Page 1

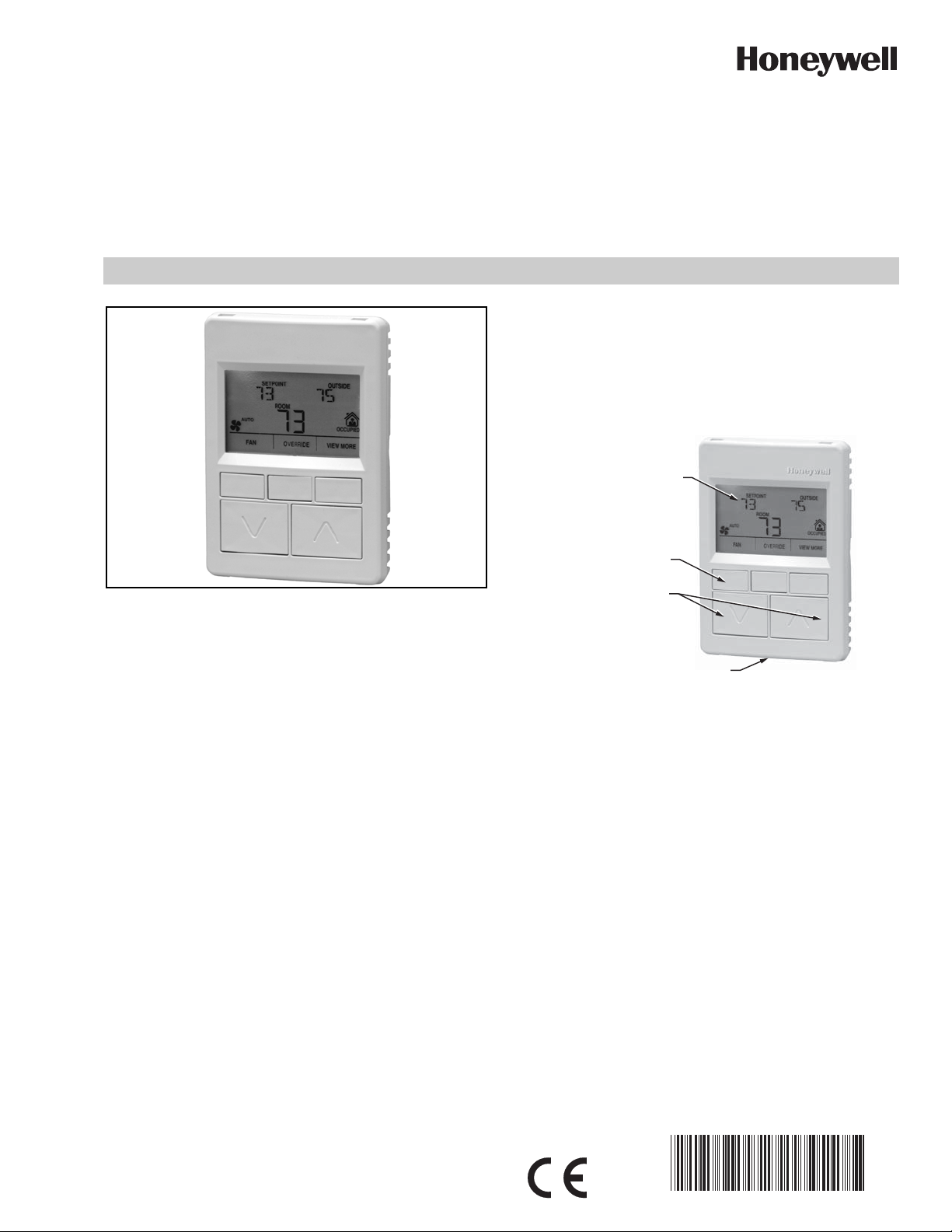

Zio®/Zio Plus LCD Wall Modules

LCD PANEL

M27344

SOFTKEYS (3)

UP/DOWN

ARROW KEYS

NETWORK BUS PORT (ON BOTTOM OF CASE)

TR70, TR71, TR75 with Sylk® Bus

OPERATING GUIDE

begins with “Initial Power-Up” on page 2, and the general

overview begins with “Operating the Zio Wall Module” on

page 19.

It is intended to guide you through the features and operation

of the TR70 Series as you interface with the programmable

controller and establish pre-programmed or custom

configurations.

APPLICATION

The Zio TR70 Series (TR70, TR70-H, TR71, TR71-H, TR75,

and TR75-H OS numbers) LCD Wall Modules provide an

operator interface for monitoring and adjusting parameters in

the wall module itself and in the programmable controller

(refer to the

or the

form 63-2663, depending on the programmable controller

used) to which it is wired. The wall module may be customized

and supports both a contractor and a tenant user interface.

NOTE: This document illustrates the wall module configura-

The wall module has a snap in mounting to a subbase that

may be mounted on a wall, on a standard utility conduit box, or

on a 60 mm wall outlet box. Wiring connections to the wall

module are made through a cutout in the back of the wall

module.

All models have a space temperature sensor, network bus

jack, and an LCD panel with three softkeys and two Up/Down

adjustment keys. Models with -H also include an onboard

humidity sensor.

Honeywell Spyder® User’s Guide,

form 63-2662,

ComfortPoint™ Programmable Controller User’s Guide,

tion process using information from the

Spyder User’s Guide

(form 63-2662).

Honeywell

PREFACE

This Operating Guide is intended to provide configuration

information (using the Niagara Workbench tool) and a general

overview of the TR70 Series operator interface. Configuration

Fig. 1. LCD Wall Module features.

Contents

Application ........................................................................ 1

Preface ............................................................................. 1

TR70 Series Features ....................................................... 2

Compatibility ............................................................. 2

Initial Power-Up ................................................................. 2

Setup and Configuration ................................................... 3

Initial Setup and Configuration .................................. 3

Selecting the Wall Module ......................................... 3

TR71/TR75 Labels .................................................... 3

Navigation and Memory Usage ................................. 3

Wall Module Configuration ........................................ 4

General Settings ................................................... 5

Categories and Parameters .................................. 5

Home Screen Options ........................................... 9

Occupancy and Override ...................................... 10

Fan Command ....................................................... 12

System Status and Command .............................. 13

Schedule/Time ...................................................... 14

Password ............................................................... 15

Preview .................................................................. 16

Completing the Setup and Configuration .................. 17

Operating the Zio Wall Module ......................................... 19

Contractor Mode Operation ...................................... 19

Tenant Mode Operation ............................................ 22

63-2719-03

Page 2

ZIO®/ZIO PLUS LCD WALL MODULES

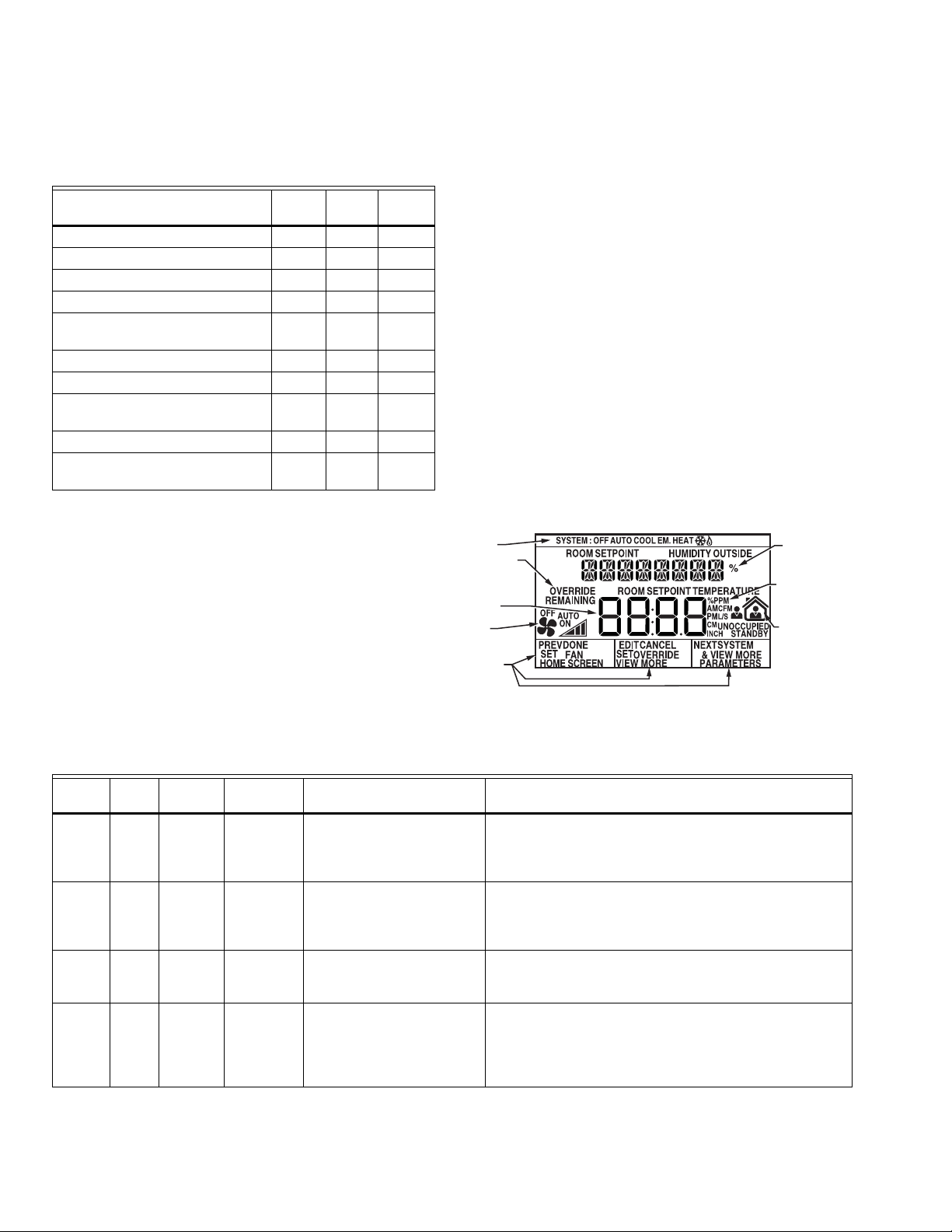

SYSTEM

STATUS

AREA

FAN

INFORMATION

SOFTKEY

LABELS

LABEL/

VALUE

(8 CHAR.)

CURRENT

DISPLAYED

VALUE

OCCUPANCY

STATUS

ENGINEERING

UNITS

OVERRIDE

INFORMATION

M27353

TR70 SERIES FEATURES

Table 1. TR70 Series Features.

Features

TR70

Scheduling x

Parameter Memory (bytes) 1K 2K 4.9K

Up to four Zios on Sylk x* x x

Enumerated Values x x

Setpoint Limits as NVs – linking

now possible

System and Fan command as NVs x x

Password protection x x

Firmware version/model visible on

display

0.5 and 5 value increments x x

"-" and "/" characters in parameter

names

* A maximum of four Zios may be wired on a single Sylk bus,

with no more than one TR70 per bus.

Compatibility

The TR70 Series LCD Wall Modules operate with the Sylk

Enhanced Spyder Controller or the Sylk Enhanced

ComfortPoint Controller. The table below provides

compatibility information for each model. The TR71/TR75 can

replace a TR70 in an installation where an upgrade to WEBsAX or Spyder or reprogramming is not desired. Features like

scheduling, additional memory, etc. will not be available.

Zio

Zio

Zio Plus

TR71

TR75

xx

xx

xx

Likewise, a TR71 can be replaced by another TR71 or TR75

without reprogramming required. A TR75 can only be

replaced with a TR75 where no reprogramming is desired.

INITIAL POWER-UP

IMPORTANT

1. Make sure the TR70 Series wall module is properly

mounted and properly wired and connected to the

programmable controller.

2. Refer to the Zio™ LCD Wall Modules TR70 Series

with Sylk™ Bus – Installation Instructions, form 620271, for specific installation requirements.

Upon initial power-up before configuring the wall module, the

LCD screen displays the phrase “PLEASE LOAd” in the Label/

Value area of Fig. 2. This phrase alternates with any onboard

sensor display such as temperature. The TR71/TR75 also

display the firmware revision number, model number and Sylk

bus address as shown in Fig. 27.

Fig. 2 illustrates all the possible LCD Wall Module display

elements. Only those elements pertinent to the current

configuration and status actually display.

Fig. 2. TR70 Series Wall Module - LCD screen.

Table 2. Compatibility.*

ScenarioSpyde

r Tool

1 5.200+Latest YES New TR71/75 functionality

Spyder

Firmware

Compatible

? Zio TR70/TR71/TR75* What can be done?

Ideal scenario

available (if TR70 is present,

then only TR70

functionality)

2 5.200+Old YES Only with TR70 functionality

(TR71/75 can be used, but

Spyder firmware can be upgraded (this becomes scenario

1)

only TR70 functionality will

be there)

3 < 5.18 Latest NO Tool does not recognize the

new Spyder

Spyder Tool can be upgraded (this becomes scenario 1)

Spyder firmware can be downgraded (this becomes

scenario 4)

4 < 5.18 Old YES Only with TR70 functionality

(TR71/75 can be used, but

only TR70 functionality will

be there)

Both Spyder firmware and Tool can be upgraded (this

becomes scenario 1)

Spyder Tool can be upgraded (this becomes scenario 2)

Spyder firmware can be upgraded (this becomes scenario

3)

* The new Spyder tool (6.0 or greater) assumes the latest Spyder capability. At download, the Tool reads the brand/model of the

connected Spyder and determines if it matches the features on the wire sheet. If old or new Spyder is programmed with aTR70,

it can be physically replaced with a TR71 or TR75.

63-2719—03 2

Page 3

ZIO®/ZIO PLUS LCD WALL MODULES

VAV_Temp_NoBal_NwOvrdTime

VAV_Temp_MnMxBal_NwOvrdTime

VAV_Temp_KfacBal_NwOvrdTime

VAV_Temp_NoBal_AllOverride

SBusWallModule

M27820

RIGHT CLICK

DRAG

AND

DROP

1

2

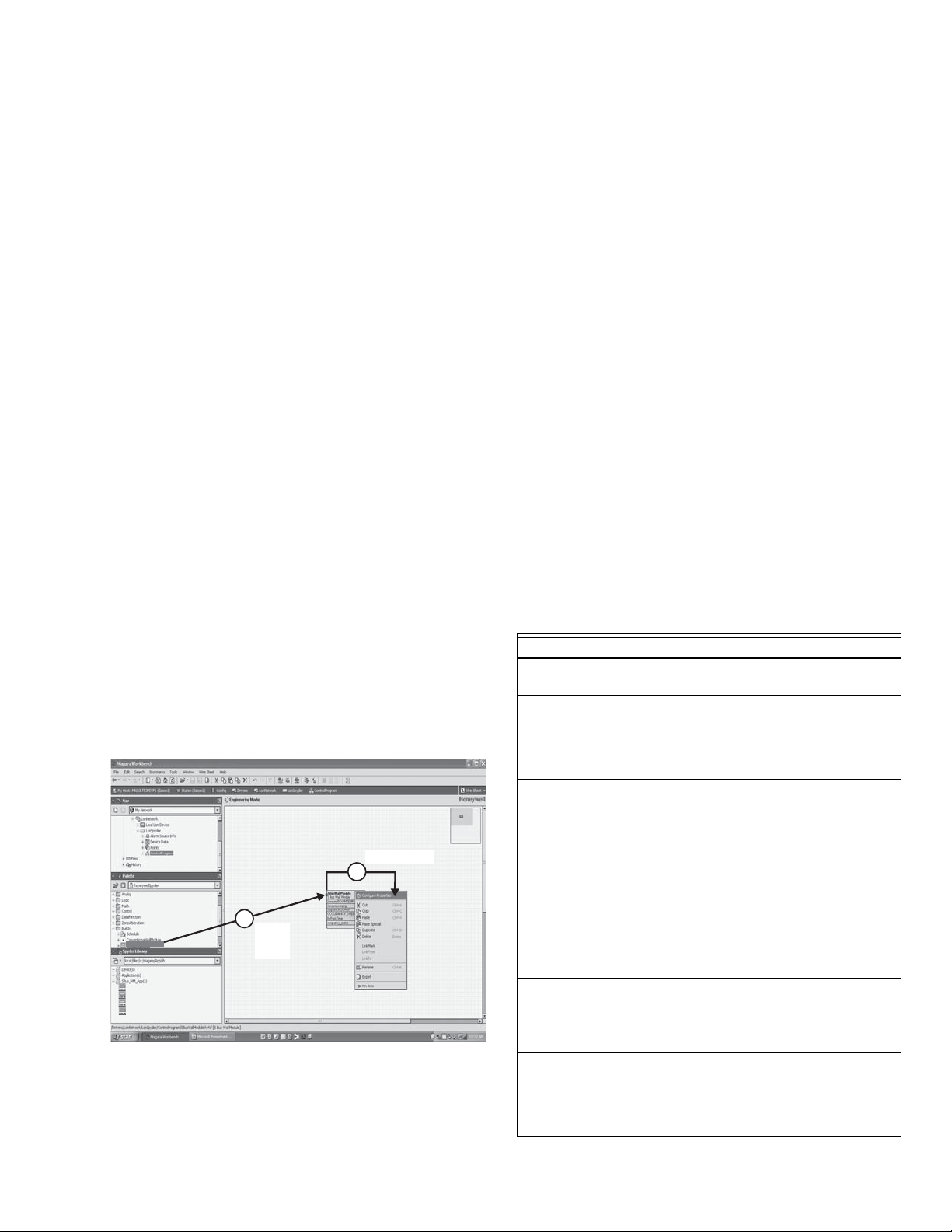

SETUP AND CONFIGURATION

Initial Setup and Configuration

Once the wall module is wired to the controller, you configure

the wall module using the PC-based, Niagara Workbench

Tool. Refer to the applicable programmable controller User’s

Guide. (Refer to the Honeywell Spyder User’s Guide, form 632662, or the ComfortPoint Programmable Controller User’s

Guide, form 63-2663, depending on the programmable

controller used.) This tool is used to configure the wall module

for either the Spyder or the ComfortPoint programmable

controller.

Confirm Bus Address Setting

Check to ensure that the Wall Module’s bus address dial

(located on the back of the module) is set to match the setting

in the configuration tool. TR70 models can be set from 1–5

and TR71/TR75 can be set from 1–10 (0 on the Zio address

dial is equal to 10 in the configuration tool). The address must

be different for each device on the Sylk bus. Up to four Zios

per Spyder are allowed with any combination of TR71/TR75s

and up to three Zios are allowed if one or more is a TR70

model.

Selecting the Wall Module

You will use the Sylk S-Bus wall module function block from

the Palette’s Built-In folder (see Fig. 3). This configuration has

nothing programmed except the room temperature parameter

and occupancy status.

1. Add the Sylk S-Bus Wall Module function block to the

wire sheet via a left click, drag, and drop. See callout 1

in Fig. 3.

2. Right click on the S-Bus Wall Module function block to

open the Configuration Properties menu. See callout 2

in Fig. 3.

3. Left click on the title, Configuration Properties. This

action starts the Configuration Wizard. The Configuration Wizard steps (see Fig. 5 on page 4) are used to

configure the wall module.

Fig. 3. Niagara Tool Interface - S-Bus wall module selection.

TR71/TR75 Labels

The TR71/TR75 allows the use of the following special

characters in label fields such as Categories and Parameter

Names: underscore ( _ ) to insert a space, hyphen ( - ), and

forward slash ( / ). The TR70 allows use of the underscore

( _ ) character to insert a space.

Navigation and Memory Usage

The Honeywell Spyder Tool uses an intuitive, window-based

interface. A Help button on each screen provides assistance

with any entry or process.

IMPORTANT

NOTE: At any time, clicking the Preview button (lower left of

Navigation

Table 3 describes the navigation buttons at the bottom of the

wall module window. See the bottom of Fig. 7 on page 5 for

the location of these buttons. Buttons are greyed when

unavailable.

Help When clicked, this button provides context sensitive

Preview When clicked, this button displays the updated wall

Save to

Library

Back Takes you backward one step in the wizard

Next Takes you forward one step in the wizard interface.

Finish Clicking this button commits all changes to the

Cancel Prompts you with a confirmation message.

Use the Help button to display context specific help

for the current window or pane display. See the lower

left corner of Fig. 6 on page 5 for the location of the

Help button.

main window, see Fig. 6 on page 5) displays the

updated wall module LCD as a pop-up. Preview simulates the actual wall module interface and allows

you to verify the operation of the current configuration of the wall module. See “Preview” on page 16.

Table 3. Navigation Buttons.

Item Function/Use

help for the currently selected item or parameter.

module LCD in a pop-up window pane. Preview is

fully interactive and simulates the actual wall

module interface as currently configured (see

“Preview” on page 16 for details).

For new custom configurations and standard

configurations.

Clicking the button opens the Save to Library

screen (shown in Fig. 25 on page 17). This action

allows you to save the entire current wall module

configuration.

The Save to Library button is disabled until you

change the configuration (application). After a

change is made, you can save the new

configuration into the library under a new name.

interface.

database, closes the Configuration Wizard, and

returns you to the wire sheet.

If you reply Yes, then all selections/entries made

since the Save to Library button or Finish button

was last pressed are ignored, and the wizard

interface quits.

3 63-2719—03

Page 4

ZIO®/ZIO PLUS LCD WALL MODULES

SAVE BUTTON

A SAVE button is available on screens that allow entries or

selections. It is enabled whenever any change is made on the

screen, and allows you to save your selections/entries at any

time. See the ROOMSP Details area of the Categories and

Parameters window in Fig. 12 on page 7 for an example of the

SAVE button.

Save is enabled whenever a change is made to the current

page. When you press the SAVE button, the preview screen

displays and your changes are reflected in the preview.

If you try to leave the current screen without saving (click

another icon or press the Back or Next button) and have made

changes, a warning message appears.

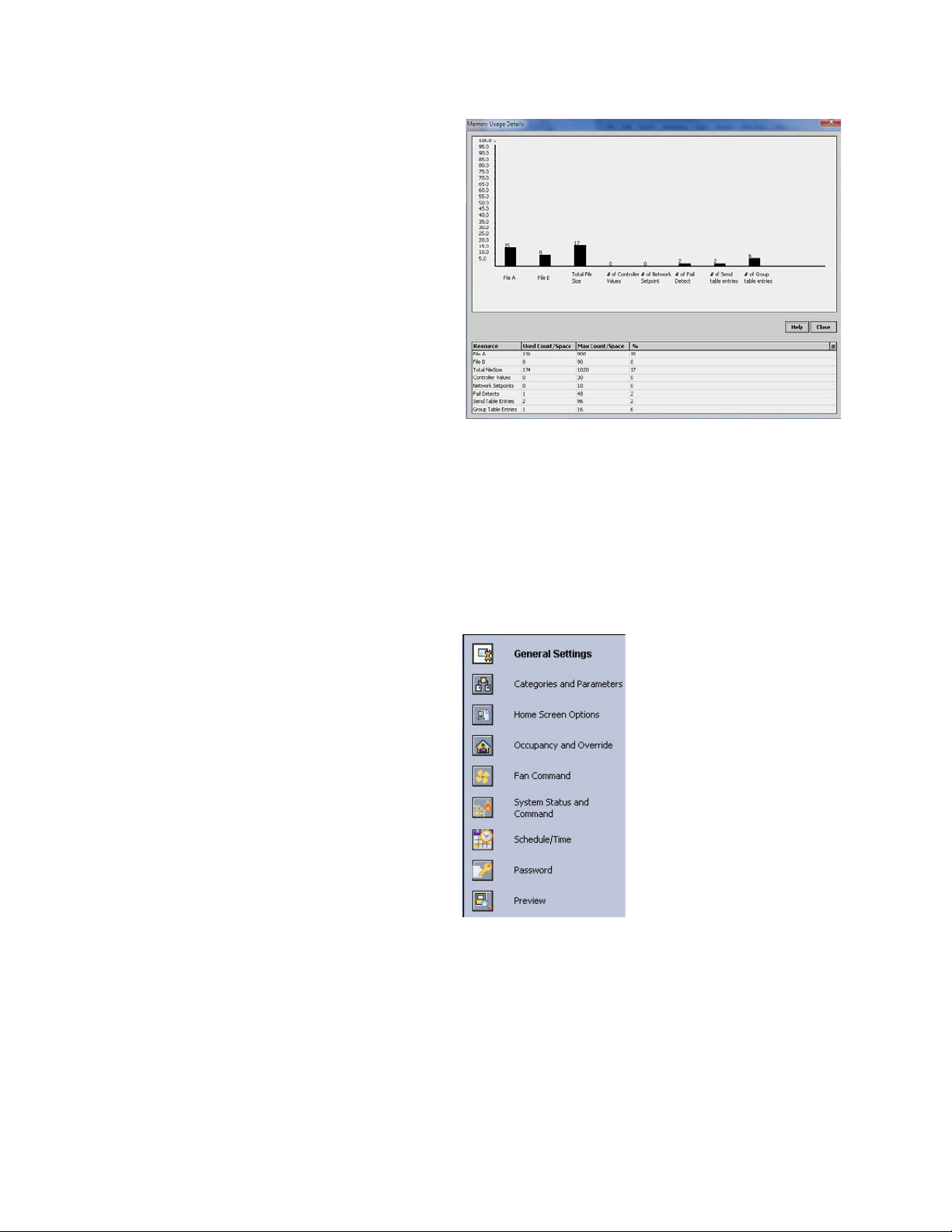

Memory Usage

The wall module has a fixed amount of memory available for

configuration data. The TR70 has 1,020 bytes of memory, the

TR71 has 2,000 bytes of memory, and the TR75 has 4,950

bytes of memory. To view the current memory use information

click on the Memory Usage Details button. A new window

opens and displays a bar graph indicating the percentage of

current memory used in each memory category.

Each of the memory categories should be below 100%. See

Fig. 4 on page 4.

NOTE: For a single Zio memory usage must be equal to or

less than 100% in order to download the configuration to the programmable controller. If using multiple

Zios, you should also check the Spyder Resource

usage. Total Zio memory use is limited to 5K bytes

on Spyder.

Fig. 4. Memory Usage Details screen.

Wall Module Configuration

To begin configuring the wall module:

1. Right click on the configuration’s function block to open

the Configuration Properties menu.

2. Left click on Configure Properties. The Configuration

Wizard opens. The Configuration Wizard steps (see Fig.

5) are used to configure the wall module.

View the online help in the WEBs-AX Workbench to see

troubleshooting tips for reducing memory usage in the TR70

Series if memory use is above 100%.

The following warning message displays when the memory

usage is greater than 100%:

“Warning: Memory Limit Exceeded. The current wall

module configuration requires more memory than the wall

module model can support. You will need to change the

configuration so that the memory usage is 100% or less

before pressing the FINISH button.”

See “General Settings”.

See page 5.

See page 9.

See page 10.

See page 12.

See page 13.

See page 14.

See page 15.

See page 16.

Fig. 5. Wall Module - Configuration Wizard window showing

Menu selections only.

63-2719—03 4

Page 5

ZIO®/ZIO PLUS LCD WALL MODULES

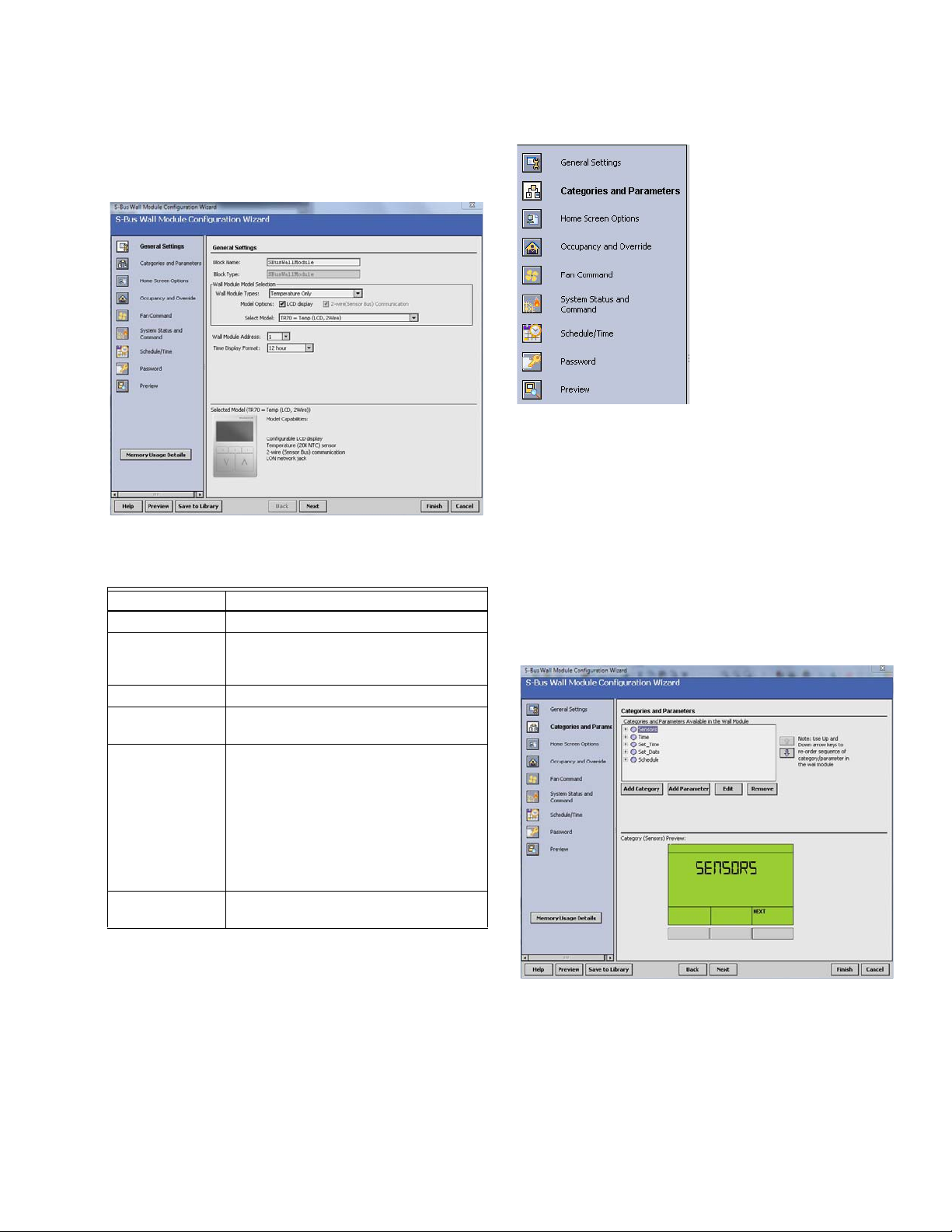

General Settings

Using Fig. 6 and Table 4 as a guide, configure the General

Settings. An image of the selected model and its capabilities

updates in the display at the bottom of the window.

Fig. 6. General Settings screen.

Table 4. General Settings.

Item Function/Use

Block Name The wizard displays S-Bus Wall Module.

Wall Module

Ty pe

Model Options Click LCD Display.

Select Model Select the appropriate model, TR70,

Wall Module

Address

Time Display

Format

If you are creating a customized configuration or modifying a

pre-programmed configuration, continue with “Categories and

Parameters” on page 5.

If you are using a pre-programmed configuration as is,

continue with “Preview” on page 17.

Select the appropriate type (Temperature

Only, or a combination of Temperature,

and/or Humidity) from the drop down list.

TR71, or TR75, from the drop down list.

Select a unique address for each TR70

Series devices connected to the Spyder.

TR70 can be set from 1-5 and TR71/

TR75s can be set from 1-10. The

address selected must match the

address setting at the wall module (using

the rotary switches). If setting the TR71/

TR75 rotary switch to 0, set the address

to 10 in the configuration tool.

Select 12 or 24 hour format.

Categories and Parameters

I Categories and

Parameters selection from

Wizard Menu

The categories and parameters menu item allows you to

create, edit, and delete categories and parameters.

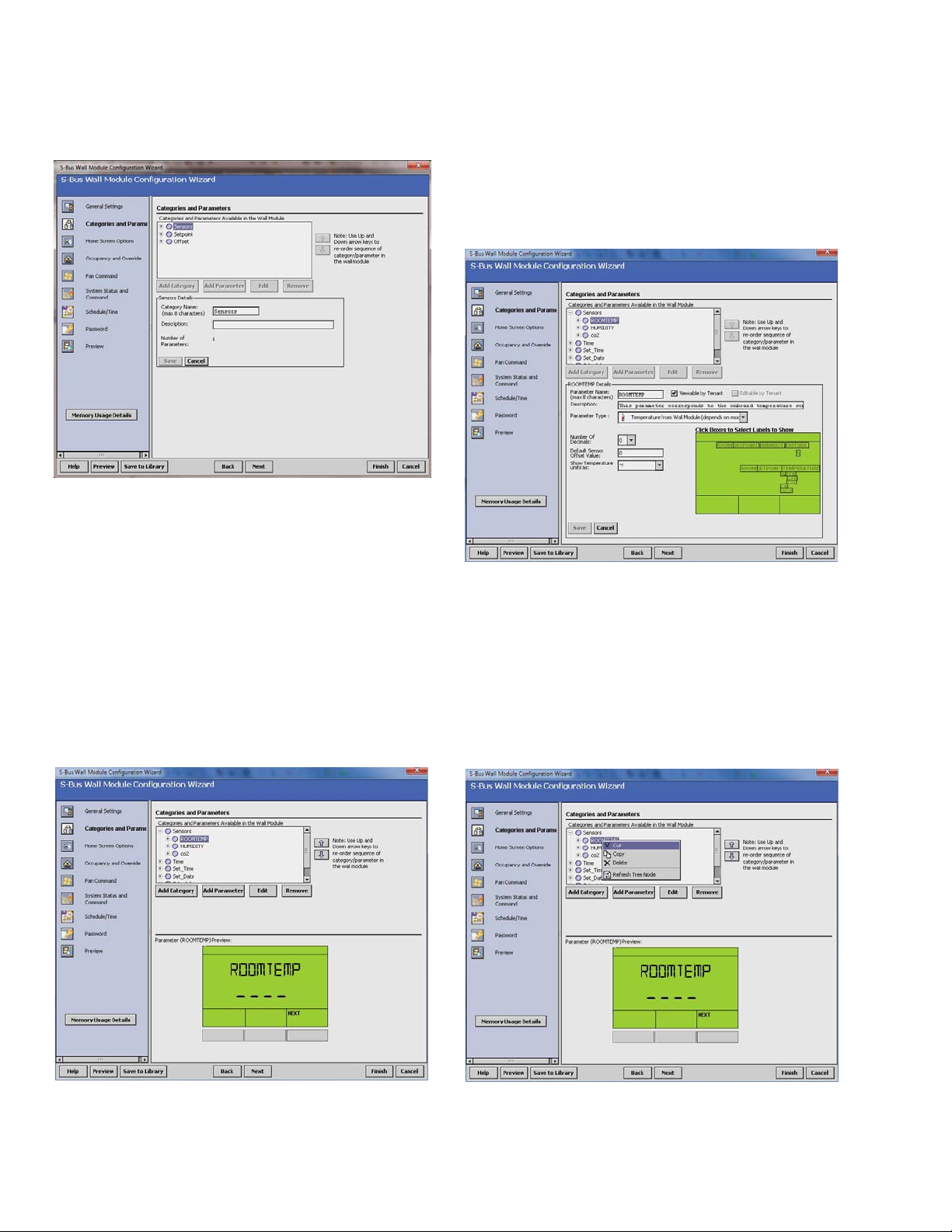

ADDING A CATEGORY

Fig. 7 shows the categories listed in tree format in the main

window where you can add, edit, or remove them. In the

bottom pane, Category Preview (at the bottom of Fig. 7)

shows the current selected item.

Clicking the Add Category button displays a details pane

below the category and parameter tree as shown in Fig. 8.

NOTE: You can use the Remove button to delete unused

categories and parameters to free up memory

space.

Fig. 7. Category Preview.

CATEGORY DETAILS

When you select a category from the Categories tree list and

click the Edit button, a details pane displays for that category

(see Fig. 8 on page 6).

Here you can enter a category name and description. The

number of parameters in this category are shown. The

description text you enter is loaded to the controller but cannot

be seen in the preview.

5 63-2719—03

Page 6

ZIO®/ZIO PLUS LCD WALL MODULES

Fig. 8. Adding a Category.

Here you can select Viewable by Tenant and Editable by

Tenant.

As an example, Fig. 10 shows the Details for the ROOMTEMP

parameter. Here you would enter the description, select the

parameter type from its drop-down list, enter the decimal

accuracy, default sensor offset value, temperature units, and

select the desired Home screen labels for the wall module.

ADDING A PARAMETER

Fig. 9 shows the categories and parameters listed in tree

format in the main window. The parameters are listed under

each category. Click on the box next to the category item to

expand that item in the tree. You can add, edit, or remove

parameters under each category. In the bottom pane,

Category Preview (at the bottom of Fig. 9) shows the current

selected item.

Clicking the Add Parameter button displays a details pane

below the category and parameter tree as shown in Fig. 10.

NOTE: You can use the Remove button to delete unused

categories and parameters to free up memory

space.

Fig. 10. Adding a Parameter.

CUT/COPY/DELETE CATEGORIES AND PARAMETERS

A right-click accessible context menu allows you to cut, copy,

paste, and delete parameters across categories. See Fig. 11.

You can also drag/drop parameters in the tree and the result is

a copy/paste per standard Niagara behavior.

You can also click (highlight) any item in the tree and then click

the Remove button to delete any selected parameter or its

category.

Fig. 9. Parameter Preview.

PARAMETER DETAILS

When you select a parameter from the tree list and click the

Edit button, a details pane displays for that parameter.

63-2719—03 6

Fig. 11. Cut/Copy/Delete Categories and Parameters.

Page 7

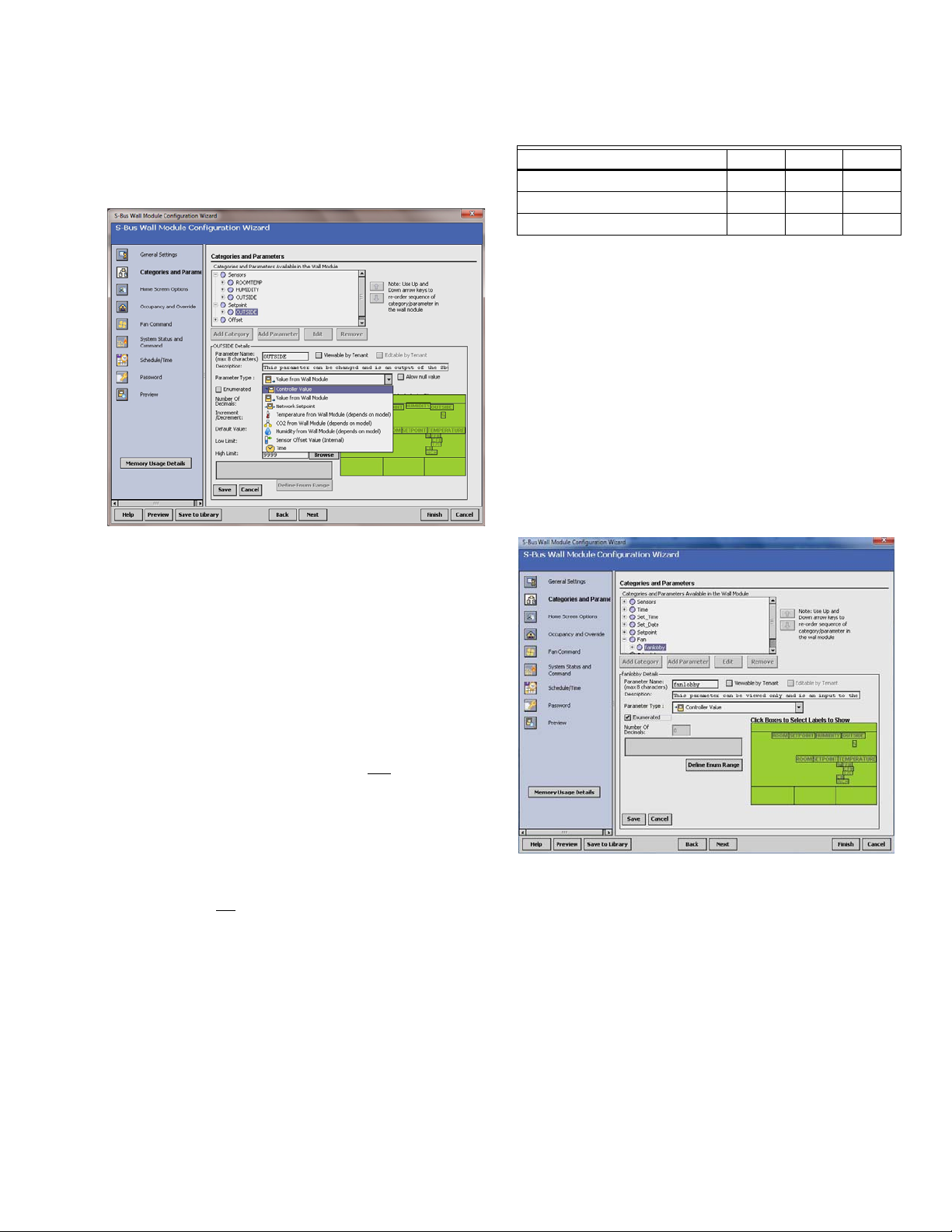

PARAMETER TYPES AND LIMITS

See Fig. 12 for an illustration of the Parameter Type drop

down list. There is a limit to the number of parameters that can

be configured. In addition to the parameter limit, there is also a

memory limit (see “Memory Usage” on page 4).

ZIO®/ZIO PLUS LCD WALL MODULES

Table 5. TR70 Series Parameter Capacity Guidelines.*

Parameter Type TR70 TR71 TR75

Controller Value 30 95 250

Value From Wall Module 20 50 180

Network Setpoints 10 50 125

* The TR71/TR75 may vary from these capacity numbers

depending on label names, parameter limit reuse, and other

devices that Zio interacts with on the Sylk bus.

NOTE: Network Variables need to be linked to the appropri-

ate S-Bus wall module’s function block slots. See

“Link Slots on the Wire Sheet” on page 18 for details.

PARAMETER OPTIONS

The TR71 and TR75 support additional parameter control.

See Table 1 on page 2 for details.

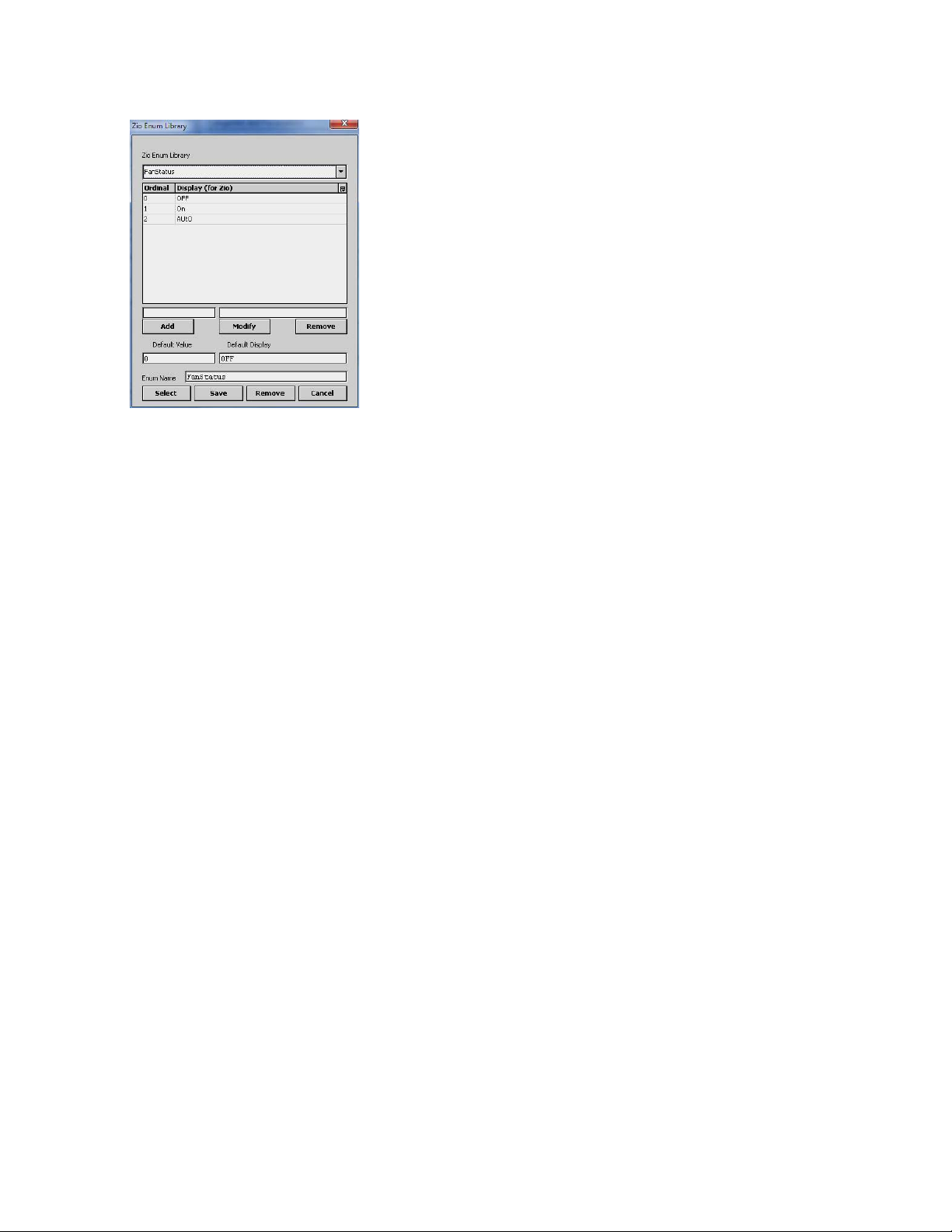

ENUMERATED VALUES

Meaningful enumerated values can be displayed using the

Enumerated option.

From the Add/Edit parameter window check the Enumerated

box and click on the Define Enum Range as shown in Fig. 13.

Fig. 12. Parameter Type selection.

The individual parameters are defined as:

— Controller Value

• These are read-only inputs to the wall module from

the controller and include system status and

occupancy status, if configured. Controller Value

parameters take up less memory than other

parameters.

— Value From Wall Module

• These are outputs from the wall module such as

room setpoint.

— Network Setpoints

• A network setpoint is a network variable from the

controller that you want to view and

wall module.

— Sensors

• 2 sensors (Temperature and Humidity)

• 2 Sensor Offset Values (temperature and humidity)

See Table 5 for the individual parameter maximums.

change at the

IMPORTANT

You can not

maximize all of these parameters

together. The size of the data files limits the total

number. See the memory usage tool by clicking on

the Memory Usage Details button in the left pane of

the Configuration Wizard.

Fig. 13. Click on the Enumerated Checkbox, then the Define

Enum Range button.

Once in the Zio Enum Library dialog box (Fig. 14), click on the

dropdown to see pre-defined facets or define your own. For

more detailed information see the online help in the

Configuration Wizard.

7 63-2719—03

Page 8

ZIO®/ZIO PLUS LCD WALL MODULES

Fig. 14. Select from the existing library or define enumerated

values.

HIGH/LOW LIMIT PARAMETER LINKING

This option allows for changes to a setpoint's high or low limit

directly at a Zio by linking the high and low limit to a related

setpoint. For example, for an occupied heat parameter, you

could assign the related unoccupied heat setpoint parameter

as the low limit and the occupied cooling setpoint parameter

as the high limit. To assign a setpoint to another setpoint's

high or low limit, click on the Browse button next to the Low

Limit or High Limit field. From the Select Parameter dialog box

you can select the appropriate setpoint.

This feature is an alternative to assigning a numeric value in

the High/Low Limit fields, which require any change be made

in the configuration tool and then loaded to Spyder.

Continue with “Home Screen Options” on page 9.

63-2719—03 8

Page 9

ZIO®/ZIO PLUS LCD WALL MODULES

Home Screen Options

I Home Screen Options

selection from Wizard Menu

Fig. 15, shows the Home Screen Options window and lists the

Home screens currently configured, where you can add, edit,

or remove them.

DEFAULT HOME SCREEN

The current default Home screen always displays at the top of

the list. You can select any item in the list and click the Set As

Default button to change the default Home screen.

• When selecting a parameter to display on the

Home screen, note the maximum number of digits

allowed, which varies from 3 to 4 depending on

where the parameter displays on the LCD.

• Click on the desired label box above each

parameter to choose that label text to display on the

wall module.

• When you complete your Home screen selections, click the

Save button on the lower left of the Details pane.

After you choose the settings, use the Preview at the bottom

left of the wizard window to exercise the Home screen and

cycle through its options.

NOTE: You can use the Remove button to delete unused

Home screen options to free up memory space.

PREVIEW

The bottom pane, Home Screen Option Preview, displays the

current selected item’s Home screen. When more than one

Home screen is configured, you can click the softkey button

rectangle, below “Next” in the preview pane, to cycle through

all the Home screens in the list.

ADD OR CHANGE HOME SCREENS

Clicking the Add or Edit button displays the Details pane

below the Home screen options tree (see Fig. 16).

You use the Details pane to create or change a Home screen:

•The Option Name item allows you to enter a 1 to 32

character description that displays in the Home Screen

Options Available list.

•The Set as Default selection, if clicked, causes this Home

screen to be the initial Home screen for the wall module

(after the configuration is downloaded to the wall module).

•The Description text you enter allows more information to

be entered on the home screen and will be loaded to the

controller but cannot be previewed.

•Use the Option Type selection to choose either single or

multiple (1 to 3) parameters to display on the Home screen.

• For the Single Parameter option type, there is an

option to display a custom label up to 8 characters

in length.

• In the lower right of the window, you select the desired

Home screen labels for the wall module. The number of

parameters allowed (1-3) is based on your Option Type

selection.

Fig. 15. Home Screen Options.

Fig. 16. Home Screen Details.

If you are finished with your configuration, go to “Preview” on

page 16, otherwise continue with “Occupancy and Override”

on page 10.

9 63-2719—03

Page 10

ZIO®/ZIO PLUS LCD WALL MODULES

STANDARD SETTINGS ADVANCED SETTINGS

Occupancy and Override

I Ocupancy and Override

Fig. 17 shows the Occupancy and

Override options in the main

window for standard and

selection from Wizard Menu

advanced settings. Clicking the Show Advanced Settings

button displays the advanced settings.

NOTES:

1. The preview at the bottom of the window displays

the occupancy option currently selected.

2. If an Override option is selected, the Override

softkey displays in the preview. Pressing the Override softkey cycles through the available override

options.

ENABLE OCCUPANCY OVERRIDE

Clicking the Enable Occupancy Override box enables this

feature and also enables the current Occupancy status (3:00

hours as shown in Fig. 17).

Clicking on the Settings button for the Valid States That You

Can Override section opens the Override to Occupied

Settings dialog box where you can configure values to any

desired number from 0 to 255. To conserve Zio memory,

choose the same Override Type and Timed Override Details

for Occupied, Unoccupied and Standby.

Fig. 17. Occupancy and Override screens.

OCCUPANCY STATUS DISPLAY OPTIONS

Here you select how the override status displays on the LCD.

The options are:

• Show effective occupancy status – LCD shows the actual

63-2719—03 10

occupancy status taking into account the programmable

controller configuration.

• Show occupancy override status – LCD shows the

occupancy override status initiated from the LCD,

independent of the programmable controller configuration.

• Do not show occupancy or override status – LCD does not

show occupancy or override, regardless of what the user

initiates and the programmable controller configuration.

Page 11

OVERRIDE SETTINGS

TIMED OVERRIDE IN HOURS

TIMED OVERRIDE IN DAYS

Clicking the Settings button displays the Override to

Occupancy settings pop-up (see Fig. 18), where you can

select Continuous (default) or Timed (hours or days) Override

settings.

ZIO®/ZIO PLUS LCD WALL MODULES

Fig. 18. Override to Occupied Settings (Hours or Days).

Clicking the Timed Override in Hours/Days boxes enable the

Override details where you can enter the desired override

timings.

Clicking the Use Network Bypass Time Only box disables all

other override details. The timed override details will be

determined by the programmable controller configuration. This

option only applies to Occupancy override settings.

Unoccupied and Standby do not use bypass.

ADVANCED SETTINGS

When the Show Advanced Settings button is clicked,

overrides to Occupied, Unoccupied, and Standby options are

possible.

The Override to Unoccupied selection’s Settings button

displays pop-ups similar to the Override to Occupied Settings

shown in Fig. 18, but the timings apply to Unoccupied status.

NOTE: The Override to Unoccupied Settings does not have

a Network Bypass option.

If you are finished with your configuration, go to “Preview” on

page 16, otherwise continue with “Fan Command” on

page 12.

11 63-2719—03

Page 12

ZIO®/ZIO PLUS LCD WALL MODULES

STANDARD SETTINGS ADVANCED SETTINGS

Fan Command

Fig. 19, shows the Fan Command options in the main window

for standard and advanced settings. Clicking the Show

Advanced Settings button displays the advanced settings.

I Fan Command selection from

Wizard Menu

Fig. 19. Fan Command screens.

Clicking the Enable Fan Command box enables the fan state

value selections.

The TR71/TR75 has the Set as Network Setpoint checkbox

allowing the fan command to be configured as a network

setpoint. This option is not available on the TR70.

The default Fan Command option is: 2 State (On / Auto). The

default for the Fan State is selectable if Zio is commanding the

fan. If the fan commend is a network setpoint, then the default

value is set on the controller's network setpoint. The Fan

command value cannot be changed from Zio in the Contractor

mode.

63-2719—03 12

Table 6. Fan State Values.

Selectable

Fan State Fan State Values

2 State On / Auto

3 state On / Off / Auto

5 State Off / Auto / Low / Medium / High

• Low, medium, and high are the three states of

the fan speed indicator triangle. See Fig. 29

on page 19 for an example.

After you choose the setting, use the Fan Command Preview

at the bottom of the window to exercise the Fan softkey to

cycle through the options. If the Set as Network Setpoint box

is checked for the TR71/TR75, the Preview screen will not

emulate Zio's device behavior.

If you are finished with your configuration, go to “Preview” on

page 16, otherwise continue with “System Status and

Command” on page 13.

Page 13

ZIO®/ZIO PLUS LCD WALL MODULES

STANDARD SETTINGS ADVANCED SETTINGS

System Status and Command

I System Status and

Command selection from

Wizard Menu

Fig. 20 shows the System Status and Command options in the

main window. Clicking the Show Advanced Settings button

displays the advanced settings.

Fig. 20. System Status and Command screen.

Clicking the Show System Status box enables the System

Status line including the snowflake (cool) and flame (heat)

icons and the System softkey on the LCD as shown in the

Preview area at the bottom of the screen.

The System softkey on the LCD is enabled only when the

Enable System Command option is selected.

The Enable System Command selections control the values

that display on the System Status line at the top of the wall

module’s LCD screen.

For TR71/TR75s click on the System Command checkbox to

allow the System Command to be configured as a network

setpoint.

The default System Command option is: Off / Heat (Heat

Only). The System commands are selectable. The System

command value cannot be changed from Zio in the Contractor

mode.

Off / Heat (Heat Only)

Off / Cool (Cool Only)

Off / Heat / Cool (No Auto Changeover)

Off / Auto / Heat / Cool (Auto Changeover)

Off / Auto / Heat / Cool / Emergency Heat (Heat Pump)

After you choose the setting, use the Preview button at the

bottom of the window to verify your configuration. If the Set as

Network Setpoint box is checked for the TR71/TR75, the

Preview screen will not emulate Zio's device behavior.

If you are finished with your configuration, go to “Preview” on

page 16, otherwise continue with “Schedule/Time” on

page 14.

13 63-2719—03

Table 7. System State Values.

Selectable System States

Page 14

ZIO®/ZIO PLUS LCD WALL MODULES

Schedule/Time

I Schedule/Time Options

selection from Wizard Menu

Fig. 21. Schedule/Time for TR75.

As shown in Fig. 21, the TR75 can provide access to the

Spyder Schedule. This option is not available for use with the

TR70/TR71 as shown in Fig. 22.

The Schedule/Time options allow for if and how the Spyder

schedule and Spyder time clock is accessed from Zio, whether

or not the tenant can view or edit, etc. We recommend setting

the time in Spyder before configuring the Schedule/Time in

the configuration tool.

NOTE: Setting an invalid time at Zio will cause Spyder to set

the time to invalid.

63-2719—03 14

Fig. 22. Schedule/Time for TR70/TR71 is not supported so all

options are grayed out.

You also have the ability to configure how the Spyder schedule

will display at the TR75: 8 day schedule, 7 day schedule, 5-2-1

day schedule, or the 5-2 schedule. If using the 5-2-1 or 5-2

day schedule, you should configure the Spyder for the same

schedule.

NOTE: If multiple Zios are used, we recommended using the

same schedule display option for all Zios.

If you are finished with your configuration, go to “Preview” on

page 16, otherwise continue with “Password” on page 15.

Page 15

Password

ZIO®/ZIO PLUS LCD WALL MODULES

I Password Option selection

from Wizard Menu

Fig. 23. Assign Password for TR71/TR75

As shown in Fig. 23, the TR71/TR75 can be configured with a

password that limits access to contractor level system

changes from the TR71/TR75. The password option is not

available for the TR70.

The password can be assigned an eight character label that is

displayed at the TR71/TR75 and a four digit password from

0000 to 9999. All TR71/TR75s on a Spyder can have the

same or unique passwords.

If the password option is enabled and the password is

forgotten, it can be retrieved through the WEBs-AX

Workbench in the Configuration Wizard.

Go to “Preview” on page 16.

15 63-2719—03

Page 16

ZIO®/ZIO PLUS LCD WALL MODULES

Preview

I Preview selection from

Wizard Menu

Preview is a great way to verify all your configuration and

setup parameters to ensure that they work exactly the way you

want them to function.

Preview simulates the actual wall module interface and allows

you to verify the operation of the current configuration of the

wall module. Clicking on the three softkey rectangles below

the labels of the preview display exercises the features you

have configured.

NOTE: Since the up and down arrow keys do not display in

Preview mode, no adjustments to parameters (e.g

setpoint temperature) can be made.

Fig. 24 shows your current configuration of the wall module

Home screen. You can select either the Tenant or Contractor

view. The three softkeys in the preview LCD display are

interactive and function just like the ones on the physical wall

module display.

Fig. 24. Preview screen.

To complete the configuration, continue with “Completing the

Setup and Configuration” on page 17.

63-2719—03 16

Page 17

ZIO®/ZIO PLUS LCD WALL MODULES

Completing the Setup and Configuration

For custom configurations, begin with “Custom Configurations

Only”, otherwise continue with “All Configurations”.

Custom Configurations Only

If you are customizing a configuration, use the Save to Library

button to save your configuration. Clicking the button displays

a pop-up window as illustrated in Fig. 25.

All Configurations

To complete the configuration process, perform the following

sections in this order:

1. “Preview”

2. “Confirm Memory Usage is within Limits”

3. “Finish the Configuration”

4. “Link Slots on the Wire Sheet” on page 18

Preview

Use the Preview button or Preview menu selection to see how

the wall module LCD screen will operate for your selected

configuration (see “Preview” on page 16).

Confirm Memory Usage is within Limits

To view the current memory use information click on the

Memory Usage Details button. A new window opens and

displays a a bar graph indicating the percentage of current

memory used in each memory category.

Each of the memory categories should be below 100%. You

can also click on the Memory Usage button below the bar

graph to quickly view the percent used by each of the memory

categories in the last column of the table. See Fig. 4 on

page 4 for an illustration. If necessary, go back and remove

unneeded categories, parameters, or Home screens.

If using multiple Zios on one Sylk bus, check Spyder Resource

usage also.

Fig. 25. Save to Library screen pop-up.

Finish the Configuration

Click the Finish button to commit all your changes to the

database, close the Configuration Wizard, and return to the

wire sheet.

17 63-2719—03

Page 18

ZIO®/ZIO PLUS LCD WALL MODULES

Link Slots on the Wire Sheet

This section describes how parameters may be linked to the

wall module. Refer the user to the Spyder User Guide, form

63-2662, for more specific information on variables and wire

sheet logic.

The S-Bus Wall Module function block can be dropped into

existing applications to replace the Conventional Wall Module

block. You can see an example in Fig. 26. A maximum of four

Zios may be wired on a single Sylk bus, with no more than one

TR70 per bus.

When making links from existing blocks to the wall module

function block input slots, there is no need to break the

existing links from these existing blocks. The new tool allows

for multiple output connections.

When connecting to slots on function blocks which lie on

different wire sheets, remember that you can save time by

using the Link Mark method, a standard Niagara Workbench

linking mechanism.

Fig. 26. Example of the S-Bus Wall Module block dropped into a Venom VAV application.

63-2719—03 18

Page 19

ZIO®/ZIO PLUS LCD WALL MODULES

OPERATING THE ZIO WALL MODULE

There are two modes of operation:

• Contractor mode provides features a contractor would use

such as selecting the Home screen, selecting parameters

the tenant can view, and monitoring/modifying controller

parameters, which includes balancing.

• Tenant mode provides features a tenant would use such as

changing the setpoint, fan speed or system mode, initiating

override, or monitoring/modifying permitted controller

parameters. See page 22 for information about Tenant

Mode operation.

Contractor Mode (Entering and Exiting)

Contractor mode allows access to the Setup function of the

wall module.

To enter and exit the Setup function – Press the Up and Down

arrow keys and the middle softkey all at the same time (see

Fig. 1 on page 1 for key positions). The TR71/TR75 will

display the revision and model before going to the next screen

as shown in Fig. 27.

Contractor Mode Operation

Contractor mode allows advanced options (such as modifying

configured parameters) using the softkeys. Contractor mode

also allows for customizing the tenant’s view including setting

the tenant’s Home screen and controlling the tenant’s “View

More” access, which can provide the tenant with a view of the

configured parameters.

Contractor Home Screen Softkeys

M27357

Fig. 29. Typical Contractor LCD display.

The three softkeys on the contractor Home screen (see Fig.

29) provide the following:

Fig. 27. On power-up, screen displays revision and Zio model

number.

If the password option is enabled you will be prompted to

enter a four digit password as shown in Fig. 28. Use the up/

down arrow keys to change the first number and use the Done

and Next softkeys to navigate from one digit to the next.

SET HOME SCREEN allows the contractor to choose among

multiple Home screen options for the tenant.

The tenant’s Home screen choices are created by the Configuration Wizard and downloaded to the wall module. Each

wall module may have different Home screen choices. The

contractor, using the softkeys, may choose which Home

screen should be used, and may configure the Tenant view

to show a subset (or none) of the configured parameters.

• When the contractor clicks the SET HOME

SCREEN softkey, The display changes as shown in

Fig. 30, and the softkeys change to DONE,

CANCEL, and NEXT.

• Clicking the NEXT softkey cycles through the

configured Home screens (see “Home Screen

Options” on page 9).

• Click the DONE softkey when the desired Home

screen displays.

• The CANCEL softkey exits the Home screen

display without saving any changes.

Fig. 28. Password entry screen.

19 63-2719—03

Page 20

ZIO®/ZIO PLUS LCD WALL MODULES

M27378

Fig. 30. Sample Contractor display showing

Home screen setup.

SET VIEW MORE allows the contractor to provide parameter

access (view only or adjustable) to the tenant’s VIEW

MORE softkey.

• Clicking the VIEW MORE softkey displays the first

configured parameter as shown Fig. 31, and the

softkeys change to DONE, CANCEL, and NEXT.

• The Up and Down arrow keys switch the parameter

between YES and NO (view or no view in Tenant

Mode). YES means that the tenant has access to

the parameter in the View More screen. NO means

the tenant does not have access to the parameter.

• If NO is selected for all

parameters, then the VIEW

MORE softkey does not display in tenant mode.

• The NEXT softkey moves to the next parameter.

• Click the DONE softkey when finished.

• The CANCEL softkey exits VIEW MORE without

saving changes to that parameter.

• When clicked, the EDIT softkey drops you into the

parameter list for the displayed category and

displays the first parameter in that category (e.g.

the HUMIDITY parameter in the SET PNTS

category as shown in Fig. 32).

• If the parameter has been configured as adjustable

by the tool, the Up and Down arrow keys adjust the

value of the parameter.

• The NEXT softkey displays the next parameter or

category.

• Click the DONE softkey when finished.

Fig. 31. Set View More parameter display.

PARAMETERS allows the contractor to monitor and/or adjust

parameters in the programmable controller.

• Clicking the PARAMETERS softkey displays the

first configured category as shown in Fig. 31, and

the softkeys change to DONE, EDIT, and NEXT.

63-2719—03 20

Fig. 32. Parameter display showing editing sequence.

Page 21

Sample Contractor LCD Displays

M27358

M27359

The contractor mode allows advanced options using the

softkeys. Contractor mode also allows for customizing the

Tenant view including setting the tenant’s Home screen and

View More access.

The LCD display may be customized for the contractor. This

section includes three examples of the various contractor

Home and Parameter screens that are configurable for the

LCD Wall Module. Not all possible screens are illustrated

here. There are many other configurable screens.

M27357

Fig. 33. Sample Contractor Home screen display with System

Status, Setpoint, Outside Temperature,

and Room Temperature (predominant).

ZIO®/ZIO PLUS LCD WALL MODULES

Fig. 36. Sample Contractor parameter display for TR71/TR75

showing enumerated value displays with label instead of

numeric value.

NOTE: Any configured parameter may be displayed.

Editing the Schedule or Time

The Schedule option lets you modify the schedule and change

Spyder's time. The desired scheduling option (8 day, 7 day,

etc.) is setup in the Configuration Wizard (see “Wall Module

Configuration” on page 4) and based on that selection, option

screens vary. The example below shows the flow for viewing/

editing a schedule. Use the Edit softkey to move to the next

screen and use the up/down arrows to change values. When

editing an event, use the Next softkey to go between editing

the time and changing the state (OCC/UNOCC/STANDBY).

Fig. 34. Sample Contractor parameter display showing a user-

created discharge air parameter value.

To remove a programmed event, use the up/down arrow keys

to scroll the time to either 12:00 p.m. or 12:00 a.m. Just before

reaching 12:00 the time will change to four dashes (- - - -).

Press the Done softkey at this point to remove a programmed

event.

In the 5-2 or 5-2-1 schedule options: “5” means Monday Friday and Monday's events are shown on the Zio. The “2”

means Saturday and Sunday and Saturday's events are

shown on the Zio. And “1” means holiday. When Monday is

changed, the TR75 copies that event to Tuesday - Friday and

sends the controller the change for Monday through Friday.

The same occurs for Saturday and Sunday when a change is

made to Saturday. When a Holiday is modified it is also sent to

the controller.

Fig. 35. Sample Contractor parameter display showing sensor

setpoint value (CO

sensor from controller).

2

Fig. 37. Schedule display for contractor.

21 63-2719—03

Page 22

ZIO®/ZIO PLUS LCD WALL MODULES

M27354

TENANT HOME SCREEN SOFTKEYS

As shown in Fig. 40, there can be three softkeys configured for

the tenant’s Home screen – FAN, OVERRIDE, and SYSTEM

& VIEW MORE.

NOTES:

1. The Fan and Override settings are optional for

Home screen setup.

2. If the System Command option is not enabled,

then the SYSTEM softkey does not display on the

tenant’s Home screen.

3. If there are no parameters configured for tenant

access, the VIEW MORE softkey does not display

on the tenant’s Home screen.

Fig. 38. Select the day.

Fig. 39. Select the Event to edit the time and occupancy state.

Tenant Mode Operation

The tenant, using the softkeys and arrow keys, may change

the setpoint, fan speed, system mode (heat/cool), or initiate

override, if these features are configured. The tenant may

change the Occupancy Override parameter to Occupied,

Unoccupied, or Standby. And, the override can be timed in

minutes, days, or be continuous.

FAN allows the tenant to adjust the fan settings depending on

the fan options (2, 3, or 5 position) configured.

As shown in Fig. 41, each click of the FAN softkey changes

the fan icon display between:

• 2 position: ON and AUTO

• 3 position: OFF, AUTO, and ON

• 5 position: OFF, AUTO, and the three states of the fan

speed indicator (low, medium, and high)

Fig. 41. Fan display for Tenant showing 5-position setting with

fan at medium speed.

OVERRIDE allows the tenant to override the Occupancy set-

tings (see Fig. 42).

Fig. 40. Typical Tenant LCD display.

63-2719—03 22

• Depending on the occupancy/override

configuration, each click of the OVERRIDE softkey

changes the occupancy icon displays between

STANDBY, OCCUPIED, and UNOCCUPIED.

• If an override is set by the tenant, the OVERRIDE

softkey changes to CANCEL OVERRIDE.

• Clicking the CANCEL OVERRIDE softkey cancels

the override.

Page 23

ZIO®/ZIO PLUS LCD WALL MODULES

M27352

M27354

M27355

Fig. 42. Override display for Tenant.

SYSTEM & VIEW MORE Depending on the configuration,

this softkey allows the tenant to change the system state

and view/adjust configured parameters (see Fig. 43).

• The first click displays the system information and the

Up and Down arrow keys change the system state

between OFF, AUTO, COOL, HEAT, and EM.HEAT

(emergency heat).

• Clicking the VIEW MORE/NEXT softkey displays each

viewable parameter.

• If the contractor enables tenant access to a parameter,

then the tenant can use the Up and Down arrow keys

to adjust the parameter’s value, otherwise the tenant is

able to only view the parameter and its value.

NOTE: When the contractor configures a parameter and

selects the Editable by Tenant check box, this

enables the tenant to adjust the parameter’s value.

See Fig. 12 on page 7 for an example.

NOTE: Home screens can display one to three of any of the

following parameters: temperature setpoint, room

temperature, room humidity, outdoor humidity, and

outdoor temperature, and time, or one of virtually any

parameter in the controller.

SAMPLE TENANT HOME SCREEN DISPLAYS

Figures Fig. 44 through Fig. 49 illustrate typical tenant home

screens.

Fig. 44. Sample Tenant Home screen with Room Temperature

and Setpoint (predominant).

The Fan and Occupied settings are optional for Home screen

setup. If there are no parameters configured for tenant access,

the “View More” softkey does not display on the tenant’s

Home screen.

• Click the CANCEL softkey to exit the display without

saving changes to the parameter.

• Click the DONE softkey when finished.

Fig. 43. System and View More display for Tenant.

Tenant Home Screen Display

The LCD display may be customized for the tenant. This

section includes a few examples of the various tenant Home

screens that are configurable for the LCD Wall Modules. Not

all possible Home screens are illustrated here. There are

many other configurable Home screens.

Fig. 45. Sample Tenant Home screen with System Status,

Setpoint, Outside Temperature, and

Room Temperature (predominant).

Fig. 46. Sample Tenant Home screen with Humidity and

Room Temperature (predominant).

23 63-2719—03

Page 24

ZIO®/ZIO PLUS LCD WALL MODULES

M27379

M27498

Fig. 47. Sample Tenant Home screen with Room Temperature

and Time (predominant).

NOTE: In Fig. 47, there are no Fan, System, or View More

softkey options configured for this Home screen.

NOTE: In Fig. 48, the Home screen is configured with only a

single, custom parameter. See “Preview” on page 9.

M27356

Fig. 49. View More display showing CO2 sensor value from

controller.

NOTE: As shown in Fig. 49, any configured parameter may

be displayed to the tenant.

Fig. 48. Sample Tenant Home screen with a single, custom

parameter.

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark

© 2012 Honeywell International Inc.

63-2719—03 S.B. 04-2012

Printed in United States

Loading...

Loading...