Honeywell V5004TF Installation Instructions Manual

V5004TF

Installation instructions Einbauanleitung

Keep instructions for later use!

Anleitung zum späteren Gebrauch

aufbewahren!

32336560-001

Kombi-QM Pressure Independent Balancing and Control Valve

Kombi-QM Druckunabhängiges Strangregulier- und Regelventil

GB

1 Actuator's features. . . . . . . . . . . . . . . . . . . 3

2 Installation Instructions . . . . . . . . . . . . . . . 3

3 External Interface . . . . . . . . . . . . . . . . . . . 6

4 Control Method . . . . . . . . . . . . . . . . . . . . . 7

5 Initial Setting . . . . . . . . . . . . . . . . . . . . . . . 7

6 Ratio of Value of Flow According to Flow

Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7 Manual Override Operation . . . . . . . . . . . 10

8 General . . . . . . . . . . . . . . . . . . . . . . . . . . 10

D

1 Funktionsmerkmale des Stellantriebs . . . 11

2 Einbauanleitung. . . . . . . . . . . . . . . . . . . . 11

3 Externe Schnittstelle . . . . . . . . . . . . . . . . 14

4 Regelmethode . . . . . . . . . . . . . . . . . . . . .15

5 Anfangs-Einstellung. . . . . . . . . . . . . . . . . 15

6 Verhältnis des Volumenstromwerts gemäß

Volumenstromkennlinie . . . . . . . . . . . . . .18

7 Handbetätigung . . . . . . . . . . . . . . . . . . . .18

8 Allgemeines . . . . . . . . . . . . . . . . . . . . . . . 18

MU0H-2327GE23 R0618 2 Honeywell GmbH

GB

1 Actuator's features

• Proportional control

• analogue (voltage and current), PWM, 3 points and ON/

OFF

• Position detecting

• 4-digit display

• 3 buttons to set parameters

• Position control method to set actuator

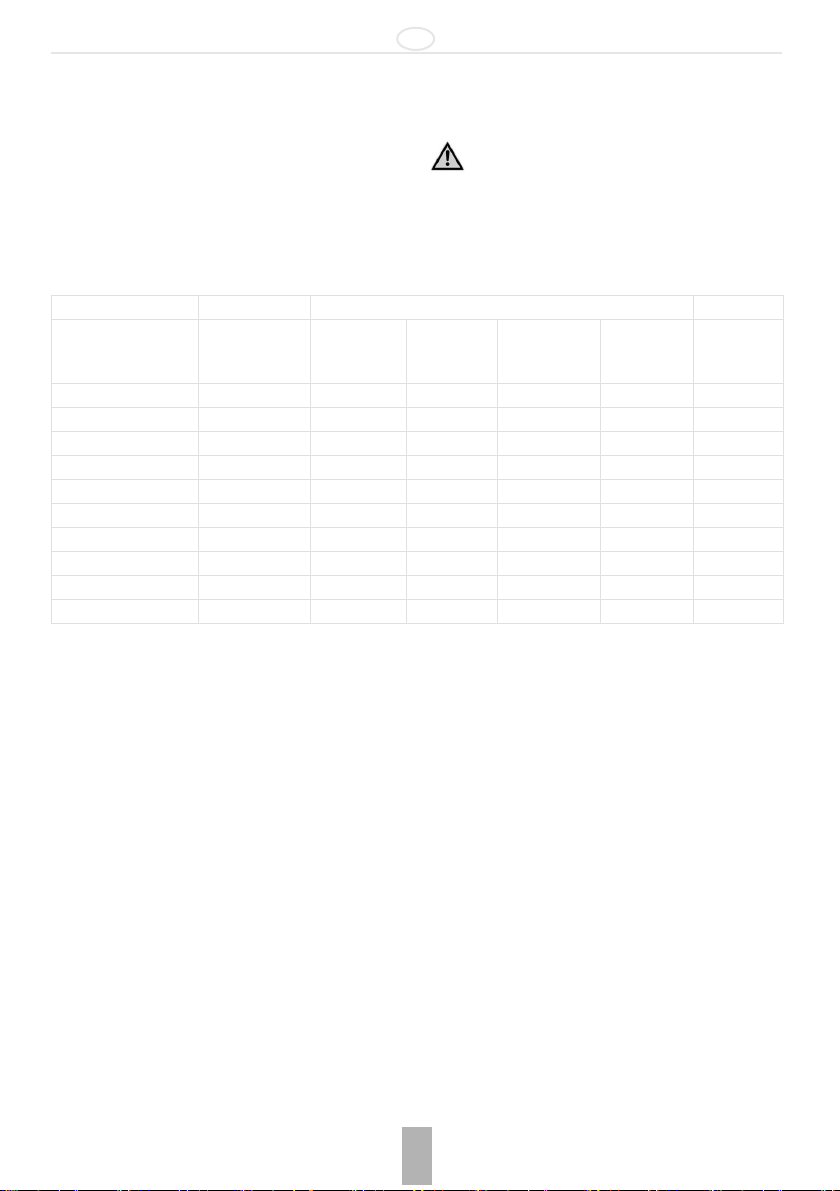

OS-No. Flow [I/h] ∆ [kPa]

at 30%

flow

V5004TF1050 2000 - 20000 21 25 31 40 600

V5004TF1065 3000 - 30000 26 29 30 30 600

V5004TF1080 3000 - 30000 23 25 30 30 600

V5004TF1100 5500 - 55000 16 20 24 30 600

V5004TF1125 9000 - 90000 21 25 31 35 600

V5004TF1150 15000 - 150000 31 35 41 50 600

V5004TF1200LF 20000 - 200000 31 35 36 40 400

V5004TF1200HF 30000 - 300000 32 37 38 40 400

V5004TF1250LF 30000 - 300000 30 30 33 40 400

V5004TF1250HF 50000 - 500000 38 49 58 65 400

2. To set the flow on the V5004TF use the digital display

and three buttons on the Smart actuator.

When it is switched on, the Zero Detection function

automatically starts: the display shows “Go 0“. Wait

while the actuator is running and the end stroke is

found: finally the display will change to “0”.

To enter the settings browser, press the button MODE.

Press UP and DOWN buttons to select the setting.

Press MODE to show different options and browse

using UP and DOWN buttons. Once the option is found,

press MODE to confirm as the selection.

2 Installation Instructions

1. Mount the valve with the arrow in the direction of the

flow

CAUTION!

Mounting it in the wrong direction may damage the

system and the valve itself.

If flow reversal is possible, a non-return valve should be

mounted.

Minimum differential pressure above which the valve begins

to exercise its regulating effect:

Startup Pressure

∆[kPa]

at 50%

flow

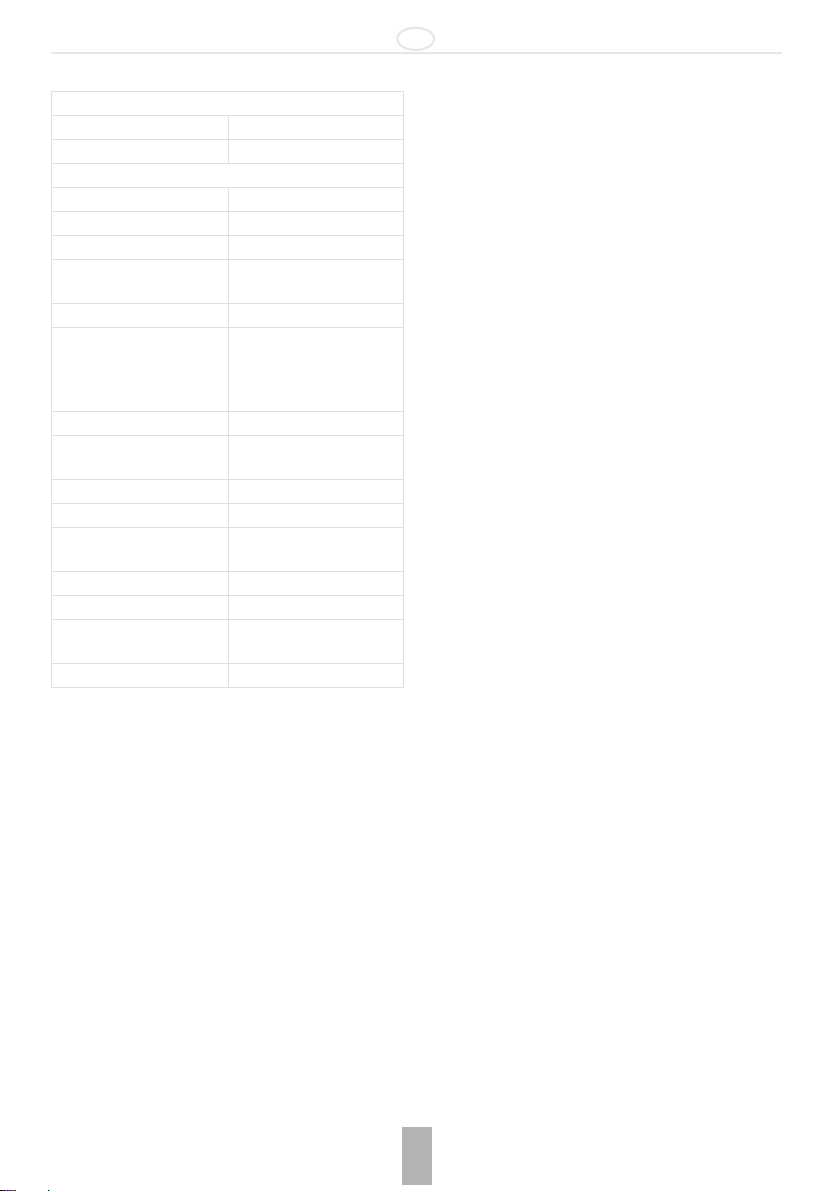

SET1 Input indication selection with internal

SET2 Control signal selection

SET3 Min. flow rate setting

SET4 Max. flow rate setting

SET5 Setting display mode during operation

SET6 Rotation angle compensation

SET7 Flow rate offset compensation

SET8 Power failure mode

SET9 Flow rate unit selection

SET10 Control curve selection

SET11 Max. voltage control signal

SET12 Min. voltage control signal

SET13 Actuator rotation speed

SET14 Feedback signal selection

∆[kPa]

at 80% flow

control signal

∆[kPa]

at 100%

flow

∆[kPa]

MU0H-2327GE23 R0618 3 Honeywell GmbH

1 Display

1

3

2

4

5

2 Button UP

3 Button MODE

4 Button DOWN

5 Manual override

GB

Provided the differential pressure is higher than the start up

pressure, the valve keeps flow constant at the set value.

3. Operating Control

To ensure that the valve is working in its operating differential

pressure range.

Measure the differential pressure across the valve as shown

in the picture below.

2.1 M5004

2.1.1Application

Electromotive actuators M5004 - 24V are used with many

kind of control systems used for HVAC applications, including

ON/OFF, floating, proportional managed by thermostat or

BMS handling analogue signals or PWM digital, of HVAC

2.1.2Dimensions

Overview

4. Maintenance and Cleaning

Use a damp cloth to clean the actuator.

Do not use any detergent or chemical product that may

seriously damage or compromise the function of the valve.

installations where V5004TF PICV balancing valves are

used; in order to properly set the presetting, see the specific

section devoted to actuator setting.

For further information about electrical connections, see the

specific section.

Dimensions in mm

2.1.3Approvals

•CE

Honeywell GmbH 4 MU0H-2327GE23 R0618

GB

2.1.4Technical Data

Operating temperatures

Ambient temperature range: -20°C…+60°C*

Storage temperature range: -20°C...+80°C*

Specifications

Weight: 0.975 kg

Power supply: 24V AC/DC – 50/60 Hz

Connecting cable: 18 AWG

Connection to valve: 8mm square. Easy fitting

gear

Operating life: 50.000 cycles

Control signal: 0(2)-10V 0(4)-20mA

(with 500 Ω resistor*)

ON/OFF

3 points floating PWM

Power consumption: 5 W; 2.5 W stand-by

Nominal torque: 10 Nm Max, self-limited at 7

Nm

Current absorption: 80 mA, Load max 380 mA

Feedback: 0(4) - 20 mA and 0(2) – 10 V

Manual Override: Through release button and

6mm Allen key

Protection class / IP Rating: II / IP54

Motor: Brushless DC motor

Running speed: Selectable: 1 RPM or 1.5

RPM

Fail safe: Through additional battery

*1no condensation

1

1

2.1.5Installation

If the actuator M5004 is purchased with the valve Honeywell

V5004TF, it is already installed onto the valve. If it is bought

as a spare part, follow the next procedure:

1. Completely open the valve with an 8 mm spanner (max

torque 7 Nm)

2. Install the actuator in the same position of that has been

previously removed

3. Insert the three pins in the specific buttonholes on the

fixing plate

4. Turn the fixing ring

5. Close the valve by means of the actuator which has to

be electrically connected

6. If the actuator reaches the end-stroke before the valve

is completely closed, adjust the actuator mounting

position

7. Unplug and plug the power to the actuator to perform a

new Zero Detection cycle.

Be sure the actuator is not mounted upside down to avoid any

damage due to condensation from the valve stem. Please

note that care must be taken to actuator installation: little

angular deviations can compromise the correct actuator

operation

2.1.6Settings

Actuator M5004 is delivered already set at max flow rate of

the valve where it is mounted (SET 4); if it is bought as spare

part, the customer must inform Honeywell about valve type

the actuator will be mounted on, allowing Honeywell's

technicians to properly set it.

When the actuator is powered, the valve V5004TF

corresponding code is displayed on the 4 digits screen. Verify

using the table at the end of the next page that the shown

code corresponds the installed valve. If an issue occurs,

contact Honeywell’s technicians.

To set the actuator, use the 3 buttons and the display on the

upper side. When it is switched on, the Zero Detection

function automatically starts: the display shows “Go 0“. Do not

carry out any operation while the actuator is running and the

end stroke is found: finally it displays “0”. To enter the settings

browser, push the button MODE. Use UP and DOWN buttons

to select the parameter, then push MODE to show different

options (option browsing is carried out through UP and

DOWN buttons); push MODE to confirm the selection.

SET1 Input indication selection with internal

control signal

SET2 Control signal selection

SET3 Min. flow setting

SET4 Max. flow setting

SET5 Setting display mode during operation

SET6 Rotation angle compensation

SET7 Flow offset compensation

SET8 Power failure mode

SET9 Flow rate unit selection

SET10 Control curve selection

SET11 Max. voltage control signal

SET12 Min. voltage control signal

SET13 Actuator rotation speed

SET14 Feedback signal selection

MU0H-2327GE23 R0618 5 Honeywell GmbH

GB

2

1

2.1.7Removal

If the actuator has to be removed, follow the next procedure:

1. Turn the connection ring between valve and actuator

2. Remove the actuator

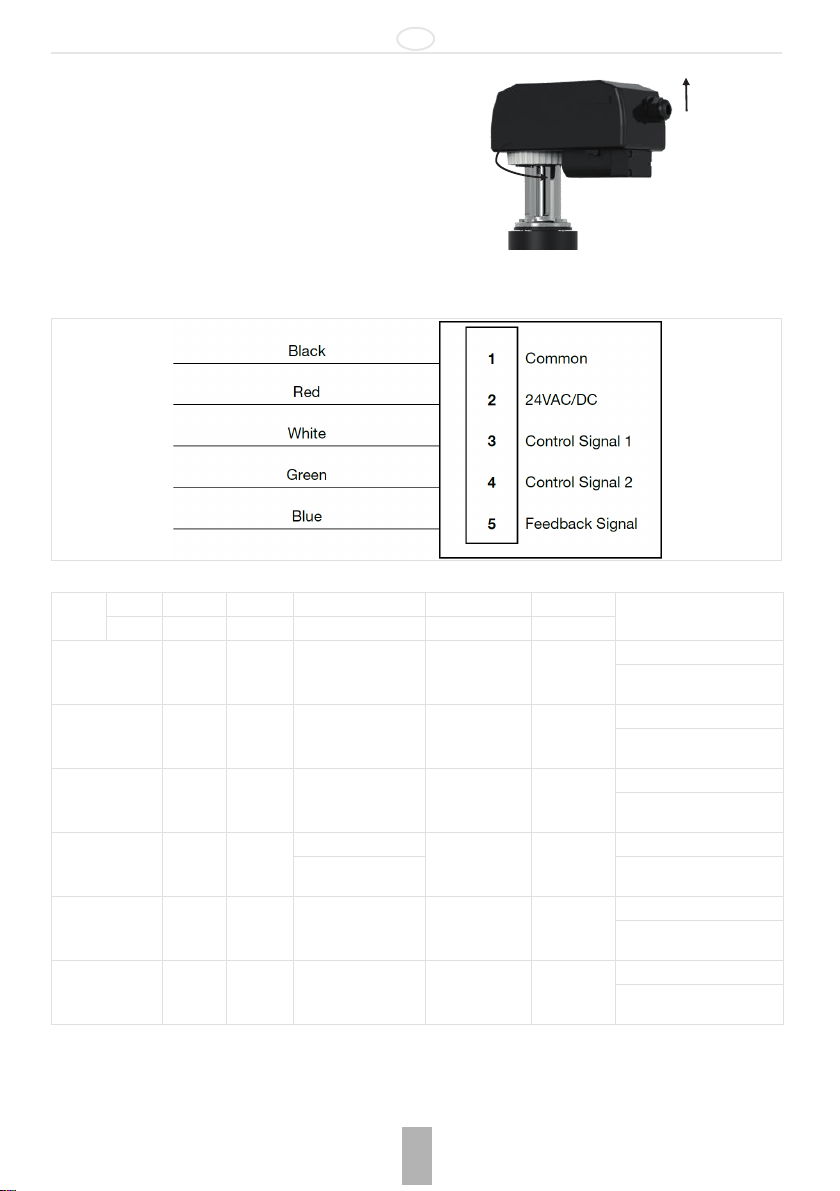

3 External Interface

3.1 Wires indication

3.2 Actuator Wiring Guide

Number 1 2 3 4 5

Input

Colour Black Red White Green Blue

Internal control Common 24 AC/DC

Voltage signal Common 24 AC/DC

Current signal Common 24 AC/DC

ON/OFF signal Common 24 AC/DC

3 points floating Common 24 AC/DC Opening 24 V AC/DC

PWM control Common 24 AC/DC PWM signal

• and are power cables

• and are signal cables

• is the exclusive feedback cable

0 - 10 V DC

2 - 10 V DC

0 - 20 mA

4 - 20 mA

24 V DC (open) Feedback:

0 V (close)

Closing 24

V AC/DC

Feedback:

0(2) - 10 V

0(4) - 20 mA

Feedback:

0(2) - 10 V

0(4) - 20 mA

Feedback:

0(2) - 10 V

0(4) - 20 mA

0(2) - 10 V

0(4) - 20 mA

Feedback:

0(2) - 10 V

0(4) - 20 mA

Feedback:

0(2) - 10 V

0(4) - 20 mA

Remarks

Power: cable 1 - 2

Power: cable 1 - 2

Voltage signal: cable 1 - 3

Power: cable 1 - 2

Current signal: cable 1 - 3

Power: cable 1 - 2

ON/OFF signal: cable 1 - 3

Power: cable 1 - 2

Floating 3 points: cable 3 - 4

Power: cable 1 - 2

PWM control: cable 1 - 3

Honeywell GmbH 6 MU0H-2327GE23 R0618

Loading...

Loading...