Page 1

LOW VOLTAGE MODULATING CONTROLLER

y

g

g

g

g

g

y

y

y

y

APPLICATIONS

The T8078C digital electronic controller is designed for

individual zone control of terminal units in fan coil and

air conditioning systems.

The controller provides position control of valves or

dampers (for airside control), and is capable of

mounting on a switching sub-base for manual control

of the fan speed.

T8078C has great applications flexibility built-in – all

applications and control modes can be selected simpl

bysettinga bank of switches inside the product.

Control parameters are also adjusted by means of onboard switches.

T8078C also supports a number of features that

enhance the applications capability. These include

remote sensin

an external input), remote setpoint adjustment, and

heat/cool changeover.

Installation and commissionin

special fast commissionin

internal valve synchronisation, simple user dia

LED indication, and the provision of a dia

output.

, energysavings mode (activated from

are assisted bya

checkout sequence,

nostic

nostic

T8078C

PRODUCT SPECIFICATION SHEET

FEATURES

• Modern styling makes T8078C ideal for locating in

the occupied space, particularly in offices and

hotels.

• Proportional + Integral (P+I) control form ensures

close temperature control under all operating

conditions.

• Control modes and applications configured by onboard switches.

• Choice of control Modes:

- 3-position modulating

- thermal predictive modulating (TPM)

- On/off

• Choice of Applications:

- 2-pipe fan-coil cooling

- 2-pipe fan-coil heating

- 2-pipe fan-coil cooling +2-stage on/off heating

- 2-pipe fan-coil heating +2-stage on/off cooling

- 2-pipe fan-coil heat/cool changeover

- 4-pipe fan-coil heat + cool in sequence

• Choice of control parameters:

- 1, 2, or 4 K for the Proportional Band

- 2, 4 K for the Zero Energy Band

• Automatic heat/cool changeover is achieved b

using a remote switch, or a pipe thermostat

(S4390A1004) on the supply water pipe.

• Control setpoint can be remotely adjusted by ±±±±5K.

• Energy Savings Input - a local contact closure or a

central voltage input will switch T8087C to Energ

Savings Mode, where the cooling and heating

setpoints will change to pre-defined setup and

setback temperatures, enabling maximum energ

efficiency. Setup/setback values can be set 2-8K b

means of an on-board potentiometer.

• Sensor options: On-board or external (Wall

mounted, or Remote/return air). The connection of

an external sensor is detected automatically.

• Valve commissioning sequence for fast system

check.

• Periodic valve exercise and synchronisation.

• Simple user diagnostics capability – by means of a

flashing LED mounted inside the thermostat cover.

• Diagnostic output – for communication of

diagnostic system information to a PC tool.

• Extra wide Input Voltage Specification : 18 – 30 Vac.

• Automatic calibration offset over full voltage range.

• Suitable for mounting either on the terminal unit or

on the wall (surface or wall-box mounting).

• Wiring access from the rear, and surface wiring

knockouts at the top and sides.

• Locking front cover.

1 EN0R8535 R1 2003

Page 2

INDEX OF CONTENTS

Page Contents

1 APPLICATIONS OVERVIEW

1 FEATURES OVERVIEW

3 SPECIFICATIONS

4 PRODUCT APPLICATIONS TABLE

4 SYSTEM ARCHITECTURE

5 OPERATION

5 Control Modes

5 Operating Modes

5 Comfort Mode

5 Energy Savings Mode

6 Startup & Commissioning

7 Diagnostics & Fault Indication

8 ORDERING INFORMATION

8 SYSTEM & PARAMETER SELECTION SWITCHES

8 How to Configure T8078C

9 INSTALLATION

9 Location

9 Mounting

9 Wiring

9 Layout & Terminal Connections

10 APPLICATIONS – MODULATING CONTROL

10 (1) Modulating Cooling

10 (2) Modulating Heating

11 (3) Modulating Cooling + 2-Stage On/Off Heating

11 (4) Modulating Heating + 2-Stage On/Off Cooling

12 (5) Modulating Heat / Cool Changeover

12 (6) Modulating Cooling + Heating Sequence

13 APPLICATIONS – ON/OFF CONTROL

13 (7) On/Off Cooling

13 (8) On/Off Heating

14 (9) On/Off Cooling + 2-Stage On/Off Heating

14 (10) On/Off + 2-Stage On/Off Cooling

15 (11) On/Off Heat / Cool Changeover

15 (12) On/Off Cooling + Heating Sequence

16 APPLICATIONS – TPM CONTROL (THERMO-ELECTRIC ACTUATORS)

16 (13) TPM Cooling

16 (14) TPM Heating

17 (15) TPM Cooling + 2-Stage On/Off Heating

17 (16) TPM Heating + 2-Stage On/Off Cooling

18 (17) TPM Heat / Cool Changeover

18 (18) TPM Cooling + Heating Sequence

19 ADDITIONAL FEATURES

19 Auto Heat / Cool Changeover

19 Remote Temperature Sensing

20 Remote Setpoint Adjustment

20 SUITABLE VALVES & ACTUATORS

20 OPTIONAL ACCESSORIES

2 EN0R8535 R1 2003

Page 3

SPECIFICATIONS

Power Supply:

Power Consumption:

Output Load Rating:

Setpoint Range:

Configuration/System Selection:

Control Modes:

Applications Systems:

Proportional Band (Xp):

Zero Energy Band (ZEB):

Interstage Differential (ID):

Control Point Stability:

Ambient Temperature Range:

Storage Temperature Range:

Relative Humidity:

Remote Setpoint Adjustment:

Energy Savings (Setup/Setback):

Heat/Cool Changeover:

Mounting:

Wiring:

Enclosure:

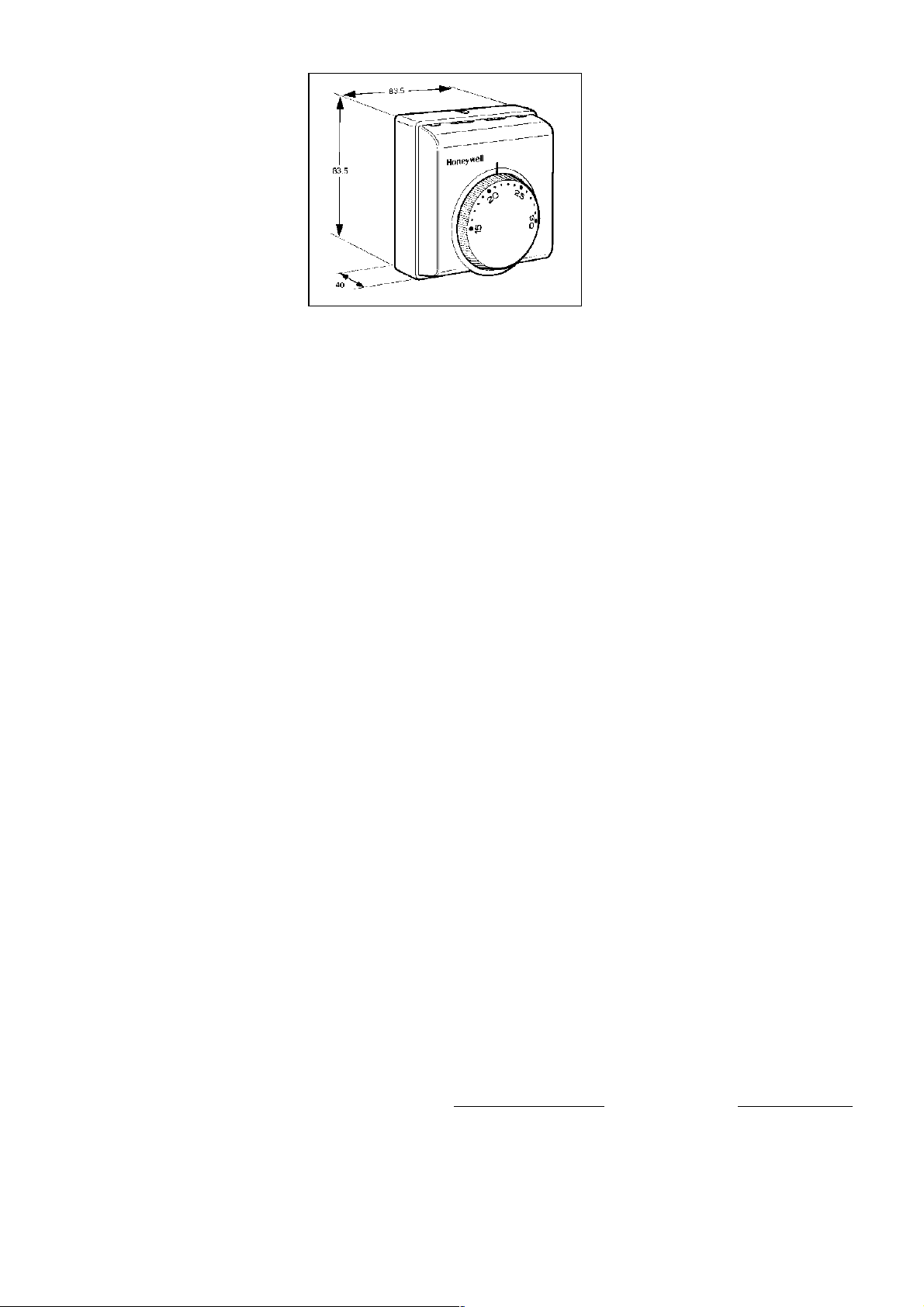

Dimensions:

Protection Class:

Approvals:

Sensors:

24 Vac nominal 50/60Hz, operating range 18 – 30 Vac

1.2 VA nominal (electronics only)

0.3 A (maximum) for all outputs at 24 Vac, with solid state switching

15 to 30 °C

Made via a bank of 6 on-board dip switches

3 different Control Modes :-

Modulating : 3-position modulating P+I control, based on adjustable proportional Band

(Xp), and 150sec valve run-time

On/Off : Primary stage control is P+I on/off output based on adjustable

Proportional Band (Xp) and a fixed cycle rate (6 cycles/hour Cooling, 6

cycles/hour heating)

: Secondary stage control is P+I on/off output based on a fixed Proportional

Band of 1K and a fixed cycle rate (6 cycles/hour Cooling, 12 cycles/hour

heating)

TPM : Special on/off control mode for thermo-electric actuators

6 different Applications System types :-

• Heat / Cool Changeover

• Cooling Only

• Cooling + optional 2-stage On/off Heating

• Heating Only

• Heating + optional 2-stage On/off Cooling

• Heating + Cooling Sequence Control

1K, 2K, or 4K (depending on system) selected using DIP switches

1K for secondary 2-stage Heating or Cooling stage control

2K or 4K selected using DIP switches

Fixed at 1K, for Systems with secondary 2-stage Heating or Cooling

±0.5K at 20°C

Operating range 0 to 40 °C

-20to55°C

10 to 90%, non condensing

±5K by remote unit, resistance input (Q979B1029, Q979C1036)

2 to 8K setup/setback possible, by means of external contact closure input

Value set by potentiometer on T8078C

Contact closure can be local or central, to control a group of T8078C (up to 50 max)

Automatic changeover by means of external contact closure input

Input can be local (from aquastat) or central from switch/relay (controls up to 50 max)

Directly onto wall or wall-box (65x65mm junction box with 60mm screw pitch) or inside

terminal unit or fan-coil

Also mounts on fan speed subbase Q6360A1025

Mounting accessory F42007789 available for other mounting configurations

14 x screw terminals capable of accepting up to 1.5mm² stranded cable

Max length of wiring to actuators is 100m @ 1.0mm², 150m @ 1.5mm²

Flame retardant plastic housing

83.5 x 83.5 x 40 mm

IP30 (IEC144)

CE mark, conforming as follows :

Directive (Amendments)

73/23/EEC (93/68/EEC) EN60730-1:2001

89/336/EEC (93/68/EEC & 92/51/EEC) EN55014-1:1997

On-board sensor , type NTC100K

Remote sensor T8109C1002 (1.5m cable) auto detected on power-up

Maximum sensor extension is 20m (using screened cable)

Standards Applied

EN60730-2-9:1995

EN55014-2:1997

3 EN0R8535 R1 2003

Page 4

PRODUCT APPLICATIONS

Basic Application Controlled Device Control Mode – details of application Application No.

2-pipe fan-coil Valve control Modulating cooling 1

“ Modulating heating 2

“ On/off cooling 7

“ On/off heating 8

“ TPM cooling (thermo-electric actuator) 13

“ TPM heating (thermo-electric actuator) 14

Airside control (damper) Modulating cooling 1

“ Modulating heating 2

Terminal unit Damper control Modulating cooling 1

“ Modulating heating 2

2-pipe fan-coil with auxillary electric heat Valve control Modulating cooling + 1or 2-stage on/off heating 3

(1 or 2-stage electric heating elements) “ On/off cooling + 1or 2-stage on/off heating 9

“ TPM cooling + 1or 2-stage on/off heating 15

Airside control (damper) Modulating cooling + 1or 2-stage on/off heating 3

2-pipe fan-coil with auxillary cooling Valve control Modulating heating + 1or 2-stage on/off cooling 4

(1 or 2-stage chillers) “ On/off heating+ 1or 2-stage on/off cooling 10

“ TPM heating + 1or 2-stage on/off cooling 16

Airside control (damper) Modulating heating + 1or 2-stage on/off cooling 4

2-pipe fan-coil with heat/cool changeover Valve control Modulating heat/cool changeover 5

“ On/off heat/cool changeover 11

“ TPM (thermo-electric actuator) heat/cool

changeover

4-pipe fan-coil Valve control Modulating cooling + heating in sequence 6

“ On/off cooling + heating in sequence 12

“ TPM cooling + heating in sequence 18

Airside control (damper) Modulating cooling + heating in sequence 1 or 2

17

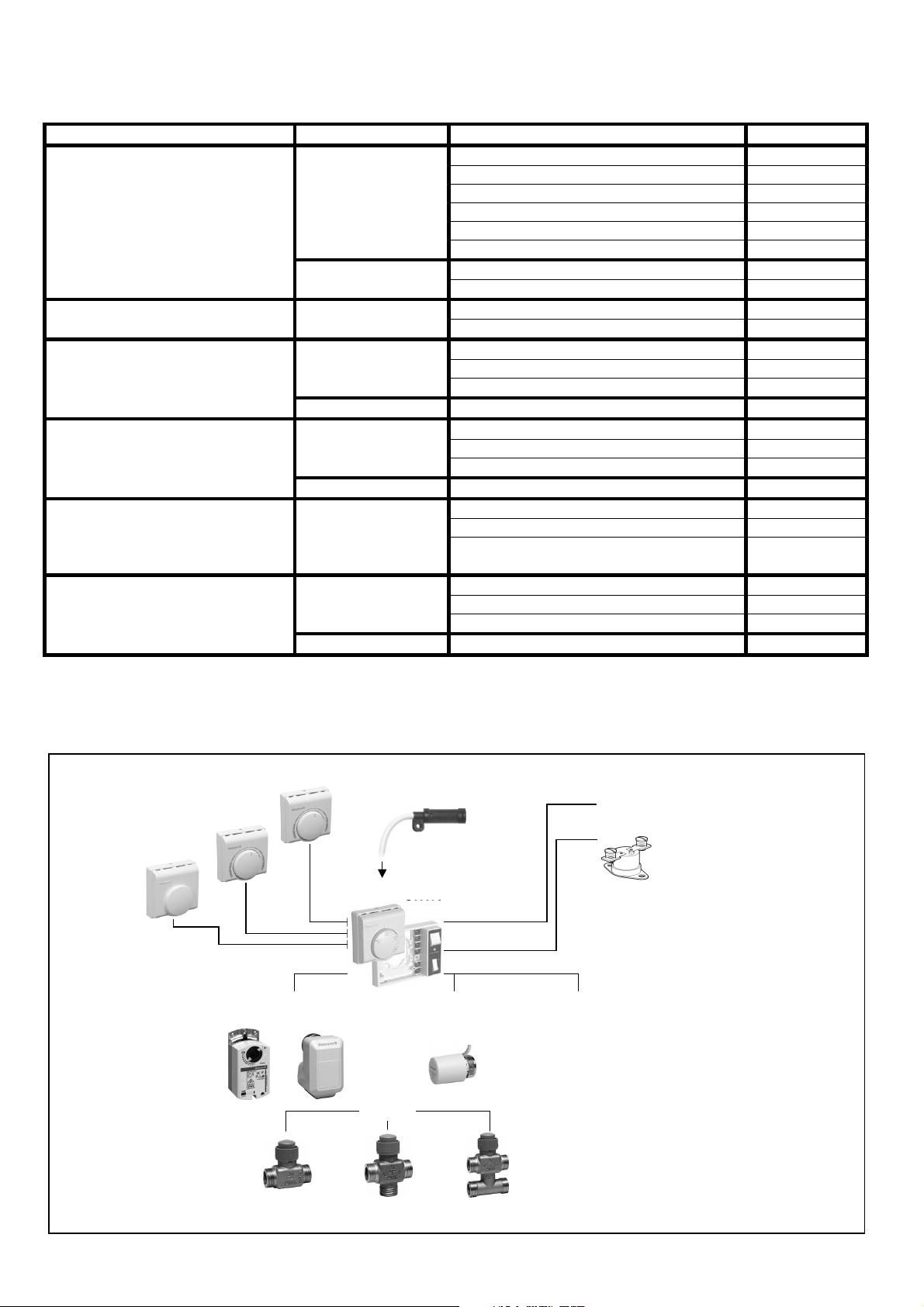

SYSTEM ARCHITECTURE

A diagram of compatible T8078B system components is shown below.

Q979C1036

Q979C1036

REMOTE SETPOINT

REMOTE SETPOINT

REMOTE SETPOINT

Q979A1020

Q979A1020

SPACE TEMP

SPACE TEMP

SENSOR

SENSOR

REMOTE SETPOINT

Q979B1029

Q979B1029

ADJUST UNIT

ADJUST UNIT

ML6161

ML6161

ML6174

ML6174

N2024

N2024

N3424

N3424

+ SENSOR

+ SENSOR

T8109C1002

T8109C1002

T8109C1002

SENSOR

SENSOR

SENSOR

T8078C CONTROLLER

T8078C CONTROLLER

MODULATING THERMAL ON/OFF

MODULATING THERMAL ON/OFF

ACTU ATORs ACTUATOR ACTU ATOR

ACTU ATORs ACTUATOR ACTU ATOR

M7410C

M7410C

M6410C

M6410C

Q6360A1025 SUB-BASE

Q6360A1025 SUB-BASE

VALVES

VALVES

M100

M100

Z100

Z100

M8450

M8450

ENERGY SAVINGS INPUT

ENERGY SAVINGS INPUT

HEAT/COOL CHANGEOVER

HEAT/COOL CHANGEOVER

S4390A1004

S4390A1004

PIPE STAT

PIPE STAT

V5822C

V5822C

V5822C

V5832C

V5832C

V5832C

V5823A

V5823A

V5823A

V5833A

V5833A

V5833A

V5823C

V5823C

V5823C

V5833C

V5833C

V5833C

4 EN0R8535 R1 2003

Page 5

OPERATION

g

gy

gy

y

Control Modes

T8078Cgives a choice of 3 different output control modes, to

suit a range of different actuators and system requirements.

Modulating Control

3-position modulating control is a control form that exactly

positions the control valve in order to satisfy the cooling or

heating demand.

For each valve actuator there are 2 control outputs, one to

drive the valve open, and another to drive the valve closed.

The controller can send out control pulses to each of these

outputs to move the valve to any position between fully

closed and 100% open. The required valve position is

calculated using a P+I algorithm, with an adjustable

Proportional Band (Xp), and valve actuator run-time of

150seconds.

This type of control gives optimum performance over a wide

range of conditions.

On/Off Control (with P+I input)

The on/off control form used by T8078C is one where the

output is cycled on and off with a fixed cycled period. The

on-time is adjusted by a P+I algorithm so the heating or

cooling demand is met and the space is controlled to

setpoint.

The cycle rate is 6cycles/hour for cooling and heating.

For the primary control stage, the Proportional Band (Xp) can

be selected to be either 1, 2, or 4K, depending on the

system.

For the secondary control stages, the Proportional Band is

fixed at 1K and the cycle rate is 6cycles/hour for cooling,

12cycles/hour for heating.

This type of on/off control ensures closer control to setpoint

than conventional on/off control based on a temperature

differential.

TPM Control (for Thermo-Electric Actuators)

Thermo-electric (or thermal) actuators are very cost effective

devices, but they present particular difficulties to control

because of the time-lags in their response to control inputs.

Therefore T8078C uses a special Thermal Predictive

Modulating (TPM) control to operate thermal actuators in the

optimum way.

This type of on/off control ensures closer control

performance when using thermal actuators than

conventional on/off control or pulse-width modulating control.

Operating Modes

T8078C has 2 main operating modes,

Energy Savings Mode

Commissioning Mode

, and also has a

which is entered immediately on

power-up.

Comfort Mode

This is the normal operating mode, where T8078C controls

to the setpoint selected by the user.

Comfort Mode

Startup /

and

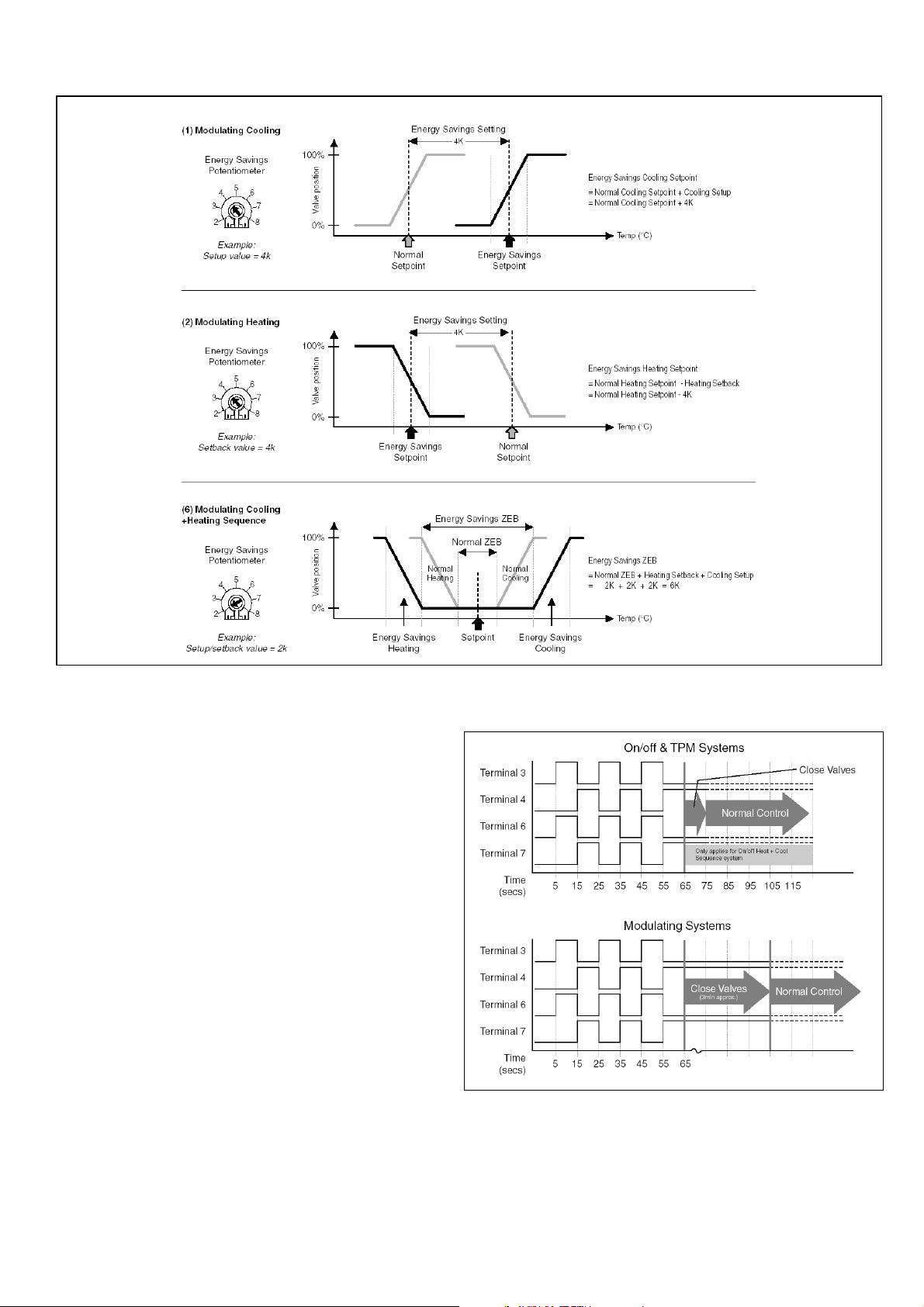

Energy Savings Mode – continued

In Energy Savings Mode the Setup/Setback values can be

set between 2-8K by means of an on-board potentiometer.

In cooling only systems (1, 7, 13) the setpoint will be

increased (setup) by the set value fixed by the potentiometer.

In heating only systems (2, 8, 14) the setpoint will be

decreased (setback).

In heat/cool changeover systems (5, 11, 17) the heating

setpoint will be decreased in heating mode, and the cooling

setpoint will be increased in cooling mode.

In coolin

+ heatingsystems (anysystem with a Zero Ener

Band) the cooling setpoint will be increased by the set value

and the heating setpoint will be decreased by the same

amount. The setpoint remains the same, but the effect is to

widen the Zero Ener

Band.

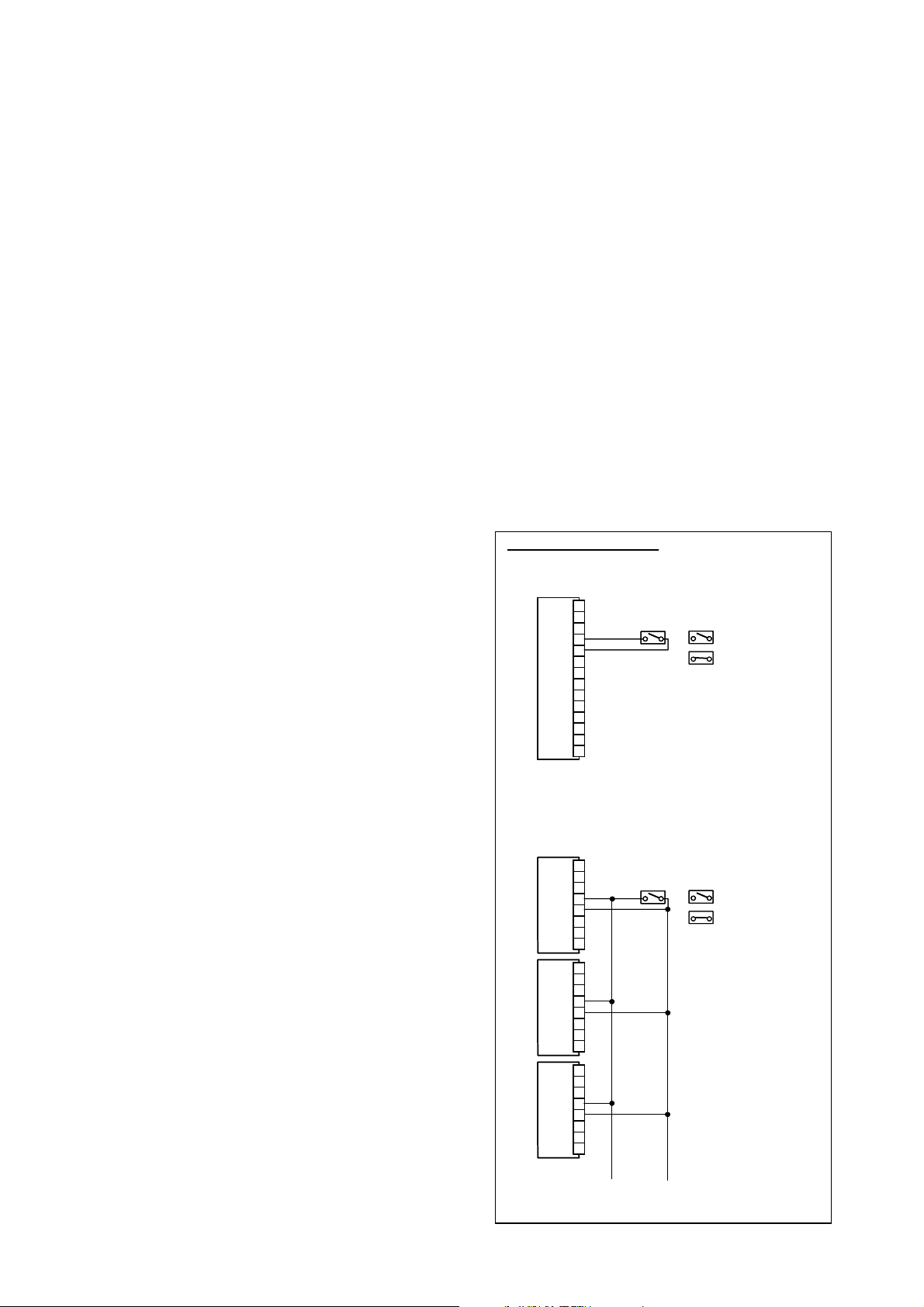

Energy Savings - From Central Location

A group of T8078C units can be switched to Energy Savings

mode using a central switch. A maximum of 50 units can be

switched this wa

the polarity of wiring connections is correct.

Each T8078C controller will switch to its own pre-defined

setback values, as set by its on-board potentiometer.

Input Wiring Connections

Input Wiring Connections

Single Unit Energy Savings

Single Unit Energy Savings

T8078C

T8078C

Central Energy Savings

Central Energy Savings

T8078C

T8078C

T8078C

T8078C

T8078C

T8078C

, but extreme care must be taken to ensure

14

14

Switch should be rated 30 Vdc

Switch should be rated 30 Vdc

13

13

0.5 mA nominal

0.5 mA nominal

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

Switch should be rated 30 Vdc

Switch should be rated 30 Vdc

0.5 mA nominal

0.5 mA nominal

11

11

10

10

11

11

10

10

= Normal Operation

= Normal Operation

= Energy Savings Mode

= Energy Savings Mode

= Normal Operation

= Normal Operation

= Energy Savings Mode

= Energy Savings Mode

Energy Savings Mode

T8078C has an Energy Management System, where the

detection of an external input signal will cause the cooling

and heating setpoints to change to pre-defined setup and

setback temperatures, enabling maximum energy efficiency.

This input signal must be in the form of a contact closure,

connected to terminals 10 and 11.

11

11

10

10

x 50 units maximum

x 50 units maximum

Take care to always observe polarity of connection

Take care to always observe polarity of connection

5 EN0R8535 R1 2003

Page 6

Energy Savings Mode - Examples

Startup & Commissioning

On power up, T8078C will immediately undergo a test and

synchronisation sequence to enable Installers and

Commissioning Engineers to test the system is wired correctly.

Test Sequence

For all control modes, the test sequence will last 60 seconds,

and will consist of switching the 4 control outputs on and off in

the sequence illustrated. The outputs are connected to

terminals 3, 4, 6, and 7.

If it is necessary to repeat the sequence, the power supply can

be switched off then back on again.

Valve Synchronisation

The synchronisation sequence will depend on what type of

Control Mode

For modulating systems, the test sequence will be followed by

a 3 minute valve synchronisation, where the valves will be

driven to the closed position in order to establish a baseline

control reference.

For on/off and TPM control systems, the valve closure

sequence will last 10 seconds.

The synchronisation sequence will be repeated 12 hours after

power up, and thereafter every 24 hours. This is designed to

ensure there will be no disturbance to temperature control

during normal hours of building occupancy.

The Diagnostic LED will pulse on and off in the sequence

illustrated for Terminal 3 if no faults are detected (see Section

entitled ‘Diagnostics & Fault Indication’ for a complete

description).

has been selected.

6 EN0R8535 R1 2003

Page 7

Diagnostics & Fault Indication

y

y

T8078C provides simple user diagnostics and fault

indication using an LED, positioned at the bottom right side

of the printed wiring board. The T8078C cover must be

removed to view the LED correctly.

By pulsing the LED on and off in predefined sequences,

T8078C is able to indicate valve position, heating or cooling

demand, or whether a fault has been detected.

The tables and graphs opposite give details of the how to

interpret the LED outputs.

Fault Indication

If a fault is detected, this will be indicated as highest priority.

Faults are indicated by 1, 2, or 3 LED pulses, followed b

second delay, then a repeat of the pulse sequence.

Most detectable faults are due to errors in reading sensor or

setpoint values. In the unlikel

event of an internal sensor or

unit setpoint fault, the controller must be replaced. If a

remote sensor fault is indicated, it is likely to be a bad

connection, so all wiring connections should be checked.

Valve Position / Cooling or Heating Demand

Valve position or cooling/heating demands are indicated by

an initial code sequence of pulses, followed by the position

or demand data, and this is repeated on a fixed cycle rate.

The duration of the data pulse provides the important

information, for example :

Valve position

The LED is switched on for a duration proportional to the

valve position, where 10s on = valve fully open

On/off or TPM demand

The LED is switched on for an amount proportional to the

on-period of the cycle, where 10s on = 100% demand.

T8078C will only provide demand or position data on the

current operating output, and this will be indicated by the

initial pulse sequence of 1, 2, or 3 pulses.

The table below shows how to determine current operating

mode & demand for each of the 18 possible control options.

a6

Suggested ActionFault

Suggested ActionFault

Replace controllerInternal Sensor out of range

Replace controllerInternal Sensor out of range

Check sensor connectionsRemote Sensor out of range

Check sensor connectionsRemote Sensor out of range

Replace controllerFaulty setpoint measurement

Replace controllerFaulty setpoint measurement

7 EN0R8535 R1 2003

Page 8

ORDERING INFORMATION

T8078C1009 : Controller

Accessory Products

Q979A1020

Q979B1029

Q979C1036

T8109C1002

S4390A1004

Q6360A1025

F42007789-001

F42006646-001

: Wall-mounted Remote Sensor

: Remote Setpoint Adjustment Unit (±5K)

: Remote Sensor + Setpoint Adjust Unit

: Remote Sensor (1.5m cable)

: Pipe-mounted Changeover Thermostat

: Fan Speed Switching Sub-base

: Wall-plate

: Range-stops

SYSTEM&PARAMETER SELECTION SWITCHES

T8078C uses a bank of 6 switches to enable configuration of the Control MODE,

the Applications SYSTEM, and appropriate Control Parameters, such as

PROPORTIONAL BAND (Xp) and ZERO ENERGY BAND (ZEB).

These switches are located on the wiring board underneath the cover, on the

bottom left hand side.

See the diagram below for an explanation of the switch settings.

How to Configure T8078C

(1) Select Control Type, using switches S1 and S2

The choices are :

TPM (optimised for thermal actuator control)

On/off

Modulating (3-position control) – sometimes also known as ‘Floating’ control.

(2) Select System Type, using switches S3 and S4

The choices are :

1-stage cooling (+ optional 2-stage on/off heating)

1-stage heating (+ optional 2-stage on/off cooling)

1-stage heat/cool changeover (activated by external input signal)

heat + cool sequence control

(3) Select Control Parameters, using switches S5 and S6

Proportional Band X

Zero Energy Band ZEB = 2K or 4K

= 1K, 2K or 4K (also dependant on system type)

p

8 EN0R8535 R1 2003

Page 9

INSTALLATION

j

Location

T8078C may be located on the wall in the space to be

controlled, or on the body of the terminal unit.

With In-built Temperature Sensor

T8078C is supplied with a built-in temperature sensor. If this

is to be used, then T8078C is the critical temperature control

element in the air-conditioning system, and must be located

about 1.5m above the floor in a position with good air

circulation at room temperature.

With Remote Temperature Sensor

T8078C supports remote temperature sensingfrom a rangeof

remote sensors or modules. In this case it is the position of

the sensor that is critical :

• for return air sensing the remote sensor must be

positioned within the terminal unit, duct, or plenum, in the

return air stream where it is not affected by other

influences

• for room temperature sensing the remote sensor or

module must be located as for a T8078C with in-built

sensor.

Please note :

1. The maximum cable run between T8078C and remote

sensor is 20m, and screened cable must be used.

2. T8078C uses it’s in-built sensor, unless it automatically

detects the presence of the remote sensor at power-up.

So the T8078C must be powered down then back up

again after a remote sensor is connected.

Mounting T8078C

T8078C can mounted directly on the wall or on a suitable

unction box of dimension 65 x 65mm maximum. Mounting

screws are supplied (2 x 25mm No. 6 woodscrews, 2 x 25mm

M3.5 screws) and there are 4 mounting hole locations on the

controller that can be used.

IMPORTANT !

The Installer must be a trained service engineer.

Isolate the power supply before commencing installation.

(3) Make the required wiring connections

(4) Re-attach the cover and tighten the locking screw to

complete the installation.

Wiring

The standard wiring access is through a hole at the top and

back of T8078B, but there are 4 wiring breakouts in the

cover to allow surface wiring, if necessary.

T8078C has 14 wiring terminals – all are suitable for the

connection of up to 1.5mm

Take care not to over-tighten the terminal screws during

installation, as this can damage the joints.

Refer to

schematics.

Applications

2

stranded cable.

pages for details of all wiring

Mounting on Q6360A1025 Fan Speed Sub-base

Where 230Vac fan-speed switching is required, T8078C can

be mounted on the Q6360A1025 switching sub-base, using

the screws supplied with Q6360.

All line voltage wiring connections should be made to the

sub-base before the controller is installed or wired. Line

voltage sub-base wiring and low voltage controller wiring

should be clearly separated and must comply with all

relevant local electrical codes.

Layout & Wiring Connections

(1) Unscrew the cover locking screw and remove the cover.

(2) Mount T8078C to the surface using the mounting screws

provided. If it is to be mounted onto a terminal unit, the

installer should use appropriate bolts or self-tapping screws.

Terminals

1. 24 volt supply

2. 24 volt supply (0v)

3. Valve 1 open

4. Valve 1 close

5. Valve common

6. Valve 2 open / stage 1 on/off control (applications

3,4,9,10,15,16)

7. Valve 2 close / stage 2 on/off control (applications

3,4,9,10,15,16)

8. Heat / Cool changeover input

9. Heat / Cool changeover input

10. Energy savings input

11. Energy savings input

12. Remote sensor input

13. Remote common (for remote sensor / setpoint inputs)

14. Remote setpoint input

9 EN0R8535 R1 2003

Page 10

APPLICATIONS – MODULATING CONTROL

(1) MODULATING COOLING

Valve position

Valve position

100%

100%

0%

0%

X

X

pC

pC

Setpoint

Setpoint

(oC)

(oC)

Applications

•2-pipefcuvalvecontrol

• terminal unit damper control

• 2-pipe fcu airside control

• 4-pipe fcu airside control

Notes

1) Proportional Band XpC=2K or 4K.

2) Use 4K Prop Band for 4-pipe airside control, and wire damper

motor as for actuator shown.

Wiring Schematics

2-port valves

T8078C

T8078C

14

14

13

13

12

12

11

11

10

10

9

9

8

8

7

7

6

COOL

COOL

COM

COM

6

5

5

4

4

-

-

+

+

3

3

2

2

1

1

M7410C

M7410C

BROWN

BROWN

BROWN

3-port valves

T8078C

T8078C

14

14

13

13

12

12

11

11

10

10

9

9

8

8

7

7

6

COOL

COOL

COM

COM

6

5

5

4

4

-

-

+

+

3

3

2

2

1

1

M7410C

M7410C

BROWN

BROWN

BROWN

WHITE

WHITE

WHITE

GREEN

GREEN

GREEN

WHITE

WHITE

WHITE

GREEN

GREEN

GREEN

T8109C SENS OR (OPTIONAL)

T8109C SENS OR (OPTIONAL)

V5822A

V5822A

V5832A

V5832A

M

M

M

24Vac

24Vac24Vac

~

~

T8109C SENS OR (OPTIONAL)

T8109C SENS OR (OPTIONAL)

V5823A,C

V5823A,C

V5833A,C

V5833A,C

M

M

M

24Vac

24Vac24Vac

~

~

(2) MODULATING HEATING

Valve position

Valve position

100%

100%

0%

0%

X

X

pH

pH

Setpoint

Setpoint

(oC)

(oC)

Applications

•2-pipefcuvalvecontrol

• terminal unit damper control

• 2-pipe fcu airside control

• 4-pipe fcu airside control

Notes

1) Proportional Band XpH=2K or 4K.

2) Use 4K Prop Band for 4-pipe airside control, and wire damper

motor as for actuator shown.

Wiring Schematics

2-port valves

T8078C

T8078C

14

14

13

13

12

12

11

11

10

10

9

9

8

8

7

7

6

6

COM

COM

5

5

4

4

-

HEAT

HEAT

-

+

+

3

3

2

2

1

1

BROWN

BROWN

BROWN

GREEN

GREEN

GREEN

3-port valves

T8078C

T8078C

14

14

13

13

12

12

11

11

10

10

9

9

8

8

7

7

6

6

COM

COM

5

5

4

4

-

HEAT

HEAT

-

+

+

3

3

2

2

1

1

GREEN

GREEN

GREEN

BROWN

BROWN

BROWN

M7410C

M7410C

WHITE

WHITE

WHITE

M7410C

M7410C

WHITE

WHITE

WHITE

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

V5822A

V5822A

V5832A

V5832A

M

M

M

24Vac

24Vac24Vac

~

~

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

V5823A,C

V5823A,C

V5833A,C

V5833A,C

M

M

M

24Vac

24Vac24Vac

~

~

10 EN0R8535 R1 2003

Page 11

APPLICATIONS – MODULATING CONTROL

(3) MODULATING COOLING + 2-STAGE ON/OFF HEATING Wiring Schematics

Valve position

Valve position

H

H

100%

100%

0%

0%

2

2

ID

ID

H

H

H

H

1

1

ZEB

ZEB

X

X

pC

pC

Setpoint

Setpoint

(oC)

(oC)

Applications

• 2-pipe fcu valve control with 1or 2 stage electric heat

• 2-pipe fcu airside control with 1or 2 stage electric heat

Notes

1) Proportional Band XpC=2K or 4K.

2) Zero Energy Band ZEB=2K or 4K.

3) Valve must be closed before heating comes on.

4) Heating stages H

5) H

1&H2

=1K (fixed).

are P+I on/off control with 1K prop. Band.

1&H2

6) Heating stages cycle rate=12c/hour (fixed).

7) Interstage Differential ID

8) Stages H

do not switch together -20s delay.

1&H2

=1K (fixed).

H

9) For airside control, wire damper motor as for actuator shown.

2-port valves

T8078C

T8078C

14

14

13

13

12

12

11

11

10

10

9

9

8

8

H

H

7

7

2

2

HEAT

HEAT

H

H

1

1

6

6

COM

COM

5

5

4

4

-

-

COOL

COOL

3

3

+

+

2

2

1

1

3-port valves

T8078C

T8078C

14

14

13

13

12

12

11

11

10

10

9

9

8

8

H

H

7

7

2

2

HEAT

HEAT

H

H

1

1

6

6

COM

COM

5

5

4

4

-

-

COOL

COOL

3

3

+

+

2

2

1

1

ELECTRIC HEAT (STAGE H

ELECTRIC HEAT (STAGE H

ELECTRIC HEAT (STAGE H1)

ELECTRIC HEAT (STAGE H1)

M7410C

M7410C

WHITE

WHITE

WHITE

BROWN

BROWN

BROWN

M

M

M

GREEN

GREEN

GREEN

ELECTRIC HEAT (STAGE H

ELECTRIC HEAT (STAGE H

ELECTRIC HEAT (STA GE H1)

ELECTRIC HEAT (STA GE H1)

M7410C

M7410C

WHITE

WHITE

WHITE

GREEN

GREEN

GREEN

M

M

M

BROWN

BROWN

BROWN

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

)

)

2

2

V5822A

V5822A

V5832A

V5832A

24Vac

24Vac

~

~

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

)

)

2

2

V5823A,C

V5823A,C

V5833A,C

V5833A,C

24Vac

24Vac

~

~

(4) MODULATING HEATING + 2-STAGE ON/OFF COOLING

Valve position

Valve position

100%

100%

0%

0%

X

X

pH

pH

Setpoint

Setpoint

ZEB

ZEB

C

C

2

2

ID

ID

C

C

C

C

1

1

(oC)

(oC)

Applications

• 2-pipe fcu valve control with 1 or 2 stage chiller

• 2-pipe fcu airside control with 1 or 2 stage chiller

Notes

1) Proportional Band XpH=2K or 4K.

2) Zero Energy Band ZEB=2K or 4K.

3) Valve must be closed before cooling comes on.

4) Cooling stages C

5) C

1&C2

=1K (fixed).

are P+I on/off control with 1K prop. Band.

1&C2

6) Cooling stages cycle rate=6c/hour (fixed).

7) Interstage Differential ID

8) Stages C

do not switch together -20s delay.

1&C2

=1K (fixed).

C

9) For airside control, wire damper motor as for actuator shown.

Wiring Schematics

2-port valves

T8078C

T8078C

14

14

13

13

12

12

11

11

10

10

9

9

8

8

C

C

7

7

2

2

COOL

COOL

C

C

1

1

6

6

COM

COM

5

5

4

4

-

HEAT

HEAT

-

+

+

3

3

2

2

1

1

BROWN

BROWN

BROWN

GREEN

GREEN

GREEN

3-port valves

T8078C

T8078C

14

14

13

13

12

12

11

11

10

10

9

9

8

8

C

C

7

7

2

2

COOL

COOL

C

C

1

1

6

6

COM

COM

5

5

4

4

-

-

HEAT

HEAT

+

+

3

3

2

2

1

1

BROWN

BROWN

BROWN

M7410C

M7410C

WHITE

WHITE

WHITE

M7410C

M7410C

WHITE

WHITE

WHITE

GREEN

GREEN

GREEN

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

COOLING (STAGE C

COOLING (STAGE C

COOLING (STAGE C1)

COOLING (STAGE C1)

V5822A

V5822A

V5832A

V5832A

M

M

M

~

~

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

COOLING (STAGE C

COOLING (STAGE C

COOLING (STAGE C1)

COOLING (STAGE C1)

V5823A,C

V5823A,C

V5833A,C

V5833A,C

M

M

M

~

~

24Vac

24Vac

24Vac

24Vac

2

2

)

)

)

)

2

2

11 EN0R8535 R1 2003

Page 12

APPLICATIONS – MODULATING CONTROL

(5) MODULATING HEAT / COOL CHANGEOVER Wiring Schematics

Valve position

Valve position

100%

100%

0%

0%

Heating

Heating

Mode

Mode

X

X

pCH

pCH

Setpoint

Setpoint

Cooling

Cooling

Mode

Mode

(oC)

(oC)

Applications

• 2-pipe fcu valve control with input signal for automatic changeover

Notes

1) Proportional Band X

=2K or 4K.

pCH

2) Wire as for Cooling control.

3) External input signal changes operating mode from cooling to heating.

4) Contact closure signal from single aquastat.

5) Contact closure signal from central control switch – ensure correct

polarity of connection to all T8078C units.

2-port valves

T8078C

T8078C

14

14

13

13

12

12

11

11

10

10

9

9

8

8

7

7

6

6

COM

COM

5

5

4

4

-

-

COOL

COOL

3

3

+

+

2

2

1

1

3-port valves

T8078C

T8078C

14

14

13

13

12

12

11

11

10

10

9

9

8

8

7

7

6

6

COM

COM

5

5

4

4

-

-

COOL

COOL

3

3

+

+

2

2

1

1

M7410C

M7410C

WHITE

WHITE

WHITE

BROWN

BROWN

BROWN

GREEN

GREEN

GREEN

M7410C

M7410C

WHITE

WHITE

WHITE

GREEN

GREEN

GREEN

BROWN

BROWN

BROWN

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

S4390A

S4390A

HEAT / COOL

HEAT / COOL

CHANGEOVER SWITCH

CHANGEOVER SWITCH

V5822A

V5822A

V5832A

V5832A

M

M

M

24Vac

24Vac24Vac

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

S4390A

S4390A

HEAT / COOL

HEAT / COOL

CHANGEOVER SWITCH

CHANGEOVER SWITCH

V5823A,C

V5823A,C

V5833A,C

V5833A,C

M

M

M

24Vac

24Vac24Vac

(6) MODULATING COOLING + HEATING SEQUENCE

Valve position

Valve position

100%

100%

0%

0%

X

X

pH

pH

ZEB

ZEB

Setpoint

Setpoint

X

X

pC

pC

(oC)

(oC)

Applications

•4-pipefcuvalvecontrol

Notes

1) Both Proportional Bands XpC&XpH=1K or 2K.

2) Zero Energy Band ZEB=2K or 4K.

3) Heat valve is closed before cooling valve opens.

4) Cool valve is closed before heating valve opens.

Wiring Schematics

2-port valves

T8078C

T8078C

14

14

13

13

12

12

11

11

10

10

9

9

8

HEAT

HEAT

COOL

COOL

COM

COM

8

7

7

-

-

+

+

6

6

5

5

4

4

-

-

3

3

+

+

2

2

1

1

BROWN

BROWN

BROWN

BROWN

BROWN

BROWN

3-port valves

T8078C

T8078C

14

14

13

13

12

12

11

11

10

10

9

9

8

8

7

7

-

-

HEAT

HEAT

COOL

COOL

COM

COM

+

+

6

6

5

5

4

4

-

-

3

3

+

+

2

2

1

1

BROWN

BROWN

BROWN

BROWN

M7410C

M7410C

GREEN

GREEN

GREEN

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

GREEN

GREEN

GREEN

M7410C

M7410C

GREEN

GREEN

WHITE

WHITE

WHITE

WHITE

GREEN

GREEN

T8109C SENS OR (OPTIONAL)

T8109C SENS OR (OPTIONAL)

V5822A

V5822A

V5832A

V5832A

M

M

M

M

M

M

24Vac

24Vac24Vac

~

~

T8109C SENS OR (OPTIONAL)

T8109C SENS OR (OPTIONAL)

V5823A,C

V5823A,C

V5833A,C

V5833A,C

M

M

M

M

24Vac

24Vac

~

~

12 EN0R8535 R1 2003

Page 13

APPLICATIONS – ON / OFF CONTROL

(7) ON/OFF COOLING Wiring Schematics

Valve position

Valve position

100%

100%

100%

0%

0%

0%

X

X

X

pC

pC

pC

Setpoint

Setpoint

Setpoint

(oC)

(oC)

(oC)

Applications

•2-pipefcuvalvecontrol

Notes

1) Control is P+I on/off.

2) Cycle rate is 6c/hour (fixed).

3) Proportional Band X

=2K or 4K.

pC

4) Can use valves that require only to be driven in one direction (for

example, with thermal actuators) or valves that require to be driven

open, then driven closed.

5) Normally closed valves: use output from (+) terminal to drive open.

6) Normally open valves: use output from (-) terminal to drive closed.

Drive open valves

T8078C

T8078C

14

14

13

13

12

12

11

11

10

10

9

9

8

8

7

7

6

6

COM

COM

5

5

4

4

-

-

COOL

COOL

+

+

3

3

2

2

1

1

Drive open / drive closed valves

T8078C

T8078C

14

14

13

13

12

12

11

11

10

10

9

9

8

8

7

7

6

6

COM

COM

5

5

4

4

-

-

COOL

COOL

+

+

3

3

2

2

1

1

ACTUATOR

ACTUATOR

COMMON

COMMON

OPEN VALVE

OPEN VALVE

ACTUATOR

ACTUATOR

COMMON

COMMON

CLOSE

CLOSE

OPEN

OPEN

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

24Vac

24Vac24Vac

~

T8109C SENS OR (OPTIONAL)

T8109C SENS OR (OPTIONAL)

24Vac

24Vac24Vac

~

(8) ON/OFF HEATING

Valve position

Valve position

Valve position

100%

100%

100%

0%

0%

0%

X

X

X

pH

pH

pH

Setpoint

Setpoint

Setpoint

(oC)

(oC)

Applications

•2-pipefcuvalvecontrol

Notes

1) Control is P+I on/off.

2) Cycle rate is 6c/hour (fixed).

3) Proportional Band X

=2K or 4K.

pH

4) Can use valves that require only to be driven in one direction (for

example, with thermal actuators) or valves that require to be driven

open, then driven closed.

5) Normally closed valves: use output from (+) terminal to drive open.

6) Normally open valves: use output from (-) terminal to drive closed.

Wiring Schematics

Drive open valves

T8078C

T8078C

14

14

13

HEAT

HEAT

COM

COM

13

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

-

-

+

+

3

3

2

2

1

1

ACTUATOR

ACTUATOR

COMMON

COMMON

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

OPEN

OPEN

~

~

24Vac

24Vac24Vac

Drive open / drive closed valves

T8078C

T8078C

14

14

13

HEAT

HEAT

COM

COM

13

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

-

-

+

+

3

3

2

2

1

1

ACTUATOR

ACTUATOR

COMMON

COMMON

CLOSE

CLOSE

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

OPEN

OPEN

~

~

24Vac

24Vac24Vac

13 EN0R8535 R1 2003

Page 14

APPLICATIONS – ON / OFF CONTROL

(9) ON/OFF COOLING + 2-STAGE ON/OFF HEATING Wiring Schematics

Valve position

Valve position

H

H

100%

100%

0%

0%

2

2

ID

ID

H

H

H

H

1

1

ZEB

ZEB

X

X

pC

pC

Setpoint

Setpoint

(oC)

(oC)

Applications

• 2-pipe fcu valve control with 1or 2 stage electric heat

Notes

1) Cooling control is P+I form, with 6c/hour cycle rate.

2) Cooling Proportional Band X

=2K or 4K.

pC

3) Zero Energy Band ZEB=2K or 4K.

4) Cooling valve must be closed before heating comes on.

5) Heating stages H

6) H

1&H2

=1K (fixed).

are P+I on/off control with 1K Prop. Band.

1&H2

7) Heating stages cycle rate=12c/hour (fixed).

8) Interstage Differential ID

9) Stages H

do not switch together -20s delay.

1&H2

=1K (fixed).

H

Drive open valves

T8078C

T8078C

14

14

13

13

12

12

11

11

10

10

9

9

8

8

H

H

7

7

2

2

HEAT

HEAT

H

H

1

1

6

6

COM

COM

5

5

4

4

-

-

COOL

COOL

3

3

+

+

2

2

1

1

Drive open / drive closed valves

T8078C

T8078C

14

14

13

13

12

12

11

11

10

10

9

9

8

8

H

H

7

7

2

2

HEAT

HEAT

H

H

1

1

6

6

COM

COM

5

5

4

4

-

-

COOL

COOL

3

3

+

+

2

2

1

1

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

ELECTRIC HEAT (STAGE H

ELECTRIC HEAT (STAGE H

ELECTRIC HEAT (STAGE H1)

ELECTRIC HEAT (STAGE H1)

ACTUATOR

ACTUATOR

COMMON

COMMON

OPEN VALVE

OPEN VALVE

~

~

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

ELECTRIC HEAT (STAGE H

ELECTRIC HEAT (STAGE H

ELECTRIC HEAT (STAGE H1)

ELECTRIC HEAT (STAGE H1)

COMMON

COMMON

CLOSEVALVE

CLOSEVALVE

OPEN VALVE

OPEN VALVE

ACTUATOR

ACTUATOR

~

~

24Vac

24Vac

24Vac

24Vac

)

)

2

2

)

)

2

2

(10) ON/OFF HEATING + 2-STAGE ON/OFF COOLING

Valve position

Valve position

100%

100%

0%

0%

X

X

pH

pH

Setpoint

Setpoint

ZEB

ZEB

C

C

2

2

ID

ID

C

C

C

C

1

1

(oC)

(oC)

Applications

• 2-pipe fcu valve control with 1 or 2 stage chiller

Notes

1) Heating control is P+I form, with 6c/hour cycle rate.

2) Heating Proportional Band X

=2K or 4K.

pH

3) Zero Energy Band ZEB=2K or 4K.

4) Heating valve must be closed before cooling comes on.

5) Cooling stages C

6) C

1&C2

=1K (fixed).

are P+I on/off control with 1K Prop. Band.

1&C2

7) Cooling stages cycle rate=6c/hour (fixed).

8) Interstage Differential ID

9) Stages C

do not switch together -20s delay.

1&C2

=1K (fixed).

C

Wiring Schematics

Drive open valves

T8078C

T8078C

14

14

13

COOL

COOL

HEAT

HEAT

COM

COM

13

12

12

11

11

10

10

9

9

8

8

C

C

7

7

2

2

C

C

1

1

6

6

5

5

4

4

-

-

+

+

3

3

2

2

1

1

COMMON

COMMON

OPEN VALVE

OPEN VALVE

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

COOLING (STAGE C

COOLING (STAGE C

COOLING (STAGE C1)

COOLING (STAGE C1)

ACTUATOR

ACTUATOR

~

~

24Vac

24Vac

Drive open / drive closed valves

T8078C

T8078C

14

14

13

COOL

COOL

HEAT

HEAT

COM

COM

13

12

12

11

11

10

10

9

9

8

8

H

H

7

7

2

2

H

H

1

1

6

6

5

5

4

4

-

-

3

3

+

+

2

2

1

1

CLOSEVALVE

CLOSEVALVE

OPEN VALVE

OPEN VALVE

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

COOLING (STAGE H

COOLING (STAGE H

COOLING (STAGE H1)

COOLING (STAGE H1)

COMMON

COMMON

ACTUATOR

ACTUATOR

~

~

24Vac

24Vac

)

)

2

2

)

)

2

2

14 EN0R8535 R1 2003

Page 15

APPLICATIONS – ON / OFF CONTROL

(11) ON/OFF HEAT / COOL CHANGEOVER Wiring Schematics

Valve position

Valve position

100%

100%

0%

0%

Heating

Heating

Mode

Mode

X

X

pCH

pCH

Setpoint

Setpoint

Cooling

Cooling

Mode

Mode

(oC)

(oC)

Applications

• 2-pipe fcu valve control with input signal for automatic changeover

Notes

1) Control is P+I form, with 6c/hour cycle rate (heating or cooling).

2) Proportional Band X

=2K or 4K.

pCH

3) Wire as for Cooling control.

4) External input signal changes operating mode from cooling to heating.

5) Contact closure signal from single aquastat.

6) Contact closure signal from central control switch – ensure correct

polarity of connection to all T8078C units.

Drive open valves

T8078C

T8078C

14

14

13

13

12

12

11

11

10

10

9

9

8

8

7

7

6

6

COM

COM

5

5

4

4

-

-

COOL

COOL

3

3

+

+

2

2

1

1

Drive open / drive closed valves

T8078C

T8078C

14

14

13

13

12

12

11

11

10

10

9

9

8

8

7

7

6

6

COM

COM

5

5

4

4

-

-

COOL

COOL

3

3

+

+

2

2

1

1

ACTUATOR

ACTUATOR

COMMON

COMMON

OPEN VALVE

OPEN VALVE

ACTUATOR

ACTUATOR

COMMON

COMMON

CLOSEVALVE

CLOSEVALVE

OPEN VALVE

OPEN VALVE

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

S4390A

S4390A

HEAT / COOL

HEAT / COOL

CHANGEOVER SWITCH

CHANGEOVER SWITCH

24Vac

24Vac24Vac

~

~

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

S4390A

S4390A

HEAT / COOL

HEAT / COOL

CHANGEOVER SWITCH

CHANGEOVER SWITCH

24Vac

24Vac24Vac

~

~

(12) ON/OFF COOLING + HEATING SEQUENCE

Valve position

Valve position

100%

100%

0%

0%

X

X

pH

pH

ZEB

ZEB

Setpoint

Setpoint

X

X

pC

pC

(oC)

(oC)

Applications

•4-pipefcuvalvecontrol

Notes

1) Both stages are P+I on/off control, with 6c/hour cycle rate.

2) Both Proportional Bands X

pC&XpH

=1K or 2K.

3) Zero Energy Band ZEB=2K or 4K.

4) Heat valve is closed before cooling valve opens.

5) Cool valve is closed before heating valve opens.

Wiring Schematics

Drive open valves

T8078C

T8078C

14

14

13

HEAT

HEAT

COOL

COOL

COM

COM

13

12

12

11

11

10

10

9

9

8

8

7

7

-

-

+

+

6

6

5

5

4

4

-

-

3

3

+

+

2

2

1

1

OPEN VALVE

OPEN VALVE

COMMON

COMMON

COMMON

COMMON

OPEN VALVE

OPEN VALVE

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

HEAT

HEAT

ACTUATOR

ACTUATOR

COOL

COOL

ACTUATOR

ACTUATOR

24Vac

24Vac24Vac

~

~

Drive open / drive closed valves

T8078C

T8078C

14

14

13

HEAT

HEAT

COOL

COOL

COM

COM

13

12

12

11

11

10

10

9

9

8

8

7

7

-

-

+

+

6

6

5

5

4

4

-

-

3

3

+

+

2

2

1

1

CLOSE VALVE

CLOSE VALVE

CLOSE VALVE

OPEN VALVE

OPEN VALVE

OPEN VALVE

COMMON

COMMON

COMMON

COMMON

COMMON

CLOSEVALVE

CLOSEVALVE

OPEN VALVE

OPEN VALVE

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

HEAT

HEAT

ACTUATOR

ACTUATOR

COOL

COOL

ACTUATOR

ACTUATOR

24Vac

24Vac24Vac

~

~

15 EN0R8535 R1 2003

Page 16

APPLICATIONS – TPM CONTROL (THERMO-ELECTRIC ACTUATORS)

13) TPM COOLING Wiring Schematic

Valve position

Valve position

100%

100%

100%

0%

0%

0%

X

X

X

pC

pC

pC

Setpoint

Setpoint

Setpoint

(oC)

(oC)

(oC)

Applications

• 2-pipe fcu valve control (with thermal actuator)

Notes

1) Special algorithm for thermal actuators.

2) Proportional Band X

=2K or 4K.

pC

3) Only suitable for normally closed valves: where actuator is

powered to drive valve open.

For normally closed valve – drive to open

T8078C

T8078C

14

14

13

COOL

COOL

COM

COM

13

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

-

+

+

3

3

2

2

1

1

ACTUATOR

ACTUATOR

COMMON

COMMON

OPEN VALVE

OPEN VALVE

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

~

24Vac

24Vac24Vac

(14) TPM HEATING

Valve position

Valve position

Valve position

100%

100%

100%

0%

0%

0%

X

X

X

pH

pH

pH

Setpoint

Setpoint

Setpoint

(oC)

(oC)

Applications

• 2-pipe fcu valve control (with thermal actuator)

Notes

1) Special algorithm for thermal actuators.

2) Proportional Band X

=2K or 4K.

pH

3) Only suitable for normally closed valves: where actuator is

powered to drive valve open.

Wiring Schematic

For normally closed valve – drive to open

T8078C

T8078C

14

14

13

HEAT

HEAT

COM

COM

13

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

-

+

+

3

3

2

2

1

1

ACTUATOR

ACTUATOR

COMMON

COMMON

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

OPEN

OPEN

~

~

24Vac

24Vac24Vac

16 EN0R8535 R1 2003

Page 17

APPLICATIONS – TPM CONTROL (THERMO-ELECTRIC ACTUATORS)

(15) TPM COOLING + 2-STAGE ON/OFF HEATING Wiring Schematic

Valve position

Valve position

H

H

100%

100%

0%

0%

2

2

ID

ID

H

H

H

H

1

1

ZEB

ZEB

X

X

pC

pC

Setpoint

Setpoint

(oC)

(oC)

Applications

• 2-pipe fcu valve control with 1or 2 stage electric heat

Notes

1) Cooling control is special algorithm for thermal actuators.

2) Only suitable for normally closed valves: where actuator is

powered to drive valve open.

3) Cooling Proportional Band X

=2K or 4K.

pC

4) Zero Energy Band ZEB=2K or 4K.

5) Heating stages H

6) H

1&H2

=1K (fixed).

are P+I on/off control with 1K Prop. Band.

1&H2

7) Heating stages cycle rate=12c/hour (fixed).

8) Interstage Differential ID

9) Stages H

do not switch together -20s delay.

1&H2

=1K (fixed).

H

For normally closed valve – drive to open

T8078C

T8078C

14

14

13

13

12

12

11

11

10

HEAT

HEAT

COOL

COOL

COM

COM

10

9

9

8

8

H

H

7

7

2

2

H

H

1

1

6

6

5

5

4

4

-

-

3

3

+

+

2

2

1

1

ELECTRIC HEAT (STAGE H

ELECTRIC HEAT (STAGE H

ELECTRIC HEAT (STAGE H1)

ELECTRIC HEAT (STAGE H1)

ACTUATOR

ACTUATOR

COMMON

COMMON

OPEN VALVE

OPEN VALVE

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

)

)

2

2

24Vac

24Vac

~

~

(16) TPM HEATING + 2-STAGE ON/OFF COOLING

Valve position

Valve position

100%

100%

0%

0%

X

X

pH

pH

Setpoint

Setpoint

ZEB

ZEB

C

C

2

2

ID

ID

C

C

C

C

1

1

(oC)

(oC)

Applications

• 2-pipe fcu valve control with 1 or 2 stage chiller

Notes

1) Heating control is special algorithm for thermal actuators.

2) Only suitable for normally closed valves: where actuator is

powered to drive valve open.

3) Heating Proportional Band X

=2K or 4K.

pH

4) Zero Energy Band ZEB=2K or 4K.

5) Cooling stages C

6) C

1&C2

=1K (fixed).

are P+I on/off control with 1K Prop. Band.

1&C2

7) Cooling stages cycle rate=6c/hour (fixed).

8) Interstage Differential ID

9) Stages C

do not switch together -20s delay

1&C2

=1K (fixed).

C

Wiring Schematic

For normally closed valve – drive to open

T8078C

T8078C

14

14

13

COOL

COOL

HEAT

HEAT

COM

COM

13

12

12

11

11

10

10

9

9

8

8

C

C

7

7

2

2

C

C

1

1

6

6

5

5

4

4

-

-

+

+

3

3

2

2

1

1

COMMON

COMMON

OPEN VALVE

OPEN VALVE

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

COOLING (STAGE C

COOLING (STAGE C

COOLING (STAGE C1)

COOLING (STAGE C1)

ACTUATOR

ACTUATOR

~

~

24Vac

24Vac

)

)

2

2

17 EN0R8535 R1 2003

Page 18

APPLICATIONS – TPM CONTROL (THERMO-ELECTRIC ACTUATORS)

(17) TPM HEAT / COOL CHANGEOVER Wiring Schematic

Valve position

Valve position

100%

100%

0%

0%

Heating

Heating

Mode

Mode

X

X

pCH

pCH

Setpoint

Setpoint

Cooling

Cooling

Mode

Mode

(oC)

(oC)

Applications

• 2-pipe fcu valve control with input signal for automatic changeover

Notes

1) Control is special algorithm for thermal actuators.

2) Only suitable for normally closed valves: where actuator is powered to

drive valve open.

3) Proportional Band X

=2K or 4K.

pCH

4) Wire as for Cooling control.

5) External input signal changes operating mode from cooling to heating.

6) Contact closure signal from single aquastat.

7) Contact closure signal from central control switch – ensure correct

polarity of connection to all T8078C units.

For normally closed valve – drive to open

T8078C

T8078C

14

14

13

COOL

COOL

COM

COM

13

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

-

-

3

3

+

+

2

2

1

1

COMMON

COMMON

OPEN VALVE

OPEN VALVE

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

ACTUATOR

ACTUATOR

S4390A

S4390A

HEAT / COOL

HEAT / COOL

CHANGEOVER SWITCH

CHANGEOVER SWITCH

24Vac

24Vac24Vac

~

~

(18) TPM COOLING + HEATING SEQUENCE

Valve position

Valve position

100%

100%

0%

0%

X

X

pH

pH

ZEB

ZEB

Setpoint

Setpoint

X

X

pC

pC

(oC)

(oC)

Applications

•4-pipefcuvalvecontrol

Notes

1) Control is special algorithm for thermal actuators.

2) Only suitable for normally closed valves: where actuator is

powered to drive valve open.

3) Both Proportional Bands X

pC&XpH

=1K or 2K.

4) Zero Energy Band ZEB=2K or 4K.

Wiring Schematic

For normally closed valves – drive to open

T8078C

T8078C

14

14

13

HEAT

HEAT

COOL

COOL

COM

COM

13

12

12

11

11

10

10

9

9

8

8

7

7

-

-

+

+

6

6

5

5

4

4

-

-

3

3

+

+

2

2

1

1

OPEN VALVE

OPEN VALVE

COMMON

COMMON

COMMON

COMMON

OPEN VALVE

OPEN VALVE

T8109C SENSOR (OPTIONAL)

T8109C SENSOR (OPTIONAL)

HEAT

HEAT

ACTUATOR

ACTUATOR

COOL

COOL

ACTUATOR

ACTUATOR

24Vac

24Vac24Vac

~

~

18 EN0R8535 R1 2003

Page 19

ADDITIONAL FEATURES

Automatic Heat / Cool Changeover

T8078C is suitable for automatic or central Heat / Cool

Changeover, if configured for this Mode of operation. This

is applicable only for 2-pipe fan-coil systems, where the

changeover is made on a seasonal demand basis.

Configuration is done by setting System switches S3 and S4

to 1 and 0 respectively.

Automatic changeover is initiated by a thermostat positioned

on the water flow pipe, detecting the presence of heated or

chilled water, and sending the appropriate signal to the

controller. A suitable product is the S4390A1004 pipethermostat.

Central changeover is initiated by a switch, and can be used

to centrally switch a group of connected T8078C controllers

from Heating to Cooling operation.

See wiring schematics for connection details.

Remote Temperature Sensor

T8078C is supplied with an on-board temperature sensor. If

remote temperature sensing is required (for example in

return air sensing applications), then a suitable Honeywell

Remote Sensor can be connected to terminals 12 and 13 as

shown in the wiring schematic.

T8078C will auto detect the presence of the Remote Sensor

on power up, and will use the Remote Sensor measurement

in preference to its internal sensor. So if a Remote Sensor is

to be connected, the power must be switched off then on

again for it to be detected.

Remote Sensors are available as wall-mounted or airflow

(return air) models. Both Q979A1020 and Q979C1036

contain the sensor in wall-mounted form, whereas

T8109C1002 is an airflow sensor supplied with 1.5 m cable.

If this cable is to be extended then the maximum cable run

will be 20m, and the extension must use screened cable.

Polarity of connection is not important, but the screen wire

must be connected to terminal 9 or 10, as shown.

T8109C1002 Sensor

Note : x 50 units maximum

Take care to always observe polarity of connection

Q979A1020 Wall-mounted Sensor

19 EN0R8535 R1 2003

Page 20

Remote Setpoint Adjustment

y

Suitable Valves & Actuators

T8078C allows its setpoint to be adjusted remotely by up to

±5K. This is achieved by the connection of a Remote

Setpoint Adjustment module to terminals 13 and 14, as

shown in the wiring schematic.

Suitable modules are :

Q979B1029 (Remote Setpoint Adjust) and

Q979C1036 (Sensor + Remote Setpoint Adjust).

Note – the polarit

is purely resistive.

To ensure measurement stability when wiring these

modules, use screened cable and connect the screen wire to

terminal 9 or 10 of T8078C as shown.

The maximum cable run will be 20m.

of connection is not important as the input

T8078C is compatible with a range of Honeywell valves and

actuators, as shown in the table below. See relevant product

Specificaton Sheets for more details.

Valve Actuators Suitable Valves

Conical Sealing

M6410C

M7410C

Modulating 3-pos, 24V~

Max of 10 actuators

(0.7VA each) to be

connected to any

T8078C output

M8450A1000

Thermo-electric, 24V~

Stroke 8mm

Max of 2 actuators (3VA

each) to be connected to

any T8078C output

M100

Thermo-electric, 24V~

Stroke 2.5mm

Z100

Thermo-electric, 24V~

Stroke 4mm

Max of 2 actuators (3VA

each) to be connected to

any T8078C output

V5822A 2-way

V5823A 3-way

V5823C 3-way+bypass

Flat Sealing

V5832A 2-way

V5833A 3-way

V5833C 3-way+bypass

Conical Sealing

V5822A 2-way

V5823A 3-way

V5823C 3-way+bypass

Flat Sealing

V5832A 2-way

V5833A 3-way

V5833C 3-way+bypass

Conical Sealing

V5822A4xxx 2-way

V5823A4xxx 3-way

V5823C4xxx 3-way+bypass

Flat Sealing

V5832A4xxx 2-way

V5833A4xxx 3-way

V5833C4xxx 3-way+bypass

Damper Actuators

Modulating 3-pos, 24V~

4Nm

ML6161B2024

5Nm

ML6161E

10Nm

ML6174E

20Nm

N2024

34Nm

N3424

Max no. to be connected

to each T8078C output

Max of 3 actuators (2VA each)

Max of 2 actuators (4VA each)

Max of 2 actuators (4VA each)

Max of 1 actuator (6VA each)

Max of 1 actuator (7VA each)

Optional Accessories

Optional accessories are available for use with T8078C:

F42006646-001 Range stops (pack of 20)

F42007789-001 Wall-plate

Q6360A1025 Fan Speed Switching Subbase

Q979A1020 Wall mounted Remote Sensor

Q979B1029 Remote Setpoint Adjust Unit (±5K)

Q979C1036 Sensor + Remote Setpoint Unit (±5K)

T8109C1002 Return Air Sensor (1.5m cable)

S4390A1004 Pipe-mounted Changeover Thermostat

Honeywell Control Systems Limited

Newhouse Industrial Estate

Motherwell ML1 5SB

United Kingdom

Honeywell

http://europe.hbc.honeywell.com

20 EN0R8535 R1 2003

Loading...

Loading...