Page 1

X-XX UL

INSTALLATION INSTRUCTIONS

®U.S. Registered Trademark

Copyright © 1998 Honeywell Inc. • All Rights Reserved

62-0152

V5011N, V5013N Two-Way and Three-Way

NPT Threaded Globe Valves

DESCRIPTION

V5011N valves are single-seated, two-way, straightthrough valves that provide control of steam, glycol

solutions (up to 50 percent concentration) and hot or

chilled water in HVAC systems requiring tight shutoff.

V5013N valves are three-way mixing valves that provide

proportional control of glycol solutions (up to 50 percent

concentration) and hot or chilled water in HVAC systems.

V5013N valves direct the flow from one of two inlets to a

common outlet (mixing).

V5011N and V5013N are suitable for actuation with

pneumatic actuators such as MP953; for actuation with

electric operators such as Modutrol IV Motors when used

with Q5001 linkage; for electric actuation using valve direct

coupled actuators such as ML6874, ML7984, ML6421,

ML7421, ML6425, and ML7425. Refer to actuator

specifications to determine dimensional, wiring and

mounting requirements for a particular actuator. Table 1

shows available size and flow capacities for the valves.

The stroke for both valves is 3/4 in. (20 mm).

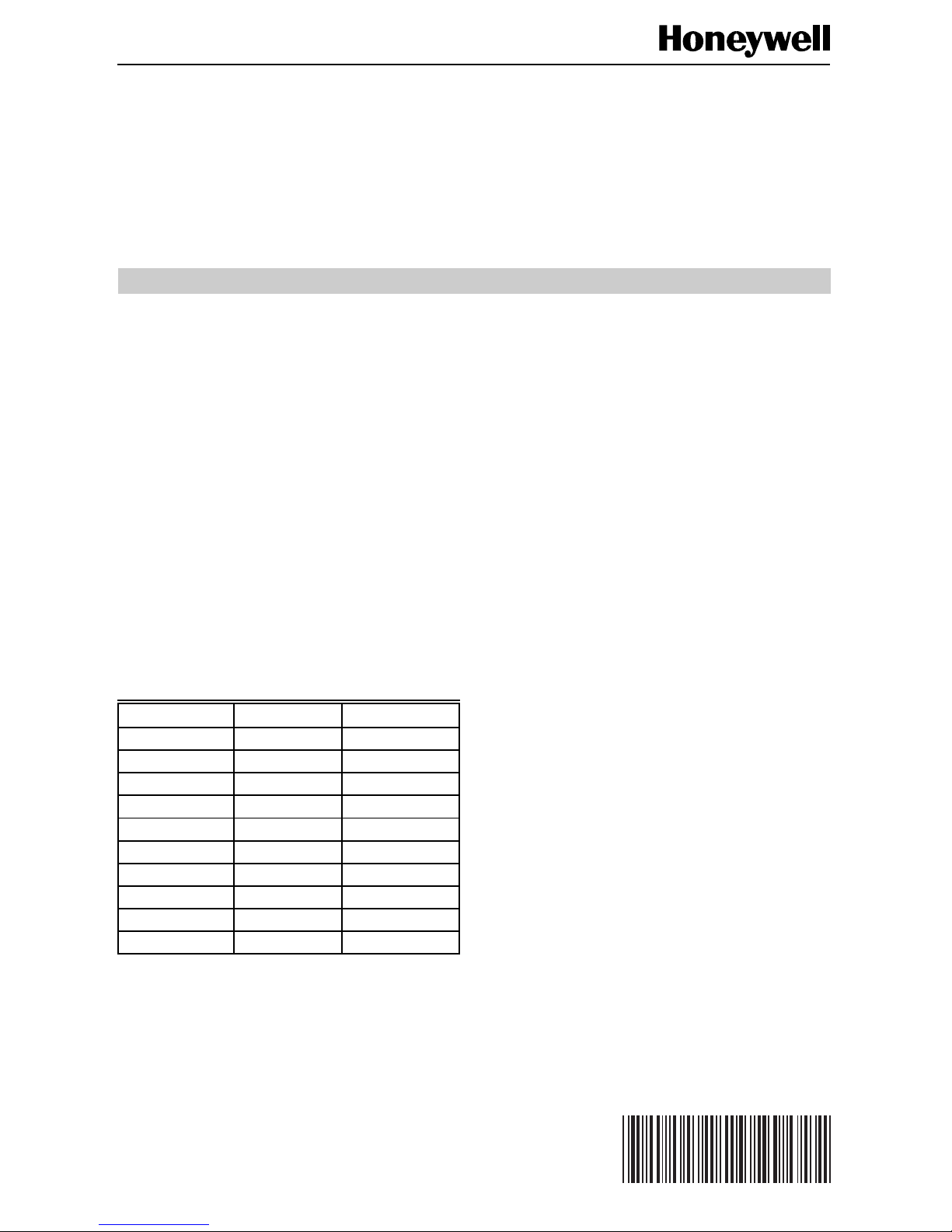

Table 1. V5011N and V5013N Size and

Flow Capacities.

Valve Size (in.) V5011N (Cv) V5013N (Cv)

1/2—DN15 0.73 —

1/2—DN15 1.16 —

1/2—DN15 1.85 —

1/2—DN15 2.9 2.9

1/2—DN15 4.7 4.7

3/4—DN20 7.3 7.3

1—DN25 11.7 11.7

1-1/4—DN32 18.7 18.7

1-1/2—DN40 29.3 29.3

2—DN50 46.8 46.8

INSTALLATION

When Installing this Product . . .

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check the ratings given on the instructions and on

the product to make sure the product is suitable for

your application.

3. Installer must be a train, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

IMPORTANT

1. Do not lift the valve by holding the stem.

2. Mount the valve body with the stem upright to

90 degrees from vertical. Do not mount the valve

with the stem pointed lower than horizontal.

3. Mount the valve with the flow arrow pointed in the

direction of flow through the valve.

4. Mount the valve between pipes which are in line.

Mounting the valve on pipes that are not aligned

causes leakage at the valve to pipe connection.

5. Ensure complete engagement on pipe to valve

body threads.

6. Hold the valve body with a clamp or pipe wrench

on the hexagonal fitting nearest the pipe to

prevent damage to the valve body while mounting on the pipe. Refer to Fig. 1.

7. Be sure to allow enough room for installation and

service. Clearance for installation of the valve is

dependent on the size of the actuator and the

pipe size of the valve.

Page 2

62-0152

2

V5011N, V5013N TWO-WAY AND THREE-WAY NPT THREADED GLOBE VALVES

Home and Building Control

Honeywell Limited-Honeywell Limitée

155 Gordon Baker Road

North York, Ontario

M2H 3N7

62-0152 G.S. 5-98

Home and Building Control

Honeywell Inc.

Honeywell Plaza

P.O. Box 524

Minneapolis, MN 55408-0524

www.honeywell.com

Location

Select a location where the valve, linkage (if used), and

actuator to be used are within the appropriate ambient

pressure and temperature ratings.

Leave sufficient clearance above the valve to accommodate installation of the actuator and allow room for

servicing the valve body. (The valve body should be

completely installed in the pipe line before the actuator and

linkage are installed.)

When selecting a location for the valve, consider actuator

mounting restrictions. Most Modutrol IV Motors require that

shafts be mounted horizontally.

Mounting

The preferred mounting position of the valve is with the

stem vertical. For steam applications, mount with the stem

at a 45 degree angle. Do not mount the valve with the

stem more than 90 degrees from the vertical (pointing

lower than horizontal). Scale and foreign material can

collect and can score the stem and cause packing

leakage. Protect the stem from damage due to bending or

scratching.

V5011N, V5013N screwed body threads conform to

American Standard Taper Pipe Threads (NPT).

Align the pipes squarely with the valve at each end

connection. If the pipes are forced into the valve, the body

can become twisted and improper seating can result.

Apply pipe dope sparingly. Be careful to prevent pipe

debris such as pipe chips, scale, etc., from entering the

piping because this material can lodge in the seat and

prevent proper closing.

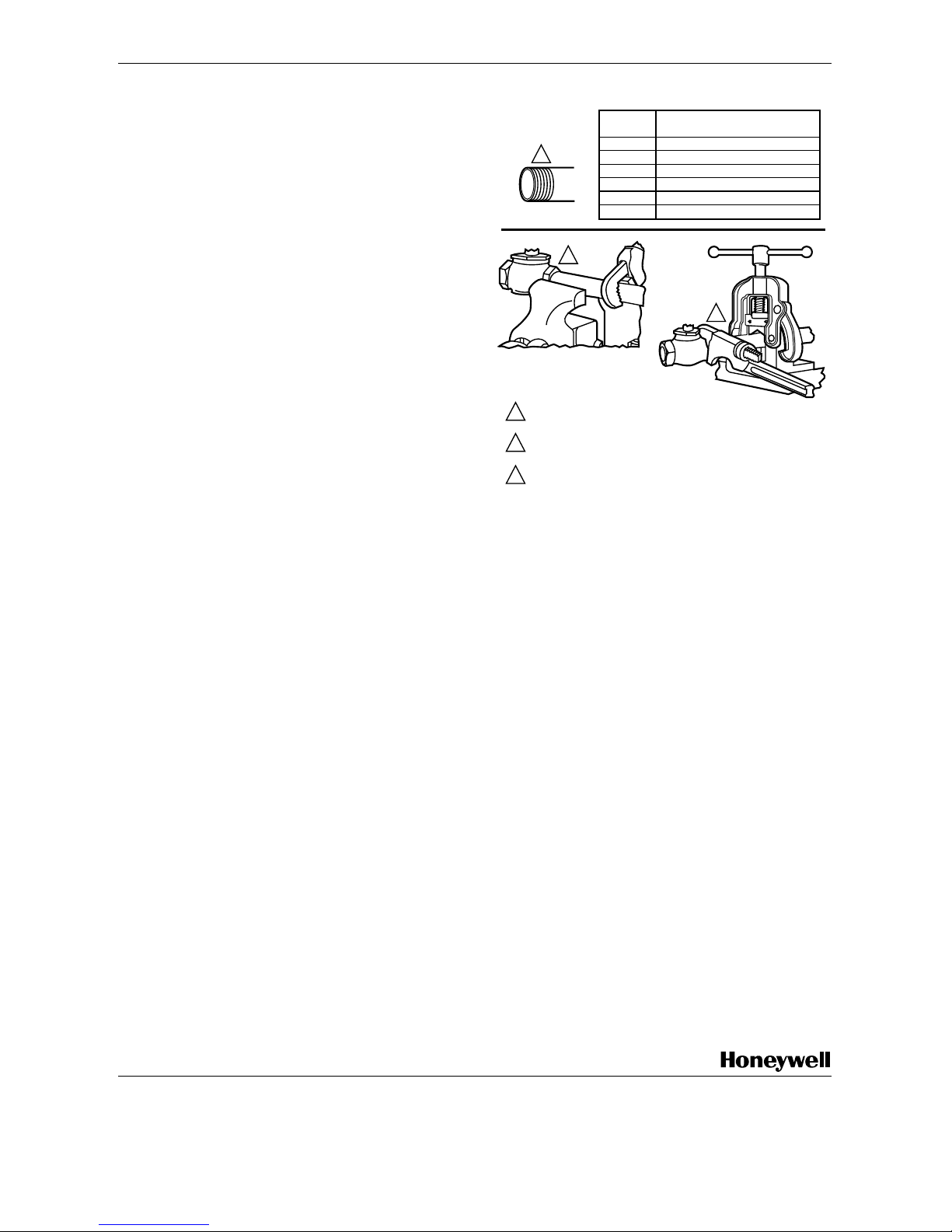

Refer to Fig. 1 for valve pipe sizes and thread lengths.

Fig. 1 also shows two effective methods of holding the

valve and pipe when attaching it. The valve will not

function properly if twisted or squeezed during installation.

Fig. 1. Installing valve with threaded connections.

CHECKOUT

Before installing linkage (if used) and actuator, make sure

that valve stem operates freely. Impaired stem operation

can indicate that the body was twisted or that the stem

was bent. Either of these conditions may require valve

replacement.

Check valve body and connections for leaks. After

installing linkage and actuator, check the operation

according to installation information provided with these

controls. Operate the system through one complete cycle

to be sure the valve controls properly.

USE VISE GRIPS WITH THE HEX END NEXT TO THE PIPE

(DO NOT TWIST OR SQUEEZE VALVE BODY).

USE VISE TO HOLD PIPE SECURELY TO PREVENT TURNING. USE

PARALLEL-JAW WRENCH TO GRIP VALVE HEX FLATS NEXT TO PIPE.

M11763A

USE PROPERLY REAMED AND CLEANED PIPE AND MODERATE

AMOUNT OF DOPE (LEAVE TWO THREADS BARE).

PIPE SIZE

(IN.)

1/2

3/4

1

1-1/4

1-1/2

2

EFFECTIVE LENGTH OF THREADS

IN IN. (MM)

1/2

9/16

11/16

11/16

11/16

3/4

(12.7)

(14.3)

(17.5)

(17.5)

(17.5)

(19.1)

1

1

2

2

3

3

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use or modification to, the

literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against any liability, cost, or damages, including

attorneys’ fees, arising out of, or resulting from, any modification to the literature by you.

Loading...

Loading...