO HOLE.

3

Fig. 27 - Wiring Honeywell V8043F to White-Rodgers System

(alternate option).

8

TR

TR

M5713

V8043F

TH TR

6

4

END SWITCH

M5714

Page 9

OPERATION

CAUTION

On 24V systems, never jumper the valve

coil terminals even temporarily. This can

burn out the heat anticipator in the

thermostat.

Automatic Operation

On a call for heat by the zone thermostat,

the valve opens and its auxiliary switch

contacts make, closing the circuit to the

system circulator. In a multizone system with

all the valve auxiliary switches wired in

parallel, any zone calling for heat can operate

the circulator. When the call for heat ends, the

valve closes by integral spring return. The

auxiliary switch contacts break the circulator

circuit.

Manual Operation

The motorized valve can be opened

manually by lifting the manual opening lever

over the stop and pushing slowly and firmly to

the MAN. OPEN position. The stop permits

the valve to be lock ed in the open position.

The valve returns to automatic position when

the valve is energized.

Normally Closed Models

With the manual opener set to AUTO and

the actuator energized, the valve is opened

as shown in Fig. 28A. When the actuator is

de-energized, a spring-return mechanism

drives the valve to the closed position as

shown in Fig. 28B. The valve can also be

opened with no electrical power by moving

the manual opening lever over the stop and

pushing slowly and firmly to the MAN. OPEN

position. The stop permits the valve to be

locked in the open position.

The valve returns to the automatic position

when the valve is energized.

Auxiliary switch is not energized when

the valve is manually opened.

NOTE: Flow direction arrow is stamped on

the valve body indicating flow

direction from Inlet Port A to Outlet

Port B.

B

AA

IN OUT

OPEN POSITION

A

Fig. 28 - V8043 operation for normally closed valve.

OUT

IN

CLOSED POSITION

B

M5951

CHECKOUT

1. Raise the setpoint on the zone

thermostat above the room

temperature to initiate a call for heat.

2. Observe all control devices—the valve

should open and the auxiliary switch

should make the circuit to the

circulator or other valve at the end of

the opening stroke.

3. Lower the setpoint on the zone

thermostat to below the room

temperature.

4. Observe the control devices. The valve

should close and the auxiliary

equipment should stop.

SERVICE

This valve should be serviced by a trained,

experienced service technician.

1. If the valve is leaking, drain the system

and check to see if the O-ring needs

replacing.

2. If the gear train is damaged, replace

the entire actuator assembly. See the

Installation section. If the motor is

burned out, replace the motor. See

Replacement Parts list in the

TRADELINE® Catalog.

NOTE: Honeywell zone valves are designed

and tested for silent operation in

properly designed and installed

systems; how ever , water noises can

occur as a result of excessive water

velocity or piping noises can occur in

high temperature (higher than 212° F

(100° C) systems with insufficient water

pressure. Valves are designed for

normal cycling operations. Product life

will be shortened if energized

continuously.

B

9

Page 10

Automation & Control

Honeywell

1985 Douglas Drive North

Golden Valley

MN 55422-3992

In Canada

Honeywell Limited/Limitée

35 Dynamic Drive

Toronto, Ontario

M1V 4Z9

10

Loading...

Loading...