Honeywell TrueZONE ARD Series, TrueZONE EARD Series, TrueZONE ZD Series Installation Instructions

Page 1

TrueZONE ARD, EARD, and ZD

Series Dampers

INSTALLATION INSTRUCTIONS

APPLICATION

ARD Series Damper

The ARD is a round damper with a 24 Vac, spring-Open return

damper motor used to control circulating air in heating,

cooling, and ventilating systems.

EARD Series Damper

The EARD is a round damper with a 24 Vac powered-open/

spring-closed motor. It is used for fresh air intake for

Ventilation or for combustion makeup air.

ZD Series Damper

The ZD is a power close and spring open damper. It has a 24volt motor used to control circulating air in HVAC systems and

used when a normally-open damper is required. The ZD is

typically used with the TrueZONE and other electronic zoning

systems.

FEATURES

• Taping Flange and non-interfering set screw

• High Temperature outer plastic for hot environments

• Redesigned all Metal Drive Train Gears

• Front facing display with LED Indication light for Open

and Close.

• Adjustable damper position range stops

• Quiet operation.

ARD Features

• Adjustable close position range stops

• Shipped as power closed/spring return open damper.

• Available in 5 to 10” inch, 12, 14, 16, 18, and 20 inch

diameter sizes.

• Male (crimped) and female (uncrimped) ends to connect to

any rigid or flexible round duct.

• Rated to operate up to 1 in. wc

• Blade closes off tightly against gasket for minimal leakage.

• Fail-safe, normally open operation

• Simple, easy-to-wire, two-wire installation with a third wire

option M4 for LED open only light

EARD Features

• Adjustable open position range stops

• Shipped as power open/spring return closed damper.

• Blade closes off tightly against gasket for minimal leakage.

• Galvanized steel

• Rated to operate up to 1 in. wc

• Simple, easy-to-wire, two-wire installation

• Male (crimped) and female (uncrimped) ends to connect to

any rigid or flexible round duct.

ZD Features

• Adjustable closed position range stops

• Rated to operate up to 1 in. wc

• Solid construction using extruded aluminum frame and

blades

• Parallel blade design for low leakage performance

• Simple, easy-to-wire, two-wire installation with a third wire

option M4 for LED open light

• Fail-safe, normally open operation

• Ordering Instructions: Order ZD (dimension 1) x

(dimension 2). (Motor is always mounted on dimension 2

side.) For example, ZD10x8TZ is a 10 in. x 8 in. damper

with the motor on the 8 in. side; but a ZD8x10TZ is a 8 in. x

10 in. damper that has the motor on the 10 in. side.

• Damper can be installed in any orientation (mounting side

can be on either the bottom or the side of the duct).

33-00040-01

Page 2

TRUEZONE ARD, EARD, AND ZD SERIES DAMPERS

M35186

4-1/16

(103)

4-41/64

(118)

3-61/64

(100)

4-31/32

(126)

SPECIFICATIONS

IMPORTANT

The specifications given in this publication do not

include normal manufacturing tolerances. Therefore,

this unit may not exactly match the listed specifications. Also, this product is tested and calibrated

under closely controlled conditions, and some minor

differences in performance can be expected if those

conditions are changed.

Motor Electrical Rating: 24 Vac, 60 Hz, 8VA.

Motor Electrical Connection: Push terminals. Solid (not

stranded) wire is recommend.

Motor Nominal Angular Rotation: 90°.

Motor Torque: Minimum 71 in.-oz. (500 millinewton meters)

output torque available when motor is energized and

device is at the spring return initial start position.

Nominal Motor Timing at 77°F (25°C) Ambient:

Energized at rated load: 30 seconds.

De-energized (spring return): 10 seconds.

Motor Ambient Temperature Rating: 40° to 140°F (5° to

60°C).

Leakage: Less than 1% at 1/2 in. wc.

Pressure Drop: Maximum at full open: 0.0329 in. wc at 800

ft/min.

Maximum Static Pressure: 1 in. wc for all models except 0.3

in. wc for ARD20.

Motor Shaft Rotation Direction: Clockwise, when ener-

gized and viewed from the base or shaft end.

Motor Mounting Means: Direct connection to damper shaft.

Motor Mounting Position: Multi-poise.

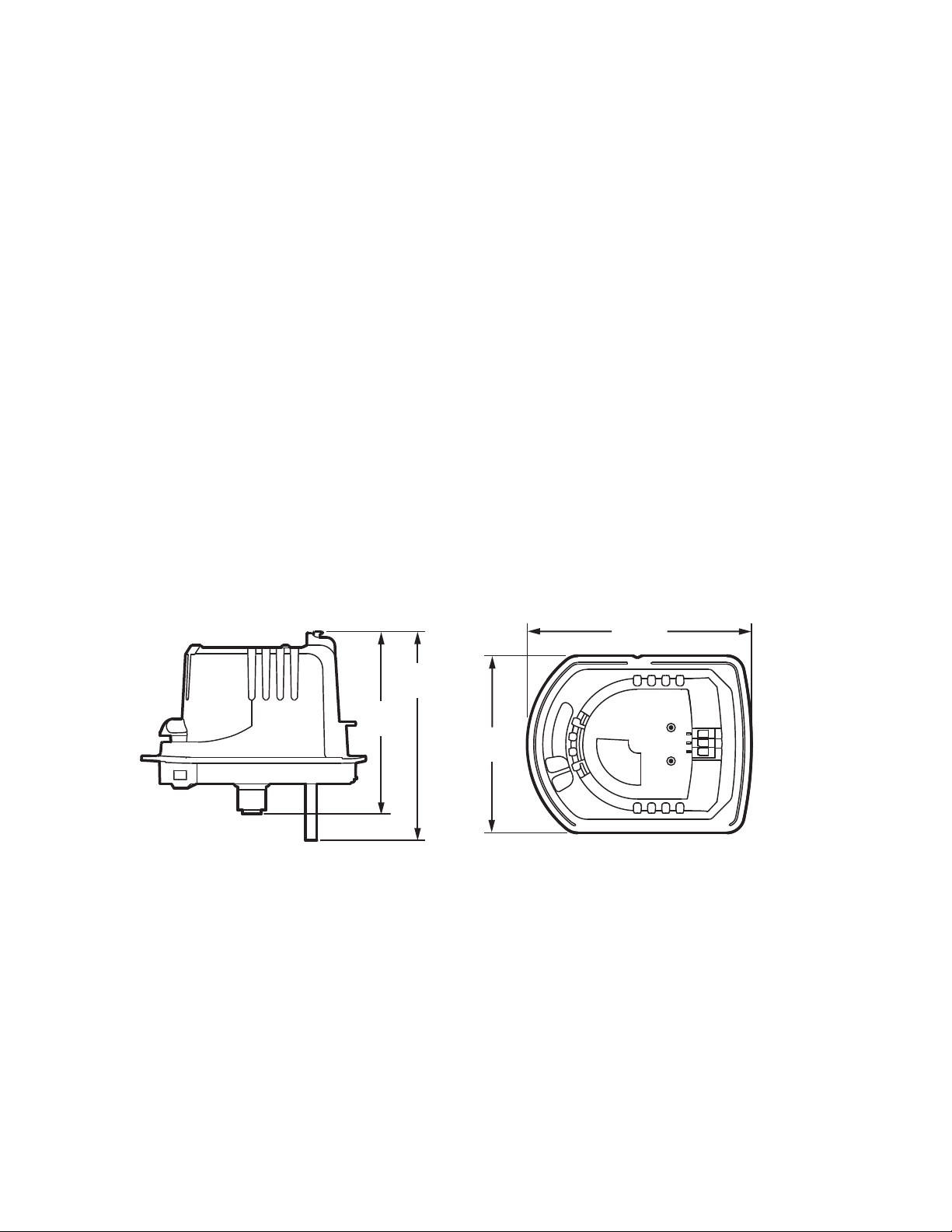

Motor Dimensions: See Fig. 1.

Construction

ARD Dampers

Frame: Galvanized steel spiral duct, crimped on down-

stream side.

ARD Sizes: 5 in., 6 in., 7 in., 8 in., 9 in., 10 in., 12 in., 14 in.,

16 in., 18 in., and 20 in. diameters.

Gauge: ARD5-ARD12: 24 Gauge frame, and 22 Gauge

Blade: ARD14-ARD20: 22 Gauge frame, and 20 Gauge

Blade

EARD Dampers

Frame: Galvanized steel spiral duct

EARD Sizes: 5-, 6-. 7-, and 8-, inch diameter sizes

ZD Dampers

Frame: Solid construction using extruded aluminum frame

and blades

ZD Sizes: Even sizes from 6in. x 6in. up to 36 in x 36 in.

Damper dimensions: All ZD dampers are actually sized 5/

32 in. smaller than the listed size to ensure correct fit.

Fig. 1. Motor and damper dimensions in in. (mm).

INSTALLATION OF ARD AND EARD DAMPERS

Before Installing this Product…

1. Read all instructions before installing this product. Fail-

ure to follow the instructions can damage the product or

cause a hazardous condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

33-00040—01 2

3. Installer must be a trained, experienced service technician.

4. Install the product in an area that is easily accessible for

checkout and service.

5. After completing installation, use these instructions to

check out the product operation.

Page 3

TRUEZONE ARD, EARD, AND ZD SERIES DAMPERS

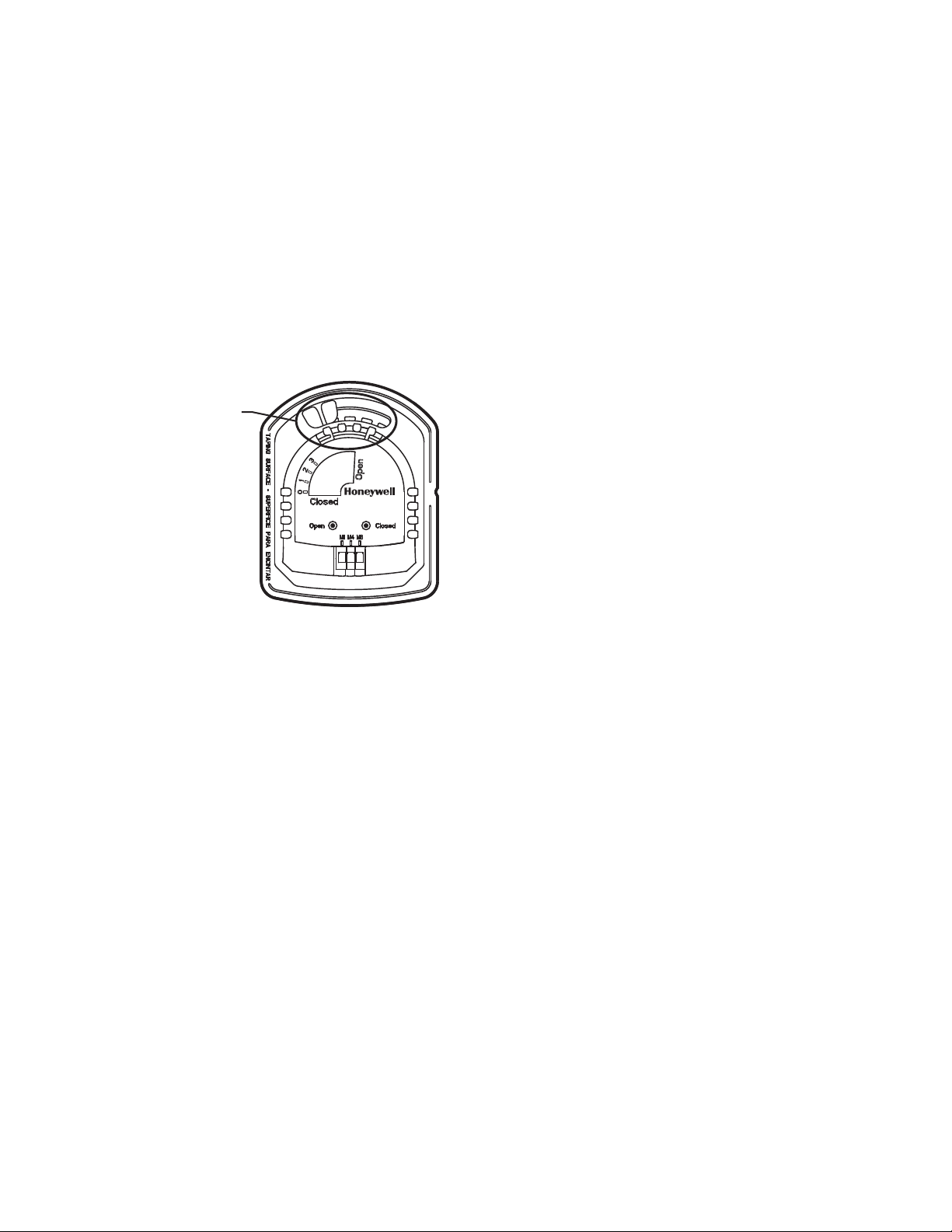

M35187

RANGE STOP

LOCATIONS

Installing the Round (ARD and

EARD) Dampers

1. Insert the crimped end of the ARD or EARD into the

uncrimped end of the rigid round duct and secure with

sheet metal screws (not provided). When using flexible

duct, slip the duct over the end of the ARD or EARD and

secure it with duct straps (not provided).

2. When installing the damper in a horizontal application,

make sure the motor actuator is located on the side or

top of the damper. Do not locate the motor on the bottom of the damper. The damper can be mounted in a

vertical duct.

3. Adjust Range stop position to desired closed positions.

ARD and ZD Dampers are completely closed in position

0. EARD Dampers are completely open in position 0.

Planning the Installation

Selecting a Location

Select a location for the zone dampers that is at least three

feet from the HVAC unit plenum in the air duct takeoff to the

respective zone and is easily accessible for checkout and

maintenance.

The ZD comes complete and ready for installation. The motor

and linkage are factory-assembled to the damper. The

damper is assembled for installation and wiring to the control

panel.

Selecting Damper Size

To ensure correct operation, be sure to select the correct zone

damper size for the air duct:

IMPORTANT

Be aware that damper sizes are built 5/32 in. smaller

than the listed dimensional sizes.

• If the damper is forced into an undersized air duct, the

excess pressure can jam the damper blades and cause

improper operation.

• When a small percentage of continuous flow is desired in a

zone, even when the damper blades are closed, adjust

motor closed position to be slightly open to maintain

desired air flow.

Fig. 2. TrueZONE Actuator range stop positions.

Wiring Multiple Dampers

When the same zone controls two or more dampers, wire the

dampers in parallel to terminals M1 and M6 on the zone

control panel.

INSTALLATION OF ZD DAMPER

When Installing this Product…

1. Read these instructions carefully. Failure to follow these

instructions can damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service technician.

4. All wiring must comply with local electrical codes, ordinances, and regulations.

5. After completing installation, use these instructions to

check out the product operation.

Selecting Location with Humidifier

Installed

IMPORTANT

Excessive lime or mineral deposits can accumulate

on damper blades and cause improper operation

when spray or atomizing type humidifiers are

installed in the furnace plenum or air supply duct with

the zone dampers.

• Spray or atomizer type humidifiers that are installed in the

furnace plenum or air supply duct are not recommended.

• Evaporative type humidifiers are recommended.

Installing the Damper

IMPORTANT

— Install dampers into a squared air duct.

— Do not weld dampers to the air ducts.

— Do not force dampers into undersized air ducts.

Excess pressure can damage damper blades.

— Be sure high limit setting is less than 200° F (93°C).

— Higher settings can damage the electric actuator.

1. Be sure the ZD is correctly sized to the air duct (see

Selecting Damper Size section).

2. Select a ZD location that is three feet from the furnace

plenum.

3. Cut a 4-in. (102 mm) opening in the accessible side of

the air duct at the location selected; ensure the opening

of the air duct is cut fully from seam to seam.

4. Secure the ZD mounting plate to the air duct with the

self-tapping sheet metal screws provided.

3 33-00040—01

Page 4

TRUEZONE ARD, EARD, AND ZD SERIES DAMPERS

CAUTION

CAUTION

WIRING

Personal Electrical Shock Hazard. Can cause

electrical shock or equipment damage.

Disconnect power before beginning installation.

The damper motor has a 24 Vac, 50/60 cycle, 8 VA rating. The

spring-return ARD and ZD damper requires 24 Vac to the two

motor leads to power the damper closed. The damper then

returns to its normal open position once power is removed.

EARD damper requires 24 Vac to the two motor leads to

power the damper open. The damper then returns to its

normal closed position once power is removed.

NOTE: Multiple dampers can be wired in parallel.

Wiring a Motor

See Fig. 3 and 7 for motor wiring hookups for ARD and ZD

Dampers

Changing Motor on ARD, EARD and

ZD Dampers

1. Disconnect the motor wiring.

2. Loosen the socket head cap set screw located between

the faceplate and the motor coupling.

3. Remove the motor.

4. Ensure damper blade is in the open position with the set

screw pointing toward the open position on the label.

5. Attach new motor to the coupling; be sure the standoff

on motor is positioned in the grommet on the faceplate

and the set screw is aligned with the motor shaft hole.

6. Tighten the set screw.

Wiring a Single ARD (Power Closed)

to a Control Panel

CLOSED

M6

OPEN

M4

COMMON

M1

ARD CONFIGURED

AS POWER CLOSED

M14843

Fig. 3. ARD configured as power closed.

Checkout

Possible Equipment Damage

Do not manually open or close the damper as this can

damage the actuator.

To check out the ARD:

1. With 24 Vac applied to the motor leads, observe the

motor powering the damper to the closed position.

2. When energized, verify that the actuator connection

coupling rotates in a clockwise direction (as viewed from

the operator base end) and that the damper shaft turns

with the coupling.

3. With power removed, observe the damper returning to

the normally-open position.

33-00040—01 4

NOTE: To remove power, disconnect one wire from the

motor.

4. If the motor does not operate smoothly and without hes-

itation throughout the complete opening and closing

stroke, examine the damper and the shaft for free rotation within the duct.

Page 5

Wiring an EARD to a W8150

M23591

HVAC

WCRYG

VISIONPRO TH9000

THERMOSTAT

H

U

M

D

H

M

V

N

T

OR

1

2

3

C

R

RC

RH

24 VAC

COMMUNICATION

TERMINALS

COMMUNICATION LED

W1

W2

W3

Y

Y2

G

O/B

AUX

AUX2

Y

Y2

G

CONV. HP

L

NOT USED

1

2

1

2

SYSTEM MONITOR

NOT USED

OUTDOOR

TEMP

SENSOR

INDOOR

TEMP

SENSOR

DISCHARGE

AIR TEMP

SENSOR

1

2

D

A

T

S

O

U

T

I

N

1

EARD

2

3

HVAC

W C RC Y G

TRUEZONE ARD, EARD, AND ZD SERIES DAMPERS

AT12 0

G

R

C

C

C

C

H

W

G

R

C

DAMPE R

AUX

REMOTE

W C R C RY G

TH81 10 U

W8150A

Fig. 4. EARD and W8150 wiring.

Wiring an EARD to a VisionPRO® IAQ Thermostat

EARD-6

M23547

Fig. 5. EARD and VisionPRO® IAQ thermostat wiring.

5 33-00040—01

Page 6

TRUEZONE ARD, EARD, AND ZD SERIES DAMPERS

123

123

123

L

C

RH

RC

W1/E

W2

W3/AUX

Y1

Y2

G

O/B

HUM

HUM

DEHUM

DEHUM

VENT

VENT

R

C

T1

T2

ZONE1

M6 M4 M1

ZONE2

M6 M4 M1

ZONE3

M6 M4 M1

1 2 3 1 2 3 1 2 3 1 2 3

DAMPERS ENVIRACOM BUS

DA MPER

XFRM

ENVIR ACOM

XFRM

REM OVE JUMPER S IF

T1 AND T2 ARE USED

HEAT COOL ZONE 1COMEM H EATFANPUR GE ZON E 3ZONE 2

W8835A

DIP SW ITCH SETTINGS

1 SEE T ABLE ON OFF

2 SEE T ABLE 1 0

3 ENVIRACOM FURN NO YES

4 P URGE T IME 2 M IN 3.5 M IN

5 PU RGE FAN HVA C PAN EL

6 PURGE DAMPER NO CHG OPEN

7 # COM P STAG ES 1 2

8 HEAT FAN HVAC PANEL

9 HP CHANGEOVER O B

10 U NUSE D

O

N

1 2 3 4 5 6 7 8 9 10

#1 #2 CONV HT STG

1 1 1

1 0 2

0 1 3

0 0 H P

24 VOLT/40 VA

TR ANSFO RMER

R

C

L1

L2

R

W1

W2

Y1

Y2

G

C

DOTTED LINES FOR 2STAG E APPLICAT ION S

SINGL E TRANSF ORMER

HEATING/COOLING SYSTEMS

REQUI RE A JUM PER TO BE

INS TAL LED C ONNECTING R H

AND RC (FACTORY INSTALLED).

123

EARD-6

M23578

POWER-CLOSED/

SPRING-OPEN

ZD DAMPER

POWER-CLOSED/

SPRING-OPEN

ZD DAMPER

POWER-CLOSED/

SPRING-OPEN

ARD DAMPER

VISIONPRO IAQ

C7835A DISCHARGE

AIR SENSOR

VISIONPRO IAQ

VISIONPRO IAQ

Fig. 6. EARD with W8835 EnviraZone panel.

33-00040—01 6

Page 7

CHECKOUT

CAUTION

CLOSED M6

M14851A

OPEN M4

COM M1

NOTE:

WHEN INSTALLING ON OLDER MASTERTROL

TM

BOARDS SUCH AS THE MARK V, JUMPER

M2-M5 ON THE PANEL.

To check out the EARD:

1. With 24 Vac applied to the motor leads, observe the

motor powering the damper to the open position.

2. When energized, verify that the actuator connection

coupling rotates in a clockwise direction (as viewed from

the operator base end) and that the damper shaft turns

with the coupling.

3. With power removed, observe the damper returning to

the normally-closed position.

TRUEZONE ARD, EARD, AND ZD SERIES DAMPERS

NOTE: To remove power, disconnect one wire from

the motor.

4. If the motor does not operate smoothly and without hesitation throughout the complete opening and closing

stroke, examine the damper and the shaft for free rotation within the duct.

ZD Damper WIRING

Personal Electrical Shock Hazard.

Can cause electrical shock or equipment damage.

Disconnect power before beginning installation.

The ZD has a 24 Vac, 50/60 cycle, .32A motor. The ZD is

wired to terminals M1 and M6 for power closed/spring return

open, with an option for M4 wire to power LED light only. The

ZD is a spring return damper that requires 24V to the two

motor leads to power the damper closed. When power is

removed from the motor, the damper springs back to its

normally-open position. When used with Honeywell

Networked Zoning, use closed and com terminals.

Fig. 7. Power closed spring return open ZD wiring.

Wiring Multiple Dampers

When the same zone controls two or more dampers, wire the

dampers in parallel to terminals M1 and M6 on the zone

control panel.

Wiring a Motor

See Fig. 7 for typical motor wiring hookup.

CHECKOUT

To check out the ZD:

1. With 24 Vac applied to the motor leads, observe the

motor powering the damper to the closed position.

2. When energized, verify that the actuator connection

coupling rotates in a clockwise direction (as viewed from

the operator base end) and that the damper shaft turns

with the coupling.

3. With power removed, observe the damper returning to

the normally-open position.

NOTE: To remove power, disconnect one wire from

the motor.

4. If the motor does not operate smoothly and without hesitation throughout the complete opening and closing

stroke, examine the damper and the shaft for free rotation within the duct.

7 33-00040—01

Loading...

Loading...