Page 1

62-0271-07

Zio®/Zio Plus LCD Wall Modules

TR70, TR71 and TR75 models with Sylk® bus

INSTALLATION INSTRUCTIONS

• Customized parameter access, by using the WEBs-AX

Workbench tool.

• Ability to link setpoint limits to a network variable.

• Programmable for: home screen options, tenant

access, contractor access, access to controller

parameters, setpoint, override, fan, and other

parameters.

• TR70 and TR71 have the ability to access and adjust

virtually any parameter in the programmable controller

(except Scheduling).

• TR75 can additionally access and adjust the controller

schedule.

• The TR71 has roughly twice the memory capacity for

parameters as the TR70, and the TR75 has more than

twice the memory capacity for parameters as the TR71.

• Ability to balance the VAV system from the wall module.

• Home screen can display one to three of any of the

PRODUCT DESCRIPTION

The TR70, TR71 and TR75 are 2-wire, non-polarity sensitive,

Sylk bus communicating wall modules, which communicate

with Spyder® and some ComfortPoint™ programmable

controllers.

All models have a space-temperature sensor, network bus

jack, and an LCD panel with three softkeys and two Up/Down

adjustment keys. The TR70-H, TR71-H and TR75-H models

include an onboard humidity sensor.

NOTES:

1. Refer to the Zio/Zio Plus LCD Wall Modules –

Specification Data, form 63-1322, for specific

model features and additional information.

2. Refer to the Zio/Zio Plus LCD Wall Modules –

Operating Guide (Form 63-2719) for information

about customizing the wall module configuration,

such as modifying the default Home screens or

creating your own application.

FEATURES

The Zio wall modules include:

• Ability to control user access to controller parameters,

including password protection on TR71 and TR75

models.

• Ability to assign labels for enumerated values.

following parameters: temperature setpoint, room

temperature, room humidity, outdoor humidity,

outdoor temperature, and time, or one of virtually any

parameter in the controller.

•Network bus jack.

• Simple 2-wire terminal connection to the

programmable controller and an optional 2-wire

terminal connection for the network. All connections

are polarity insensitive.

• Permanent retention of user configuration, including

setpoints after a power outage.

SPECIFICATIONS

Models: TR70, TR71, TR75.

TR70-H, TR71-H and TR75-H include an onboard

humidity sensor.

Environmental Ratings:

• Operating Temperature: 30°F to 110°F (-1°C to 43°C)

• Shipping Temperature: -40°F to 150°F (-40°C to 65.5°C)

• Relative Humidity: 5% to 95% non-condensing

Accessories:

50007298-001 (pack of 12) medium, cover plate;

6-7/8 x 5 in. (175 x 127 mm).

Approvals:

Class B

CE; UL94-HB plastic enclosure; FCC Part 15,

Page 2

ZIO®/ZIO PLUS LCD WALL MODULES

CAUTION

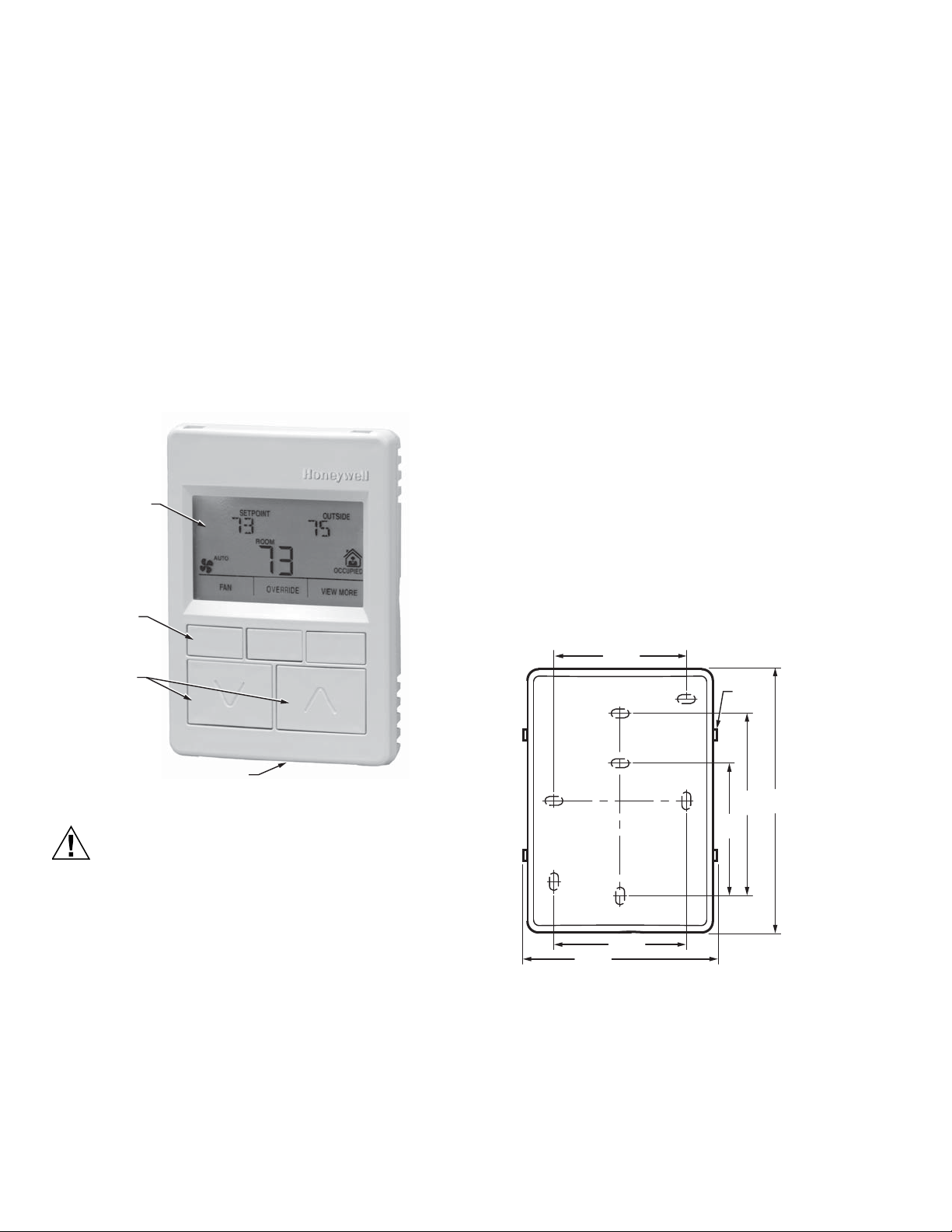

LCD PANEL

M27344

SOFTKEYS (3)

UP/DOWN

ARROW KEYS

NETWORK BUS PORT (ON BOTTOM OF CASE)

2-3/8 (60)

2-3/8

(60)

3-1/4

(83)

M27345

LOCKING

TAB S (4 )

2-3/8 (60)

3-3/8 (95)

4-1/8

(105)

Communications

The wall modules use a sensor bus (S-BUS) for

communications with the programmable controller. Wire the

two S-BUS terminals according to these installation

instructions.

The wall modules have a network bus port for L

ONMARK® or

BACnet® communications. If network communication is

needed, connect the building LON network wires to the two

terminals (NET-1 and NET-2), according to these installation

instructions. A network bus port is accessible at the bottom of

the wall module by removing the jack plug. See Fig. 1.

The network bus and S-BUS terminals (see Fig. 6 on page 4)

are insensitive to polarity, minimizing installation errors due to

mis-wiring.

BEFORE INSTALLATION

IMPORTANT

All wiring must comply with local electrical codes and

ordinances or as specified on installation wiring diagrams.

— Wall module wiring can be sized from 18 to 24 AWG (0.82

to 0.20 sq. mm), depending on the application. For

multiple Zios on the same S-BUS, 24 AWG wire is

recommended.

— For S-BUS wiring, the Zio may be mounted up to 200 ft.

(61 m) from the programmable controller. If multiple Zios

are installed, the total distance from the controller to the

last Zio should not exceed 200 ft.

— Twisted pair wire is recommended for wire runs longer than

100 ft. (30.5 m).

— All wiring is polarity insensitive.

— The cover for the wall module is packed separately from

the subbase for ease of installation.

INSTALLATION

Mount the wall module on an inside wall approximately 54 in.

(1372 mm) from the floor (or in the specified location), to allow

exposure to the average zone temperature. Do not mount the

wall module on an outside wall, on a wall containing water

pipes, or near air ducts. Avoid locations that are exposed to

discharge air from registers or radiation from appliances,

lights, or the sun.

Fig. 1. LCD Wall Module features.

Erratic System Operation Hazard.

Failure to follow proper wiring practices can

introduce disruptive electrical interference (noise).

Keep wiring at least one foot away from large inductive

loads such as motors line starters, lighting ballasts,

and large power distribution panels.

Shielded cable is required in installations where these

guidelines cannot be met.

Ground the shield only to the grounded controller

case.

The wall module can be mounted on a wall, on a standard

utility conduit box using No. 6 (3.5 mm) screws or on a 60 mm

wall outlet box (see Fig. 3). When mounting directly on a wall,

use the type of screws appropriate for the wall material.

Fig. 2. Subbase mounting holes and locking tabs.

62-0271—07 2

Page 3

Fig. 3. Mounting on standard utility conduit box or

CAUTION

M27346

STANDARD UTILITY

CONDUIT BOX

SUBBASE

NO. 6 SCREW

60 mm WALL

OUTLET BOX

SUBBASE

3.5 mm SCREW

WALL MODULE

WALL

MODULE

60 mm wall outlet box.

ZIO®/ZIO PLUS LCD WALL MODULES

Improper Electrical Contact Hazard.

Screw-type terminal blocks are designed to accept

no more than one 18 AWG (0.82 sq. mm)

conductor.

Connect multiple wires that are 18 AWG (0.82 sq. mm)

with a wire nut. Include a pigtail with this wire group

and attach the pigtail to the individual terminal block.

Wiring Wall Modules

Wire the terminal block shown in Fig. 6 as follows:

1. For single wires, strip 3/16 in. (5 mm); for multiple wires

going into one terminal, strip 1/2 in. (13 mm) insulation

from the conductor. See Fig. 5 for wiring multiple Zios.

2. Insert the wire in the required terminal location and

tighten the screw to complete the termination.

3. Review and verify the terminal connection wiring

illustrated in Fig. 6.

NOTE: The recommended wire size for the network bus

and S-BUS is Level IV, 22 AWG (0.34 sq. mm) plenum or non-plenum rated, unshielded, twisted

pair, solid conductor wire. However, larger gauge

standard thermostat wiring will also work for

runs up to 100 feet.

3 5/16 (84)

4 5/8

(117)

15/16

(24)

M27347

Fig. 4. LCD Wall Module dimensions in inches (mm).

Wiring

The LCD wall module is shipped with its mounting plate

(subbase) separate from the module. All terminal connections

can be made to the backside of the module. There are no field

adjustable/replaceable components inside the module.

Attach the wires from the programmable controller and

network to the appropriate wall module terminals, as indicated

in Fig. 6 on page 4.

TWO WIRES INTO ONE TERMINAL

1.

1/2

(13)

DAISY-CHAINING MULTIPLE ZIOS HOME RUNNING MULTIPLE ZIOS

MAX WIRE RUN FROM SPYDER

TO FARTHEST ZIO IS 200FT.

STRIP 1/2 IN.

(13MM) FROM

WIRES TO BE

ATTACHED AT

ONE TERMINAL.

2.

TWIST WIRES

TOGETHER

WITH PLIERS

(A MINIMUM OF

THREE TURNS).

TO SPYDER

TO ZIO

WALL MODULE

TERMINALS

3.

CUT TWISTED END OF WIRES TO

3/16 IN. (5 MM) BEFORE INSERTING

INTO TERMINAL AND TIGHTENING

SCREW. THEN PULL ON EACH WIRE

IN ALL TERMINALS TO CHECK FOR

GOOD MECHANICAL CONNECTION.

TO SPYDER

MAX WIRE RUN FOR EACH

HOME RUN IS 200FT.

M27348

Fig. 5. Options for Wiring Multiple Zios.

3 62-0271—07

Page 4

ZIO®/ZIO PLUS LCD WALL MODULES

M27349

SLOTS FOR SUBBASE

LOCKING TABS (X4)

0

1

2

3

4

9

8

7

6

5

WALL MODULE BUS

ADDRESS DIAL

(DEFAULT SETTING = 1)

S-BUS PROGRAMMABLE

CONTROLLER CONNECTION

NETWORK BUS

CONNECTION

EACH OF T HE TWO WIRE CONNECTI ONS FOR THE S- BUS AND NETWORK

BUS TERM INALS ARE PO LARITY IN SENSITIVE.

1 2 3 4

1

1

50028668-XXX

4321

S-BUS

S-BUS

NET-2

(optional)

NET-1

(optional)

TR70-H

YY WK

HONEYWELL

PATENT PENDING

GOLDEN VALLEY,MN

ASSEMBLED IN MEXICO

WALL

PULL THE

SCREWDRIVER

TOWARD YOU

M27350

M27351A

Fig. 6. Terminal connections, Wall Module bus address

dial, and TR70-H address dial (rear view of LCD wall

module).

Setting the Wall Module Bus Address Dial

For the TR70, ensure that the wall module bus address dial is

set to 1. For the TR71 or TR75 models, set the address to any

number from 0 to 9. (A setting of 0 on Zio is equal to 10 in the

Configuration Tool, so if the Zio is set to 0, set the address to

10 in the Configuration Tool.) Address must be different for

each device on the Sylk bus. Use a thin blade screwdriver to

turn the dial arrow. The address on the wall module must

match the address in the tool. A maximum of four Zios may

be wired on a single Sylk bus, with no more than one TR70

per bus.

Attaching the Wall Module to the Subbase

When all wiring is complete, press the LCD wall module

straight down onto the subbase until it snaps into place.

Removing the Wall Module from Subbase

To remove the wall module from its subbase:

1. Insert a thin, flat-blade screwdriver into the slot on the

right side of the wall module (see Fig. 7).

2. Pull the screwdriver toward you to release the right side

of the wall module from the subbase.

3. Pull the wall module out and away from the subbase.

Fig. 7. Removing Wall Module from Subbase.

POWER UP

After the wall module is properly wired to the controller, it will

power up. Upon initial power up, the wall module LCD panel

displays the phrase, “PLEASE LOAd” (see Fig. 8). This

phrase alternates with bus address, model and version

number (TR71 and TR75 only), and any onboard sensor

display, such as temperature, humidity, etc.

Refer to the Zio/Zio Plus LCD Wall Modules Operating Guide

(Form 63-2719) to configure and load the desired user

interface and parameters into the wall module.

Fig. 8. Wall Module LCD display at initial power up.

ComfortPoint™ is a trademark of Honeywell International Inc.

L

ONMARK® is a trademark of the LonMark Association.

BACnet® is a trademark of BACnet International.

Sylk® is a trademark of Honeywell International Inc.

Zio® is a trademark of Honeywell International Inc.

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark

© 2012 Honeywell International Inc.

62-0271—07 M.S. Rev. 01-12

Printed in United States

Loading...

Loading...