Page 1

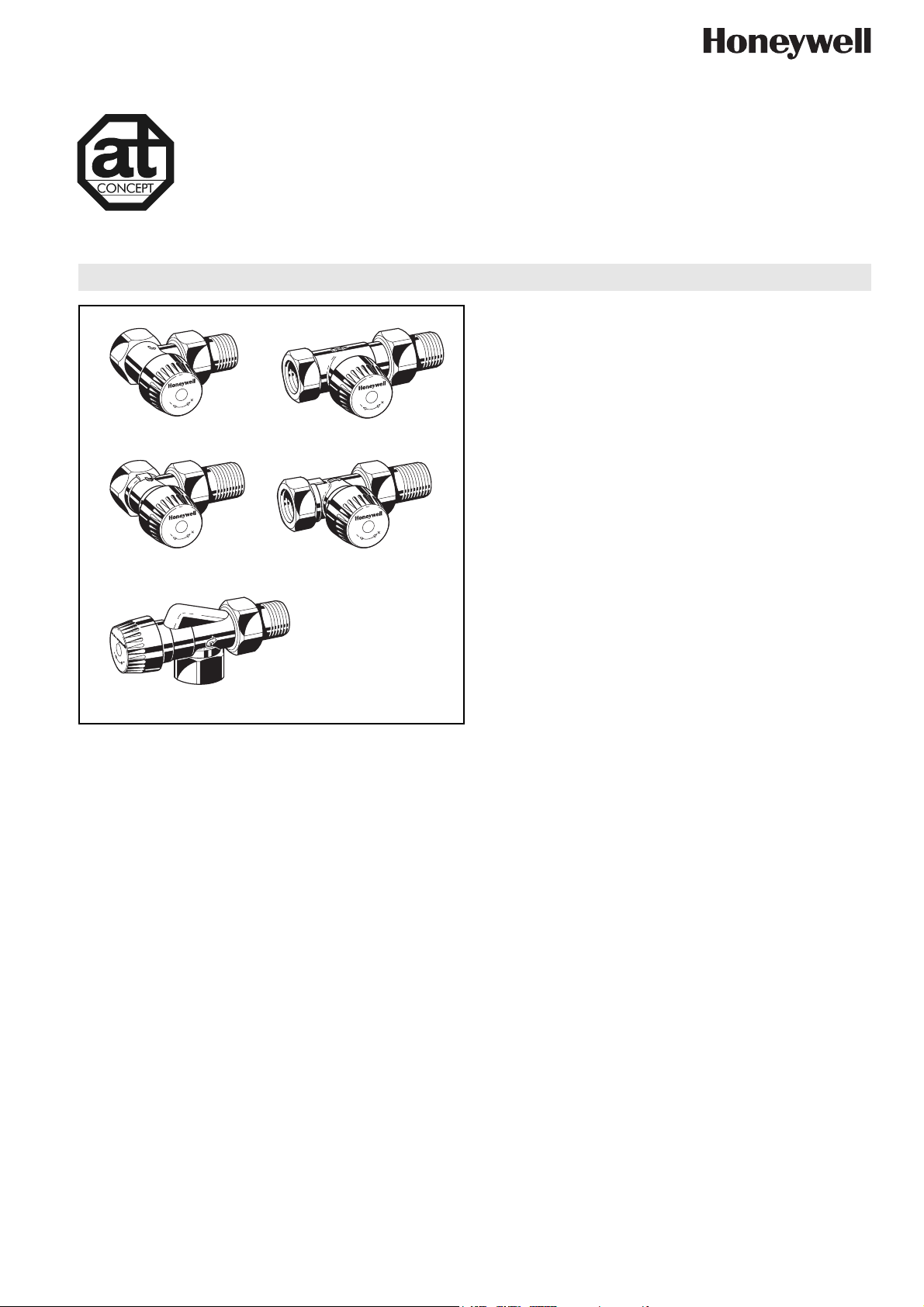

V2000FS

FS type TRV Body

FINELY PRESETTABLE RADIATOR VALVE WITH FLUSH POSITION

PRODUCT DATA

Application

1/2

1/2

Angle to DIN

1/2

Angle to NF Straight to NF

Straight to DIN

1/2

Thermostatic radiator valve bodies (TRV bodies) are fitted on

the supply or return of radiators or heat exchangers. Together

with a radiator thermostat, for example the Thera-4, they

control the room temperature by regulating the flow of hot water

into the radiator. The temperature of different rooms is

controlled individually and energy is saved.

TRV bodies of this type have quiet operation and are fitted to

the supply of radiators on two-pipe systems with small flow

rates.

The flow rate can be preset according to system requirements.

The valve insert can be replaced while the system is running

and without draining using the service tool (see ‘Accessories’).

TRV bodies of this type are suitable for

• Honeywell radiator thermostats with M30 x 1.5 connection

• Certain Honeywell MT4 actuators

• Honeywell Hometronic HR80 and Roomtronic HR40 actuators

Horizontal angle

Design

The thermostatic radiator valve body consists of:

• Valve housing PN10, DN10, 15 or 20 with

• internal thread connection to DIN2999 (ISO7) for threaded,

copper or precision steel pipe on inlet

fittings see ‘Accessories’)

• external thread connection with union-nut and radiator tailpiece on outlet

• angle to DIN and straight to DIN bodies with dimensions

according to EN215, Appendix A, Series D

• angle to NF and straight to NF bodies with dimensions

according to EN215, Appendix A, Series F

• Finely pre-settable valve insert with flush position

• Protection cap

• Union-nut and radiator tailpiece

1

(Eurocone for DN15)

1

(compression ring

Materials

• Angle/straight to DIN: valve housing made of nickel-plated

red bronze

• Angle/straight to NF and horizontal angle: valve housing

made of nickel-plated hot-forged brass

• Valve insert made of brass with EPDM O-rings and soft seals

and stainless steel spindel, brown plastic pre-setting ring

• Protection cap made of brown plastic

• Union-nut and tailpiece made of nickel-plated brass

AT-Concept

AT-Concept valves share the same valve housing design. The

valve insert can be replaced by any other AT-Concept valve

insert, i.e. BB, KV, UBG, SL, VS, FS, FV and SC.

Features

• Pre-settable fine-adjustment valve disc

• Tamper-proof presetting, visible when radiator thermostat is removed

• For heating systems with small flow rates

• With extra position for system flushing

• Quiet operation

• DIN type bodies with dimensions according to EN215,

Appendix A, Series D

• NF type bodies with dimensions according to EN215,

Appendix A, Series F

• AT-Concept valve housing and insert

• Valve insert can be replaced while system is operating

and without draining the system

• Valve opening spring is not in the water

• Standard M30 x 1.5 thermostat connection

• Supplied with brown protection cap, imprinted ‘FS’ for

clear identification

Honeywell y Subject to change EN0H-2104GE25 R0307

Page 2

V2000FS - FS TYPE TRV BODY

Specifications

Medium Heating water, water quality to

VDI2035

Operating temperature max. 130°C (266°F)

Operating pressure PN10

Differential pressure max. 2 bar (29 psi) –

k

(cv)-value 0.51

v

Nominal flow 111 kg/h

Thermostat connection M30 x 1.5

Closing dimension 11.5 mm

Stroke 2.5 mm

max. 0.2 bar (2.9 psi) recommended

for quiet operation

Identification

• Brown protection cap, ‘FS’ embossed on top of cap

• Brass valve insert with brown plastic dial on top

Installation Example

Function

Thermostatic radiator valves enable individual control of room

temperature and thus save energy.

The TRV body is controlled by the radiator thermostat. Air from

the room passing over the sensor of the radiator thermostat

causes the sensor to expand when the temperature rises. The

sensor acts onto the valve spindle and this causes the TRV

body to close. When the temperature falls the sensor contracts

and the spring-loaded valve spindle is opened. The TRV opens

in proportion to the temperature of the sensor. Only the amount

of water required to maintain the room temperature set on the

radiator thermostat can flow into the radiator.

Please Note:

• To avoid stone deposit and corrosion the composition of the

medium should conform with VDI-Guideline 2035

• Additives have to be suitable for EPDM sealings

• System has to be flushed thoroughly before initial operation

with all valves fully open

• Any complaints or costs resulting from non-compliance with

above rules will not be accepted by Honeywell

• Please contact us if you should have any special requirements or needs

Fig. 1. Angle Fig. 2. Straight

Fig. 3. Horizontal angle

EN0H-2104GE25 R0307 2 Honeywell y Subject to change

Page 3

Dimensions and Ordering Information

Fig. 4. Angle Fig. 5. Straight

h

V2000FS - FS TYPE TRV BODY

l

H

L

Fig. 6. Horizontal angle

Body type DN kvs(cv)-

value

Pipe

connection

For the supply

Angle to EN215 (D)

(Fig. 4)

10 0.51 (0.60) Rp 3/8” 26 52 22 20 — V2000EFS10

15 0.51 (0.60) Rp

1

20 0.51 (0.60) Rp 3/4" 34 66 29 19 — V2000EFS20

Straight to EN215 (D)

(Fig. 5)

10 0.51 (0.60) Rp

15 0.51 (0.60) Rp

3

1

20 0.51 (0.60) Rp 3/4" 74 106 — 25 — V2000DFS20

Angle to EN215 (F)

(Fig. 4)

Straight to EN215 (F)

(Fig. 5)

Horizontal angle

(Fig. 6)

10 0.51 (0.60) Rp

15 0.51 (0.60) Rp

10 0.51 (0.60) Rp 3/8” 50 75 — 26 — V2020DFS10

15 0.51 (0.60) Rp

10 0.51 (0.60) Rp

15 0.51 (0.60) Rp

3

1

1

3

1

NOTE: All dimensions in mm unless stated otherwise.

l L h H h

2

OS-No.

/2” 29 58 26 20 — V2000EFS15

/8” 59 85 — 25 — V2000DFS10

/2” 66 95 — 25 — V2000DFS15

/8” 24 49 20 21 — V2020EFS10

/2” 26 53 23 22 — V2020EFS15

/2” 55 82 — 26 — V2020DFS15

/8” 24 50 22 33 — V2000AFS10

/2” 26 54 26 35 — V2000AFS15

Honeywell y Subject to change 3 EN0H-2104GE25 R0307

Page 4

V2000FS - FS TYPE TRV BODY

Accessories

Pipe Connections Valve Accessories

Compression ring and nut

3/8" x 10 mm VA620A1010

3/8" x 12 mm VA620A1012

1/2" x 10 mm VA620A1510

1/2" x 12 mm VA620A1512

1/2" x 14 mm VA620A1514

1/2" x 15 mm VA620A1515

1/2" x 16 mm VA620A1516

NOTE: Support inserts have to be used for copper or soft

steel pipe with 1.0 mm wall thickness

Compression ring and nut with support insert (2 pcs

each)

3/8" x 12 mm VA621A1012

1/2" x 12 mm VA621A1512

1/2" x 15 mm VA621A1515

1/2" x 16 mm VA621A1516

Compression ring and nut with support insert for composite pipe (2 pcs each)

1/2" x 14 mm VA622B1514

1/2" x 16 mm VA622B1516

Reduction piece

1" pipe > 1/2" valve VA6290A260

1 1/4" pipe > 1/2" valve VA6290A280

Manual handwheel cap

Pre-settable, with integrated

locking device

Pressure cap – for shutting off valves on radiator oulet

for valves DN10 (3/8") VA2202A010

for valves DN15 (1/2") VA2202A015

Sealing ring for pressure cap

for valves DN10 (3/8") VA5090A010

for valves DN15 (1/2") VA5090A015

Service tool to replace valve insert

for all sizes VA8200A001

Precision pre-setting key

for all VS and FS type valves VA8201FV03

Pre-setting key

for all VS, V, FS and FV type

valves

Replacement valve insert

FS type VS1200FS01

VA2200D001

VA8201FV02

Radiator tailpiece with thread up to collar

for valves DN10 (3/8") VA5201A010

for valves DN15 (1/2") VA5201A015

Extended radiator tailpiece, nickel-plated, to be shortened

as required

3/8" x 70 mm (for DN10)

thread approx. 50 mm

1/2" x 76 mm (for DN15)

thread approx. 65 mm

Soldering tailpiece

3/8" x 12 mm (for DN10) VA5230A010

1/2" x 15 mm (for DN15) VA5230A015

VA5204A010

VA5204A015

EN0H-2104GE25 R0307 4 Honeywell y Subject to change

Page 5

Flow Diagram

V2000FS - FS TYPE TRV BODY

Pre-setting 12345678

xP = 1K (m3/h) 0.02 0.04 0.10 0.14 0.16 0.17 0.18 0.18

xP = 2K (m3/h) 0.02 0.04 0.11 0.19 0.25 0.29 0.32 0.35

kvs-value (m3/h) 0.02 0.04 0.12 0.21 0.30 0.37 0.45 0.51

NOTE: Pre-setting 8 = flush position, set by factory

Design Example

Given: Flow rate 75 kg/h

Required: Pre-setting for a required pressure loss ∆p = 90 mbar = 9 000 Pa with a P-band of 2K

Solution: The required pressure loss is found at the intersection of the flow line with the line for the

chosen valve performance P=2K

Result: Pre-setting 5

Honeywell y Subject to change 5 EN0H-2104GE25 R0307

Page 6

V2000FS - FS TYPE TRV BODY

Automation and Control Solutions

Honeywell GmbH

Hardhofweg

74821 Mosbach, Germany

Phone: +49 (6261) 810

Fax: +49 (6261) 81393

www.honeywell.com

EN0H-2104GE25 R0307

March 2007

© 2007 Honeywell International Inc.

Subject to change • All rights reserved

Manufactured for and on behalf of the Environmental and Combustion

Controls Division of Honeywell Technologies Sàrl, Ecublens, Route

du Bois 37, Switzerland or its authorized representative.

Loading...

Loading...